Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about "X-ray tube target treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating process for manufacture or reprocessing of sputter targets and x-ray anodes

ActiveUS20080216602A1Low heat introductionWide applicabilityLiquid surface applicatorsMolten spray coatingPowder mixtureNiobium

Disclosed is a process for the reprocessing or production of a sputter target or an X-ray anode wherein a gas flow forms a gas / powder mixture with a powder of a material chosen from the group consisting of niobium, tantalum, tungsten, molybdenum, titanium, zirconium, mixtures of two or more thereof and alloys thereof with at least two thereof or with other metals, the powder has a particle size of 0.5 to 150 μm, wherein a supersonic speed is imparted to the gas flow and the jet of supersonic speed is directed on to the surface of the object to be reprocessed or produced.

Owner:H C STARCK SURFACE TECH & CERAMIC POWDERS GMBH

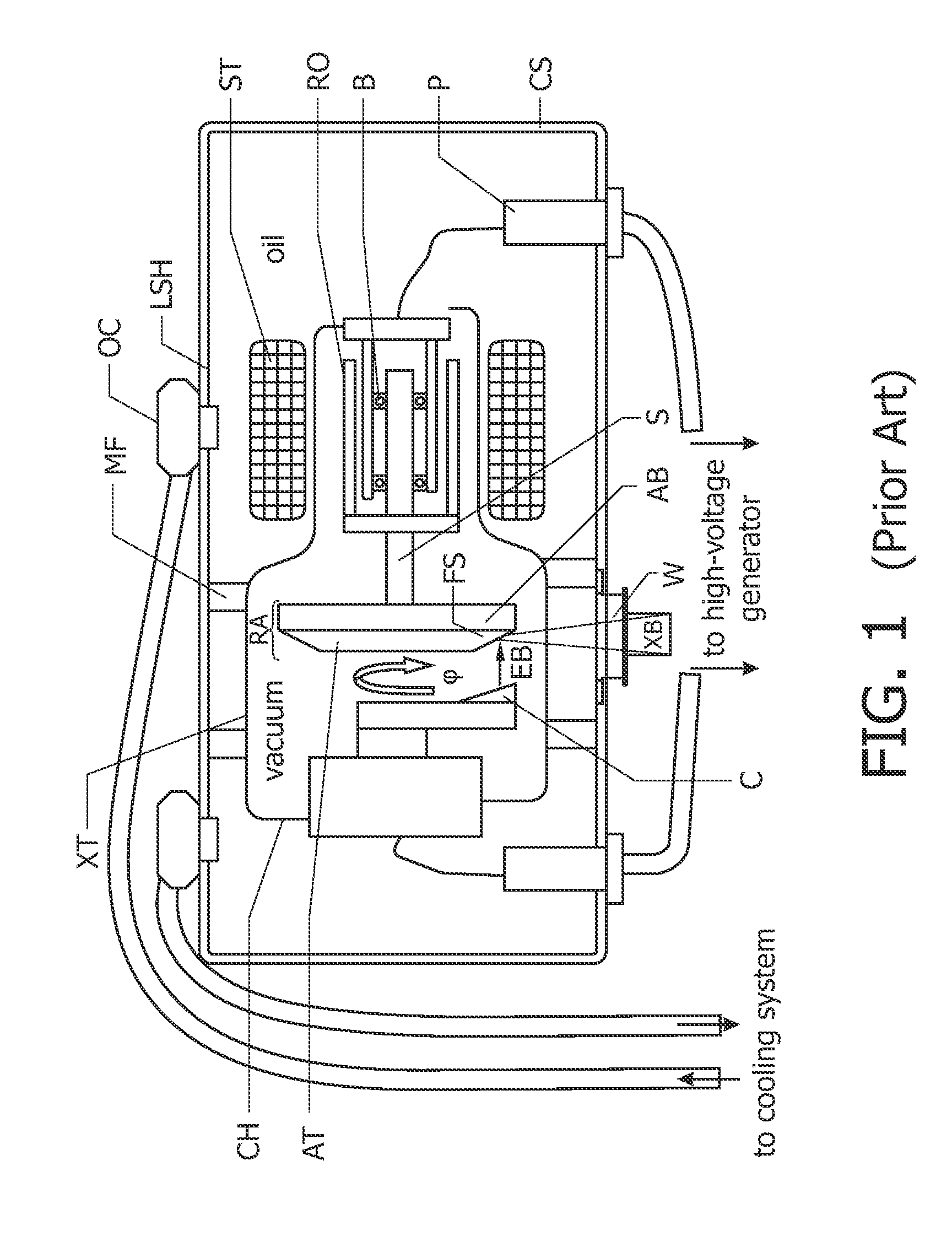

Diamond anode

ActiveUS7359487B1Avoid damageImprove cooling effectX-ray tube laminated targetsX-ray tube anode coolingOptoelectronicsMaterials science

According to one aspect of the invention a robust anode structure and methods of making and using said structure to produce ionizing radiation are disclosed. An ionizing radiation producing layer is bonded to the target side of a highly conductive diamond substrate, by a metal carbide layer. The metal carbide layers improves the strength and durability of the bond, thus improving heat removal from the anode surface and reducing the risk of delaminating the ionizing radiation producing layer, thus reducing degradation and extending the anode's life. A smoothing dopant is alloyed into the radiation producing layer to facilitate keeping the layer surface smooth, thus improving the quality of the x-ray beam emitted from the anode. In an embodiment, the heat sink comprises a metal carbide skeleton cemented diamond material. In another embodiment, the heat sink is bonded to the diamond substrate structure in a high temperature reactive brazing process.

Owner:NOVA MEASURING INSTRUMENTS INC

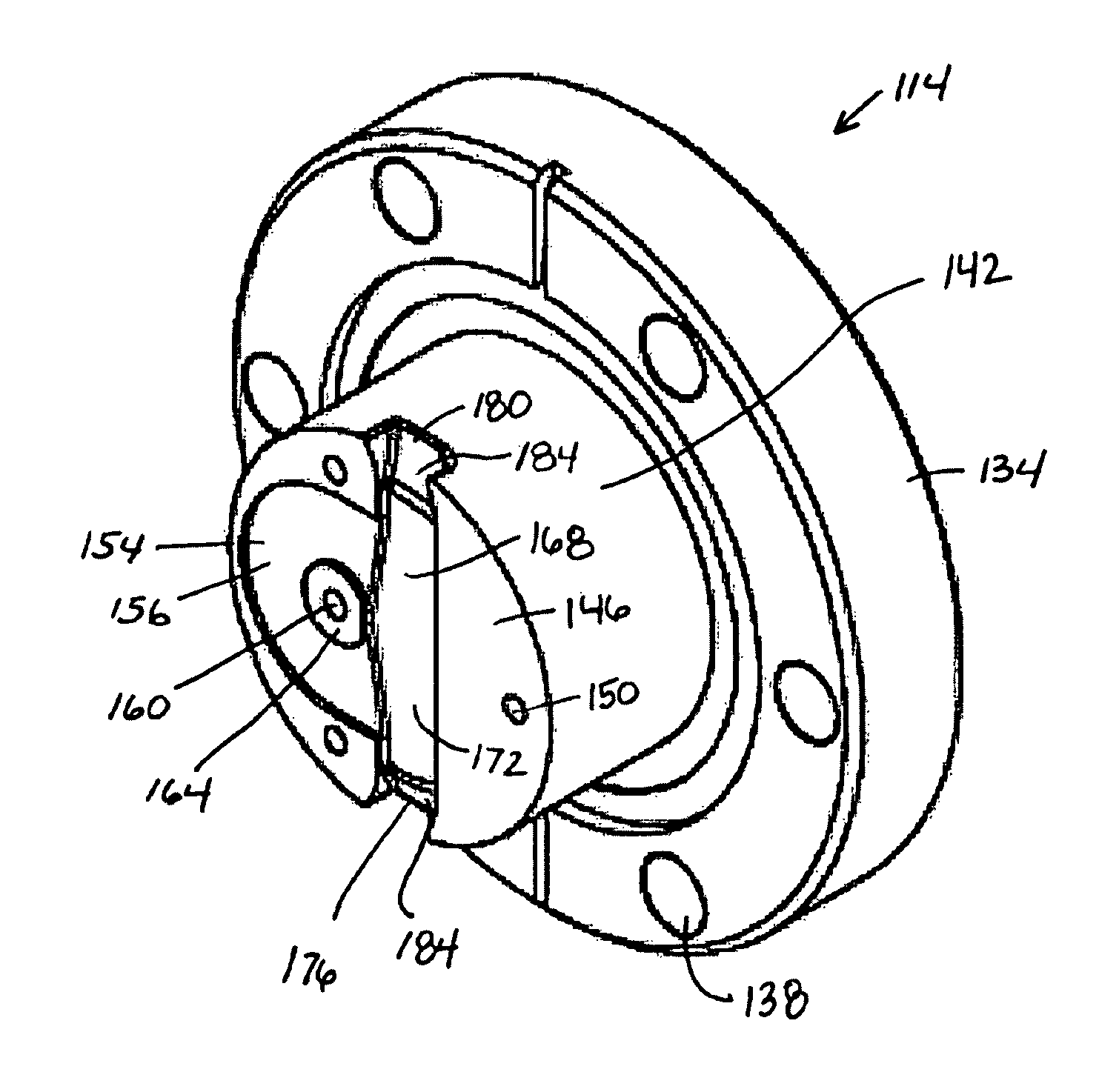

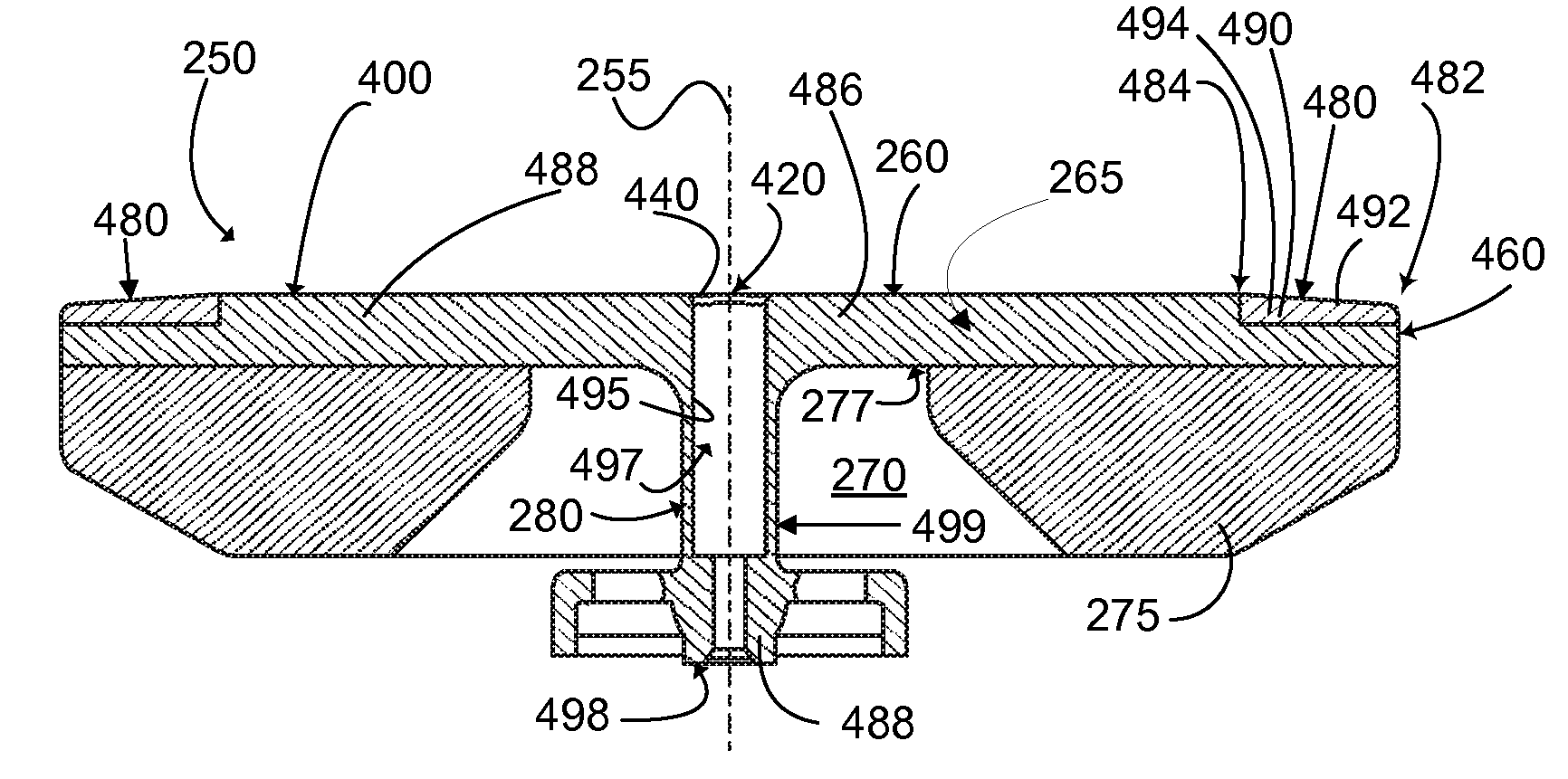

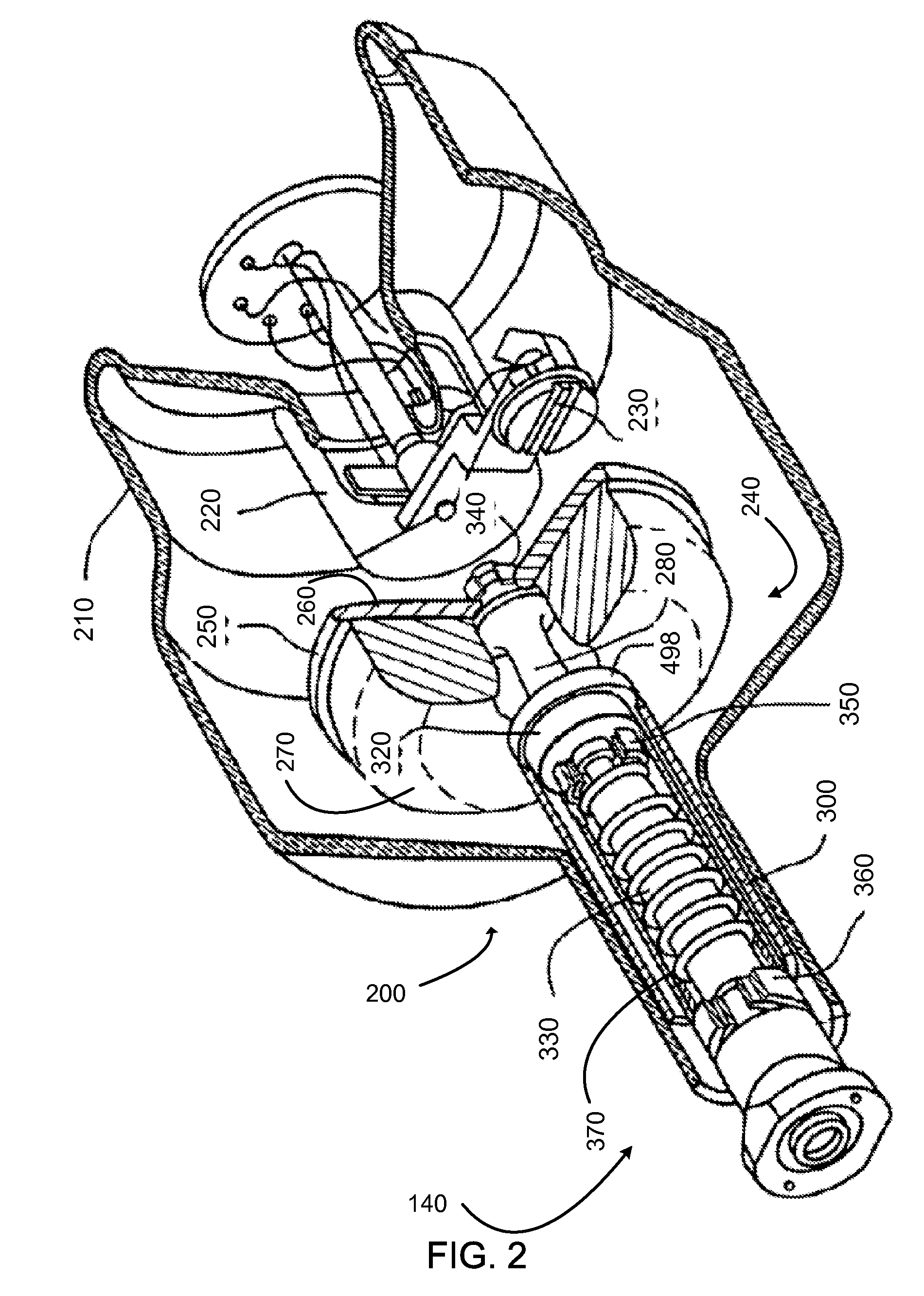

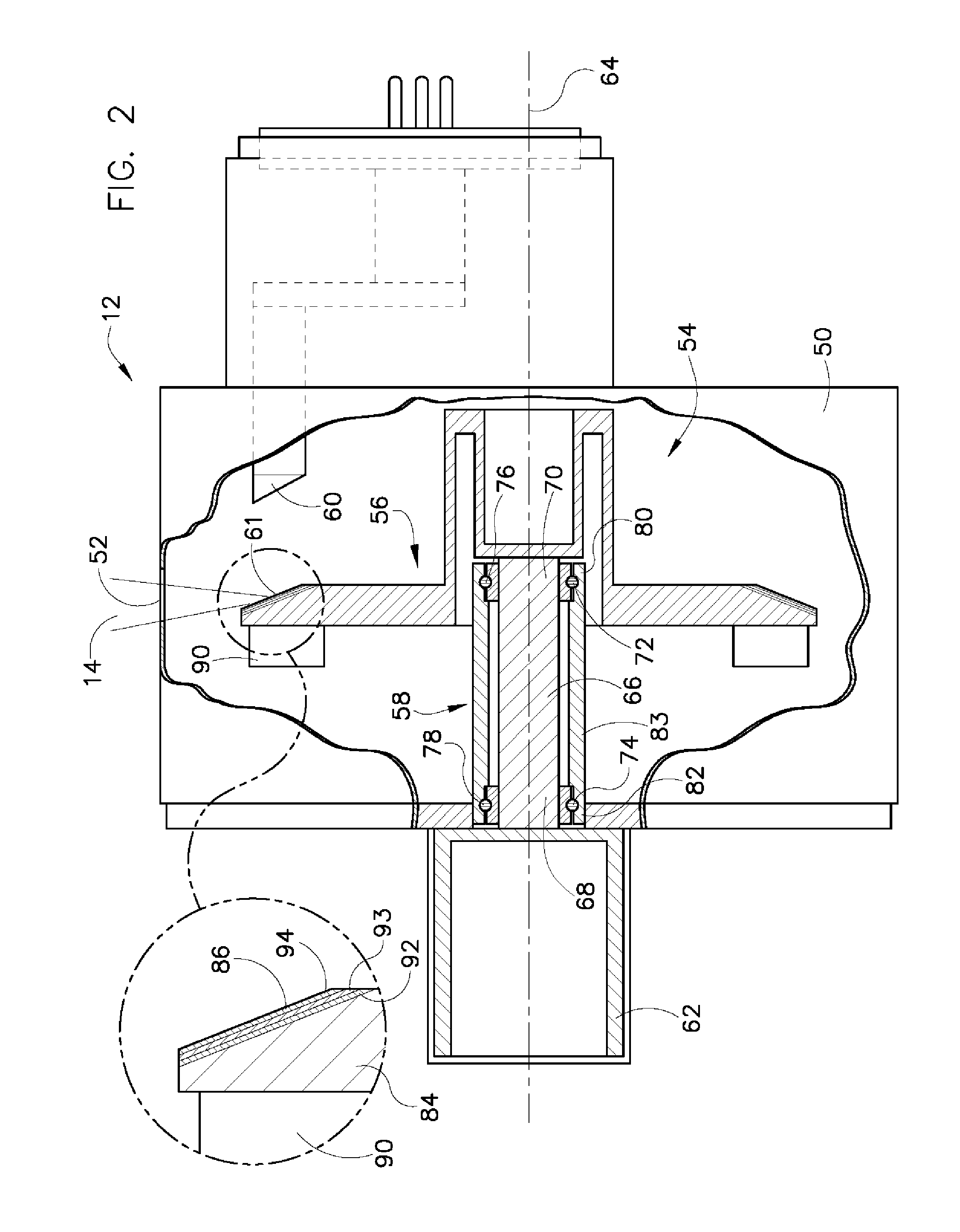

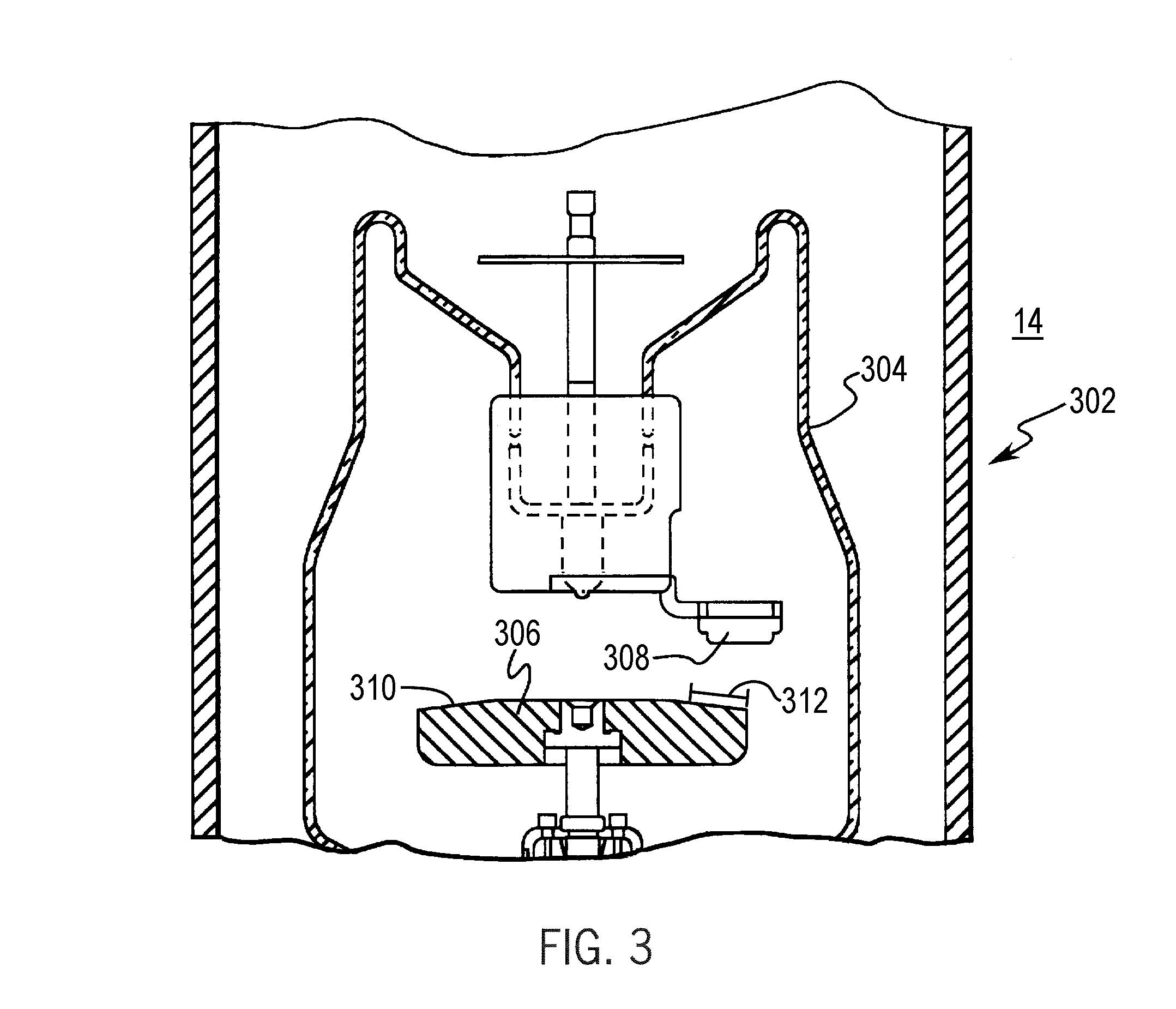

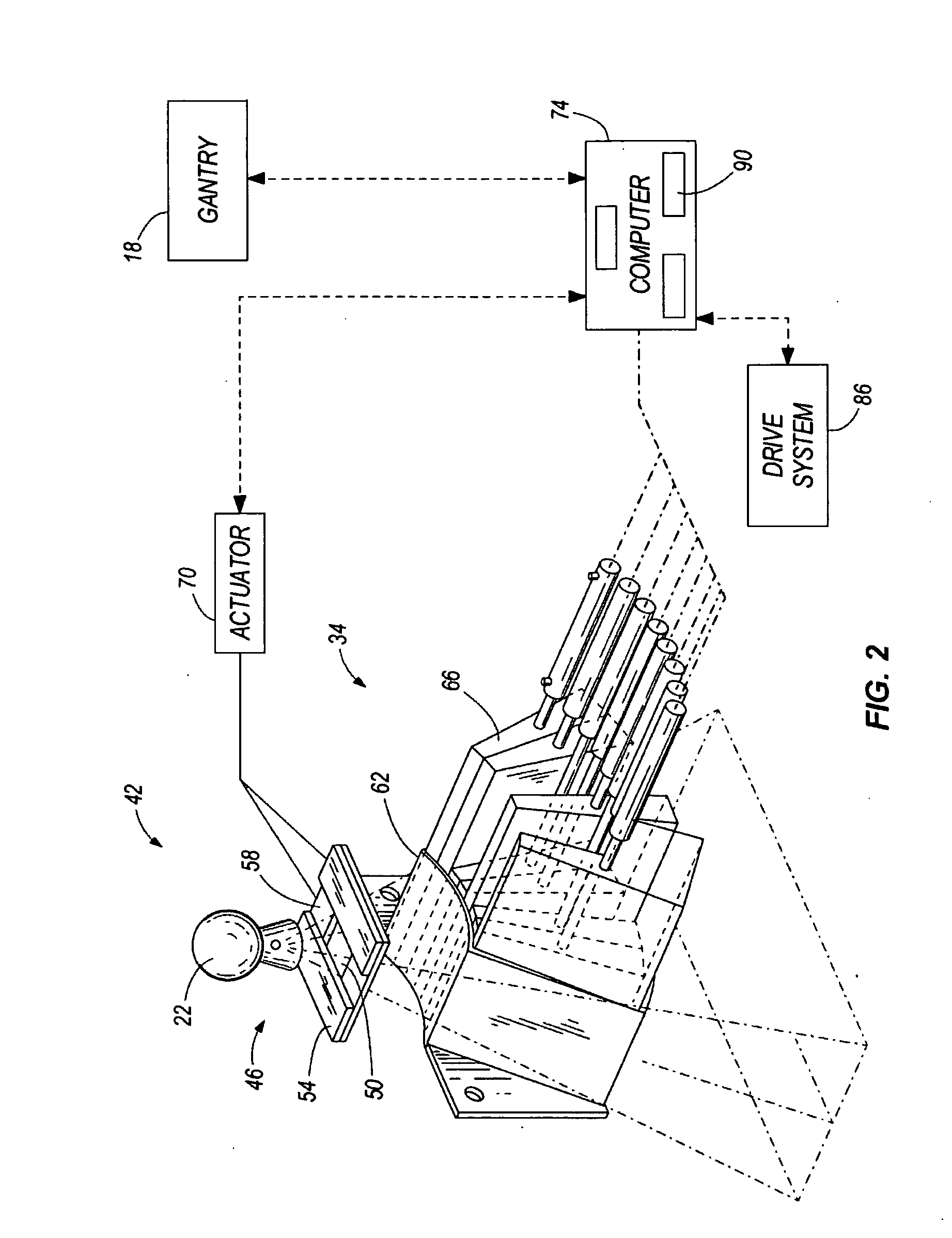

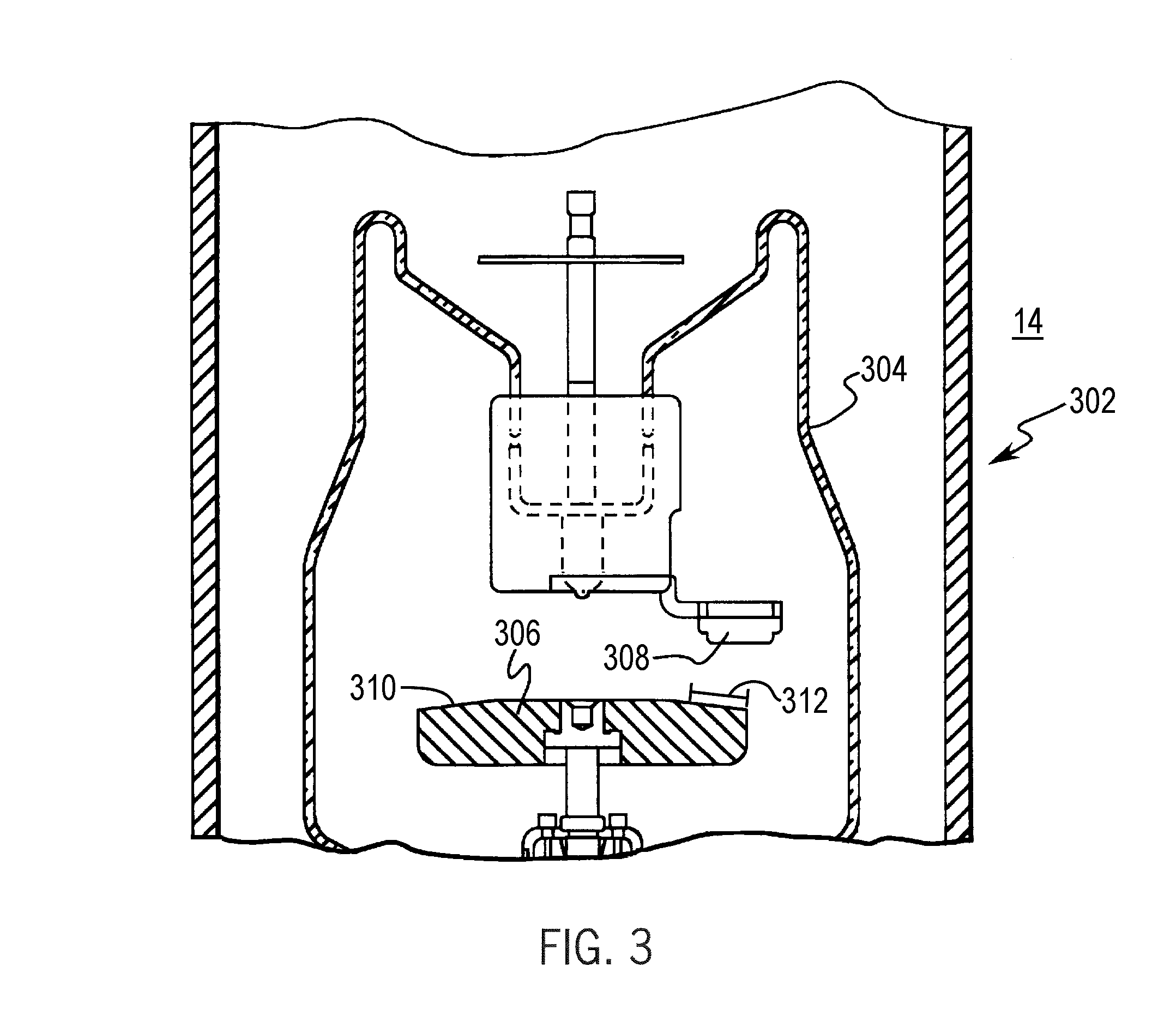

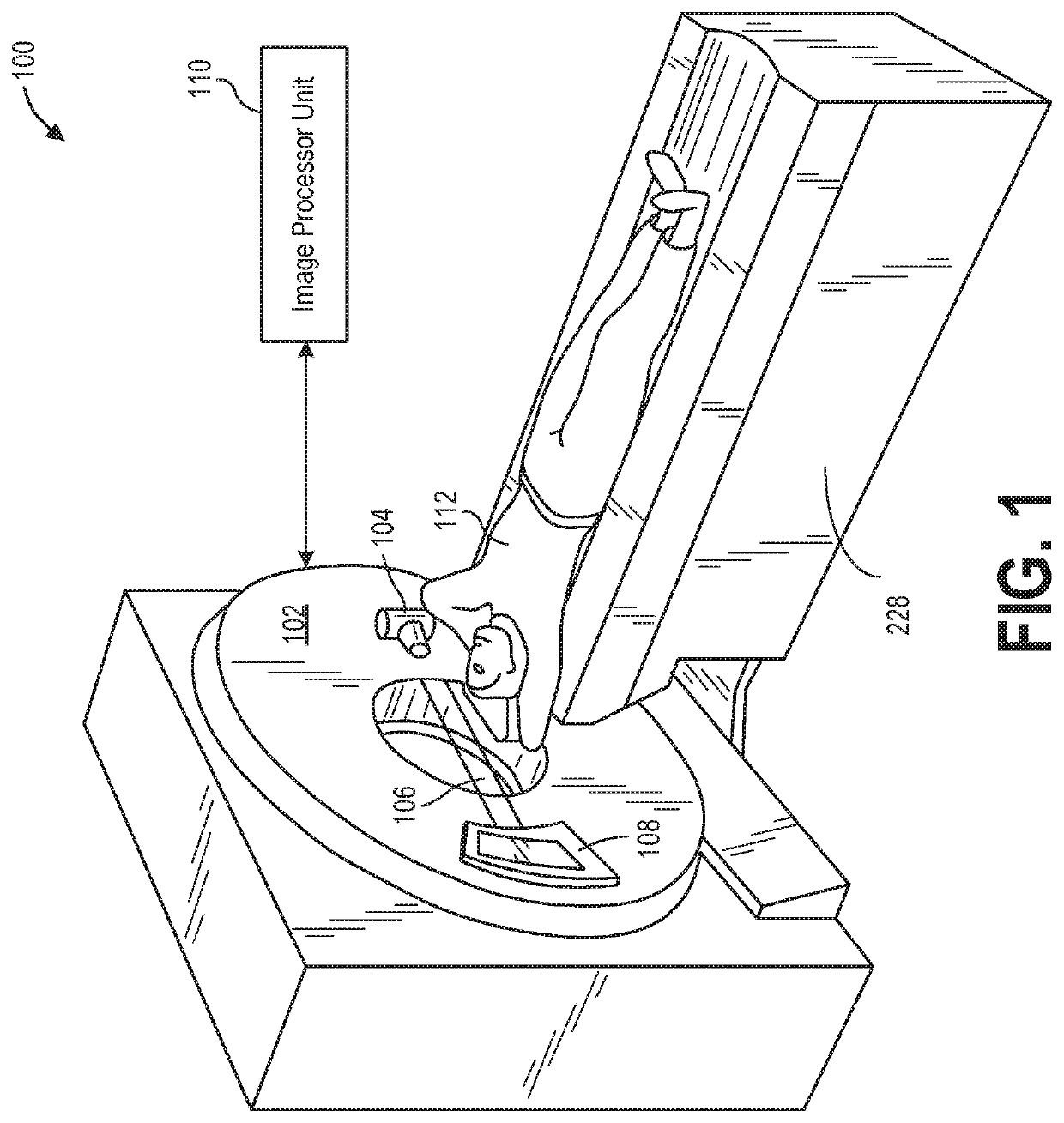

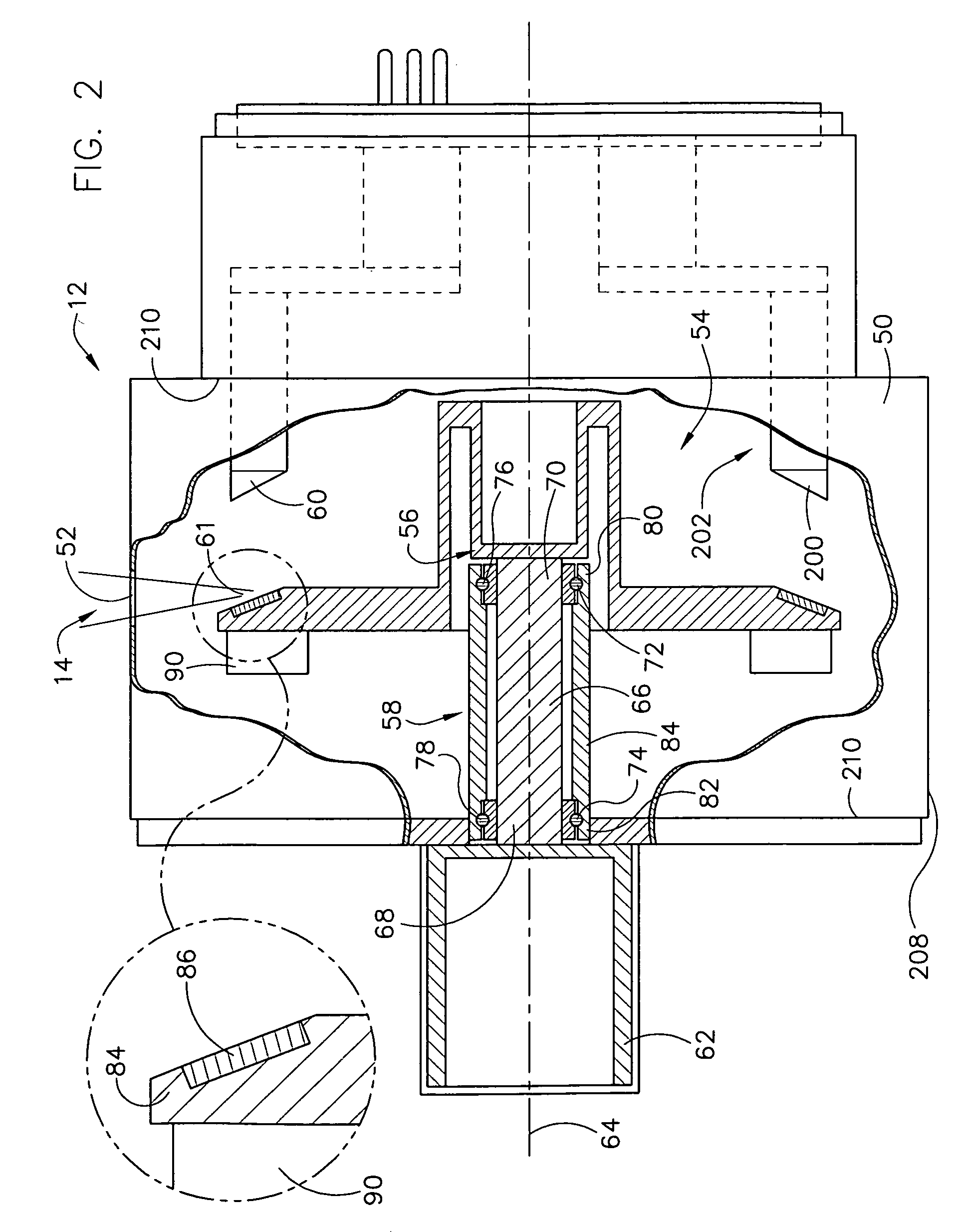

Target pedestal assembly and method of preserving the target

ActiveUS7835502B2Prolong lifeHeat dissipationX-ray tube anode coolingX-ray tube electrodesSoft x rayChemical reaction

An x-ray target pedestal assembly and a method of protecting the x-ray target from breaking down as a result of the extreme heat that is produced when an electron beam is aimed at the target to produce x-rays. The target is submerged in cooling fluid and is rotated by a constant flow of the cooling fluid over and around the target in order to dissipate heat. The fluid is guided by integrated flow diverters in the target cover. The target may also be protectively coated either in its entirety or along the electron beam path in order to further protect it from the heat of the electron beam impact or from breakdown as a result of attack of free radicals or other chemically reactive components of the cooling fluid which are produced in the extreme target environment.

