Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about "PCB positioning during processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

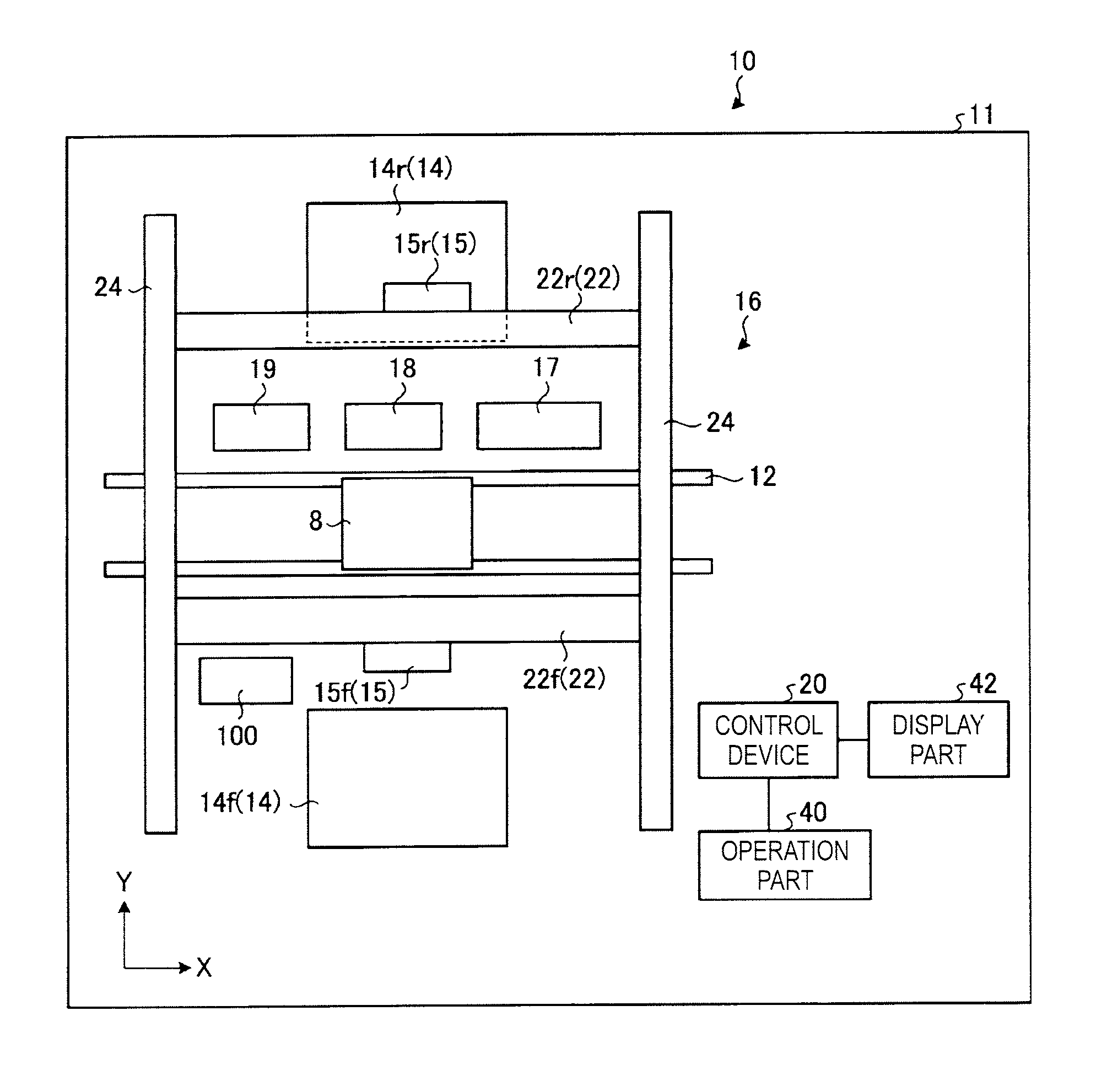

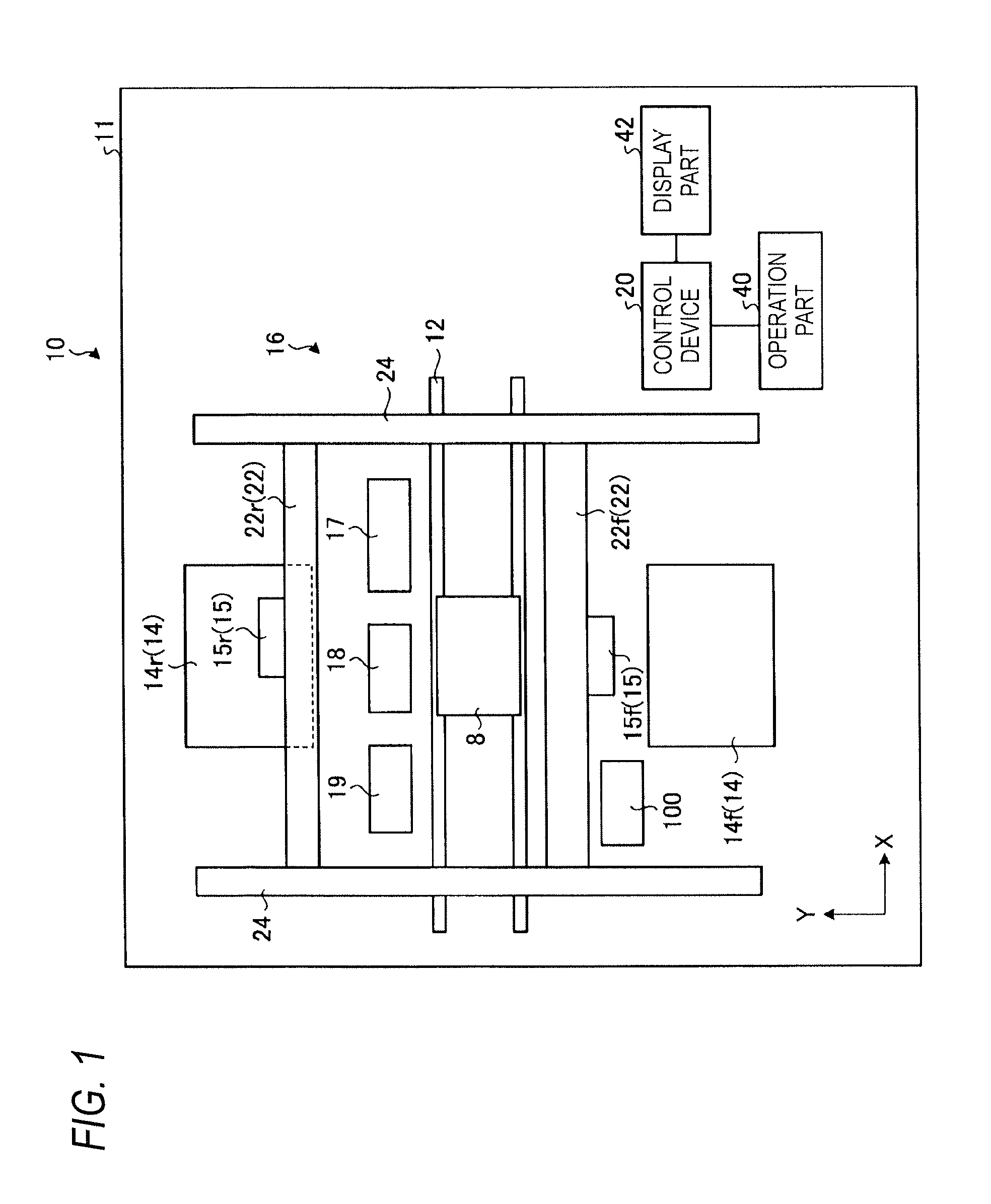

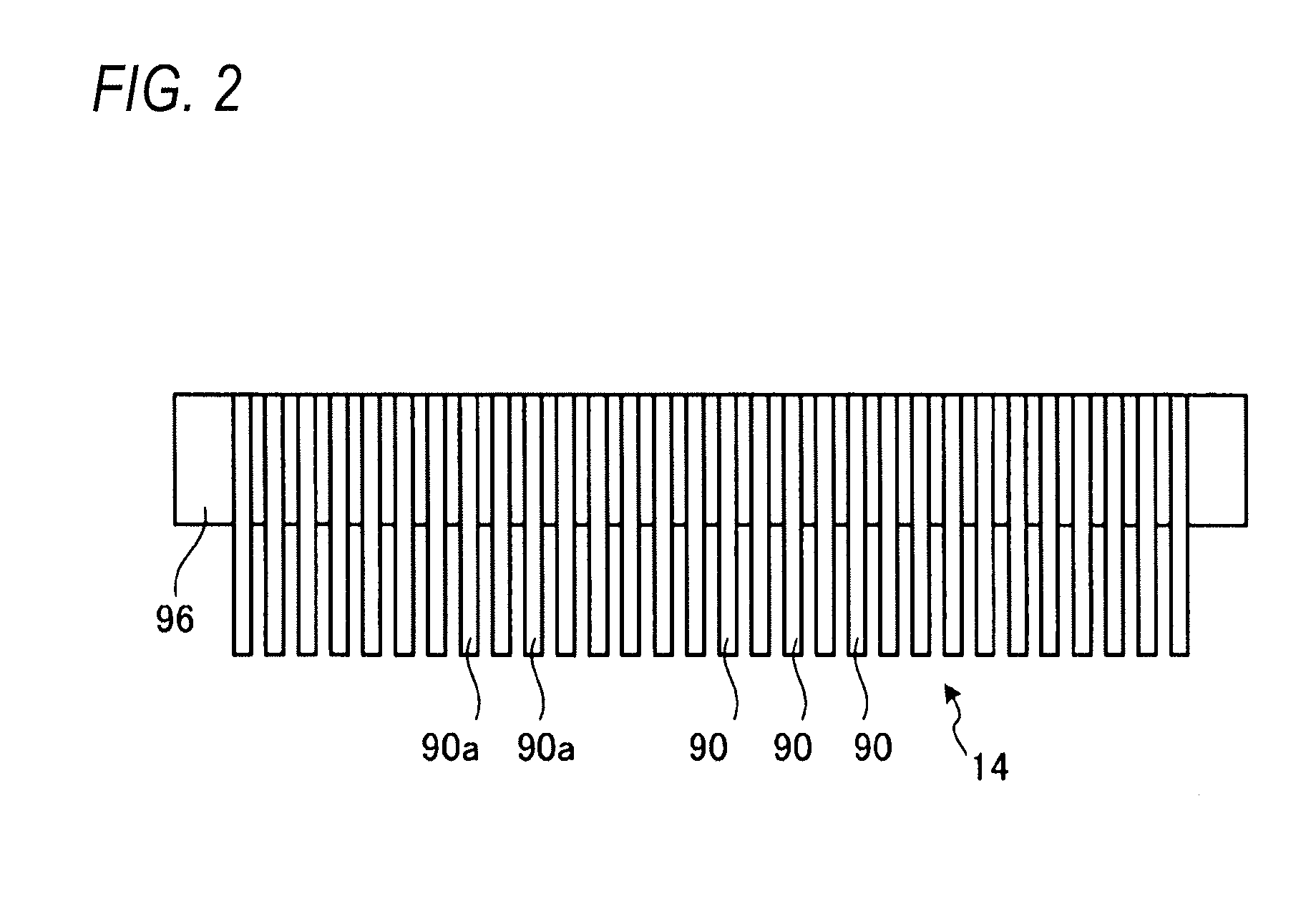

Electronic component mounting apparatus and electronic component mounting method

ActiveUS20150245549A1Efficient processingComponent to shortWelding/cutting auxillary devicesPCB positioning during processingEngineeringElectronic component

An electronic component mounting apparatus includes an electronic component supply device for supplying an electronic component, a head including a head main body and a head camera unit, and a control device. The head main body includes nozzles, a nozzle drive unit for driving the nozzles and a head support body for supporting the nozzles and the nozzle drive unit. The head camera unit is fixed to the head support body and has head cameras corresponding to the nozzles respectively for photographing electronic components. The head drives the nozzles to hold the electronic components, transfers the electronic components from the electronic component supply device to the substrate and mounts the electronic components onto the substrate. The control device synthesizes images photographed by the head cameras to generate an image with fields of the head cameras connected together, and determines a process based on the synthesized image synthesized.

Owner:JUKI CORP

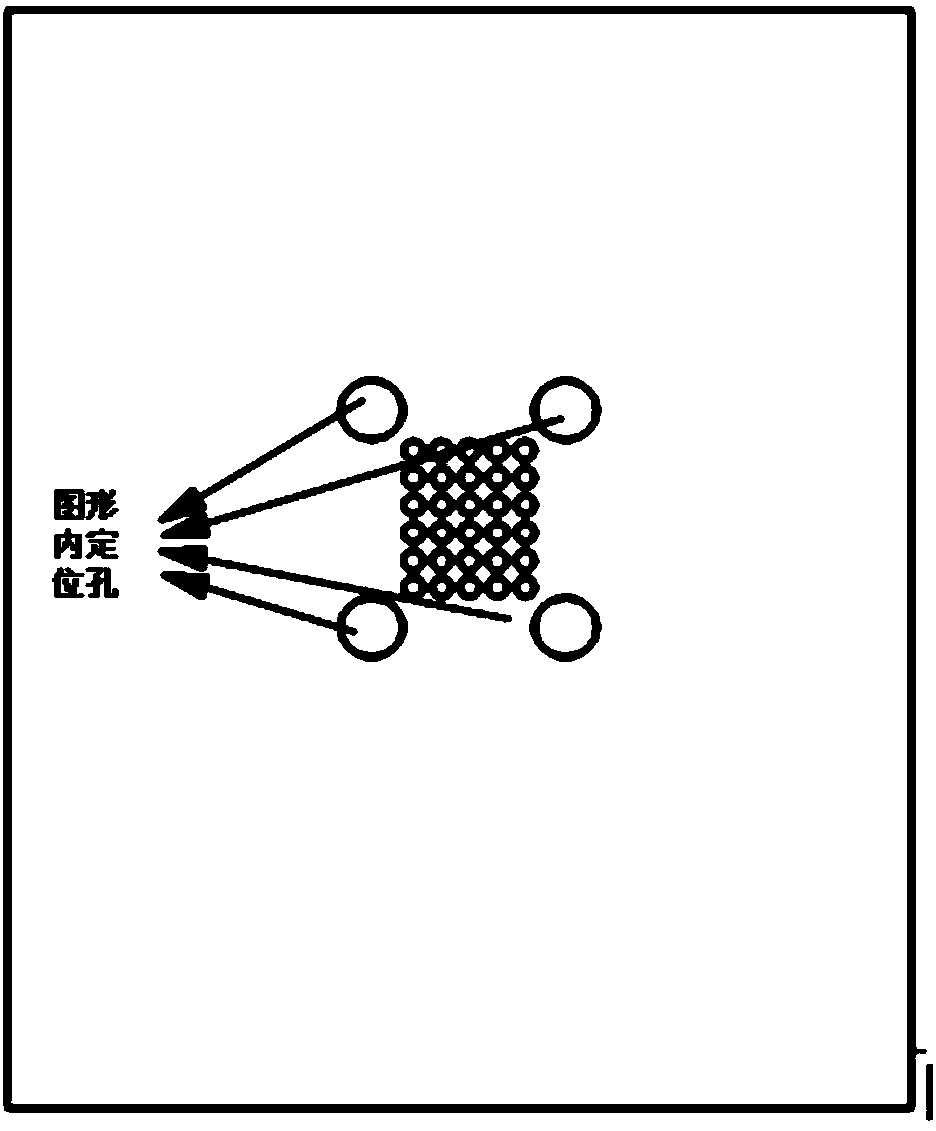

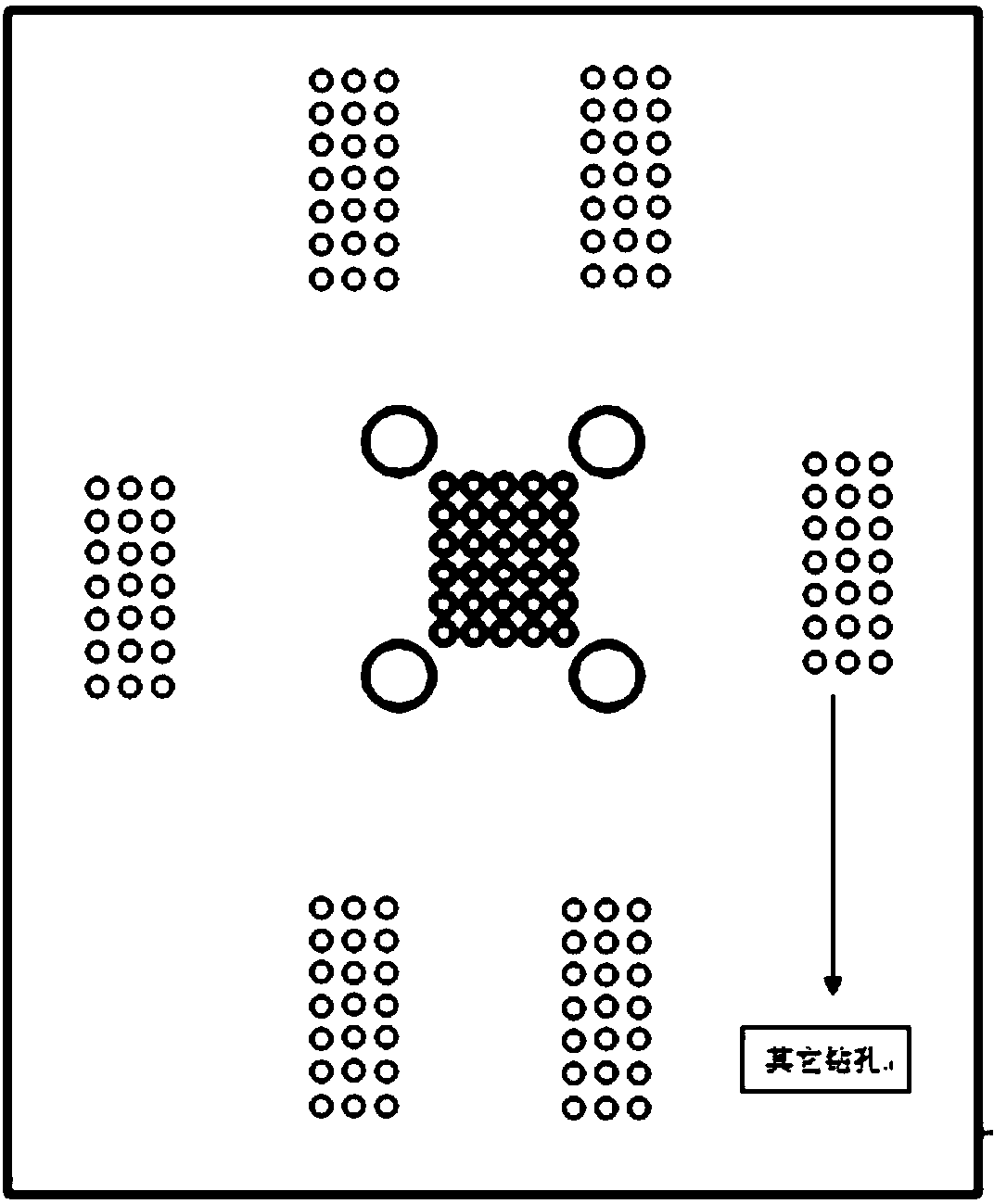

Local high-precision printed circuit board and manufacturing method thereof

ActiveCN104270889AImprove drilling alignment accuracyReduce the scrap rate of drilling deviationPCB positioning during processingElectrical connection printed elementsEngineeringPrinted circuit board

The invention discloses a local high-precision printed circuit board and a manufacturing method thereof. The whole printed circuit board is divided into a high-precision graphic area and a common graphic area. The manufacturing method comprises the steps of inner-layer graph manufacturing, press-fitting, drilling, outer-layer film drying and follow-up procedures. According to the press-fitting step, the Pin-Lam technology is adopted for conducting manufacturing; after the press-fitting step is executed, a graphic inner positioning hole is punched, so that a local expansion coefficient of the high-precision graphic area is calculated. According to the drilling step, a local drilling file is set according to the local expansion coefficient, meanwhile, an LDI datum hole is formed, drilling is carried out on the high-precision graphic area, and the datum hole is drilled; then drilling is carried out on the common graphic area through the whole board expansion coefficient. According to the outer-layer film drying step, the LDI technology is adopted. According to the manufacturing method, the drilling alignment precision of the local high-precision printed circuit board can be effectively improved, highly-difficult drilling can be carried out, the drilling misregistration scrap rate is greatly reduced, and the process is simple.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

