Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about "Other printed circuit details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

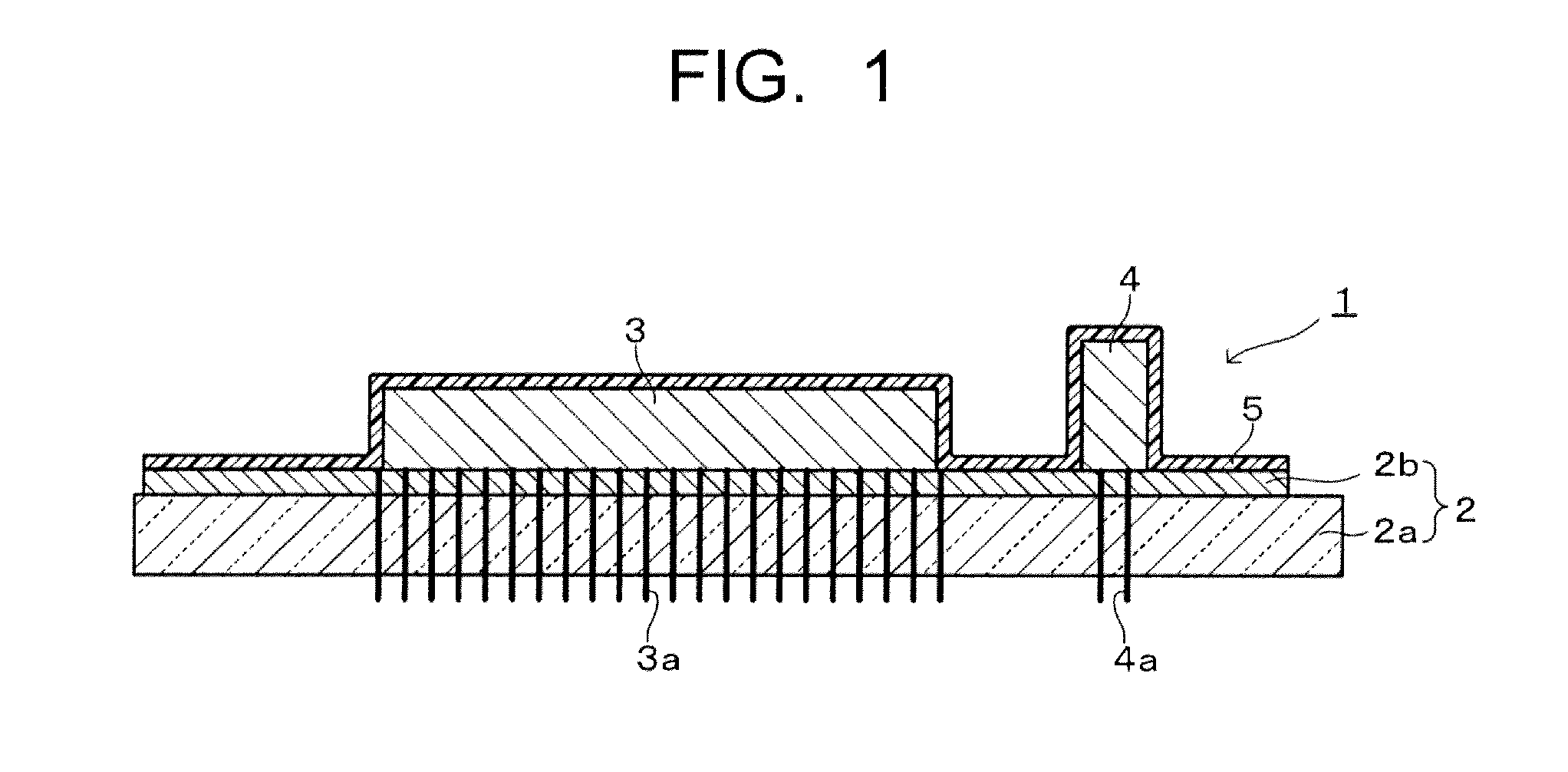

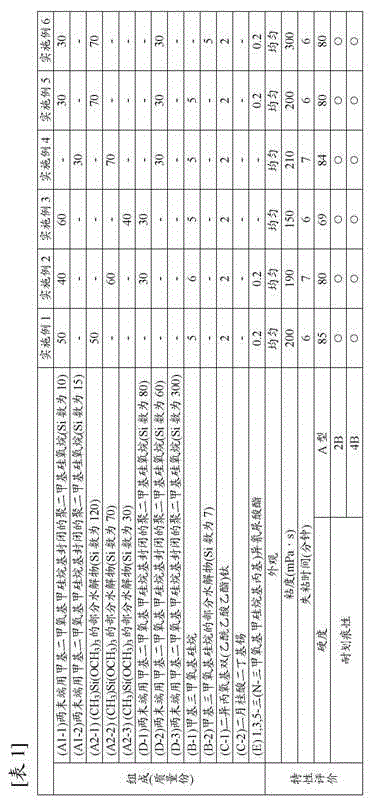

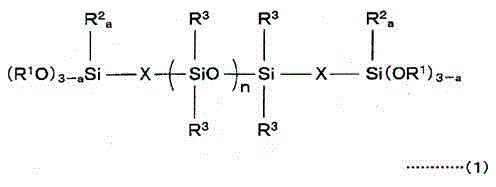

Room-temperature-curable polyorganosiloxane composition and electric/electronic apparatus

InactiveUS20150140346A1Low viscosityGood paintabilityLayered productsCoatingsSilane compoundsCross-link

This room-temperature-curable polyorganosiloxane composition contains: (A) 100 parts by mass of polyorganosiloxane consisting of: (A1) 10 to 80 parts by mass of a both ends alkoxysilyl group-terminated polyorganosiloxane and (A2) 90 to 20 parts by mass of a partial hydrolysis condensate (the number of Si atoms is 10 to 200) of a silane compound expressed by a general formula: R4bSi(OR)4-b; (B) 0.1 to 15 parts by mass of a silane compound or a partial hydrolysis condensate thereof (the number of Si atoms is 1 or more and less than 10) as a cross-linking agent; and (C) 0.1 to 15 parts by mass of an organic titanium compound as a curing catalyst. It has low viscosity and good coatability without a solvent, and forms a cured coating film excellent in scratch resistance.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

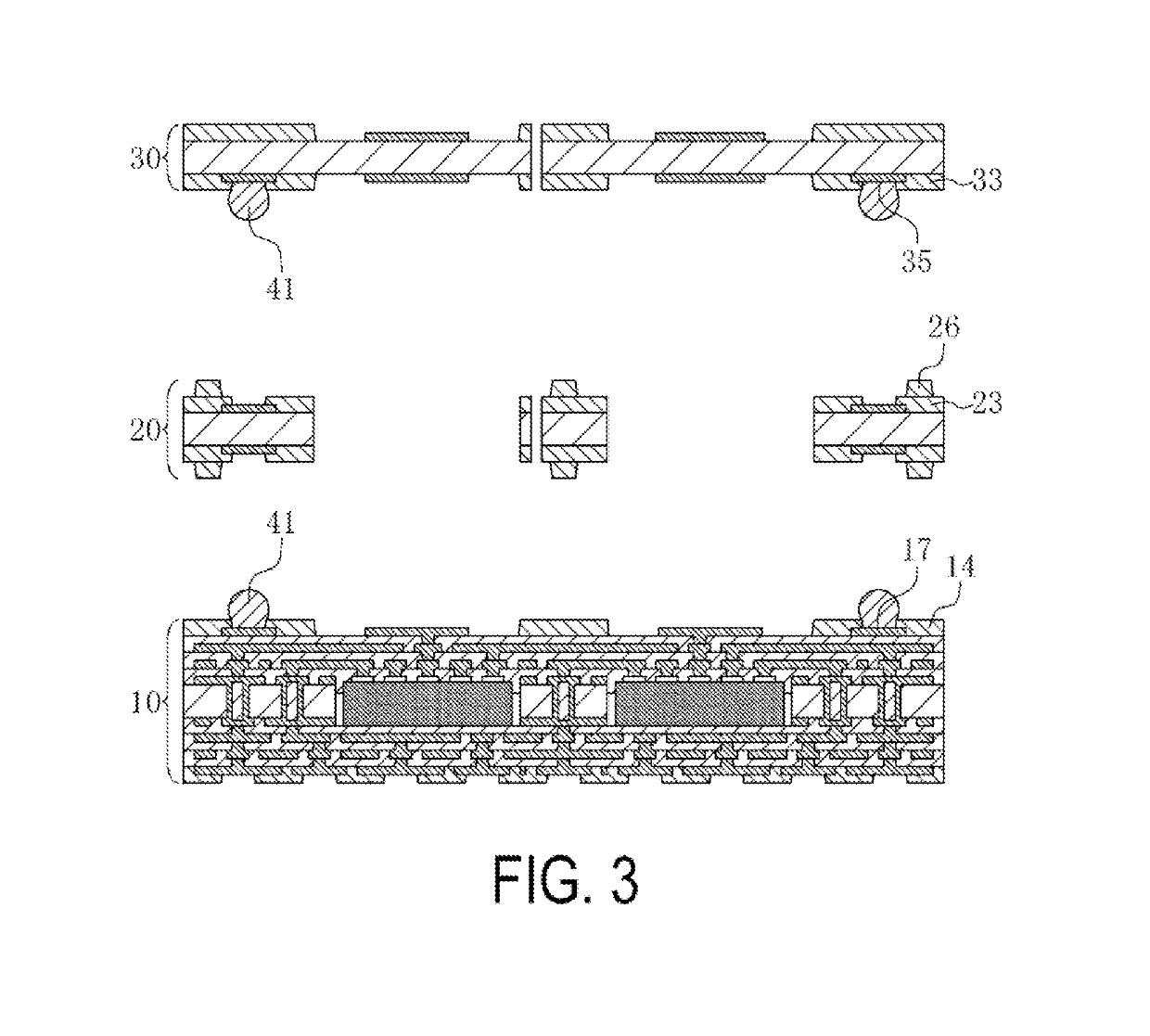

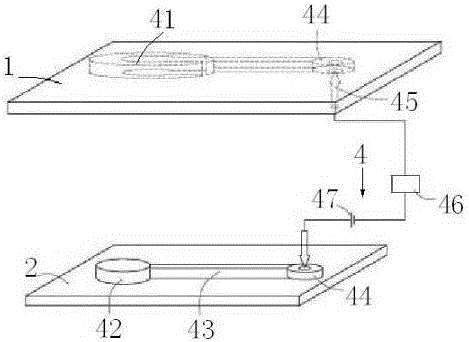

Method of making a microelectronic device

ActiveUS20170111994A1Side-by-side/stacked arrangementsSemiconductor/solid-state device detailsEngineeringConductive materials

