One-end self-sealing bamboo joint pipe type solid oxide fuel cell/electrolytic cell and preparation method of cell/electrolytic cell stack thereof

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of high cost, low volume power density and low voltage of self-supporting solid oxide fuel cells, and achieve economical preparation. cost, increased film formation speed, and the effect of reducing cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

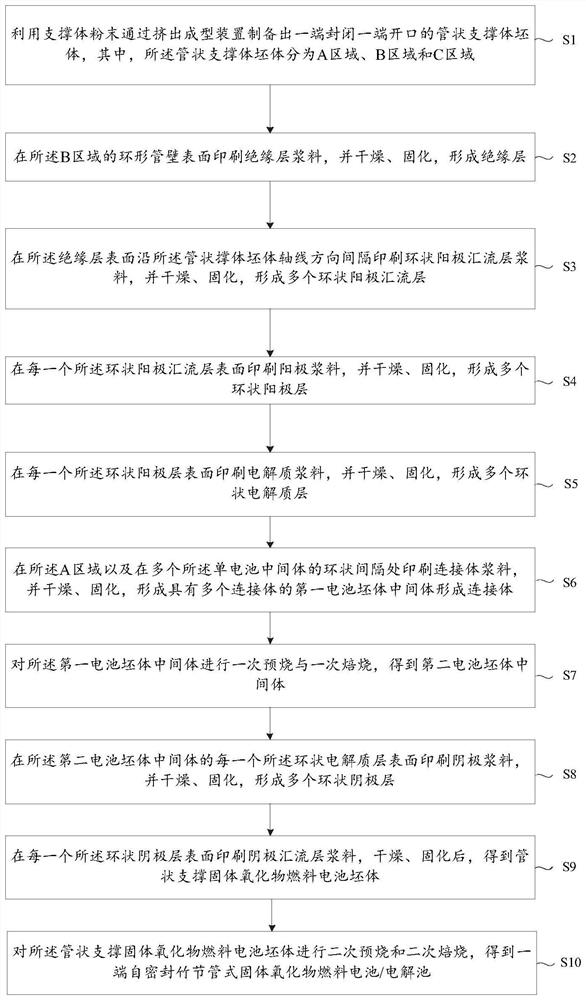

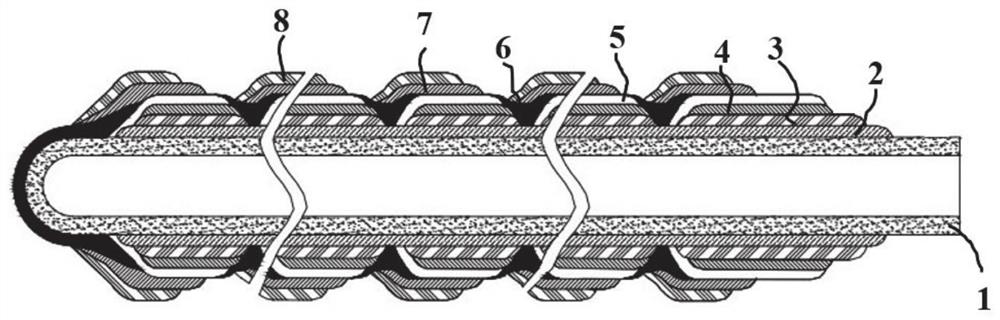

[0054] In a first aspect, the present invention provides a method for preparing a self-sealing bamboo tube type solid oxide fuel cell / electrolyzer at one end, figure 1 The flow chart of the preparation method of the self-sealing bamboo tube type solid oxide fuel cell / electrolyte at one end prepared in the embodiment of the present invention is shown, as shown in the figure. figure 1 As shown, the preparation method comprises the following steps:

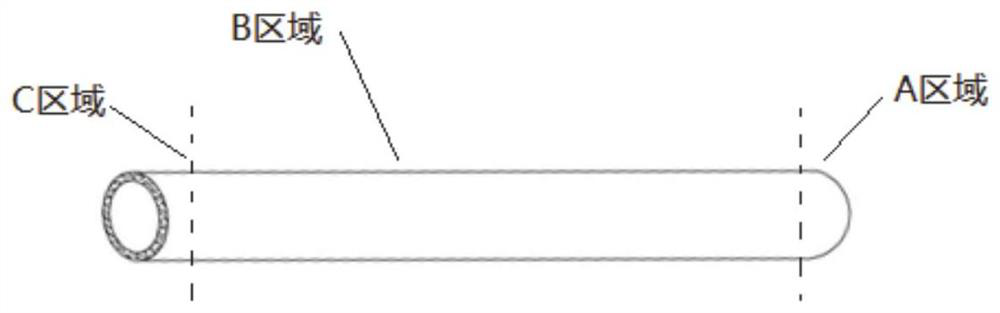

[0055] S1. Use the support powder to prepare a tubular support body with one end closed and one end open through an extrusion molding device; wherein, the tubular support body is divided into A region, B region and C region, and the A region corresponds to the The closed end of the tubular support body, the B region corresponds to the middle region of the tubular support body, the C region corresponds to the open end of the tubular support body, and the support powder is composed of different kinds of It is composed of ceramic powde...

Embodiment 1

[0089] EXAMPLES OF THE INVENTION Hereinafter, the present invention will be described in more detail by way of examples. The following description is not intended to limit the invention. The support body for the solid oxide fuel cell of the present invention is a tubular structure with one end closed, as shown in the schematic diagram. image 3 shown.

[0090] The manufacturing process of a solid oxide fuel cell support is described in accordance with the present invention. The material constituting the tube contains 3YSZ and NiO mixed powder with a mass ratio of 1:1 and 10wt% starch as a pore-forming agent, and the particle sizes are respectively 3-5 μm, 0.5-1 μm, 10-30 μm, and the mixed powder and the pore-forming agent are in Mixing in a ball mill for 6 hours, rotating speed of 360 r / min, drying and grinding at 140°C, sieving for later use, adding methyl cellulose 4wt%, glycerol 5wt%, water 14wt%, etc. as a solvent for extrusion, and mixing in a kneader After 3 hours, th...

Embodiment 2

[0102] EXAMPLES OF THE INVENTION Hereinafter, the present invention will be described in more detail by way of examples. The following description is not intended to limit the invention. The support body for the solid oxide fuel cell of the present invention is a tubular structure with one end closed, as shown in the schematic diagram. image 3 shown.

[0103] The manufacturing process of a solid oxide fuel cell support is described in accordance with the present invention. The material constituting the tube includes CSZ and NiO mixed powder with a mass ratio of 6:4 and 15wt% ammonium bicarbonate as a pore-forming agent, with particle sizes of 3-5 μm, 0.5-1 μm, and 10-30 μm, respectively. The powder was mixed in a ball mill for 6 hours, the rotating speed was 360 r / min, dried and ground at 140°C, sieved for use, and added 4wt% methylcellulose, 5wt% glycerol, 14wt% water, etc. as a solvent for extrusion molding, and placed it in a kneader. After mixing for 3 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com