Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Avoid fire accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

5182 aluminum alloy tab stock substrate and production method thereof

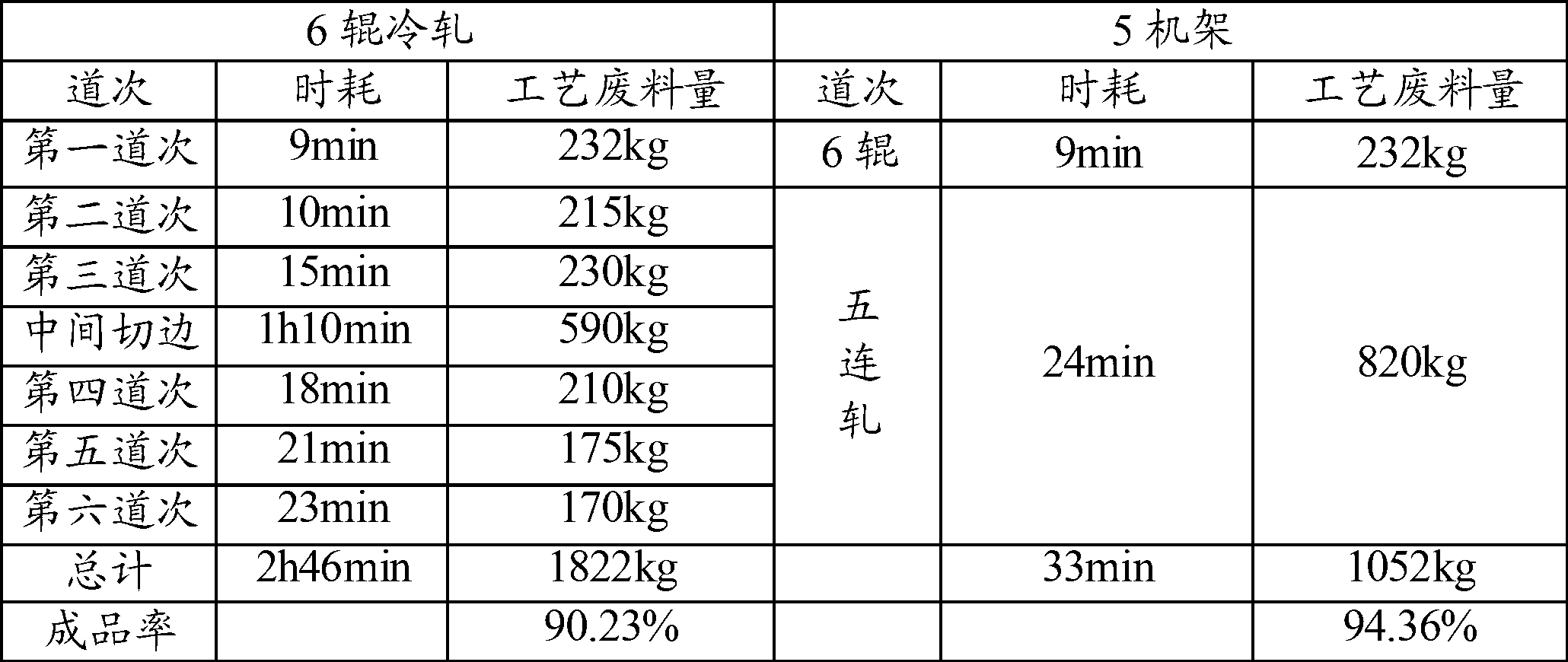

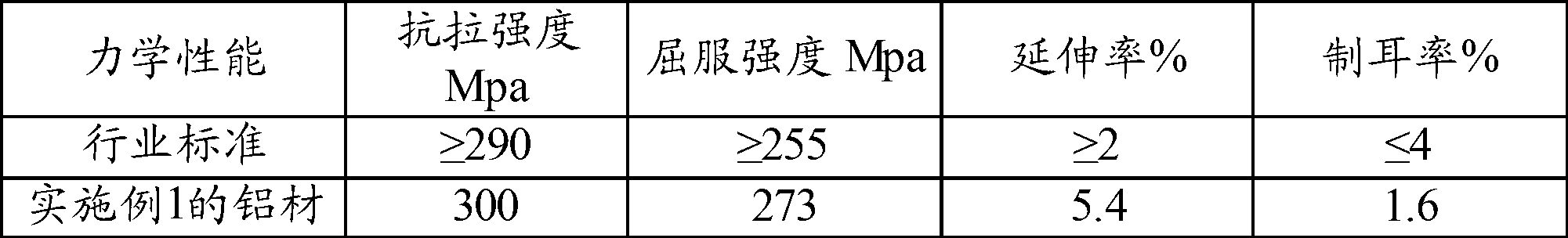

The invention discloses a 5182 aluminum alloy tab stock substrate and a production method thereof. The production method comprises the following production processes of: fusion casting, saw cutting, plane milling, heating, hot continuous rolling, six-roller one-pass cold rolling, five-stander fixe-pass continuous rolling, rectifying, coating and shearing, wherein molten aluminum subjected to fusion casting comprises the following chemical components in percentage by mass: 0.10-0.15 percent of Si, 0.23-0.30 percent of Fe, 0.02-0.07 percent of Cu, 0.33-0.40 percent of Mn, 4.45-4.80 percent of Mg, 0.02-0.07 percent of Cr, not more than 0.02 percent of Zn, 0.008-0.02 percent of Ti, not more than 0.02 percent of V, not more than 0.03 percent of each of other impurities, and the balance of Al, wherein the other impurities are not more than 0.15 percent in total; the melting temperature is 740-760 DEG C, the refining temperature is 725-740 DEG C, and the casting temperature is 670-685 DEG C; and the cold rolling process comprises the steps of directly carrying out six-roller one-pass cold rolling on a 3.0-4.5mm hot-rolled blank to reach the thickness of being 1.9-2.9, and then directly carrying out once five-stander cold continuous rolling to reach the finished-product thickness of being 0.28-0.46mm, wherein the total working rate is 89-91 percent. The production method disclosed by the invention ensures that the mechanical property of the5182 aluminum alloy tan stock substrate is stable and qualified and has the advantages of shortening the production flow and improving the production efficiency.

Owner:ALUHOUSE TECHGD CO LTD

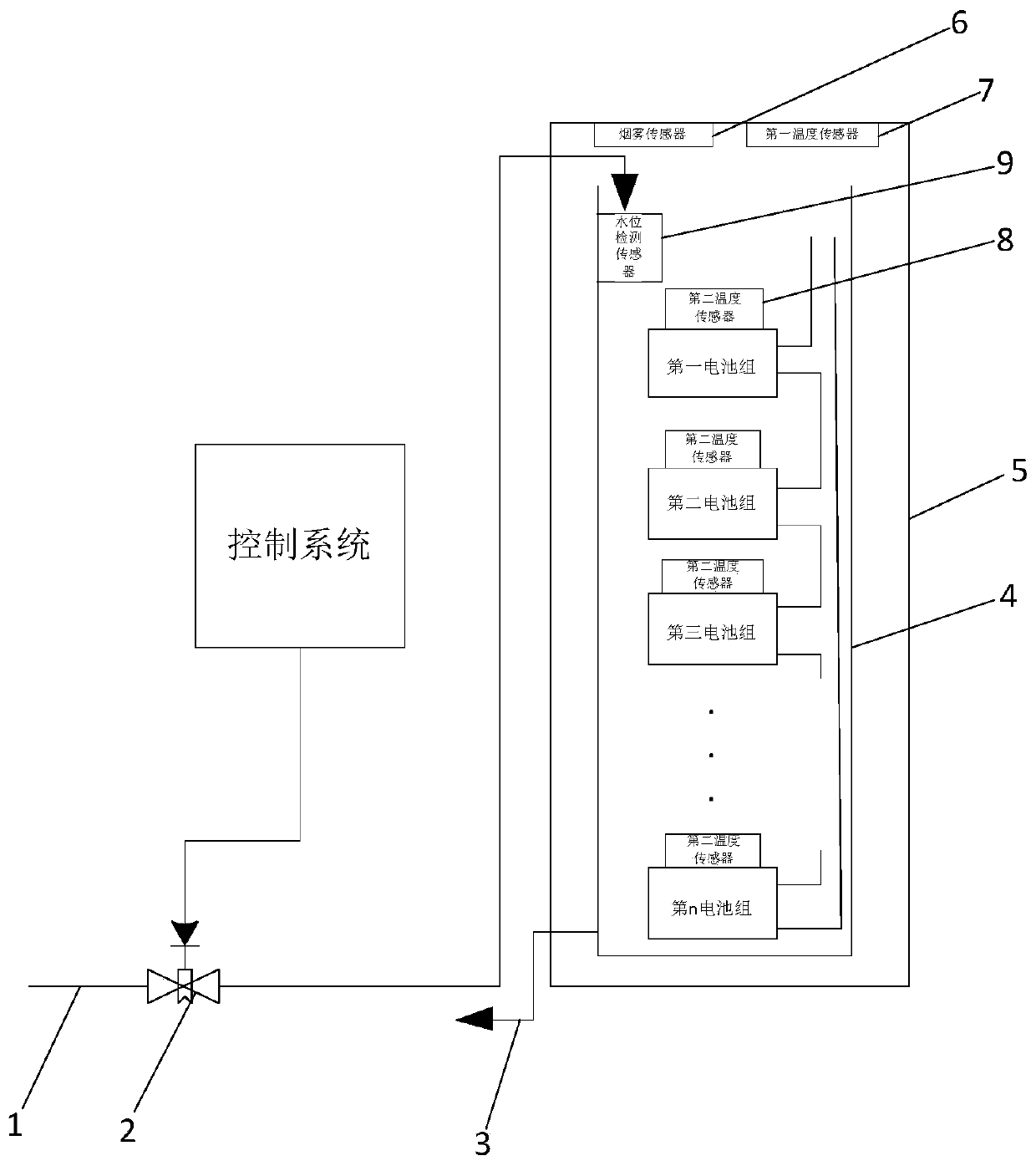

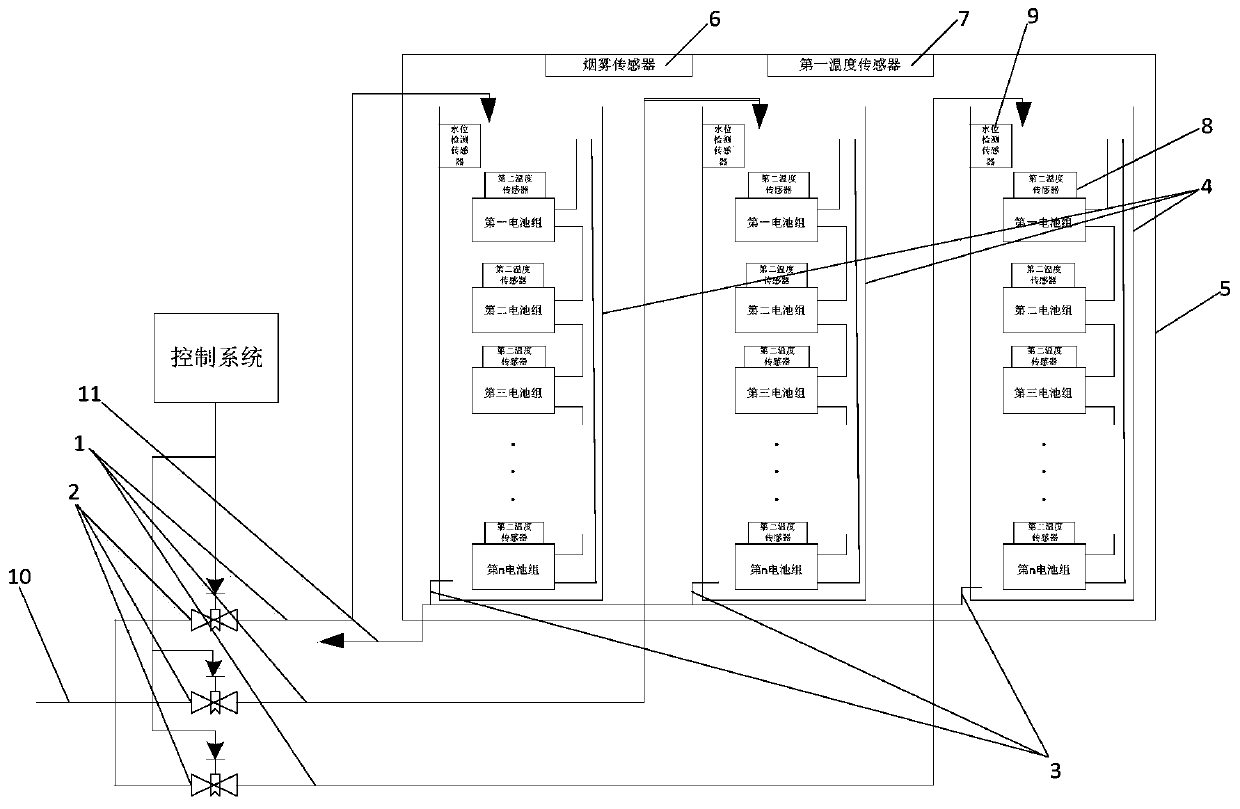

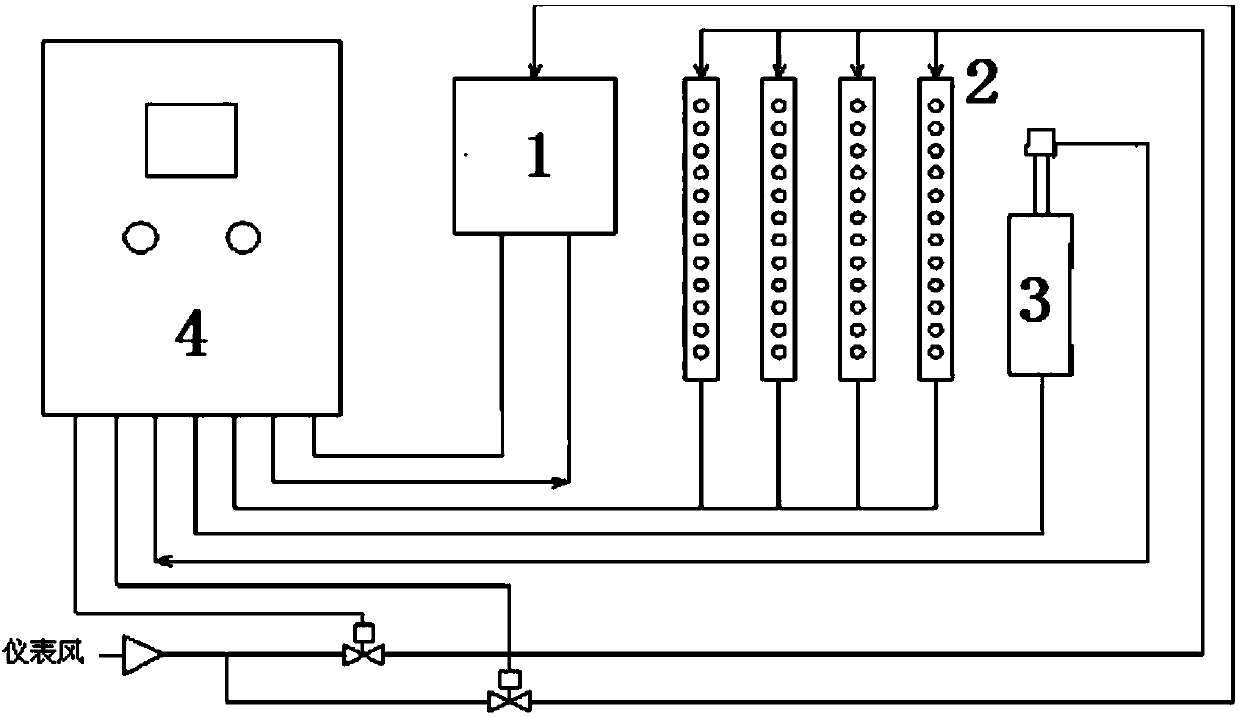

Lithium battery energy storage system cabinet automatic fire extinguishment device and system

The invention discloses a lithium battery energy storage system cabinet automatic fire extinguishment device and system. The fire extinguishment device comprises an aerosol fire extinguishment system, a water injection fire extinguishment system, an electrical fire detection device, a battery fire detection device and a control system. The electrical fire detection device and the battery fire detection device are both arranged in an energy storage system cabinet. The aerosol fire extinguishment system, the water injection fire extinguishment system, the electrical fire detection device and the battery fire detection device are all connected with the control system. The fire extinguishment system comprises a control system, an aerosol fire extinguishment system, multiple water injection fire extinguishment systems, multiple battery fire detection devices, a water inlet mother pipe, a water outlet mother pipe and multiple battery bins. The liquid immersion type fire extinguishment scheme is adopted, batteries are isolated from air by injecting liquid till the batteries are completely immersed, heat generated by battery faults is rapidly brought away through convective circulation at the same time, combustion inside and outside battery units is fundamentally eliminated, and harm caused by secondary accidents to the system and maintenance personnel is eradicated.

