Movement mechanism of spot welding machine PCB (printed circuit board)

A motion mechanism and PCB board technology, applied in PCB positioning, welding equipment, circuit board tool positioning and other directions during processing, can solve problems affecting mounting components, etc., meet production needs, facilitate popularization and use, and have a novel and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

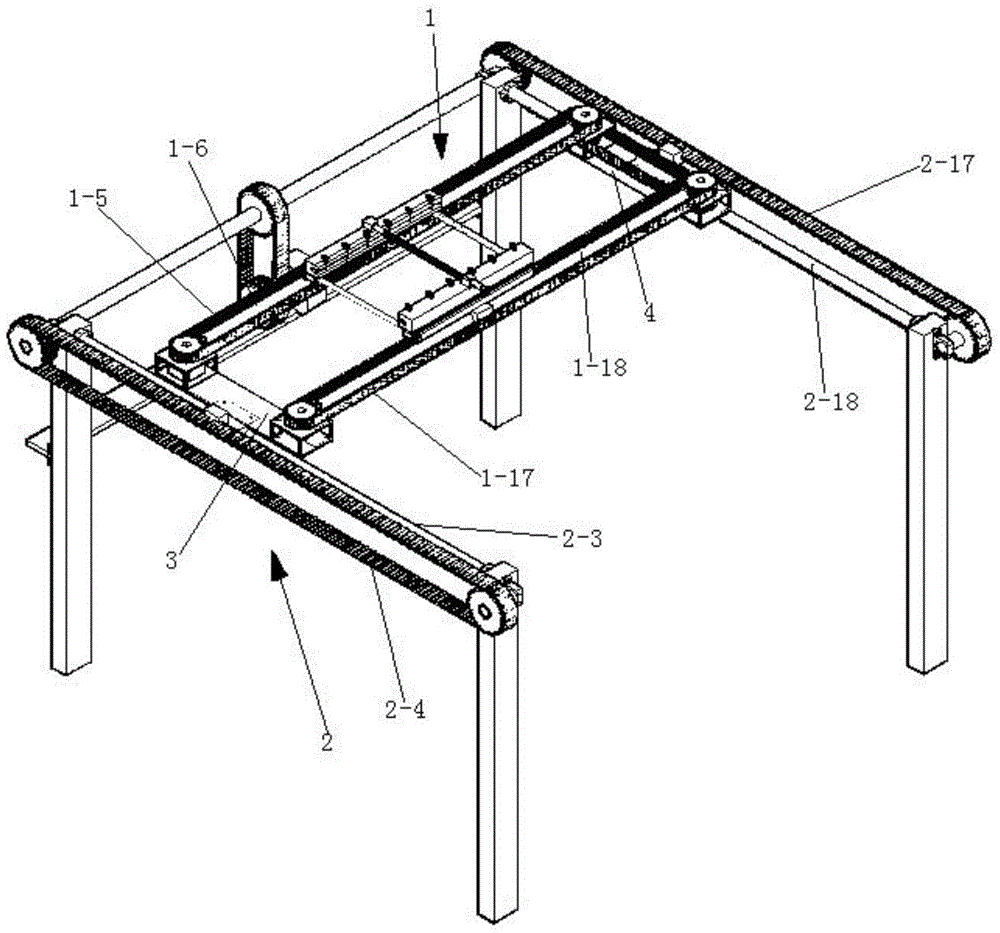

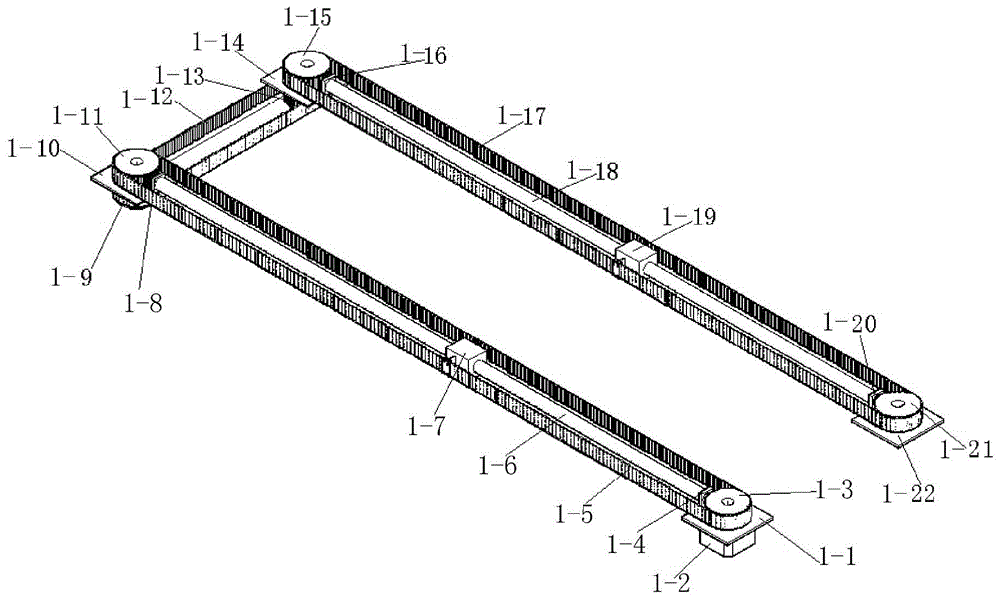

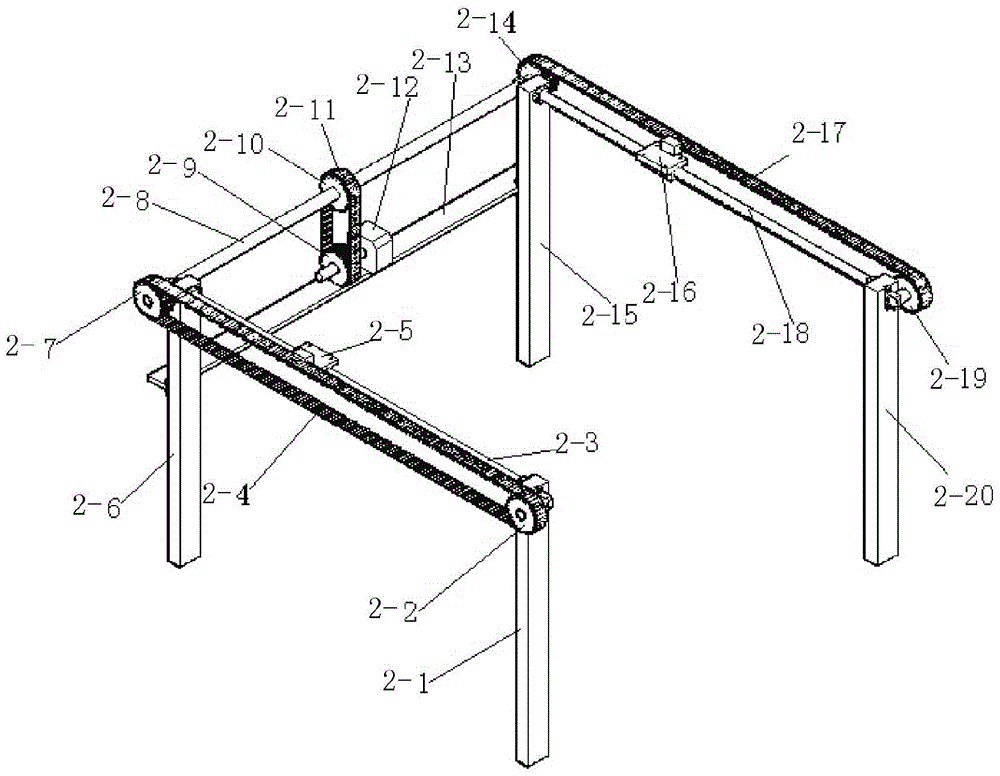

[0036] Such as figure 1 , figure 2 and image 3The movement mechanism of a spot welding machine PCB board shown includes a Y-axis movement mechanism 2 and an X-axis movement mechanism 1 installed on the Y-axis movement mechanism 2; the X-axis movement mechanism 1 includes a horizontally arranged driving belt 1 -5, driven belt 1-17, the first driving pulley 1-3 and the second driving pulley 1-11 for driving the driving belt 1-5, and the first driven for driving the driven belt 1-17 Pulley 1-15 and the second driven pulley 1-21; said driving belt 1-5 is parallel to driven belt 1-17, and a transmission is arranged between said driving belt 1-5 and driven belt 1-17 Belt 1-12, a drive motor 1-2 is arranged below the first drive pulley 1-3, and the central axis of the first drive pulley 1-3 is rotated and installed between the drive motor 1-2 and the first drive pulley 1 -3 on the first mount 1-1, the drive motor 1-2 is installed on the first mount 1-1, the output shaft of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com