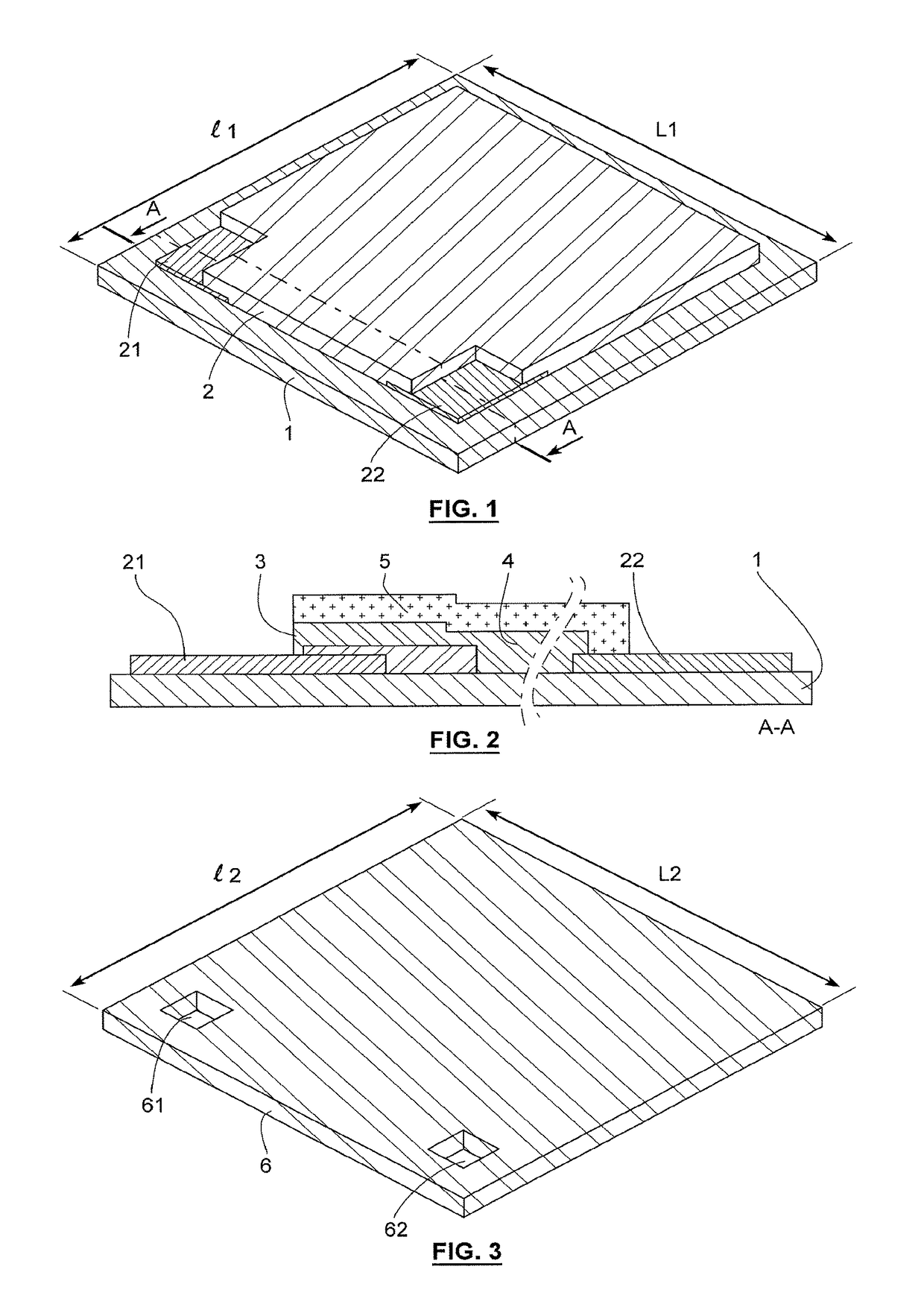

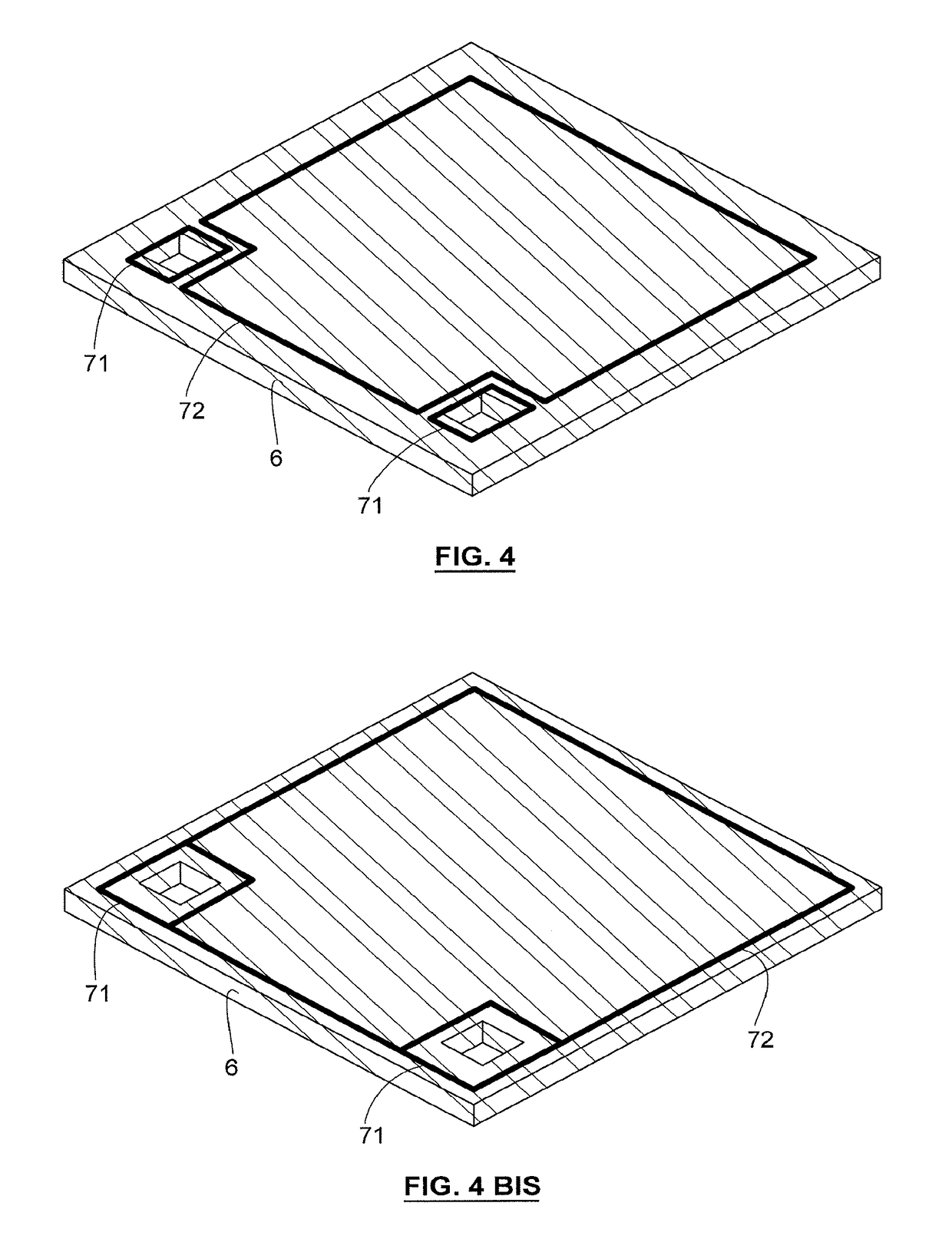

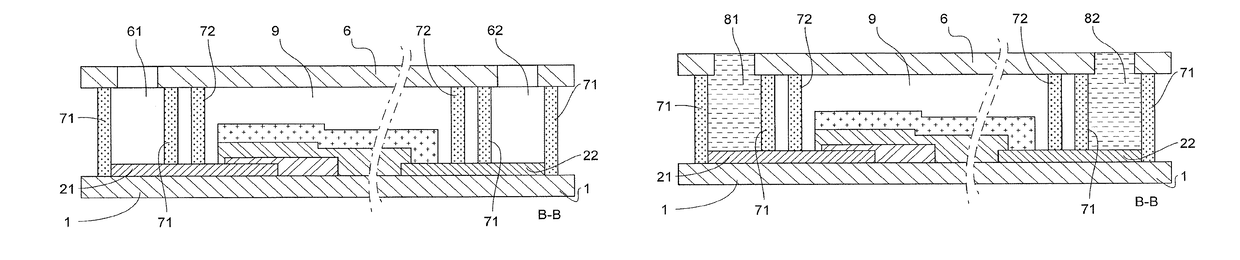

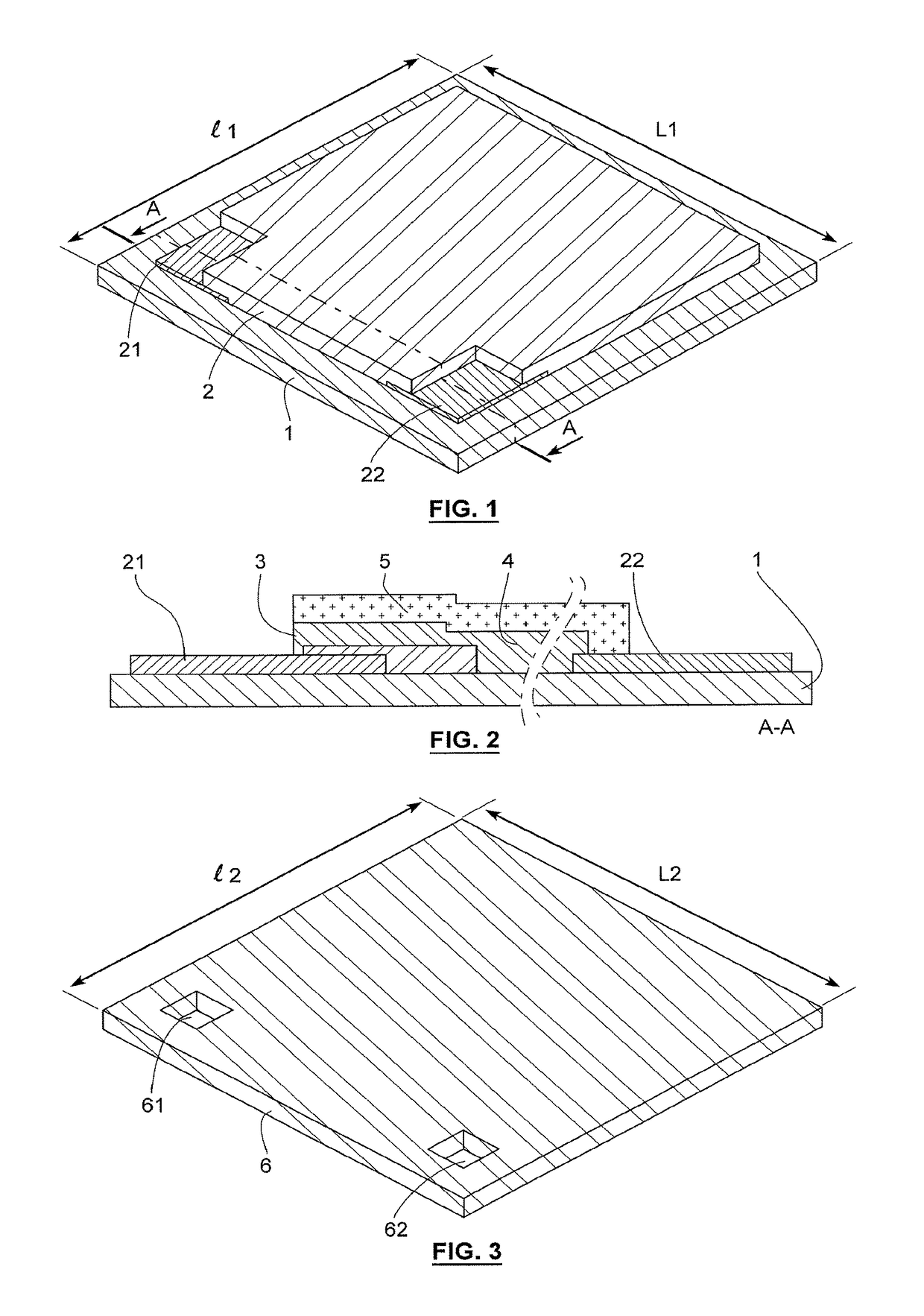

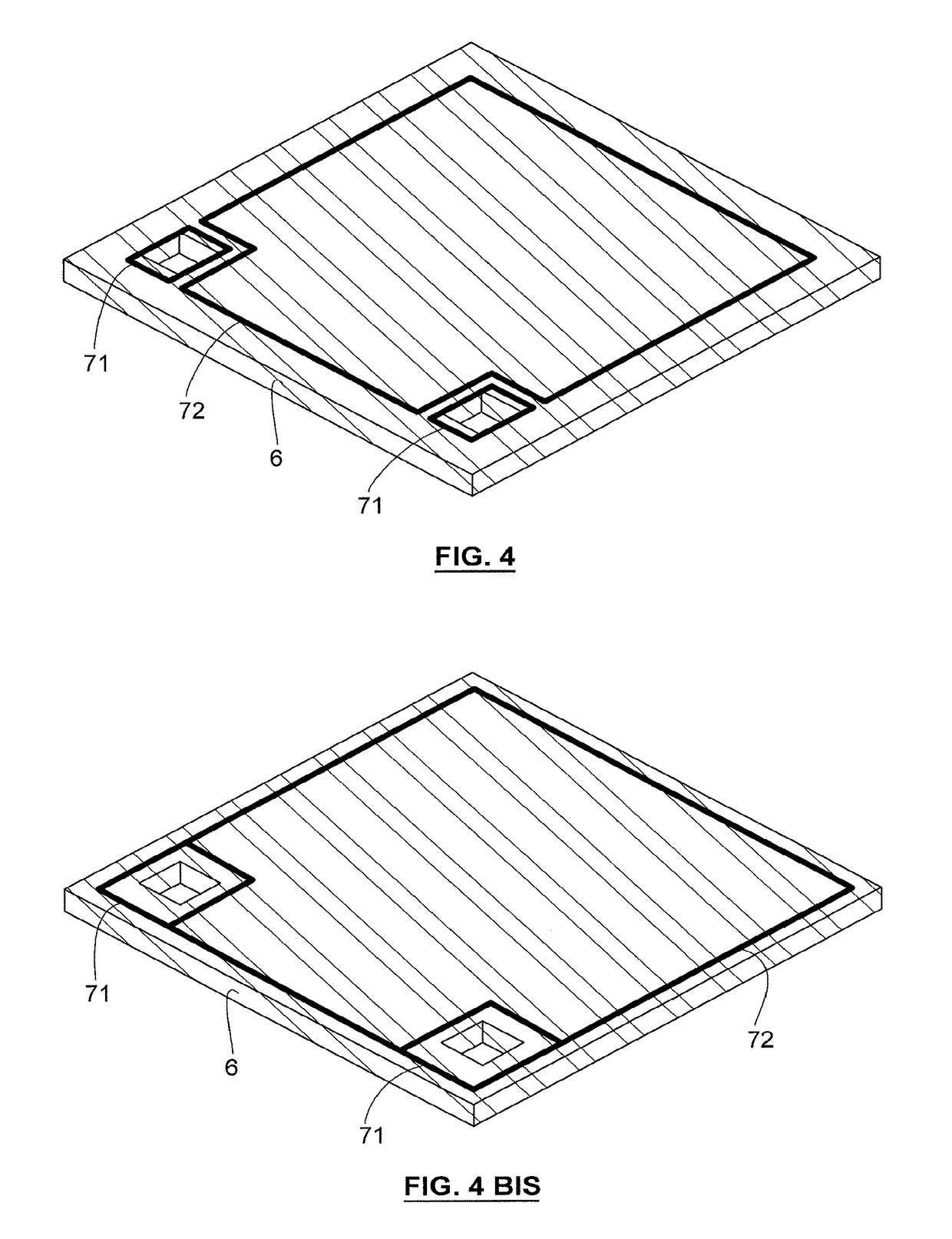

This invention relates to a method for producing an electrical system comprising a support (1) bearing on a first face at least one device: with the device comprising at least one electronic component (2) provided with at least one electrical connector (21, 22), with the method comprising: a step of setting in place of a cover (6) positioned above the component; said cover (6) comprising at least one passage (61, 62) according to a dimension in thickness of the cover (6) in such a way as to form an access space to the at least one electrical connector (21, 22), a step of forming a sealing seam (71) in such a way that the component is encapsulated in a