A kind of rattan plastic extrusion molding production line and its method

A technology of extrusion molding and production line, which is applied in the directions of bundling materials, thin material processing, and conveying filamentous materials, etc., can solve the problem of not being able to change rolls and automatically bundling, etc., to achieve simple structure, stable winding tension, and accelerated cooling. The effect of shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

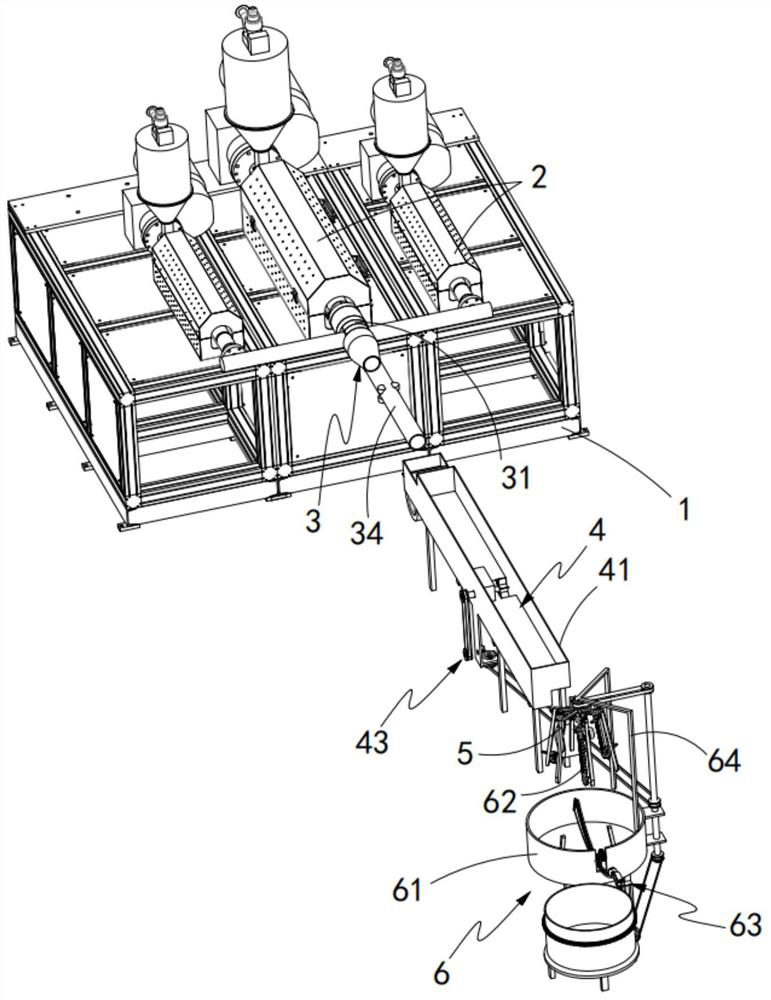

[0080] like figure 1 , 2 Shown, a kind of extrusion molding production line of rattan plastic, comprises: workbench 1 and at least one group of melting extruder 2 that is arranged on described workbench 1, also comprises:

