Small-size printed circuit board (PCB) clamping device

A technology of PCB board and clamping device is applied in the field of PCB board manufacturing process, which can solve the problem of taking up a lot of process time, and achieve the effects of improving mass production efficiency, reasonable structure and convenient board placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

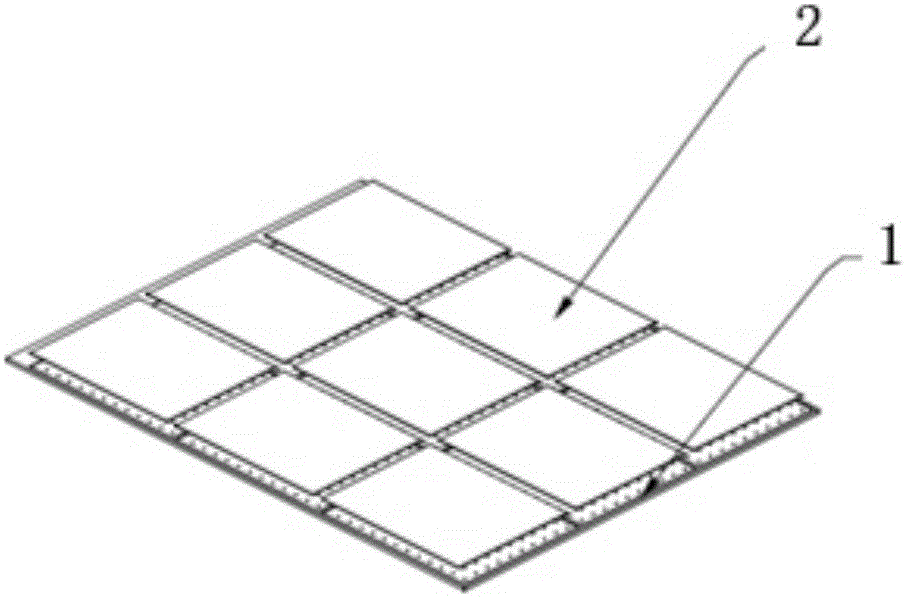

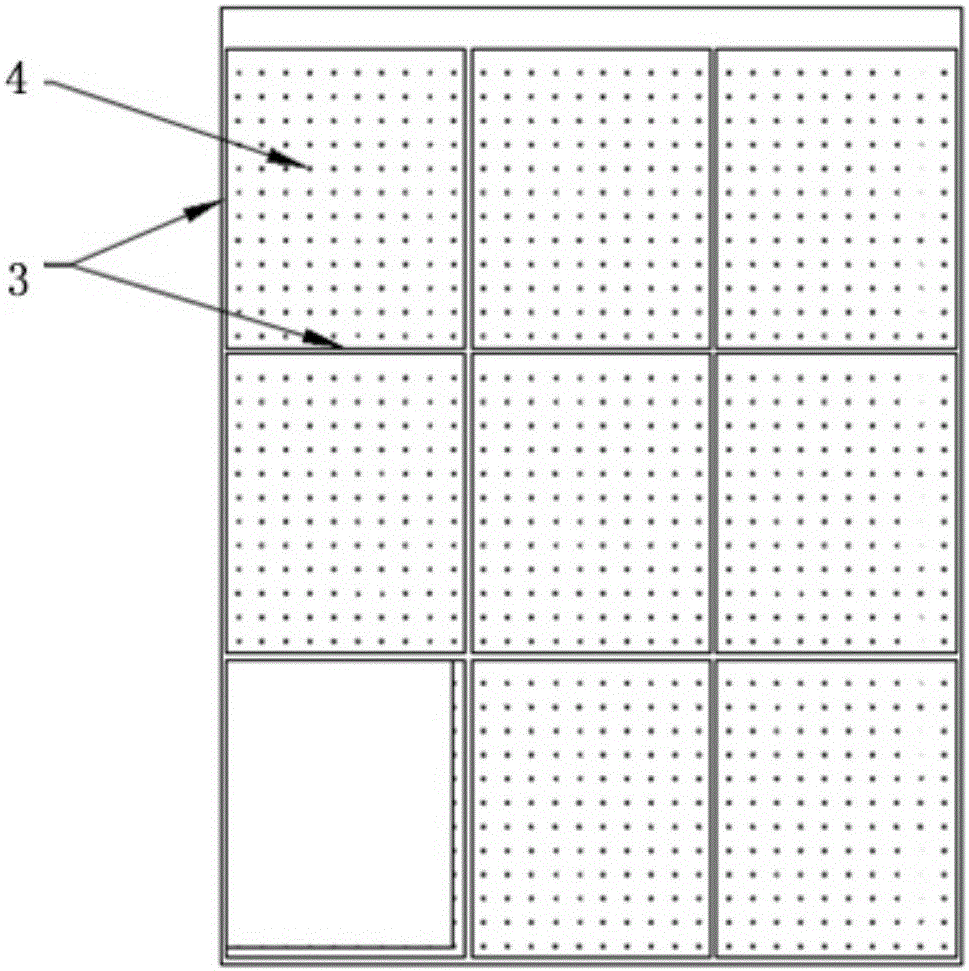

[0021] Before the small PCB board exposure processing, the small PCB board according to figure 1 The array shown is placed on the special clamping device, and placed according to the position of the initial positioning edge. A total of 9 small boards can be placed, and the special clamping device with 9 small boards placed on the suction cup of the LDI equipment , turn on the vacuum. At this time, the suction cup vacuum absorbs the small-sized PCB board through the through hole of the special clamping device, completes the fixing of the PCB, and then performs PCB exposure processing, and then closes the suction cup vacuum after the processing is completed, removes the special clamping device, and puts another piece on it. The special fixture device for the PCB board reciprocates in this way to complete the exposure of a large number of small-sized PCB boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com