Anode, and x-ray generating tube, x-ray generating apparatus, and radiography system using the same

A technology for generating devices and X-rays, which is applied in the parts of X-ray tubes, X-ray tubes, X-ray tube electrodes, etc. It can solve the problems of difficulty in ensuring X-ray output, inability to obtain tube current, etc., and achieve vacuum leakage suppression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

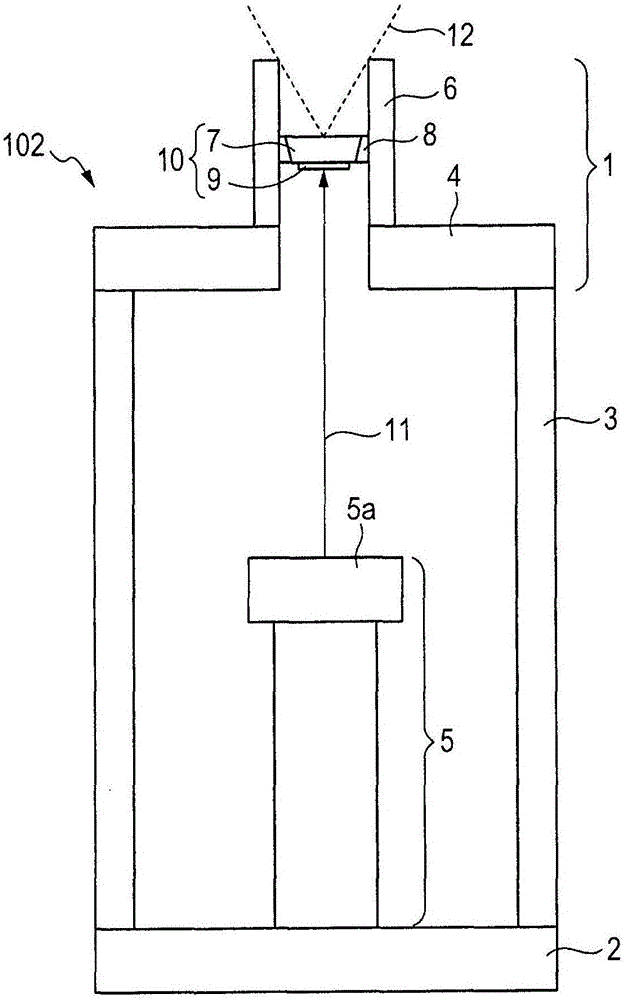

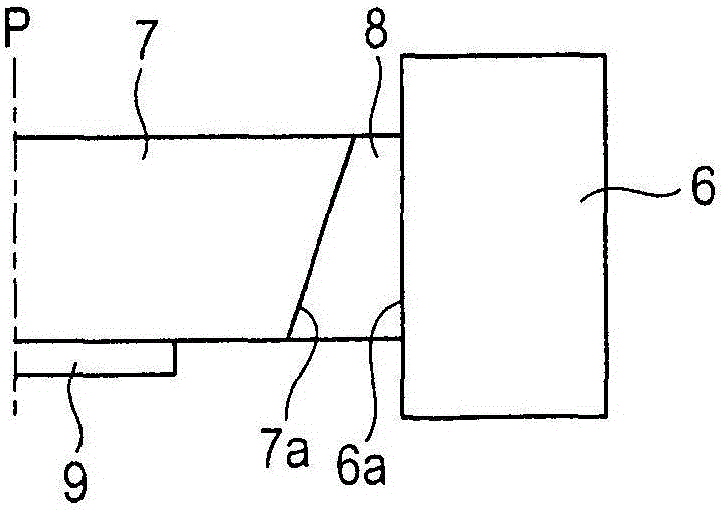

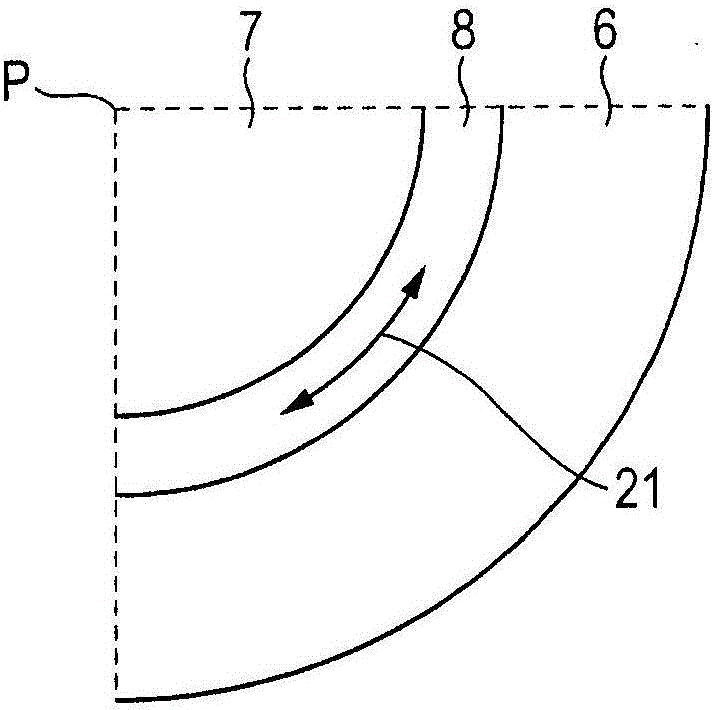

[0065] The anode 1 according to the first embodiment of the present invention is described. This example is a case in which the tubular anode member 6 is cylindrical and the transmissive substrate 7 of the target 10 is in the shape of a disc concentric with the inner circumference of the tubular anode member 6 in plan view. Such as Figure 1B As shown in , in the anode of the present invention, the bonding material 8 has a thickness that varies in a direction along the central axis P of the tubular anode member 6 (hereinafter referred to as “central axis P”). Note that in the present invention, the thickness of the bonding material 8 is the width of the bonding material 8 in a direction perpendicular to the central axis P of the tubular anode member 6, that is, in this case, the thickness of the bonding material 8 on the tubular anode member. 6 the width in the radial direction as well as in the transverse direction Figure 1B The paper width. Note that the bonding material...

no. 2 example

[0088] Figure 5 is a partial sectional view for schematically showing the structure of an anode according to another exemplary embodiment of the present invention. In this embodiment, the transmissive substrate 7 has a support surface 7 b for supporting the target layer 9 . Furthermore, the tubular anode member 6 has a tube inner circumference for supporting the transmissive substrate 7 . In addition, the tubular anode member 6 of this embodiment includes an annular protruding portion 41 protruding inward from the inner circumference of the tube in the direction of the tube diameter, which is the difference between the tubular anode member of this embodiment and the reference Figure 1A to Figure 3B The tubular anode member of the first embodiment described differs in that. The annular convex portion 41 has a bear surface 41a opposite to the outer periphery of the support surface 7b. The bonding material 8 extends from a gap in the tube axial direction extending in the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com