Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Achieve self-sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

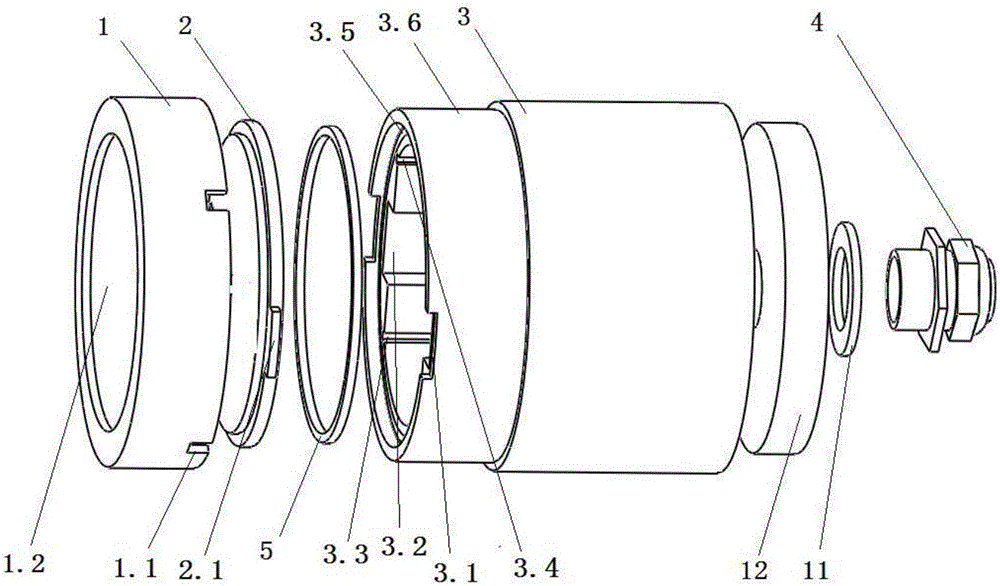

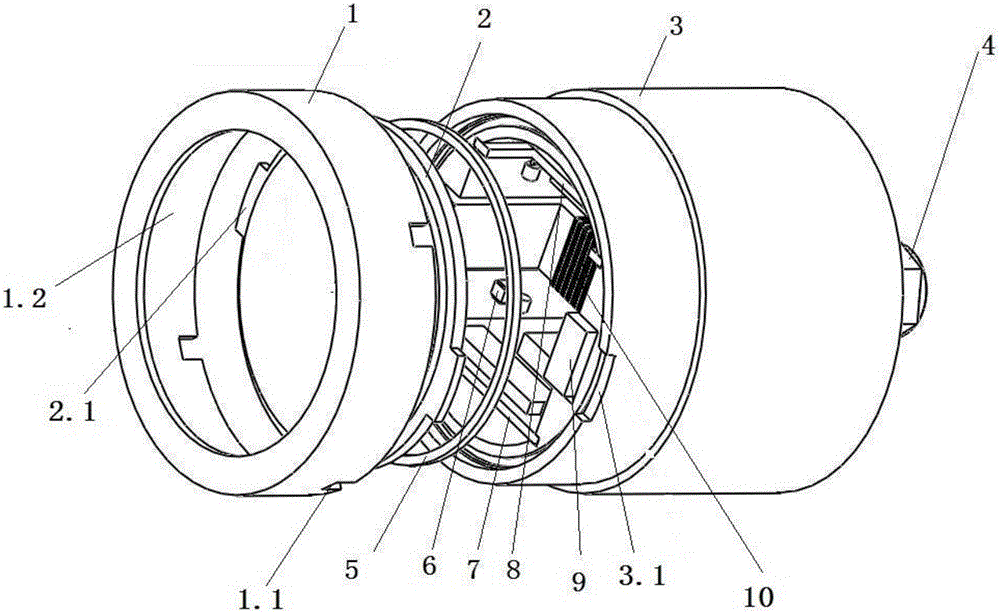

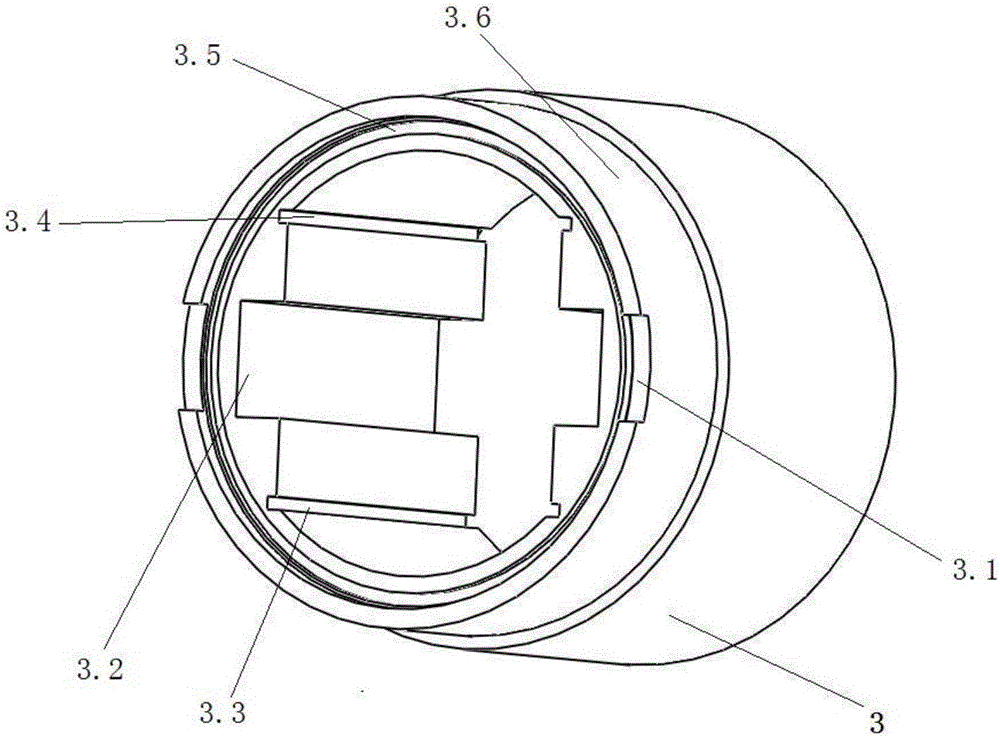

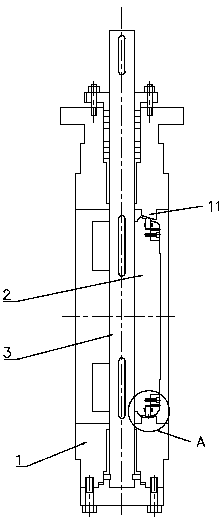

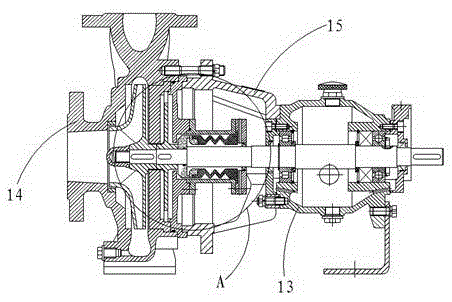

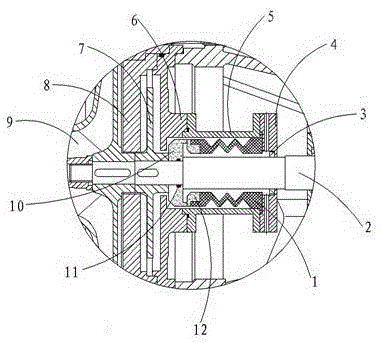

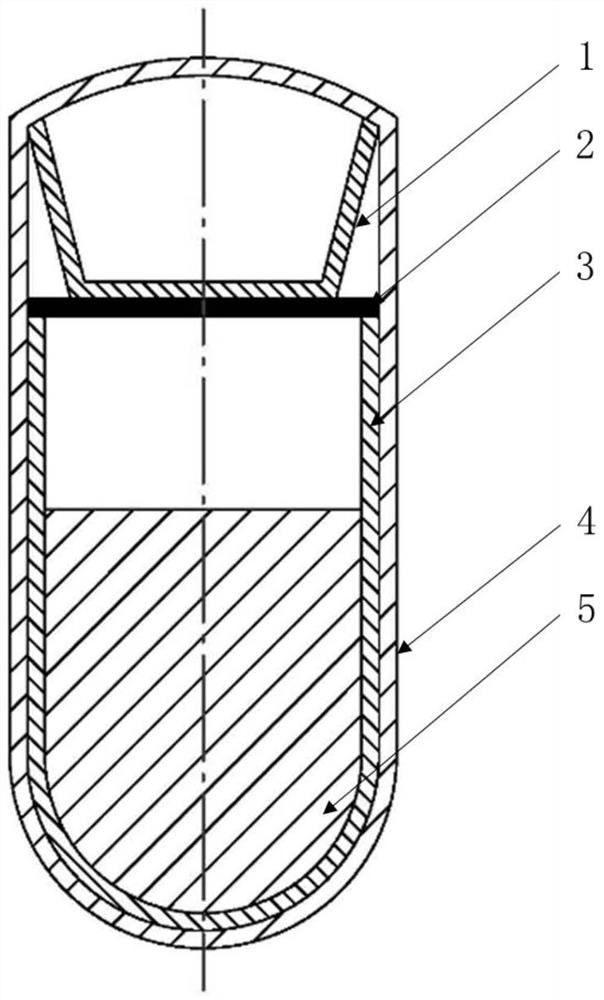

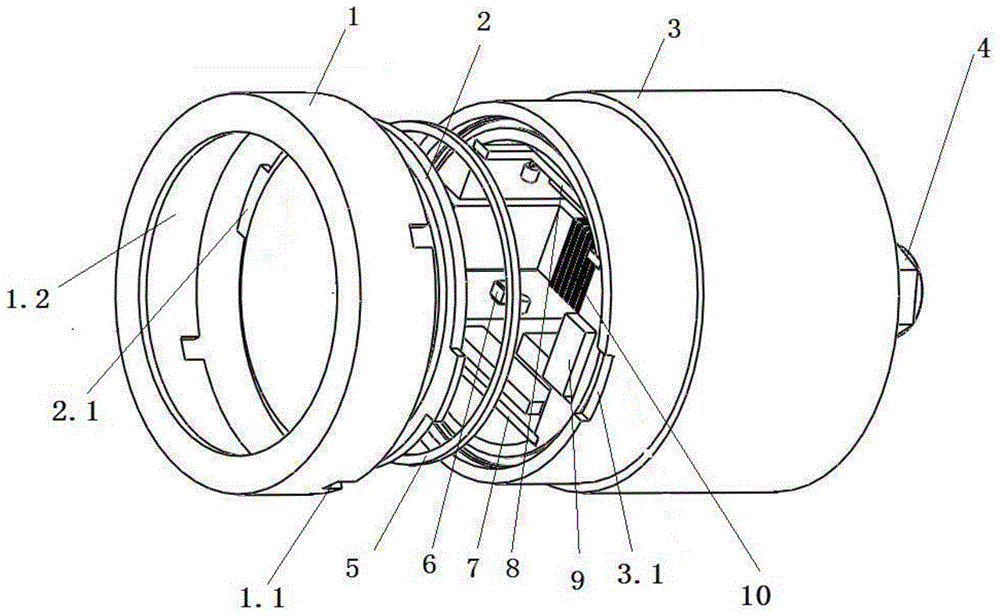

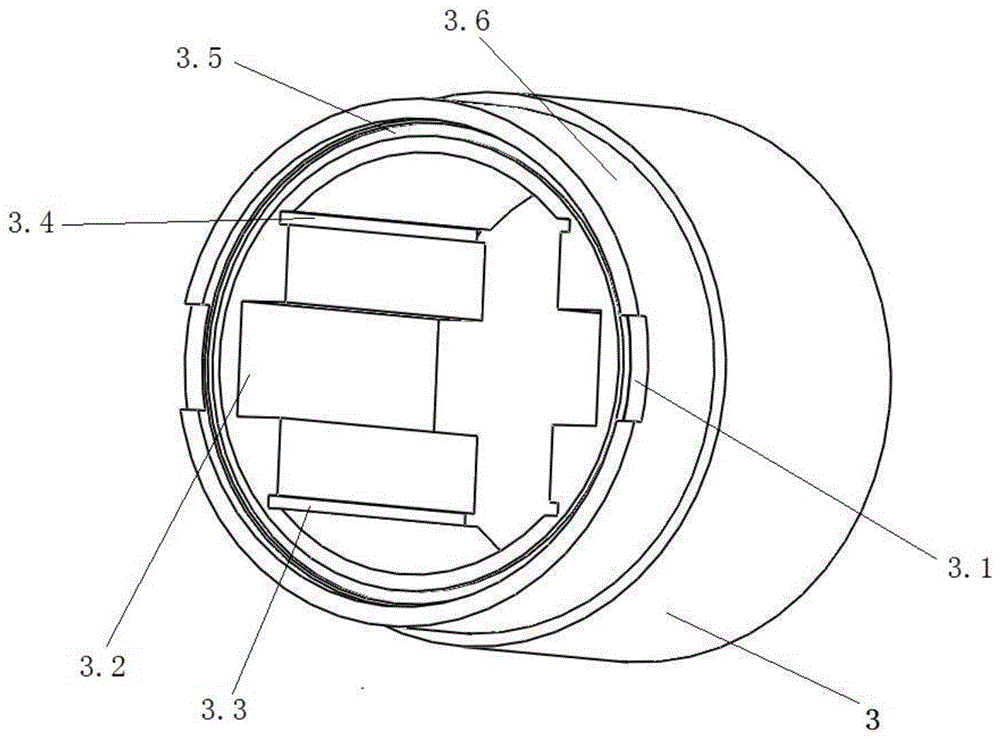

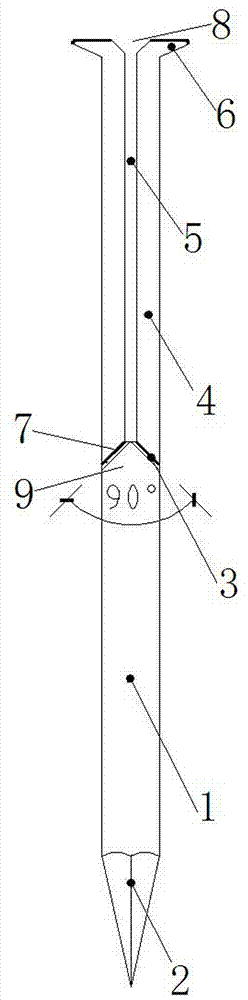

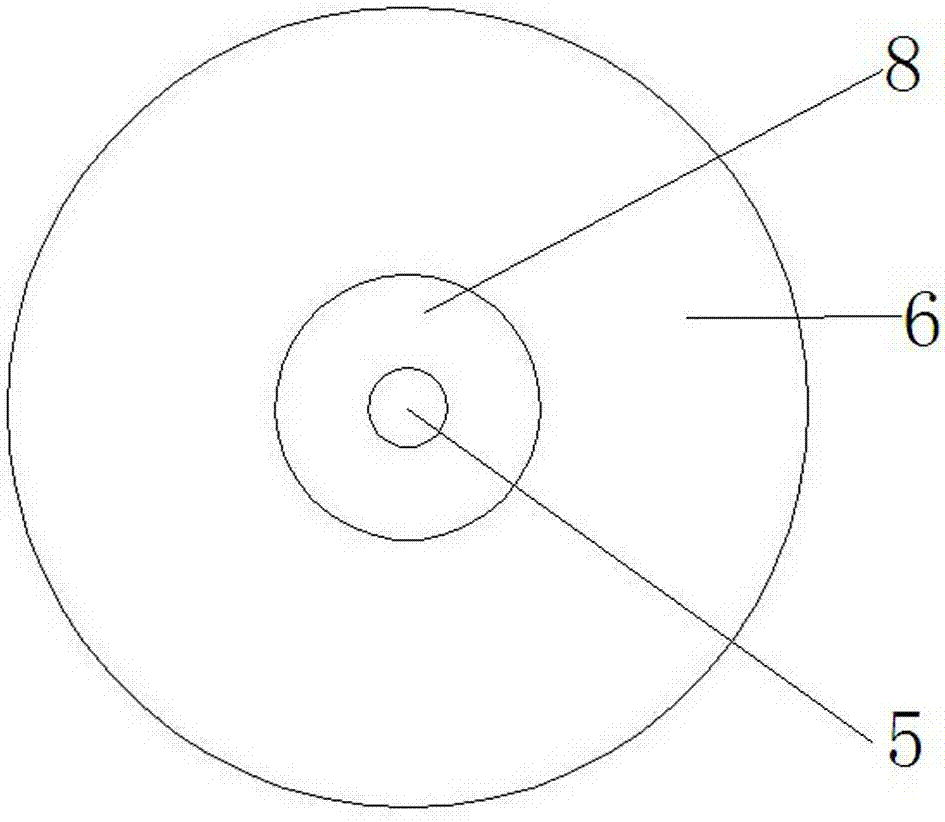

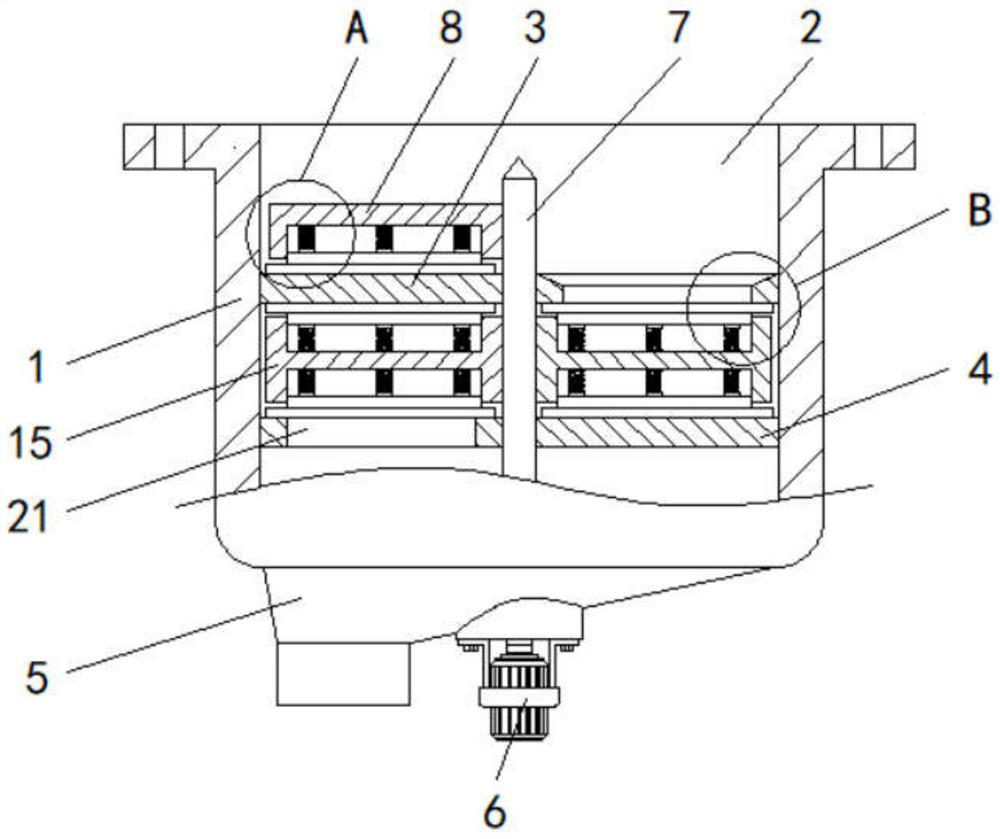

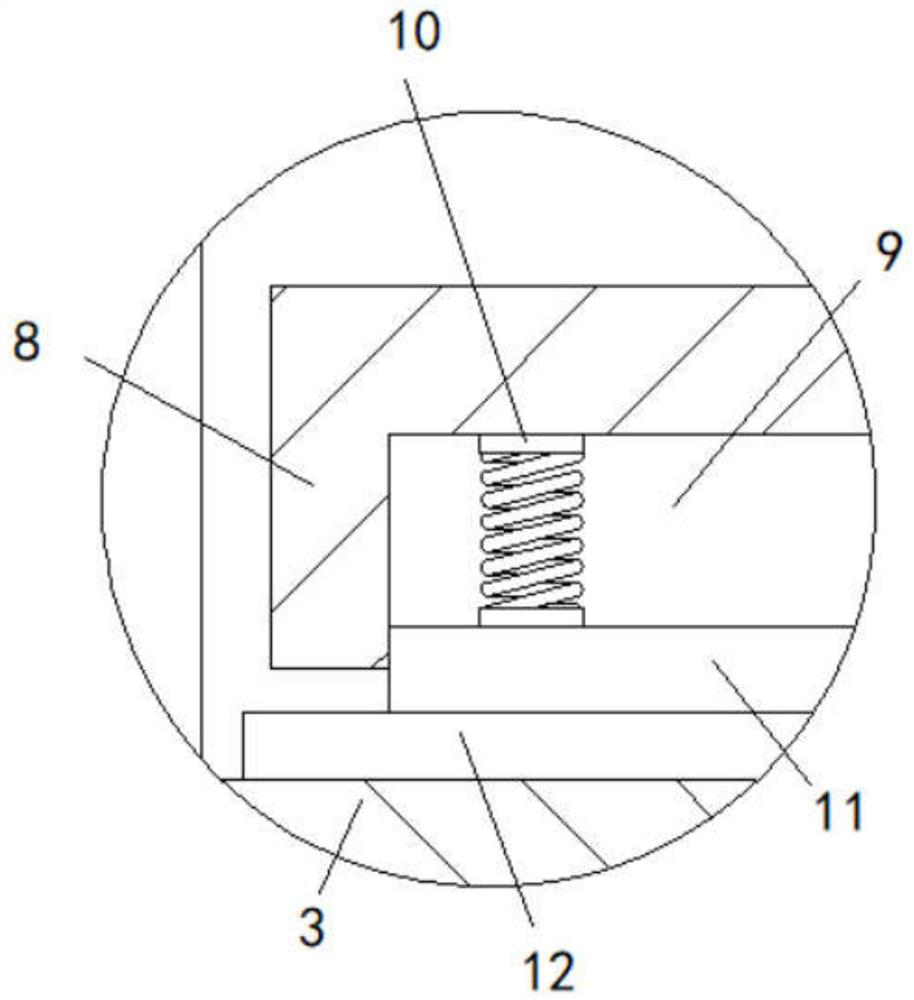

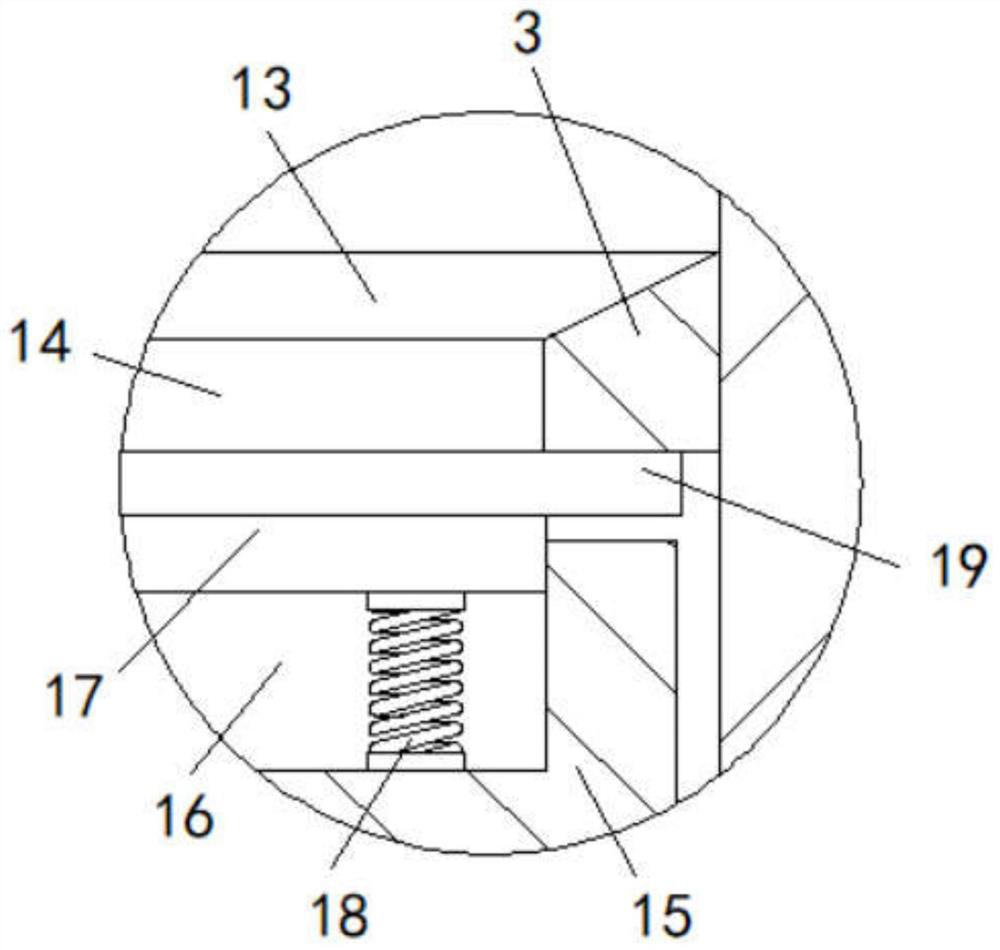

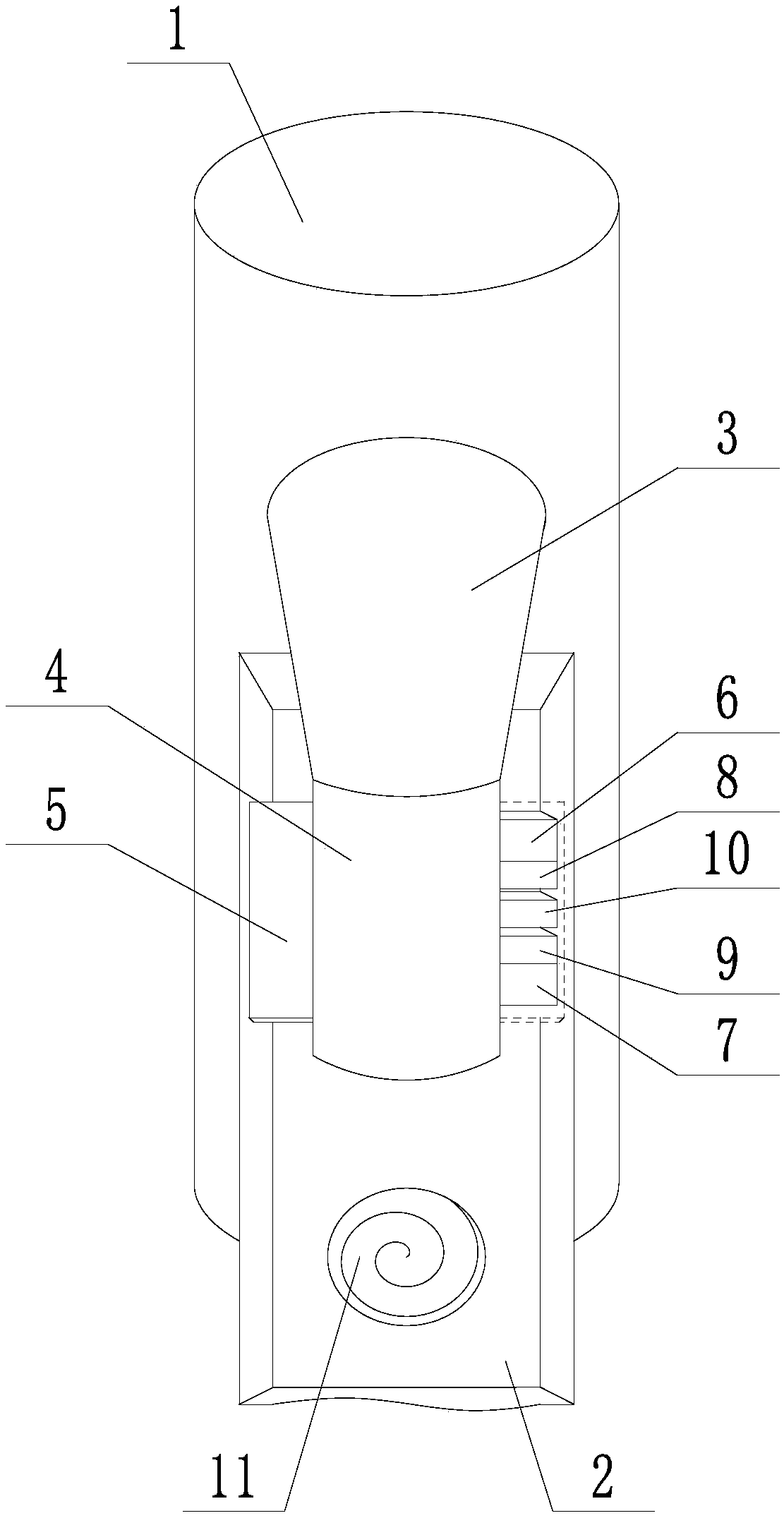

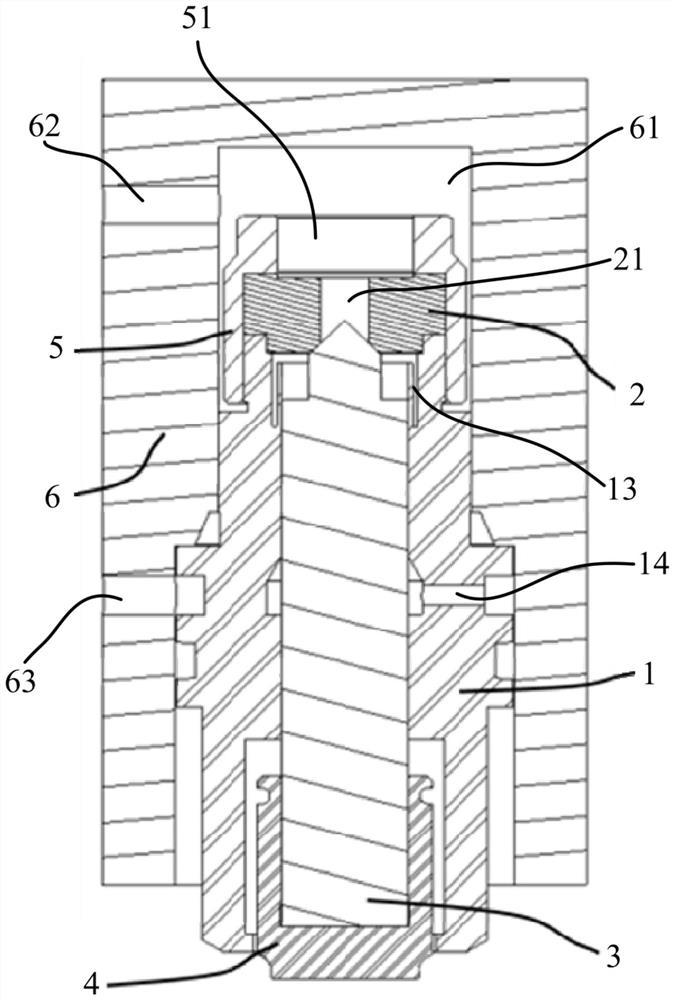

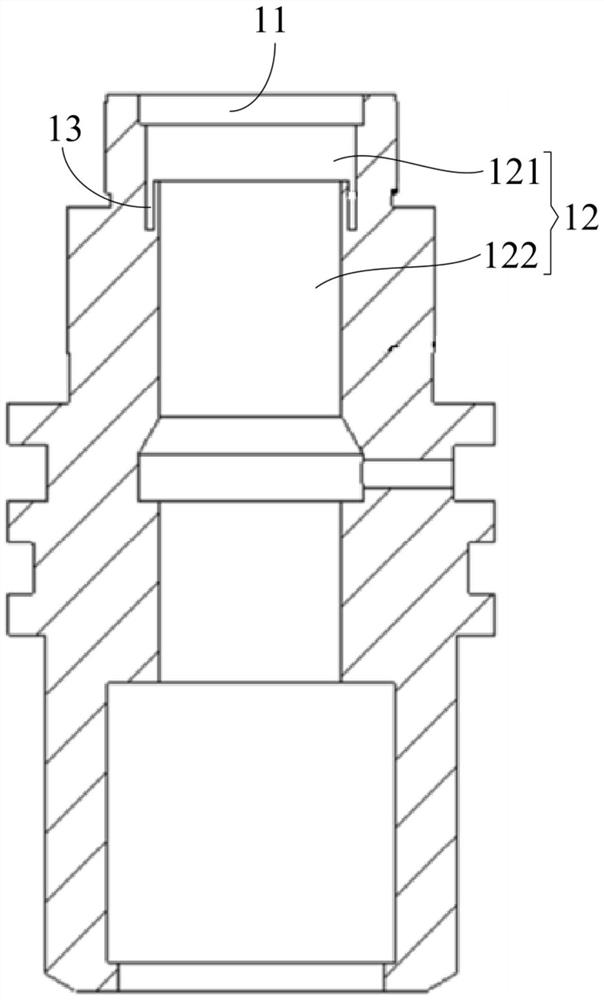

Underwater metal structure defect detecting probe based on alternating current electromagnetic field

ActiveCN105004784AReduce volumeReduce distractionsMaterial magnetic variablesUltrasound attenuationEngineering