Owner:西安奇点能源股份有限公司

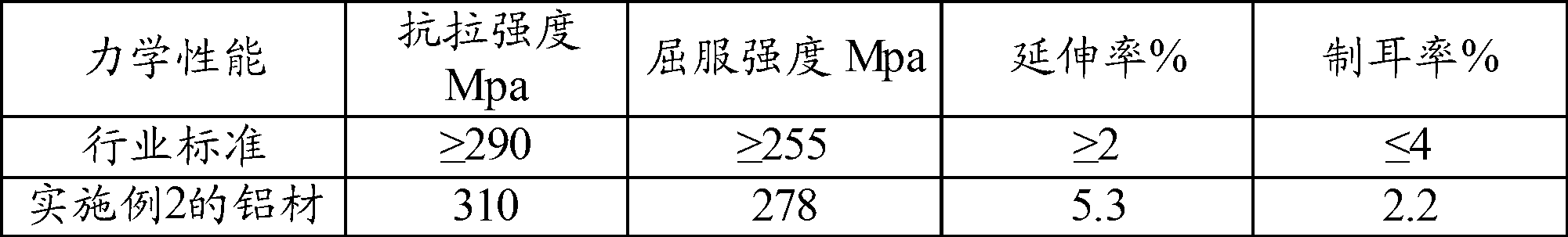

Aluminum material of zip-top two-sheet can body and production method thereof

The invention discloses an aluminum material of a zip-top two-sheet can body and a production method thereof; the production process comprises casting, saw-cutting, face-milling, heating, hot continuous rolling and cold-rolling, wherein casted molten aluminum consists of the following chemical components by mass percentage: 0.17-0.23% of Si, 0.38-0.48% of Fe, 0.145-0.21% of Cu, 0.85-0.90% of Mn, 1.18-1.23% of Mg, not greater than 0.025% of Cr, not greater than 0.02% of Zn, not greater than 0.02% of Ti, not greater than 0.10% of other impurities each of which accounts for not greater than 0.03%, and the balance of Al; smelting temperature is at 720-750 DEG C; refining temperature is at 725-740 DEG C; and casting temperature is 660-700 DEGC. The cold-rolling process comprises the following steps of: by a five-stand cold continuous rolling production line, rolling an aluminum material from 2.2-2.5mm to 0.27-0.28mm in the first time of forming, and distributing reduction rates of the first to the fifth stands as: 25-35%, 25-38%, 25-38%, 30-50% and 35-50%. The production method disclosed by the invention not only guarantees the stable and qualified mechanical performance of the aluminum material of the zip-top two-sheet can body, but also shortens the production process and improves the production efficiency.

Owner:ALUHOUSE TECHGD CO LTD

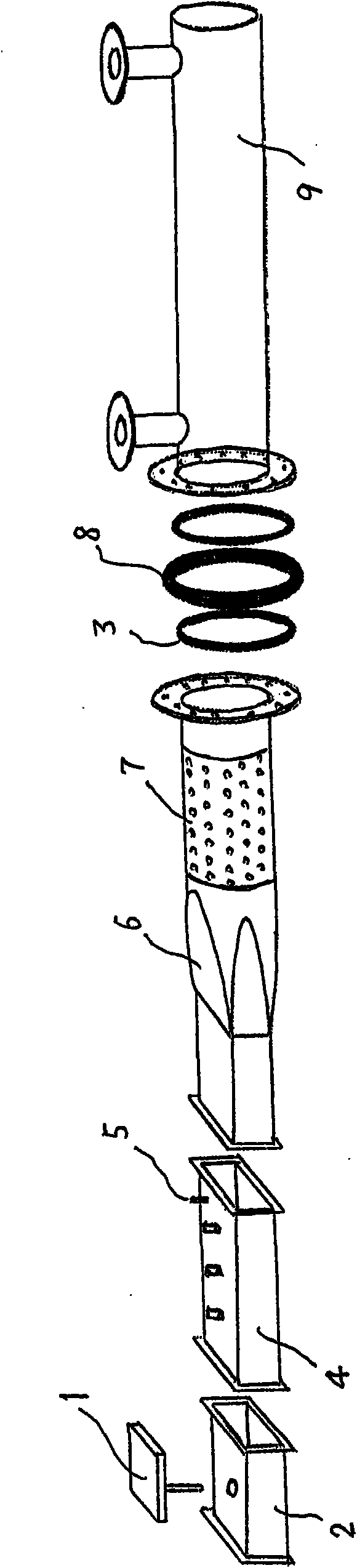

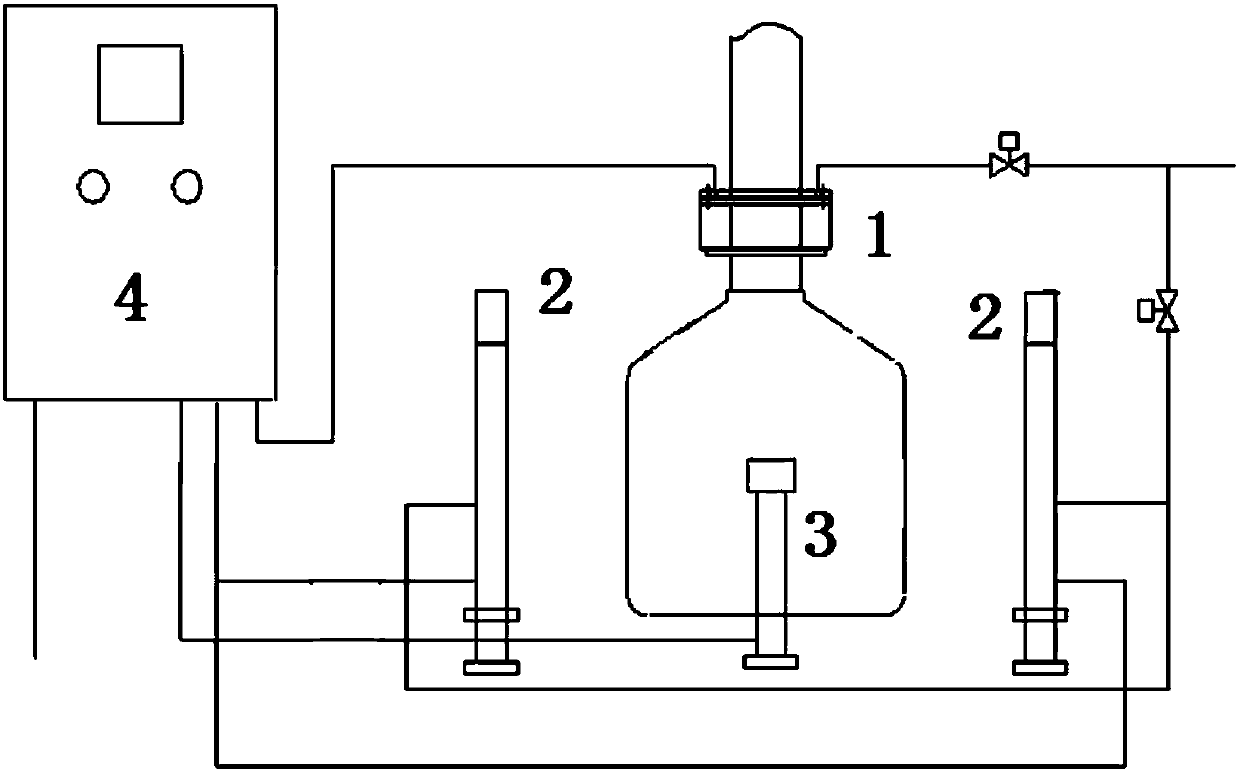

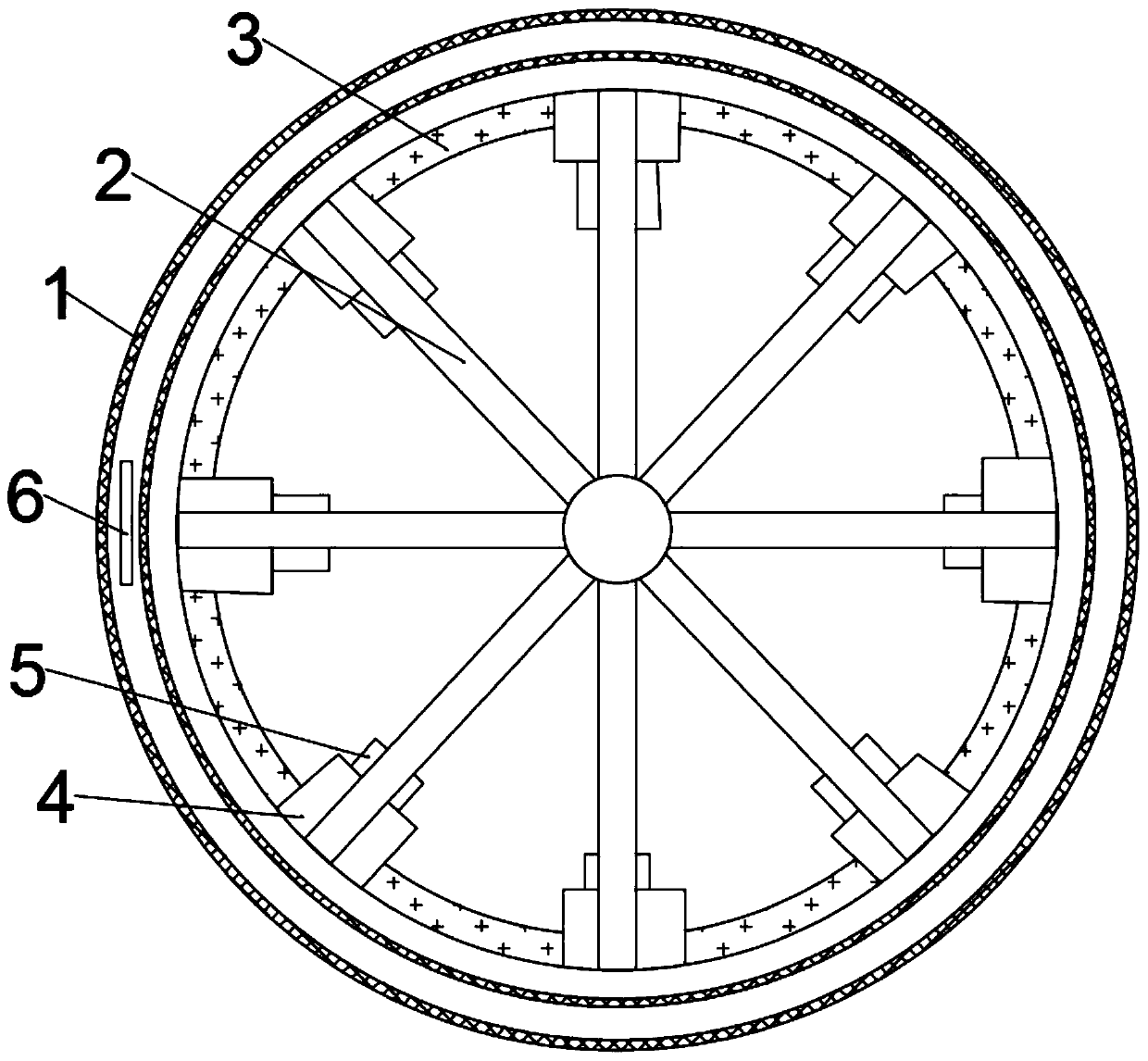

Liquefied petroleum gas or gasoline desulphurization microwave reaction kettle

InactiveCN101560407AImprove desulfurization effectAvoid fire hazardsGaseous fuelsRefining by electric/magnetic meansMicrowaveCombustible gas

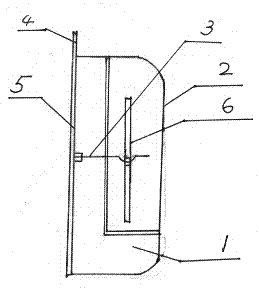

The invention relates to a liquefied petroleum gas or gasoline desulphurization microwave reaction kettle, and belongs to the technical field of application of microwave in desulphurization. The reaction kettle structurally comprises a microwave source (1), a microwave coupler (2), a tuner (4), a transition waveguide (6), a ventilated security isolator (7), an isolation window (8) and a reaction cavity (9) according to a microwave conduction order; the reaction cavity (9) is provided with a cylindrical container with a feeding opening and a discharge hole on the lateral surfaces close to two ends respectively, the cylindrical end close to the feeding opening is closed, and the cylindrical end close to the discharge hole is hermetically connected with the ventilated security isolator (7) through the isolation window (8) and a sealing ring (3); and the ventilated security isolator (7) is a section of circular waveguide, and the lateral surface of the ventilated security isolator (7) is provided with a ventilation hole. The reaction kettle has good desulphurization effect on combustible liquid, and can avoid fire accidents caused by micro-leakage of combustible gas.

Owner:JILIN UNIV

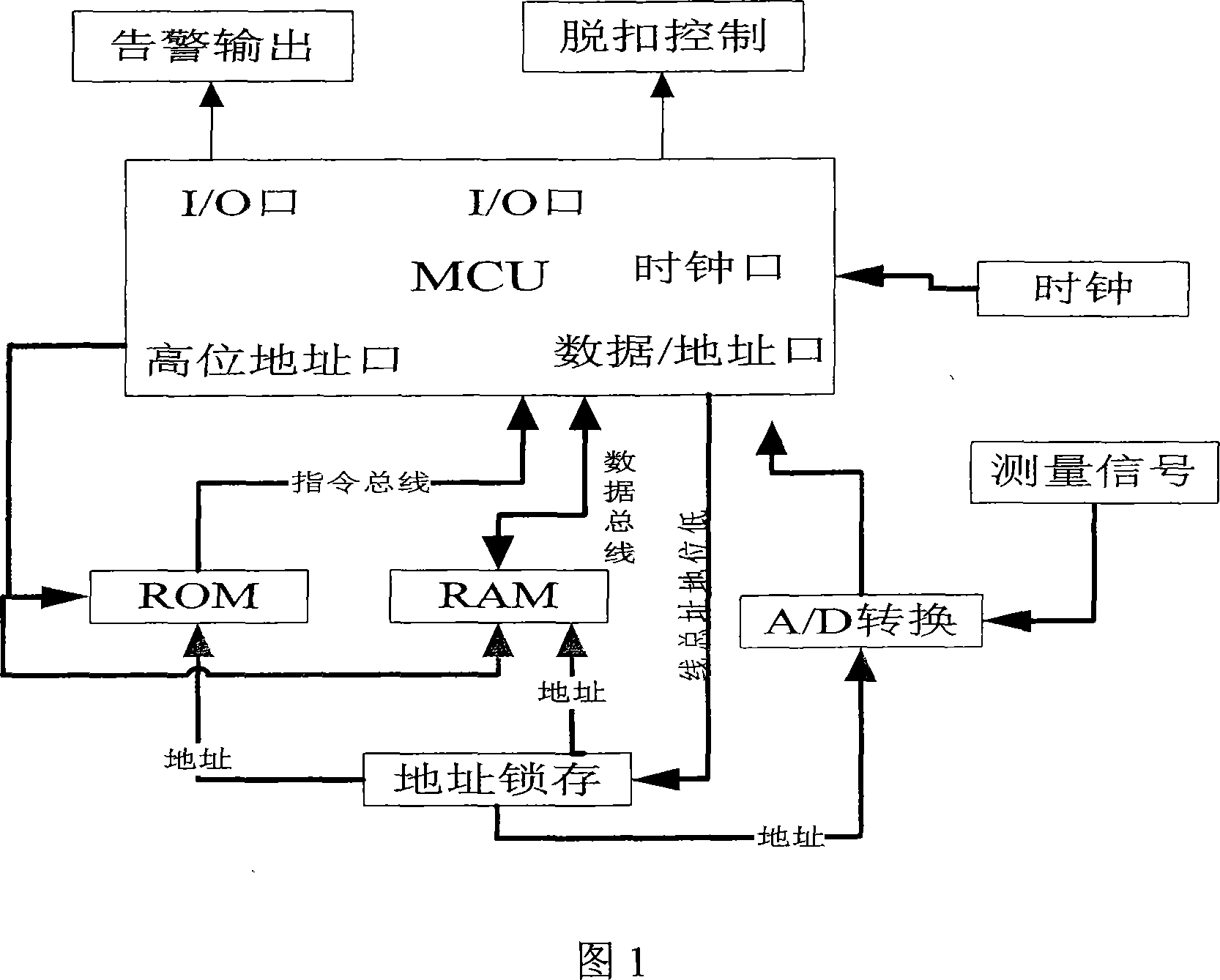

Intelligent power arrester

InactiveCN101064430AAvoid fire accidentsLow costResistance/reactance/impedenceResistorsVaristorInductor

The invention discloses a intelligent power source arrester, it is a trip protecting device with physical and intelligent method, it includes intelligentized embedded control system and temperature sensor, the temperature sensor is embedded into the surface of the zincite piezoresistance of the power source arrester, and insulated with the zincite piezoresistance, another temperature sensor is used to detect the temperature of entironment; the embedded CPU system can detect the parameters of power source arrester module on line, and break the poor power source arrester, the current mutual-inductor is in the trip device, it can feed back the drain current parameter of the piezoresistance to the CPU to realize the online detection of power source arrester, and judging whether the power source arrester is bad according to the set data. The cost of the invention is low, performance is reliable, the danger of self-ignite induced by bad power source arrester can be stopped, the action of trip is precise and quick, protection is in time.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method and system for increasing calsium and remelting flyash in boiler and high temperature desulfurizing in boiler

InactiveCN101069805AAvoid fire accidentsImprove desulfurization effectLighting and heating apparatusDispersed particle separationCombustorIncreased calcium

The present invention provides a boiler fly ash calcium-increasing remelting-intrafurnace desulfurizing method and its system. Said method includes the following steps: (1), making the fly ash discharged by boiler be passed through remelting system, then making collection, pressurization and distribution; (2), making the fly ash having need of increasing calcium undergo the process of calcium-increasing treatment; and (3),spraying the calcium-increased fly ash into the furnace cavity to make secondary combustion, remelting and desulfurization. Said system includes boiler coal-feeding belt system, powder-making system, combustor, boiler, dust-remover, boiler blower and stack, etc. Said system also includes a fly ash calcium-increasing system connected with boiler and a fly ash remelting system connected with dust-remover, and the fly ash remelting system is connected with said fly ash calcium-increasing system.