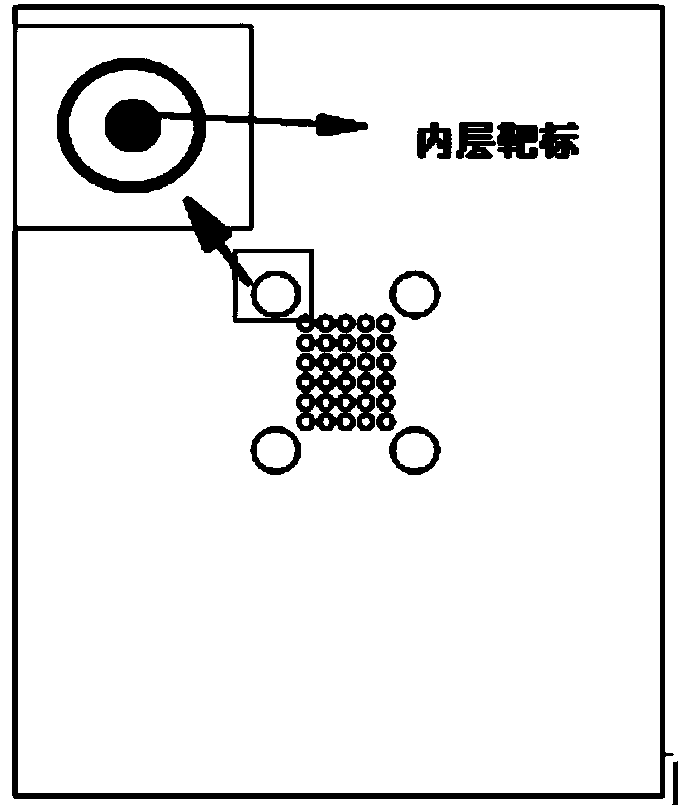

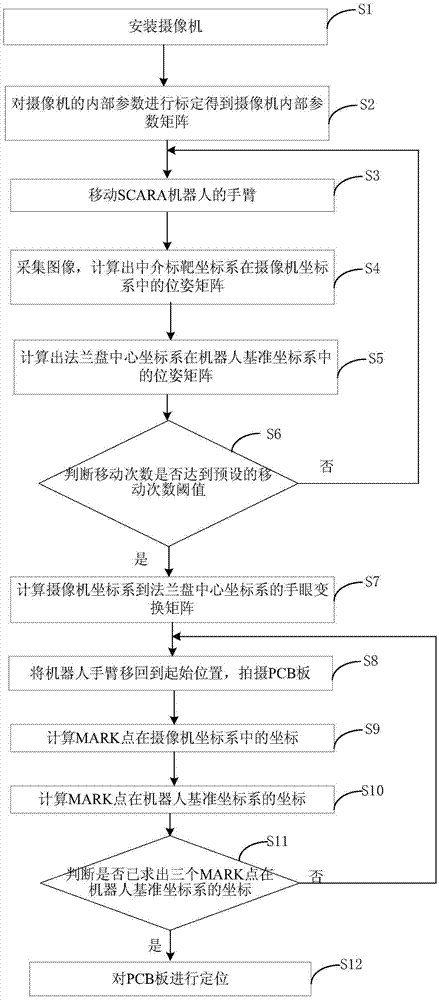

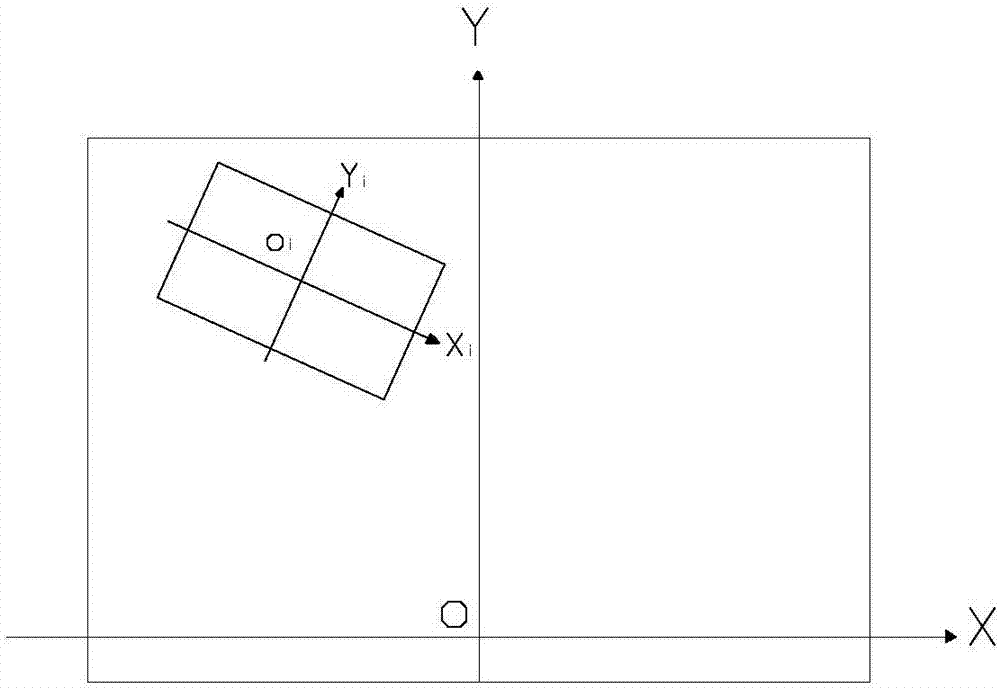

PCB board positioning method based on SCARA robot

ActiveCN105451461ARealize high-precision positioningPrinted circuit assemblingPCB positioning during processingEngineeringFlange

The invention relates to the high precision assembling and measurement field, and provides a PCB board positioning method based on an SCARA robot. The PCB board positioning method comprises steps of installing a camera, moving an arm of the SCARA robot, collecting an image, calculating an attitude array of an intermediary agent target coordinate system in a camera coordinate system and an attitude array of a flange coordinate system in a robot standard coordinate system, calculating a hand-eye switching array from the camera coordinate system to the flange center coordinate system, calculating the coordinates of three MARK points in the robot standard coordinate system and positioning the PCB board through the coordinate. The technical scheme provided by the invention realizes the high precision positioning of the PCB board without any auxiliary device, is widely applicable to the assembling of the robot, visual measurement and positioning and visual servo.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Fabrication method of rigid-flex board for preventing gold finger of flexible board from deviation

ActiveCN105407658AAvoid misalignmentGuaranteed dimensional accuracyPCB positioning during processingMultilayer circuit manufactureLaser cuttingEngineering

The invention discloses a fabrication method of a rigid-flex board for preventing a gold finger of a flexible board from deviation. The fabrication method comprises the following steps of S1, carrying out cutting; S2, fabricating an inner-layer pattern, and fabricating a positioning pattern on a waste region at the side edge of a top end of a gold finger region on a flexible board at an inner layer, wherein the positioning pattern comprises three positioning points; S3, coating and laminating a protection membrane on a region, needed to be protected, of the flexible board at the inner layer; S4, carrying out laser cutting, respectively cutting positioning grooves at the two ends of the gold finger by the positioning pattern, and making the two ends of the gold finger to be directly formed; and S5, laminating the inner layer and an outer layer. According to the method disclosed by the invention, the inner-layer pattern is fabricated and the positioning pattern is simultaneously fabricated on the waste region at the side edge of the top end of the gold finger region, the two positioning grooves are cut at each of the two sides of the gold finger by positioning of the positioning pattern during the laser cutting process, the gold finger is then directly formed, so that the gold finger of the flexible board at the inner layer is already subjected to shape fabrication before lamination, the size precision of the gold finger is ensured, and the deviation of the gold finger is prevented.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

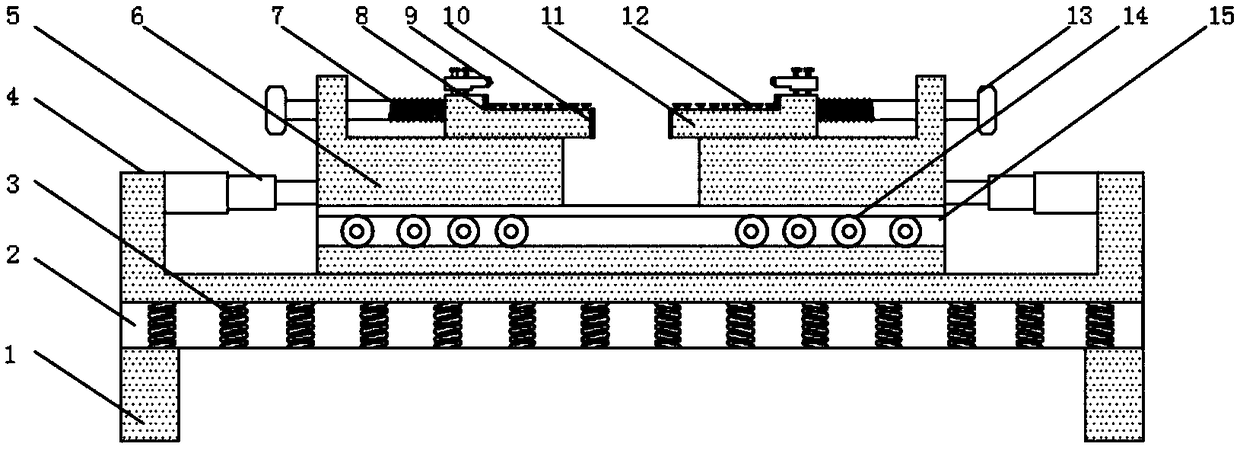

Automatic clamping and positioning device for PCB

InactiveCN108811342AHigh degree of freedom of adjustmentHigh precisionPCB positioning during processingCircuit board tools positioningEngineeringPulley

The invention discloses an automatic clamping and positioning device for a PCB. The automatic clamping and positioning device comprises a U-shaped base and a sliding block. A damping layer is arrangedat the surface of the bottom of the U-shaped base; and a damping spring is arranged inside the damping layer. Telescopic rods are arranged at the surfaces of the sides of the U-shaped base; a slidingblock is arranged at one end of each telescopic rod in a pushing manner; a sliding rail is arranged at the bottom of the sliding block; and sliding pulleys are arranged at one side of the sliding block inside the sliding rail in a sliding manner. According to the invention, the telescopic rods arranged at the two sides of the U-shaped base push the sliding blocks to slide in the sliding rail; andclamping blocks are driven by the sliding blocks to clamp and fix a PCB. Moreover, infrared on-off calibration sensors are used for carrying out automatic on-off calibration; if fine adjustment is needed, rotary knobs are adjusted to screw fine-adjustment screw rods to carry out fine adjustment, so that the adjustment freedom of the PCB is improved substantially and automatic clamping is realized; and the precision of PCB clamping is improved.

Owner:黄永锋

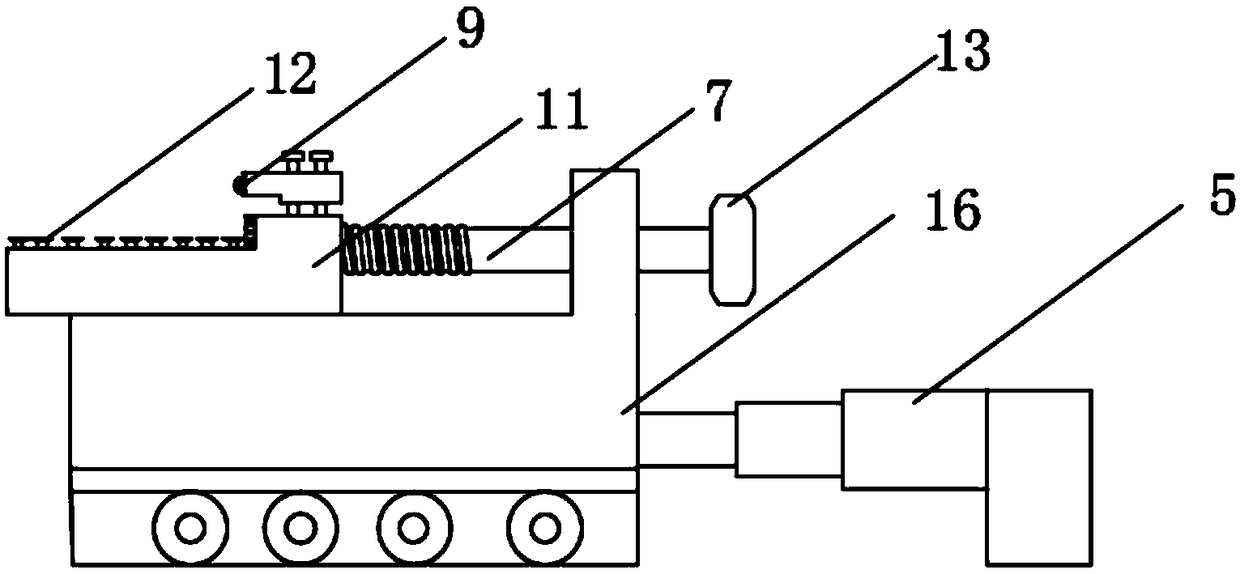

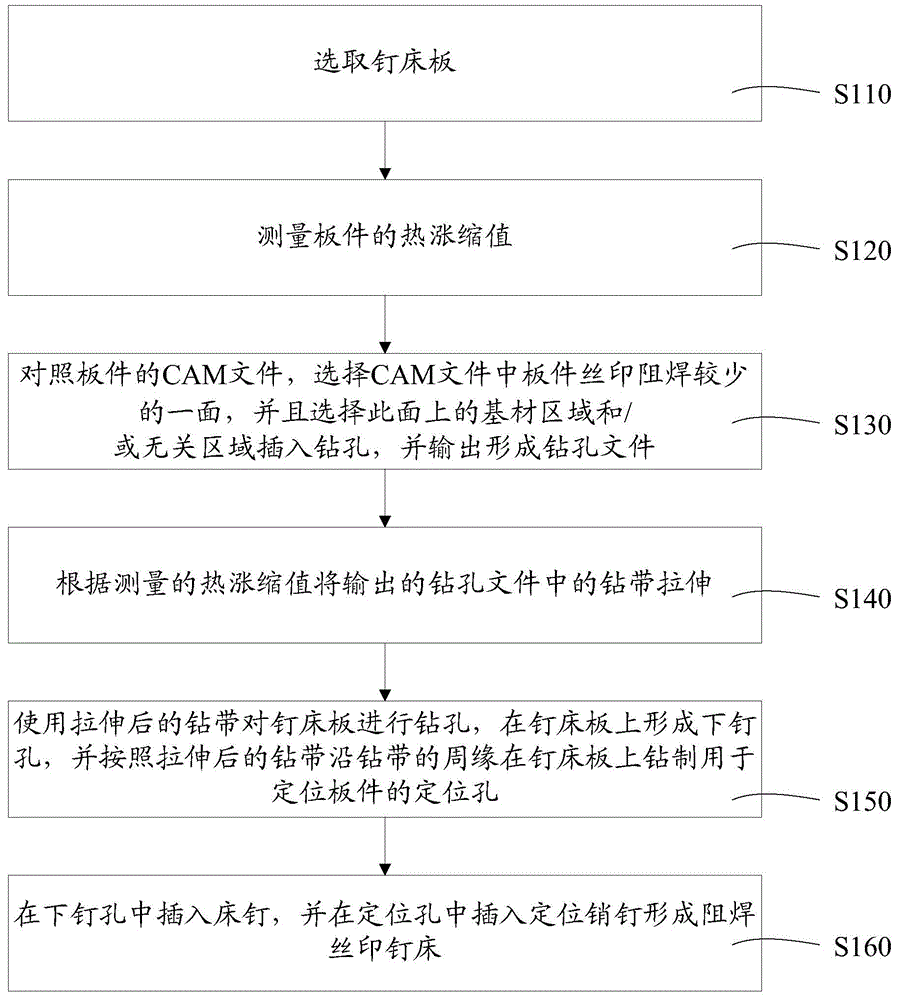

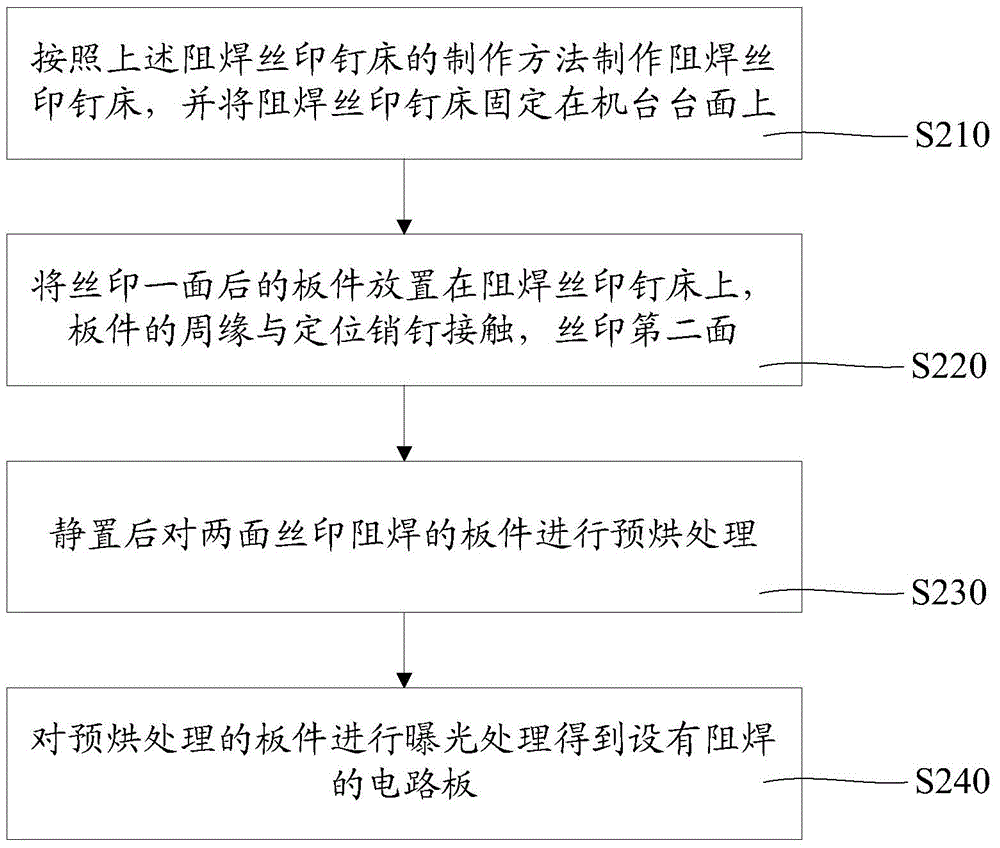

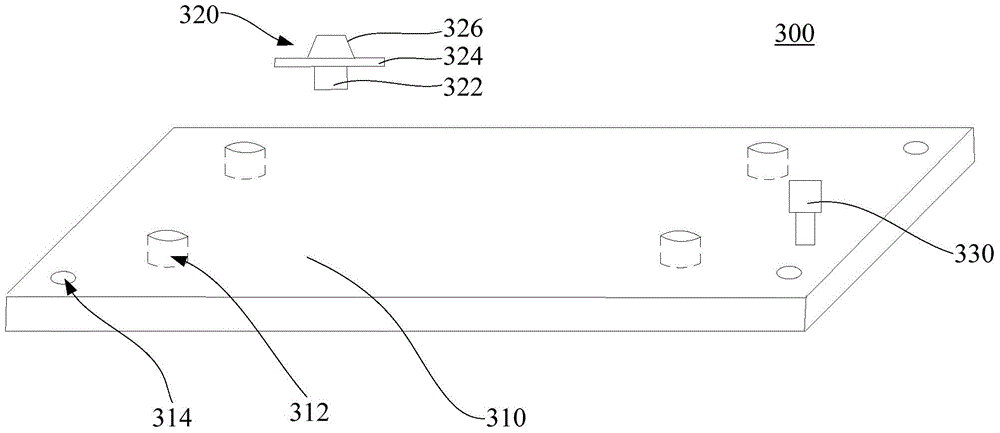

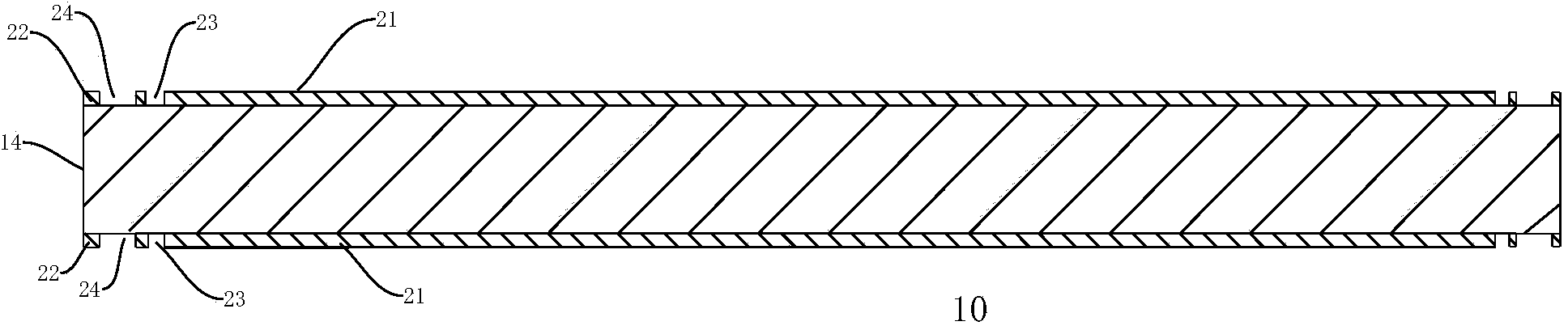

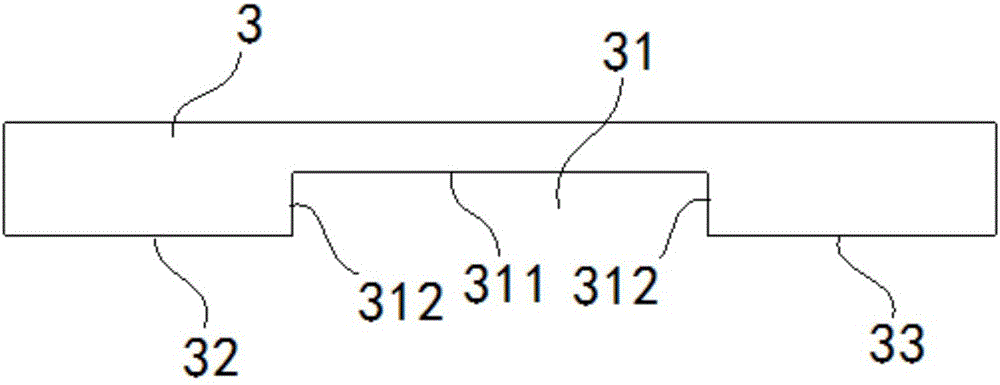

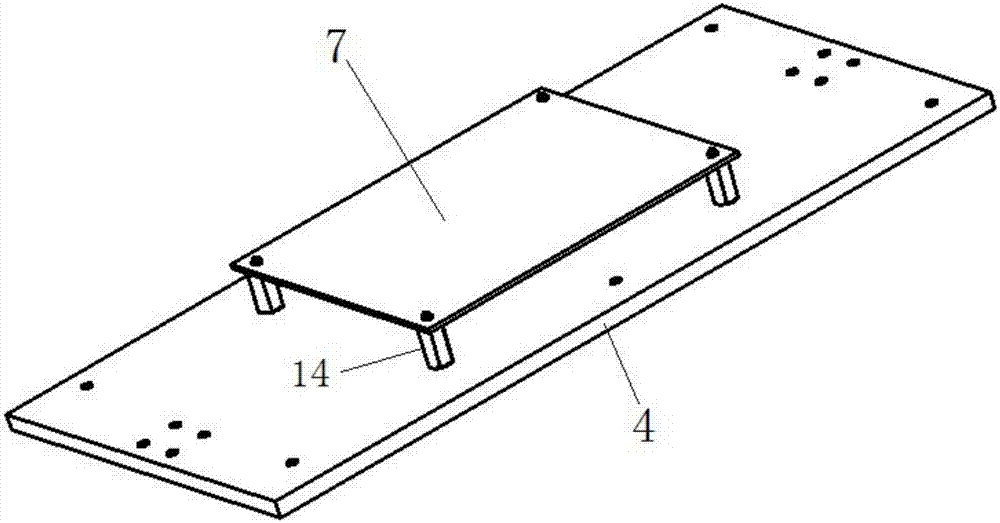

Manufacturing method and screen printing method of solder-masked and screen-printed nail bed and solder-masked and screen-printed nail bed

