Fruity probiotic yogurt slice containing antifreeze sericin peptide and method for preparing same

A technology of probiotics and yogurt tablets, applied in the field of probiotic yogurt tablets and its preparation, to achieve the effects of high number of viable bacteria, simple and easy production process, and delay skin aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

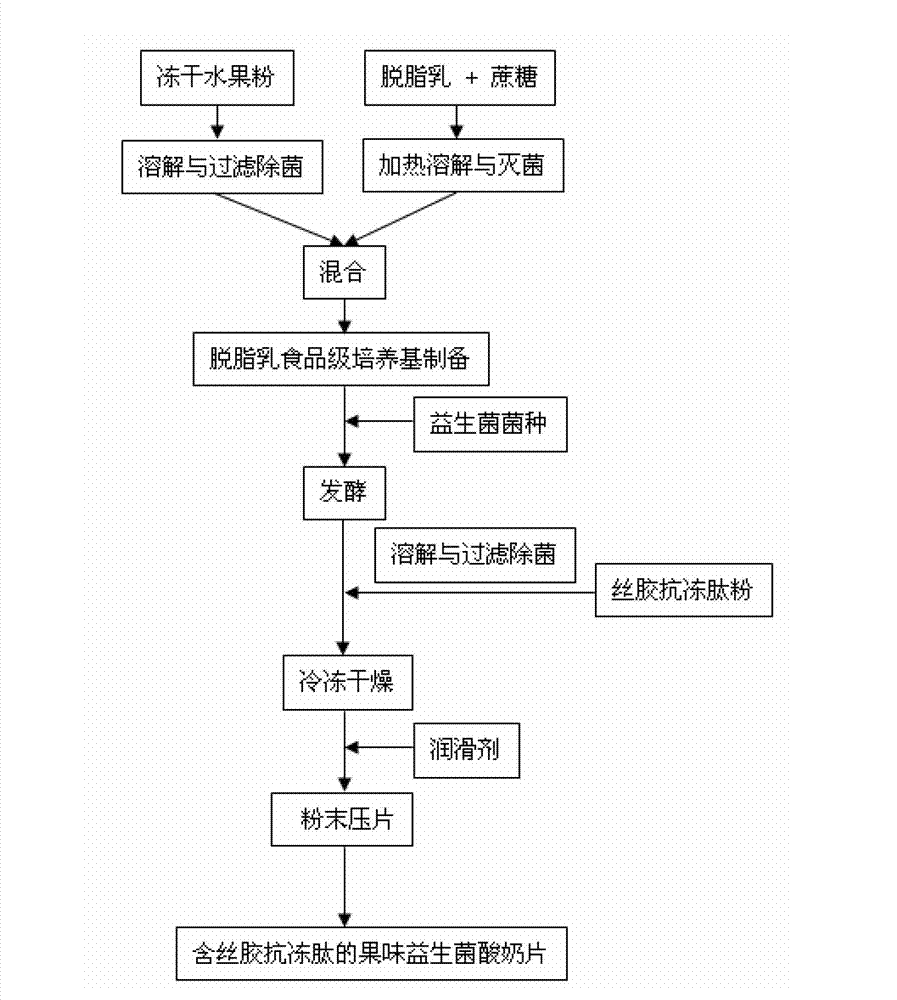

Image

Examples

Embodiment 1

[0034] This embodiment prepares 250 active yogurt tablets, with an average tablet weight of 800mg, and its raw material components are formulated according to the following weight: New Zealand Fonterra skimmed milk powder 120g, sucrose 50g, Lactobacillus bulgaricus powder (Lactobacillus bulgaricus LB340) provided by Danisco ) and Bifidobacterium bifidum BB02 powder (Bifidobacterium bifidum BB02) each 1.5g, Rosa roxburghii seedless powder 10g, sericin peptide provided by Huzhou Xintiansi Biotechnology Co., Ltd. Powder 12g, magnesium stearate 2g.

[0035] The specific preparation method of this embodiment is as follows:

[0036] 1. Weigh 120g of skimmed milk powder and 50g of sucrose, mix well, measure 700mL of deionized water, heat to 50°C in a water bath, then slowly add the mixture of skim milk and sucrose while stirring, and place in a 50°C water bath Stir well under the conditions to dissolve the material completely, then sterilize in a pressure steam sterilizer at 121°C f...

Embodiment 2

[0041] In this example, 300 active yogurt tablets were prepared, with an average tablet weight of 500 mg, prepared from raw material components according to the following weight: skimmed milk powder 105g, sucrose 20g, Lactobacillus bulgaricus LB340 2.4g, banana freeze-dried powder 8g, sericin peptide Powder 8g, magnesium stearate 1.5g.

[0042] The specific preparation method of this embodiment is as follows:

[0043] 1. Weigh 105g of skimmed milk powder and 20g of sucrose, mix well, measure 425mL of deionized water, heat to 50°C in a water bath, then slowly add the mixture of skim milk and sucrose while stirring, and place in a 50°C water bath Stir well under the conditions to dissolve the material completely, then sterilize in a pressure steam sterilizer at 121°C for 15 minutes, and cool naturally to room temperature for later use. Weigh 8g of banana freeze-dried powder, add 180mL of sterilized deionized water, filter and sterilize through a microfilter with a membrane pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com