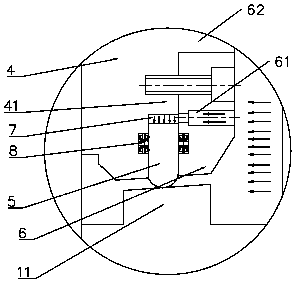

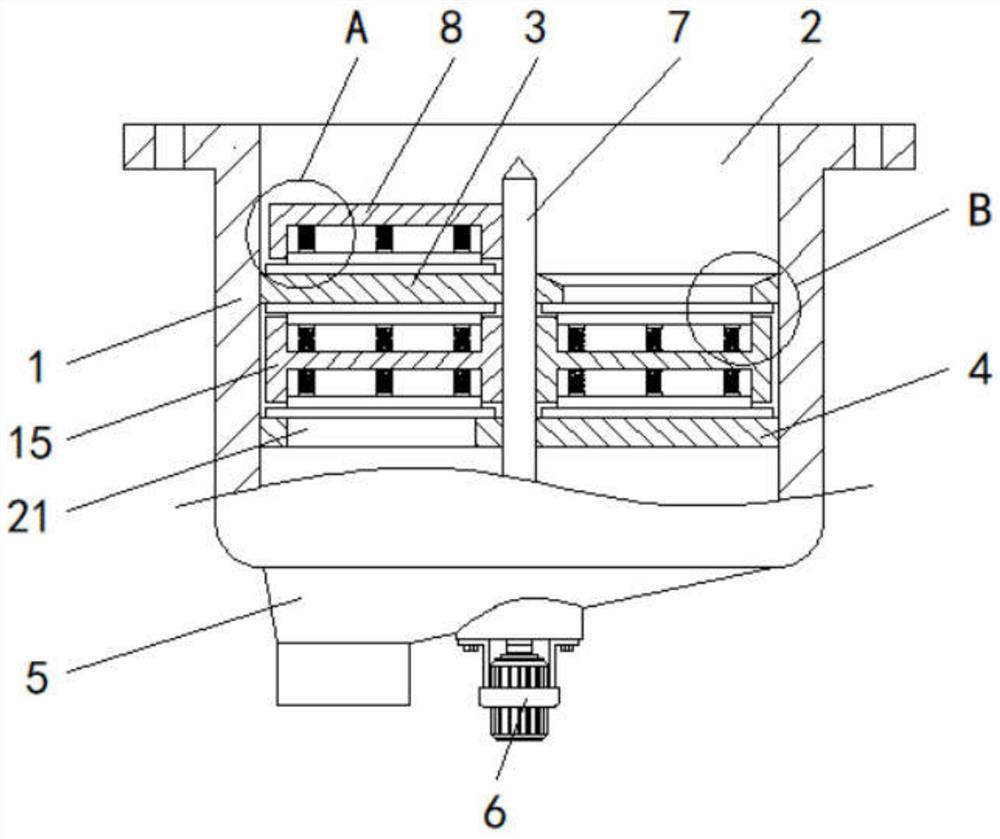

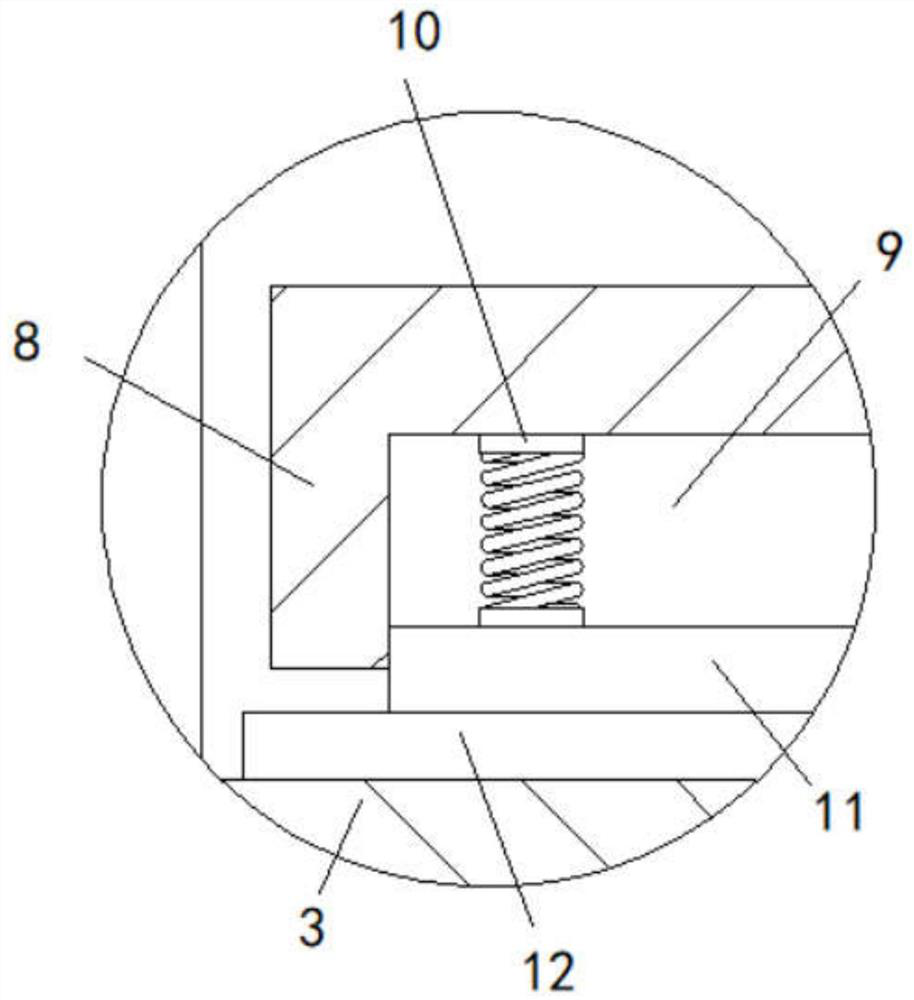

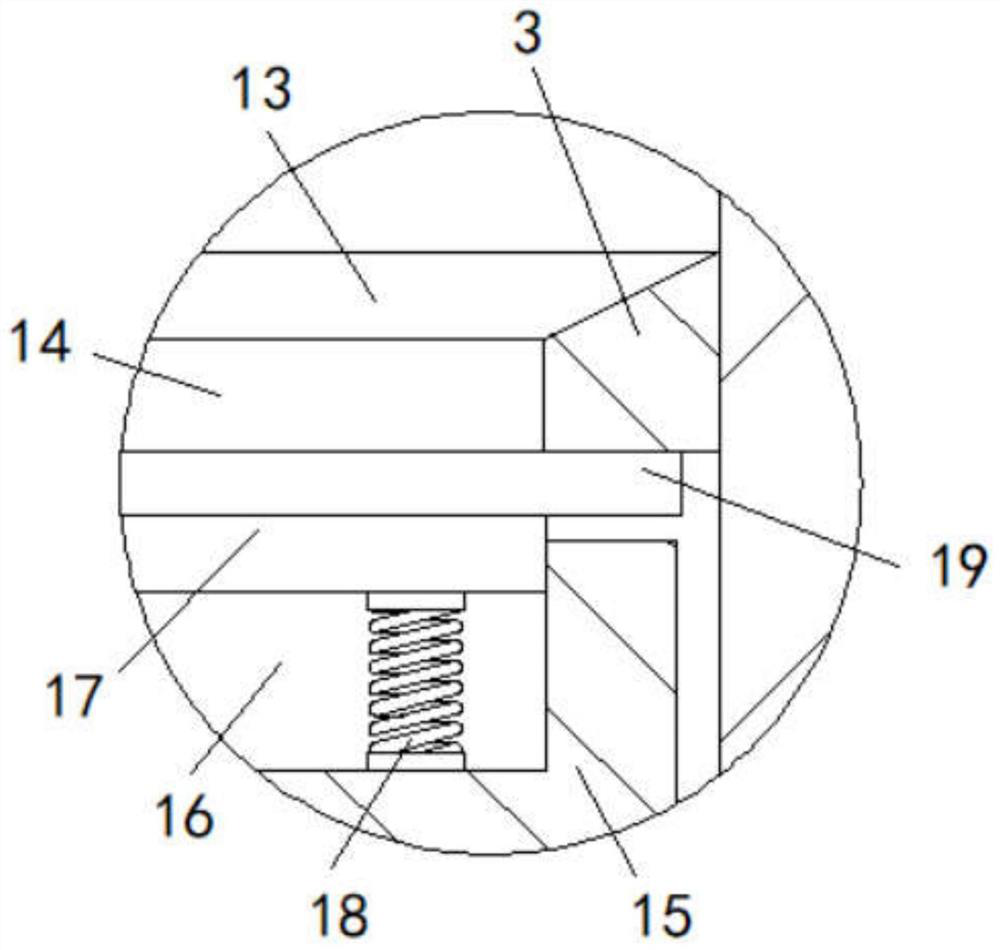

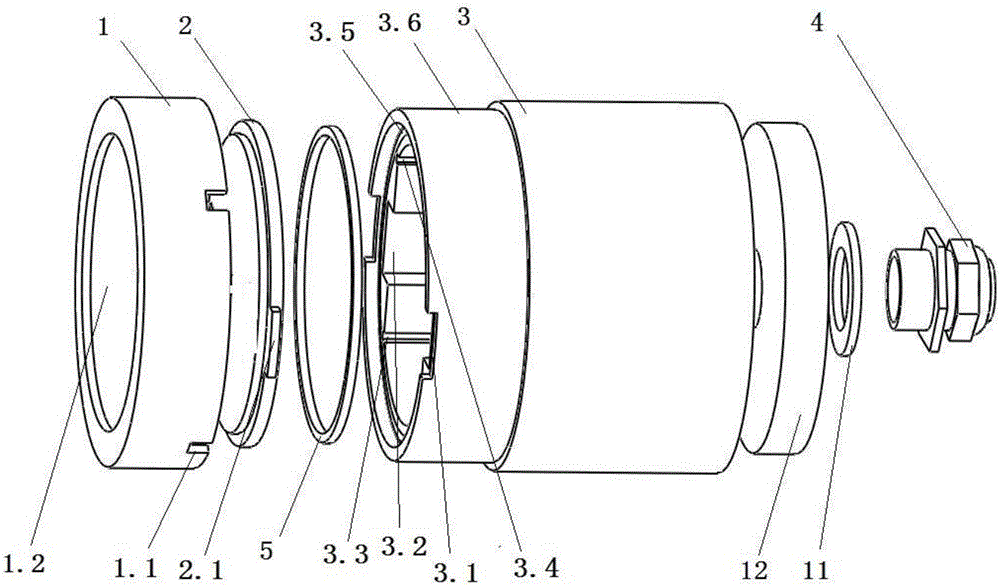

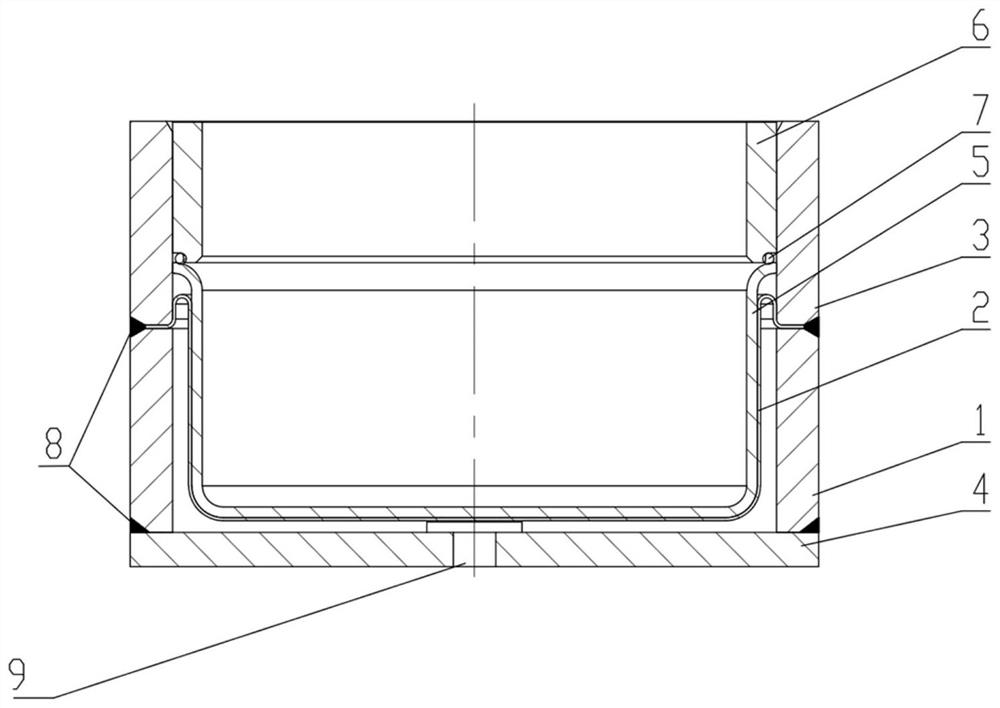

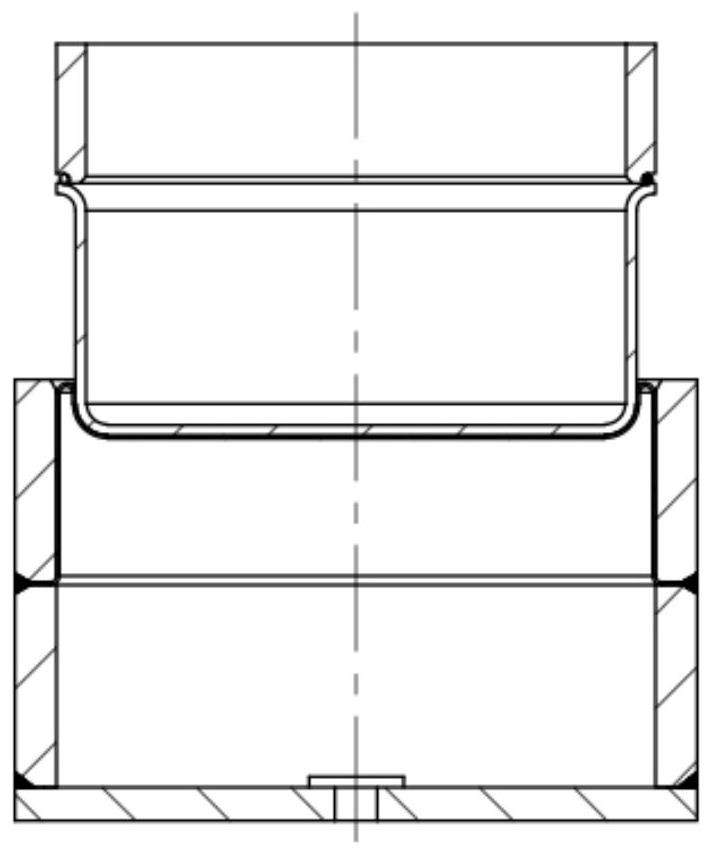

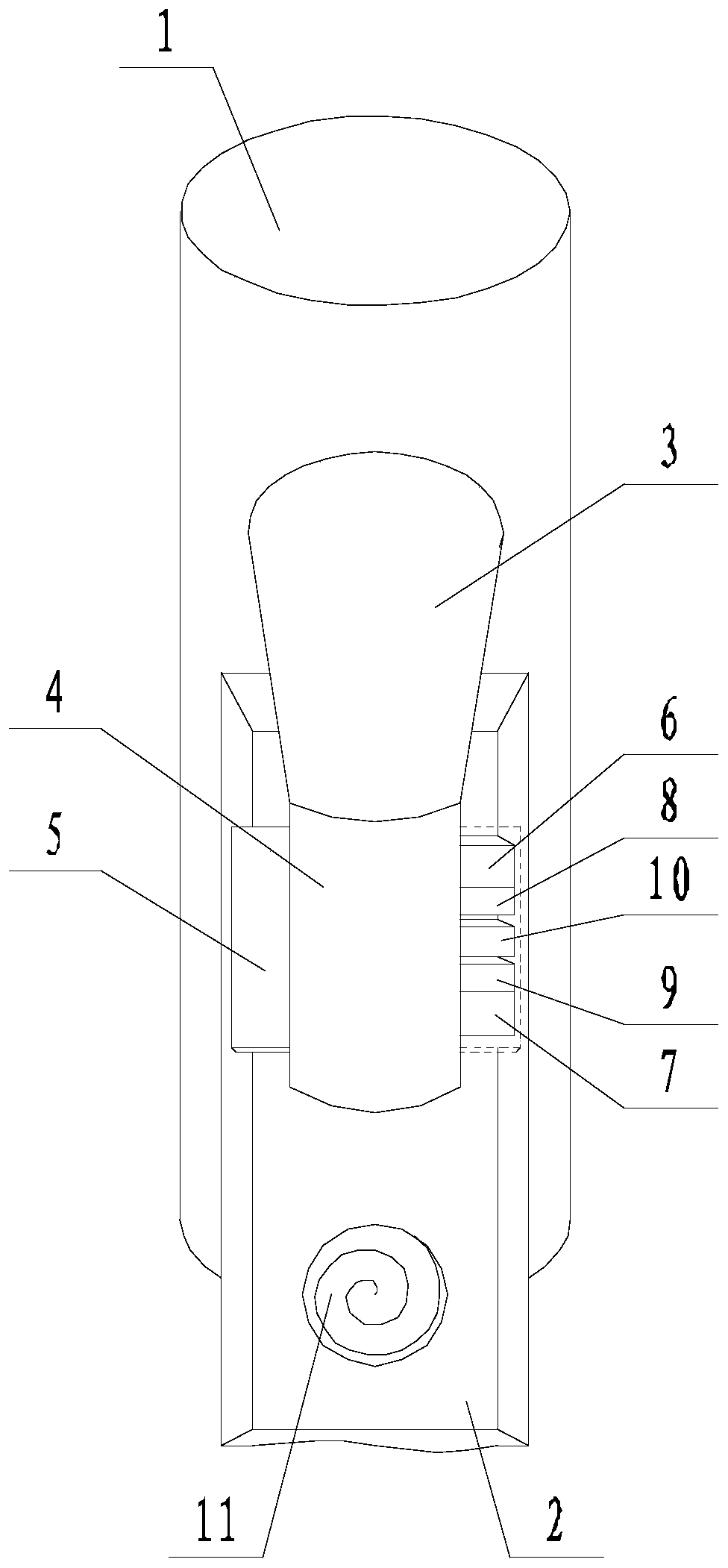

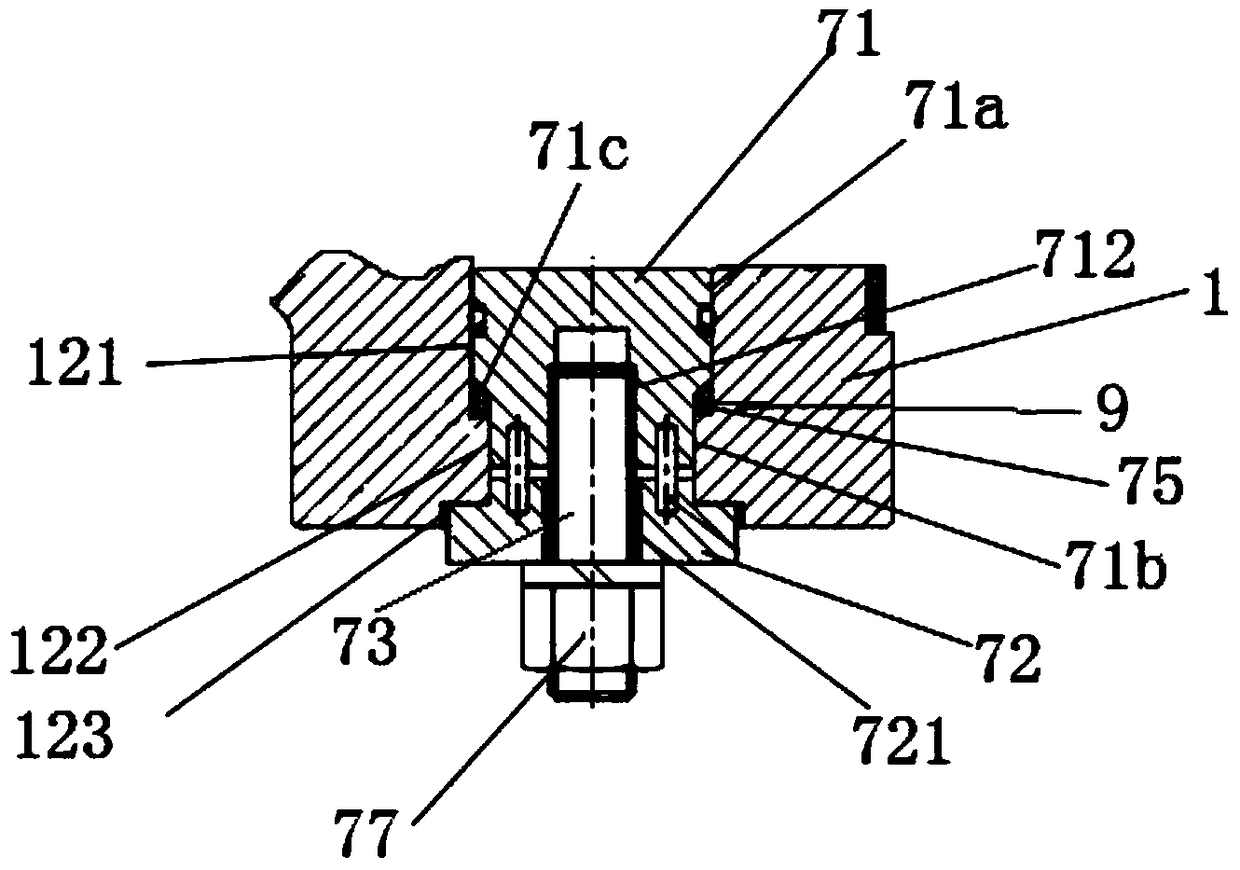

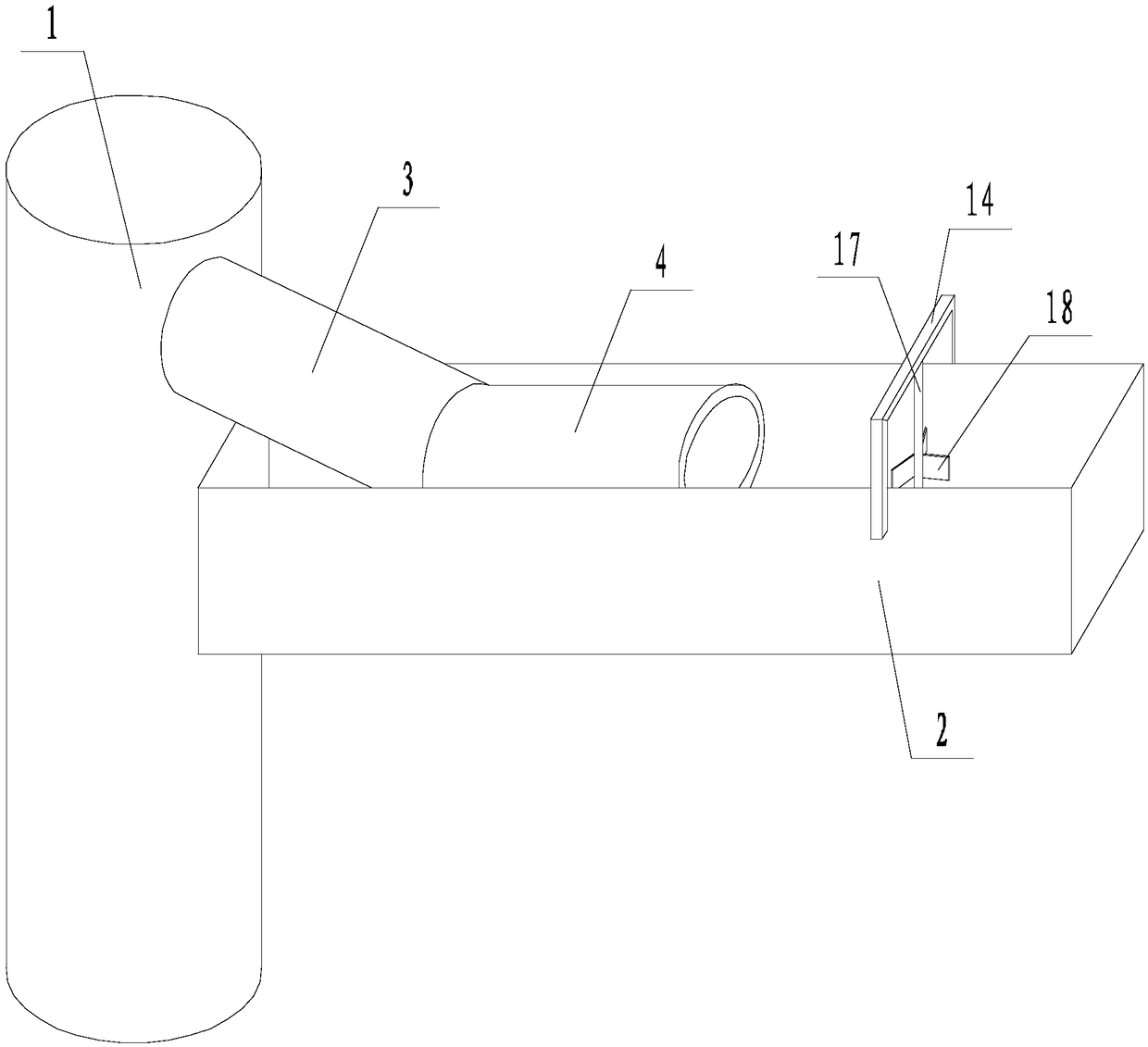

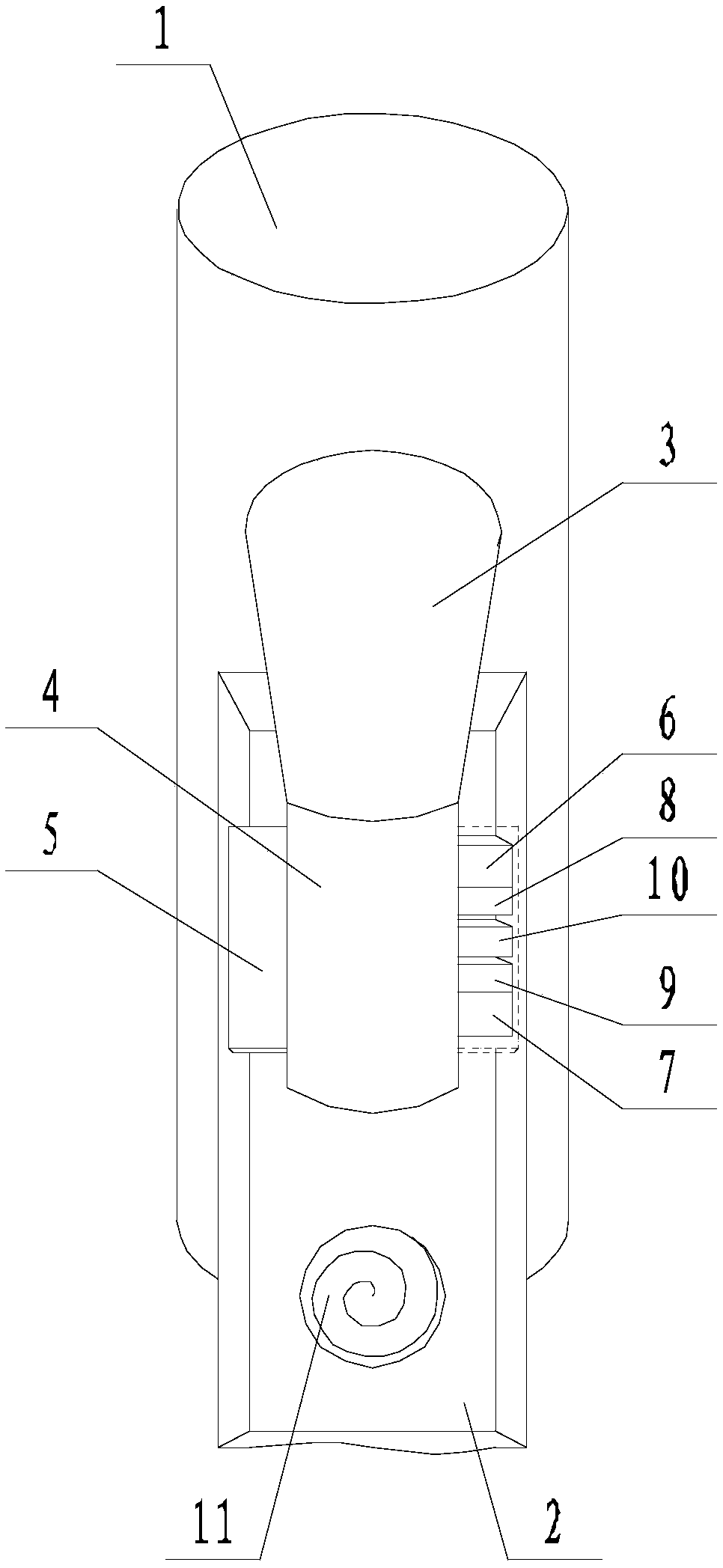

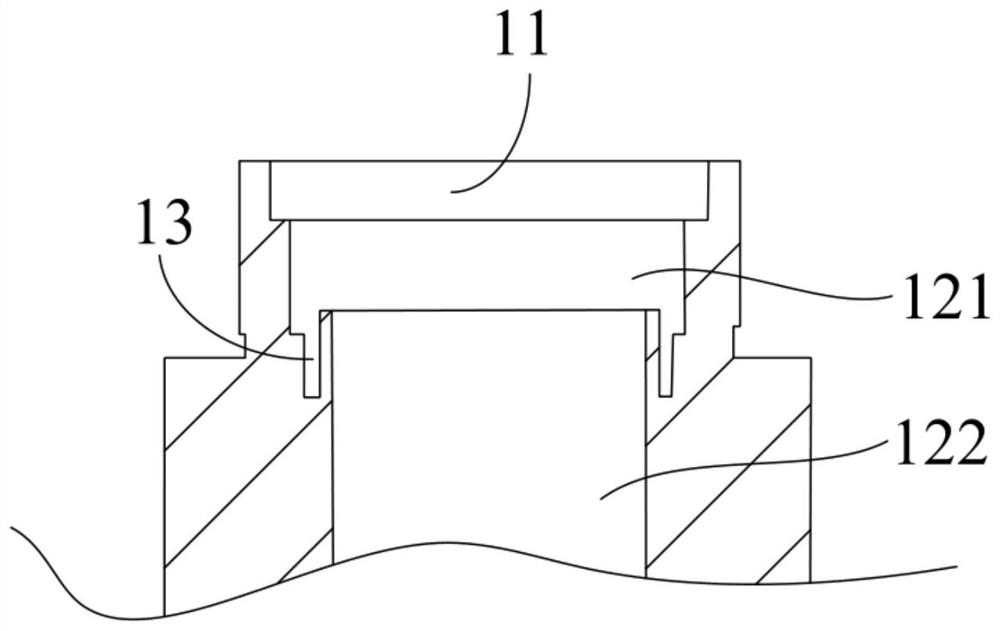

The invention discloses an underwater metal structure defect detecting probe based on an alternating current electromagnetic field. The underwater metal structure defect detecting probe mainly comprises a gland, a bottom cover, a cylinder, a seal joint, an O ring, a detection coil, an excitation circuit, a conditioning circuit, a U-shaped magnetic core, an excitation coil, a seal gasket and a top cover, wherein the detection coil is mounted in a central groove of the bottom cover and connected with the conditioning circuit; the conditioning circuit is mounted in a clamping groove I in the cylinder; the excitation circuit is mounted in a clamping groove II in the cylinder and connected with the excitation coil; the bottom cover is tightly pressed to the bottom of the cylinder by the gland; water isolation space is formed among the bottom cover, the O ring and the cylinder, and a self-sealing effect is realized. The underwater metal structure defect detecting probe has the benefits as follows: the probe for detecting defects of an underwater metal structure is designed by the aid of an alternating current electromagnetic field detection technology, the problem about underwater sealing and the problems of signal attenuation and the like can be solved effectively, and the defects of the underwater metal structure can be detected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Metal seal three-eccentric center butterfly valve

ActiveCN111043332AElastic contact sealing effect is goodGood self-sealingLift valveButterfly valveMechanics