ActiveCN104363714APrevent top injuryAccurate placementScreen printersPCB positioning during processingScreen printingSolder mask

The invention relates to a manufacturing method and screen printing method of a solder-masked and screen-printed nail bed and the solder-masked and screen-printed nail bed. Nail distributing efficiency and nail distributing accuracy can be improved. According to the manufacturing method of the solder-masked and screen-printed nail bed, the nail distribution positions of the nail bed are obtained through CAM file manufacturing, a drill band is stretched and adjusted according to the heat expansion and contraction value of a plate to be screen-printed and solder-masked, and therefore the precision of the nail distribution positions is high. Through the method, operators can be prevented from mechanically looking for the nail distribution positions, efficiency is high, the situation that the nailing positions are wrong due to the fact that the experience of staff is insufficient can be avoided, and high operability is achieved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

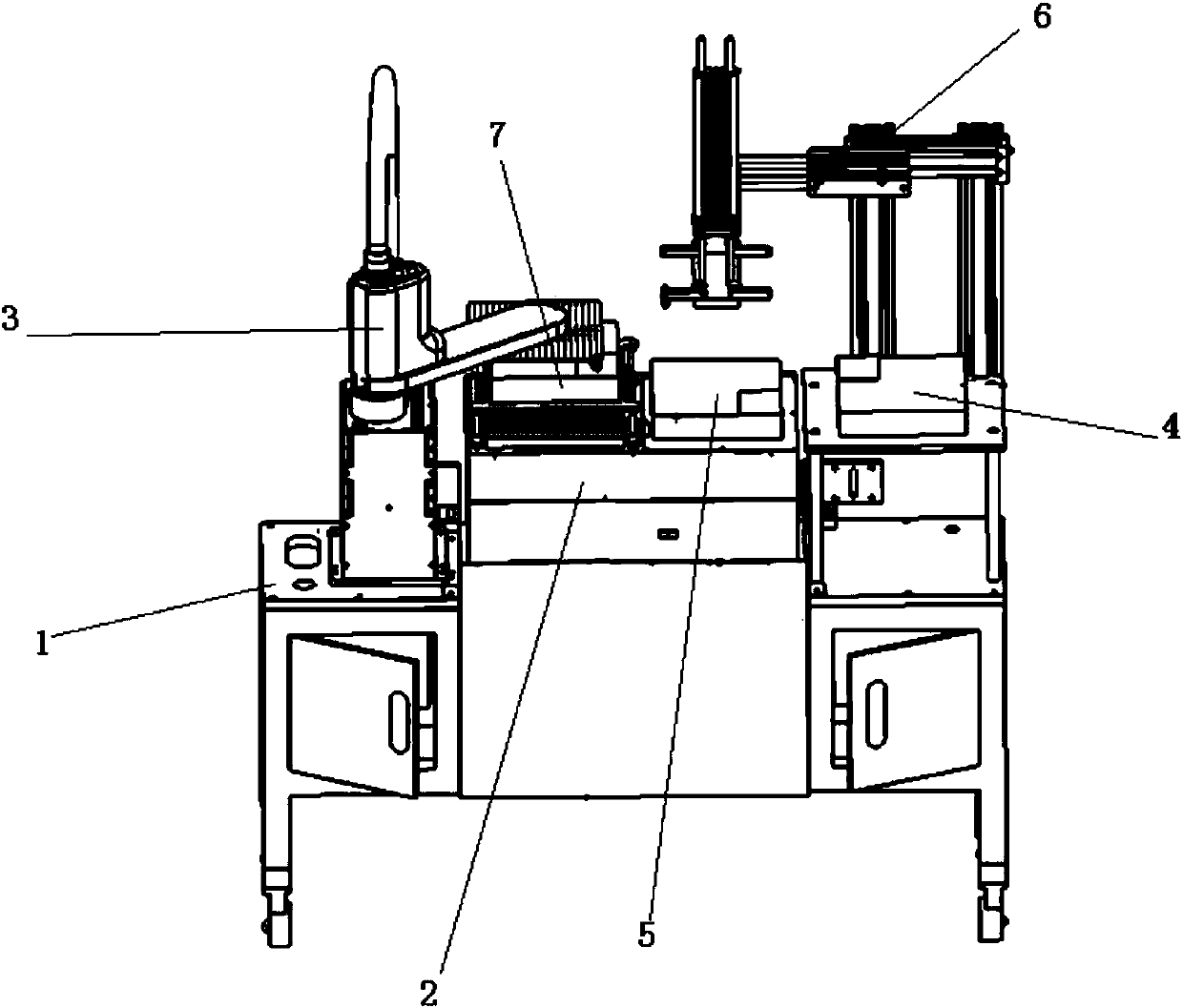

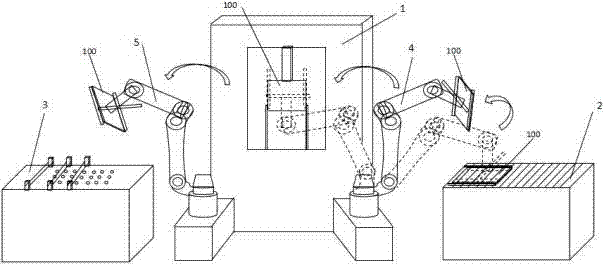

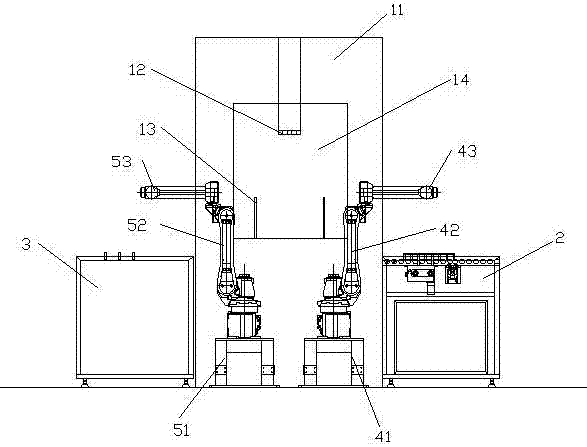

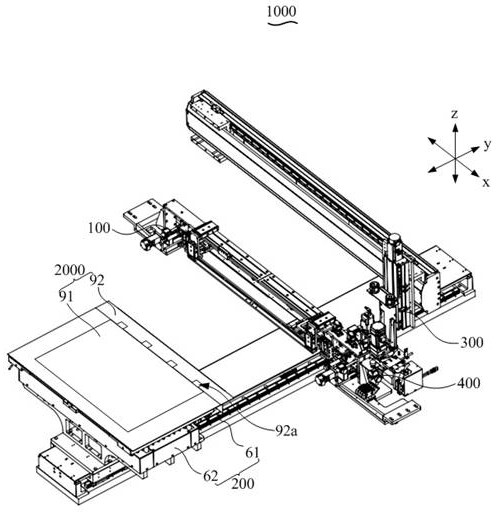

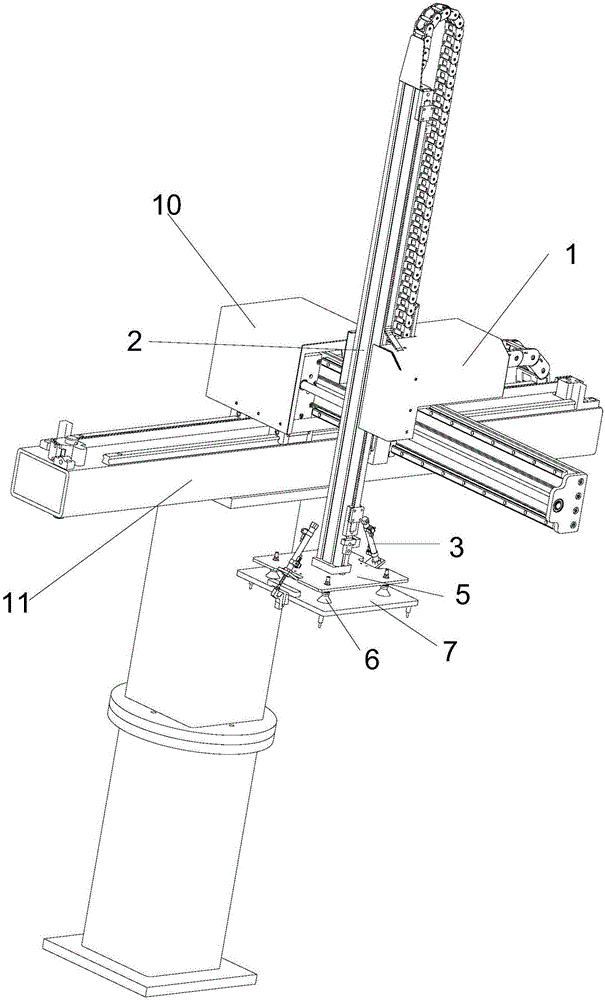

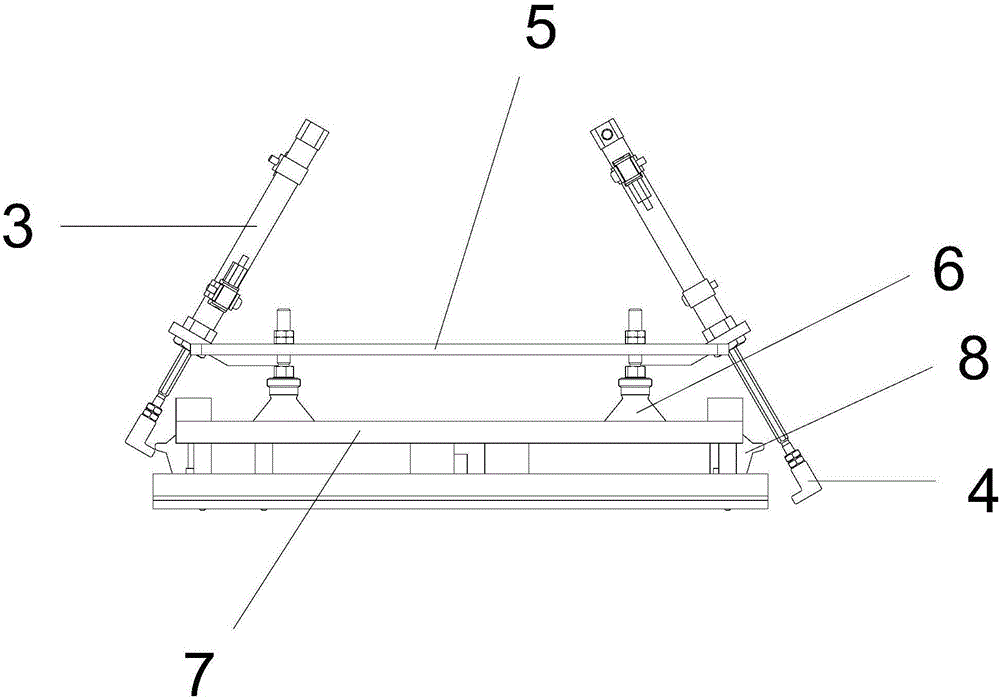

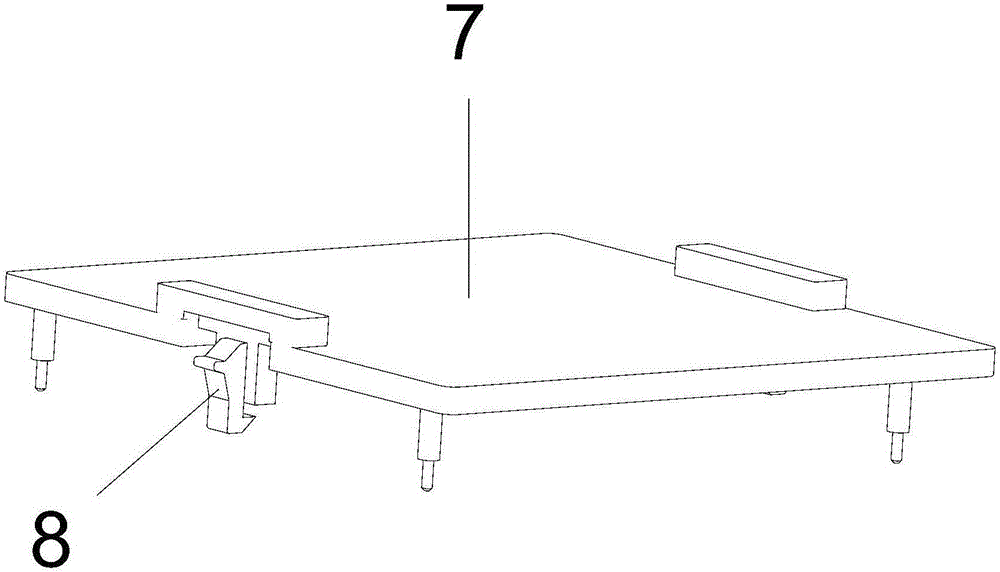

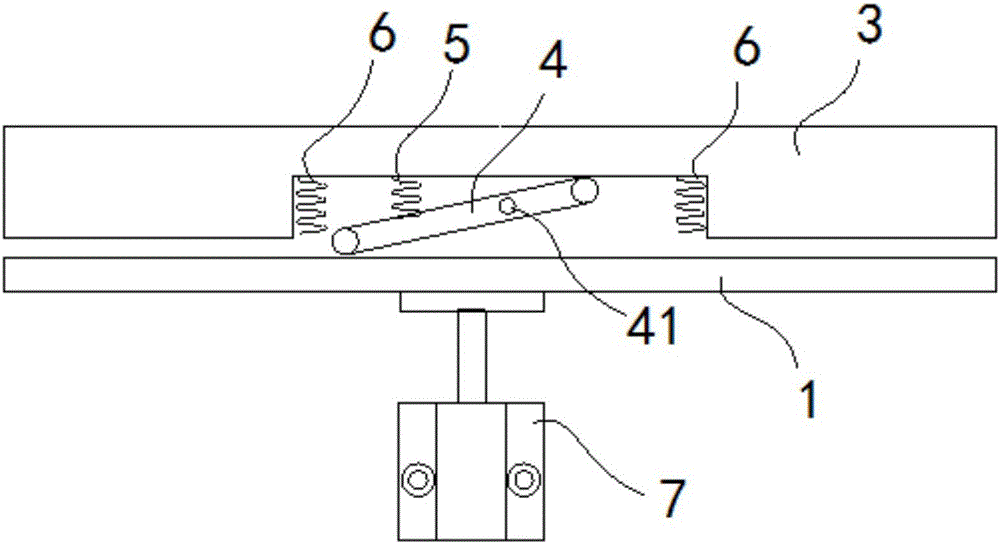

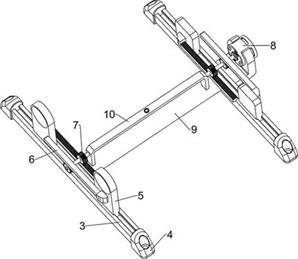

Single-arm robot stamping and carrying apparatus

ActiveCN107801307AGuaranteed positioning accuracyPerfect protection functionProgramme-controlled manipulatorLaminating printed circuit boardsStampingEngineering

The invention discloses a single-arm robot stamping and carrying apparatus. The single-arm robot stamping and carrying apparatus comprise a machine table; a linear lifting platform is arranged in themiddle part of the machine table; a liftable robot carrying apparatus is arranged at one end, positioned on the linear lifting platform, of the machine table; an isolation paper placement plate and anisolation paper carrying apparatus for carrying isolation paper to a finished product placement plate one by one are arranged at the other end, positioned on the linear lifting platform, of the machine table; the finished product placement plate is positioned on the linear lifting platform; and the linear lifting platform is also provided with a supplied material plate structure with a compensating and lifting function. The single-arm robot stamping and carrying apparatus is mainly specific to flexible FPC board stamping and carrying. The apparatus is a four-axis robot with a liftable base; the Z axis of the robot is positioned on the base, so that the robot can walk in the narrow space of upper and lower modules of a punch conveniently; a suction cup is arranged at the tail end of the robot, and a product protection function is added at the suction cup adsorption position; the suction cup is rotatable, so that a secondary stamping function of the symmetrical products can be realizedconveniently; and the four-axis robot with the liftable base is mainly used for material carrying.