Owner:殷大众

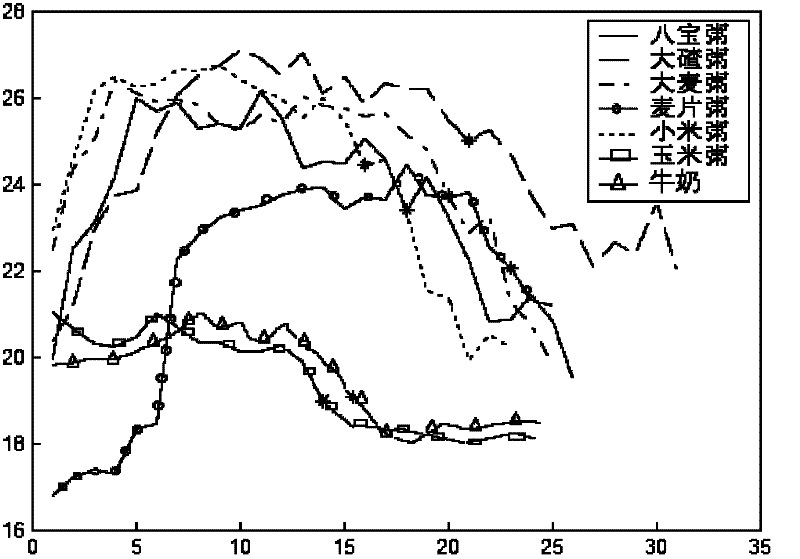

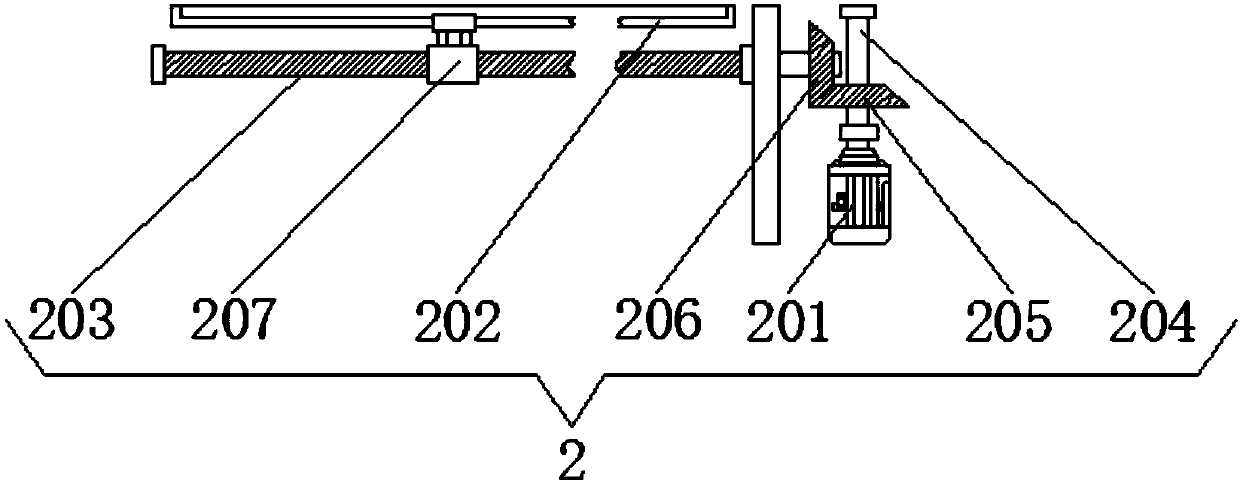

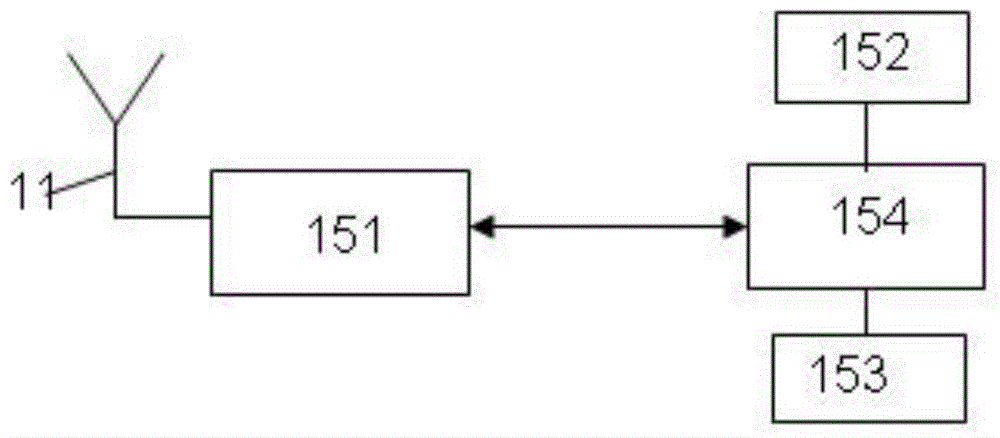

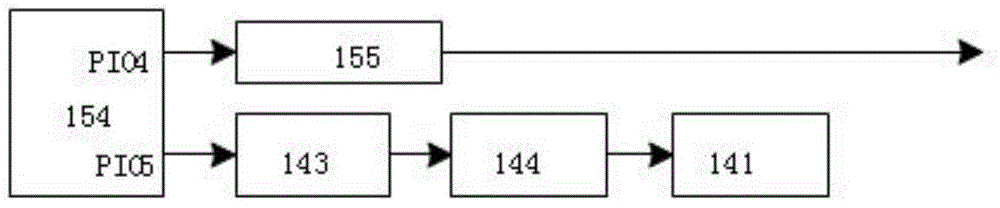

Method and device for automatically controlling porridge and milk cooking firepower based on human eye vision principle

InactiveCN102360185APrevent overflowSimple structureCharacter and pattern recognitionProgramme control in sequence/logic controllersCamera controlBoiling point

Owner:OCEAN UNIV OF CHINA

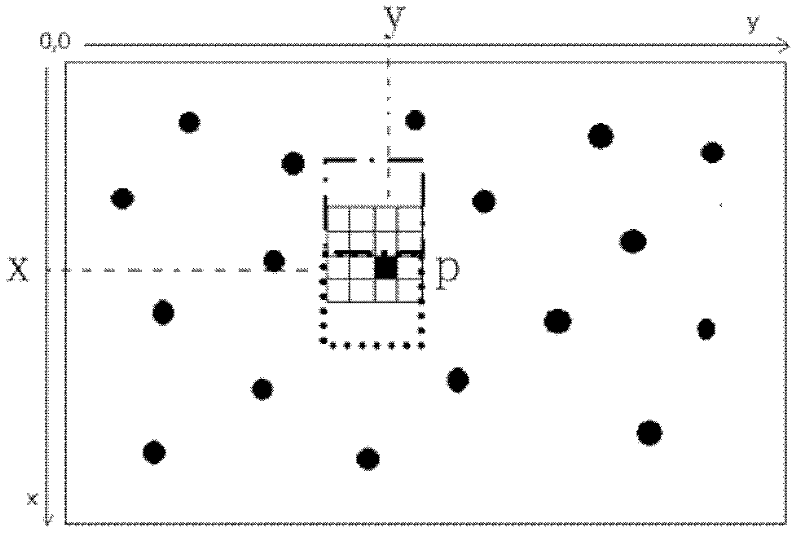

Building fire protection intelligent monitoring system based on Internet of things

InactiveCN110161891AEasy to monitorAvoid fire accidentsProgramme controlComputer controlFire protectionCoupling

The invention discloses a building fire protection intelligent monitoring system based on Internet of things. The system includes a mounting device and a moving device. The mounting device includes amounting plate. Screws are threadedly connected to the two sides of the mounting plate through threaded holes. A first vertical plate and a second vertical plate are fixedly connected to the two sidesof the bottom of the mounting plate. A horizontal plate is fixedly connected to the bottom parts of the first vertical plate and the second vertical plate. The moving device includes a first motor, afirst slide rail and a threaded rod. A rotating rod is fixedly connected to one end of an output shaft of the first motor through a coupling. The top end of the rotating rod is connected to one sideof the bottom of the mounting plate through a bearing. The invention relates to the technical field of monitoring systems. The building fire protection intelligent monitoring system based on Internetof things can realize the movement of a moving box and the swing of a camera so as to increase a monitoring range of the monitoring system, and so the monitoring is fuller and more comprehensive, thepracticality of the device is improved and the safety of a building is improved.

Owner:协建(江苏)智能装备有限公司

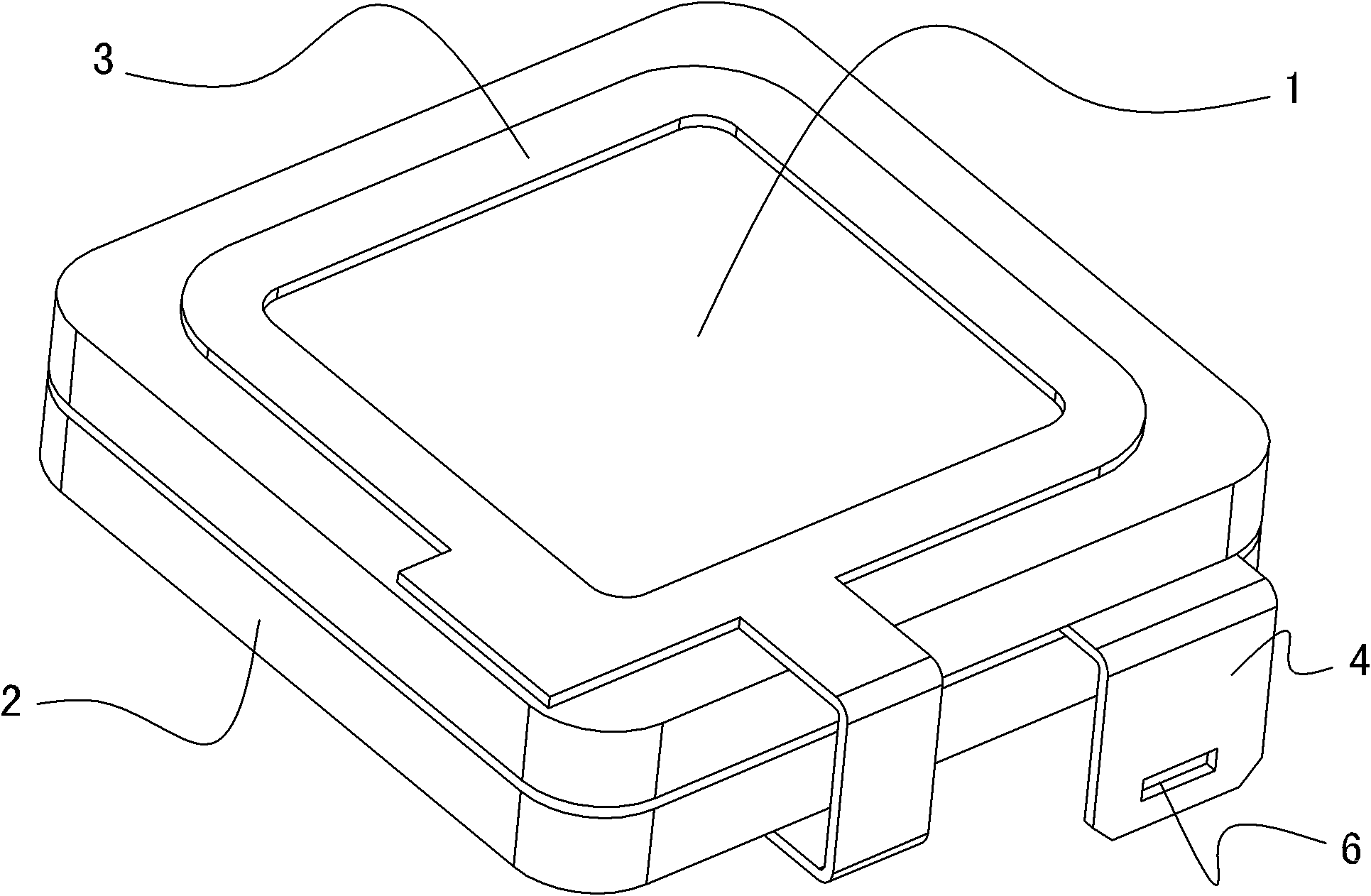

Fire hazard alarm wireless communication base

ActiveCN104036610AEnsure Structural IntegrityGuaranteed aestheticsFire alarmsWork periodRF front end

The invention discloses a fire hazard alarm wireless communication base. The fire hazard alarm wireless communication base comprises an antenna and a base housing. The base housing is internally provided with a circuit board and an alarm playing unit. The circuit board is provided with a wireless communication module; the wireless communication module comprises an RF front transceiver, a FLASH memory, a RAM memory and an MCU control unit; and the alarm playing unit comprises a loudspeaker, a vocal chamber, and a voice integration circuit and a power amplifier circuit which are arranged on the circuit board. According to the invention, the fire hazard alarm wireless communication base has an evacuation alarm function and also has the advantages of node signal loss monitoring, low power consumption and long life work period; and through an appearance structural design, the fire hazard alarm wireless communication base can be individually combined with various independent fire hazard trigger members or fire hazard linkage devices and the like to form a wireless fire hazard alarm terminal product, and the fire hazard alarm wireless communication base is an important front part of an ideal wireless fire hazard alarm system and has a wide application value.

Owner:SHANGHAI FIRE RES INST OF MEM

Dry-type air-core shunt reactor group protection sampling circuit and application thereof and protection method

PendingCN108872653AAchieve protectionMeet insulation requirementsOverload protection arrangementsMeasurement using digital techniquesOvervoltageLow voltage

The invention discloses a dry-type air-core shunt reactor group protection sampling circuit and application thereof and a protection method, which belong to the technical field of reactor overvoltageprotection. With a neutral point as reference potential, through an overvoltage absorption and power frequency voltage sampling circuit, protection on switching overvoltage is realized, and voltage signals of the reactor are extracted at the same time. Current signals flowing through the reactor are extracted through a low-voltage current sensor, and in combination of voltage signals of each reactor, resistive current and sensitive current are calculated. As a high insulation level is required for the neutral point to the ground, the insulation requirement is met when a measurement result is transmitted through an optical fiber. Thus, the switching overvoltage level of a neutral point-ungrounded dry-type air-core shunt reactor is reduced, inter-turn short circuit fault can be effectively discovered, and fire accidents are avoided.

Owner:JILIN ELECTRIC POWER RES INST +2

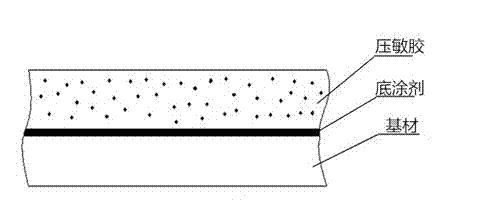

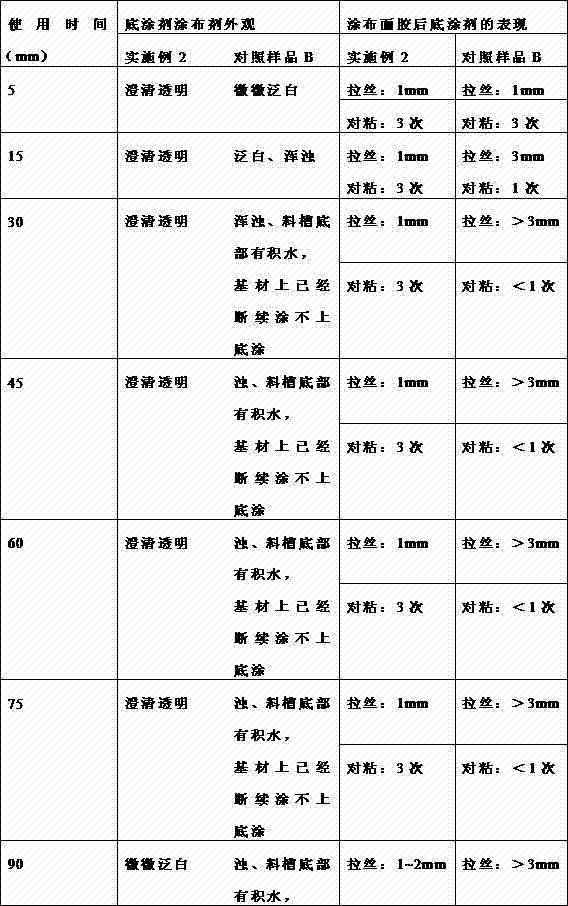

Release agent type coating agent in humid environment and preparation method of release agent type coating agent

The invention discloses a release agent type coating agent in a humid environment. The release agent type coating agent comprises a release agent, a crosslinking agent, a catalyst, an anchoring agent, a moisture scavenger and a solvent, wherein the moisture scavenger comprises a main moisture scavenger and an auxiliary moisture scavenger; and the moisture scavenger is one or more compounds capable of reacting with water at a room temperature, and comprises an organic moisture scavenger and an inorganic moisture scavenger. A preparation method of the release agent type coating agent in the humid environment comprises the following steps: sequentially preparing a release agent diluent, a crosslinking agent diluent, a catalyst diluent, an anchoring agent diluent and a moisture scavenger diluent and mixing with the solvent evenly; and preparing the release agent type coating agent in the humid environment; coating the release agent type coating agent on the surface of a base material; and finally desolventizing and solidifying in a drying oven, so as to avoid sticking of a pressure sensitive adhesive product.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

Piezoresistor for lightning protection

ActiveCN101887790ADisaster reductionAvoid fire accidentsResistor terminals/electrodesOvervoltage protection resistorsVaristorEngineering

The invention discloses a piezoresistor for lightning protection, comprising two piezoresistor substrates arranged in a laminated way, wherein the inner electrodes of the two piezoresistor substrates are opposite and are respectively electrically connected with tripping electrodes, the outer electrodes of the two piezoresistor substrates are respectively electrically connected with connection electrodes, the middle of each piezoresistor substrate is provided with a through hole, and a tripping point of each tripping electrode is arranged on the tripping electrode at the through hole; or the connecting end of the tripping electrode is arranged in the through hole, is electrically connected with the inner electrode of the piezoresistor substrate, and is insulated with the outer electrode of the piezoresistor substrate. In the invention, the tripping electrodes are arranged in the middle of the piezoresistor substrates, thus the heat generated by the piezoresistor can be most quickly transmitted to the tripping electrodes to make the tripping electrodes trip in time when the piezoresistor substrates begin degrading so that disaster accidents caused by the delayed separation of an SPD (Surge Protection Device) from the circuits can be reduced.

