Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Accelerated cooling and setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

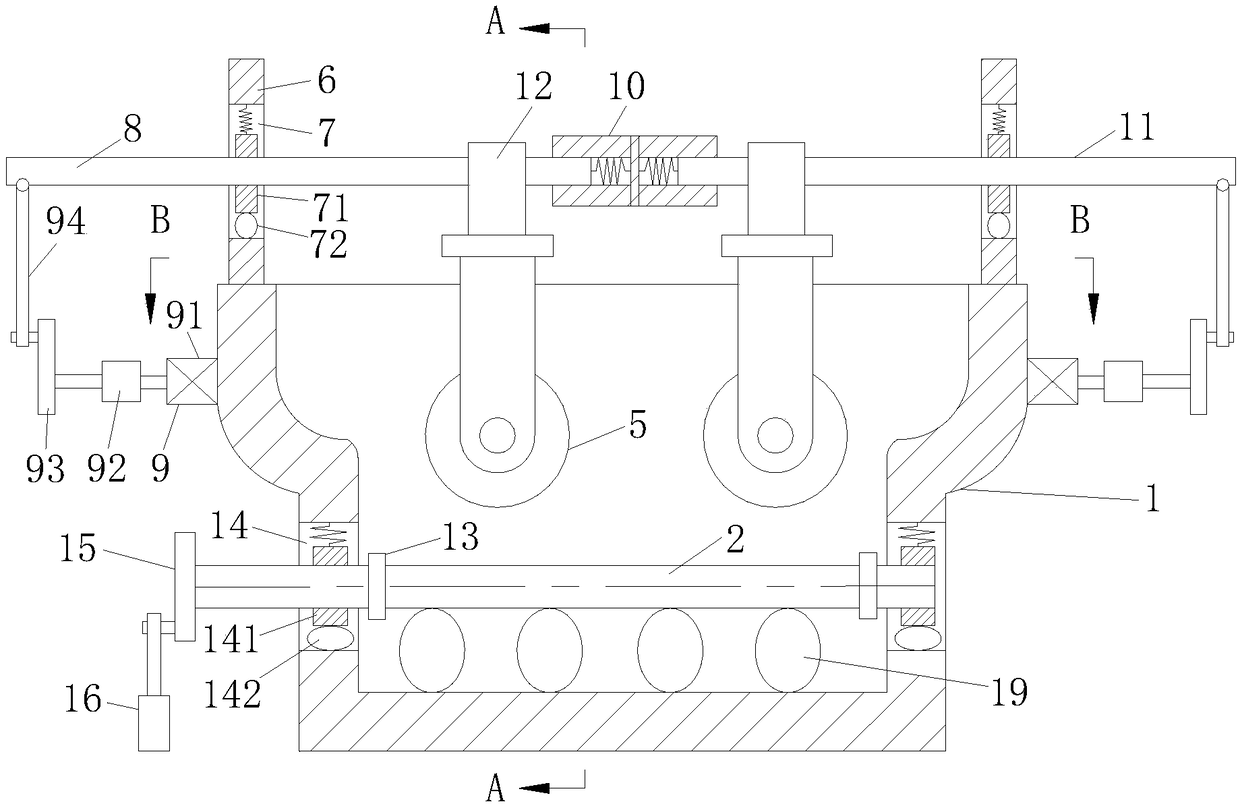

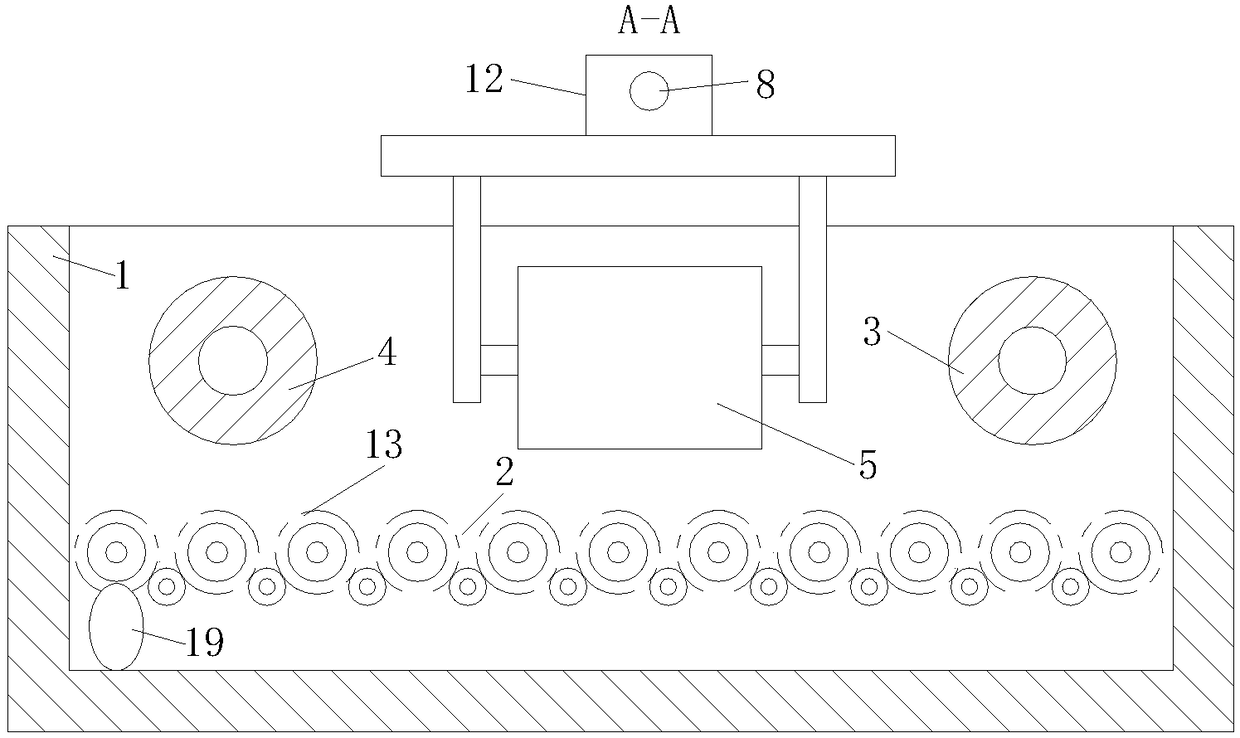

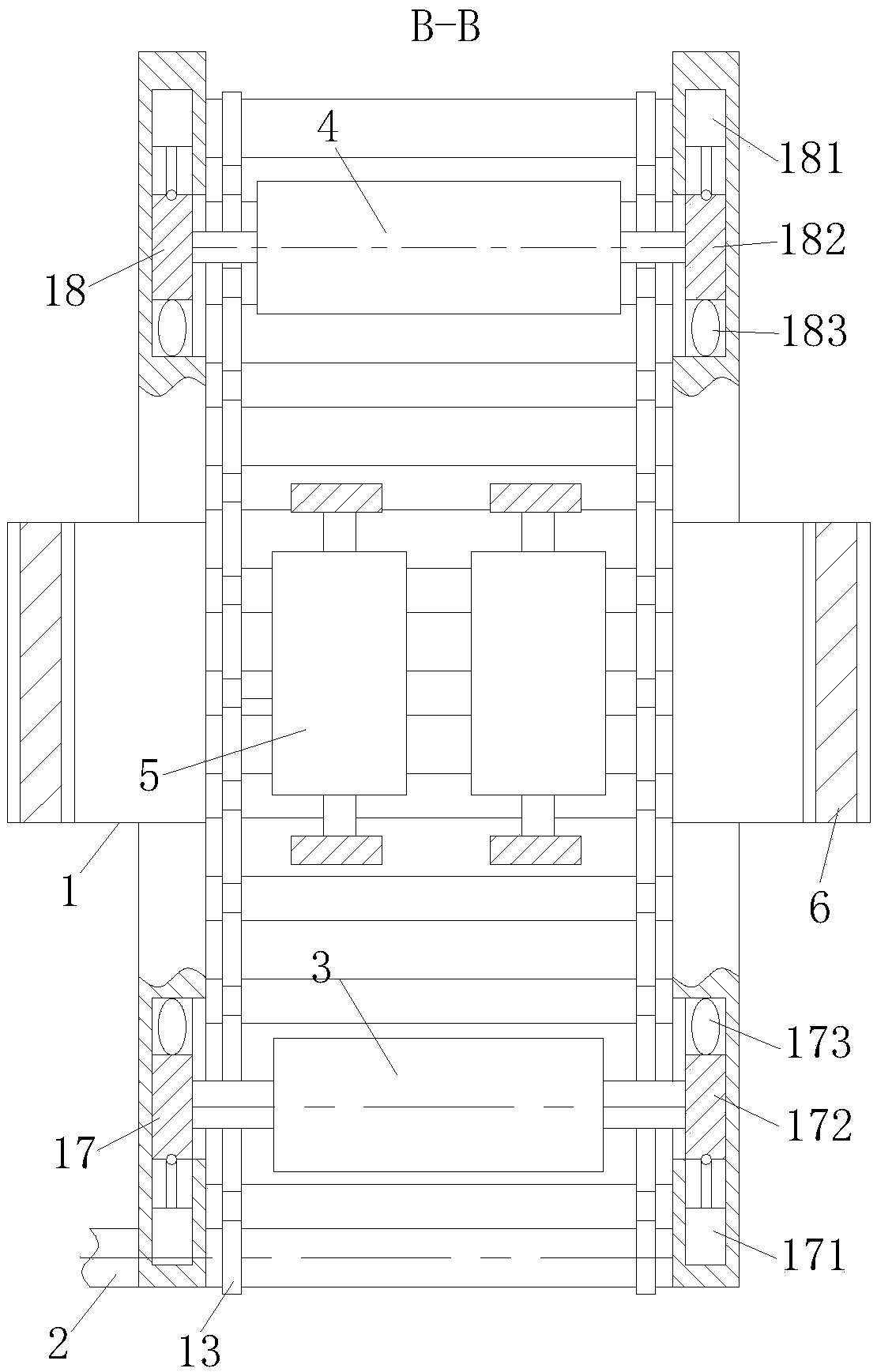

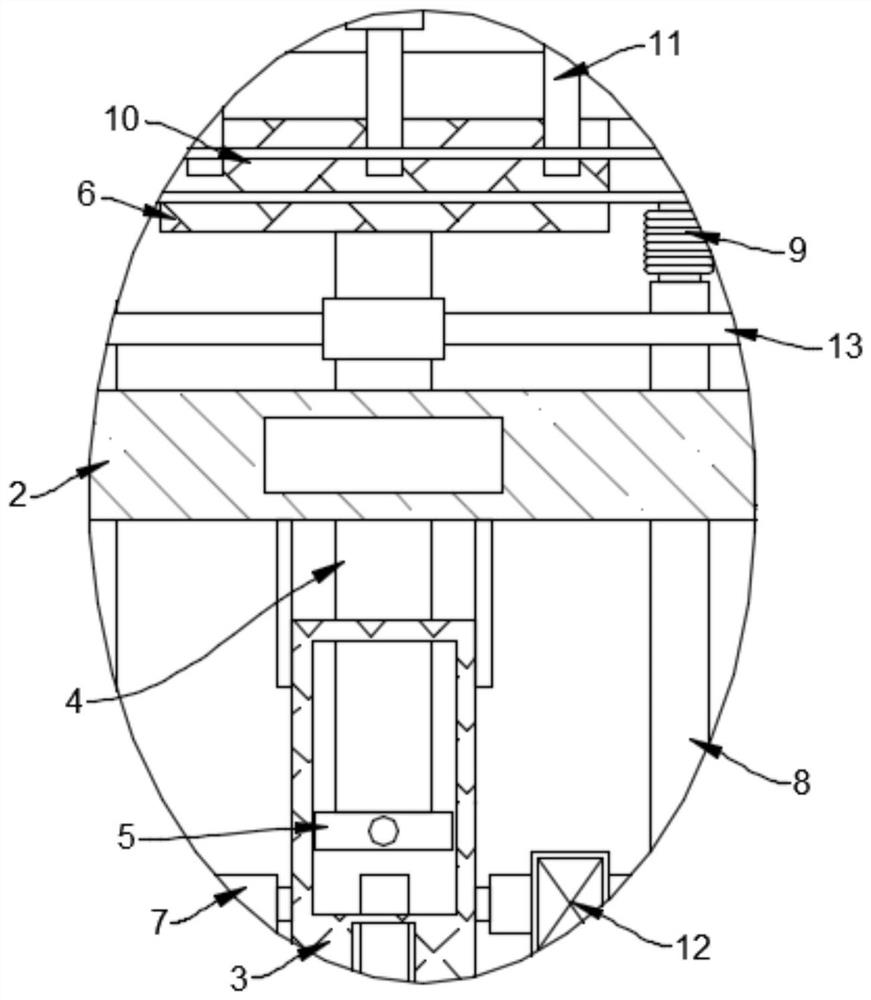

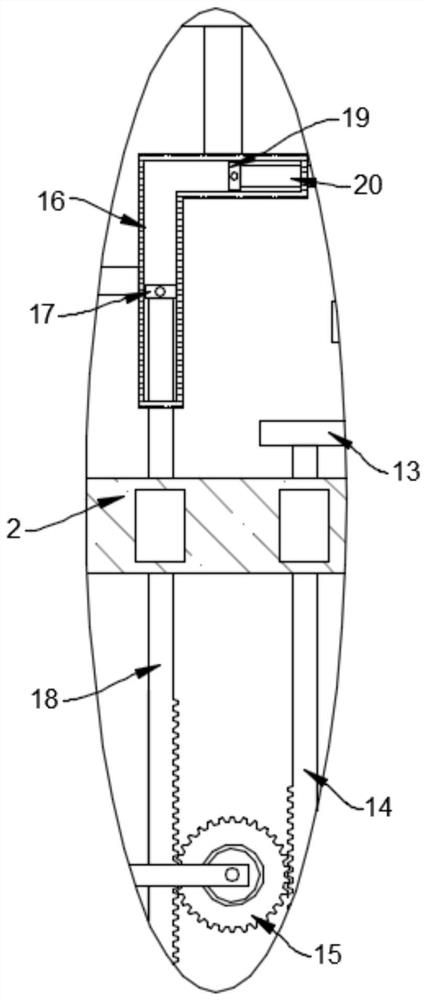

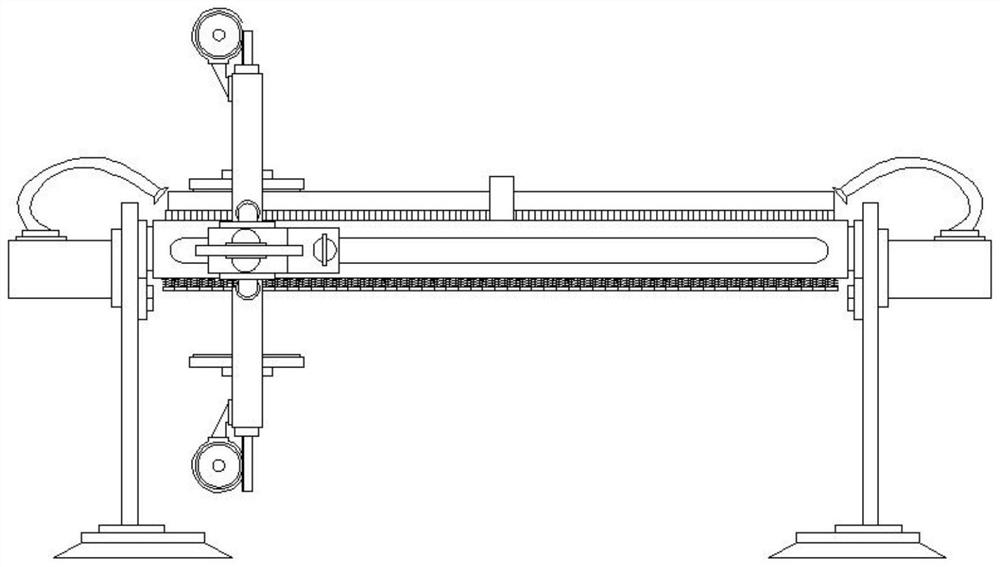

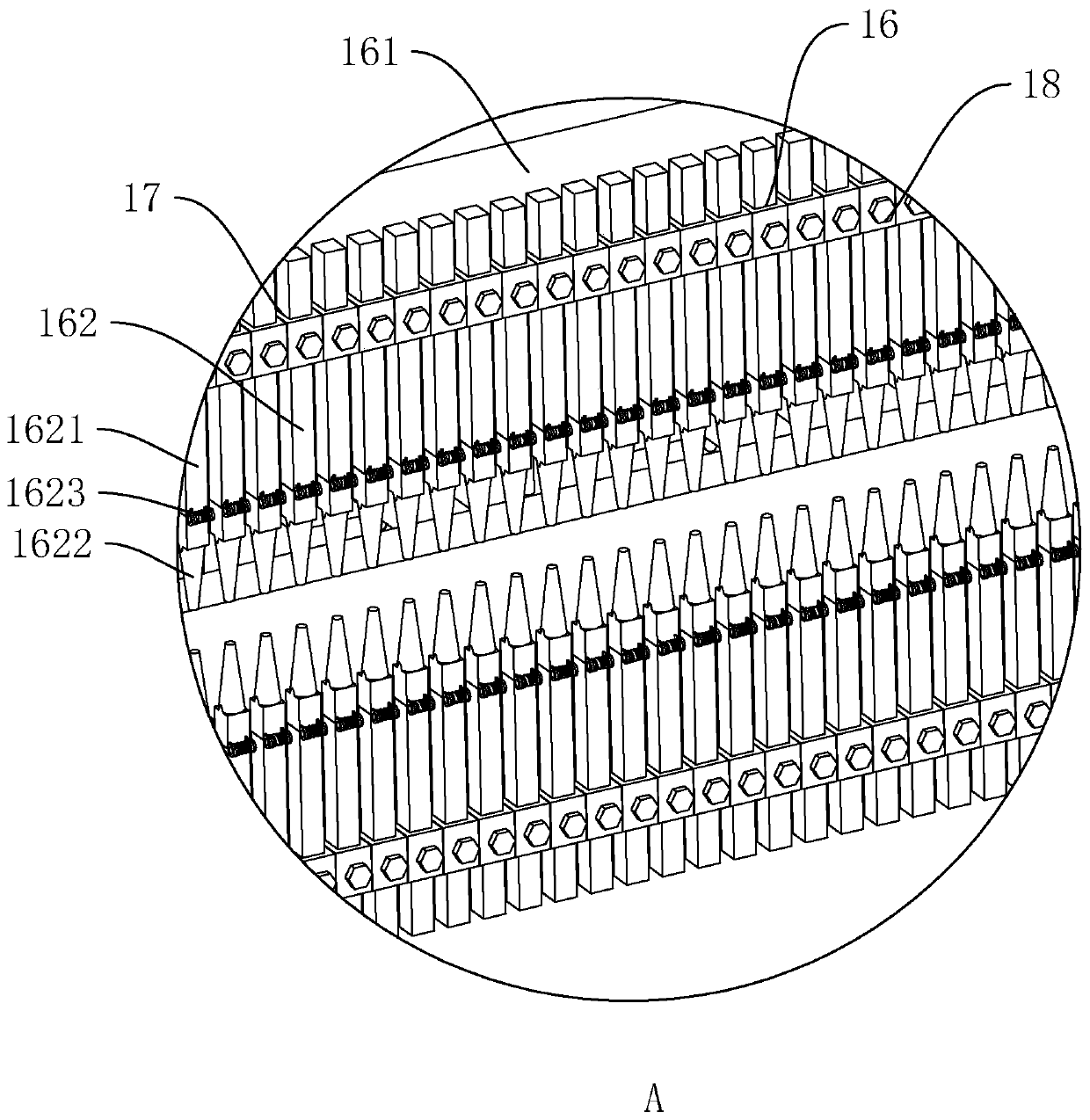

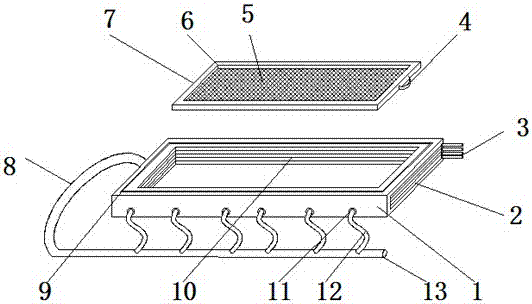

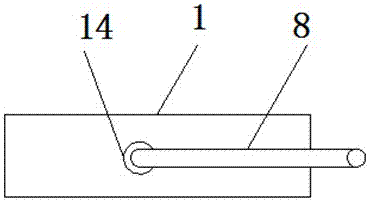

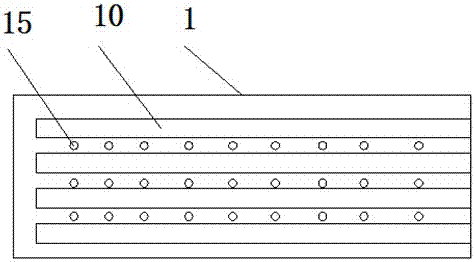

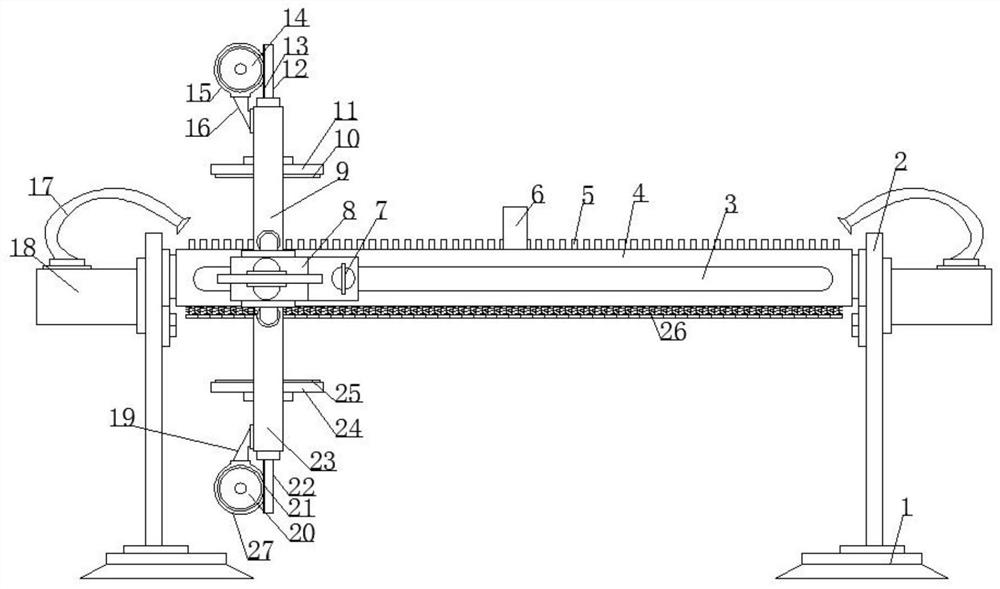

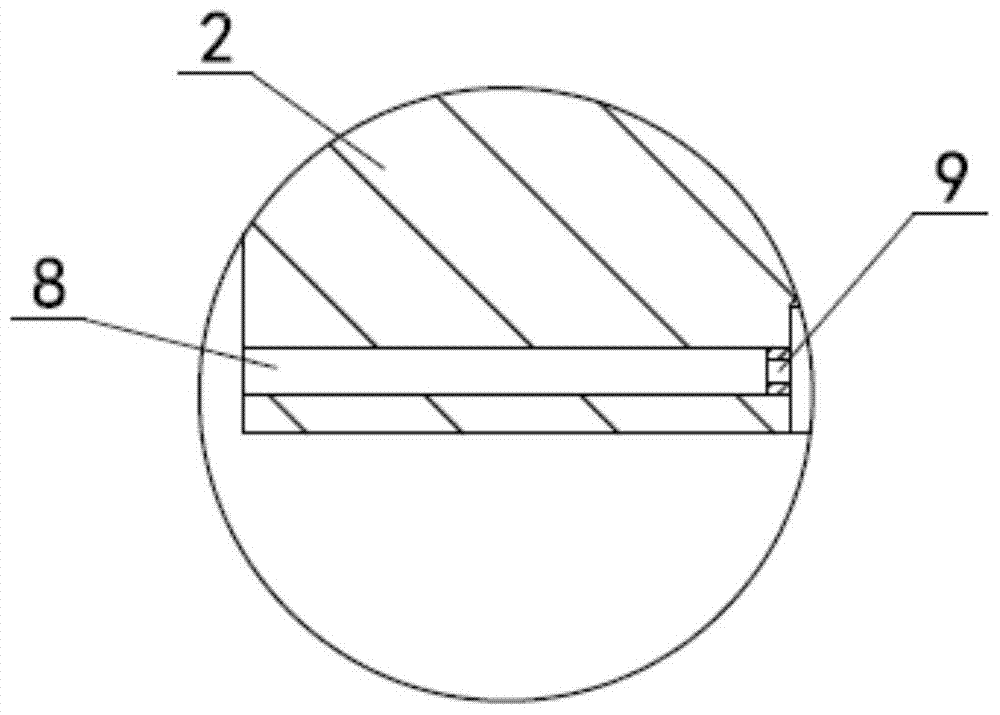

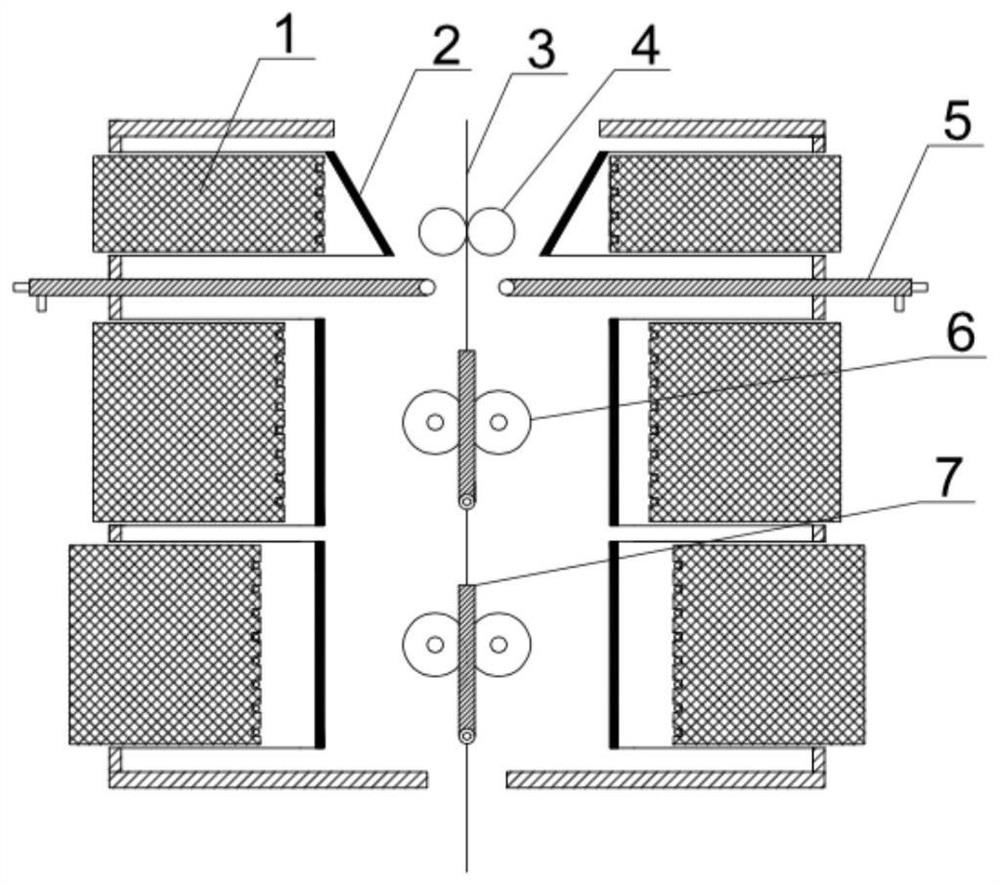

Plywood pre-pressing sizing device

PendingCN109176760AImprove delivery efficiencyHigh strengthPlywood pressesVeneer pressesGear wheelEngineering

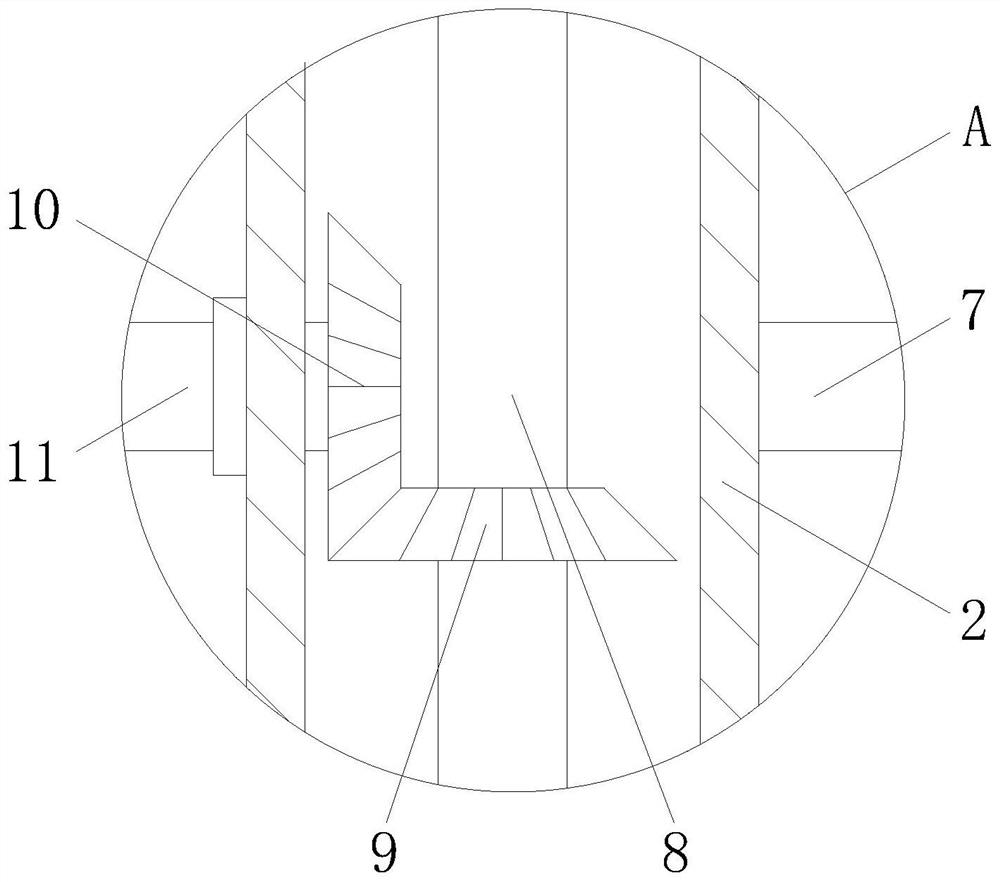

The invention belongs to the technical field of plywood processing, and particular discloses a plywood pre-pressing sizing device. The plywood pre-pressing sizing device comprises a machine frame, conveying rollers, a first pressing roller, a second pressing roller and two side pressing rollers. A set of conveying rollers are evenly arranged at the bottom of the machine frame. The two side pressing rollers are symmetrically disposed at the intermediate position of the upper portion of the machine frame, the first pressing roller is disposed on one side of the side pressing rollers, and the second pressing roller is disposed on the other side of the side pressing rollers. Limiting rods are disposed at the top of the machine frame. The limiting rods are provided with vertical first limitinggrooves, and power modules are disposed on the outer sides of the limiting rods. The power modules each comprise a motor, a first cylinder, a turntable and a connecting rod, and the two ends of each of the conveying rollers are separately sleeved with gears. First sliding units are disposed at both ends of the first pressing roller, and second sliding units are disposed at both ends of the secondpressing roller. According to the plywood pre-pressing sizing device, a method of pressing in sections is adopted, and the first and second sliding units are synchronously linked, so that the first pressing roller and the second pressing roller can rotate and press plywood in a reciprocating mode, and the pressing efficiency and the strength of the plywood are improved.

