Spliced type buried pipeline

A splicing, pipeline technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing elements, etc., can solve the problems of broken water pipes, large damage of water pipes, cutting off water pipes, etc., and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

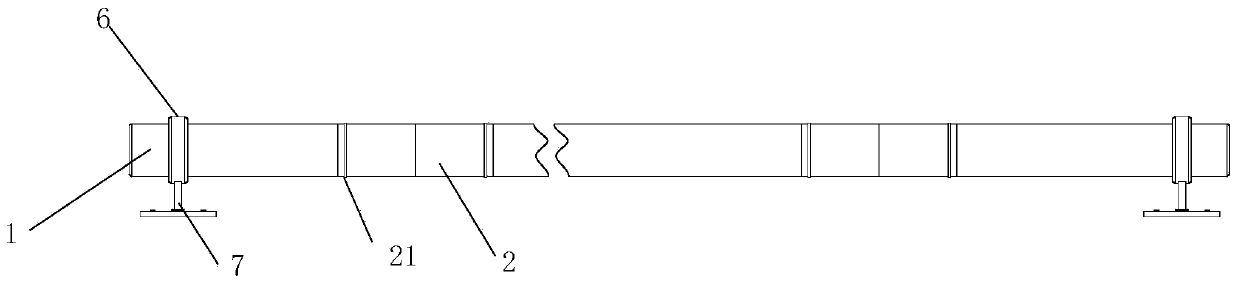

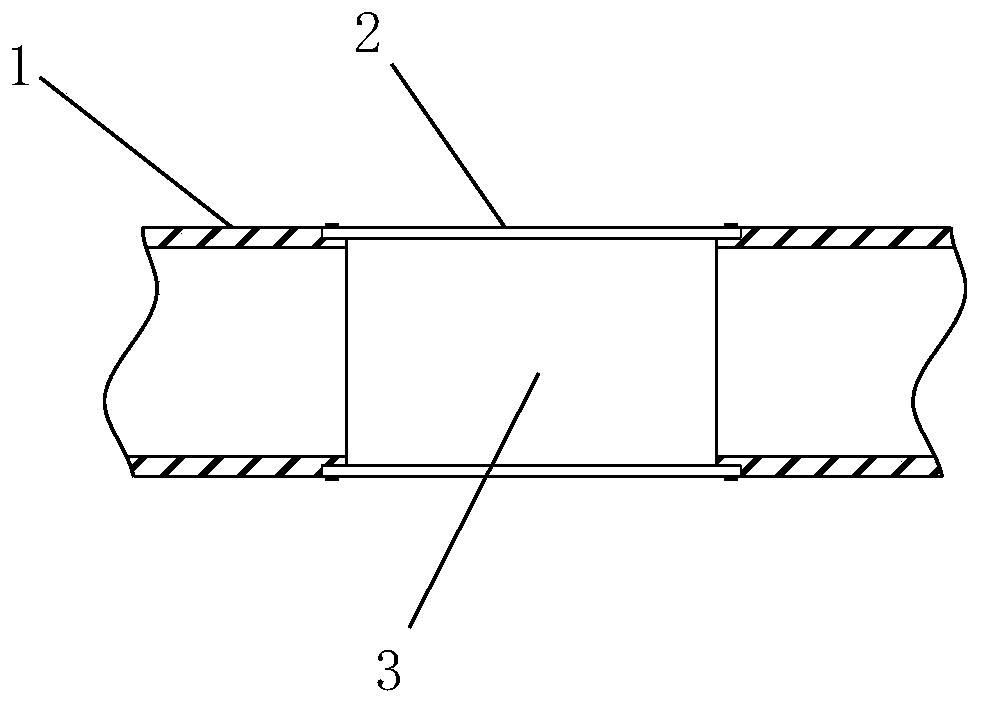

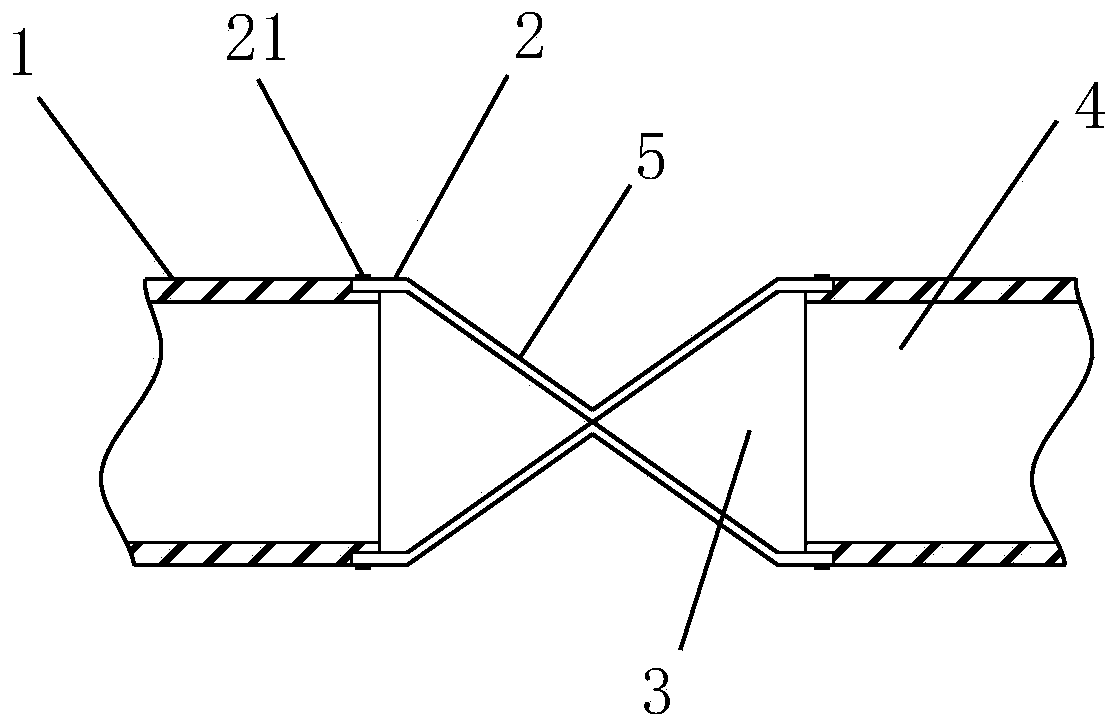

[0019] like figure 1 As shown, the local buried splicing pipeline includes more than one cylindrical pipeline body 1, an elastic connecting part 2 is arranged between adjacent pipeline bodies 1, and a pipe with openings on both sides is arranged in the middle of each pipeline body 1. Pipe cavity 4, two sides of each pipe body 1 respectively form an assembly convex part, the assembly convex part is fixed in the elastic connection part 2, and there is a transition channel 3 in the middle of the elastic connection part 2, when the elastic connection part 2 In the natural state, the middle of the transition channel 3 is sealed.

[0020] The assembly openings on both sides of the elastic connecting part 2 are circular, and a turning section 8 is formed in the middle. When the elastic connecting part is in a natural state, the elastic connecting parts located on both sides of the turning section 8 form an inclined surface 5, as Figure 4 As shown, an angle greater than or equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com