Owner:SHENZHEN KEANDA ELECTRONICS TECH

Thermochromic TPE (thermoplastic elastomer) material

The invention discloses a thermochromic TPE (thermoplastic elastomer) material. The thermochromic TPE material is prepared from TPE, polyester staple fibers, epoxy resin, a curing agent, a chromogenic agent, color developing agent, flame retardants and an adhesive. The thermochromic TPE material is high in elasticity, strength and rebound resilience and has a characteristic of availability for injection molding. The thermochromic TPE material can be controlled to realize a thermochromic function at a set temperature through selection of different chromogenic agents and color developing agents, warning of the internal temperature of the material can be realized, and fire accidents can be avoided by warning when the temperature is overhigh; due to addition of the flame retardants, combustion of the material can be prevented in case of inevitable fire, so that loss caused by fire disasters is reduced; by joint use of halogen-free flame retardants and synergistic flame retardants, flame retardation effects are remarkably improved.

Owner:邓韵

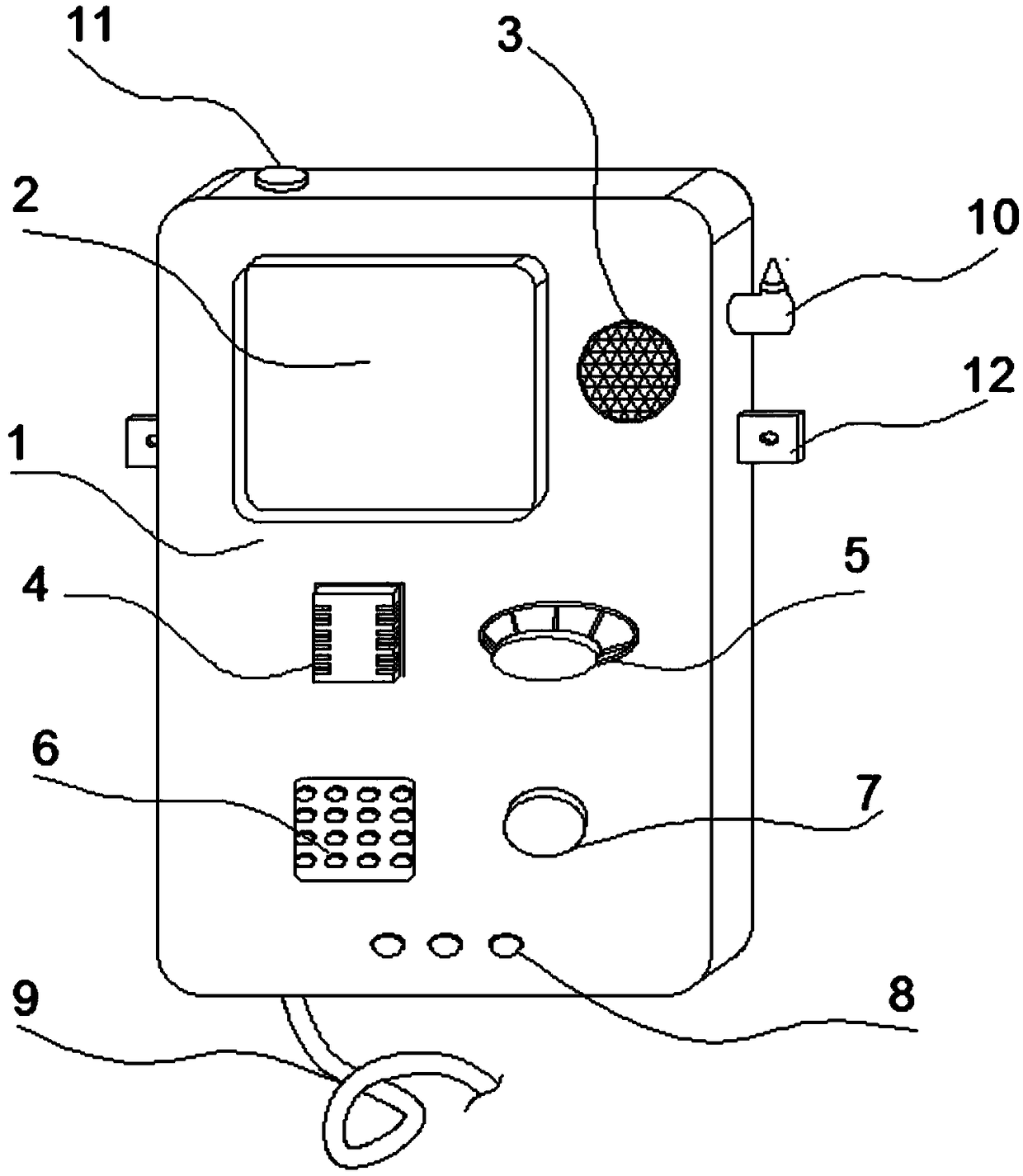

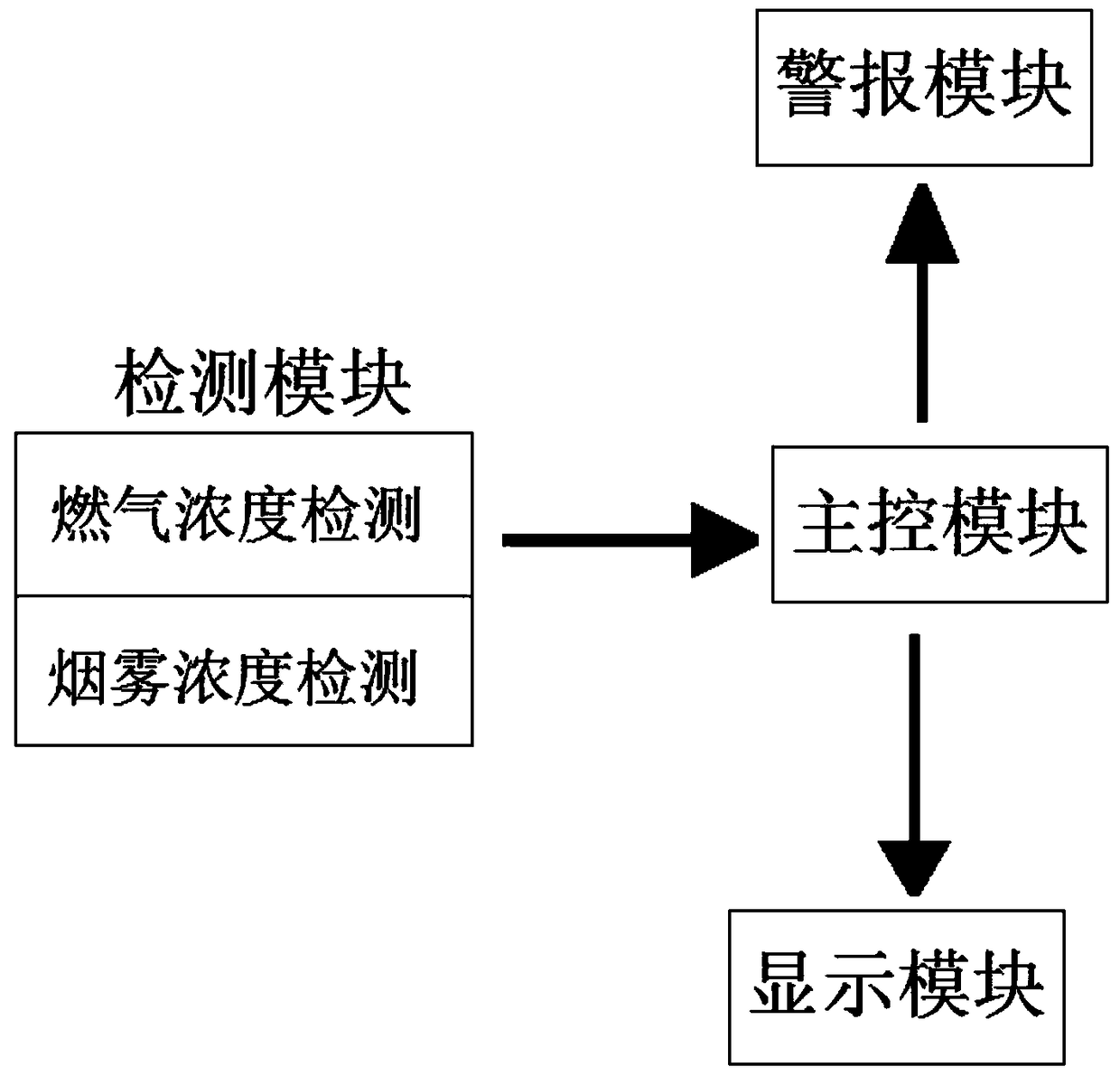

Kitchen monitoring and alarming device and method

InactiveCN108961690AAvoid spillsAvoid accidentsFire alarm smoke/gas actuationEngineeringDevice failure

The invention, which relates to the field of monitoring and alarming technology, provides a kitchen monitoring and alarming method. A main control module, a detection module, an alarm module and a display module are arranged. The detection module detects the harmful gas concentration in air in a kitchen in real time and displays the information through the display module. The main control module determines whether the current harmful gas concentration reaches a preset threshold; if the current harmful gas concentration in the air is greater than a preset value, the main control module controlsthe alarm module to generate alarm information and the information is displayed by the display module; and the alarm module carries out alarming with sounds. After certain time, if the concentrationof harmful gas in the air does not decrease, the main control module cuts off a gas valve. According to the invention, the gas concentration and the smoke concentration in the kitchen air can be detected in real time; alarming is carried out when the as concentration is too high and the gas is cut off timely. Meanwhile, the device fault information is sent wirelessly and the merchant is informed of repairing timely, so that the occurrence of security incidents is reduced.

Owner:LISHUI YIFANJIA MOLD TECH CO LTD

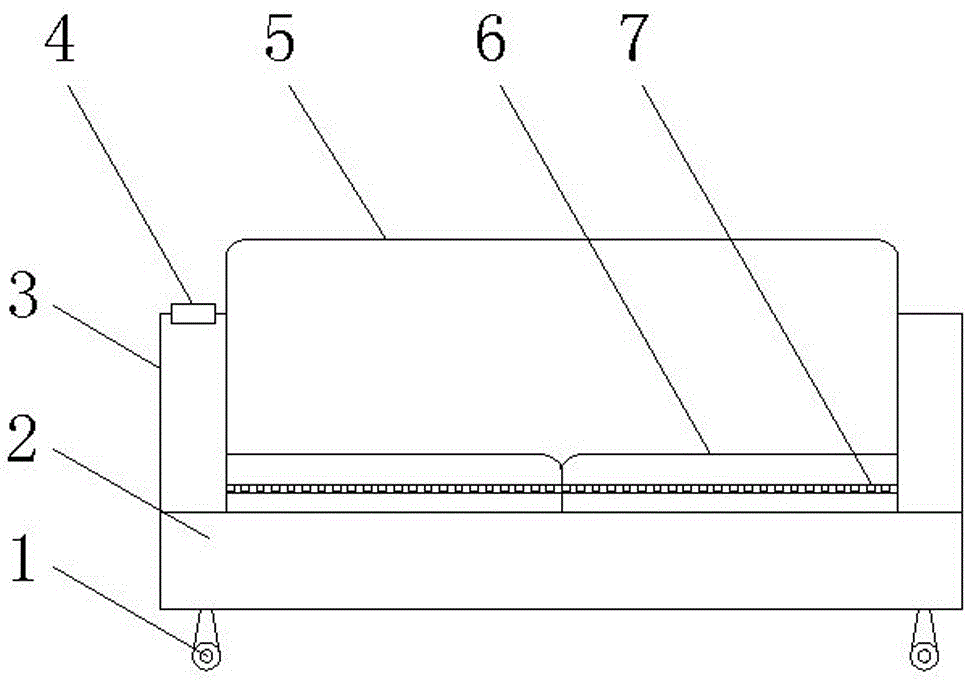

Sofa with heating function

InactiveCN106235746AWith heating functionAvoid fire accidentsStuffed mattressesSpring mattressesEngineeringFire accident

The invention discloses a sofa with heating function, comprising a sofa base, a controller, a sofa back cushion, a seat cushion, a heating pad, a sponge layer, a temperature sensor and a support part; sofa armrests are mounted on two sides of the sofa base through rotary fixtures, the sofa back cushion is mounted on the sofa base through a rotary fixture and is positioned between the two sofa armrests, the seat cushion is placed on the sofa base, the heating pad is mounted in the seat cushion, the sponge layer is arranged in the seat cushion, a first flame-retardant layer is attached to the lower surface of the sponge layer, the heating pad is attached to the lower surface of the first flame-retardant layer, a second flame-retardant layer is attached to the lower surface of the heating pad and is attached to the support part, and the temperature sensor is mounted in the sponge layer of the seat cushion. The flame-retardant layers are fitted to the heating pad, and it is possible to prevent sponge from being ignited and avoid a fire accident.

Owner:吕萍华

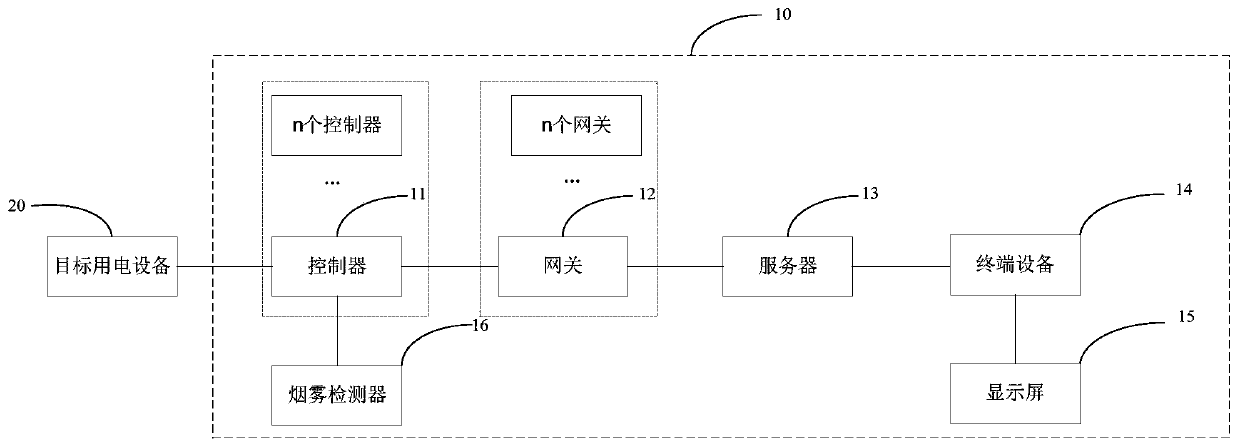

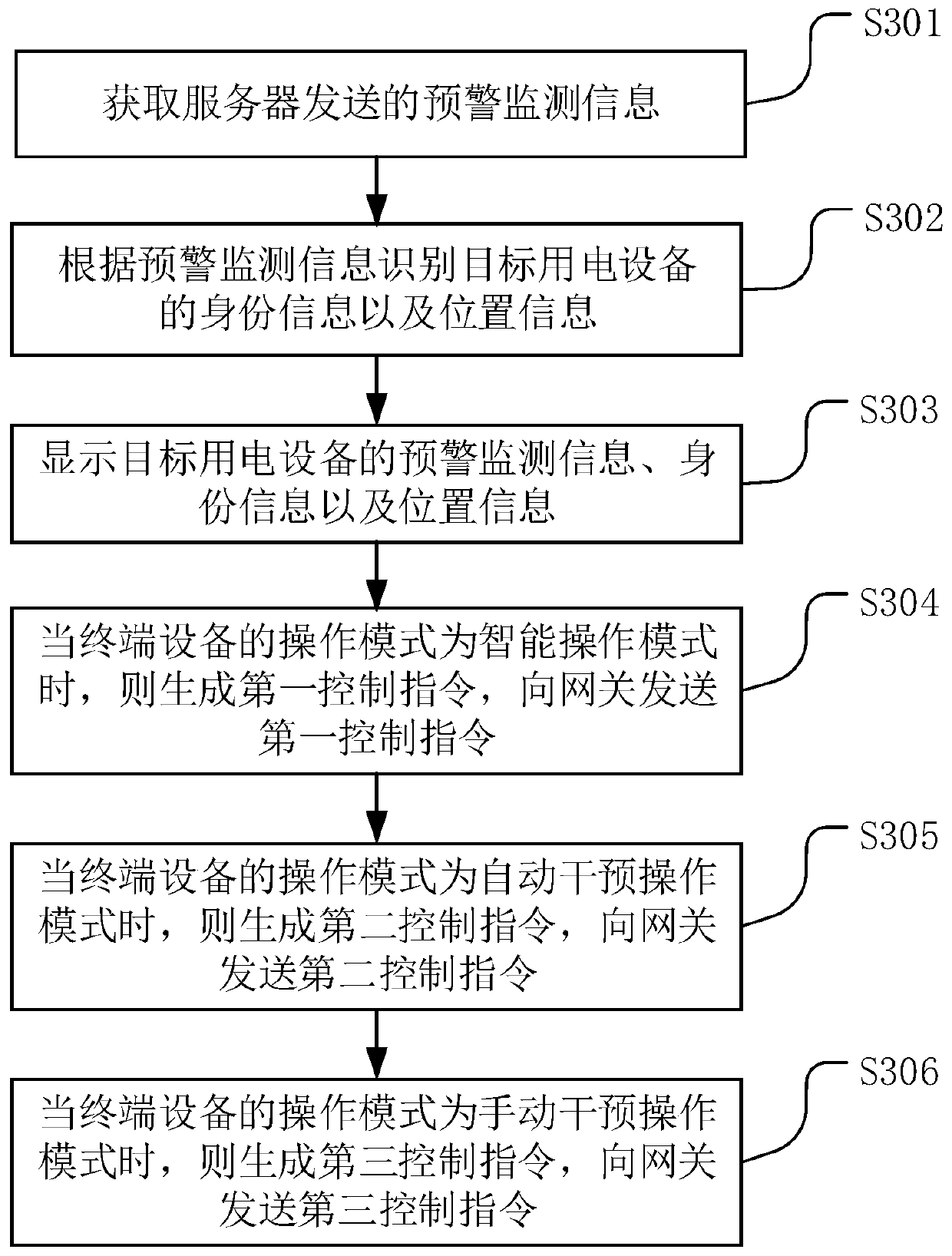

Electric equipment safety early warning monitoring intelligent control system, method and device and terminal equipment