Owner:孙霞伢

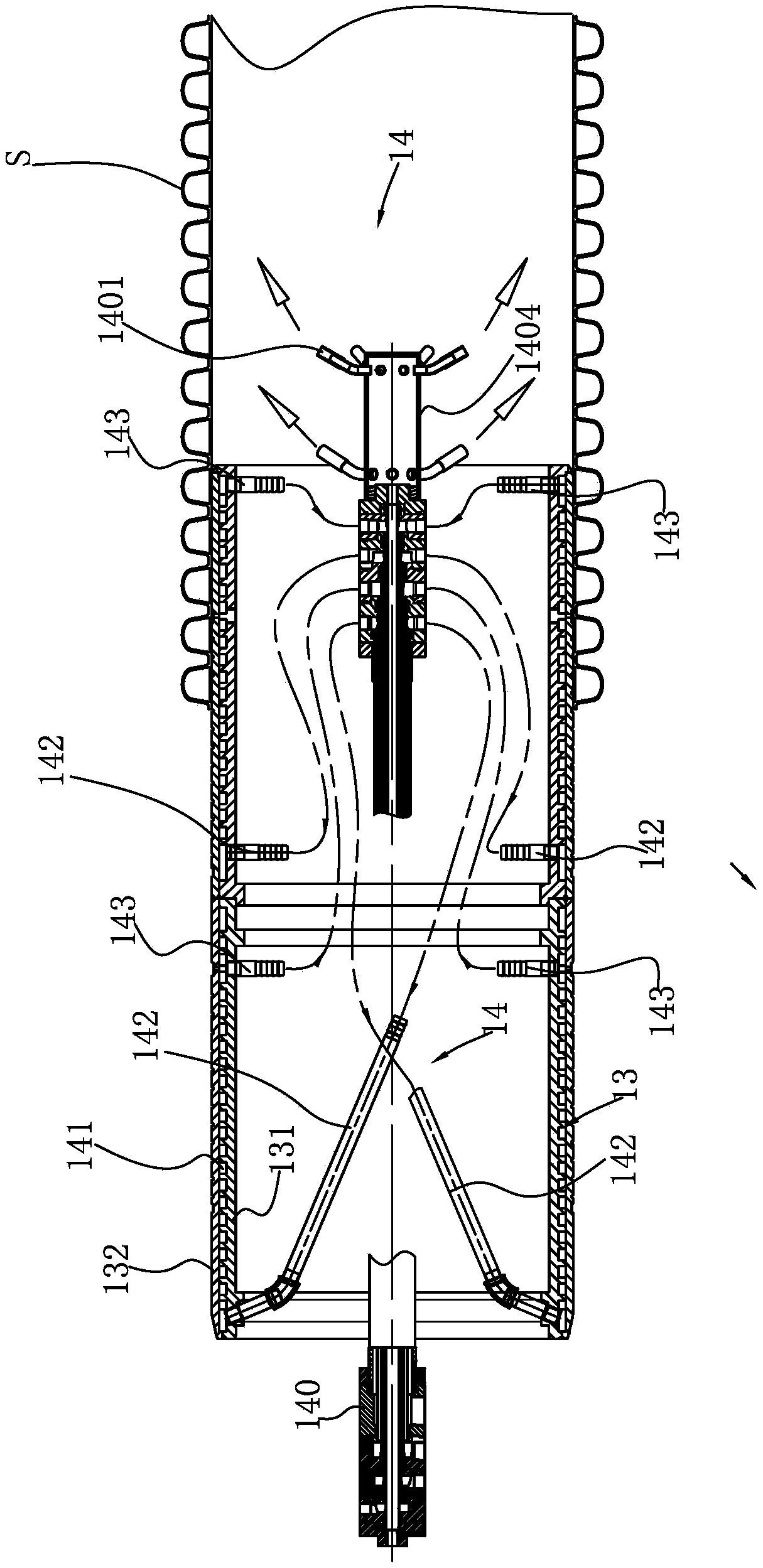

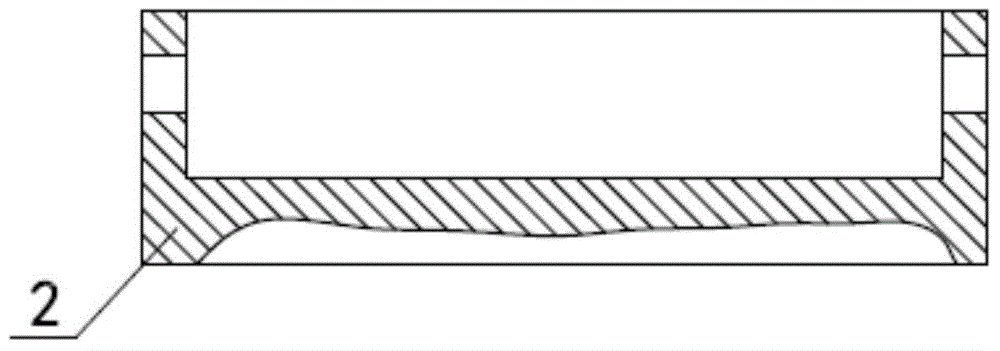

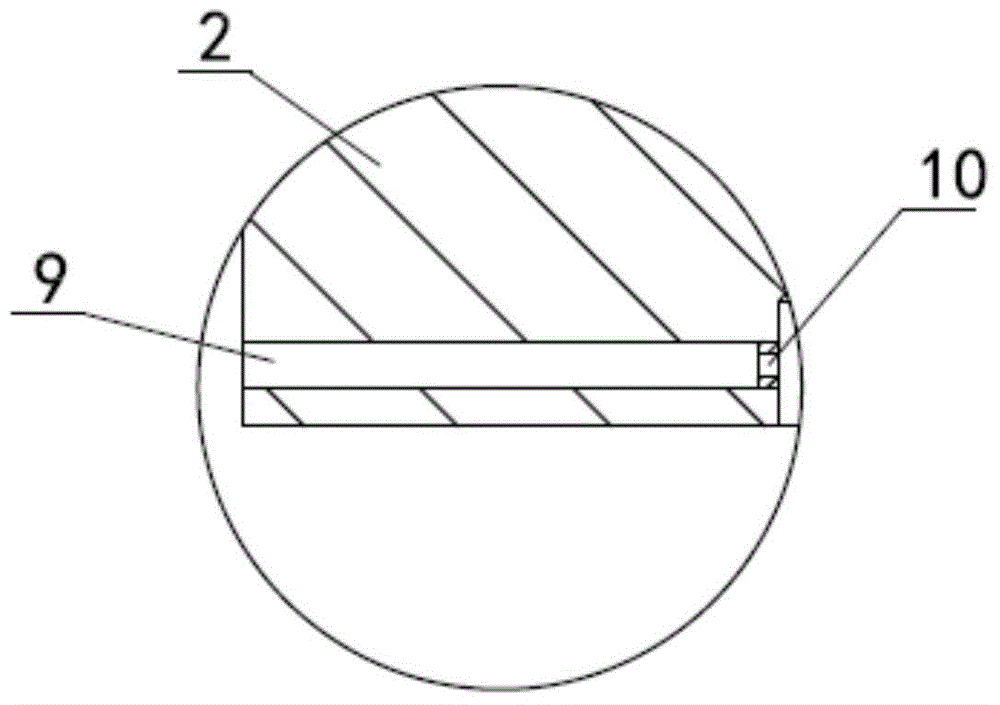

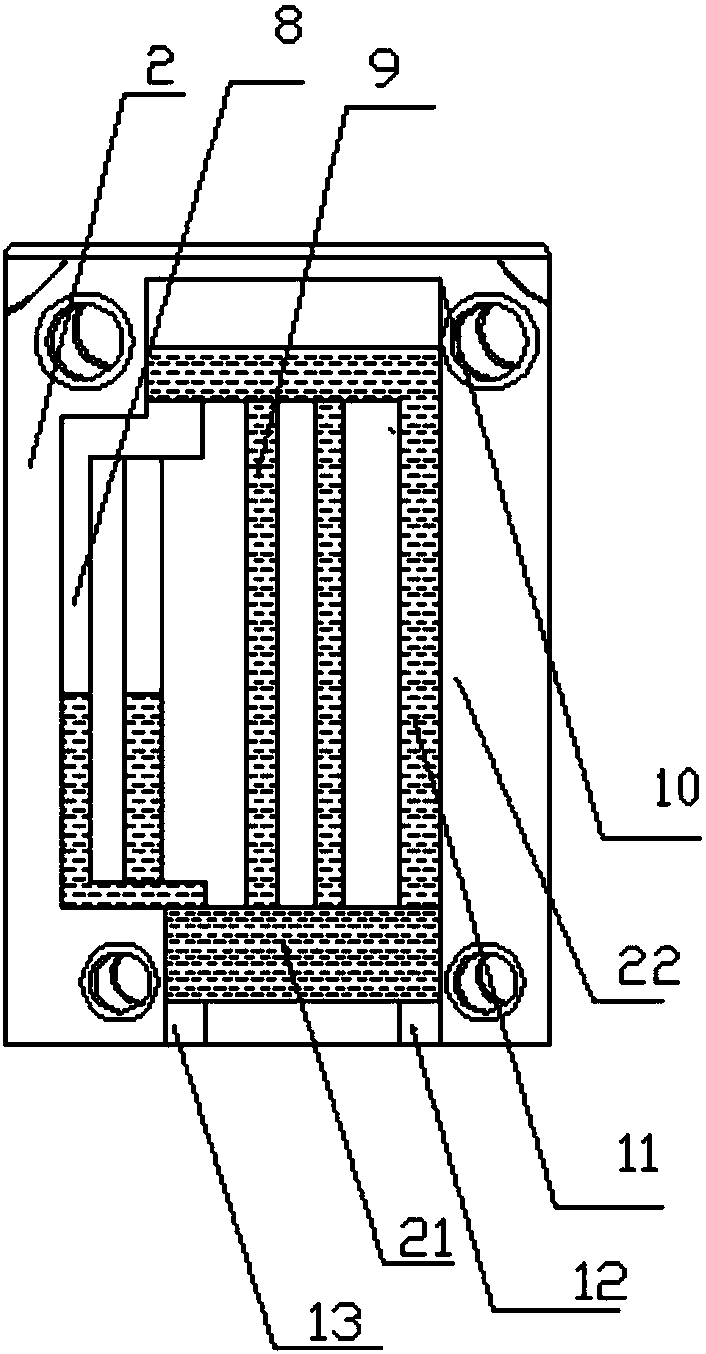

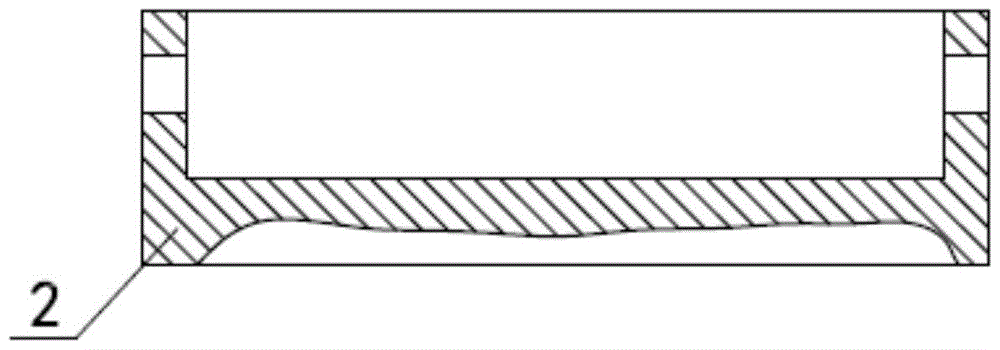

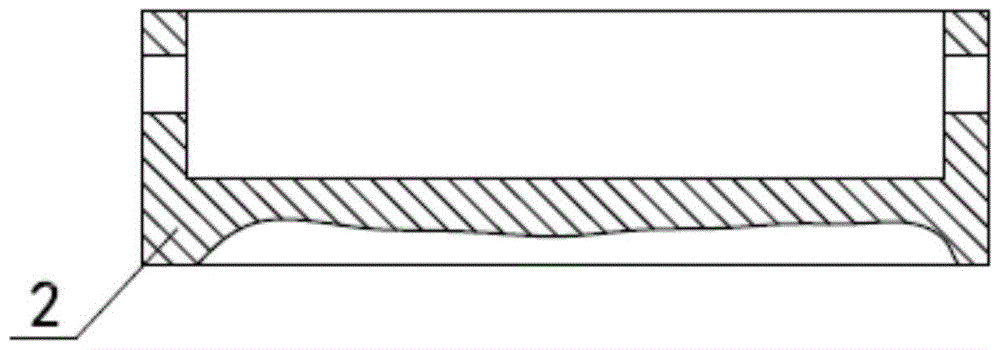

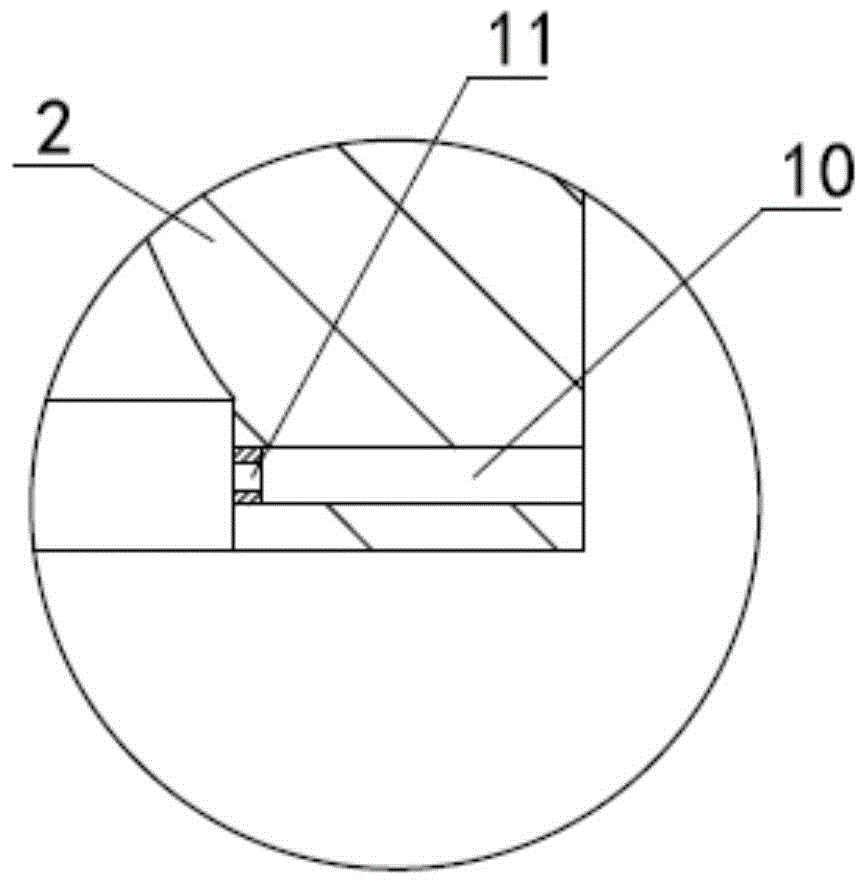

Cooling system for plastic corrugated pipe equipment

PendingCN109531956AImprove efficiencyAccelerated cooling and settingTubular articlesPipingAir channel

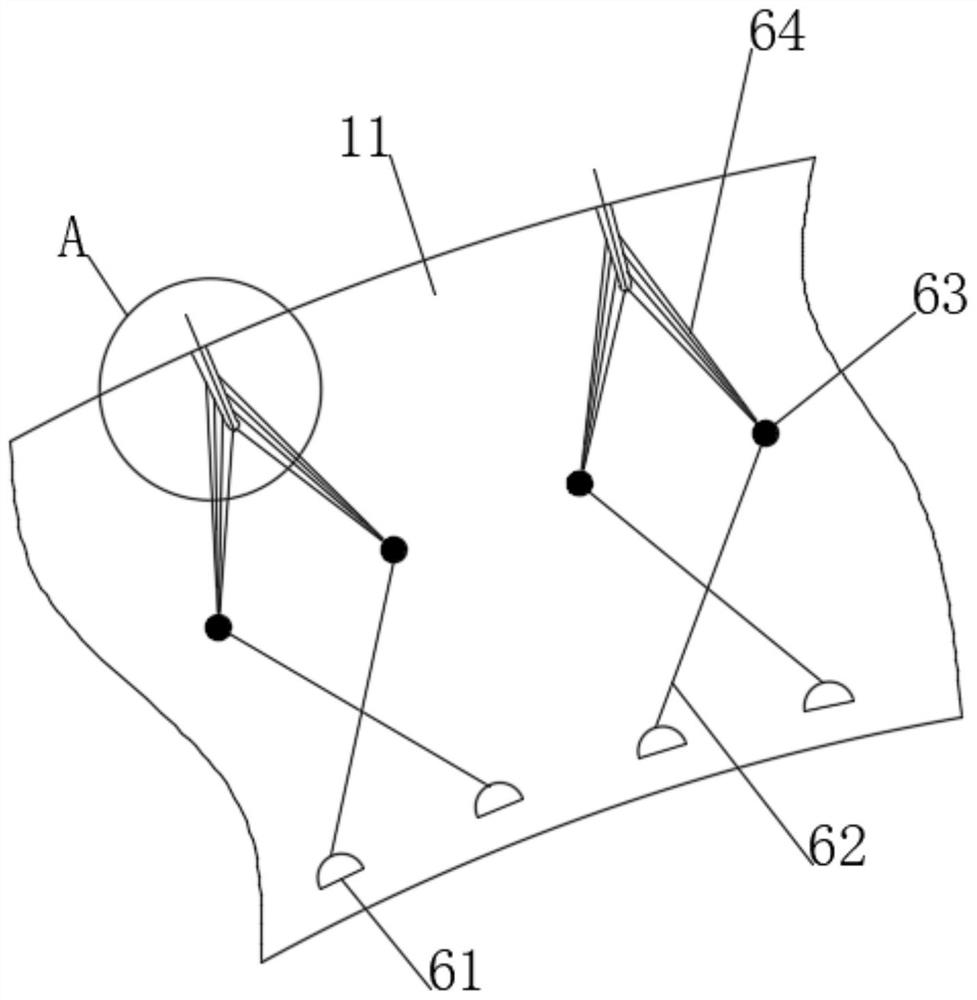

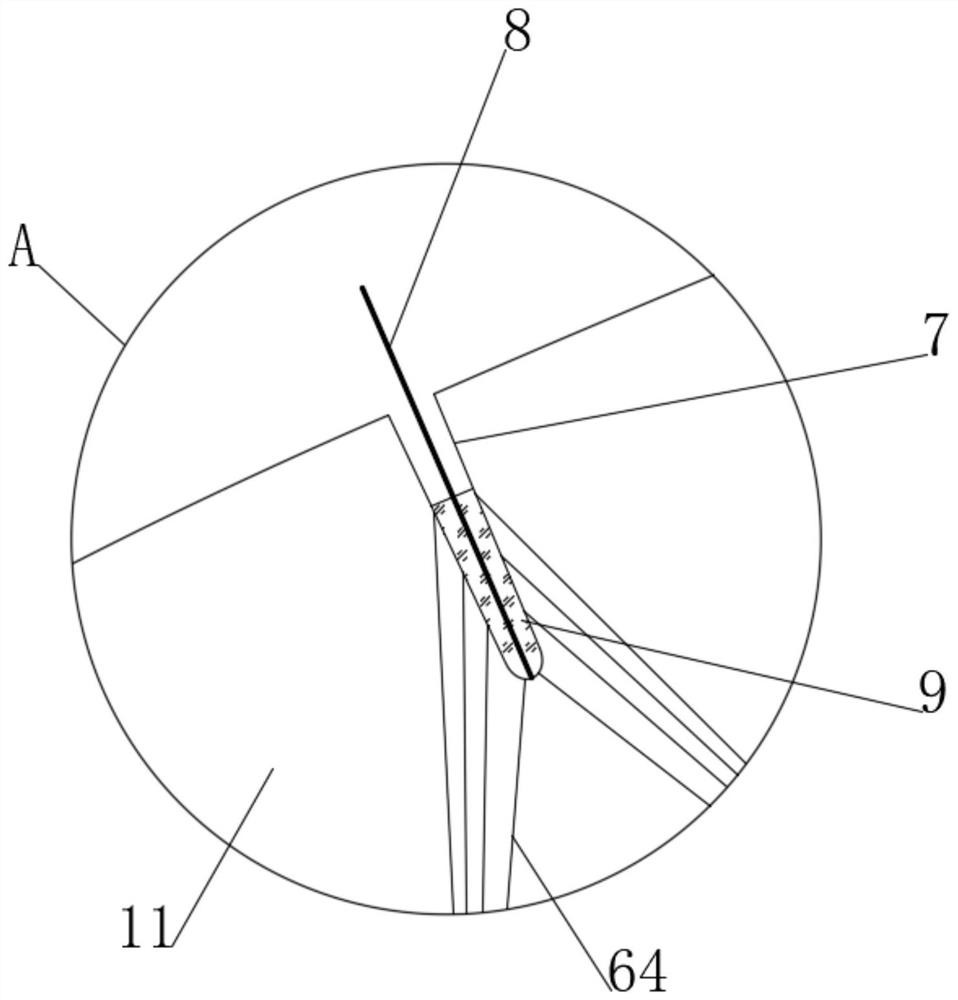

The invention discloses a cooling system for plastic corrugated pipe equipment. The cooling system for the plastic corrugated pipe equipment comprises a molding module cooling device which is arrangedon a molding module and a diameter fixing sleeve cooling device which is arranged on a diameter fixing sleeve, wherein the diameter fixing sleeve cooling device comprises a main pipeline assembly which is provided with a water channel and an air channel; the main pipeline assembly passes through an inner cavity of the diameter fixing sleeve in the axial direction; the inner part of the peripheralwall of the diameter fixing sleeve is provided with a diameter fixing sleeve cooling water channel; a plurality of diameter fixing sleeve water distribution pipe groups are connected between the diameter fixing sleeve cooling water channel and the main pipeline assembly; a plurality of air outlets which communicate with the air channel are formed in the tail end of the main pipeline assembly; andthe molding module cooling device comprises a molding module water cooling device and a molding module air cooling device. The inner wall and the outer wall of a corrugated pipe are cooled through the diameter fixing sleeve cooling device and the molding module cooling device, so that the inner wall and the outer wall of the corrugated pipe are quickly cooled, and the plastic corrugated pipe is further cooled through a corrugated pipe secondary air cooling device, so that the plastic corrugated pipe is quickly cooled, subsequent cutting is convenient to carry out, and the production efficiency of the plastic corrugated pipe is improved.

