Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about "X-ray tube bonding/fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

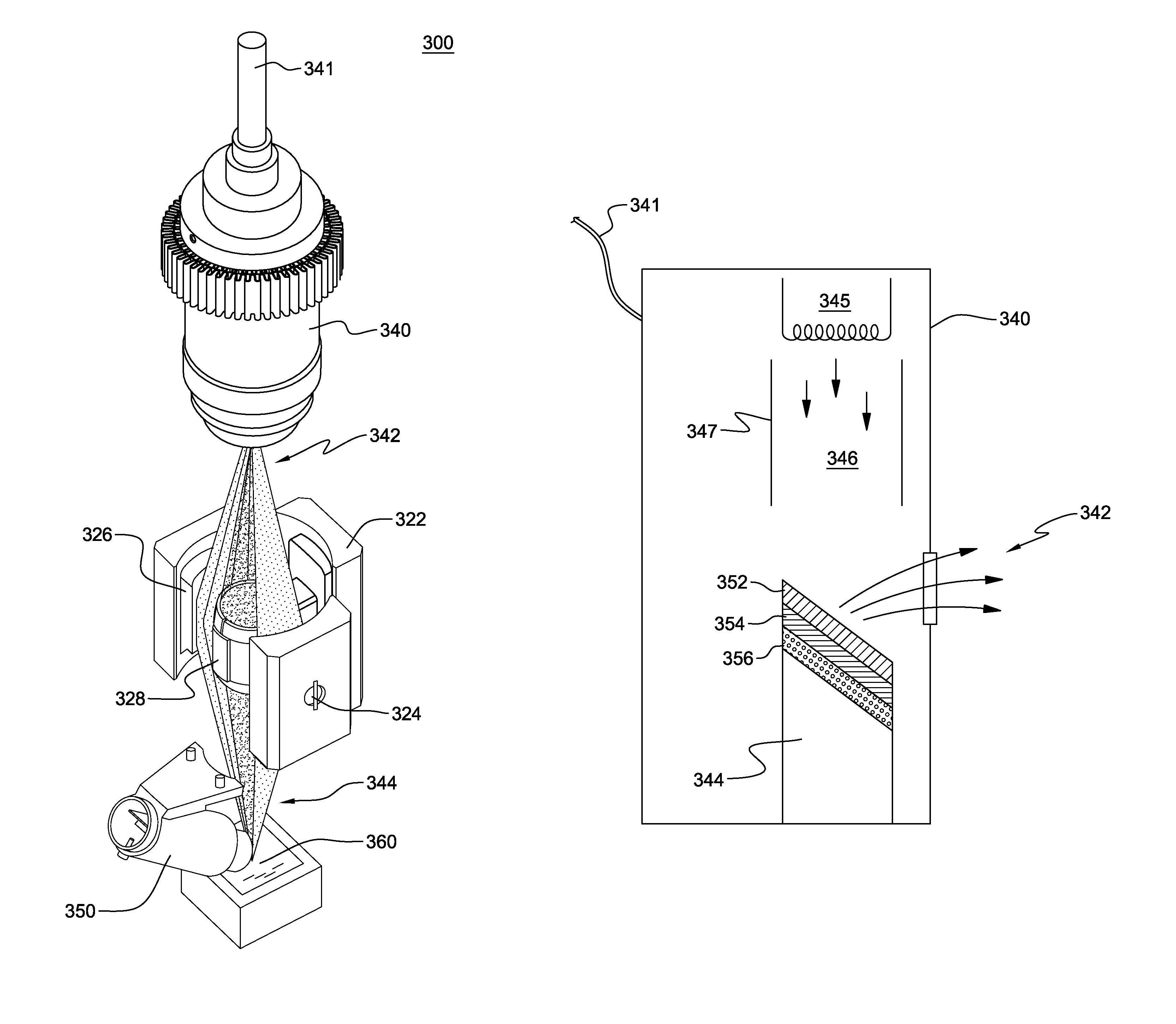

Coating process for manufacture or reprocessing of sputter targets and x-ray anodes

ActiveUS20080216602A1Low heat introductionWide applicabilityLiquid surface applicatorsMolten spray coatingPowder mixtureNiobium

Disclosed is a process for the reprocessing or production of a sputter target or an X-ray anode wherein a gas flow forms a gas / powder mixture with a powder of a material chosen from the group consisting of niobium, tantalum, tungsten, molybdenum, titanium, zirconium, mixtures of two or more thereof and alloys thereof with at least two thereof or with other metals, the powder has a particle size of 0.5 to 150 μm, wherein a supersonic speed is imparted to the gas flow and the jet of supersonic speed is directed on to the surface of the object to be reprocessed or produced.

