Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Avoid compression set" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

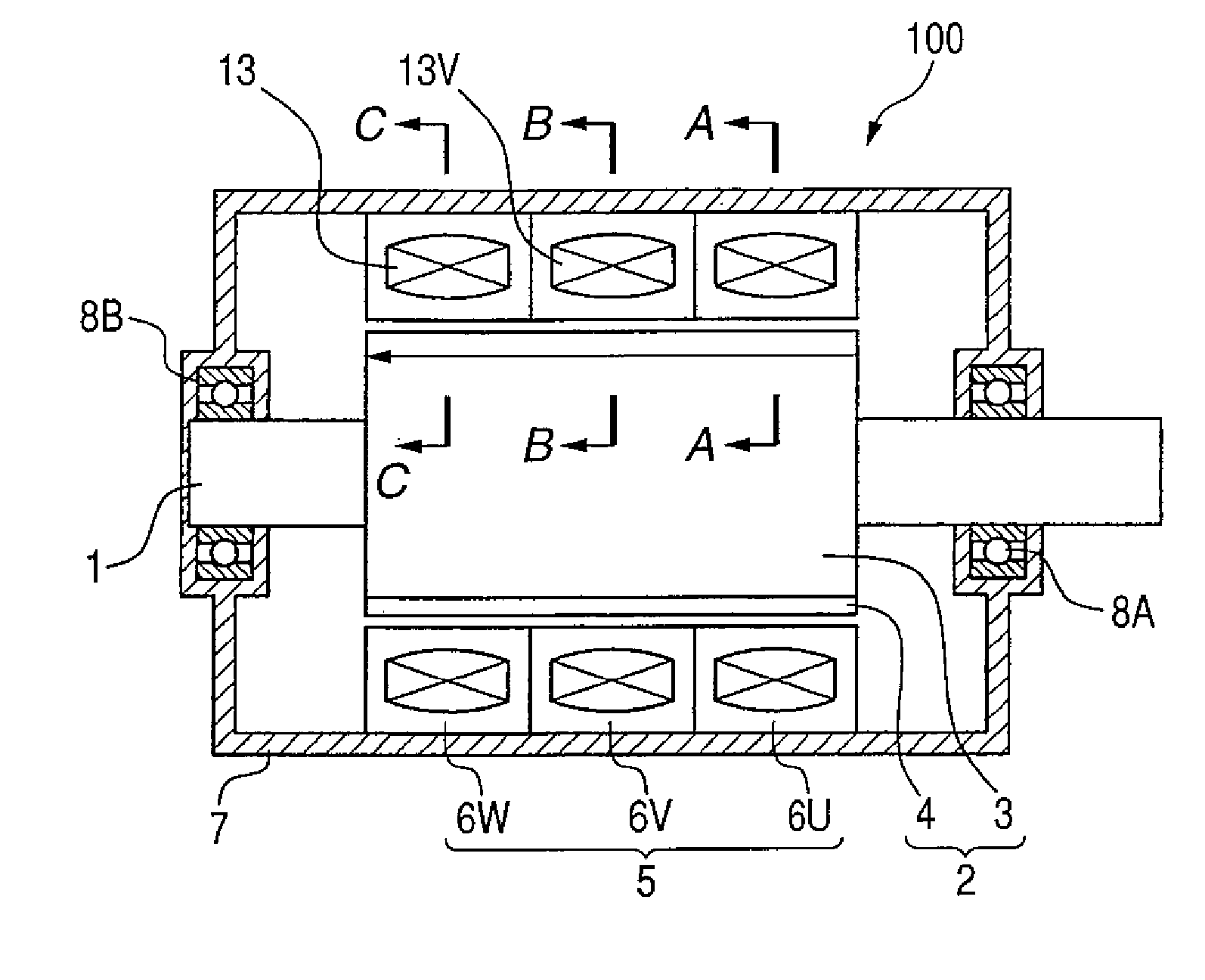

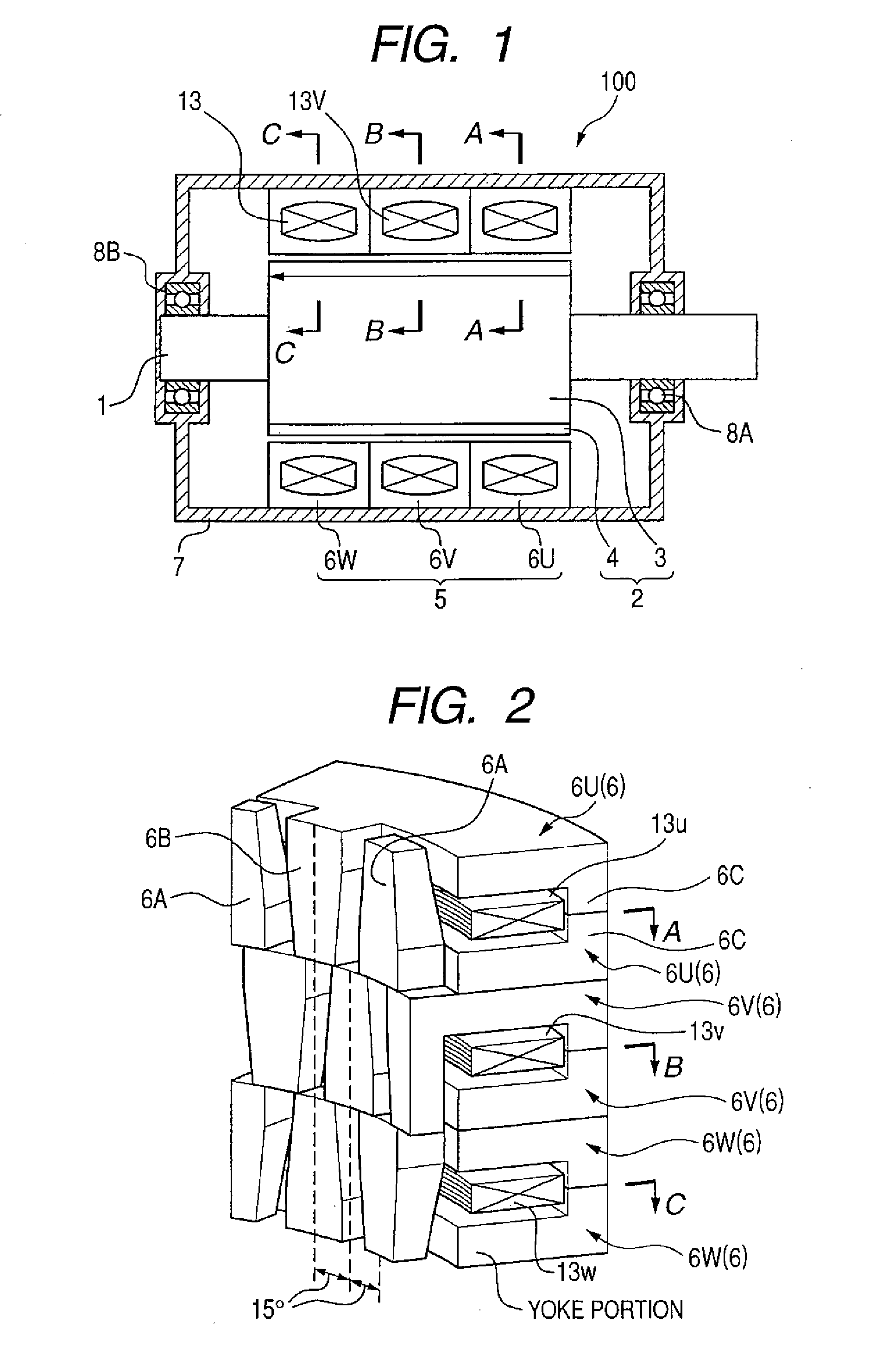

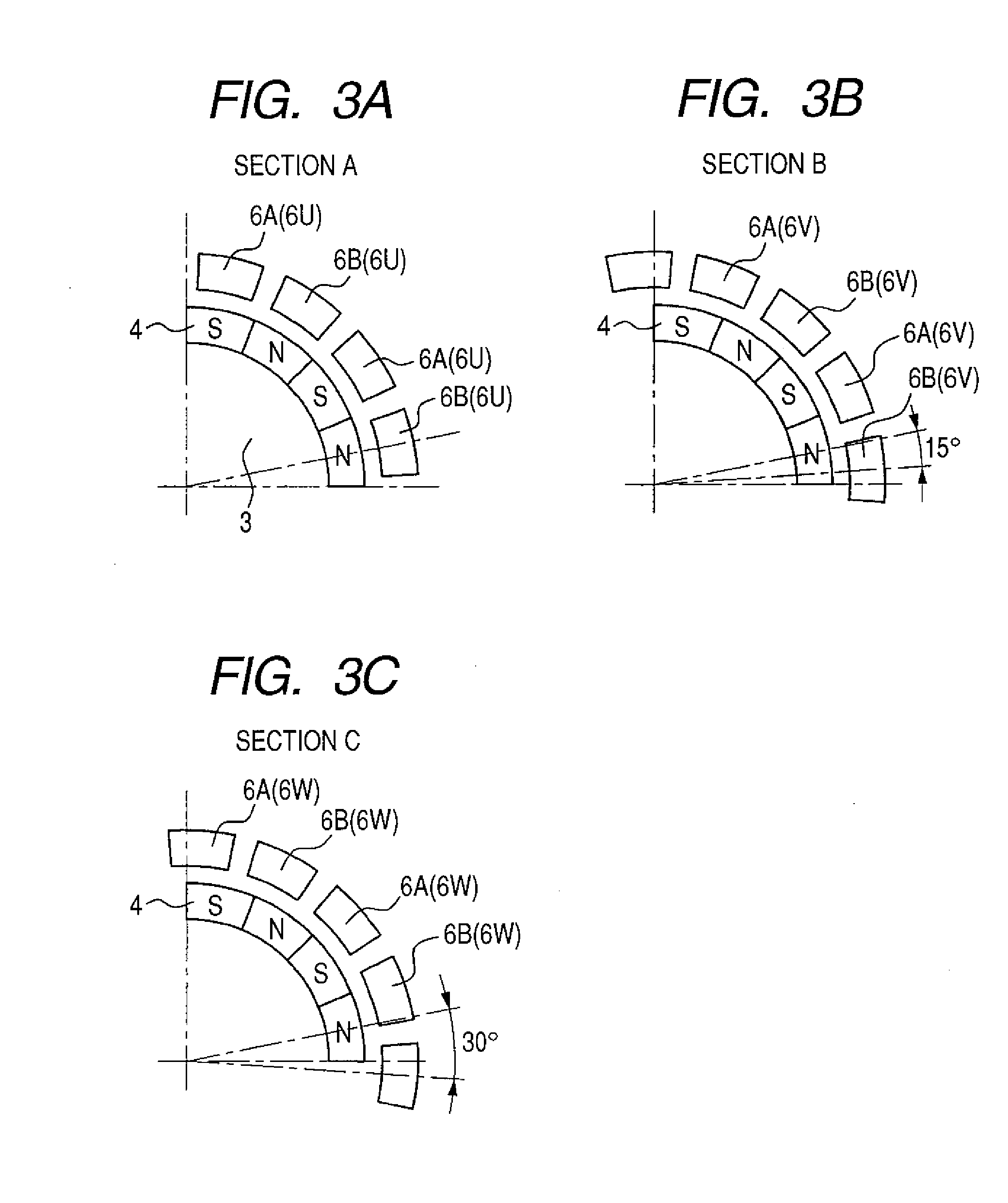

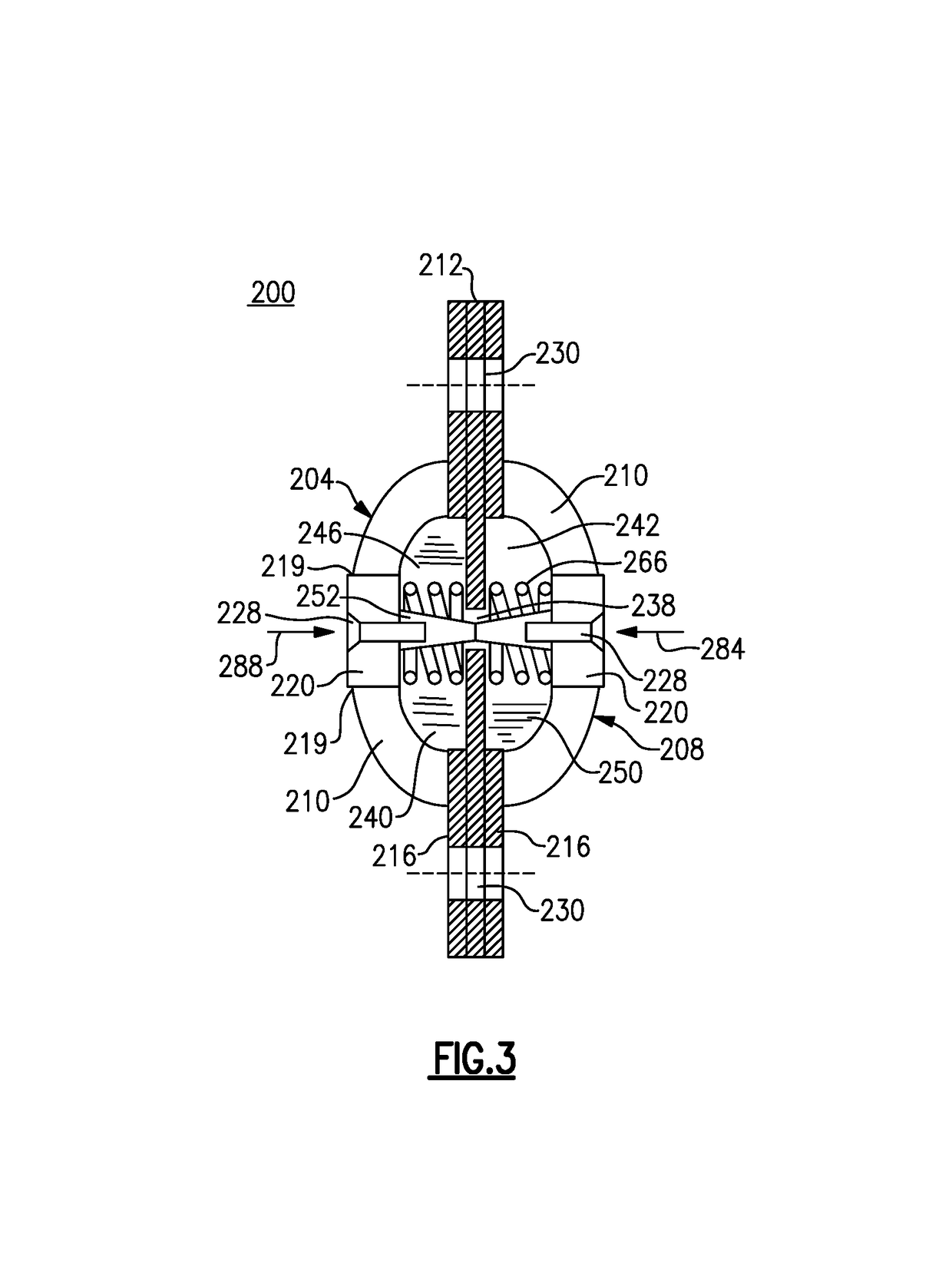

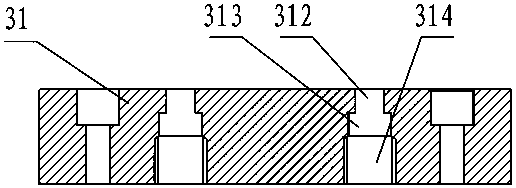

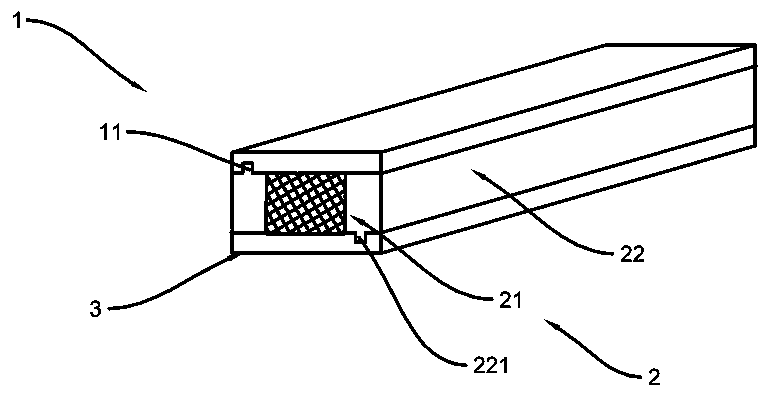

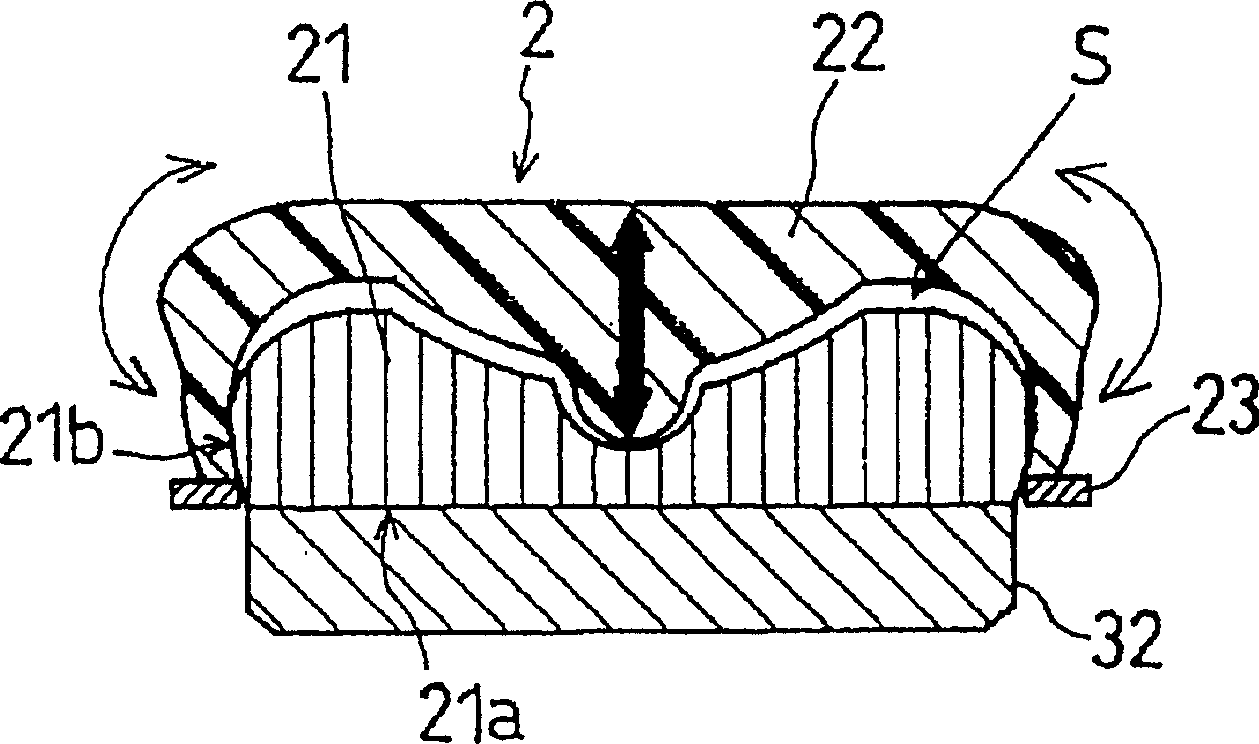

Claw Teeth Type Electric Rotary Machine and Manufacturing Method for Stators

InactiveUS20080018196A1Avoid compression setHigh mechanical strengthWindingsMagnetic circuit stationary partsEngineeringNon magnetic

A claw teeth type electric rotary machine comprises a stator including an annular core with claws formed from a powder core and an annular coil installed inside the annular core, and a rotor rotatably positioned inside the stator. An inner edge of the annular core is provided with plural claw poles which are protruded at a predetermined interval in a circumferential direction and extended in an axial direction of the annular core so as to alternately meshes with each other. The stator comprises the annular core with claws, the annular coil, and a molded nonmagnetic potting material filled between the annular core with claws and annular coil, so that the annular core with claws and annular coil are integrated with the molded potting non-magnetic material.

