Chamber components for processing chambers and methods of making articles

A technology for processing chambers and chambers, which is applied in the field of chamber process rings, and can solve the problems of deposition chamber yield reduction, particle defects, and process shifts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

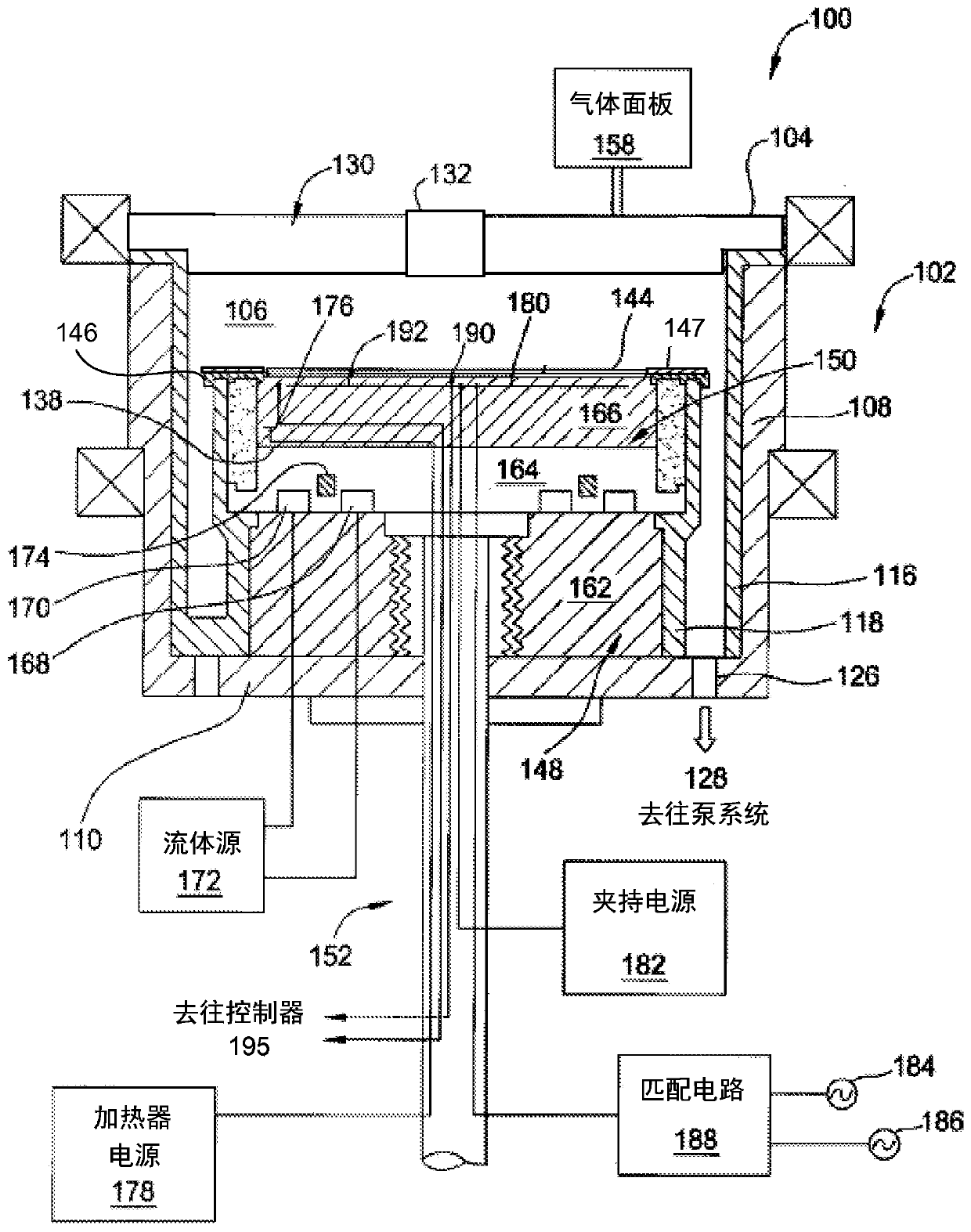

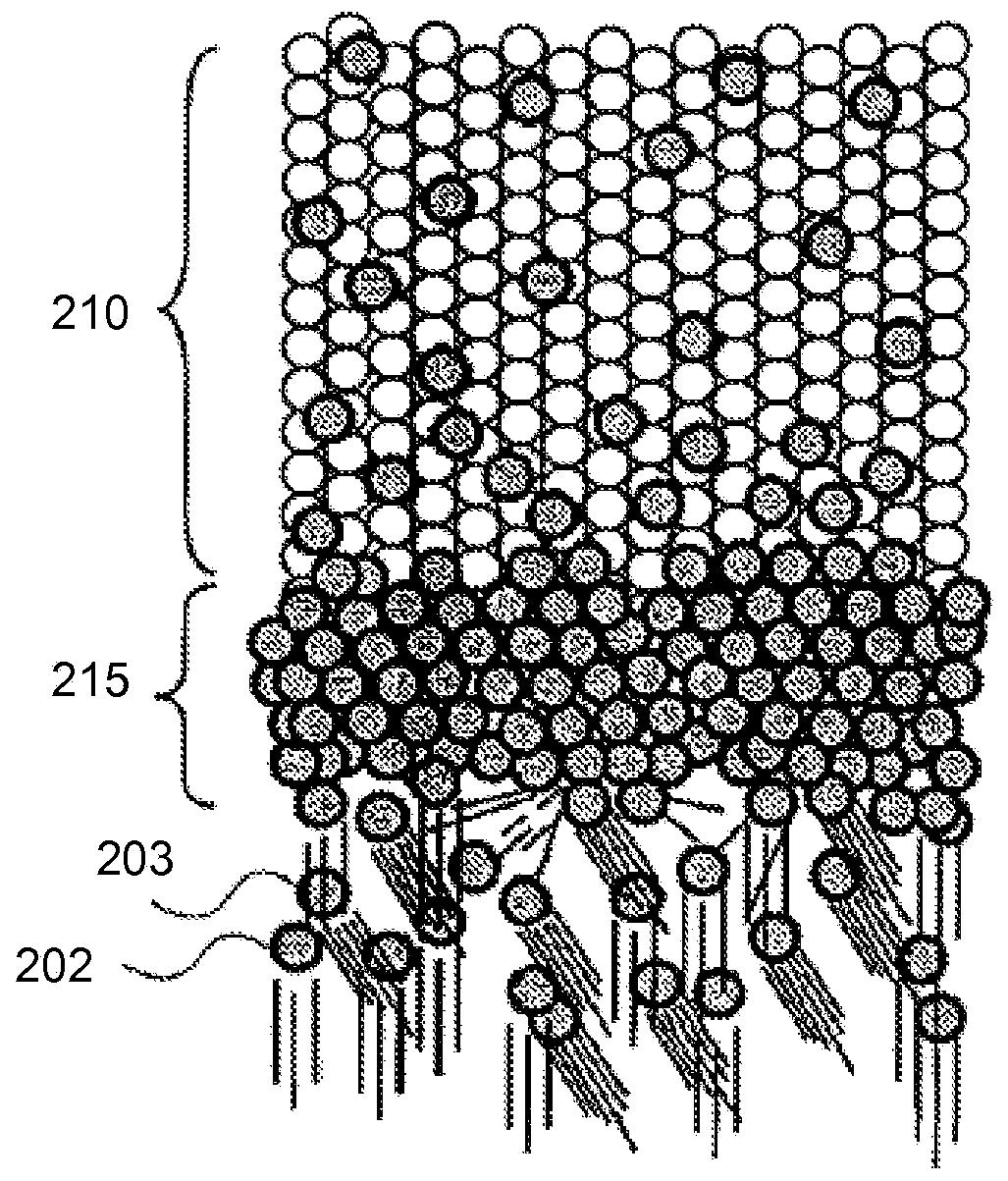

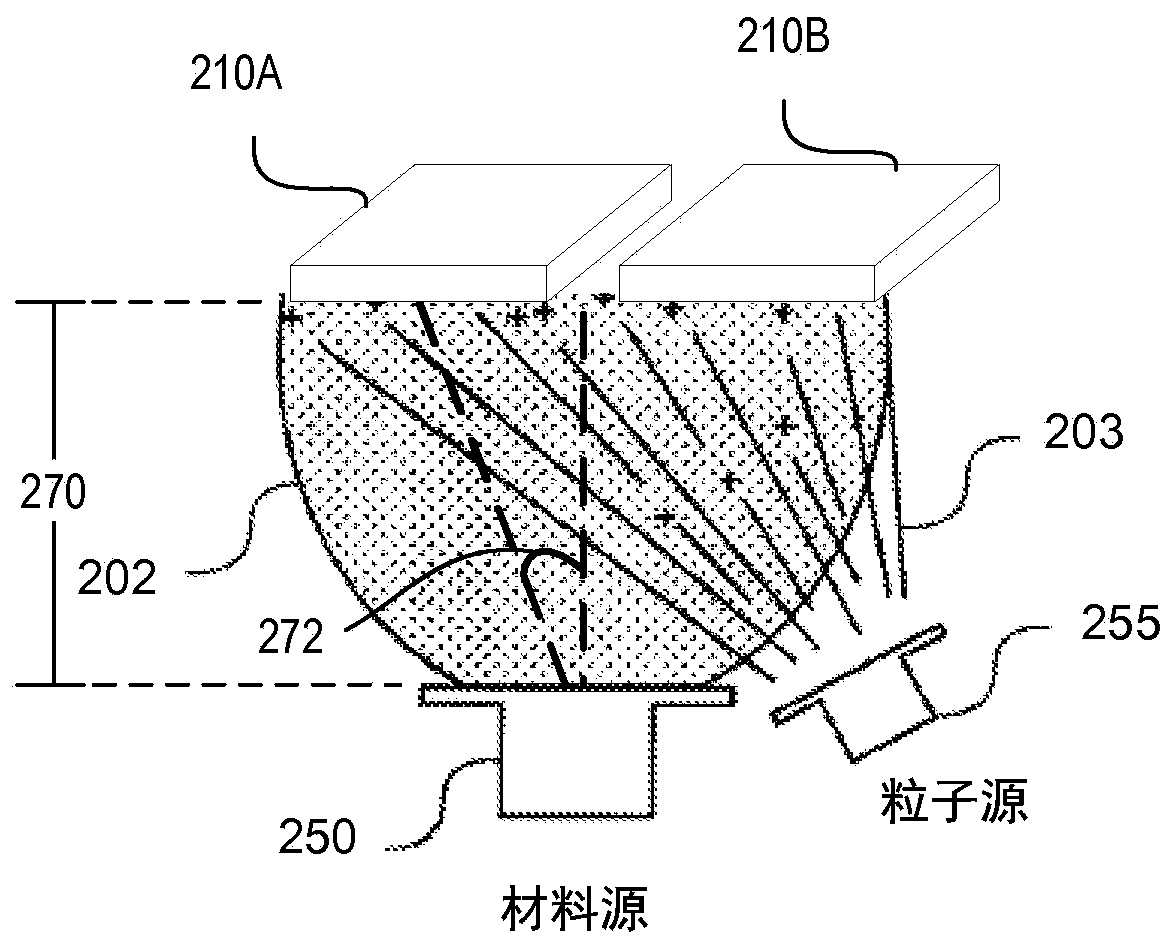

[0018] Embodiments of the present invention provide an article, such as a ring, with a corrosion-resistant thin film protective layer to enhance the useful life of the ring and reduce on-wafer defects without affecting plasma uniformity. The protective layer can have a thickness of up to about 300 microns and can provide plasma corrosion resistance for protecting the ring. The protective layer can be formed on the ring using ion assisted deposition (IAD), for example, using electron beam IAD (EB-IAD). The thin film protective layer can be Y 3 al 5 o 12 (YAG), Y 4 al 2 o 9 (YAM), Er 2 o 3 、Gd 2 o 3 、Er 3 al 5 o 12 (EAG), Gd 3 al 5 o 12 (GAG), including Y 4 al 2 o 9 with Y 2 o 3 -ZrO 2 A solid solution ceramic compound or another rare earth oxide. The improved corrosion resistance provided by the thin film protective layer improves the useful life of the ring while reducing maintenance and manufacturing costs. Furthermore, a sufficiently thick IAD coating c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com