Owner:H C STARCK SURFACE TECH & CERAMIC POWDERS GMBH

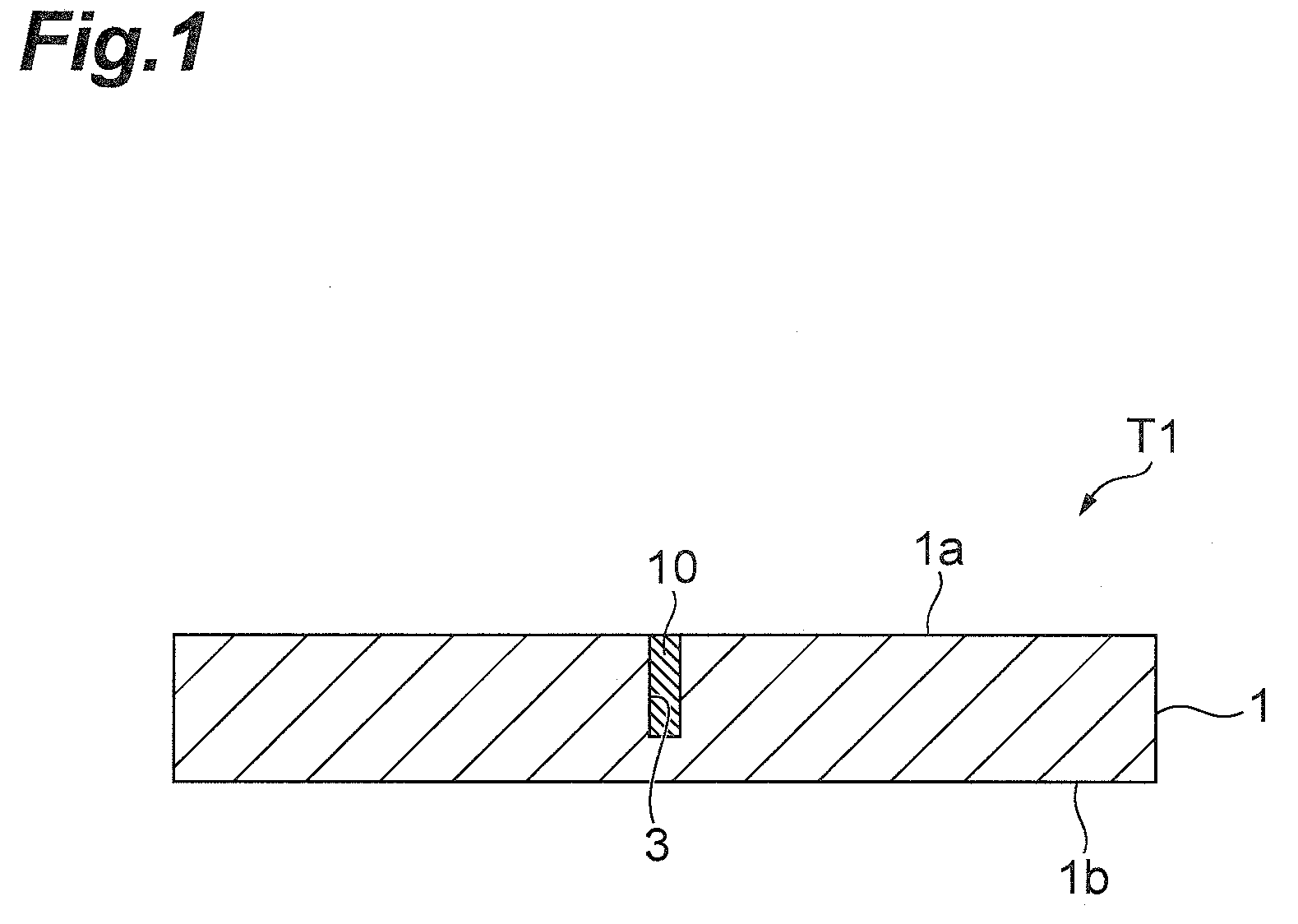

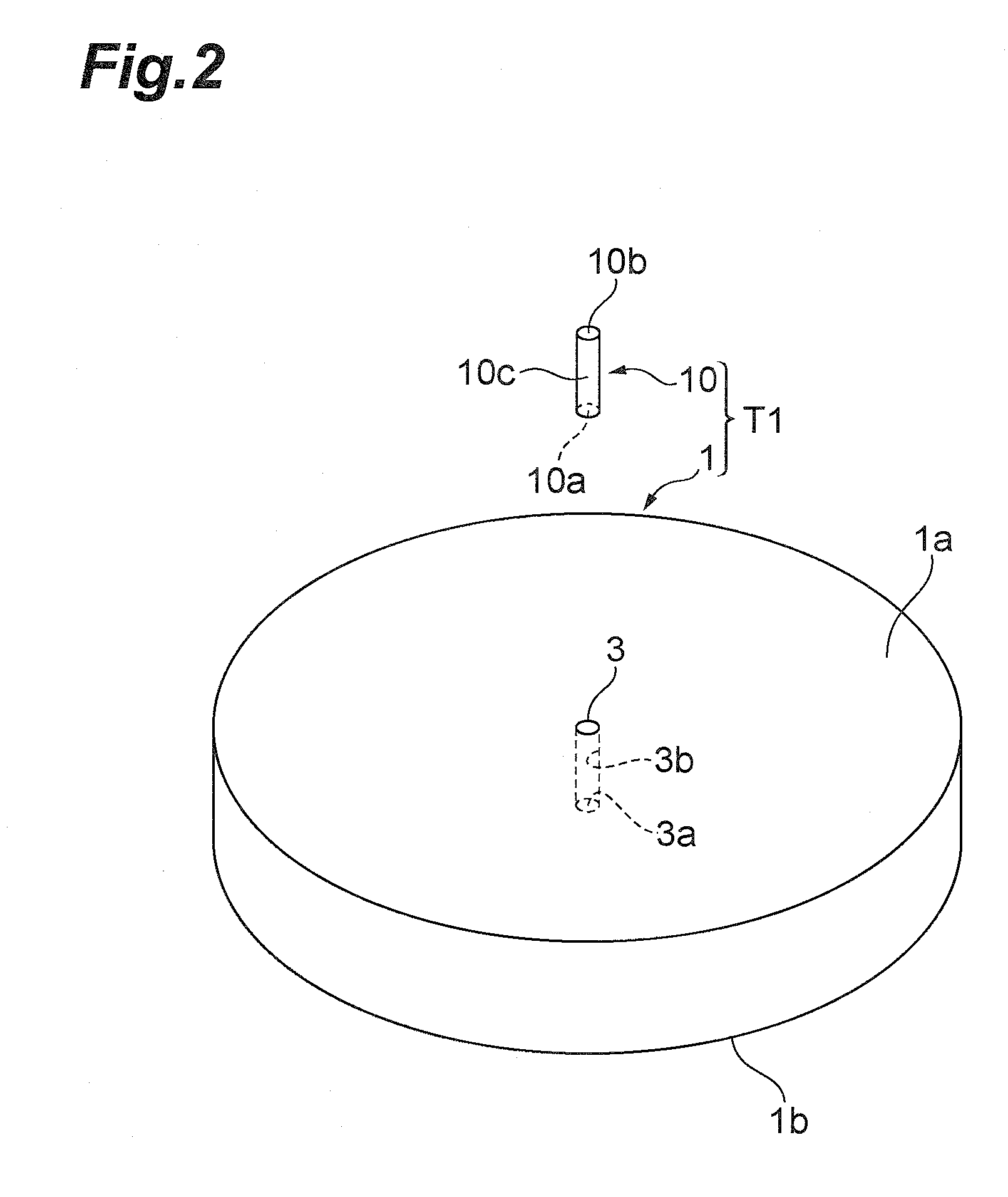

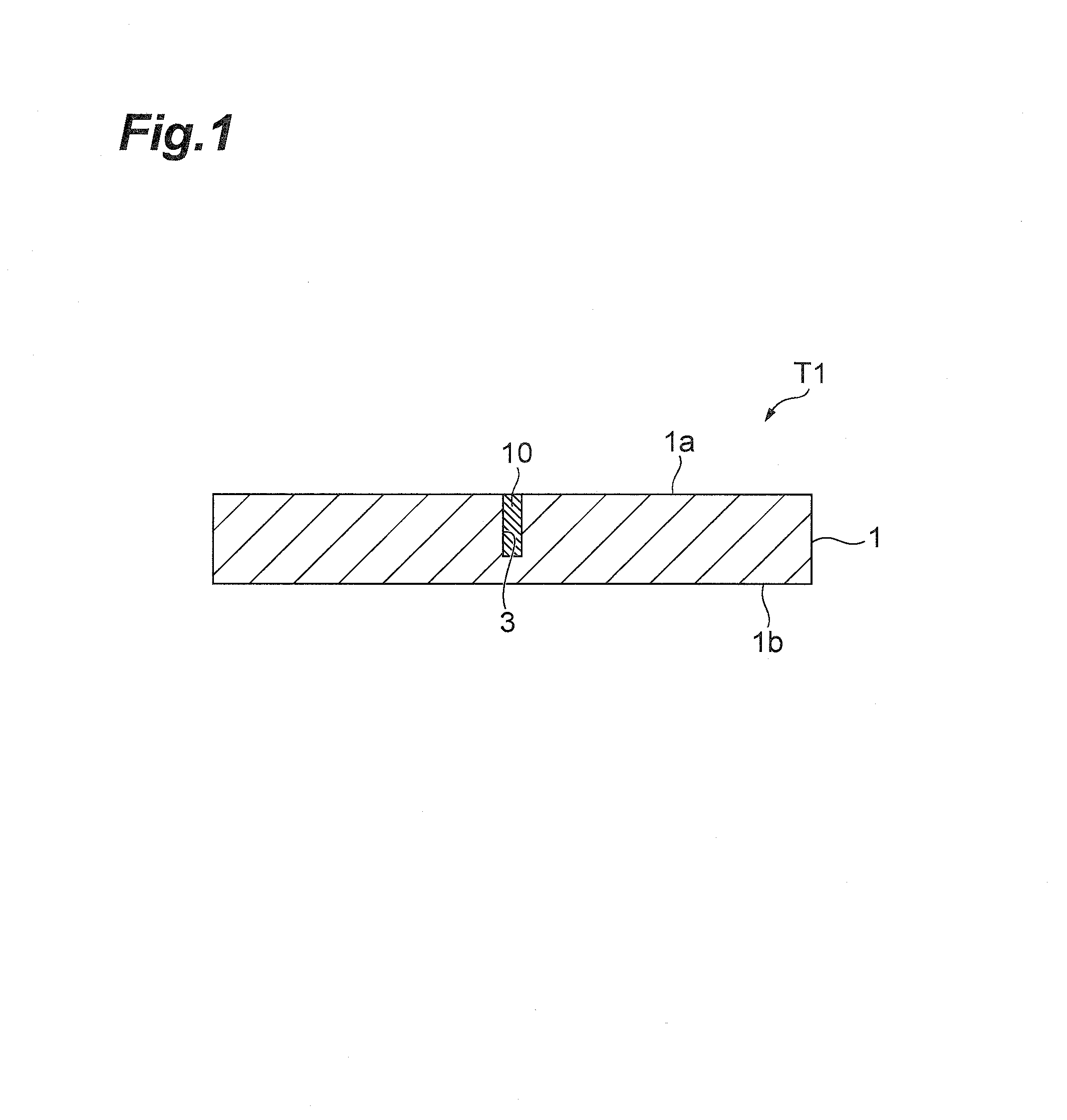

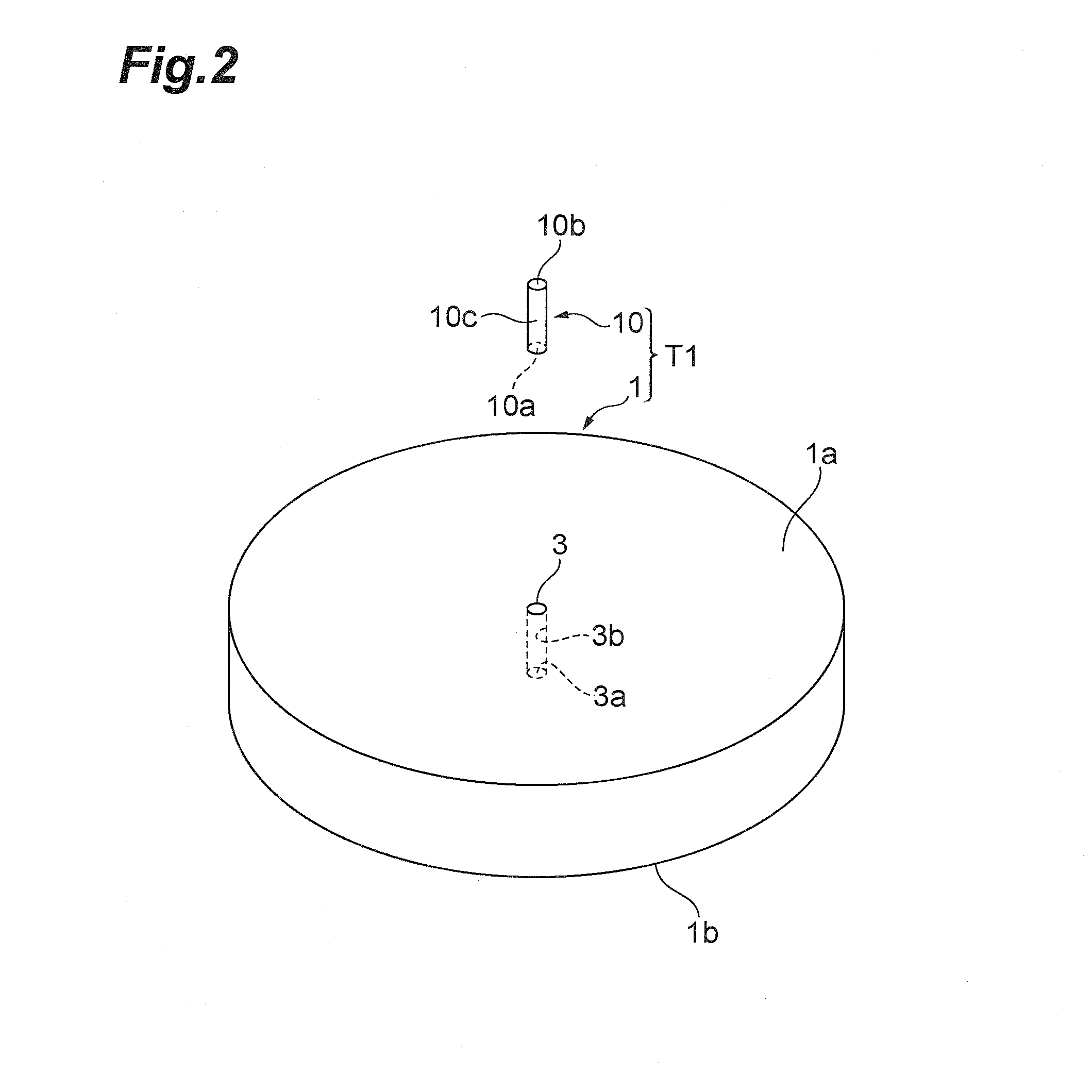

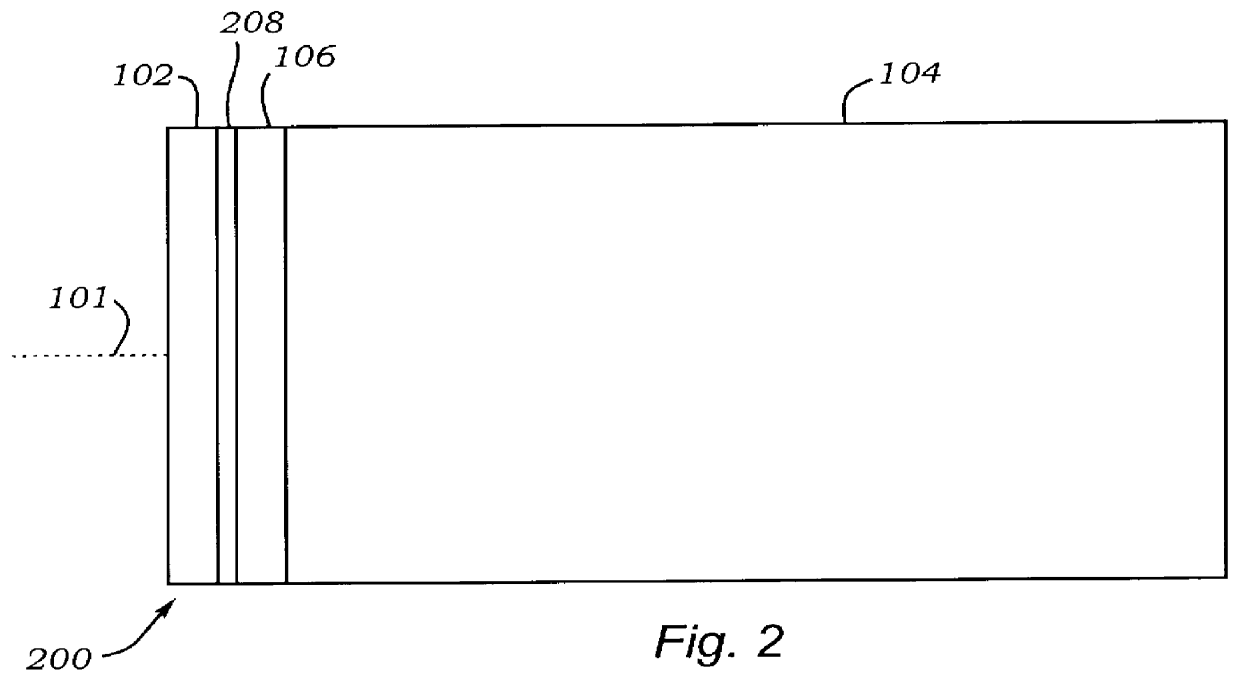

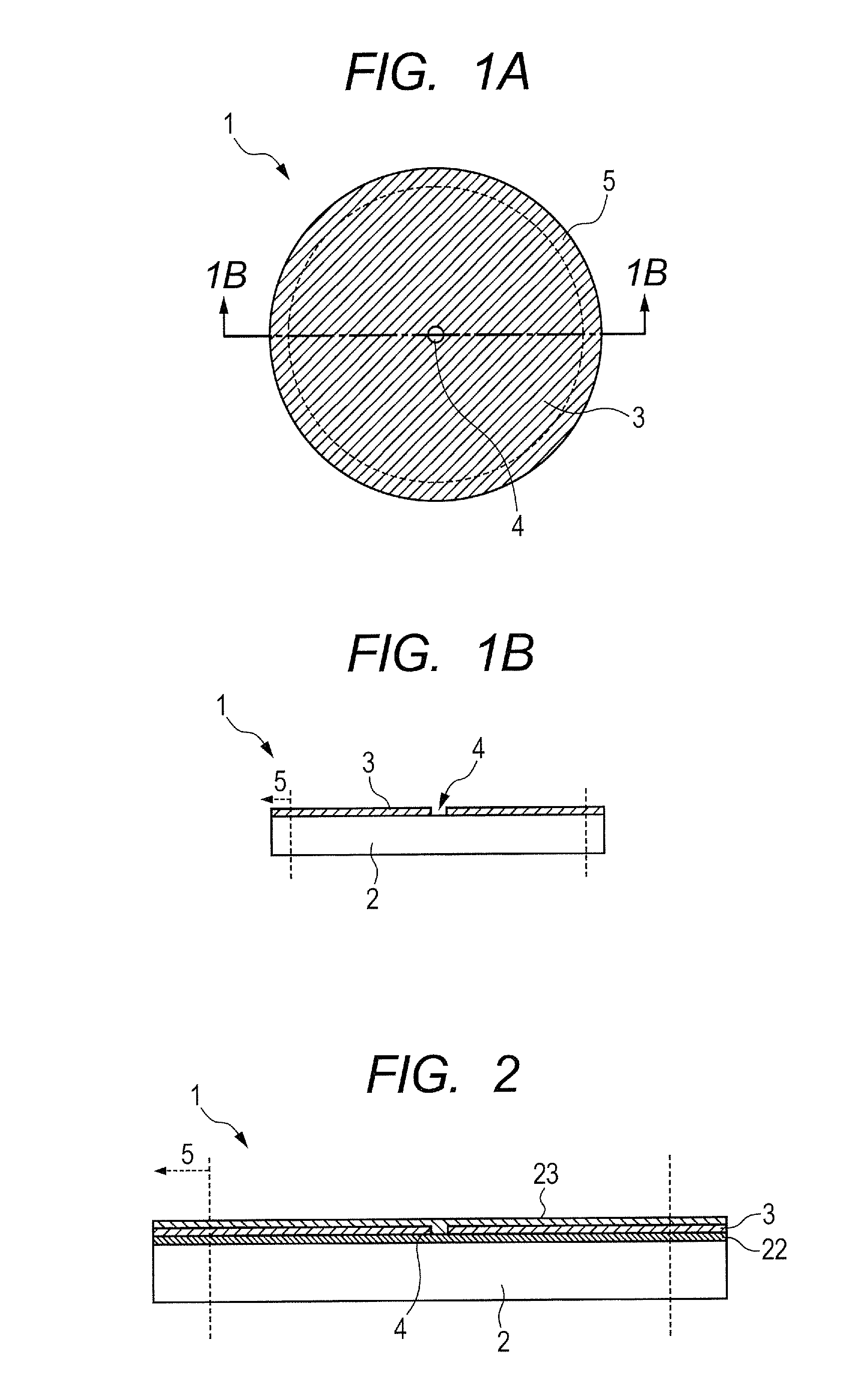

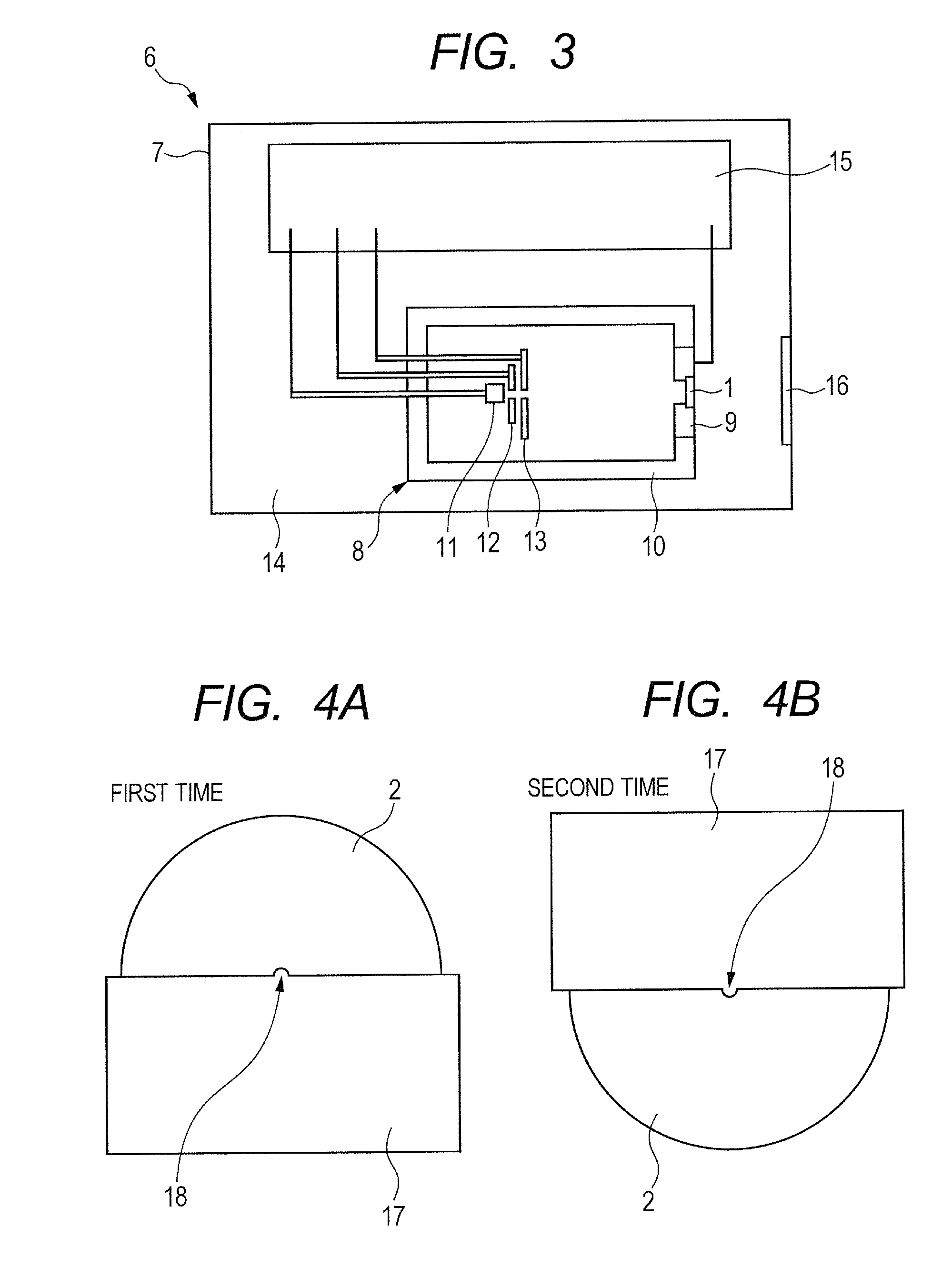

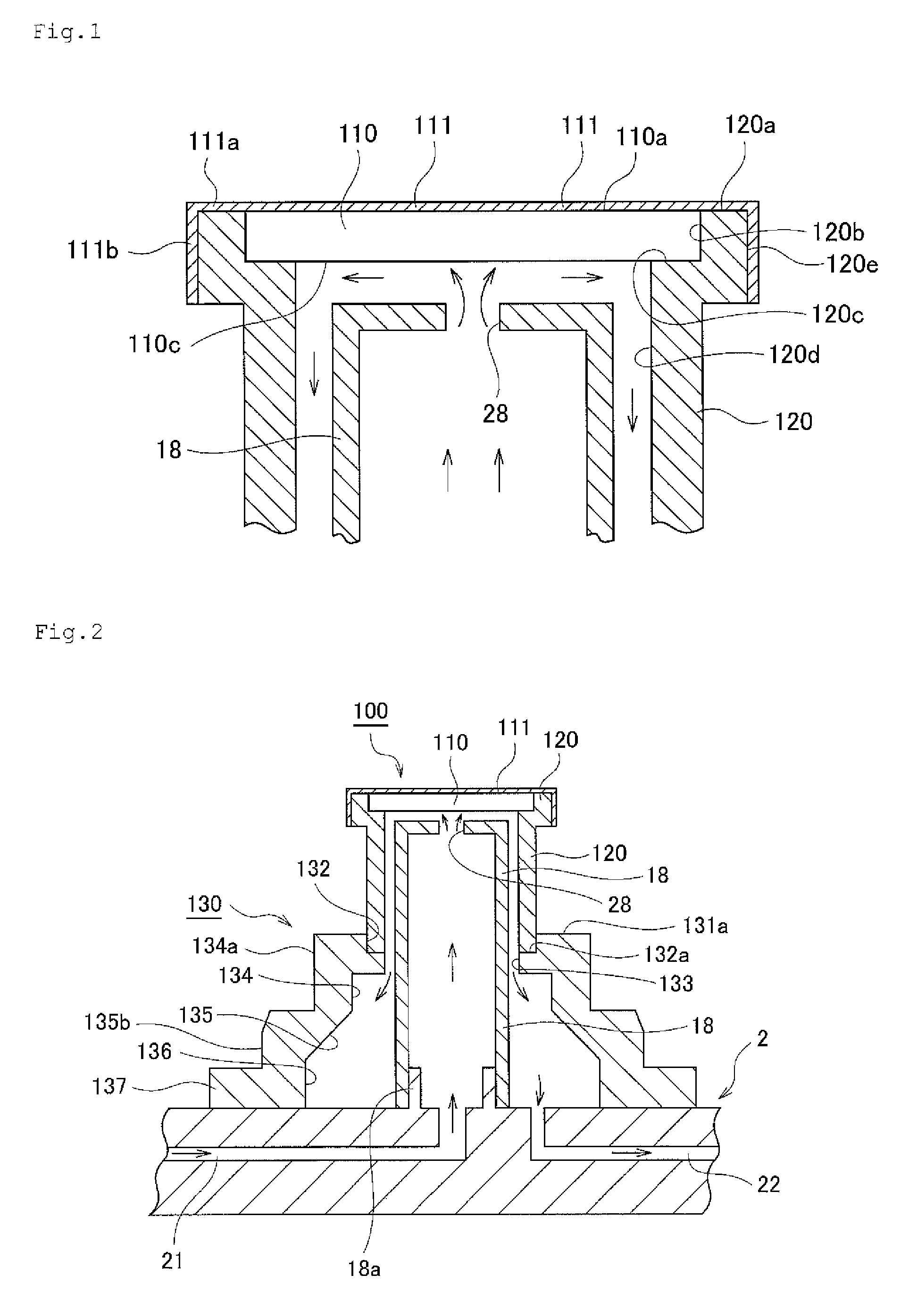

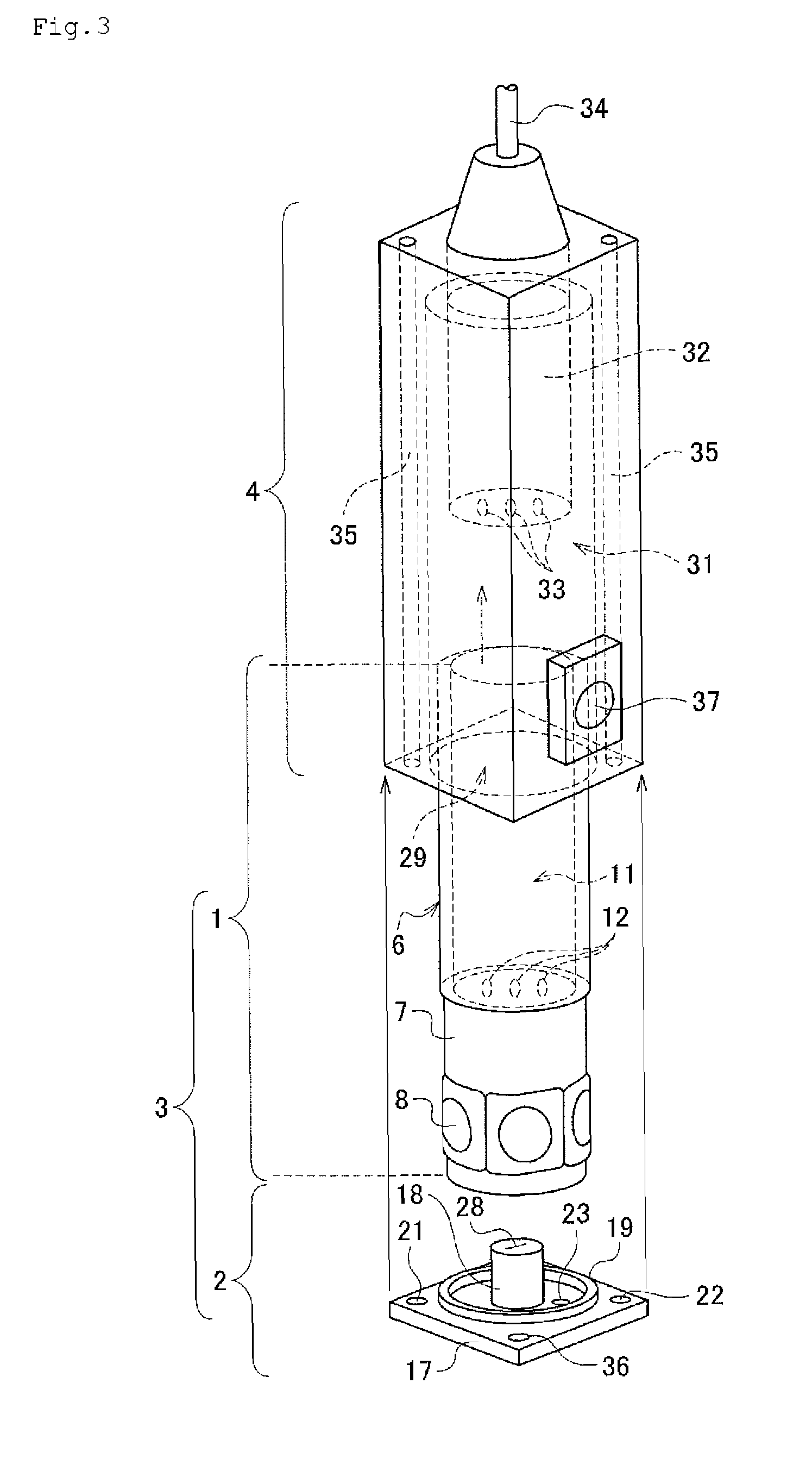

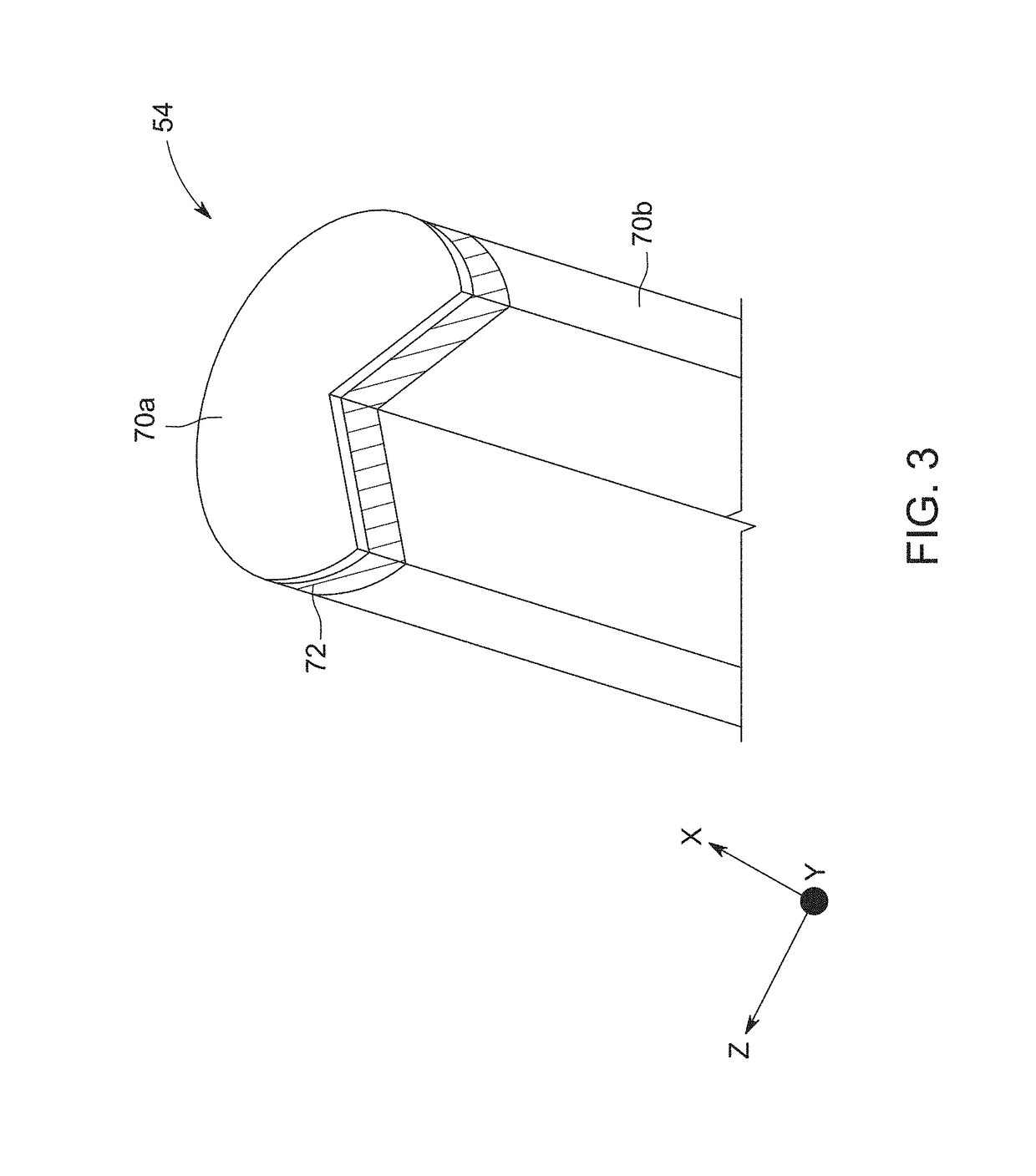

Target for x-ray generation, x-ray generator, and method for producing target for x-ray generation

ActiveUS20110058655A1Simplify production facilitySimple stepsX-ray tube anode coolingX-ray tube electrodesSoft x rayX-ray generator

A target for X-ray generation has a substrate and a target portion. The substrate is comprised of diamond and has a first principal surface and a second principal surface opposed to each other. A bottomed hole is formed from the first principal surface side in the substrate. The target portion is comprised of a metal deposited from a bottom surface of the hole toward the first principal surface. An entire side surface of the target portion is in close contact with an inside surface of the hole.

Owner:HAMAMATSU PHOTONICS KK

Diamond anode

ActiveUS7359487B1Avoid damageImprove cooling effectX-ray tube laminated targetsX-ray tube anode coolingOptoelectronicsMaterials science

According to one aspect of the invention a robust anode structure and methods of making and using said structure to produce ionizing radiation are disclosed. An ionizing radiation producing layer is bonded to the target side of a highly conductive diamond