Owner:JAPAN SERVO CO LTD +2

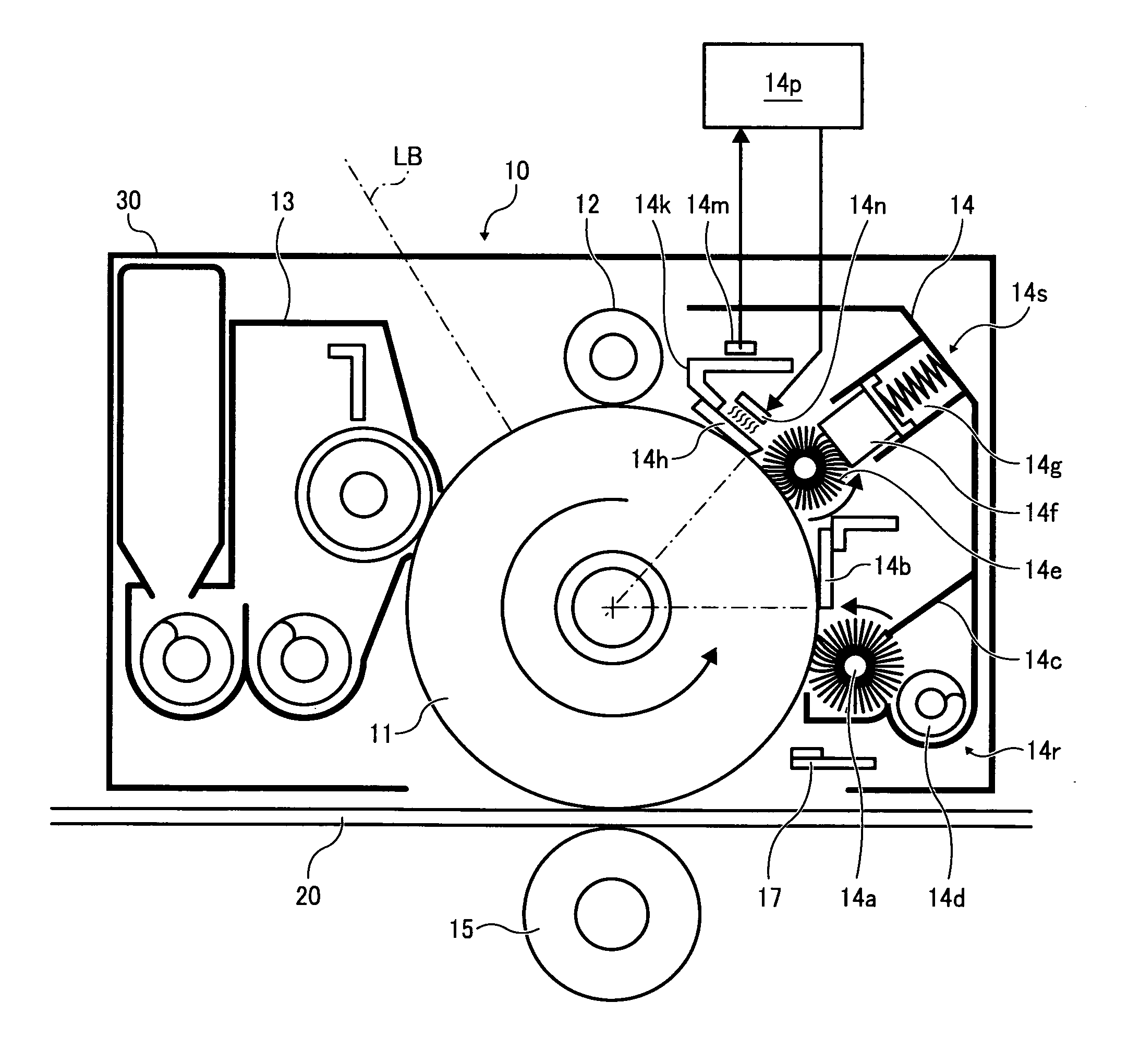

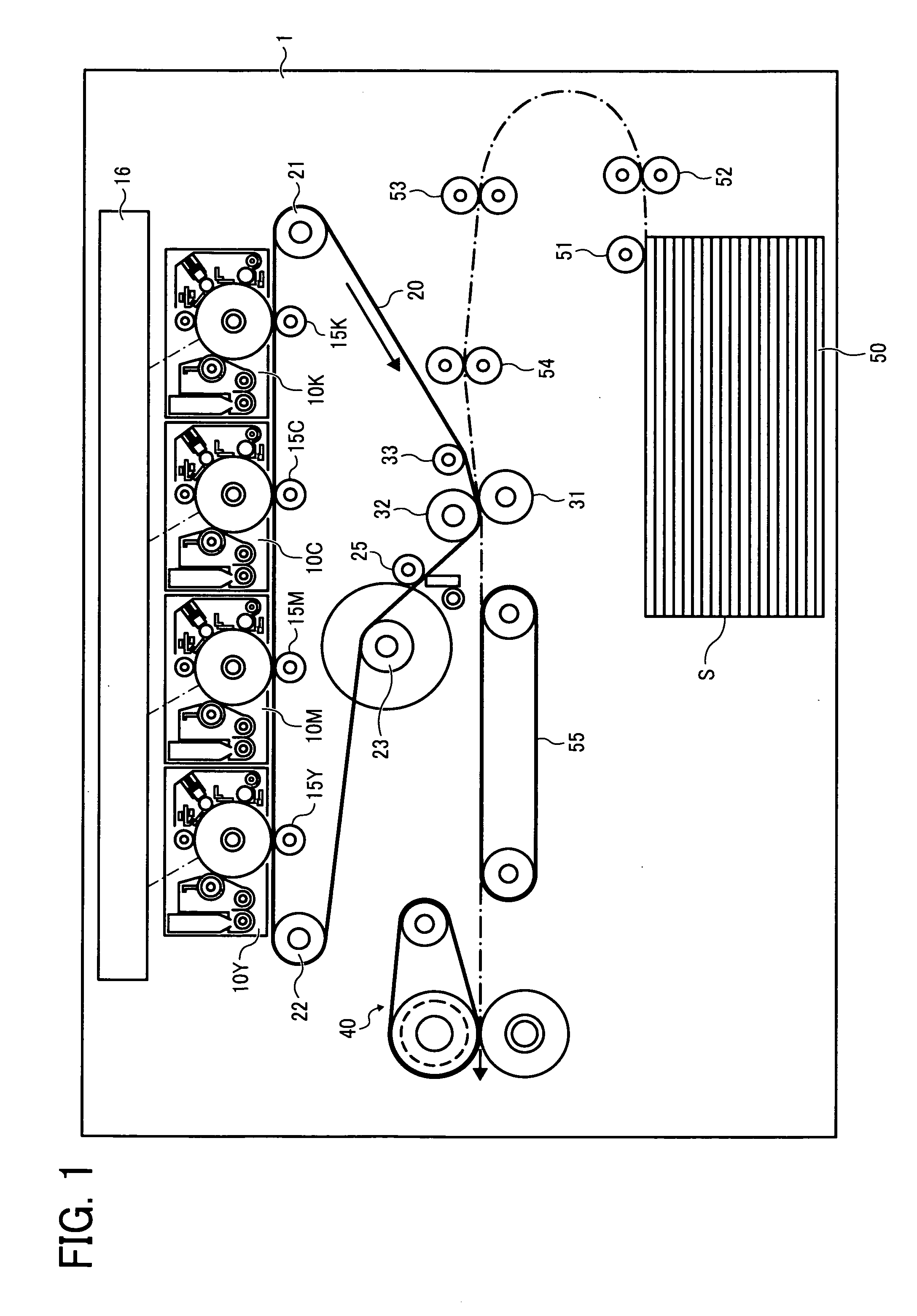

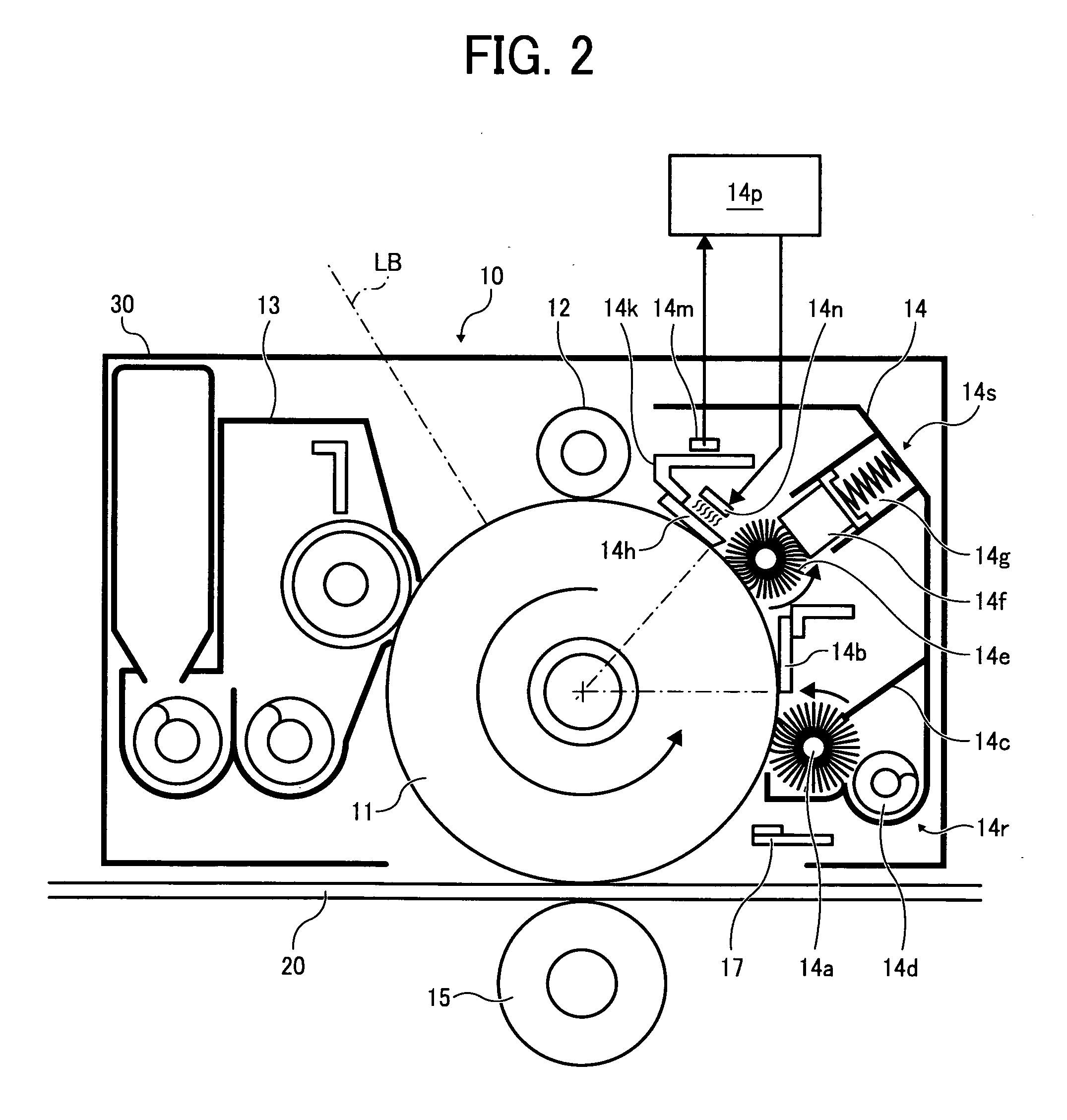

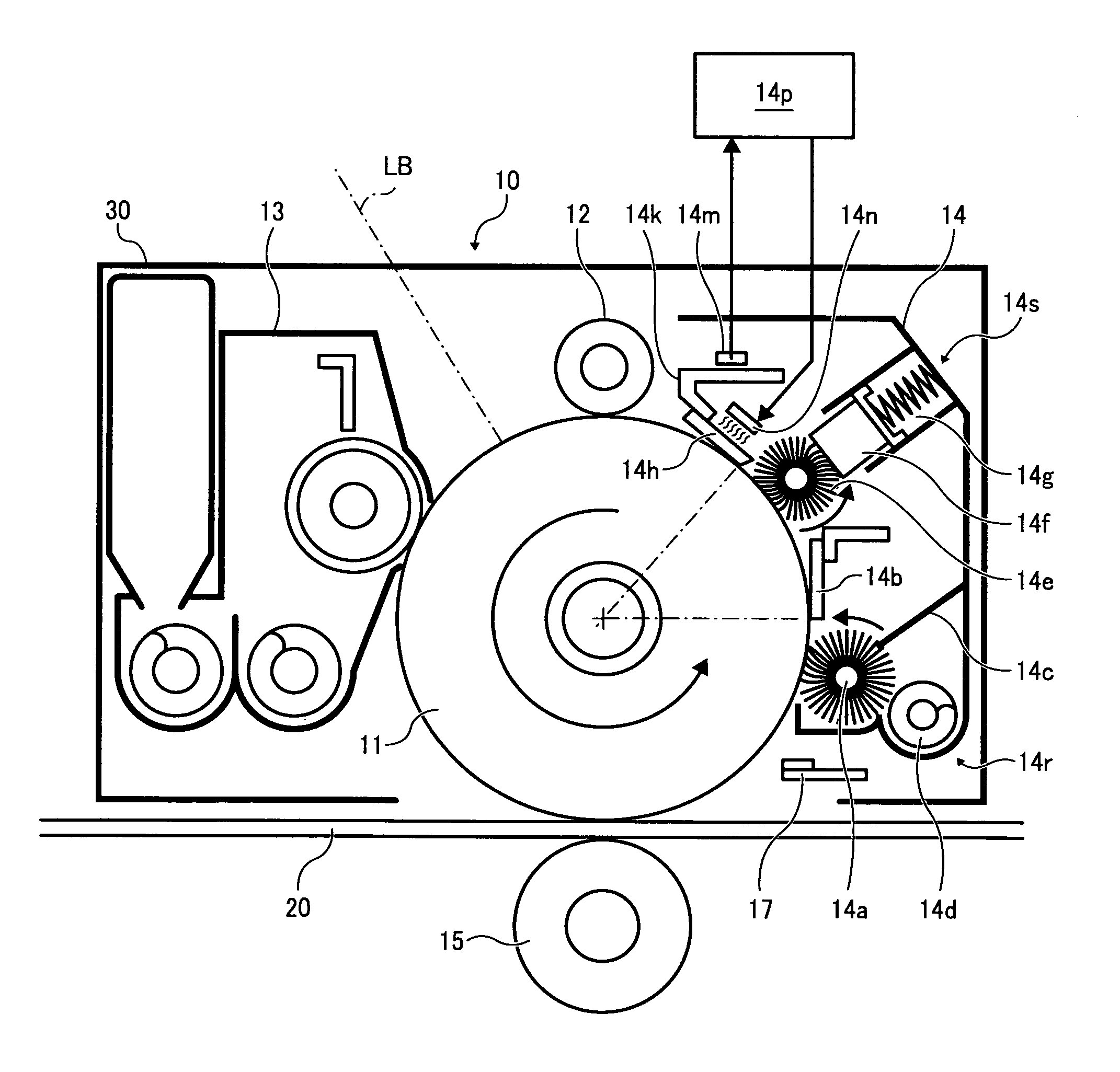

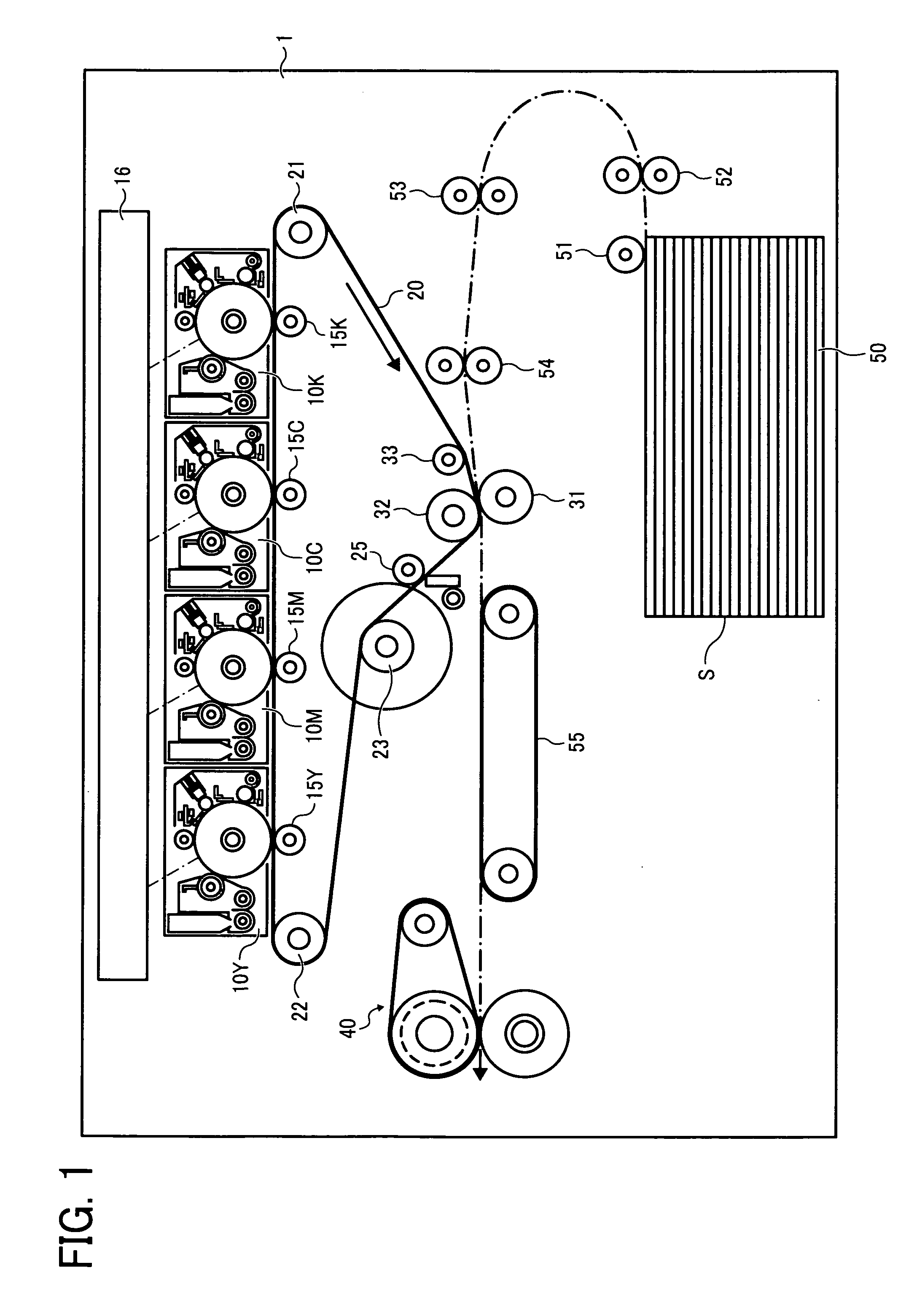

Cleaning unit, process cartriedge incorporating same, and image forming apparatus incorporating the cleaning unit

InactiveUS20100189461A1Avoid compression setElectrographic process apparatusTemperature controlImage formation

A cleaning unit, which can be incorporated in a process cartridge removably installable in an image forming apparatus, includes a lubricant applicator to apply lubricant to an image carrier, a first blade disposed upstream from the lubricant applicator in a direction of rotation of the image carrier with its distal end held in contact with the image carrier to remove residual toner remaining on the image carrier, a second blade disposed downstream from the lubricant applicator in the direction of rotation of the image carrier with its distal end held in contact with the image carrier to regulate the amount of lubricant applied to the image carrier, a temperature measuring member to measure a temperature of or near the second blade, a heater, and a temperature controller to control the heater to heat the second blade so that the measured temperature falls within a given set temperature range.