Owner:潍坊中云科研有限公司

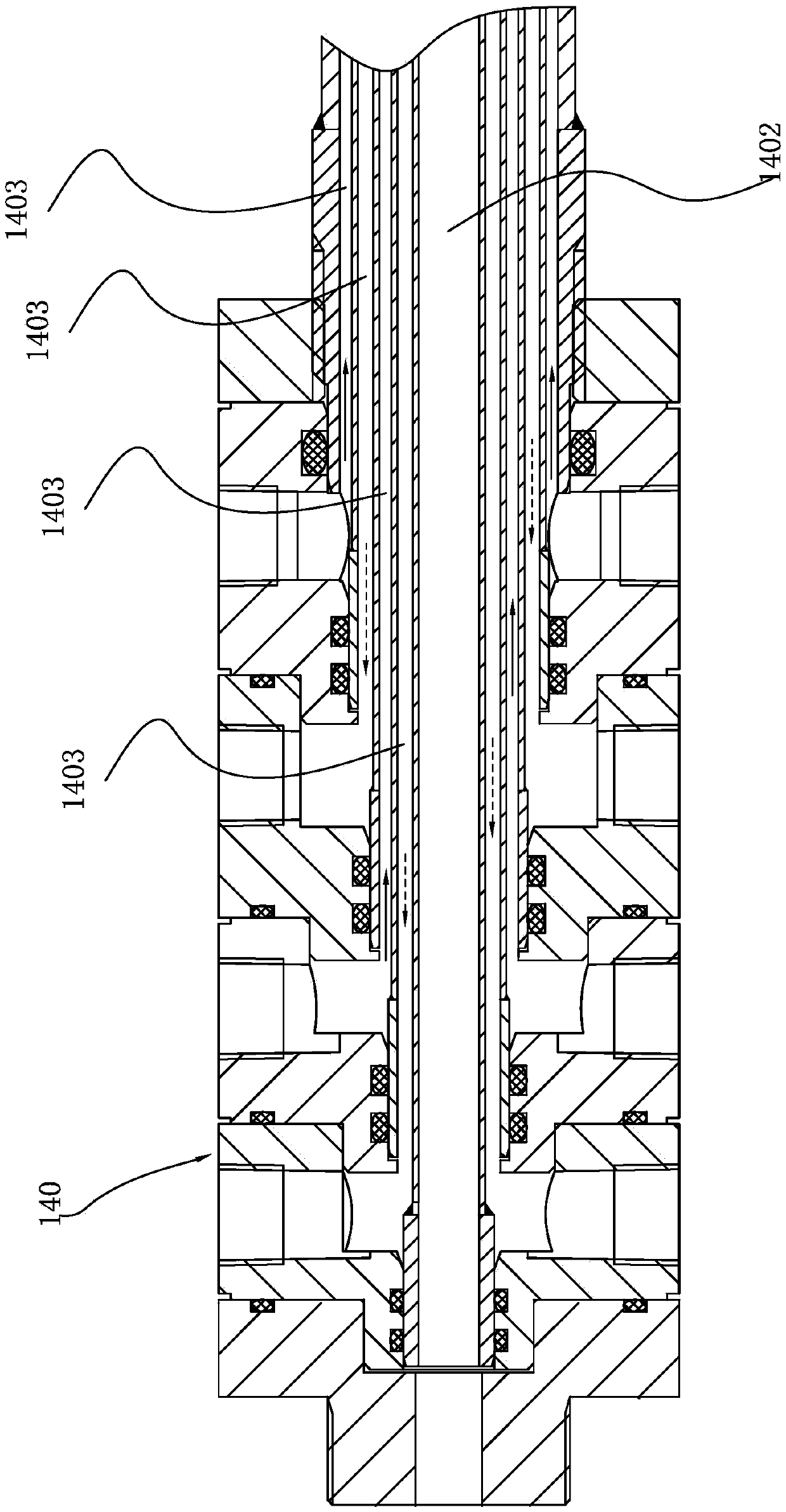

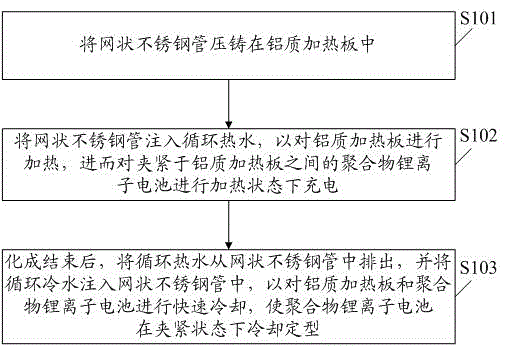

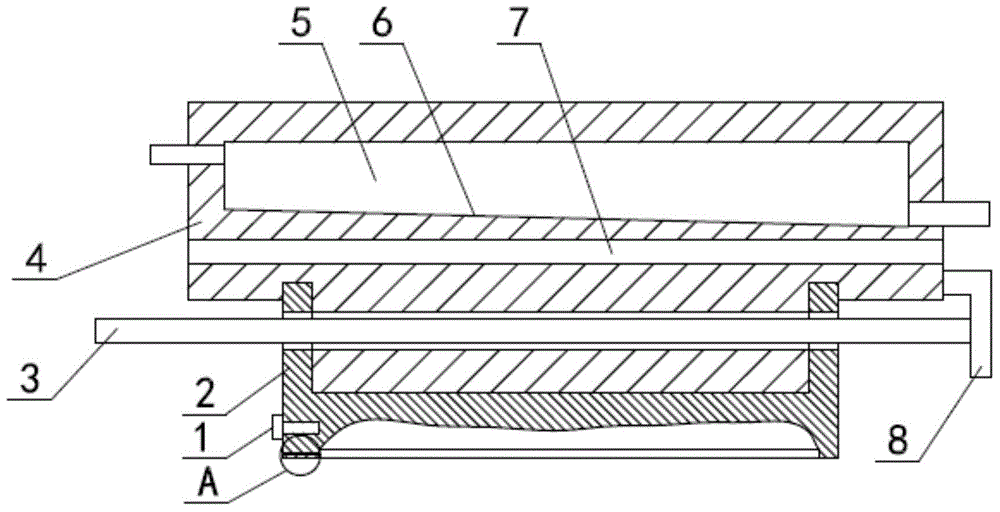

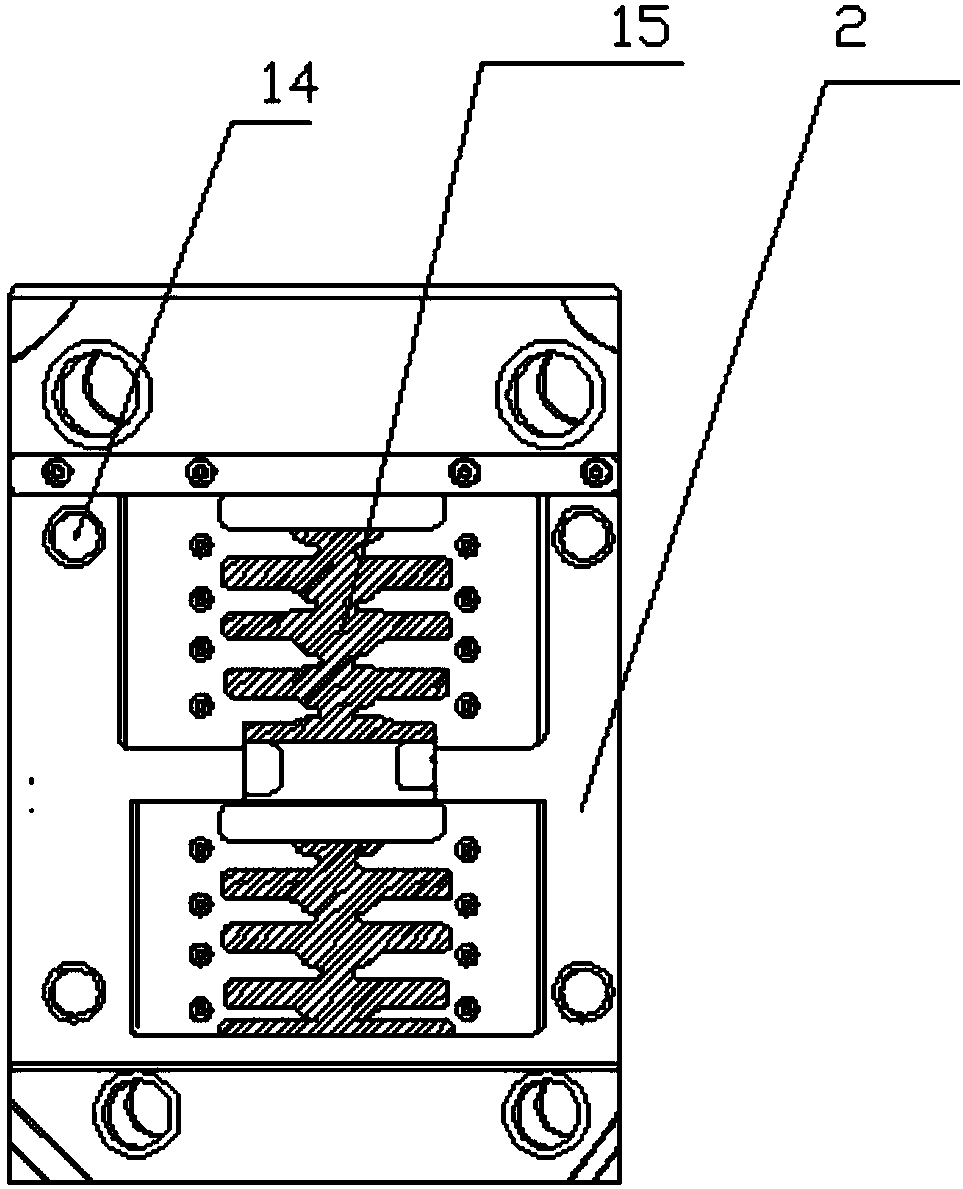

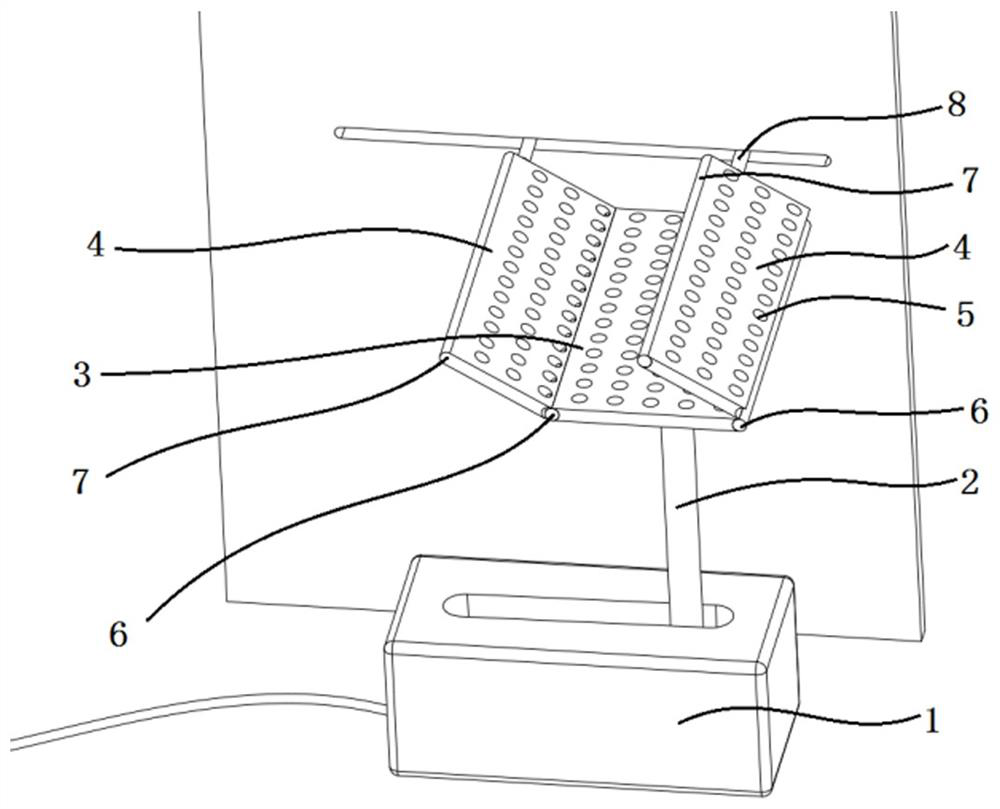

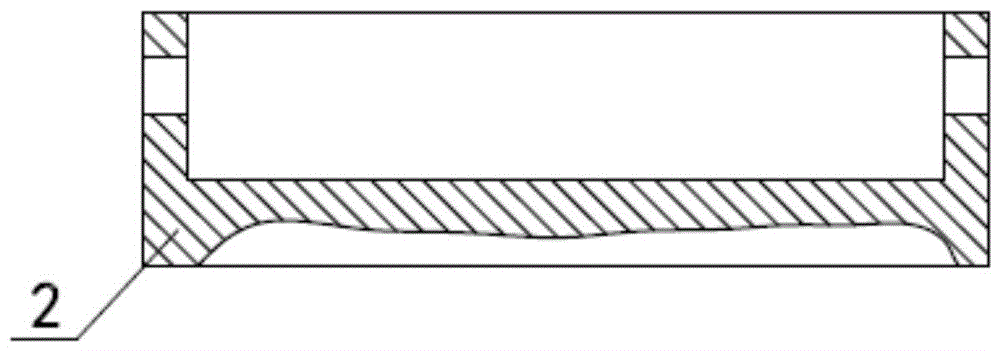

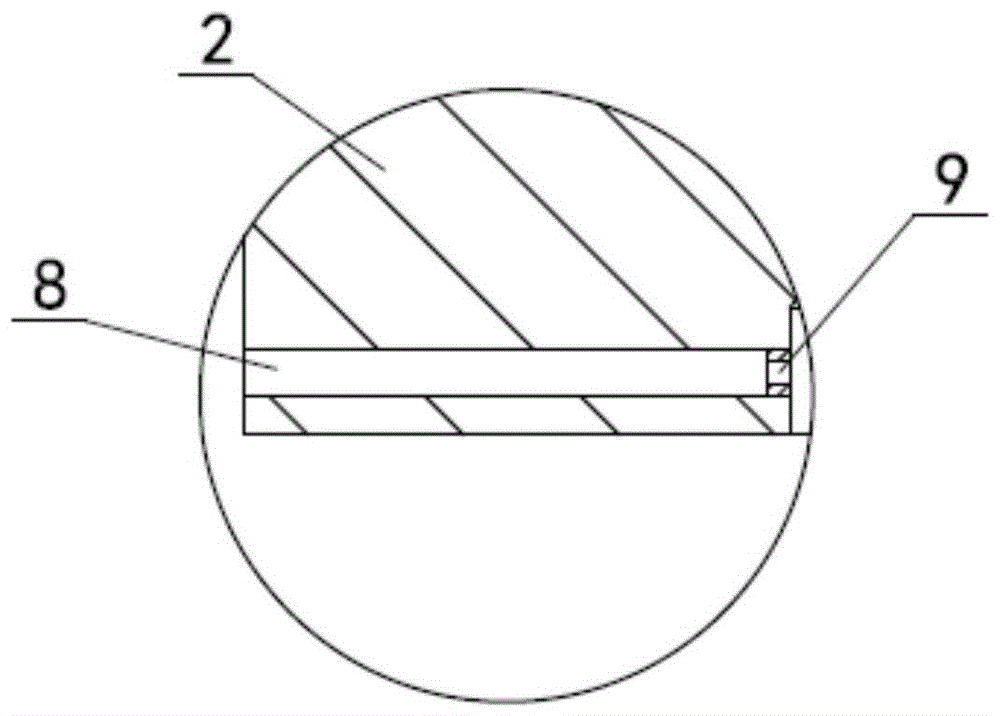

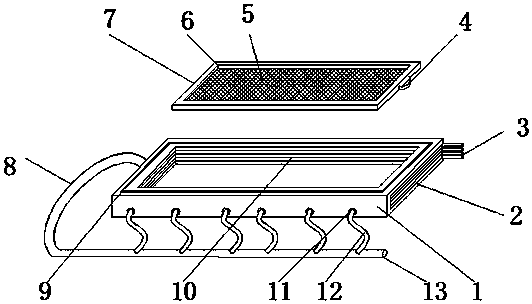

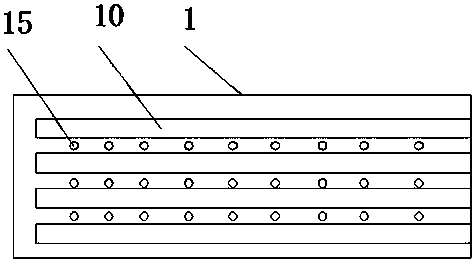

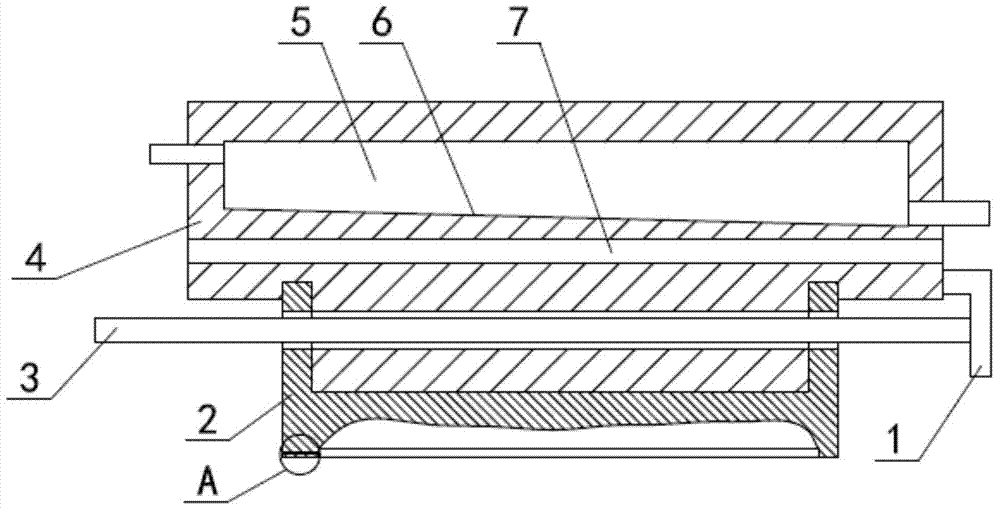

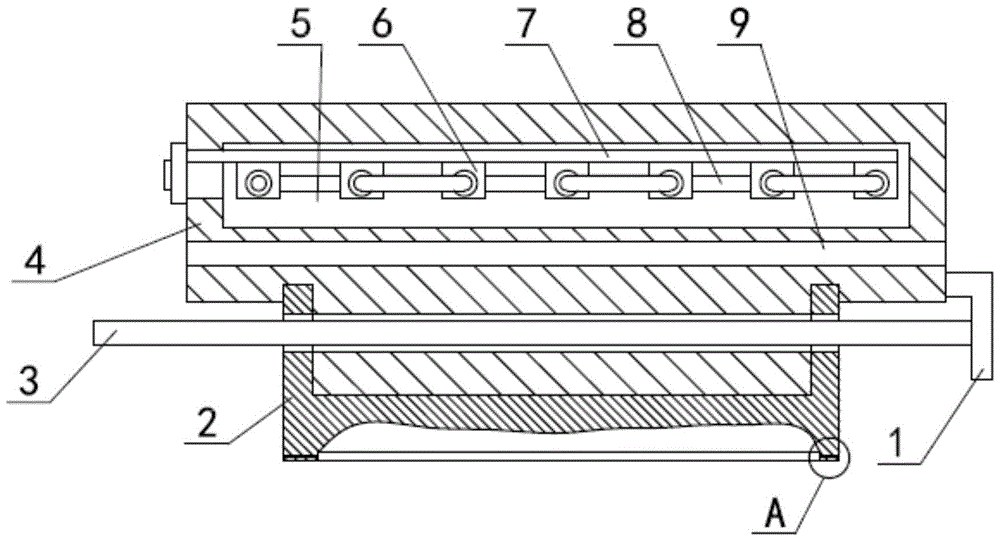

Heating method of polymer lithium ion battery high-temperature fixture formation equipment

InactiveCN105206877AEvenly heatedFast heatingCell electrodesFinal product manufacturePressure castingMetallurgy

A heating method of polymer lithium ion battery high-temperature fixture formation equipment comprises the following steps: casting reticulation electrothermal tubes or reticulation stainless steel tubes respectively under pressure in two aluminum heating plates; electrifying the reticulation electrothermal tubes or injecting circulating hot water into the reticulation stainless steel tubes, so as to heat the aluminum heating plates, and further charging a polymer lithium ion battery tightly clamped between the aluminum heating plates when the battery is being heated. Therefore, the reticulation electrothermal tubes or the reticulation stainless steel tubes are cast into the aluminum heating plates under pressure through heating of aluminum ingots for melting, pressure casting and integral formation; when the reticulation electrothermal tubes are electrified or circulating hot water is injected into the reticulation stainless steel tubes, the aluminum heating plates are heated, and both surfaces of each aluminum heating plate radiate heat uniformly, so that the upper and lower aluminum heating plates can be used for charging the polymer lithium ion battery tightly clamped between the aluminum heating plates when the polymer lithium ion battery is in a heated state, both sides of the battery are heated uniformly, temperature rise is fast, the capacity of a formed battery plays a role sufficiently, and the battery is thinner, even in surface, and beautiful.

Owner:杨国乐

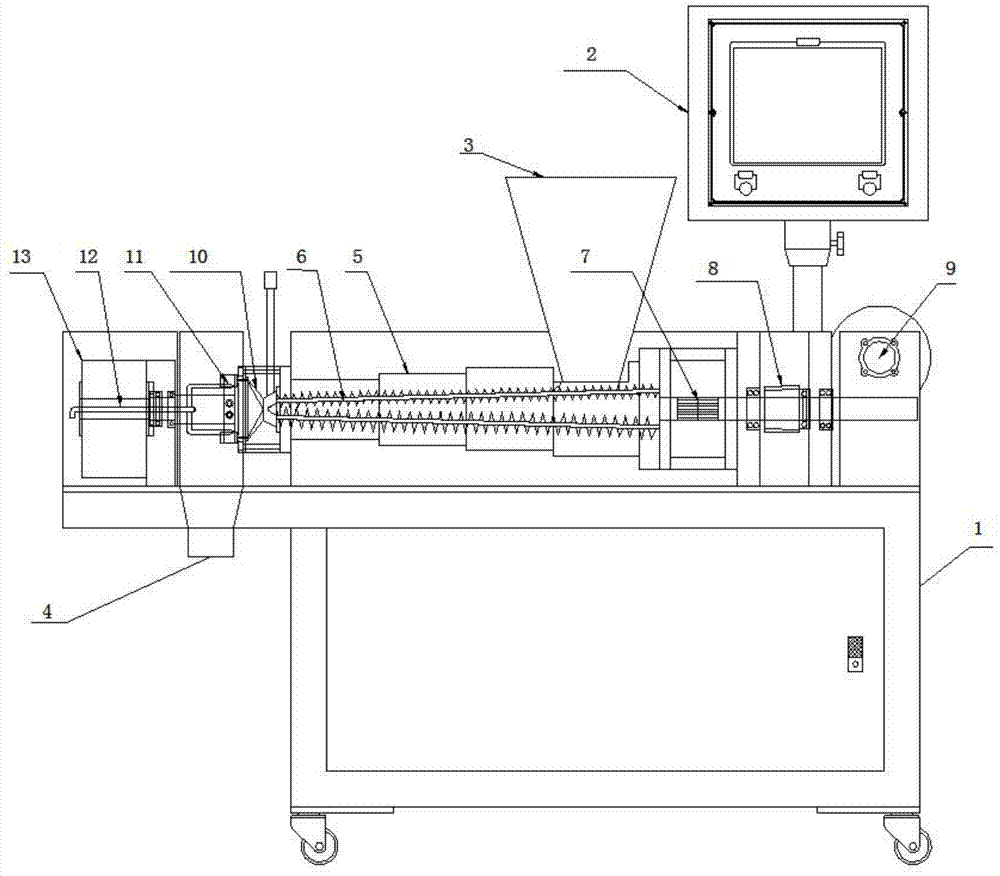

Double-screw pelletizer based on inorganic powder

The invention discloses a double-screw pelletizer based on inorganic powder. The double-screw pelletizer comprises a machine body, an operation panel, a double-screw material squeezing device and a particle cutting device, wherein the operation panel is fixed on one side of the position above the machine body, the double-screw material squeezing device is located in the middle of the machine body, and the particle cutting device is located on the other side of the machine body; the double-screw material squeezing device is composed of a material chamber, double screws, a motor and a double-shaft distribution gear box; the double screws are horizontally arranged in the material chamber, and the double-shaft distribution gear box is connected with the motor and the double screws; when the double-screw pelletizer works, the double screws rotate to squeeze materials out of the material chamber so that the materials can make contact with a particle cutter rotating rapidly, the mixed materials are cut into particles through the particle cutter, and meanwhile processing is completed after cooling and shaping are conducted. The double-screw pelletizer has the advantages of being high in particle cutting speed, high in efficiency and the like.