substrate, by a metal carbide layer. The metal carbide layers improves the strength and durability of the bond, thus improving heat removal from the anode surface and reducing the risk of delaminating the ionizing radiation producing layer, thus reducing degradation and extending the anode's life. A smoothing dopant is alloyed into the radiation producing layer to facilitate keeping the layer surface smooth, thus improving the quality of the x-ray beam emitted from the anode. In an embodiment, the heat sink comprises a metal carbide skeleton cemented diamond material. In another embodiment, the heat sink is bonded to the diamond substrate structure in a high temperature reactive brazing process.

Owner:NOVA MEASURING INSTRUMENTS INC

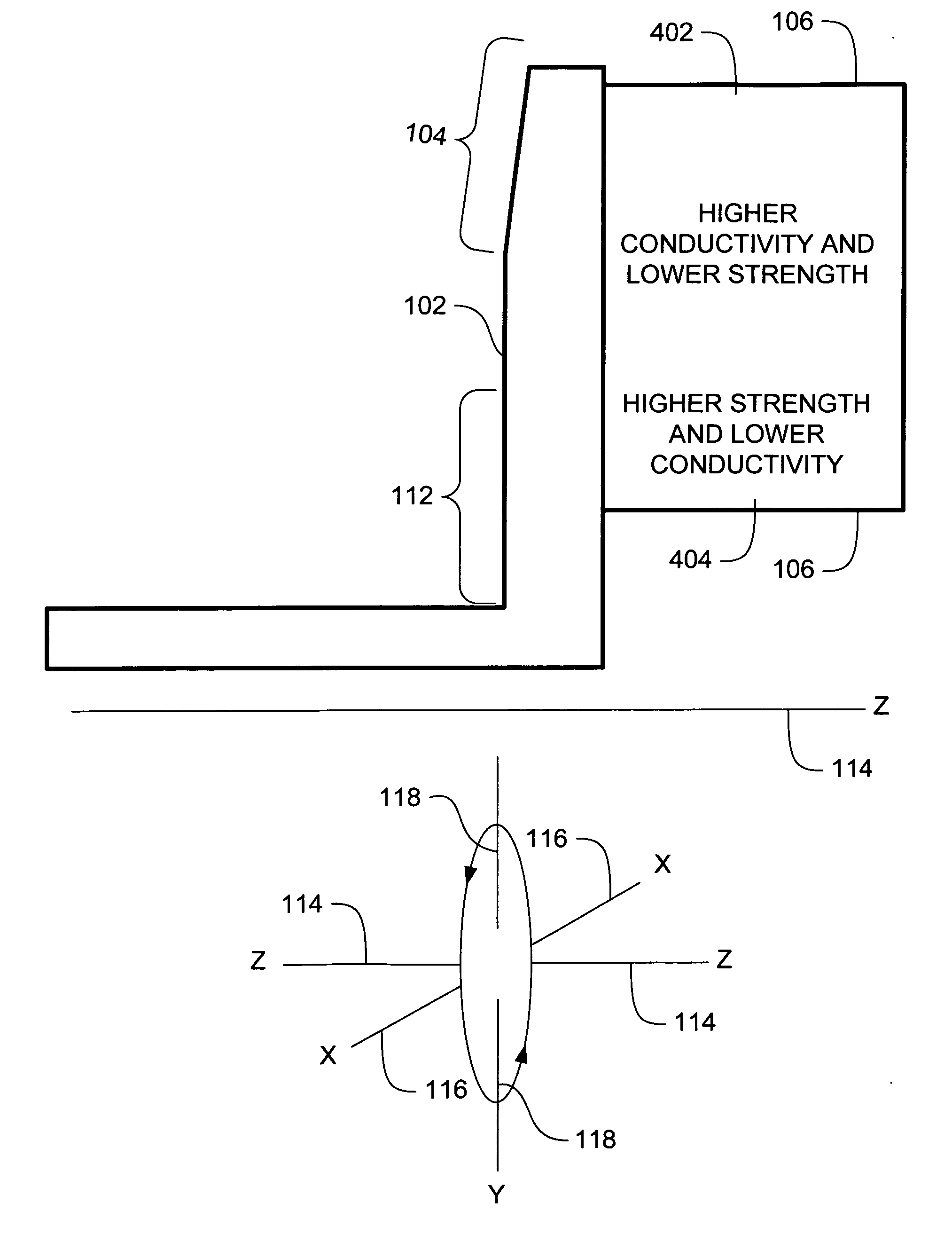

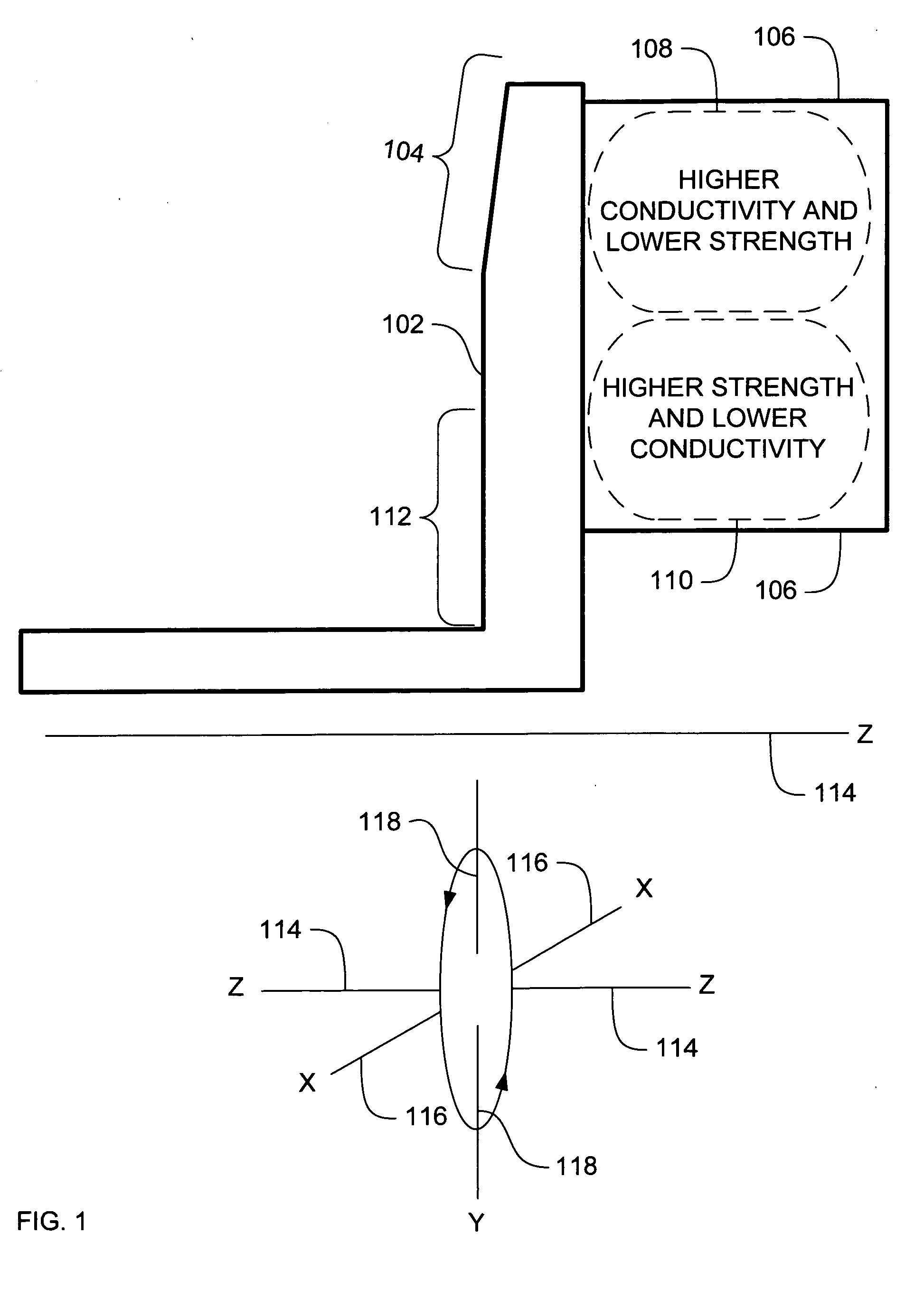

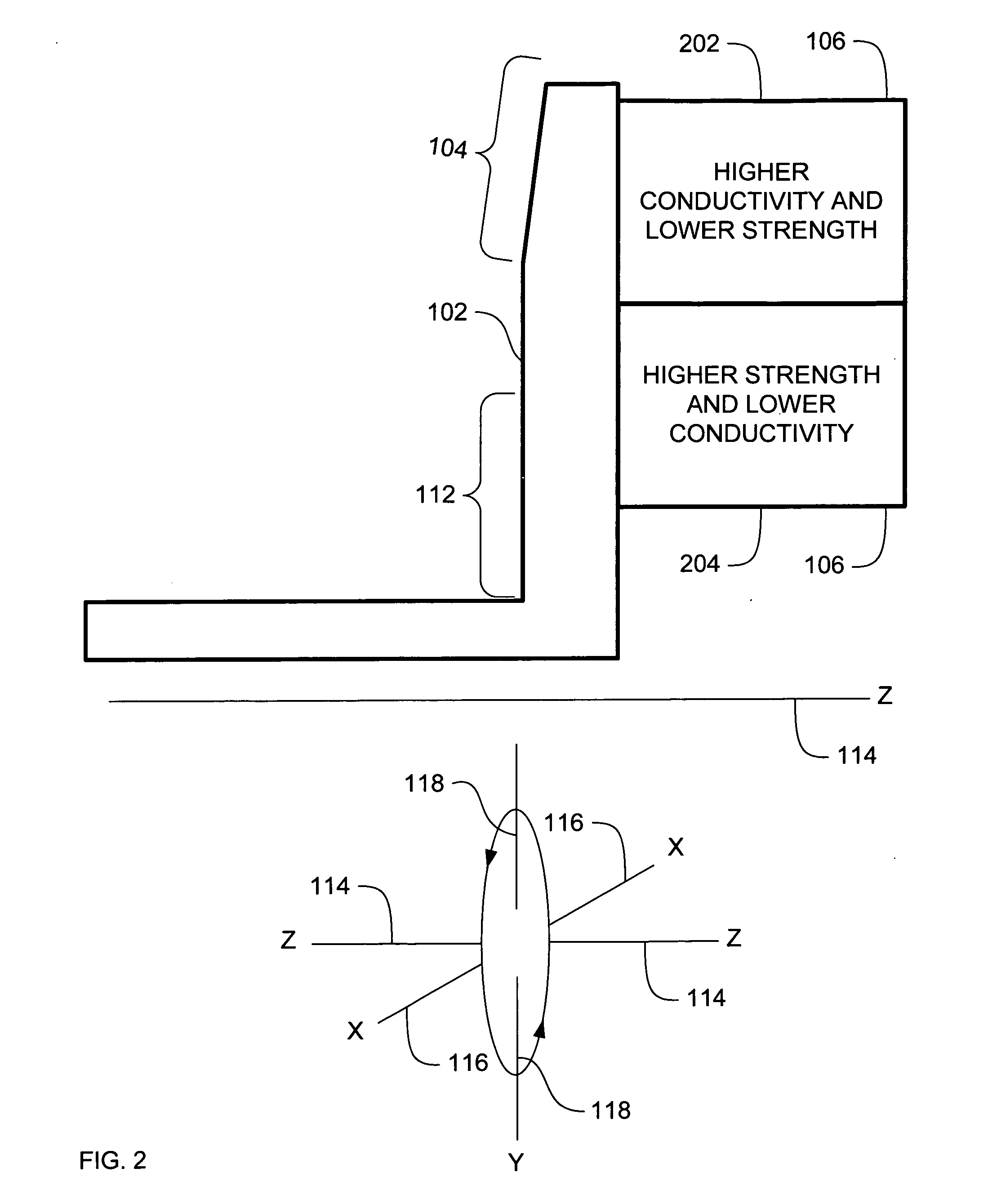

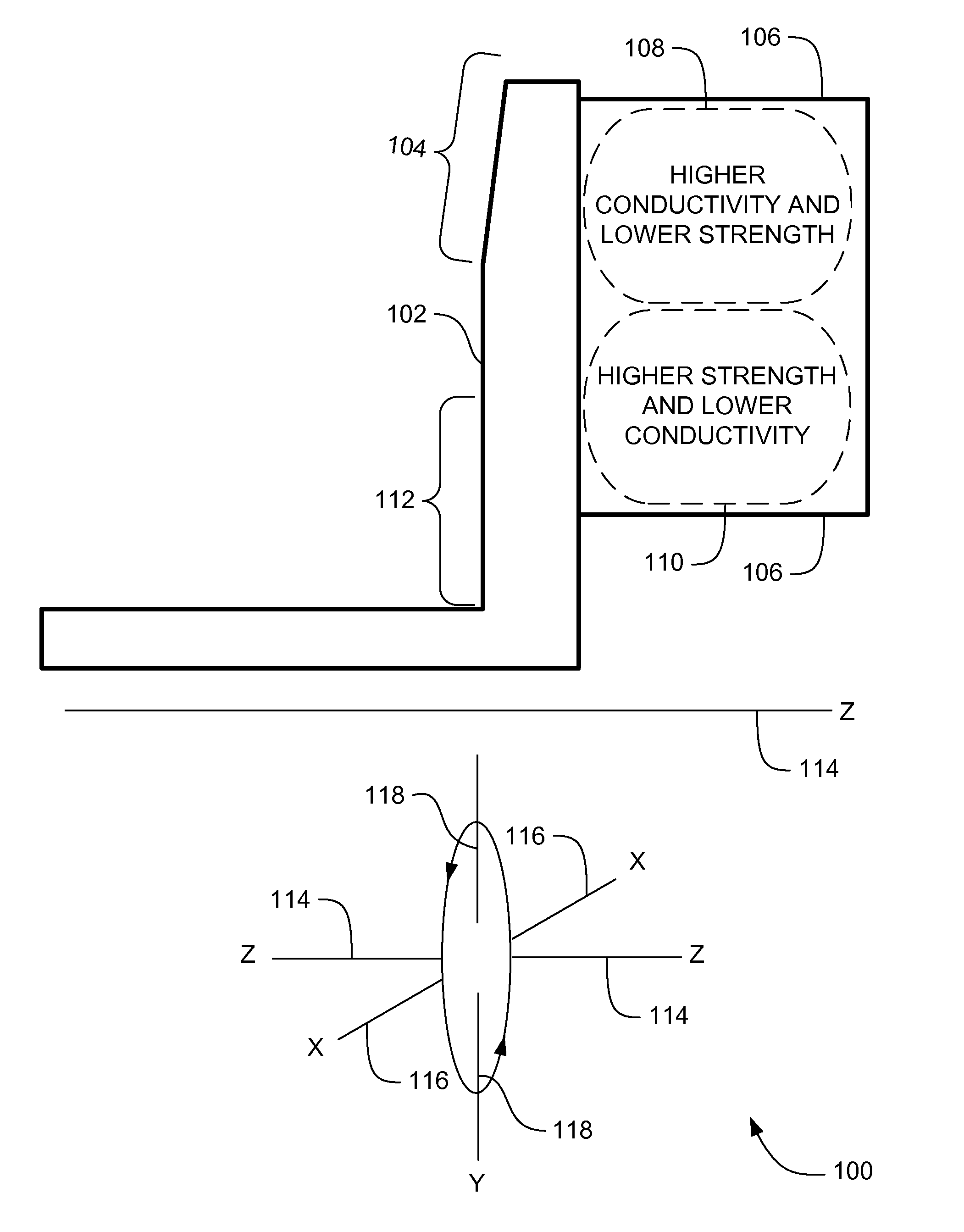

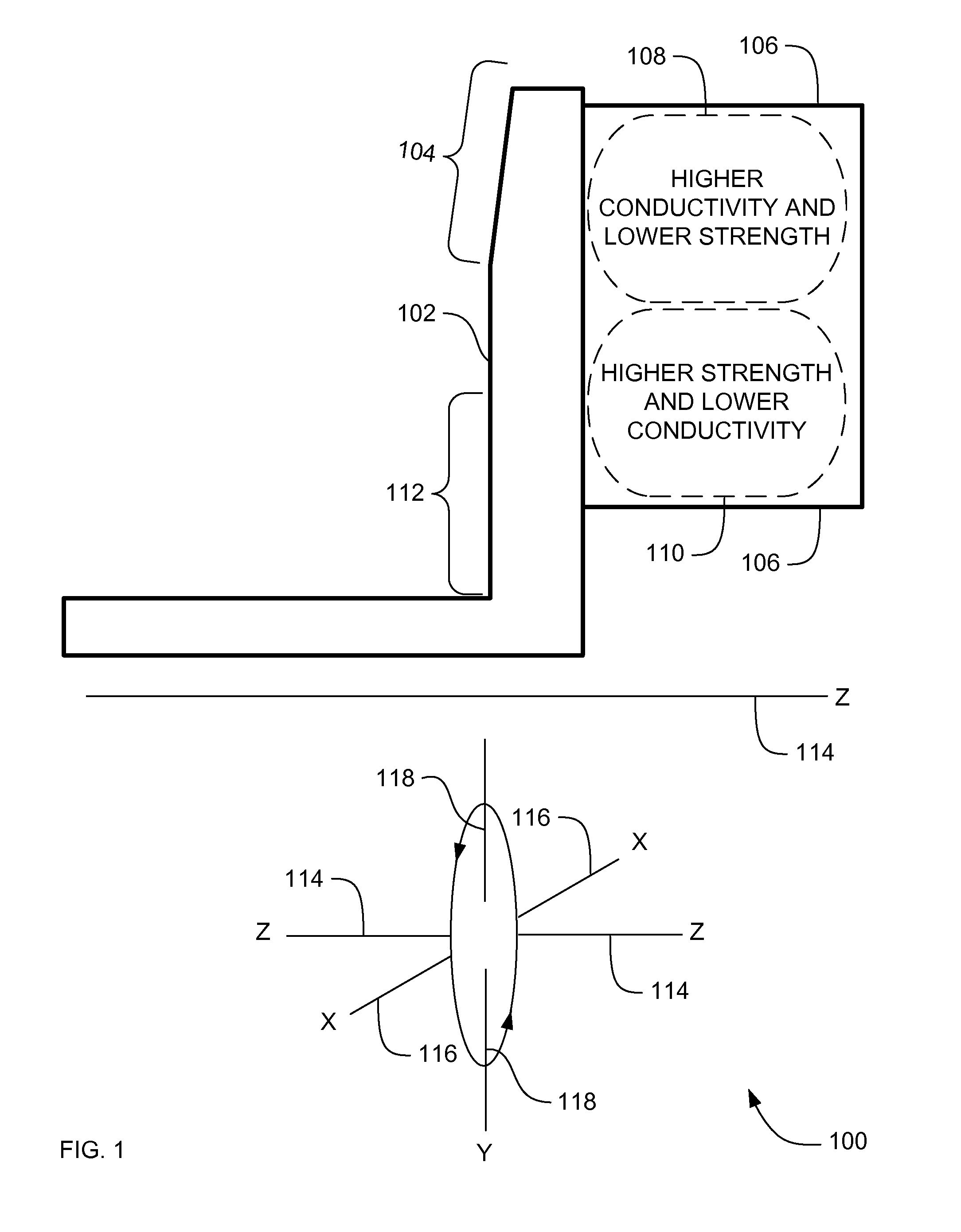

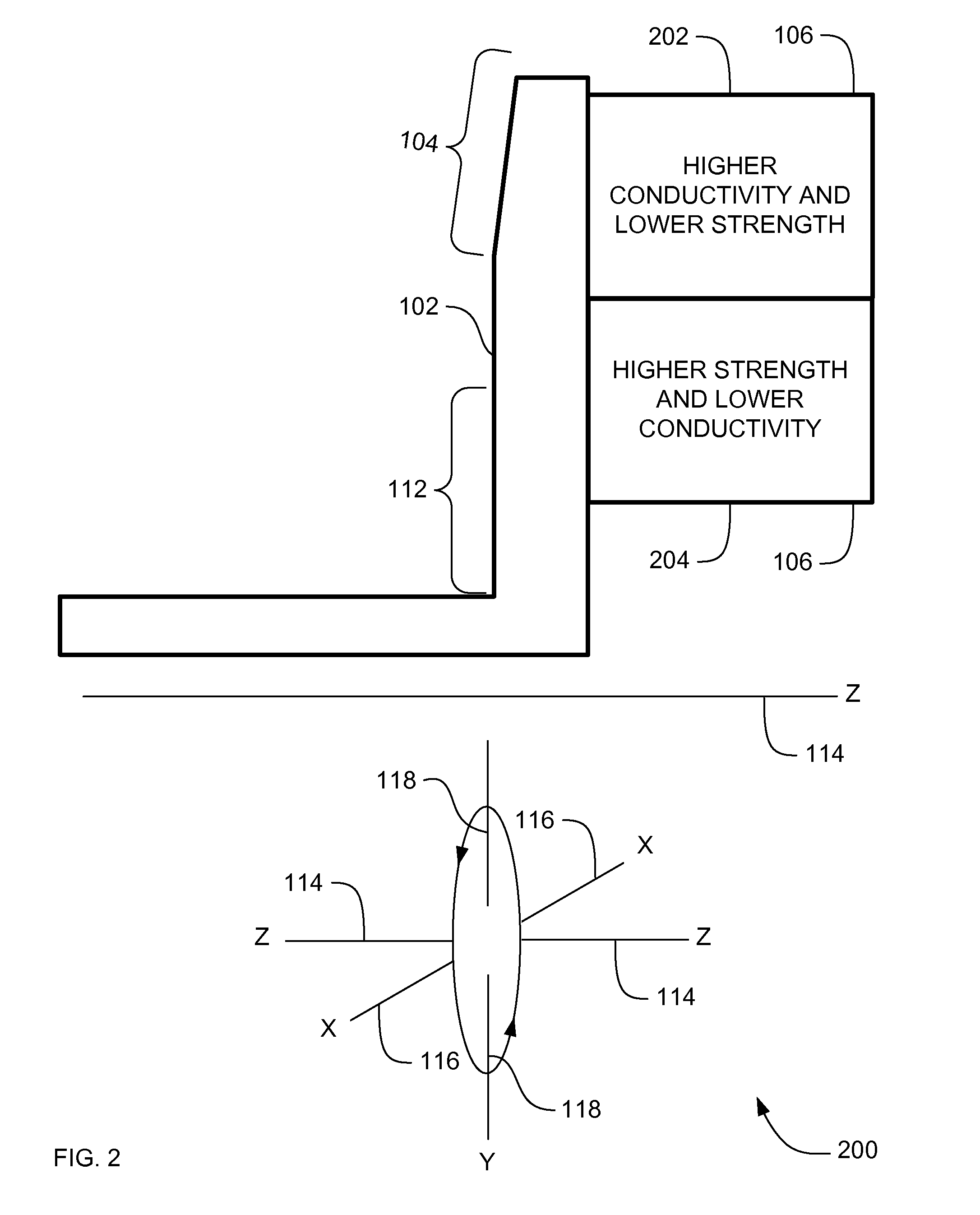

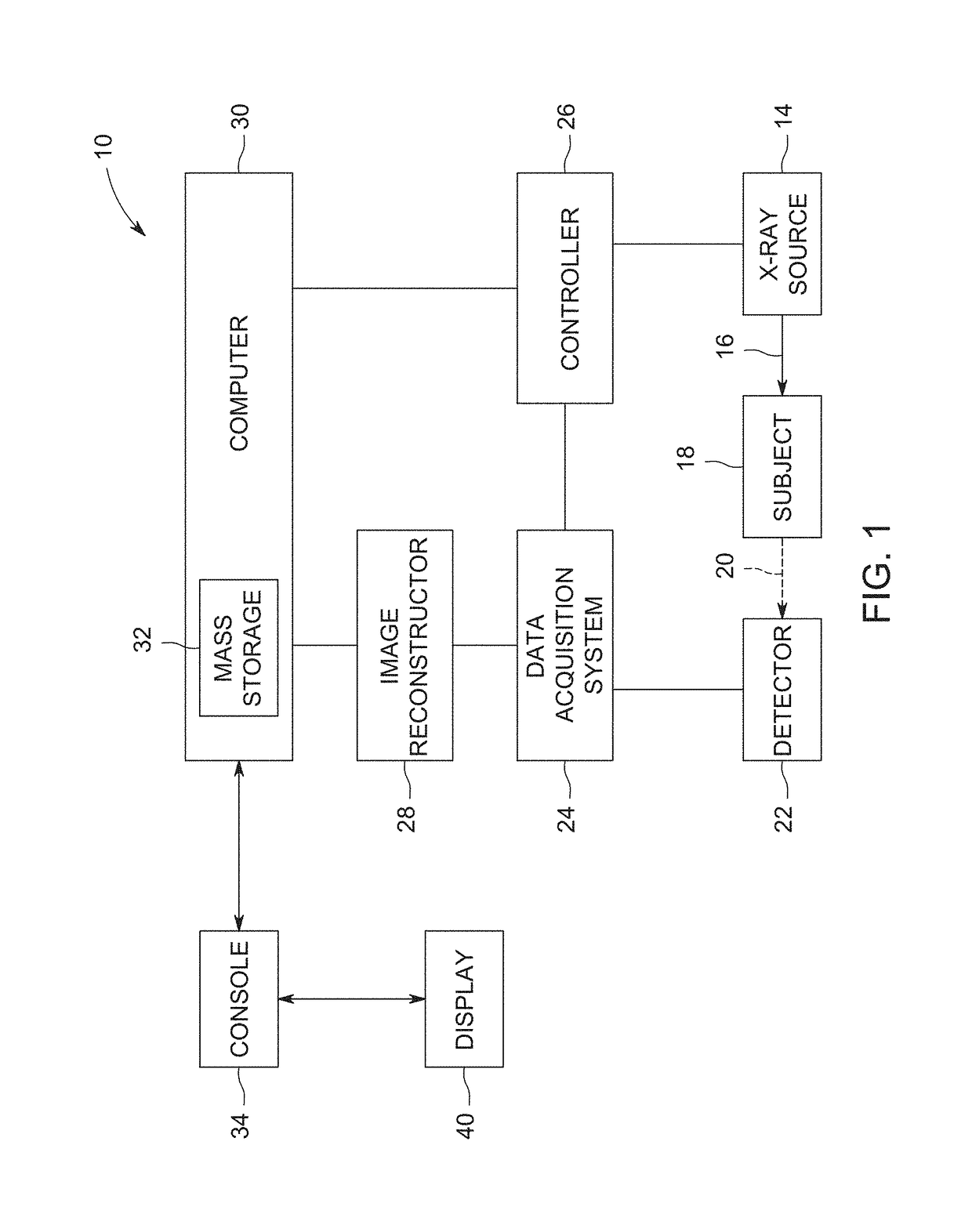

Systems, methods and apparatus of a composite X-Ray target

ActiveUS20070071174A1High mechanical strengthLow thermal conductivityX-ray tube anode coolingX-ray tube electrodesX-raySystems approaches

Systems, methods and apparatus are provided through which in some embodiments an X-Ray energy target includes composite material that varies spatially in thermal properties, and in some embodiments, the composite material varies spatially in strength properties. In some embodiments, the spatial variance is a continuum and in other embodiments, the spatial variance is a plurality of distinct portions.