Owner:RICOH KK

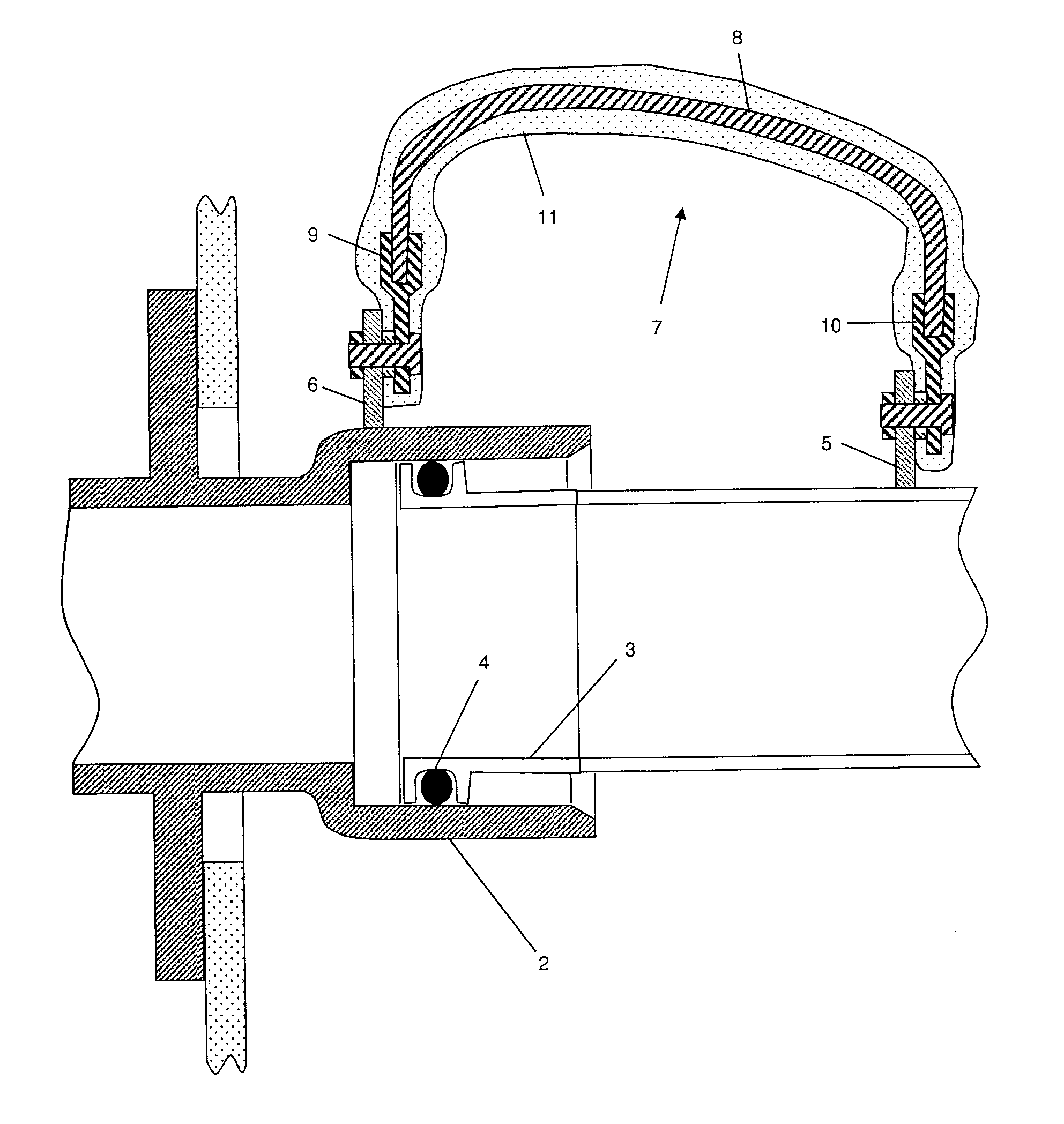

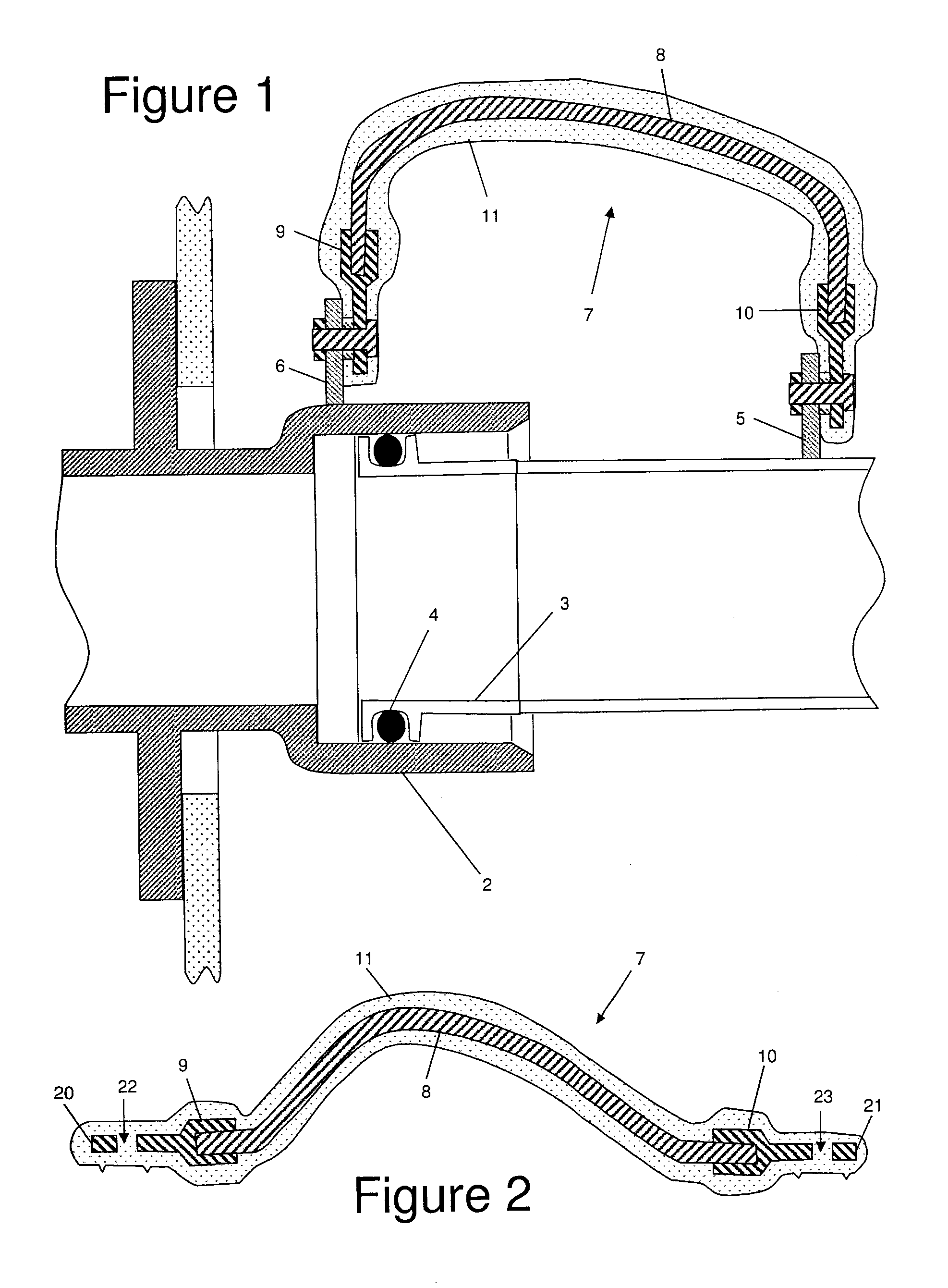

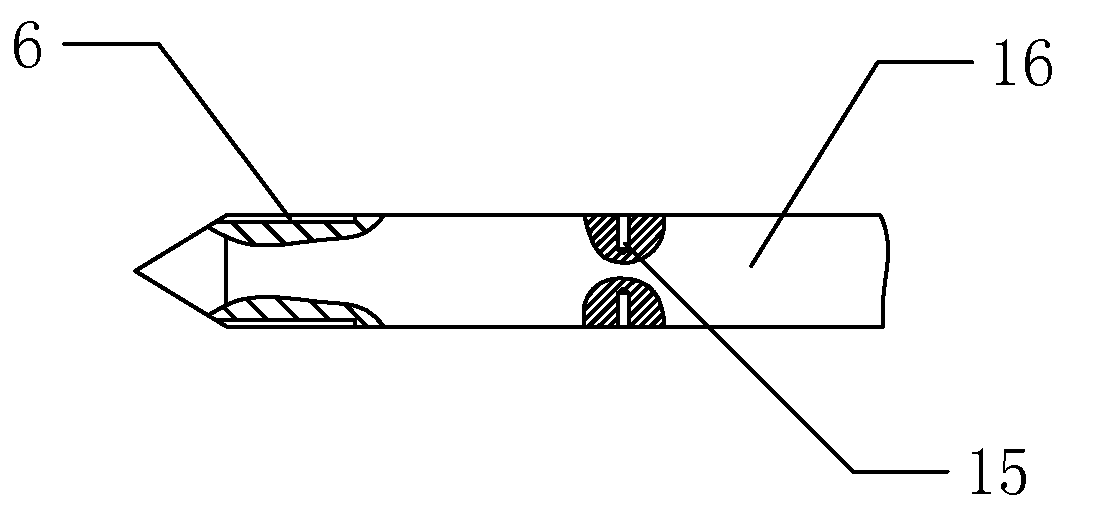

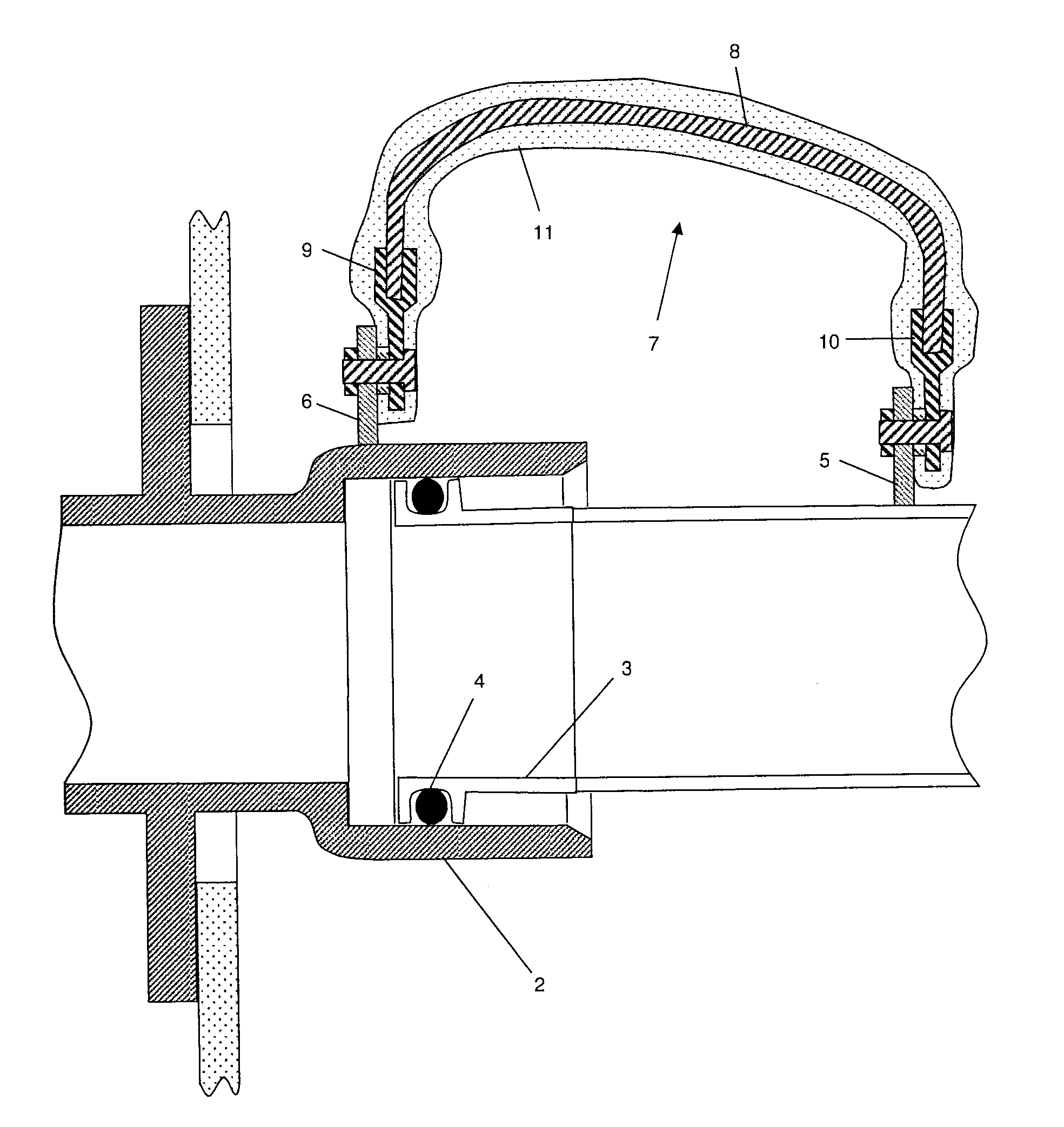

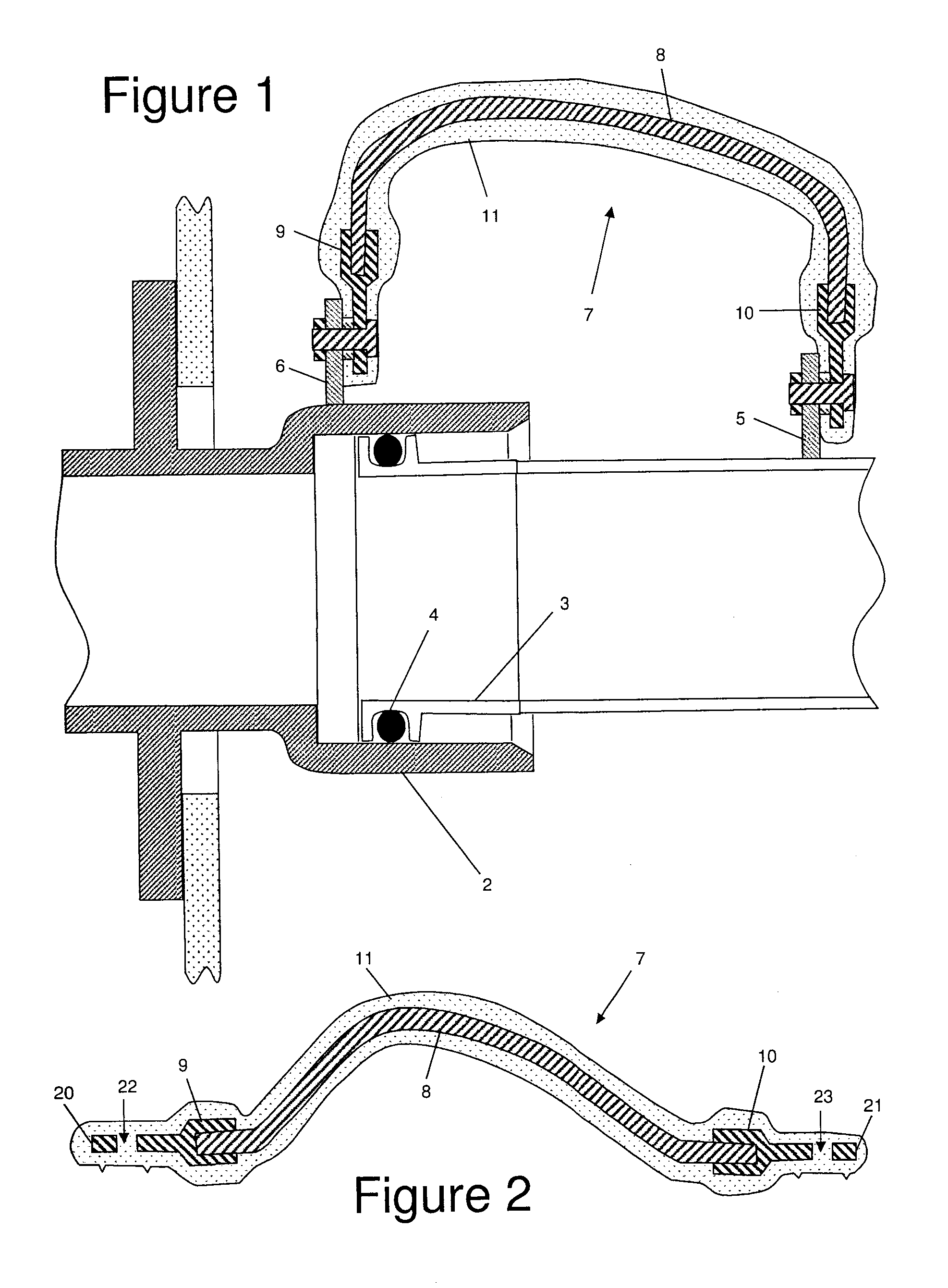

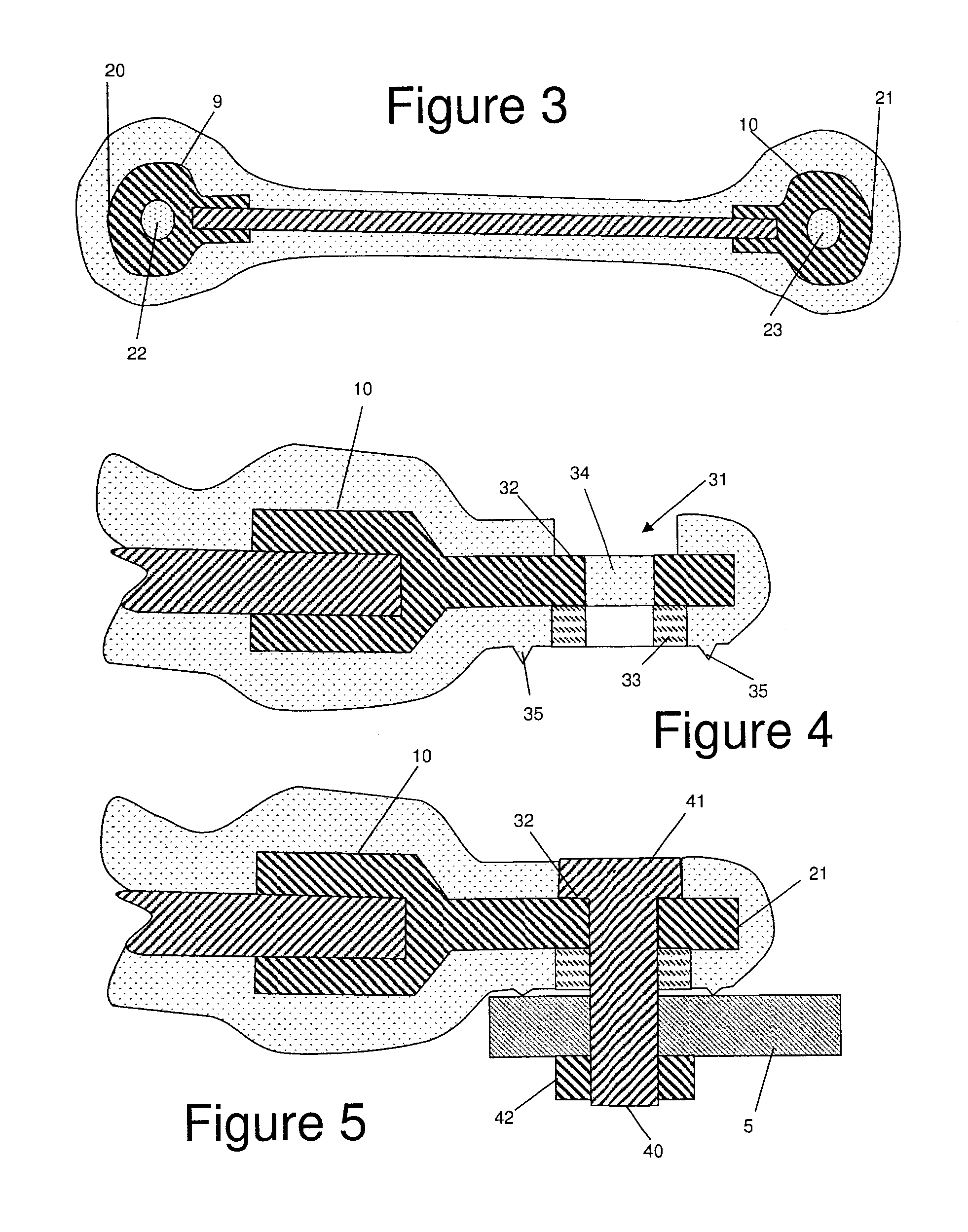

Bonding lead

ActiveUS20100226061A1Avoid compression setLine/current collector detailsPlastic/resin/waxes insulatorsElastomerElectrical connection

A joint on an aircraft, a bonding lead for use in such a joint, and a method of manufacturing such a joint. The bonding lead comprises an elongate conductive core with a pair of end faces at the extremities of its length. The conductive core is encapsulated along at least a majority of its length and at both end faces in a barrier layer typically formed from an elastomer. The lead is encapsulated along its length in the barrier layer apart from at a first contact region towards a first end of the bonding lead and a second contact region towards a second end of the bonding lead. A first electrical connector passes through a first hole in the barrier layer to engage the first contact region of the conductive core and provide an electrical connection between the conductive core and the first component; and a second electrical connector passes through a second hole in the barrier layer to engage the second contact region of the conductive core and provide an electrical connection between the conductive core and the second component.