Owner:东莞市本润机器人科技股份有限公司

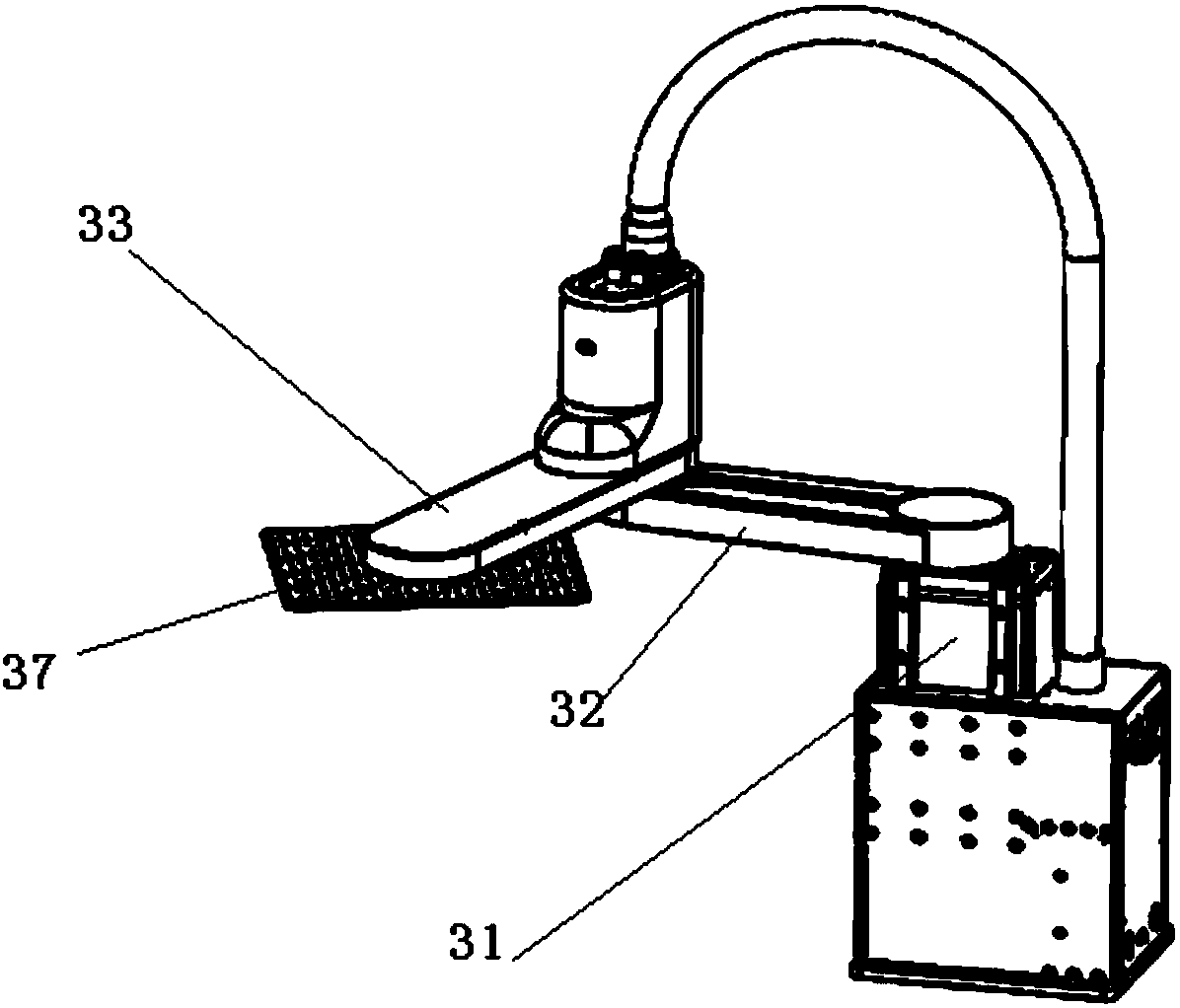

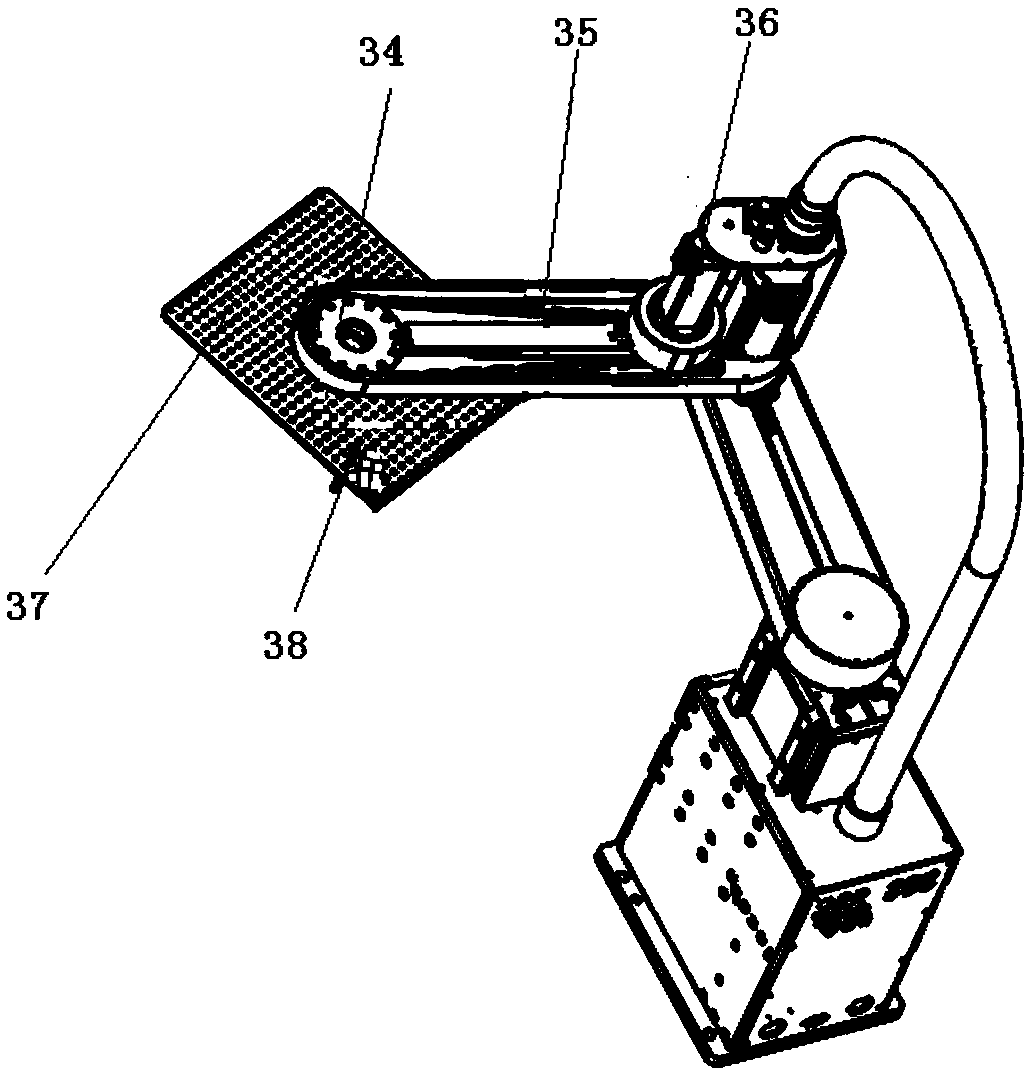

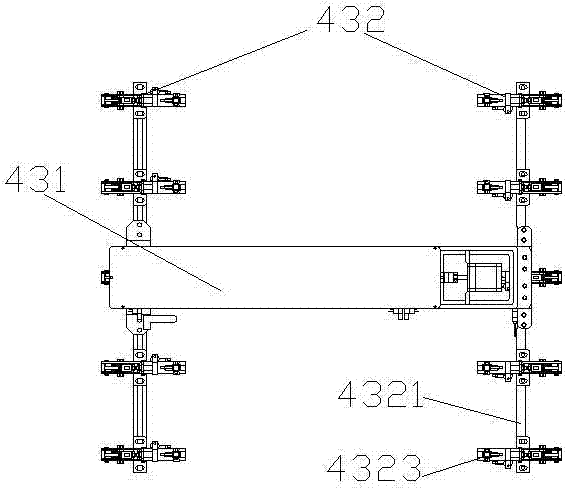

Automatic tin spraying device of PCB and control method thereof

PendingCN107509324AAvoid damageSave manual loadingPrinted circuit assemblingPCB positioning during processingEngineeringManipulator

The present invention discloses an automatic tin spraying device of a PCB and a control method thereof. The device comprises a tin spraying mechanism with an operation window, a pretreatment mechanism, a post-treatment mechanism and a manipulator mechanism; the pretreatment mechanism, the manipulator mechanism and the post-treatment mechanism are arranged in order along a horizontal direction, the tin spraying mechanism and the manipulator mechanism are arranged in order along a vertical direction, and the manipulator mechanism is located in front of the tin spraying mechanism; and the manipulator mechanism comprises a first manipulator configured to transfer a PCB from the pretreatment mechanism to the tin spraying mechanism and a second manipulator configured to transfer the PCB from the tin spraying mechanism to the post-treatment mechanism, the first manipulator and the second manipulator are located in front of the operation window and are in mirror image arrangement taking the tin spraying mechanism as a center. The manipulator mechanism is employed to realize automatic board put-on and put-down of the PCB in the tin spraying process so as to improve the production efficiency and reduce the damaging of the PCB caused by manual operation.

Owner:江西景旺精密电路有限公司

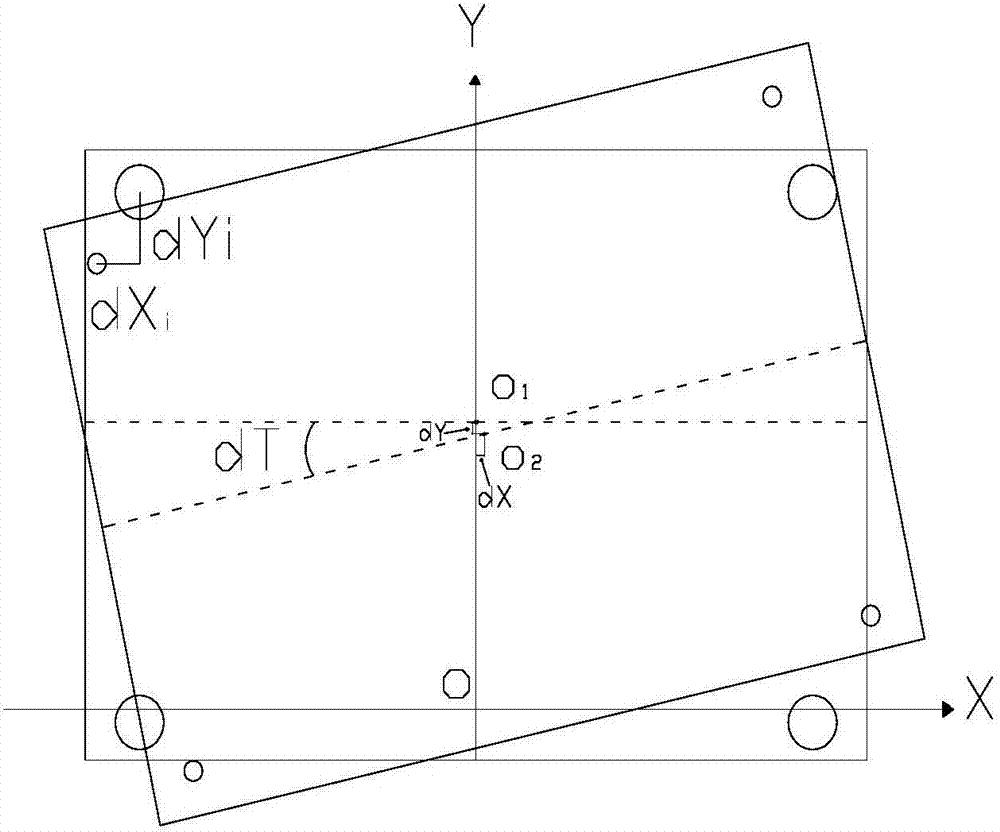

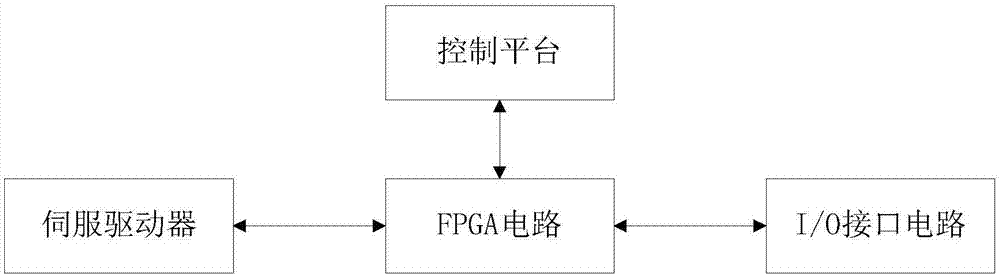

Three-axis positioning device and method based on machine vision

PendingCN107072047AAccurate acquisitionOvercome positioning errorPCB positioning during processingMachine visionControl engineering

The invention discloses a three-axis positioning device and method based on machine vision, and the method comprises the steps: carrying out the positioning of a PCB and a film; building a machine platform coordinate system, respectively taking a first alignment element center and a second alignment element center as origins of coordinates, and building a first coordinate system and a second coordinate system; obtaining an alignment inclined angle, and solving the difference of the first and second alignment element centers in the machine platform coordinate system in the X-axis direction as a first difference value and the difference of the first and second alignment element centers in the machine platform coordinate system in the Y-axis direction as a second difference value according to the position coordinates of the first and second alignment element centers in the machine platform coordinate system; judging whether the alignment inclined angle, the first difference value and the second difference value are within a preset error range or not: carrying out no adjustment if the alignment inclined angle, the first difference value and the second difference value are within the preset error range, or adjusting the position. According to the invention, the method achieves the positioning control based on CCD machine vision, can quickly and accurately obtain the position information, solve a problem of positioning errors in a production and manufacturing process of the PCB, and improve the alignment precision and speed.

Owner:GUANGZHOU QIEZHI INTELLIGENT TECH CO LTD

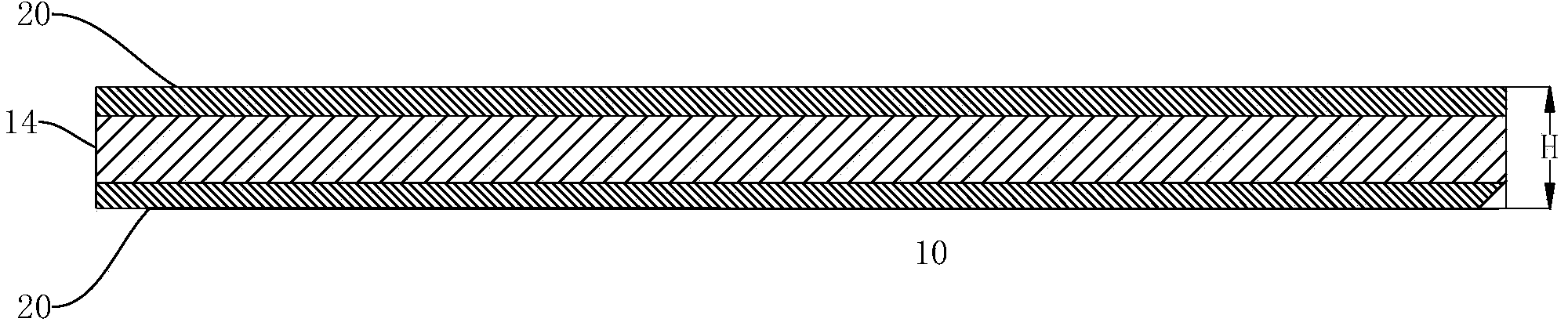

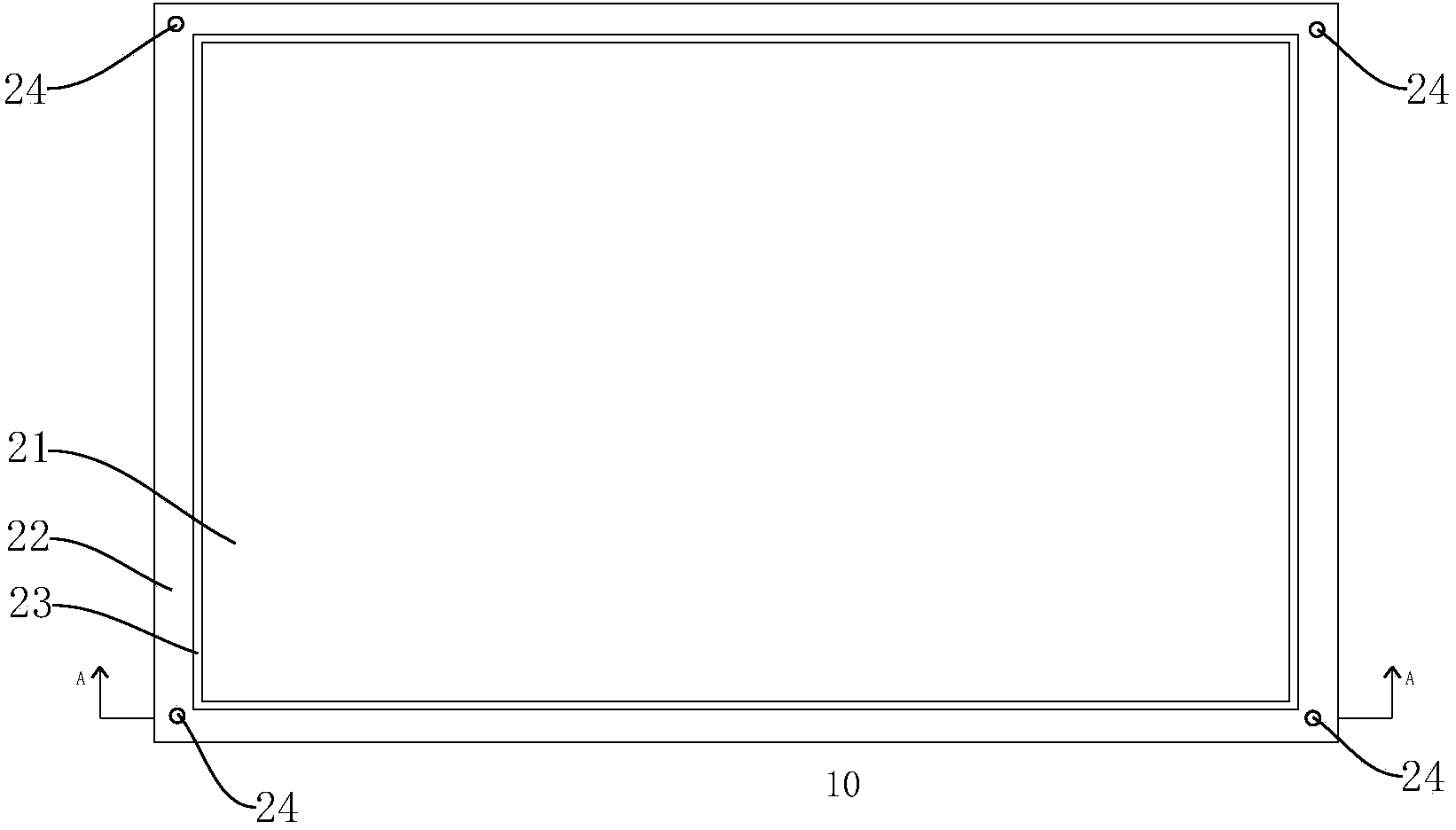

Manufacturing method of ultrathin printed circuit board, and ultrathin printed circuit board

ActiveCN104394665AAvoid scrappingAvoid yieldPCB positioning during processingMultilayer circuit manufactureWrinkle skinCopper foil

The invention discloses a manufacturing method of an ultrathin printed circuit board, and an ultrathin printed circuit board. According to the manufacturing method, copper foils and bonding plates are laminated at a support plate in hot-pressing mode and the thin copper foils and the thin bonding plates are supported by the support plate. Therefore, plate thickness limitation by equipment in production of electroplating and graph transferring and the like can be effectively eliminated; deformation like warping, bending, and small wrinkle existence and the like of carriers including a first copper foil, a second copper foil and a conductive layer and the like during the lamination and hot pressing process can be effectively improved; and problems of scrapping of the printed circuit board and low yield of the board due to insufficient hardness and poor smoothness of the laminated object can be solved.

Owner:SHANGHAI MEADVILLE ELECTRONICS +1

Processing and shaping method of PCB

InactiveCN106304637ASmall mechanical tolerancesQuick exclusionPCB positioning during processingInsulating layers/substrates workingHydrocarbon solventsEngineering

The present invention provides a processing and shaping method of a PCB. The method mainly comprises (1) a PCB feeding step the PCB; (2) a V-shaped groove making step of using a CNC automatic device to make a V-shaped groove, wherein the angle of the V-shaped groove is between 35 degrees and 90 degrees; (3) a PCB milling step of firstly adopting a CNC program to make, then milling the first board and inspecting the size until the size is qualified, then producing, cleaning the PCB and discharging; (4) a connecting finger bevel edge making step, wherein the included angle of the bevel edge and a horizontal line is between 15 degrees and 65 degrees, and the residual thickness is 1 / 3 of the thickness of the PCB; (5) a PCB cleaning step of firstly feeding the PCB, then using the hydrocarbon solvent PCB cleaning water to clean the surface of the PCB, wherein the temperature at cleaning is 30 DEG C, and cleaning time is 1-2 hours, and then carrying out the ultrasonic washing, blow-drying, drying and cooling operations, and discharging the PCB after cooling; (6) a discharging step.

Owner:安徽广德威正光电科技有限公司

Grouting printing technology of film switch

InactiveCN104333983AQuality assuranceGuaranteed accuracyPCB positioning during processingElectric switchesMembrane switchEngineering

The invention provides a grouting printing technology of a film switch. The technical process comprises: preparation of a PET film circuit board, drilling of conducting holes, drilling of positioning holes, printing, drying and UV printing. When the conducting holes are drilled, processing is carried out through referring to and comparing with hole positions at a film so as to ensure precision of the drilled holes. The positioning holes are drilled in the PET film circuit board and then positioning is carried out twice by use of sleeve needles on a printer during the printing, such that deviations are not generated in dual-face printing, and the grouting printing quality is ensured.