Owner:TOMOTHERAPY INC

Low-energy method for fabrication of large-area sputtering targets

ActiveUS7910051B2Low heat introductionWide applicabilityLiquid surface applicatorsMolten spray coatingMetalEnergy method

In various embodiments, large-area sputtering targets are formed by providing a plurality of sputtering targets each comprising a backing plate and a refractory metal layer disposed thereon, and spray depositing a refractory metal powder on an interface between the sputtering targets, the refractory metal powder consisting essentially of the same metal as each refractory metal layer, thereby joining the refractory metal layers of the sputtering targets.

Owner:H C STARCK SURFACE TECH & CERAMIC POWDERS GMBH

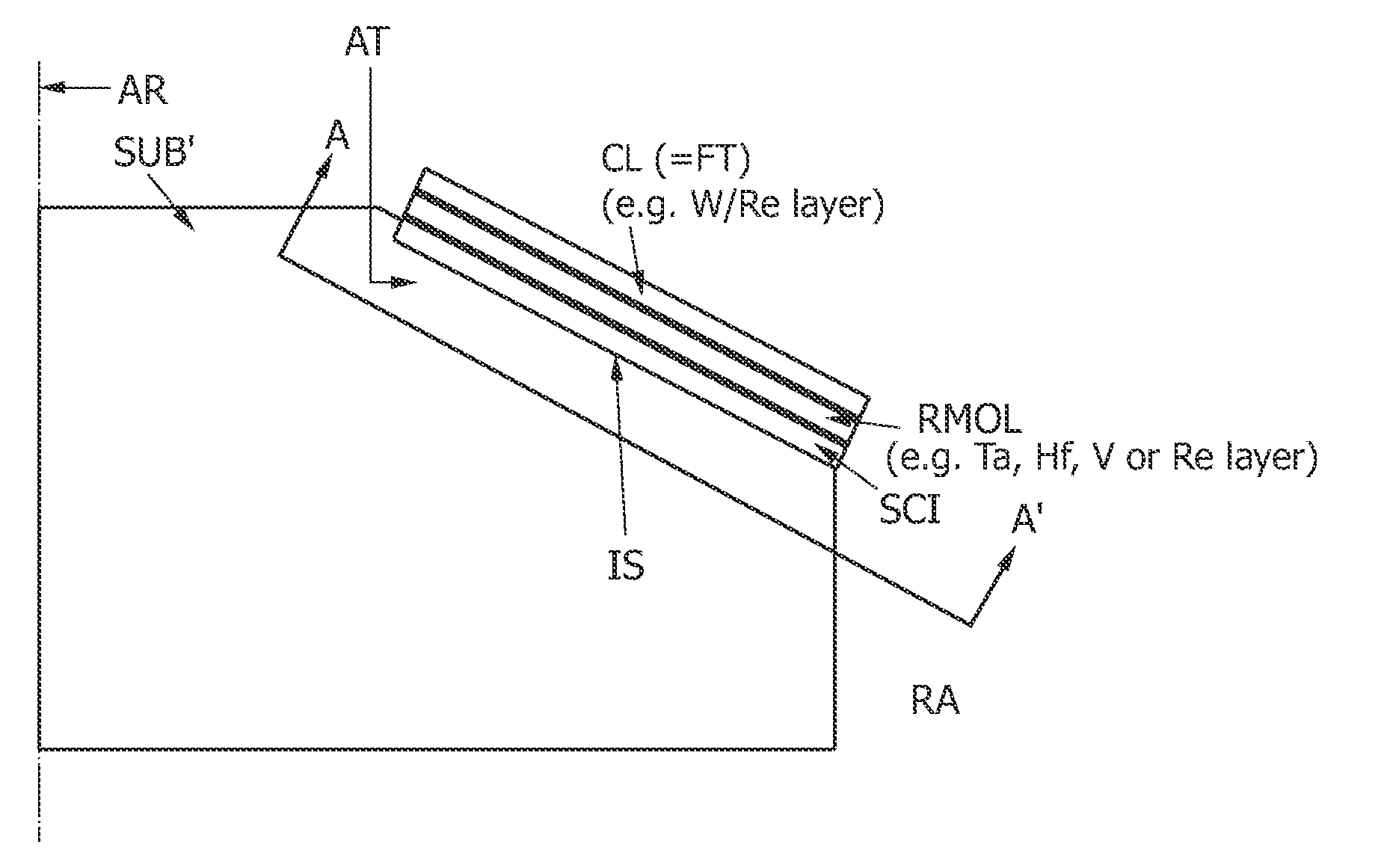

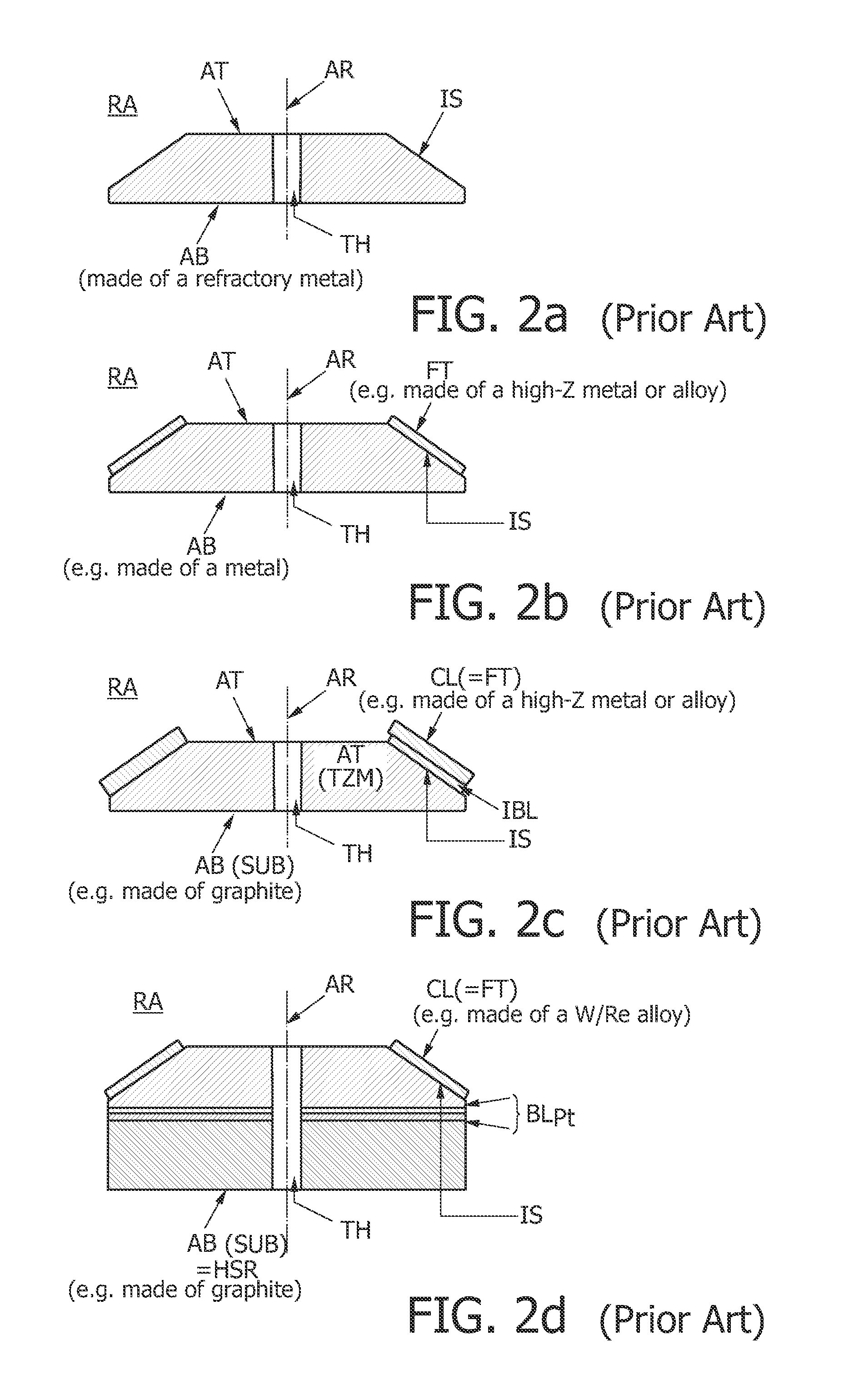

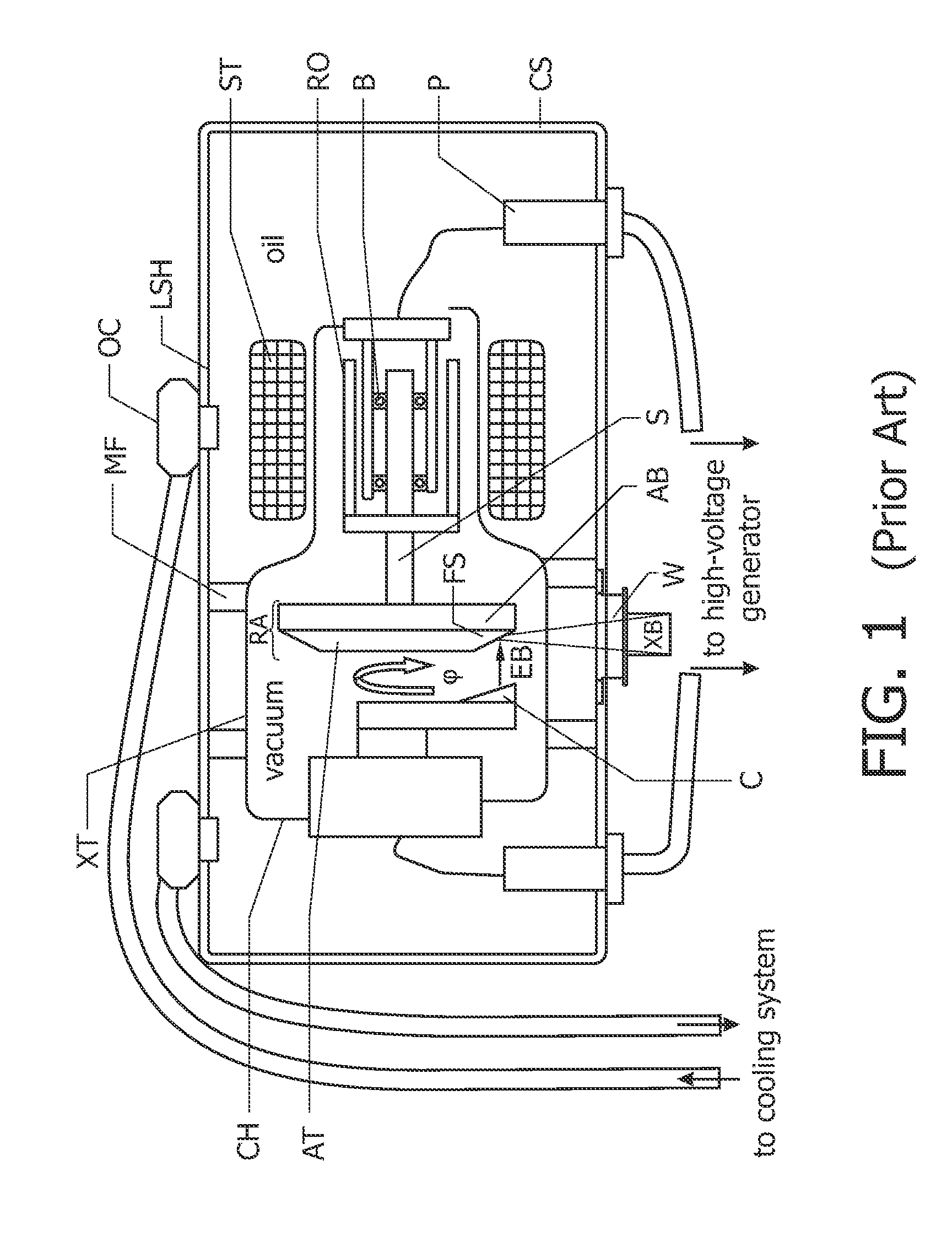

Attachment of a high-Z focal track layer to a carbon-carbon composite substrate serving as a rotary anode target

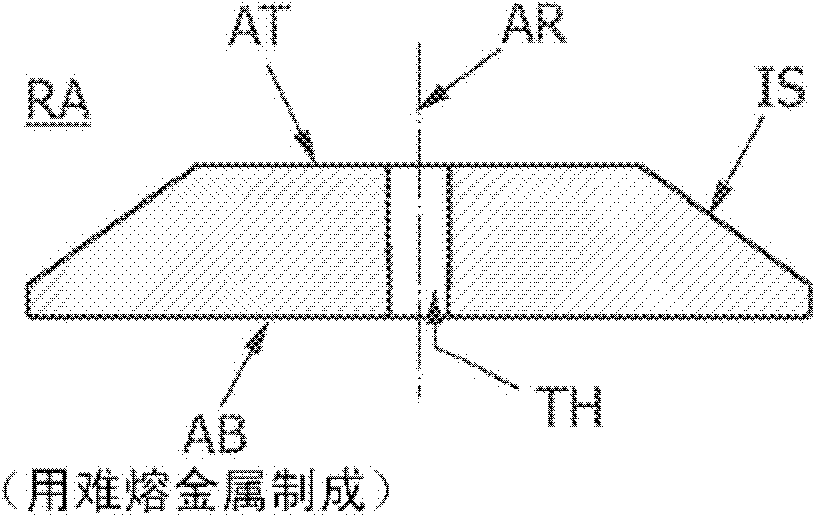

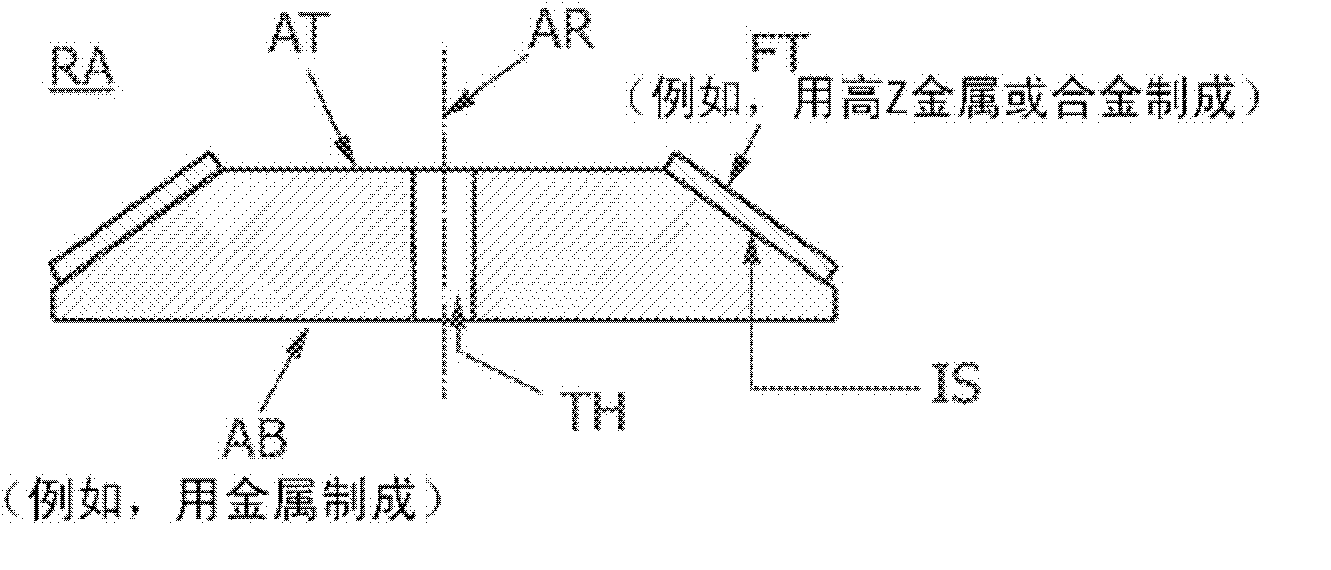

InactiveUS8553843B2Solve the slow scanning speedX-ray tube laminated targetsX-ray tube electrodesRheniumCarbon composites

The present invention refers to hybrid anode disk structures for use in X-ray tubes of the rotary anode type and is concerned more particularly with a novel light weight anode disk structure (RA) which comprises an adhesion promoting protective silicon carbide (SiC) interlayer (SCI) deposited onto a rotary X-ray tube's anode target (AT), wherein the latter may e.g. be made of a carbon-carbon composite substrate (SUB′). Moreover, a manufacturing method for robustly attaching a coating layer (CL) consisting of a high-Z material (e.g. a layer made of a tungsten-rhenium alloy) on the surface of said anode target is provided, whereupon according to said method it may be foreseen to apply a refractory metal overcoating layer (RML), such as given e.g. by a tantalum (Ta), hafnium (Hf), vanadium (V) or rhenium (Re) layer, to the silicon carbide interlayer (SCI) prior to the deposition of the tungsten-rhenium alloy. The invention thus leverages the tendency for cracking of the silicon carbide coated carbon composite substrate (SUB′) during thermal cycling and enhances adhesion of the silicon carbide / refractory metal interlayers to the carbon-carbon composite substrate (SUB′) and focal track coating layer (CL) by an interlocking mechanism. Key aspects of the proposed invention are: a) controlled formation of coating cracks (SC) in the silicon carbide layer (SCI) and b) conformal filling of SiC crack openings with a refractory metal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

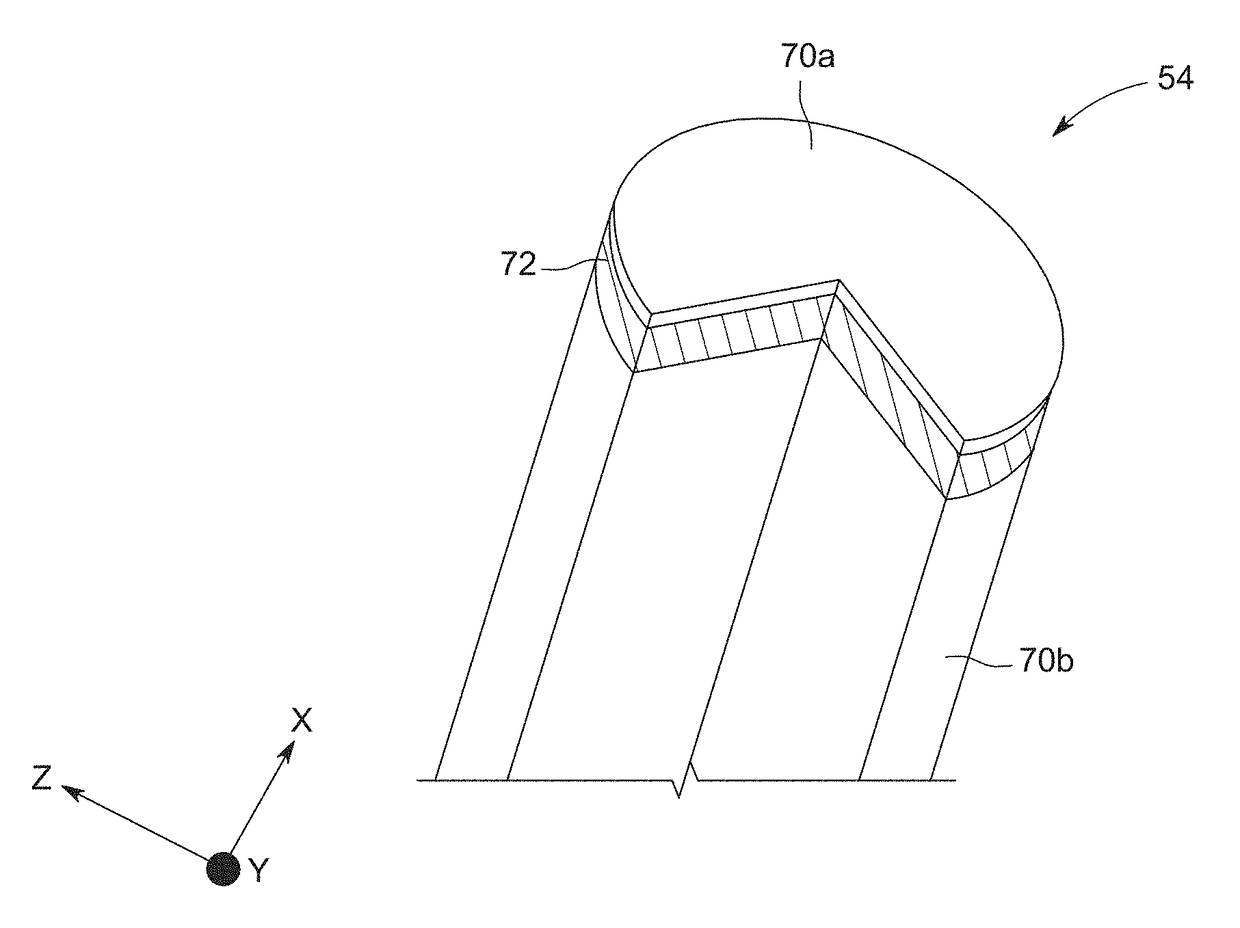

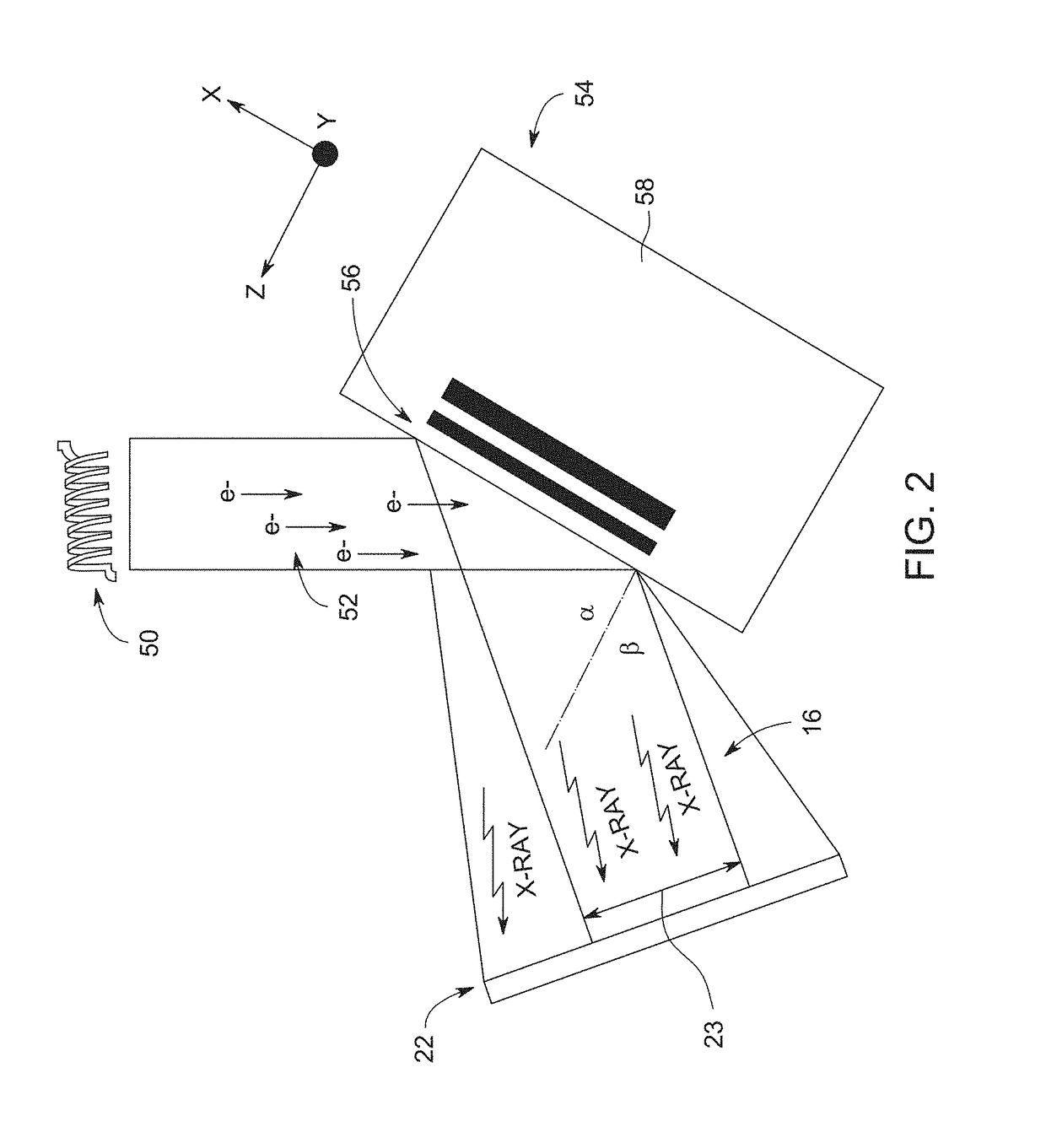

X-ray system, X-ray apparatus, X-ray target, and methods for manufacturing same

In some embodiments, an X-ray target includes a target cap formed of a substrate material and a focal track layer of emitting material, and at least one of the substrate material and the emitting material has a density greater than about 95.0% of theoretical density. In some embodiments, a method of manufacturing an X-ray target includes forming an intermediate target cap form of substrate material and a focal track layer of emitting material, and compacting the intermediate target cap form by application of gas pressure at elevated temperature to form a final target cap form, and at least the substrate material is dense substrate material having a final density greater than an intermediate density or the emitting material is dense emitting material having a final emitting material density greater than an intermediate emitting material density.

Owner:GENERAL ELECTRIC CO

Apparatus for x-ray generation and method of making same

Owner:GENERAL ELECTRIC CO

X-ray anode focal track region

A focal track region of an x-ray anode in an example is electrochemically etched. In a further example, an x-ray anode comprises a thermally-compliant focal track region for impingement of electrons from an x-ray cathode to create an x-ray source. The thermally-compliant focal track region comprises a pattern of discrete relative expanses and gaps.

Owner:GENERAL ELECTRIC CO

Attachment of a high-z focal track layer to a carbon-carbon composite substrate serving as a rotary anode target

InactiveUS20110249803A1Cleanliness and surface characteristicPromote divisionX-ray tube laminated targetsX-ray tube electrodesRheniumCarbon composites

The present invention refers to hybrid anode disk structures for use in X-ray tubes of the rotary anode type and is concerned more particularly with a novel light weight anode disk structure (RA) which comprises an adhesion promoting protective silicon carbide (SiC) interlayer (SCI) deposited onto a rotary X-ray tube's anode target (AT), wherein the latter may e.g. be made of a carbon-carbon composite substrate (SUB′). Moreover, a manufacturing method for robustly attaching a coating layer (CL) consisting of a high-Z material (e.g. a layer made of a tungsten-rhenium alloy) on the surface of said anode target is provided, whereupon according to said method it may be foreseen to apply a refractory metal overcoating layer (RML), such as given e.g. by a tantalum (Ta), hafnium (Hf), vanadium (V) or rhenium (Re) layer, to the silicon carbide interlayer (SCI) prior to the deposition of the tungsten-rhenium alloy. The invention thus leverages the tendency for cracking of the silicon carbide coated carbon composite substrate (SUB′) during thermal cycling and enhances adhesion of the silicon carbide / refractory metal interlayers to the carbon-carbon composite substrate (SUB′) and focal track coating layer (CL) by an interlocking mechanism. Key aspects of the proposed invention are: a) controlled formation of coating cracks (SC) in the silicon carbide layer (SCI) and b) conformal filling of SiC crack openings with a refractory metal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

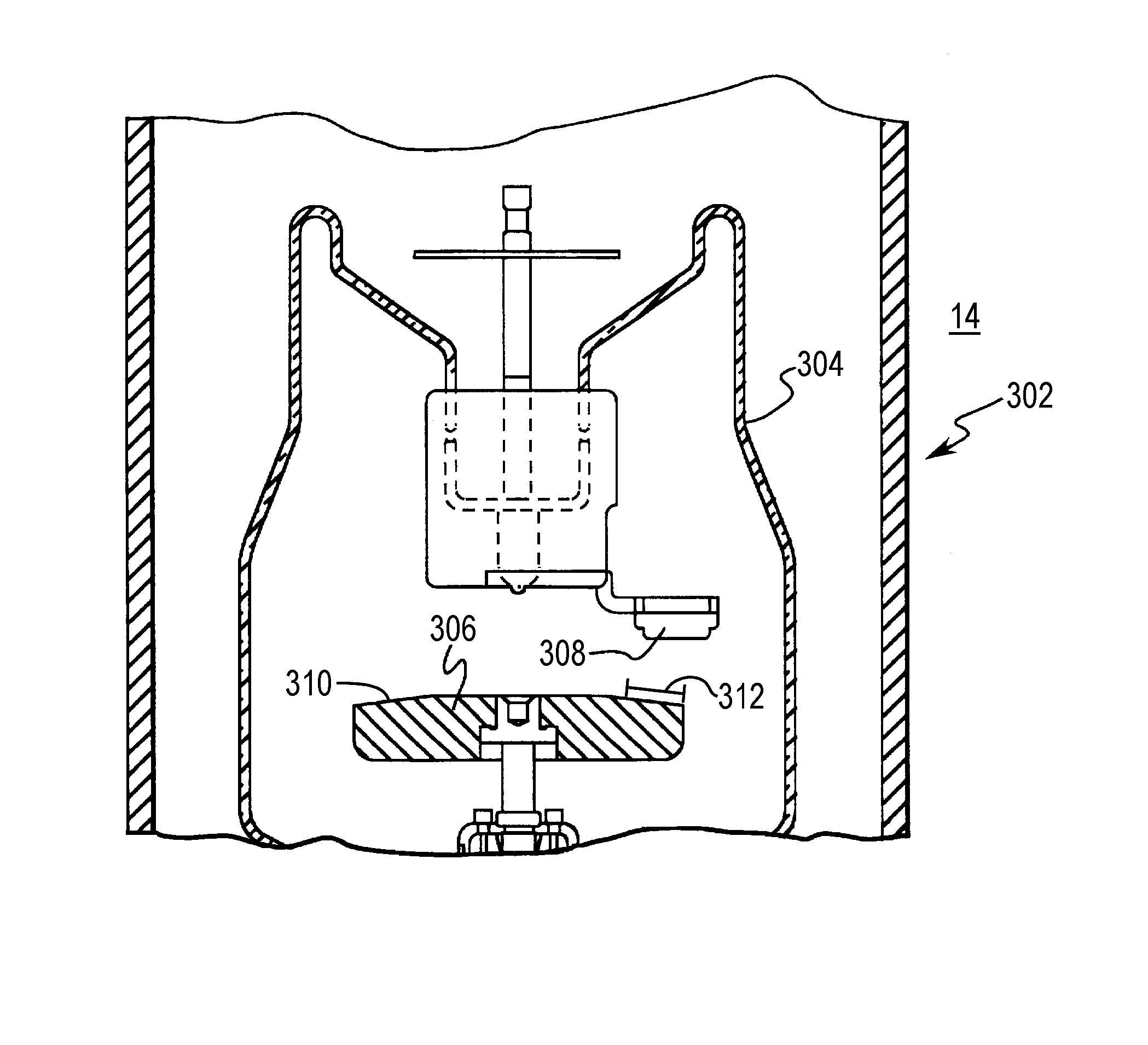

Target pedestal assembly and method of preserving the target

ActiveUS20100202593A1Prolong target lifeHeat dissipationX-ray tube anode coolingX-ray tube electrodesSoft x rayChemical reaction

An x-ray target pedestal assembly and a method of protecting the x-ray target from breaking down as a result of the extreme heat that is produced when an electron beam is aimed at the target to produce x-rays. The target is submerged in cooling fluid and is rotated by a constant flow of the cooling fluid over and around the target in order to dissipate heat. The fluid is guided by integrated flow diverters in the target cover. The target may also be protectively coated either in its entirety or along the electron beam path in order to further protect it from the heat of the electron beam impact or from breakdown as a result of attack of free radicals or other chemically reactive components of the cooling fluid which are produced in the extreme target environment.