The invention discloses a metal seal three-eccentric center butterfly valve. The valve is characterized in that the inner diameter of a metal seal ring is larger than the diameter of a mounting boss,a floating space is formed between the metal seal ring and the mounting boss, two end faces of the metal seal ring are in sliding seal fit with a butterfly plate and a limiting part, and multiple through holes are formed in the limiting part, and communicate with the floating space. The butterfly valve has the advantages that due to the floating space, the metal seal ring can slightly move and elastically deform in the radial direction, the floating space can better adapt to a valve base seal face, when the floating space is in seal fit with the valve base seal face, the better seal effect isachieved, meanwhile, a medium can pass through a through hole to enter the floating space, medium pressure is provided for the metal seal ring, the self seal effect is achieved, the seal effect of thespace and the valve base seal face can be further ensured, dual-way seal is achieved, and no leakage exists.

Owner:KCM VALVE

Preparation method of self-sealing planar solid oxide fuel cell

ActiveCN106571475AAchieve self-sealing effectOvercoming Sealing DifficultiesSemiconductor lasersSealing/support meansFuel cellsNanotechnology

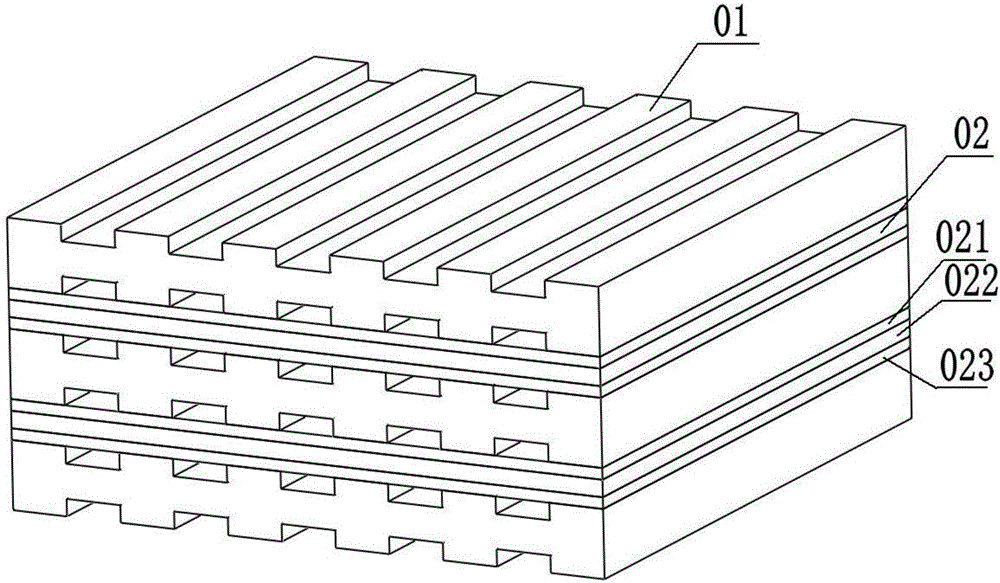

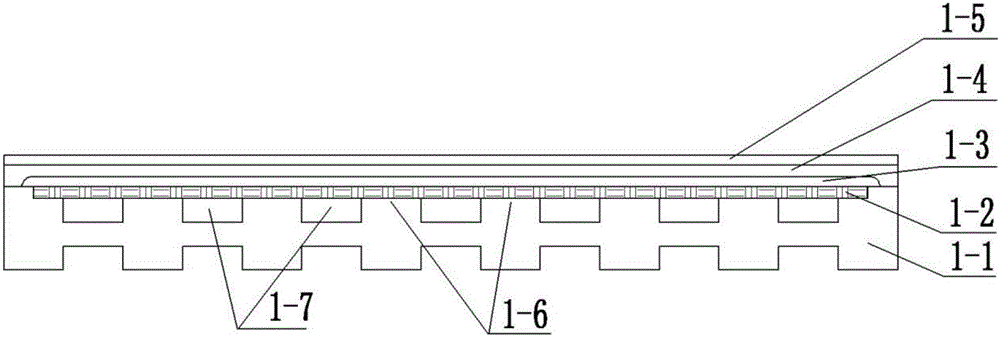

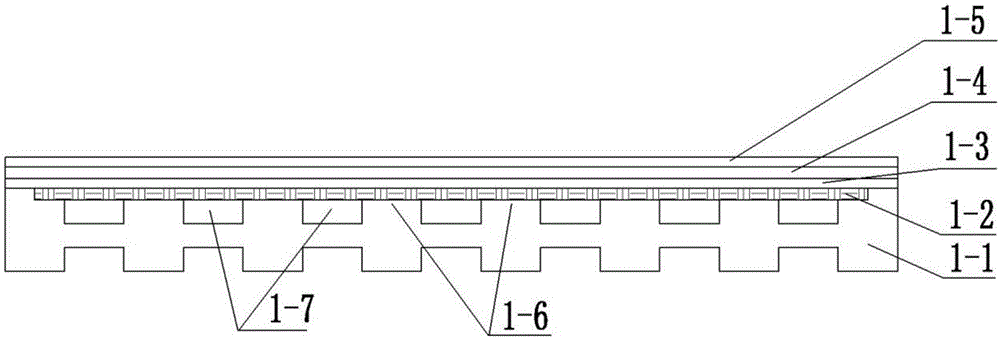

The invention discloses a preparation method of a self-sealing planar solid oxide fuel cell, wherein the preparation method comprises the following steps: (1) processing a metal connecting pole having a gas passageway structure; (2) allowing a porous metal layer and the metal connection pole to form a whole; (3) trimming the upper surface of the whole formed by the porous metal layer and the metal connection pole, to obtain a surface for spraying; (4) preparing an anode layer on the surface of the porous metal layer by a spraying method; (5) preparing an electrolyte layer on the surface of the anode layer by a spraying method; and (6) preparing a cathode layer on the surface of the electrolyte layer by a spraying method. Because the battery connecting pole and the porous stainless steel substrate are subjected to edge sealing treatment in advance, the self-sealing effect is realized after preparation of a battery is completed, and the problem of the sealing of the battery is effectively overcome.