PendingCN111341063AReal-time controlReal-time securityAlarmsNetwork connectionsThe InternetTerminal equipment

The embodiment of the invention is suitable for the technical field of the Internet of Things, and provides an electric equipment safety early warning monitoring and intelligent control system, methodand device, terminal equipment and a computer readable storage medium. The method comprises the steps that the terminal equipment obtains early warning monitoring information sent by a server; identifying identity information and position information of the electric equipment according to the early warning monitoring information; and early warning monitoring information, identity information andposition information of the electric equipment are displayed, and the early warning monitoring information is information acquired by the controller from the electric equipment, sent to the gateway and sent to the server from the gateway. Visibly, the operation and maintenance personnel can remotely detect, control and maintain the electric equipment in real time through the early warning monitoring information, the identity information and the position information of the electric equipment displayed by the terminal equipment, so that the operation and maintenance personnel can immediately eliminate faults and hidden dangers without manual inspection, and the effects of avoiding fire accidents and being efficient and energy-saving are achieved.

Owner:洪阳伟业光电科技(苏州)有限公司

Platinum catalytic system primer in humid environment and preparation method of platinum catalytic system primer in humid environment

InactiveCN104387833AGuarantee coating qualityAvoid increased energy consumptionCoatingsSolventPressure sensitive

The invention discloses a platinum catalytic system primer in a humid environment. The platinum catalytic system primer comprises a primer, a cross-linking agent, a catalyst, an anchoring agent, a water remover and a solvent, wherein the water remover comprises a primary water remover and an auxiliary water remover. The water remover is one or more compounds capable of reacting with water at the normal temperature; the water remover comprises an organic water remover and an inorganic water remover. A preparation method of the primer comprises the following steps of preparing primer diluent, cross-linking agent diluent, catalyst diluent, anchoring agent diluent, water remover diluent in sequence and uniformly mixing the diluent with the solvent to prepare the platinum catalytic system primer in the humid environment; coating the platinum catalytic system primer on the surface of a base material; and finally, desolventizing and curing in an oven, thereby coating a pressure sensitive adhesive.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

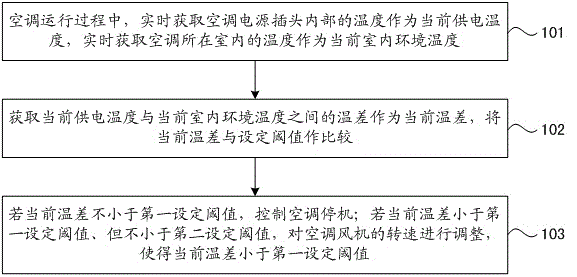

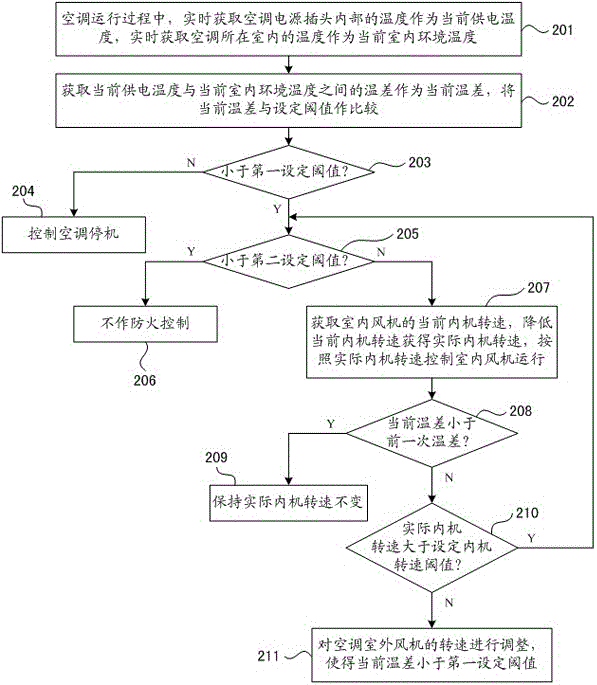

Fire prevention control method of fixed-frequency air conditioner

InactiveCN106839303AAvoid overheating and fire accidentsGuaranteed adjustable comfortMechanical apparatusSpace heating and ventilation safety systemsTemperature differenceEngineering

The invention discloses a fire prevention control method of a fixed-frequency air conditioner. The method includes: during air conditioner operation, acquiring the temperature in an air conditioner power plug in real time to serve as the current power supply temperature, and acquiring the indoor temperature of a room where the air conditioner is located to serve as the current indoor environment temperature; acquiring the temperature difference between the current power supply temperature and the current indoor environment temperature to serve as the current temperature difference, and comparing the current temperature difference with set thresholds; if the current temperature difference is not smaller than the first set threshold, controlling the air conditioner to shut down; if the current temperature difference is smaller than the first set threshold and not smaller than the second set threshold, regulating the rotation speed of an air conditioner fan to allow the current temperature difference to be smaller than the first set threshold. By the fire prevention control method, air conditioner temperature regulating comfortableness can be guaranteed while fire prevention control accuracy and reliability are increased.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Method for static measurement and elimination during polyester chip packaging operation

InactiveCN107640374AAddressing Static ShockAvoid fire accidentsPackagingElectrostatic chargesMeasurement devicePolyester

The invention relates to a method for static measurement and elimination during polyester chip packaging operation, and aims at mainly solving the safety problems that static sparking is likely to occur and operators are likely to suffer from electric shock in the prior art. By adopting the method for the static measurement and elimination during the polyester chip packaging operation, static caused by polyester chips and a packaging bag can be measured and eliminated. According to the technical scheme, a static measurement and elimination device includes a pipeline static eliminating device,a surface static eliminating device, a static measurement device and a PLC control cabinet, wherein the pipeline static eliminating device is installed on the upper end of a packaging blanking pipe ofthe polyester chips and used for eliminating the static carried by the polyester chips or generated during conveying of the polyester chips; the surface static eliminating device is installed on theperiphery of the packaging bag and used for eliminating the static on the surface of the packaging bag; the static measurement device is arranged on a packaging machine operation platform and used formeasuring the voltage of the static on the surface of the packaging bag; operators use the PLC control cabinet to control the implementation of the method for the static measurement and elimination during the polyester chip packaging operation. The method can well solve the problems above, and is applicable to the static measurement and elimination during the polyester chip packaging operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

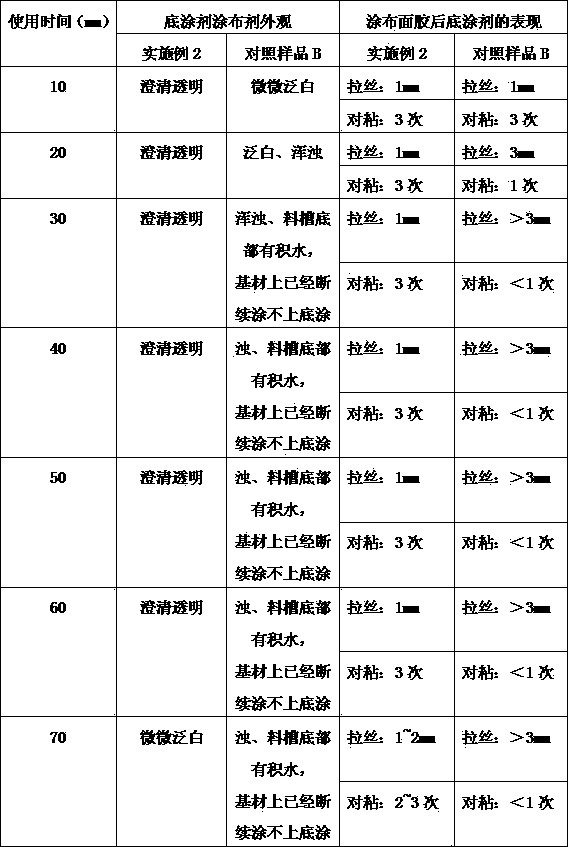

Bottom sizing agent for humid environment and preparation method of bottom sizing agent

The invention discloses a bottom sizing agent for a humid environment. The bottom sizing agent comprises a bottom sizing agent, a crosslinking agent, a catalyst, a catalytic promoter, an anchoring agent, a moisture scavenger and a solvent. The preparation method of the bottom sizing agent comprises the following steps: sequentially preparing a bottom sizing agent diluent, a crosslinking agent diluent, a catalyst diluent, an anchoring agent diluent and a moisture scavenger diluent with the solvent evenly, so as to prepare the bottom sizing agent; coating the bottom sizing agent on the surface of a base material; and finally desolventizing and solidifying in a drying oven, so as to coat a pressure sensitive adhesive. Condensate water which is generated by solvent evaporation gradually reacts by adding substances which can react with water at a room temperature to an ordinary bottom sizing agent, but not destroy chemical components of the bottom sizing agent; the coating quality of bottom coating is ensured; a fire accident caused by energy consumption increase and electrostatic accumulation generated by cooling and dehumidifying a bottom coating room is avoided; the variety and amount of the moisture scavenger are changed; and the operational use time of the bottom sizing agent in the humid environment can be adjusted.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

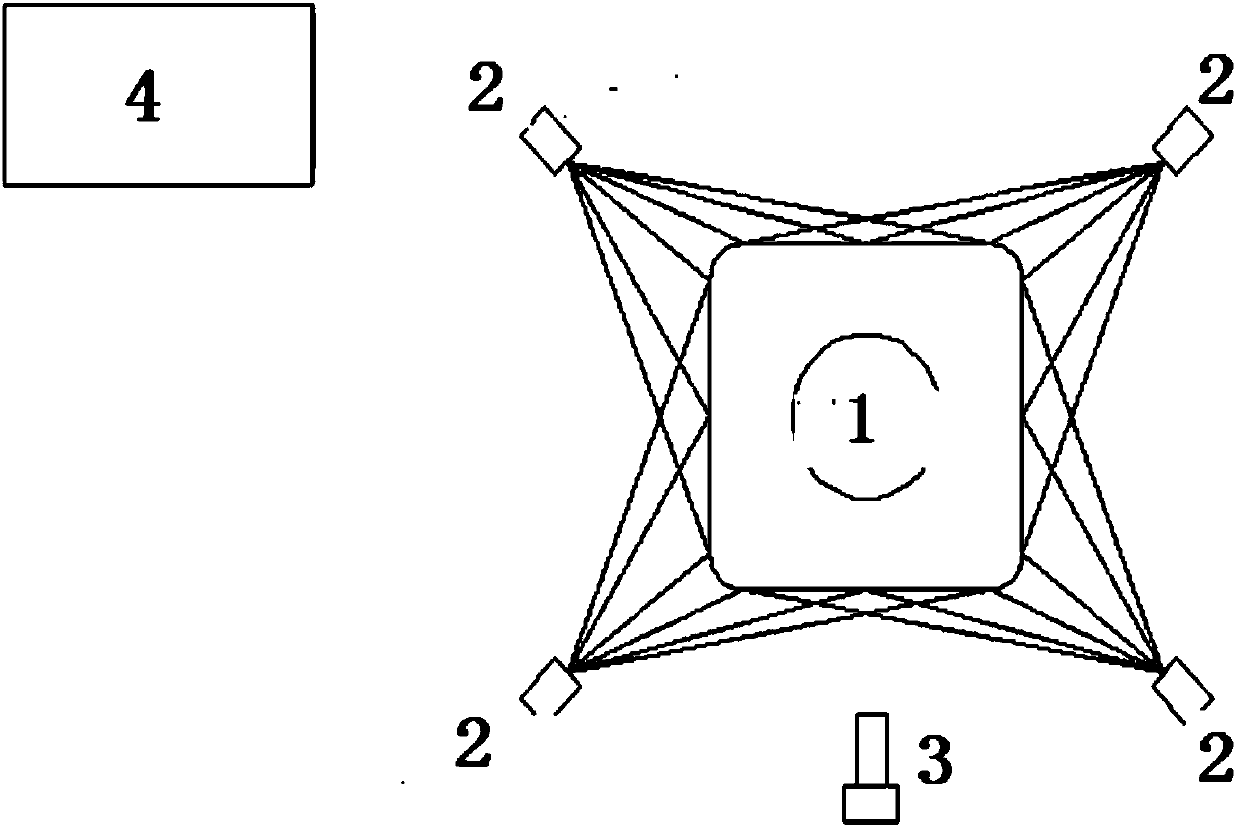

Automatic alarm fire extinguishing system for high-voltage hollow reactor

PendingCN110755774AImprove fire response efficiencyAvoid fire accidentsTransformers/inductances coolingFire rescuePipingProcess engineering

The embodiment of the invention discloses an automatic alarm fire extinguishing system for a high-voltage hollow reactor. The reactor comprises a reactor body, a supporting frame is arranged in the hollow position inside the reactor body, a cooling water pipe is wound on the supporting frame, a plurality of spraying structures are arranged on the cooling water pipe, the spraying structures are connected with the cooling water pipe through a control valve, the control valve comprises a shell and an electromagnetic module, a manual module and a temperature control module which are connected withthe shell, a temperature detection unit is arranged on the reactor body, the temperature detection unit is electrically connected with a control loop, and the electromagnetic module is electrically connected with the control loop. According to the system, the temperature of the reactor is monitored in real time through the temperature detection unit arranged in the reactor body and the temperature information is fed back to the control circuit, and when the temperature is higher than the set value, the spraying structures are controlled through the control circuit to help the reactor to perform automatic cooling and fire extinguishing.