Owner:PINGXIANG GREENLONG IND

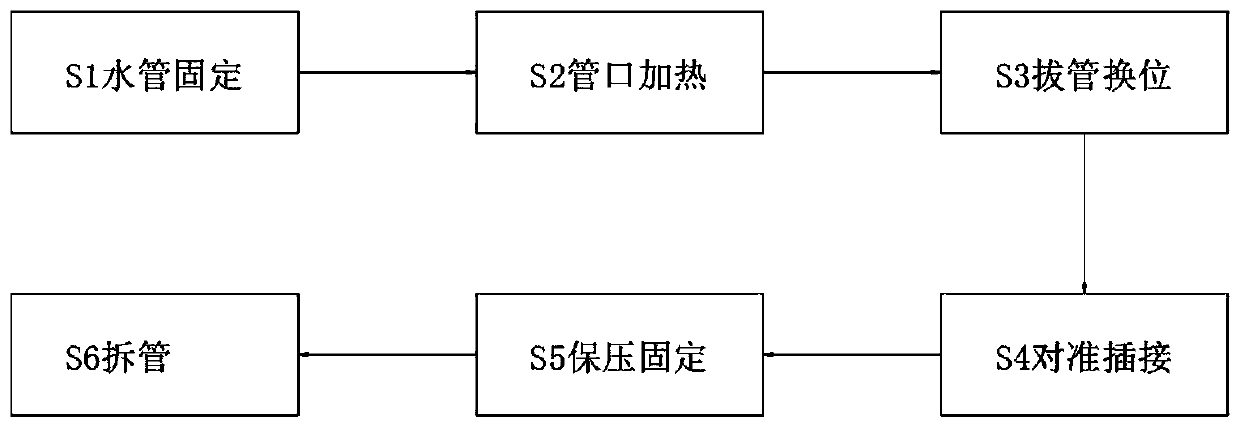

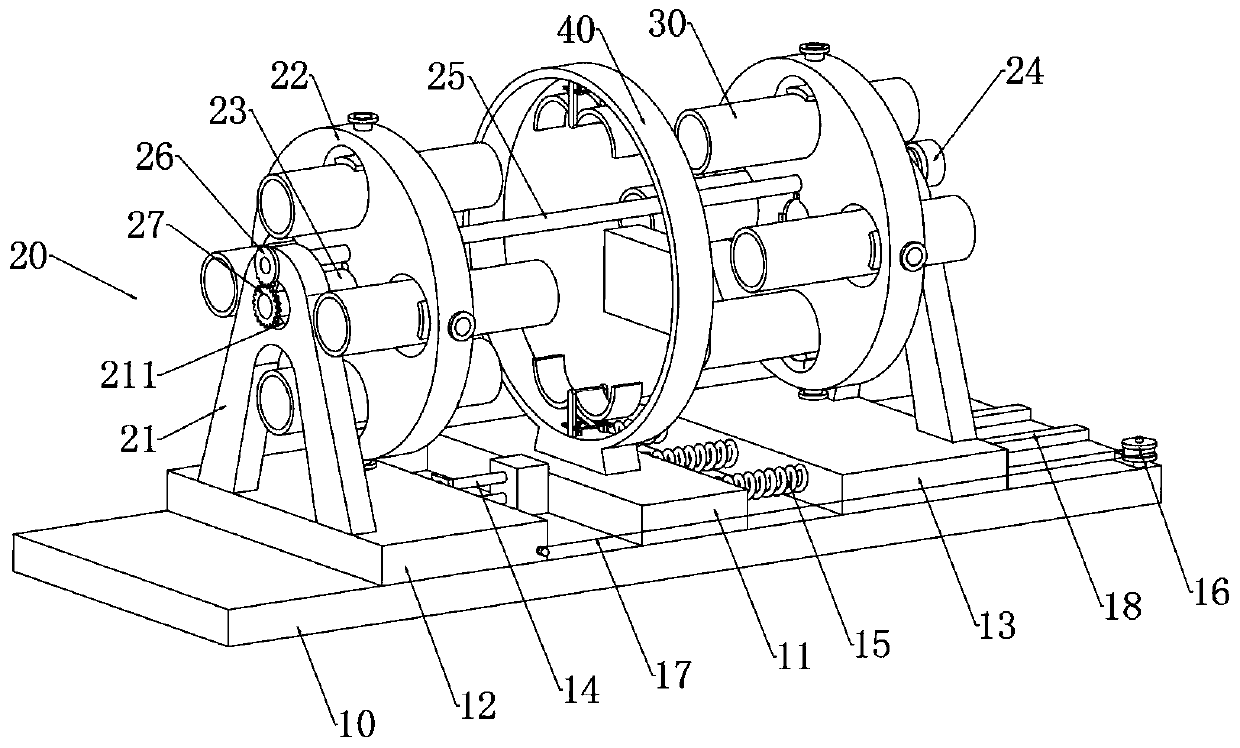

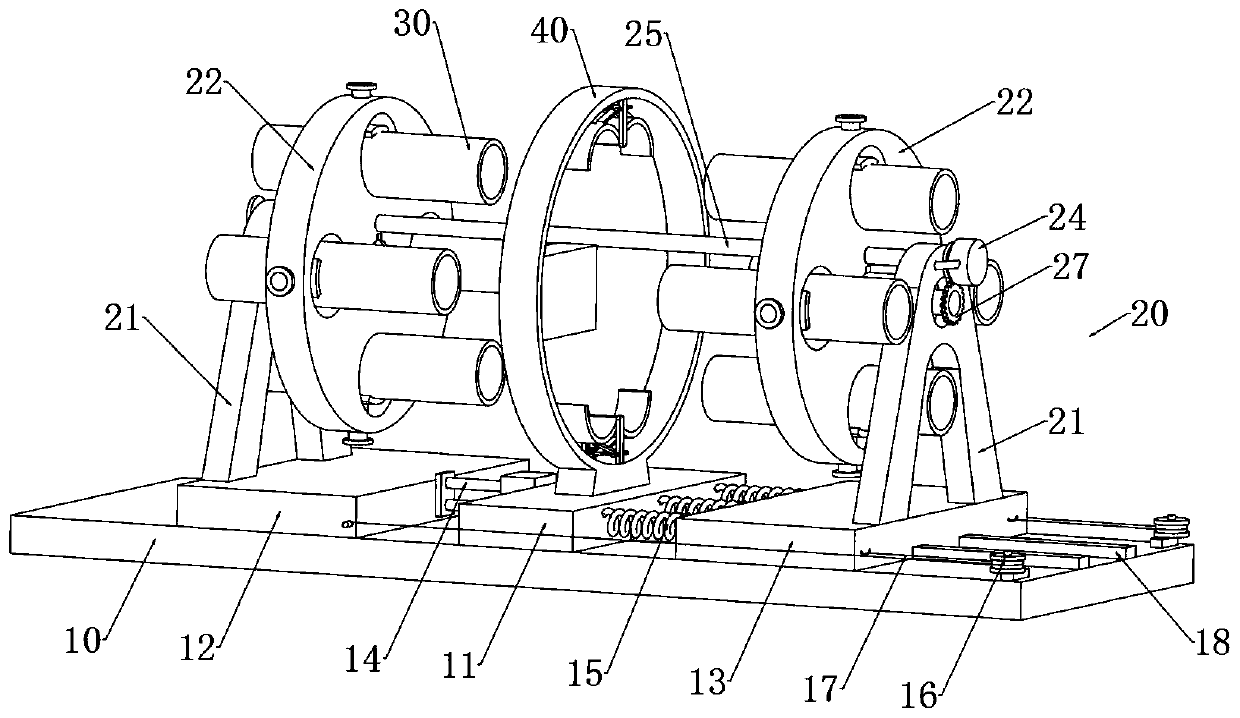

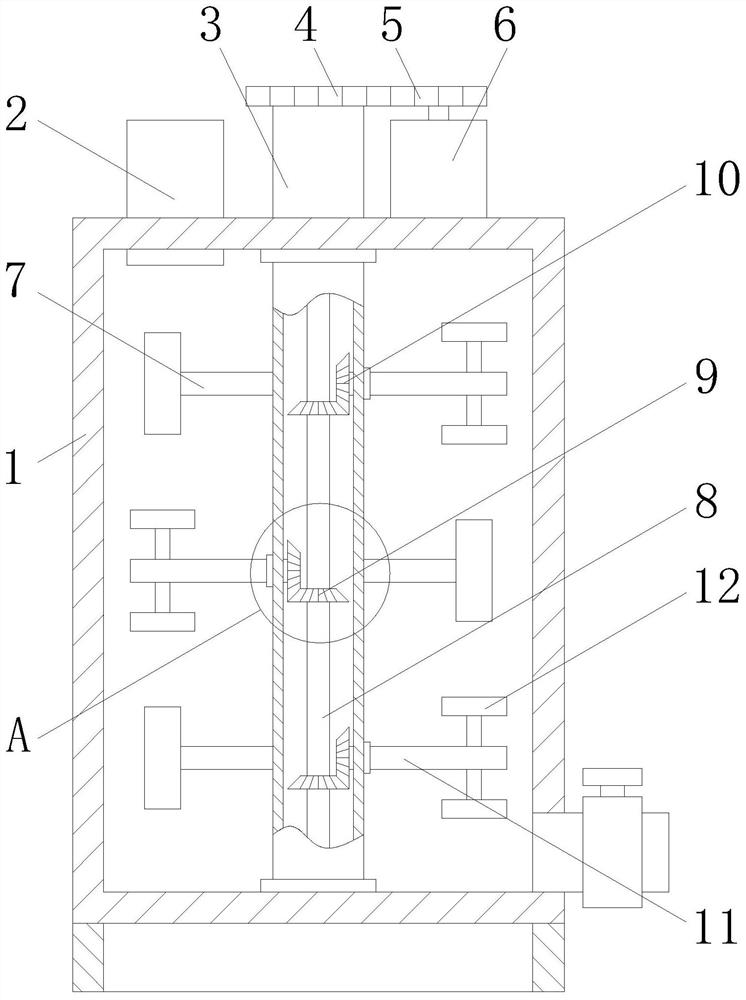

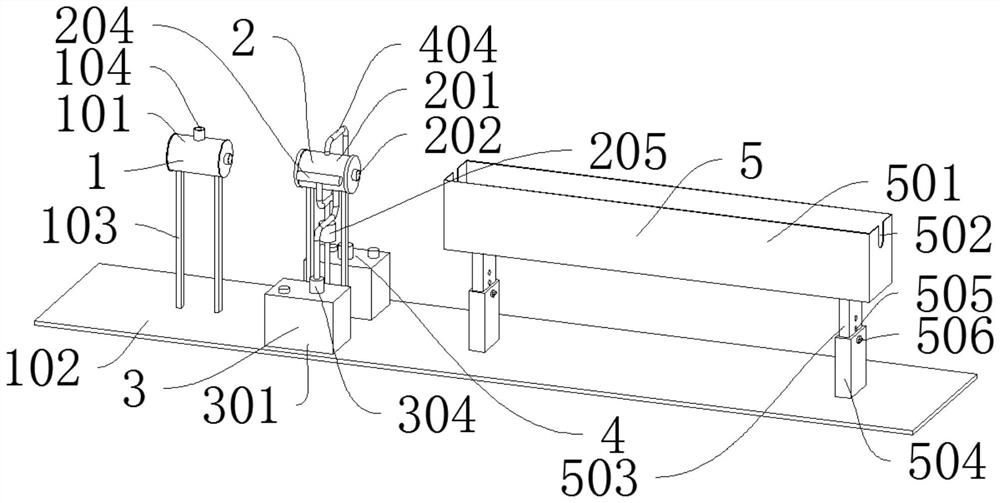

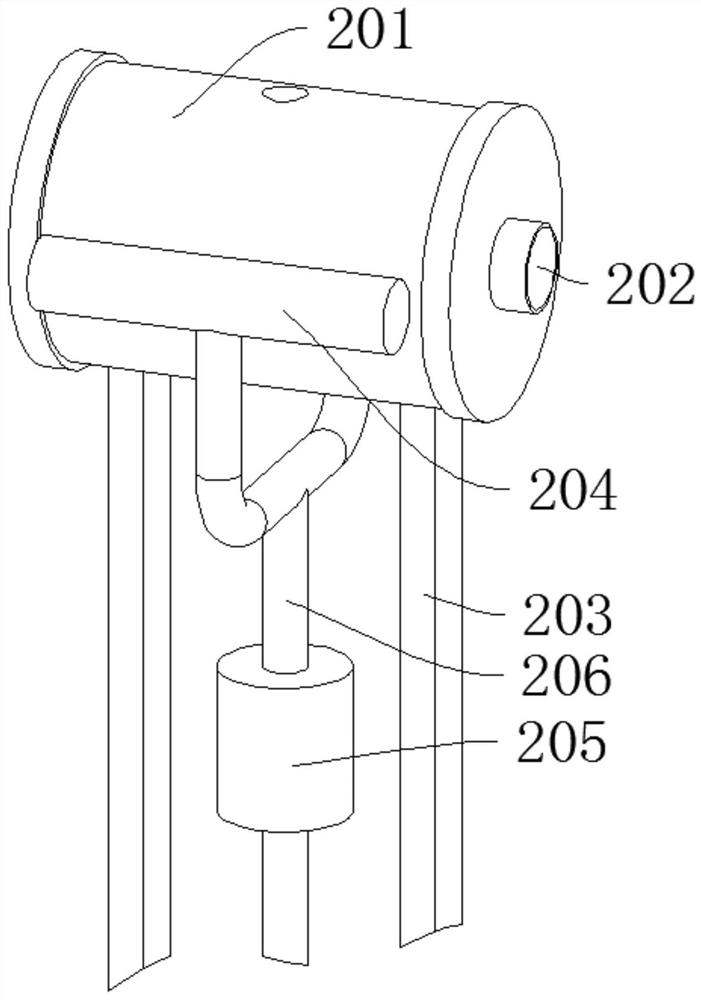

Hot melting connection processing technology for PPR water pipes

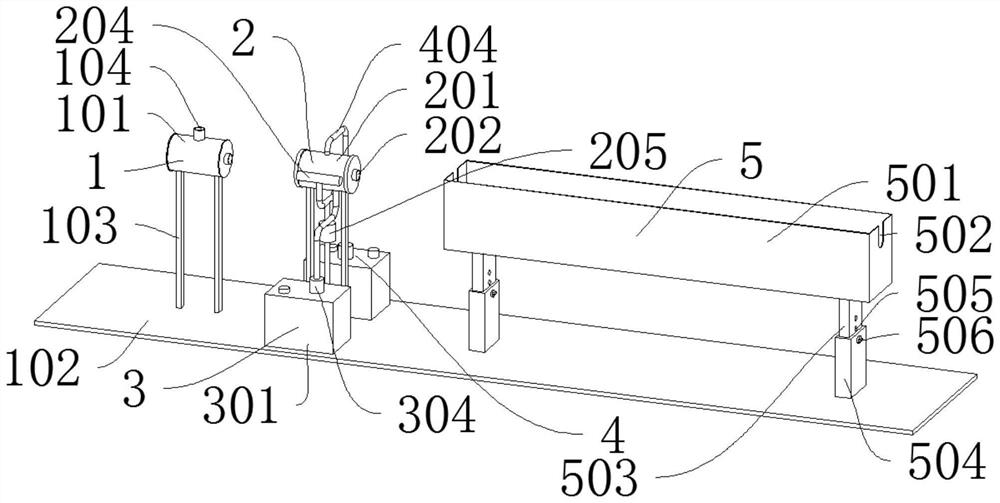

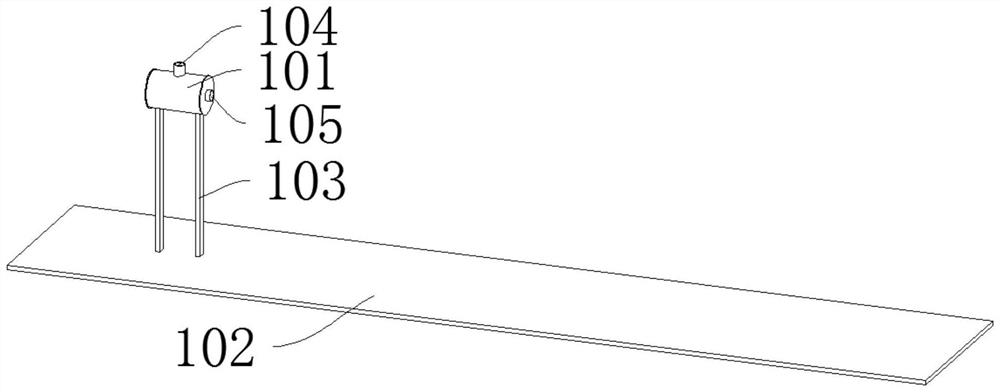

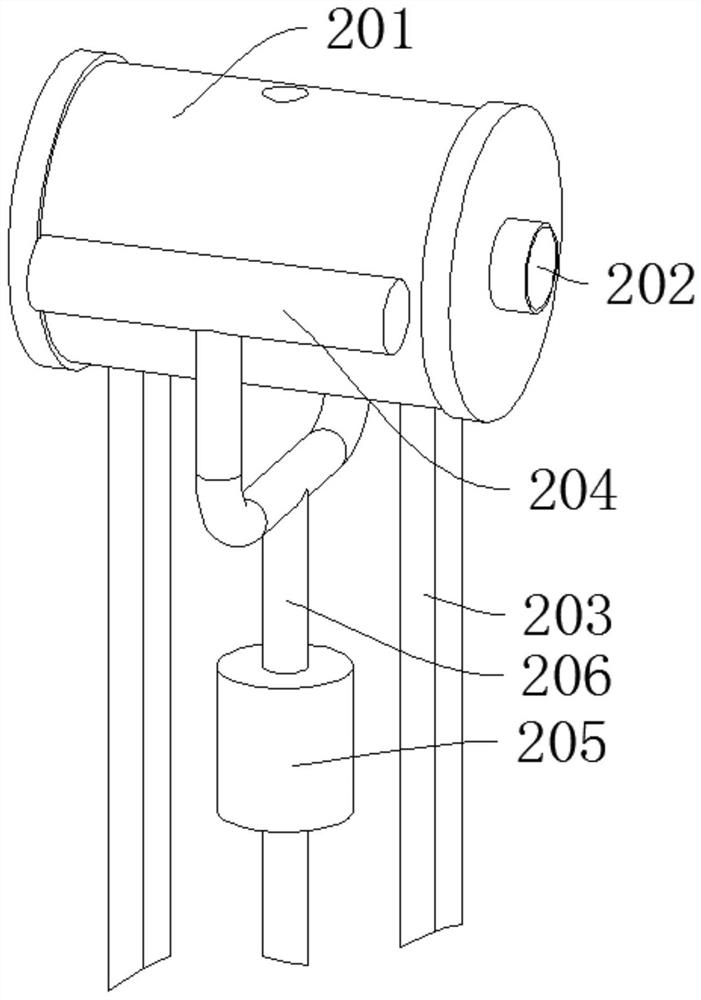

The invention relates to a hot melting connection processing technology for PPR water pipes. The hot melting connection processing technology for the PPR water pipes adopts a following hot melting connection machine, the hot melting connection machine comprises a bottom plate and fixing devices arranged at the top of the bottom plate, wherein the PPR water pipes are fixed to the fixing devices, and a melting connection device is arranged in the middle of the top of the bottom plate. By cooperation of an air cylinder and fixed pulleys, the air cylinder drives two rotating discs to be synchronously close to each other or away from each other, the pipes are fixed in the rotating discs and can move with the same distance simultaneously, a rotating shaft is utilized for driving two incomplete gears to rotate, so that the two rotating discs simultaneously rotate for the same angle, the skewed condition of the pipes during aligned inserting connection is avoided, and the error is smaller as compared with that of manual operation; and the joints of the pipes are subjected to pressure-maintaining fixation by arc-shaped plates, cooling shaping of the pipes are accelerated, furthermore, the shaking or moving condition of the pipes is avoided, and the two pipes can be subjected to hot melting and pressure-maintaining fixation simultaneously respectively by arrangement of multiple stations.

Owner:台州蓝锐机电科技有限公司

Manufacturing and processing technology of antibacterial plastic airplane meal box

InactiveCN112810036AReduces cases of poor antimicrobial efficacyImprove uniformityDomestic articlesDrive wheelElectric machinery

The invention discloses a manufacturing and processing technology of an antibacterial plastic airplane meal box. The technology comprises the following step that A, raw materials are mixed, wherein an antibacterial agent is added into the plastic particle raw materials, and then stirring is carried out by using a stirring device, so that the antibacterial agent and plastic particles are uniformly mixed. The stirring device comprises a stirring tank, a stirring mechanism is arranged inside the stirring tank, and the stirring mechanism is composed of a feeding pipe, a supporting pipe, a driven wheel, a driving wheel, a stirring motor, a plurality of first stirring blades, a supporting rod, a plurality of first bevel gears, a plurality of second bevel gears, a plurality of rotating shafts and a plurality of second stirring blades. According to the manufacturing and processing technology, the rotation of the driven wheel can drive the supporting pipe and the first stirring blades to rotate, and the rotation of the supporting pipe drives the rotating shafts and the second stirring blades to rotate through the second bevel gear and the first bevel gear, so that the stirring mechanism can stir the materials in the stirring tank in multiple directions, and the stirring uniformity of the materials can be improved.

Owner:苏州德文塑业有限公司

Rounding method for cable sheath

PendingCN112743801AGuaranteed rounding requirementsSave waterDomestic articlesStructural engineeringElectrical and Electronics engineering

The invention discloses a rounding method for a cable sheath. The method comprises the steps that a cable passes through a cylindrical box at a certain speed, the surface of the sheath is tightly attached to a circular shaping sleeve through the vacuum setting in the cylindrical box, and the roundness of the surface of the sheath is ensured; through the spraying arrangement in the cylindrical box, cooling and shaping of the sheath are accelerated, and the rounding requirement of the sheath in the moving process is met; and through the arrangement of suction backflow of the cylindrical box, vacuum suction force is resisted, water liquid backflow recycling is guaranteed, and water resources are saved.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Auxiliary device for welding of large ironware

InactiveCN112676745AAvoid high temperatureAccelerated cooling and settingWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention discloses an auxiliary device for welding of large ironware. The auxiliary device comprises a side frame, a truss is horizontally welded to the side frame, and a water cooling assembly and a limiting assembly are respectively arranged on the truss. According to the auxiliary device, a collector filled with cooling liquid is arranged below the truss, the collector is used for providing movable support for a bearing rod and a bearing table, a rotating transmission gear is used for being in engaged connection with a driving rack and a driven rack, the driven rack and a driving piston move upwards, and a limiting clamping plate is further promoted to horizontally move so as to clamp and limit a to-be-welded object; and the collector slidably provided with the bearing rod and a high-pressure piston in a sleeving mode is arranged, a cooling sleeve is mounted through a discharging pipe and a backflow pipe, thus the cooling liquid in the collector enters the cooling sleeve under the action of heavy pressure, it is ensured that the heated cooling liquid can directionally flow in the collector and the cooling sleeve, thus the periphery of the to-be-welded object is subjected to low-temperature conduction, the circumstance that the to-be-welded object is in a high-temperature state overall is avoided, and cooling shaping of the welding position of the to-be-welded object can also be accelerated.