Owner:TOMOTHERAPY INC

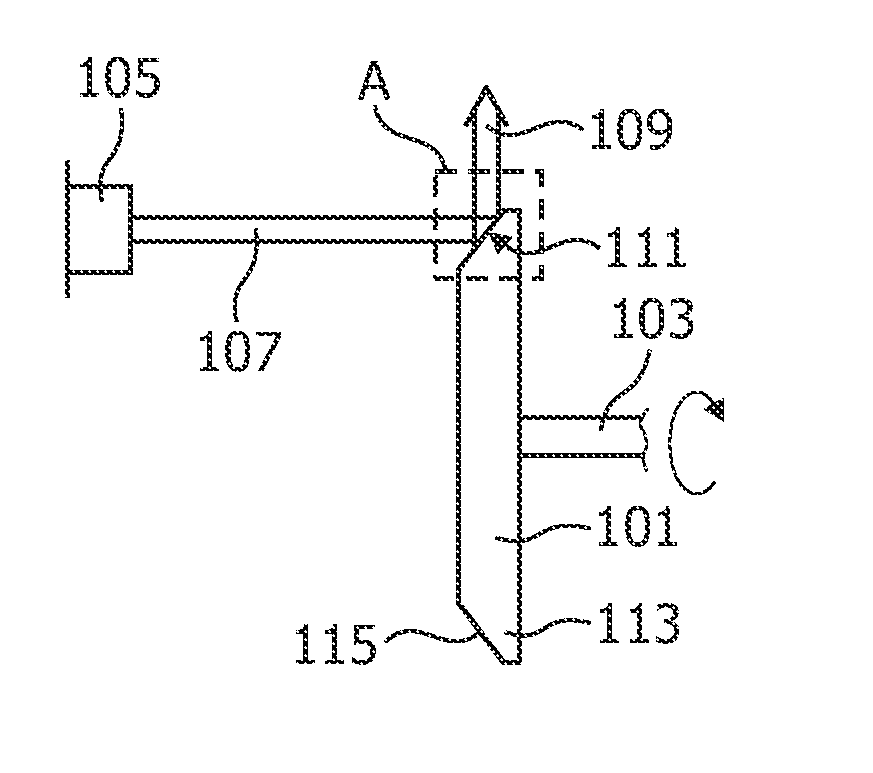

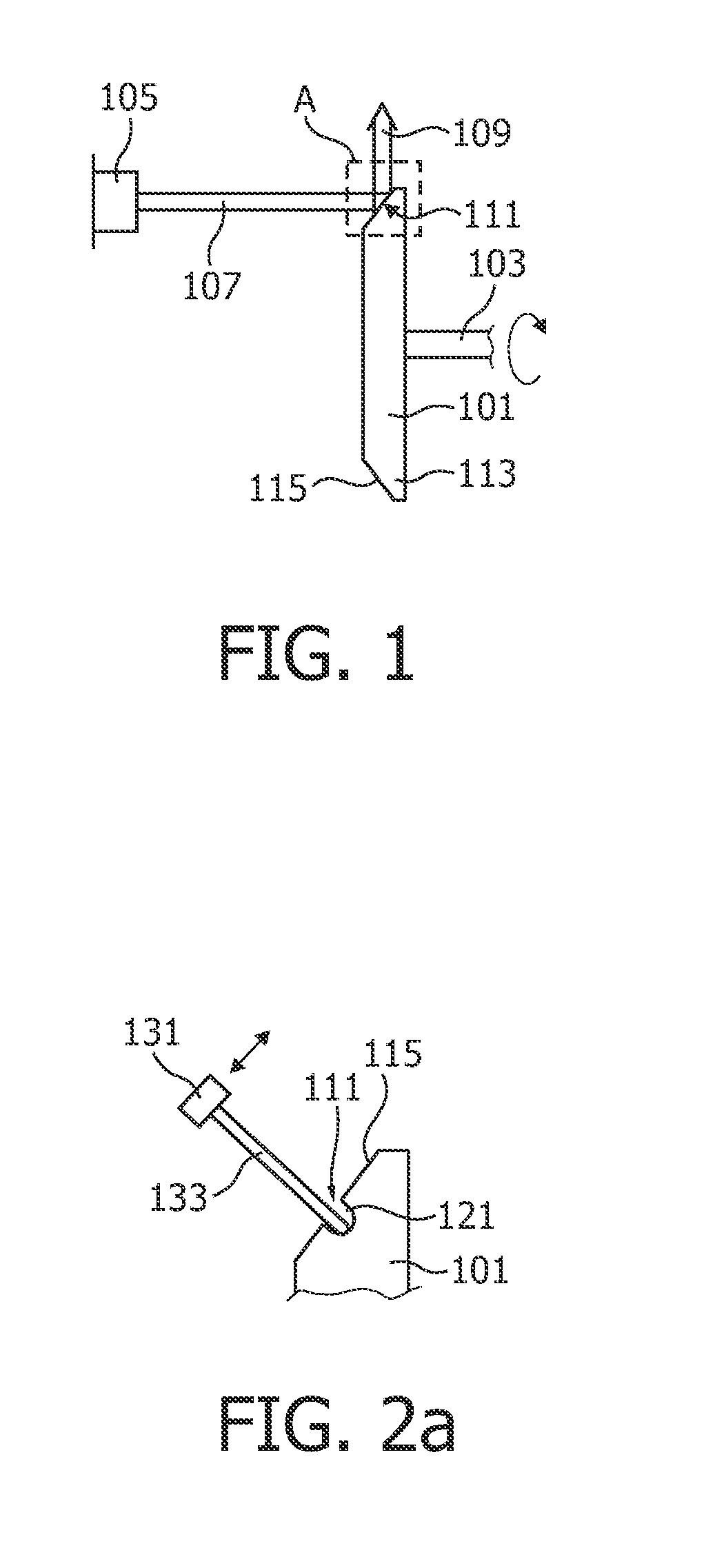

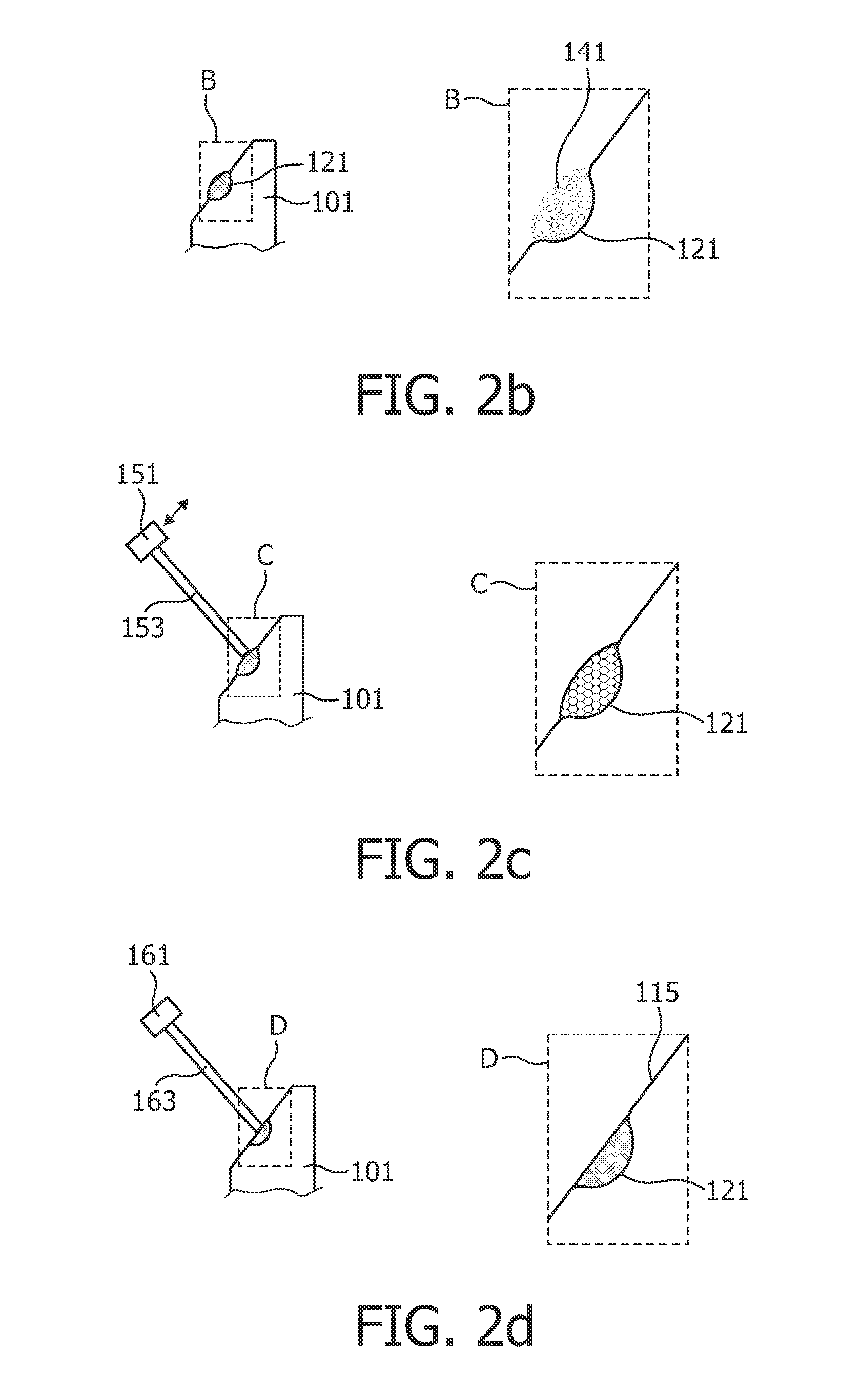

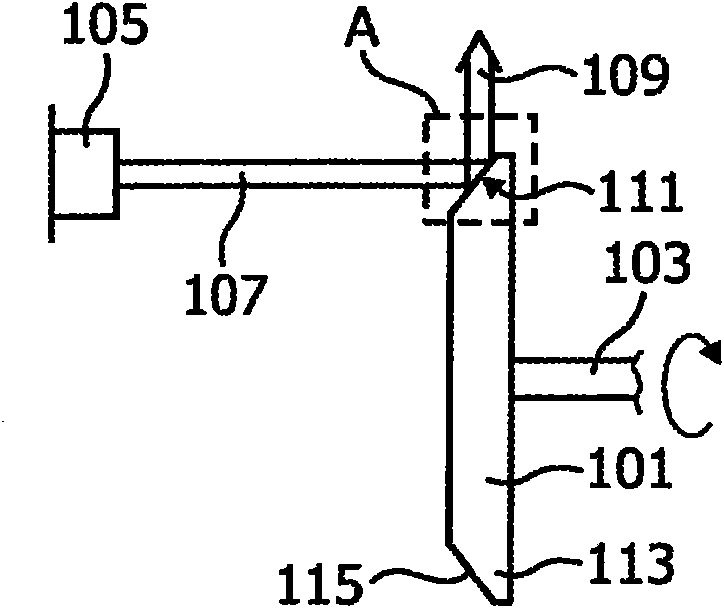

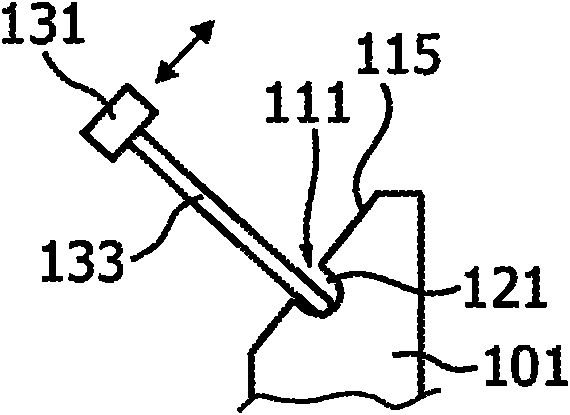

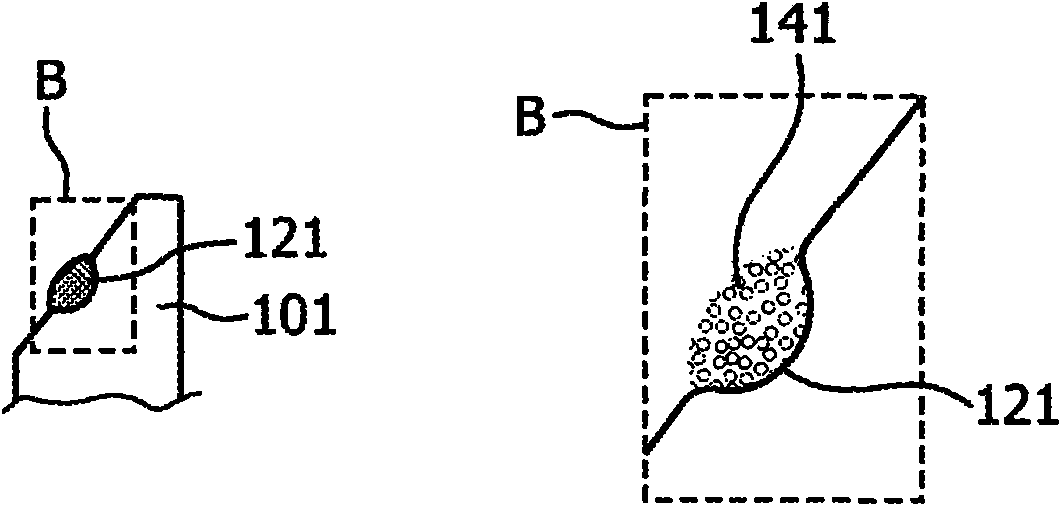

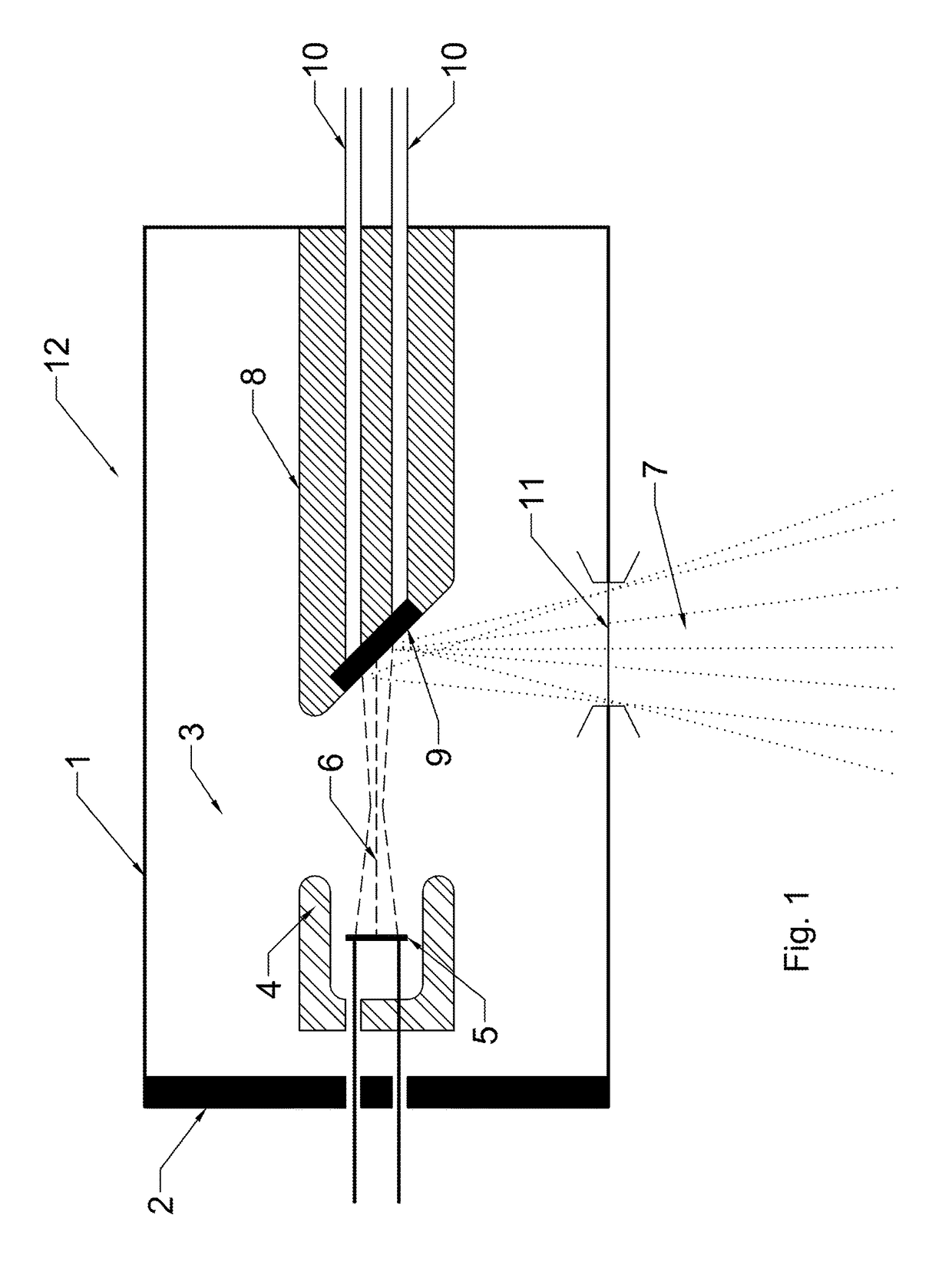

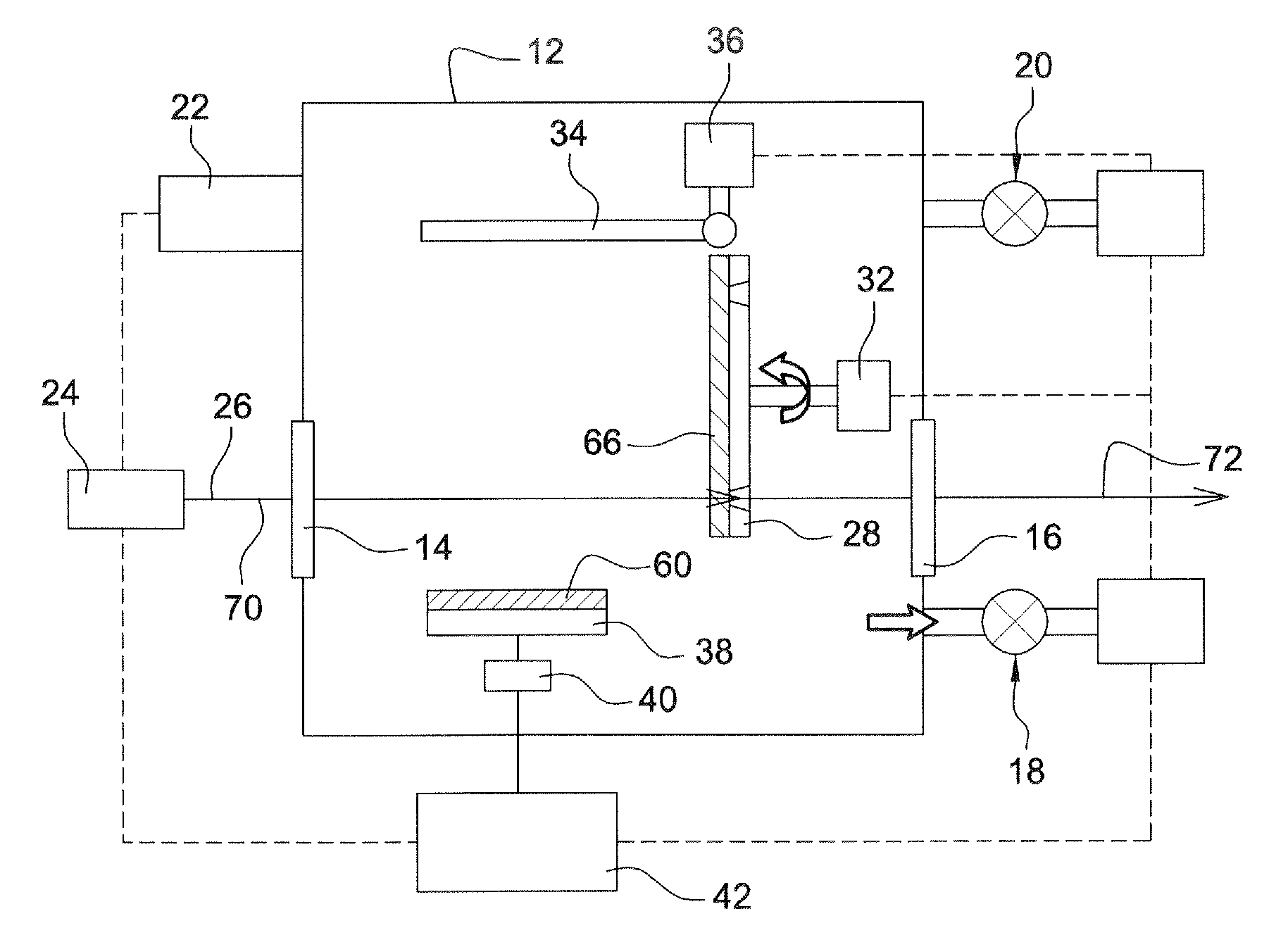

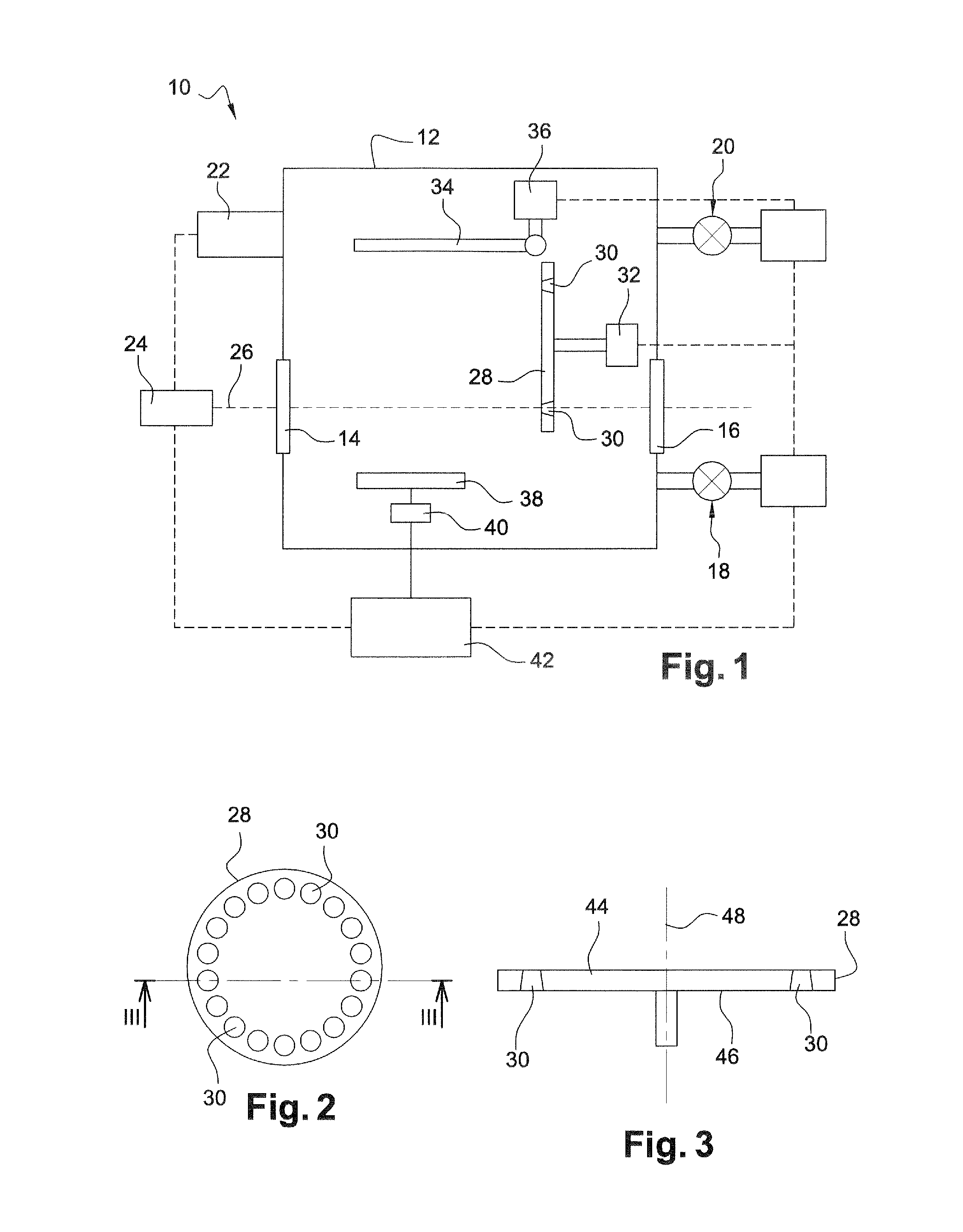

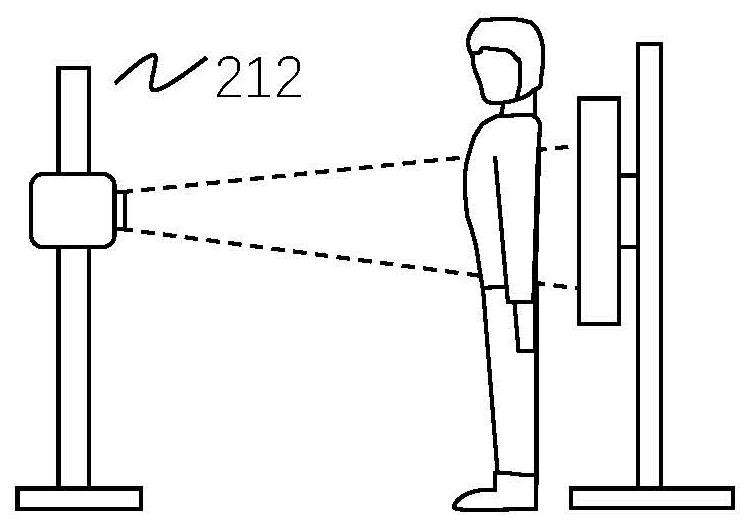

Method and apparatus for applying material to a surface of an anode of an x-ray source, anode and x-ray source

InactiveUS20110211676A1Avoid pollutionReduce in quantityLiquid surface applicatorsElectric discharge heatingRheniumX-ray

A method and an apparatus for locally applying material to the surface of an anode of an X-ray source as well as a corresponding anode is presented. Anode material such as a repair material for filling a recess (121) in an X-ray emitting surface (115) is applied to the X-ray emitting surface of an anode (101). The location where such material is to be applied may be detected using a laser beam (133). The applied repair material including particles (41) of anode material such as tungsten, rhenium or molybdenum, is subsequently locally sintered using a high-energy laser beam (151). The sintered material may then be melted using a high-energy electron beam (163). Using such method, a damaged surface of an anode may be locally repaired. Alternatively, structures of different anode materials or of protrusions having different levels can be provided on the X-ray emitting surface (115) in order to selectively manipulate the X-ray emitting characteristics of the anode (101).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

X-ray anode focal track region

A focal track region of an x-ray anode in an example is electrochemically etched. In a further example, an x-ray anode comprises a thermally-compliant focal track region for impingement of electrons from an x-ray cathode to create an x-ray source. The thermally-compliant focal track region comprises a pattern of discrete relative expanses and gaps.

Owner:GENERAL ELECTRIC CO

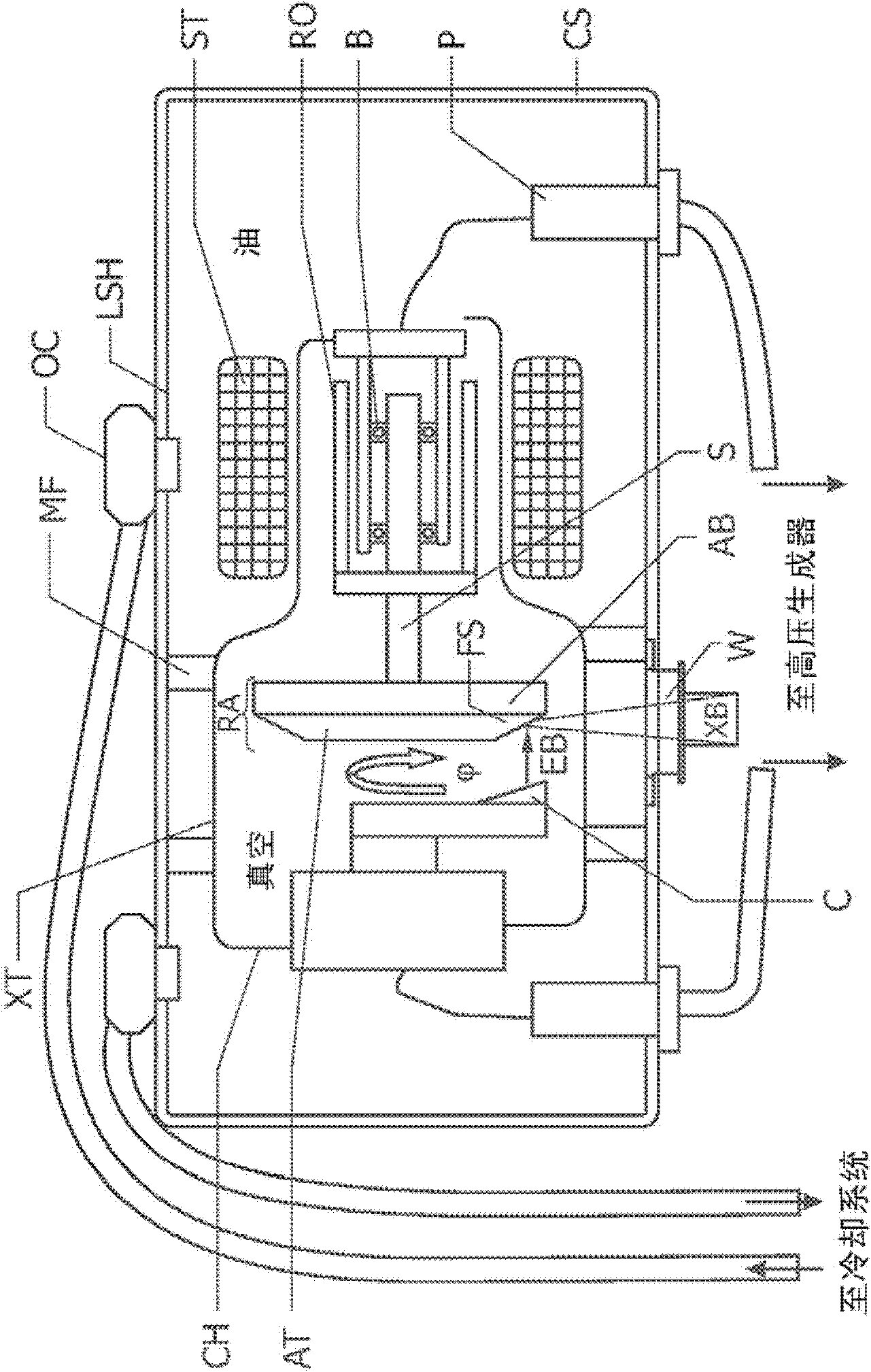

Attachment of a high-z focal track layer to a carbon-carbon composite substrate serving as a rotary anode target

InactiveCN102257591ATemperature to increase densityIncrease temperatureX-ray tube laminated targetsX-ray tube electrodesRheniumCarbon composites

The present invention refers to hybrid anode disk structures for use in X- ray tubes of the rotary anode type and is concerned more particularly with a novel light weight anode disk structure (RA) which comprises an adhesion promoting protective silicon carbide (SiC) interlayer (SCI) deposited onto a rotary X-ray tube's anode target (AT), wherein the latter may e.g. be made of a carbon-carbon composite substrate (SUB'). Moreover, a manufacturing method for robustly attaching a coating layer (CL) consisting of a high-Z material (e.g. a layer made of a tungsten-rhenium alloy) on the surface of said anode target is provided, whereupon according to said method it may be foreseen to apply a refractory metal overcoating layer (RML), such as given e.g. by a tantalum (Ta), hafnium (Hf), vanadium (V) or rhenium (Re) layer, to the silicon carbide interlayer (SCI) prior to the deposition of the tungsten-rhenium alloy. The invention thus leverages the tendency for cracking of the silicon carbide coated carbon composite substrate (SUB') during thermal cycling and enhances adhesion of the silicon carbide / refractory metal interlayers to the carbon-carbon composite substrate (SUB') and focal track coating layer (CL) by an interlocking mechanism. Key aspects of the proposed invention are: a) controlled formation of coating cracks (SC) in the silicon carbide layer (SCI) and b) conformal filling of SiC crack openings with a refractory metal.

Owner:KONINK PHILIPS ELECTRONICS NV

Method and apparatus for applying material to a surface of an anode of an x-ray source, anode and x-ray source

A method and an apparatus for locally applying material to the surface of an anode of an X-ray source as well as a corresponding anode is presented. Anode material such as a repair material for filling a recess (121) in an X-ray emitting surface (115) is applied to the X-ray emitting surface of an anode (101). The location where such material is to be applied may be detected using a laser beam (133). The applied repair material including particles (41) of anode material such as tungsten, rhenium or molybdenum, is subsequently locally sintered using a high-energy laser beam (151). The sintered material may then be melted using a high-energy electron beam (163). Using such method, a damaged surface of an anode may be locally repaired. Alternatively, structures of different anode materials or of protrusions having different levels can be provided on the X-ray emitting surface (115) in order to selectively manipulate the X-ray emitting characteristics of the anode (101).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

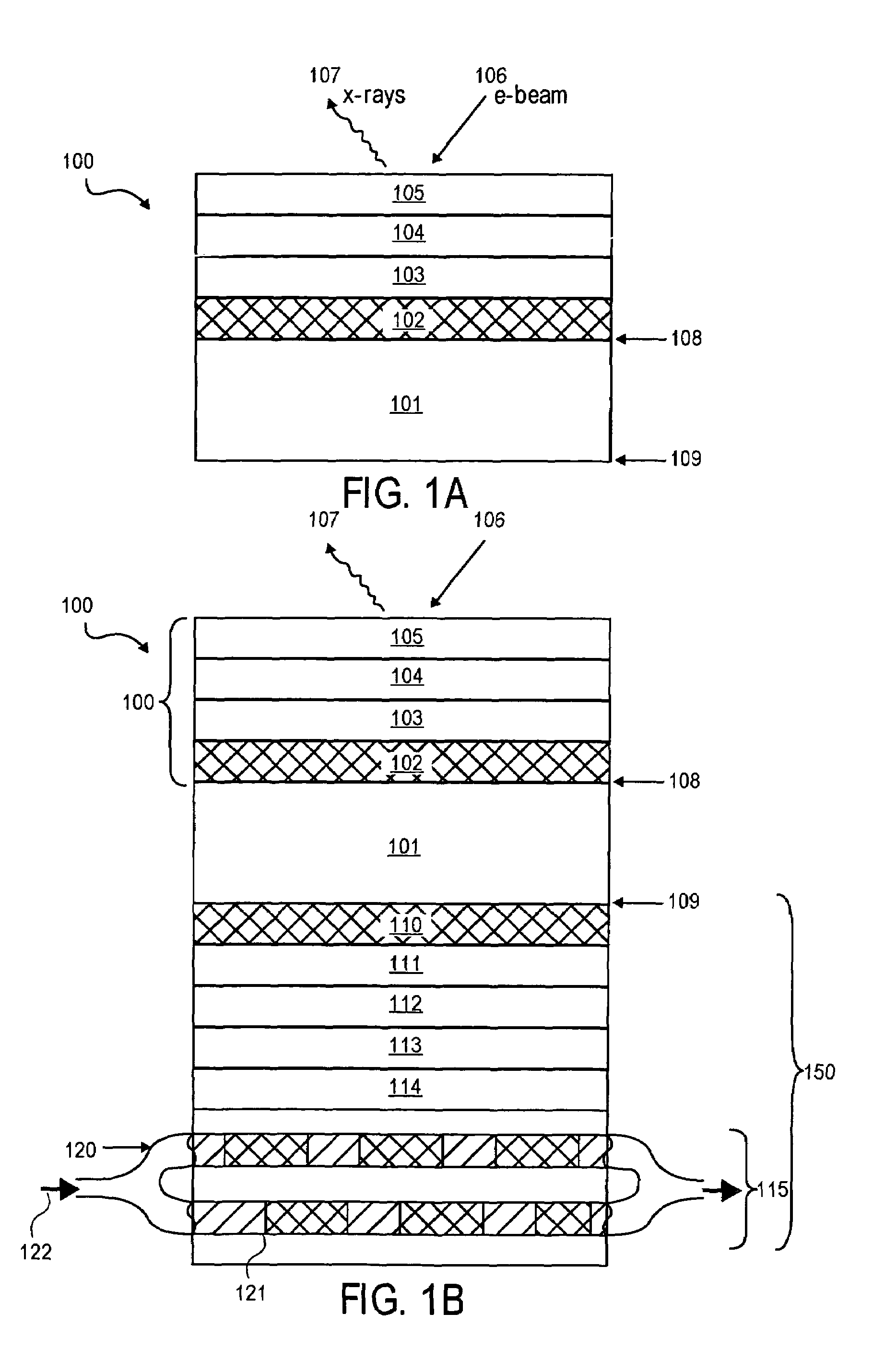

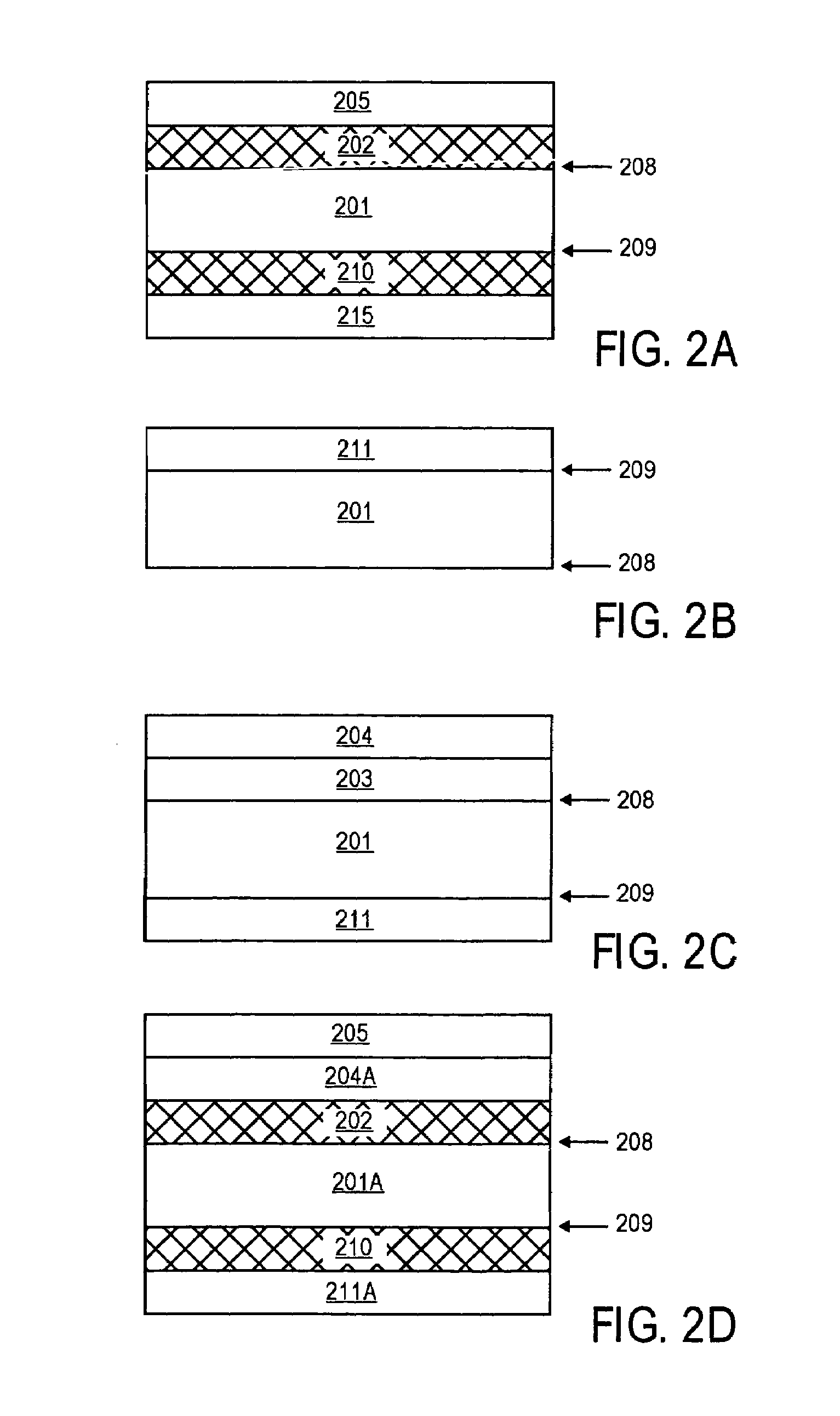

High temperature annealing in x-ray source fabrication

The present disclosure relates to multi-layer X-ray sources having decreased hydrogen within the layer stack and / or tungsten carbide inter-layers between the primary layers of X-ray generating and thermally-conductive materials. The resulting multi-layer target structures allow increased X-ray production, which may facilitate faster scan times for inspection or examination procedures.

