Nanofocus X-ray tube

An X-ray tube and X-ray technology, which is applied in the field of nano-focused X-ray tubes, can solve the problems of high equipment costs, large installations, and high costs, and achieve the effects of increasing service life, reducing equipment costs, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

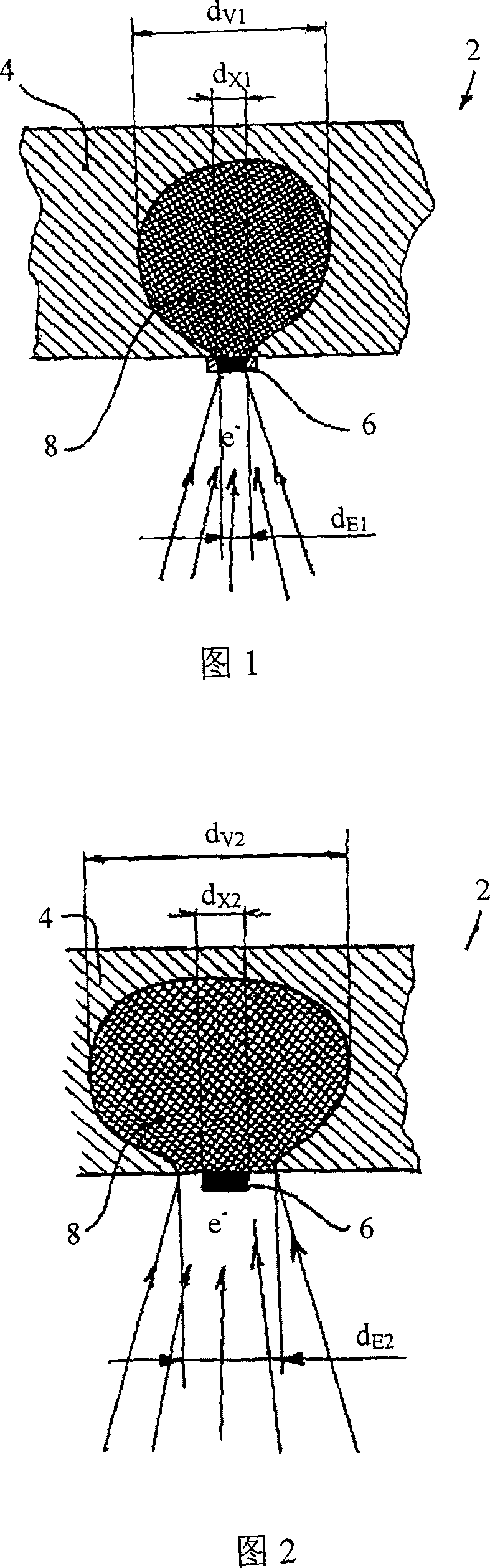

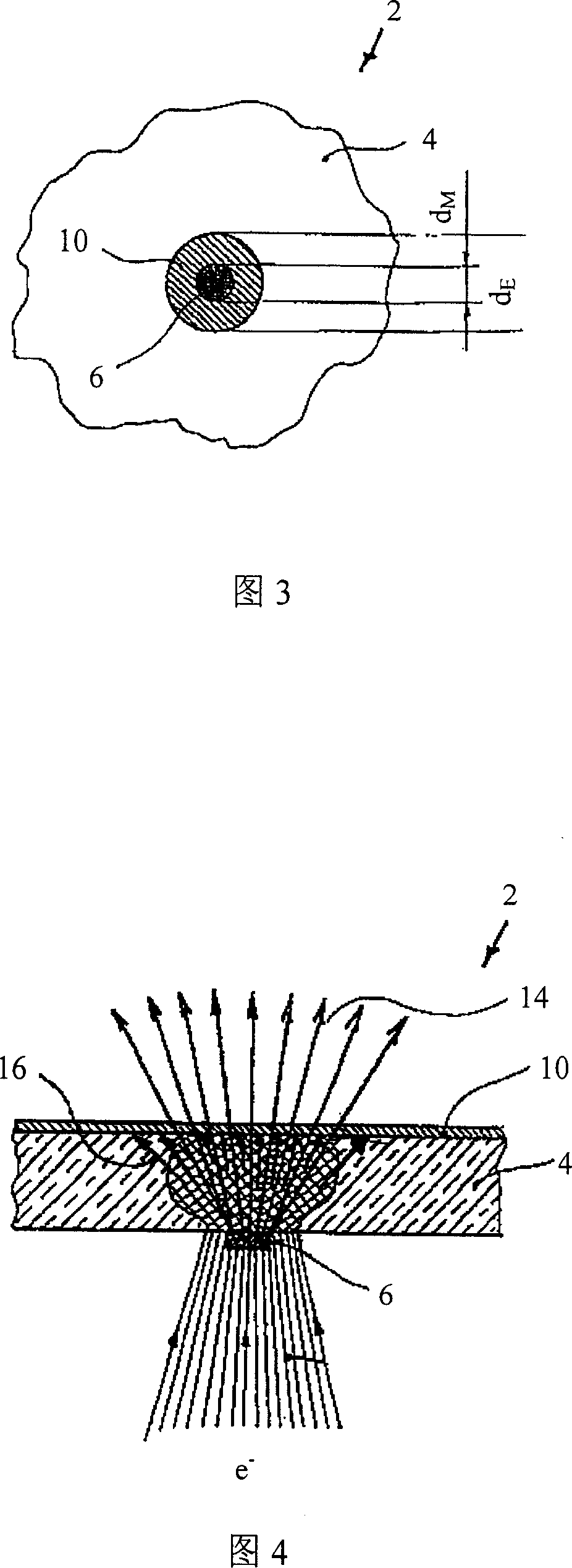

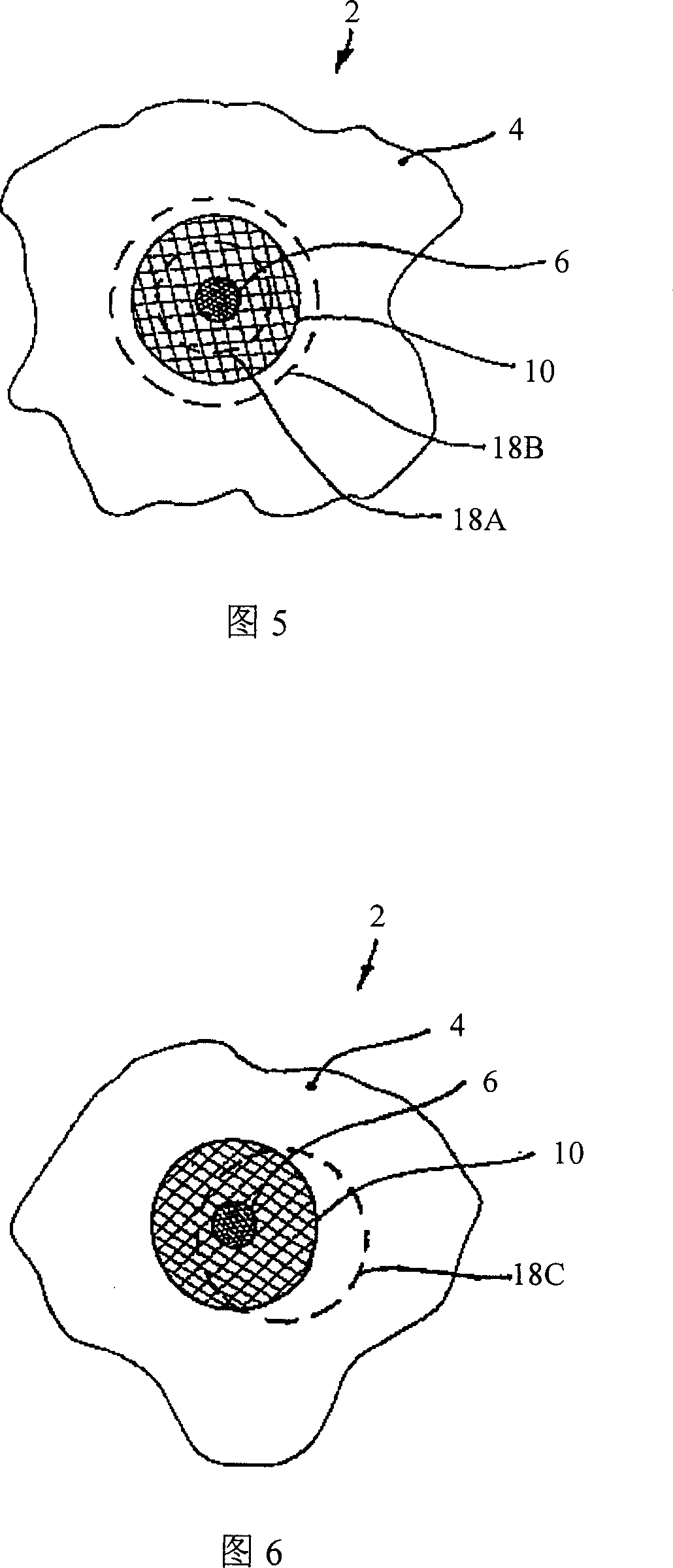

[0038] 1 shows a first embodiment of an object 2 for a nanofocus X-ray tube according to the invention, which object 2 is provided with a carrier element 4 and in this embodiment is provided with a The target element 6 on the carrier element 4, which consists of a target material, is used to emit x-rays. The carrier element 4 basically consists of a carrier material with a lower density and higher thermal conductivity, ie diamond, whose thermal conductivity is ≧20 W / (cm×K).

[0039] According to the present invention, the diamond used as the carrier material has improved electrical conductivity, and metal ions are added in this embodiment. As a result, the carrier material is made electrically conductive by the dosing, charges can be discharged from the carrier element 4 , and charging of the carrier element 4 and the object 2 is avoided.

[0040] The target element 6 consists of a material with relatively high density, in this embodiment tungsten. When shot with charged par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com