sealed cavity (9) delimited by the first face of the support (1), the first face of the cover (6) and the sealing seam (7), The method comprises a step of filling with a conductive material of is at least one passage (61, 62) of the cover (6) in such a way as to establish an electrical continuity between the conductive material and the at least one electrical connector (21, 22), formant a tapping (81, 82) and in that the sealing seam (7) comprises a dielectric material.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

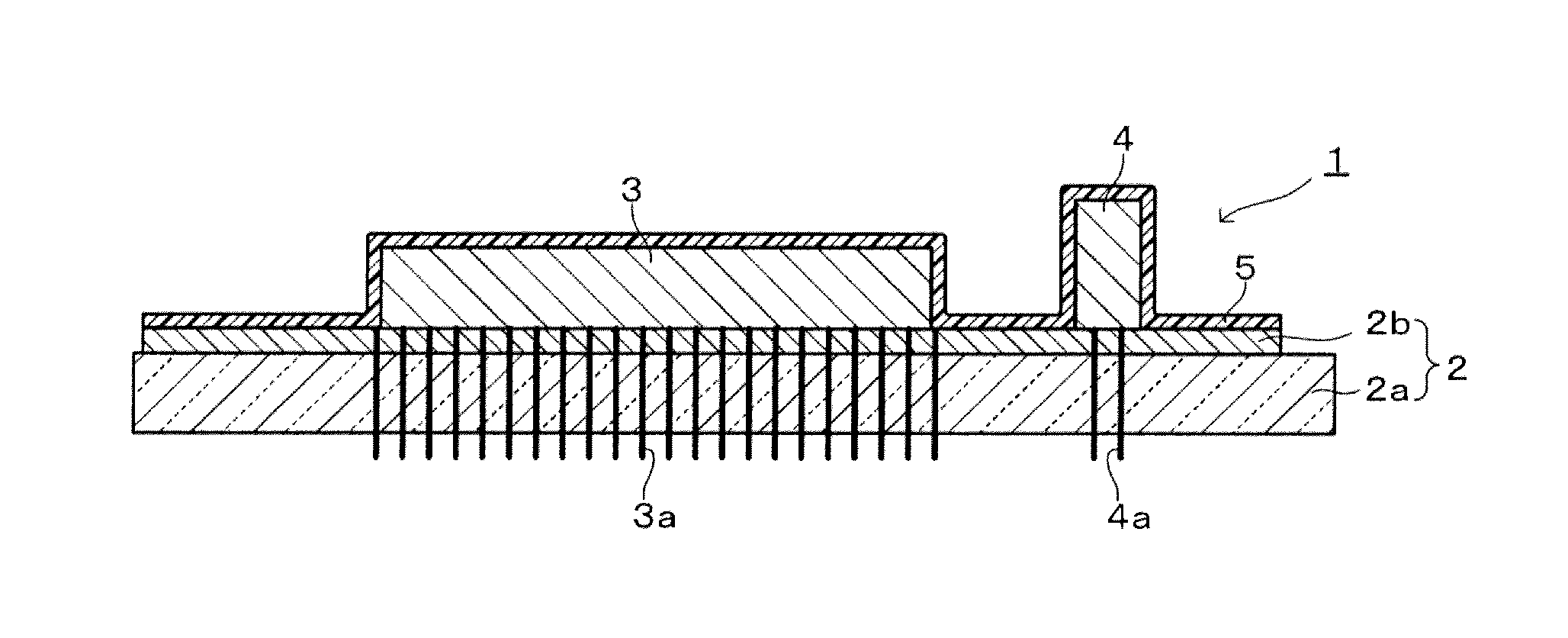

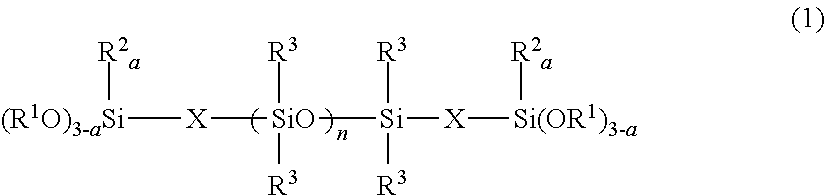

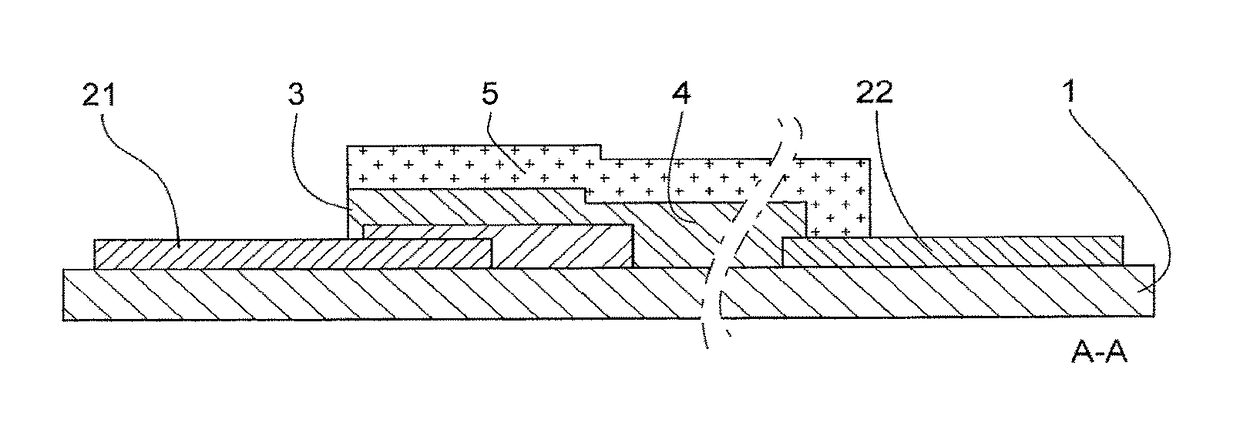

Electronic device and method for manufacturing electronic device

ActiveUS20170359900A1Evenly and uniformly applyLow costFinal product manufactureInsulating layers/substrates workingElectrical conductorEngineering

