Circuit board aligning method

A circuit board and together technology, applied in the field of circuit board manufacturing, can solve the problem of epoxy resin boards being unable to align

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

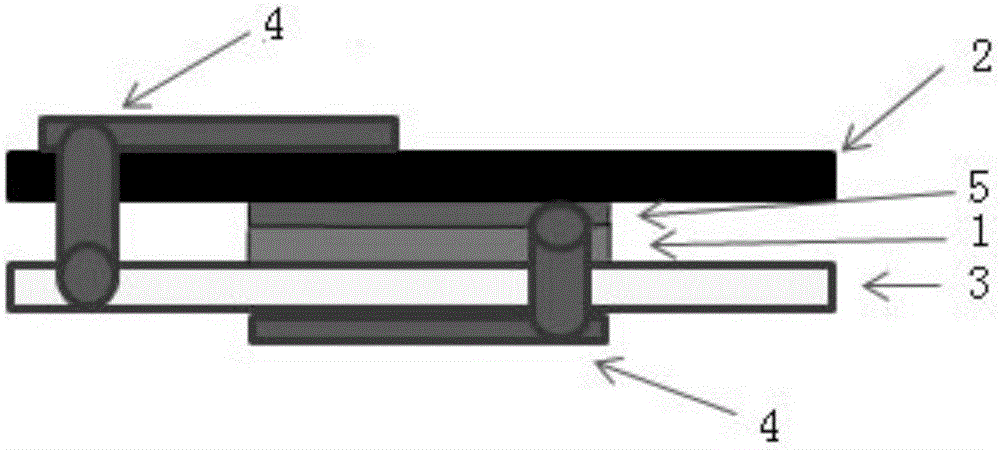

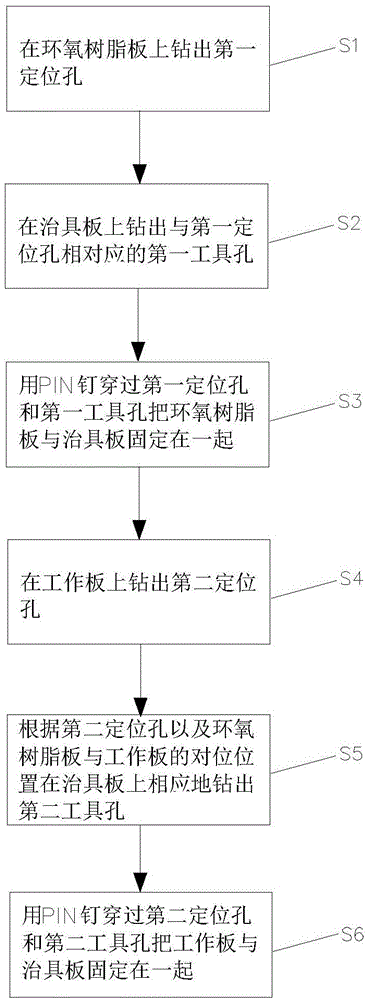

[0022] Such as Figure 1~2 As shown, the circuit board alignment method of the present invention uses the fixture board 3 to assist the alignment of the epoxy resin board 1 with inconsistent size and the working board 2, and the alignment pre-stacking process includes the following steps:

[0023] S1. Drill two first positioning holes on the epoxy resin board 1, assuming that the diameter of the first positioning holes is 2.45mm.

[0024] S2. Drill two first tool holes corresponding to the first positioning hole on the fixture plate 3. The aperture of the first tool hole is 0.05mm smaller than the aperture of the first positioning hole, that is, 2.4mm. The PIN nail passing through the first positioning hole and the first tool hole is better fixed to the jig plate 3 , and can easily pass in and out with the epoxy resin plate 1 .

[0025] S3. Use a P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com