Rotatable mower header and differential feeding method

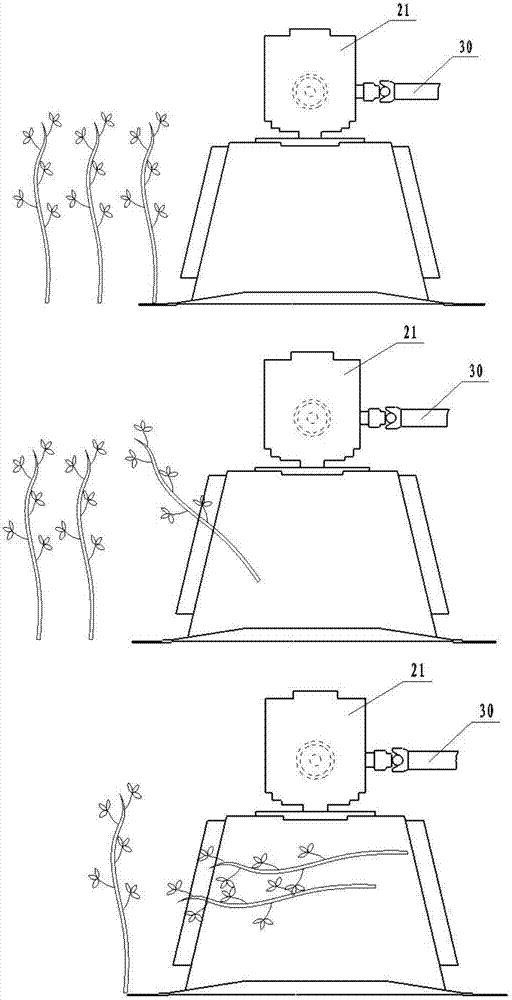

A lawn mower and rotary technology, applied in the direction of headers, harvesters, agricultural machinery and implements, etc., can solve the problems affecting the quality of forage grass products, the destruction of forage grass leaves, and the high protein content, so as to facilitate subsequent operations. , The effect of preventing the forage from leaning forward and having strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to accompanying drawing.

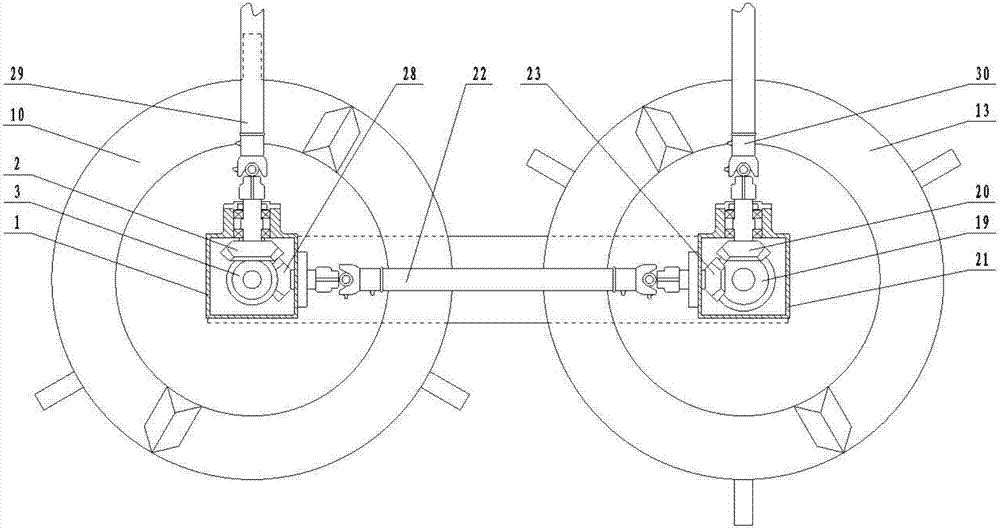

[0024] Such as figure 1 Shown is the top view of the lawn mower cutting platform of the present invention. The power is passed into the header from two directions, and one direction is passed into the left gearbox 1 by the left universal joint 29, and the left universal joint 29 is connected with the first bevel gear 2 in the left gearbox 1, which is the left cutter head 10, the right The cutter head 13 provides power; the other direction is passed into the right gear box 21 by the right universal joint 30, and the right universal joint 30 is connected with the seventh bevel gear 20 in the right gear box 21, which is the left material guide roller 7, the right material guide The drum 16 provides the power.

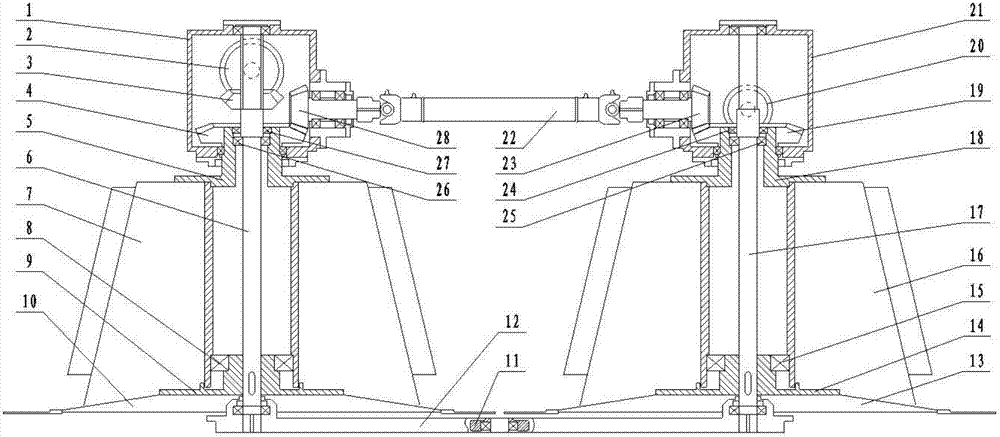

[0025] Such as figure 2 Shown is the schematic diagram of the cutting platform of the mower of the present invention. The power is provided by the left universal joint 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com