Owner:MANTHEY DIANE MANT

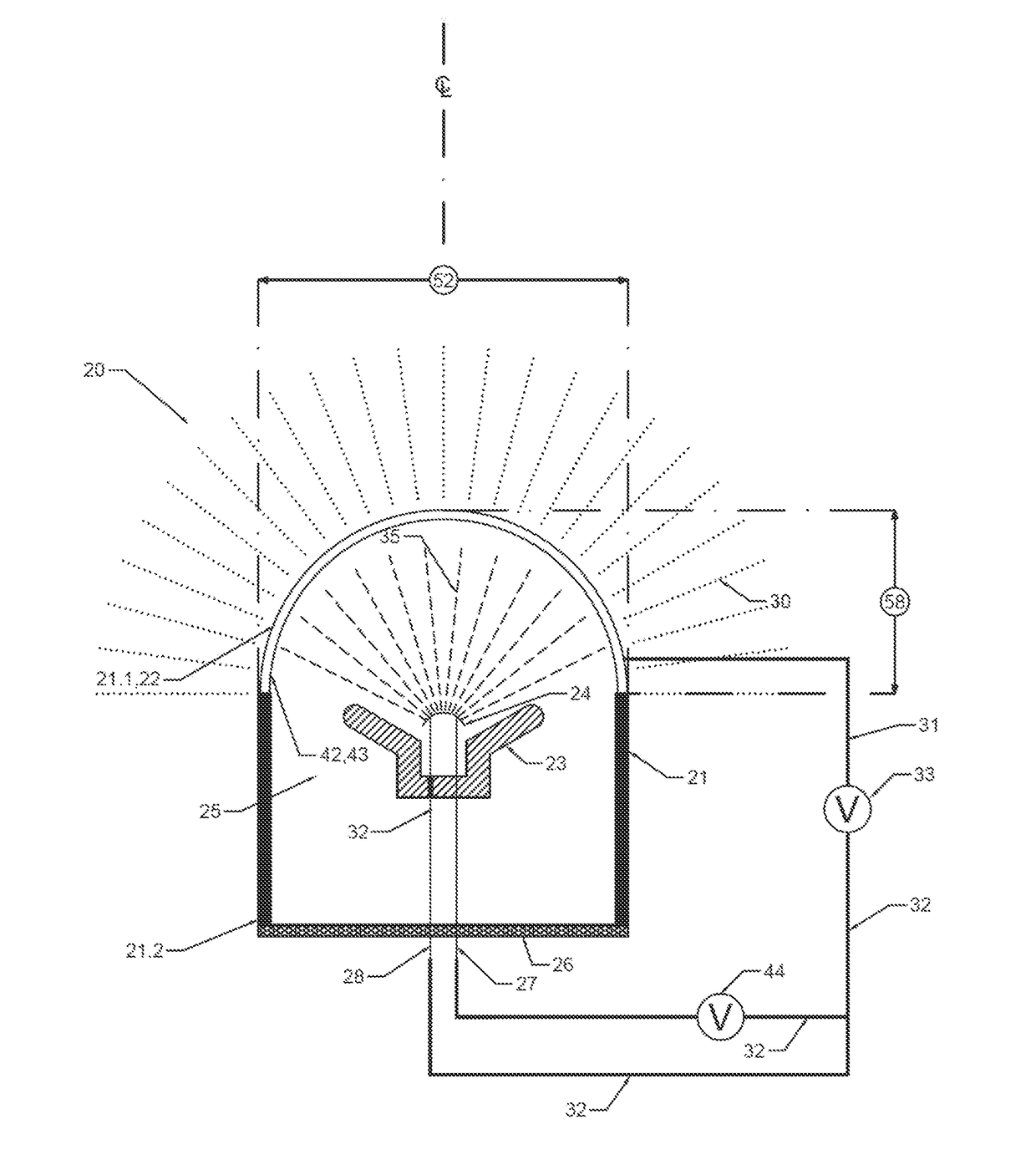

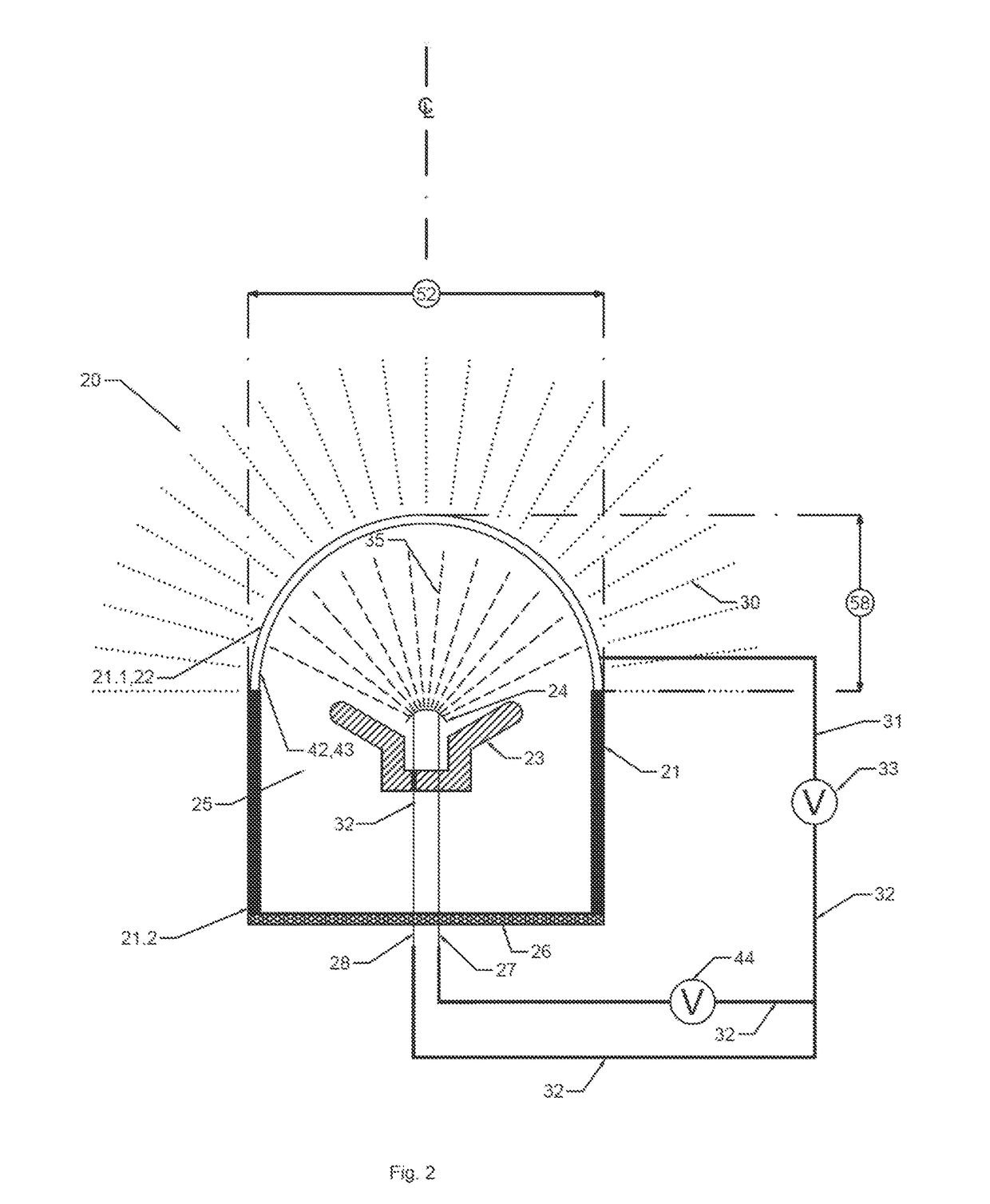

High dose output, through transmission & relective target x-ray system and methods of use

ActiveUS20180047540A1Increase surface areaX-ray tube electrodesDischarge tube solid anodesX-rayHigh doses

A high dose output, through transmission and reflective target x-ray tube and methods of use includes, in general an x-ray tube for accelerating electrons under a high voltage potential having an evacuated high voltage housing, a hemispherical shaped through and reflective transmission target anode disposed in said housing, a cathode structure to deflect the electrons toward the hemispherical anode disposed in said housing, a filament located in the geometric center of the anode hemisphere disposed in said housing, a power supply connected to said cathode to provide accelerating voltage to the electrons.

Owner:RAD SOURCE TECH

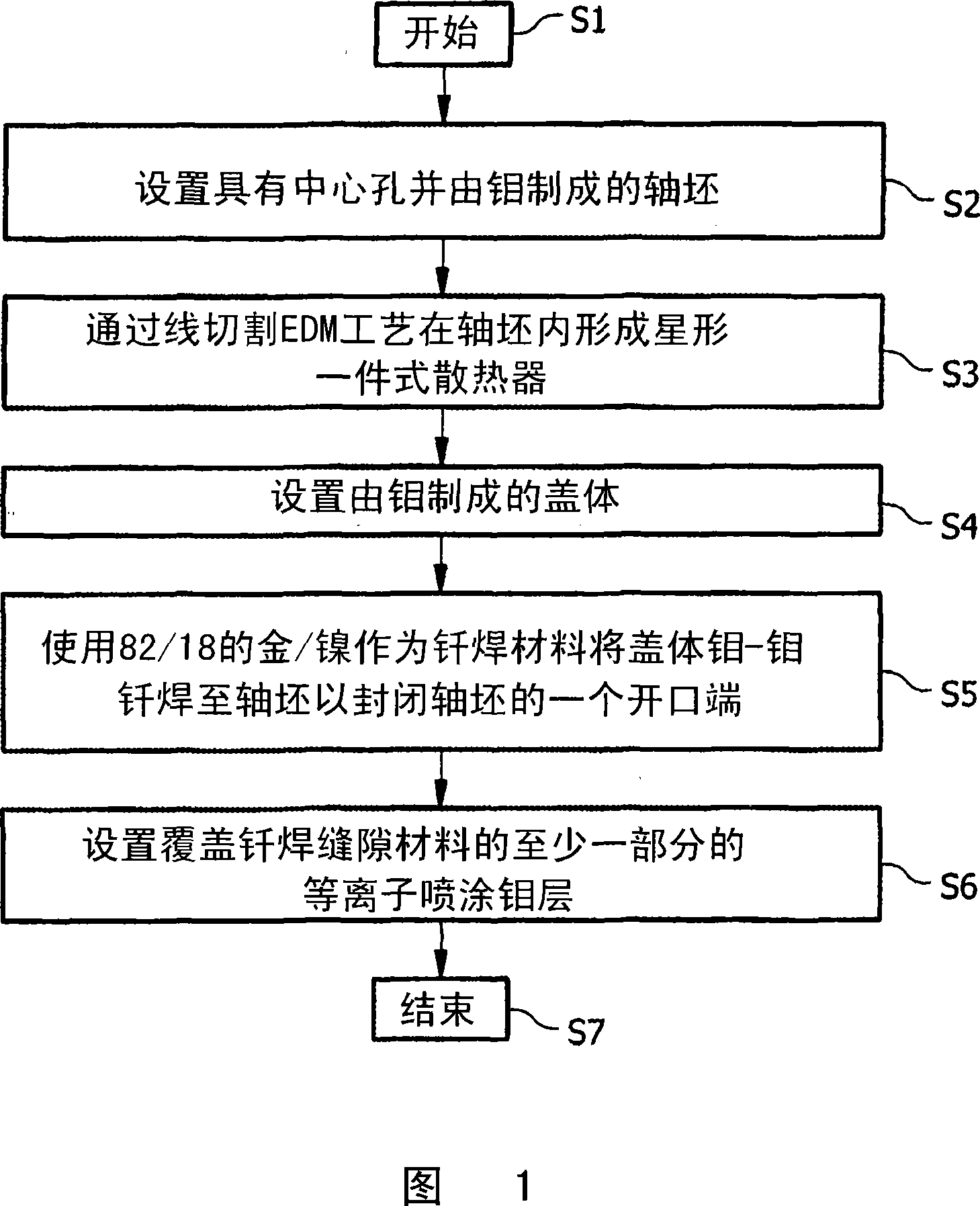

Molybdenum-molybdenum brazing and rotary-anode x-ray tube comprising such a brazing

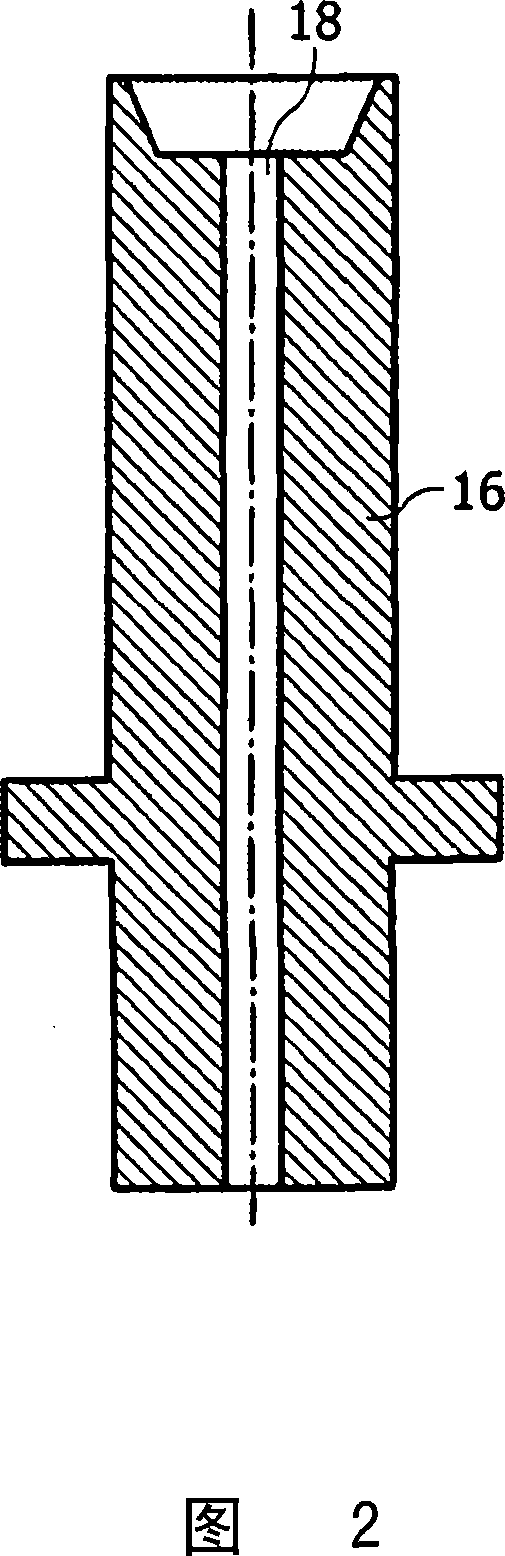

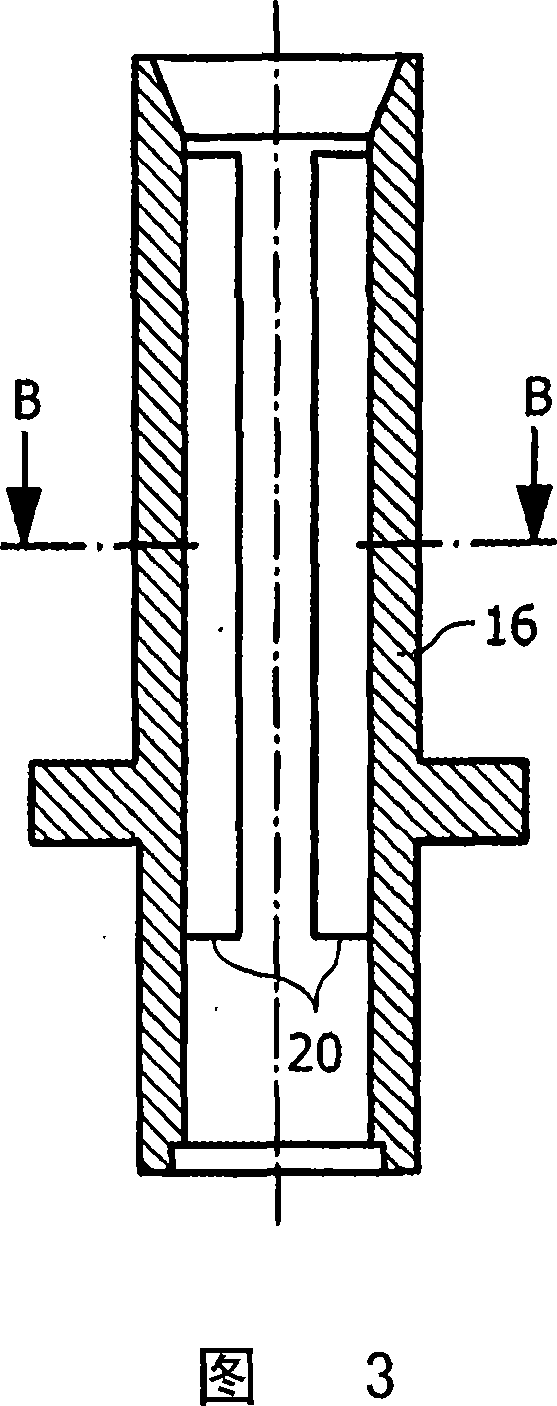

The present invention relates to a method for providing a molybdenum-molybdenum or molybdenum aaloy-molybdenum alloy brazing. In accordance with the invention this method comprises the following steps: - providing at least two parts (16, 22) made of molybdenum or a molybdenum alloy; - brazing together said two parts (16, 22) using a brazing material (26); and - providing a plasma-sprayed molybdenum of molybdenum alloy layer (28) at least on a portion of the brazing material (26) that would be accessible otherwise. Furthermore, the present invention is directed to a rotary-anode X-ray tube (14) which is equipped with a spiral groove bearing (12) comprising, as a first part (16), an axle blank (16) having a center bore (18) and being made of molybdenum or a molybdenum alloy and, as a second part (22), a cap (22) made of molybdenum or an molybdenum alloy, wherein, for closing one open axial end (24) of said axle blank (16), said axle blank (16) and said cap (22) are brazed together using the method in accordance with the invention.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method and system for manufacturing a target for the emission of photon radiation, particularly x rays, or of particles, particularly protons or electrons, by laser firing

ActiveUS20140287140A1Use directlyEasy to disassembleX-ray tube electrodesVacuum evaporation coatingSoft x rayFilling materials

A method of manufacturing a target for the generation of radiation of photons, protons or electrons by means of a laser, including: forming a support including first and second surfaces connected by openings, and forming in an enclosure a layer of material on the first surface by protecting the first surface with a protection element, injecting into the enclosure a gas of filling material, adjusting the pressure in the enclosure and the temperature of the support to form plugs of material in the openings of the support, and maintaining the temperature of the support and the pressure in the enclosure at values to maintain the plugs, followed by withdrawing the protection clement from the first surface, and forming a layer of metallic material on the first surface of the support and on the plugs. The pressure and support temperature are then modified to remove the plugs.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

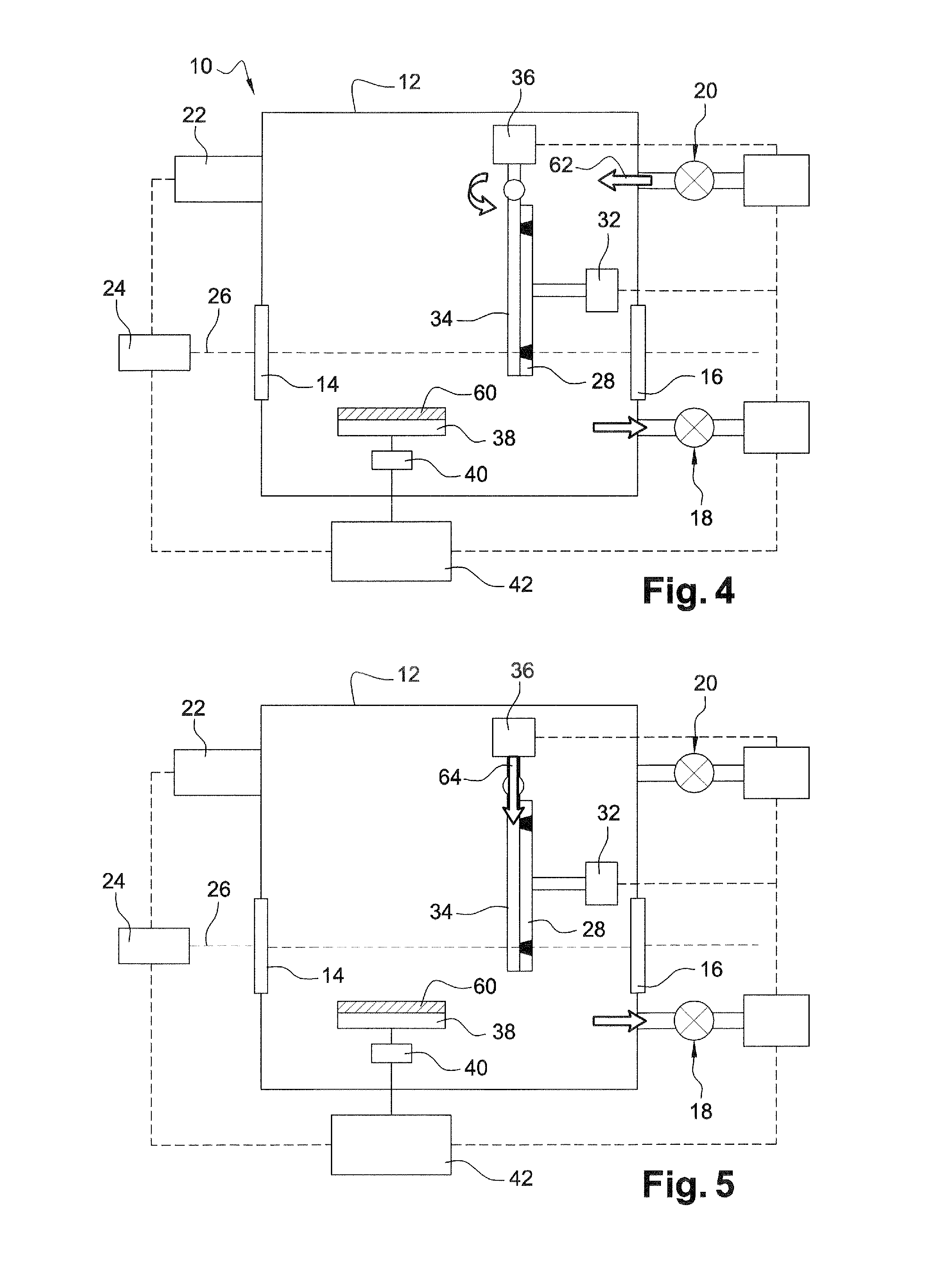

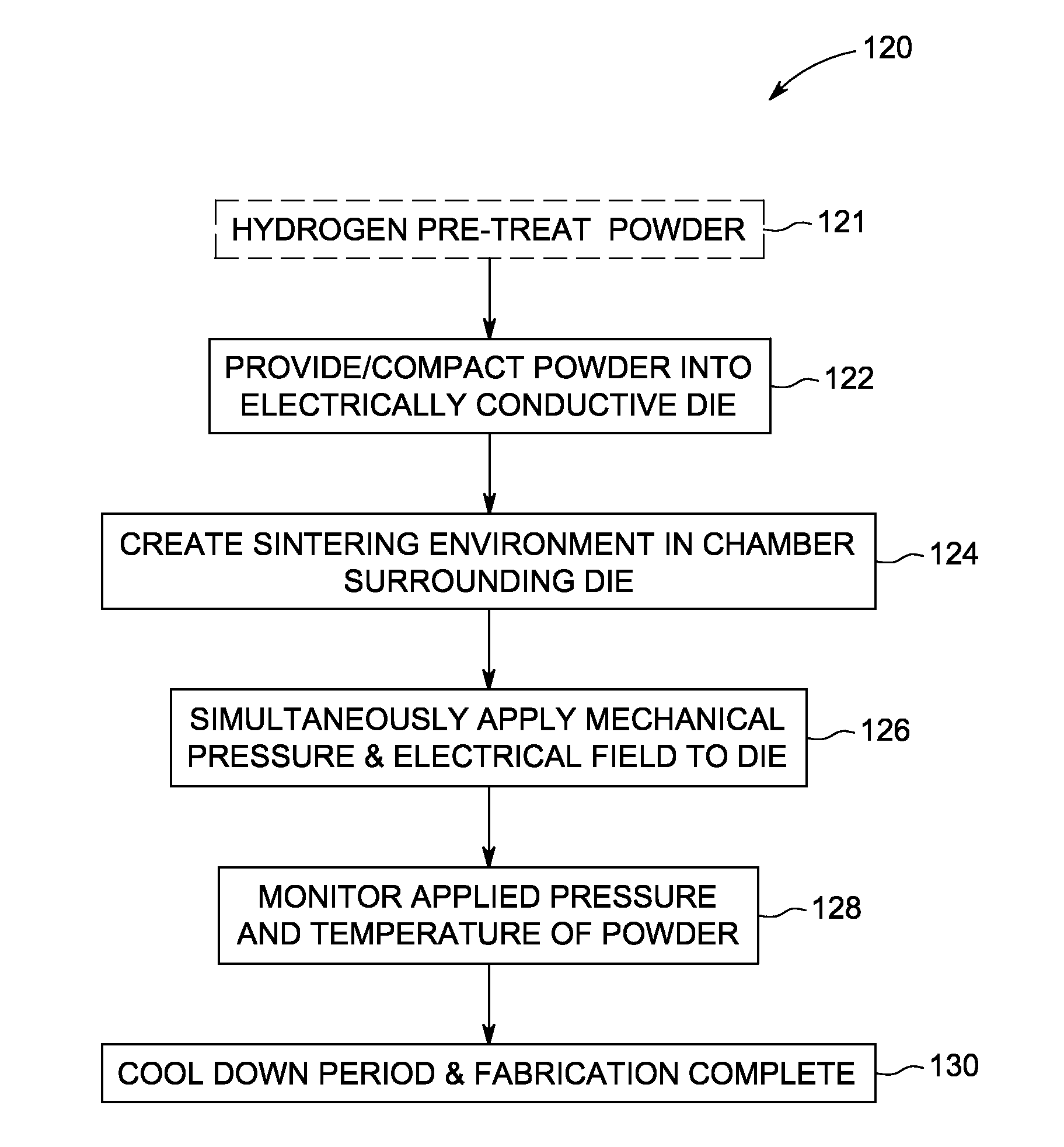

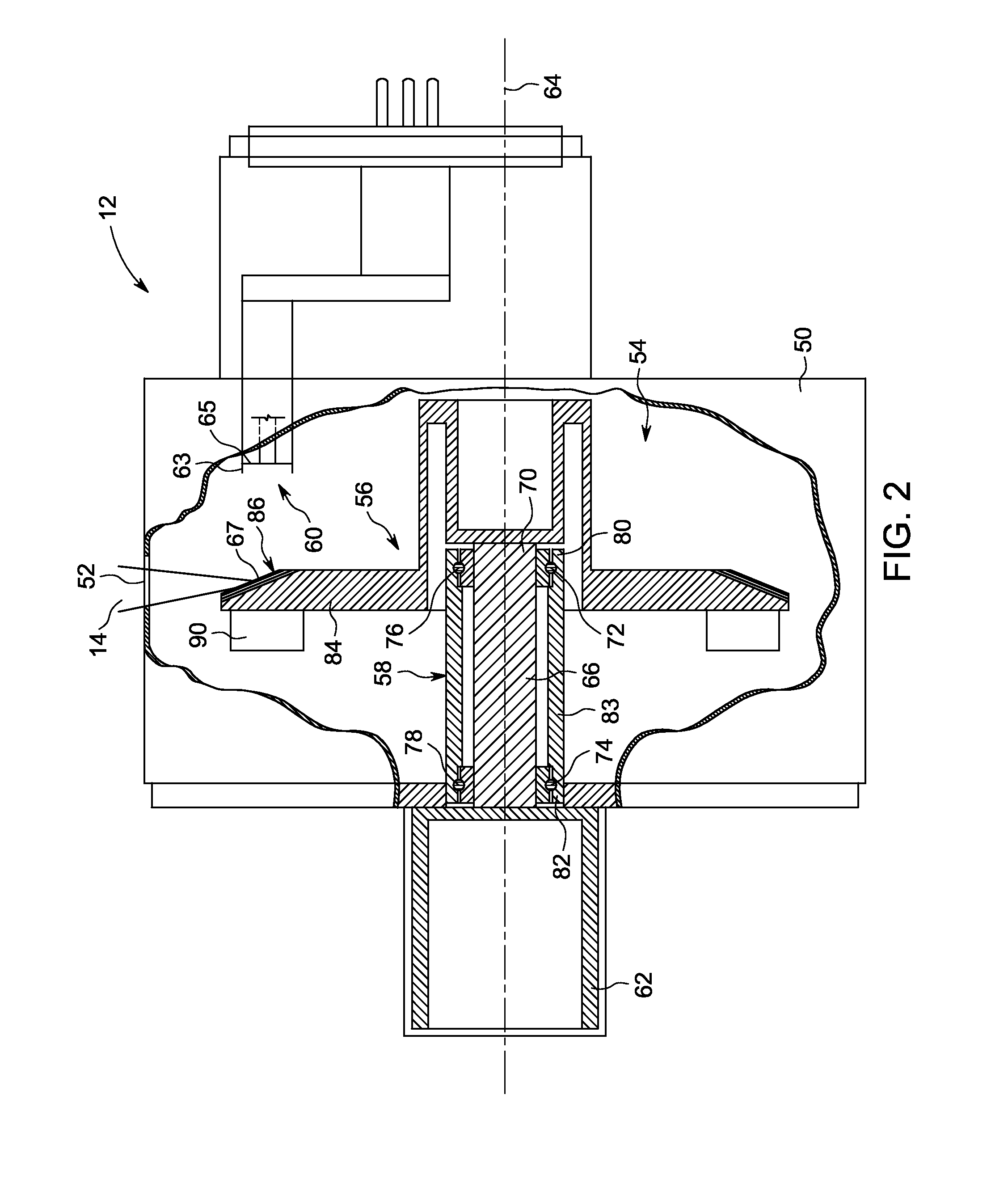

Field assisted sintering of x-ray tube components

ActiveUS20140362977A1X-ray tube electrodesNon-emitting electrodes manufactureMechanical pressureMaterials science

A system and method for x-ray tube components is disclosed. The method of fabricating an x-ray tube component includes providing a powder into an electrically conductive die constructed to have a cavity shaped as the x-ray tube component being fabricated and simultaneously applying a mechanical pressure and an electric field to the die so as to cause sintering of the powder and thereby fabricate the x-ray tube component, wherein the electric field applied to the die directly passes through the die to the powder, so as to generate heat internally within the powder responsive to the applied electric field.