Owner:浩燃科技(中山)有限公司

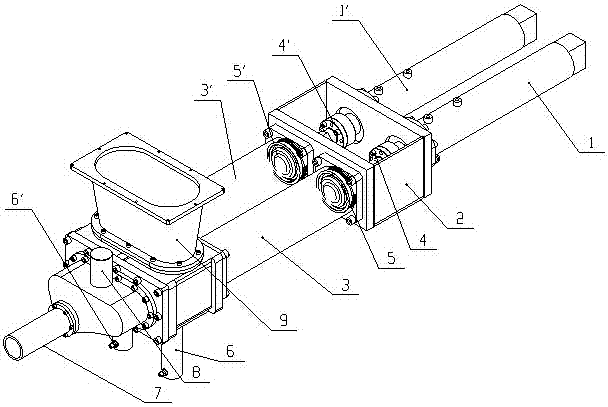

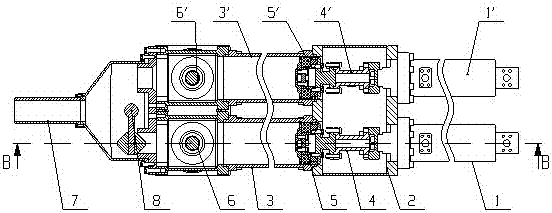

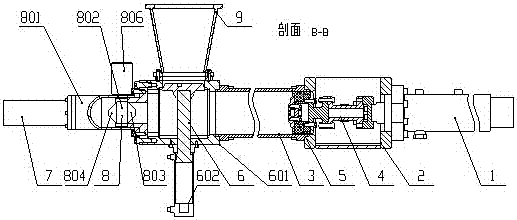

Double-cylinder type sludge pump with discharging seal switching apparatus

PendingCN107956666AAchieve continuous outputSaving export resistancePositive displacement pump componentsPiston pumpsSludgeReciprocating motion

A double-cylinder type sludge pump with a discharging seal switching apparatus comprises a left main driving cylinder. The left main driving cylinder is connected with a left conveying cylinder via awater tank. A piston rod of the left main driving cylinder is connected with a left concrete piston via a left connecting rod. The left concrete piston and the left connecting rod perform reciprocating motion in the left conveying cylinder under the effect of the left main driving cylinder. A right main driving cylinder is connected with a right conveying cylinder via the water tank. A piston rodof the right main driving cylinder is connected with a right concrete piston via a right connecting rod. The right concrete piston and the right connecting rod perform reciprocating motion in the right conveying cylinder under the effect of the right main driving cylinder. A conveyer pipe is connected with the discharging seal switching apparatus. The discharging seal switching apparatus is connected with a left feeding device and a right feeding device. The left feeding device and the right feeding device are connected with a pre-filler. Exit resistance of a pumping system can be reduced, self-abrasion of the equipment during a pumping process can be reduced, equipment cost can be reduced, reliability of the equipment can be improved, and service lifetime of the equipment can be prolonged.

Owner:长沙紫宸科技开发有限公司

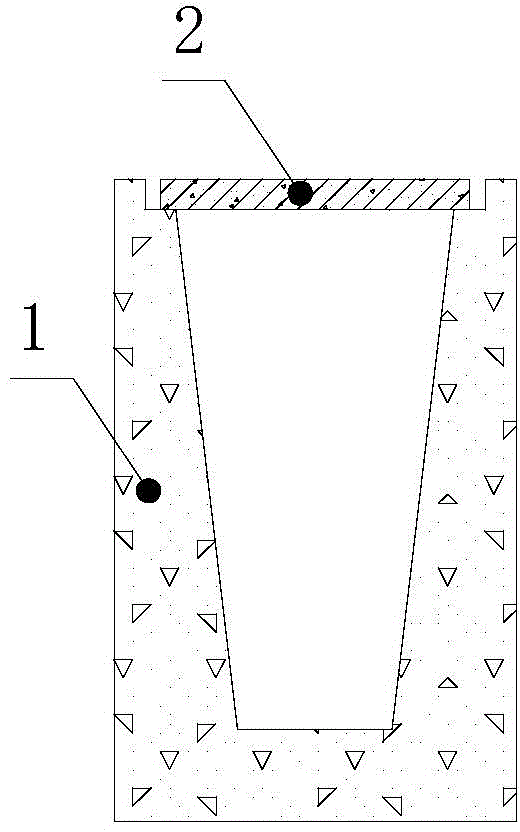

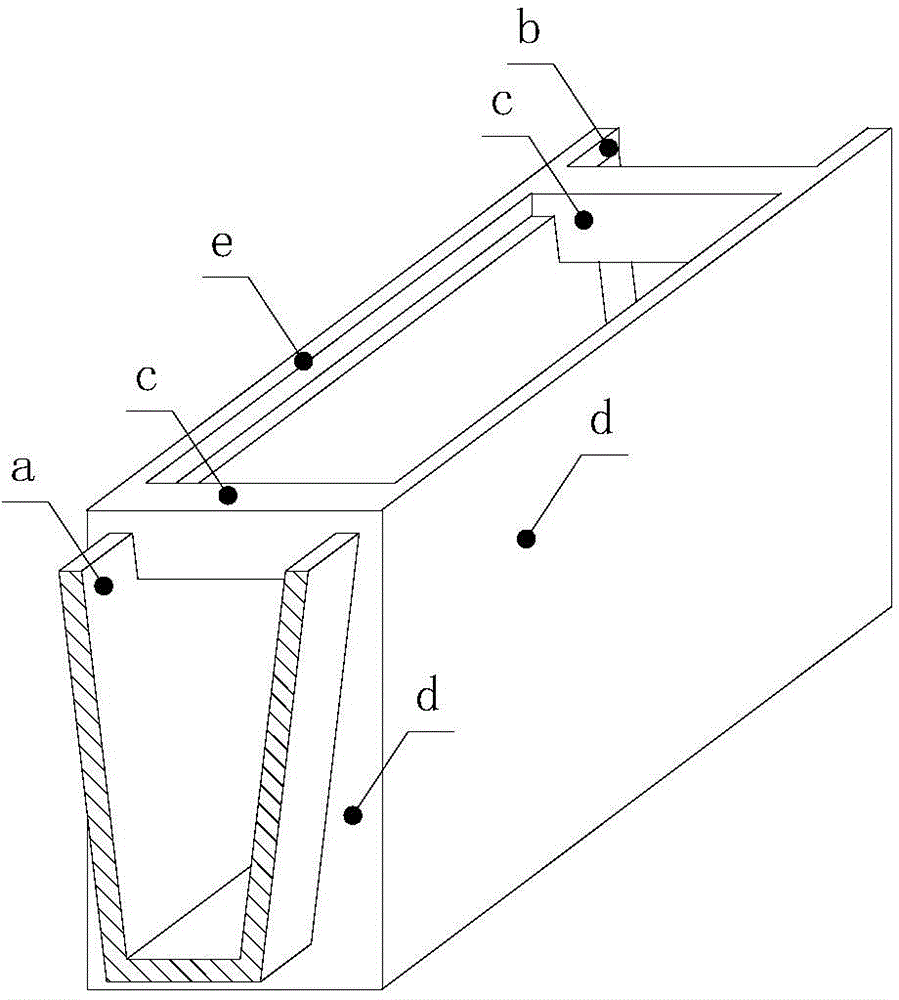

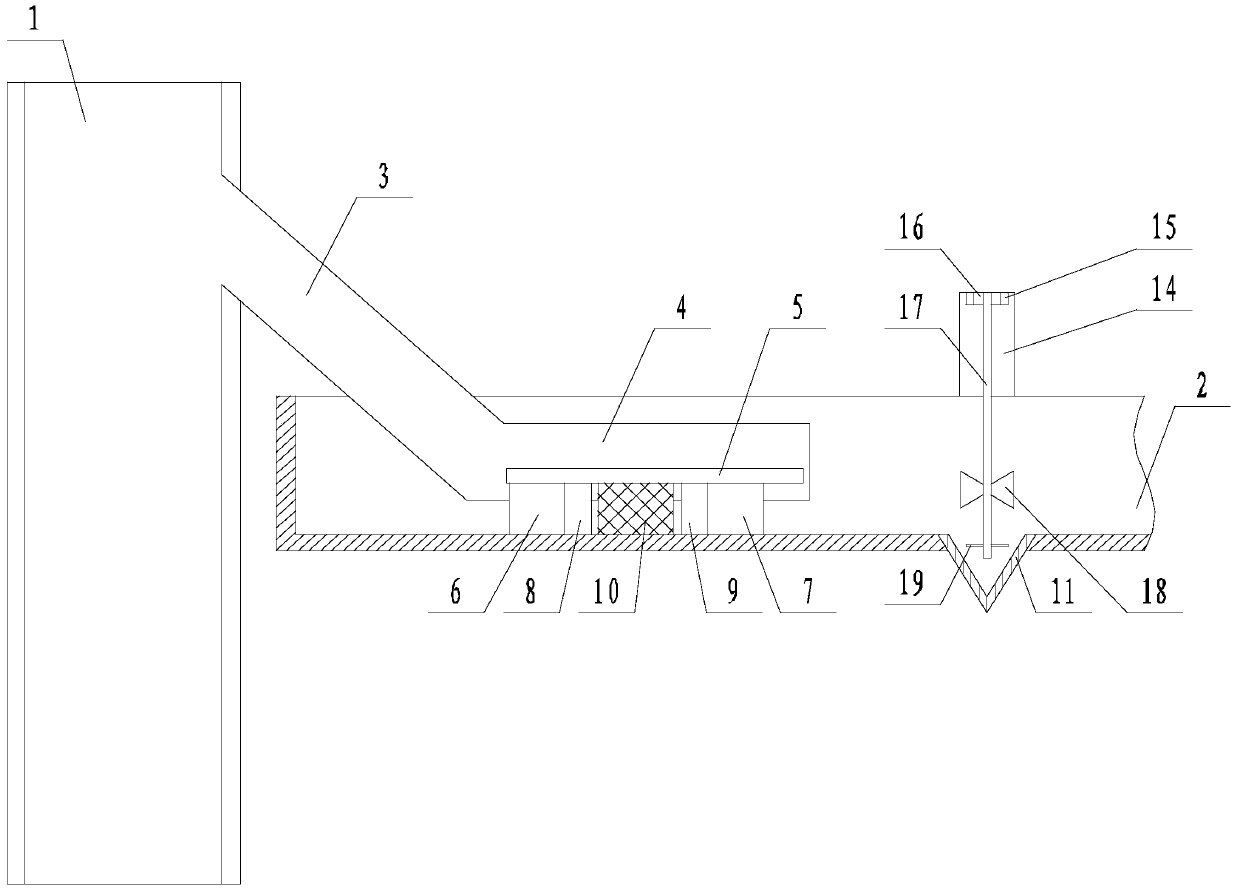

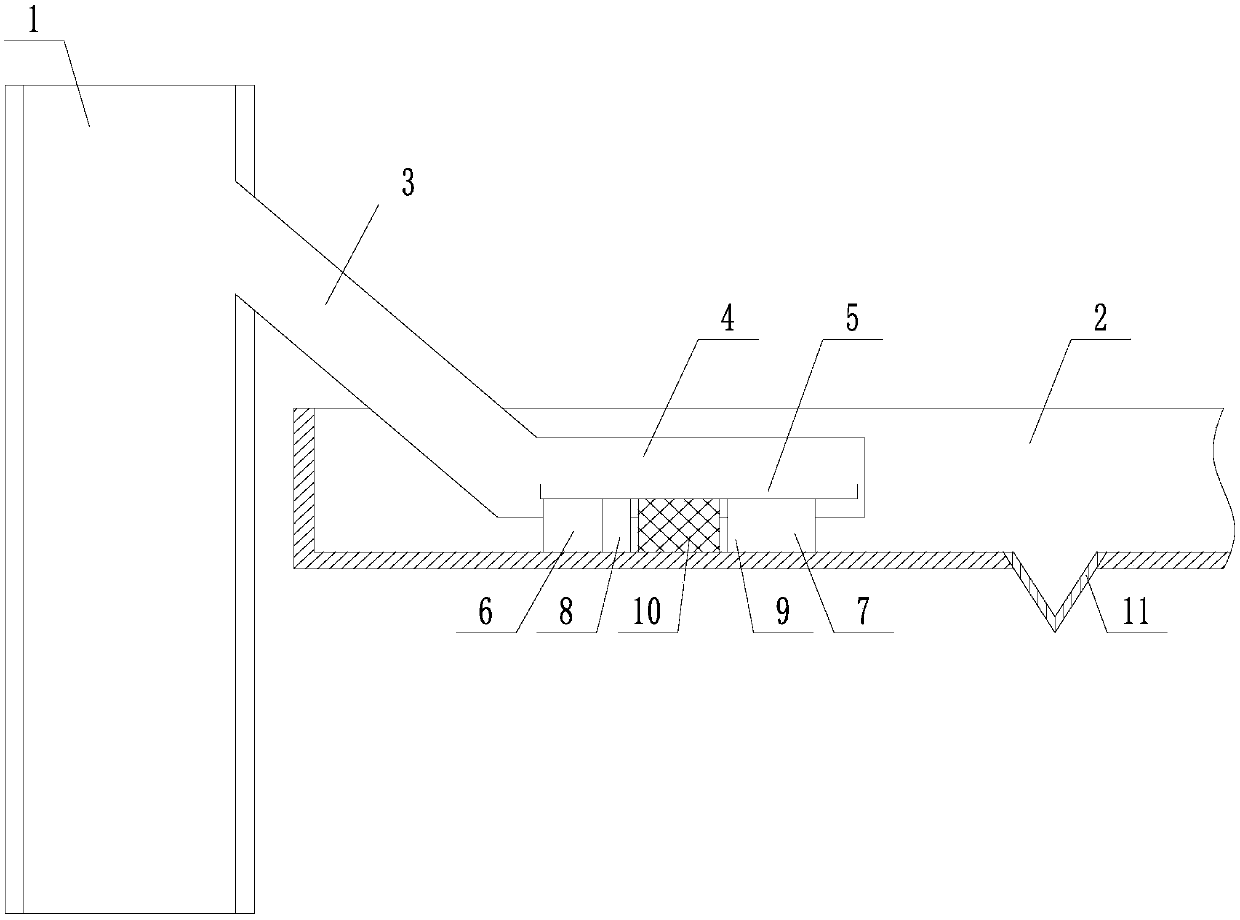

Narrow-deep type prefabricated drainage gutter

InactiveCN105804211AReduce widthWork lessSewerage structuresPaving gutters/kerbsEngineeringSmall footprint

Owner:SHANGHAI PUDONG ARCHITECTURAL DESIGN & RES INST

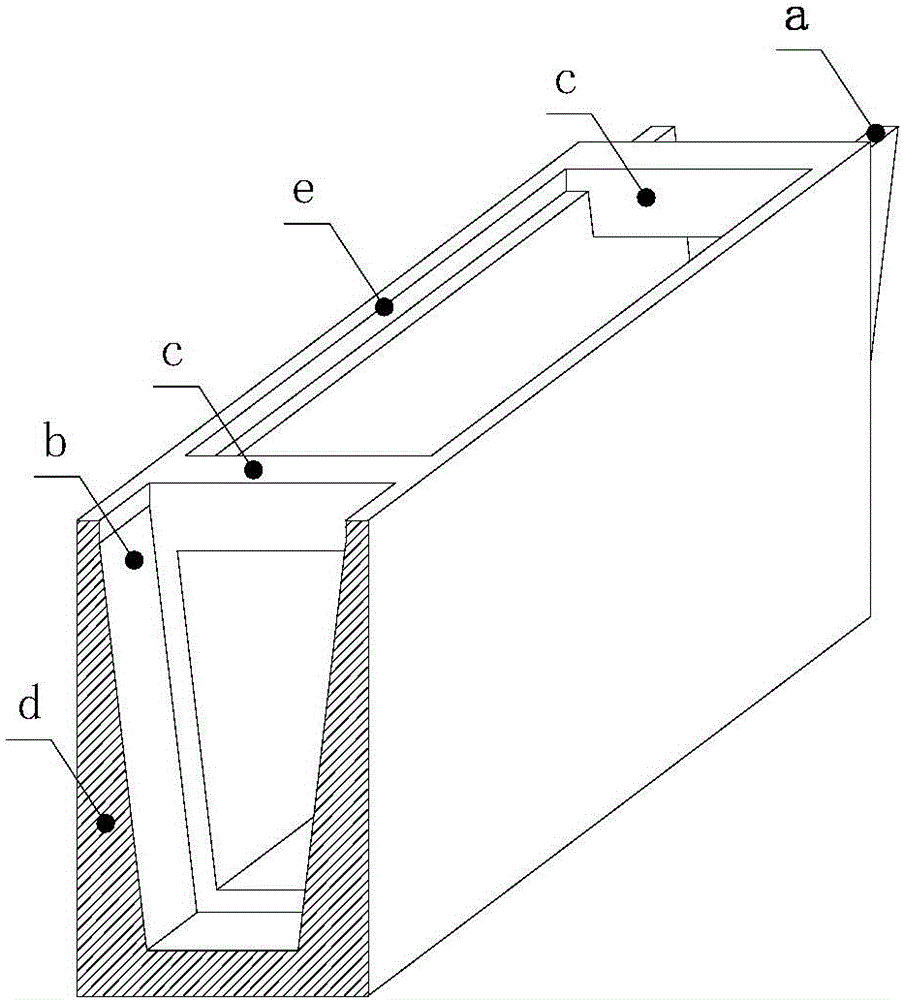

Self-adjusting waterless seal

ActiveCN103321946BExtended service lifeSolve the problem of heating and adding cooling water for coolingPump componentsPumpsImpellerEngineering

An automatic adjusting non-water sealing device is formed by a secondary impeller, a dynamic sealing ring, a static sealing ring, an M-shaped rubber corrugated pipe, an O-shaped sealing ring, a pump shaft, a sealing gland and a sealing cavity shell. The dynamic sealing ring is fixedly arranged on the pump shaft through the O-shaped sealing ring. The secondary impeller is arranged on the pump shaft and located at the left end of the dynamic sealing ring. The M-shaped rubber corrugated pipe is arranged between the static sealing ring and the sealing gland, and two ends of the M-shaped rubber corrugated pipe are fixed through the static sealing ring and the sealing gland. The dynamic sealing ring is arranged between the secondary impeller and the static sealing ring. The natural sealing effect can be achieved due to the fact that the pipe diameter of the M-shaped rubber corrugated pipe 1 generates different negative pressures when the secondary impeller rotates, and the negative pressures force deformation amount to be different. A mutual friction phenomenon does not occur between the dynamic sealing ring and the static sealing ring, and the service life of the sealing device is greatly prolonged.

Owner:温州市康而达实业有限公司

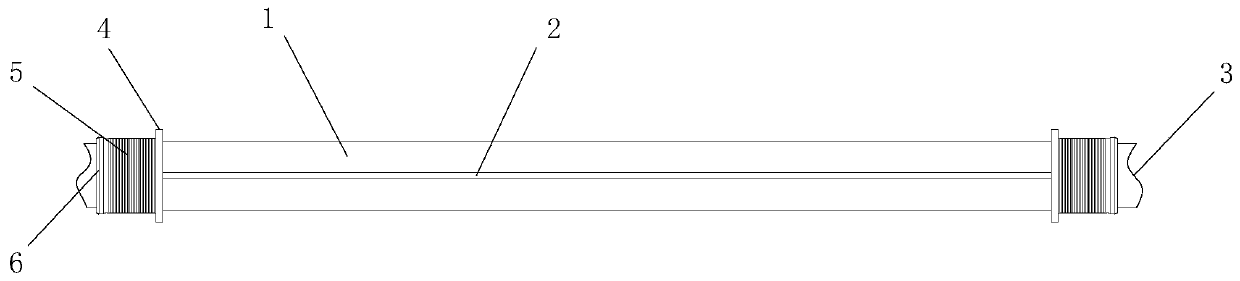

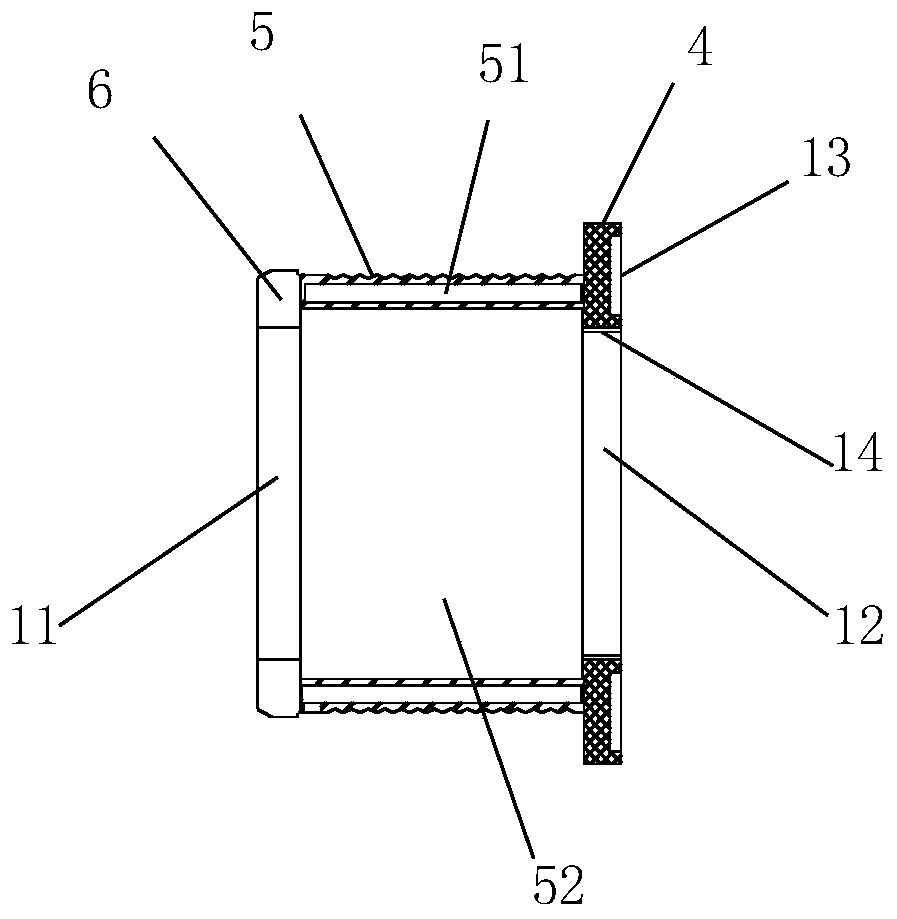

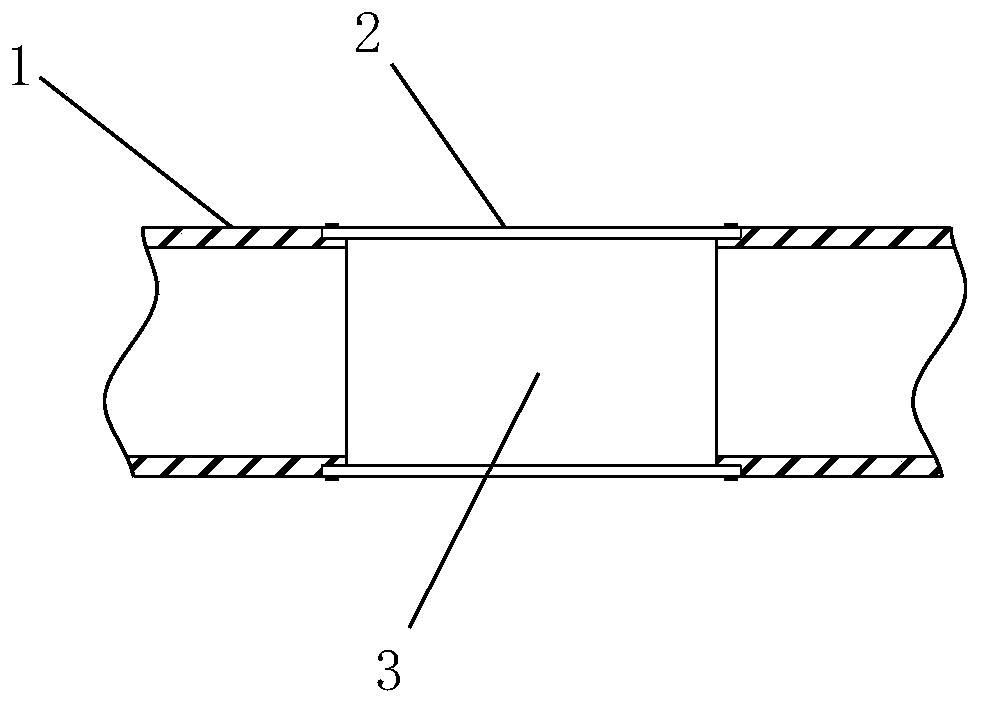

Self-sealing instrument pipe fitting

PendingCN111911719APrevent slippageEasy to operateSleeve/socket jointsFluid pressure sealed jointsPipe fittingStructural engineering

The invention relates to a self-sealing instrument pipe fitting. The self-sealing instrument pipe fitting comprises an outer cylinder, the two ends of the outer cylinder are connected with a pipelinerespectively, the pipeline is inserted into the outer cylinder, a circle of abutting plate is arranged in the middle of the interior of the outer cylinder, and a sealing device is arranged on the inner wall, making contact with the pipeline, of the outer cylinder. The sealing device comprises a plurality of air bag films, a pressurizing device and a rubber sealing belt, the pressurizing device isused for inflating and deflating the air bag films, the air bag films are fixed to the inner wall of the outer cylinder, the rubber sealing belt is connected with the outer side faces of the air bag films, and every two adjacent air bag films are separated through a partition plate. The two ends of the outer cylinder are provided with non-closed sealing anti-disengaging rings, the two ends of thesealing anti-disengaging rings are connected through protruding connecting tables, and screw holes and tightening nuts are arranged on the connecting tables. Double sealing is conducted through the sealing device and the sealing anti-disengaging rings, operation is easy, and the sealing effect is good.