Owner:MURATA MFG CO LTD

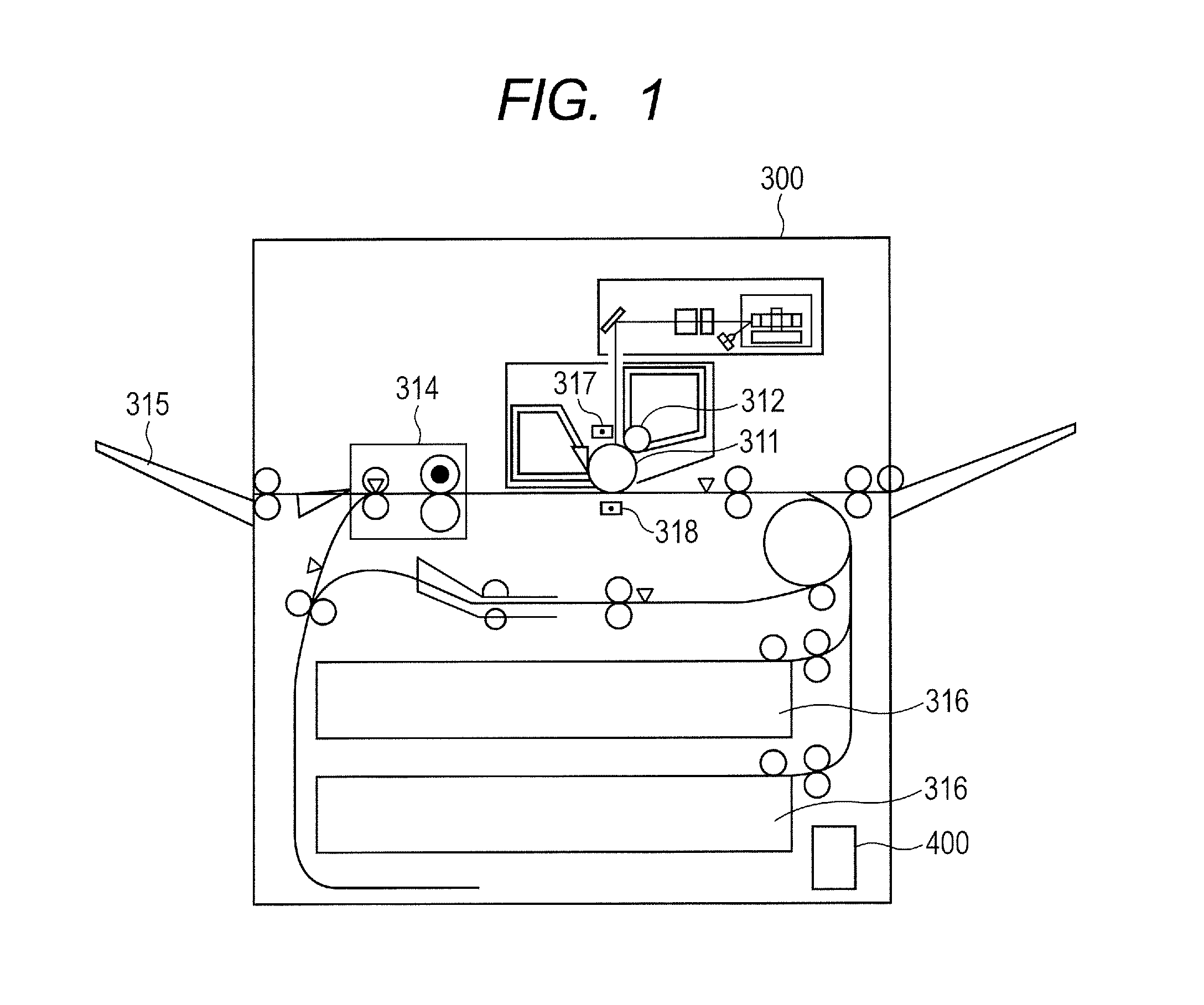

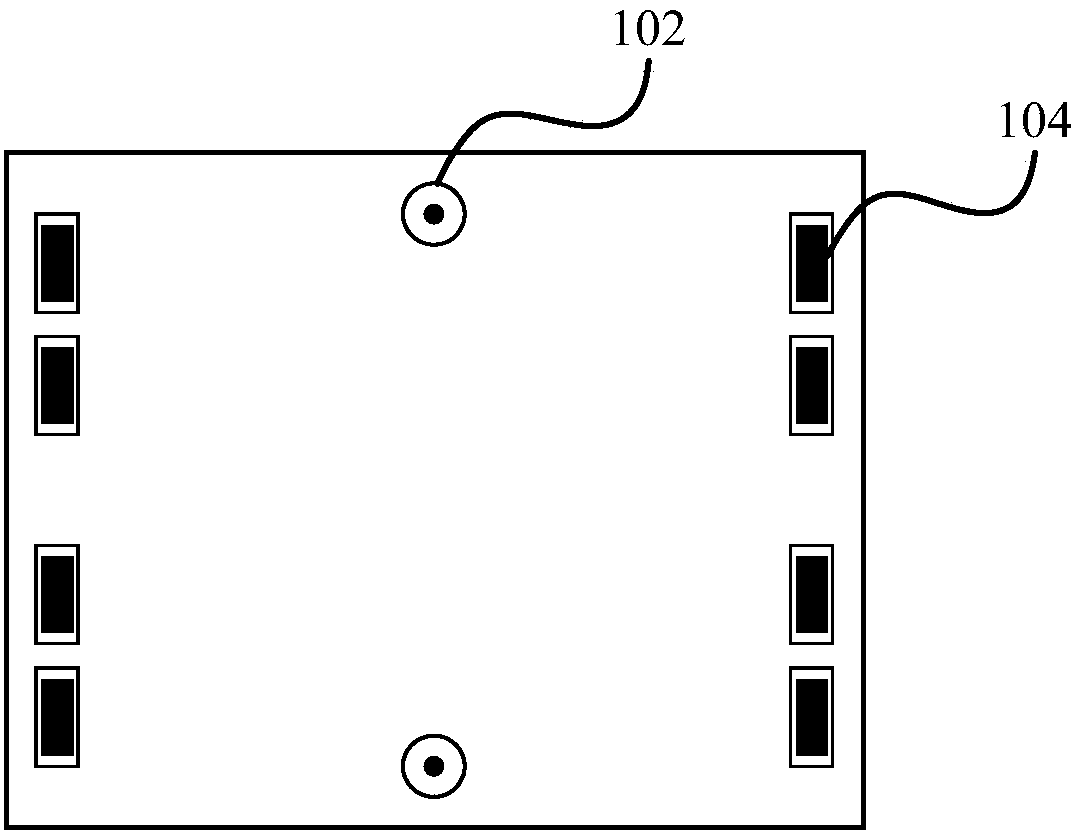

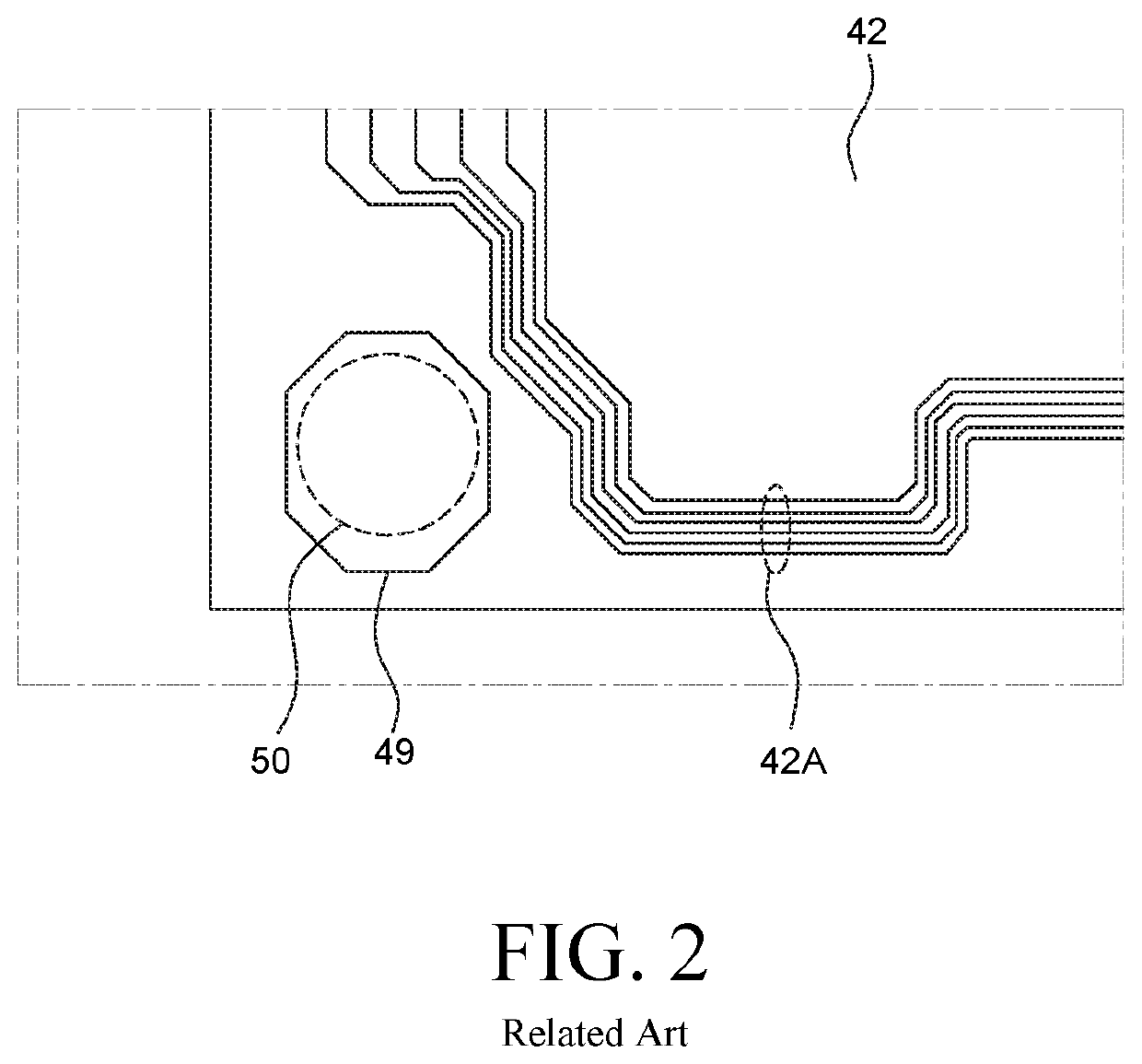

Printed board and image forming apparatus

ActiveUS20150216036A1Reduce area requirementsEasy to performInspection/indentification of circuitsElectrographic process apparatusImaging equipmentElectrical and Electronics engineering