Owner:AIRBUS OPERATIONS LTD

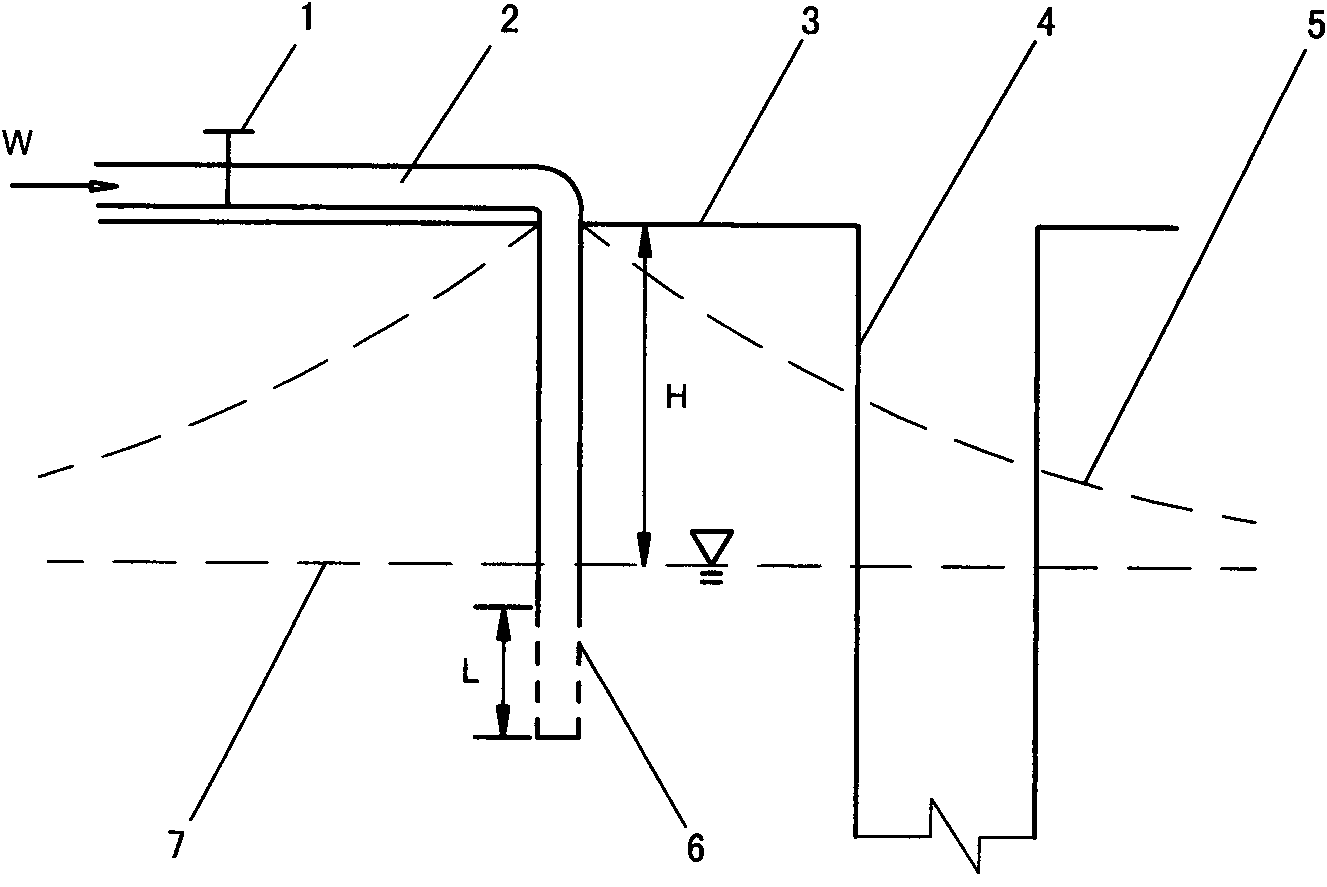

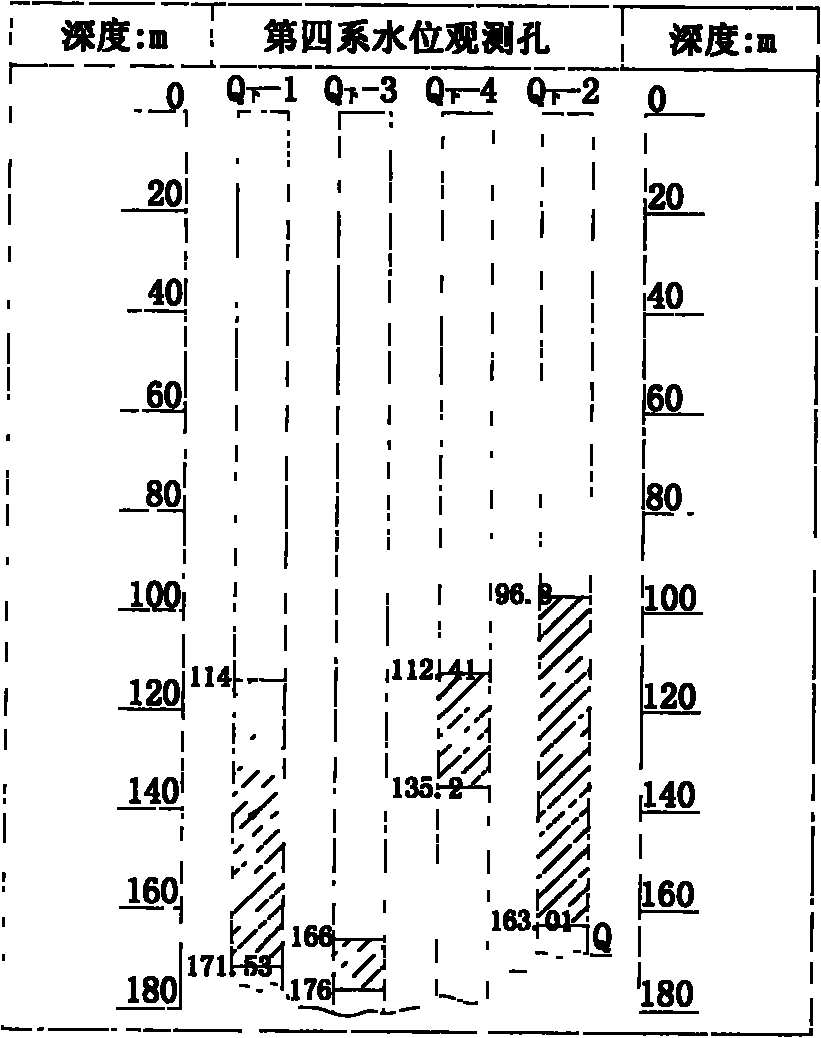

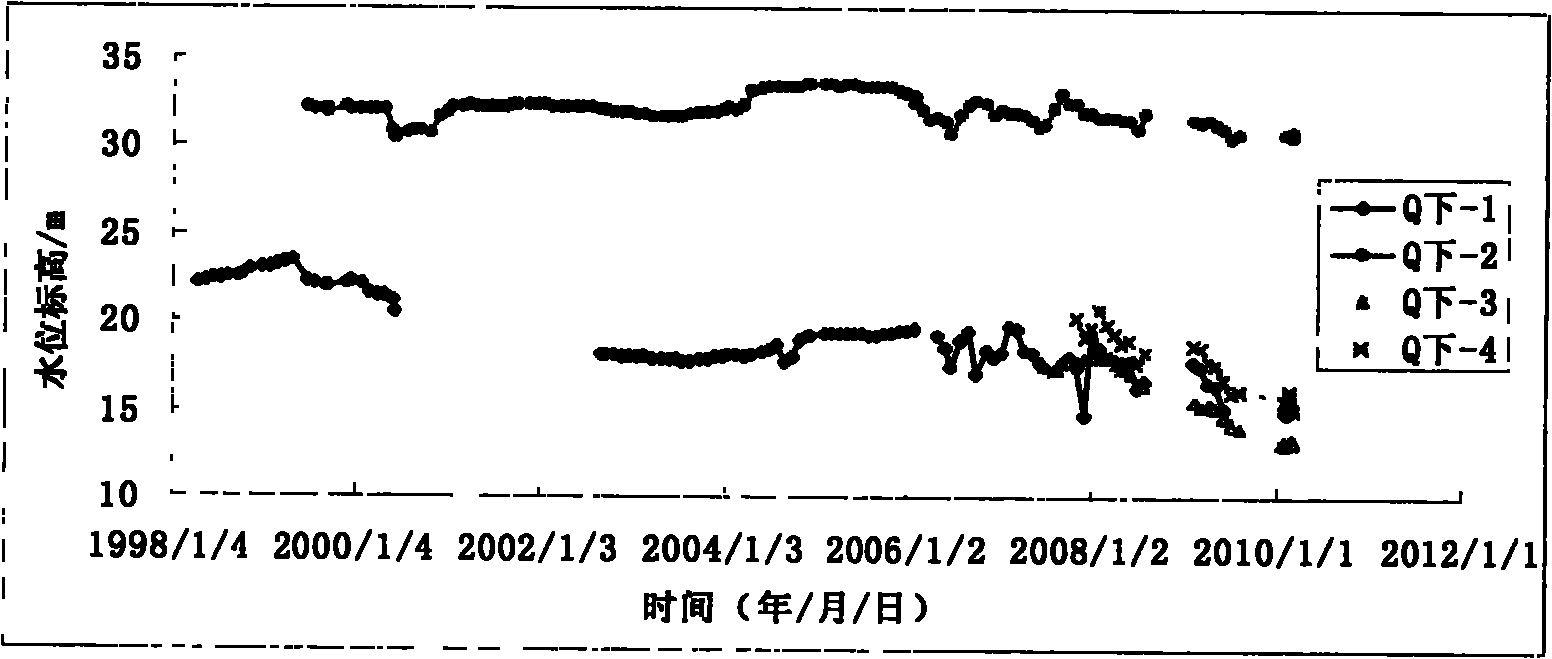

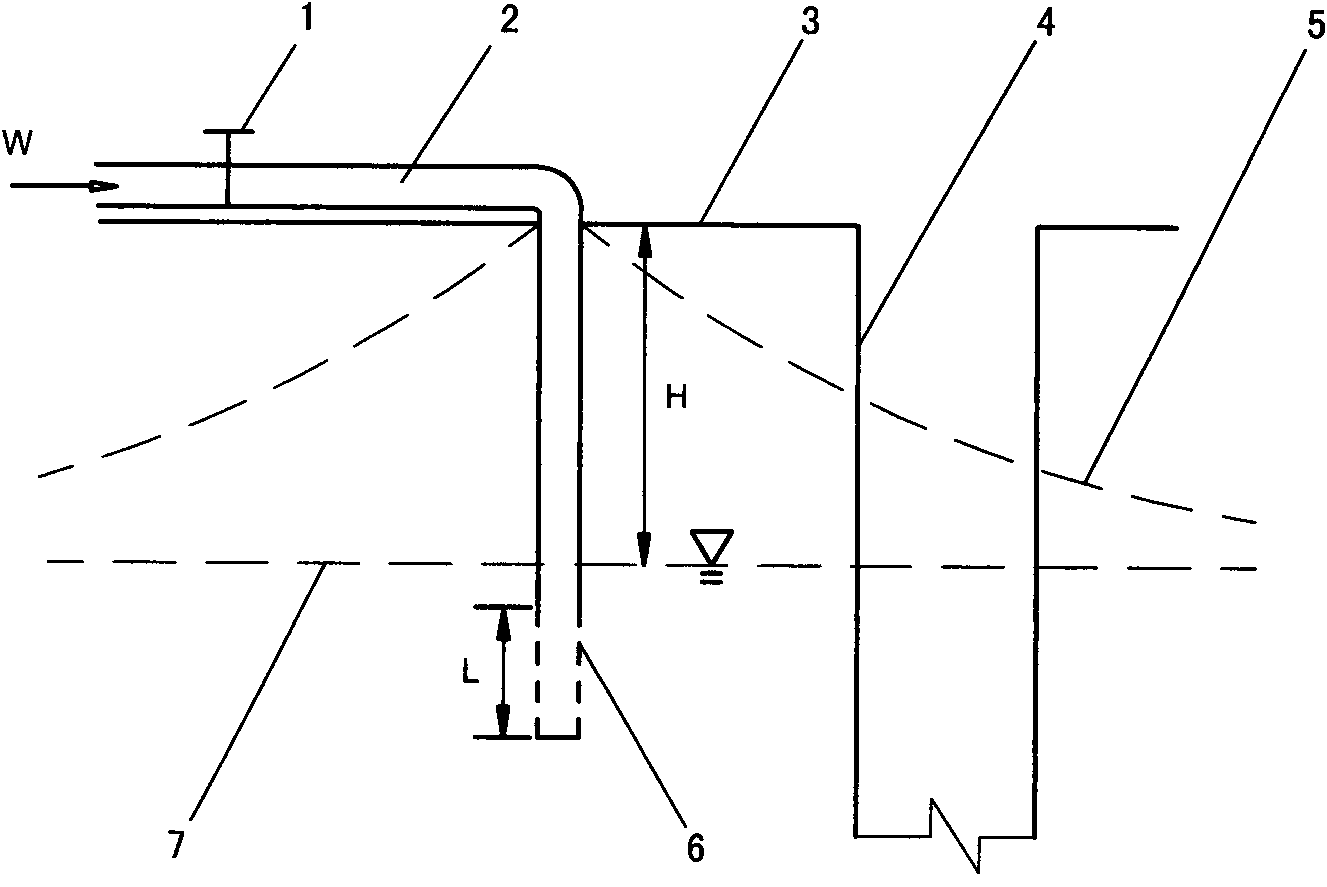

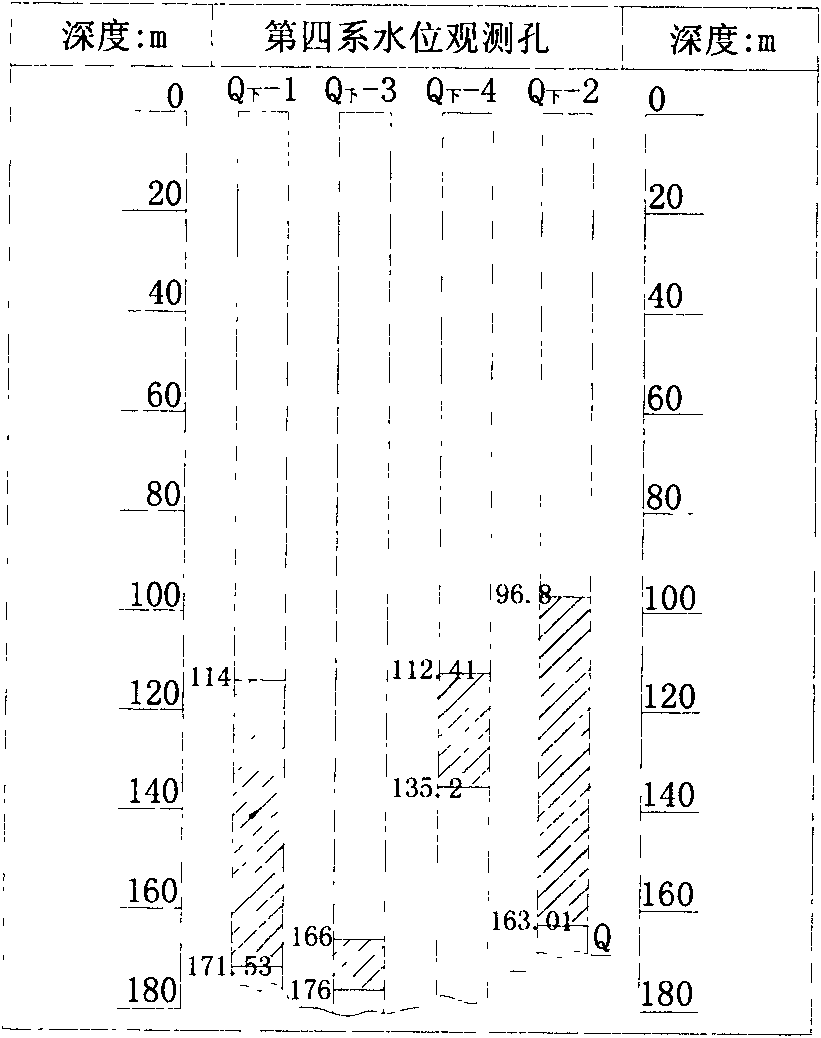

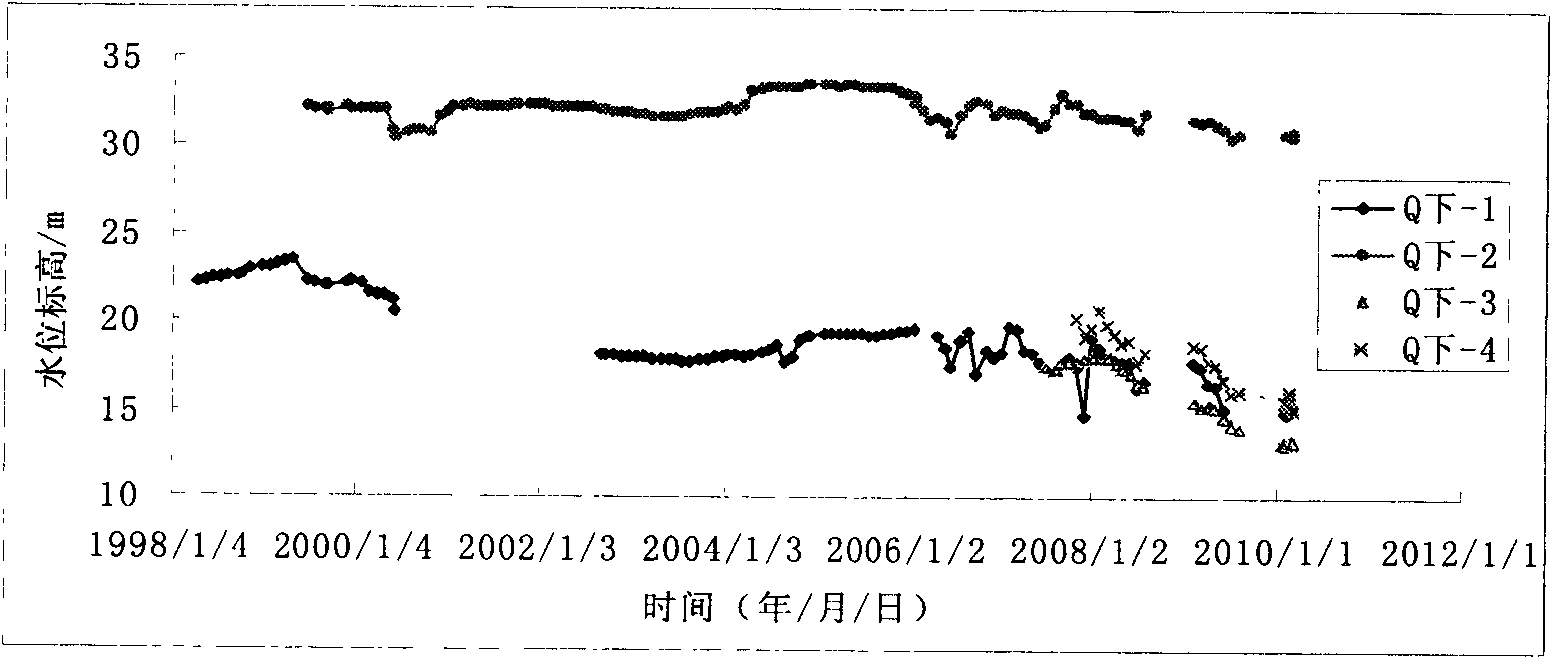

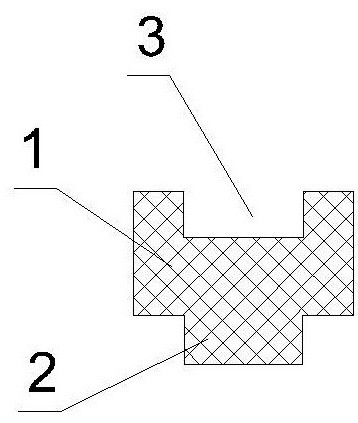

Method for preventing vertical shaft wellhole from being damaged

ActiveCN101985881AAvoid destructionWater level increased and stabilizedMining devicesShaft equipmentTap waterEngineering

The invention relates to a method for preventing a vertical shaft wellhole from being damaged by adopting a ground water injection water level stabilization method, comprising the following concrete steps: 1) analyzing the alluvium structure and water regimen, and selecting a loose aquifer of which the water level continuous descends within over three years from the alluvium as a water injection position; 2) constructing a water injection hole around the wellhole with the shape consistent with that of a long-term hydrological observation well; 3) injecting water into the water injection position by tap water or a water pump through a water injection hole; and 4) monitoring the water injection effect in the water injection process, wherein the monitoring contents comprise aquifer water level monitoring and well wall variation monitoring, and the water injection rate is adjusted based on the monitored water injection effect. The method can ensure the water levels of the wellhole and theaquifer nearby to be increased and relatively steady, reduce compression deformation and additional pressure strain on the well wall caused by loosened soil layers around the wellhole due to drop of the water level, thus preventing the well wall from being damaged. Researching from the perspective of hydrology-geological conditions of mines, in the invention, a method for fundamentally solving the problem of preventing the wellhole from being damaged is searched out based on the well wall fracture mechanism, and has obvious prevention effect, is convenient to construction, and is safe and economic.