Owner:JIANGSU HAIWEI GROUP

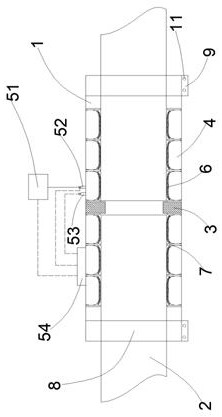

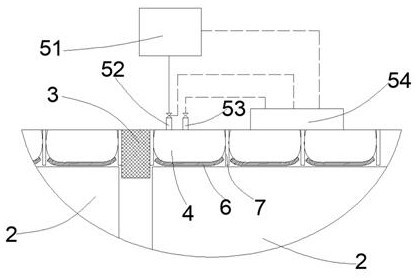

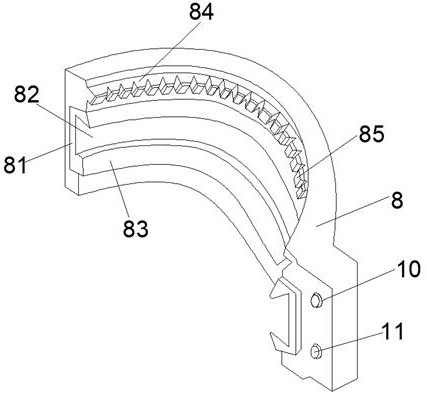

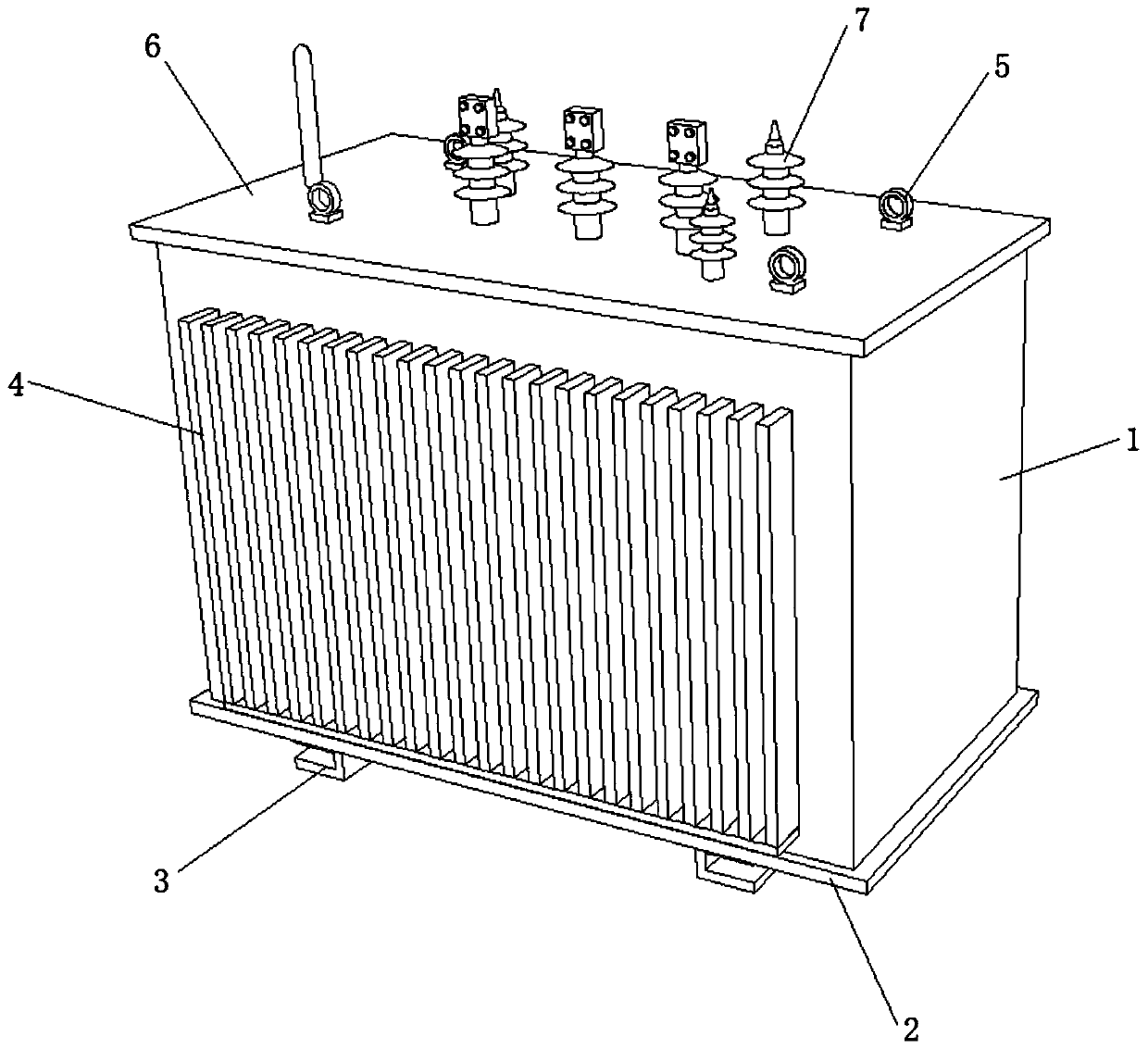

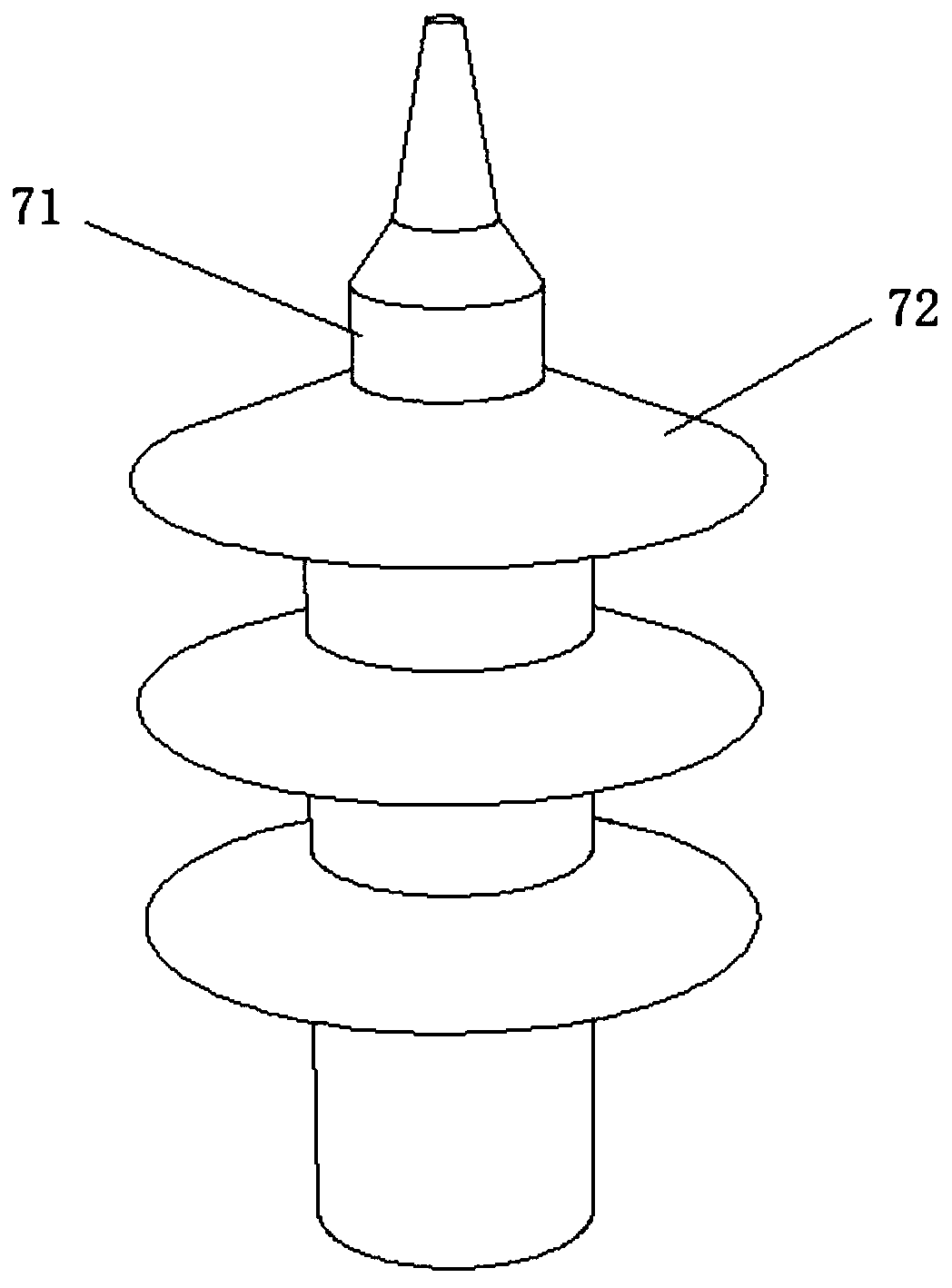

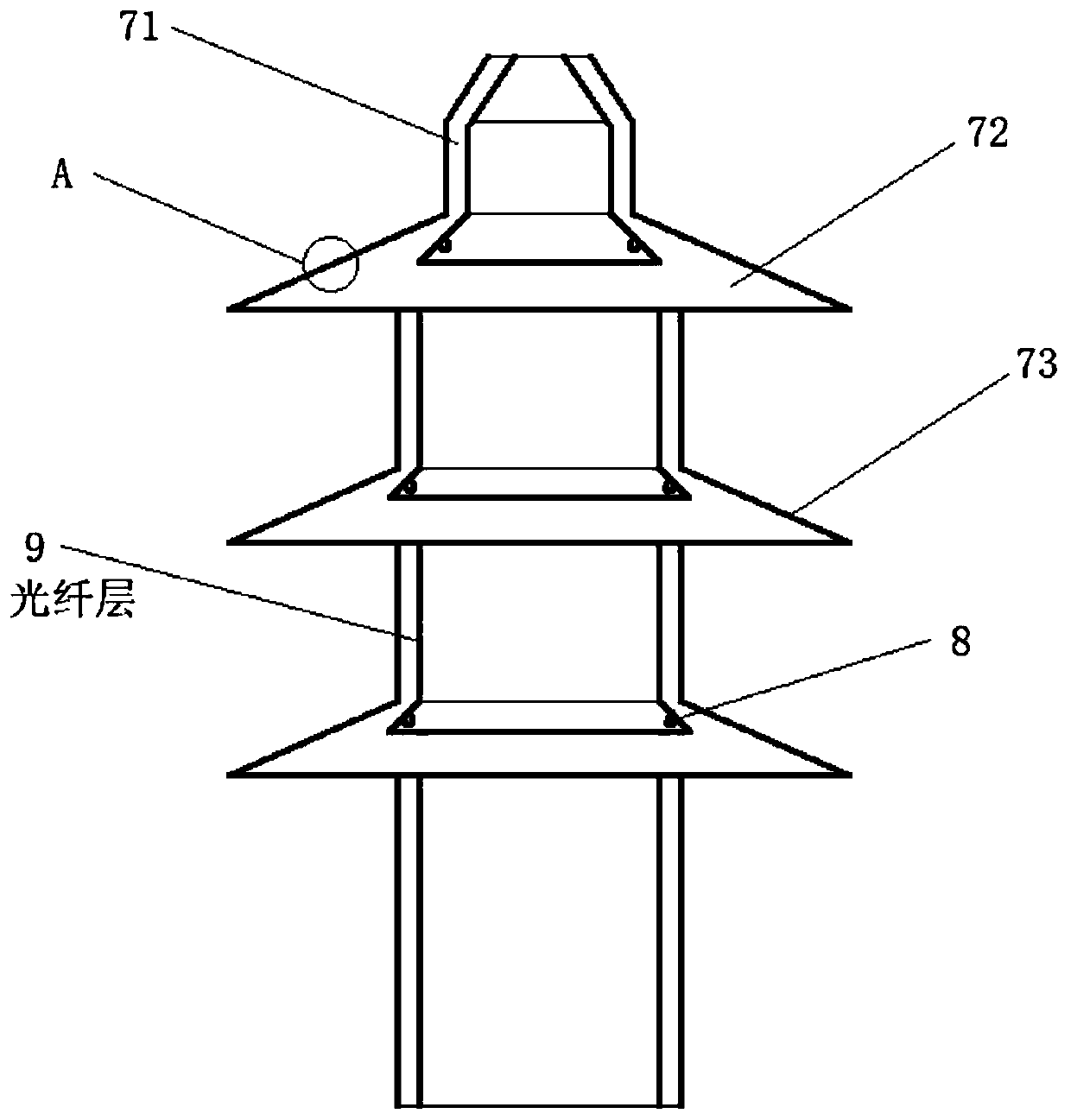

Light-transmitting box-type transformer

ActiveCN110729097AEasy and durable storageAchieve self-sealing effectTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerLight beam

The invention discloses a light-transmitting box-type transformer, and belongs to the field of transformers. The light-transmitting box-type transformer comprises a transformer body with a top plate and a bottom plate respectively installed at the upper and lower ends. A sleeve is connected on the upper end of the transformer body. The sleeve comprises an insulating tube body and a plurality of insulating umbrellas. A photochemical layer is connected at the inner wall of each insulating umbrella. A light-transmitting layer wraps the surface of each insulating umbrella. The light-transmitting layer comprises a healing layer and a transparent layer. A transparent self-healing body is arrange in the healing layer. The photochemical layer and the light-transmitting layer are respectively arranged on the inner wall and the outer surface of the transformer sleeve, and the healing layer is arranged in the light-transmitting layer. When the inner wall of the transformer sleeve cracks and expands to the light-transmitting layer, the transparent self-healing body in the healing layer is utilized to fill the gap to achieve the self-sealing effect. In addition, the light beam emitted by the photochemical layer is emitted outward from the gap through the transparent self-healing body so that maintenance personnel can more easily observe the crack position and take maintenance measures in time.

Owner:JIANGSU HAIKAI ELECTRIC

Drainage pipeline

InactiveCN111442153AImprove flexibilityReduce wastePipe elementsPipe protection against damage/wearEnvironmental geologyStructural engineering

Owner:吴航君

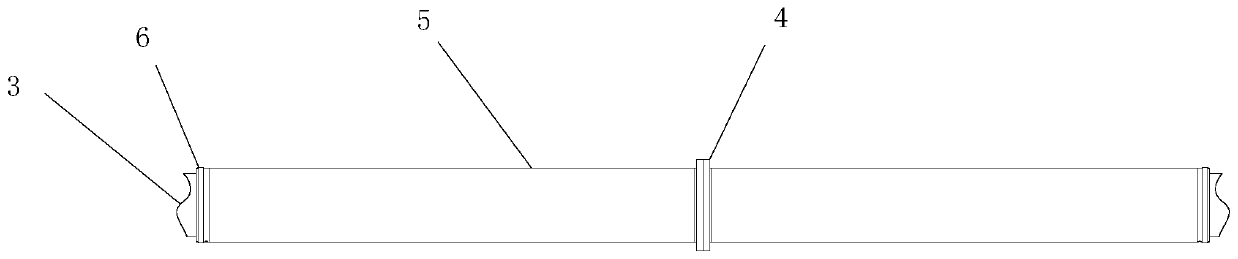

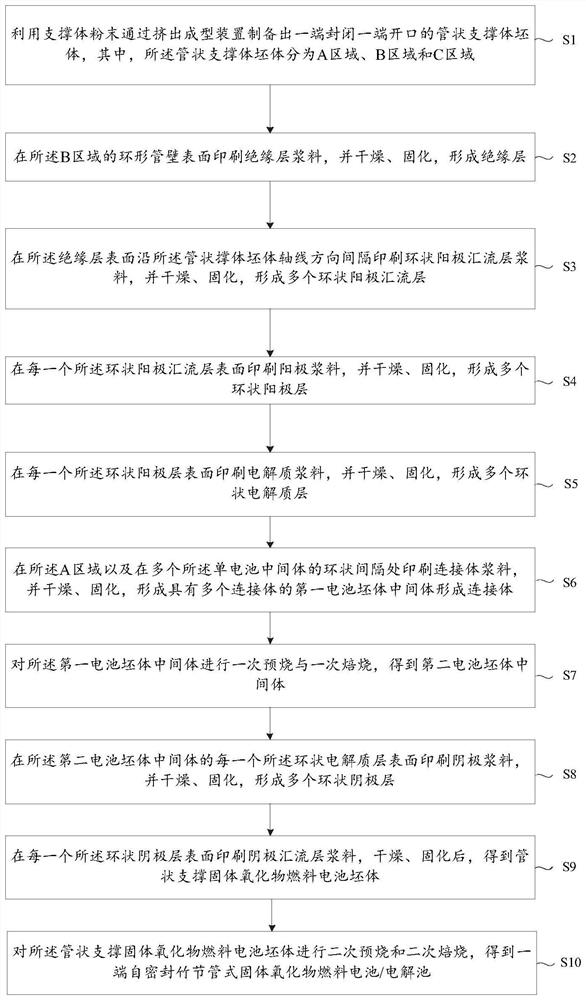

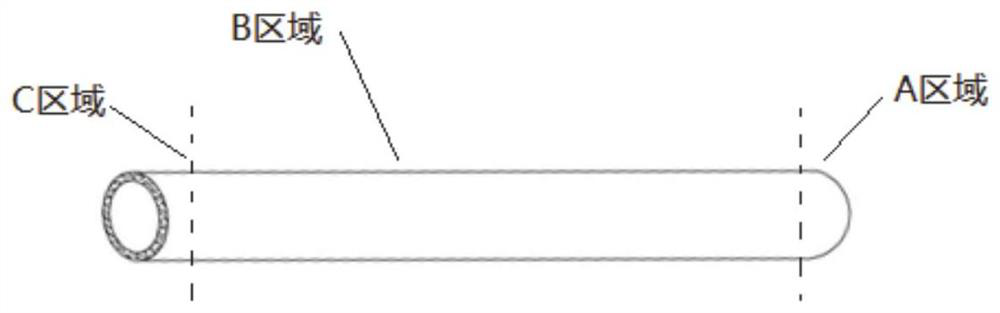

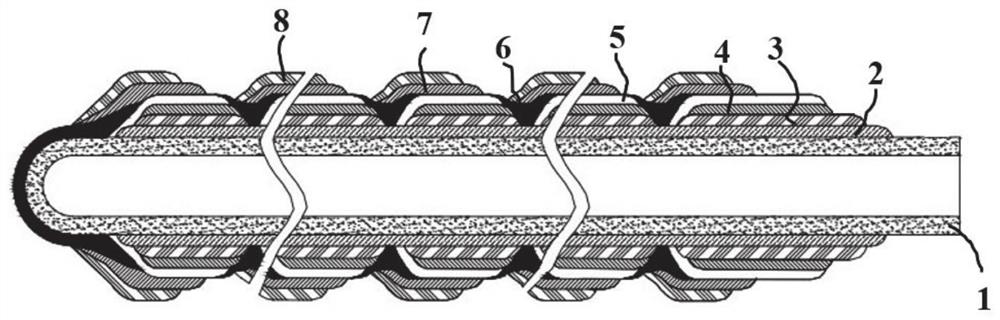

One-end self-sealing bamboo joint pipe type solid oxide fuel cell/electrolytic cell and preparation method of cell/electrolytic cell stack thereof

PendingCN114824388AFast film formationImprove preparation efficiencySolid electrolyte fuel cellsComposite materialElectrical battery

The invention provides a bamboo joint tube type solid oxide fuel cell / electrolytic cell with one self-sealed end and a preparation method of a cell / electrolytic cell stack thereof, and the preparation method comprises the following steps: taking ceramic powder with different properties in a hydrogen environment as a raw material for preparing a support body to obtain a tubular metal ceramic support body blank with a closed end; and then preparing an insulating layer on the surface of the annular tube wall of the support body blank, and preparing a plurality of single batteries connected in series on the surface of the insulating layer, so that a plurality of single battery structures are prepared on the surface of the metal ceramic circular tube-shaped support body. By adopting the screen printing technology, the film forming speed of a plurality of single cell series structures on the support body is effectively improved, the preparation efficiency is effectively improved, the preparation method is simplified, the preparation cost is saved, and commercialized popularization of the solid oxide fuel cell is facilitated.