Owner:CANON KK

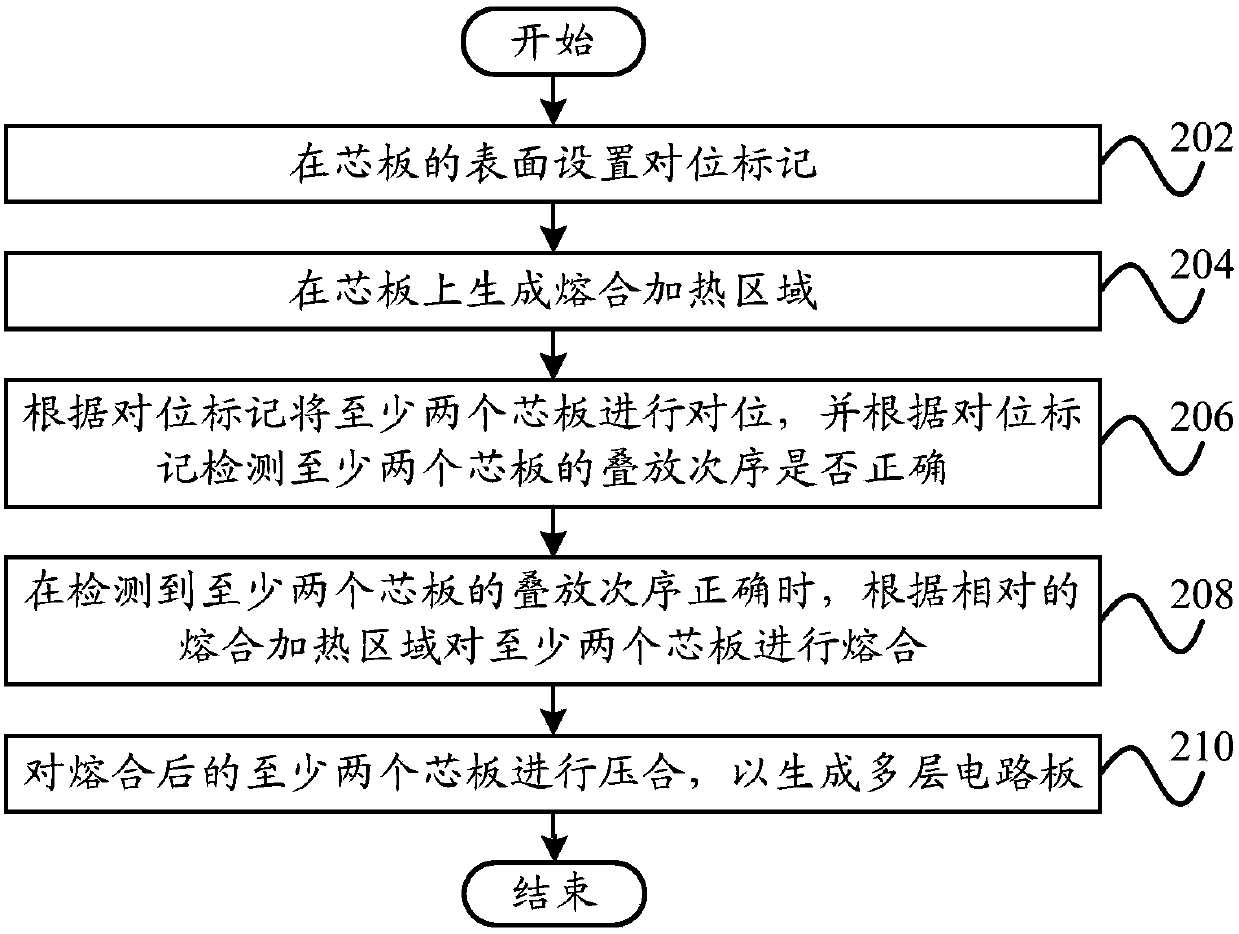

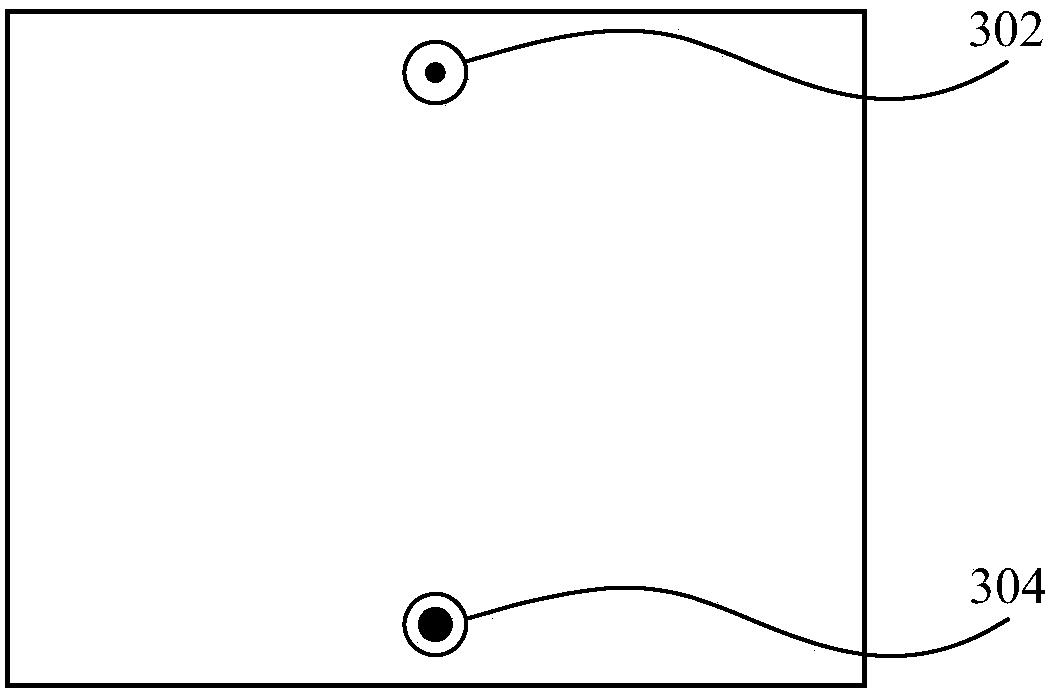

Multi-layer circuit board and fabrication method of same

ActiveCN107708285APlay a foolproof roleReduce scrap rateInspection/indentification of circuitsMultilayer circuit manufacturePunchingOn board

The invention provides a multi-layer circuit board and a fabrication method of the same. The multi-layer circuit board comprises at least two optical alignment marks and at least two melting heating regions, wherein the at least two optical alignment marks are arranged on core boards by etching and are used for aligning at least two core boards, and the at least two melting heating regions are arranged on board edges of the core boards and are used for melting after the alignment of the at least two core boards is completed. By the technical scheme, the punching and repeated alignment processis reduced, abnormal alignment caused by an abnormal factor such as alignment hole deformation is prevented, the alignment accuracy is improved, and the production efficiency and the production quality of the circuit board are improved.