Owner:GENERAL ELECTRIC CO

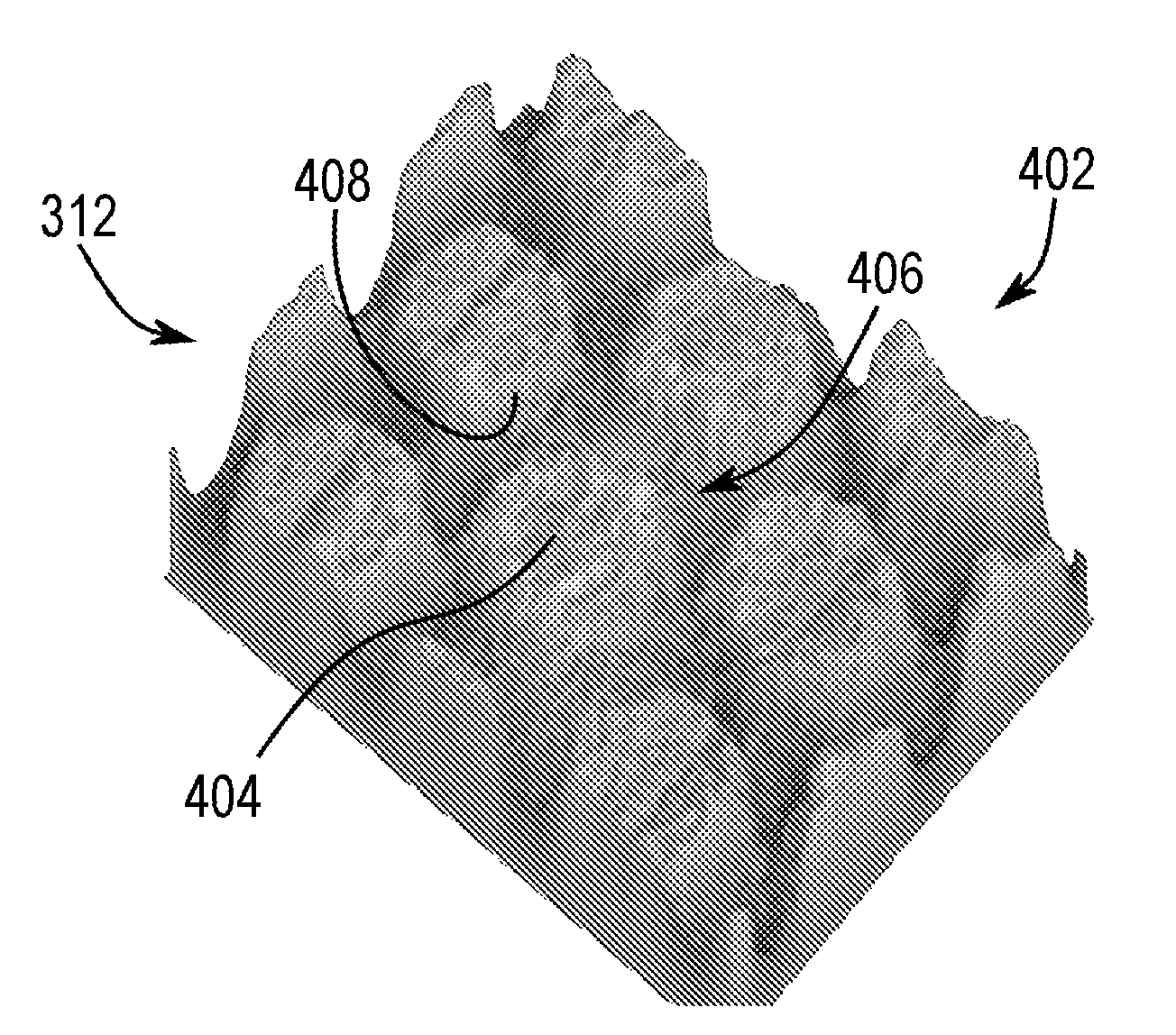

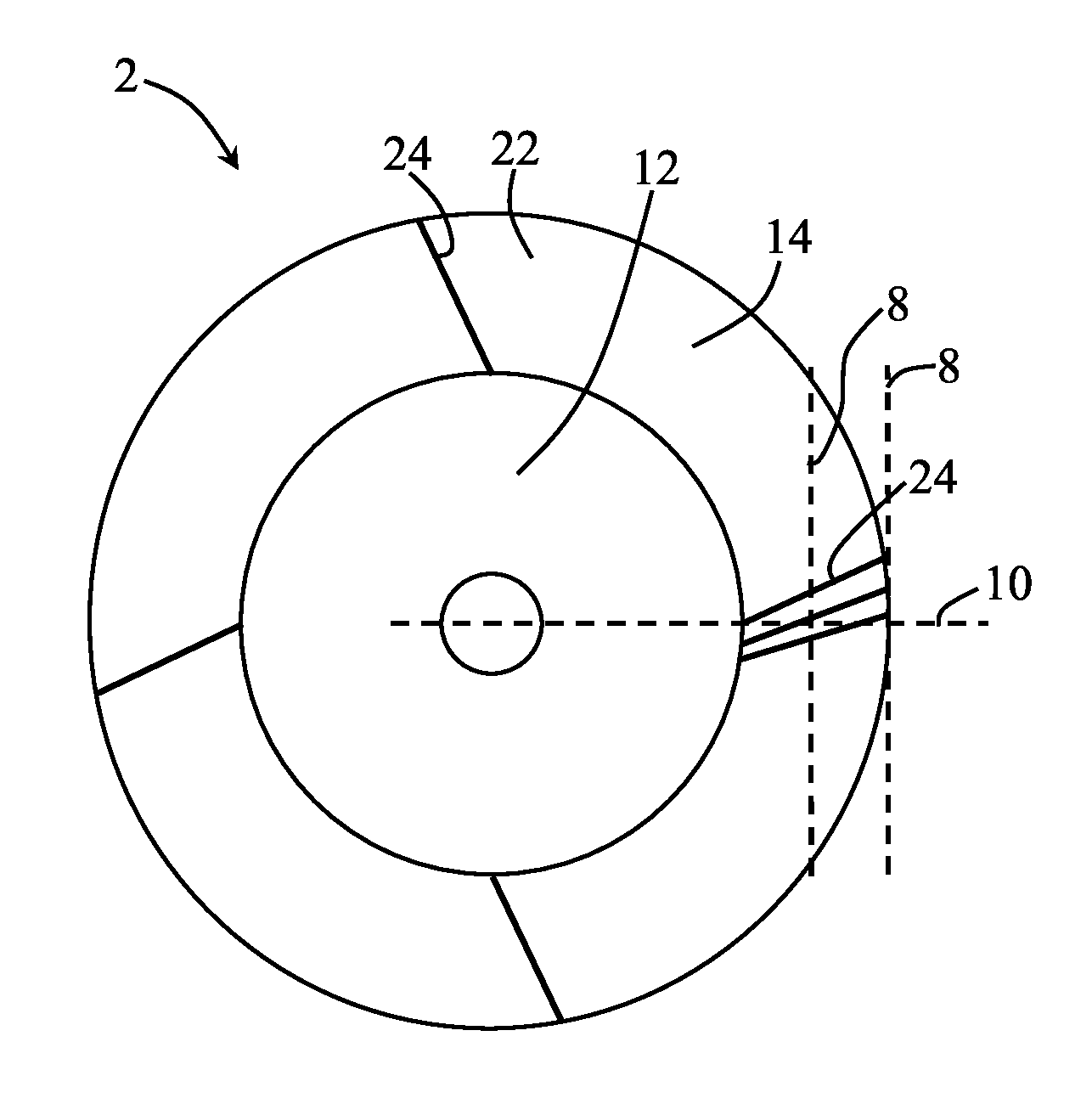

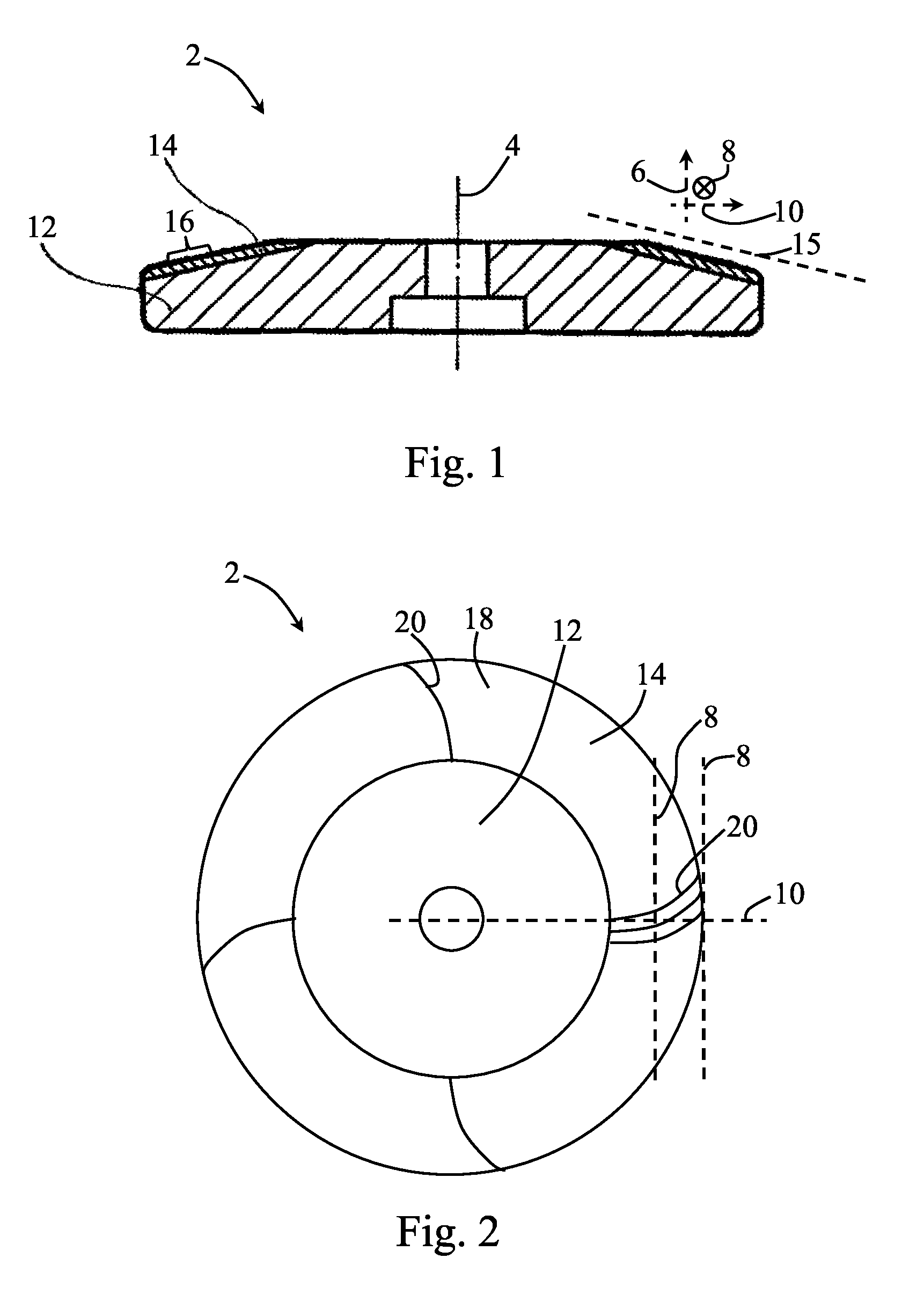

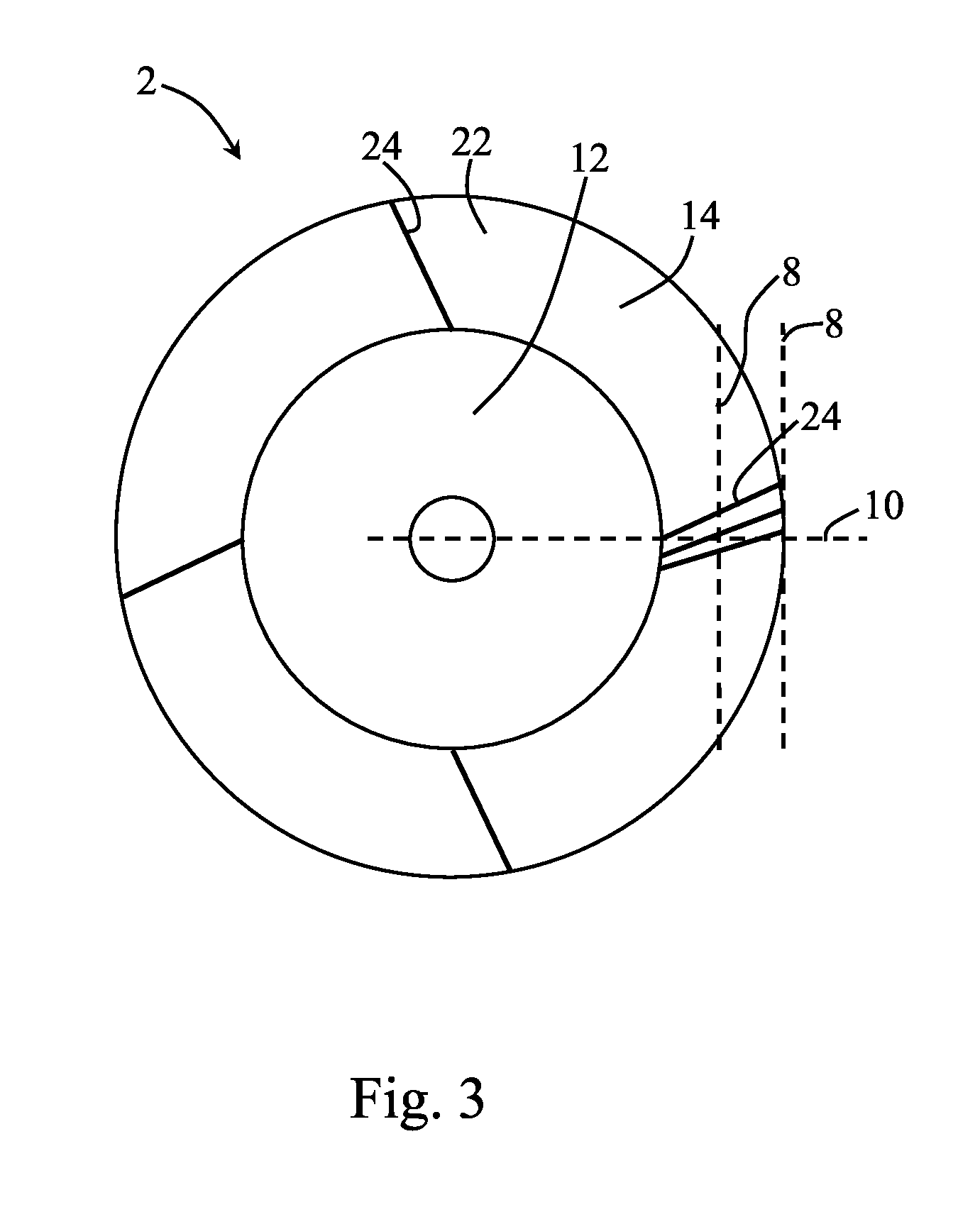

Rotating X-ray anode with an at least partly radially aligned ground structure

ActiveUS9543108B2Low production costOccurrence of fatigue effects during use can be suppressedX-ray tube electrodesNon-emitting electrodes manufactureAngular degreesX-ray

A rotating x-ray anode has an annular focal track. The surface of the focal track has a directed ground structure. Over the circumference of the annular focal track and over the radial extent of the focal track, the alignment of the ground structure is inclined relative to a tangential reference direction in the respective surface portion in each case by an angle that lies in the range from 15°, including, up to and including 90°. A corresponding method for producing a rotating x-ray anode is described.