Owner:GENERAL ELECTRIC CO

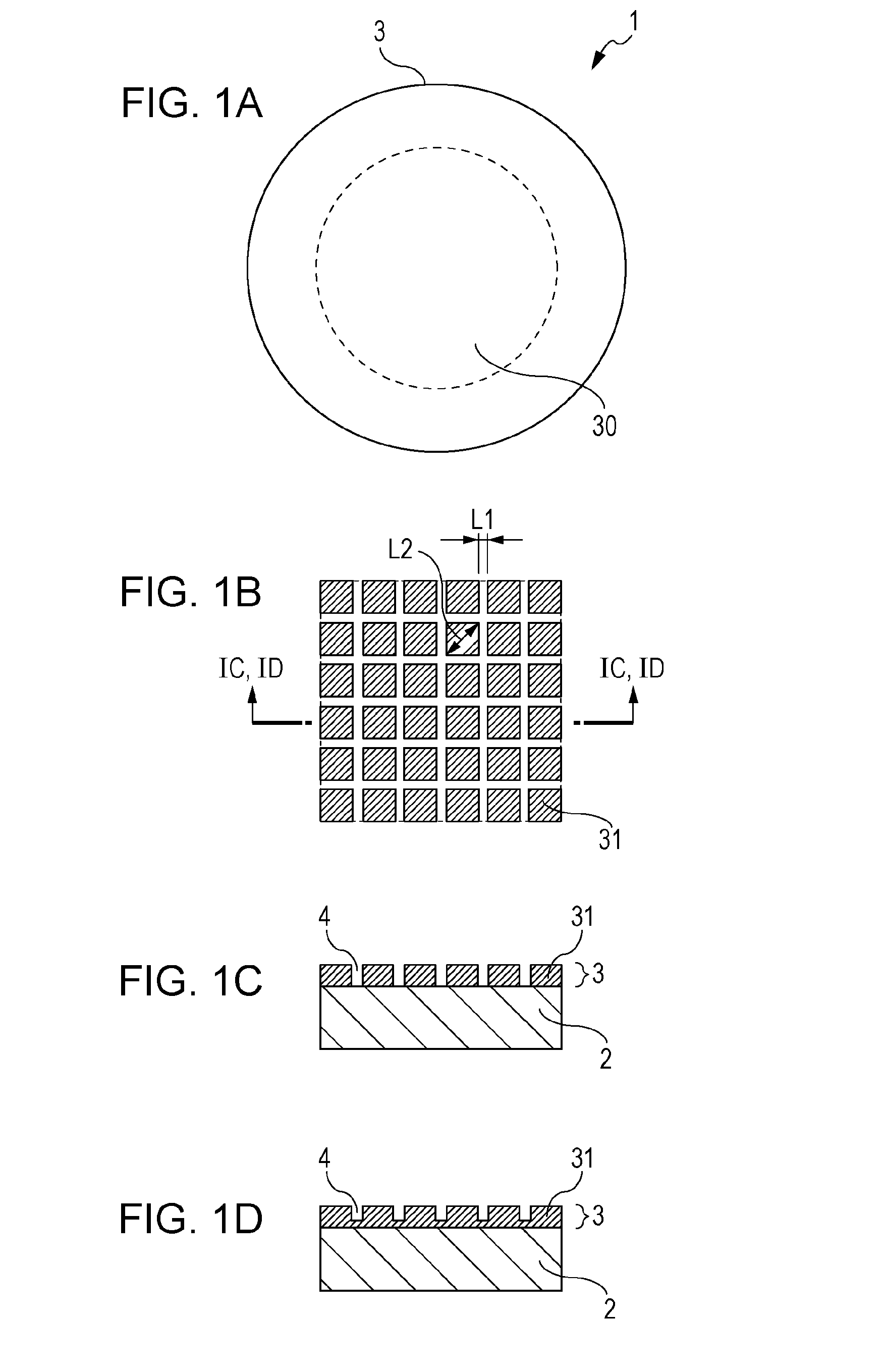

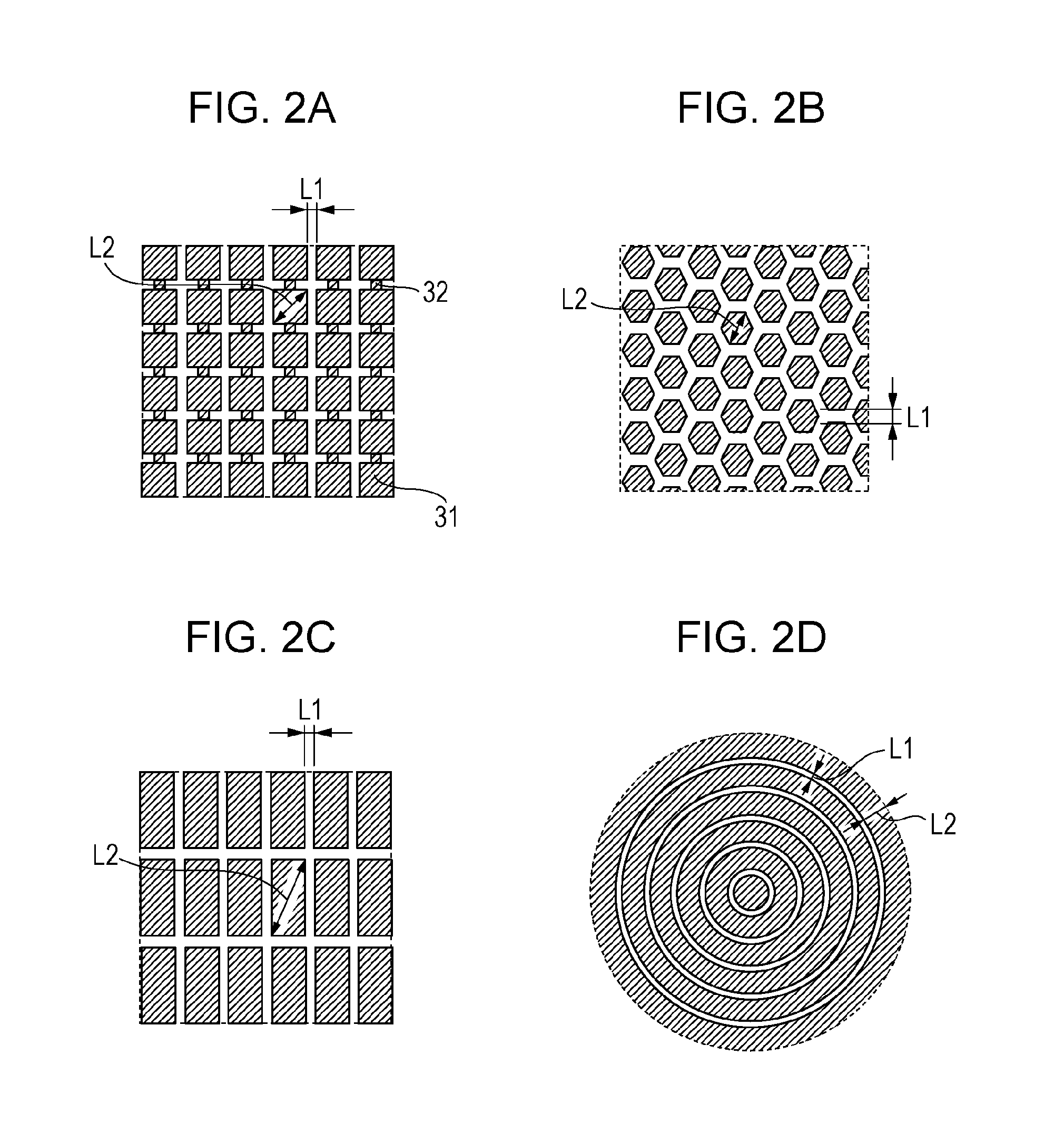

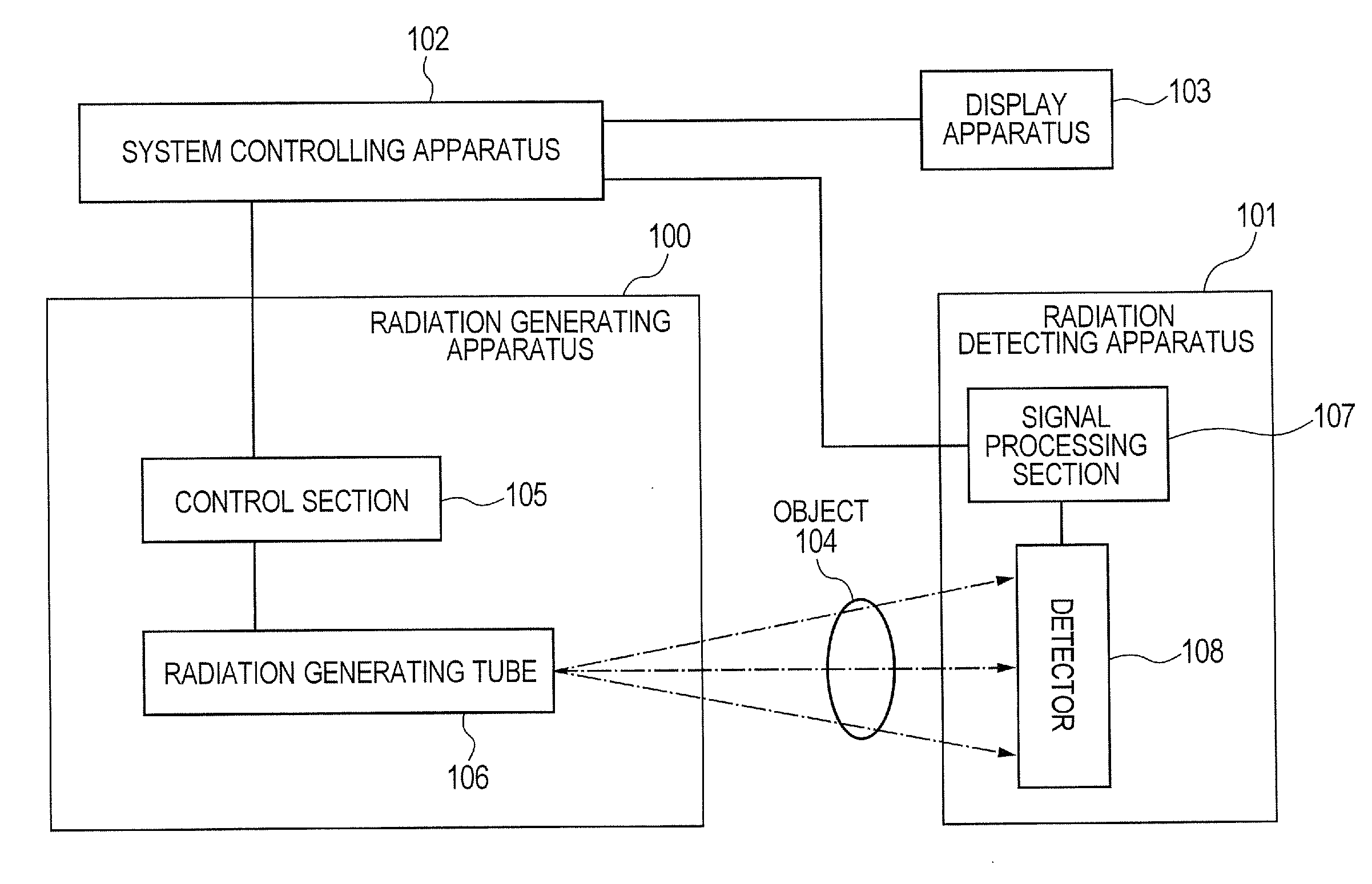

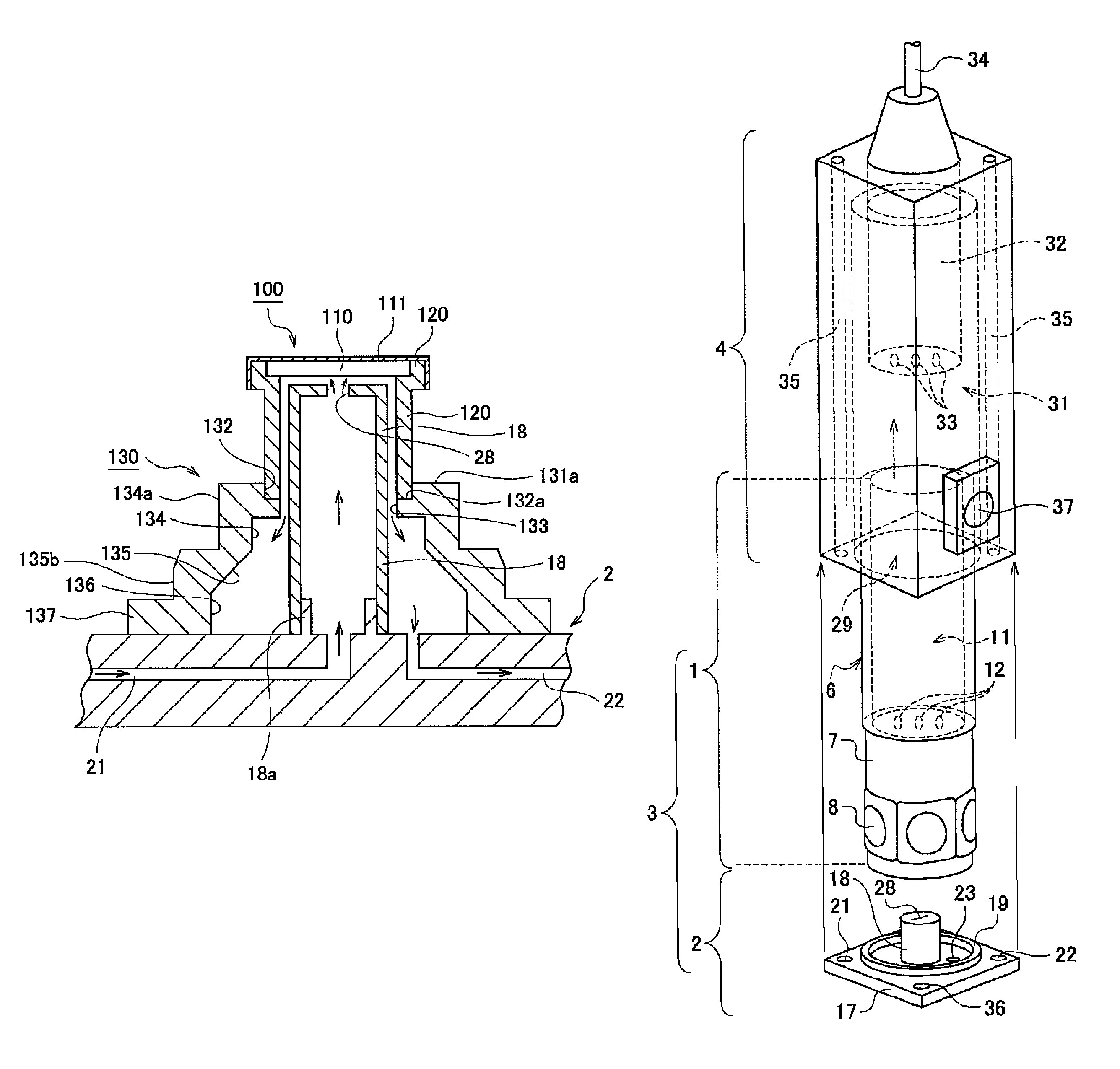

Target structure and radiation generating apparatus

InactiveUS20130195246A1Avoid separationImprove reliabilityX-ray tube electrodesX-ray tube bonding/fixingElectronStress radiography

A radiation-transmissive type target structure includes a target layer formed on a substrate. The target layer has a thickness equal to or less than 20 μm, and is configured to generate radiation in response to irradiation of electrons. A surface of the target layer is formed with projecting portions and depressed portions, the depressed portions have a depth of at least half the thickness of the target layer. Advantageously, separation of the target layer at an interface between the substrate and the target layer is substantially prevented. A radiation generating apparatus and a radiography system equipped with the target structure are also disclosed.

Owner:CANON KK

Target for X-ray generation, X-ray generator, and method for producing target for X-ray generation

ActiveUS8416920B2Improve cooling effectX-ray tube anode coolingX-ray tube electrodesX-ray generatorMetal

A target for X-ray generation has a substrate and a target portion. The substrate is comprised of diamond and has a first principal surface and a second principal surface opposed to each other. A bottomed hole is formed from the first principal surface side in the substrate. The target portion is comprised of a metal deposited from a bottom surface of the hole toward the first principal surface. An entire side surface of the target portion is in close contact with an inside surface of the hole.

Owner:HAMAMATSU PHOTONICS KK

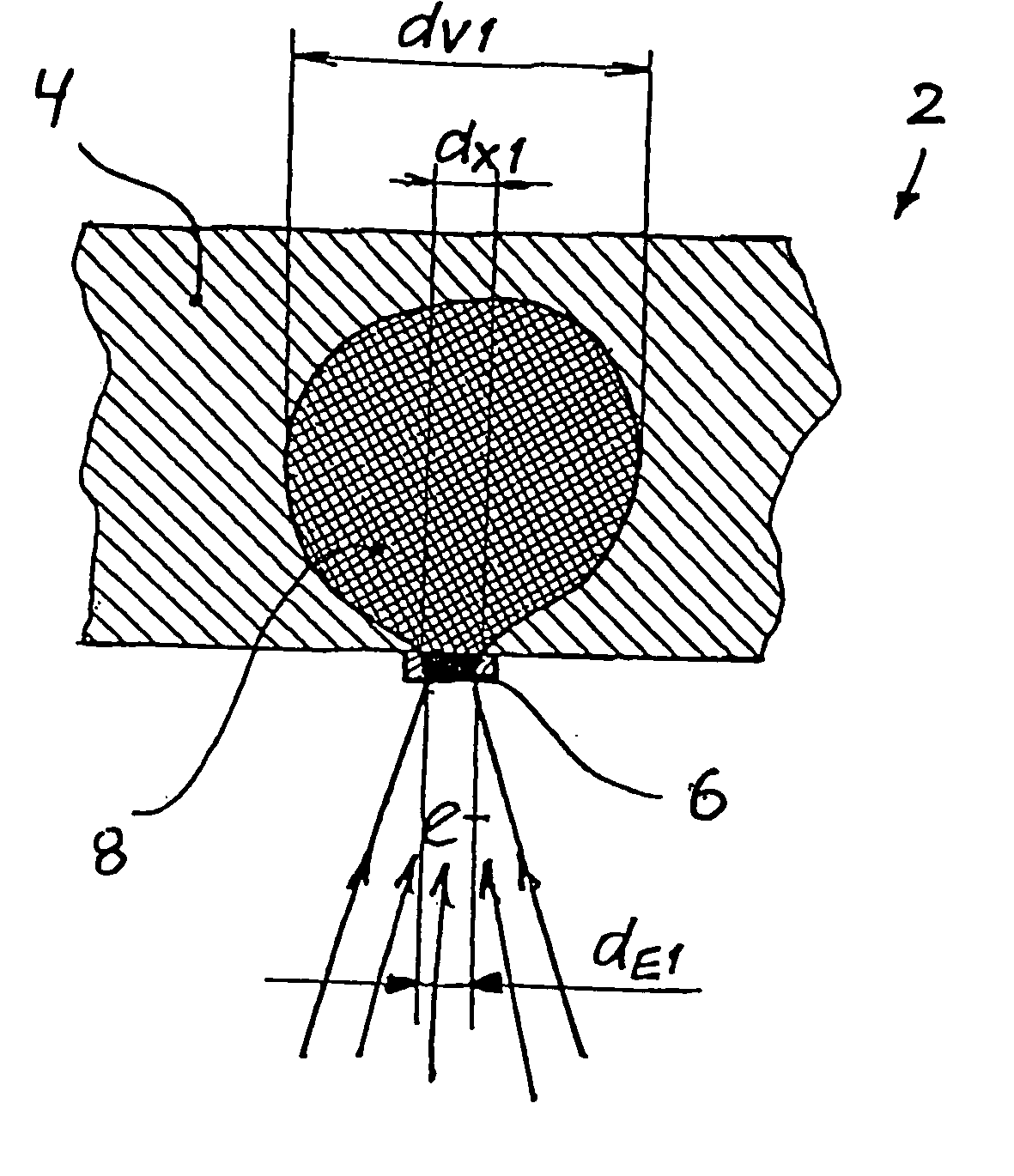

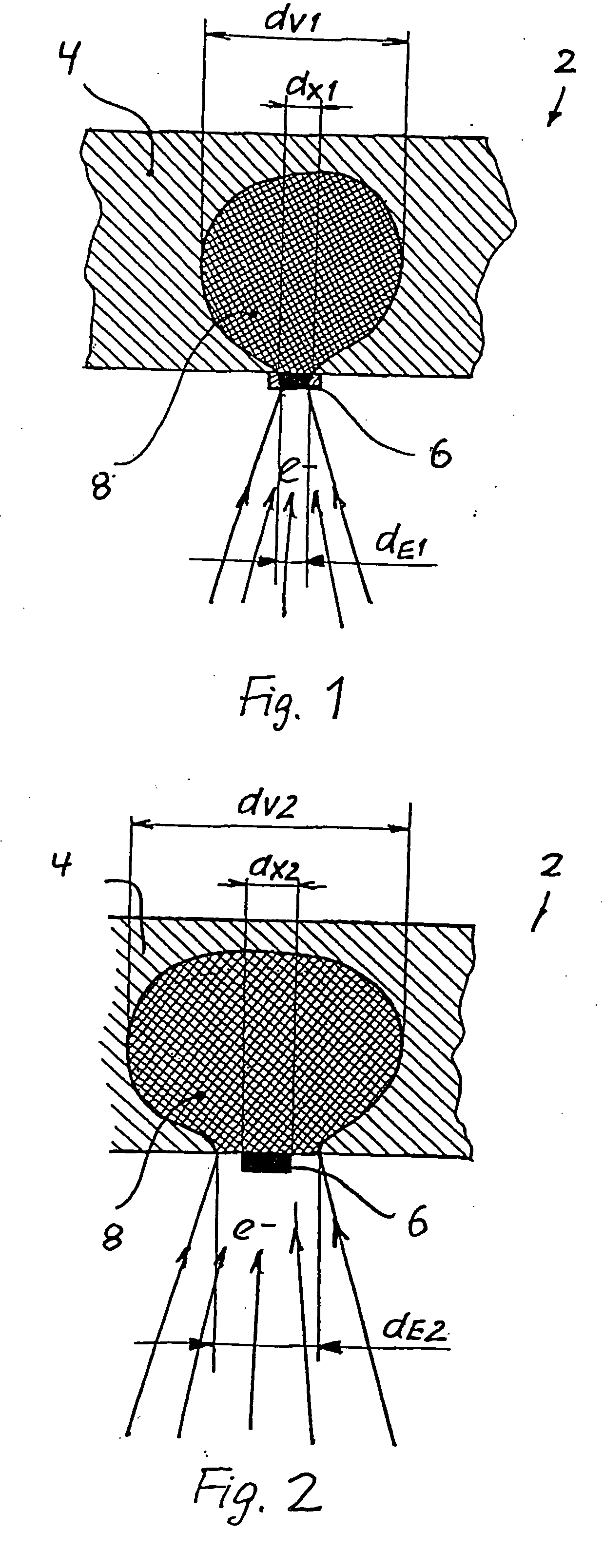

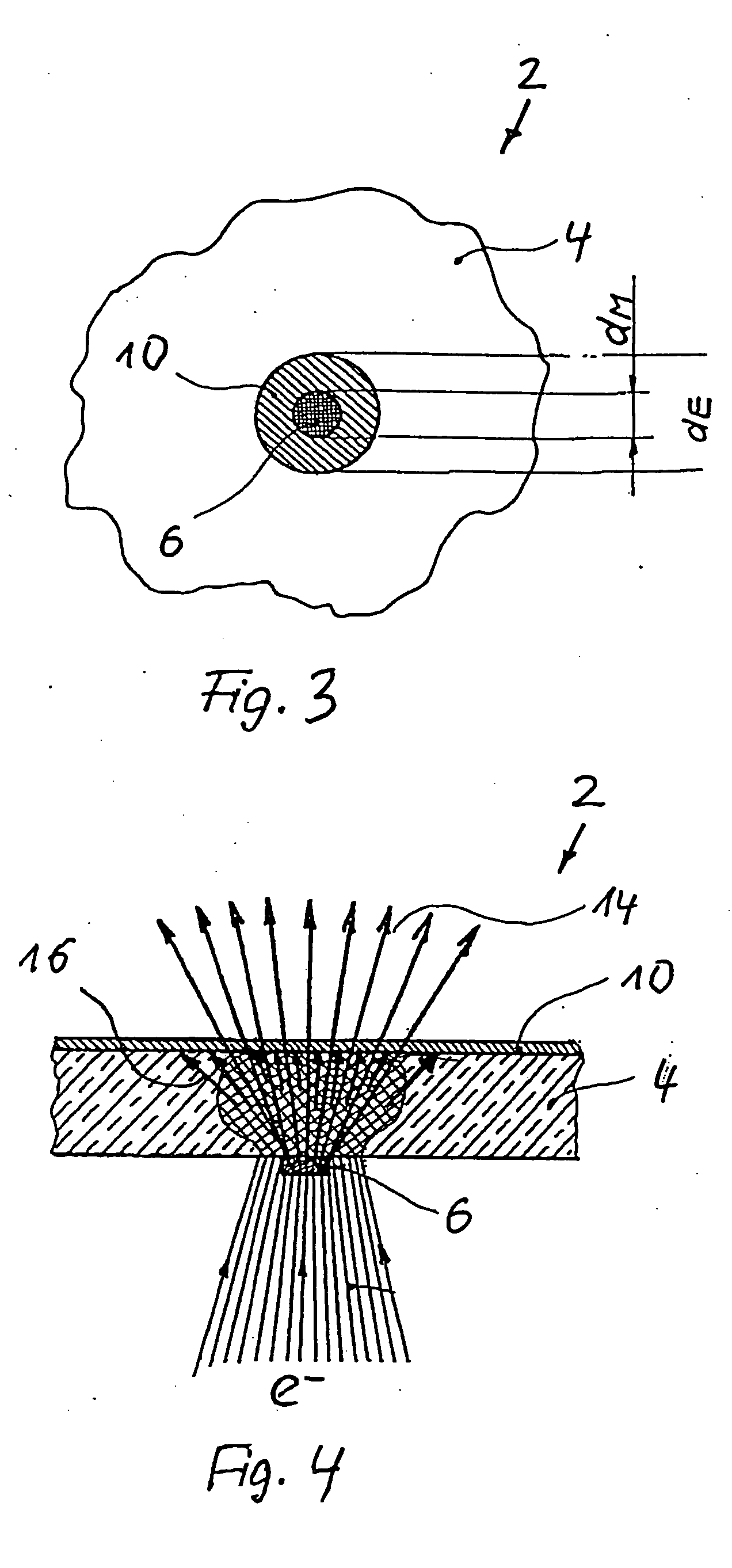

Nanofocus x-ray tube

InactiveUS20080089484A1Easy constructionReduce manufacturing costX-ray tube electrodesCathode ray concentrating/focusing/directingX-rayNanostructure

Nanofocus x-ray tube, includes a target, and a device for directing an electron beam onto the target. The target includes at least one target element made of a target material for generating x-rays, the at least one target element including a nanostructure having a diameter ≦about 1000 nm. The nanostructure is formed by a microstructuring procedure on a substrate element made of a substrate material, and the target element only partly covers the substrate element. The electron beam cross-section of the x-ray tube, in use, is selected to be sufficiently larger than the cross-section of the target element, such that the electron beam always irradiates the entire surface of the target element. Still further, the substrate material may be diamond, or the substrate material may include diamond, and being doped to raise the electrical conductivity.

Owner:COMET

Low-energy method for fabrication of large-area sputtering targets

ActiveUS7910051B2Low heat introductionWide applicabilityLiquid surface applicatorsMolten spray coatingMetalEnergy method

In various embodiments, large-area sputtering targets are formed by providing a plurality of sputtering targets each comprising a backing plate and a refractory metal layer disposed thereon, and spray depositing a refractory metal powder on an interface between the sputtering targets, the refractory metal powder consisting essentially of the same metal as each refractory metal layer, thereby joining the refractory metal layers of the sputtering targets.

Owner:H C STARCK SURFACE TECH & CERAMIC POWDERS GMBH

X-ray target assembly

An x-ray transmission target assembly is disclosed. According to an aspect of the invention, an x-ray target assembly comprises an x-ray generating layer, a thermal buffer, and a support, wherein the thermal buffer is disposed between the x-ray generating layer and support. Another aspect of the invention is directed to a novel material for use as an x-ray generating layer in an x-ray target assembly.

