Peroxide vulcanized fluororubber and preparation method thereof

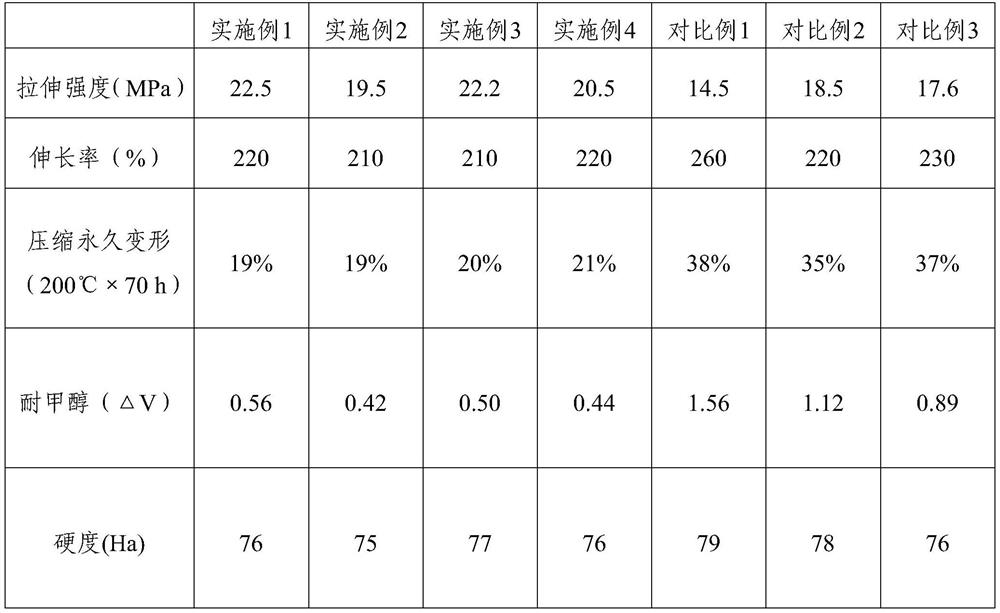

A vulcanized fluororubber and peroxide technology, which is applied in the field of fluororubber synthesis, can solve the problems of large compression set value, high pressure change limit application, unfavorable industrial production, etc., achieve low compression deformation, solve high compression deformation, The effect of shortening the dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of peroxide vulcanized fluororubber, and its preparation method comprises the following steps:

[0034] (1) Carry out the emulsion polymerization of the present invention in a 50L reactor. Add 30L of deionized water to the reaction kettle. The reactor should be evacuated, and when the oxygen content is ≤30ppm, add 35g of ammonium perfluorooctanoate and 60g of bromotrifluoroethylene, and heat the contents of the reactor to 95°C. Raise the pressure of the reactor to 2.0 MPa with the initial mixed monomers of vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene at a ratio of 40:25:35 (molar ratio). Add 15g potassium persulfate and 30g diiodomethane to start reaction;

[0035] (2) After the polymerization reaction is carried out, the potassium persulfate solution with a mass concentration of 3.18% is continuously added, and the rate of addition is 50g / 10min; the absolute pressure in the reactor is maintained at 2.0±0.3MPa...

Embodiment 2

[0040] The present embodiment provides a kind of peroxide vulcanized fluororubber, and its preparation method comprises the following steps:

[0041](1) Carry out the emulsion polymerization of the present invention in a 50L reactor. Add 30L of deionized water to the reaction kettle. The reactor should be evacuated, and when the oxygen content is ≤30ppm, add 32g of sodium perfluorooctanoate and 55g of trifluoroiodoethylene, and heat the contents of the reactor to 85°C. The initial mixed monomer vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene ratio is 43:22:35 (molar ratio) to raise the pressure of the reactor to 2.5MPa. Add 12g potassium persulfate and 28g 1,4-diiodobutane to start the reaction;

[0042] (2) After the polymerization reaction was carried out, the continuous addition of mass concentration was 3.5% potassium persulfate, and the addition rate was 55g / 10min; the absolute pressure in the reactor was maintained at 2.5 ± 0.3MPa by adding the mixed m...

Embodiment 3

[0047] The present embodiment provides a kind of peroxide vulcanized fluororubber, and its preparation method comprises the following steps:

[0048] (1) Carry out the emulsion polymerization of the present invention in a 50L reactor. Add 30L of deionized water to the reaction kettle. The reactor should be evacuated, and when the oxygen content is less than or equal to 30ppm, add 35g of ammonium perfluorooctanoate and 62g of 3,3,4,4-tetrafluoro-4-bromobut-1-ene, and heat the contents of the reactor to 90°C. Raise the pressure of the reactor to 2.7 MPa with the initial mixed monomers vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene at a ratio of 50:20:30 (molar ratio). Add 15g potassium persulfate and 50g 1,4-diiodoperfluorobutane to start the reaction;

[0049] (2) After the polymerization reaction is carried out, the potassium persulfate solution with a mass concentration of 3.8% is continuously added, and the feeding rate is 60g / 10min; the absolute pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com