Owner:GUANGDONG POWER GRID CO LTD +1

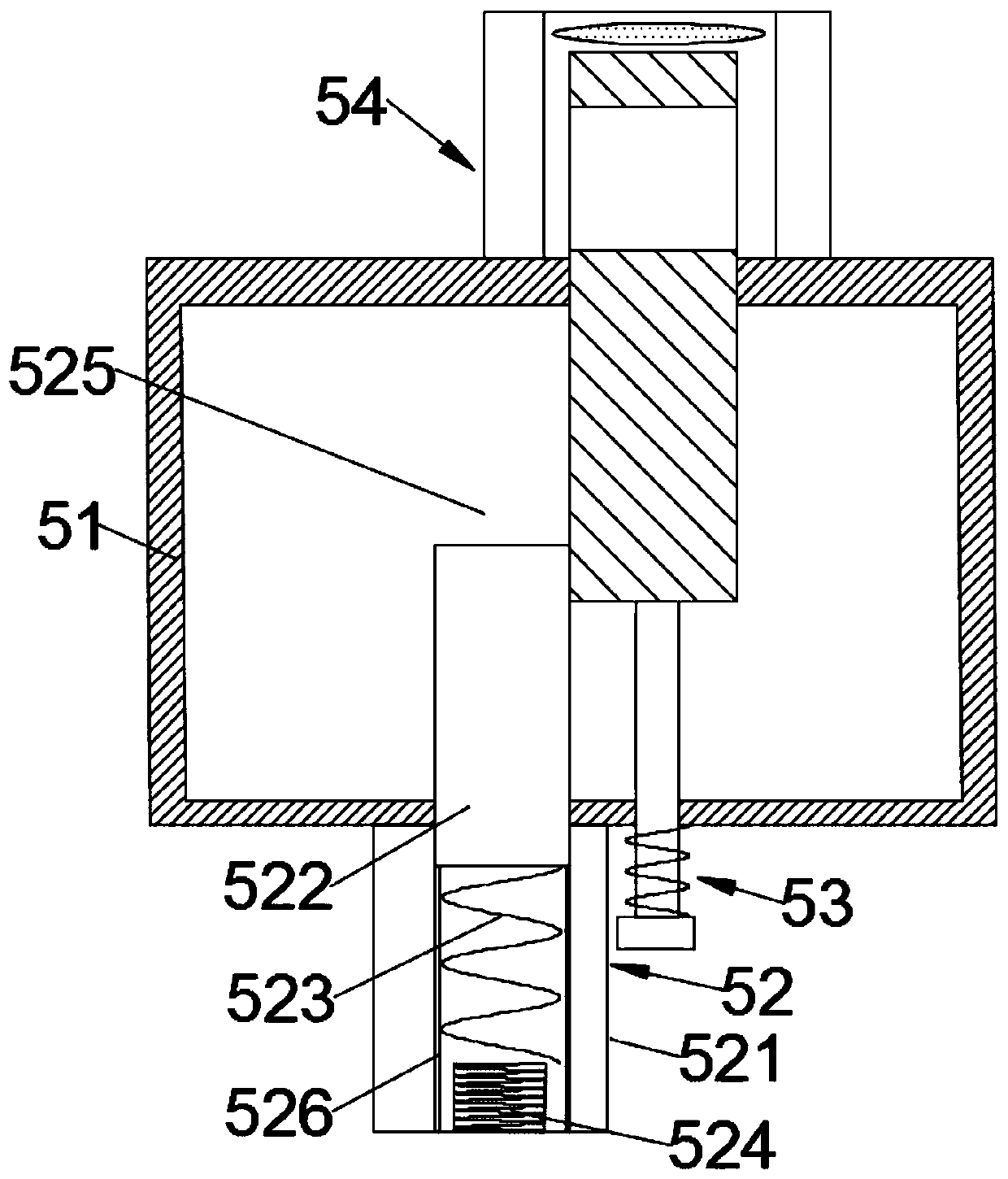

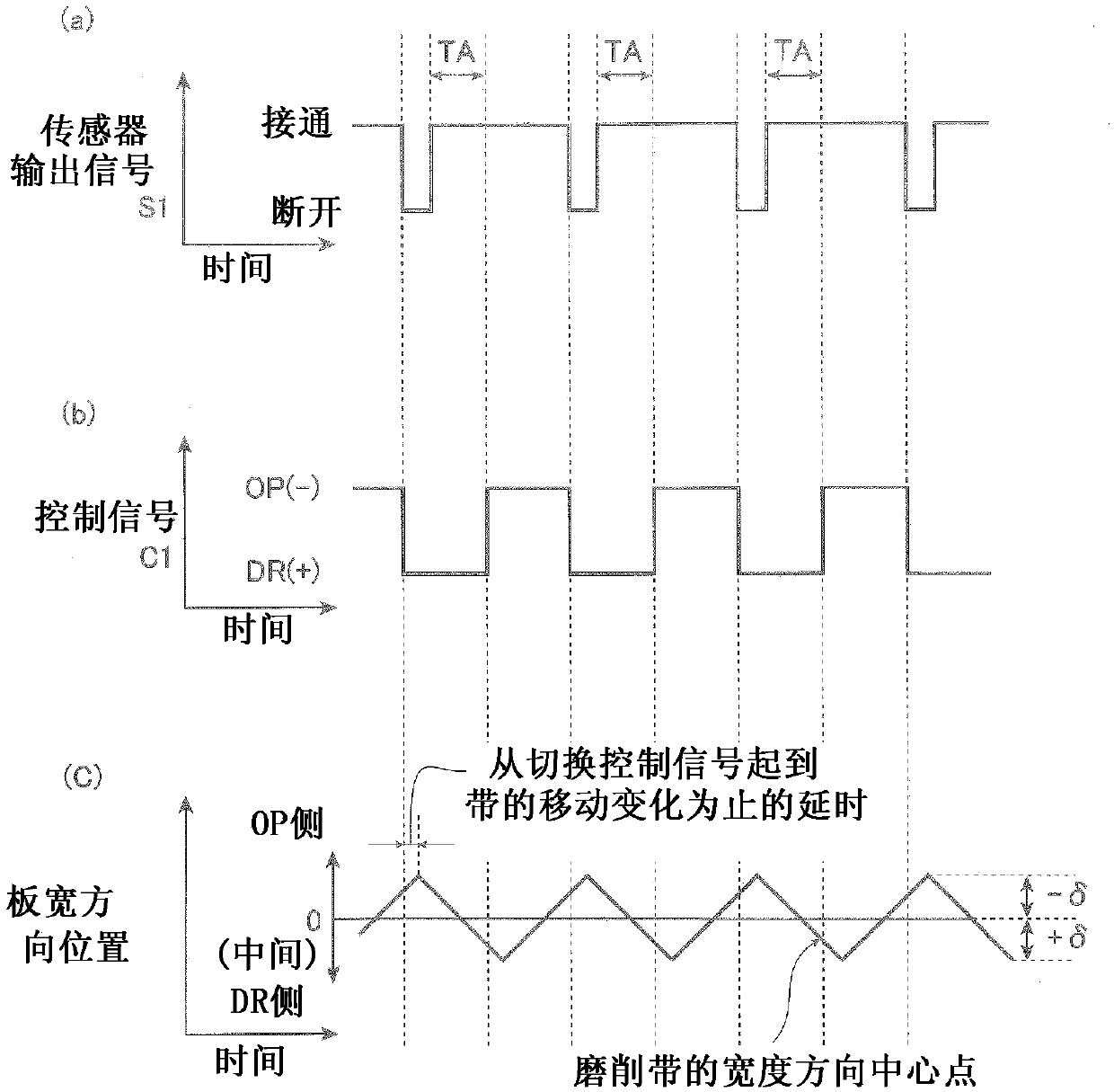

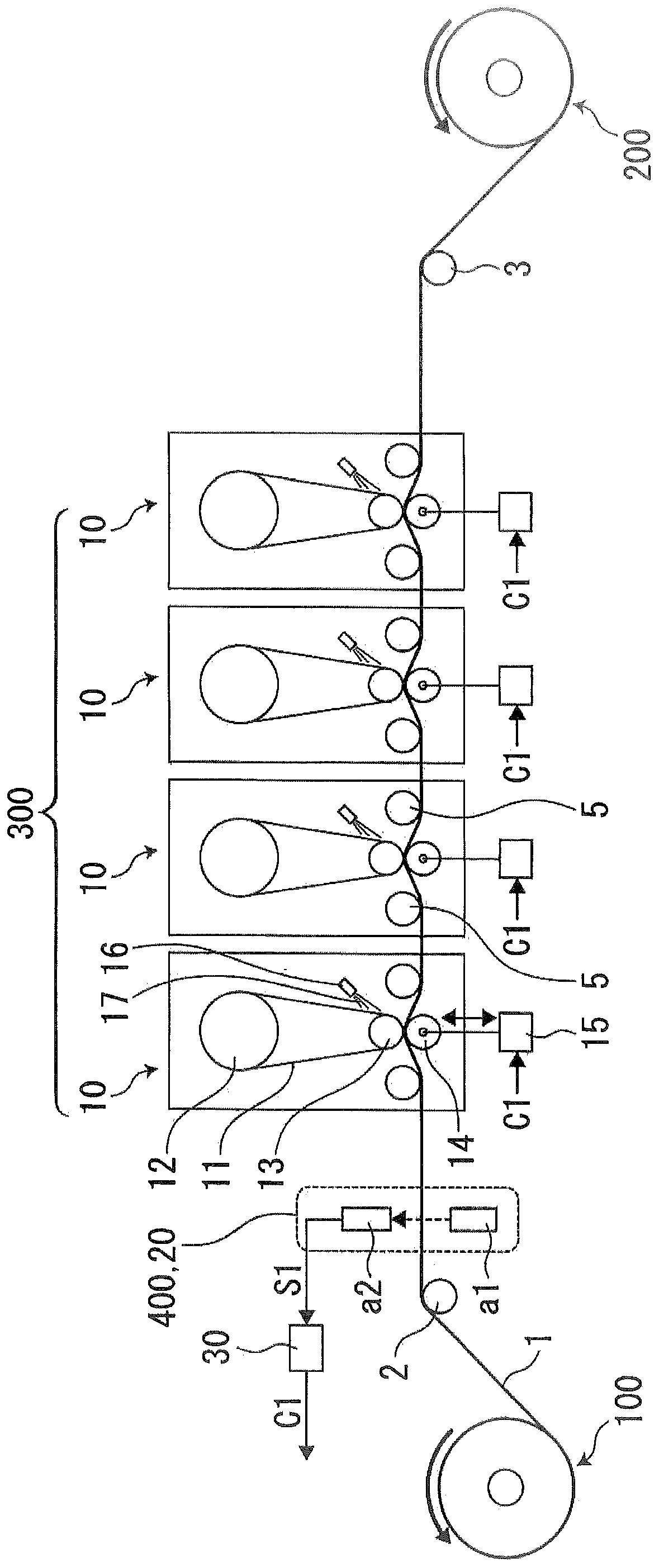

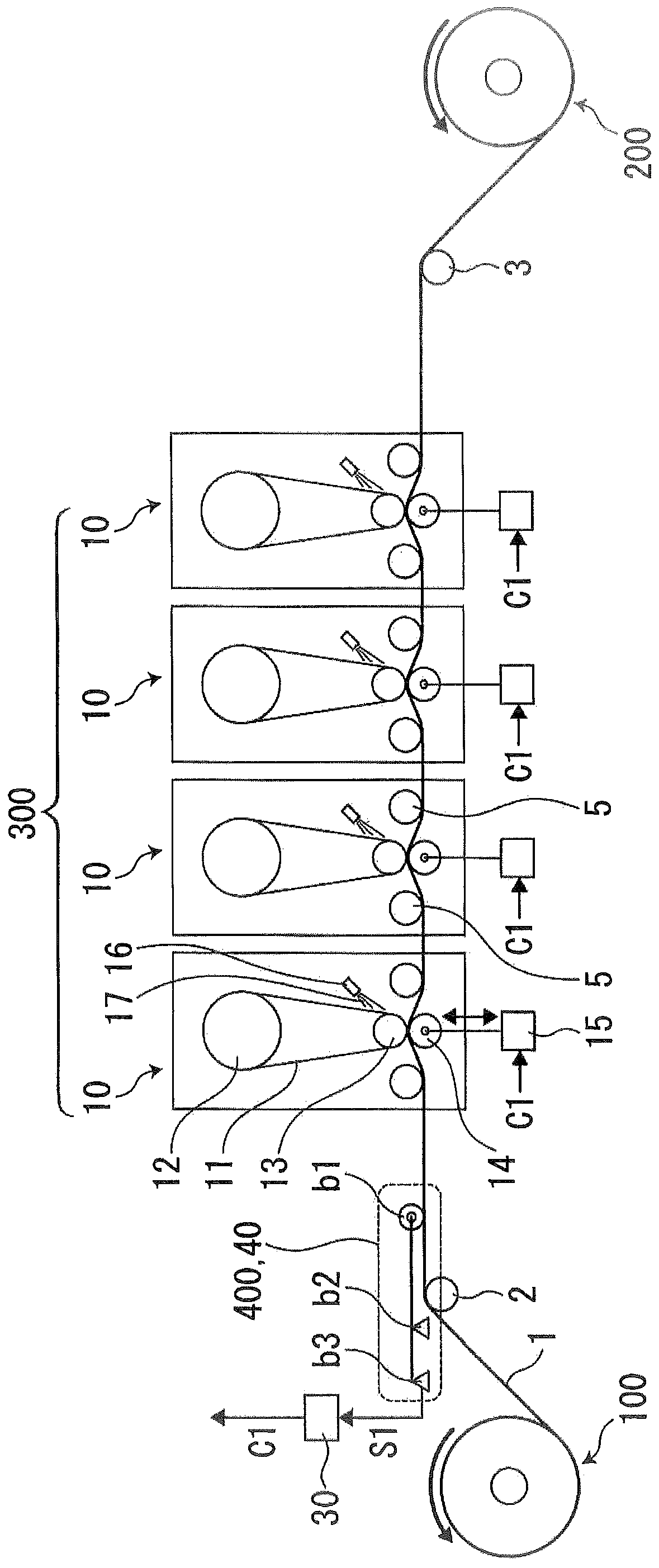

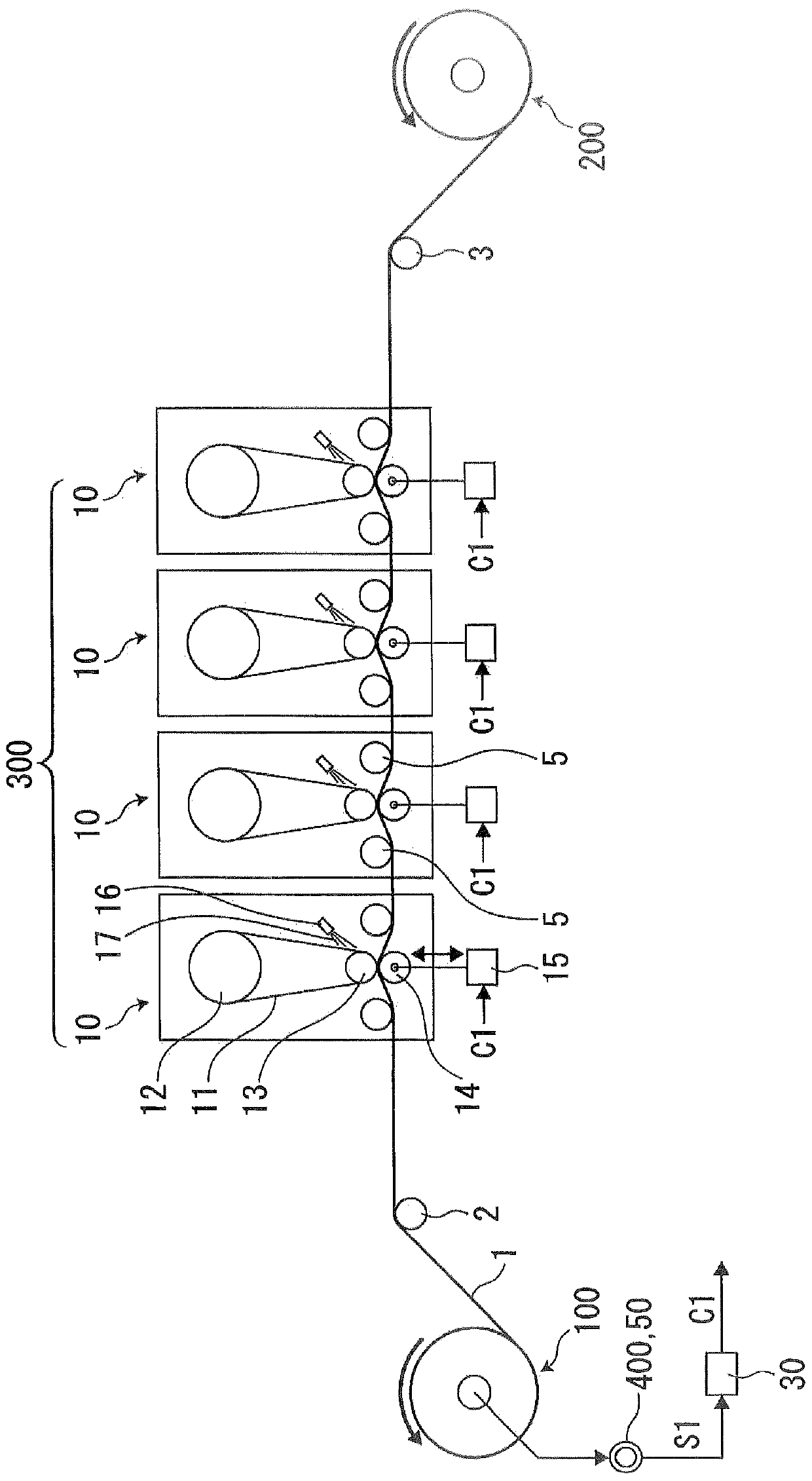

A belt-type grinding device for a metal belt and a belt-type grinding method for the metal belt

ActiveCN109719597AAvoid fire accidentsGood effectBelt grinding machinesGrinding feed controlControl signalEngineering

The present invention addresses the problem of providing a belt-type grinding device for a metal belt and a belt-type grinding method for the metal belt, which are useful for preventing a fire accident in a grinding operation. This belt-type grinding device is provided with: a rotating grinding belt that grinds the entire surface of a metal belt in a through-plate; a belt reciprocating actuator that reciprocates the grinding belt in the plate width direction of the metal belt; an end detection sensor for detecting the end of the grinding belt in the width direction; and a control unit that uses the sensor output signal of the end detection sensor to generate a control signal for controlling the belt reciprocating actuator.

Owner:JFE STEEL CORP

Briquette drying method

ActiveCN103398559AReduce lossesSolve dust accumulationDrying machines with progressive movementsDrying solid materialsHeat lossesBriquette

The invention relates to a briquette drying method. A drying furnace used by the briquette drying method comprises a furnace body, a coal outlet hopper arranged at the bottom of the furnace body, an air channel arranged in the furnace body and a coal channel arranged in the furnace body. The coal channel comprises a longitudinal coal channel and a horizontal coal channel which are communicated with each other, wherein the horizontal coal channel is arranged at the bottom in the furnace body, and the longitudinal coal channel and the air channel are distributed at interval and are arranged above the horizontal coal channel. The air channel is communicated with the horizontal coal channel through a dust exhaust hole, coal rods can previously enter the longitudinal coal channel through the top of the drying furnace and then slowly move downwards along the longitudinal coal channel to enter the horizontal coal channel, the coal rods is in contact with hot air to exchange heat with the hot air in a moving-downwards process, and finally the coal rods can move downwards to a tray to be vibrated and discharged by a vibrator. The drying furnace can automatically exhaust dust, is small in heat loss in exhausting dust, effectively solves the problem that dust accumulation in air channel, guarantees even distribution of the hot air and is high in heat utilization rate. Meanwhile, the drying furnace solves the problems of coal accumulation, fire caused by overhigh negative pressure and uneven coal output quantity.