Owner:NEW FOUNDER HLDG DEV LLC +1

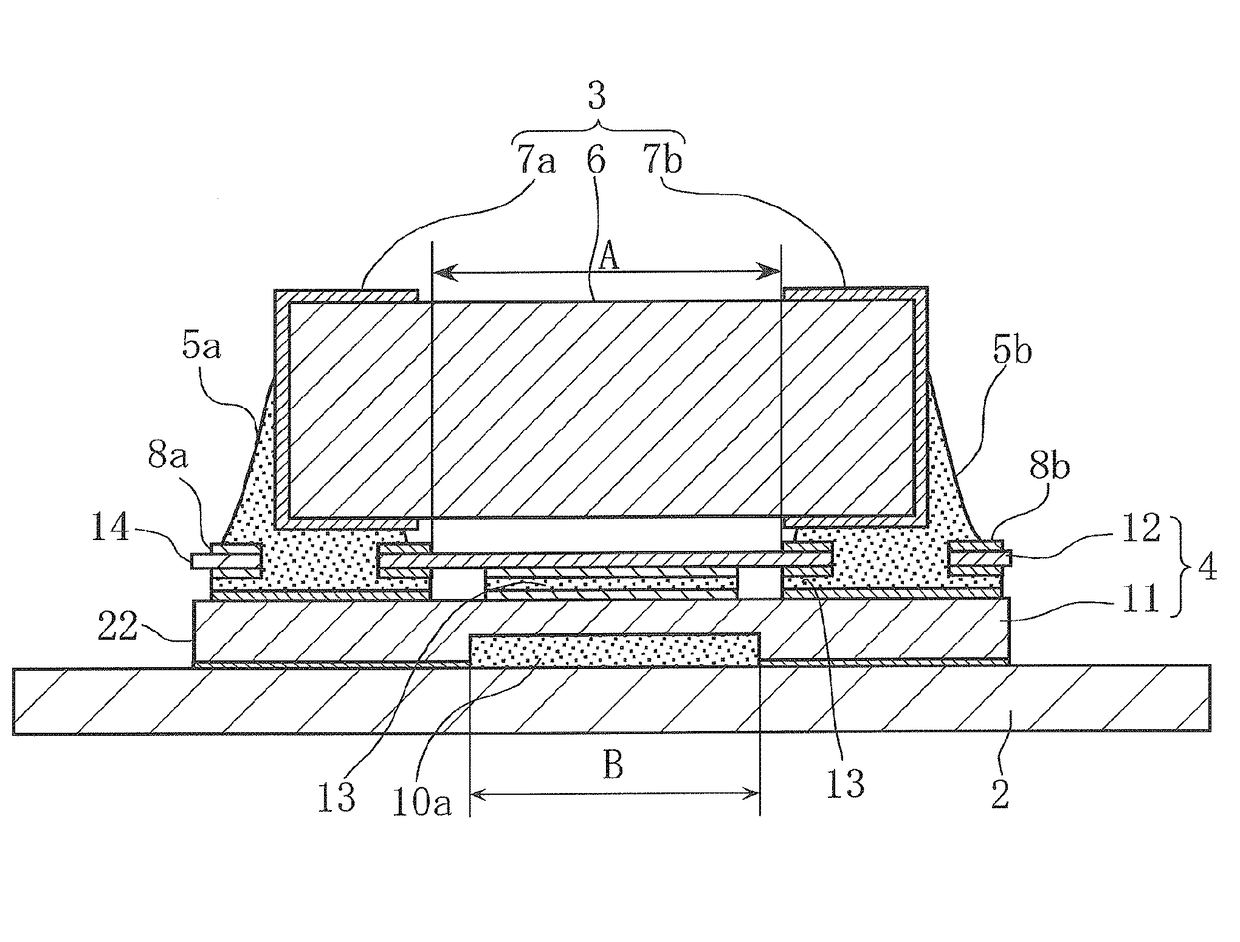

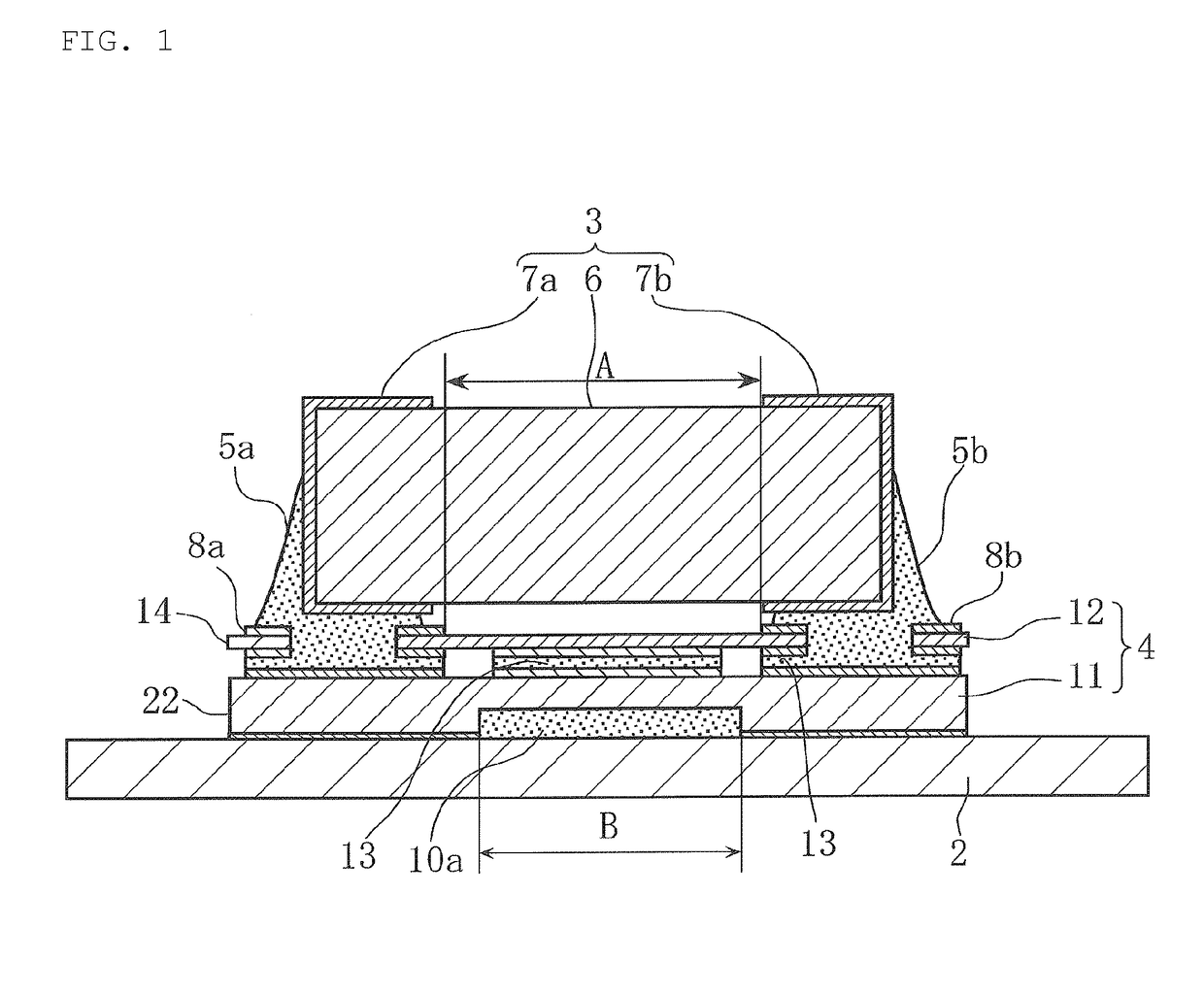

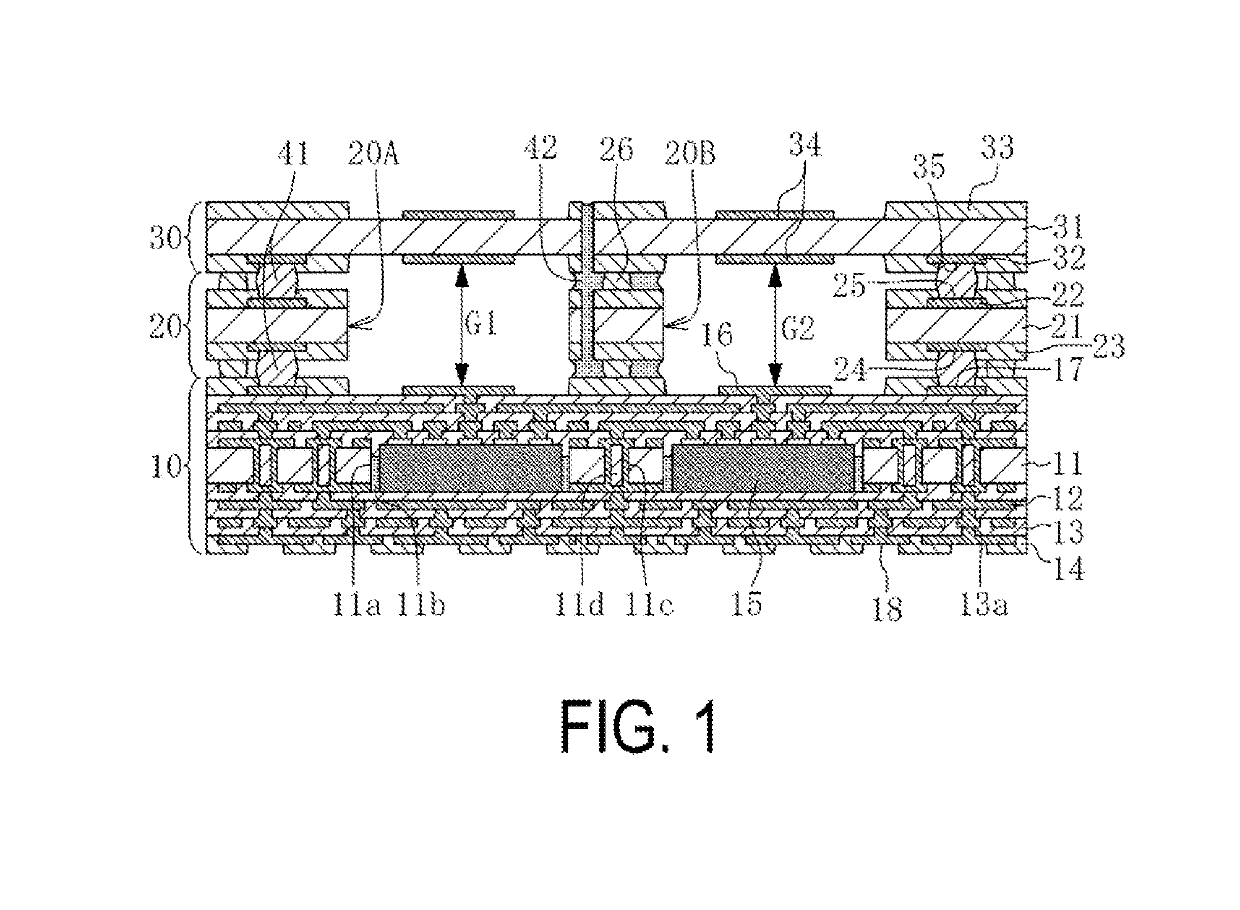

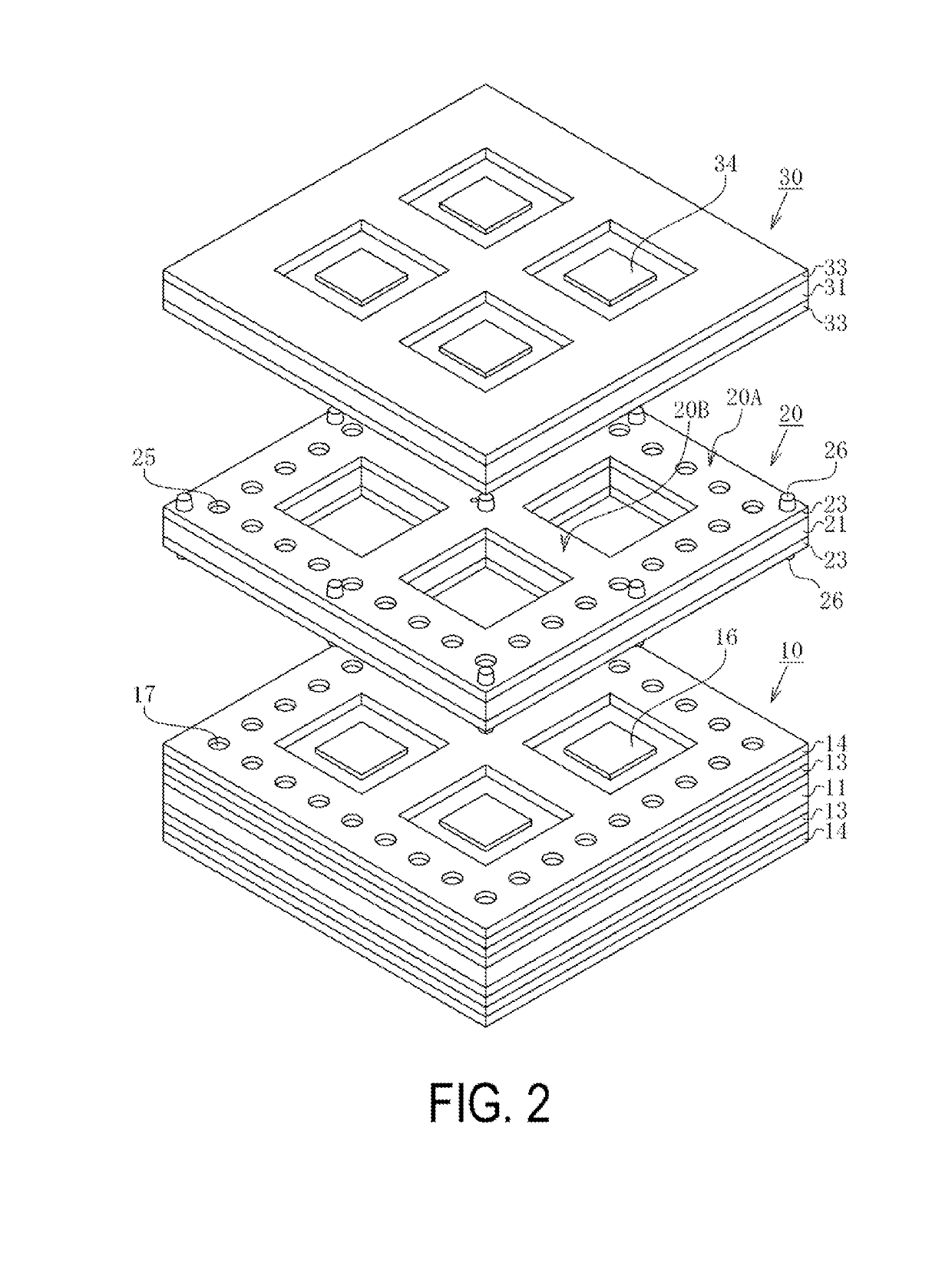

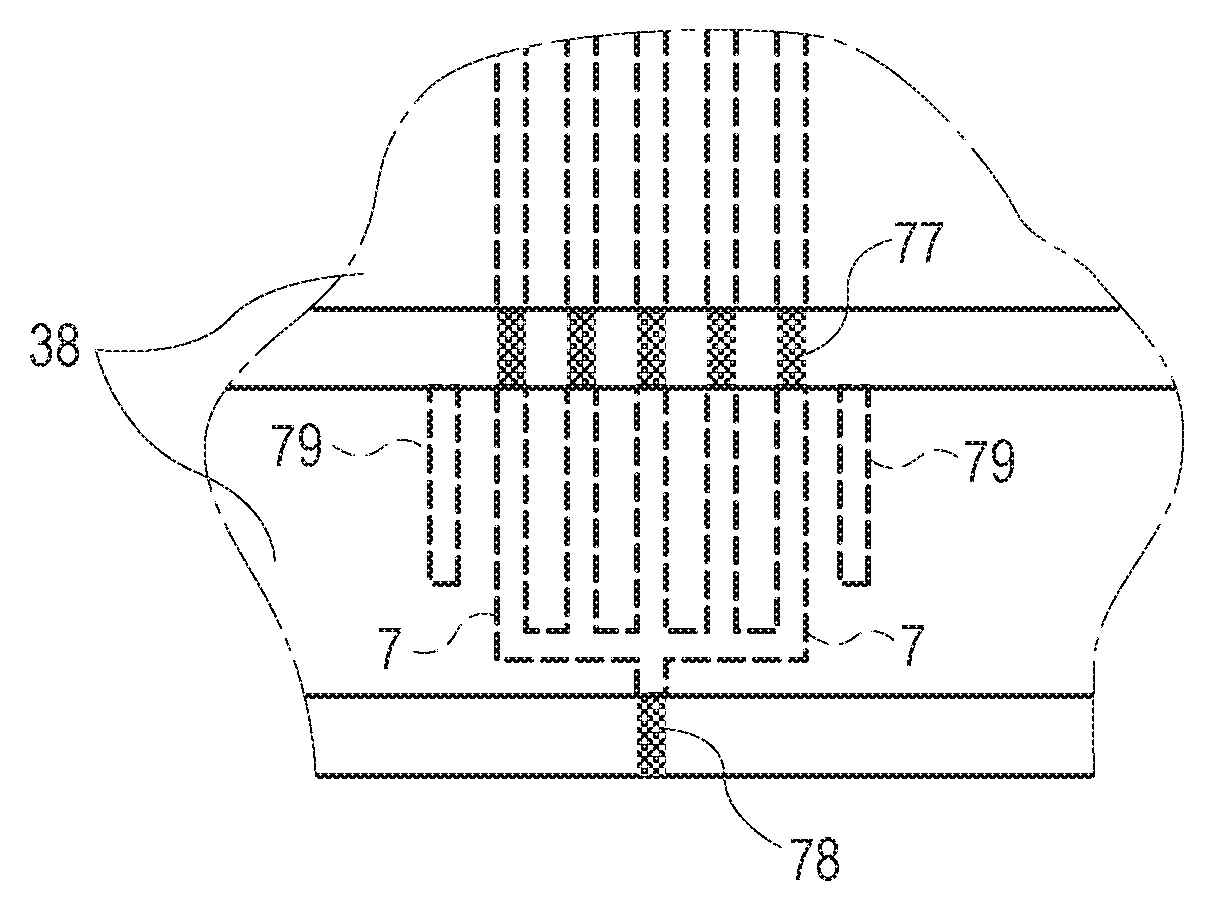

