Processing and positioning component for pcb

A technology for positioning components and pcb boards, which is applied in the direction of PCB positioning, electrical components, and assembling printed circuits with electrical components during processing, which can solve the problem that mobile phone PCB boards cannot be processed in batches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

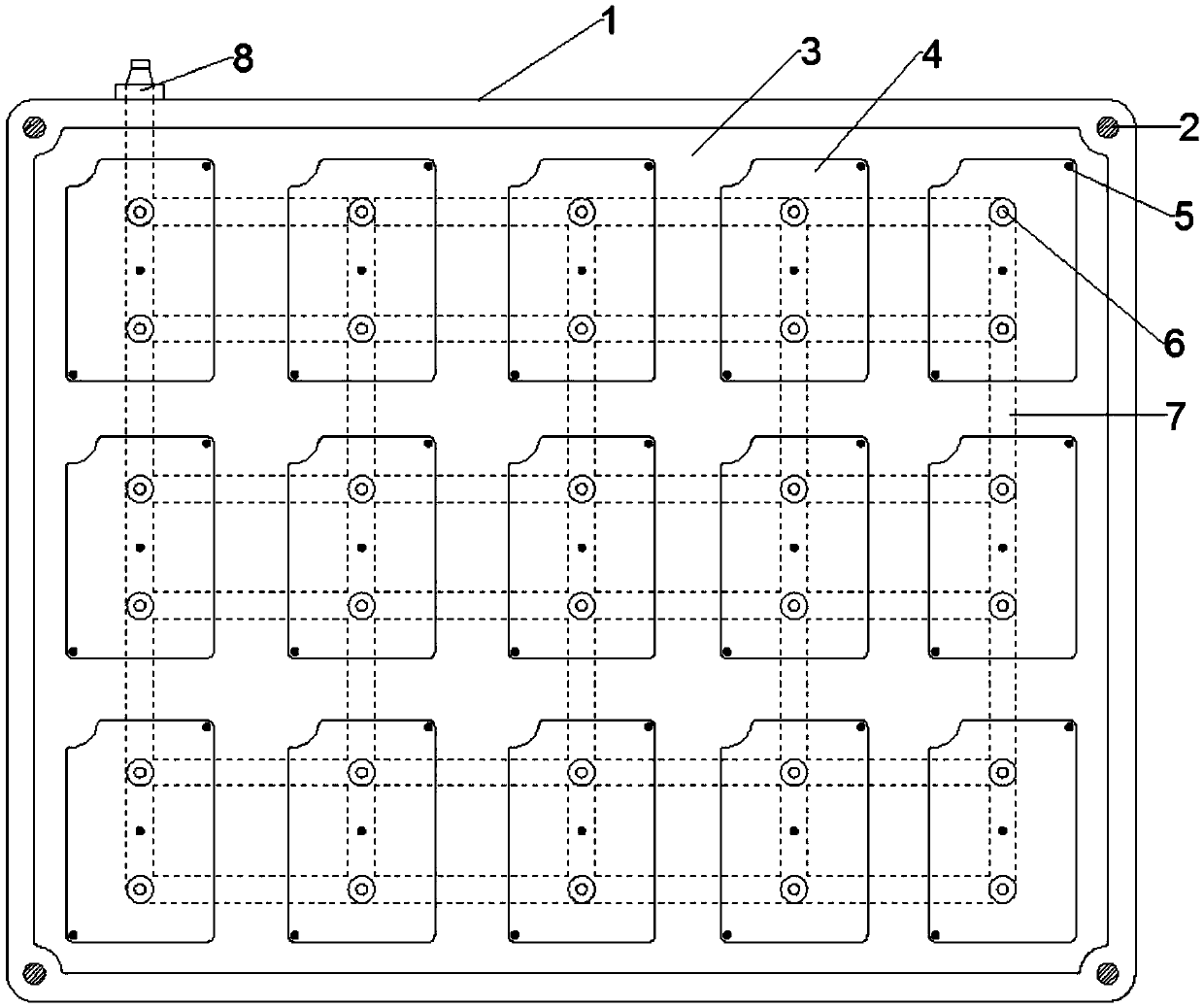

[0020] Embodiment 1: When the actual carrier tray is used, a pcb board processing and positioning assembly includes a tray body 1, the upper surface of the tray body 1 is rectangular, and the four corners of the tray body 1 are respectively fixed with a tray positioning device 2, and the tray body 1 The upper surface is fixedly provided with a feeding trough 3, and the lower surface of the feeding chute 3 is fixedly provided with a plurality of mounting holes 4, and the surface of the mounting hole 4 is fixedly provided with a plurality of fixing bolts 5, and the surface of the mounting hole 4 is fixedly provided with a plurality of fixing holes 6, The inside of the tray body 1 is fixedly provided with an air channel 7 corresponding to the fixing hole 6 , and the side of the tray body 1 is fixedly provided with an air suction port 8 .