Owner:兖矿能源集团股份有限公司 +1

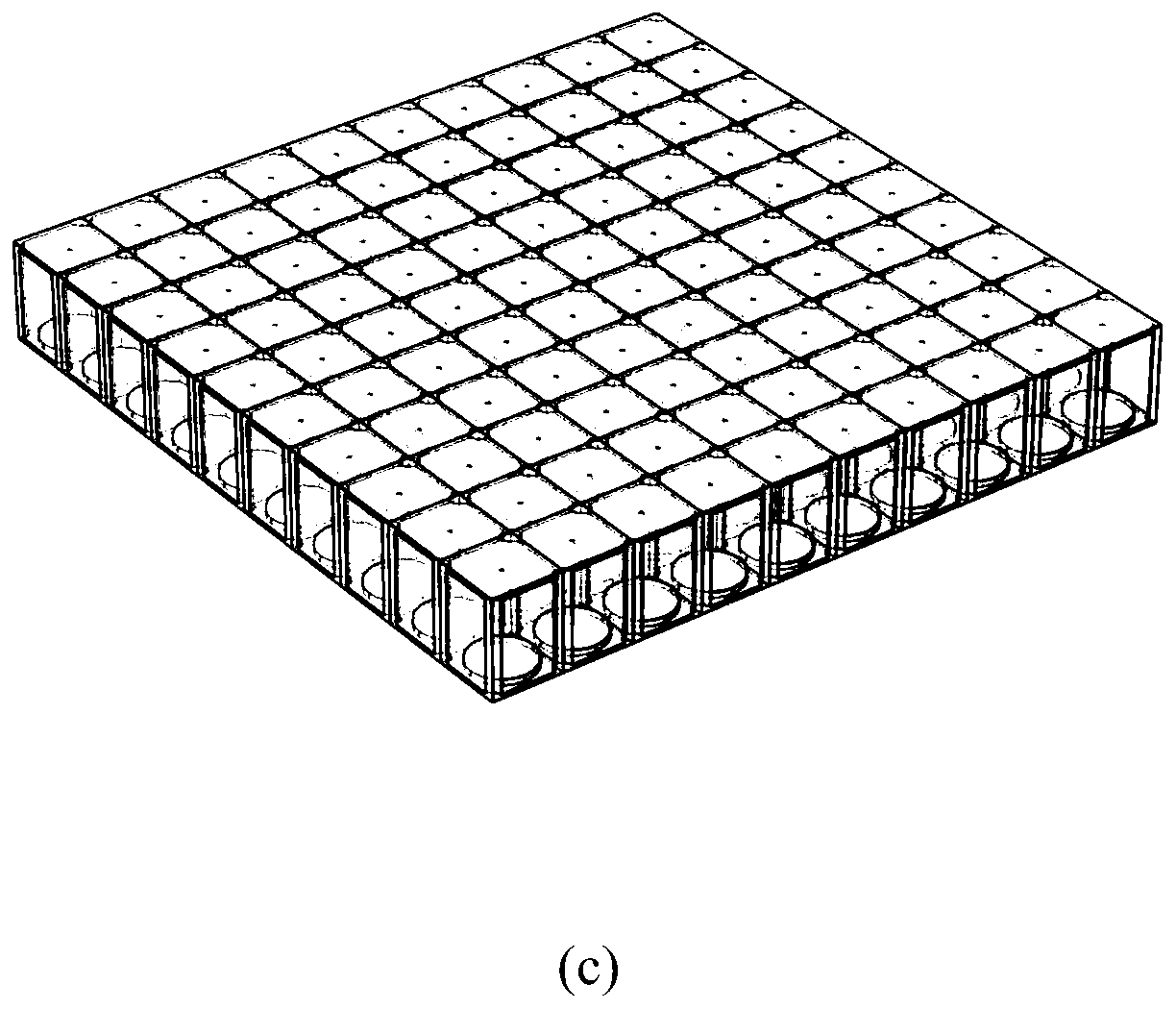

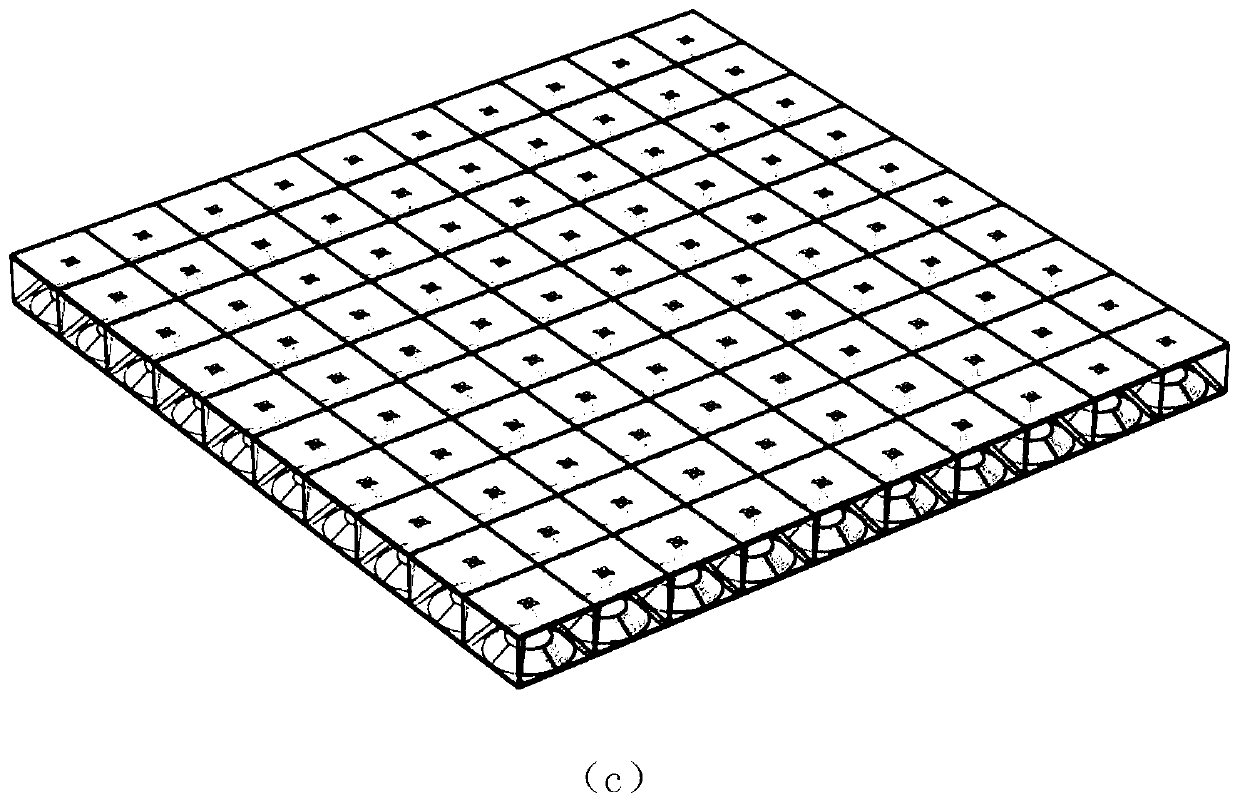

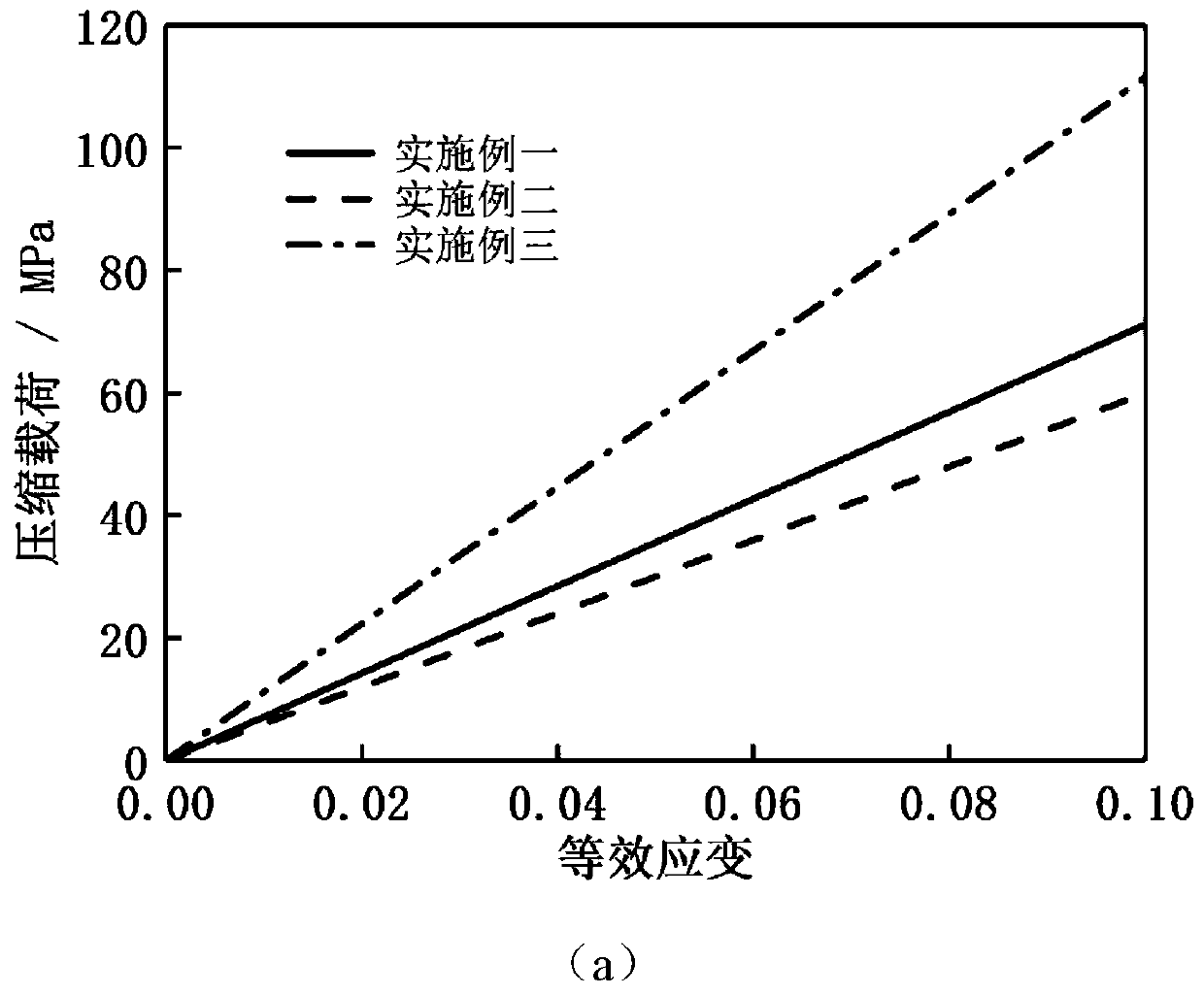

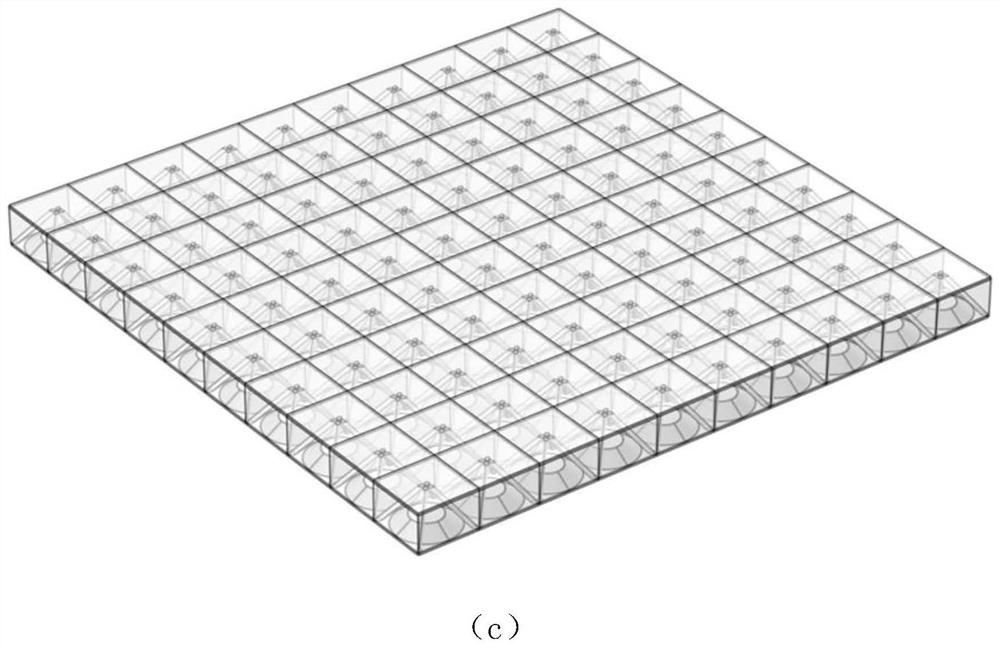

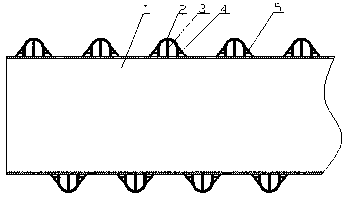

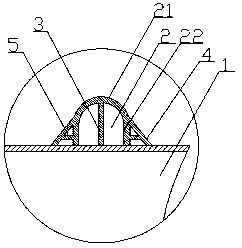

Straight-column type lattice-enhanced mixed underwater sound absorption structure

InactiveCN110310617AAchieve lightweight designImprove sound absorption performanceSound producing devicesResonanceAcoustics

The invention discloses a straight-column type lattice-enhanced mixed underwater sound absorption structure. The straight-column type lattice-enhanced mixed underwater sound absorption structure comprises cubic cells; a cavity and a local resonance body are arranged in each cubic cell; the cavity and the local resonance body are located in the center of each cubic cell in the horizontal direction;the local resonance body is close to the top of each cubic cell; the cavity is located at the bottom of each cubic cell of a damping layer in the vertical direction; and the cubic cells are arrayed to form the straight-column type lattice-enhanced mixed underwater sound absorption structure. The underwater sound absorption structure disclosed by the invention has excellent sound absorption performance and good water pressure resistance, and meanwhile, the lightweight design of the underwater sound absorption structure is realized; and the underwater sound absorption structure is a multifunctional integrated structure with the functions of bearing, sound absorption, sound insulation and light weight.

Owner:XI AN JIAOTONG UNIV +1

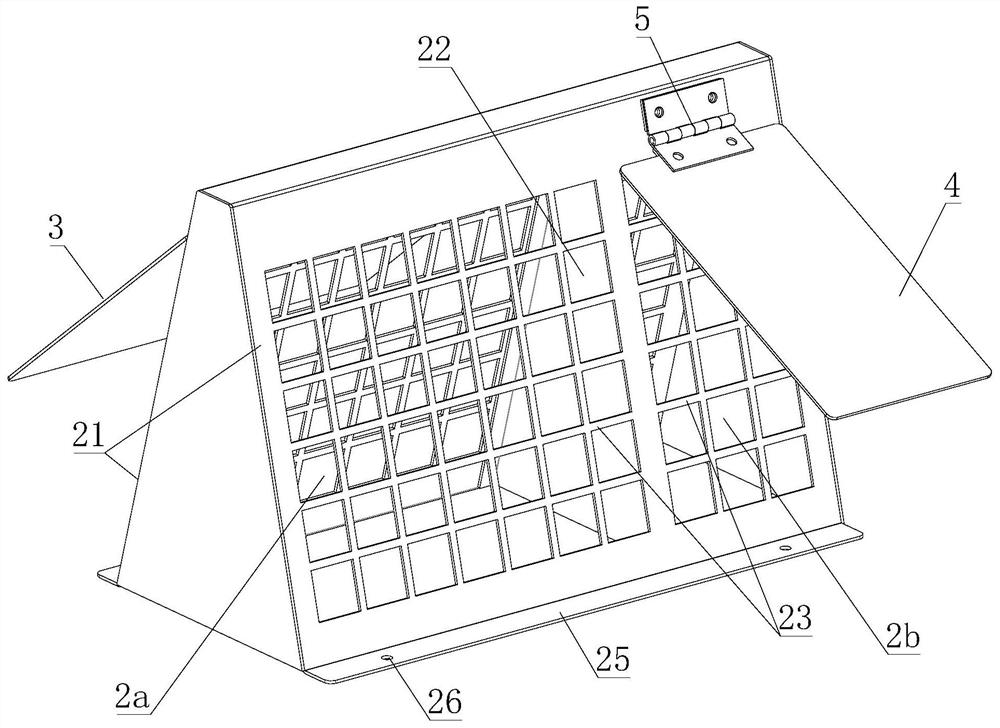

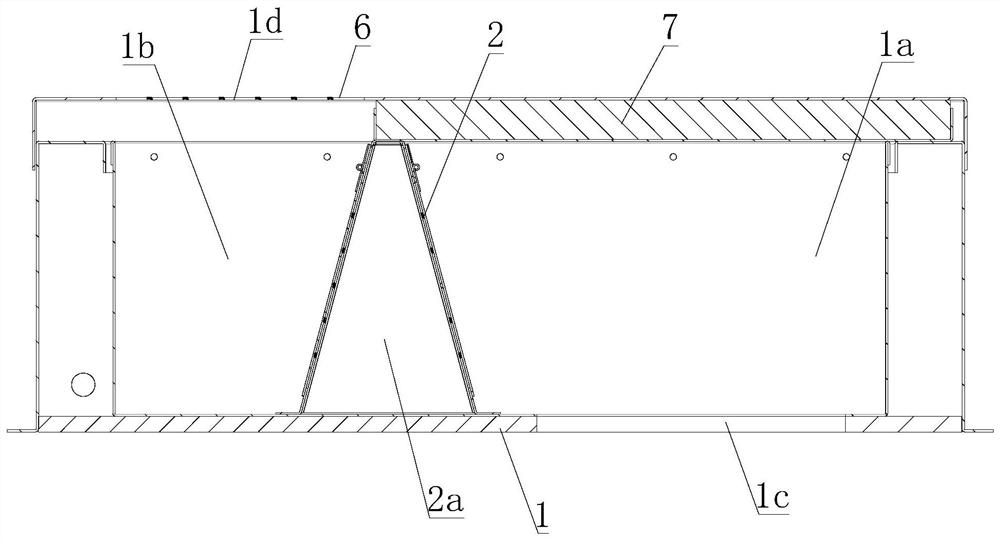

Bidirectional pressure balancing device and environmental test box

PendingCN113694973APrevent guaranteeAvoid compression setHeating or cooling apparatusWeather/light/corrosion resistanceInterior spaceThermodynamics

The invention discloses a bidirectional pressure balancing device and an environmental test box, the bidirectional pressure balancing device comprises a pressure relief box, a partition part is installed in the pressure relief box, the partition part divides the internal space of the pressure relief box into a first chamber and a second chamber, any side of the first chamber is provided with a first vent hole, any side of the second chamber is provided with a second vent hole, the partition part is provided with an exhaust channel and an air inlet channel, the end, close to the second chamber, of the exhaust channel is provided with an air outlet partition plate, the upper end of the air outlet partition plate is rotationally connected with the partition part, and the end, close to the first chamber, of the air inlet channel is provided with an air inlet partition plate; the upper end of the air inlet partition plate is rotationally connected with the partition part. The test box has the beneficial effects that the effect of bidirectional pressure balance can be achieved, the test box can be guaranteed at high temperature, and compression deformation of the test box can be prevented at low temperature.

Owner:重庆哈丁环境试验技术股份有限公司

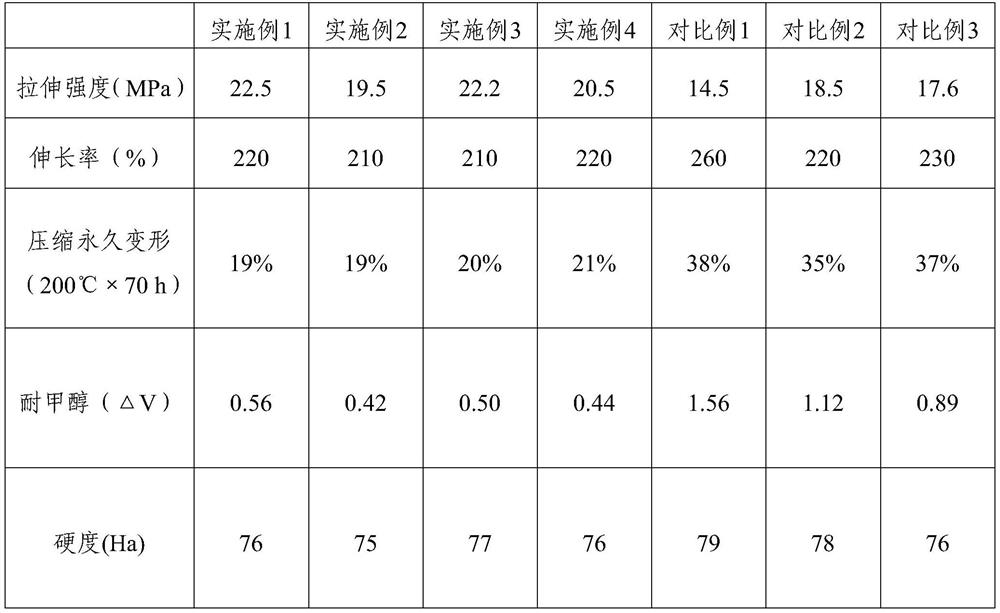

Peroxide vulcanized fluororubber and preparation method thereof

The invention relates to the field of fluororubber synthesis, and especially relates to peroxide vulcanized fluororubber and a preparation method thereof. The preparation method of the peroxide vulcanized fluororubber comprises the following step: carrying out polymerization reaction by taking vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene as mixed monomers, wherein in the polymerization reaction process, the mole number of tetrafluoroethylene in a reaction kettle is always kept to be 15-25% of the total mole number of the mixed monomers, and the mole numbe of hexafluoropropylene in the reaction kettle is always kept to be 25-35% of the total mole numbe of the mixed monomers. The obtained peroxide vulcanized fluororubber has high fluorine content and low compression deformation at the same time; the problem that the cross-linking density of peroxide vulcanized fluororubber with high fluorine content is reduced in the vulcanization processing process due to non-uniform distribution of TFE and HFP in a molecular chain segment in the polymerization process is effectively solved; and meanwhile, the reaction time is controlled to be shorter, so that the branching reaction is prevented, the effectiveness of a monomer at a vulcanization point in a chain link is ensured, and the problem of higher compression deformation is solved.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Cleaning unit, process cartridge incorporating same, and image forming apparatus incorporating the cleaning unit

InactiveUS8315535B2Avoid compression setElectrographic process apparatusTemperature controlImage formation

Owner:RICOH KK

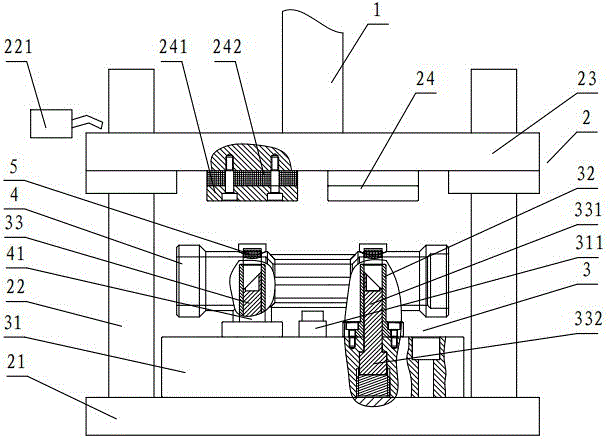

Fixture for milling spline shaft

InactiveCN104308590APrevent slippingAvoid defects of low processing qualityTailstocks/centresPositioning apparatusEngineering

The invention discloses a fixture for milling a spline shaft. The fixture comprises a front tip and a rear tip, wherein the front tip is abutted against the front end of the spline shaft, the rear tip is abutted against the rear end of the spline shaft, and the outer wall of the rear tip is provided with a sliding groove; the fixture also comprises a compressing sleeve and a threaded sleeve, wherein the compressing sleeve is arranged on the outer wall of the rear tip in a sleeving manner and connected to the rear top by a flat key, the flat key is positioned in the sliding groove, the front end of the compressing sleeve is abutted against the rear end of the spline shaft, the threaded sleeve is arranged on the outer wall of the rear tip in a sleeving manner and in threaded connection with the rear tip, the threaded sleeve is positioned behind the compressing sleeve, and a compressed spring is also arranged between the threaded sleeve and the compressing sleeve and abutted against both the threaded sleeve and the compressing sleeve. The invention, overcoming the technical defect that the existing fixture for milling the spline shaft is low in machining efficiency and precision, provides the fixture for milling the spline shaft, which is high in machining efficiency and precision.