Owner:XI AN JIAOTONG UNIV

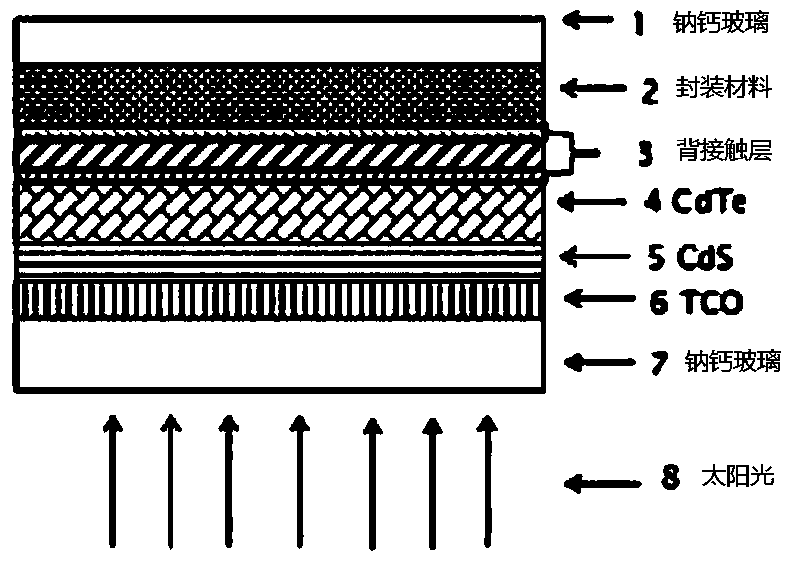

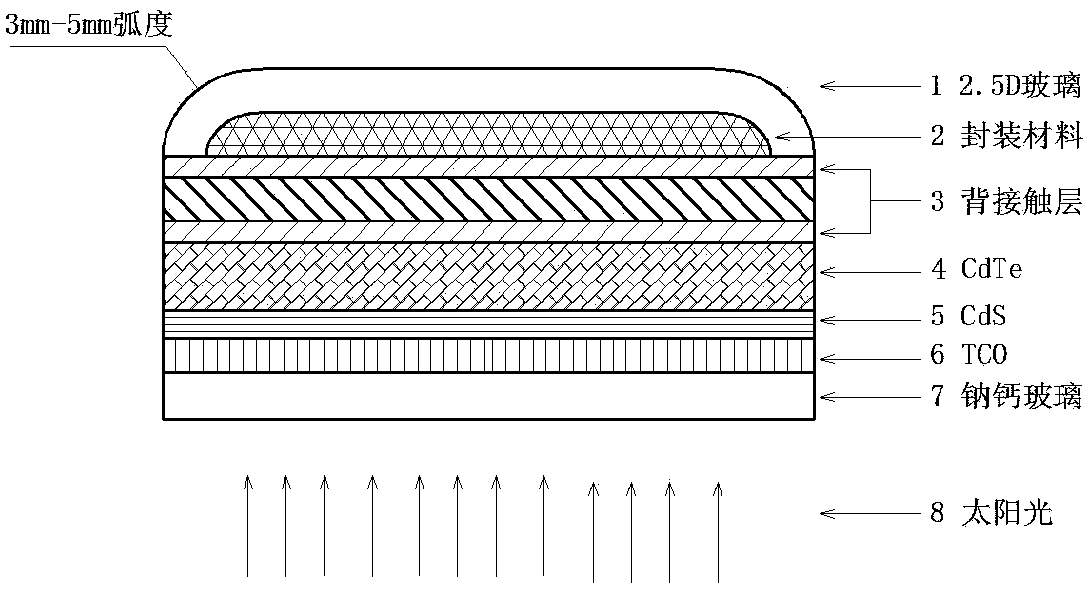

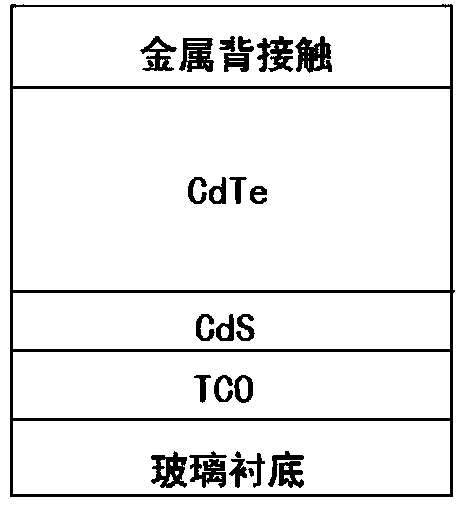

Preparation method of modified cadmium telluride thin film solar cell

InactiveCN107611219AImprove visual effectsSave sealing materialFinal product manufacturePhotovoltaic energy generationChemistryBackplane

The invention discloses a preparation method of a modified cadmium telluride thin film solar cell, which comprises the following steps: (1) preparing a solar electrode slice; (2) covering the upper surface of the solar electrode slice prepared in step (1) with a back contact layer transition layer, and bonding a backplane to the back contact layer transition layer to get a prefabricated component,wherein the backplane is 2.5D toughened glass; and (3) laminating the prefabricated component at high pressure under vacuum, and removing a vacuum bag, thus obtaining a modified cadmium telluride thin film solar cell. The invention provides a preparation method of a modified cadmium telluride thin film solar cell. The cadmium telluride thin film solar cell prepared by the invention has the characteristics of good self-sealing effect, rounded corners, good overall visual effect, wide application range, low use cost, and the like.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Aluminum antimonide polycrystalline material synthesizing process device and synthesis method

ActiveCN112458535AAvoid lostAvoid formingPolycrystalline material growthSingle crystal growth detailsGraphitePolycrystalline material

The invention relates to an aluminum antimonide polycrystalline material synthesizing process device and a synthesis method. High-purity antimony and high-purity aluminum are put into a silicon nitride ceramic crucible, a graphite gasket is covered and nested in a quartz crucible, an air gap exists between the graphite gasket and the upper surface of the silicon nitride ceramic crucible, and highvacuum in the silicon nitride ceramic crucible is not influenced during vacuumizing; after vacuumizing, a quartz plug and the quartz crucible are welded, and finally the quartz plug and the quartz crucible are synthesized in an inclinable rotating tubular furnace in a rotating mode, so that synthesis of single-phase aluminum antimonide in a small-cavity crucible without additional compensation isachieved, and elements are not lost in the synthesis process. According to the process device, the silicon nitride ceramic crucible does not react with an aluminum antimonide melt at high temperature,antimony evaporation is inhibited, the effect of cracking of the reaction that the outer quartz crucible adsorbs the aluminum element is prevented, it is guaranteed that melt components are not lostin the synthesis process, and the graphite gasket has the effect of adsorbing residual oxygen at high temperature. The synthesized aluminum antimonide polycrystalline material has the characteristic of uniform single-phase components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

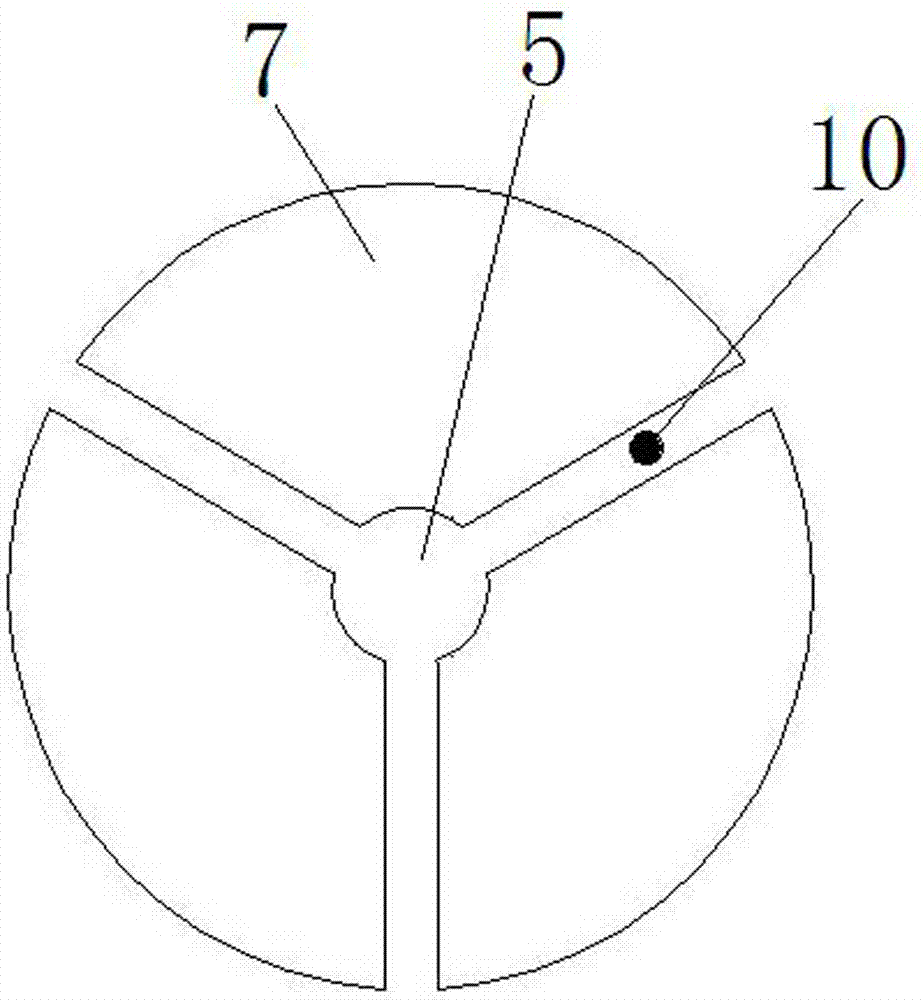

Self-sealing type double-layer horizontal rotating disc dust-discharging valve

ActiveCN111674852AAchieve self-sealing effectSmall footprintRotary conveyorsElectric machineEngineering

The invention relates to the technical field of dust-discharging valves, and discloses a self-sealing type double-layer horizontal rotating disc dust-discharging valve, which comprises a dust-discharging valve body, a dust-discharging groove is formed in the top of the dust-discharging valve body, a first partition plate is fixedly mounted in the dust-discharging groove, a second partition plate located at the bottom of the first partition plate is fixedly mounted in the dust-discharging groove, the bottom of the dust-discharging valve body is fixedly connected with a discharging pipe communicating with the dust-discharging groove, the bottom of the discharging pipe is fixedly connected with a rotating motor, and an output shaft of the rotating motor is fixedly connected with a rotating shaft which sequentially penetrates through the dust-discharging valve body, the second partition plate and the first partition plate and extends to the top of the first partition plate. According to the self-sealing type double-layer horizontal rotating disc dust-discharging valve, the problems that a disc-type dust-discharging valve is simple in structure and small in occupied space, has high adaptability to the characteristics of dust and is wide in application range, however, the self-sealing performance of the existing disc-type dust-discharging valve is low, a sealing strip is abraded in the using process, and consequently, the sealing performance is reduced are solved.

Owner:YANGZHOU WEIPENG AUTOMATION TECH

Probe for Defect Detection of Underwater Metal Structures Based on AC Electromagnetic Field

ActiveCN105004784BReduce volumeReduce distractionsMaterial magnetic variablesUltrasound attenuationEngineering

The invention discloses an underwater metal structure defect detecting probe based on an alternating current electromagnetic field. The underwater metal structure defect detecting probe mainly comprises a gland, a bottom cover, a cylinder, a seal joint, an O ring, a detection coil, an excitation circuit, a conditioning circuit, a U-shaped magnetic core, an excitation coil, a seal gasket and a top cover, wherein the detection coil is mounted in a central groove of the bottom cover and connected with the conditioning circuit; the conditioning circuit is mounted in a clamping groove I in the cylinder; the excitation circuit is mounted in a clamping groove II in the cylinder and connected with the excitation coil; the bottom cover is tightly pressed to the bottom of the cylinder by the gland; water isolation space is formed among the bottom cover, the O ring and the cylinder, and a self-sealing effect is realized. The underwater metal structure defect detecting probe has the benefits as follows: the probe for detecting defects of an underwater metal structure is designed by the aid of an alternating current electromagnetic field detection technology, the problem about underwater sealing and the problems of signal attenuation and the like can be solved effectively, and the defects of the underwater metal structure can be detected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

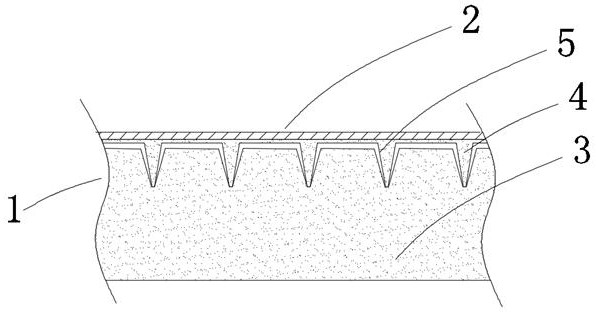

Self-shearing pin for heat-insulation building formworks

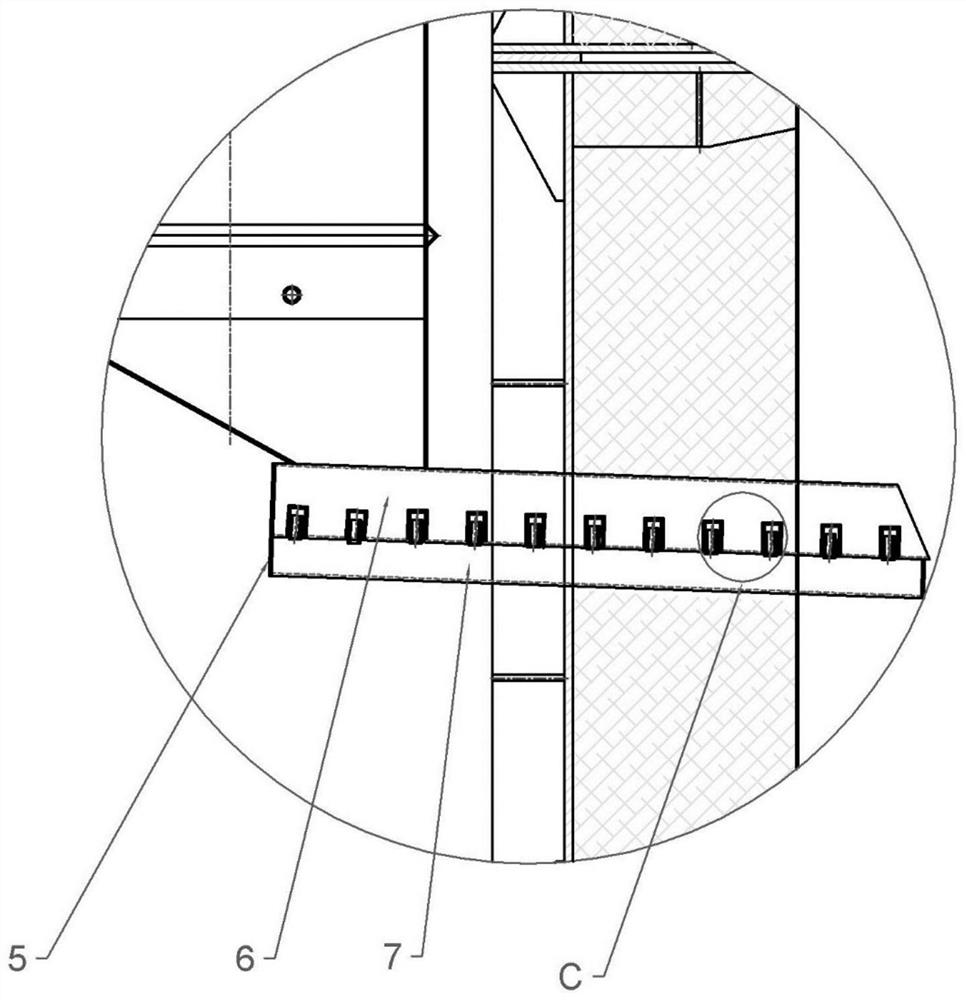

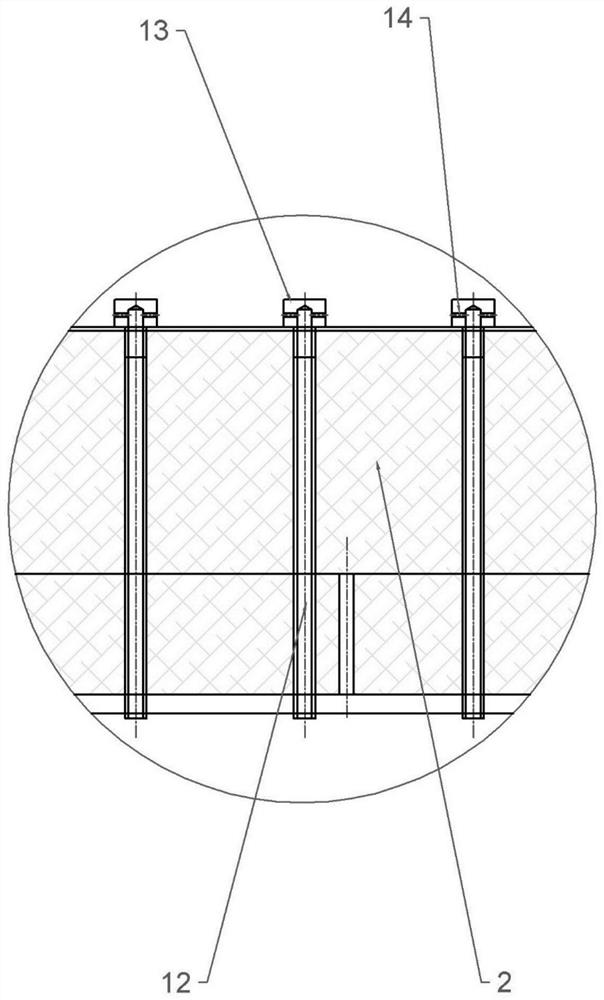

ActiveCN104847110AReasonable designCompact structureAuxillary members of forms/shuttering/falseworksEngineeringAcrylonitrile butadiene styrene

The invention relates to a self-shearing pin for heat-insulation building formworks. The self-shearing pin is suitable to be used as a fixing connector for the heat-insulation building formworks and wood ridges of connecting formwork frames and comprises an iron pin, a modified ABS (acrylonitrile butadiene styrene) pin rod and an adhesive layer. The rear end of the iron pin is adhered with the front end of the modified ABS pin rod by the adhesive layer, a conical pin head is arranged at the front of the iron pin, and a conical connecting head is arranged at the rear end of the iron pin; a pin cap is arranged at the rear end of the modified ABS pin rod, a pin rod is arranged in the middle of the modified ABS pin rod, and a conical connecting fork is arranged at the front end of the modified ABS pin rod; water guide grooves are formed in the conical connecting fork; a center water guide hole is formed in the center of the pin rod and is communicated with the water guide grooves formed in the conical connecting fork.

Owner:NANJING JINGYEDA NEW BUILDING MATERIALS

A self-sealing double-layer horizontal rotary disc ash unloading valve

ActiveCN111674852BAchieve self-sealing effectSmall footprintRotary conveyorsElectric machineEngineering

The invention relates to the technical field of ash unloading valves, and discloses a self-sealing double-layer horizontal rotary disk ash unloading valve, which includes a main body of the ash unloading valve, and an ash unloading slot is opened on the top of the main body of the ash unloading valve, and the ash unloading slot A first partition board is fixedly installed inside, a second partition board at the bottom of the first partition board is fixedly installed inside the ash discharge tank, and a discharge pipe communicating with the ash discharge tank is fixedly connected to the bottom of the main body of the ash discharge valve , the bottom of the discharge pipe is fixedly connected with a rotating motor, and the output shaft of the rotating motor is fixedly connected with a rotating shaft that runs through the main body of the ash unloading valve, the second partition plate and the first partition plate in sequence and extends to the top of the first partition plate . The self-sealing double-layer horizontal rotary disc ash discharge valve solves the problem that the disc ash discharge valve has a simple structure, a small footprint, strong adaptability to the characteristics of ash material, and a wide range of applications. However, the existing disc ash discharge valve automatically The sealing is not strong, and the sealing strip will be worn during use, which will lead to the problem of reduced sealing.

Owner:YANGZHOU WEIPENG AUTOMATION TECH

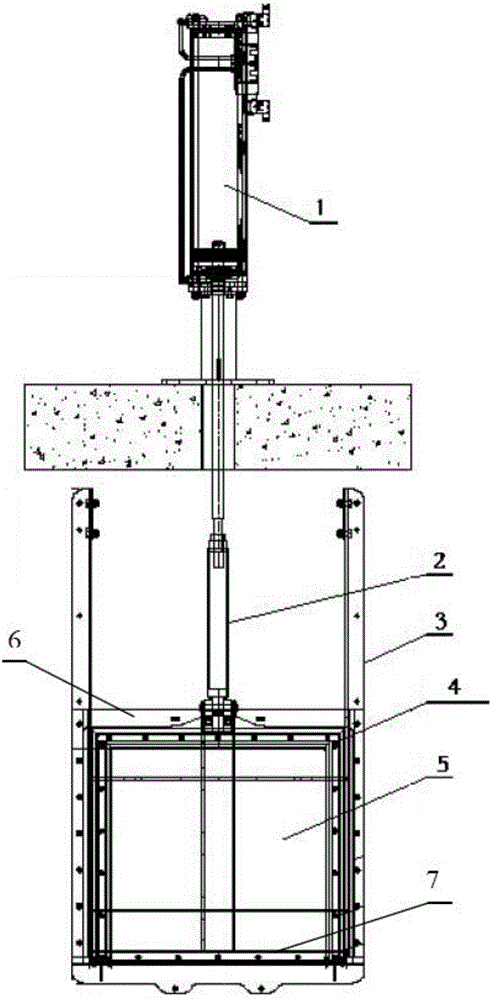

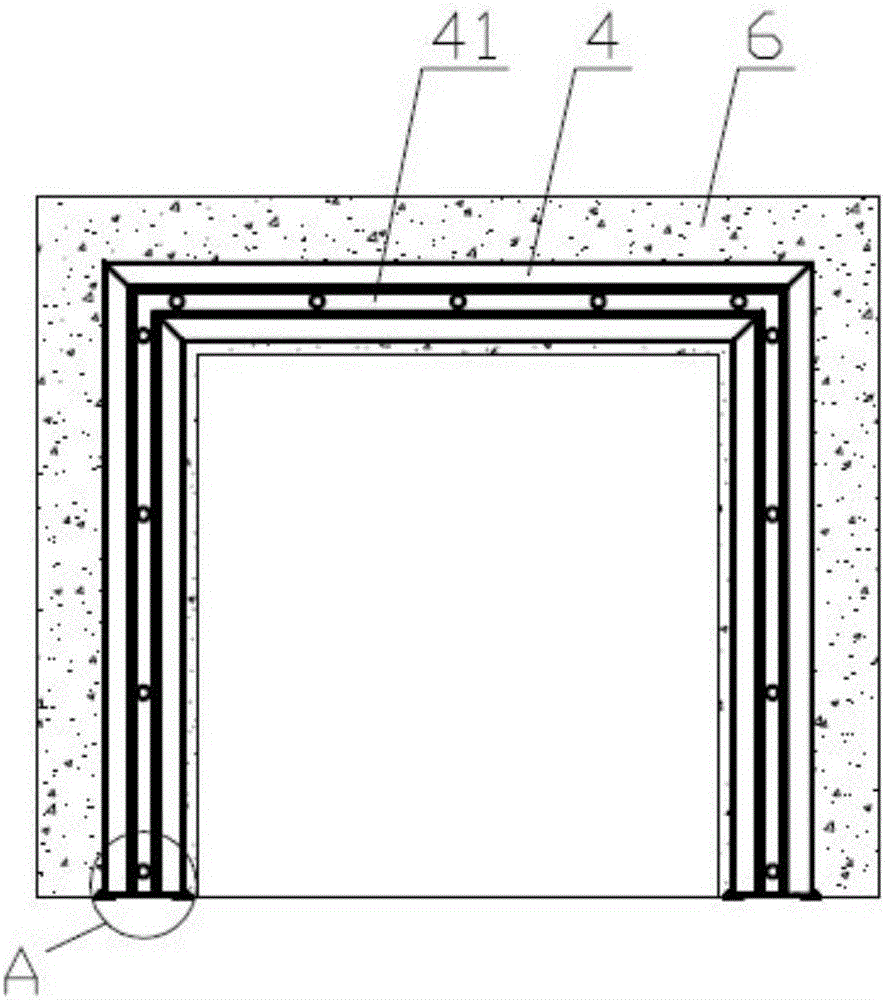

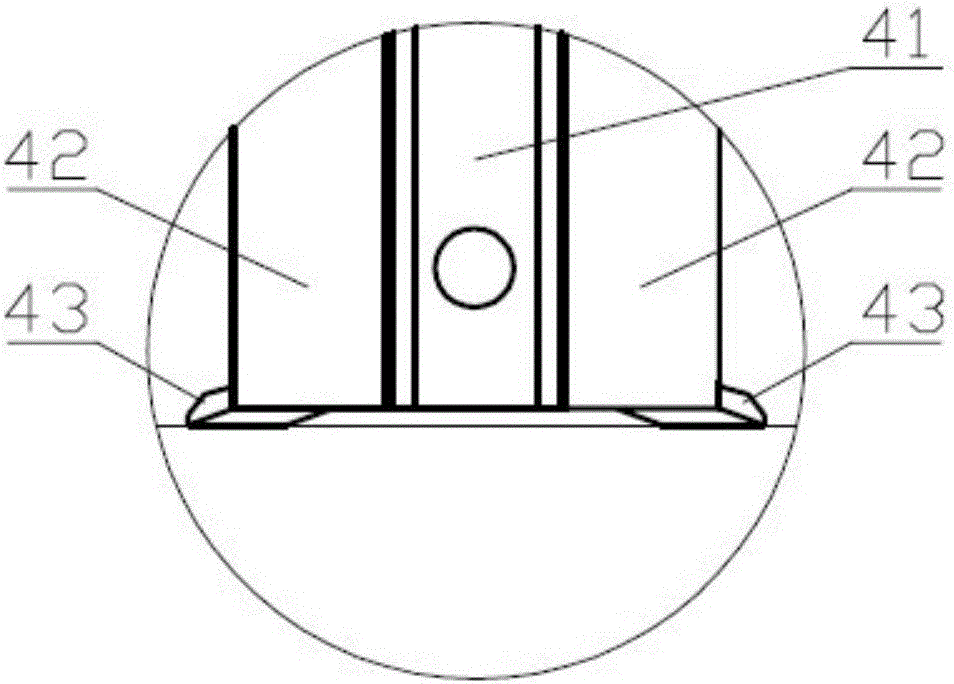

Self-sealing gate

ActiveCN105780742AAchieve self-sealing effectBarrages/weirsWater channelElectrical and Electronics engineering

The invention discloses a self-sealing gate. The self-sealing gate comprises a gate flap, a frame body and a driving device, wherein the gate flap is arranged on the frame body; and the gate flap is driven by the driving device to lift; and the self-sealing gate further comprises a sealing assembly rack which is located on one side of the gate flap and is parallel to the gate flap, a first sealing strip which is arranged between the sealing assembly rack and the gate flap and a second sealing rubber strip which is arranged along the edge of the bottom of the gate flap. According to the self-sealing gate provided by the invention, by additionally arranging the sealing assembly rack, and arranging the first sealing rubber strip between the gate strip and the sealing assembly rack and the second sealing rubber strip on the bottom of the gate flap, a sealing surface is transferred to a position between the gate flap and the sealing assembly rack from a position between the gate flap and a gate groove, so that the problem that sealing performance between the gate flap and the gate groove is poor is avoided; and the first sealing rubber strip and the second rubber strip reach a self-sealing effect under fluid pressure action at a gate closing state through further improvement, so that a water channel is fully sealed.