Owner:AIRDRIE PARTNERS I LP +1

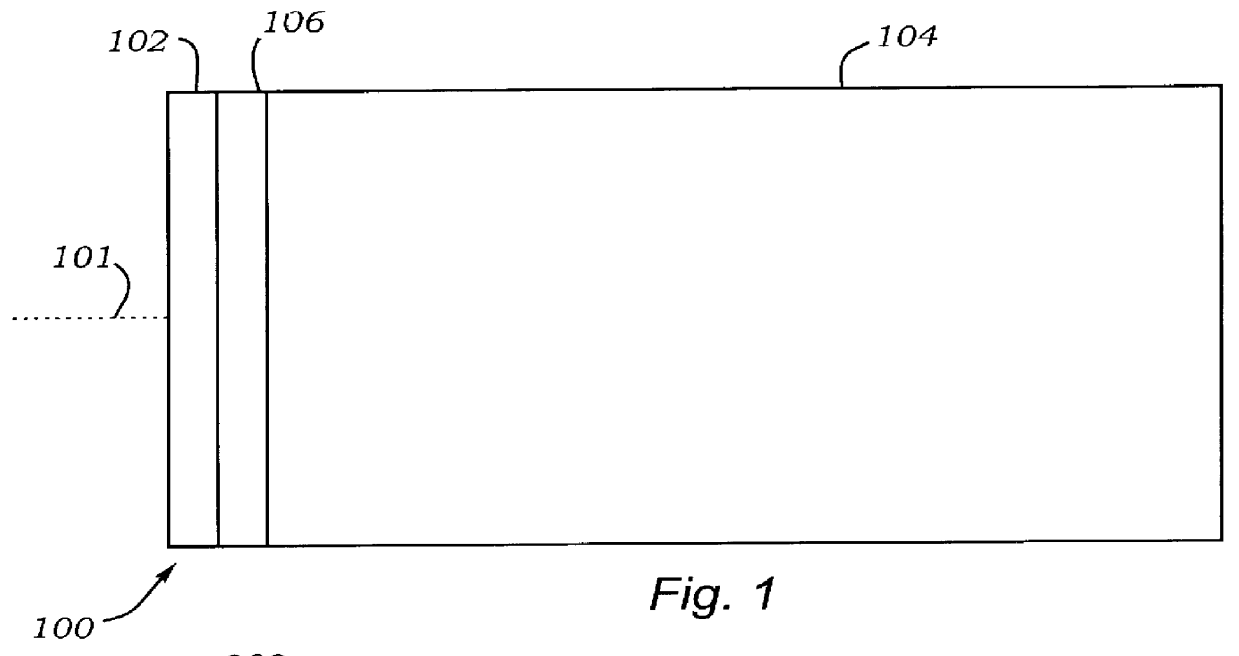

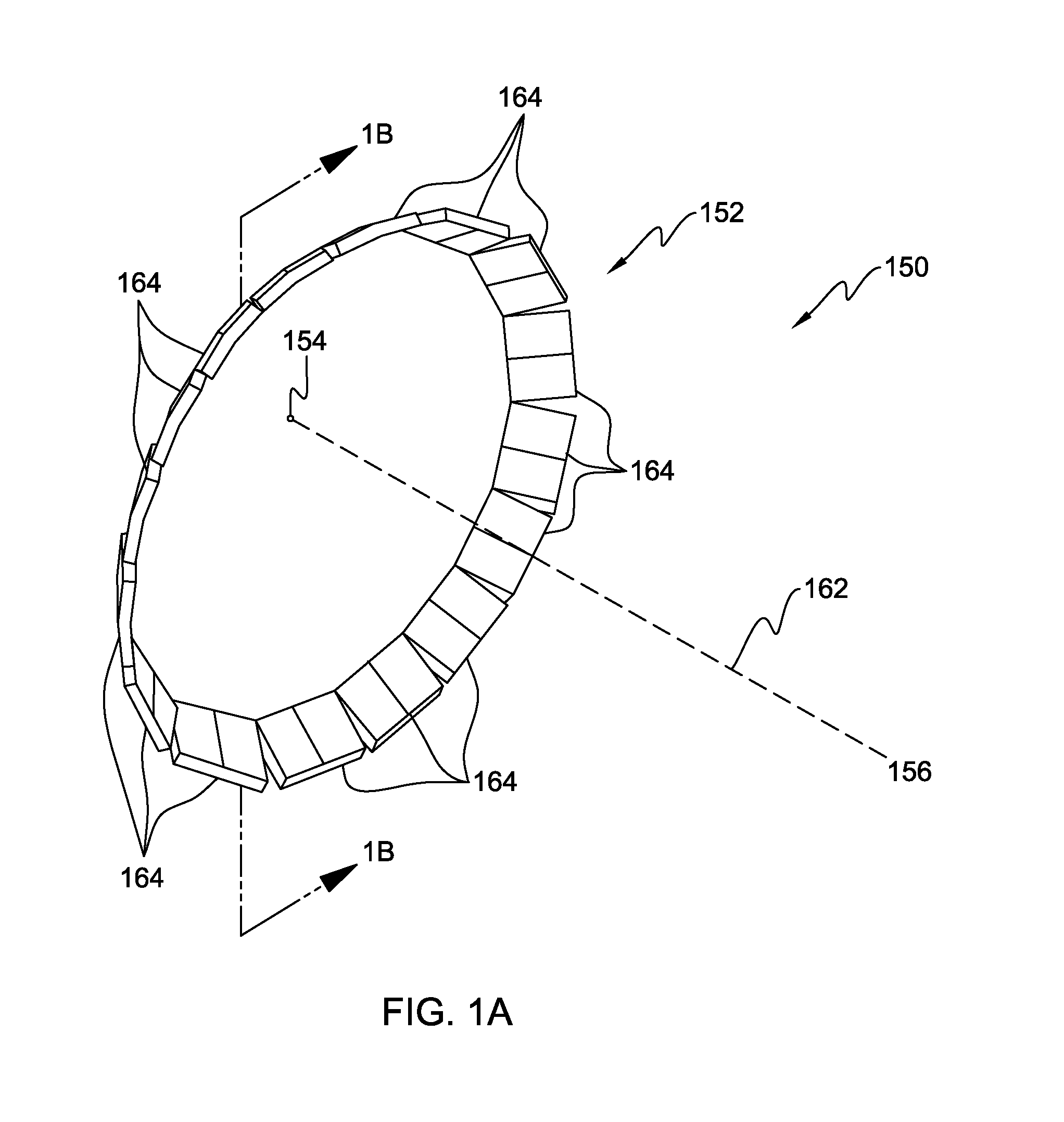

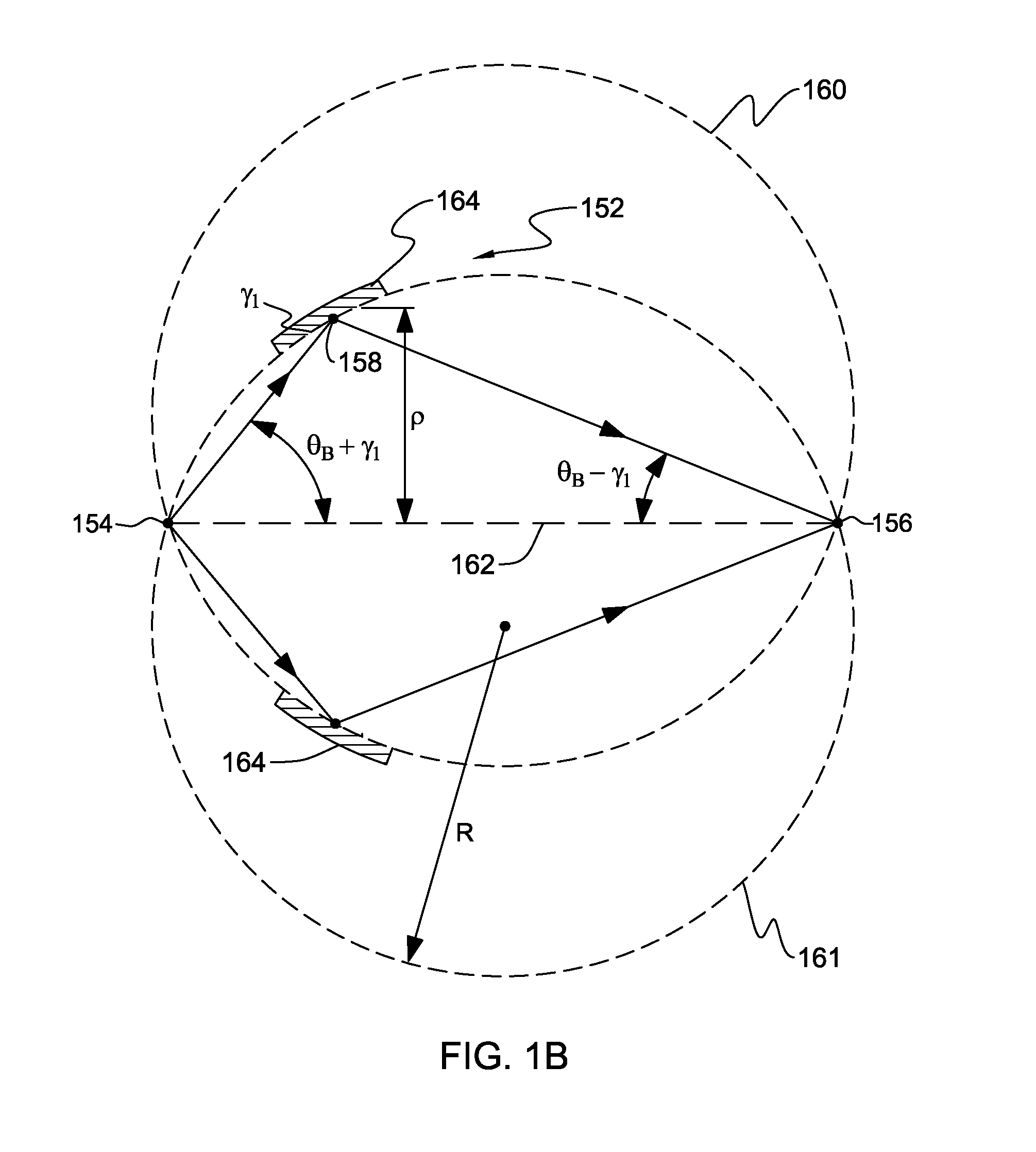

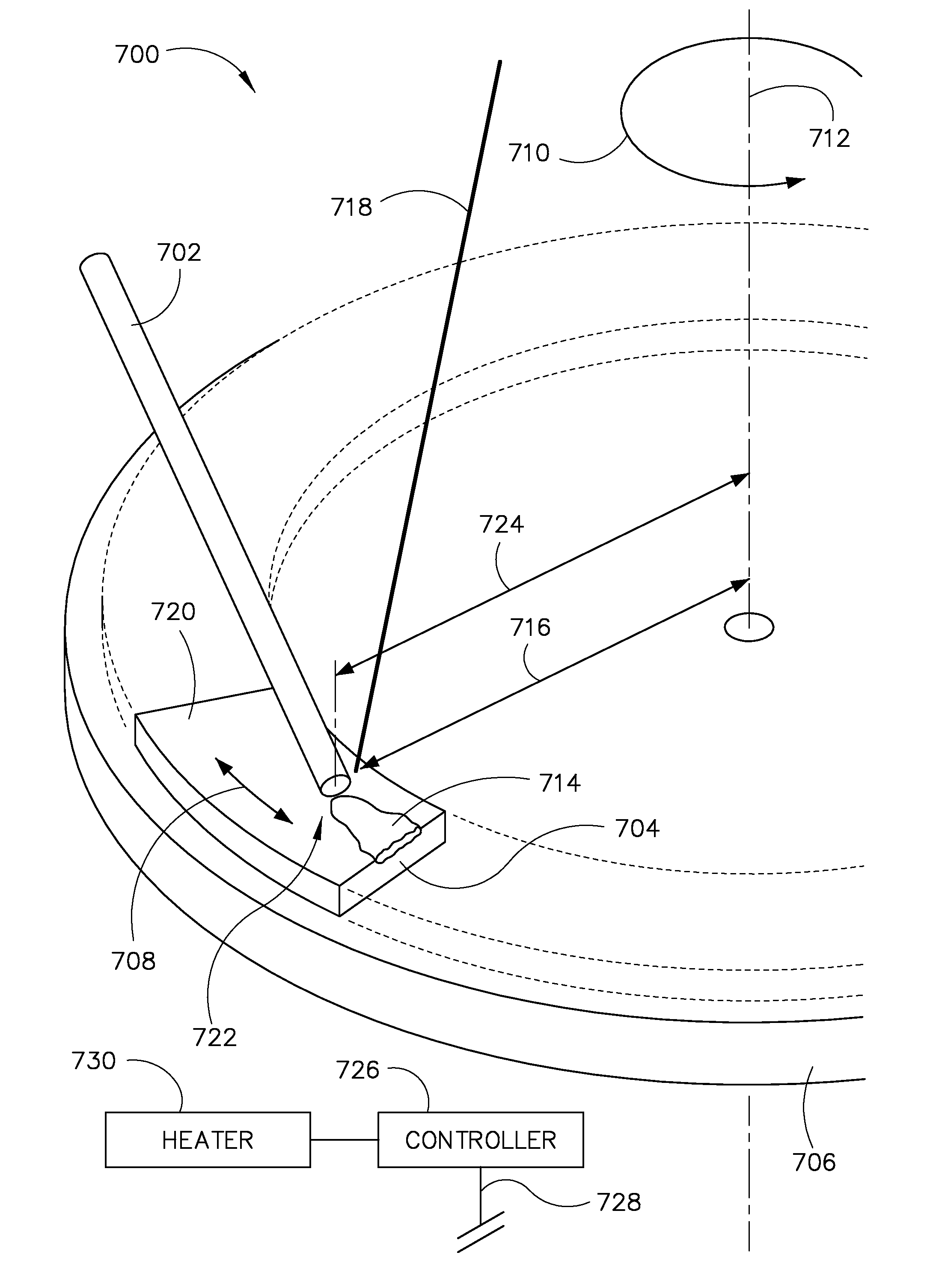

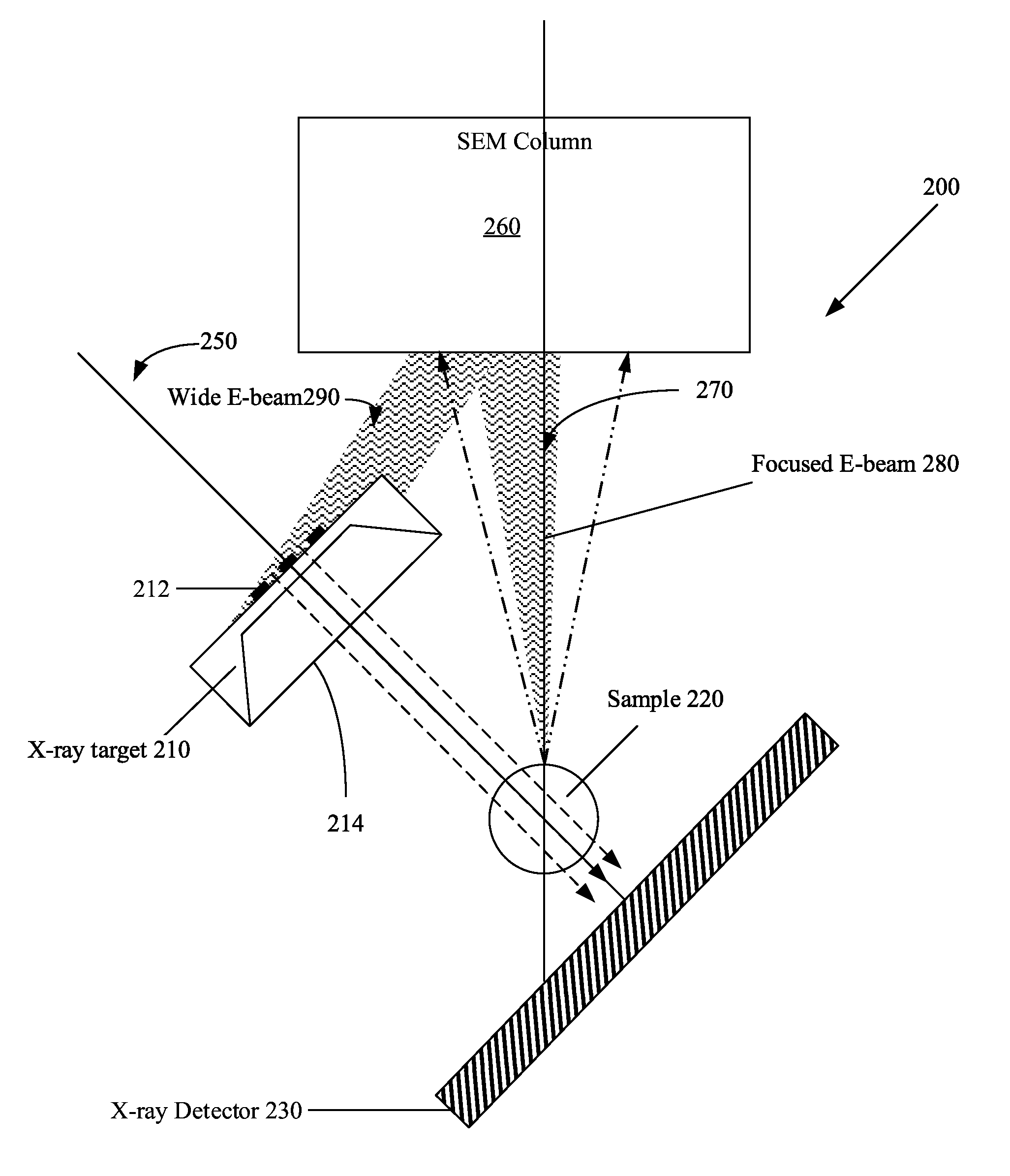

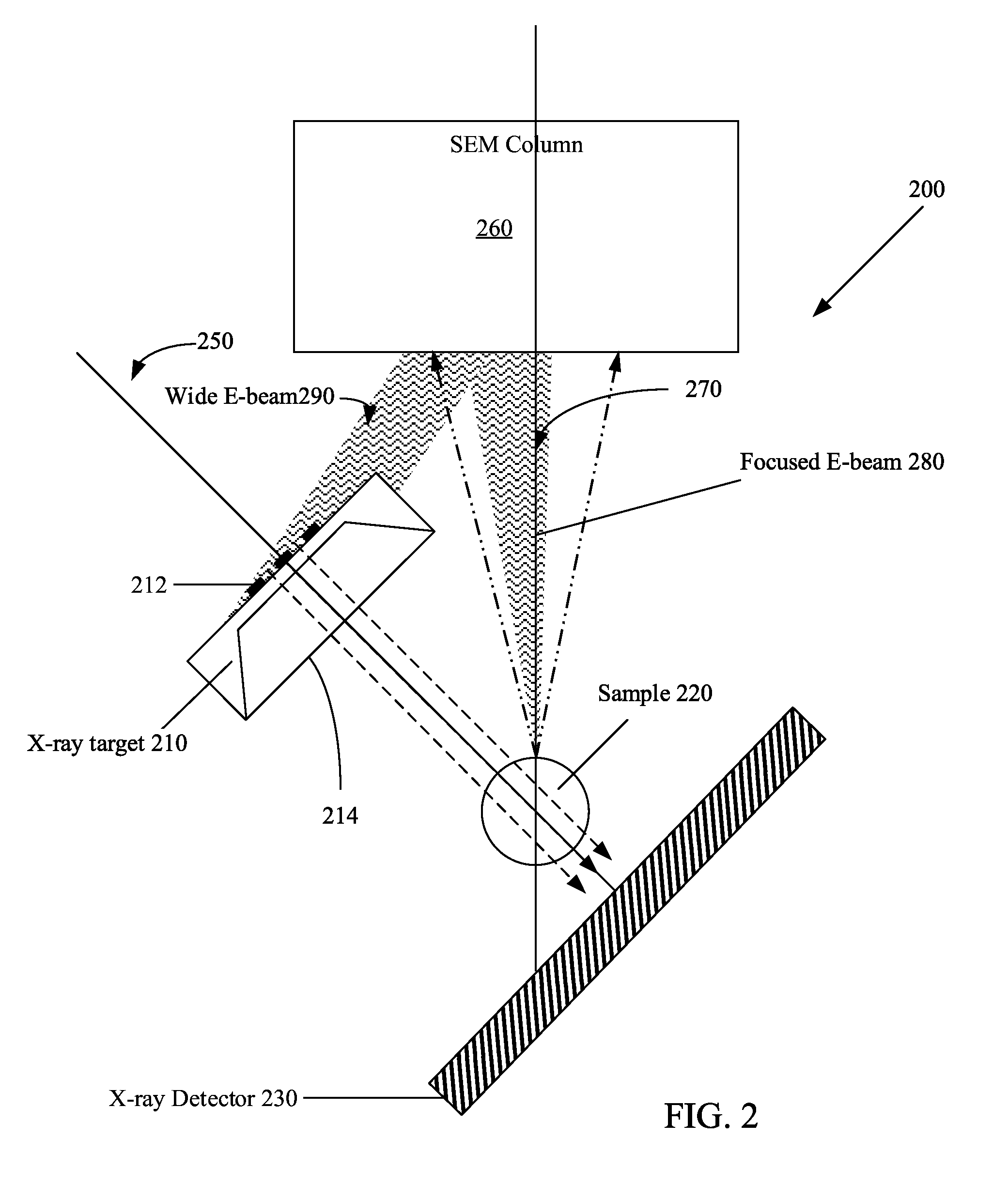

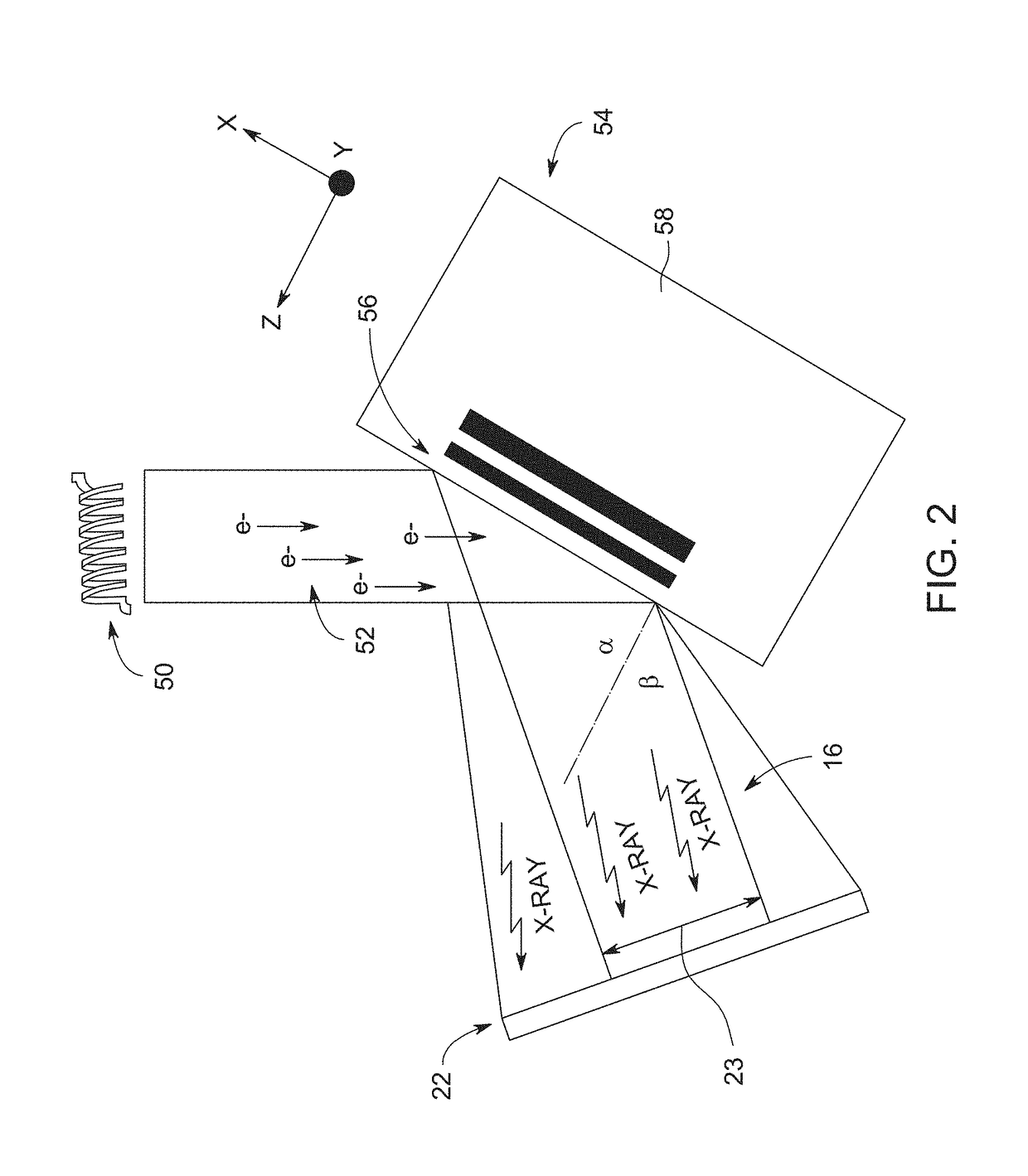

X-ray analyzer having multiple excitation energy bands produced using multi-material x-ray tube anodes and monochromating optics

ActiveUS20150043713A1Lower levelX-ray tube laminated targetsMaterial analysis using wave/particle radiationMulti materialFluorescence

An x-ray tube includes a target on which electrons impinge to form a diverging x-ray beam. The target has a surface formed from first and second target materials, each tailored to emit a respective x-ray energy profile. A first x-ray optic may be provided for directing the beam toward the sample spot, the first x-ray optic monochromating the diverging x-ray beam to a first energy from the energy emitted by the first target material; and a second x-ray optic may be provided, for directing the beam toward the sample spot, the second x-ray optic monochromating the diverging x-ray beam to a second energy from the energy emitted by the second target material. Fluorescence from the sample spot induced by the first and second monochromated energies is used to measure the concentration of at least one element in the sample, or separately measure elements in a coating and underlying substrate.

Owner:X-RAY OPTICAL SYSTEM INC

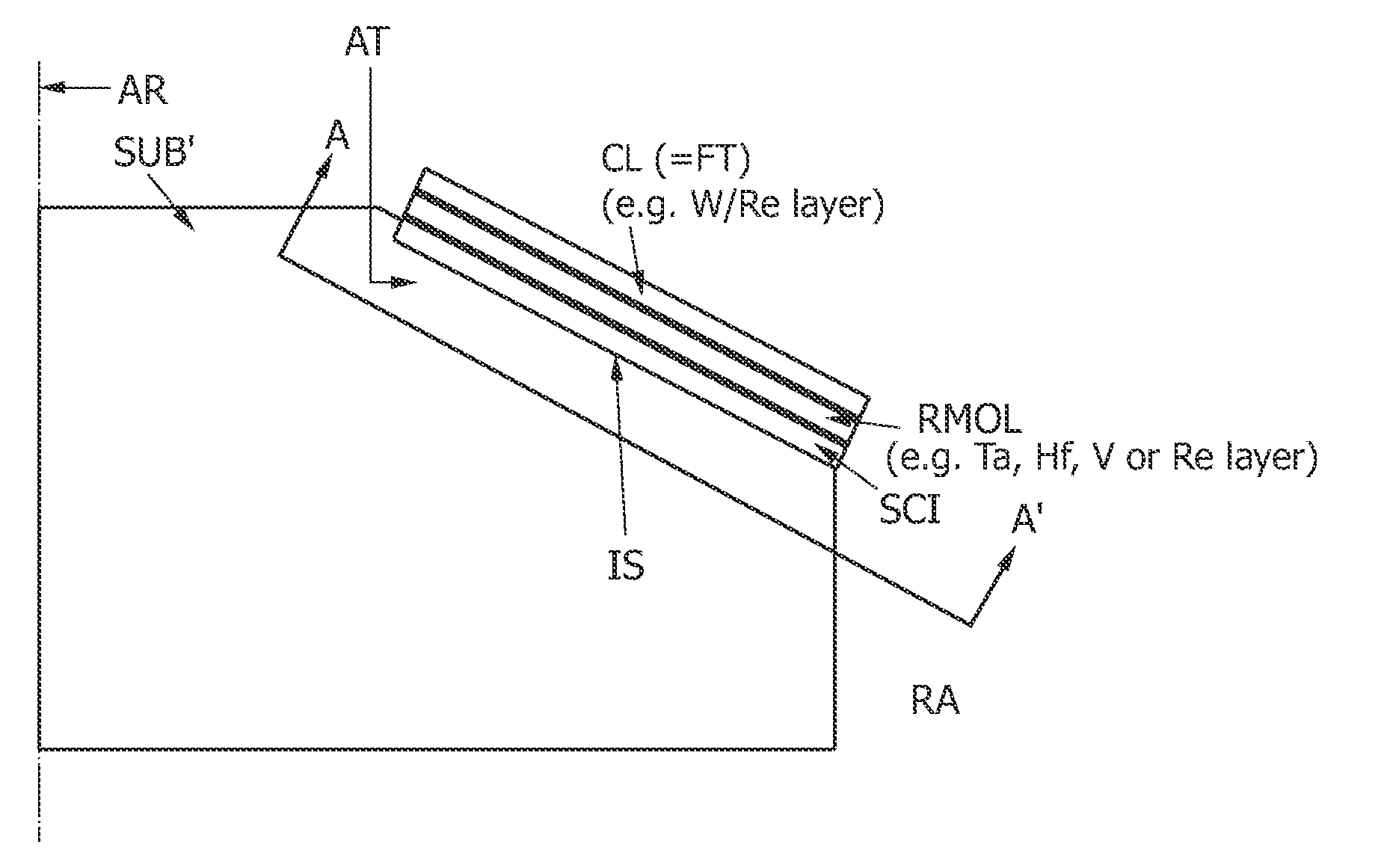

Attachment of a high-Z focal track layer to a carbon-carbon composite substrate serving as a rotary anode target

InactiveUS8553843B2Solve the slow scanning speedX-ray tube laminated targetsX-ray tube electrodesRheniumCarbon composites

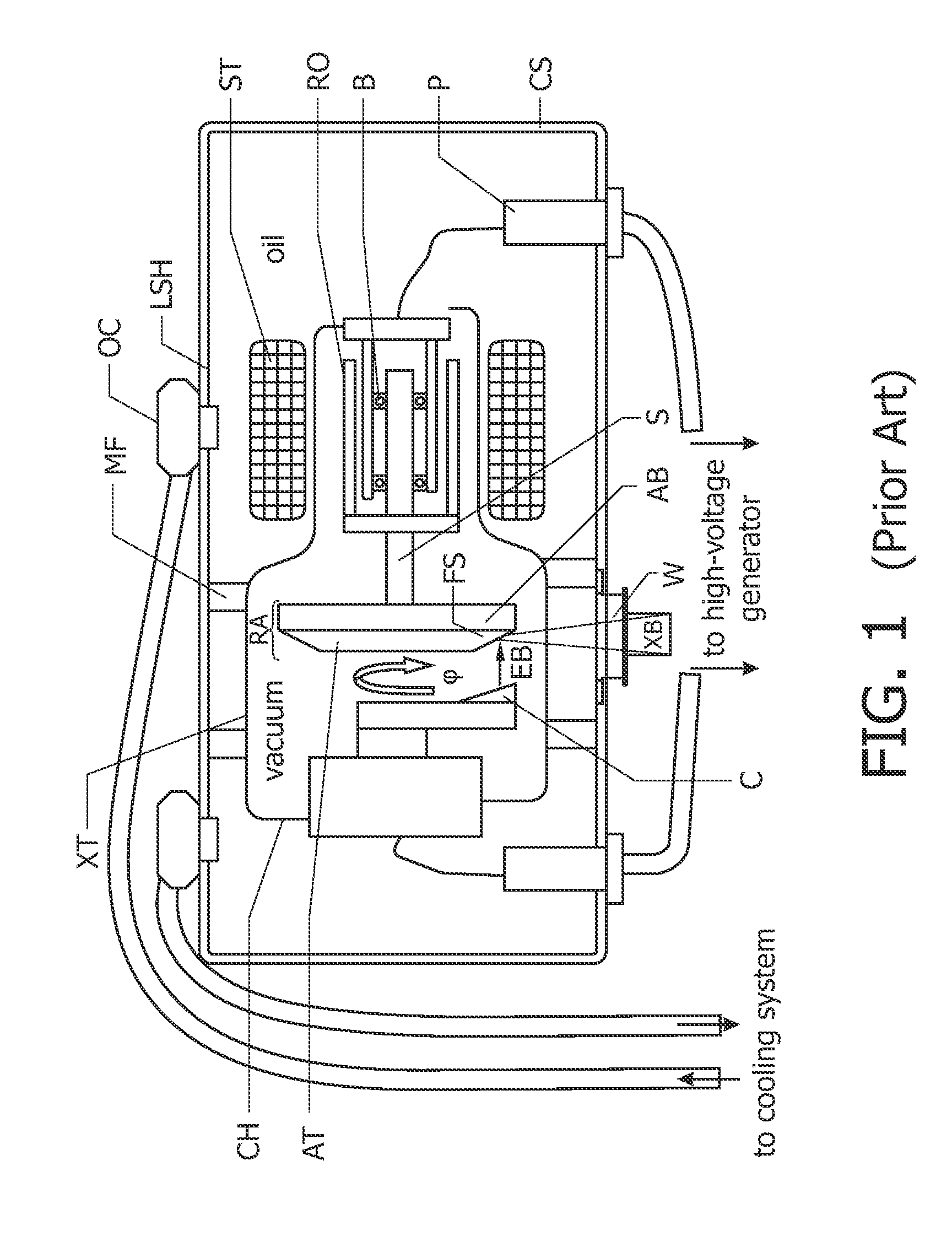

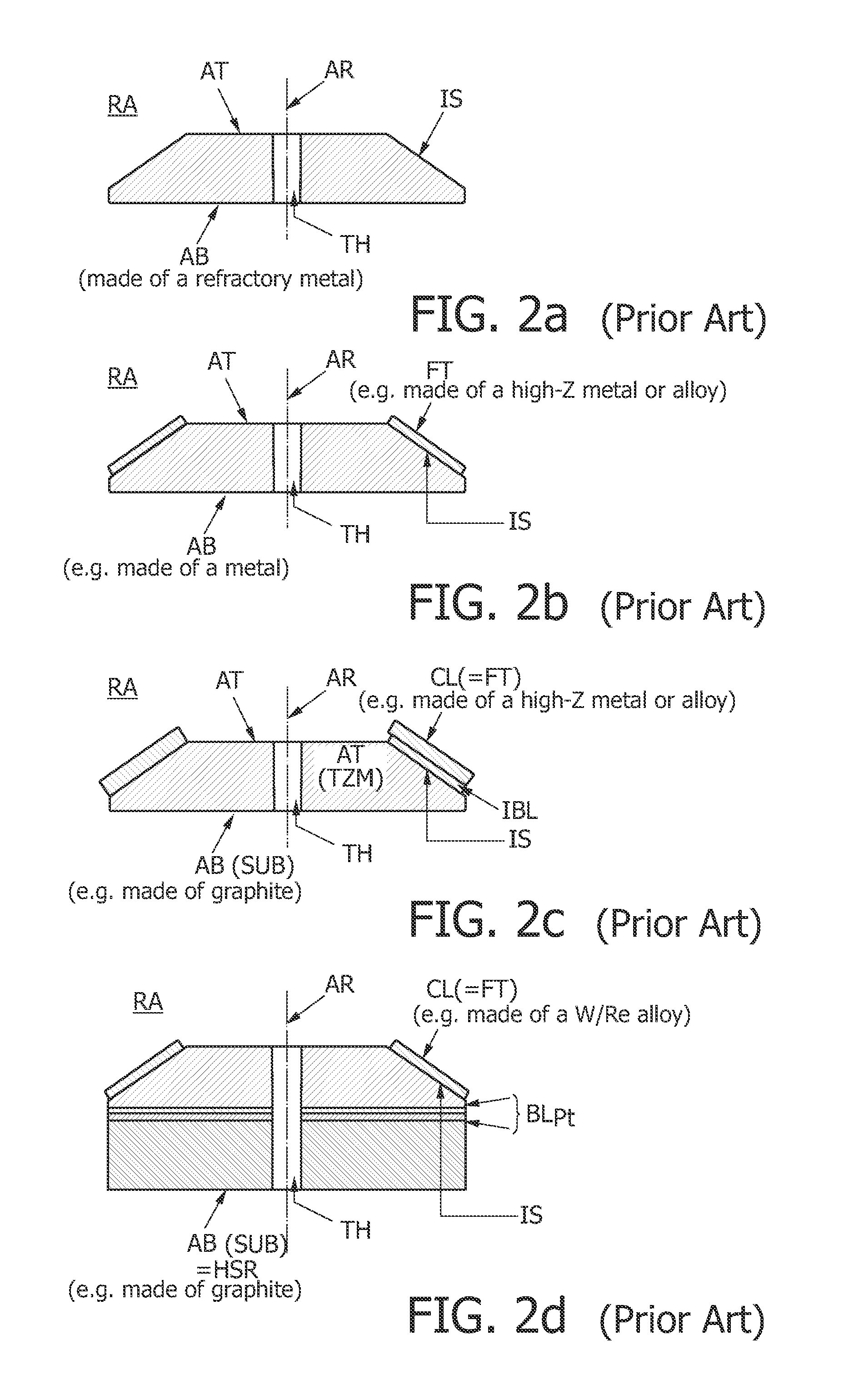

The present invention refers to hybrid anode disk structures for use in X-ray tubes of the rotary anode type and is concerned more particularly with a novel light weight anode disk structure (RA) which comprises an adhesion promoting protective silicon carbide (SiC) interlayer (SCI) deposited onto a rotary X-ray tube's anode target (AT), wherein the latter may e.g. be made of a carbon-carbon composite substrate (SUB′). Moreover, a manufacturing method for robustly attaching a coating layer (CL) consisting of a high-Z material (e.g. a layer made of a tungsten-rhenium alloy) on the surface of said anode target is provided, whereupon according to said method it may be foreseen to apply a refractory metal overcoating layer (RML), such as given e.g. by a tantalum (Ta), hafnium (Hf), vanadium (V) or rhenium (Re) layer, to the silicon carbide interlayer (SCI) prior to the deposition of the tungsten-rhenium alloy. The invention thus leverages the tendency for cracking of the silicon carbide coated carbon composite substrate (SUB′) during thermal cycling and enhances adhesion of the silicon carbide / refractory metal interlayers to the carbon-carbon composite substrate (SUB′) and focal track coating layer (CL) by an interlocking mechanism. Key aspects of the proposed invention are: a) controlled formation of coating cracks (SC) in the silicon carbide layer (SCI) and b) conformal filling of SiC crack openings with a refractory metal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

High density low pressure plasma sprayed focal tracks for X-ray anodes

InactiveUS7601399B2Avoid heat conductionReduce pressureLiquid surface applicatorsMolten spray coatingSoft x rayRhenium

This invention involves the application of dense, metallurgically bonded deposits of tungsten and tungsten rhenium coatings onto preformed based x-ray anodes to be used as focal tracks. The coatings are applied by low pressure DC plasma spraying. The invention also includes heat treatments that further densify the as-applied coatings improving their suitability for use as focal tracks.