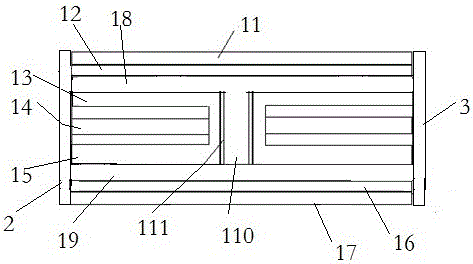

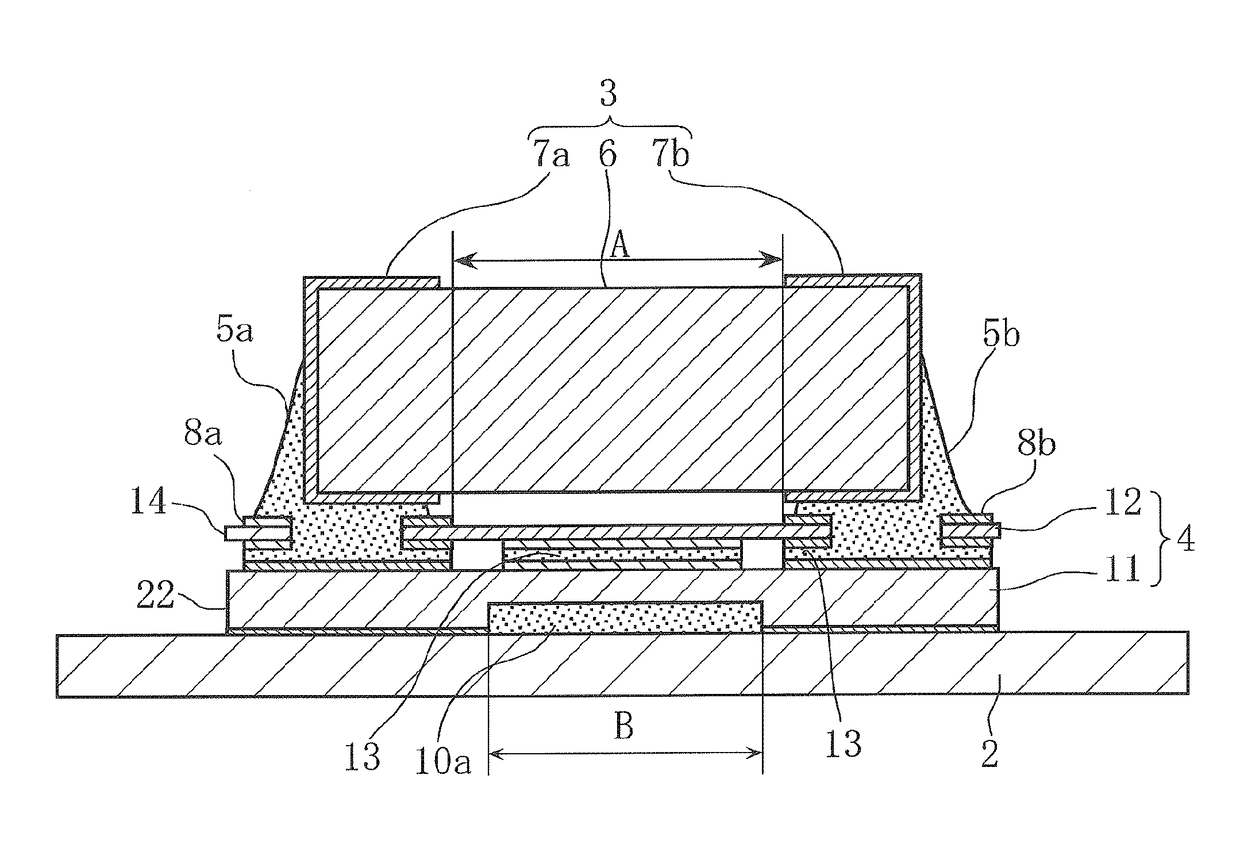

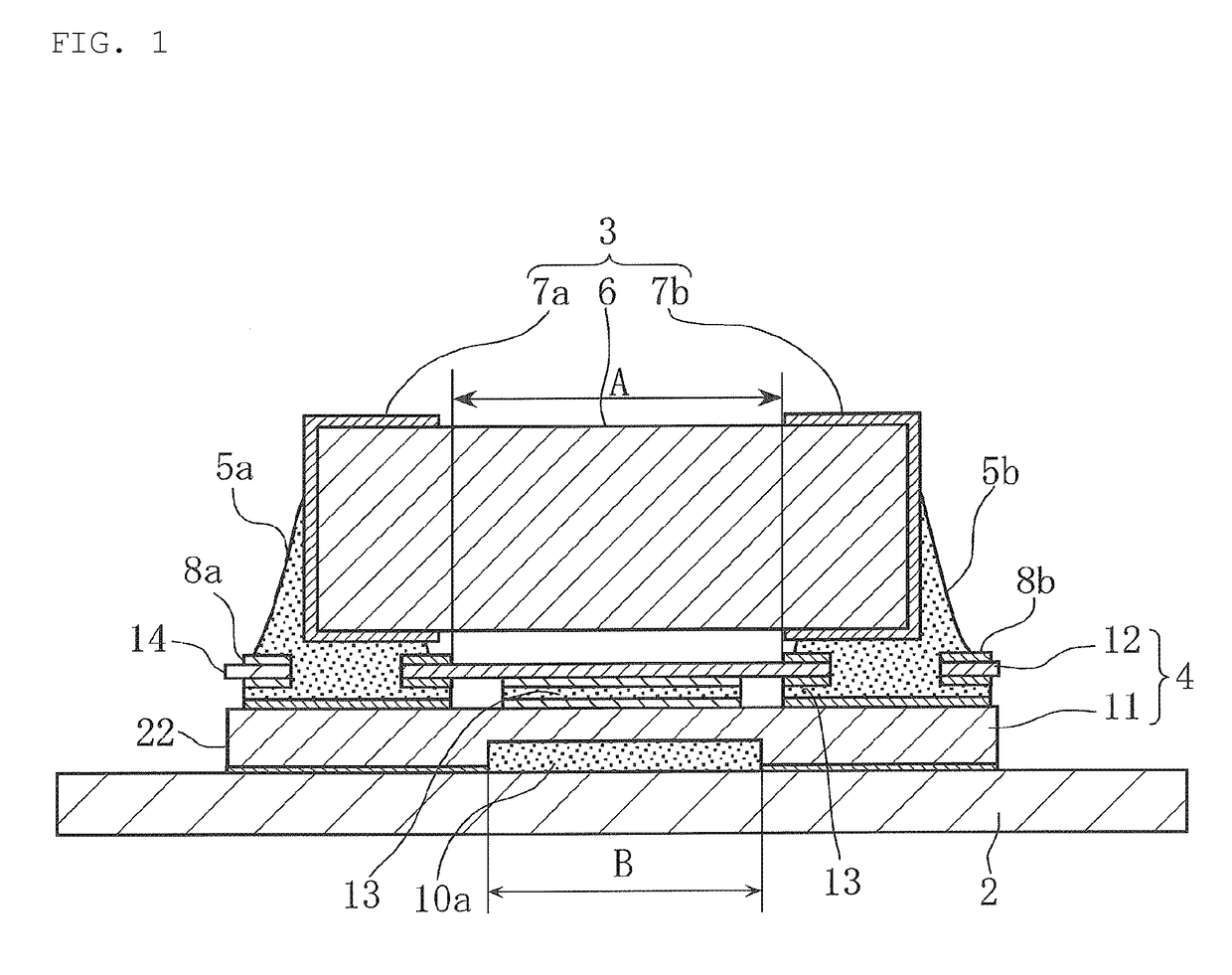

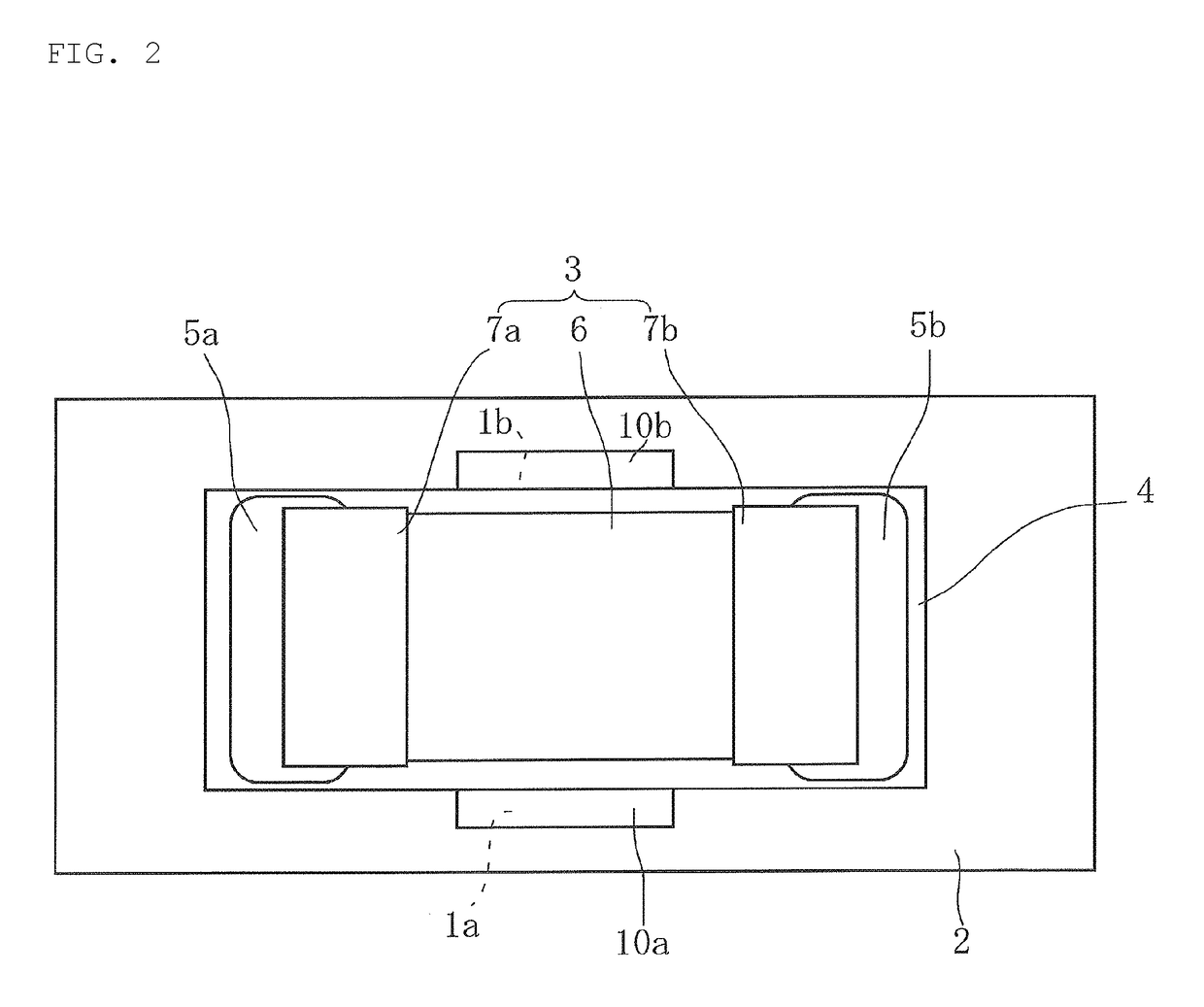

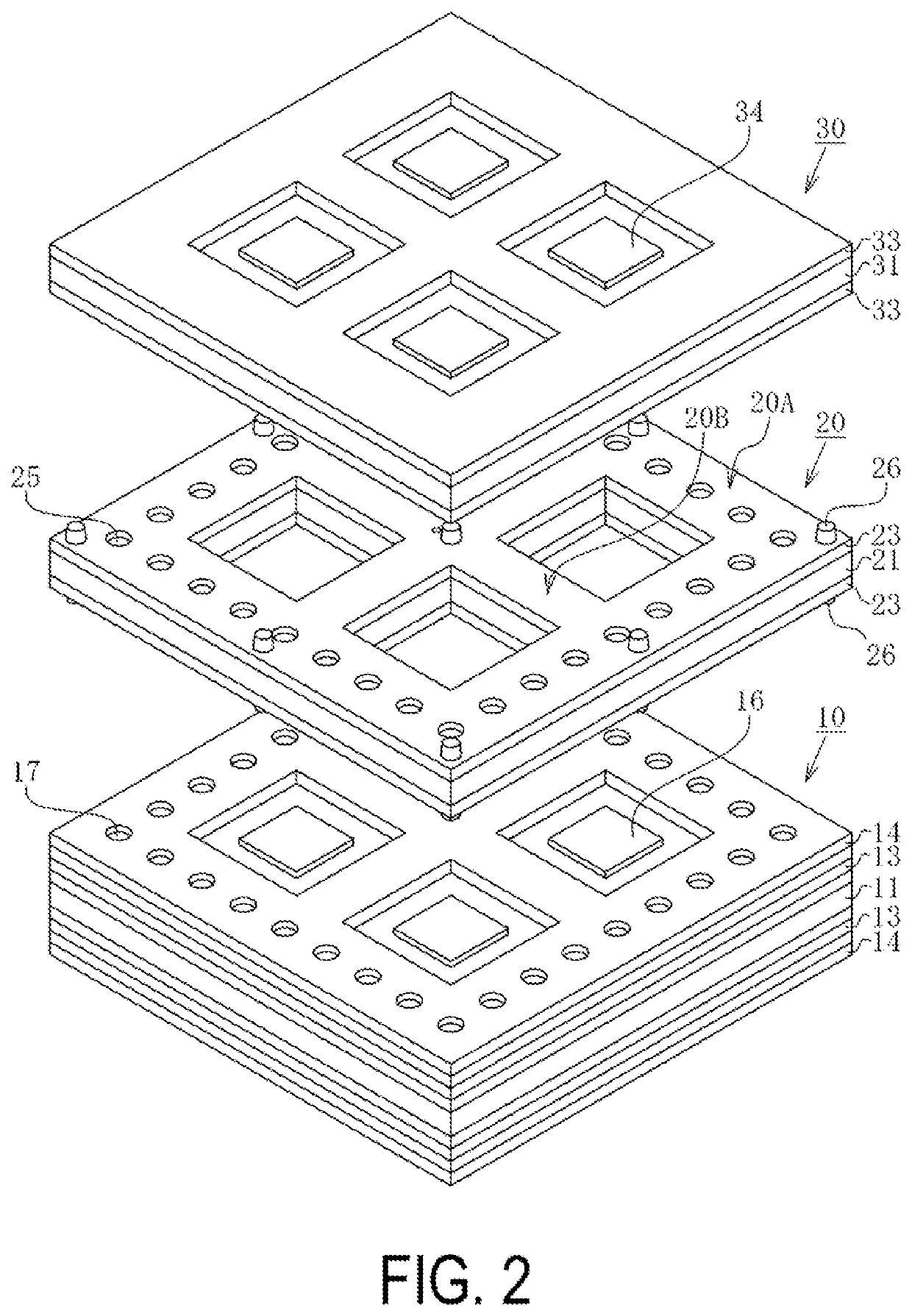