Owner:SUZHOU MENHOW ELECTRONICS CO LTD

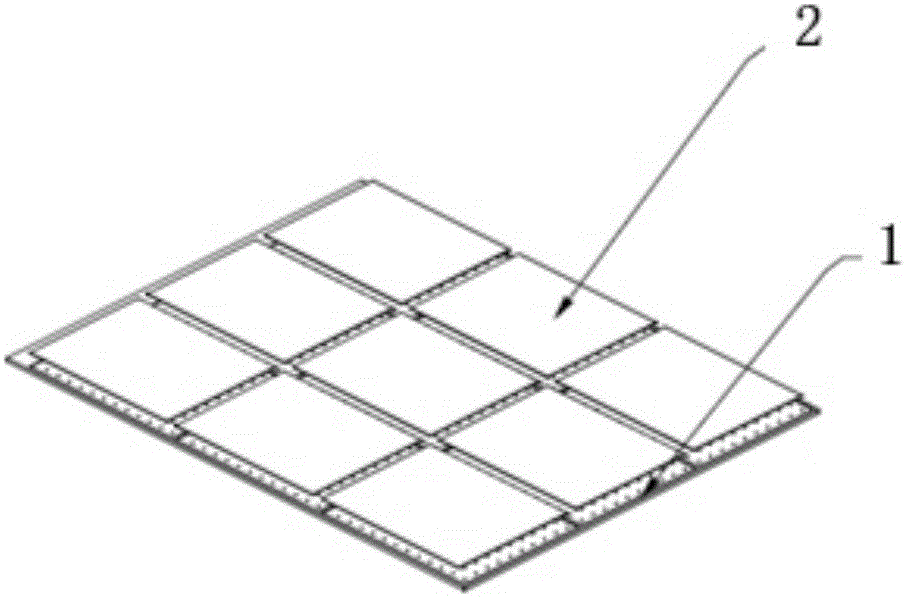

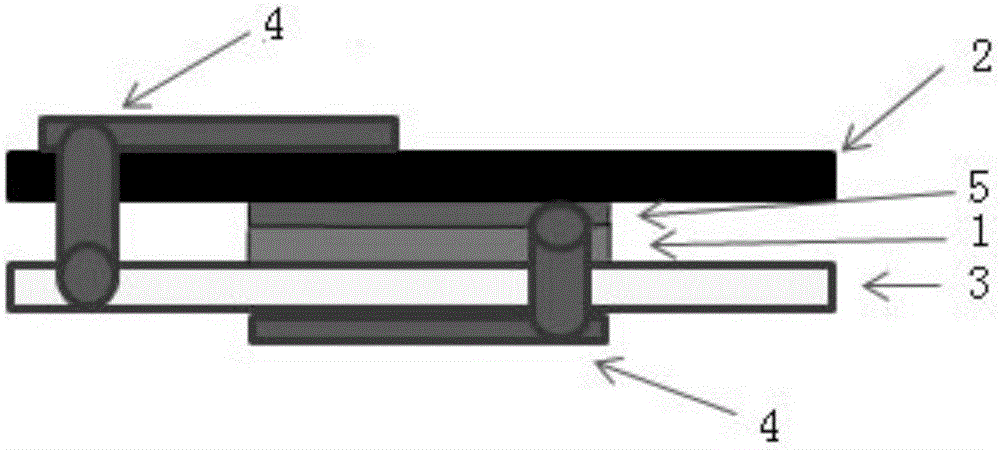

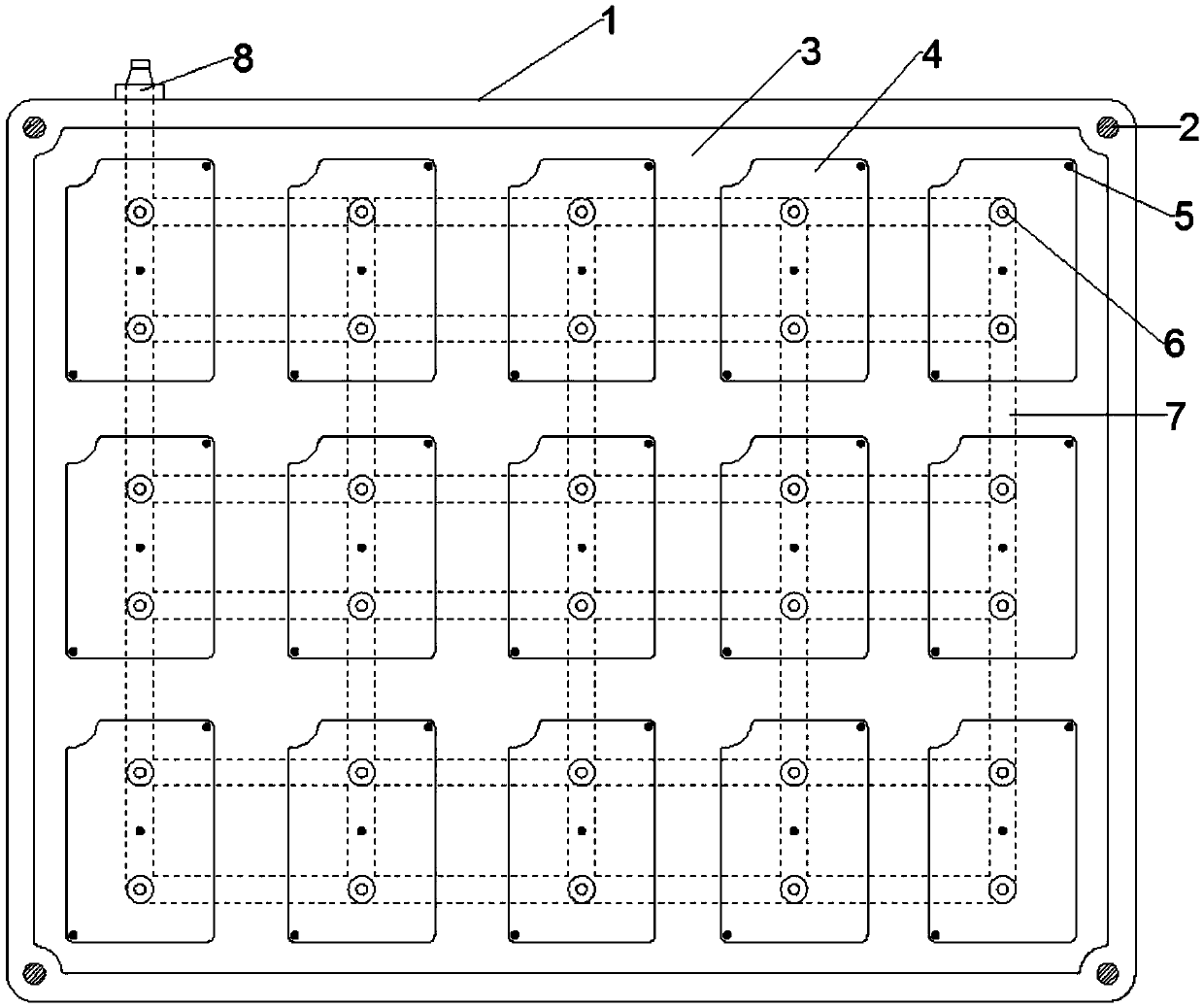

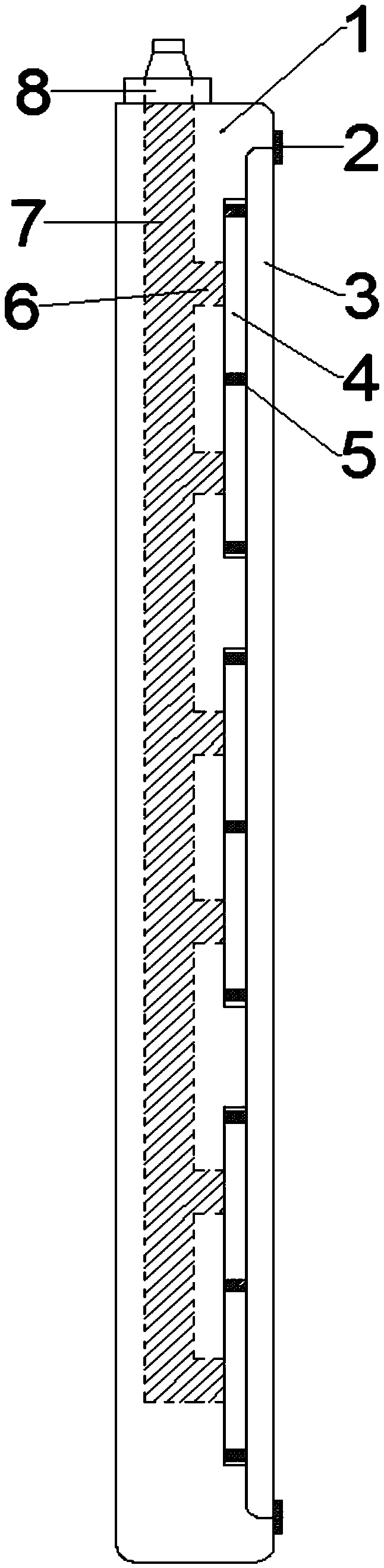

Small-size printed circuit board (PCB) clamping device

InactiveCN105101644AImprove mass production efficiencyReasonable structurePCB positioning during processingCircuit board tools positioningVacuum pumpingPrinted circuit board

The invention discloses a small-size printed circuit board (PCB) clamping device, which comprises a clamping structure, wherein limiting sides are arranged on the clamping structure; the surface of the clamping structure is divided into a plurality of PCB placement regions through the limiting sides; the PCB placement regions are used for placing PCBs; through holes are formed in the surfaces of various PCB placement regions; the other ends of the through holes are connected with a vacuum-pumping device; and the vacuum-pumping device finishes adsorption of the PCBs on the PCB placement regions through exhausting the through holes. The small-size PCB clamping device is reasonable in structure; board placement is facilitated; and the mass production efficiency of the small-size PCBs is greatly improved.

Owner:HEFEI ADVANTOOLS SEMICON

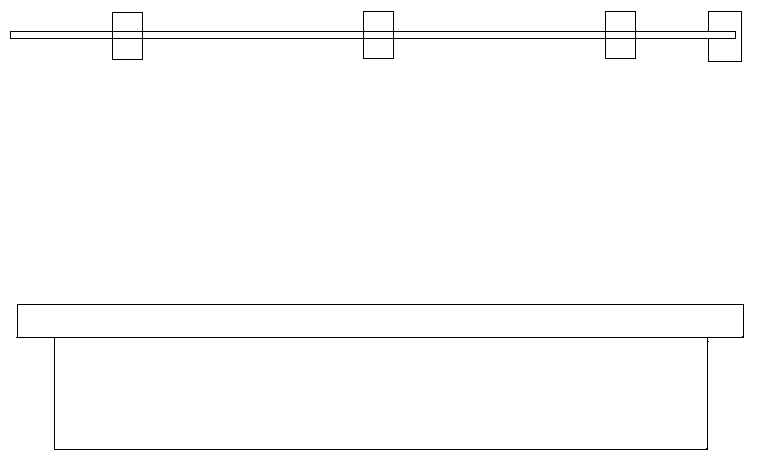

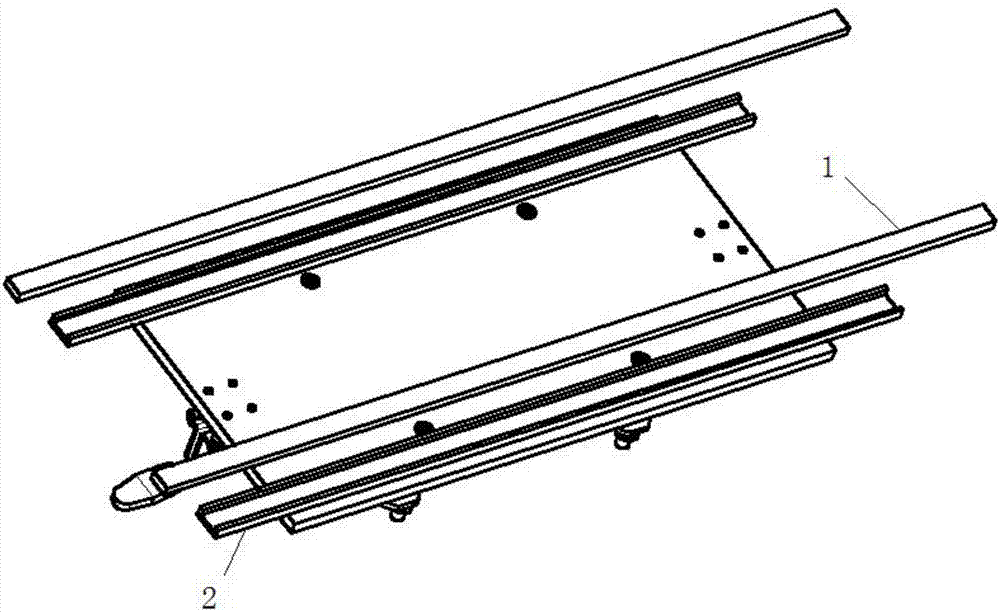

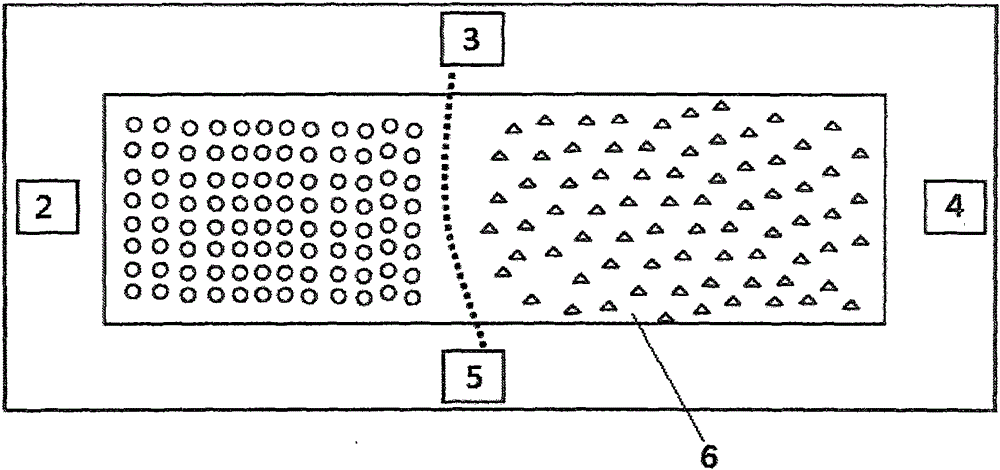

Board arrangement device and board arrangement method

InactiveCN104303608AAvoid driftingImprove lamination qualityPCB positioning during processingMultilayer circuit manufactureEngineeringElectrical and Electronics engineering

The invention relates to the technical field of PCB production equipment and particularly relates to a board arrangement device and a board arrangement method. The board arrangement device comprises a chassis, a board arrangement table, an infrared sensor, a fixing clamp and a position line production piece. The board arrangement table is arranged on the chassis. The fixing clamp is arranged on the edge of the board arrangement table. The position line production piece is arranged above the board arrangement table. Rays emitted by the position line production piece form a positioning wireframe on the board arrangement table. A lifting mechanism which drives the board arrangement table to move up and down is arranged between the chassis and the board arrangement table. In the board arrangement, the height of the board arrangement table is lowered upon laminating a board layer. The lifting mechanism is arranged to enable a top board layer of the board arrangement table to be lowered to an initial height, so that a phenomenon that the position of each board layer is shifted in the same board disk is prevented, and the PCB lamination quality is improved. As a projector projects the positioning wireframe with the scale on the board arrangement table, the lamination center of each board disk can be accurately positioned, so that lamination centers of the board disks are located on the same line during the lamination of different board disks, and the PCB lamination quality is improved further.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Cloud-based PCB folding device

ActiveCN114401587AImprove folding efficiencyHigh precisionPCB positioning during processingStructural engineeringMechanical engineering

The invention discloses a cloud-based PCB turnover device, the cloud-based PCB turnover device comprises a turnover mechanism, a controller and a cloud server, the controller is electrically connected with the turnover mechanism and is in signal connection with the cloud server, and the cloud server is used for monitoring the controller and controlling the turnover mechanism to turn over the turnover mechanism. The folding mechanism comprises a mounting frame, a positioning assembly, a pressing assembly, an adjusting adsorption assembly and a bending assembly, and a folding station used for placing a to-be-folded product is formed on the mounting frame; the positioning assembly is used for shooting and positioning a to-be-folded product; the downward pressing assembly is connected with the mounting frame and can move towards or away from the folding station so as to press the back plate; the adjusting adsorption assembly can drive the PCB to move so that an included angle can be formed between the hole diameter direction of the inserting hole and the placing plane of the product to be turned over. And the bending assembly can pass through the jack to abut against the board surface of the PCB and drive the PCB to be folded towards the direction of the back board. The PCB folding equipment based on the cloud end provided by the invention is high in folding precision.

Owner:SHENZHEN YUANSHUO AUTOMATION TECH

Printed circuit board positioning device based on ratchet wheel positioning principle

InactiveCN111836478AEasy flip operationReduce the difficulty of turning operationPrinted circuit assemblingPCB positioning during processingRatchetElectric machine

The invention relates to the technical field of printed circuits. The invention further discloses a printed circuit board positioning device based on the ratchet wheel positioning principle. The positioning device comprises a supporting frame and the outer portion of the supporting frame is fixedly connected with an overturning motor. A main gear is fixedly connected to the outer part of the overturning motor; the outer portion of the main gear is connected with an overturning toothed bar in an engaged mode. an overturning gear is connected to the outer part of the overturning toothed bar in ameshing manner; a fixing frame is fixedly connected to the outer part of the overturning gear; a moving motor is fixedly connected to the interior of the fixing frame; the overturning motor, a main gear, the overturning toothed bar, the overturning gear and the fixing frame are matched for use; therefore, the effect of conveniently adjusting the angle of the fixing frame is achieved, the printedcircuit substrate can be adjusted to a proper angle, dispensing and welding operation is facilitated, the using effect is effectively improved, overturning operation of the printed circuit board is facilitated, operation is easy, the overturning operation difficulty of the printed circuit board is reduced, time waste is effectively reduced, and the working efficiency is improved.

Owner:项新华

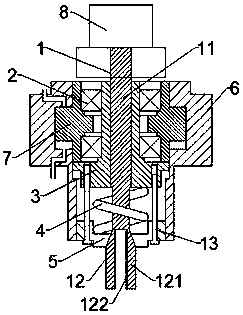

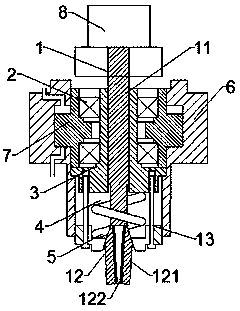

Clamping device for circuit board processing

InactiveCN106455336ASimple structureImprove stabilityPCB positioning during processingEngineeringPiston

The invention provides a clamping device for circuit board processing. The clamping device is mounted at the end part of a mechanical arm, is used for clamping a circuit board, and comprises a clamping head, a bearing, a pushing sleeve, a spring, a locking plate, a first cylinder and a piston, wherein the clamping head comprises a rotating rod as well as a clamping part connected to the lower end of the rotating rod and consisting of two clamping plates; each clamping plate can be elastically deformed in the opposite direction, and the outer side of the end, connected with the rotating rod, of each clamping plate is a conical surface; a motor is connected to the top end of the clamping head; a through hole matched with the rotating rod is formed in the pushing sleeve, and the pushing sleeve is rotatably supported inside the piston; an inner conical hole matched with the outer conical surfaces of the clamping plates is formed in the locking plate, and the locking plate is slidably arranged below the inner cavity of the first cylinder; the rotating rod of the clamping head is inserted into the through hole in the pushing sleeve; the clamping part is placed inside the inner conical hole in the locking plate; the spring sleeves the clamping head, and the two ends of the spring are pressed against the pushing sleeve and the locking plate respectively. The clamping device has the advantages that the clamping device can flexibly clamp the circuit board, can maintain relatively high stability so as to prevent falling, and improves the processing accuracy.

Owner:南京万云信息技术有限公司

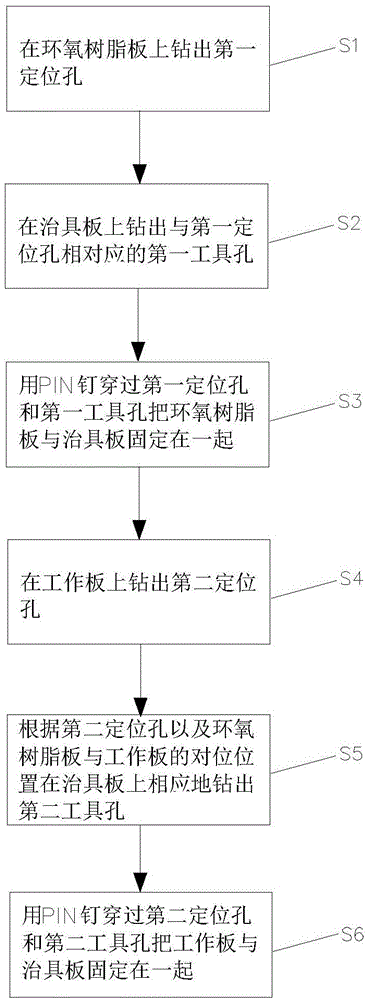

Circuit board aligning method

ActiveCN105072828APCB positioning during processingCircuit board tools positioningIndustrial engineering

The invention relates to the circuit board manufacture field, especially to a circuit board aligning method. The method includes drilling a first positioning hole in an epoxy resin plate, drilling a first tool hole, in a tool plate, corresponding to the first positioning hole, fixing the epoxy resin plate and the tool plate together through pins passing through the first positioning hole and the first tool hole, drilling a second positioning hole in a working plate, correspondingly drilling a second tool hole in the tool plate according to the second positioning hole and the aligning position of the epoxy resin plate and the working plate, and fixing the working and the tool plate together through pins passing through the second positioning hole and the second tool hole. The tool plate is respectively fixed with the epoxy resin plate and the working plate, and the epoxy resin plate is aligned and overlapping with the working plate indirectly. The problems of inconsistency of the sizes of the epoxy resin plate and the working plate and impossibility of aligning with the working plate when the epoxy resin plate is smaller than the working plate can be solved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

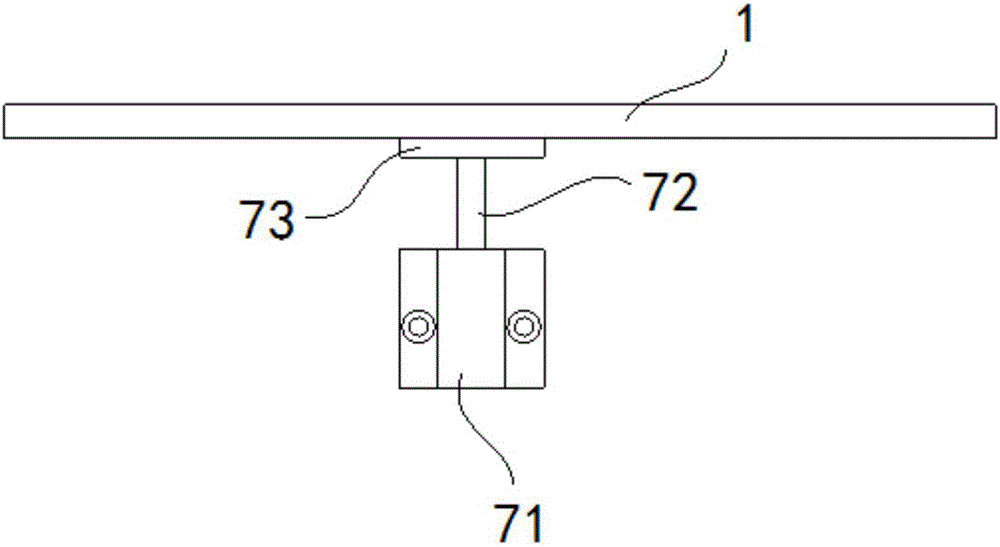

Positioning and clamping device for PCB (Printed Circuit Board) labelling machine

InactiveCN104507259APCB positioning during processingInsulating layers/substrates workingEngineeringPrinted circuit board

The invention discloses a positioning and clamping device for a PCB (Printed Circuit Board) labelling machine. The positioning and clamping device comprises a bracket, wherein the middle part of the bracket is penetrated from top to bottom, thereby forming a hollow region; an electrical cylinder capable of moving up and down is arranged below the hollow region; a first fixing plate and a second fixing plate which are arranged oppositely are fixed on the bracket; a first fixing upright post and a first adjusting upright post which are arranged vertically are fixed on the inner side of the first fixing plate; a second fixing upright post and a second adjusting upright post which are arranged vertically are fixed on the inner side of the second fixing plate; the first adjusting upright post and the second adjusting upright post are adjustable in a first direction; the first direction refers to a direction in which the first adjusting upright post gets close to or far away from the first fixing upright post; the first fixing plate and / or the second fixing plate are / is adjustable in a second direction relative to the bracket; the second direction is vertical to the first direction in a horizontal plane coordinate system. The positioning and clamping device can adapt to different PCB overall dimensions, and the repeated positioning accuracy of the structure is + / -0.02.