Owner:GUANGZHOU QIYUN MACHINERY CO LTD

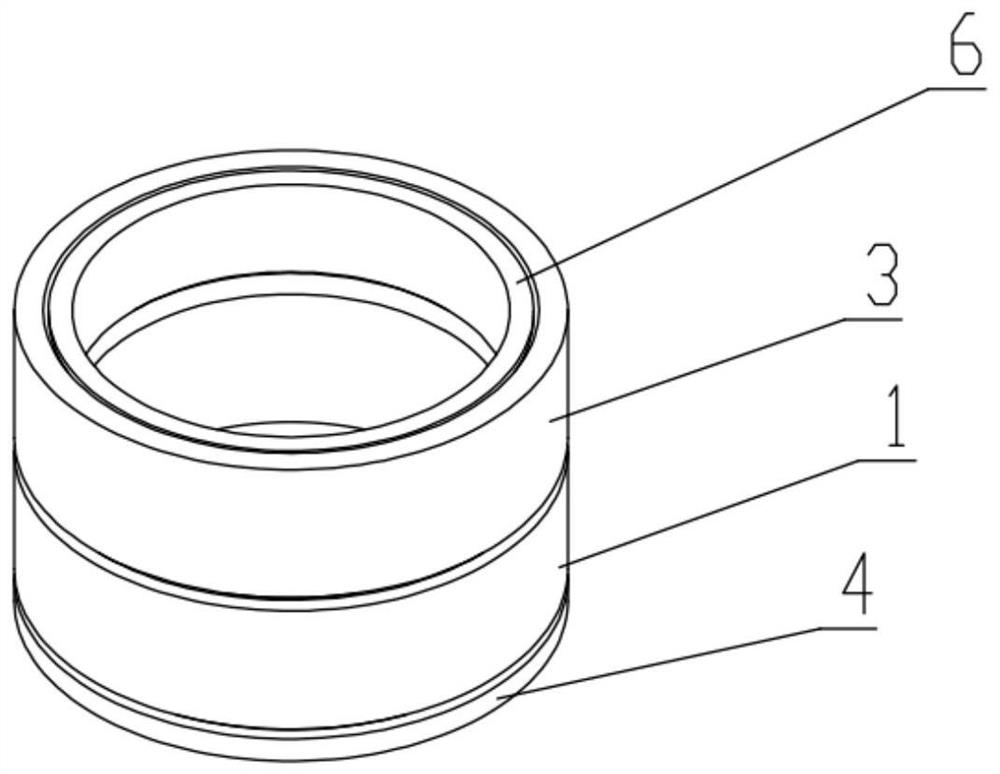

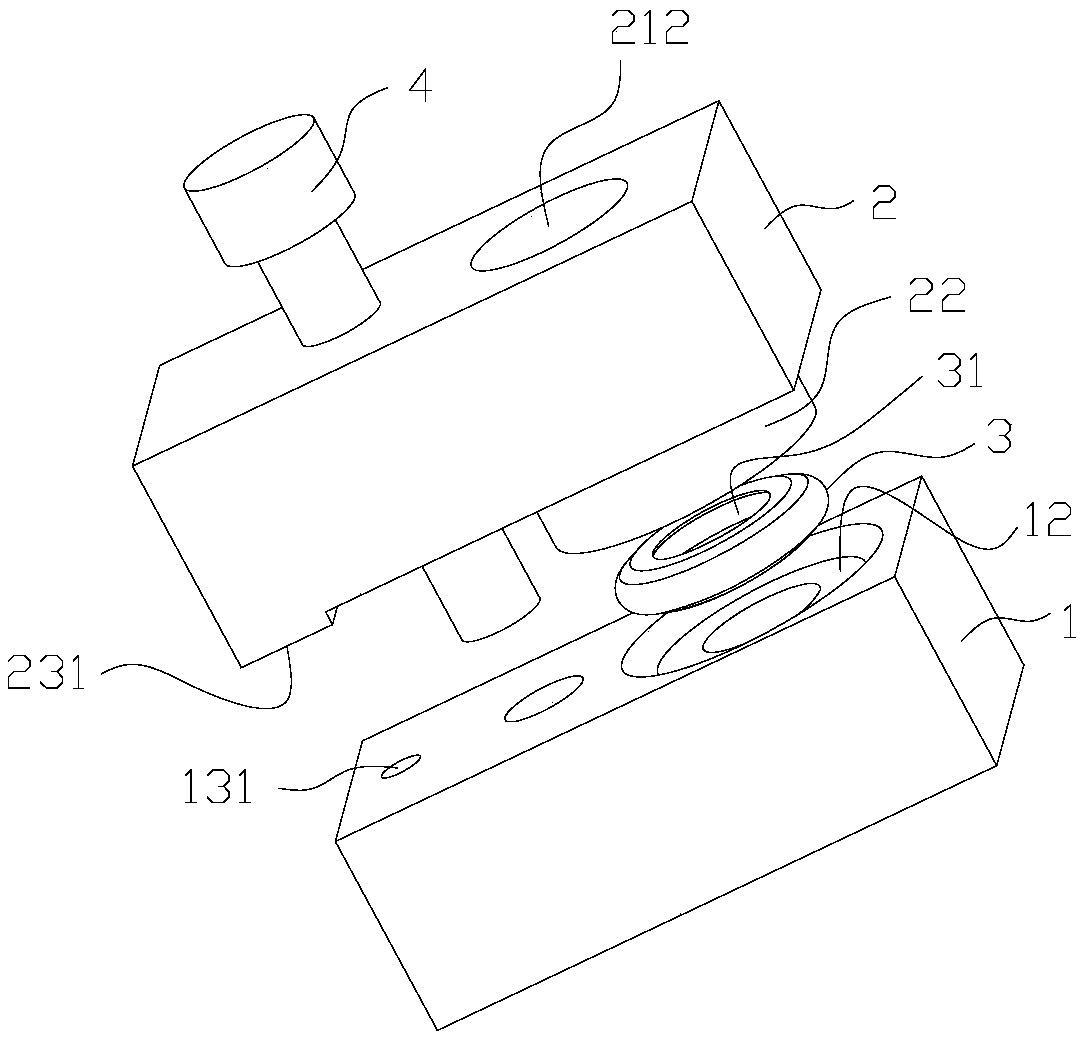

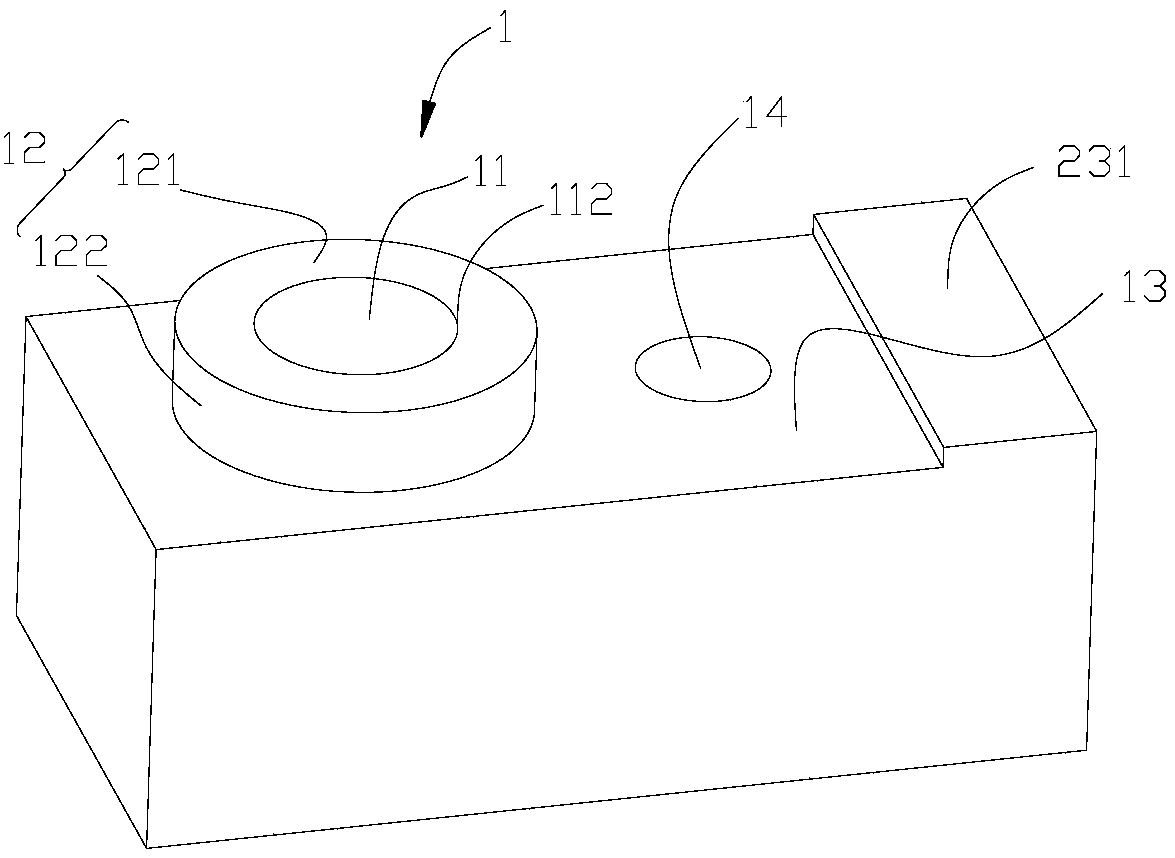

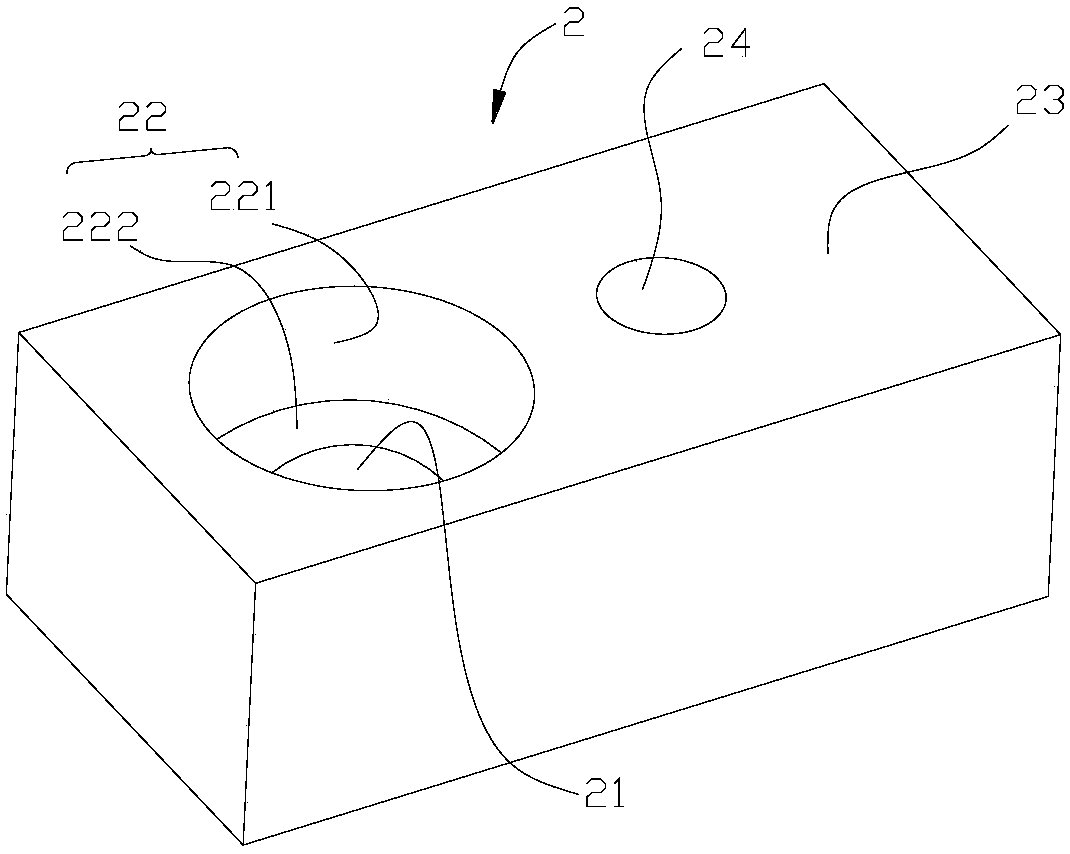

Self-sealing loading unit and open type load box structure based on self-sealing loading unit

PendingCN113186992AAchieve self-sealing effectRealize modular assemblyFoundation testingModular constructionStructural engineering

Owner:ZHEJIANG OUGAN MASCH CO LTD

Anti-blocking and anti-corrosion structure for the junction of the flare tube and the return tank

ActiveCN109113668BSolve problems prone to corrosion phenomenaReduce corrosion rateFlushingEngineeringElectrochemical corrosion

The invention discloses an anti-blocking and anti-corrosion structure for the junction of a horn pipe and a backflow groove. The electrically communicating whole is composed of a parallel guiding pipe, an inclined guiding pipe and the horn pipe and does not make contact with the backflow groove, and an electrochemical corrosion passage between the horn pipe and the backflow groove is directly cutoff; a ceramic mounting plate, a first ceramic cushion block, a first rubber sealing pad, a bearing frame, a second rubber sealing pad and a second ceramic cushion block are matched to conduct mounting bearing, sealed protection and automatic reinforcing, thus the problem that in the prior art, the junction of the horn pipe and the backflow groove are extremely prone to corrosion is solved, and the purposes of decreasing the corrosion rate of the junction of the horn pipe and the backflow groove and decreasing the maintenance and replacement frequency are achieved; and meanwhile, the anti-blocking and anti-corrosion structure is high in stability, can be self-sealed, and can significantly lower the blocking risk of the backflow groove.

Owner:MIANYANG FEIYUAN TECH CO LTD

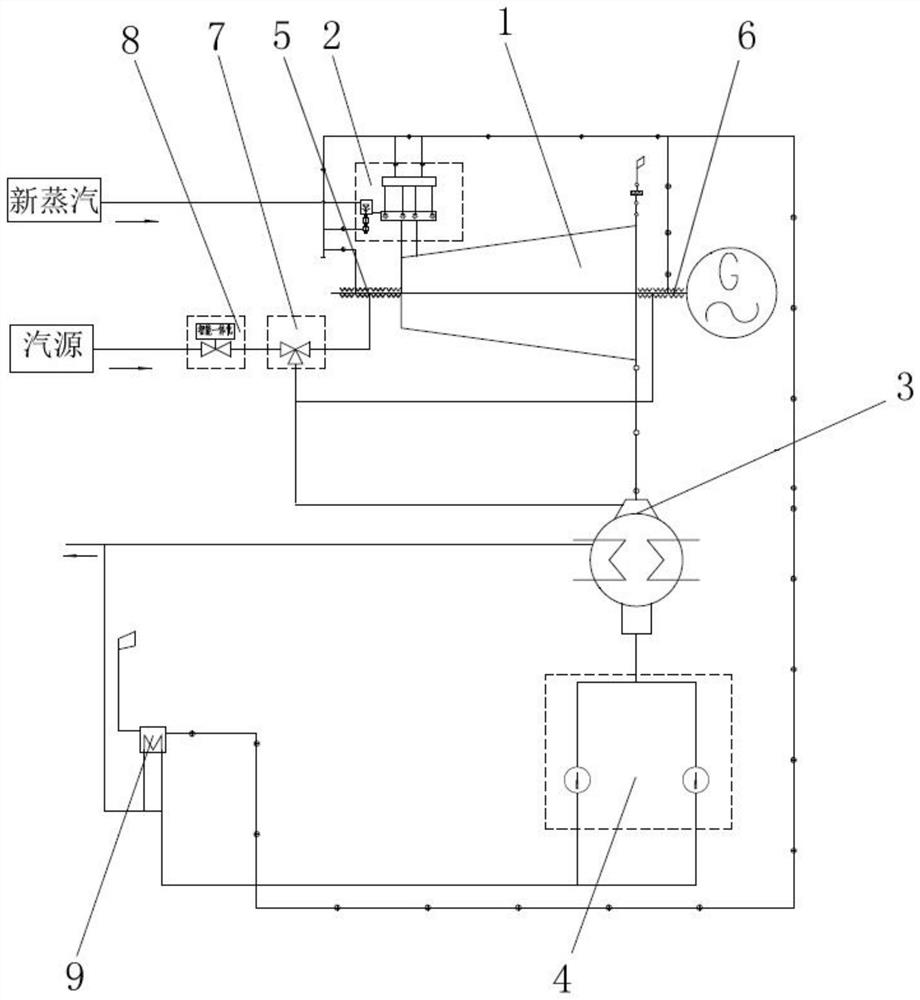

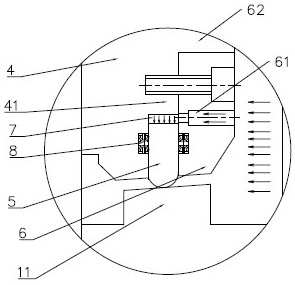

Shaft seal system of small steam turbine thermal system

PendingCN112096464AShorten the timeAchieve self-sealing effectLeakage preventionMachines/enginesEngineeringPhysics

The invention relates to a shaft seal system of a small steam turbine thermal system. The shaft seal system comprises a steam turbine, a three-way valve and an adjusting valve. A front steam seal bodyis arranged at the front end shaft part of the steam turbine, and a rear steam seal body is arranged at the rear end shaft part of the steam turbine. A first end port of the three-way valve is connected with a steam source through the adjusting valve, a second end port of the three-way valve communicates with the front steam seal body, and a third end port of the three-way valve communicates withthe rear steam seal body. During startup, the steam source passes through an adjusting valve and the three-way valve to reach a front steam seal to leak steam, so that the startup time is greatly shortened; and the front steam seal body is connected with the rear steam seal body through a three-way valve, so that a self-sealing effect can be achieved.

Owner:CHINA CHANGJIANG ENERGY CORP GROUP

Metal seal triple eccentric butterfly valve

ActiveCN111043332BElastic contact sealing effect is goodGood self-sealingLift valveEngineeringButterfly valve

Owner:KCM VALVE

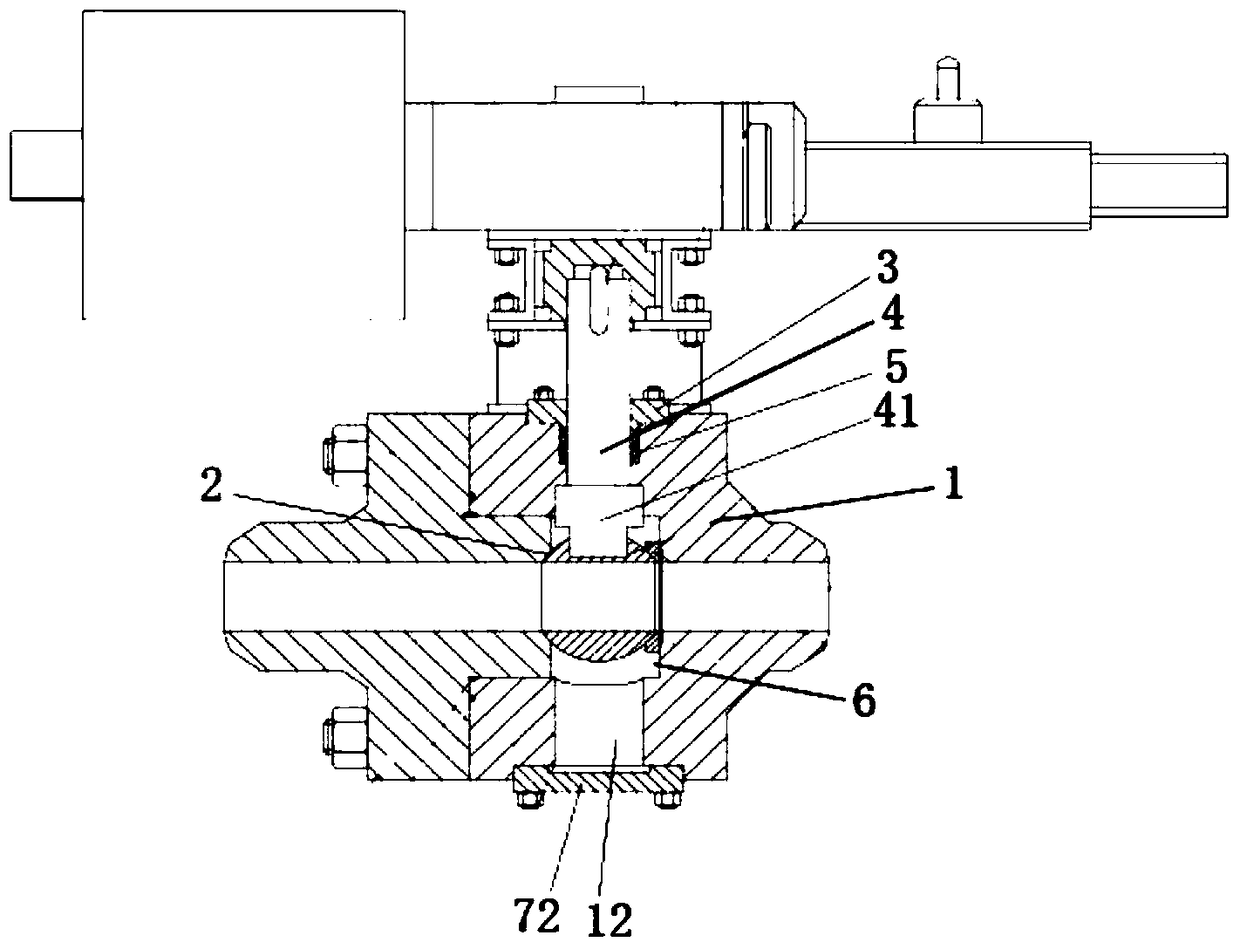

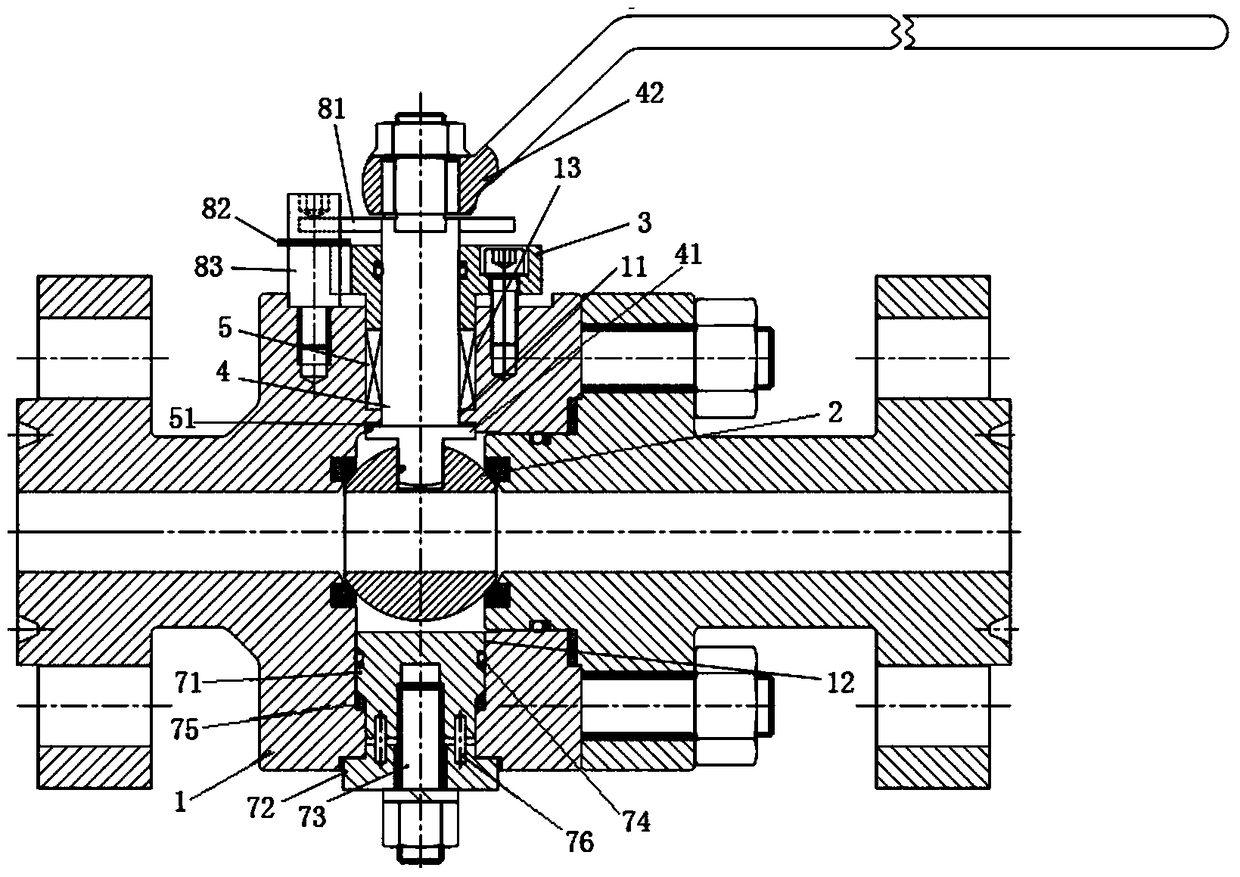

A floating ball valve

ActiveCN104747750BImprove sealingRealize "downloading"Plug valvesValve housingsEngineeringHigh pressure