[0021] As a preferred solution, the number of 5 fixing bolts in each mounting hole 4 is three; as a preferred solution, the number of 6 fixing ...

Embodiment 2

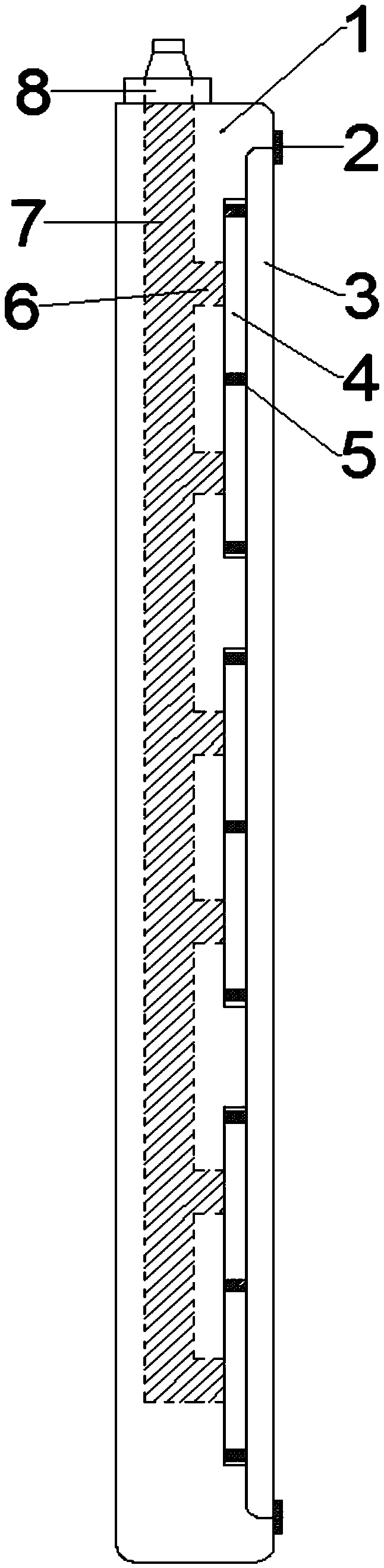

[0023] Embodiment 2: After using the carrier tray, a pcb board processing and positioning assembly includes a tray body 1, the upper surface of the tray body 1 is rectangular, and the four corners of the tray body 1 are respectively fixed with tray positioning devices 2, and the upper surface of the tray body 1 The surface is fixed with a feed trough 3, the lower surface of the feed trough 3 is fixed with a plurality of installation holes 4, the surface of the installation hole 4 is fixed with a plurality of fixing bolts 5, the surface of the installation hole 4 is fixed with a plurality of fixing holes 6, the tray The inside of the main body 1 is fixedly provided with an air passage 7 corresponding to the fixing hole 6 , and the side of the tray main body 1 is fixedly provided with an air suction port 8 .

[0024] As a preferred solution, the number of 5 fixing bolts in each mounting hole 4 is three; as a preferred solution, the number of 6 fixing holes in each mounting hole 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com