Owner:SUZHOUSCON AUTOMATION TECH

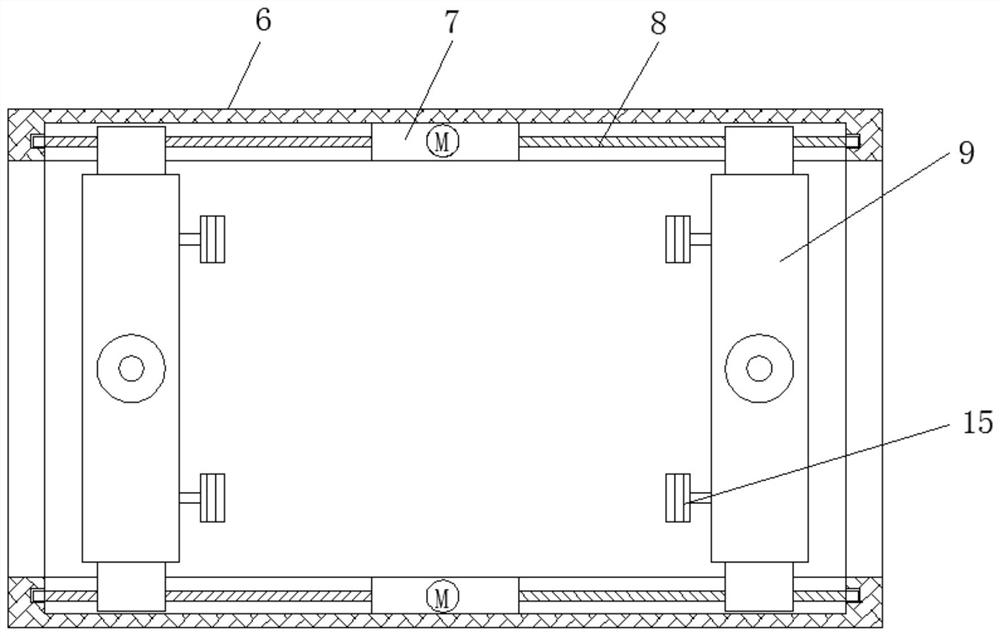

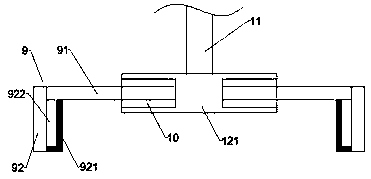

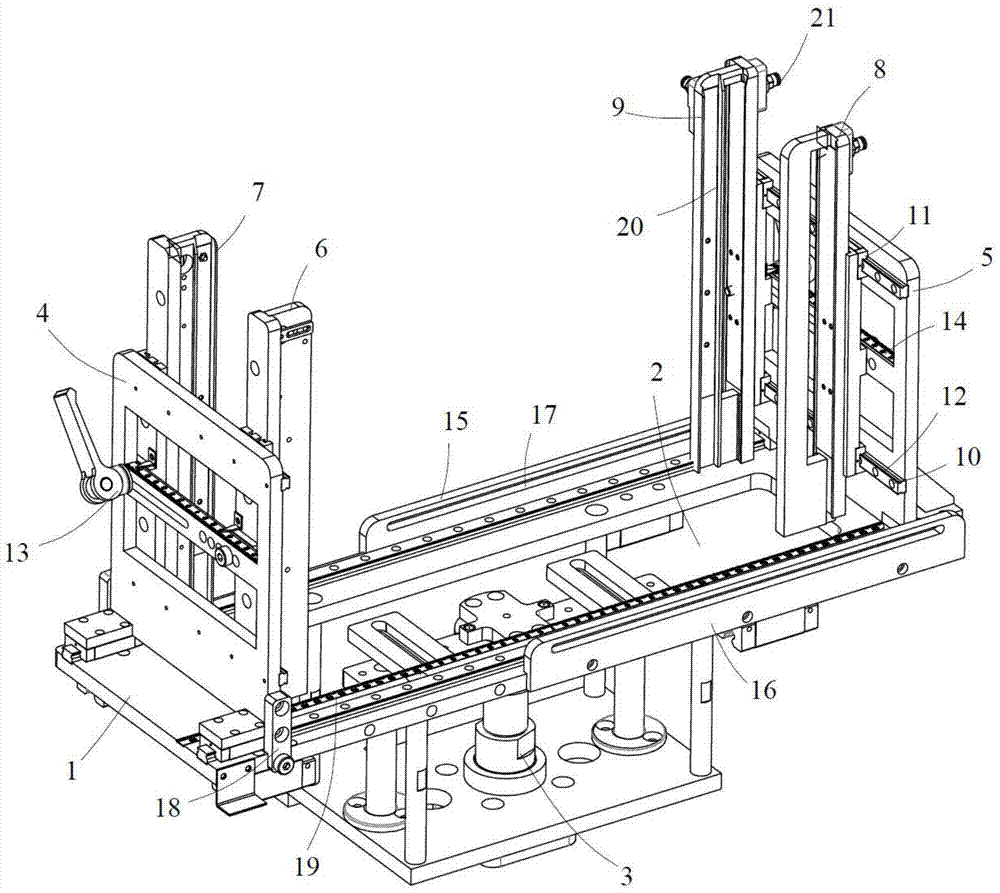

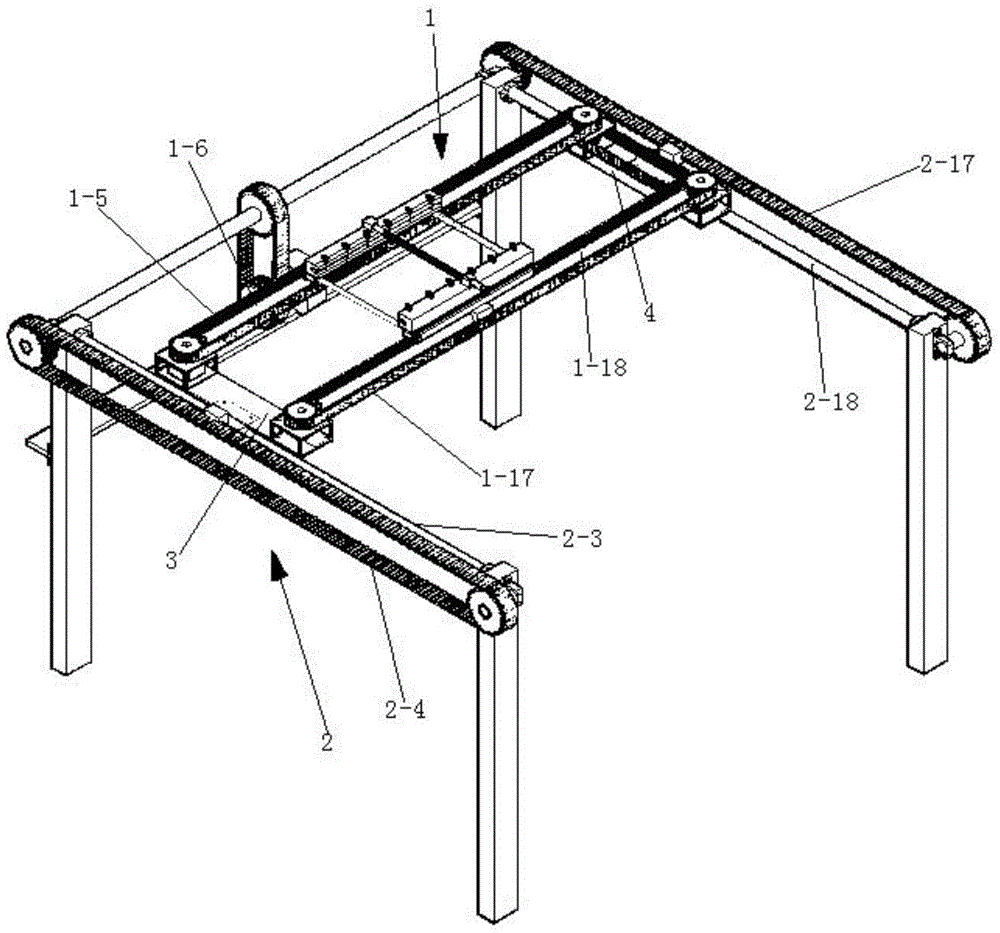

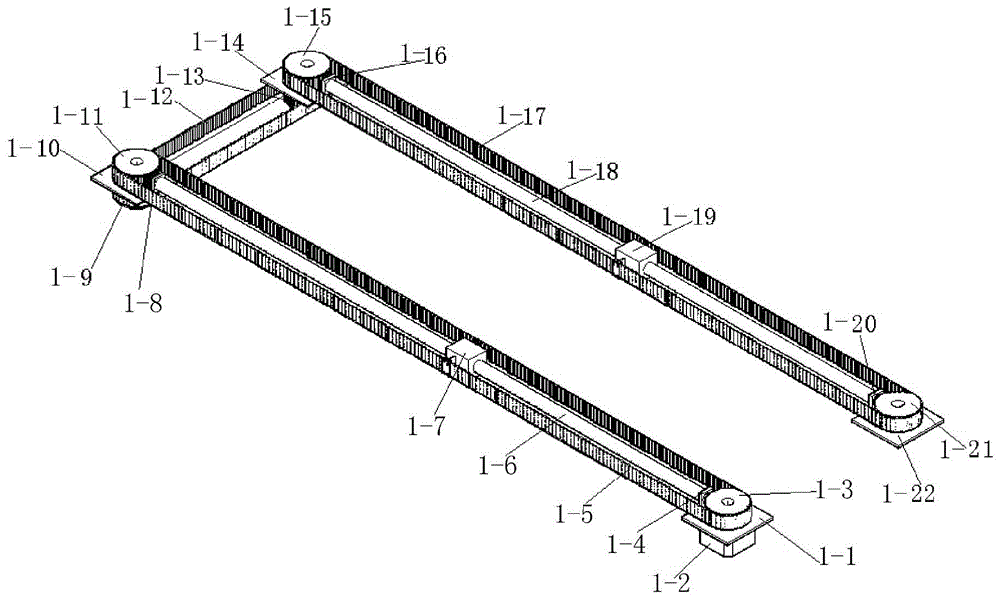

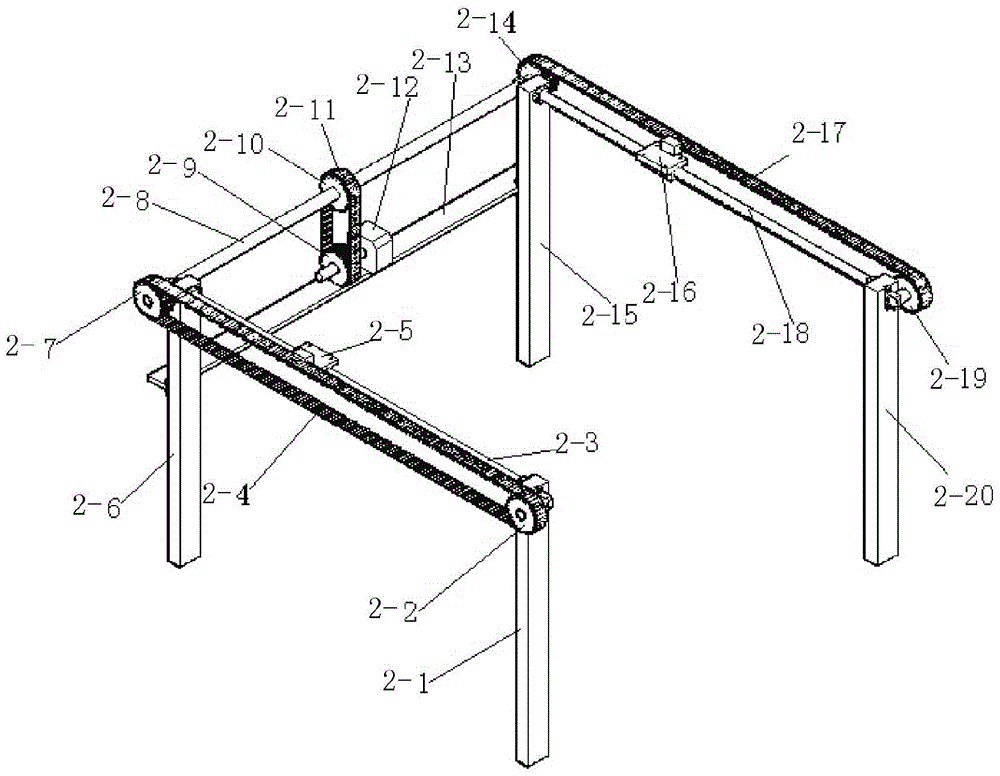

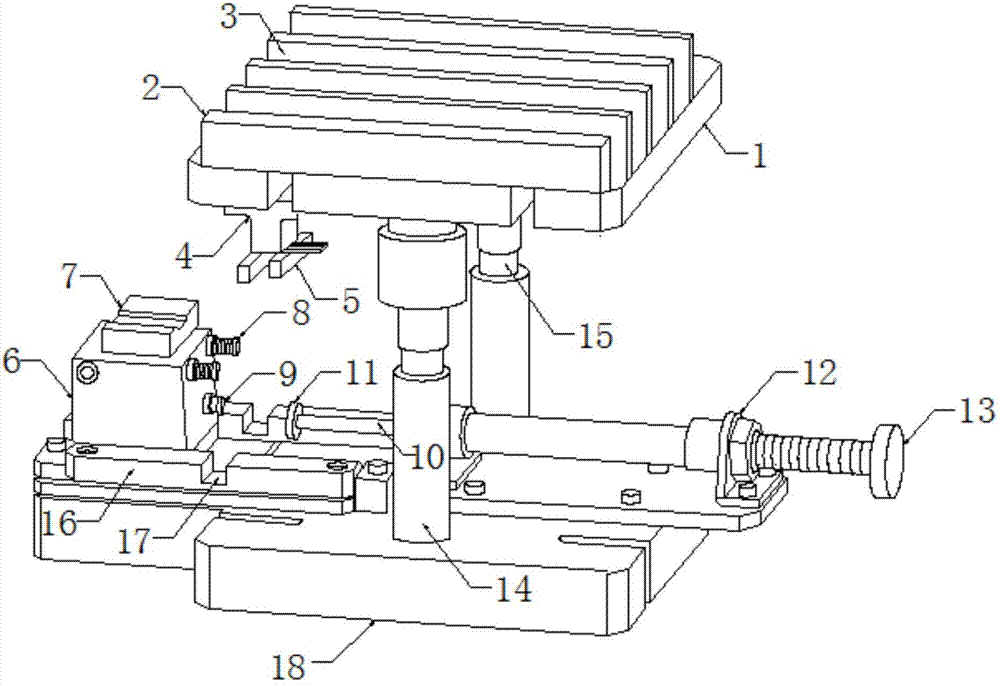

Movement mechanism of spot welding machine PCB (printed circuit board)

InactiveCN104668703ASimple structureNovel and reasonable designPrinted circuit assemblingPCB positioning during processingTransmission beltEngineering

The invention discloses a movement mechanism of a spot welding machine PCB (printed circuit board). The movement mechanism comprises a Y-axis movement mechanism and an X-axis movement mechanism, the X-axis movement mechanism comprises a driving belt, a driven belt, a first driving belt pulley, a second driving belt pulley, a first driven belt pulley, a second driven belt pulley, a first guide rod and a second guide rod, a first slider is mounted on the first guide rod, one side face of the first slider is connected with the driving belt, a second slider is mounted on the second guide rod and is in sliding fit with the second guide rod, and one side face of the second slider is connected with the driven belt. The Y-axis movement mechanism comprises a first driven transmission belt, a second driven transmission belt, a first sliding rod and a second sliding rod, a first moving block is mounted on the first sliding rod and connected with the first driven transmission belt, and a second moving block is mounted on the second sliding rod and connected with the second driven transmission belt. The movement mechanism of the spot welding machine PCB can drive the PCB to do combined motion of an X-axis direction and a Y-axis direction.

Owner:SHAANXI ZIZHU ELECTRON

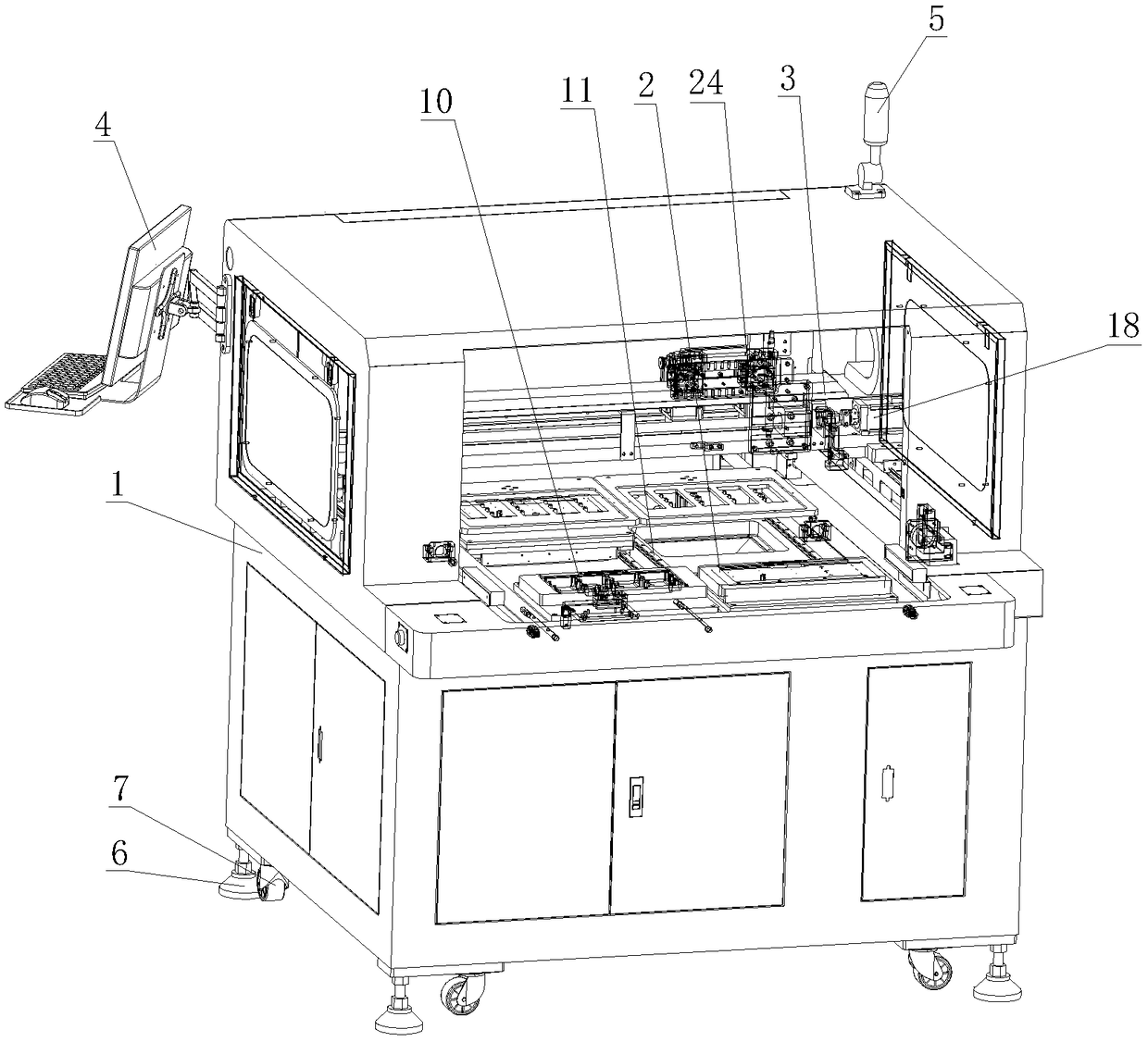

Curved plate separator

ActiveCN108340432AEasy to moveEasy accessPCB positioning during processingInsulating layers/substrates workingAgricultural engineeringManipulator

The invention discloses a curved plate separator. The curved plate separator comprises a plate separator body, a plate separating jig in / out mechanism and an XYZ module plate separating mechanism, wherein a computer is arranged on the left side of the back end of the plate separator; a bottom plate is arranged at the center of the plate separator body, and the plate separating jig in / out mechanismand the XYZ module plate separating mechanism are located at the upper end of the bottom plate; a plate separating jig fixing plate is arranged at the front end of the plate separating jig in / out mechanism, a plate separating jig is arranged at the upper end of the plate separating jig fixing plate, a linear guide rail is arranged at the back end of the plate separating jig in / out mechanism, anda plate separating jig in / out air cylinder is arranged at the left end of the linear guide rail. When the curved plate separator is used, a PCBA plate is clamped by a manipulator, the PCBA plate movesto a plate separating jig to be separated, and the plate separating jig is sent to the XYZ module plate separating mechanism to be separated by means of the plate separating jig in / out air cylinder.The curved plate separator disclosed by the invention is compact in integral structure, extra-high in rigidity, simple and safe to operate and convenient to pick and place products, and improves the productivity greatly and reduces the labor intensity.

