Lithium battery film thickness gauge

A thickness gauge and lithium battery technology, applied in instruments, measuring devices, etc., can solve the problems of difficulty in guaranteeing stability and accuracy, unstable elastic deformation, and large measuring force of the sensor, so as to improve the measurement stability and improve the measurement Accuracy, the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

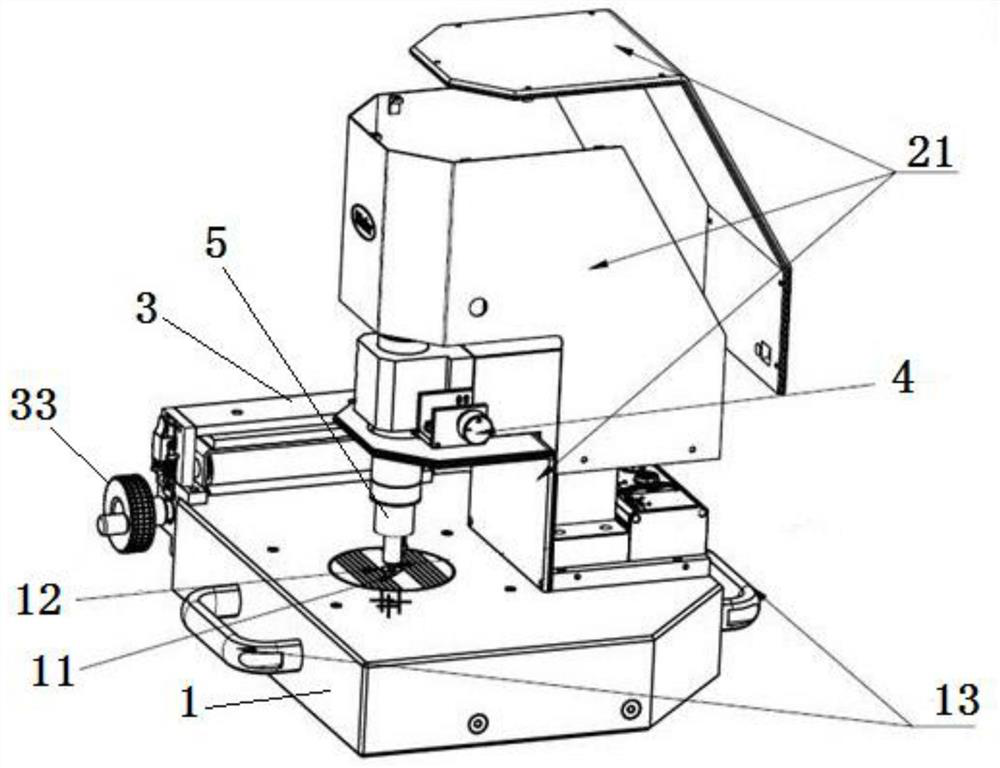

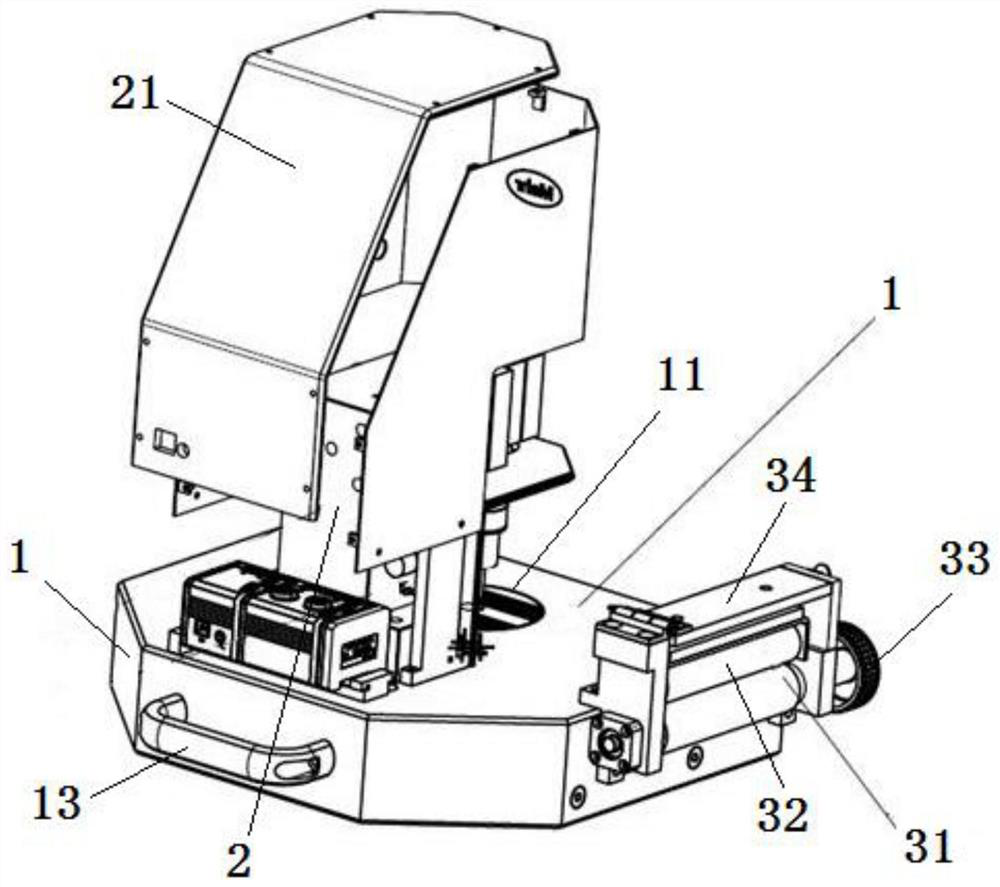

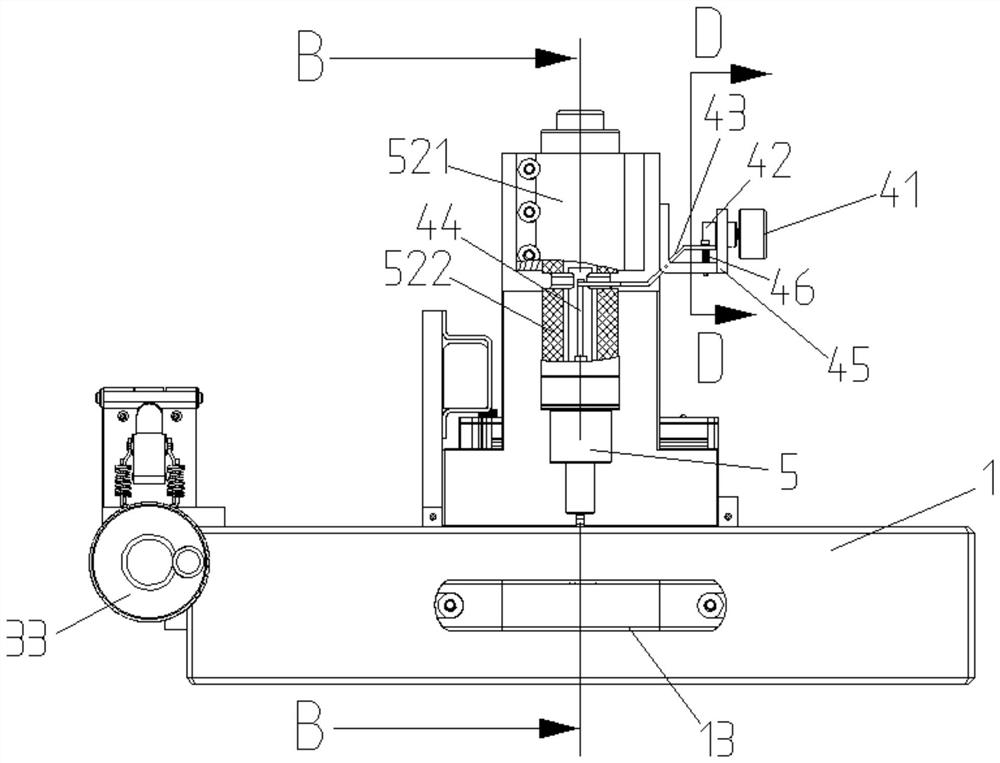

[0045] as attached Figure 1-8 As shown, a lithium battery film thickness gauge includes a measuring base 1, a measuring arm 2, a film moving mechanism 3, a lifting mechanism 4 and a measuring mechanism 5; the measuring base 1 is provided with a measuring arm 2; The measuring wall 2 is provided with a lifting mechanism 4; the lifting mechanism 4 is provided with a measuring mechanism 5, and the lifting mechanism 4 drives the measuring mechanism 5 to carry out lifting movement; one side of the measuring base 1 is provided with a film moving mechanism 3 ; Because the thickness of the film is very thin and very soft, it is easy to cause tensile deformation by manual dragging, and the film moving mechanism 3 is used to move the film, so that the moving process is smooth and even and not easy to wrinkle, ensuring the accuracy of the measurement; The measuring position 11 is connected with an adsorption device; the measuring mechanism 5 includes a measuring probe 51, a tiny sensor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com