Owner:柳州化工股份有限公司

Monitoring device used for high voltage switch cabinet

PendingCN107860494AAvoid burning high voltage switchgearAvoid fire accidentsThermometer applicationsEngineeringHand held

The invention provides a monitoring device used for a high voltage switch cabinet, and belongs to the field of electric power detection. The monitoring device comprises a mobile telescopic supportingmember, temperature sensors and a power supply module. The mobile telescopic supporting member comprises an external supporting member, an internal supporting member and a base. The internal supporting member is provided with through holes. A supporting frame used for arranging the temperature sensors is fixedly connected in the through hole. The external supporting member is provided with a box which is internally provided with the power supply module, a first control unit and a communication module. A handheld control terminal maintains communication with the first control unit through the communication module. The temperature of the moving and static contacts can be directly detected through the temperature sensors arranged on the mobile telescopic supporting member and transmitted to the handheld control terminal through the first control unit and the communication module, the work personnel can know the temperature of all the moving and static contacts in the high voltage switch cabinet anytime through the handheld control terminal and the heating moving and static contacts can be maintained in time so that the situation of burnout of the high voltage switch cabinet and the fire accident can be avoided.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +1

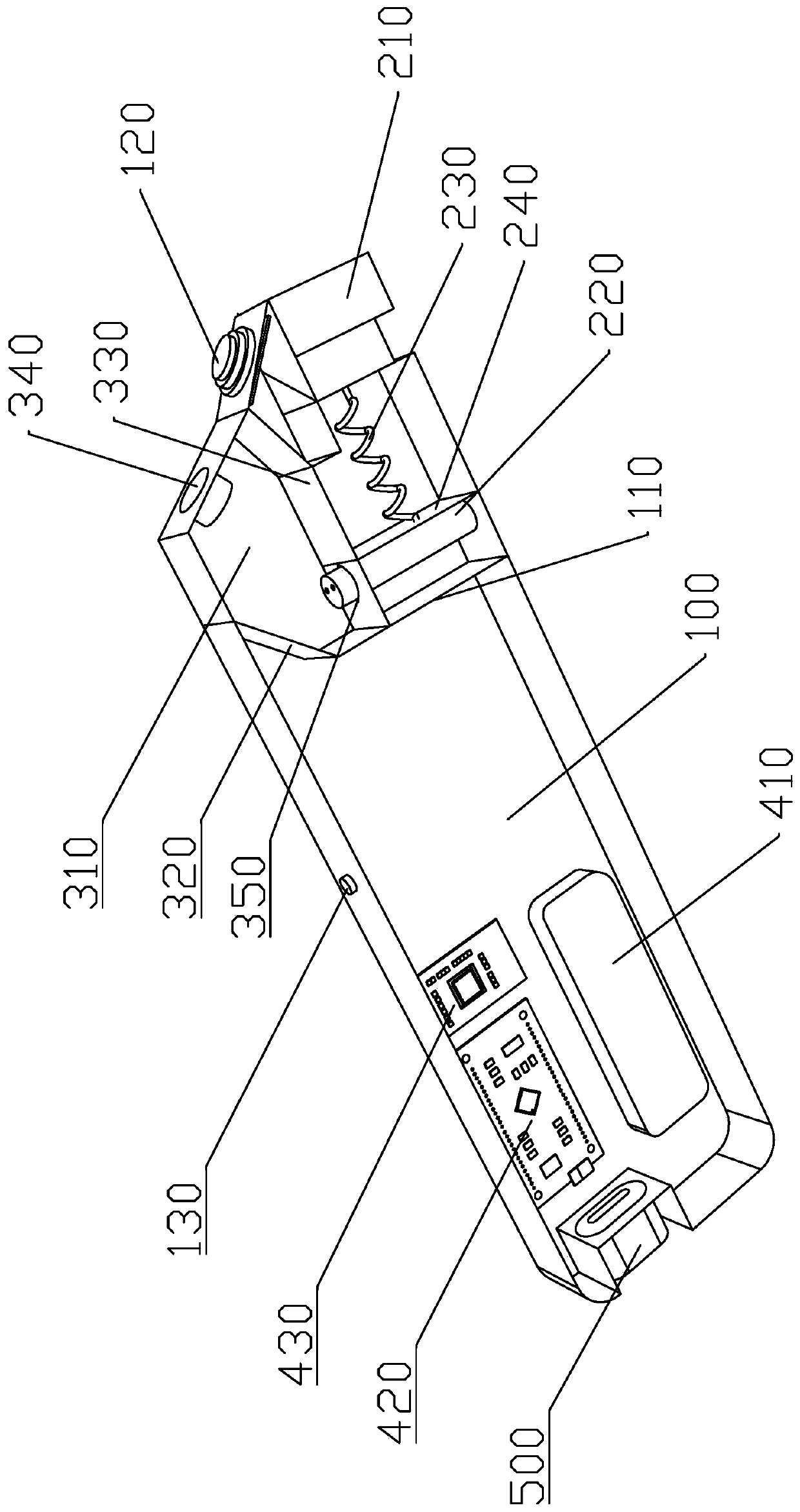

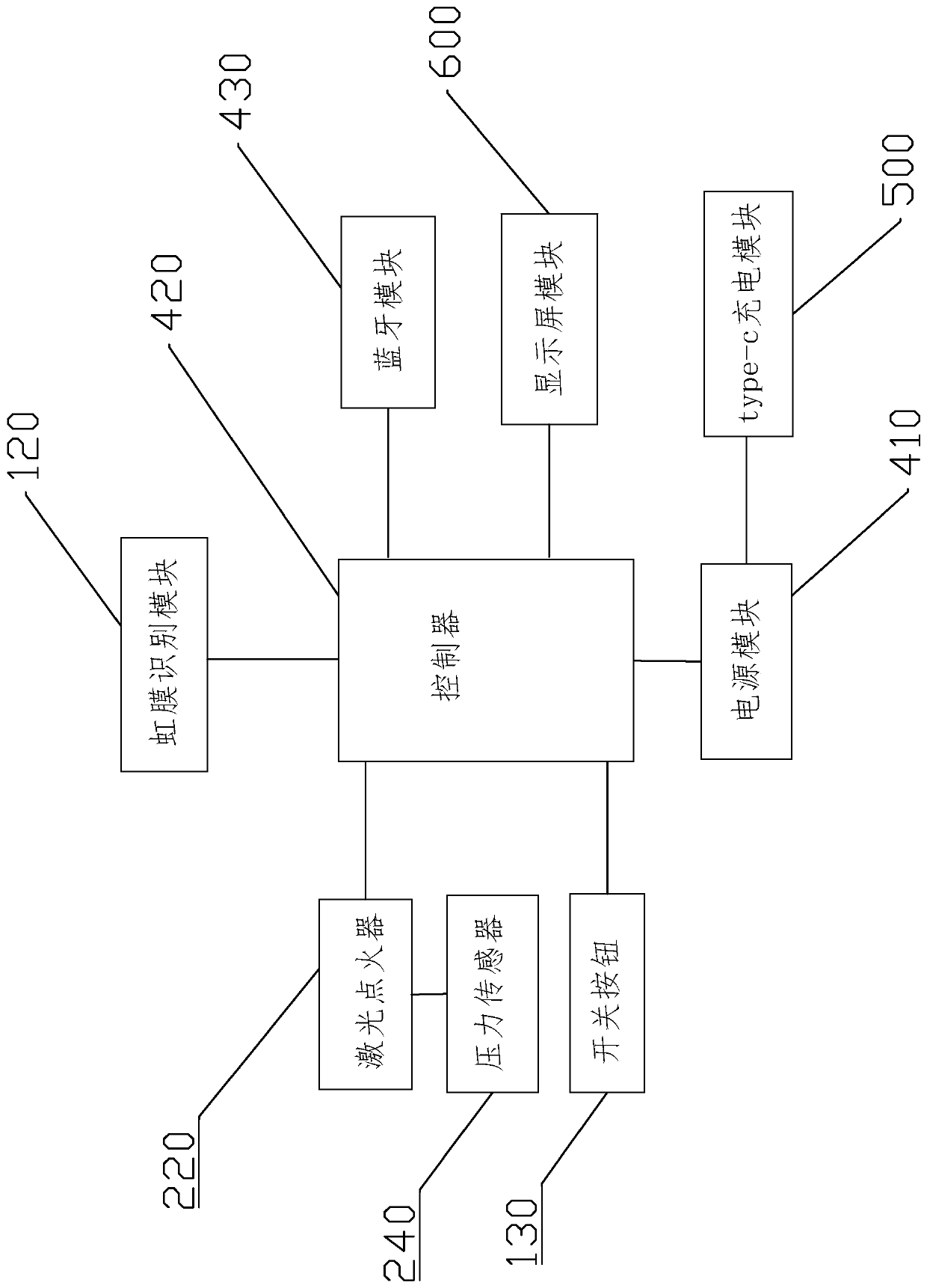

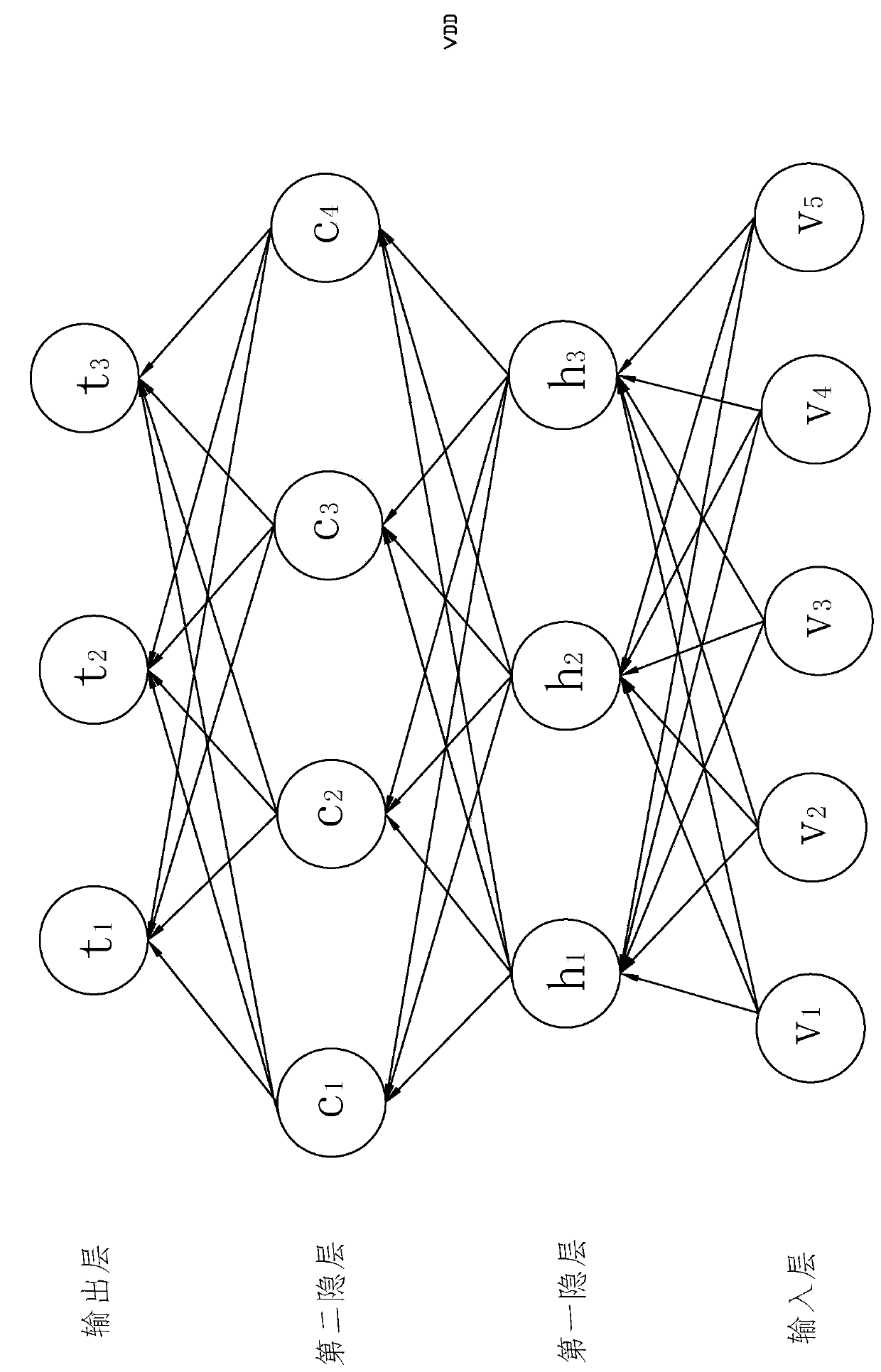

Laser lighter and control method

PendingCN109764356AImprove securityAvoid fire accidentsCharacter and pattern recognitionCombustion ignitionLaser lightElectric energy

The invention discloses a laser lighter and control method. The laser lighter includes a machine body, wherein the machine body includes a hollow cavity, an iris recognition module and a switch button; the hollow cavity is divided into a first part and a second part from top to bottom by a splitter board, and the first part is provided with an ignition structure and a light focusing structure; theignition structure includes an ignition button and a laser igniter, the light focusing structure includes an ignition cavity, and the ignition cavity is formed by enclosing a part of a light reflecting board, a light focusing board, and the splitter board and the inner wall of the hollow cavity; and the second part includes a controller, a Bluetooth module and a power module, and the power moduleis used for providing electric energy for the laser igniter. According to the laser lighter, non-contact collecting is conducted on iris information of users, pre-entering iris information is processed and matched, the laser lighter is intelligently controlled to execute igniting operation, children are prevented from using the laser lighter as toys to cause a fire accident due to curiosity, andsafety of the laser lighter is improved.

Owner:FOSHAN POLYTECHNIC

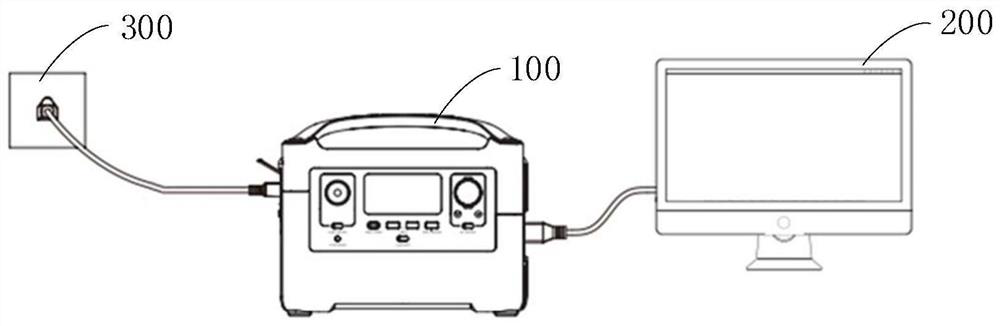

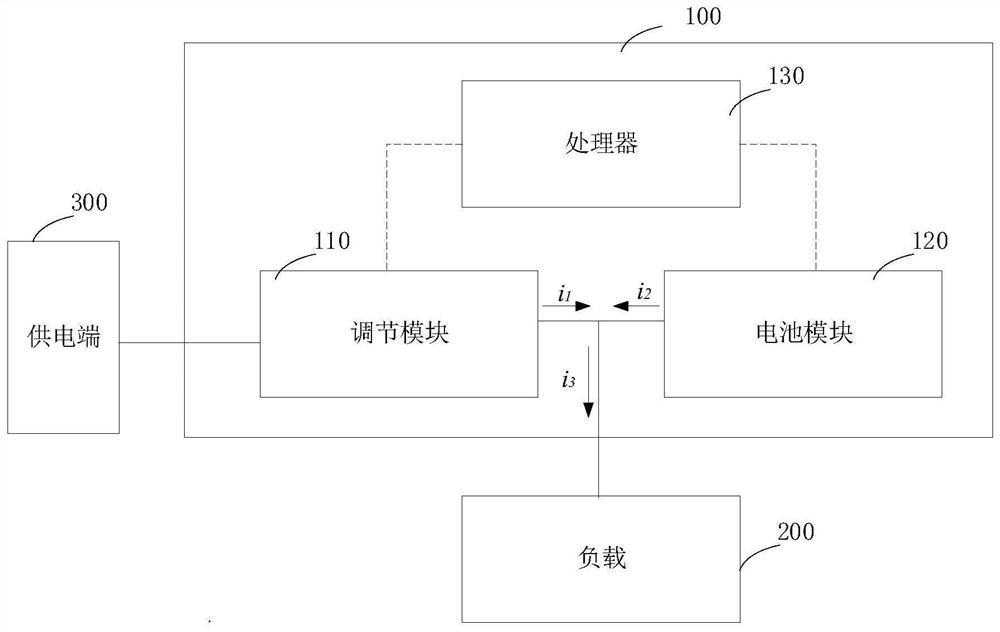

Electric quantity control method and device of energy storage equipment and energy storage equipment

ActiveCN112928798AReduce the number of charge and discharge cyclesExtended service lifeSecondary cells charging/dischargingElectric powerAutomotive engineeringElectrical battery

The invention discloses an electric quantity control method and device of energy storage equipment and the energy storage equipment, the energy storage equipment comprises a battery module and an adjusting module, and the method comprises the steps of: when a power supply end normally supplies power, obtaining the current electric quantity of the battery module; judging whether the current electric quantity reaches a preset electric quantity threshold value or not; judging whether the load is in a power utilization state or not; and if the current electric quantity reaches the electric quantity threshold value and the load is in a power utilization state, adjusting the output voltage of the adjusting module, so that the battery current of the battery module is reduced to a first set range, and the electric quantity of the battery module is maintained in a preset electric quantity range. The electric quantity of the battery module of the energy storage equipment can be maintained at the preset electric quantity threshold value, the service life of the energy storage equipment can be prolonged, overcharge can be effectively prevented, and fire accidents are avoided.