Owner:PLANSEE SE

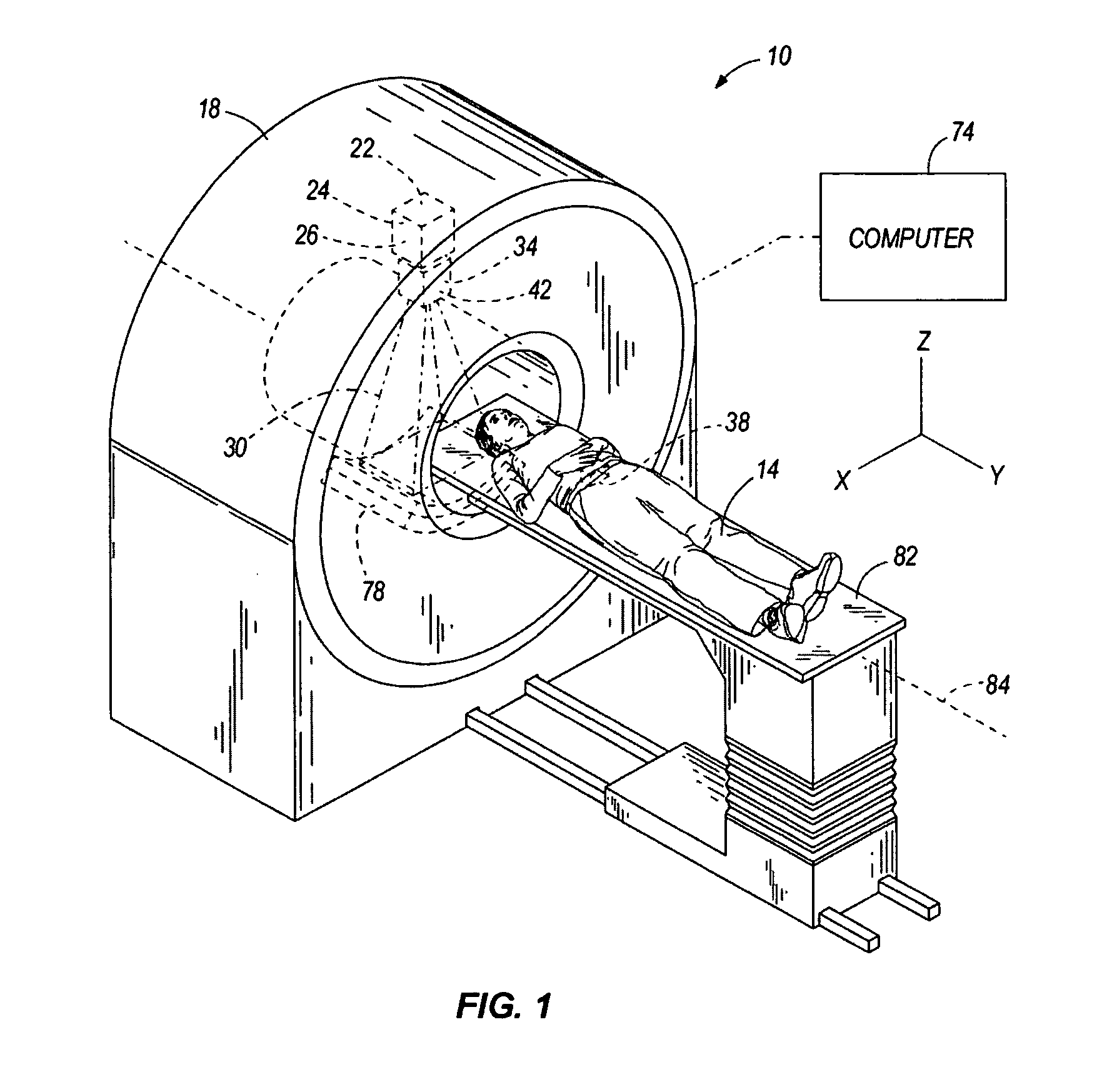

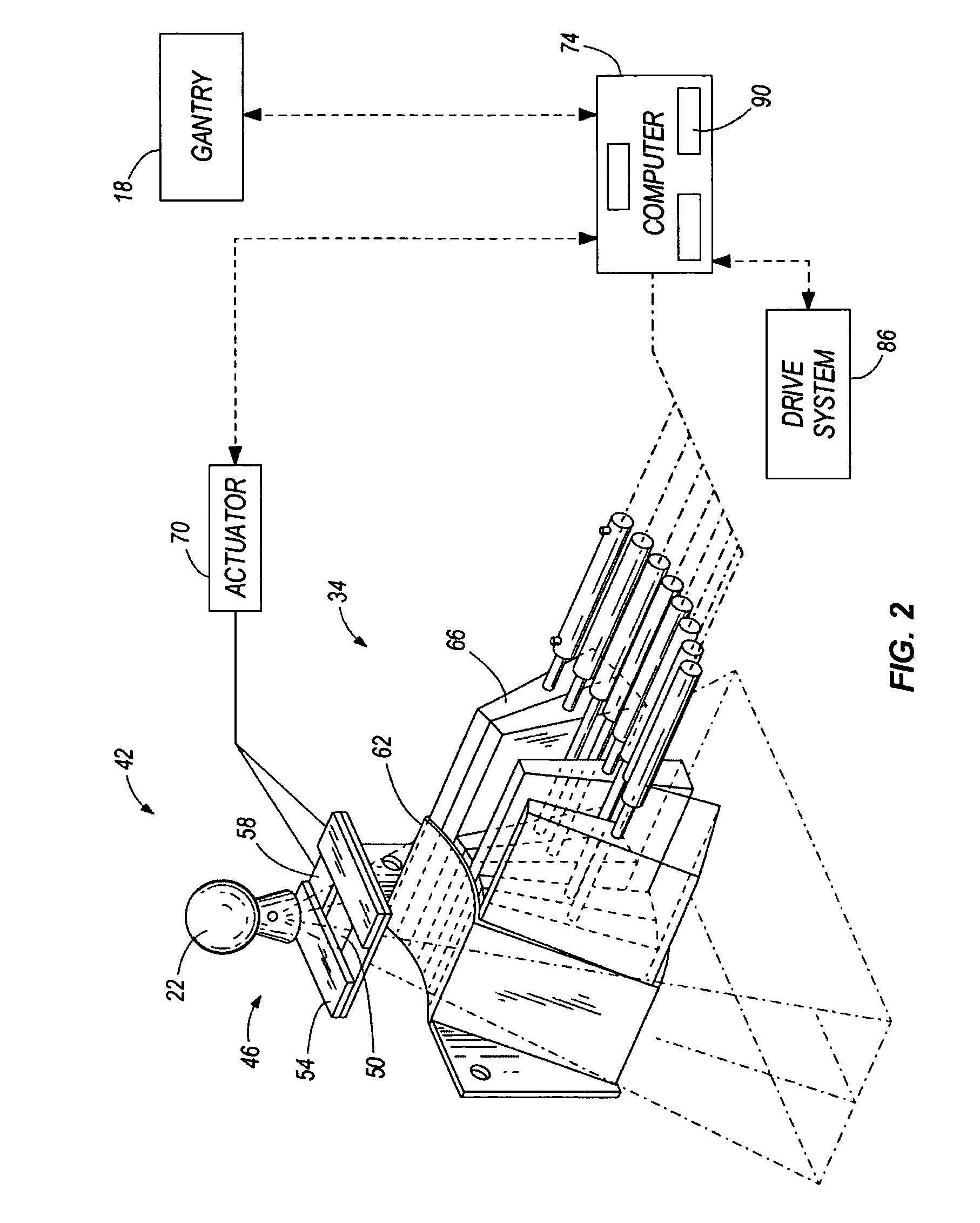

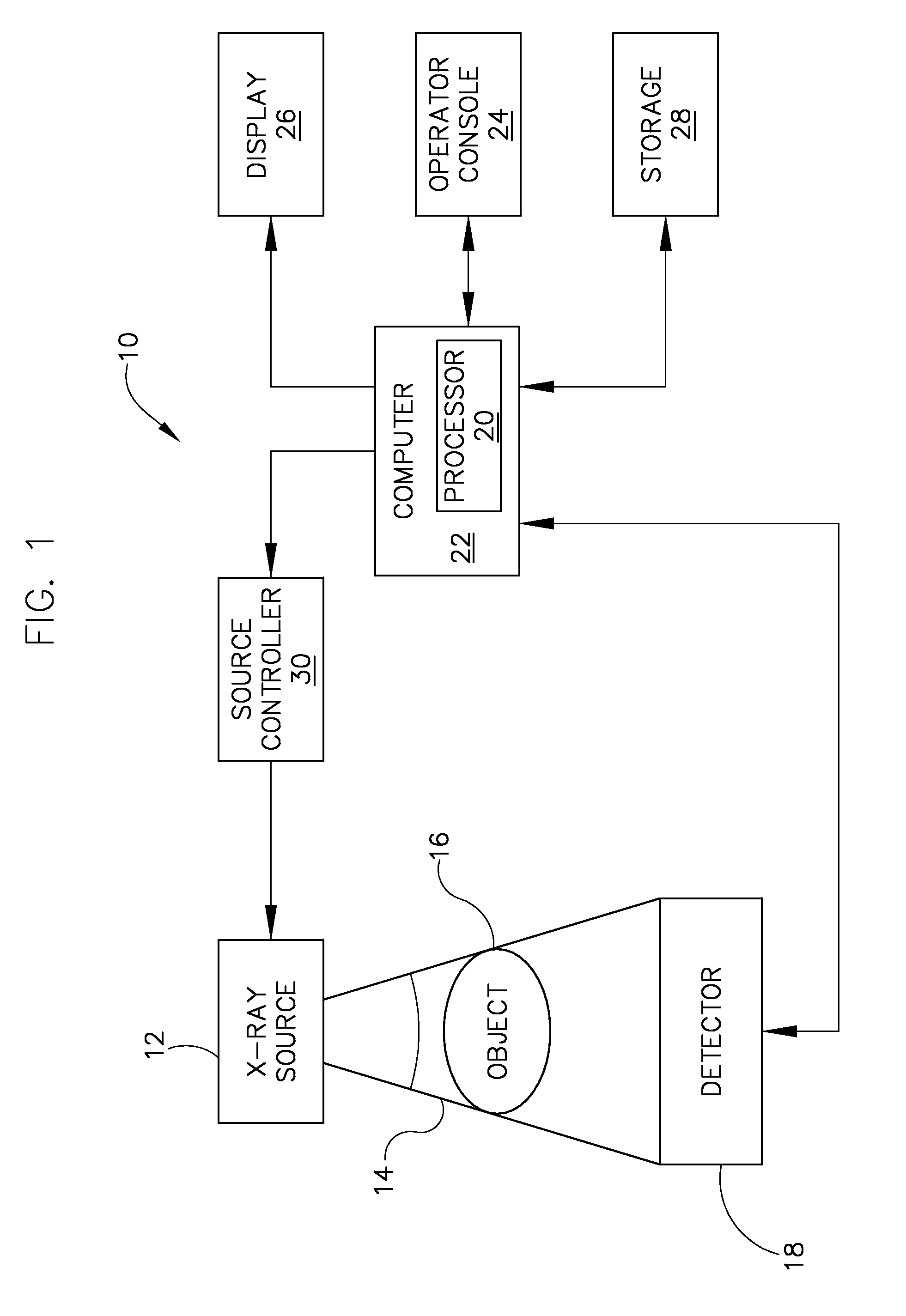

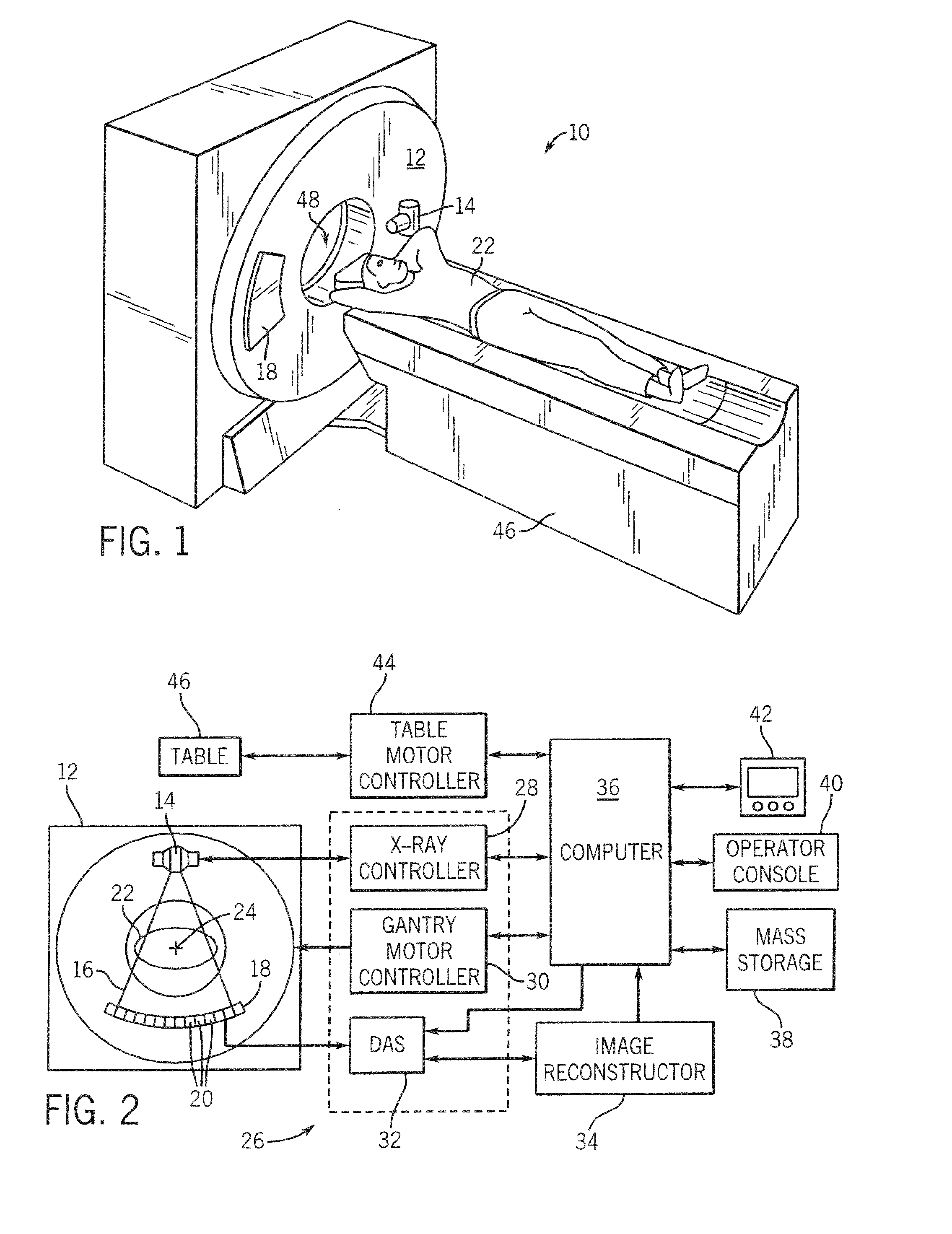

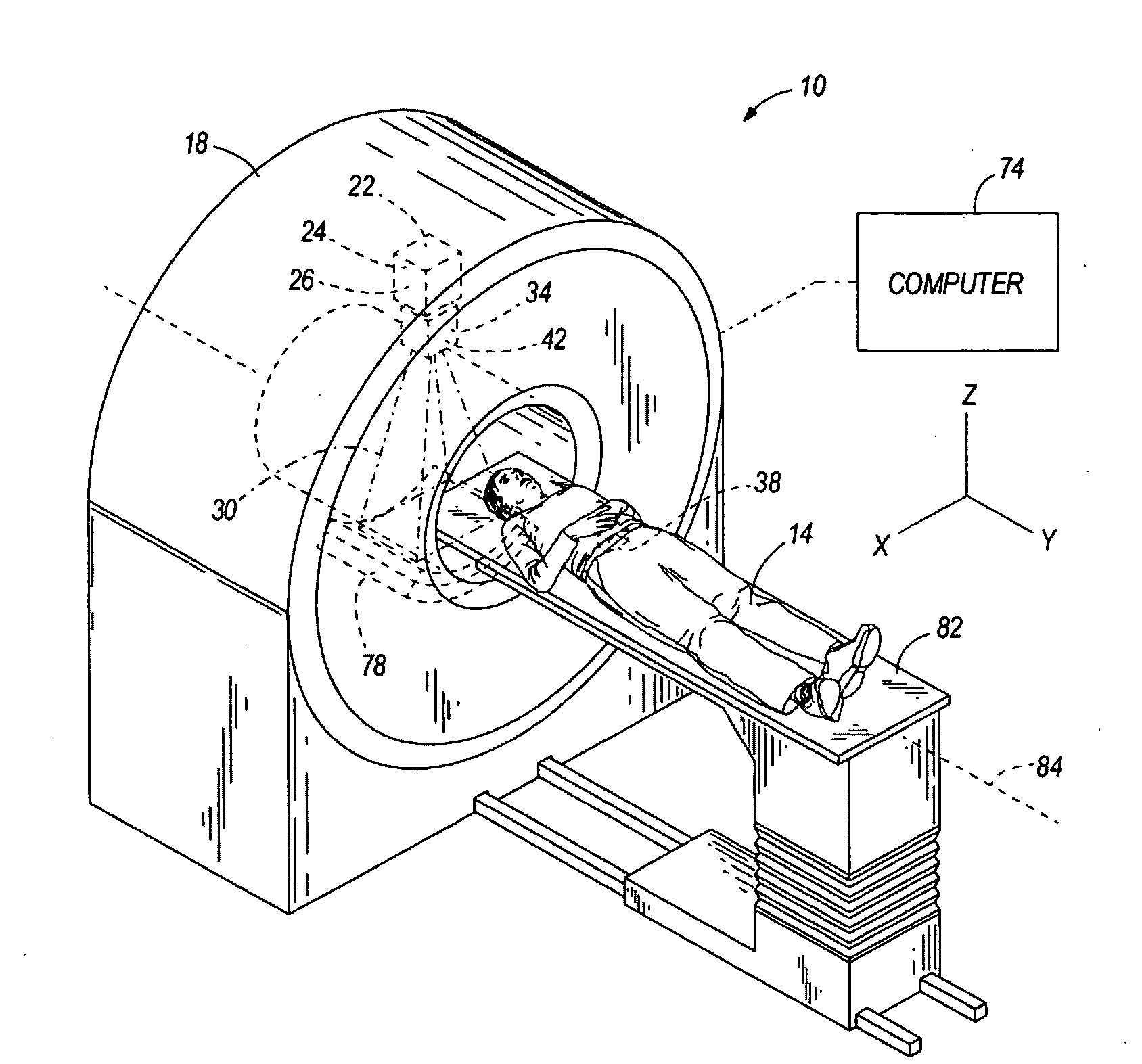

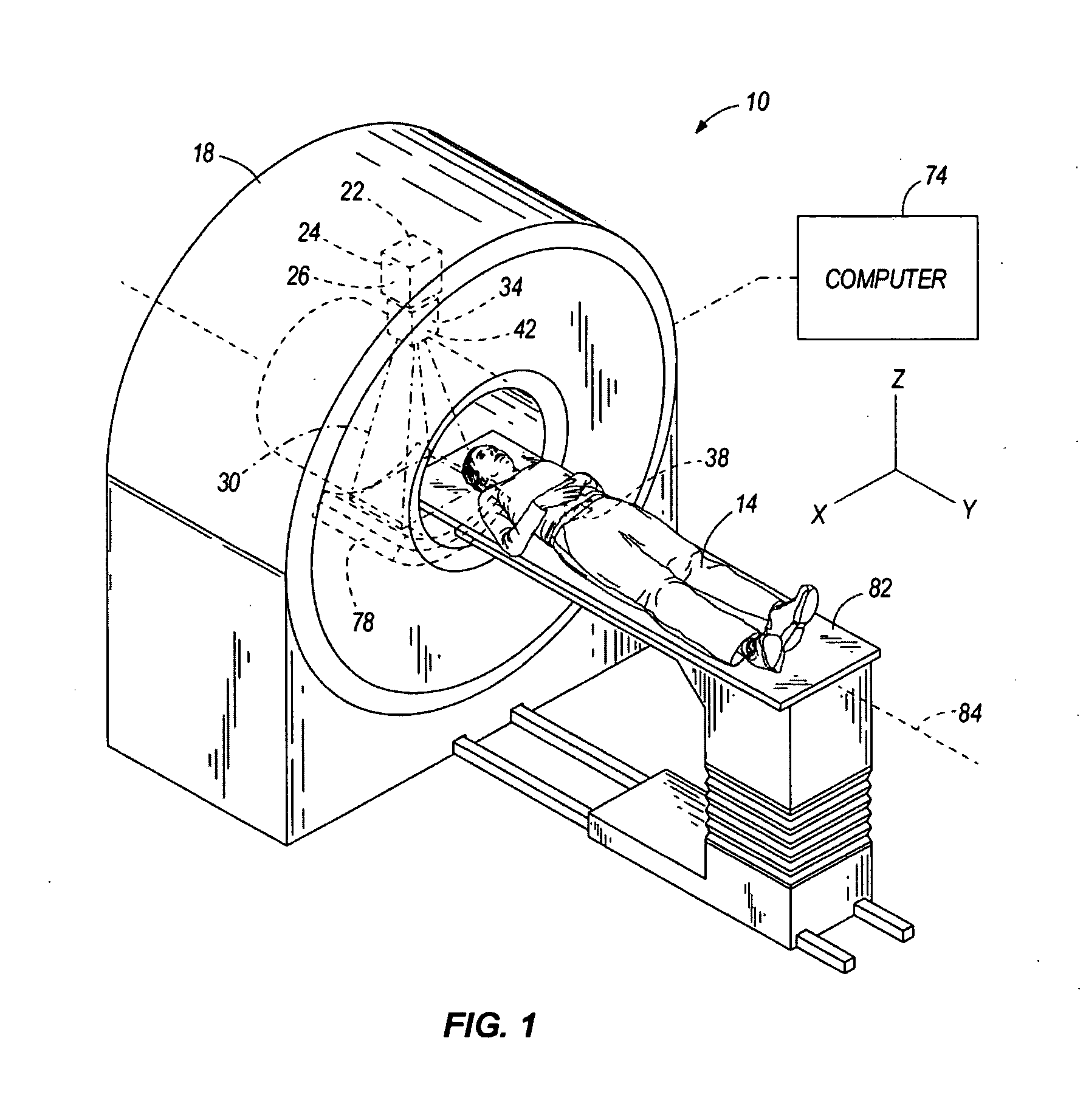

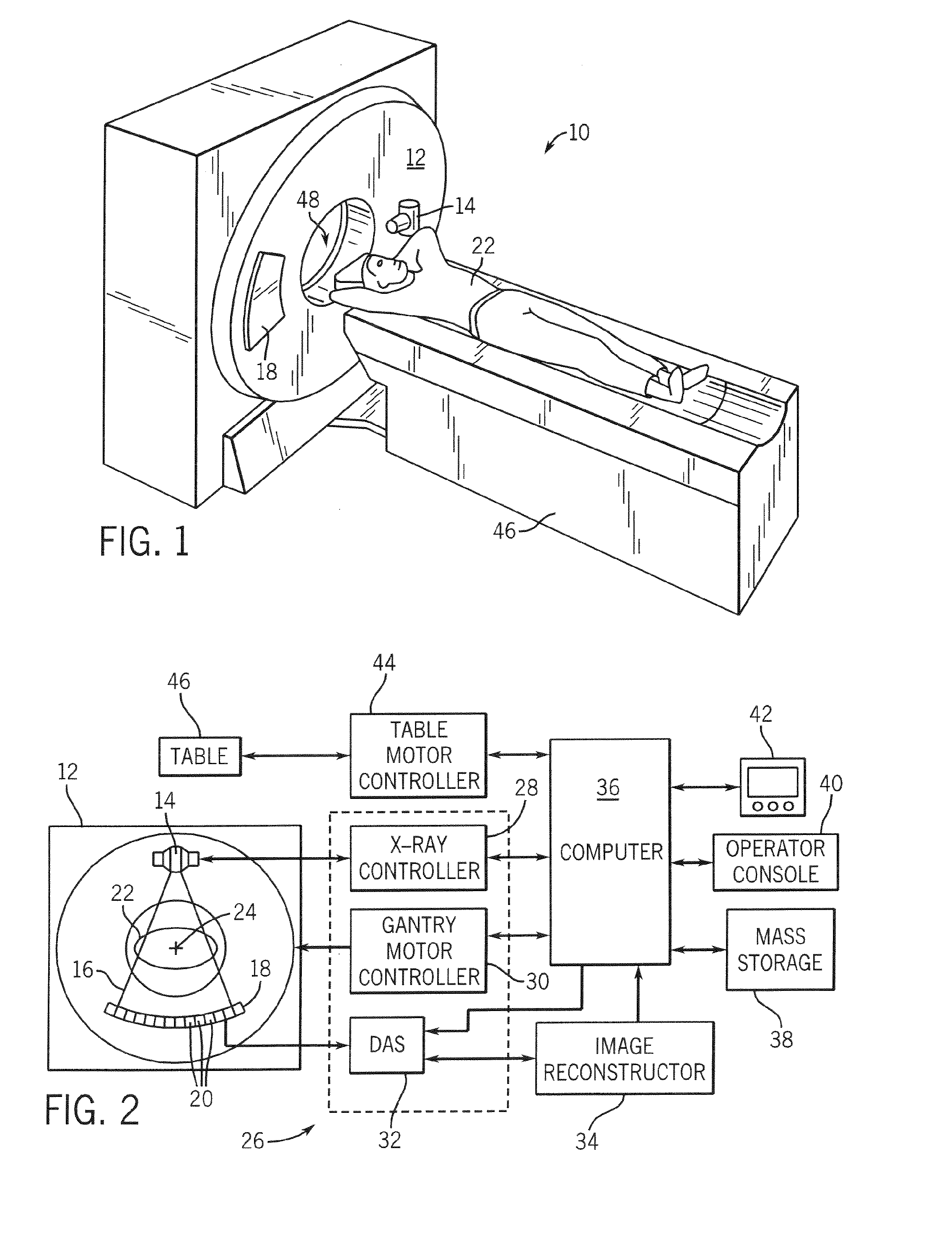

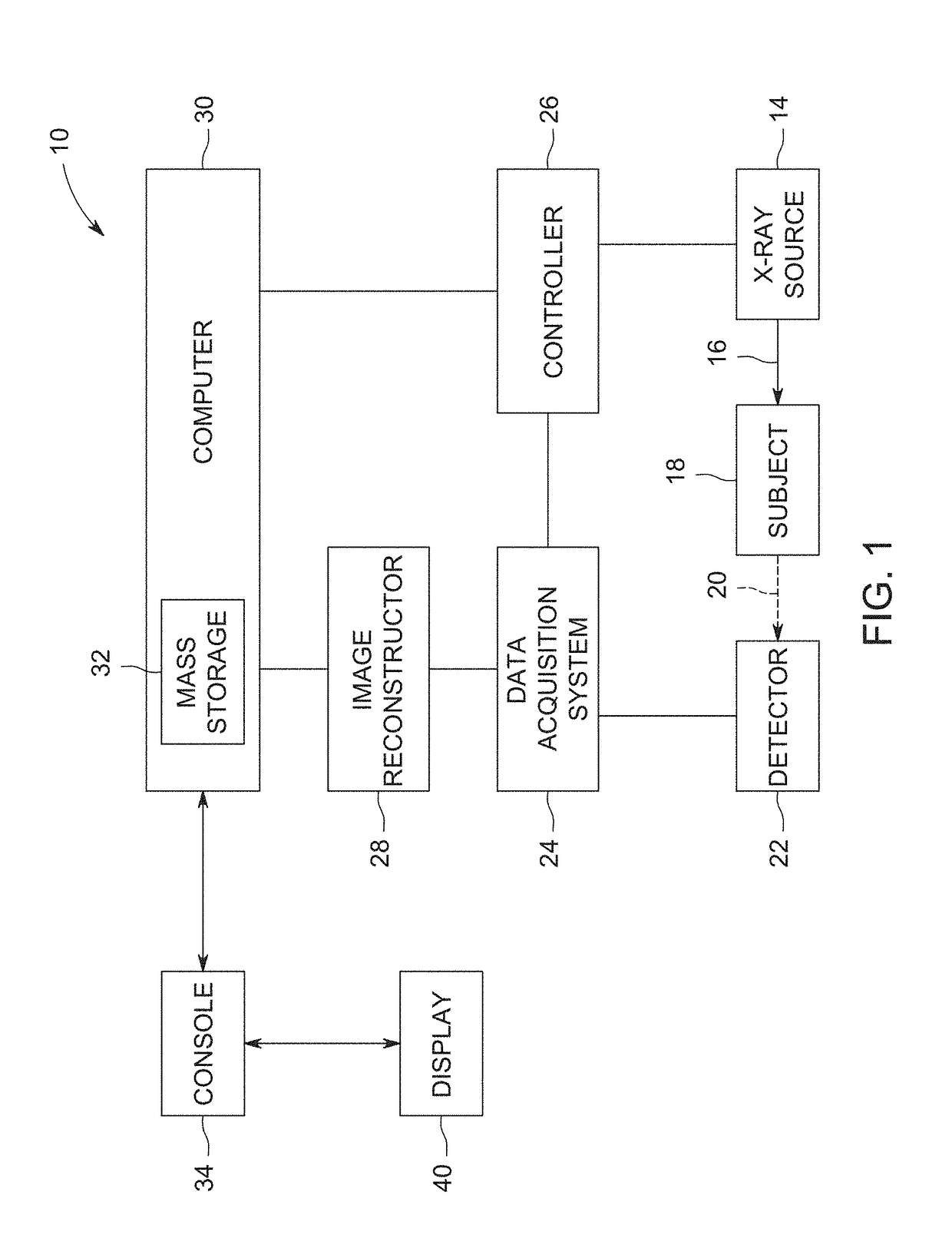

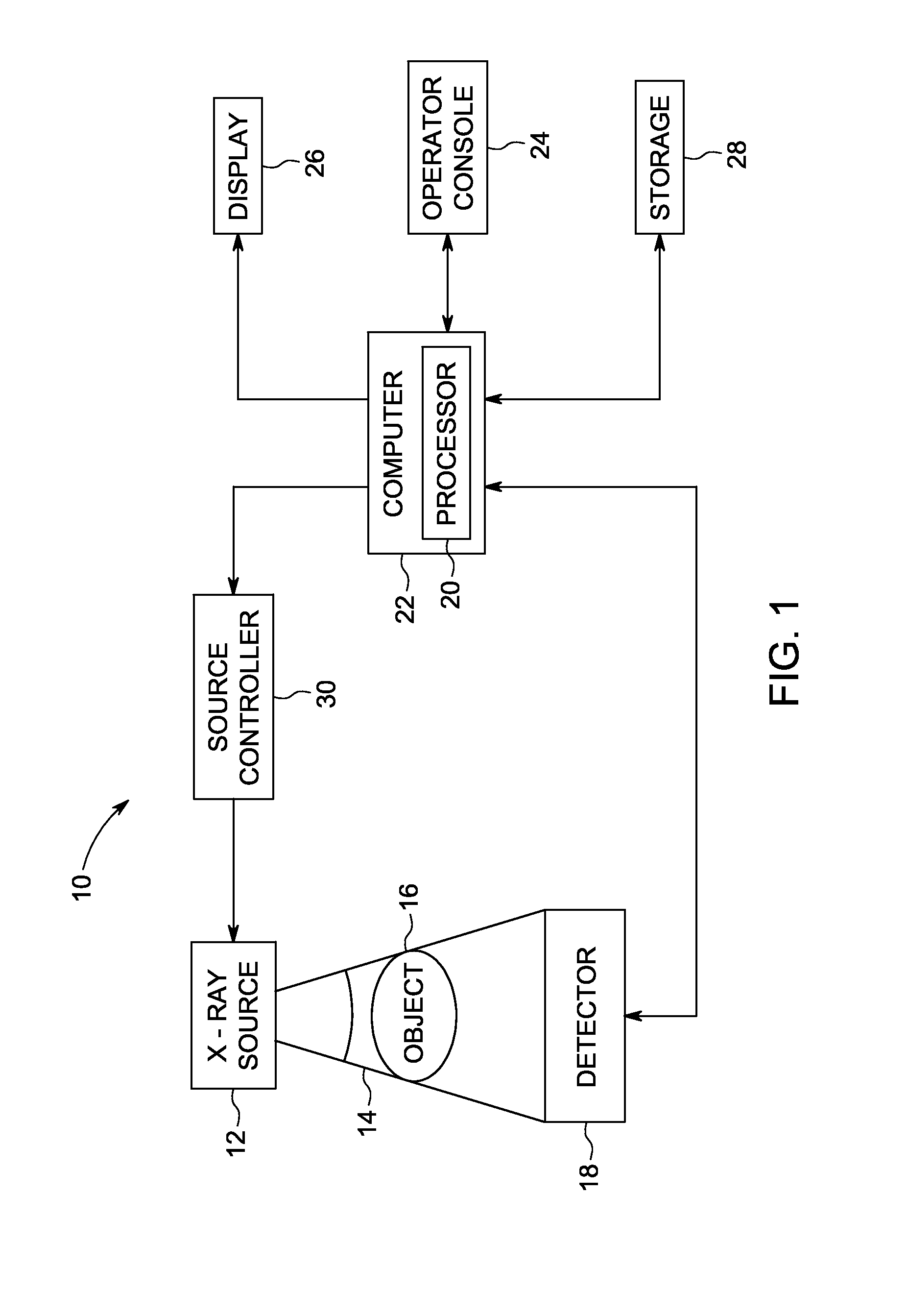

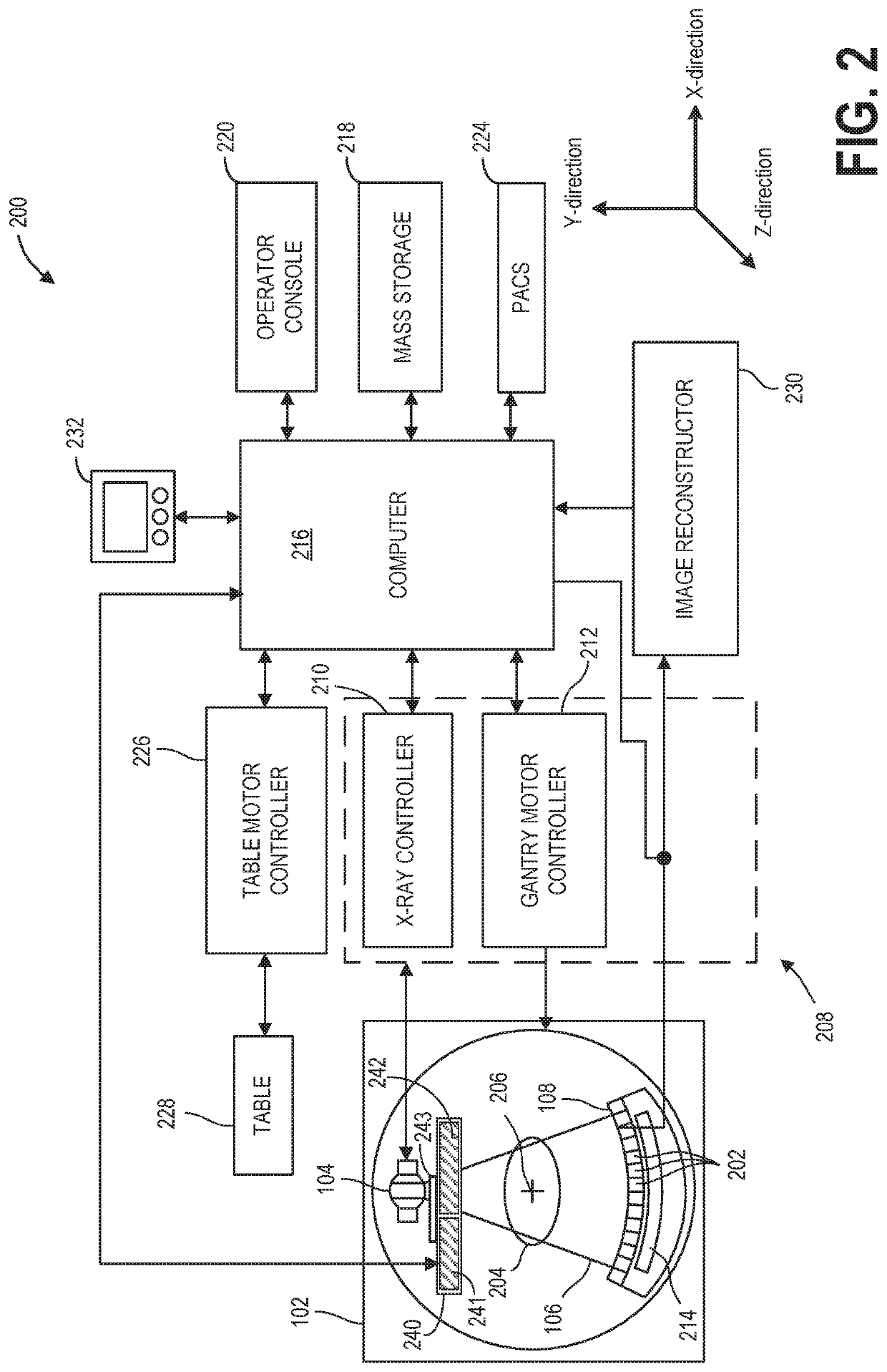

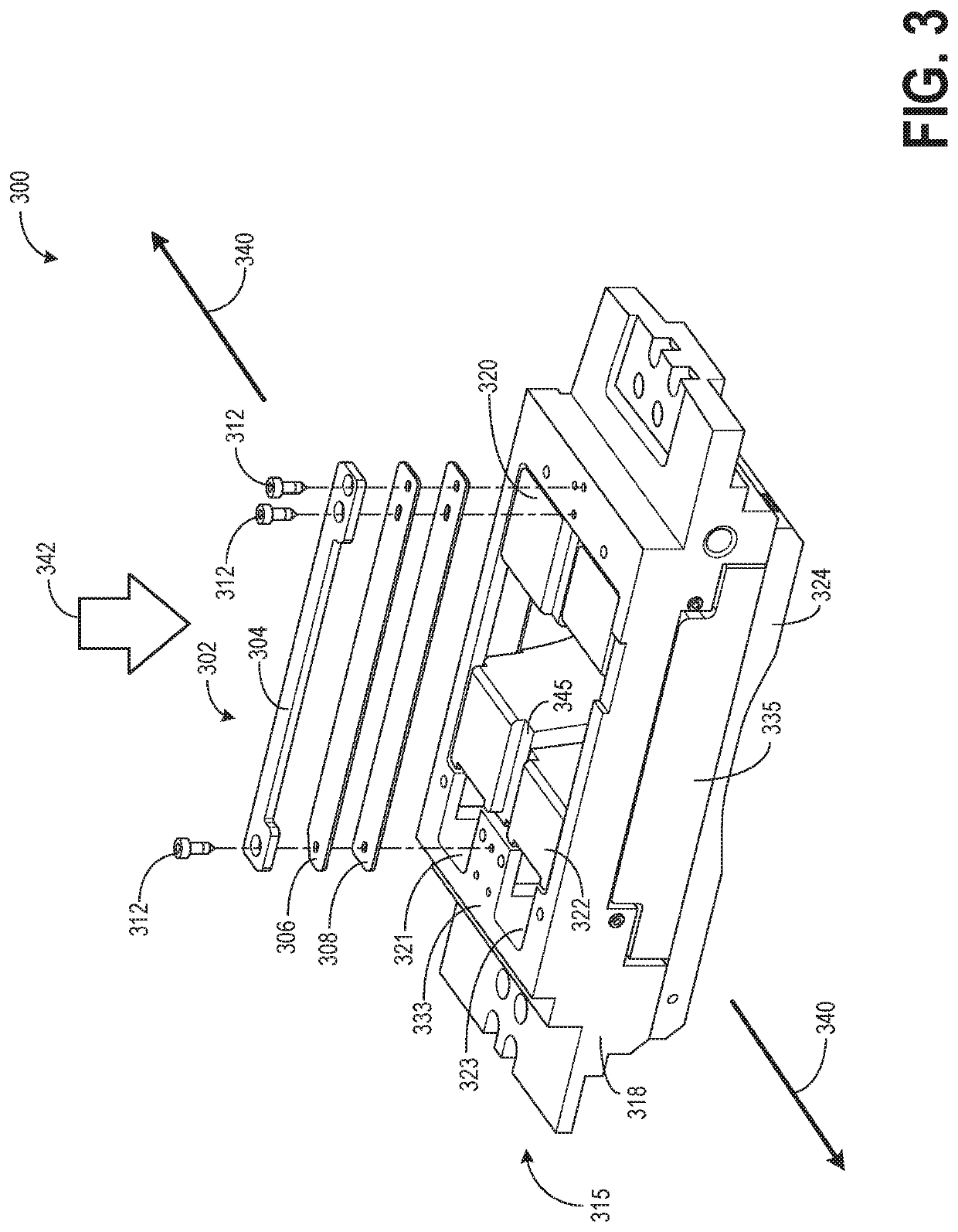

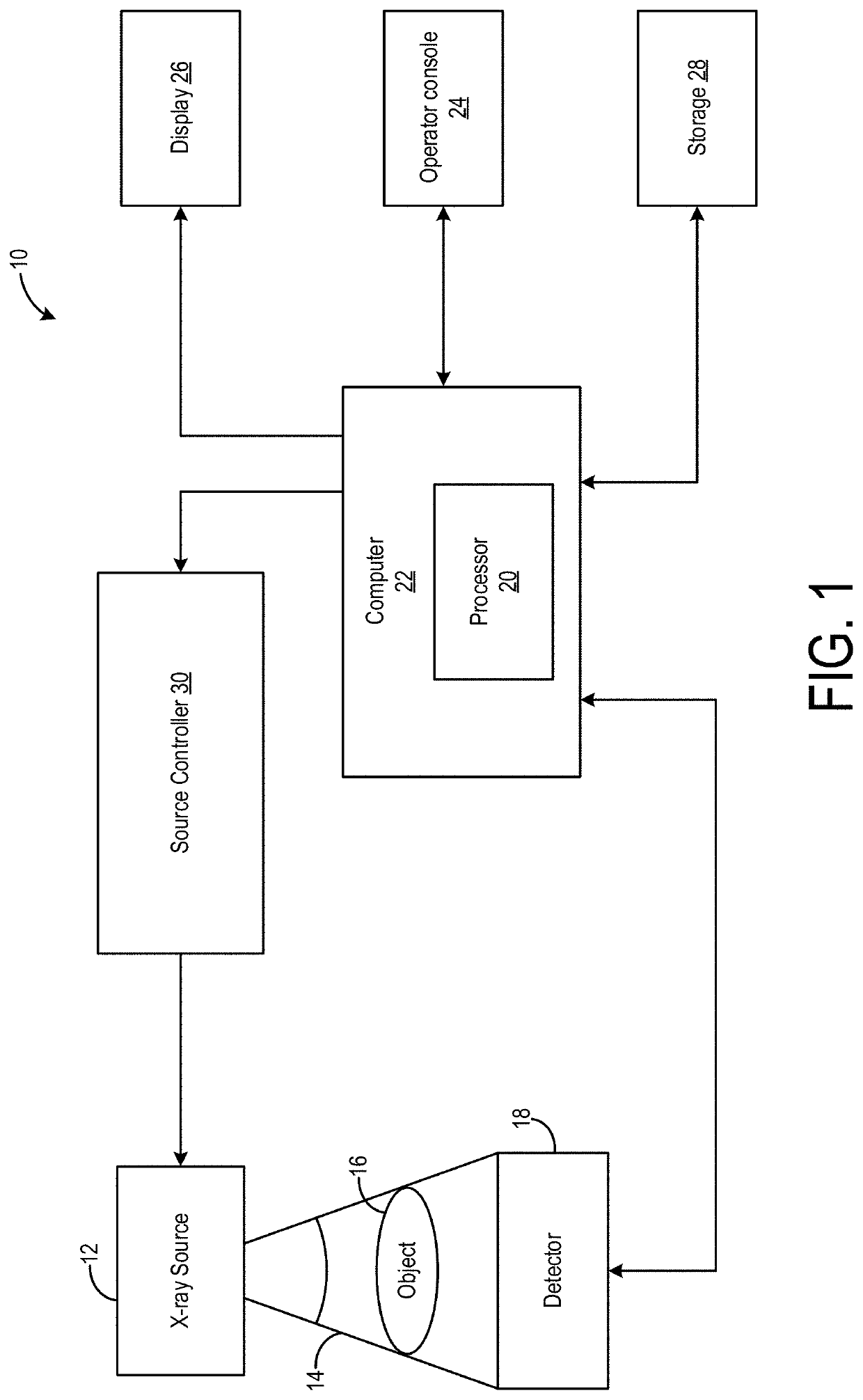

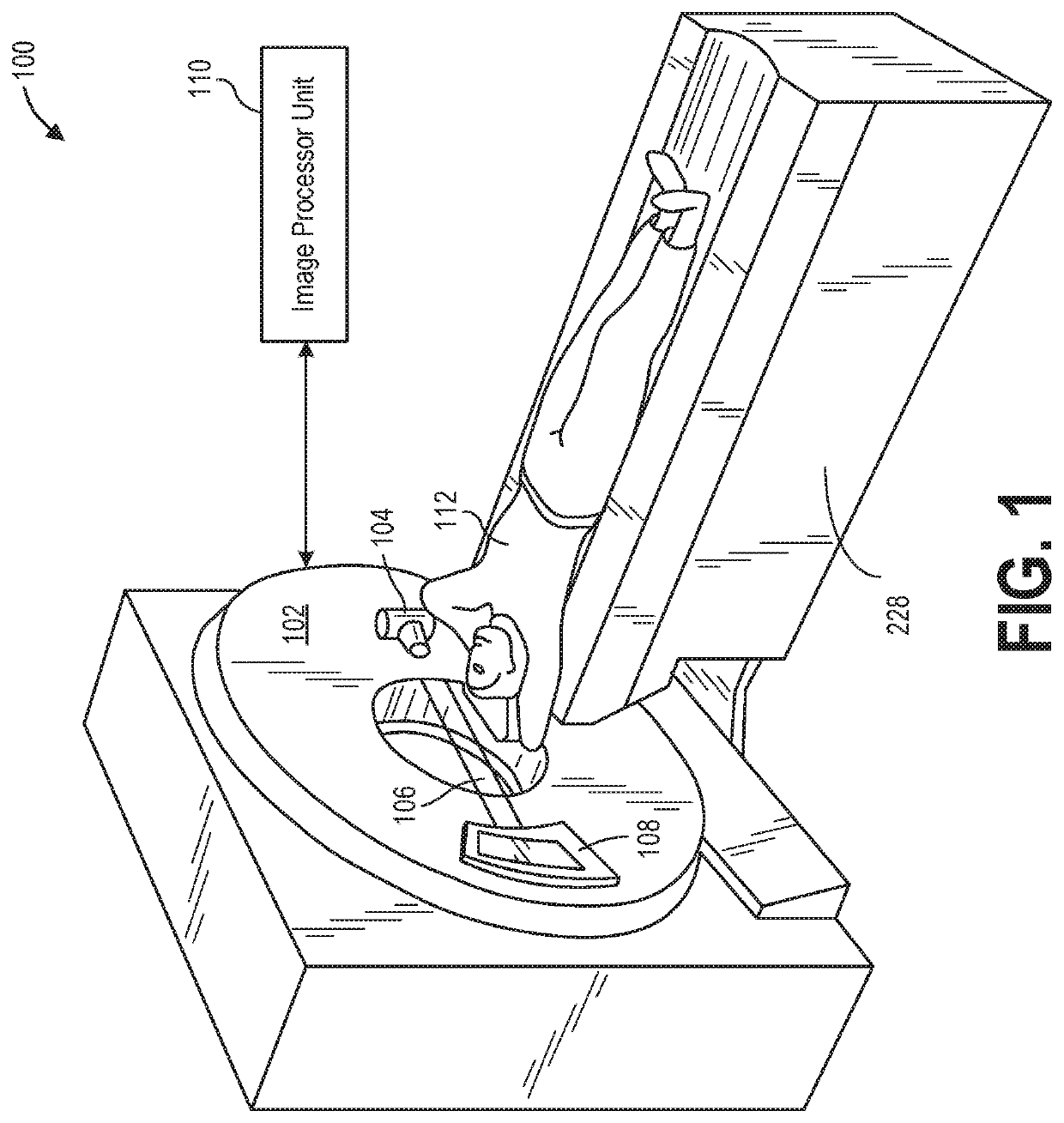

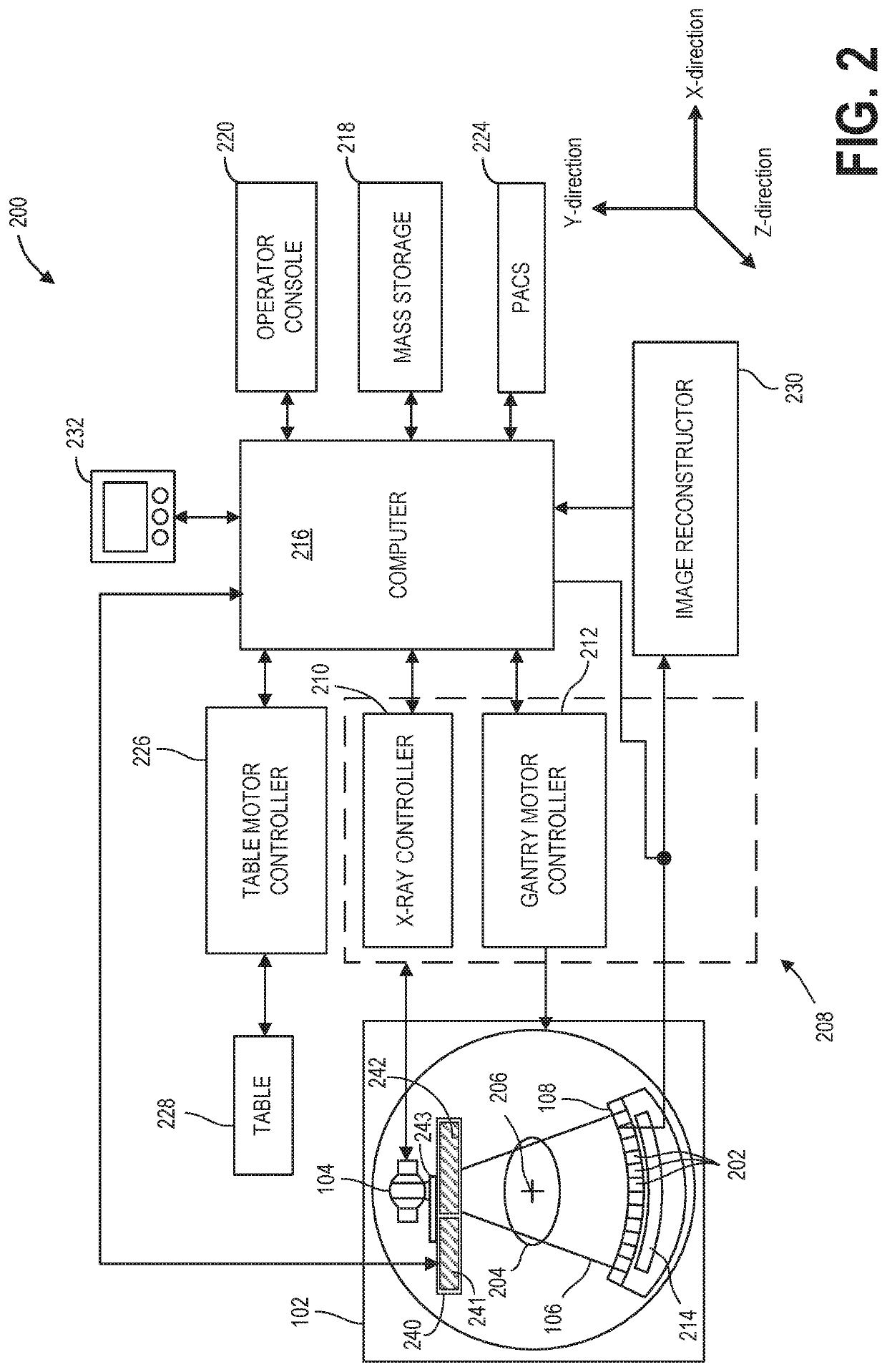

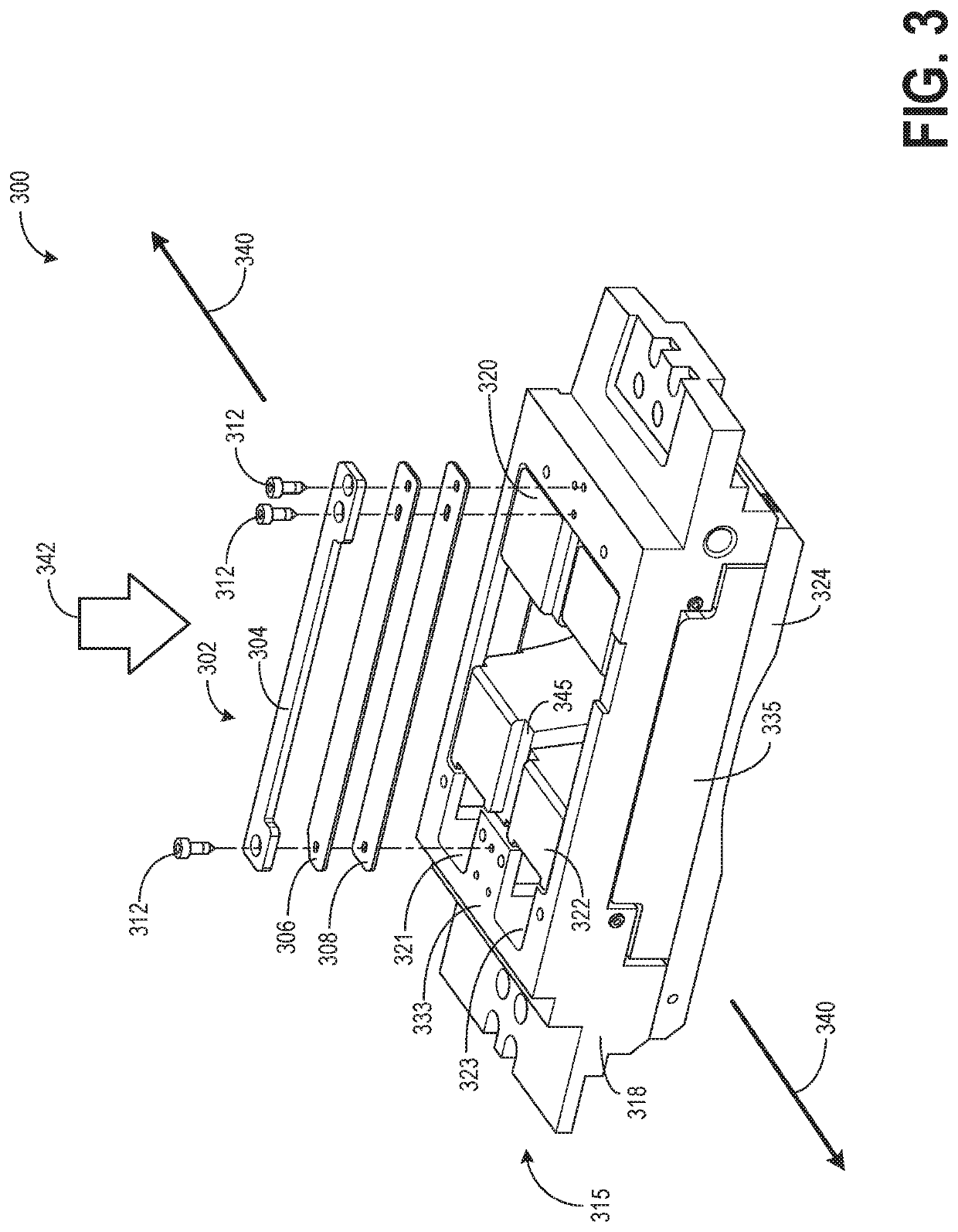

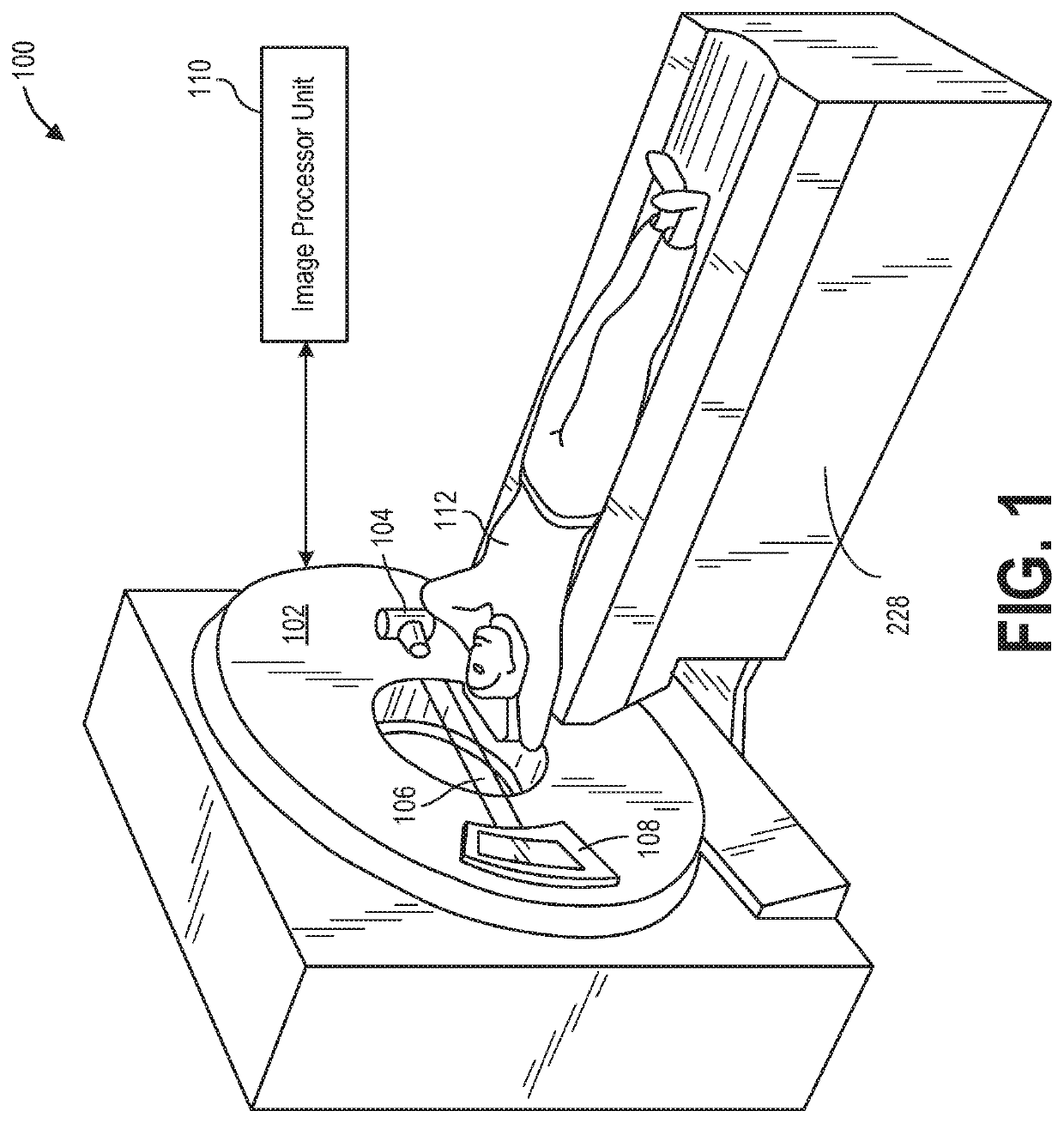

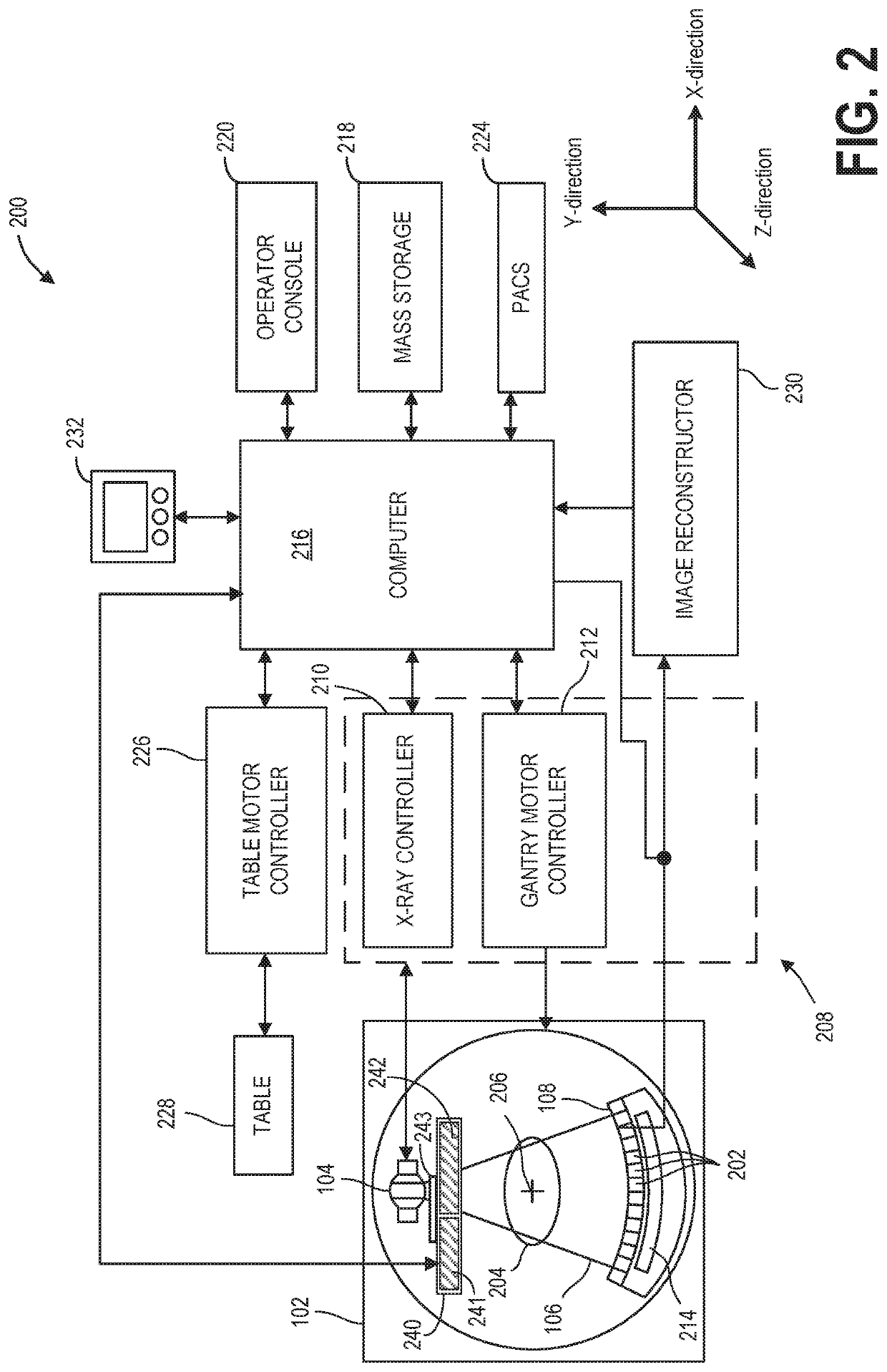

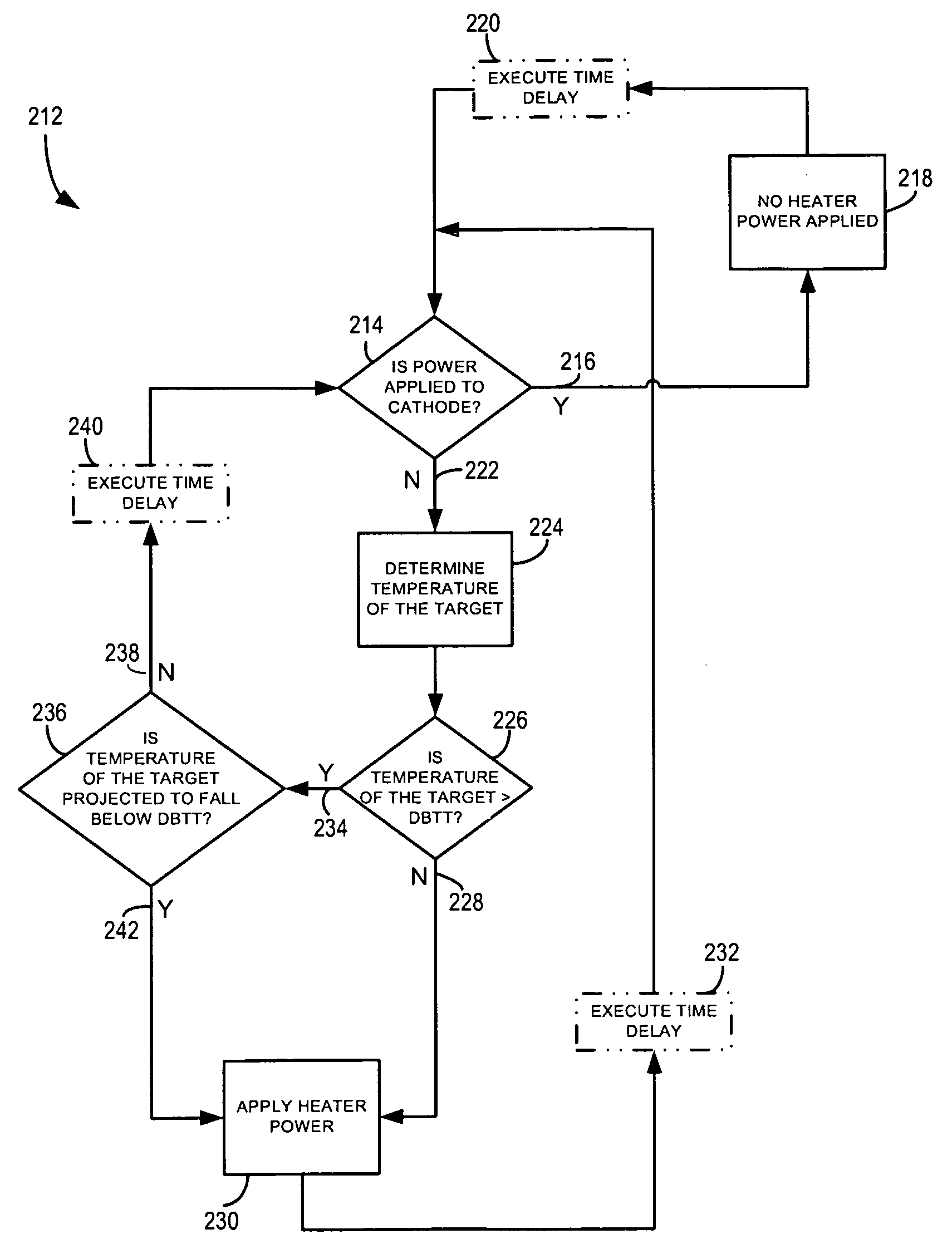

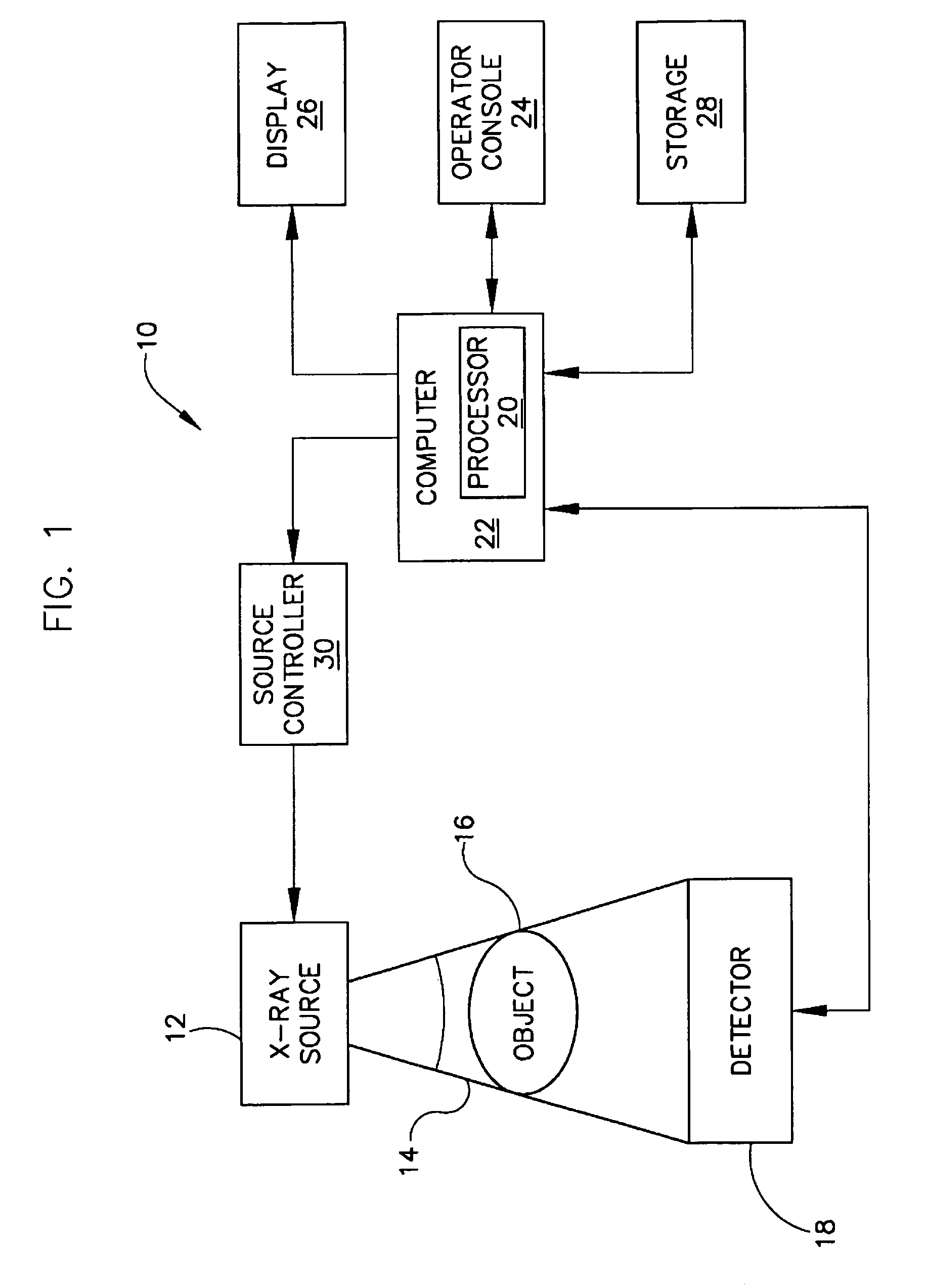

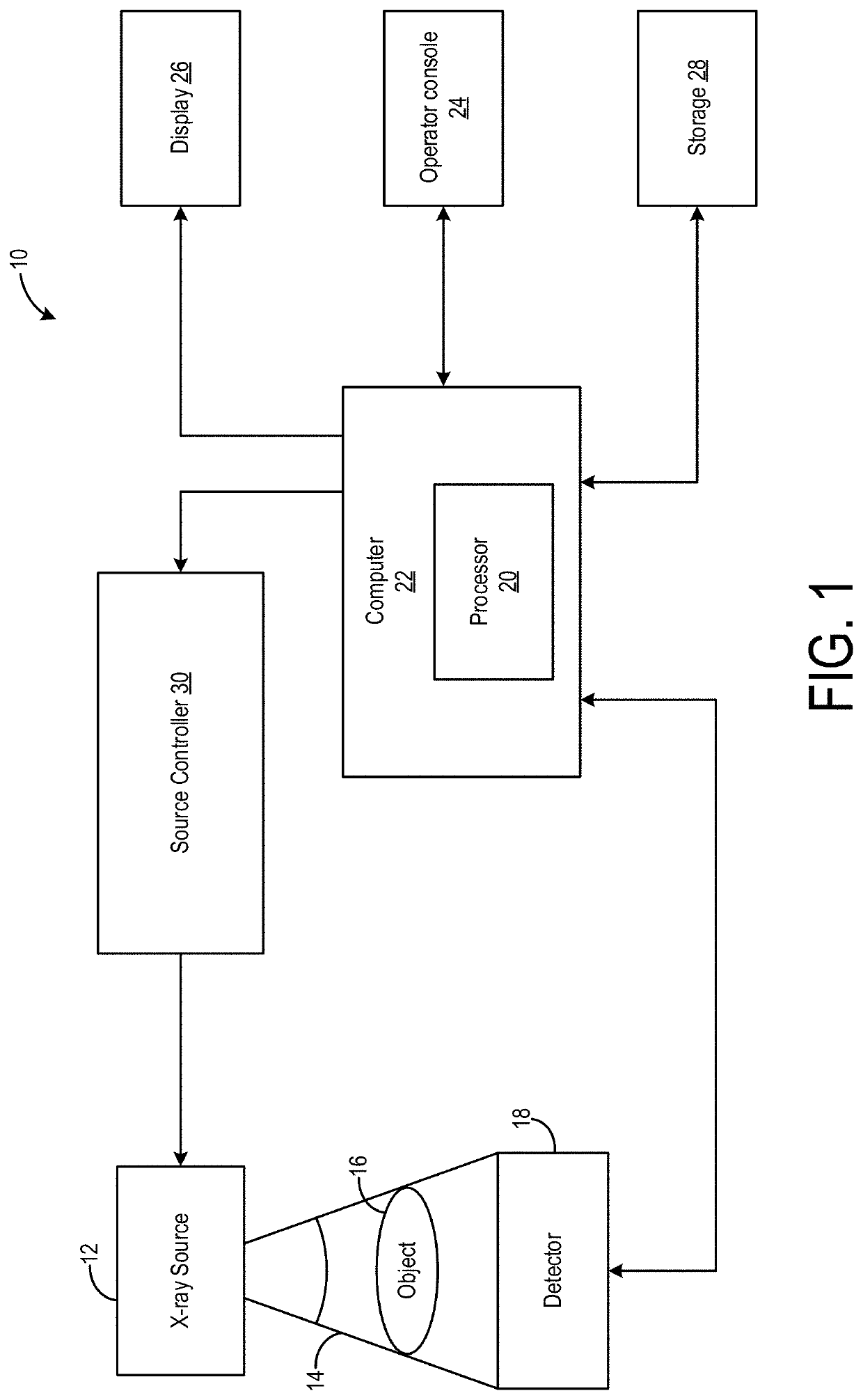

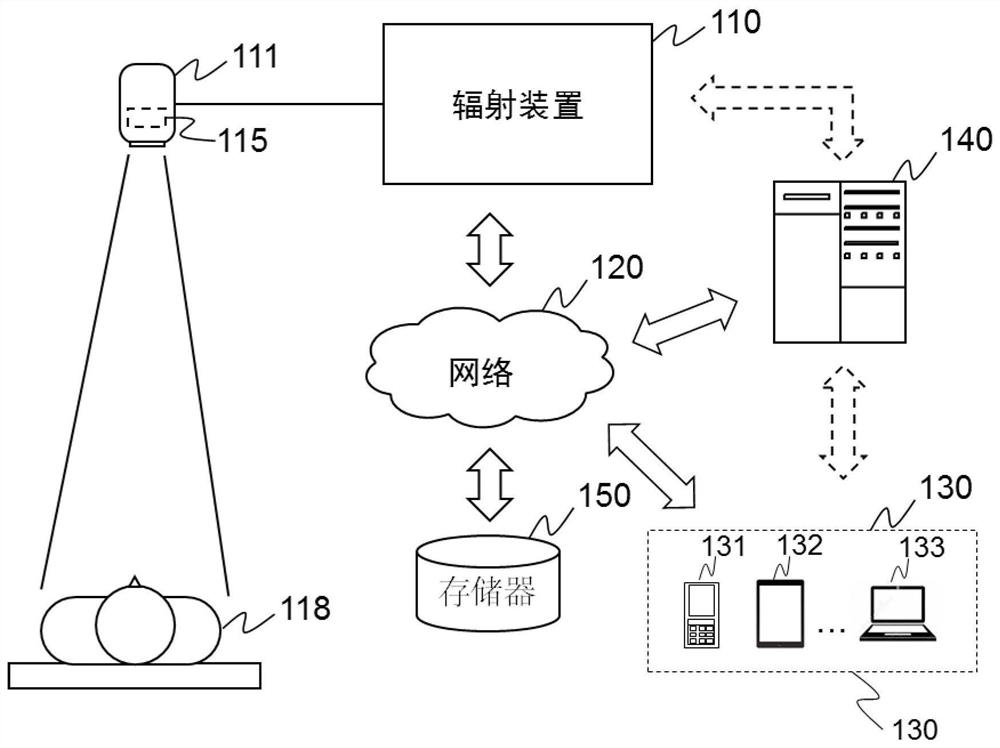

Methods and systems for x-ray tube conditioning

ActiveUS20210045706A1Simple introductionRadiation diagnostic image/data processingRadiation diagnostic device controlComputed tomographyRay

Various methods and systems are provided for x-ray tube conditioning for a computed tomography imaging method. In one embodiment, x-ray may be generated in an x-ray tube of a radiation source prior to a diagnostic scan to warmup the x-ray tube to a desired temperature for the diagnostic scan. The power delivered to the x-ray tube during warmup may be adjusted in a closed loop system based on an initial temperature of the x-ray tube and the desired temperature for the diagnostic scan. During tube warmup, by placing a blocking plate coupled to a collimator blade in a path of the x-ray beam, the x-ray beam may be blocked from exiting a collimator.

Owner:GE PRECISION HEALTHCARE LLC

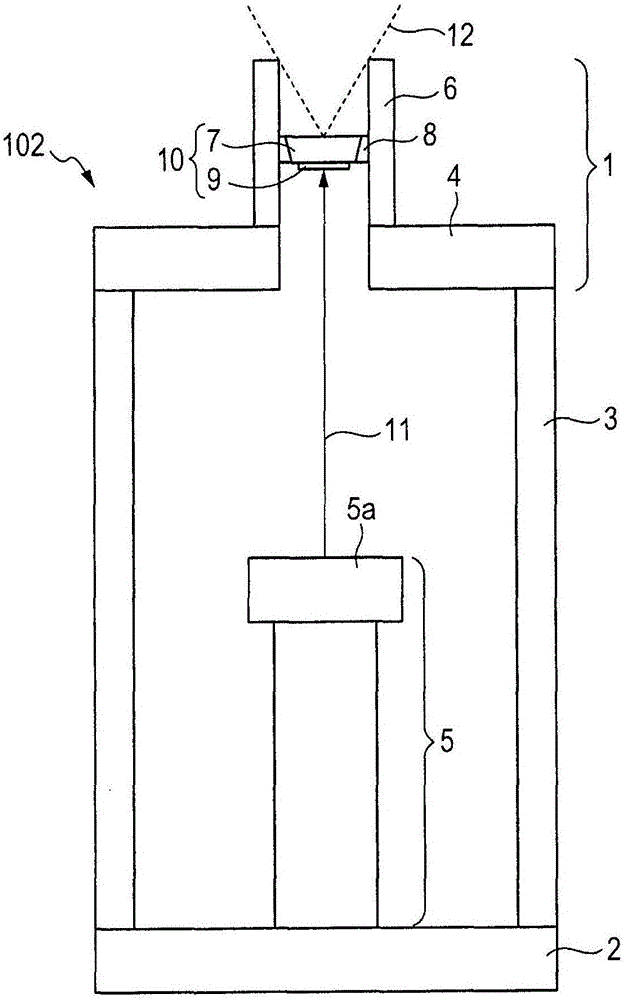