Owner:马则力克

Injection molding process of metal piece for radar

InactiveCN106216684AImprove anti-corrosion performanceGuaranteed firmnessTransportation and packagingMetal-working apparatusWater vaporAdhesive

The invention discloses an injection molding process of a metal piece for a radar. The injection molding process of the metal piece for the radar is characterized in that metal powder used in a step (1) is rolled steel pelleting powder containing 20 percent of aluminum powder; the contained aluminum powder can form a compact oxidation film on the surface of the rolled steel pelleting powder after being melted, so that the anti-corrosive property of the metal powder is greatly improved; the matching ratio of the metal powder in the step (1) to an adhesive is 5 to 2, and is the excellent material matching, so that the fastness of the metal piece is ensured; a mixture of the metal powder in the step (1) and the adhesive is dried at the temperature of 90 DEG C for 40min, so that the impact of water vapor on the metal piece can be prevented due to drying; the temperature for cooling molding in a step (5) is 10 DEG C, the cooling time is 5h, the cooling and the sizing of the metal piece can be accelerated with the temperature, and meanwhile, the performance of the metal piece is ensured; and in a step (6), a manipulator system is used for demoulding. The process can prevent the metal piece from being impacted, so that the quality of the formed metal piece is prevented from being damaged.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

Rounding device for cable sheath

PendingCN112659519AAccelerated cooling and settingGuaranteed rounding requirementsDomestic articlesCoatingsElectrical and Electronics engineeringWater tanks

The invention discloses a rounding device for a cable sheath. The rounding device comprises a main machine device for injection molding of the cable sheath, and further comprises a shaping device for rounding of the cable sheath, a water tank device for containing cooling water is arranged below the shaping device, an auxiliary box device for generating vacuum is arranged behind the water tank device, and a cooling device for cooling the cable sheath is arranged on one side of the shaping device. According to the rounding device, through vacuum setting in a cylindrical box, the surface of the sheath is tightly attached to a circular shaping sleeve, and the roundness of the surface of the sheath is guaranteed; through spraying setting in the cylindrical box, cooling shaping of the sheath are accelerated, and the rounding requirement of the sheath during moving is guaranteed; and through suction backflow setting of the cylindrical box, vacuum suction force is resisted, the water liquid backflow reutilization is guaranteed, and water resources are saved.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

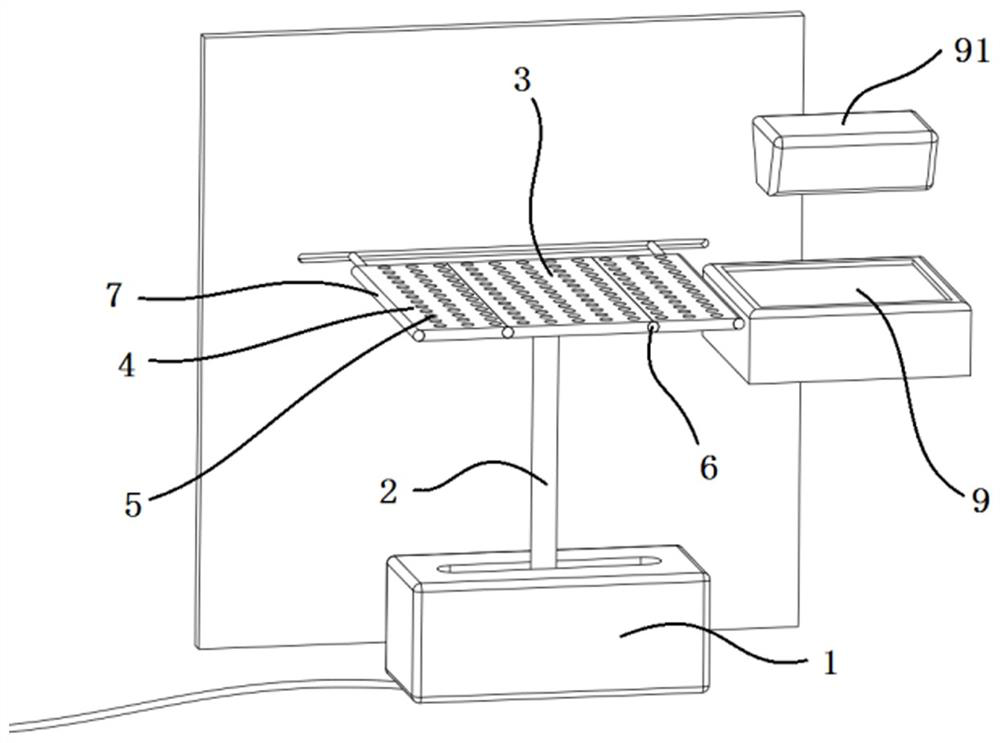

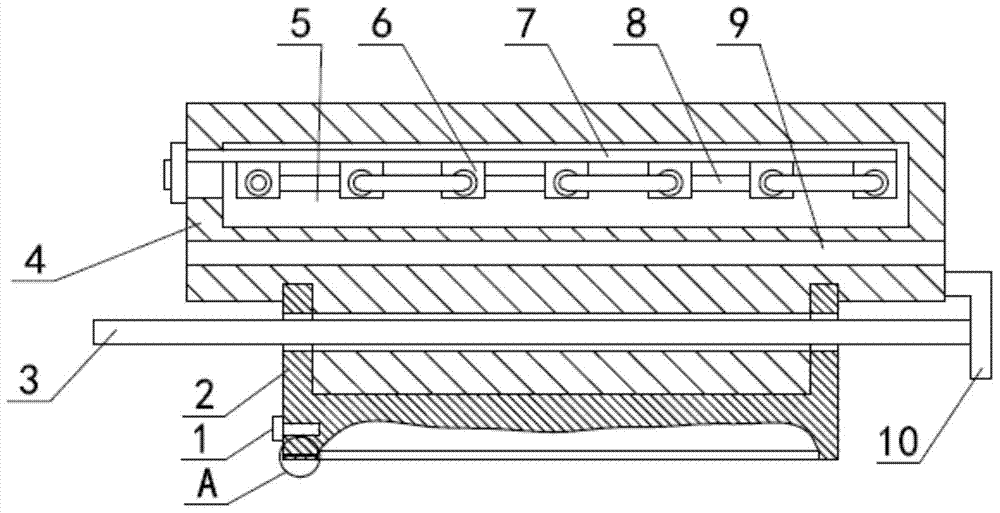

Injection upper mold with cooling for injection molding of fan blades

The invention relates to an injection upper mold with cooling for injection molding of fan blades and belongs to the technical field of injection molds. The injection upper mold with cooling comprises an upper mold body, wherein an injection channel is horizontally arranged at the bottom left part of the upper mold body, a heating aluminum block for heating the upper mold body is arranged at the upper part of the upper mold body, a groove is downwards formed in the upper surface of the upper mold body, a convex block matched with the groove downwards extends from the lower surface of the heating aluminum block, a heating cavity for steam heating is arranged in the heating aluminum block, the bottom surface of the heating cavity is an inclined plane which is high at the left and low at the right, a cooling water cavity is transversely formed in the heating aluminum block below the heating cavity, a boss with an annular structure is arranged on the inner side wall of the injection channel, and an electric heating bar is arranged on the upper mold body above the injection channel by penetration. The injection upper mold with cooling, provided by the invention, has the advantages of simple structure, uniform heating of the upper mold body, high heating speed, high production efficiency and convenience in mounting, and can ensure the product qualification rate.

Owner:ANHUI ANYUAN PLASTIC

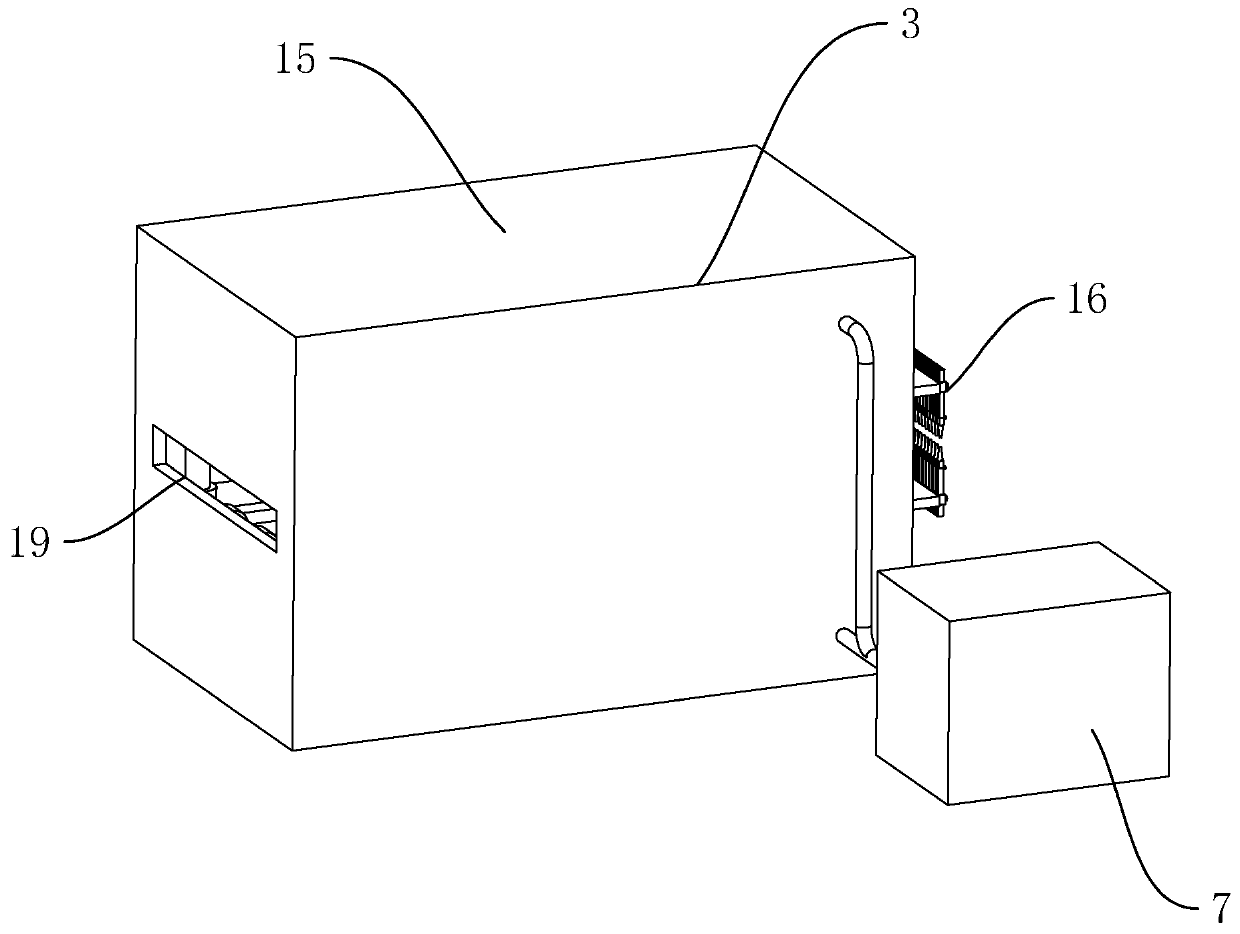

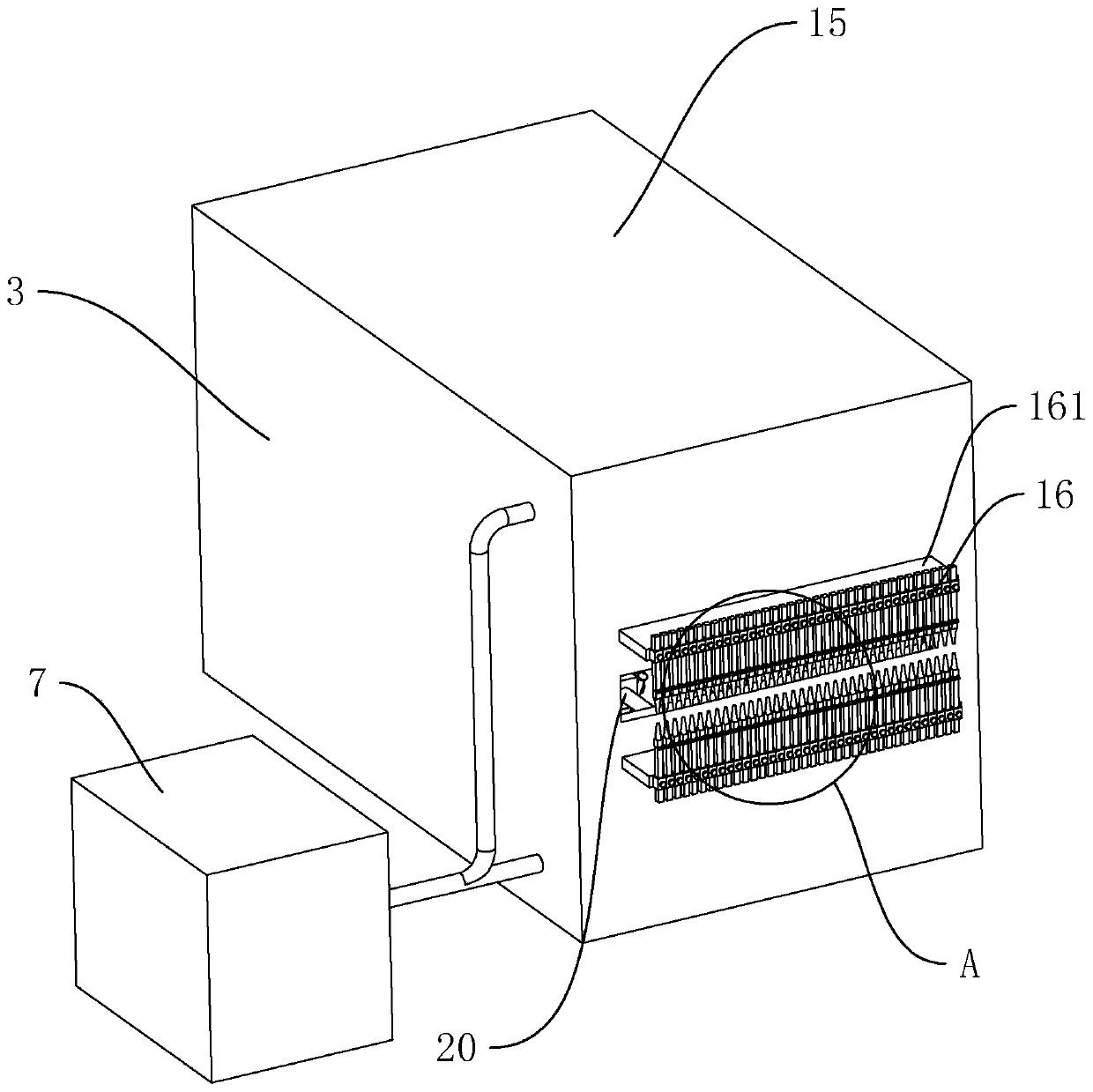

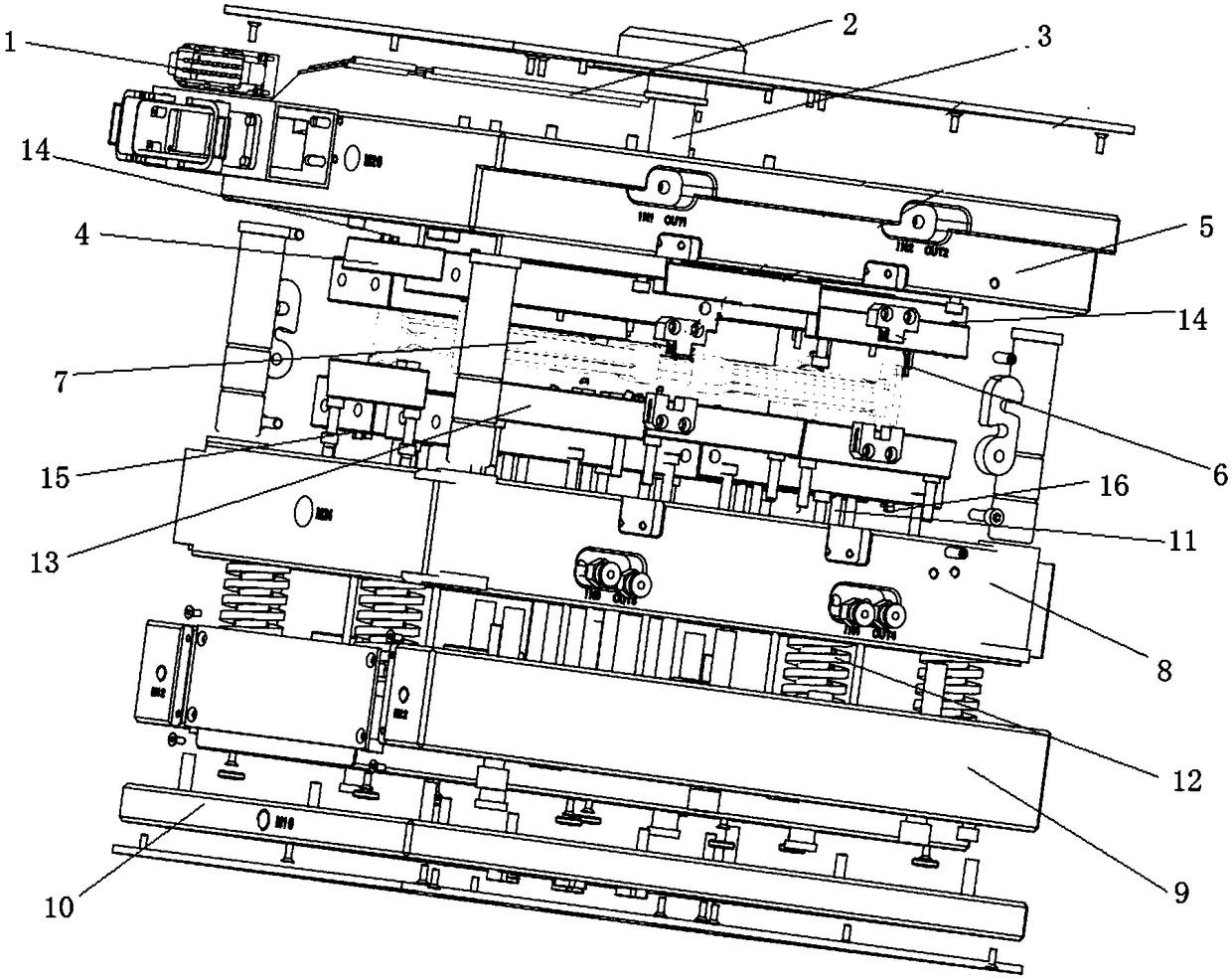

Efficient cleaning control device for computer mainboard

ActiveCN112296473AAvoid exposureAccelerated cooling and settingSoldering auxillary devicesAir pumpCoil spring

The invention aims to solve the problem that an existing computer mainboard is not easy to clean efficiently, and discloses an efficient cleaning control device for a computer mainboard. The efficientcleaning control device comprises a carrying plate, wherein supporting plates are symmetrically and fixedly installed on the left side face and the right side face of the carrying plate, and bases are fixedly installed at the bottom ends of the supporting plates. Air pumps are fixedly installed on the upper sides of the outer surfaces of the supporting plates, the air outlet ends of the air pumpscommunicate with ventilation pipes, inserting rods are evenly inserted into the carrying plate, the lower sides of the surfaces of the inserting rods are sleeved with spiral springs, an elastic bandis fixedly connected to the middle of the upper surface of the carrying plate, a guide frame is welded to the side face of the carrying plate, a sliding block sleeves the surface of the guide frame, afastening screw is installed between the sliding block and the guide frame, and a first supporting frame and a second supporting frame are fixedly installed on the upper surface and the lower surfaceof the sliding block correspondingly. By means of the efficient cleaning control device, by reasonably utilizing the control over soldering on the mainboard, pins of components can be controlled, andthe cleaning effect on the mainboard can be improved conveniently.

Owner:BINZHOU UNIV

Metal mold facilitating accelerating cooling forming

The invention provides a metal mold which is convenient for quick cooling and shaping, and relates to the field of mold equipment. The metal mould, the mold body includes an upper mold and a lower mold, both ends of the lower mold are provided with fixing holes, the bottom of the lower mold is provided with a fixing plate, one end of the fixing plate is provided with a fixing bar, and the fixing bar is provided with a fixing screw , the fixed plate is provided with a first heat dissipation rib, the top of the lower mold is provided with an inner cavity, both sides of the inner cavity are provided with small fixing holes, the inside of the lower mold is provided with a cooling device, and one end of the cooling device is provided with a liquid inlet hole and a liquid outlet hole, the other end of the cooling device is provided with a gas-liquid separation chamber, and one end of the liquid inlet hole and the liquid outlet hole is provided with a liquid storage chamber. The metal mold is externally connected to the condenser through the liquid outlet hole and the liquid inlet hole, the cooling liquid enters the liquid storage cavity, and the cooling liquid is circulated in the liquid return pipe and the condensation pipe in the lower mold by the rising pipe, so as to accelerate the cooling of the mold The purpose is to facilitate the rapid shaping of the mold and to speed up the work efficiency.