Owner:ECOFLOW TECH LTD

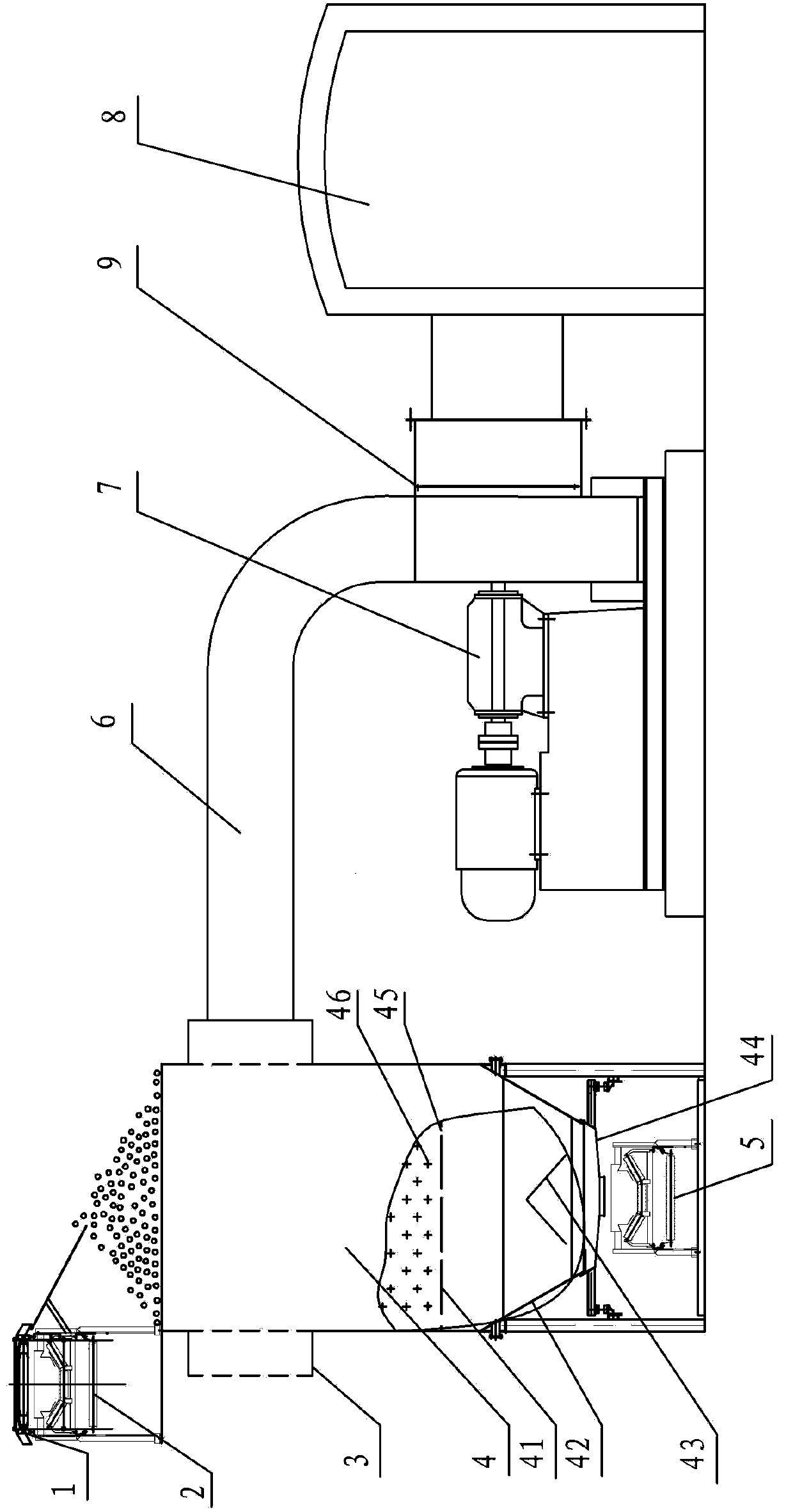

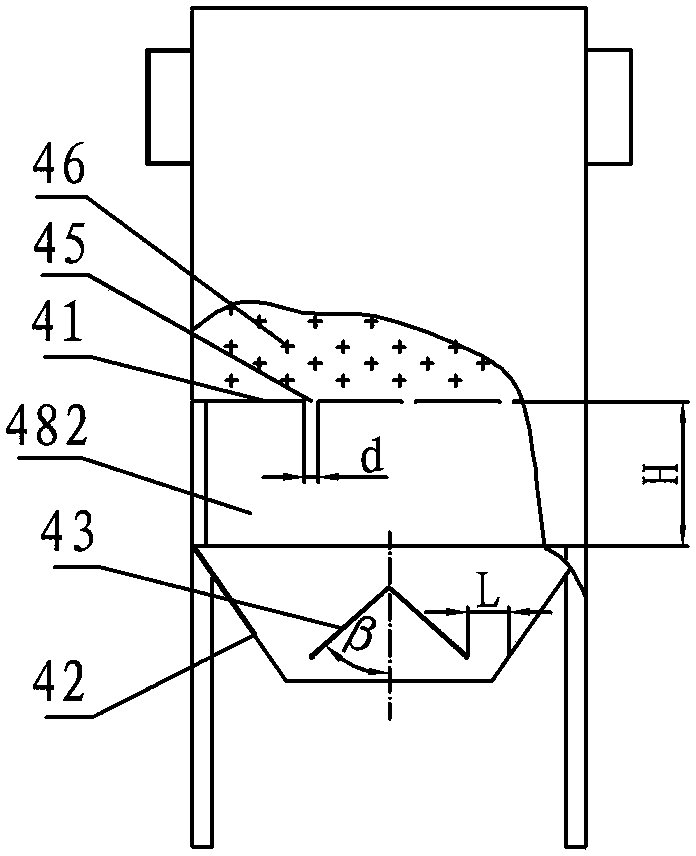

Continuous grinding method and continuous grinding production line for metal strip

ActiveCN109848805AAvoid fire accidentsBelt grinding machinesGrinding feed controlMetal stripsDriving current

The present invention addresses the problem of providing a continuous grinding method for a metal strip and a continuous grinding production line for a metal strip, which are useful for preventing anignition accident during grinding work, in particular for preventing an ignition accident associated with a through-plate abnormality (plate cracking, tail breaking). The invention discloses a continuous grinding method for a metal strip. a metal belt is released by the pay-off reel; the direction is changed by an inlet side deflection guide roller; a grinding frame row is used for whole-surface grinding; the outlet side deflection guide roller is used for turning; a tension coiler is used for coiling and recycling; Whether a plate is present or not for detecting the presence or absence of themetal strip is detected. the tachometer is used for detecting the rotating speed of the pay-off reel; At least one of a galvanometer for detecting the drive current of the pay-off reel or the tensioncoiler and a tension meter for detecting the tension of the metal strip is used as an operation sensor, and the occurrence of a through-plate abnormality of the metal strip is detected according to asensor output signal S1 (or S2) of the operation sensor.

Owner:JFE STEEL CORP

Containing box for conveniently combusting mosquito-repellent incense

InactiveCN104322477ASolve the burning methodEasy to useAnimal repellantsFumigatorsPublic placeFire - disasters

The invention provides a containing box for conveniently combusting mosquito-repellent incense. The containing box is composed of an L-shaped containing box, a protection mesh cover, a bracket and a suspension ring. The containing box can be conveniently and flatly put on a desktop or can be suspended on the needed position; the protection mesh cover is designed so that children are prevented from being scalded by careless contact and fire disasters are prevented from accidentally occurring; the containing box has a fashionable and clean appearance and is suitable for public places and families to use.

Owner:张义兵

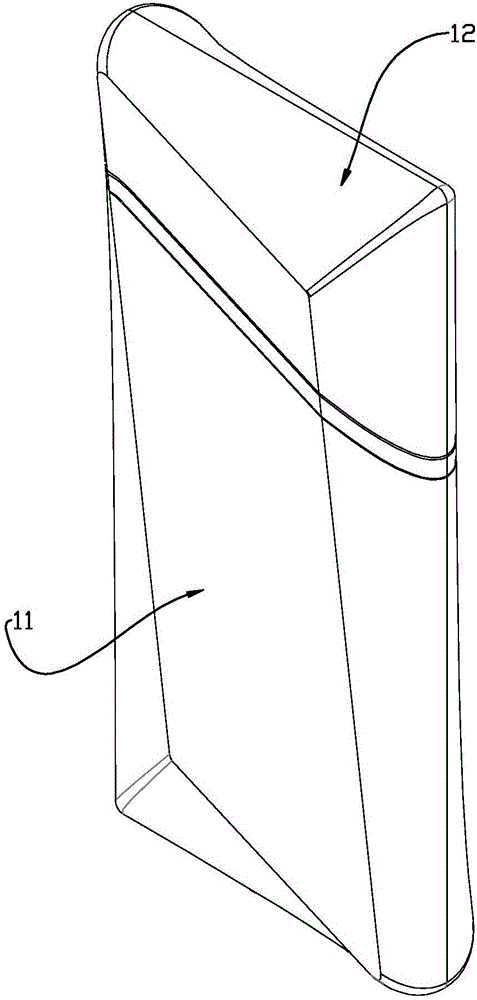

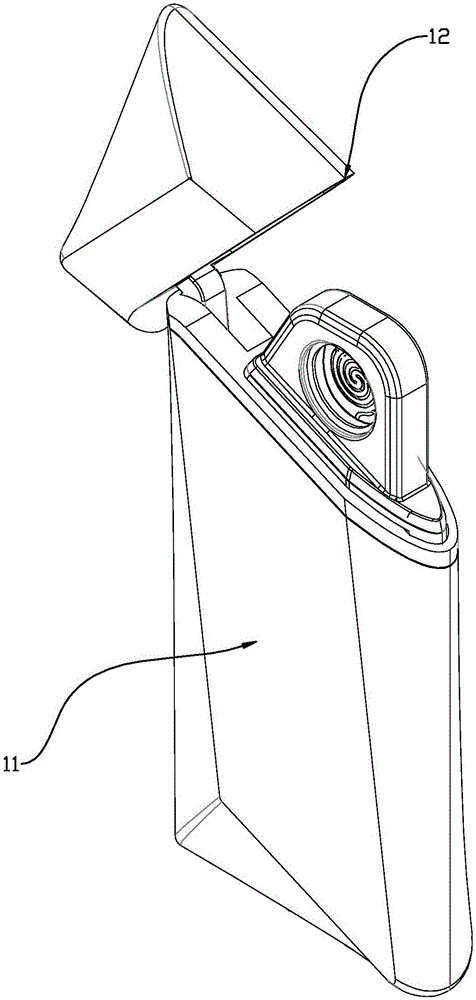

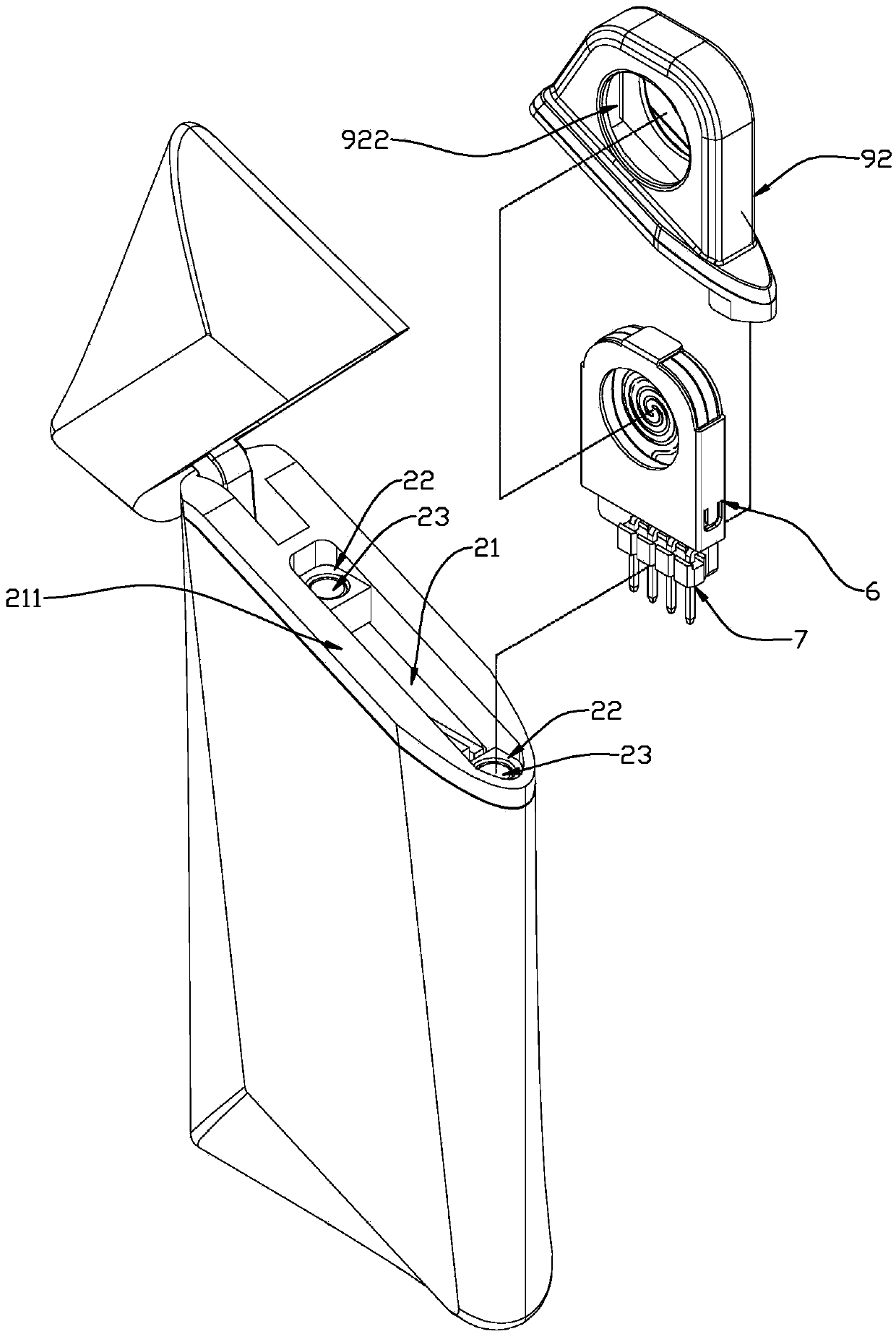

Cigarette lighter with electric heating unit easy to replace

The invention discloses a cigarette lighter with an electric heating unit easy to replace. The cigarette lighter comprise a shell and a cover, and a middle frame, a circuit board, a battery, a switch, the electric heating unit and an electric heating unit cover are installed in the shell and the cover; a socket for allowing the electric heating unit to insert is formed in the middle frame; the electric heating unit comprises an electric heating part, an electric heating circuit board electrically connected with the electric heating part, an insulating sheet and a housing, the electric heating part, the electric heating circuit board and the insulating sheet are sequentially installed in the housing in a sandwich structure to form an integral structure, a through hole for allowing local of the electric heating part to be exposed is formed in the housing, and the electric heating circuit board is inserted into the socket through the extension end exposed out of the housing and matched with an insertion groove formed in the circuit board through a contact pin to form close insertion fitting; the electric heating unit cover is provided with an installation cavity for allowing the electric heating unit to slide in and a cigarette lighting opening corresponding to the electric heating part, and the electric heating unit cover is attracted to the middle frame through magnetic sheets. The cigarette lighter has the advantages of being stable in electrical contact, firm in installation structure, easy, convenient and rapid to disassemble and replace and the like.

Owner:WENZHOU DIANWANG ELECTRONICS TECH CO LTD

A cigarette lighter with an easy-to-replace electric heating unit

The invention discloses a cigarette lighter with an electric heating unit easy to replace. The cigarette lighter comprise a shell and a cover, and a middle frame, a circuit board, a battery, a switch, the electric heating unit and an electric heating unit cover are installed in the shell and the cover; a socket for allowing the electric heating unit to insert is formed in the middle frame; the electric heating unit comprises an electric heating part, an electric heating circuit board electrically connected with the electric heating part, an insulating sheet and a housing, the electric heating part, the electric heating circuit board and the insulating sheet are sequentially installed in the housing in a sandwich structure to form an integral structure, a through hole for allowing local of the electric heating part to be exposed is formed in the housing, and the electric heating circuit board is inserted into the socket through the extension end exposed out of the housing and matched with an insertion groove formed in the circuit board through a contact pin to form close insertion fitting; the electric heating unit cover is provided with an installation cavity for allowing the electric heating unit to slide in and a cigarette lighting opening corresponding to the electric heating part, and the electric heating unit cover is attracted to the middle frame through magnetic sheets. The cigarette lighter has the advantages of being stable in electrical contact, firm in installation structure, easy, convenient and rapid to disassemble and replace and the like.

Owner:WENZHOU DIANWANG ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com