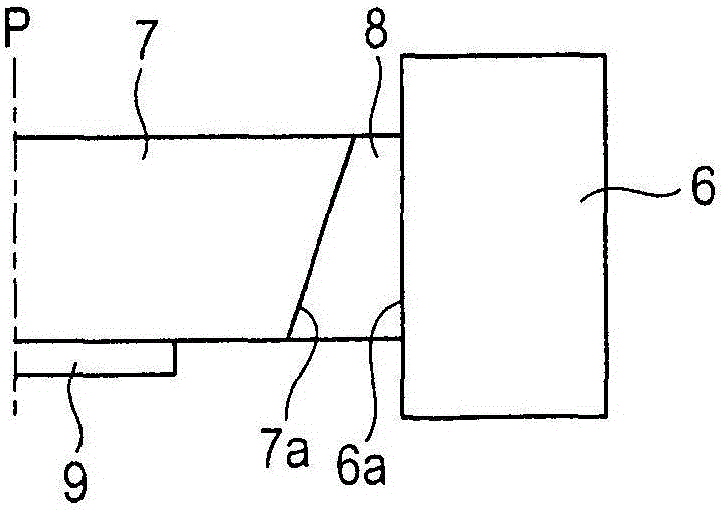

Anode, and x-ray generating tube, x-ray generating apparatus, and radiography system using the same

ActiveCN106537549AX-ray tube electrodesMounting/support/spacing/insulation of electrode assembliesX-rayStress radiography

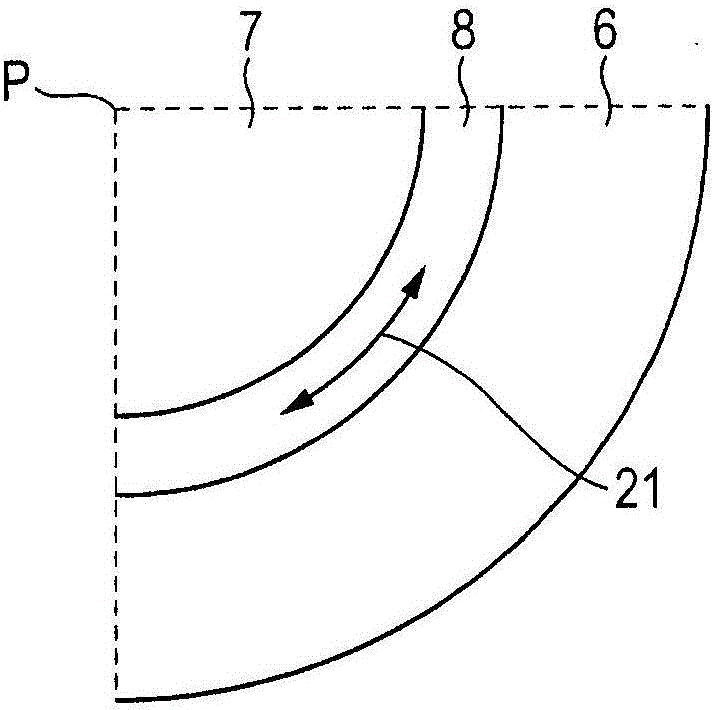

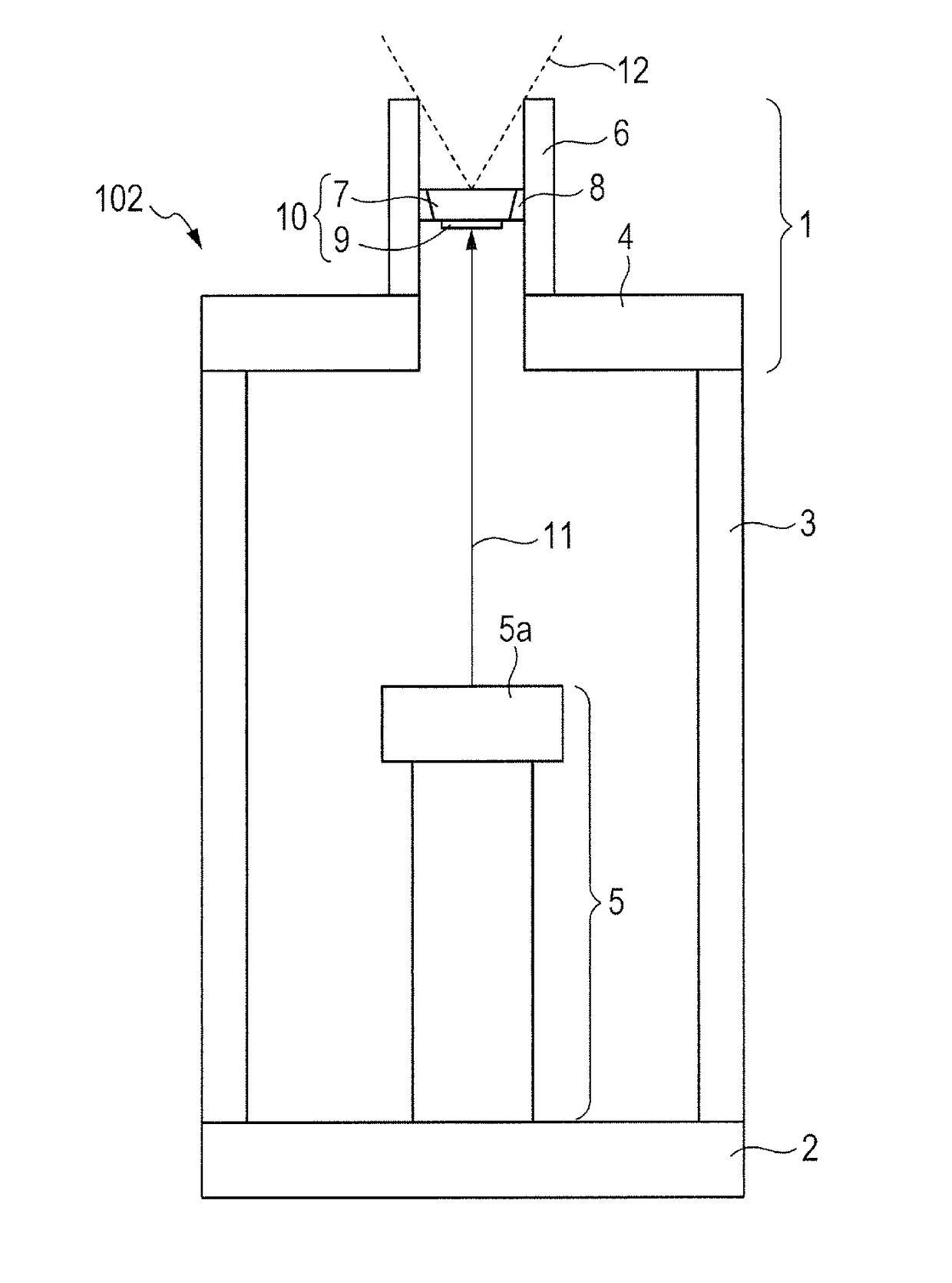

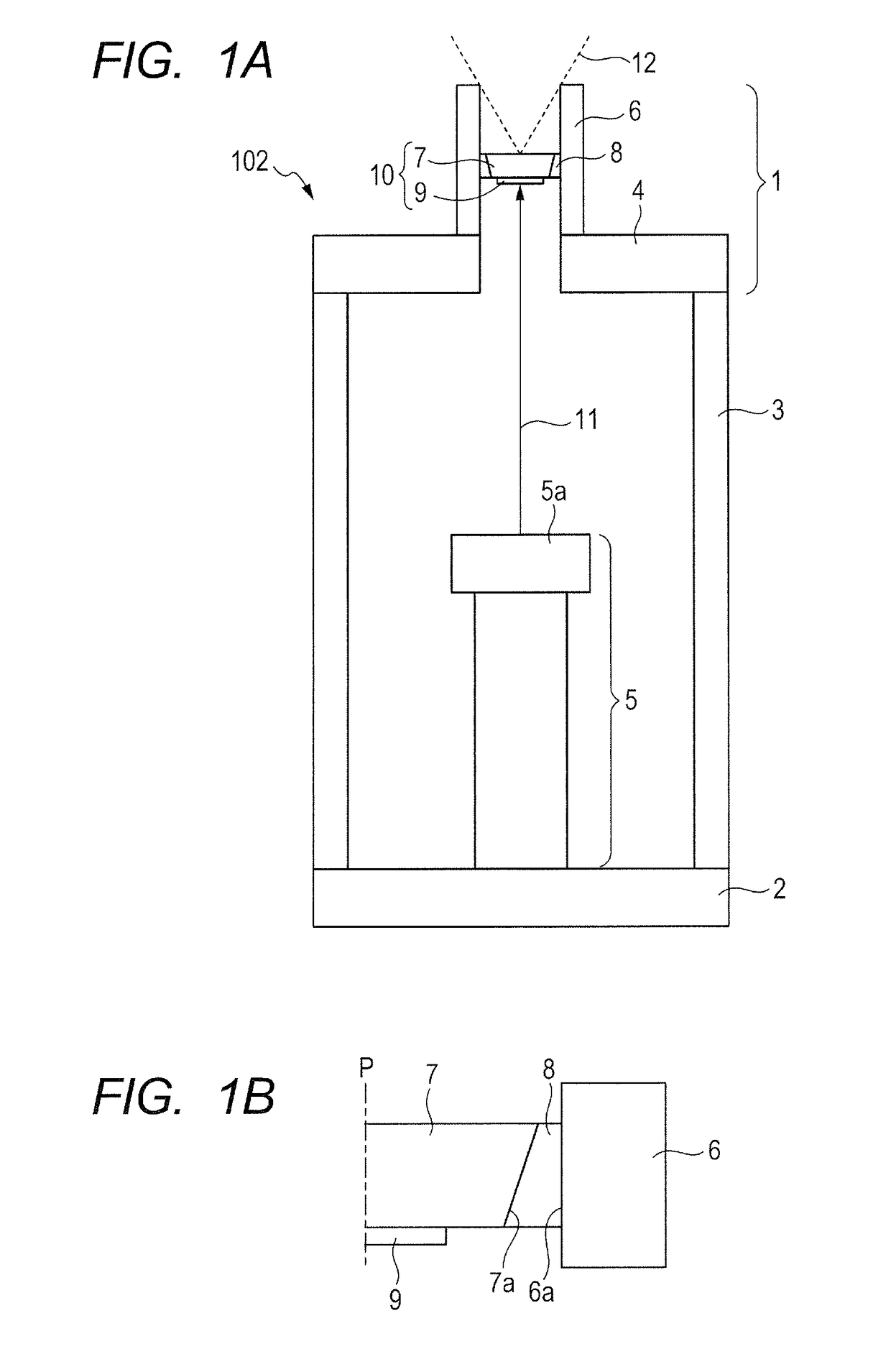

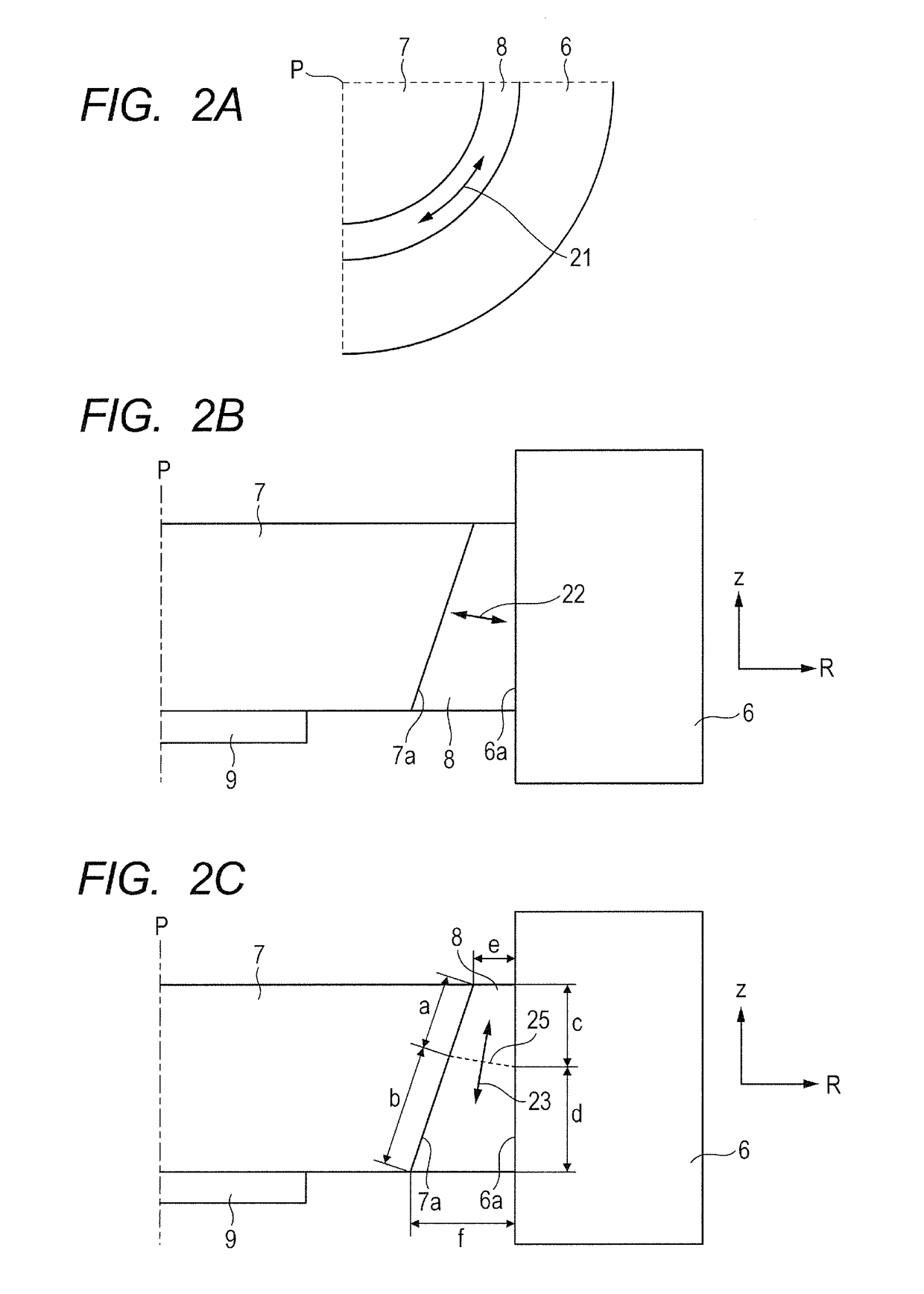

A thickness of a bonding material (8) is varied in a radial direction orthogonal to a central axis (P) of the tubular anode member (6), the bonding material (8) being used for bonding a transmitting substrate (7) for supporting a target layer (9) and a tubular anode member (6) in a direction along the central axis (P). Thus, a region in which a circumferential tensile stress of the bonding material (8) is alleviated is formed in the direction along the central axis (P) to prevent a crack from developing in the bonding material (8).

Owner:CANON KK

Anode, and x-ray generating tube, x-ray generating apparatus, and radiography system using the same

ActiveUS20170213686A1Highly reliable X-rayInhibit the development of cracksX-ray tube electrodesMounting/support/spacing/insulation of electrode assembliesX-rayStress radiography

A thickness of a bonding material (8) is varied in a radial direction orthogonal to a central axis (P) of the tubular anode member (6), the bonding material (8) being used for bonding a transmitting substrate (7) for supporting a target layer (9) and a tubular anode member (6) in a direction along the central axis (P). Thus, a region in which a circumferential tensile stress of the bonding material (8) is alleviated is formed in the direction along the central axis (P) to prevent a crack from developing in the bonding material (8).

