Clamping tool of circuit board production line

A technology for clamping tooling and circuit boards, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of complex implementation steps, high manufacturing costs, and high maintenance costs, and achieve low maintenance costs, convenient operation, and satisfactory purchase effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

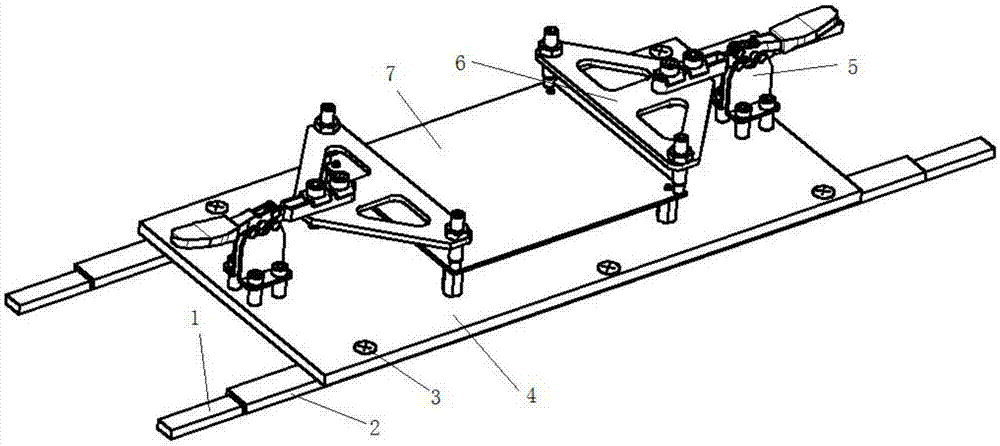

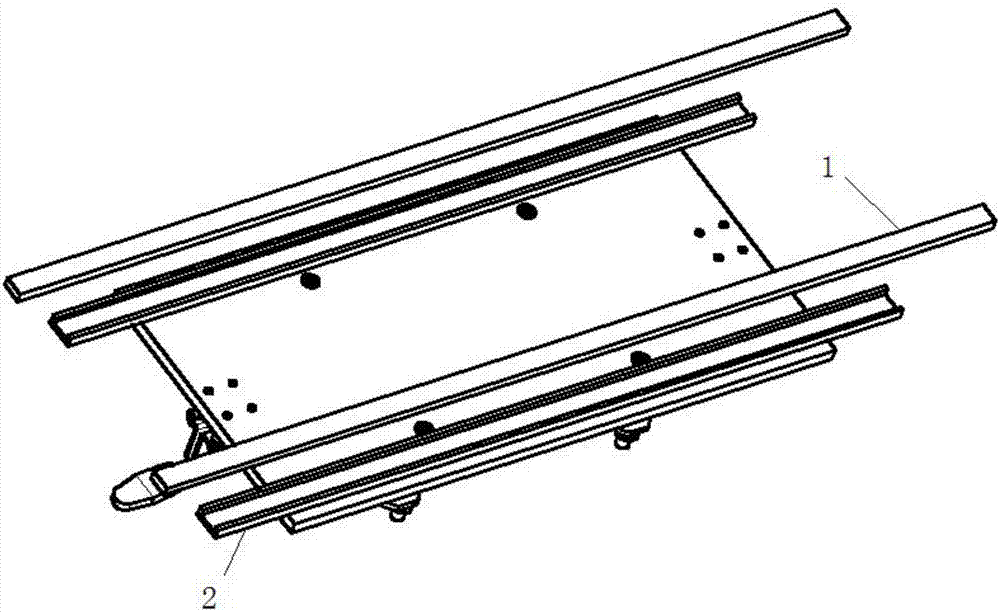

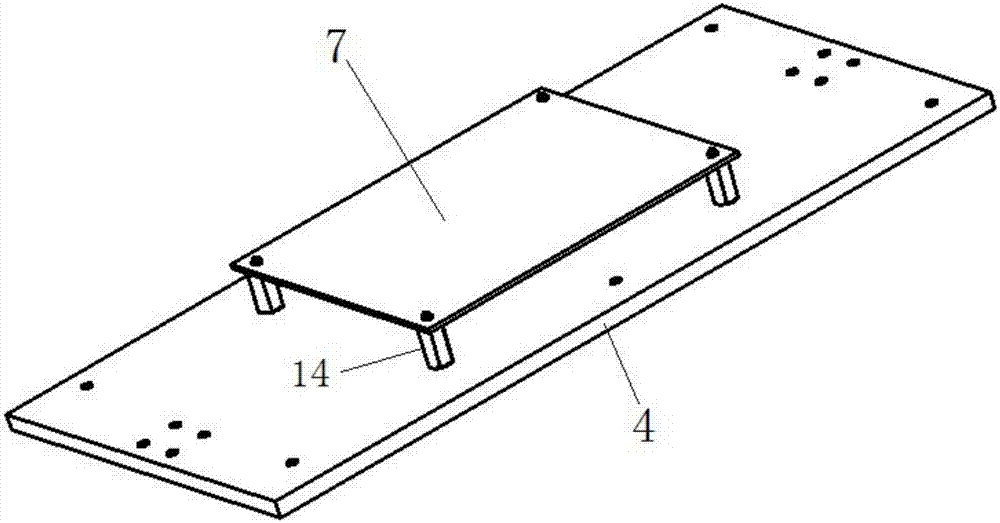

[0019] refer to Figure 1-5 , a clamping tool for a circuit board production line, including an elbow clamp. The front end of the elbow clamp 5 is provided with a mounting frame 501 for fixing the splint 6, and the bottom of the mounting frame 501 is provided with a splint 6 for supporting the rubber contact 12. The splint 6 is an isosceles triangular steel plate, and its obtuse angle apex and the mounting frame 501 are fixed by bolts 8. A gasket 10 is arranged between the bolt 8 and the upper end surface of the mounting frame 501 to reinforce the stability of the structure. The two sides of the splint 6 Each acute angle is provided with a resin limit bolt 13 that ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com