Owner:SURFACE MODIFICATION SYST

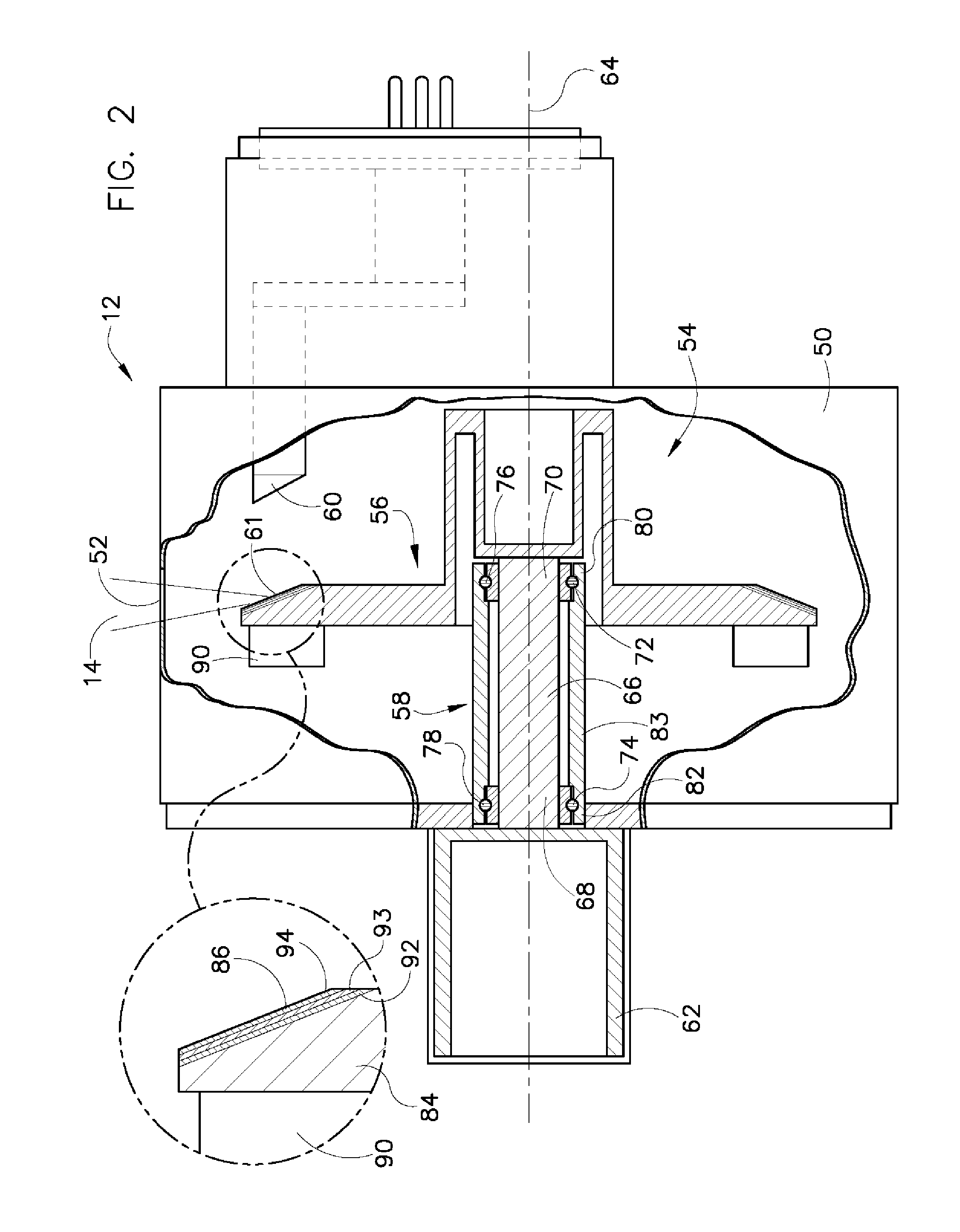

X-ray tube anode comprising a coolant tube

ActiveUS9263225B2Thermally matched wellImprove thermal conductivityX-ray tube anode coolingX-ray tube electrodesX-rayCoolant

Owner:RAPISCAN SYST INC (US)

Apparatus for x-ray generation and method of making same

Owner:GENERAL ELECTRIC CO

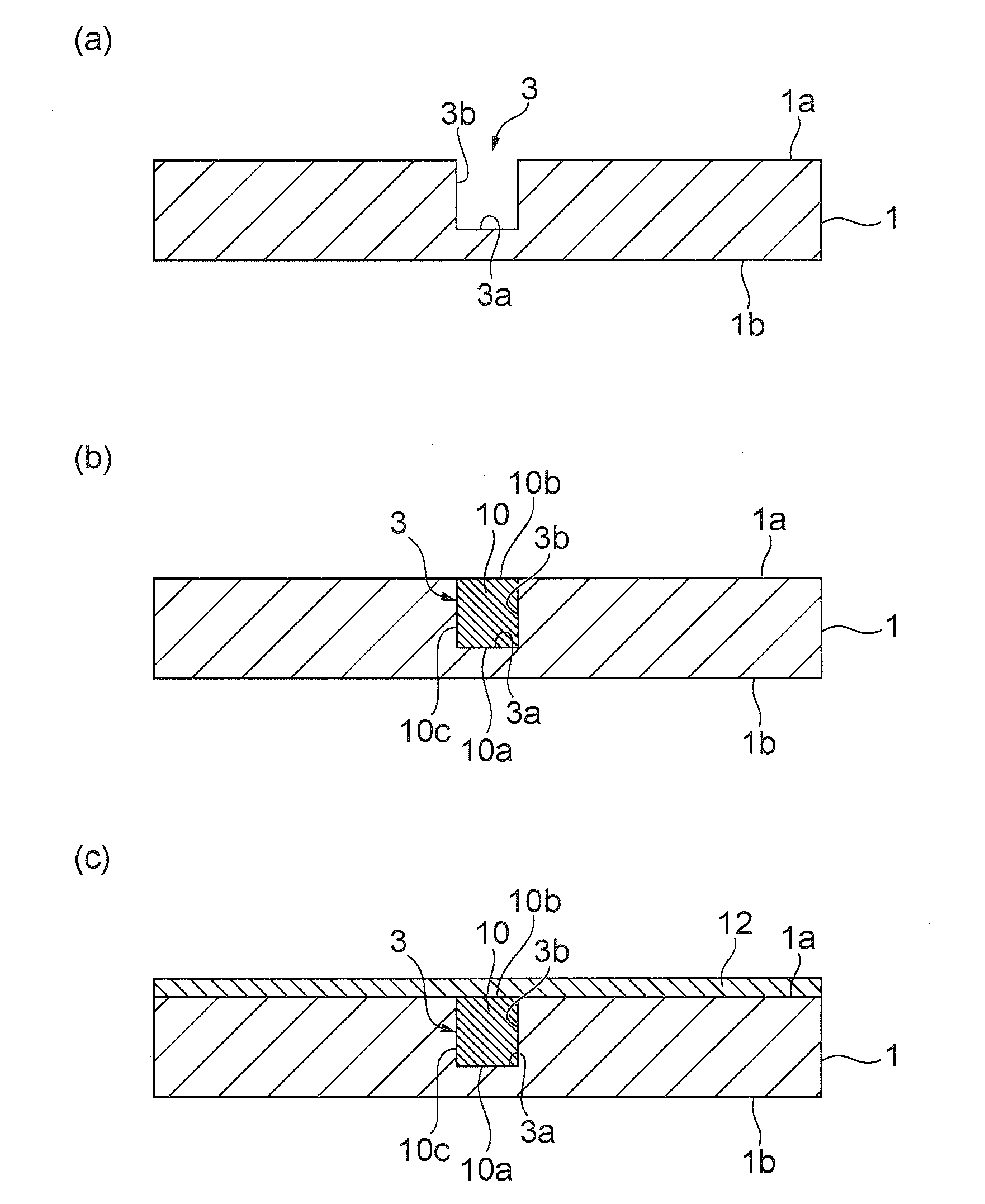

Radiation generating target, radiation generating tube, radiation generating apparatus, and radiation imaging system

The present invention provides a transmission type radiation generating target which can suppress the exfoliation or the crack of a target layer in an interface between a supporting substrate and the target layer, even when the density of incident electrons has been enhanced or the potential of the target has been enhanced. The transmission type radiation generating target includes a supporting substrate, and a target layer which is arranged on the supporting substrate and generates radiation in response to irradiation with an electron beam, wherein the target layer has an opening through which the supporting substrate is exposed, and the opening overlaps with a position at which the density of the irradiation with the electron beam is maximum.

Owner:CANON KK

Systems, methods and apparatus of a composite X-Ray target

ActiveUS7382864B2High mechanical strengthLow thermal conductivityX-ray tube anode coolingX-ray tube electrodesX-raySystems approaches

Systems, methods and apparatus are provided through which in some embodiments an X-Ray energy target includes composite material that varies spatially in thermal properties, and in some embodiments, the composite material varies spatially in strength properties. In some embodiments, the spatial variance is a continuum and in other embodiments, the spatial variance is a plurality of distinct portions.

Owner:GENERAL ELECTRIC CO

Target for X-ray generator, method of manufacturing the same and X-ray generator

ActiveUS9020101B2Improve thermal conductivityAvoid damageCathode ray tubes/electron beam tubesX-ray tube electrodesElectricityThermal contact

There is provided a target for an X-ray generator, including: a holder part made of an electrically conductive material and having an opening part; a diamond plate air-tightly joined to the holder part so as to close the opening part; a thin film target provided on a surface of the diamond plate, with its outer peripheral part extending to the holder part to be electrically connected to the holder part, wherein the holder part is configured to be electrically connected to a power supply of the X-ray generator, and the diamond plate is incorporated into the X-ray generator with one side disposed in a vacuum atmosphere where the thin film target is formed, and an opposite side thereto disposed at a side where the diamond plate is brought into thermal contact with a refrigerant and cooled.

Owner:RIGAKU CORP

Target for x-ray generator, method of manufacturing the same and x-ray generator

ActiveUS20130259207A1Improve thermal conductivitySame thermal effectX-ray tube electrodesVacuum evaporation coatingConductive materialsThermal contact

There is provided a target for an X-ray generator, including: a holder part made of an electrically conductive material and having an opening part; a diamond plate air-tightly joined to the holder part so as to close the opening part; a thin film target provided on a surface of the diamond plate, with its outer peripheral part extending to the holder part to be electrically connected to the holder part, wherein the holder part is configured to be electrically connected to a power supply of the X-ray generator, and the diamond plate is incorporated into the X-ray generator with one side disposed in a vacuum atmosphere where the thin film target is formed, and an opposite side thereto disposed at a side where the diamond plate is brought into thermal contact with a refrigerant and cooled.

Owner:RIGAKU CORP

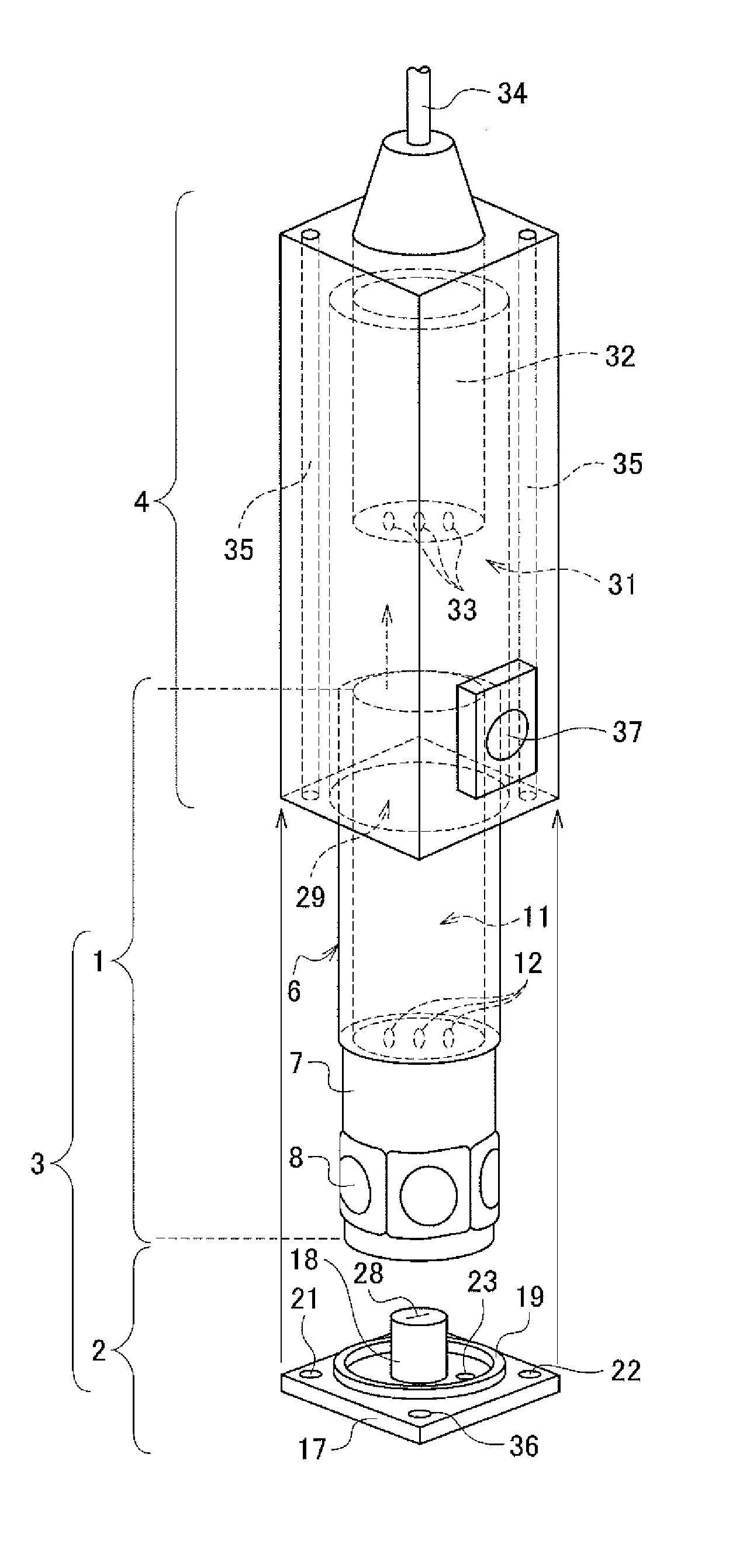

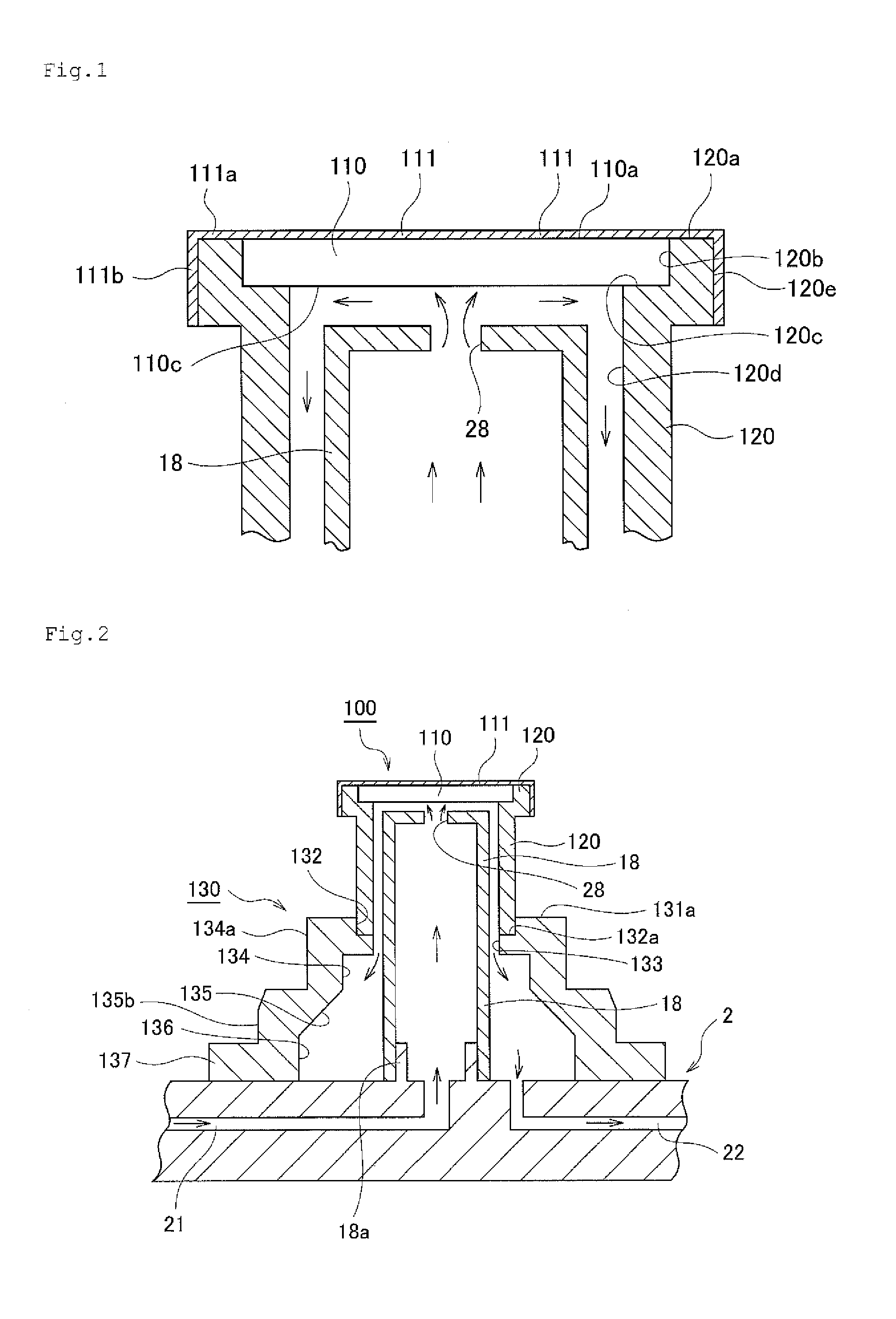

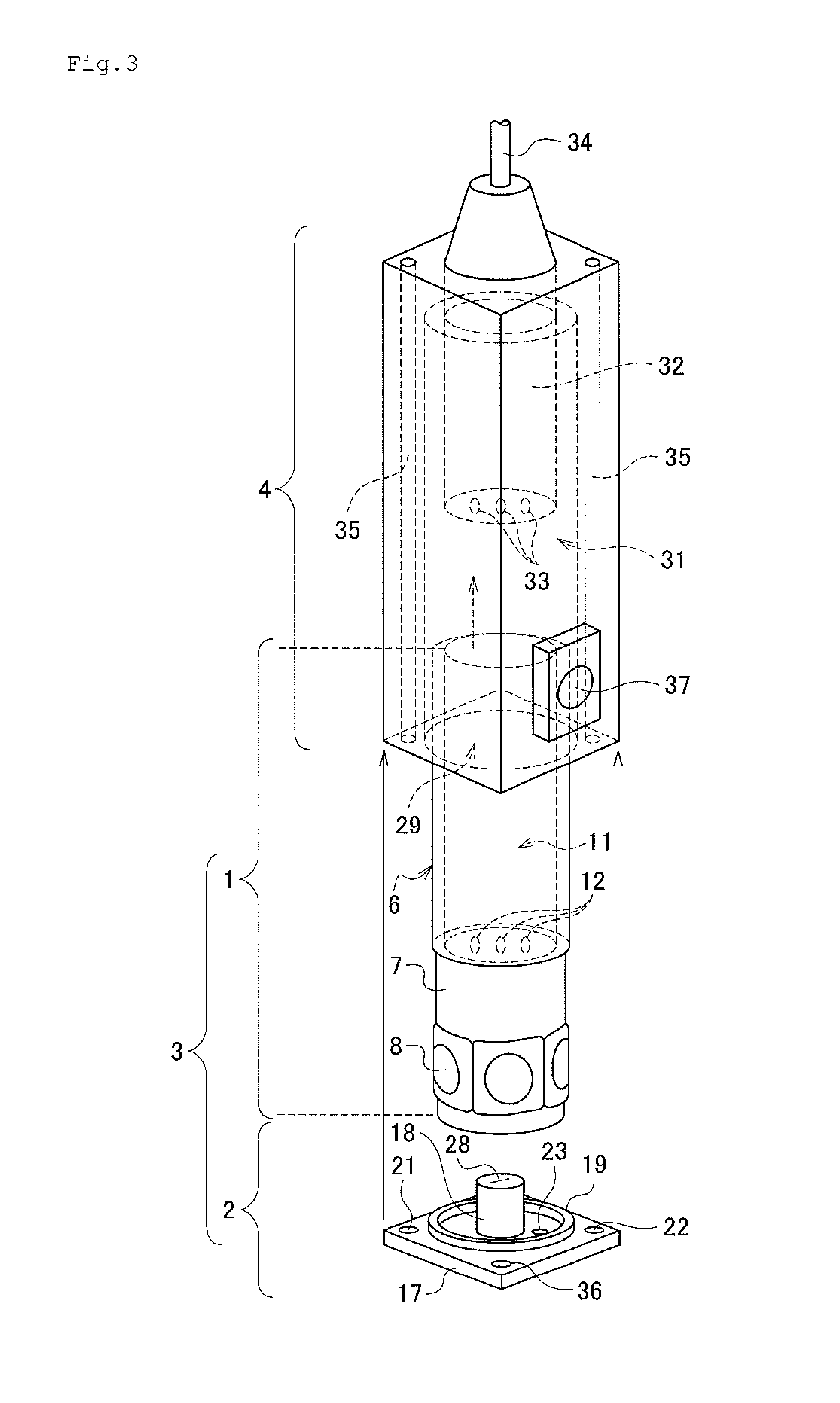

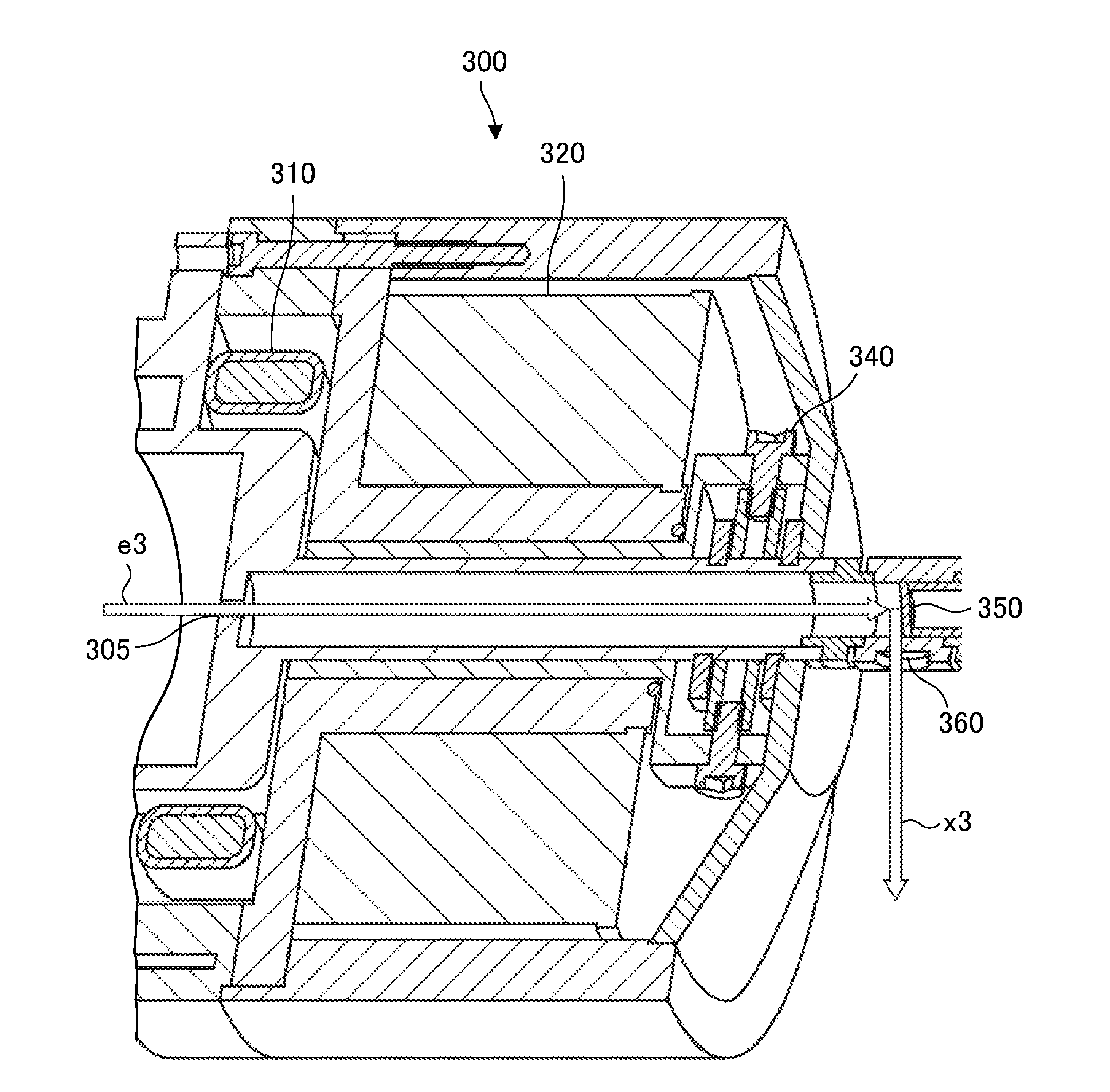

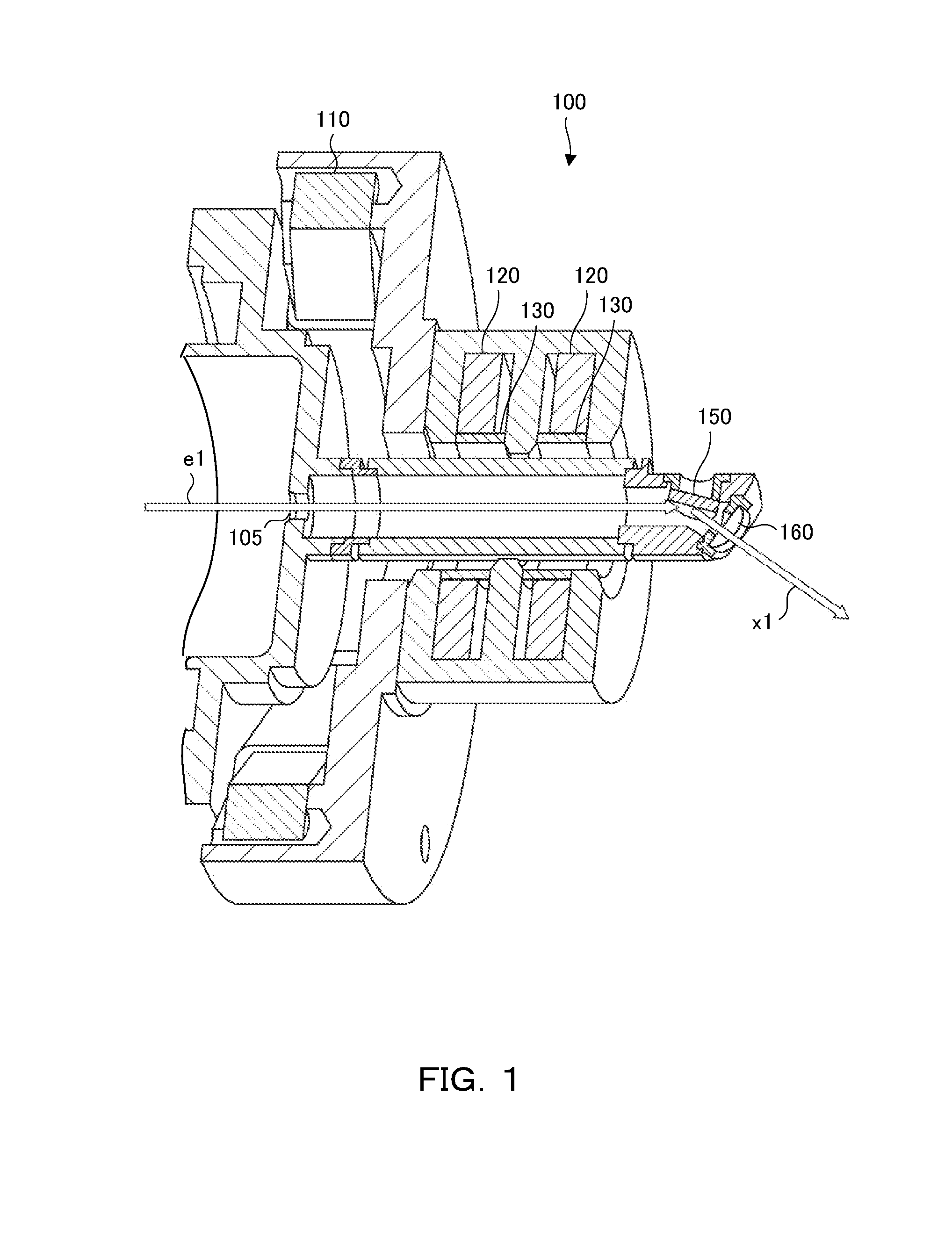

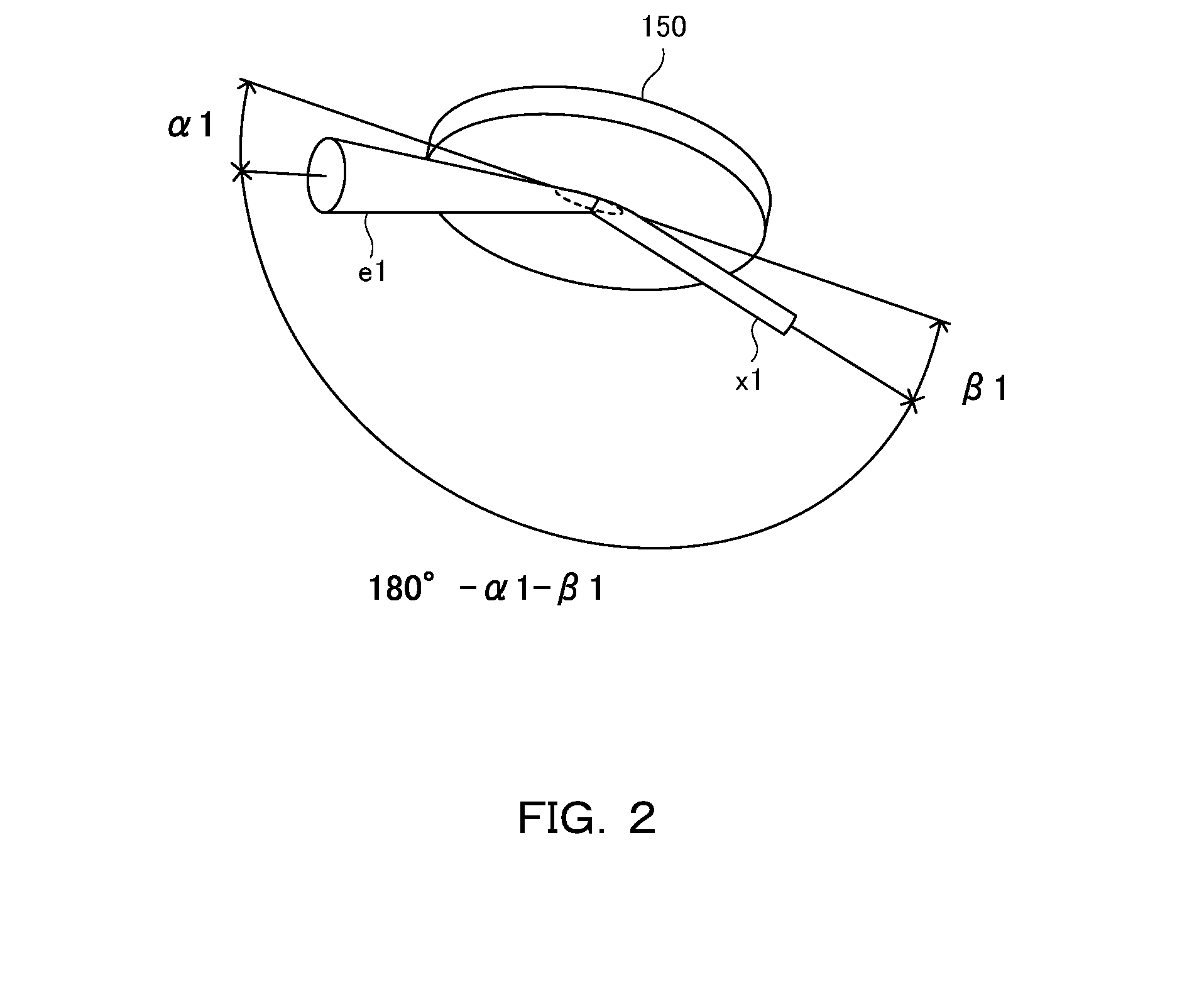

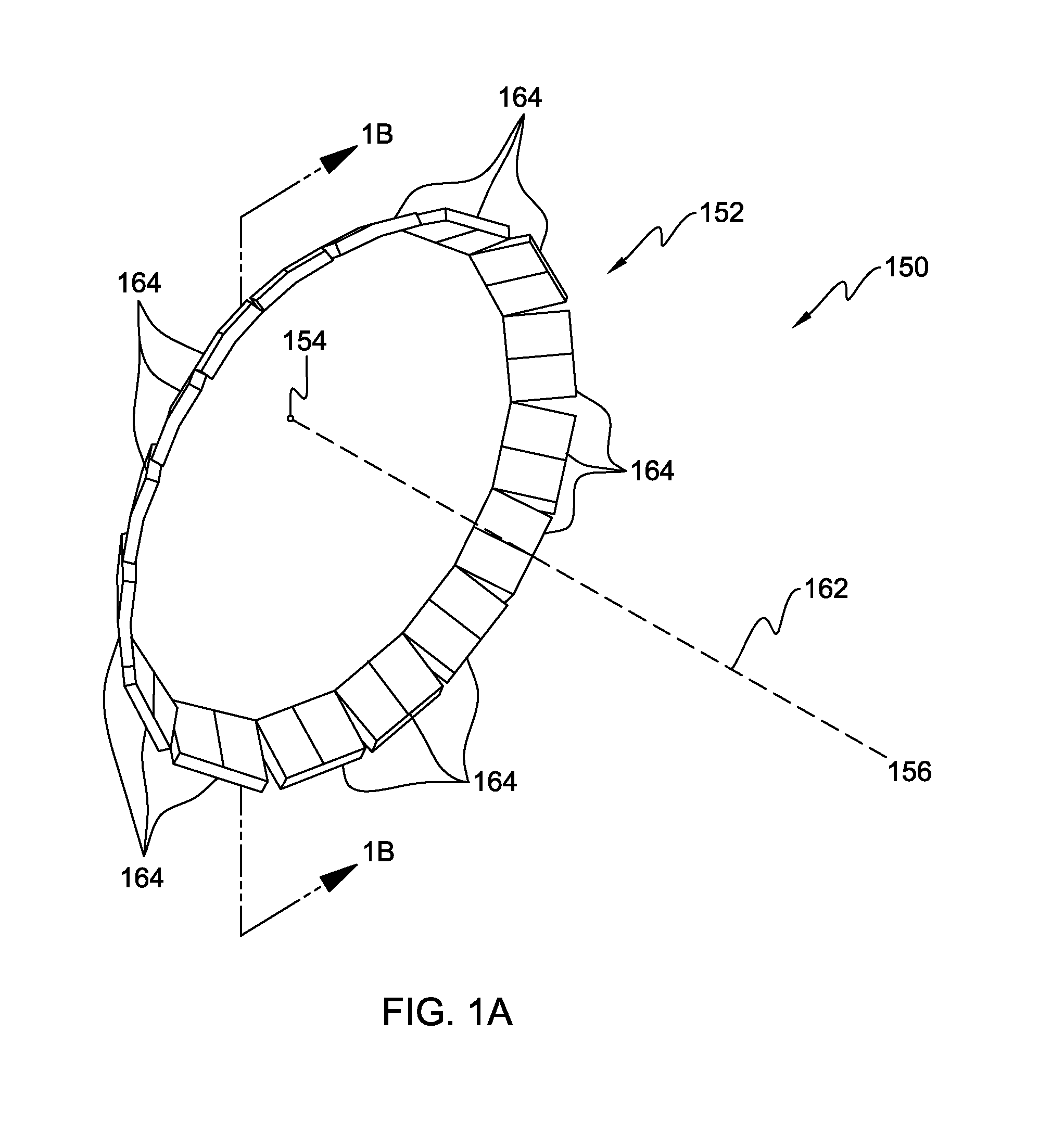

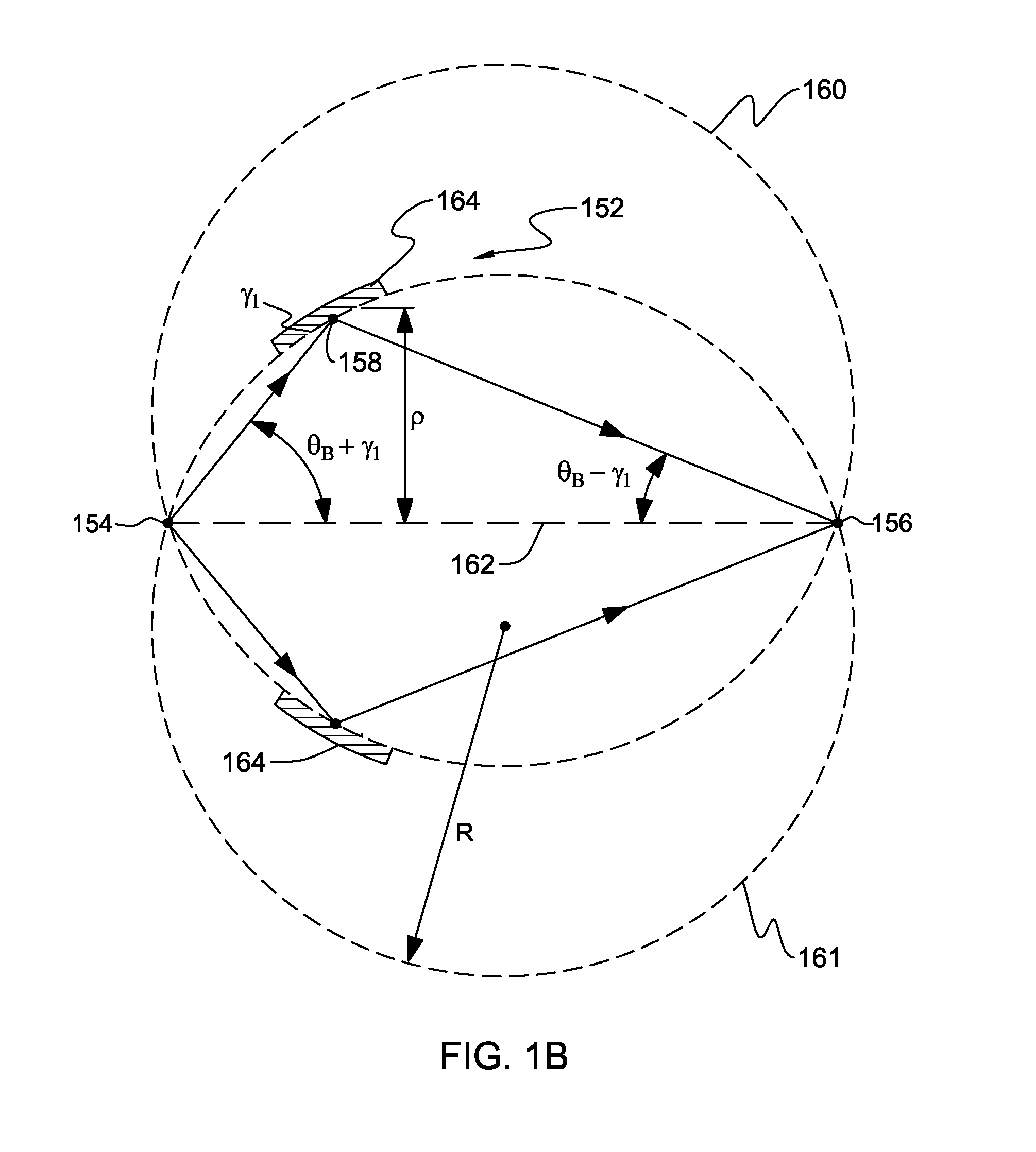

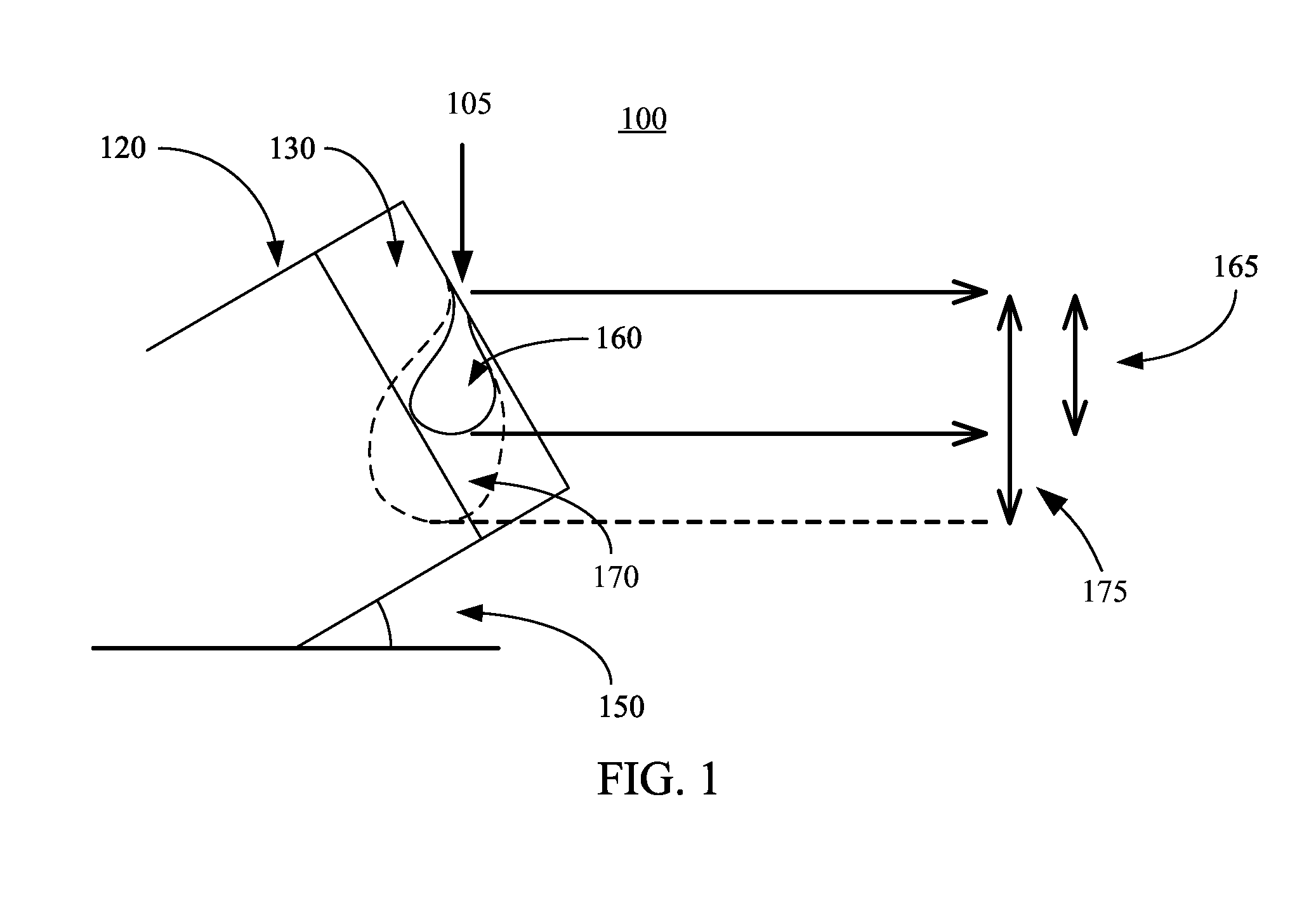

X-ray generating apparatus

ActiveUS20140105367A1Compact and lightweight configurationPrecise positioningX-ray tube electrodesCathode ray concentrating/focusing/directingSoft x rayX-ray