Owner:CANON KK

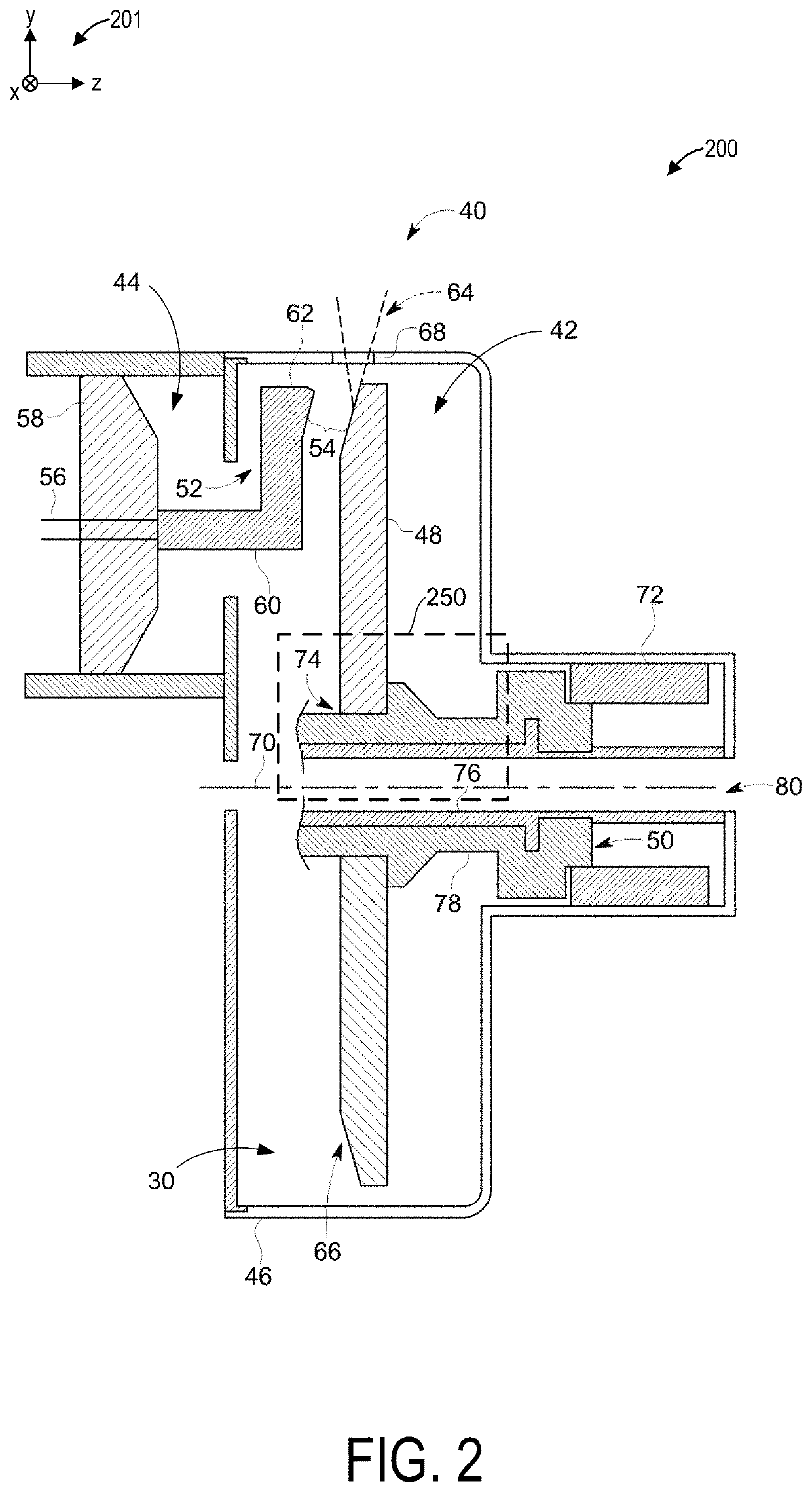

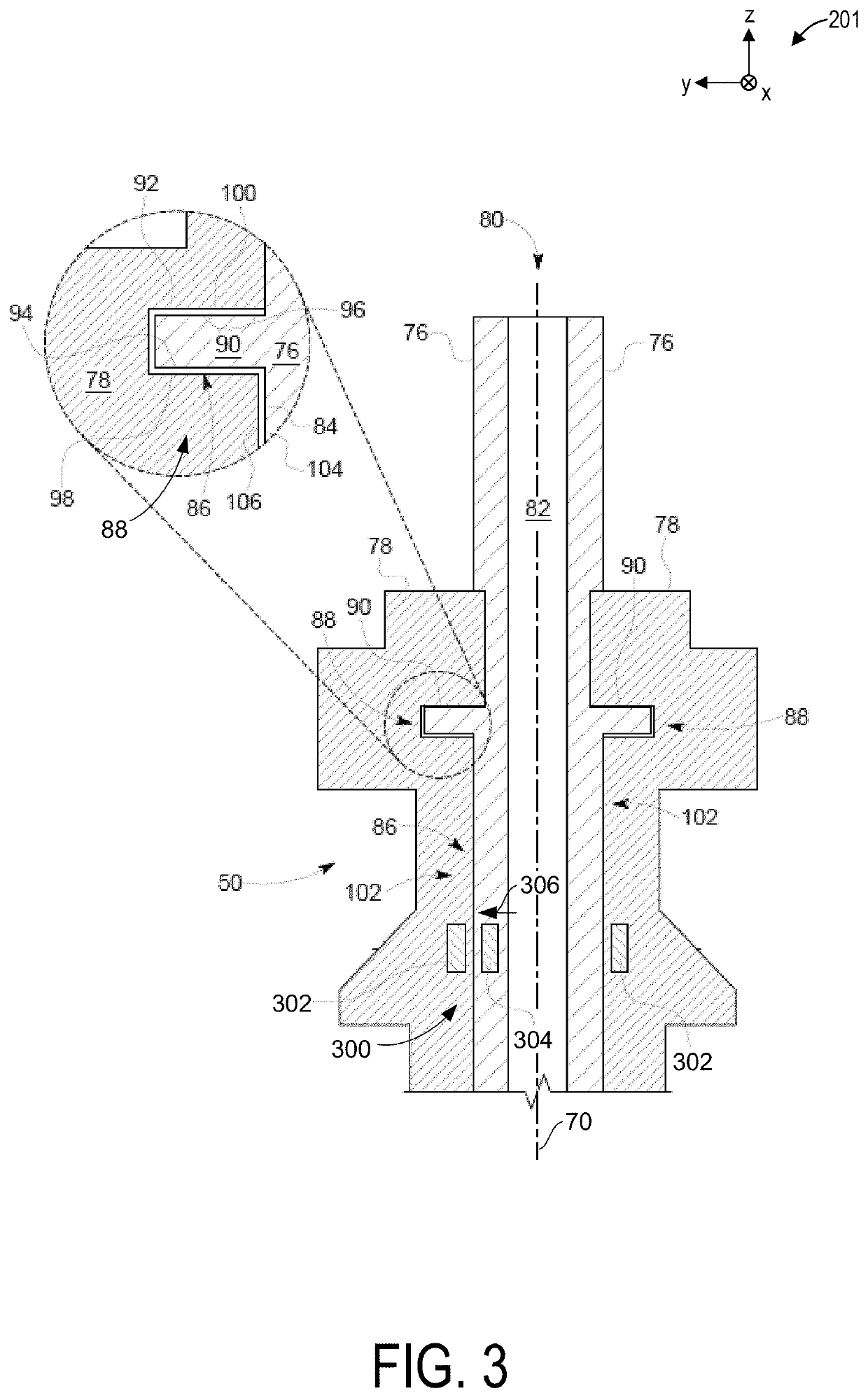

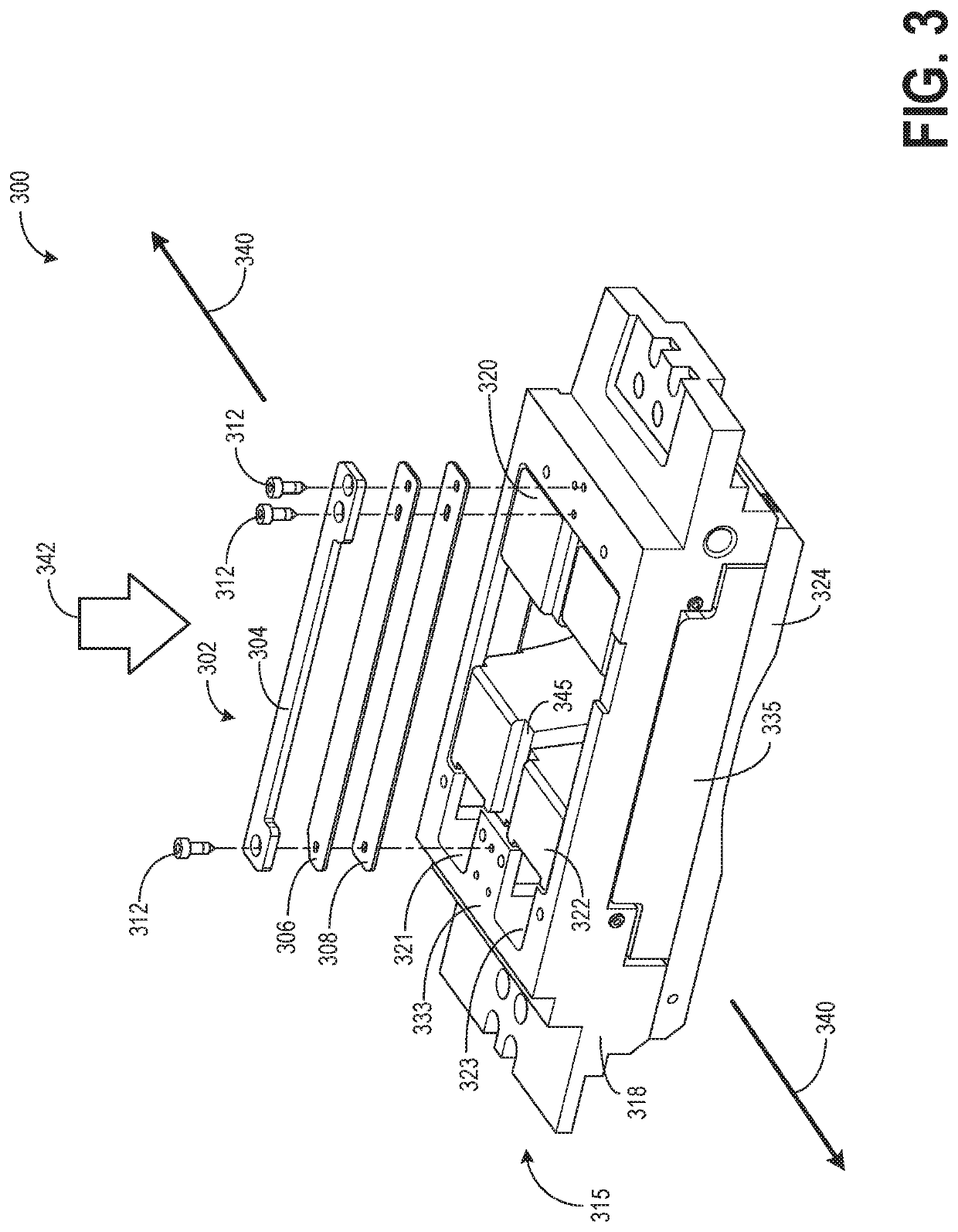

Methods and systems for a magnetic motor x-ray assembly

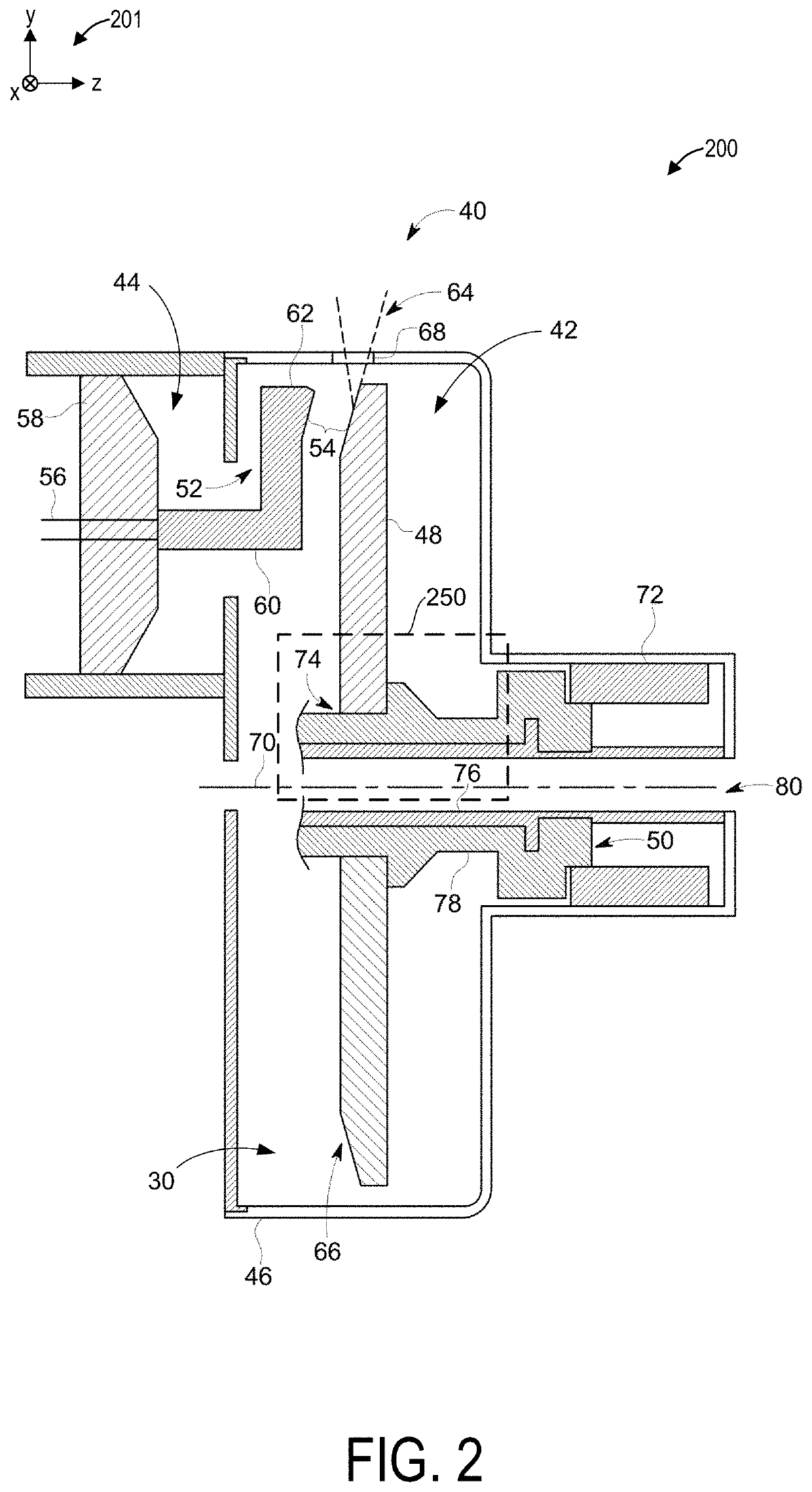

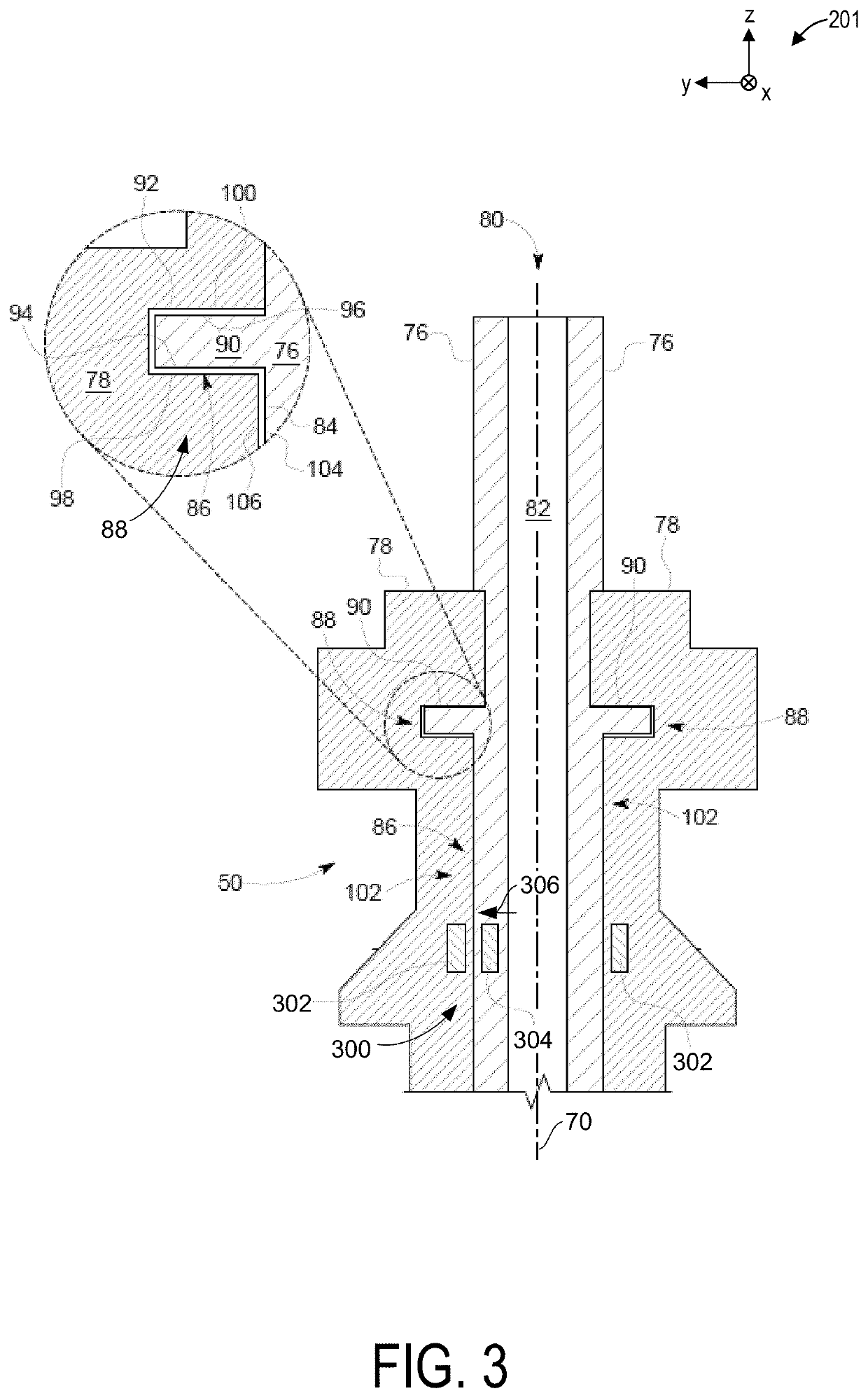

ActiveUS20210350996A1Reduced footprintImprove motor performanceX-ray tube anode coolingX-ray tube electrodesMechanical engineeringMagneto

Various methods and systems are provided for an x-ray imaging system. In one example, an x-ray tube of the imaging system includes a rotor with a core forming a continuous unit with at least one of a retention sleeve and a bearing assembly sleeve. The rotor further includes one or more magnets disposed in the core and maintained in place by the retention sleeve.

Owner:GE PRECISION HEALTHCARE LLC

Methods and systems for X-ray tube conditioning

ActiveUS11096642B2Radiation diagnostic device controlHandling using diaphragms/collimetersLight filterRay

Various methods and systems are provided for x-ray tube conditioning for a computed tomography imaging method. In one embodiment, a scout scan may be carried out prior to a diagnostic to warmup the x-ray tube to a desired temperature for the diagnostic scan. A scout scan parameter optimizing algorithm may be used to determine scout scan parameters based on a selected patient absorbed dose range and an amount of energy to be imparted to an x-ray tube during the scout scan preceding a diagnostic scan. By using a hardening filter in the path of the x-ray beam, radiation absorbed dose of the subject being scanned may be limited to the selected patient absorbed dose range.

Owner:GE PRECISION HEALTHCARE LLC

Methods and systems for X-ray tube conditioning

ActiveUS11147528B2Radiation diagnostic image/data processingRadiation diagnostic device controlComputed tomographyRay

Various methods and systems are provided for x-ray tube conditioning for a computed tomography imaging method. In one embodiment, x-ray may be generated in an x-ray tube of a radiation source prior to a diagnostic scan to warmup the x-ray tube to a desired temperature for the diagnostic scan. The power delivered to the x-ray tube during warmup may be adjusted in a closed loop system based on an initial temperature of the x-ray tube and the desired temperature for the diagnostic scan. During tube warmup, by placing a blocking plate coupled to a collimator blade in a path of the x-ray beam, the x-ray beam may be blocked from exiting a collimator.

Owner:GE PRECISION HEALTHCARE LLC

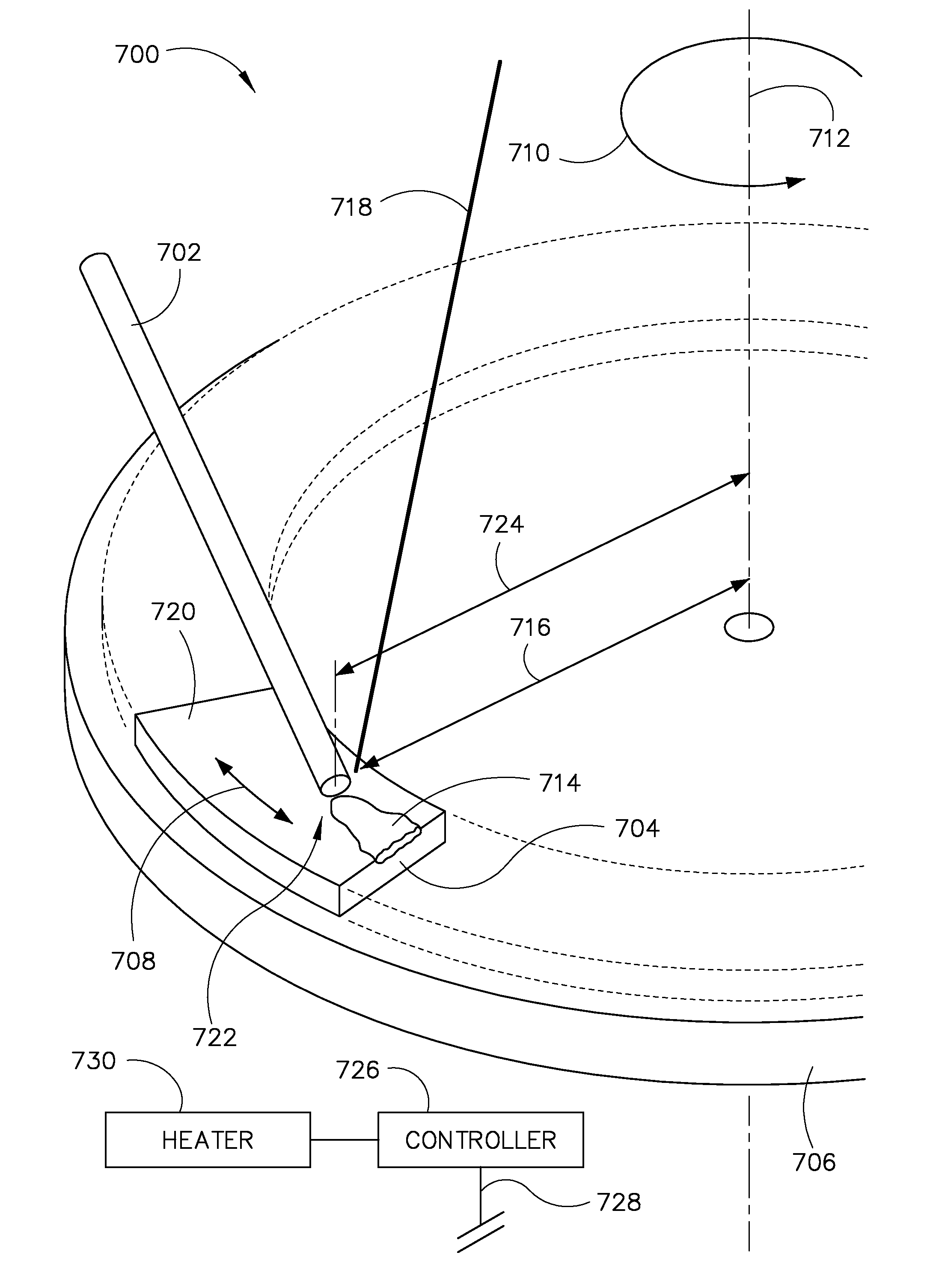

System and method to maintain target material in ductile state

An x-ray tube includes a frame, an anode for generating x-rays disposed within the frame, a cathode disposed within the frame, where the cathode is configured to selectively emit an electron beam toward the anode, and at least one heating element disposed within the frame and configured to heat a portion of the anode.

Owner:GENERAL ELECTRIC CO

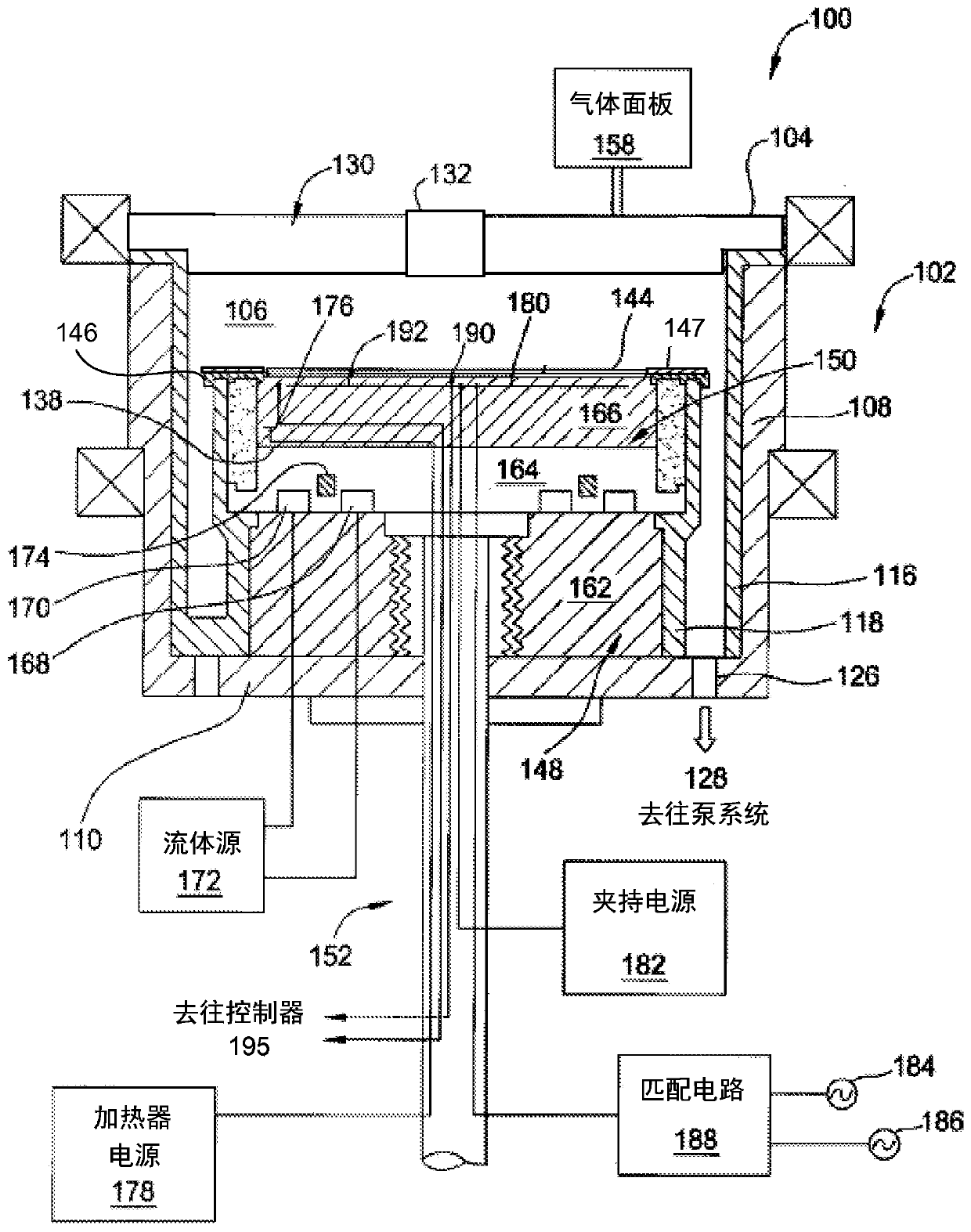

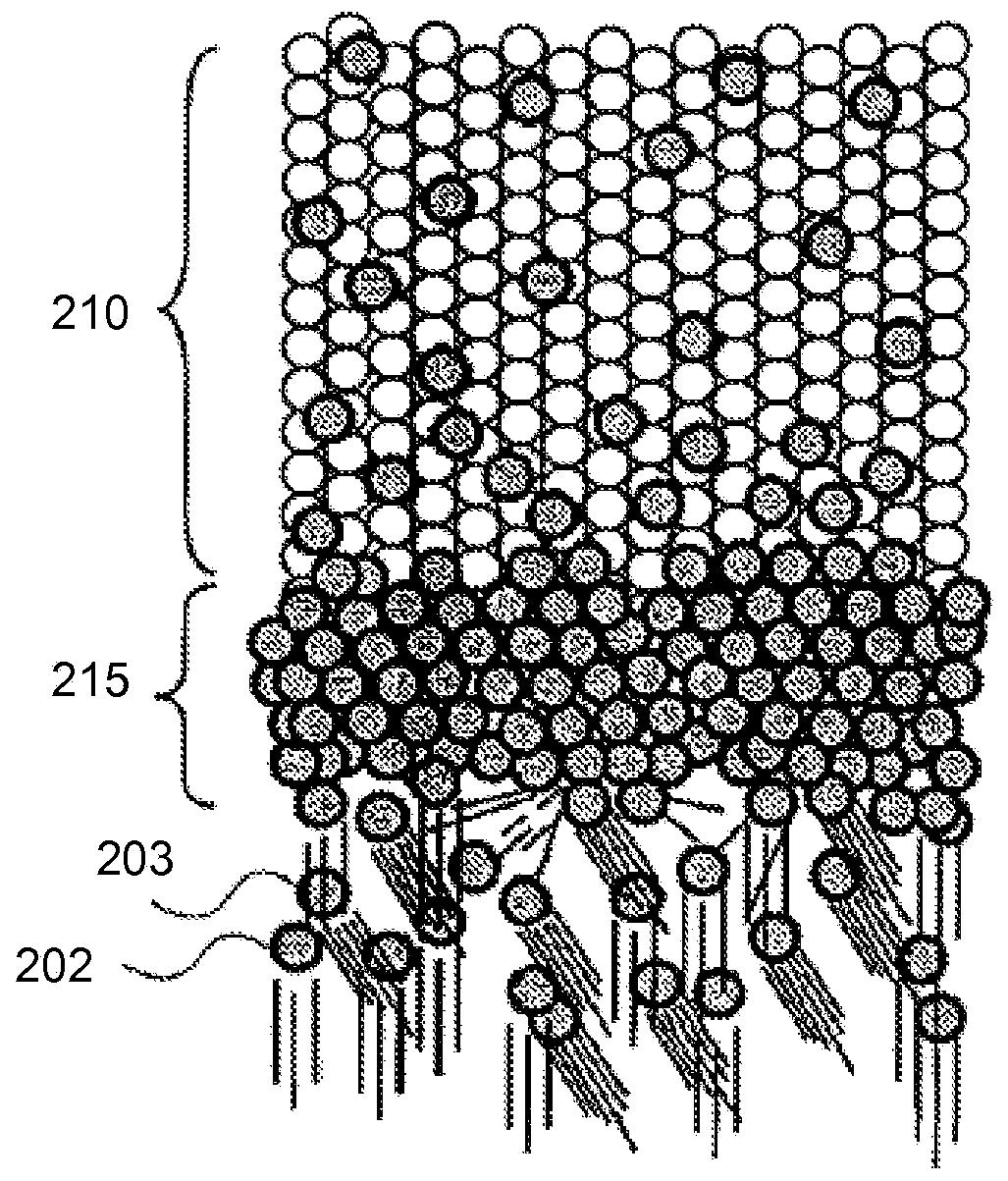

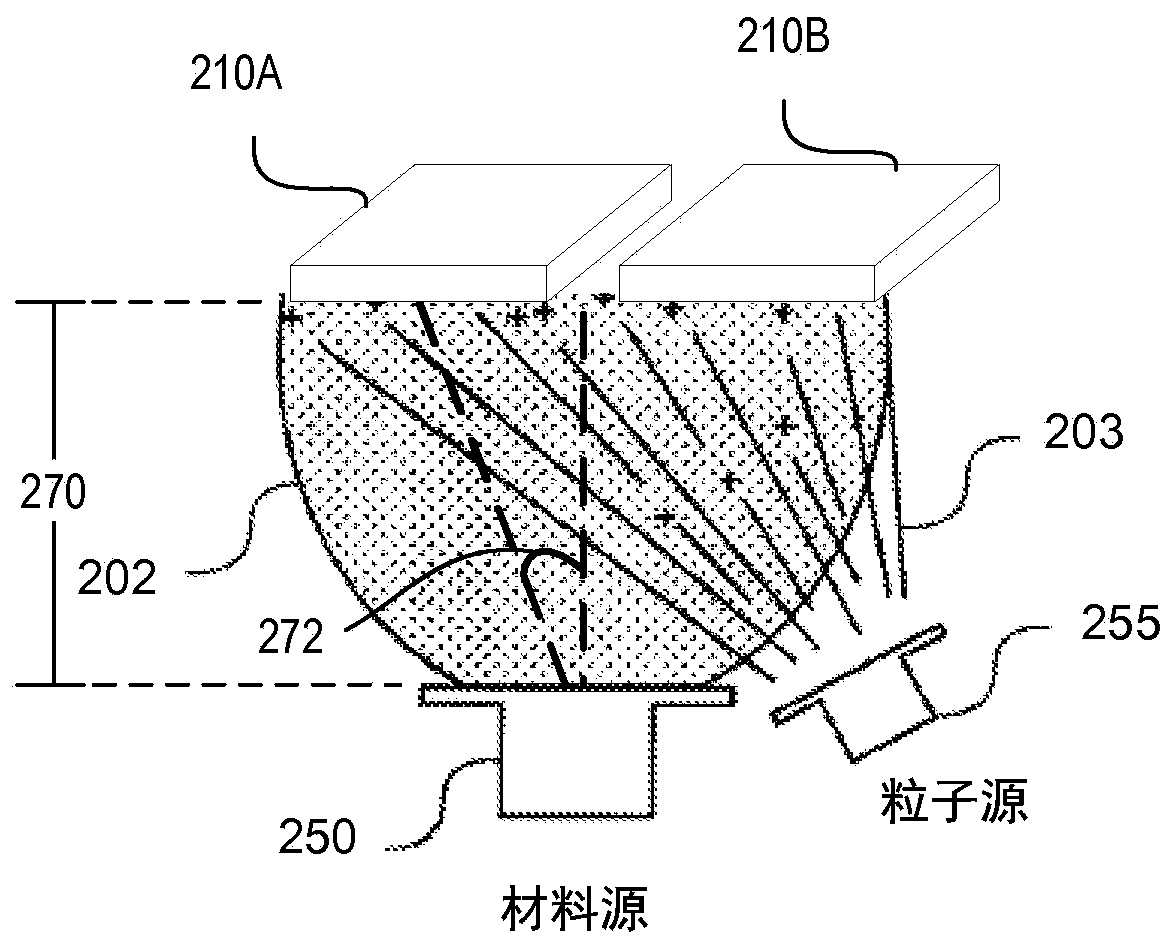

Chamber components for processing chambers and methods of making articles

ActiveCN107978507BVacuum evaporation coatingSemiconductor/solid-state device manufacturingSurface roughnessEngineering

Owner:APPLIED MATERIALS INC

Methods and systems for a magnetic motor X-ray assembly

ActiveUS11309160B2Reduced footprintImprove motor performanceX-ray tube anode coolingX-ray tube bearing assembly coolingEngineeringMechanical engineering

Various methods and systems are provided for an x-ray imaging system. In one example, an x-ray tube of the imaging system includes a rotor with a core forming a continuous unit with at least one of a retention sleeve and a bearing assembly sleeve. The rotor further includes one or more magnets disposed in the core and maintained in place by the retention sleeve.

Owner:GE PRECISION HEALTHCARE LLC

A target assembly and its manufacturing method

ActiveCN109308985BSimple manufacturing processExtended service lifeX-ray tube laminated targetsX-ray tube anode coolingManufacturing technologyProcess engineering

The present invention relates to a target assembly and its manufacturing method. The target assembly includes a first target, a base, and a window. Wherein, the first target has the ability to generate first radiation when it is hit by a beam, the base is used to support the first target, and the window is permeable to at least part of the beam. The window and the base form at least part of a sealed chamber in which the first target is located, wherein the sealed chamber is filled with air having a normal oxygen content or a lower than normal oxygen content. Compared with the traditional solution, the target assembly of the present invention is assembled in the air, which simplifies the manufacturing process. The target in the target assembly is in a sealed environment, and will not undergo further oxidation reaction with the air outside the sealed environment, nor will it cause mass loss due to volatilization of oxidation products, thereby improving its service life.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com