Owner:CHONGQING TIANYE MOLD PUNCHING MFG

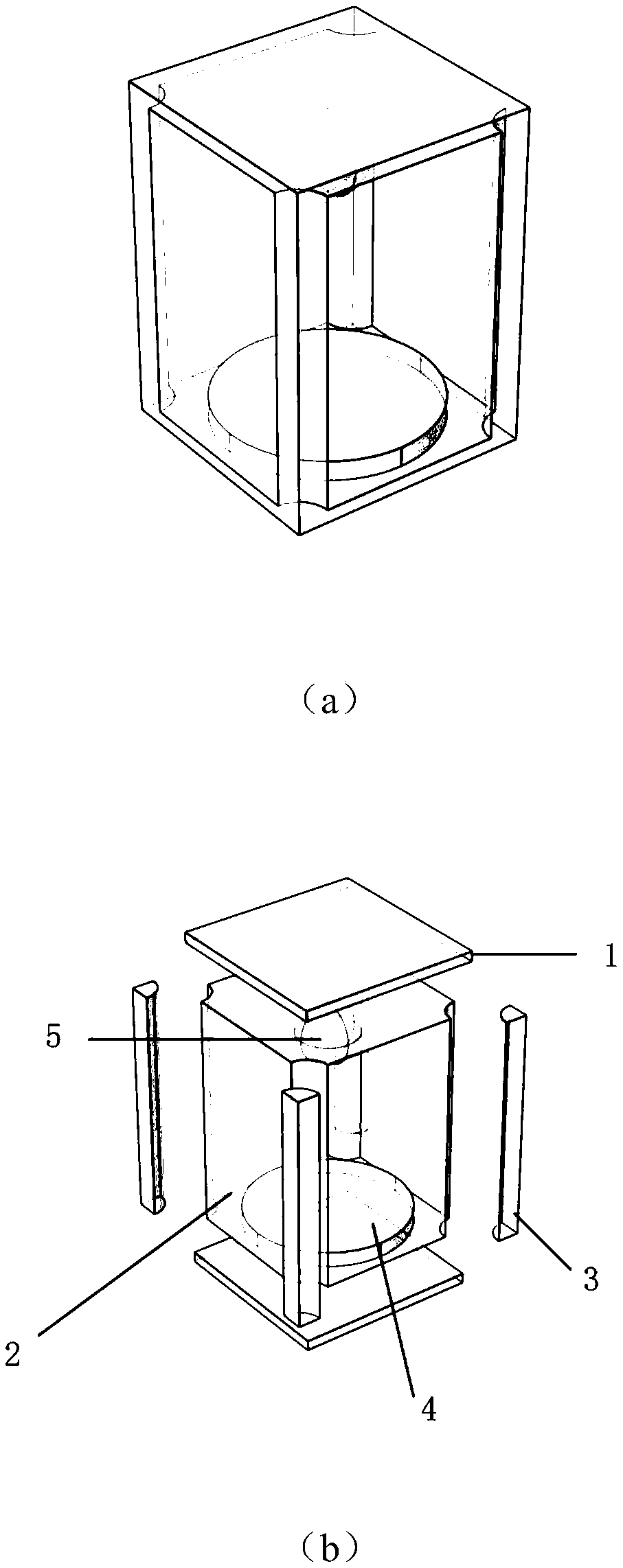

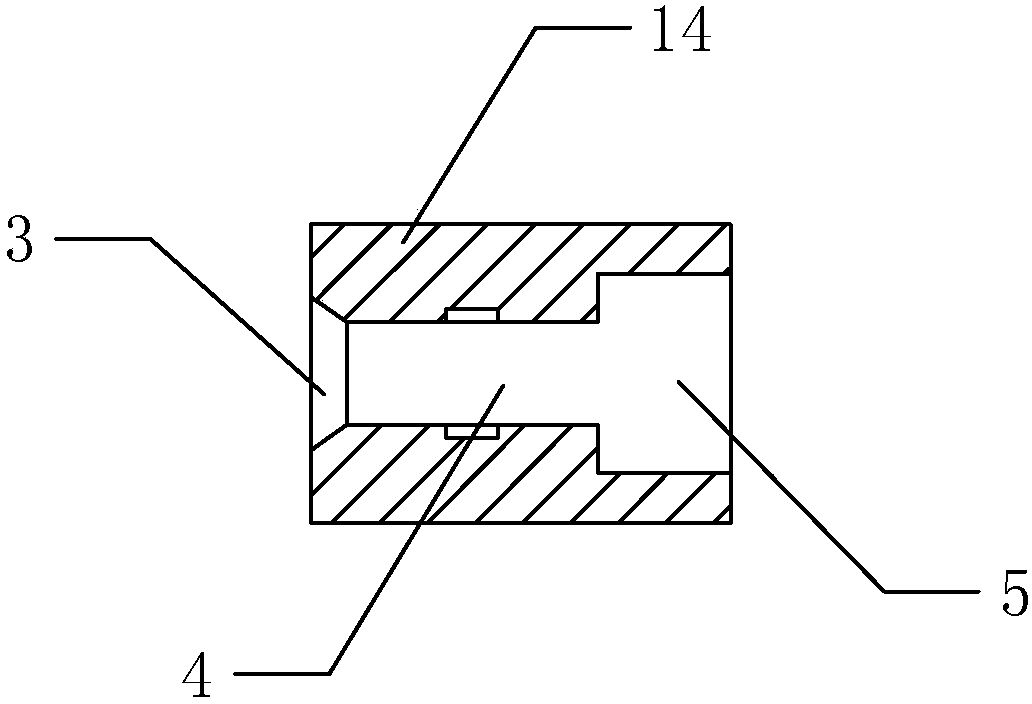

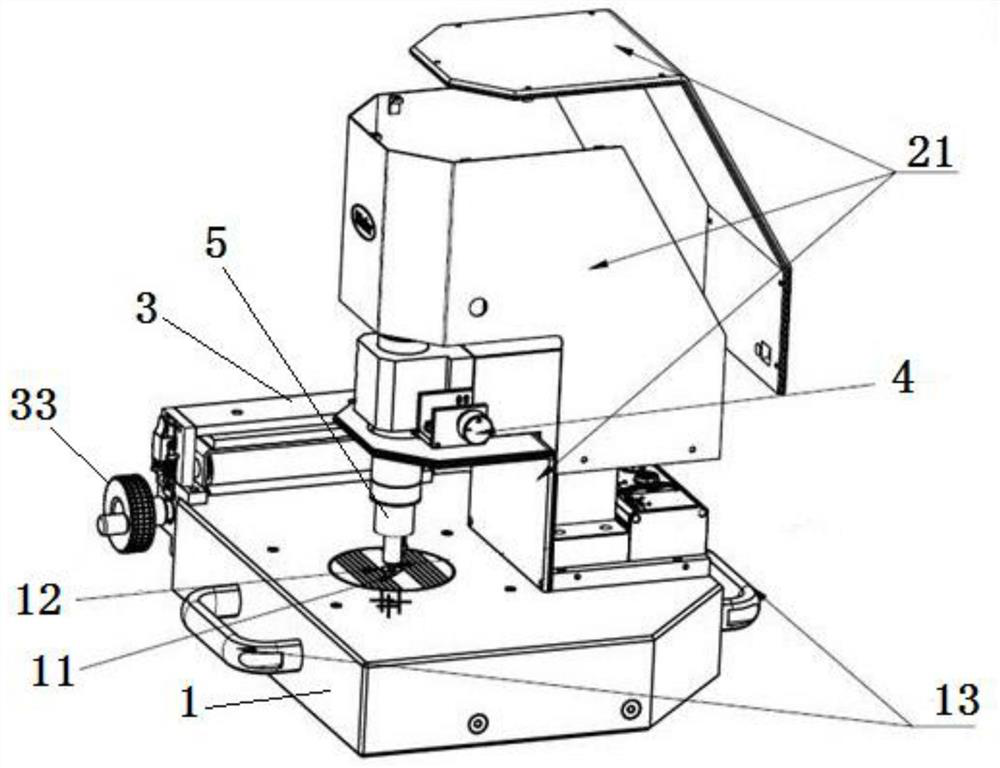

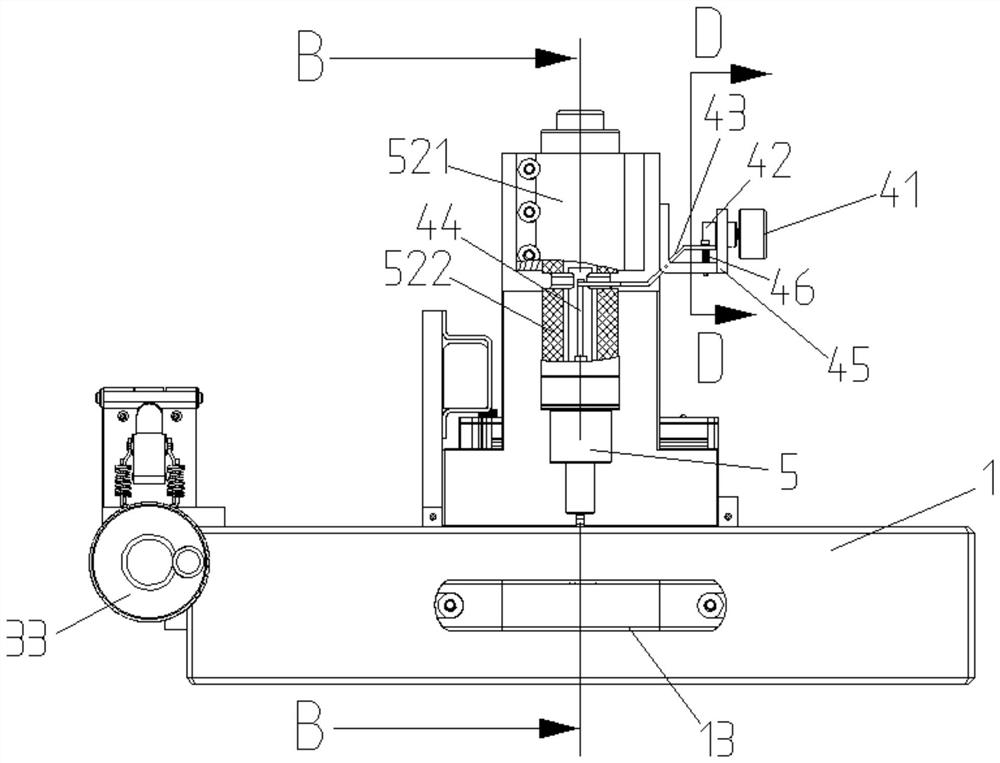

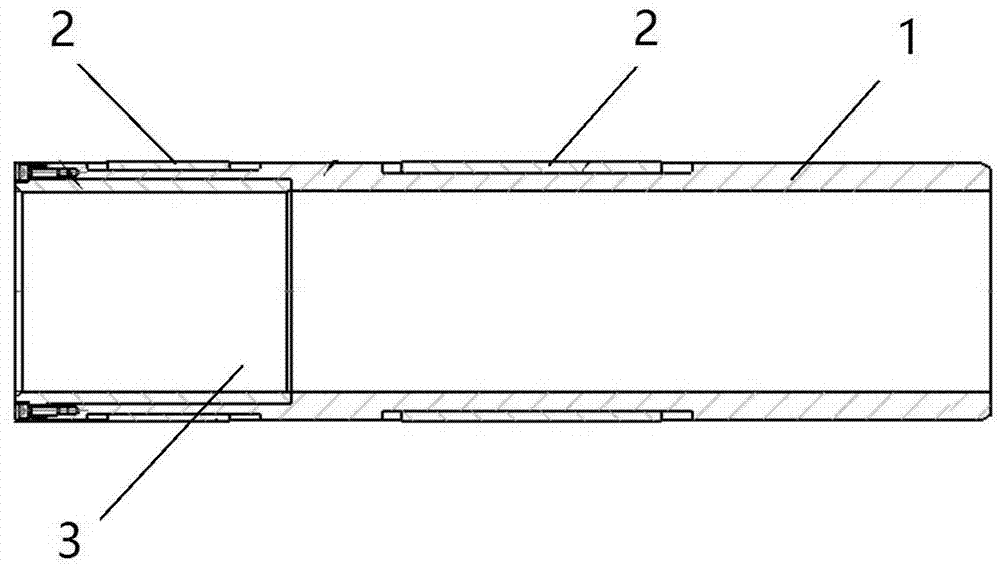

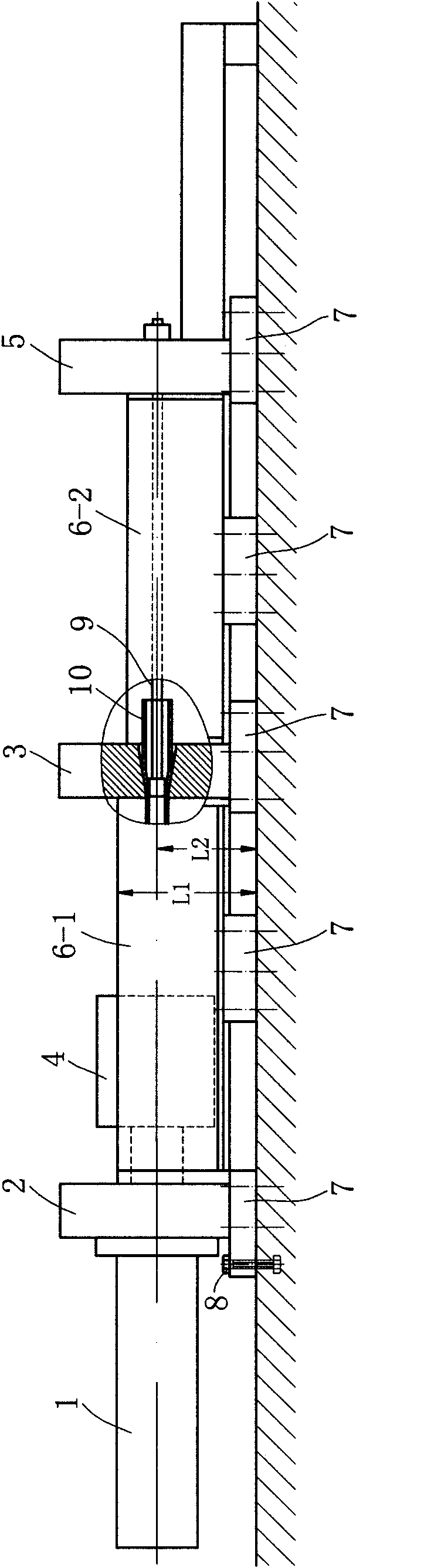

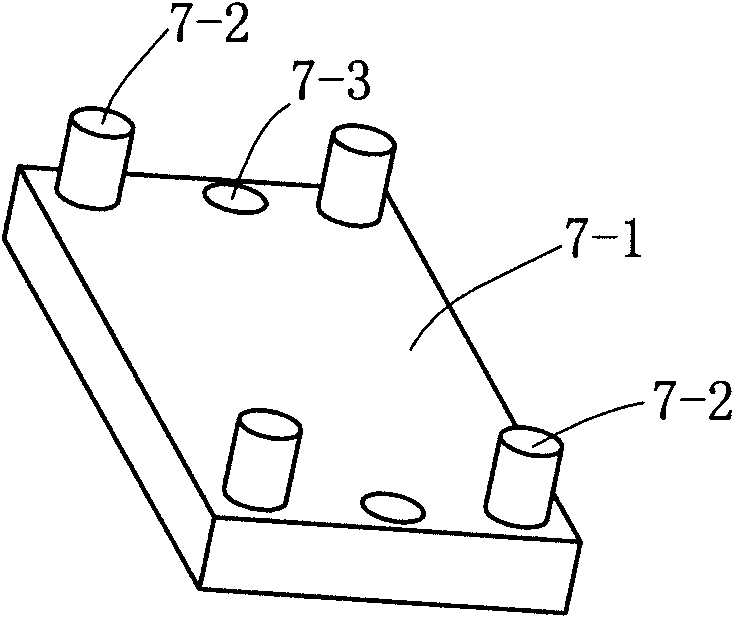

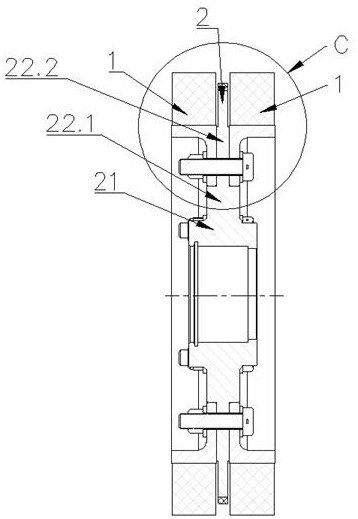

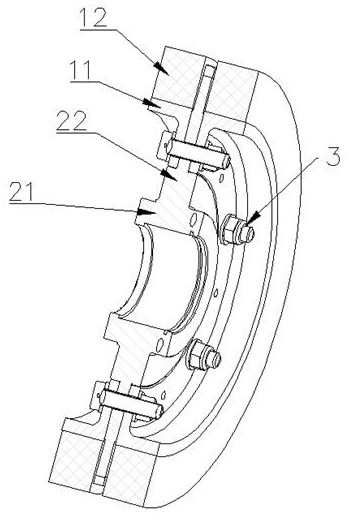

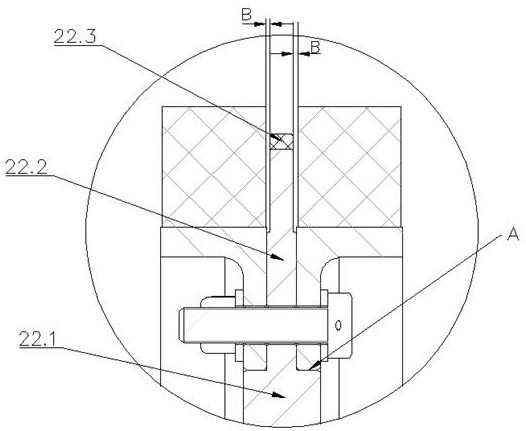

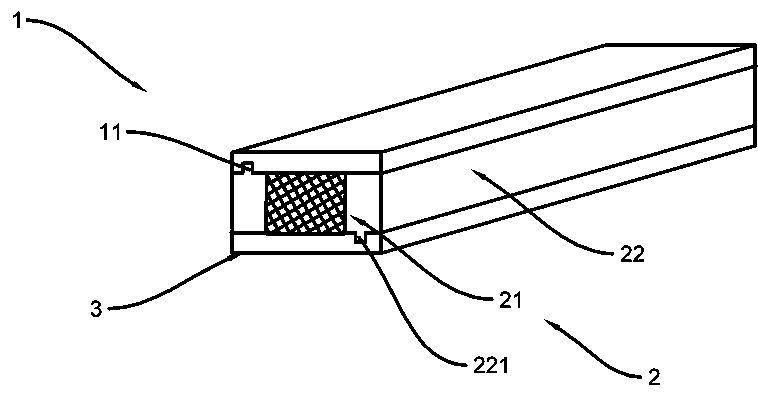

Mounting device for ultrasonic heat meter reflector

ActiveCN105698972ATroubleshooting exact-corresponding installation issuesAvoid compression setCalorimeterEngineeringBilateral symmetry

The invention discloses a mounting device for an ultrasonic heat meter reflector, which comprises a press punch, a down pressing device and a positioning device, wherein the down pressing device comprises a bottom plate, left and right guide columns fixed at two ends of the bottom plate, a pressing plate movably sleeving the guide columns and a pressing head arranged on the pressing plate; the positioning device comprises a base fixed with the bottom plate, guide sleeves fixed on the base, and left and right positioning columns located in left and right guide sleeves, upper end surfaces of the left positioning column and the right positioning column are inclined planes with the same inclination and in bilateral symmetry and corresponding to inclined planes of left and right reflectors in a pipe segment body. The guide structure of the guide column is adopted to guide the down pressure to be uniform and stable, the horizontally-symmetrical and accurately-fixed positioning column structure is arranged on the fixed base, a limiting structure with the inclined plane is arranged on the positioning column, the three structures are supported and collaborated mutually, and the accurate corresponding mounting problem of the reflection surface of the reflector can be solved.