Owner:KELI ELECTRONICS EQUIP

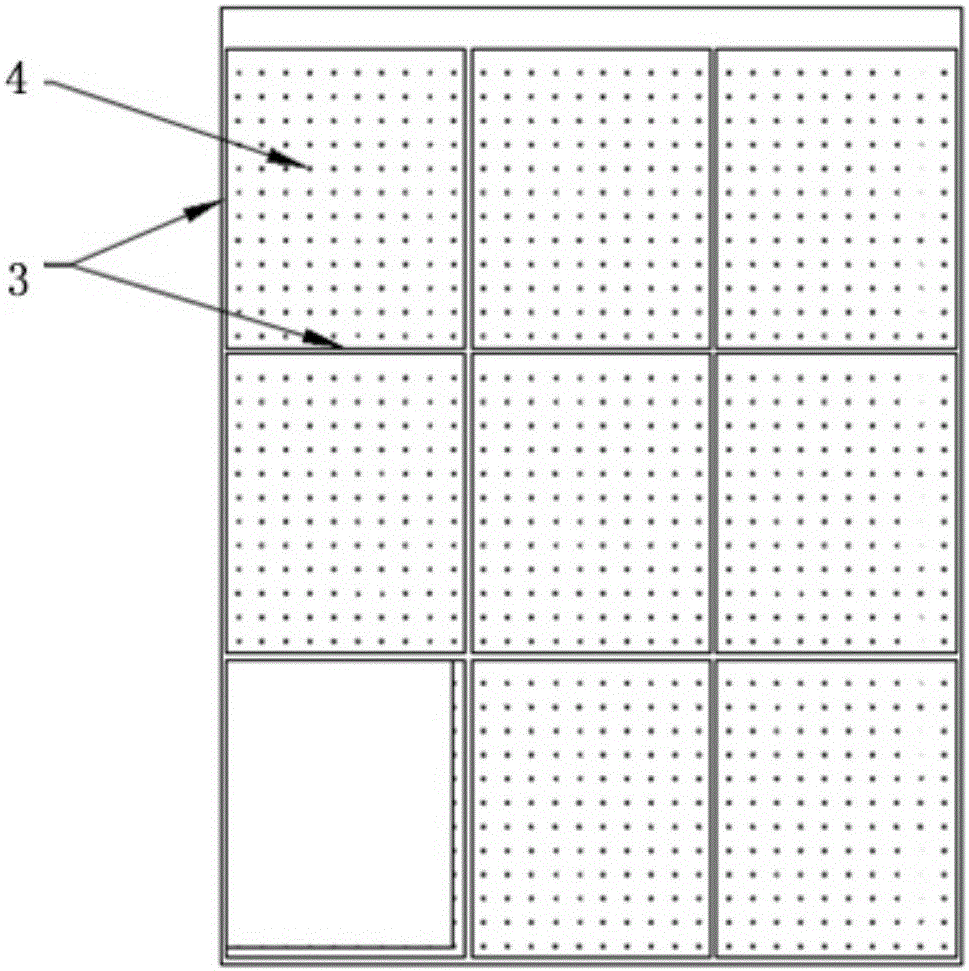

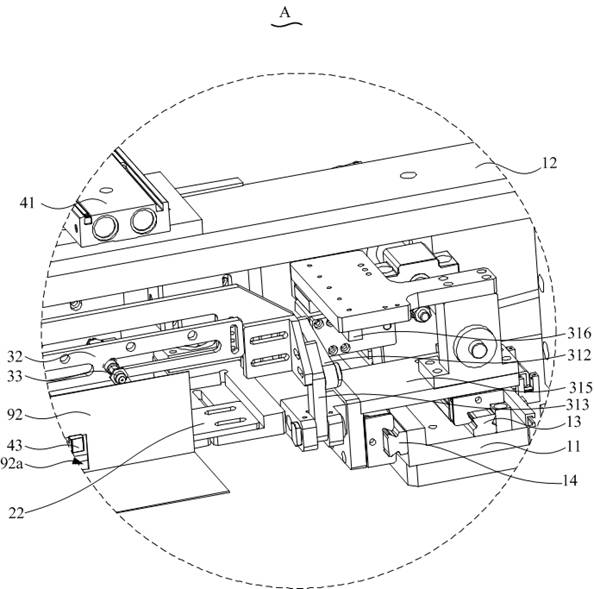

Processing and positioning component for pcb

InactiveCN105578786APrecise positioningRealize the function of negative pressure fixing mobile phone PCBPrinted circuit assemblingPCB positioning during processingBiochemical engineeringMobile phone

The invention relates to the technical field of carrier devices, and particularly provides a processing and positioning component for a pcb. The processing and positioning component for the pcb comprises a tray body. The four corners of the tray body are fixedly provided with a tray positioning device respectively. A material feeding groove is fixedly arranged on the upper surface of the tray body. Plural installing holes are fixedly arranged on the lower surface of the material feeding groove. Plural fixing bolts are fixedly arranged on the surface of the installing holes. Plural fixing holes are fixedly arranged on the surface of the installing holes. The internal part of the tray body is provided with air channels which are fixedly arranged in a way of being corresponding to the fixing holes. The side surface of the tray body is fixedly provided with an air suction port. Accurate positioning of the tray body on an SMT machine can be realized by arrangement of the positioning devices, accurate positioning of a mobile phone PCB on the tray body can be realized by arrangement of the installing holes and the fixing bolts, and the function of fixing the mobile phone PCB through negative pressure can be realized by arrangement of the fixing holes, the air channels and the air inlet so that accurate positioning and processing of the mobile phone PCB can be realized in batches.

Owner:TIANJIN HUAMAI TECH

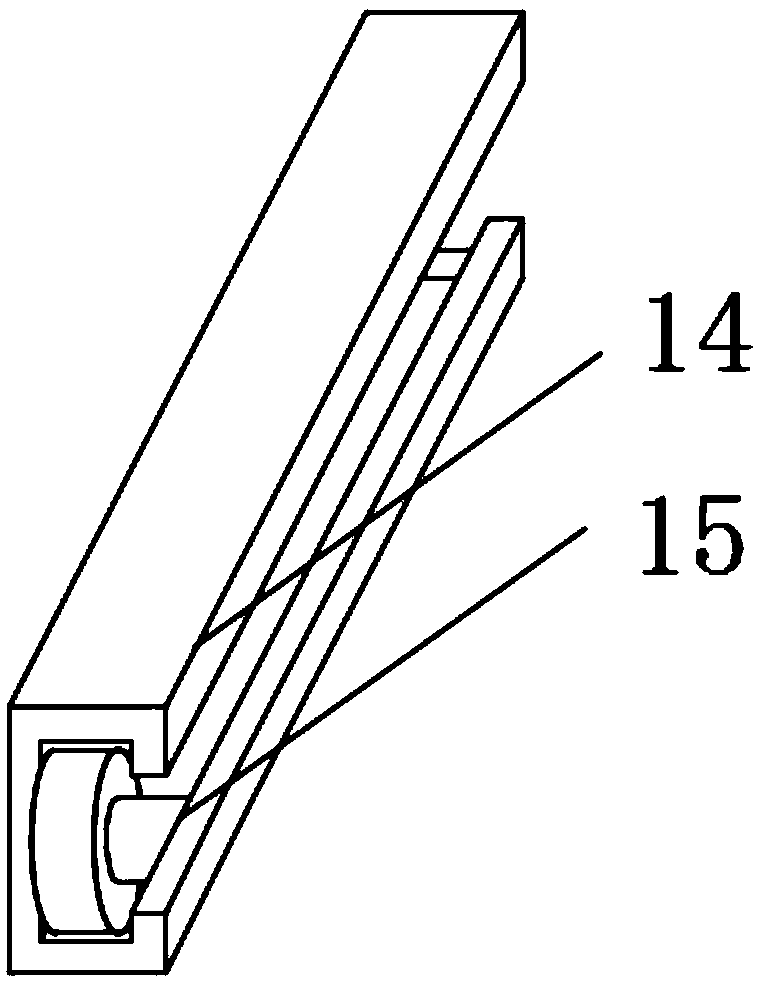

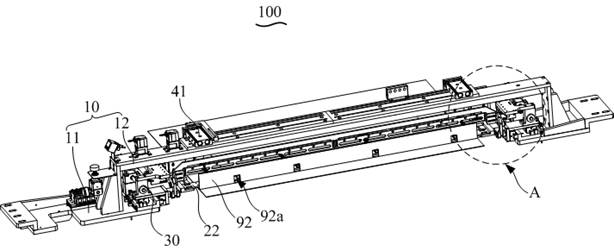

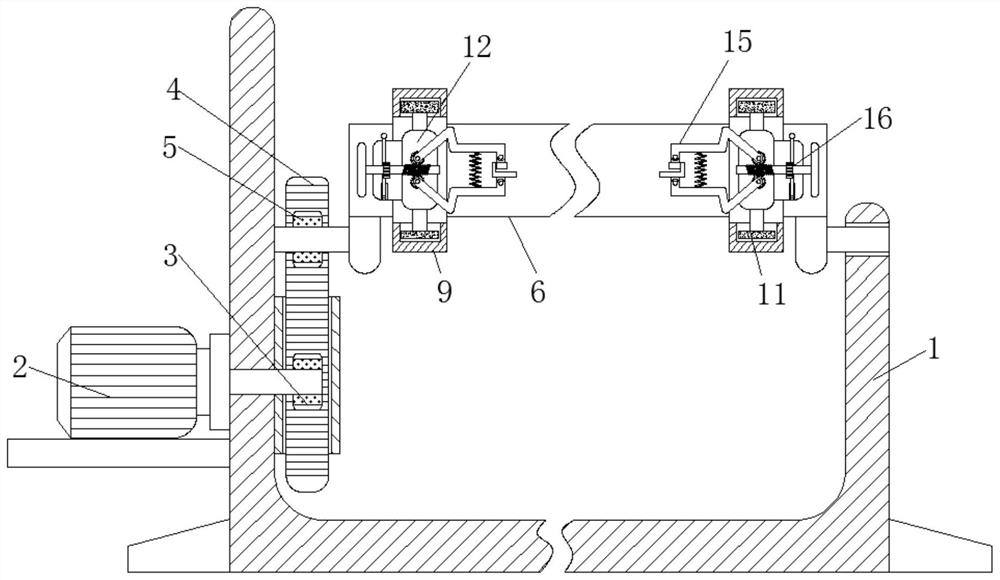

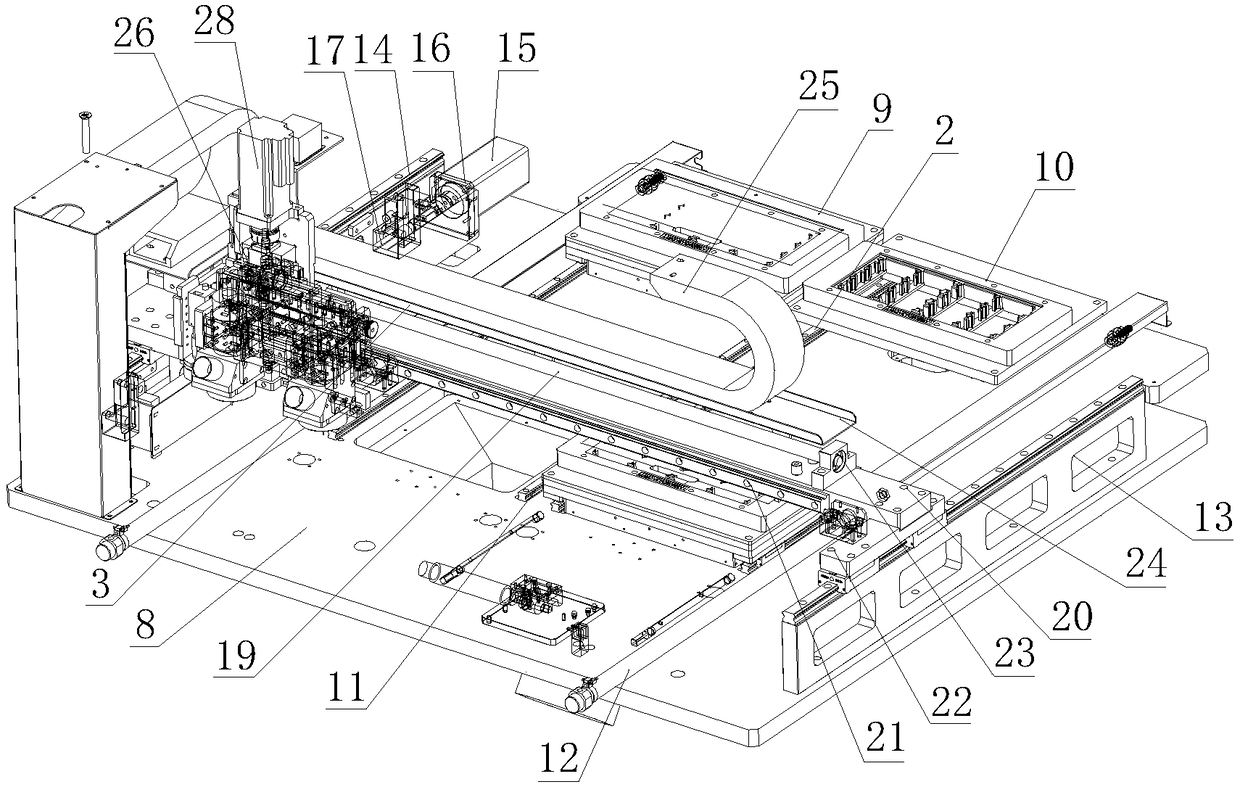

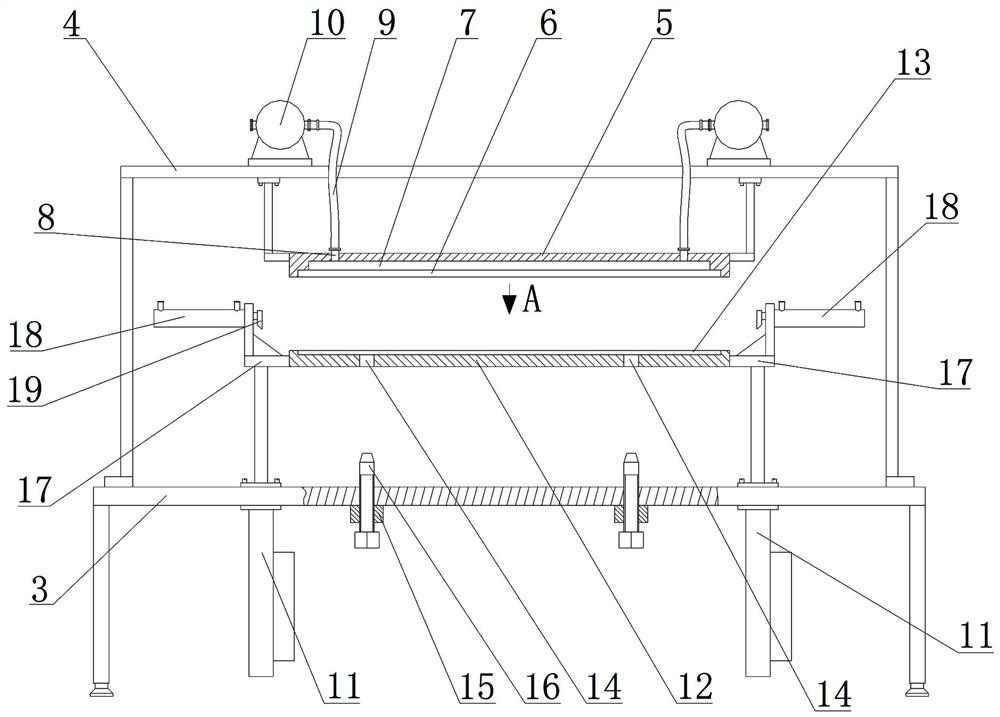

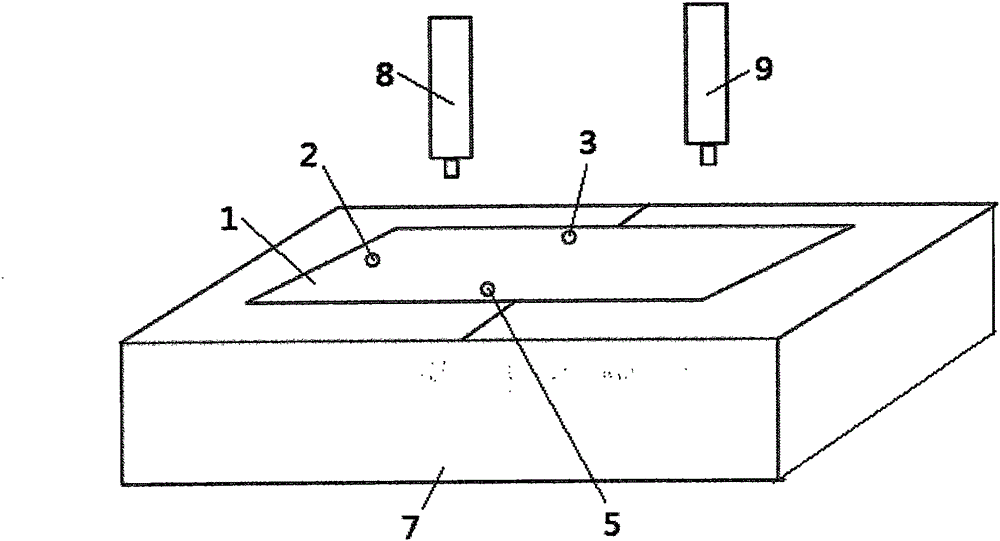

Forming device and method for precisely forming high-frequency and high-speed printed circuit board

ActiveCN114885503AHigh forming precisionCompact structurePCB positioning during processingIncreasing energy efficiencyEngineeringPrinted circuit board

The invention discloses a forming device and method for precisely forming a high-frequency and high-speed printed circuit board, a jacking electric cylinder (11) is fixedly arranged on the table top of a workbench (3), a piston rod of the jacking electric cylinder (11) penetrates through the workbench (3), a positioning plate (12) is fixedly arranged at the extending end of the jacking electric cylinder (11), and a positioning groove (13) located under a groove (6) is formed in the top surface of the positioning plate (12); two through holes (14) penetrating through the bottom surface of the positioning plate (12) are formed in the groove bottom of the positioning groove (13), two jacking mechanisms arranged under the through holes (14) respectively are arranged on the table top of the workbench (3), each jacking mechanism comprises a nut (15) welded to the bottom surface of the workbench (3), and an ejector rod (16) is in threaded connection with the interior of each nut (15). The high-frequency high-speed printed circuit board forming device has the advantages of being compact in structure, improving the forming precision of finished high-frequency high-speed printed circuit boards, improving the forming quality of products and being easy to operate.