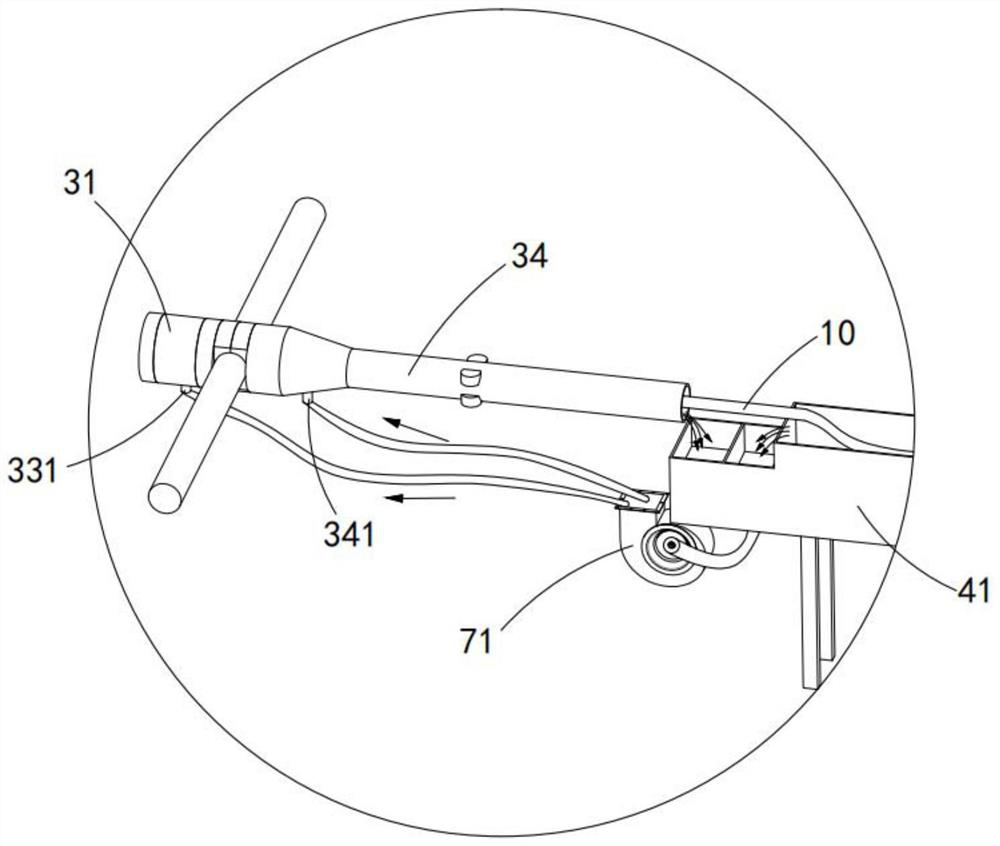

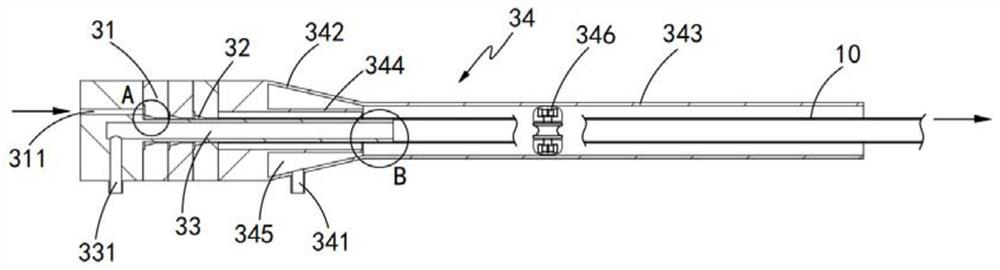

[0081] Die head assembly 3, described die head assembly 3 gathers the raw material of described melting extruder 2 and extrudes rattan plastic strip 10;

[0082] Cooling device 4, described cooling device 4 is arranged on the discharge end of described die head assembly 3, and it comprises the cooling water tank 41 that cools described rattan plastic strip 10 and allows this rattan plastic strip 10 to pass through, is arranged on the cooling The impeller unit 42 on the path of the water tank 41 and the transmission unit 43 drivingly connected with the impeller unit 42;

[0083] A winding frame 5, the winding frame 5 is arranged at the tail end of the cooling water tank 41, and the transmission unit 43 drives the winding frame 5 to rotate to wind the ratta...

Embodiment 2

[0129] like figure 1 and 22 Shown, a kind of extrusion molding production method of rattan plastic, comprises the following steps:

[0130] Step 1, the melting extrusion process, the melting extruder 2 heats and melts the plastic masterbatch, and extrudes it from the die body 31, and the raw material forms an annular tubular rattan plastic strip 10 when passing through the extrusion ring 32 and outputs it outward;

[0131] Step 2, the cooling and shaping process, the cooling water tank 41 performs water cooling work on the outer wall of the rattan plastic strip 10 being conveyed forward, and at the same time another cooling water enters the inside of the inner pipe 33 from the first water injection port 331 and rushes towards the rattan plastic strip 10 The inner wall of the road cooling water cools the inner wall of the rattan plastic strip 10 and provides outward support for the rattan plastic strip 10 to make it finalized;

[0132] Step 3, the winding process, the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com