Owner:NINGBO JIEKELONG PRECISION MFG

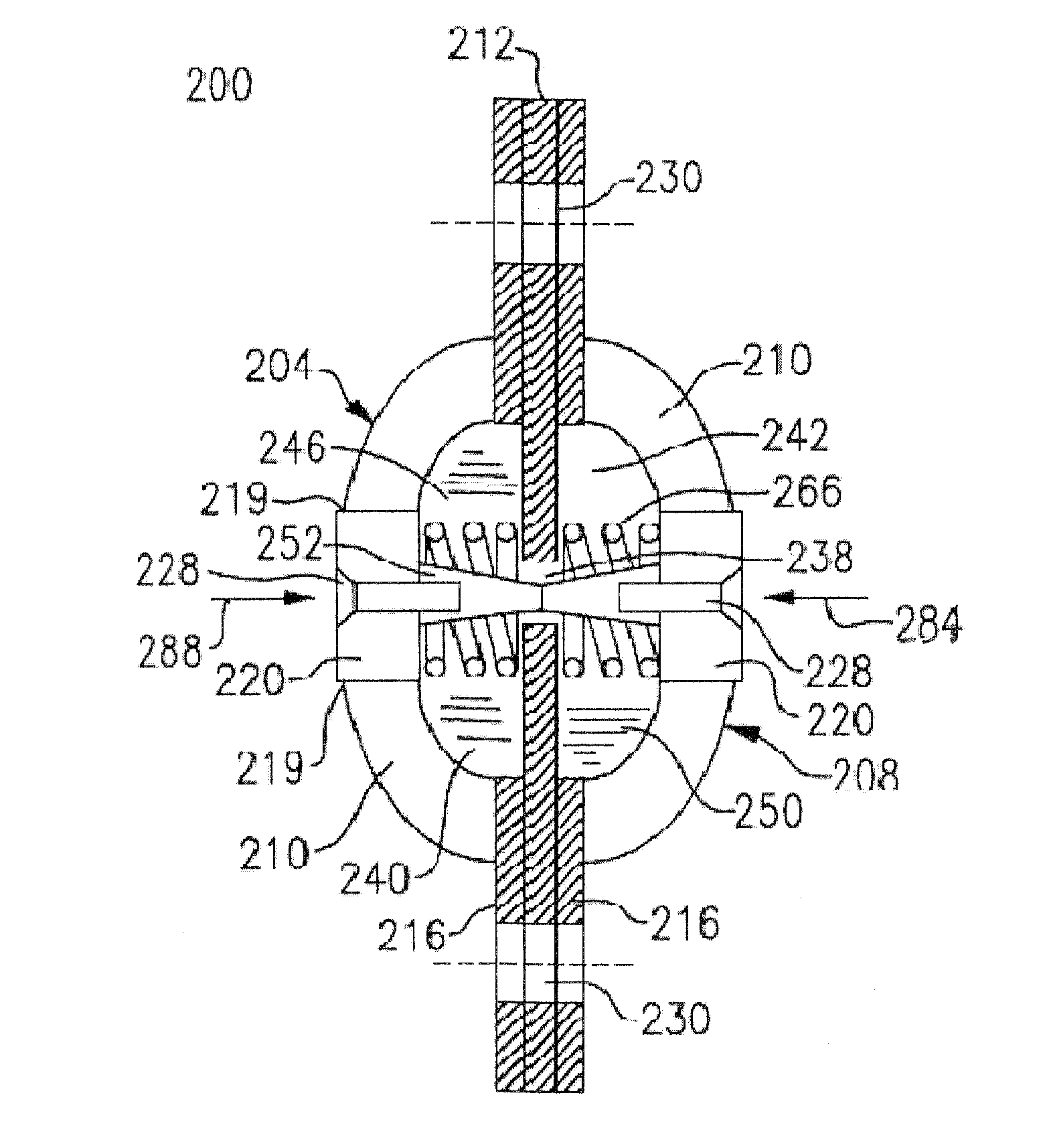

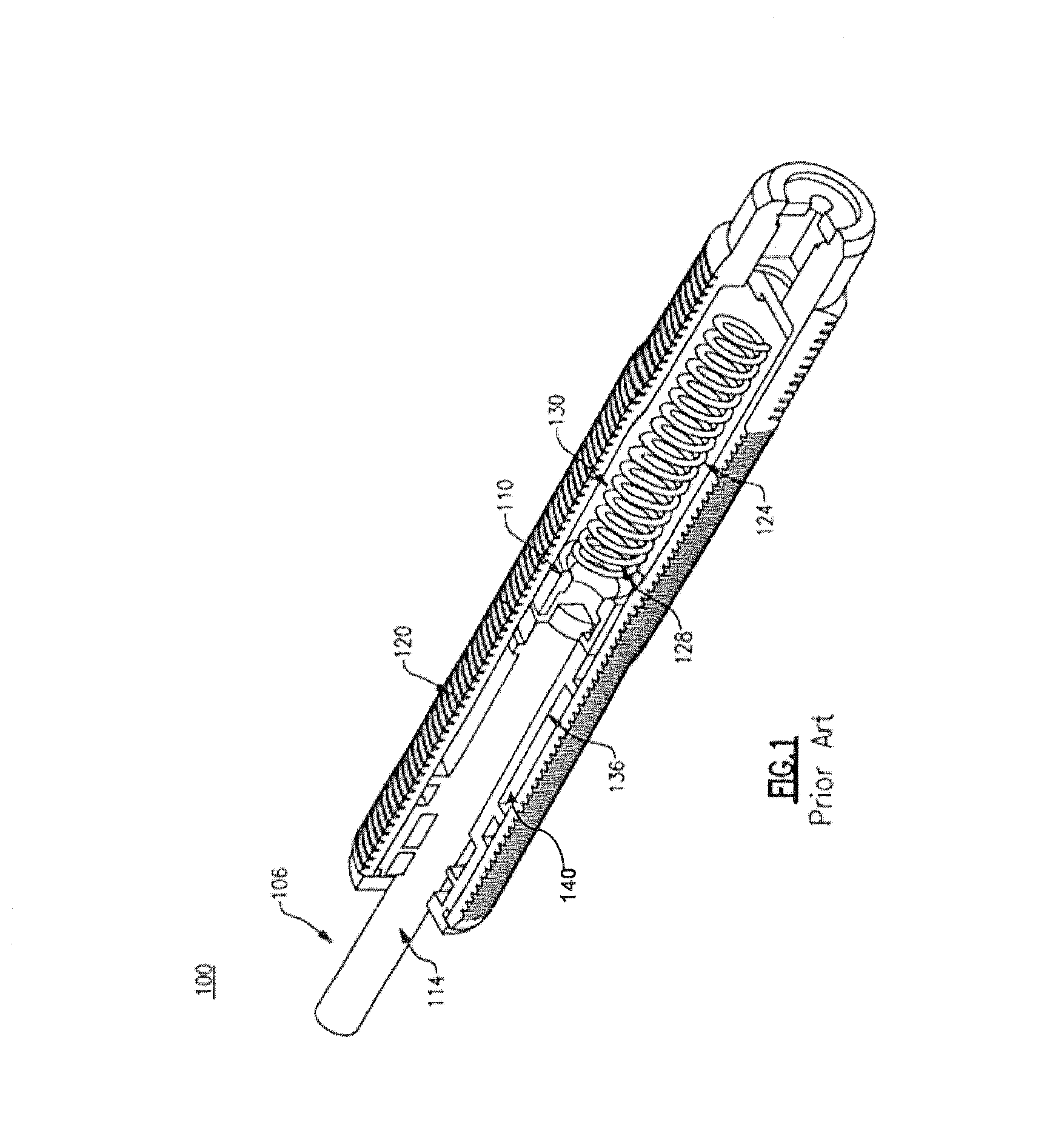

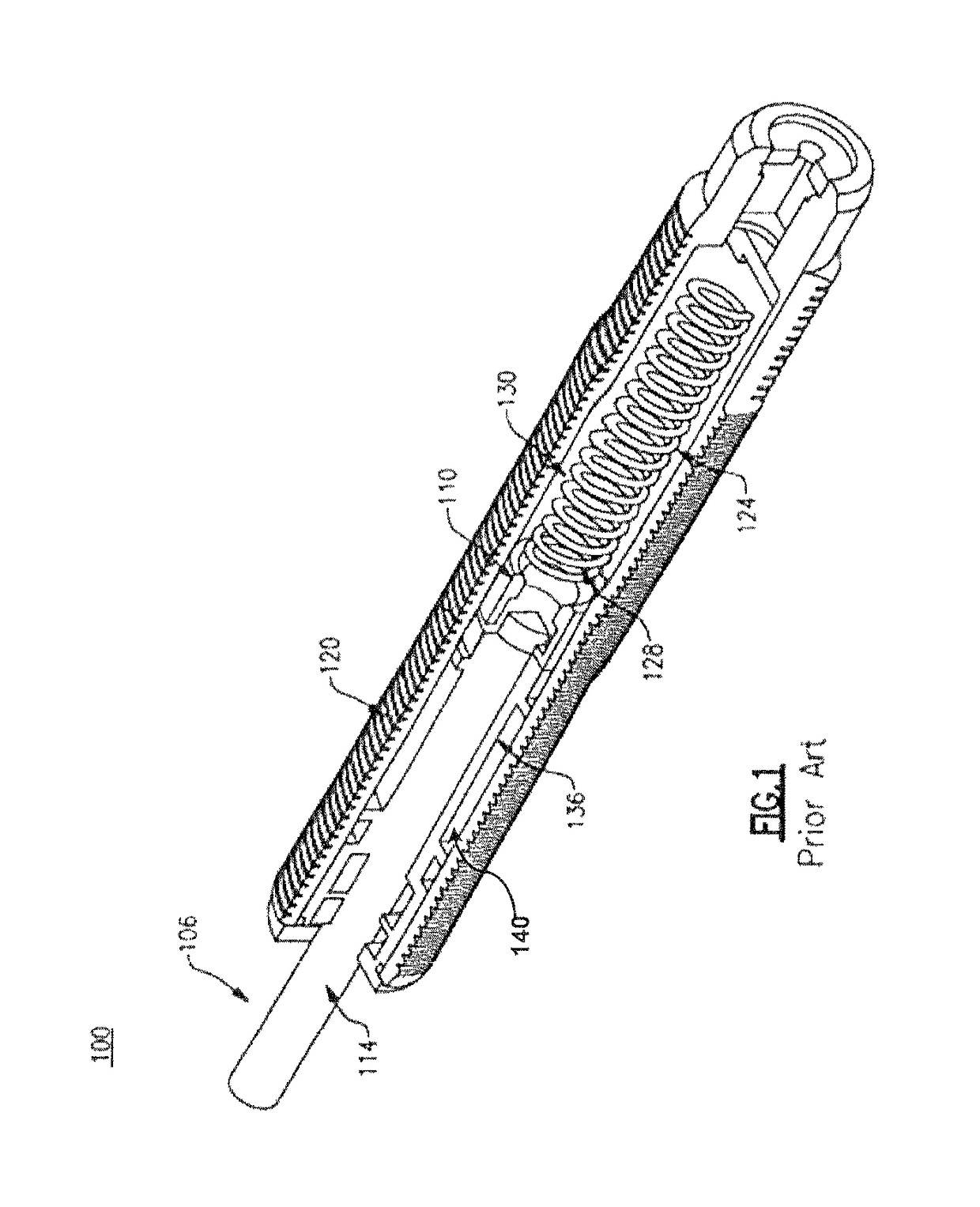

Compliant elastomeric shock absorbing apparatus

A shock absorbing apparatus includes a flexible membrane defining an accumulator cavity, and a compression assembly defining a compression cavity. The compression assembly is disposed within the flexible membrane such that viscous fluid contained within the cavities may be exchanged therebetween by a damping orifice, fluid conduit and or valve mechanism. The accumulator cavity deforms in response to the application of a transmitted impact load, and is capable of storing and releasing potential energy in response to the application and cessation of the transmitted impact load.

Owner:ITT MFG ENTERPRISES LLC

Pyramid lattice reinforced cavity type underwater sound absorption structure

ActiveCN110176224AImprove mechanical propertiesGuaranteed acoustic performanceSound producing devicesPyramidOptics

The invention discloses a pyramid lattice reinforced cavity type underwater sound absorption structure which comprises cells.A pyramid lattice structure is arranged in each cell; a cavity is formed inthe pyramid lattice structure; and a plurality of cell arrays are arranged to form the pyramid lattice reinforced cavity type underwater sound absorption structure. The pyramid lattice reinforced cavity type underwater sound absorption structureis excellent in sound absorption performance and good in water pressure resistance, the lightweight design of the underwater sound absorption structure isrealized meanwhile, and thepyramid lattice reinforced cavity type underwater sound absorption structure is a kind of multifunctional integrated structure with load bearing-sound absorption-lightweight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

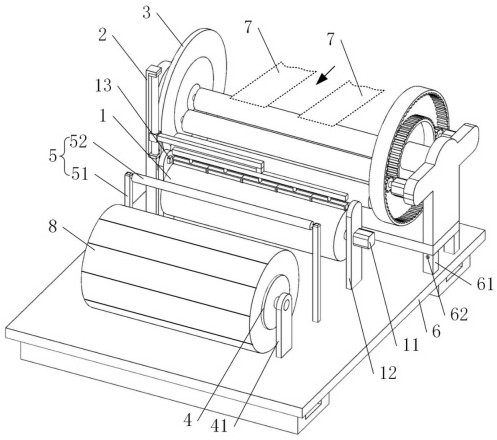

Tire rubber sheet winding device and using method thereof

The invention relates to the technical field of tire production equipment, in particular to a tire rubber sheet winding device and a using method thereof. The tire rubber sheet winding device comprises a winding roller connected with a first servo motor, a rubber sheet fixing assembly arranged above the winding roller, an auxiliary roller assembly and a winding roller, wherein the auxiliary roller assembly and the winding roller are arranged at the two sides of the winding roller respectively; a cloth liner is wound around the winding roller, and a rubber sheet is conveyed to the highest point of the winding roller through the auxiliary roller assembly; the rubber sheet fixing assembly comprises a lifting mechanism, the lifting mechanism is connected with a rubber belt fixing mechanism, and a rubber belt with the bonding face facing the winding roller is arranged below the rubber belt fixing mechanism; and one end of the auxiliary roller assembly is in butt joint with the rubber sheet conveying mechanism, and the other end of the auxiliary roller assembly can rotate to be close to or away from the highest point of the winding roller. According to the tire rubber sheet winding device, automatic winding operation is achieved, and the winding quality and the winding stability are improved.

Owner:山东盛海橡胶有限公司

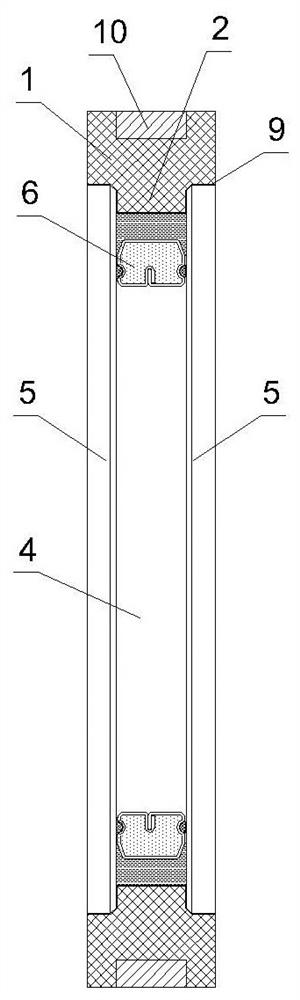

Expansion compression type packer

ActiveCN102650202BAvoid compression setImprove securitySealing/packingHydraulic cylinderHigh pressure

The invention provides an expansion compression type packer which comprises a sleeve and a packer center tube, a throttler and a check valve which are arranged in the sleeve. The throttler is arranged at the top end of the packer center tube; the check valve is arranged at the bottom end of the packer center tube; and an expansion rubber barrel, a compression rubber barrel, a retractable bracket and a compression rubber barrel bracket are sequentially arranged outside the packer center tube between the throttler and the check valve from top to bottom. A compression hydraulic cylinder of a compression type packer is saved; by additionally arranging the retractable steel sheet bracket, the rubber barrels are prevented from entering an annulus to form the jamming of a drilling tool after being compressed and deformed, the safety and the reliability of resisting the high temperature and the high pressure are improved, and the expansion compression type packer has low cost and high construction efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

A Pyramid Lattice Enhanced Cavity Underwater Sound Absorbing Structure

ActiveCN110176224BImprove mechanical propertiesGuaranteed acoustic performanceSound producing devicesDot matrixUnderwater

The invention discloses a pyramid-shaped lattice-enhanced cavity-type underwater sound-absorbing structure, which includes a cell, a pyramid lattice structure is arranged inside the cell, a cavity is arranged in the pyramid lattice structure, and a plurality of cell arrays are arranged Constitute a pyramid-shaped lattice enhanced cavity-type underwater sound-absorbing structure. The invention has excellent sound absorption performance and good water pressure resistance performance, and at the same time realizes the lightweight design of the underwater sound absorption structure, and is a multi-functional integrated structure of bearing-sound absorption-lightweight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Bonding lead

ActiveUS8254078B2Avoid compression setLine/current collector detailsFuel tank safety measuresElastomerElectrical connection

A joint on an aircraft, a bonding lead for use in such a joint, and a method of manufacturing such a joint. The bonding lead comprises an elongate conductive core with a pair of end faces at the extremities of its length. The conductive core is encapsulated along at least a majority of its length and at both end faces in a barrier layer typically formed from an elastomer. The lead is encapsulated along its length in the barrier layer apart from at a first contact region towards a first end of the bonding lead and a second contact region towards a second end of the bonding lead. A first electrical connector passes through a first hole in the barrier layer to engage the first contact region of the conductive core and provide an electrical connection between the conductive core and the first component; and a second electrical connector passes through a second hole in the barrier layer to engage the second contact region of the conductive core and provide an electrical connection between the conductive core and the second component.

Owner:AIRBUS OPERATIONS LTD

Compliant elastomeric shock absorbing apparatus

Owner:ITT MFG ENTERPRISES LLC

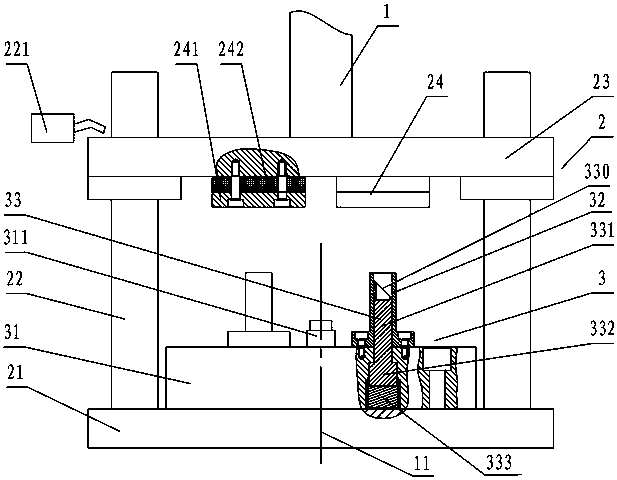

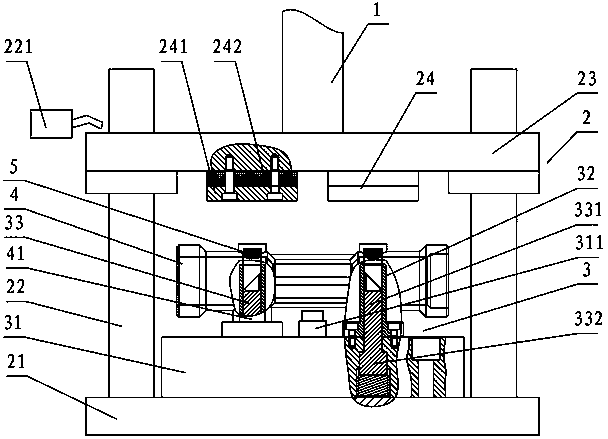

Lithium battery film thickness gauge

ActiveCN113188499ASmall compression deformationGuaranteed high precision measurementMeasurement devicesEngineeringMechanical engineering

The invention discloses a lithium battery film thickness gauge which comprises a measuring base, a measuring arm, a film moving mechanism, a lifting mechanism and a measuring mechanism, wherein the measuring arm is arranged on the measuring base; the lifting mechanism is arranged on a measuring wall; the measuring mechanism is arranged on the lifting mechanism; the film moving mechanism is arranged on one side of the measuring base; a measurement position on the measurement base is connected with an adsorption device; and the measuring mechanism comprises a measuring probe, a micro sensor and a high-precision analog-to-digital conversion module. According to the lithium battery film thickness gauge, the contact surface is increased and the compression deformation of the film is reduced by the measuring mechanism, and high-precision measurement is ensured; the lifting structure is used for avoiding compression deformation of the film caused by rapid movement impact; an over-range gap is connected between the lifting rod and the sensor, so that the influence of the lifting mechanism on the sensor is avoided; the film moving mechanism avoids deformation caused by manual dragging, so that the movement is smooth and uniform; and the measurement position is connected with the adsorption device, so that the film is in complete contact with the measurement platform, and accurate measurement is ensured.

Owner:马尔精密量仪(苏州)有限公司

A Mounting Device for Ultrasonic Heat Meter Reflector

ActiveCN105698972BTroubleshooting exact-corresponding installation issuesAvoid compression setVolume meteringCalorimeterEngineeringBilateral symmetry

The invention discloses a mounting device for an ultrasonic heat meter reflector, which comprises a press punch, a down pressing device and a positioning device, wherein the down pressing device comprises a bottom plate, left and right guide columns fixed at two ends of the bottom plate, a pressing plate movably sleeving the guide columns and a pressing head arranged on the pressing plate; the positioning device comprises a base fixed with the bottom plate, guide sleeves fixed on the base, and left and right positioning columns located in left and right guide sleeves, upper end surfaces of the left positioning column and the right positioning column are inclined planes with the same inclination and in bilateral symmetry and corresponding to inclined planes of left and right reflectors in a pipe segment body. The guide structure of the guide column is adopted to guide the down pressure to be uniform and stable, the horizontally-symmetrical and accurately-fixed positioning column structure is arranged on the fixed base, a limiting structure with the inclined plane is arranged on the positioning column, the three structures are supported and collaborated mutually, and the accurate corresponding mounting problem of the reflection surface of the reflector can be solved.

Owner:NINGBO JIEKELONG PRECISION MFG

Cable winding device for electric power maintenance

InactiveCN111186723APlay a role in groomingEasy to fixFilament handlingWinding machineControl theory

The invention discloses a cable winding device for electric power maintenance. A winding mechanism, a drive mechanism and a wire collecting mechanism are included. The winding mechanism is connected with the drive mechanism. A power shaft is arranged at the middle portion of a winding ring. The winding ring and the power shaft are fixedly connected through connecting rods. Through the arrangementof the winding ring, the cable dredging function is achieved. The connecting rod combined manner is a triangular combination, stability of the winding ring is improved, and the compression deformationphenomenon caused by a too heavy cable is avoided. The cable is fixed to a cable head fixing clamp, a runner back plate fixes the winding cable, and cable loosening is avoided. The runner back plateis provided with knotting holes, a bundling rope penetrates through the knotting holes, cable bundle-by-bundle tidying is convenient, and time is saved. When a runner starts to rotate, the cable is twisted on the runner back plate. The device is high in stability, time and labor are saved, the winding meters can be freely set, and the workload of workers is reduced.