Owner:SICHUAN HAIYING ELECTRONICS TECH

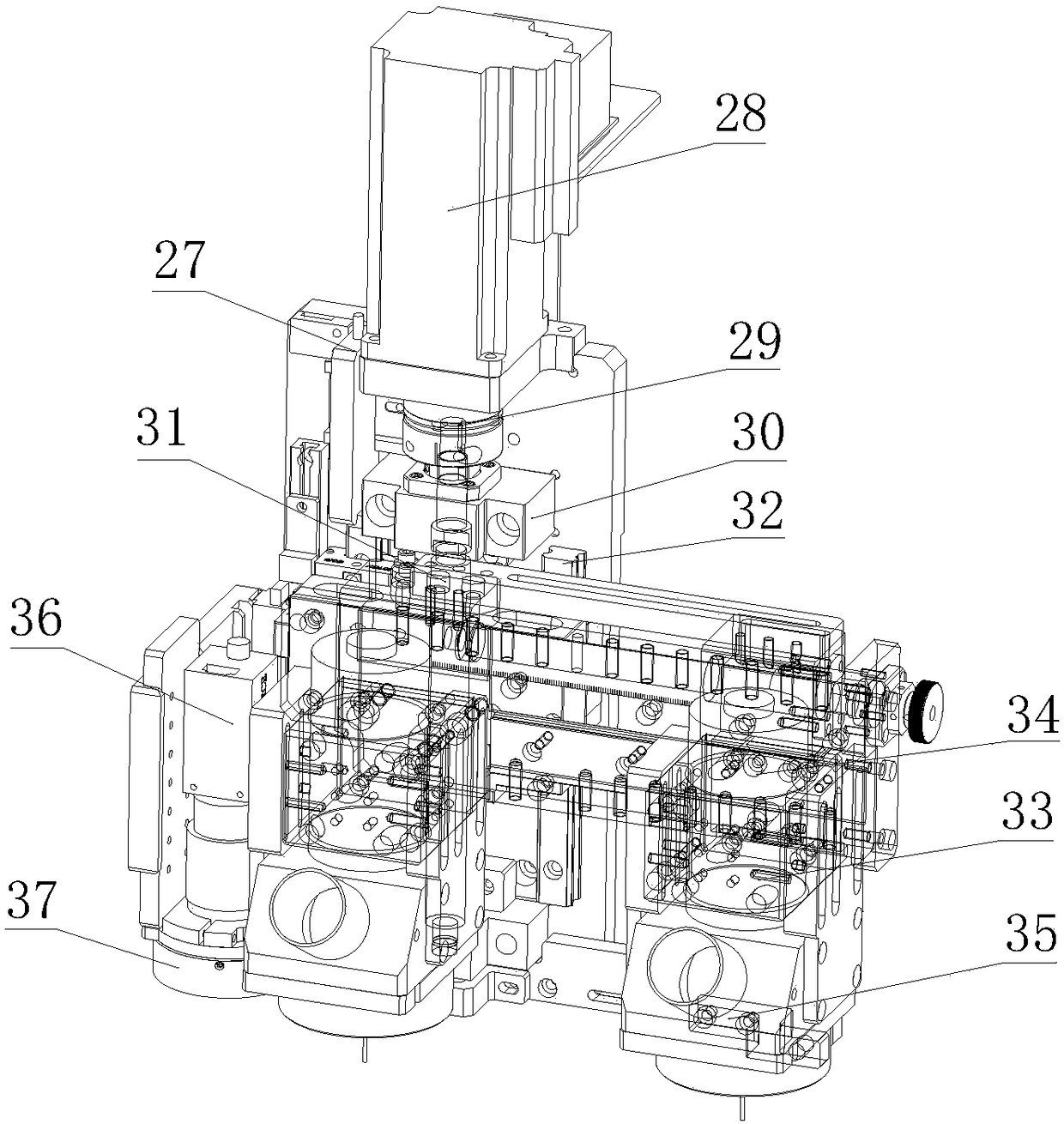

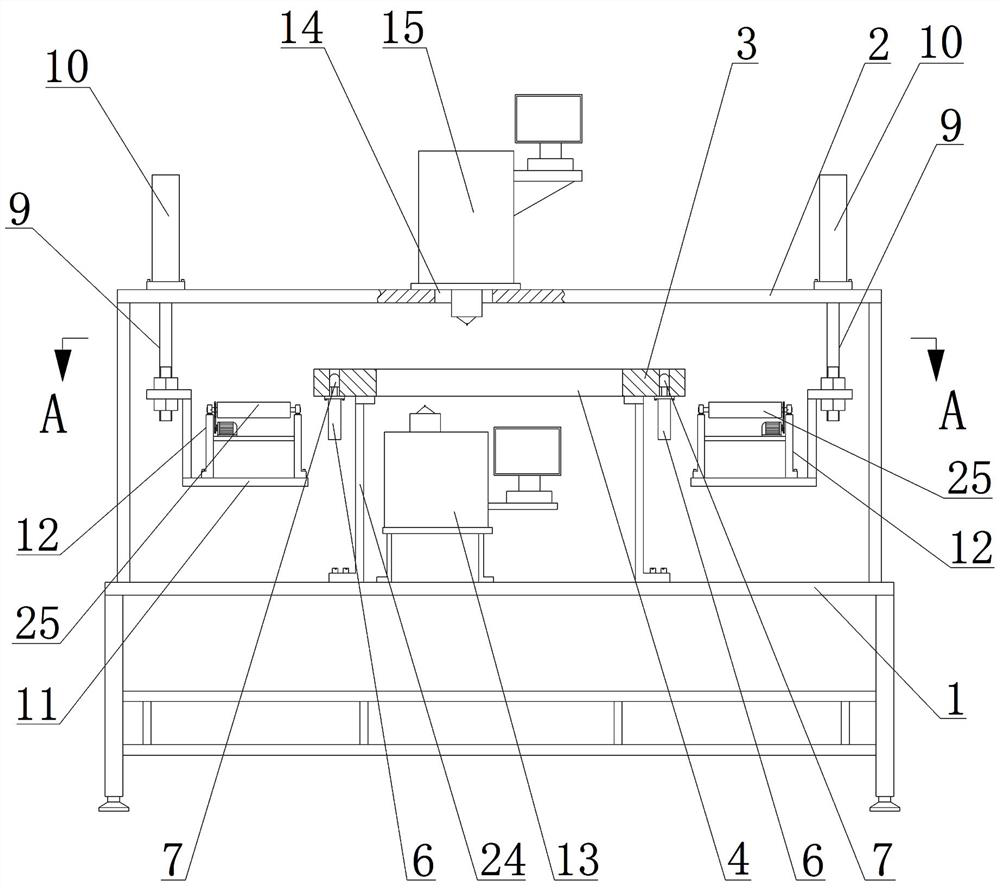

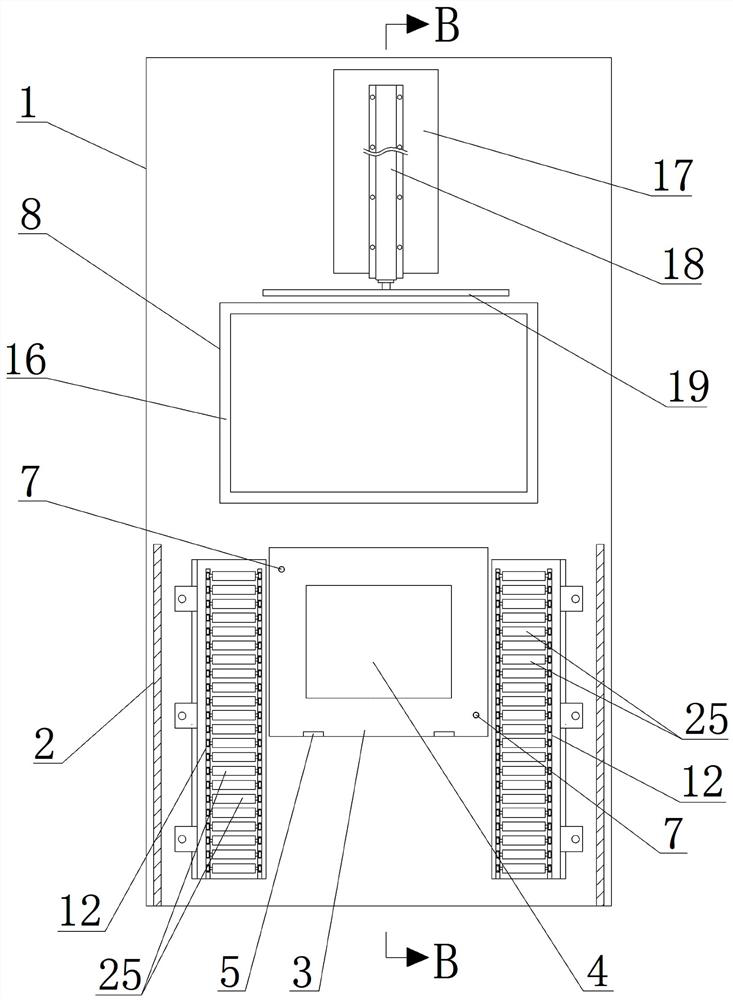

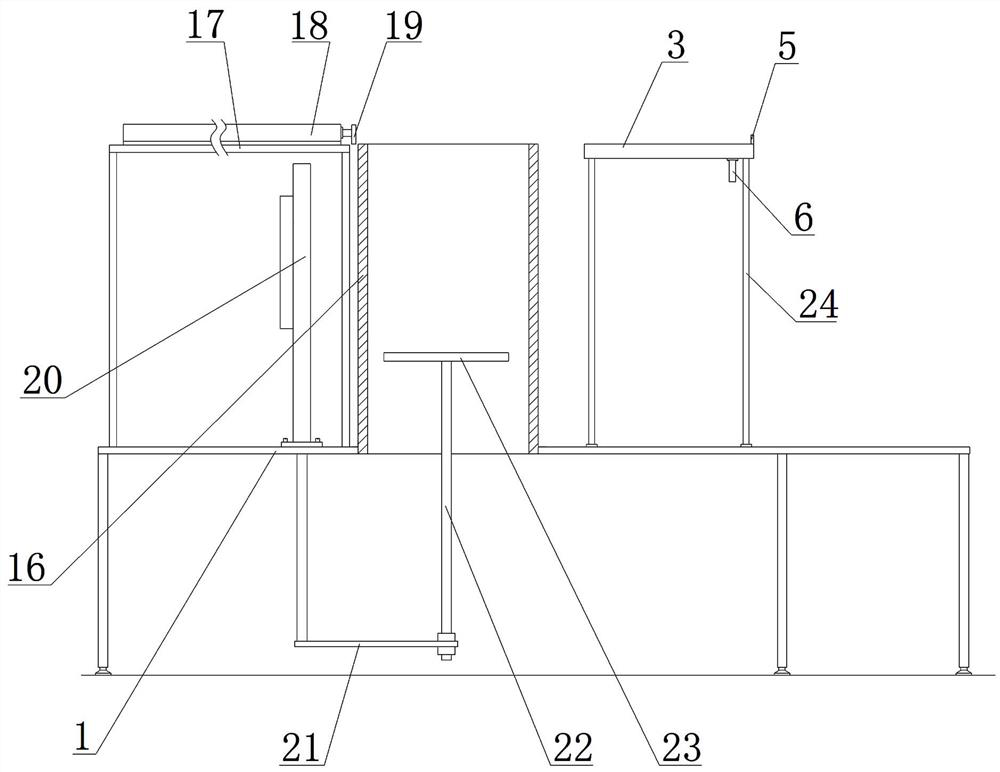

Device and method for double-sided precise targeting of HDI (High Density Interconnection) plate

ActiveCN114599149AReduce work intensityHigh target shooting efficiencyPCB positioning during processingInspection/indentification of circuitsHigh densityPilot hole

The invention discloses a double-sided precise targeting device and method for an HDI plate, and relates to the technical field of double-sided targeting of the HDI plate, the double-sided precise targeting device comprises a workbench, a portal frame fixedly arranged on the workbench, and a limiting plate fixedly arranged on the top surface of a positioning table and located on the front edge of the positioning table; jacking air cylinders fixedly arranged on the positioning table are arranged under the two guide holes, and floating columns slidably installed in the guide holes are fixedly arranged at the acting ends of piston rods of the jacking air cylinders. An automatic feeding device located on the rear side of the positioning table is arranged on the workbench, and material lifting and conveying devices are arranged on the cross beam of the portal frame and located on the left side and the right side of the positioning table. The device has the beneficial effects that the working intensity of workers is relieved, the targeting efficiency of the HDI plate is greatly improved, and the drilling efficiency of the HDI plate is greatly improved.

Owner:四川英创力电子科技股份有限公司

Automatic clamp upper cover fetching device for automated production of circuit boards

InactiveCN106346505AImprove efficiencySuitable for high-volume production operationsGripping headsPCB positioning during processingElectrical and Electronics engineeringSeries production

The invention discloses an automatic clamp upper cover fetching device for automated production of circuit boards. The automatic clamp upper cover fetching device comprises a rack, a positioning mechanism and a die fetching mechanism, the positioning mechanism and the die fetching mechanism are mounted on the rack, a first mechanical arm is horizontally inserted at the top of the rack, a second mechanical arm is vertically inserted on the first mechanical arm, the die fetching mechanism is mounted on the second mechanical arm, a lifting rod is mounted on the second mechanical arm, a sucker frame is fixed at the lower end of the lifting rod, a lifting cylinder is fixed on each of two sides of the sucker frame, a lifting cylinder extensible rod is connected with a lifting claw, a sucker is mounted on the undersurface of the sucker frame, upper cover buckles are symmetrically arranged on two sides of a clamp upper cover, buckle grooves are symmetrically formed in two sides of a clamp baseplate, and the upper cover buckles are embedded in the buckle grooves for matched connection. The automatic clamp upper cover fetching device can realize automated clamp upper cover fetching during circuit board assembling and is suitable for large-batch production, stable in control and convenient to maintain.

Owner:ZHEJIANG ZHONGZHI ROBOT CO LTD

Surface mounting machine clamping device

InactiveCN105101666AReduce quality problemsAvoid damagePrinted circuit assemblingPCB positioning during processingSurface mountingEngineering

The invention discloses a surface mounting machine clamping device. The surface mounting machine clamping device includes a first clamping plate, a second clamping plate, a lever, a compression spring, tension springs and an air cylinder; the middle of the second clamping plate is provided with a groove which comprises a first groove surface and two second groove surfaces which are opposite to each other; the first end of the lever is arranged above the first clamping plate; the second end of the lever contacts with the first groove surface of the second clamping plate; the first end of the compression spring is connected with the lever; the second end of the compression spring is connected with the first groove surface; the first ends of the tension springs are connected with the first groove surface; and the air cylinder is connected with the lower surface of the first clamping plate. According to the surface mounting machine clamping device adopted, the lever, the compression spring and the tension springs are arranged between the first clamping plate and the second clamping plate, so that a buffering mechanism can be formed, and therefore, the first clamping plate and the second clamping plate slowly clamp a PCB, and damage to the PCB caused by large impact generated in a machining process can be avoided. The surface mounting machine clamping device has the advantages of simple structure, convenient operation, fast response, high machining precision, high production efficiency, low processing cost and high automation degree.

Owner:SUZHOU SIKABO COMM TECH

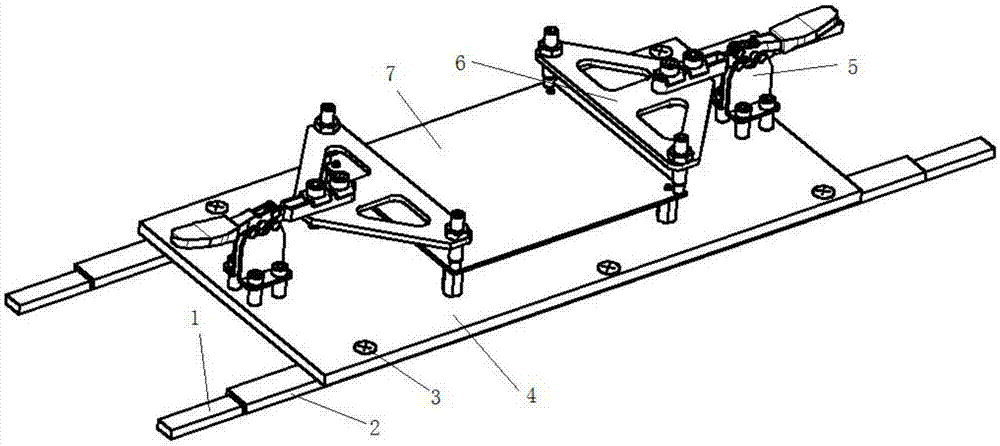

Clamping tool of circuit board production line

InactiveCN108012425AWon't breakMeet purchase needsPCB positioning during processingProduction lineAcute angle

The invention discloses a clamping tool of a circuit board production line. The clamping tool comprises toggle clamps, wherein the front end of each toggle clamp is provided with an installation frame, a clamping plate is arranged below each installation frame, each clamping plate is an isosceles triangle shaped steel plate, the obtuse-angle apex of each clamping plate is fixedly with the corresponding installation frame through a bolt, a gasket is arranged between the bolt and the upper end surface of the corresponding installation frame, each clamping plate is provided with resin limiting bolts penetrating through the clamping plate at two acute angles, each resin limiting bolt is provided with a nut above the clamping plate, the bottom of each resin limiting bolt is fixedly connected with a rubber contact, each toggle clamp is fixedly connected with a sliding table through four bolts, each bolt is provided with a cylindrical strut pin in a sleeved manner, the sliding table is provided with two opposite toggle clamp mechanisms and is fixedly connected with four hexagonal strut pins opposite to the rubber contacts, and a clamping platform is fixedly connected above the hexagonal strut pins. The clamping tool is novel in structure, improves the operation efficiency of manual operations required on the circuit board production line and improves the production efficiency.

Owner:HEFEI YOUYI MEDIA TECH CO LTD

PCB welding jig

ActiveCN107148165AEasy to useEasy to holdPrinted circuit assemblingPCB positioning during processingArchitectural engineeringMulti dimensional

The invention discloses a PCB welding jig. The PCB welding jig comprises a supporting cover plate and a base, wherein the bottom of the supporting cover plate is fixedly connected with a telescopic rod; a sleeve is fixed on the base; the telescopic rod is embedded in the sleeve and is movably connected with the sleeve; the bottom of the supporting cover plate is connected with a clamping head through a connecting piece; a positioning block is fixed at one end of the surface of the base; an elastic supporting piece is fixed on the side end face of the positioning block; an air pump is installed on the positioning block; an air nozzle is installed on the positioning block on the bottom of the elastic supporting block, and communicates with the air pump; a positioning piece is fixed at one end of the base, and a threaded rod is arranged on the positioning piece in a penetrated manner; one end of the threaded rod is connected with a positioning rod, and an extrusion head is fixed at the end of the positioning rod. The PCB welding jig is compact in structure and convenient to use, a PCB can be clamped well, the PCB is extremely stable in the welding process through multi-dimensional positioning, and a PCB to be machined is convenient to place in the welding process, so that the PCB welding jig is convenient for workers to use, and the machining time is reduced.

Owner:佛山市顺德区金御海电子科技有限公司

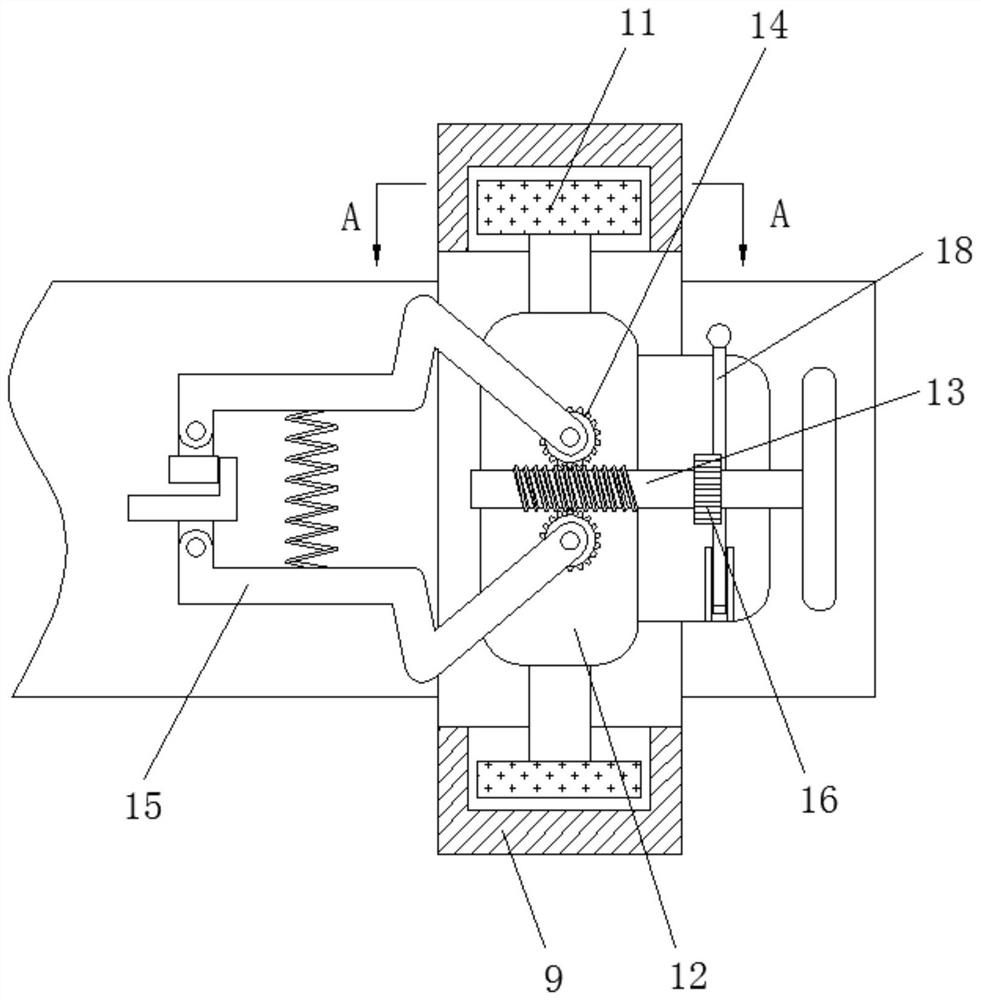

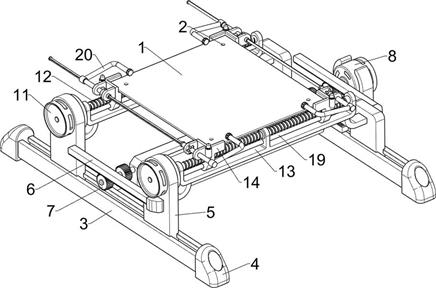

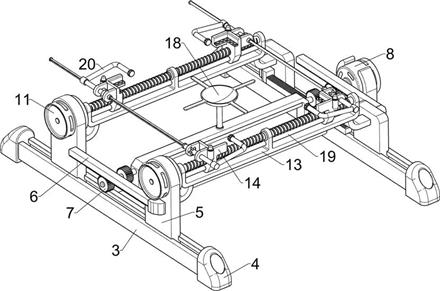

Printed circuit board positioning assembly

ActiveCN113543499AAvoid dentsPrecise positioningPCB positioning during processingConductive material chemical/electrolytical removalMechanical engineeringPrinted circuit board

The invention aims to provide a printed circuit board positioning assembly, which: comprises a left-right adjusting device comprising a sliding rail, a first mounting plate, a rack, a gear and a first servo motor and capable of performing left-right positioning on a printed circuit board; a front-back adjusting device comprising a second servo motor, a worm rod, a third mounting plate and a sliding rod and capable of positioning the printed circuit board front and back; a placing device comprising a sliding block, a positioning rod, an insulating ring and an insulating pad and used for placing the printed circuit board; and a lifting device composed of a tray and capable of carrying out center lifting on the printed circuit board with the four corners positioned so as to prevent the phenomenon that the middle of the large printed circuit board is sunken, and a pressing rod can press and fix the printed circuit board after heat transfer printing paper is laid so as to facilitate production of the printed circuit board.

Owner:深圳市恒讯通电子有限公司

Boring processing method of super-long circuit board

A boring processing method of a super-long circuit board comprises the steps of: 1, forming a first positioning hole, a second positioning hole, a third positioning hole and a fourth positioning hole, which are needed by boring, in the circuit board by using an X ray target-shooting machine, wherein the first positioning hole and the third positioning hole are opposite to each other, and the second positioning hole and the fourth positioning hole are opposite to each other; 2, utilizing the first positioning hole, the second positioning hole and the fourth positioning hole to fix the circuit board to a processing bench of a boring machine, and utilizing a first shaft of the boring machine to machine a region which is arranged on a connecting line between the second positioning hole and the fourth positioning hole and is close to the side of the first positioning hole; and 3, utilizing the second positioning hole, the third positioning hole and the fourth positioning hole to fixed to the circuit board to the processing bench, and utilizing a second shaft of the boring machine to machine a region which is arranged on a connecting line between the second positioning hole and the fourth positioning hole and is close to the side of the third positioning hole. The method can be adopted by a common boring machine to machine the super-long board, the production efficiency is improved, and the equipment cost is lowered.

Owner:SHENZHEN XUNJIEXING TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com