Owner:屠雪丰

Process method of spandex super-soft velvet

InactiveCN111155260AAccelerated cooling and settingSucessive textile treatmentsTextile treatment by spraying/projectingMechanical engineeringIndustrial engineering

The invention discloses a process method of a spandex super-soft velvet. The process method comprises the following steps of step S1, manufacturing a gray fabric; step S2, placing the gray fabric on asetting machine for pre-setting; step S3, adopting a napping machine to nap the surface of the gray fabric; step S4, carrying out one-time ironing on the fabric manufactured in step S3 on a single-roller ironing machine; step S5, using a wool shearing machine to shear long wools of the fabric manufactured in step S4; step S6, dyeing the fabric manufactured in step S5; step S7, drying the fabric manufactured in step S6 in a drying machine; step S8, performing low-temperature setting on the fabric manufactured in step S7 on the setting machine; step S9, performing steam treatment on the fabric,and using a wool sucking machine to suck away surface floating wools of the fabric; and step S10, horizontally transporting the fabric subjected to steam treatment in step S9 to an air jet device andperforming oblique air jet treatment on the side surface of the other side fabric attached to a drum. According to the process method provided by the invention, the fabric is subjected to the obliqueair jet treatment, so that both the upper side and the lower side of the fabric are fluffy, and the fluff of the fabric is more uniform.

Owner:TONGXIANG HENGHUA TEXTILE CO LTD

Cooling shaping device for stone paper wallpaper base material

The invention discloses a cooling shaping device for a stone paper wallpaper base material. The cooling shaping device comprises a total water inlet pipe and a cooling tank fixed to the ground. Through holes are formed in the outer wall of one side of the total water inlet pipe, and water inlet pipes are clamped into the inner walls of the through holes. Transverse water inlet holes are formed inthe outer wall of the side, opposite to the total water inlet pipe, of the cooling tank, and the outer walls of the water inlet pipes are sleeved with the inner walls of the transverse water inlet holes. The outer wall of the side, away from the cooling tank, of the total water inlet pipe is sleeved with a branch pipe, and a branch pipe hole is formed in the outer wall of one side of the cooling tank. The outer wall of the branch pipe is sleeved with the inner wall of the branch pipe hole, and an annular groove is formed in the edge of the outer wall of the top of the cooling tank. According to the cooling shaping device, through shaping boards which are overlaid layer by layer, draining shaping is conducted, taking for use is convenient, no mutual interference exists during shaping, the thickness is more uniform, wrinkling is not prone to occurring, a plurality of pieces of stone paper are shaped simultaneously, through transverse and longitudinal cold water pipes, cooling is accelerated, meanwhile, the shaping efficiency is improved, and the yield is increased; and the whole device is simple and compact in structure, capable of being quickly put into production and low in requirement for the environment.

Owner:临沂星岳数据科技有限公司

Electric heating rod type with cooling injection molding upper mold for fan blade

The invention relates to an electric heating bar type injection upper mold with cooling for fan blades and belongs to the technical field of injection molds. The electric heating bar type injection upper mold with cooling comprises an upper mold body, wherein a heating aluminum block for heating the upper mold body is arranged at the upper part of the upper mold body, a groove is downwards formed in the upper surface of the upper mold body, a convex block matched with the groove downwards extends from the lower surface of the heating aluminum block, a heating cavity is transversely formed in the middle part of the heating aluminum block, electric heating bars are mounted at the left end and right end of the heating cavity, a cooling water cavity is transversely formed in the heating aluminum block below the heating cavity, a water inlet is formed in the left end of the cooling water cavity, and a water outlet is formed in the right end of the cooling water cavity. The electric heating bar type injection upper mold with cooling, provided by the invention, has the advantages of simple structure, uniform heating of the upper mold body, high heating speed, high production efficiency and convenience in mounting, and can ensure the product qualification rate.

Owner:珠海市上源塑料制品有限公司

A bidirectional pleated fabric preparation device and its debugging method

ActiveCN112144267BRealize three-dimensional mechanized processingReduce labor costsHeating/cooling textile fabricsTransmissivity measurementsStructural engineeringMechanical engineering

Owner:SUZHOU JINGJIEWEI FABRIC TECH CO LTD

Electric heating rod type with cooling injection molding upper mold for cpu fan blade

Owner:ANHUI ANYUAN PLASTIC

A cooling and setting device for the production of stone paper wallpaper base material

The invention discloses a cooling shaping device for a stone paper wallpaper base material. The cooling shaping device comprises a total water inlet pipe and a cooling tank fixed to the ground. Through holes are formed in the outer wall of one side of the total water inlet pipe, and water inlet pipes are clamped into the inner walls of the through holes. Transverse water inlet holes are formed inthe outer wall of the side, opposite to the total water inlet pipe, of the cooling tank, and the outer walls of the water inlet pipes are sleeved with the inner walls of the transverse water inlet holes. The outer wall of the side, away from the cooling tank, of the total water inlet pipe is sleeved with a branch pipe, and a branch pipe hole is formed in the outer wall of one side of the cooling tank. The outer wall of the branch pipe is sleeved with the inner wall of the branch pipe hole, and an annular groove is formed in the edge of the outer wall of the top of the cooling tank. According to the cooling shaping device, through shaping boards which are overlaid layer by layer, draining shaping is conducted, taking for use is convenient, no mutual interference exists during shaping, the thickness is more uniform, wrinkling is not prone to occurring, a plurality of pieces of stone paper are shaped simultaneously, through transverse and longitudinal cold water pipes, cooling is accelerated, meanwhile, the shaping efficiency is improved, and the yield is increased; and the whole device is simple and compact in structure, capable of being quickly put into production and low in requirement for the environment.

Owner:临沂星岳数据科技有限公司

Injection upper mould with cooling function and for CPU (Central Processing Unit) fan blade

The invention relates to an injection upper mould with the cooling function and for a CPU (Central Processing Unit) fan blade and belongs to the technical field of injection moulds. The injection upper mould comprises an upper mould body; an injection channel is horizontally formed on the left lower portion of the upper mould body; the upper portion of the upper mould body is provided with a heating aluminum block which is used for heating the upper mould body; the upper surface of the upper mould body is downward to form a groove; the lower surface of the heating aluminum block extends downward to form a protruding block which is matched with the groove; a heating chamber which is used for performing steam heating is formed inside the heating aluminum block; the heating aluminum block portion which is located on the left side of the heating chamber is provided with a steam inlet; the heating aluminum block portion which is located on the right side of the heating chamber is provided with a steam outlet; the bottom surface of the heating chamber is an inclined surface, wherein the left portion of the inclined surface is higher than the right portion of the inclined surface; a cooling water chamber is horizontally formed in the heating aluminum block portion which is located below the heating chamber; the inner side wall of the injection channel is provided with a boss which is of an annular structure. According to the injection upper mould with the cooling function and for the CPU fan blade, the structure is simple, the upper mould body is uniformly heated, the heating speed is high, the production efficiency is high, the installation is convenient, and the qualified rate of products is ensured.

Owner:重庆开确科技有限公司

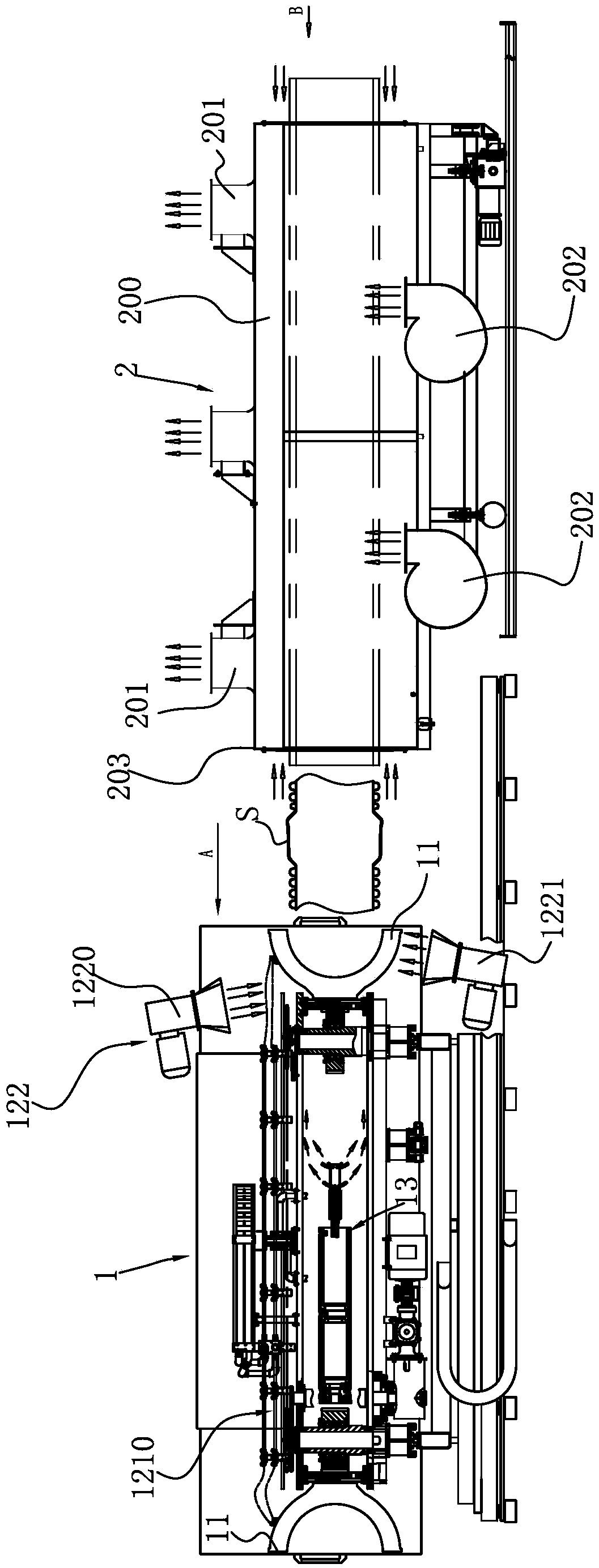

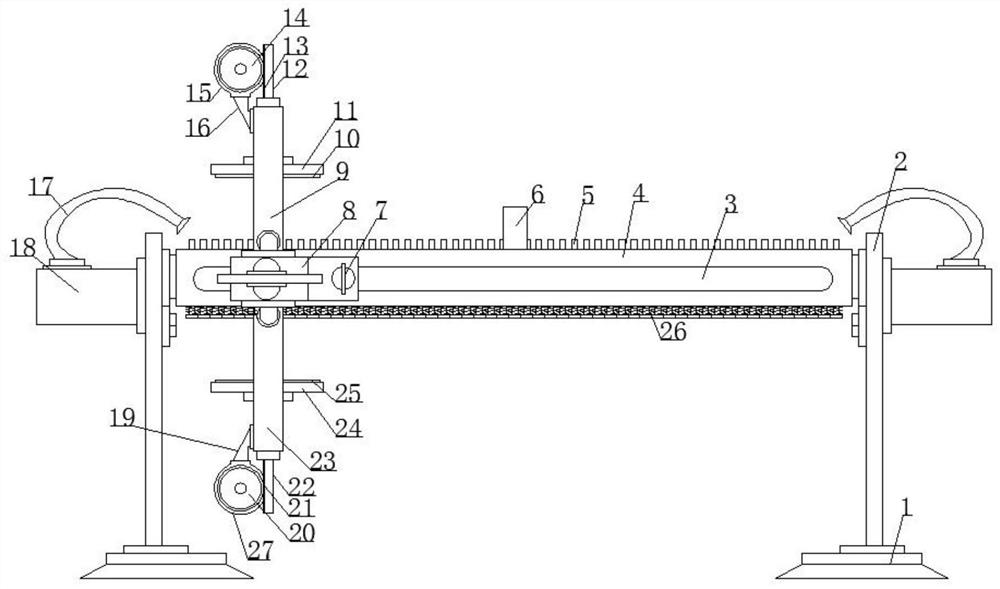

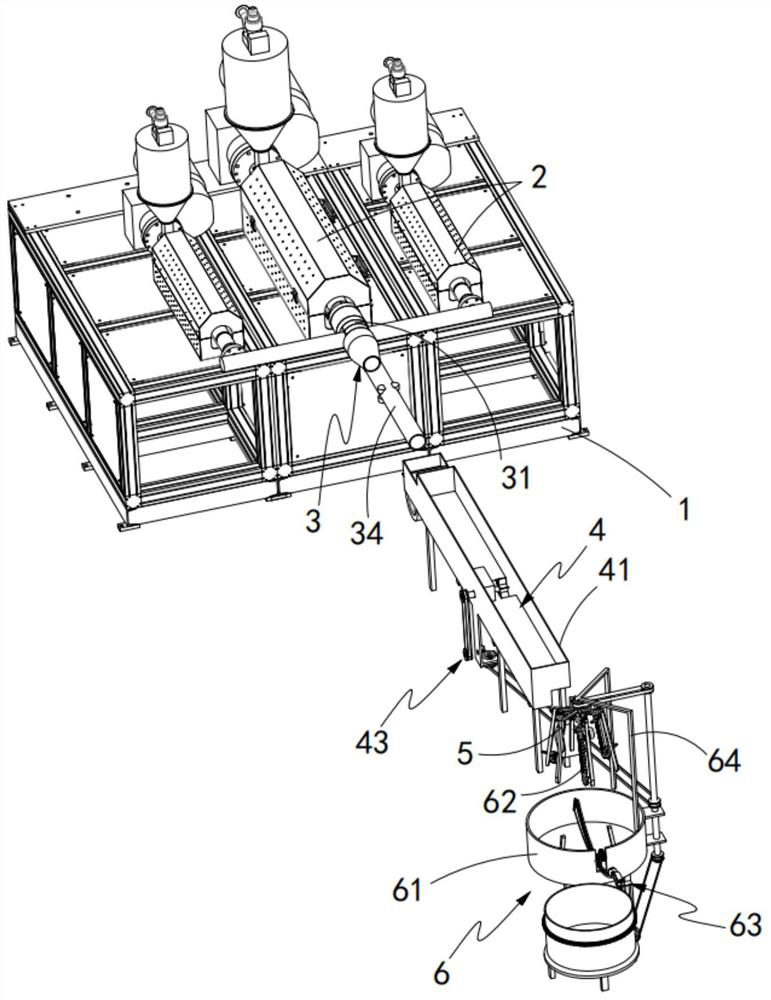

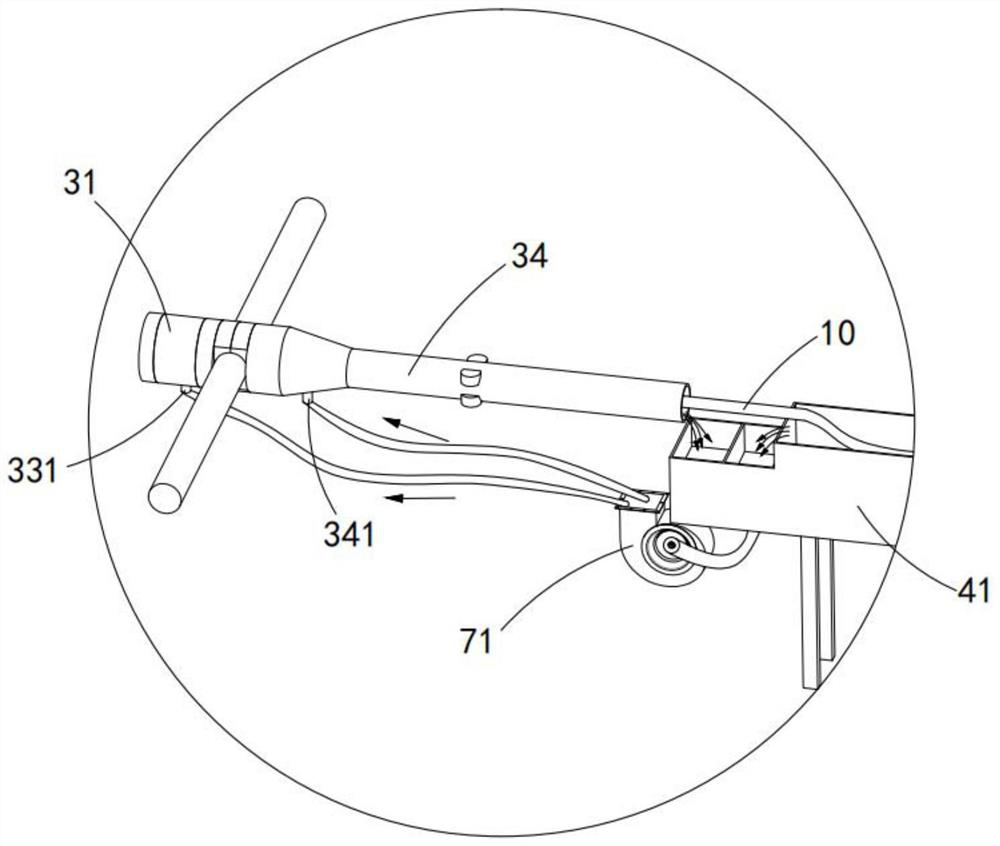

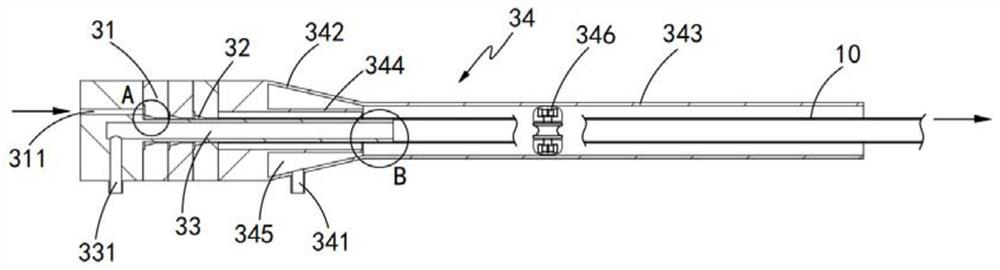

A kind of rattan plastic extrusion molding production line and its method

ActiveCN112477065BAccelerated cooling and settingEasy to operateFilament handlingBinding material applicationMelt extrusionWorkbench

The invention relates to a rattan plastic extrusion molding production line and its method. The production line includes a workbench and at least one group of melting extruders arranged on the workbench, and also includes: a die head assembly; a cooling device; a winding frame, The transmission unit drives the winding frame to rotate to wind the rattan plastic strip; and the roll changing and binding device, which includes a water storage bucket, a roll changing assembly, a binding assembly and a bracket, and the rolling assembly is arranged in the winding frame and it is driven with the winding frame Connecting, the roll changing component undertakes the rattan plastic strip being rolled and moves downward, and the binding component bundles the rattan plastic strip replaced by the roll changing component; the method includes melt extrusion process, cooling and shaping process, winding process, and roll changing process and the binding process. By setting up the roll-changing strapping device to cooperate with the movement of the winding frame, the rattan plastic strips with a certain number of turns are measured and rolled down, and then the strapping component automatically bundles the rattan plastic strips, which speeds up the cooling and shaping of the rattan plastic strips and greatly improves the efficiency.