Owner:新沂市高新科技产业园运营管理有限公司

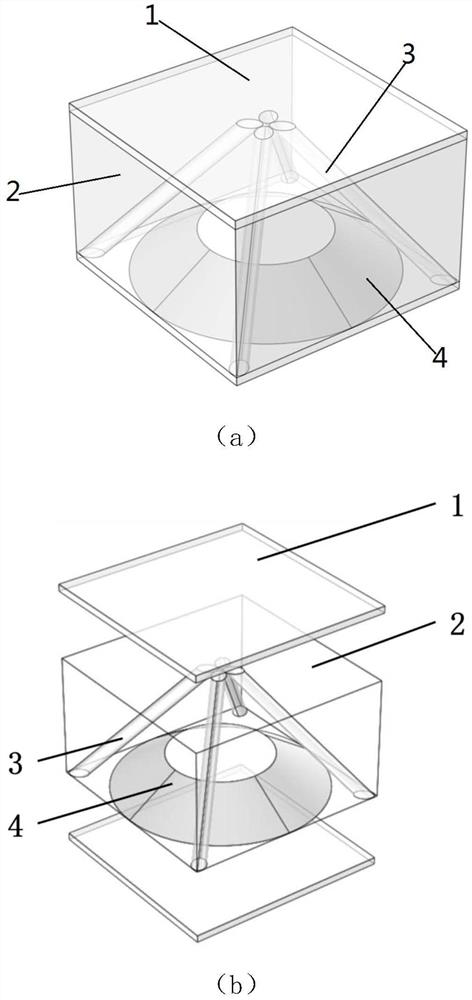

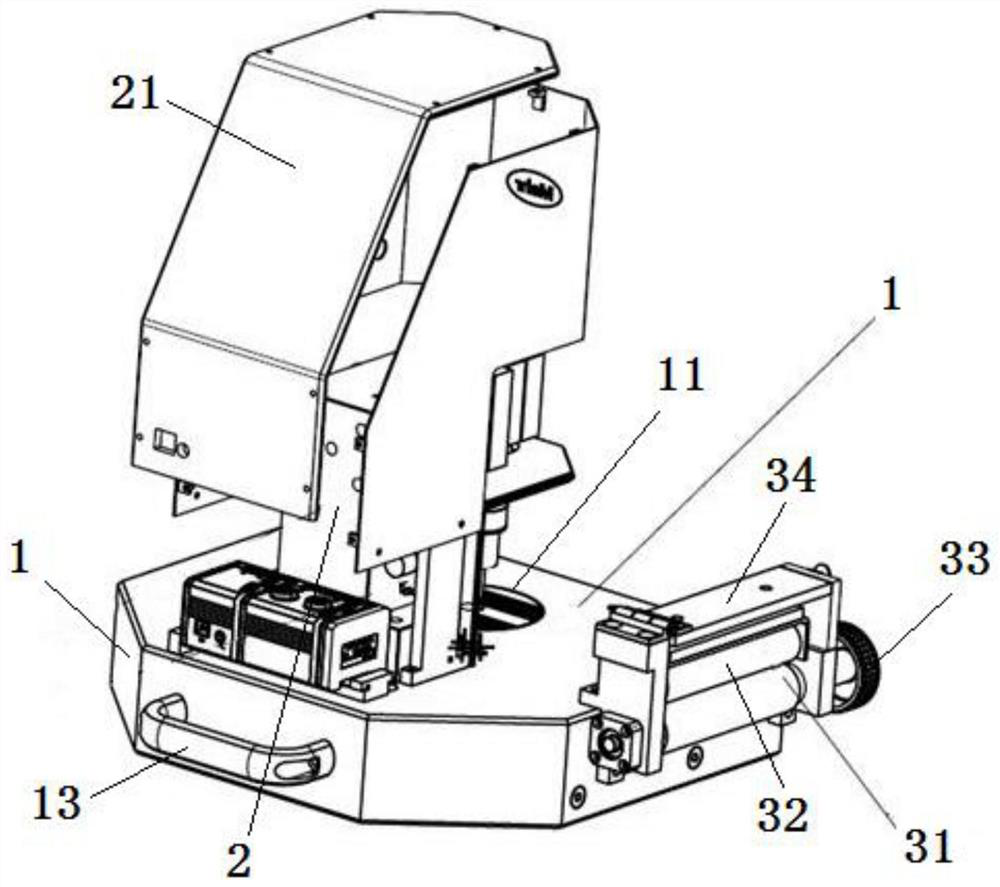

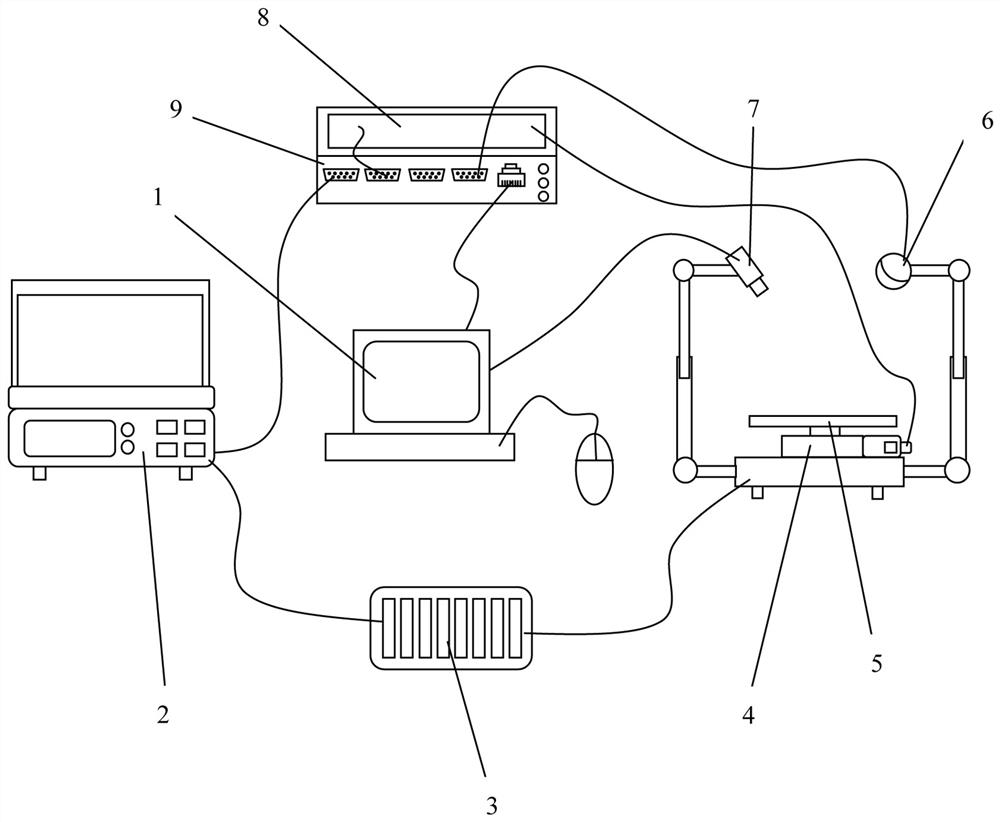

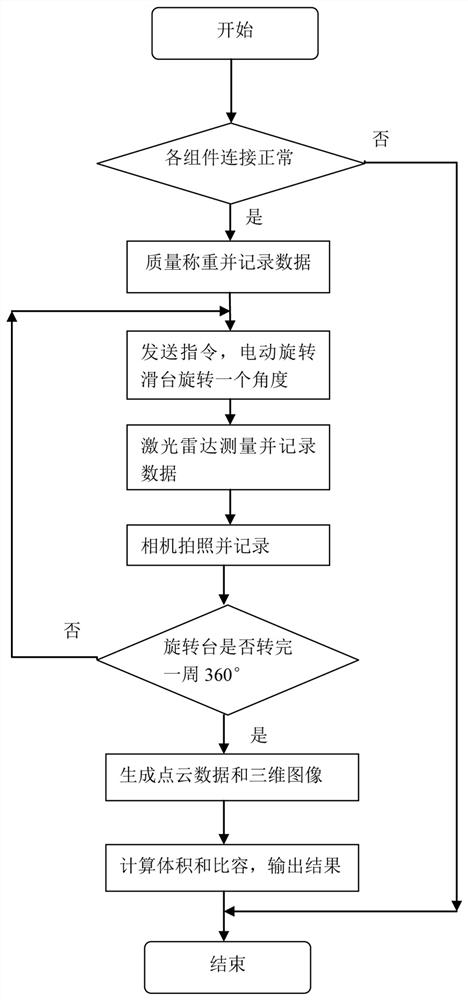

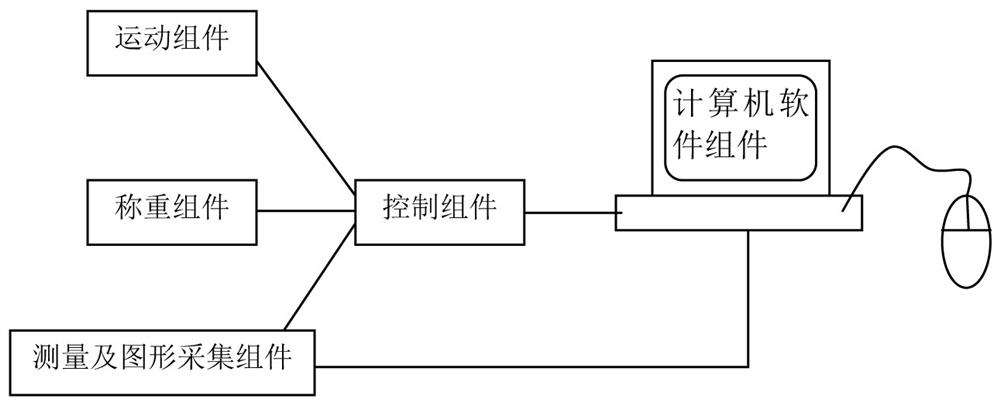

Fermented flour food specific volume rapid measurement and three-dimensional reconstruction imaging device

PendingCN112414894ARapid specific volumeAvoid a series of problems that arise in the measurementUsing optical means3D modellingGraphicsMotor drive

The invention provides a fermented flour food specific volume rapid measurement and three-dimensional reconstruction imaging device. The device comprises a control assembly, a motion assembly, a weighing assembly, a measurement and graph acquisition assembly, a computer and a power supply assembly. The motion assembly comprises an electric rotary sliding table and an objective table; the weighingassembly comprises an electronic balance; the measurement and graph acquisition assembly comprises a laser radar and an image acquisition camera; the control assembly comprises a motor driving controller module and a serial server module which are connected with the electric rotary sliding table; the power supply assembly is used for supplying power to each assembly; and the computer summarizes the measurement information of each assembly, and completes three-dimensional calculation and image generation according to the rotation angle of the electric rotary sliding table, the image informationof the image acquisition camera and the measurement information of the laser radar. The device has the advantage that the specific volume and the three-dimensional appearance form of the detected food can be quickly obtained.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preventing vertical shaft wellhole from being damaged

ActiveCN101985881BAvoid destructionWater level increased and stabilizedMining devicesShaft equipmentRegimenEngineering

The invention relates to a method for preventing a vertical shaft wellhole from being damaged by adopting a ground water injection water level stabilization method, comprising the following concrete steps: 1) analyzing the alluvium structure and water regimen, and selecting a loose aquifer of which the water level continuous descends within over three years from the alluvium as a water injection position; 2) constructing a water injection hole around the wellhole with the shape consistent with that of a long-term hydrological observation well; 3) injecting water into the water injection position by tap water or a water pump through a water injection hole; and 4) monitoring the water injection effect in the water injection process, wherein the monitoring contents comprise aquifer water level monitoring and well wall variation monitoring, and the water injection rate is adjusted based on the monitored water injection effect. The method can ensure the water levels of the wellhole and theaquifer nearby to be increased and relatively steady, reduce compression deformation and additional pressure strain on the well wall caused by loosened soil layers around the wellhole due to drop of the water level, thus preventing the well wall from being damaged. Researching from the perspective of hydrology-geological conditions of mines, in the invention, a method for fundamentally solving the problem of preventing the wellhole from being damaged is searched out based on the well wall fracture mechanism, and has obvious prevention effect, is convenient to construction, and is safe and economic.

Owner:兖矿能源集团股份有限公司 +1

Intelligent medicine bottle

PendingCN114426141AEasy to takeEasy to pourClosuresDischarging meansMedication takingBiomedical engineering

The invention relates to the technical field of medicine bottles, and discloses an intelligent medicine bottle which comprises a bottle body, a fixed bearing is fixedly arranged on the inner bottom wall of the bottle body, a rotating shaft is connected to the inner wall of the fixed bearing, a rotating plate is fixedly installed at the top of the rotating shaft, and a cover plate is fixedly installed at the top of the rotating plate. The cover plate is rotationally arranged at the top of the bottle body; the seven medicine storage cabinets correspond to seven days of a week respectively, the three storage spaces of each medicine storage cabinet correspond to three times of medicine taking every day respectively, medicine needing to be taken every time every day in one week is prepared and sequentially placed in the storage spaces in the medicine storage cabinets, and when medicine taking is needed, the cover plate is rotated to enable the rotating shaft to rotate through the rotating plate, so that medicine taking is achieved. The rotating shaft rotates to enable different medicine storage cabinets to correspond to medicine outlet holes, so that different medicines can be poured out, and the medicines can be conveniently taken every day; the device is novel in design and simple in structure and has the advantage of being convenient for elderly patients to use.

Owner:田乐媛

A processing method for high-precision stepped deep-hole parts

The invention specifically discloses a machining method of a high-precision step deep hole part, and solves the problems of weak straightness and incapability of guaranteeing the size and shape precision in a traditional boring process of the step deep hole part. The machining method comprises the following steps: (1) the deep hole part is divided into a part body I and a part body II; (b) an inner hole of the part body I is machined as a finished hole; the outer circle leaves a working allowance; then, an inner hole of the part body II is machined; the outer circle leaves a working allowance; and then, the part body II is welded with the part body I; (c) after welding, a plug is pressed in an outer end hole of the part body II; a center hole is formed in the outer end surface of the plug; and the outer circles of the part body I and the part body II are machined to reach the size of a finished product; (d) a guide cylinder is manufactured; and (e) the inner hole of the part body II is roughly bored and finely bored. The straightness of the part reaches the stated technical requirement; and the problem of deformation of a thin-wall part is prevented.

Owner:SHANXI PINGYANG IND MACHINERY

Hydraulic cold drawn pipe machine

The invention discloses a hydraulic cold tube drawing bench, which comprises a main cylinder seat, a drawing die seat, a clamping dolly which is arranged between the main cylinder seat and the drawing die seat and is driven by a main cylinder, a core rod seat used for penetrating a positioning core rod, and an end which is fixedly connected with the main cylinder seat, the drawing die seat and the core rod seat sequentially on two independent section lathe beds; the main cylinder seat, the lathe bed, the drawing die seat, the lathe bed and the core rod seat are axially arranged. The inventionis characterized in that: the lower parts of the main cylinder seat, the core rod seat and the lathe beds are all provided with lateral displacement limit devices containing concave positioning grooves; the concave positioning groove consists of a bottom plate and two side baffles or consists of L-shaped pieces formed by a bottom plate and side baffles and arranged symmetrically along the longitudinal axis. The lateral displacement limit devices are fixedly connected with groundwork. The invention has the advantages that: by using the simple structure, the invention effectively overcomes compression deformation of the lathe beds, and has low cost, convenient installment and low requirement for the ground which can be widely applied to metallurgical industry to reduce or expand pipe blanks.

Owner:CHANGZHOU LIAN HYDRAULIC EQUIP

Spiral corrugated pipe structure

InactiveCN110878867AImprove radial compression performanceImprove axial bending performanceRigid pipesMaterial consumptionStructural engineering

The invention discloses a spiral corrugated pipe structure. The structure includes a smooth wall pipe arranged in the structure and a winding pipe spirally wound outside the smooth wall pipe, the middle part of the interior of the winding pipe is provided with supporting stand plates arranged along the length direction of the winding pipe, the lower sides of the supporting stand plates are connected to the outer wall of the smooth wall pipe, and the upper sides are connected to the top of the winding pipe; and two sides, along the axial direction of the smooth wall pipe, of the winding pipe are respectively provided with supporting inclined plates, the upper ends of the supporting inclined plates are connected to the outer side of the winding pipe, the lower ends are connected to the outerwall of the smooth wall pipe, and the supporting inclined plates are arranged along the length direction of the winding pipe and are integrally formed with the winding pipe. The structure has the characteristics of less material consumption and strong bending and compression resistance.

Owner:黔东南三友管业有限公司

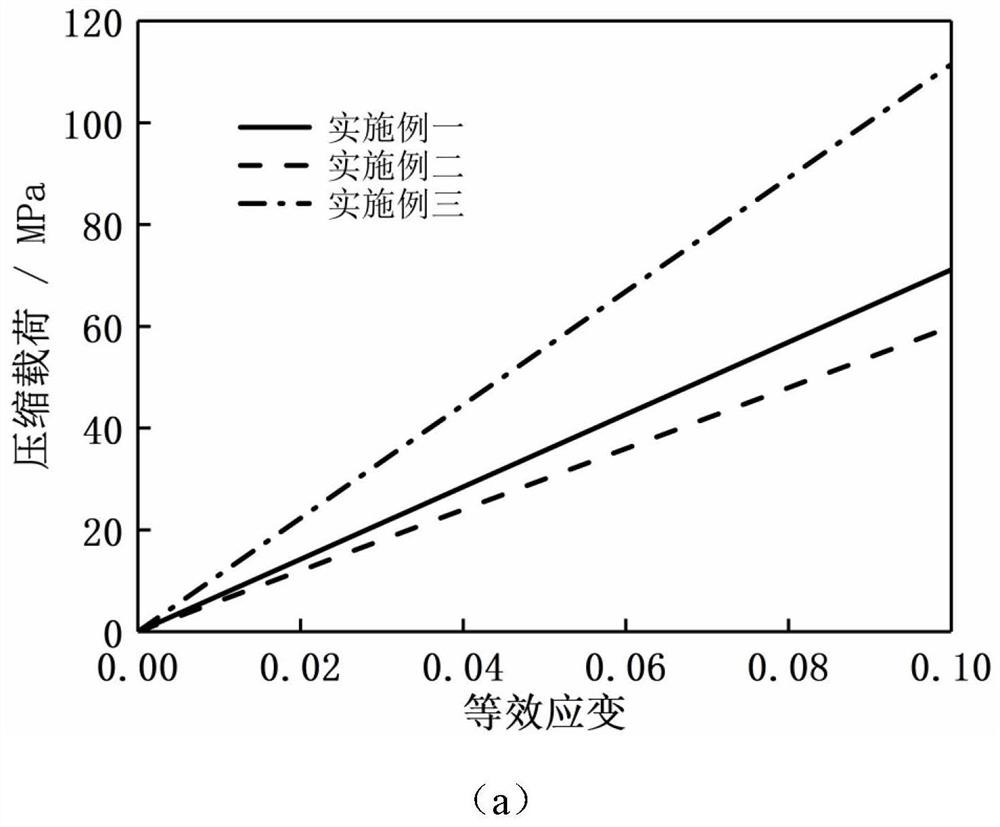

Composite solid wheel for rail transit vehicles and its stiffness design method

ActiveCN109109560BThe combined structure is simple and reliableEasy to assembleRail-engaging wheelsControl theoryRail transit

The combined solid wheel for rail transit vehicles is characterized in that it includes a wheel vulcanized body formed by vulcanizing the inner metal and the outer rubber and a flange connection plate that can be installed in cooperation with the axle, and the number of the wheel vulcanized body is two and Coaxially aligned, the flange connection plate is sandwiched between two wheel vulcanized bodies, and is detachably connected with the wheel vulcanized body. The outer diameter of the flange connection plate is smaller than the outer diameter of the wheel vulcanized body, and the flange connection The disc projects between the rubber layers of the two wheel vulcanized bodies. The invention provides a simple and reliable combined structure, easy to assemble and replace, can realize the non-linear radial stiffness of the wheel in the load-bearing process, improve the comfort of the vehicle, and has the function of stop and limit, and can realize the radial deformation of the wheel limit, improve the safety and reliability of vehicle operation. The invention also provides a method for designing the stiffness of a combined solid wheel for a rail transit vehicle.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Glued laminated timber side splicing solid wood floor

InactiveCN109866485AAvoid compression setGuaranteed StrengthWood layered productsFlooringSolid woodSurface layer

The invention provides a glued laminated timber side splicing solid wood floor, and relates to the technical field of floors. The glued laminated timber side splicing solid wood floor comprises a surface layer, a substrate layer and a bottom layer from the top to the bottom in sequence; and the surface layer and the bottom layer are separately provided with mortises, the substrate layer comprisesa glued laminated timber board and side splicing wood strips arranged on two sides of the glued laminated timber board and used for clamping the glued laminated timber board, and each side splicing wood strip is provided with tenons cooperating with corresponding mortises. According to the solid wood floor provided by the invention, the glued laminated timber board is arranged between the bottom layer and a surface layer bottom plate, so that strength of the floor surface can be ensured, and the wear resistance and strength of the floor surface provided by the invention are higher than those of a floor surface of a glued laminated timber board in the prior art; at the same time, two sides of the glued laminated timber board are provided with the side splicing wood strips, the side splicingwood strips can play a supporting role, so that compression deformation of the glued laminated timber board can be prevented; and the structures of the mortises and the tenons are arranged, so that relative sliding among the layers can be avoided, deformation of the floor can be prevented, and the floor has strong deformation resistance and a stable structure.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Hollow glass externally inlaid with thermal insulation material section and manufacturing and mounting method thereof

PendingCN112901032AImprove insulation effectImprove shock resistanceUnits with parallel planesGlass pane fixingThermal insulationSealant

The invention discloses hollow glass externally inlaid with thermal insulation material section. A connecting groove is formed between adjacent glass of the hollow glass and a sealant, a connecting tenon is manufactured in the middle of the external thermal insulation material section, the connecting tenon in the middle of the external thermal insulation material section is inserted into the connecting groove of the hollow glass, and the external thermal insulation material section and the hollow glass are combined together.

Owner:王广武

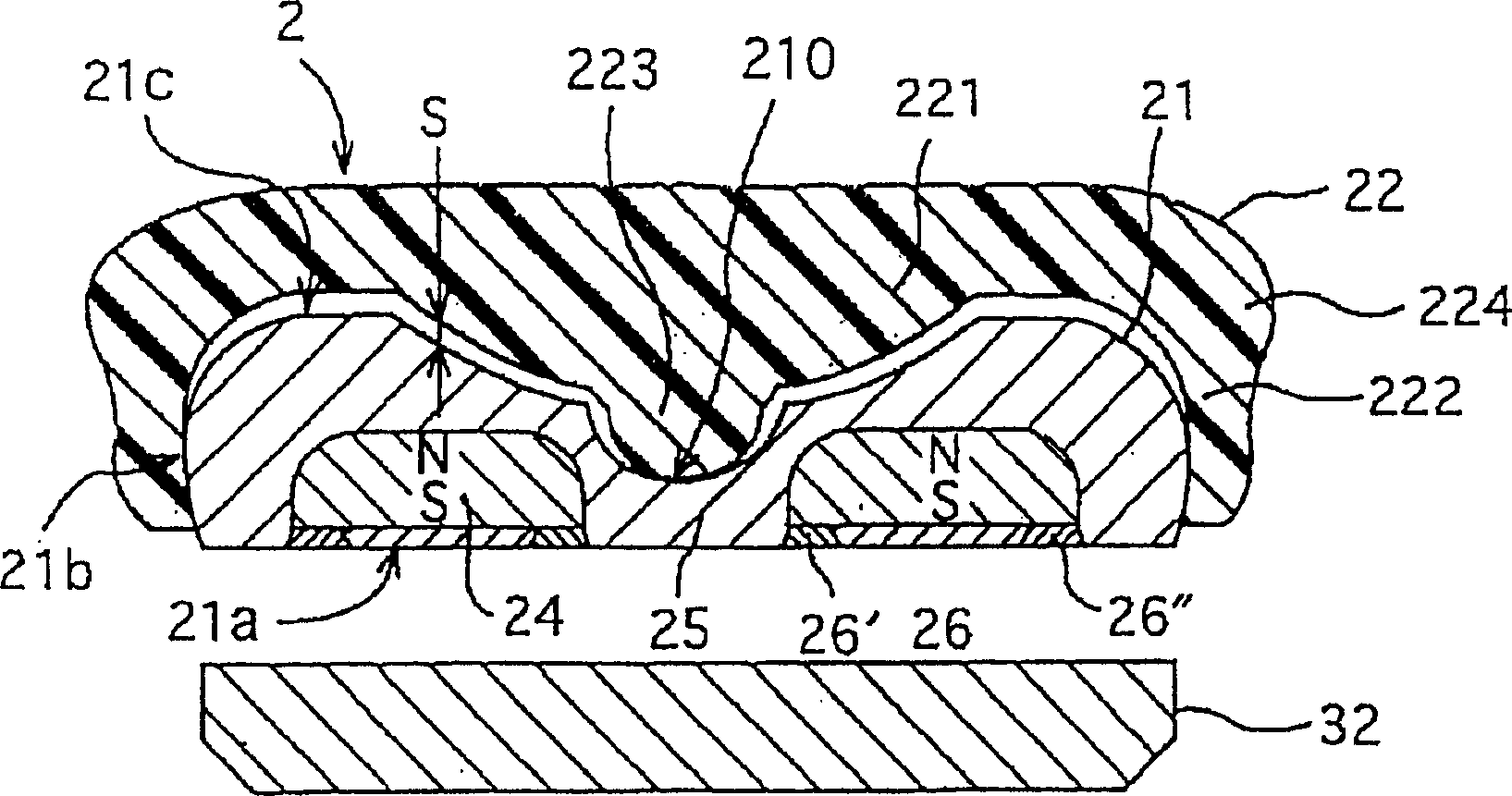

False tooth attachment and method and spacer for fixing same

InactiveCN1248658CAvoid compression setPrevent peelingDental implantsFastening prosthesisRoot capMagnetic tension force

A false tooth attachment (2) having a high resiliency with respect to a pressing force due to occlusion of teeth and giving a suitable sinking motion to a false tooth at the time of occlusion of teeth, comprising a magnet member (21) adapted to be attracted by a magnetic force to a root cap buried in a dental root, and a cap (22) covering the surface of the magnet member (21) which is on the opposite side of the surface thereof attracted to the root cap, the attachment being buried in a dental plate, the magnet member (21) having in the central portion of a rear surface (21c) thereof a recess (210), in which a projection (223) of the cap (22) of a hard resin is fitted in a contacting state, the projection (223) being elastically deformed and contracted due to an occlusion pressure, so that a circumferential portion (222) integrally molded with the body (22) of the cap (22) is moved slidingly on a side circumferential surface (13) of the magnet member (21) to cause the thickness of the false tooth attachment (2) to decrease, whereby the false tooth suitably sinks at the time of occlusion of the teeth to improve the resiliency and sense of use of the false tooth.

Owner:AICHI STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com