The invention provides a floating ball valve. A through hole is formed in the bottom of the valve body, so that a valve rod smaller than the inner diameter of the through hole is installed in a valve rod installation hole through the through hole and a cavity, and lower mounting of the valve rod and blowing-out prevention are achieved. In addition, the through hole is set to be of a structure with a first through hole portion and a second through hole portion of which the inner diameter is smaller than that of the first through hole portion, a valve plug can not be blown out of the bottom of a valve body under the action of high-pressure media through the function of a protrusion of the second through hole portion, and after the valve plug is connected with a lower cover board, upward movement of the valve plug is blocked by a valve deck, so that after the valve plug and the lower cover board are connected, upward and downward movement of a whole sealing assembly is limited. Meanwhile, the valve plug is in sealed fit with the inner wall of the first through hole portion and / or the second through hole portion, the high-pressure media are prevented from being leaked from the gap between the through hole and the valve plug, the sealing performance of the ball valve is improved, and the ball valve can adapt to media of higher pressure.

Owner:NEWAY VALVE SUZHOU

Anti-blocking and anti-corrosion structure for junction of horn pipe and backflow groove

ActiveCN109113668ASolve problems prone to corrosion phenomenaReduce corrosion rateFlushingElectricityEngineering

The invention discloses an anti-blocking and anti-corrosion structure for the junction of a horn pipe and a backflow groove. The electrically communicating whole is composed of a parallel guiding pipe, an inclined guiding pipe and the horn pipe and does not make contact with the backflow groove, and an electrochemical corrosion passage between the horn pipe and the backflow groove is directly cutoff; a ceramic mounting plate, a first ceramic cushion block, a first rubber sealing pad, a bearing frame, a second rubber sealing pad and a second ceramic cushion block are matched to conduct mounting bearing, sealed protection and automatic reinforcing, thus the problem that in the prior art, the junction of the horn pipe and the backflow groove are extremely prone to corrosion is solved, and the purposes of decreasing the corrosion rate of the junction of the horn pipe and the backflow groove and decreasing the maintenance and replacement frequency are achieved; and meanwhile, the anti-blocking and anti-corrosion structure is high in stability, can be self-sealed, and can significantly lower the blocking risk of the backflow groove.

Owner:MIANYANG FEIYUAN TECH CO LTD

Anticorrosion structure of return outlet of trumpet tube

ActiveCN109098680ASolve problems prone to corrosion phenomenaReduce corrosion rateCorrosion preventionPipe protection against corrosion/incrustationWhole bodyEngineering

The invention discloses an anticorrosion structure of a return outlet of the trumpet tube. A parallel guide tube, an inclined guide tube and the trumpet tube form an electric communication whole body,the whole body is not in contact with a backflow groove, a channel for electrochemical corrosion between the trumpet tube and the backflow groove is cut off directly, by cooperation of a ceramic mounting plate, a first ceramic cushion block, a first rubber sealing pad, a carrying frame, a second rubber sealing pad and a second ceramic cushion block, mounting carrying, sealing protection and automatic reinforcing are carried out, the problem that a position where a trumpet tube is connected with a backflow groove in the prior art is corroded quite easily is solved, and purposes of relieving the corrosion rate of the position where the trumpet tube is connected with the backflow groove and reducing the maintaining and changing frequency are achieved.

Owner:MIANYANG FEIYUAN TECH CO LTD

High-performance composite rubber strip for self-sealing safety tire and production method of high-performance composite rubber strip

InactiveCN114571917AAchieve self-sealing effectAvoid crowdingTyre partsTyresMechanical engineeringComposite material

The high-performance composite rubber strip comprises a self-sealing material layer and an elastic film arranged on the upper side of the self-sealing material layer, the self-sealing material layer comprises a self-sealing filling material and a supporting piece layer wrapped on the side, close to the elastic film, in the self-sealing filling material, and the supporting piece layer is composed of a plurality of bowl-shaped supporting pieces; the concave face of the supporting piece faces the side away from the elastic film. Each supporting piece is connected with the adjacent supporting piece, and the joint is a weak point easy to break; the self-sealing rubber strip body is used for being laid on the inner side of a tire to achieve the tire self-sealing effect. When the sharp part of the supporting piece pierces, the sharp part enters or slides into the concave part of the supporting piece, the supporting piece bears the sharp part, the sharp part jacks up the supporting piece, the peripheral self-sealing filling material is promoted to draw close to the sharp part to form sealing, the adhesive tape does not need to be sprayed, the interior of the tire is treated, and then the adhesive tape is attached, so that the production cost is low, and in addition, the safety of the tire is improved. And the rubber strip can be replaced, so that the service life of the self-sealing tire is prolonged.

Owner:南通骏标自密封安全轮胎科技有限公司

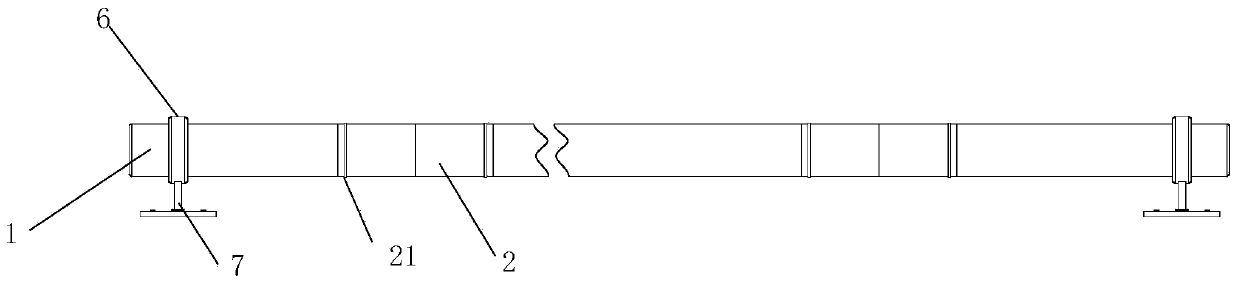

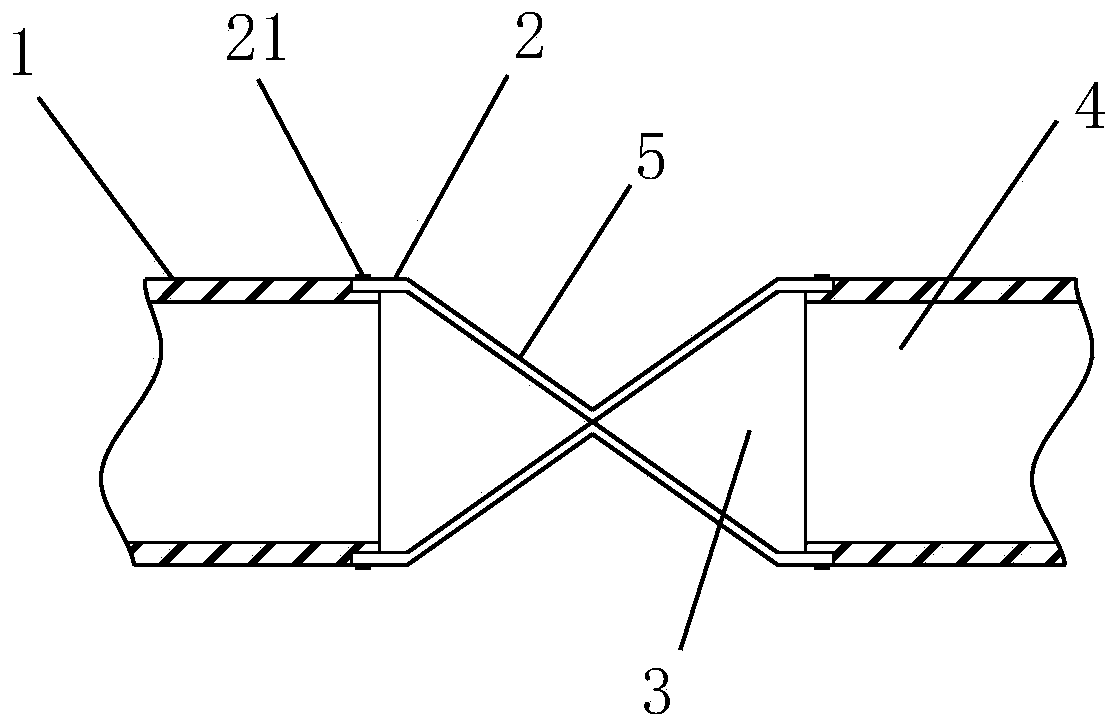

Spliced type buried pipeline

ActiveCN110469734AAchieve self-sealing effectFast blockingAdjustable jointsMechanical engineeringNatural state

The invention discloses a spliced type buried pipeline. The pipeline includes more than one cylindrical pipeline body, an elastic connecting part is arranged between every two adjacent pipeline bodies, the middle of each pipeline body is provided with a pipeline cavity, the two sides of each pipeline cavity are provided with openings, the two sides of each pipeline body form assembly convex partsrespectively, the assembly convex parts are fixed in the elastic connecting parts, the middle of each elastic connecting part is provided with a transition channel, and when the elastic connecting parts are in natural states, the middles of the transition channels are sealed. The pipeline is especially suitable for being buried in the ground, can move rapidly after being cut off and achieves automatic sealing, not only water can be prevented from flowing out continuously, but also the pipeline can be quickly away from an operation area, and the pipeline is safer.

Owner:义乌市君胜科技有限公司

Electromagnetic actuator and electromagnetic execution system

PendingCN114508594AIncrease forceGap decreases or stays the sameSpindle sealingsLift valveEngineeringElectromagnetic valve

The invention discloses an electromagnetic actuator and an electromagnetic actuating system, and belongs to the technical field of electromagnetic valves.The electromagnetic actuator comprises a valve body, a valve seat and a valve element, the valve body is provided with a mounting hole and a middle hole which are communicated, and the hole diameter of the mounting hole is larger than that of the middle hole; the valve seat is mounted in the mounting hole, and the valve seat is provided with a first through hole communicated with the middle hole; a valve element is movably arranged in the middle hole in a penetrating mode, and one end of the valve element can abut against the valve seat and seal the first through hole. A groove communicated with the first through hole is formed in the valve body and / or the valve element, the depth direction of the groove is parallel to the extending direction of the valve body, and the groove is used for containing high-pressure fluid so that the high-pressure fluid can extrude the valve element to abut against the valve body or extrude the valve body to abut against the valve element. The electromagnetic actuator and the electromagnetic execution system provided by the invention have good sealing performance, and the probability of leakage is reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

In-furnace heat adjusting system for horizontal high-temperature kiln

ActiveCN112833670AAvoid reverse flowPlay the role of self-sealingMaintainance of heating chambersCharge manipulationThermodynamicsMechanical engineering

The invention relates to the technical field of casting material treatment and discloses an in-furnace heat adjusting system for a horizontal high-temperature kiln. The system comprises a furnace body, wherein a transverse sealing plate is arranged in the furnace body, the sealing plate divides the furnace body into a first chamber and a second chamber, the sealing plate is uniformly provided with a plurality of communicating pieces, a side part of the furnace body is provided with a communicating part, and the communicating part communicates with a first furnace body and a second furnace body. The communicating part comprises a closing box and a sand discharging pipe, and the sand discharging pipe communicates with the lower part of the closing box; the sand discharging pipe is provided with a partition plate along a length direction, the partition plate divides the sand discharging pipe into a sand discharging cavity and an air cavity, the air cavity communicates with an air source, the sand discharging cavity is internally provided with a plurality of exhaust parts, the exhaust part comprises an outer pipe and an inner pipe, the upper end of the outer pipe is closed, the inner pipe is located in the outer pipe and two ends of the inner pipe communicate with the outer pipe and the air cavity respectively, and an air outlet is formed in the side part of the outer pipe; a discharge opening is formed in the side part of the furnace body, and a communicating part is arranged at the discharge opening and the length of the sand discharging pipe is greater than three times of the height of the sand discharging pipe. By adopting the system, an effect of saving energy sources can be achieved.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Pipeline switching device and automobile air conditioning system

ActiveCN110715125AAchieve self-sealing effectSleeve/socket jointsAutomobile air conditioningEngineering

The invention discloses a pipeline switching device and an automobile air conditioning system using the same. The pipeline switching device comprises a fastener, an annular part, a first connecting block and a second connecting block, wherein the first connecting block comprises a first channel and an abutting part; the second connecting block comprises a second channel and a containing part; andthe annular part is arranged on the containing part and abuts against the abutting part and the bottom wall of the containing part, so that the sealing connection between the first channel and the second channel is realized.

Owner:SANHUA HLDG GRP

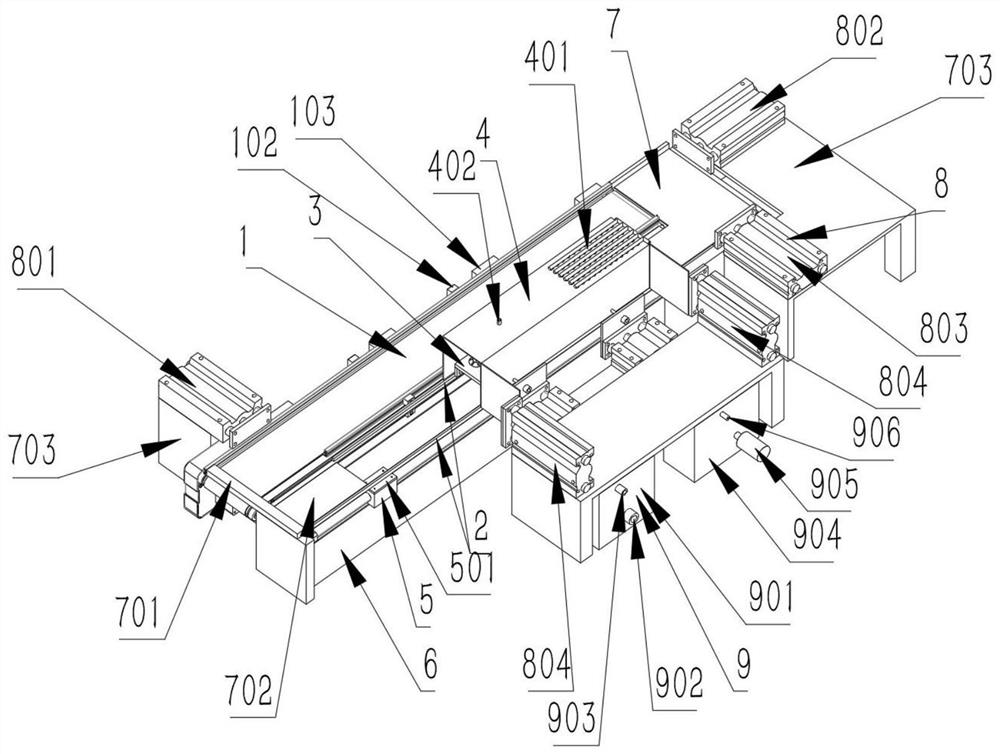

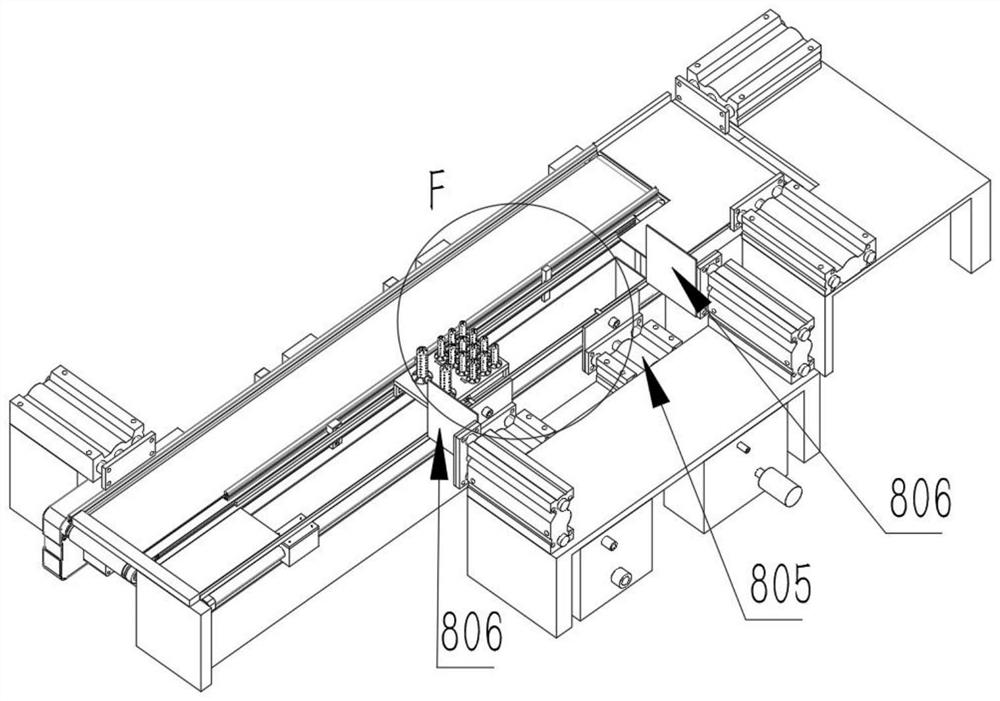

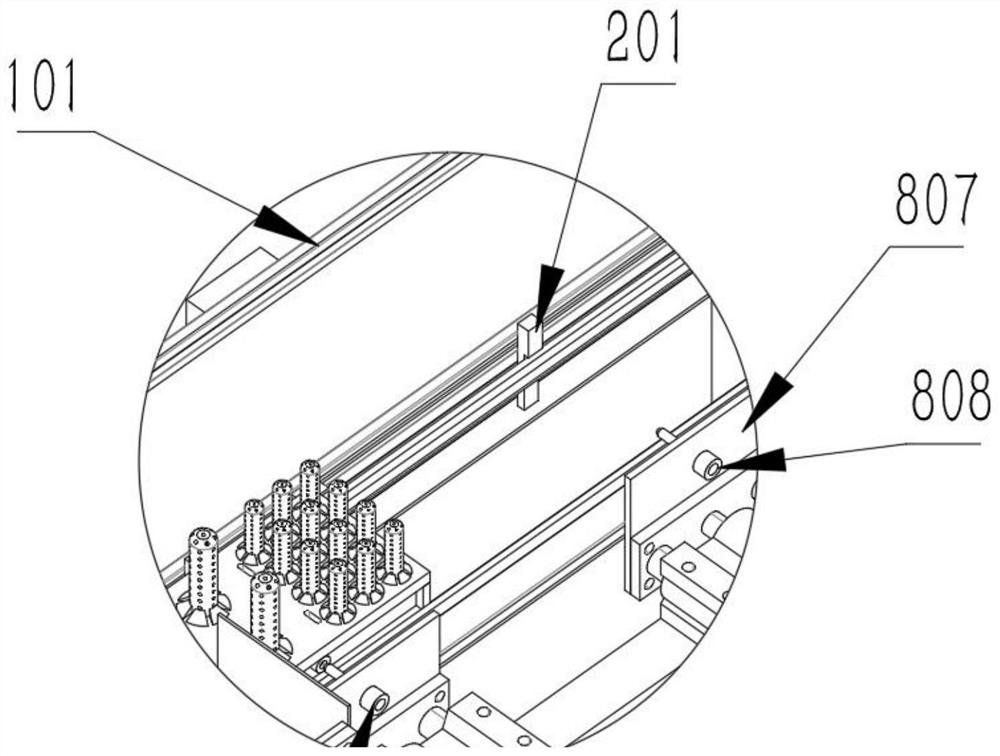

Continuous cleaning glass instrument cleaning device for school experiments

ActiveCN114273356AAchieve self-sealing effectAchieve cleaning effectHollow article cleaningDrying gas arrangementsEngineeringAssembly line

The invention discloses a continuous cleaning glass instrument cleaning device for school experiments, and belongs to the field of experimental apparatuses, the continuous cleaning glass instrument cleaning device comprises a return conveying belt, a sliding guide rail and bearing tables, the return conveying belt is located on the left side of the sliding guide rail, the sliding guide rail and the return conveying belt are located on the same horizontal plane, and a plurality of bearing tables are placed on the sliding guide rail; a plurality of bearing tables can stably and horizontally move on a sliding guide rail, the tail end of the sliding guide rail is connected with a return conveying belt through an adapter plate, a blocking strip is installed on the top of the return conveying belt, the small support and the large support are good in compatibility, can be matched with most experimental instruments and can be matched with a spraying arm to conduct inside and outside cleaning and drying on the experimental instruments, and the cleaning effect is good; assembly line type operation is adopted, the number of the bearing tables can be increased according to needs, the bearing tables circulate anticlockwise on the whole equipment, and full-automatic continuous cleaning is achieved.

Owner:钱卓逸

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com