Owner:ANHUI DAIJIA CRAFT CO LTD

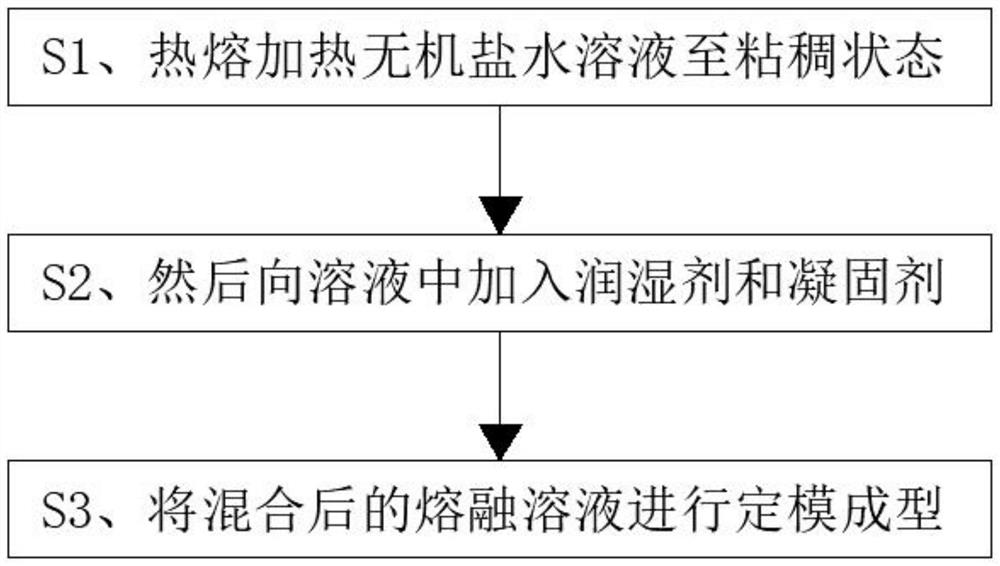

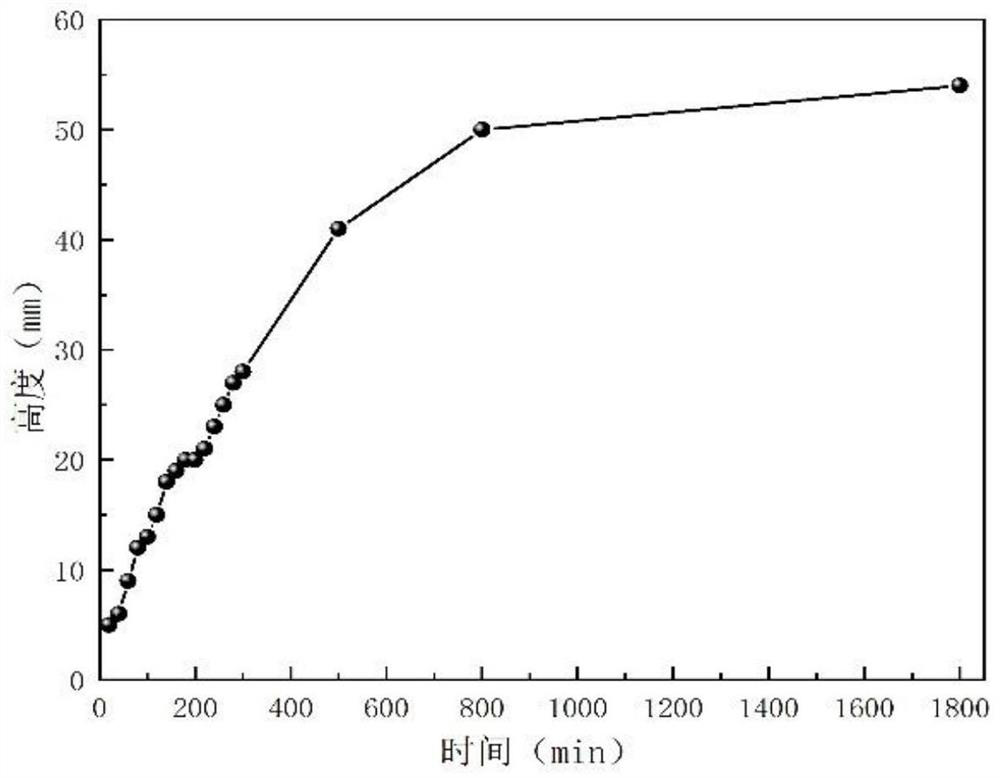

Additive for fast water injection of strong hydrophobic coal roadway short hole and preparation method of additive

PendingCN114790381AVarious cooling methodsRapid cooling treatmentDrilling compositionInorganic saltsAqueous solution

The invention provides a rapid water injection additive for a strong hydrophobic coal roadway short hole, and the rapid water injection additive is prepared from the following components in percentage by mass: 3%-5% of a wetting agent and 95%-97% of a coagulator, and the water injection additive is prepared into a solid additive through a thermal synthesis process, the invention further discloses a preparation method of the additive for rapid water injection of the strong hydrophobic coal roadway short hole. The preparation method comprises the following steps: S1, carrying out hot melting and heating on an inorganic salt aqueous solution to a viscous state; s2, adding a wetting agent and a coagulating agent into the solution; and S3, the mixed molten solution is subjected to fixed mold forming. On the basis of physicochemical properties of a strong hydrophobic coal body, a wetting agent solution with excellent properties is selected, the wettability of a coal seam is improved, solid setting is performed by adopting a thermal synthesis process, the additive is effectively prepared, the process is simple, preparation is convenient and rapid, the preparation process is simple, and operation and implementation are convenient.

Owner:HUAIBEI MINING IND

A high-efficiency cleaning control device for computer motherboards

ActiveCN112296473BAvoid exposureAccelerated cooling and settingSoldering auxillary devicesCoil springAir pump

The purpose of the present invention is to solve the existing problem that it is difficult to efficiently clean the computer main board, and discloses a high-efficiency cleaning control device for the computer main board. The bottom end of the support plate is fixedly installed with a base, and an air pump is fixedly installed on the outer surface of the support plate. The air outlet end of the air pump is connected with a vent pipe. The lower side of the rod surface is covered with a coil spring, the middle part of the upper surface of the pallet is fixedly connected with an elastic band, the side of the pallet is welded with a guide frame, and the surface of the guide frame is covered with a slider. Fastening screws are installed, and a first support frame and a second support frame are respectively fixedly installed on the upper and lower surfaces of the slider. The present invention can control the pins of components and devices by rationally utilizing the control on the solder on the main board, so as to improve the cleaning effect on the main board.

Owner:BINZHOU UNIV

Heating wire cooling injection molding upper mold for fan blades

The invention relates to an electric heating wire type injection upper mold with cooling for fan blades and belongs to the technical field of injection molds. The electric heating bar type injection upper mold with cooling comprises an upper mold body, wherein an exhaust channel is horizontally arranged at the bottom right part of the upper mold body, a heating aluminum block for heating the upper mold body is arranged at the upper part of the upper mold body, a groove is downwards formed in the upper surface of the upper mold body, a convex block matched with the groove downwards extends from the lower surface of the heating aluminum block, a heating cavity is transversely formed in the middle part of the heating aluminum block, a mounting plate is transversely arranged in the heating cavity, electric heating wires are arranged at the bottom of the mounting plate, the electric heating wires are mounted at the bottom of the mounting plate through a ceramic pipe, a cooling water cavity is transversely formed in the heating aluminum block below the heating cavity, and a boss with an annular structure is arranged on the inner side wall of the exhaust channel. The electric heating wire type injection upper mold with cooling, provided by the invention, has the advantages of simple structure, uniform heating of the upper mold body, high heating speed, high production efficiency and convenience in mounting, and can ensure the product qualification rate.

Owner:ANHUI ANYUAN PLASTIC

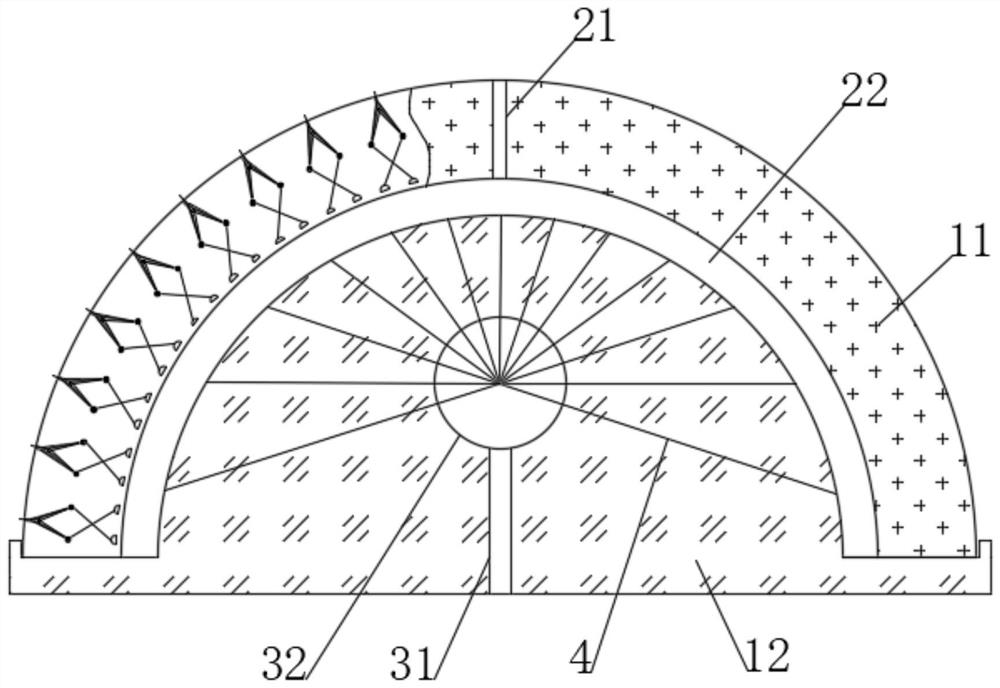

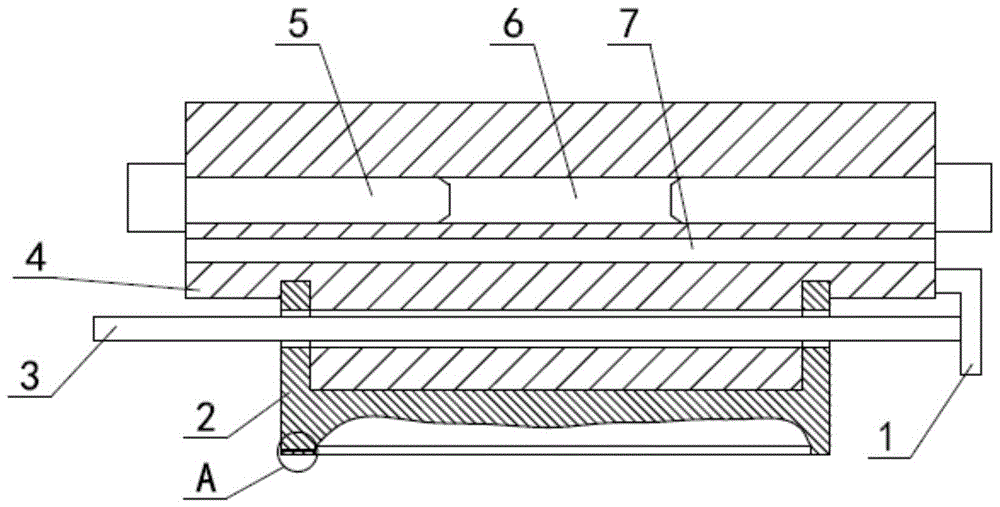

Hot runner injection mold for door check

PendingCN109130095AAccelerated cooling and settingImprove product qualityHot runnerMaterials science

The invention relates to a hot runner injection mold for a door check. The hot runner injection mold comprises a fixed mold and a moving mold, wherein a fixed mold plate and a front mold core, which is fixedly arranged on the fixed mold plate, are arranged in the fixed mold; a moving clamp plate, a support block, a moving mold plate and a rear mold core, which is arranged on the moving mold plate,are arranged in the moving mold; a cavity is formed by the front mold core and the rear mold core; the fixed mold comprises a raw material interface and a hot runner; a heating unit is arranged on the outer wall of the hot runner; the front mold core is provided with a feeding port and a gas outlet; the feeding port is connected with the hot runner; and an ejection unit is arranged in the movingmold and used for demolding. Compared with the prior art, the hot runner injection mold provided by the invention has the advantages that through the hot runner, condensing materials are avoided, or only a small condensing material handle is needed; cold runner sprue materials are basically eliminated, so that recycling is avoided; and therefore, the cost can be greatly reduced, especially for costly plastic products which cannot be processed through recycled materials.

Owner:上海奥林汽车安全系统有限公司

Electric heating wire type upper injection mold with cooling for injection molding of fan blades

The invention relates to an electric heating wire type upper injection mold with cooling for injection molding of fan blades, and belongs to the technical field of injection molds. The electric heating wire type upper injection mold comprises an upper mold main body, wherein an injection molding channel is horizontally formed in the left lower part of the upper mold main body; a heating aluminum block for heating the upper mold main body is arranged at the upper part of the upper mold main body; a groove is downwards formed in the upper surface of the upper mold main body; a convex block fitting the groove downwards extends from the lower surface of the heating aluminum block; a heating cavity is transversely formed in the middle of the heating aluminum block; a mounting plate is transversely arranged in the heating cavity; an electric heating wire is arranged at the bottom of the mounting plate; a cooling water cavity is transversely formed in the heating aluminum block below the heating cavity; a boss with an annular structure is arranged on the inner side wall of the injection molding channel; and an electric heating bar penetrates in the upper mold main body above the injection molding channel. The electric heating wire type upper injection mold has the advantages of simple structure, uniform heating of the upper mold main body, quick heating speed, high production efficiency, convenience for mounting and guarantee of product pass percent.

Owner:重庆开确科技有限公司

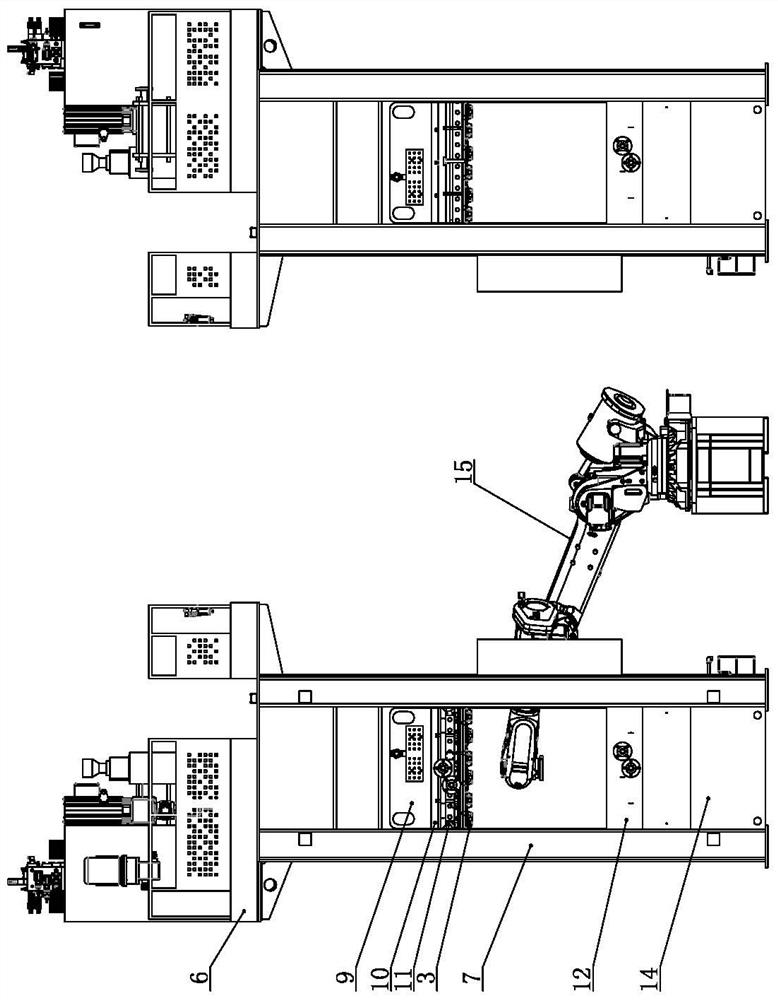

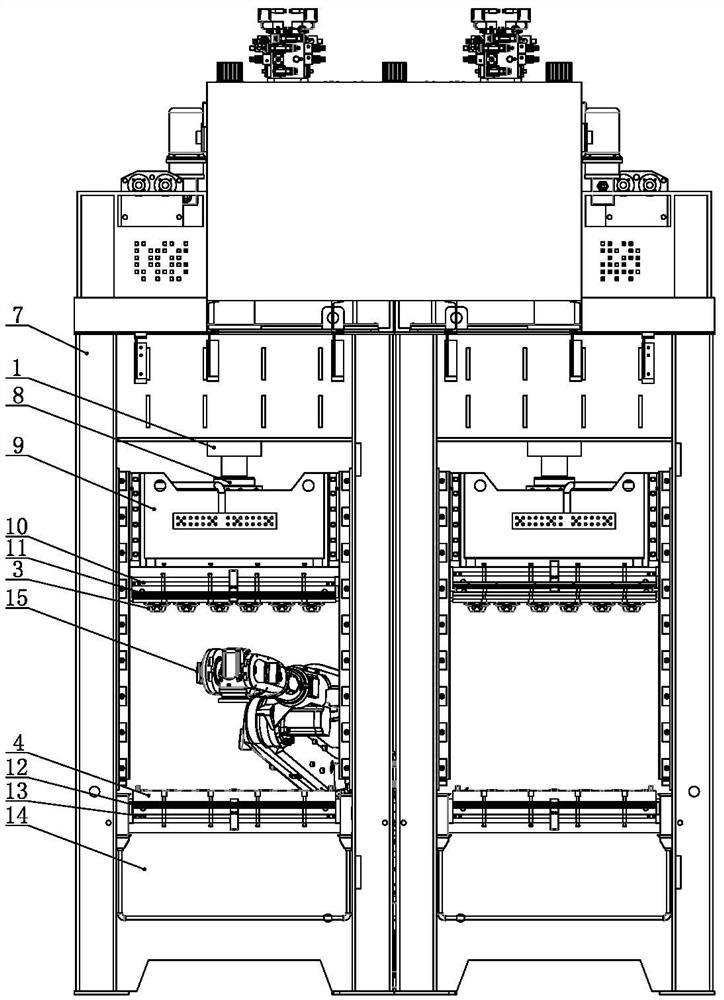

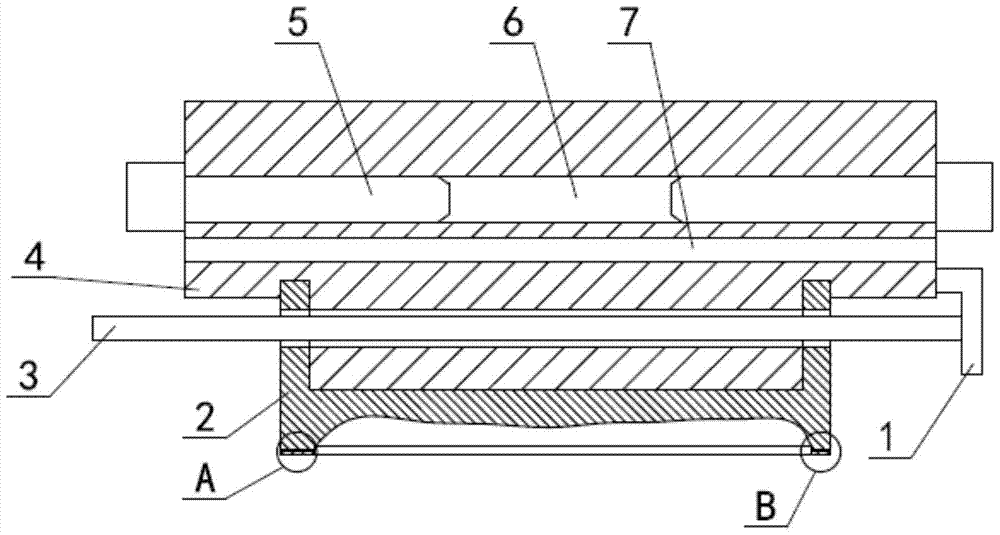

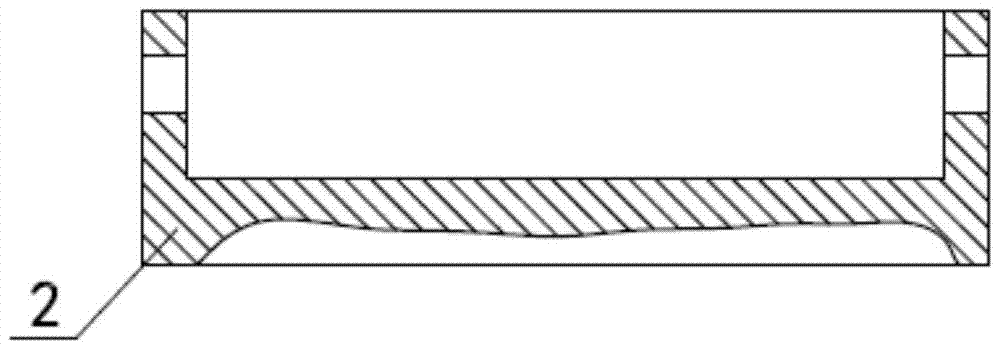

Environmental protection organic tableware wet pressing forming servo pump control system

ActiveCN112297396BAvoid flawsAccelerated cooling and settingServomotor componentsServomotorsControl systemMaster cylinder

The invention relates to an environmentally friendly organic tableware wet-press forming servo pump control system, which includes a plurality of hydraulic machines sharing a feeding robot, each hydraulic machine includes four uprights, the tops of the four uprights are connected by an upper beam, and the four uprights The bottom is connected with a workbench, and sliders are installed between the upper beam and the workbench. A master cylinder is installed in the center of the upper beam, and the lower end of the plunger of the master cylinder is connected with the top of the slider. A hot-pressing upper die is installed below the upper heat-conducting oil plate; a lower heat-conducting oil plate is installed above the workbench, and a hot-pressing lower die is installed above the lower heat-conducting oil plate. A lower heat insulating plate is provided between the workbench and the lower heat conducting oil plate, an upper heat insulating plate is provided between the slider and the upper heat conducting oil plate, and a water cooling plate is provided at the joint between the plunger of the master cylinder and the sliding block. Two hydraulic machines form a row, and the two rows are set up symmetrically. This system can wet-press and heat-form the billet in a hydraulic press, and after cooling, the finished environmental-friendly organic tableware can be obtained.

Owner:江苏扬力液压装备有限公司

Electric heating rod type with cooling injection molding upper mold for cpu fan blade

Owner:ANHUI ANYUAN PLASTIC

A shaping method suitable for flexible glass drawing

ActiveCN108249743BRapid coolingPrecise temperature controlGlass forming apparatusCarbide siliconEngineering

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com