The X-ray generating apparatus 100 applies an electron beam e1 onto a target 150 to generate X-rays x1, and includes a permanent magnet lens 120 configured to focus the electron beam e1, a correction coil 130 provided on a side of the electron beam e1 with respect to the permanent magnet lens 120 and configured to correct a focus position formed by the permanent magnet lens 120 in a traveling direction of the electron beam e1, and a target 150 onto which the focused electron beam is applied. Accordingly, the apparatus configuration can be extremely compact and lightweight in comparison with general apparatuses. Furthermore, by the correction coil 130, the intensity of the magnetic field can be finely adjusted and the focus position in the traveling direction of the electron beam e1 can be finely adjusted.

Owner:RIGAKU CORP

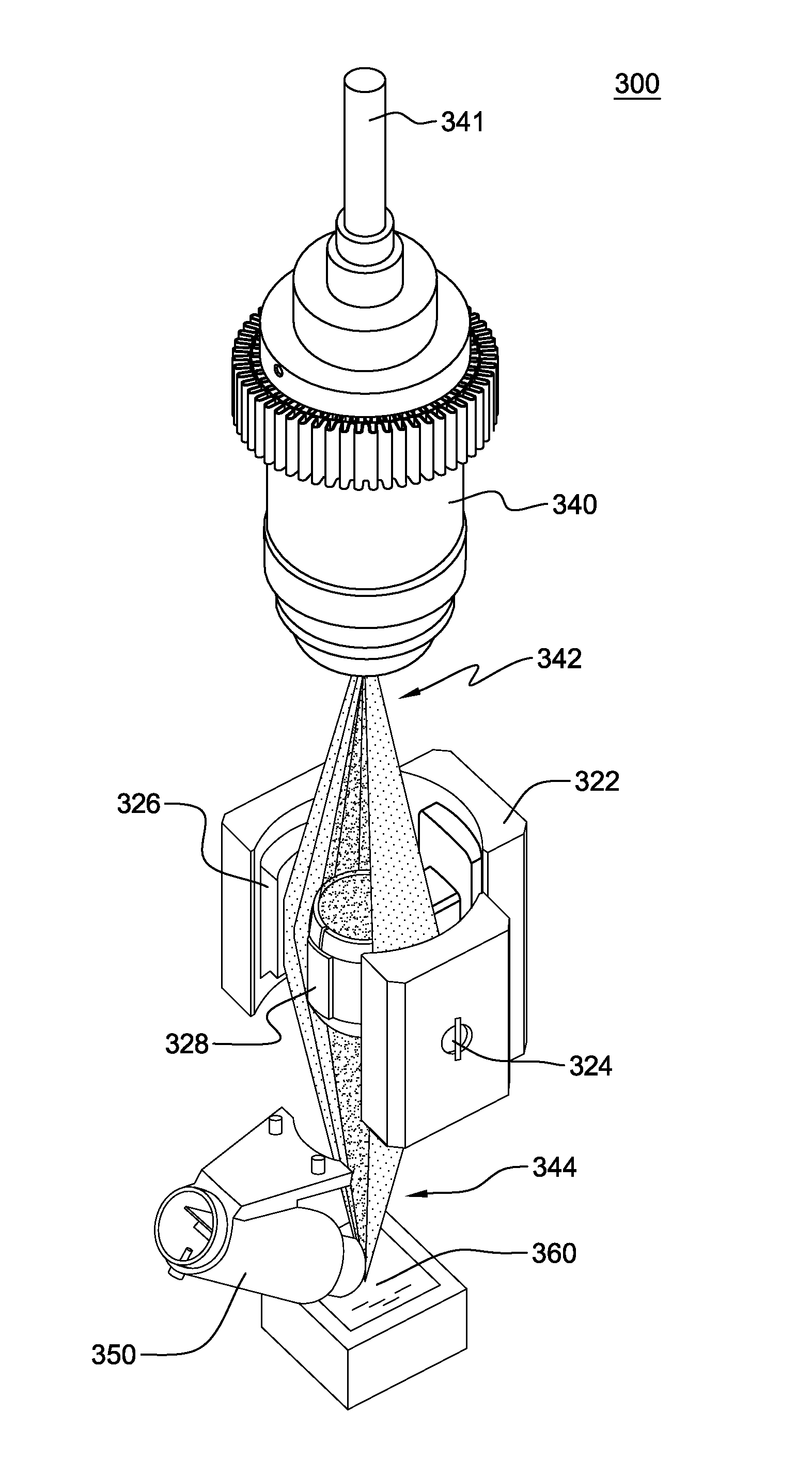

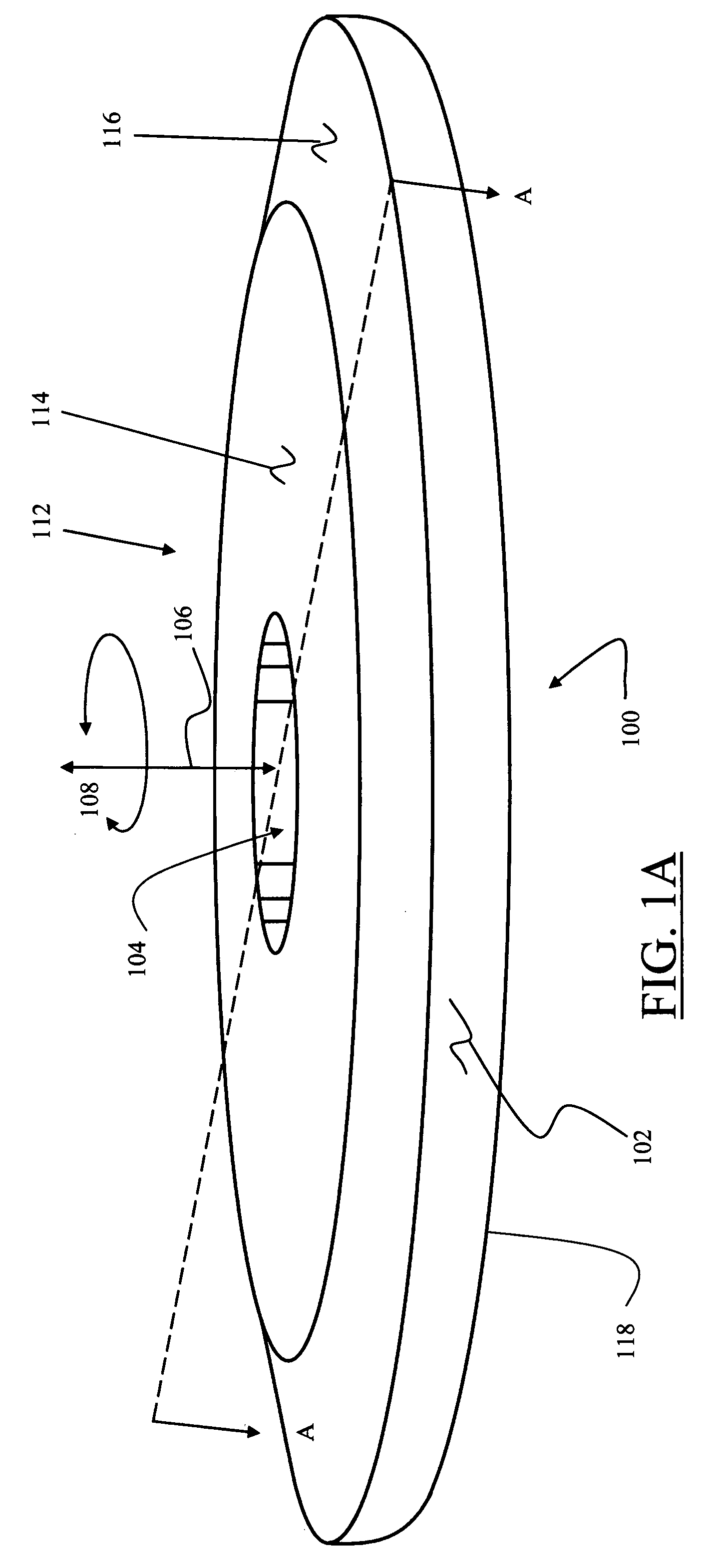

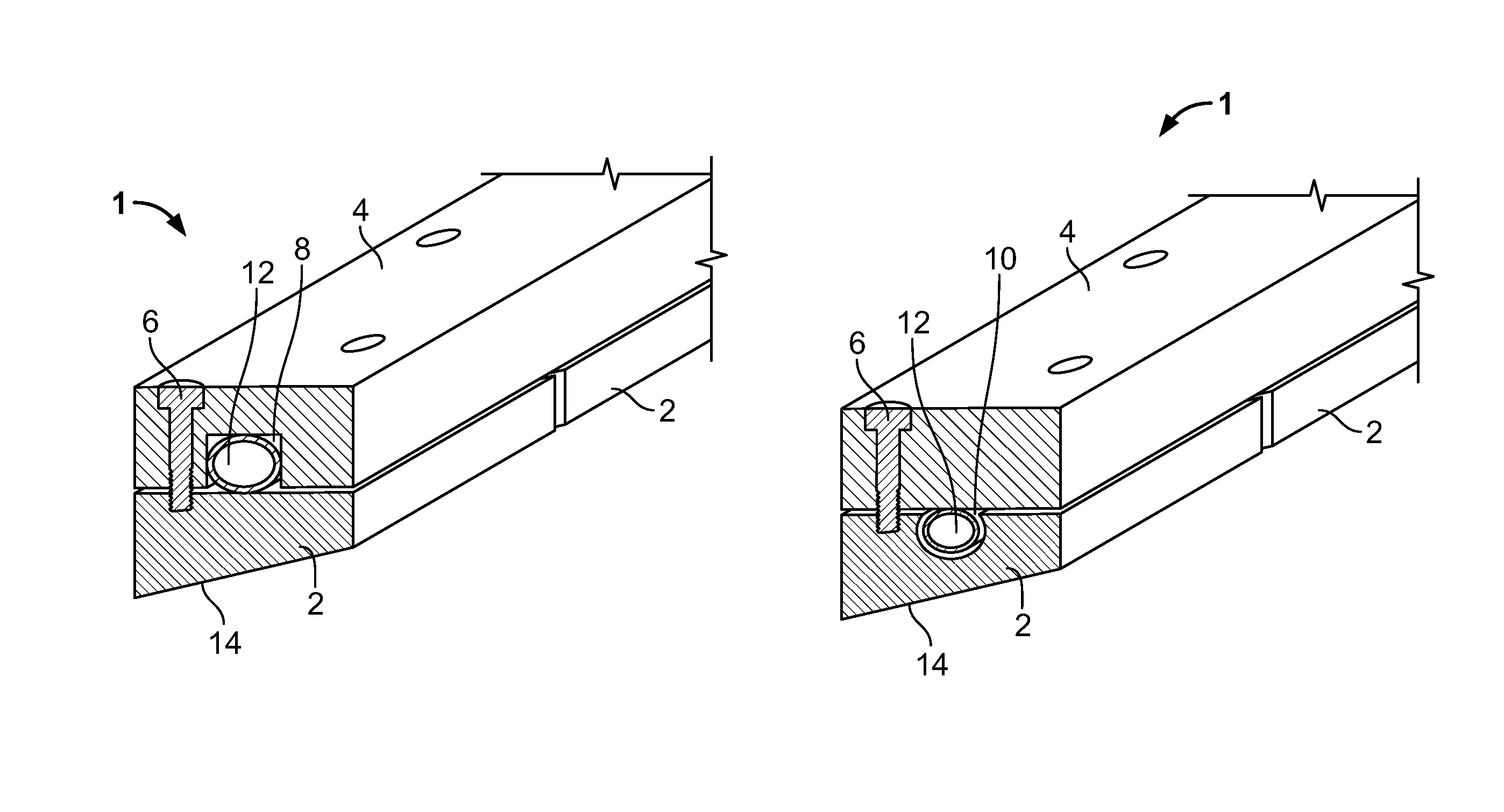

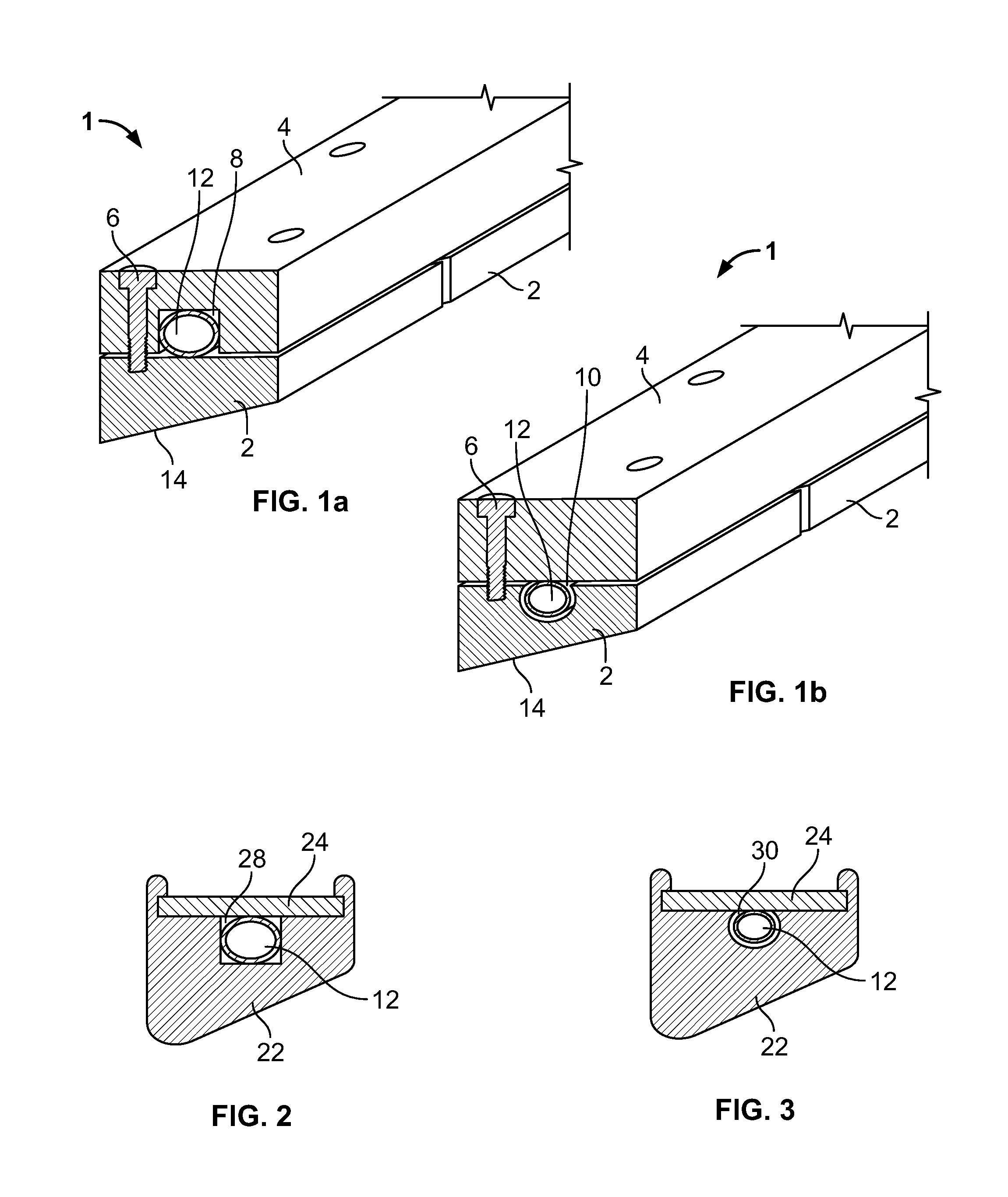

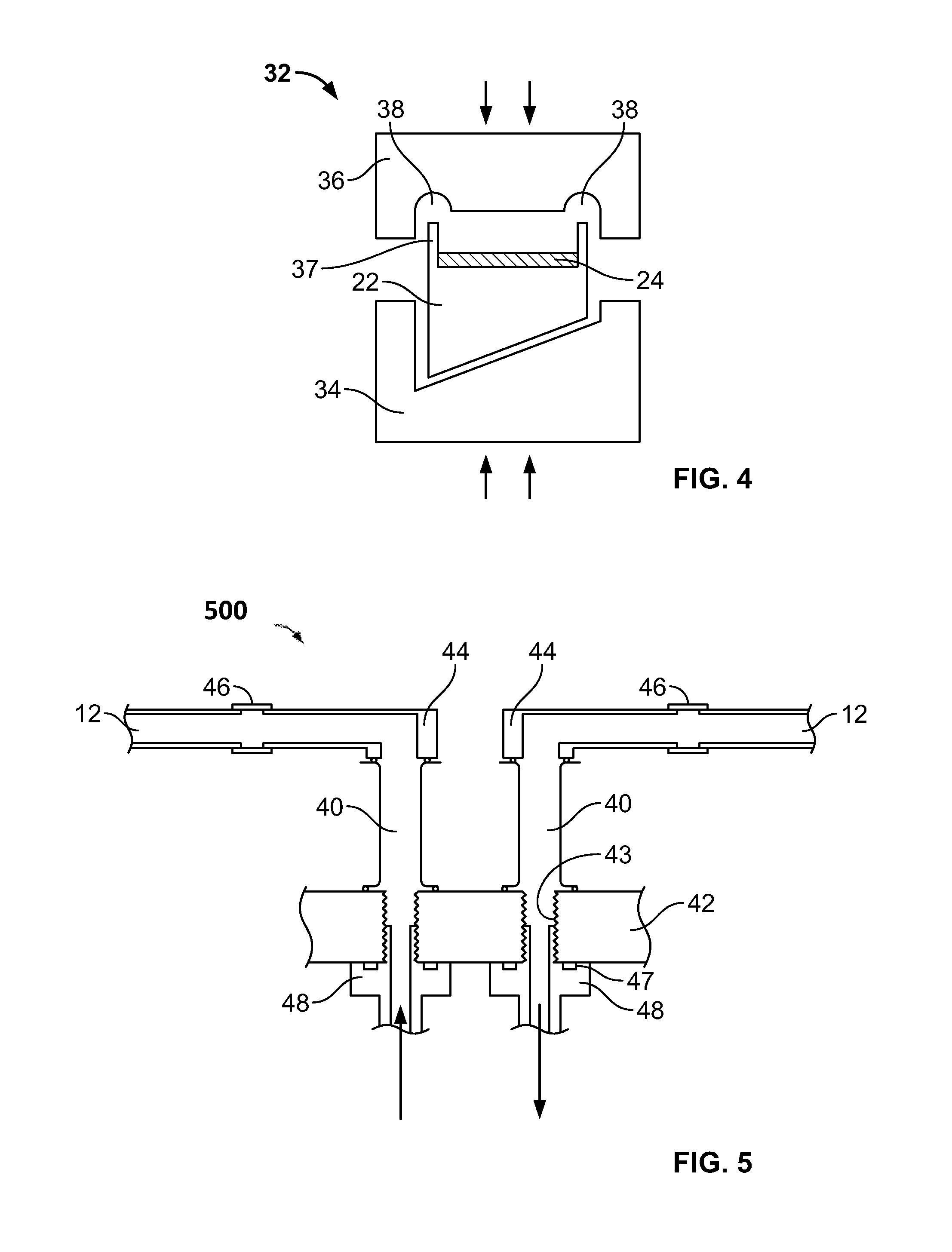

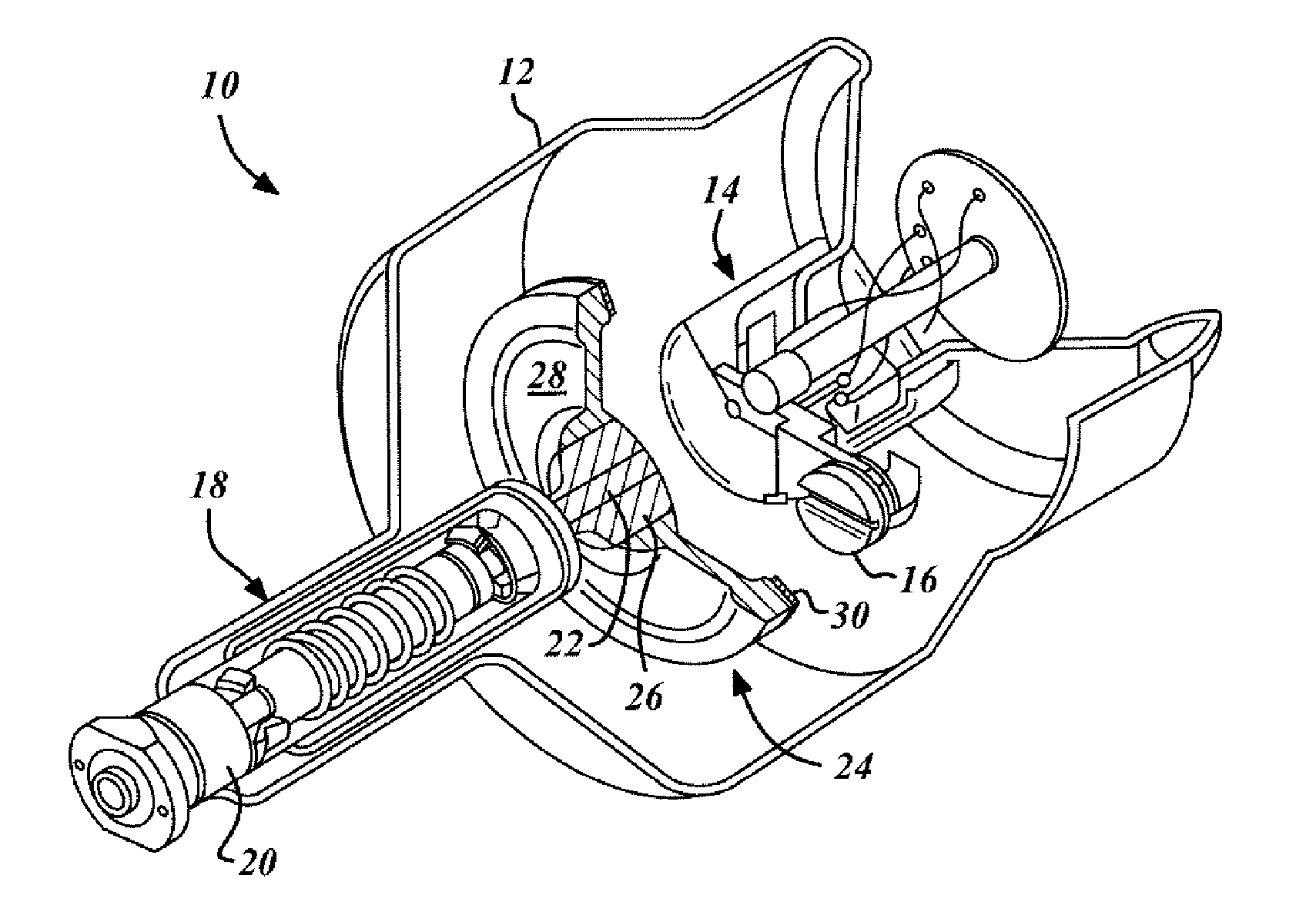

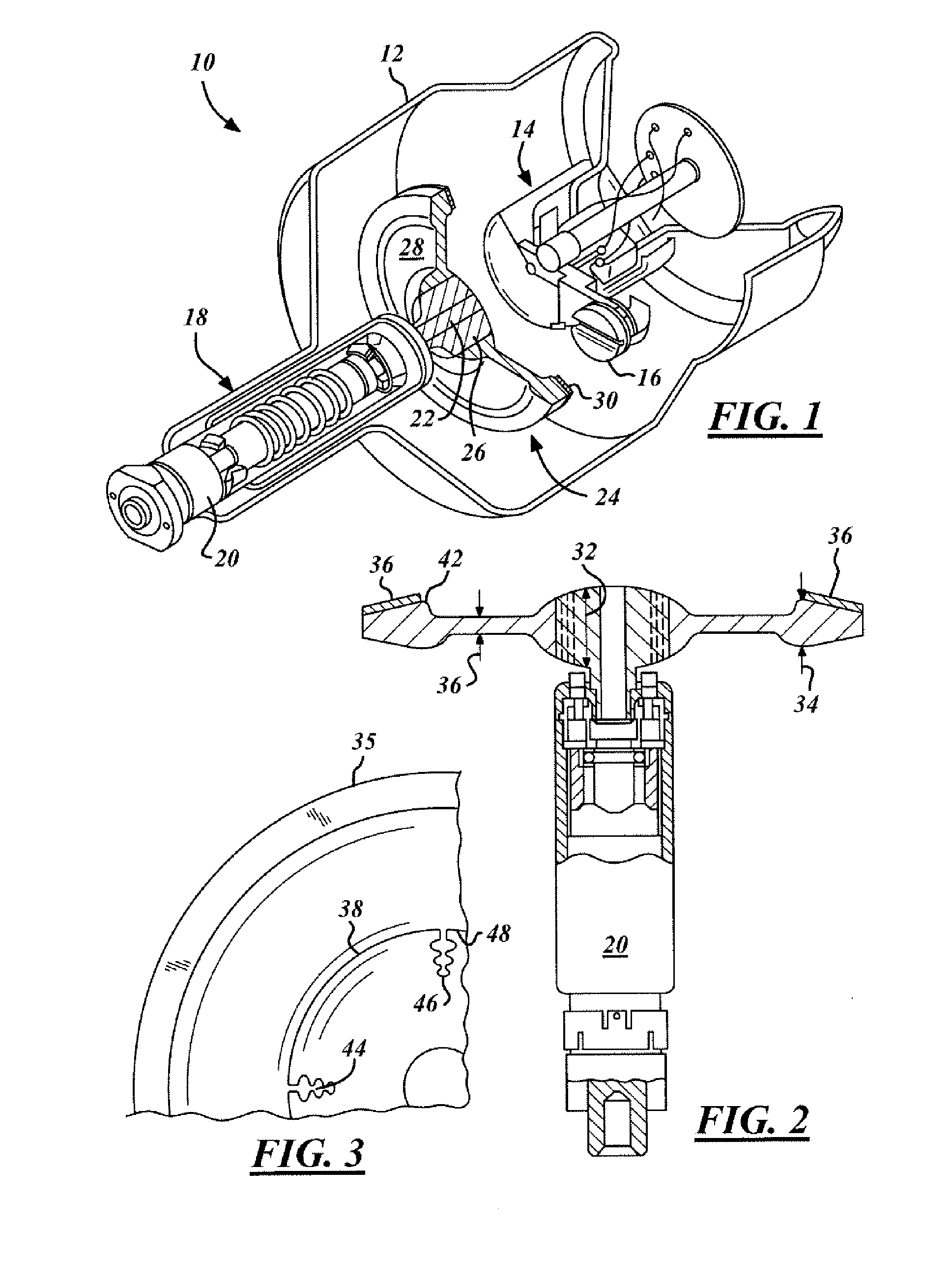

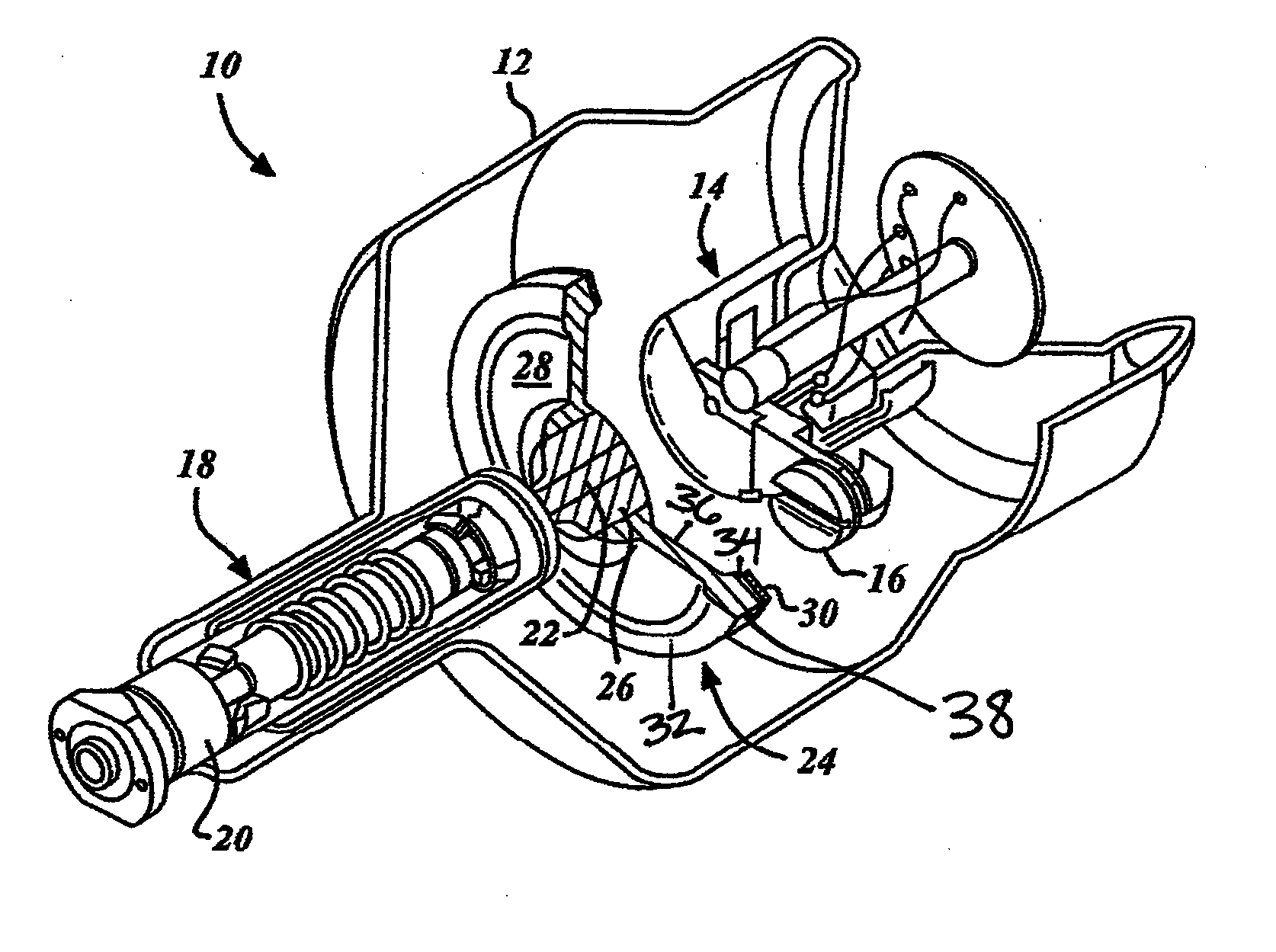

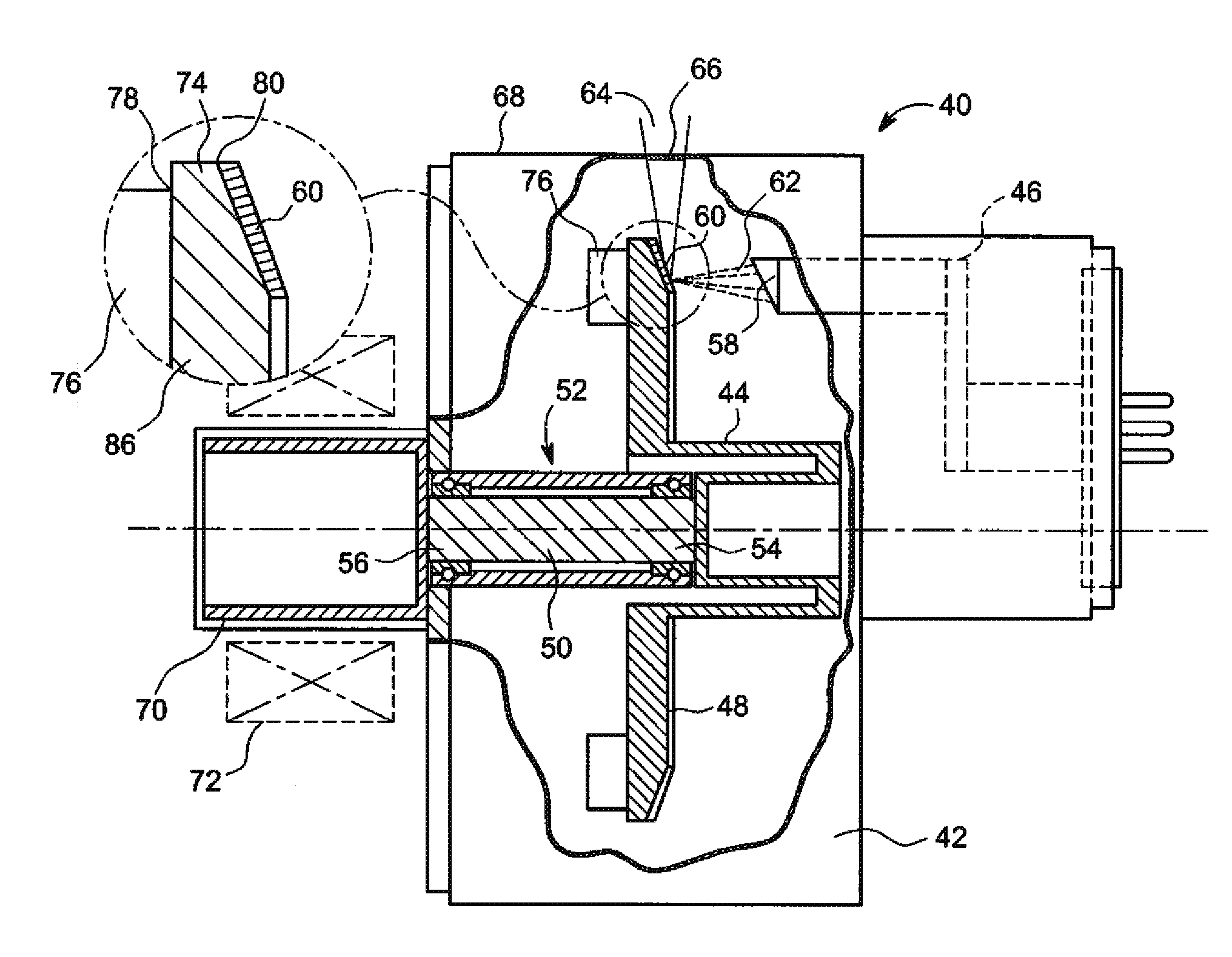

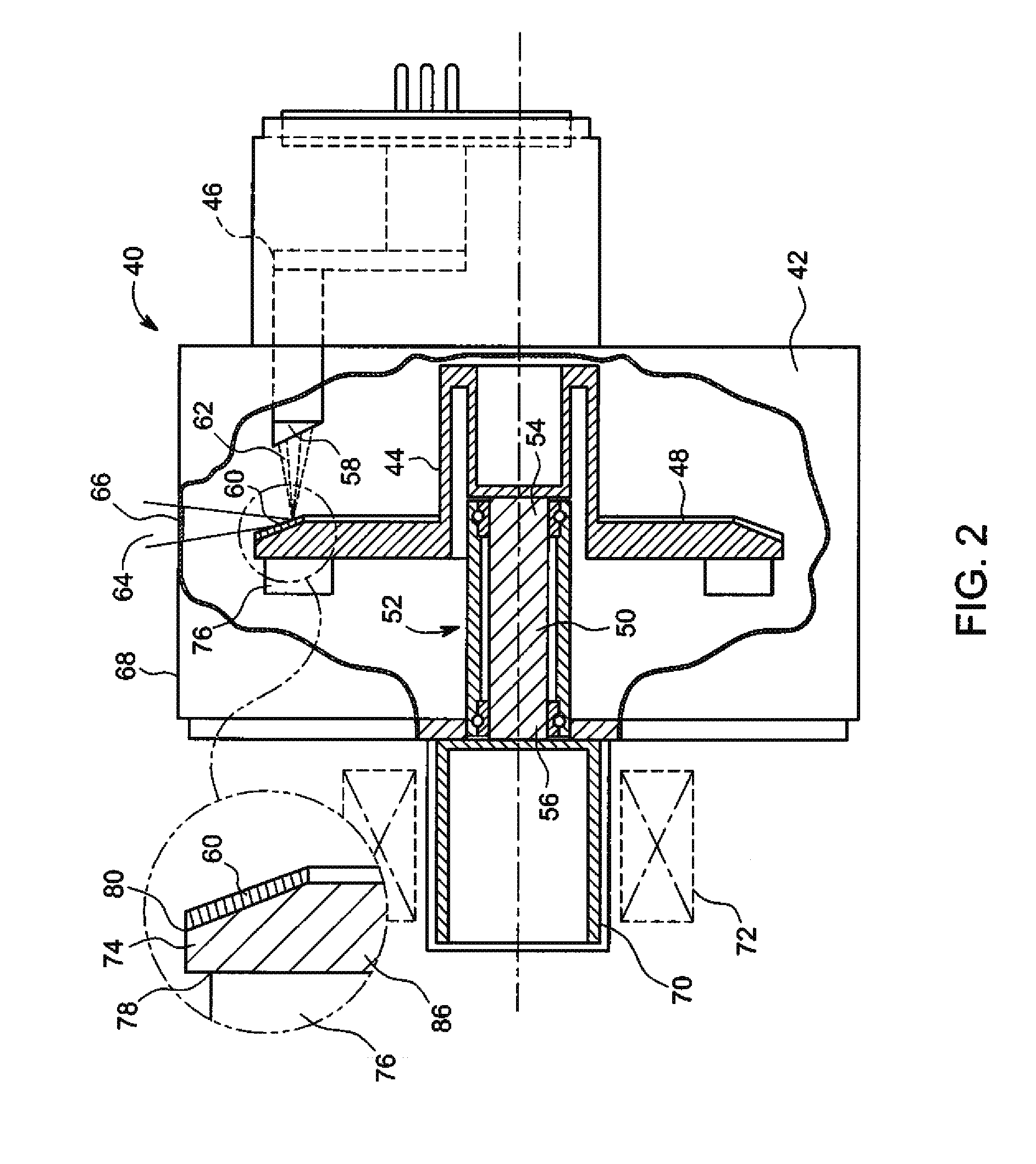

X-ray target assembly for high speed anode operation

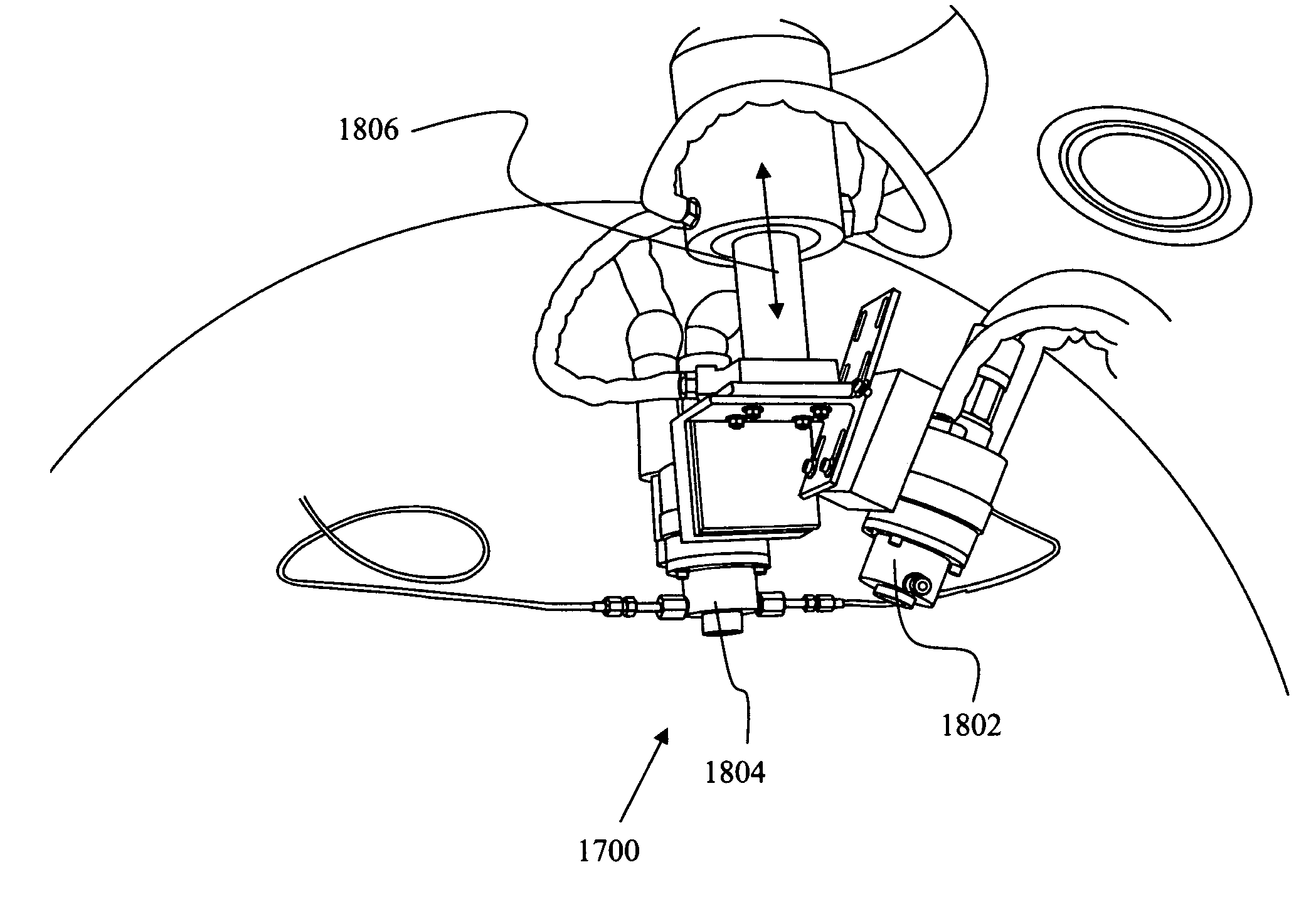

An x-ray target assembly is provided comprising a center hub element affixed to a drive shaft and an outer disc including a plurality of tab extensions removably engaging the periphery of the center hub element. A target element is mounted on an upper outer disc surface.

Owner:GENERAL ELECTRIC CO

X-ray analyzer having multiple excitation energy bands produced using multi-material x-ray tube anodes and monochromating optics

ActiveUS9449780B2Lower levelX-ray tube laminated targetsMaterial analysis using wave/particle radiationMulti materialFluorescence

An x-ray tube includes a target on which electrons impinge to form a diverging x-ray beam. The target has a surface formed from first and second target materials, each tailored to emit a respective x-ray energy profile. A first x-ray optic may be provided for directing the beam toward the sample spot, the first x-ray optic monochromating the diverging x-ray beam to a first energy from the energy emitted by the first target material; and a second x-ray optic may be provided, for directing the beam toward the sample spot, the second x-ray optic monochromating the diverging x-ray beam to a second energy from the energy emitted by the second target material. Fluorescence from the sample spot induced by the first and second monochromated energies is used to measure the concentration of at least one element in the sample, or separately measure elements in a coating and underlying substrate.

Owner:X-RAY OPTICAL SYSTEM INC

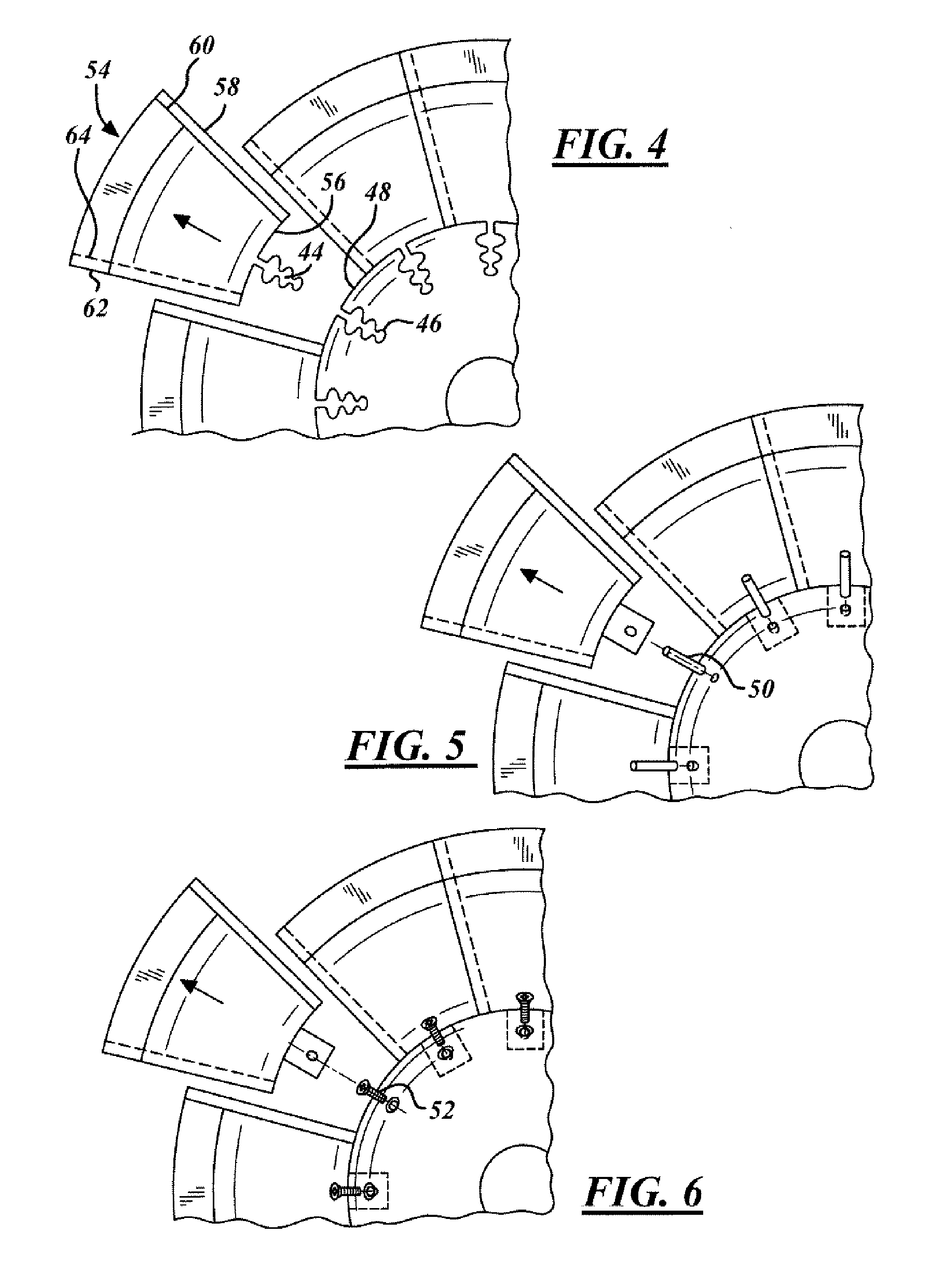

X-ray tube target assembly and method of manufacturing same

InactiveUS20080069306A1X-ray tube electrodesX-ray tube bonding/fixingInjection mouldingBiomedical engineering

An X-ray tube target assembly and method of manufacturing same is provided. The X-ray tube target assembly comprises an injection molded target disk. The injection molded target disk includes an injection molded hub member and an injection molded outer member. The injection molded outer member comprises a plurality of injection molded outer member segments that are removably attached together and removably attached to the hub member to form the injection molded target disk. A target track is formed on an outer surface on one side of an outer periphery of the injection molded outer member.

Owner:GENERAL ELECTRIC CO

High aspect ratio x-ray targets and uses of same

ActiveUS20150303021A1Simple structureEasy to useX-ray tube laminated targetsRadiation/particle handlingSoft x rayHard X-rays

An x-ray target, a method of using the x-ray target, and a computer program product with instructions for carrying out a method of using the x-ray target. The x-ray target includes a substrate made from a soft x-ray producing material and a high aspect ratio structure made from a hard x-ray producing material. The hard x-ray producing material is embedded in the substrate, formed on the substrate, cantilevered out from the edge of the substrate, or any combination thereof. The high aspect ratio structure comprises a plurality of high aspect ratio structures arranged in one or more grids or arrays, and the high aspect ratio structures in one of the one or more grids or arrays are arranged to form a Hadamard matrix structure.

Owner:FEI CO

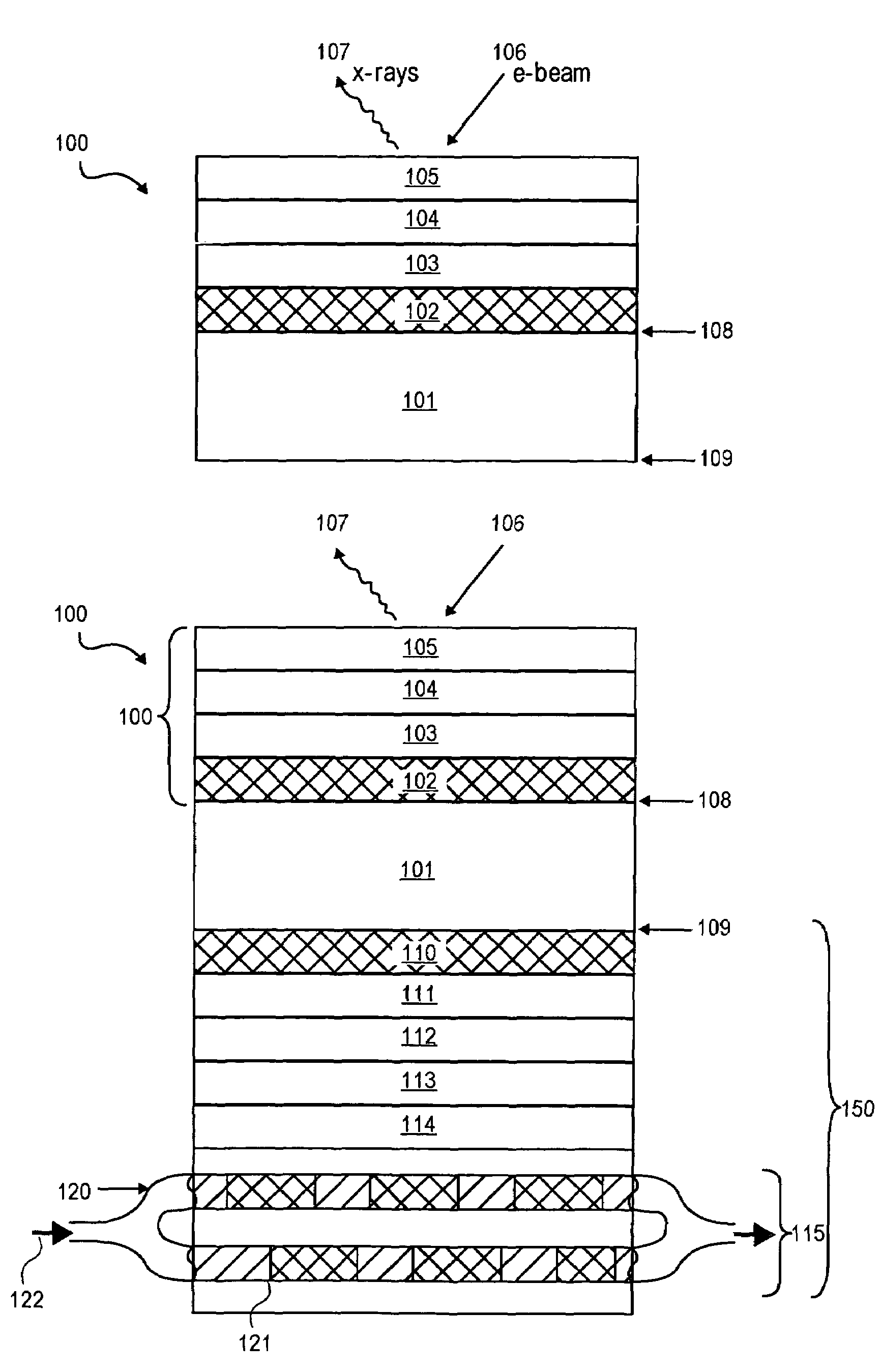

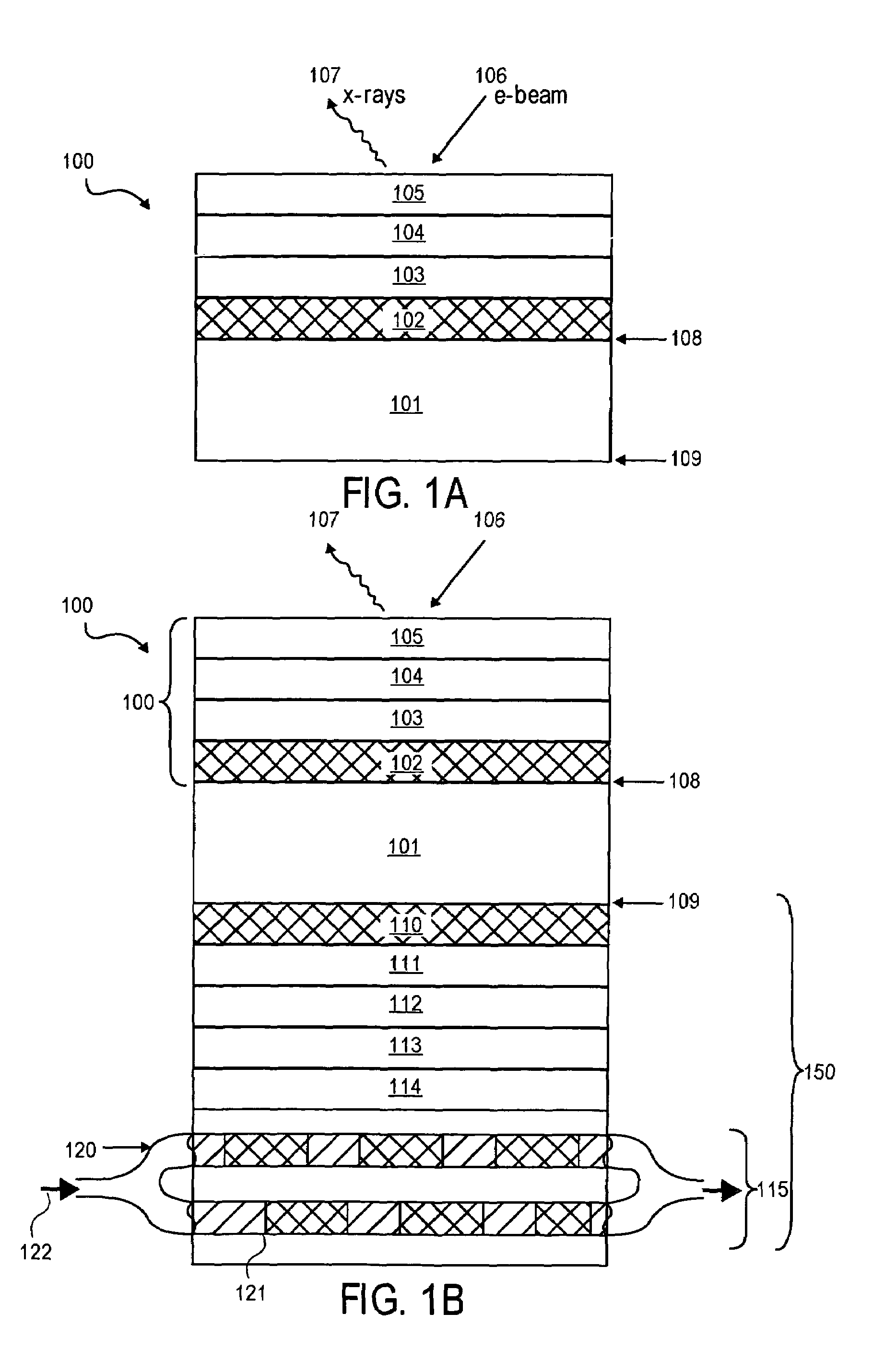

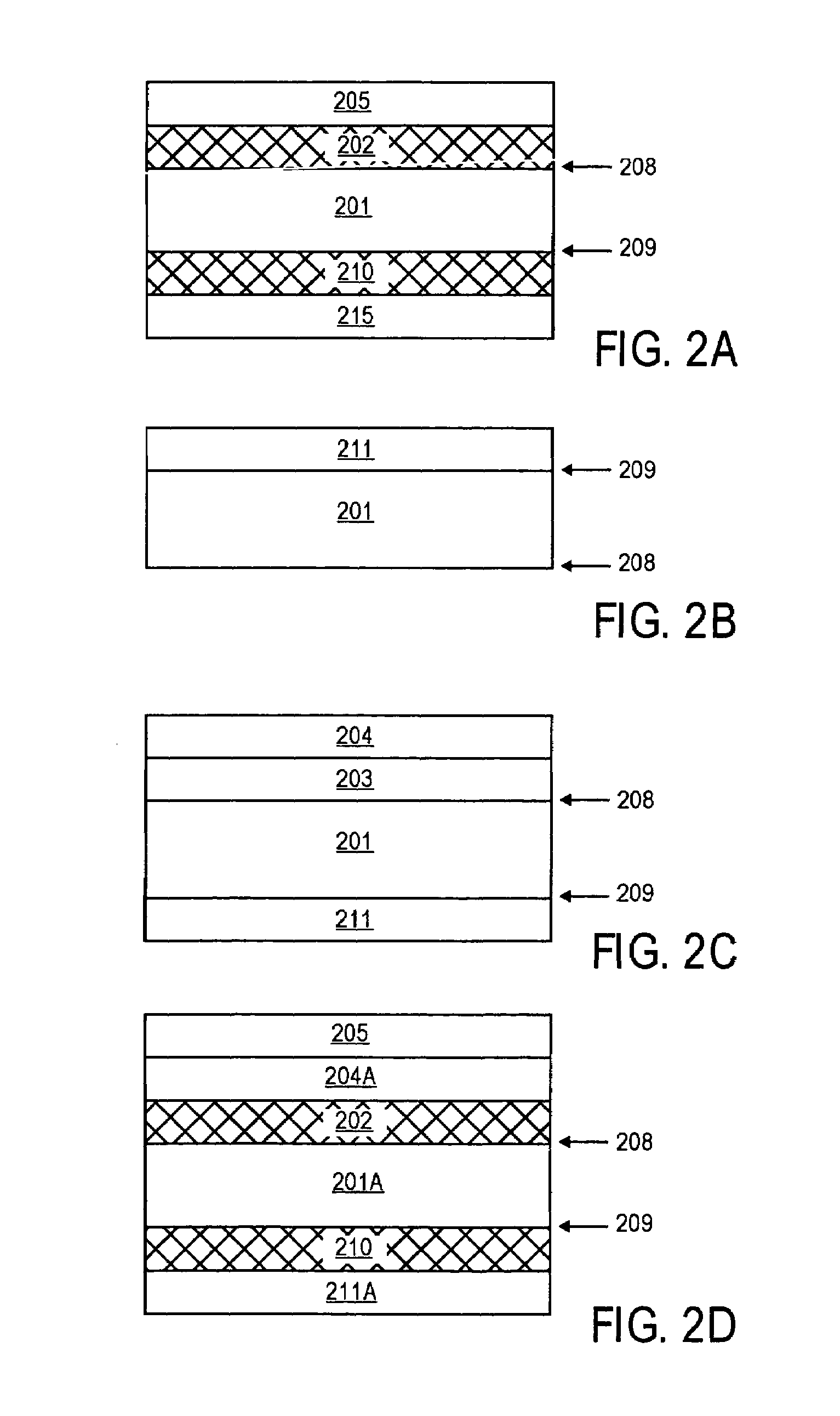

High temperature annealing in X-ray source fabrication

The present disclosure relates to multi-layer X-ray sources having decreased hydrogen within the layer stack and / or tungsten carbide inter-layers between the primary layers of X-ray generating and thermally-conductive materials. The resulting multi-layer target structures allow increased X-ray production, which may facilitate faster scan times for inspection or examination procedures.

Owner:MANTHEY DIANE MANT

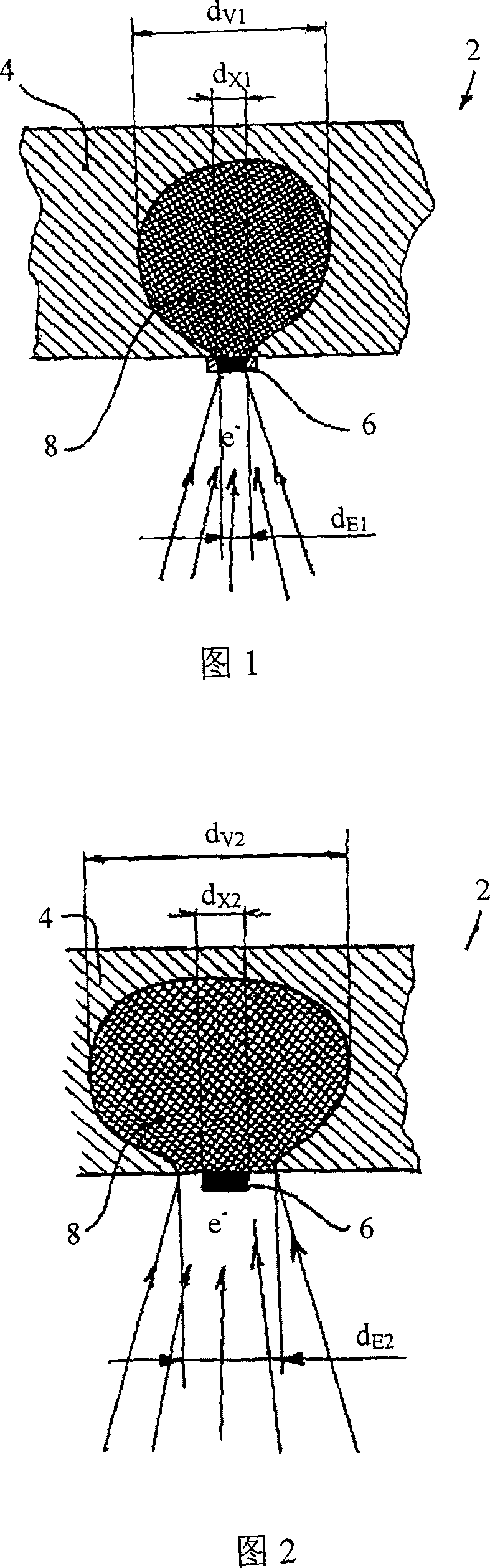

Nanofocus X-ray tube

InactiveCN1971834AInterference is not affectedX-ray tube electrodesX-ray apparatusNanostructureElectron

The invention relates to a nanofocus X-ray tube 20 pwovided with a target 4 and a device used for calibrating an electronic beam 28 on the target 4. According to the invention, the target 4 has at least one of target units 22, 24, 26 made of target material for emitting x-ray beam, and is composed by amicro-structuring process and a nanostructure formed on a carrier unit 4 composed of a carrier material, the nanostructure has a diameter less than 1 nm, wherein the target units 6, 22, 24, 26 only partly cover the carrier unit 4. When the X-ray tube 20 is operated, the electronic beam is selected with a cross section large than the cross sections of the target units 6, 22, 24, 26, in this way, the electronic beam 28 can entirely always irradiate on the target units 6, 22, 24, 26 all the time. According to the invention, the carrier material is diamond or contains diamonds, diamonds are added for increase conductive performance.

Owner:COMET

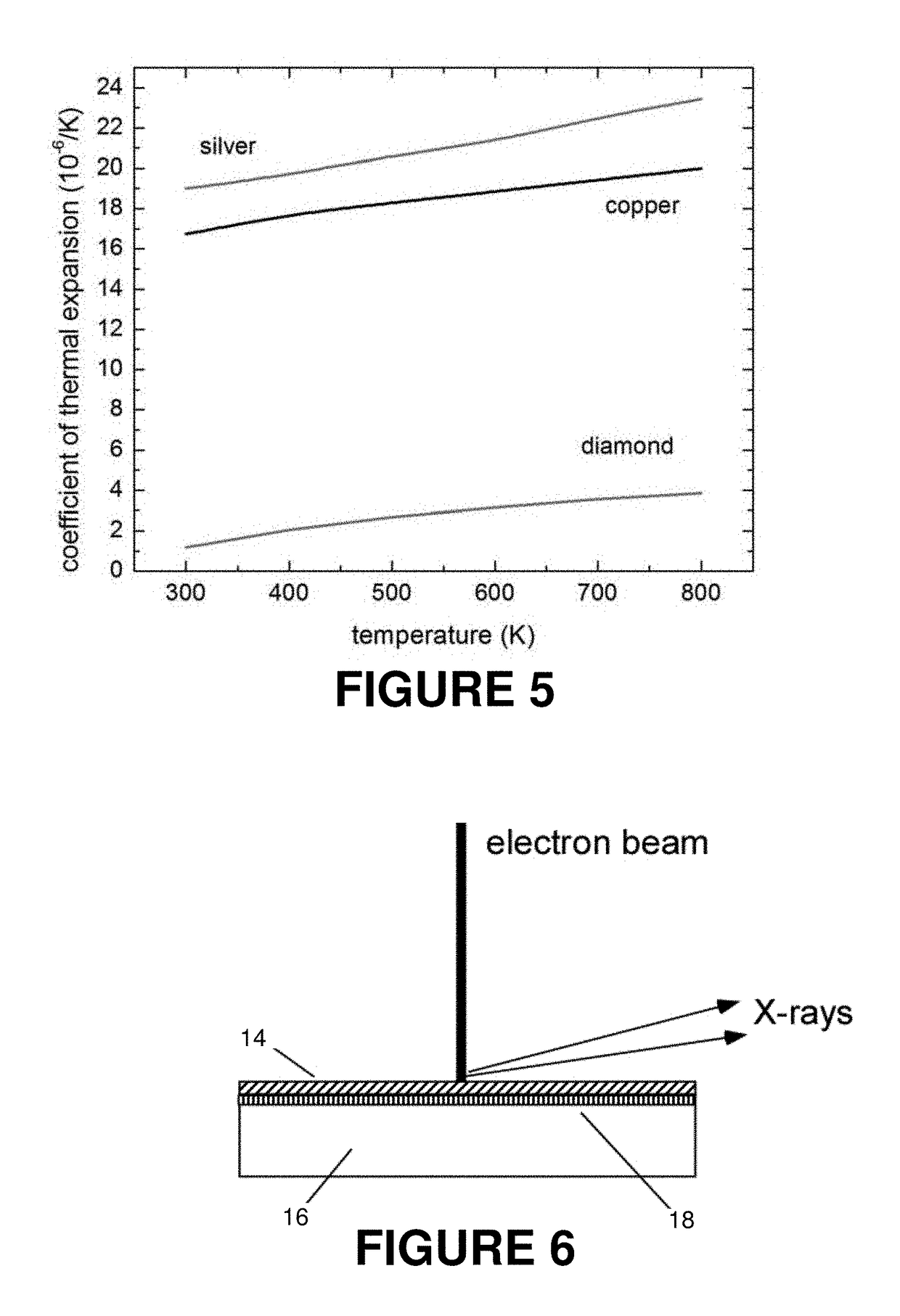

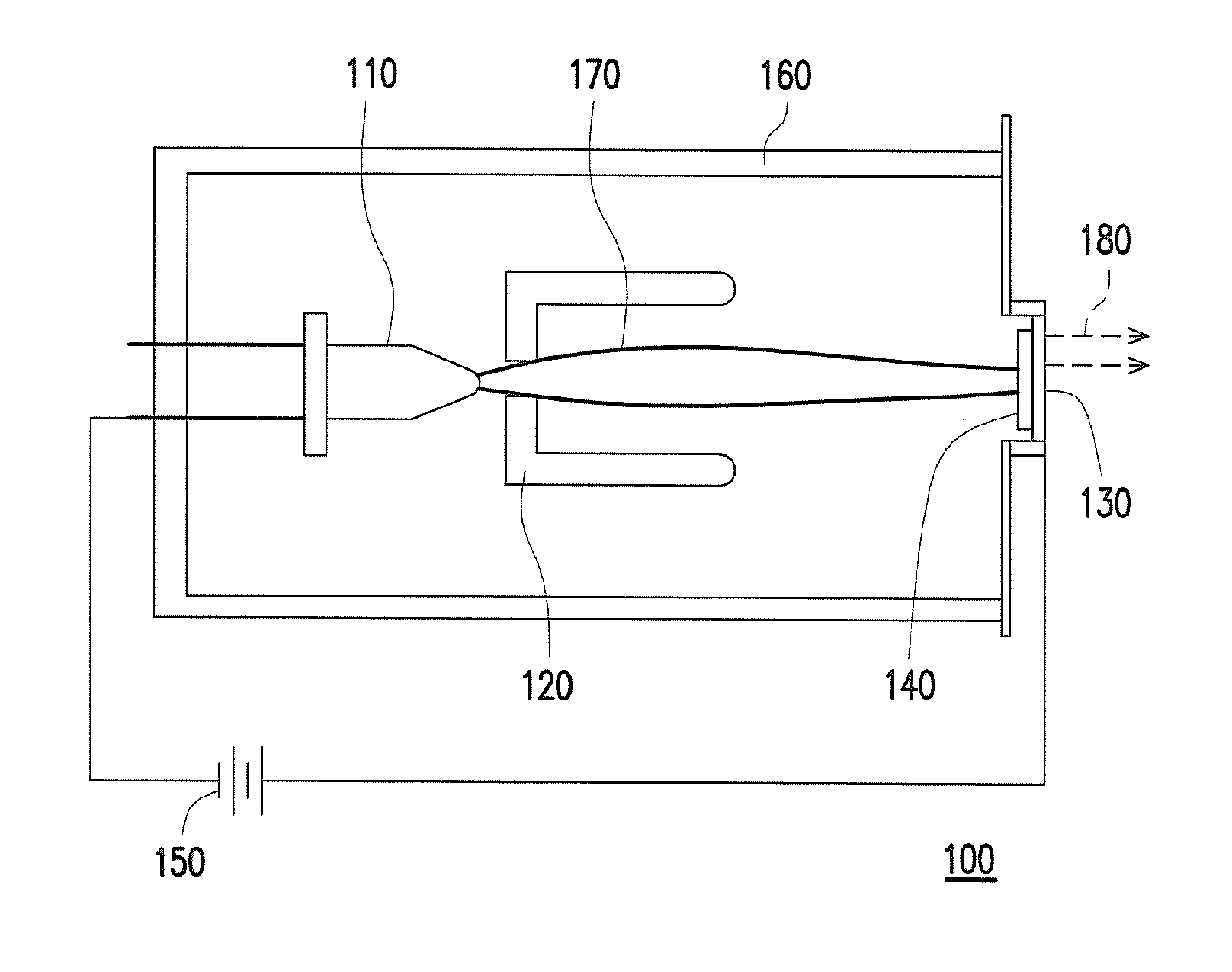

Analytical x-ray tube with high thermal performance

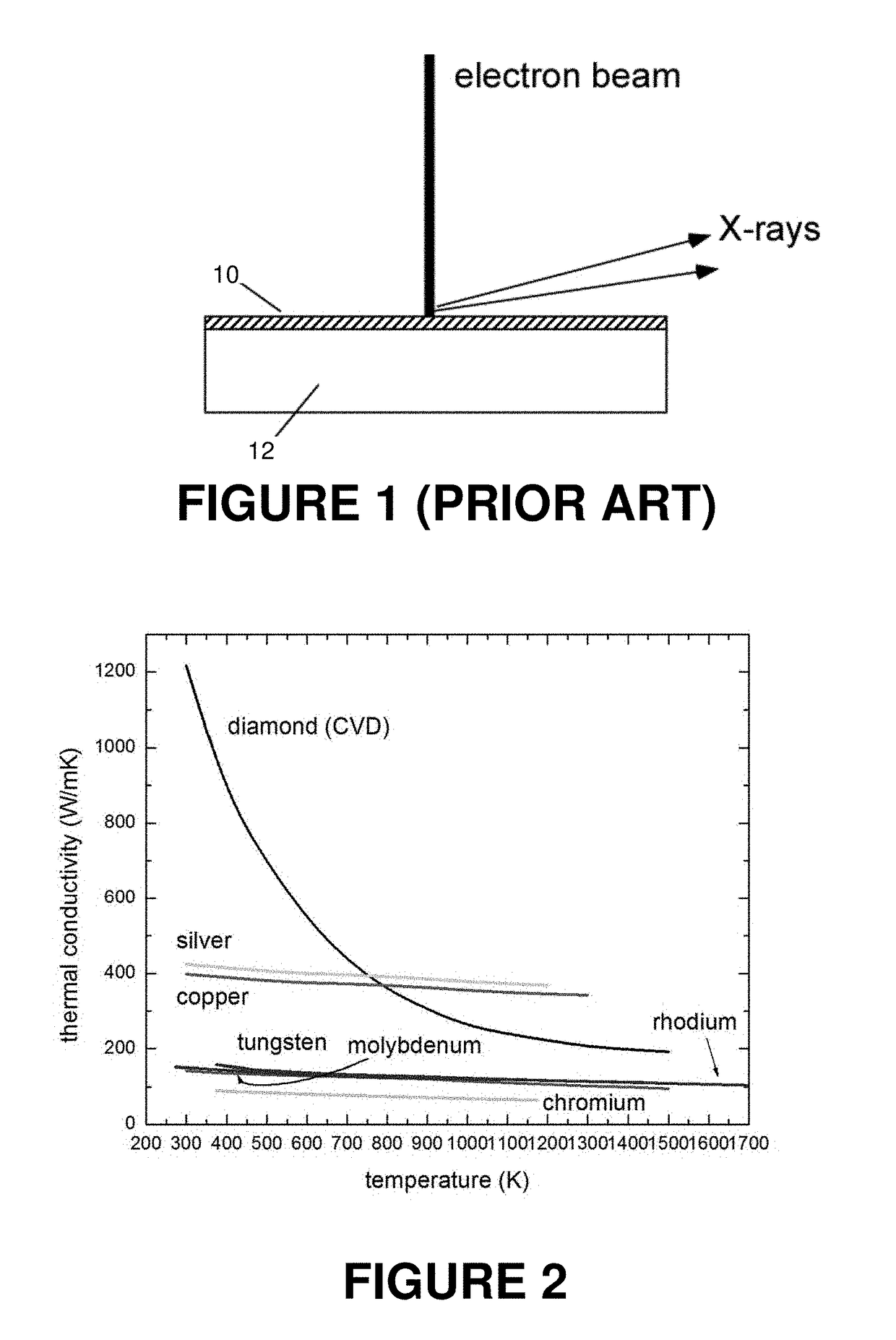

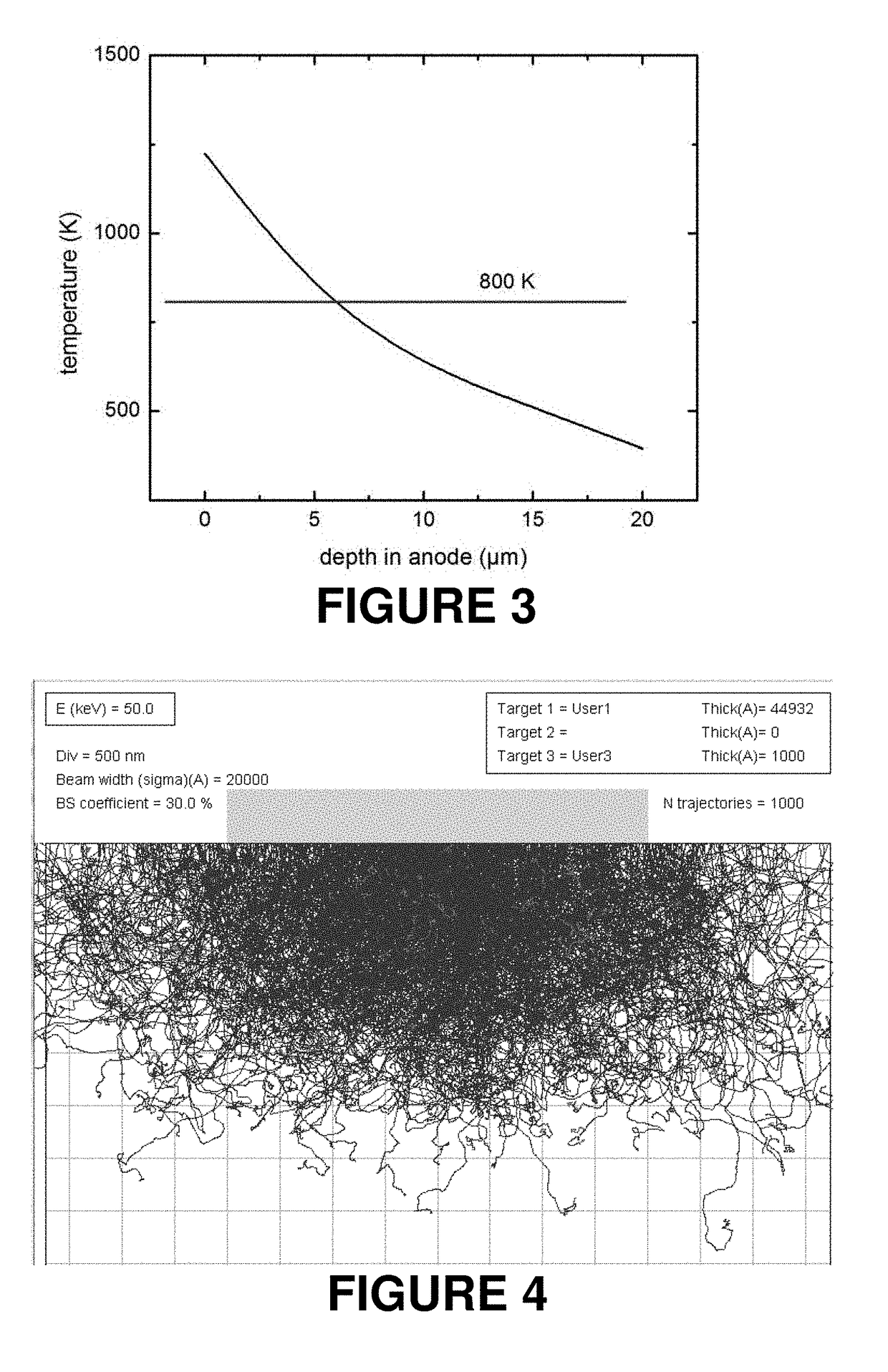

ActiveUS20190057832A1Improve thermal performanceIncrease brightnessX-ray tube anode coolingX-ray tube electrodesX-rayPenetration depth

An analytical X-ray tube with an anode target material that emits characteristic X-rays in response to excitation by an electron beam may include any of several advantageous features. The target material is deposited on a diamond substrate layer, and a metal carbide intermediate layer may be provided between the target material and substrate that provides enhanced bonding therebetween. An interface layer may also be used that provides an acoustic impedance matching between the target material and the substrate. For a low thermal conductivity target material, a heat dissipation layer of a higher thermal conductivity material may also be included between the target material and substrate to enhance thermal transfer. The target material may have a thickness that corresponds to a maximum penetration depth of the electrons of the electron beam, and the structure may be such that a predetermined temperature range is maintained at the substrate interface.

Owner:BRUKER AXS

High density low pressure plasma sprayed focal tracks for X-ray anodes

InactiveUS20080181366A1Decrease vacuum pressureAvoid heat conductionLiquid surface applicatorsMolten spray coatingSoft x rayRhenium

This invention involves the application of dense, metallurgically bonded deposits of tungsten and tungsten rhenium coatings onto preformed based x-ray anodes to be used as focal tracks. The coatings are applied by low pressure DC plasma spraying. The invention also includes heat treatments that further densify the as-applied coatings improving their suitability for use as focal tracks.

Owner:SURFACE MODIFICATION SYST

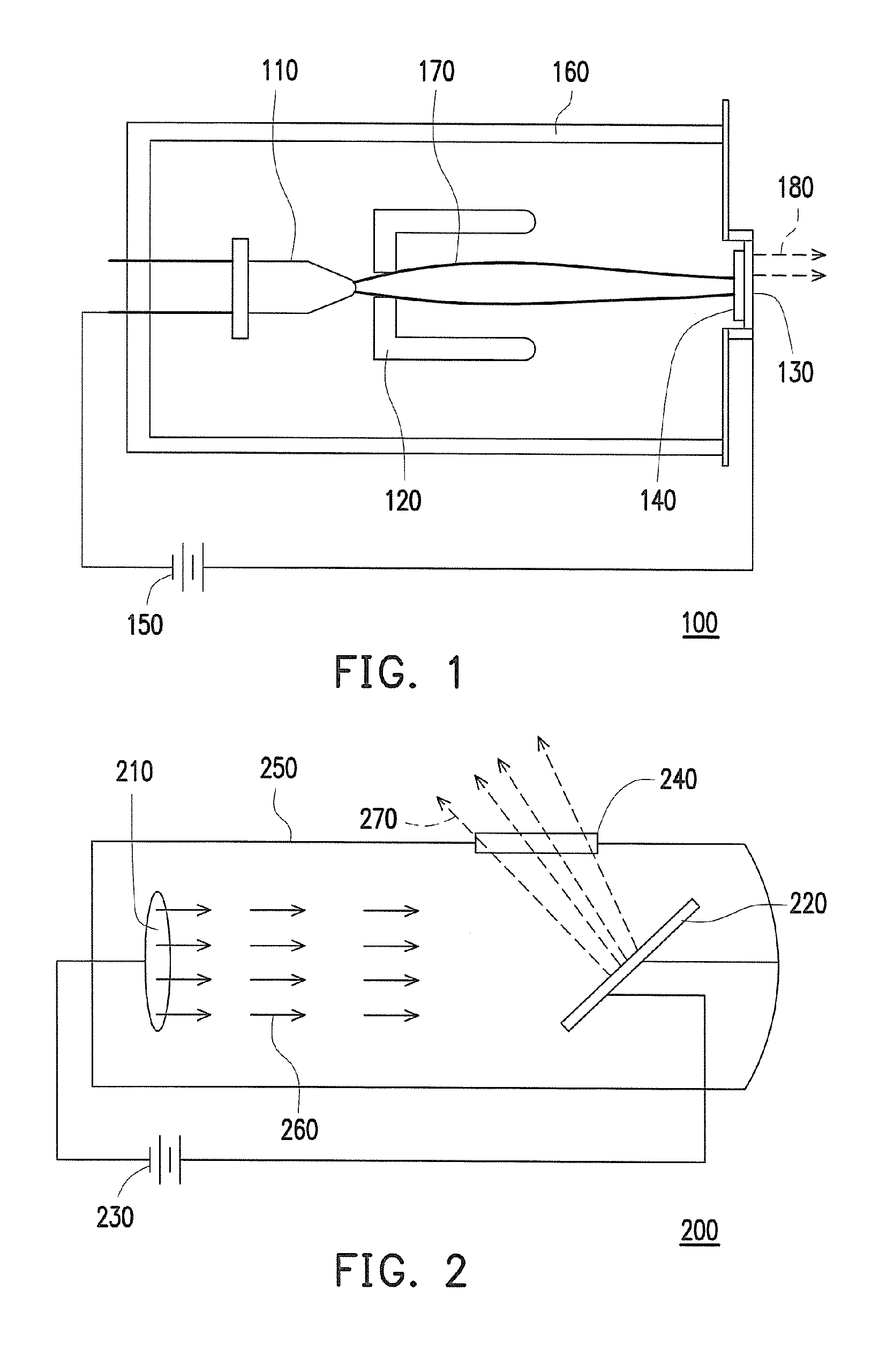

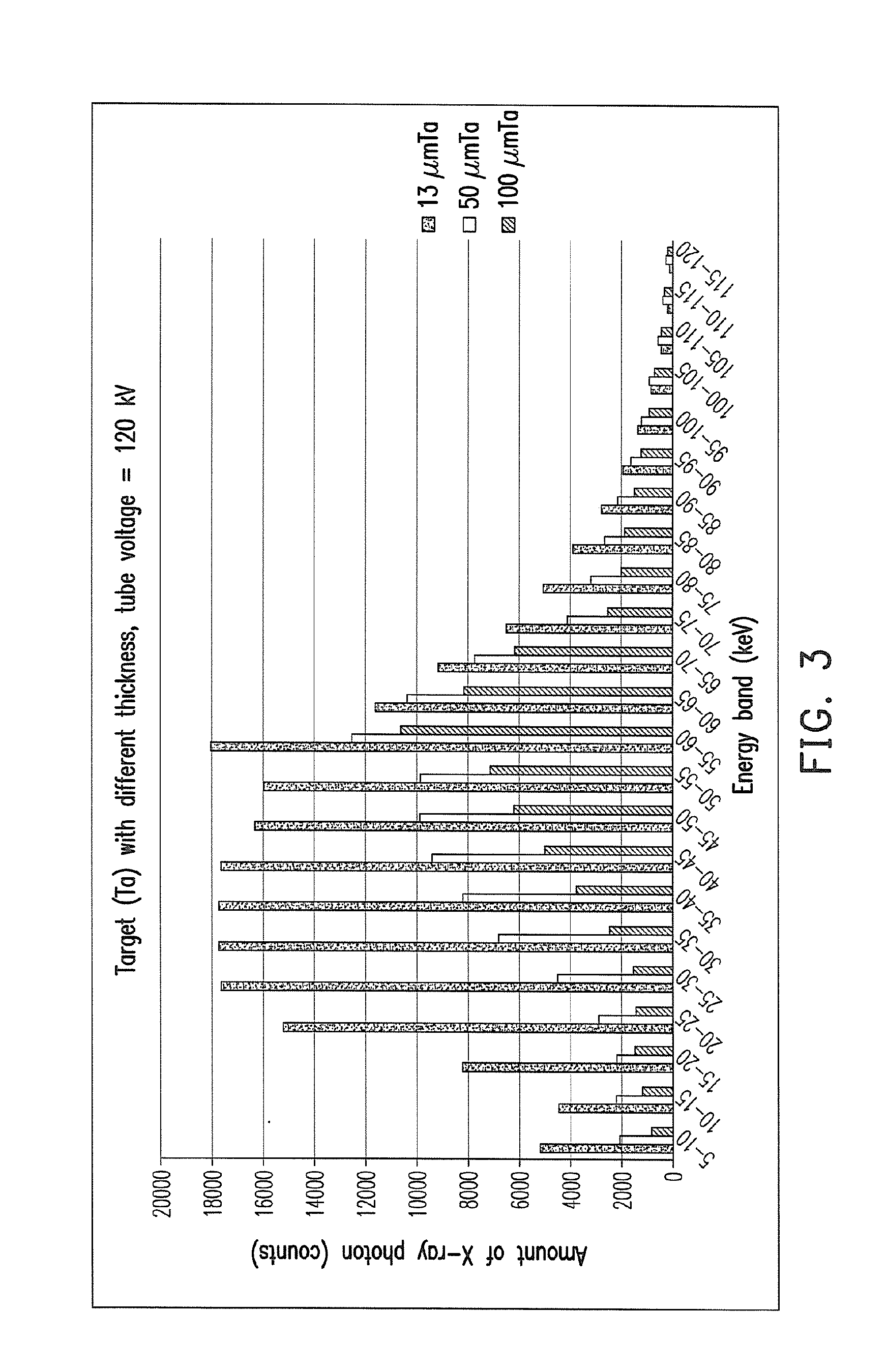

Composite target and x-ray tube with the composite target

ActiveUS20170018392A1Sufficient long service lifeWeaken energyX-ray tube laminated targetsRadiation/particle handlingHigh energyX-ray

A composite target is provided and is interacted with an electron to generate an X-ray, and an energy of the electron can be changed by controlling a tube voltage at least. The composite target includes a target body and an interposing layer which is connected with the target body. The interposing layer moves a highest peak of an energy spectrum of the X-ray toward a high energy direction. The interposing layer may be a single metal or a metal mixture. Not only a low energy photon of the X-ray can be filtered by the interposing layer, but also a distribution of the low energy photon of the X-ray can be increased by increasing a thickness of the interposing layer. As the tube voltage is enhanced, an amount of a high energy photon of the X-ray generated is dramatically increased. An X-ray tube containing the above composite target is also provided.

Owner:NANORAY BIOTECH CO LTD

X-ray tube target and method of repairing a damaged x-ray tube target

ActiveUS20110007872A1Low costHuge savingsX-ray tube anode coolingX-ray tube electrodesX-rayTime-Consuming

An x-ray tube target and method of repairing a damaged x-ray tube target. The x-ray tube target includes an original substrate and a portion of the original substrate that includes a new portion of a substrate and a new target track that is attached to a void in the original substrate. The method includes removal and replacement of damaged materials on used anode targets of x-ray tubes, thereby enabling recovery of used anode targets without the use of expensive and time consuming layer deposition methods. The method also avoids the high costs and long development cycles associated with known repair and refabrication methods for anode targets of x-ray tubes.

Owner:GENERAL ELECTRIC CO

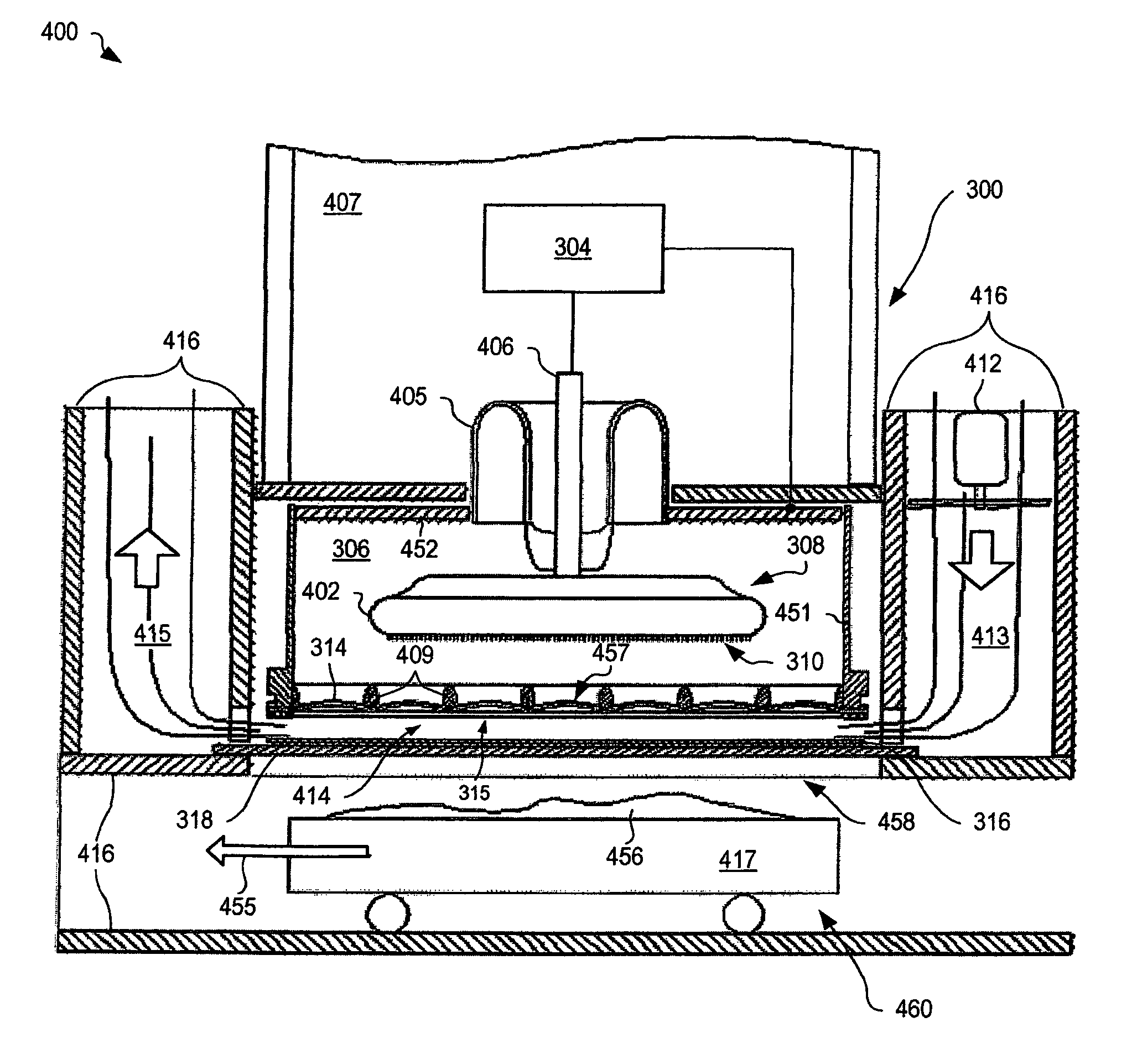

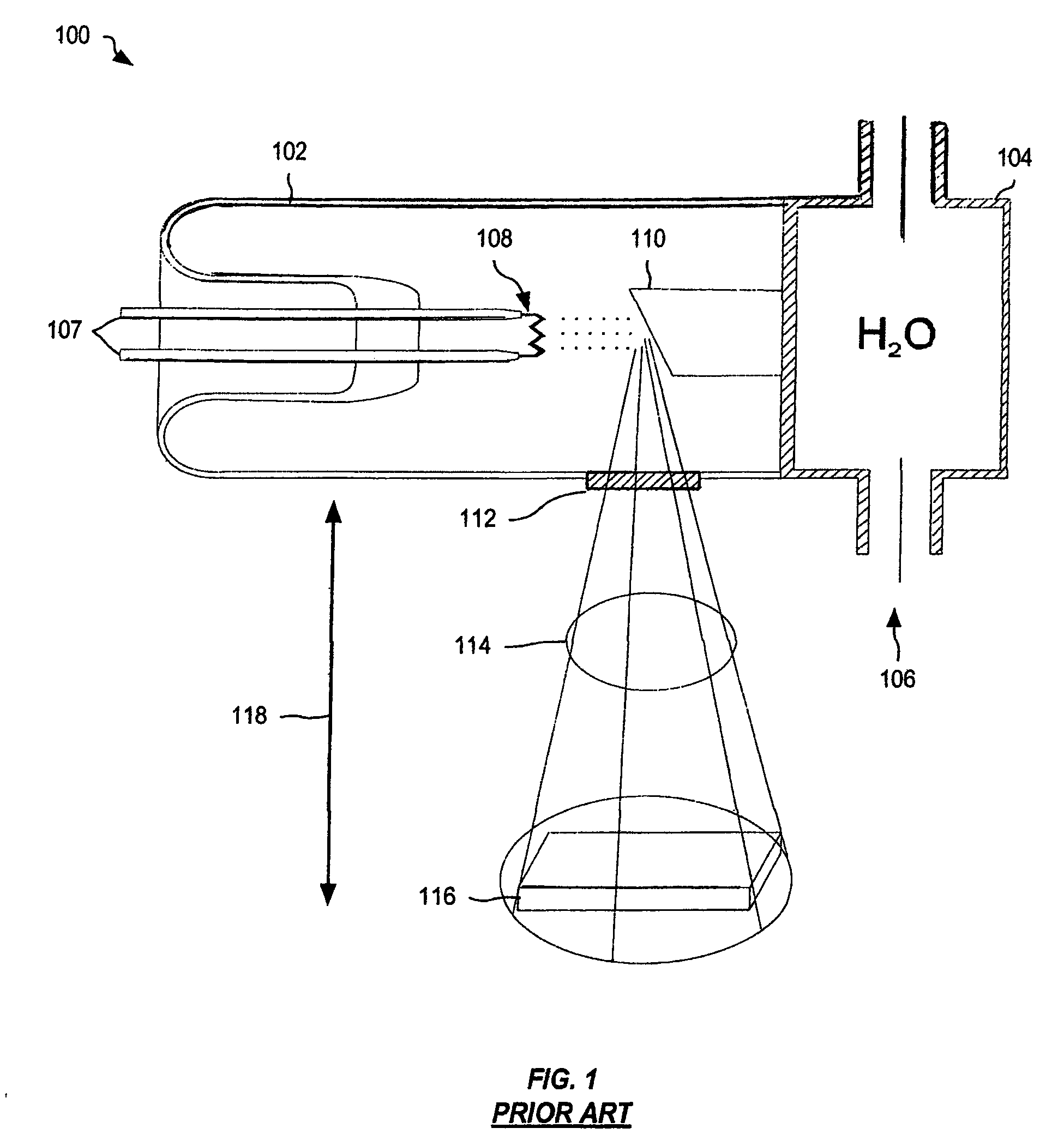

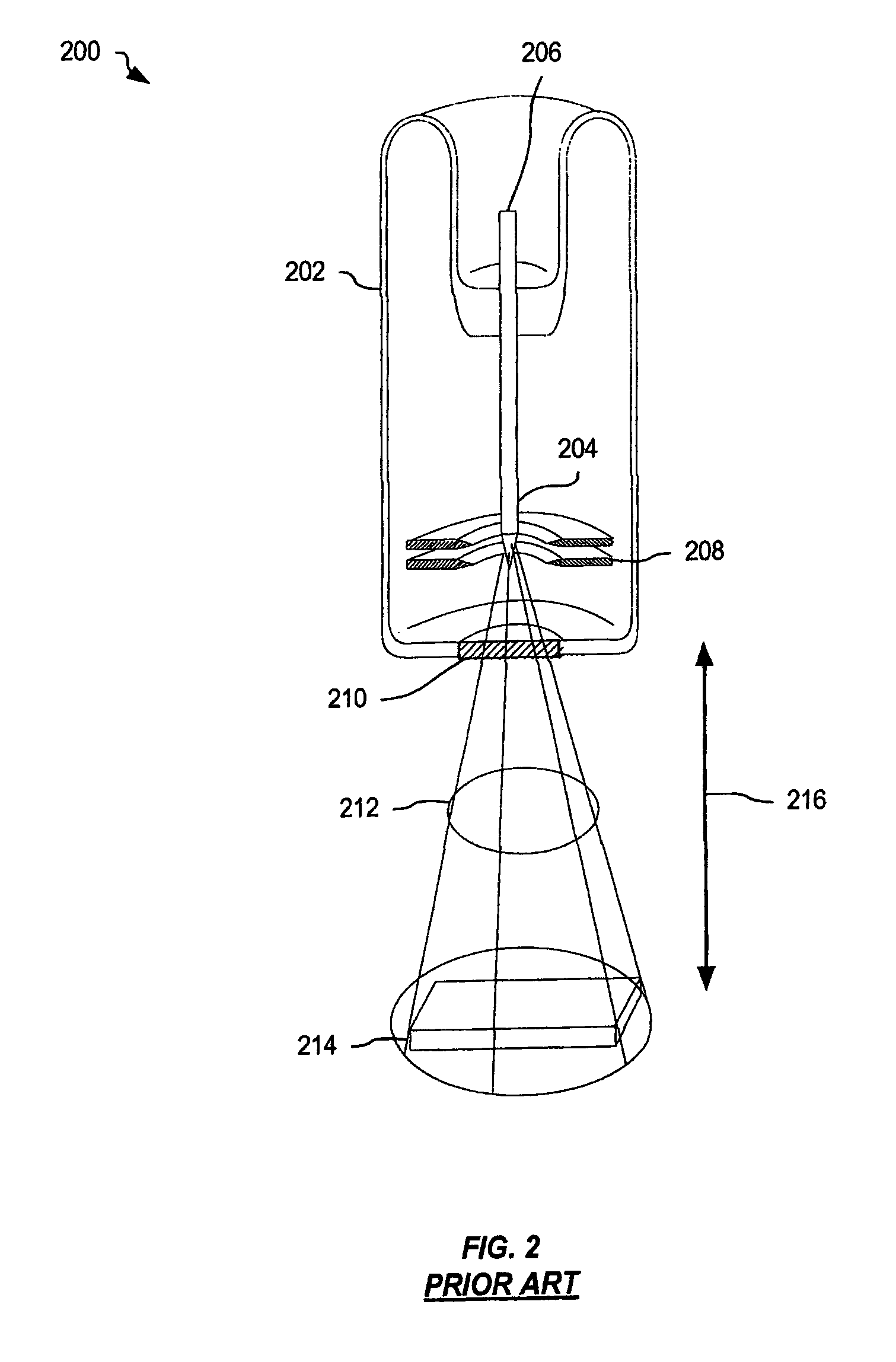

X-ray system for irradiating material used in transfusions

InactiveUS7706506B1Improve uniformityReduce necessityRadiation/particle handlingX-ray tube anode coolingShaped beamHigh energy

A system for irradiating material used in transfusions. The material can be pre-transfused blood, blood components and marrow. The system includes a vacuum chamber with a plate cathode inside. The cathode has a large beam electrode field-electron emissive surface with a selected cross-sectional shaped area. A power supply is connected to the cathode for generating negative high-voltage pulses and causing a selected cross-sectional shaped beam of electrons to be emitted. An electron window is also disposed inside the vacuum chamber and made of thin metal foil. The electron window receives the selected cross-sectional shaped beam of electrons therethrough and onto an electron target disposed outside the vacuum chamber. The electron target receives the selected cross-sectional shaped beam of electrons thereon and generates a selected cross-sectional shaped X-ray beam. A cathode filter is disposed next to the electron target and eliminates low energy beams from the spectrum of the X-ray beam. The filtered X-ray beam exposes the material to high energy beams for irradiation.

Owner:APPLIED X RAD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com