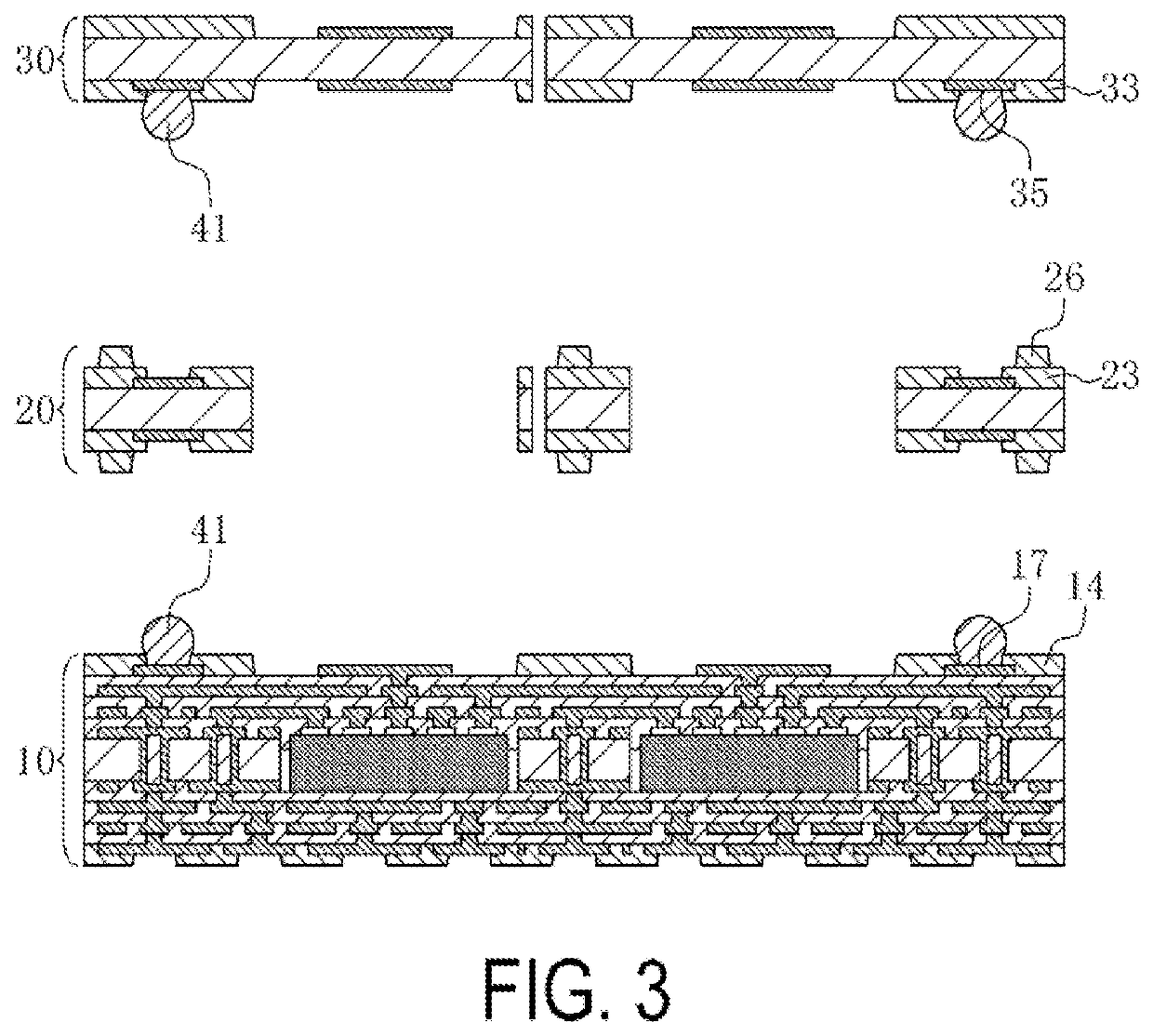

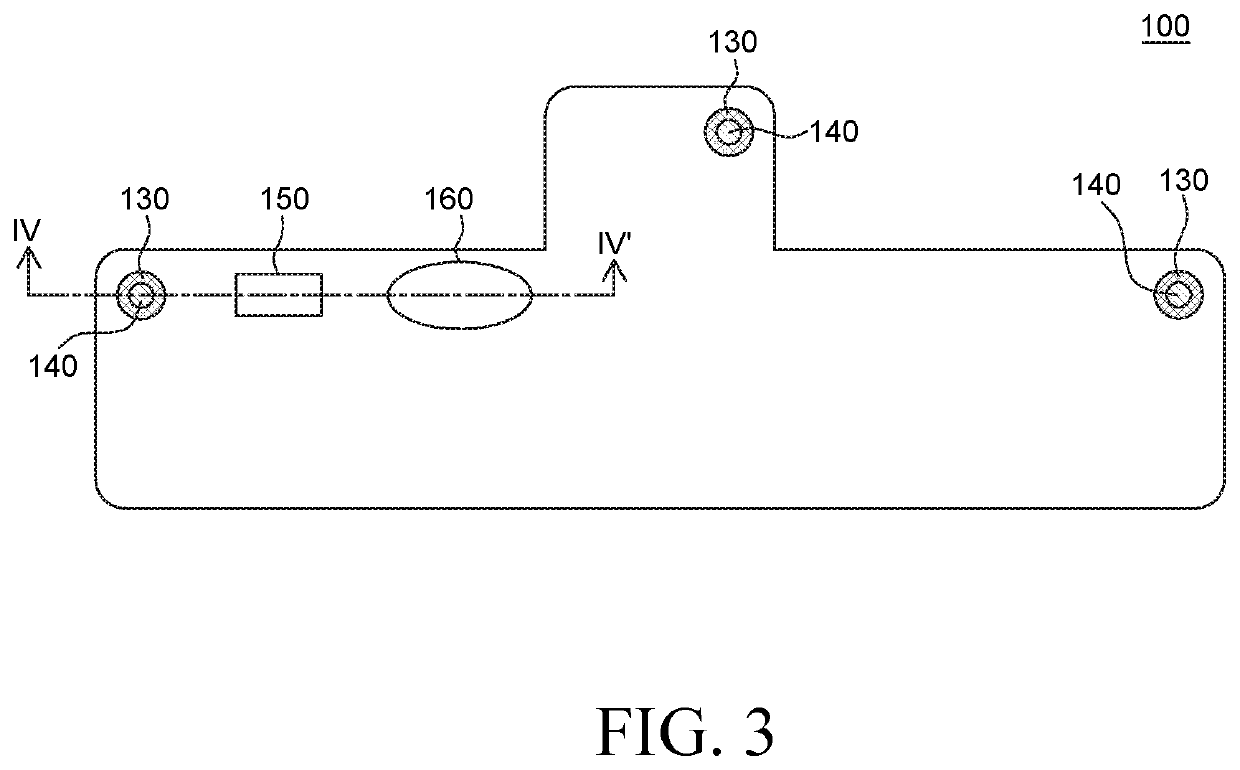

Antenna module

ActiveUS20190334231A1Semiconductor/solid-state device detailsSolid-state devicesAntenna substrateElectrical and Electronics engineering

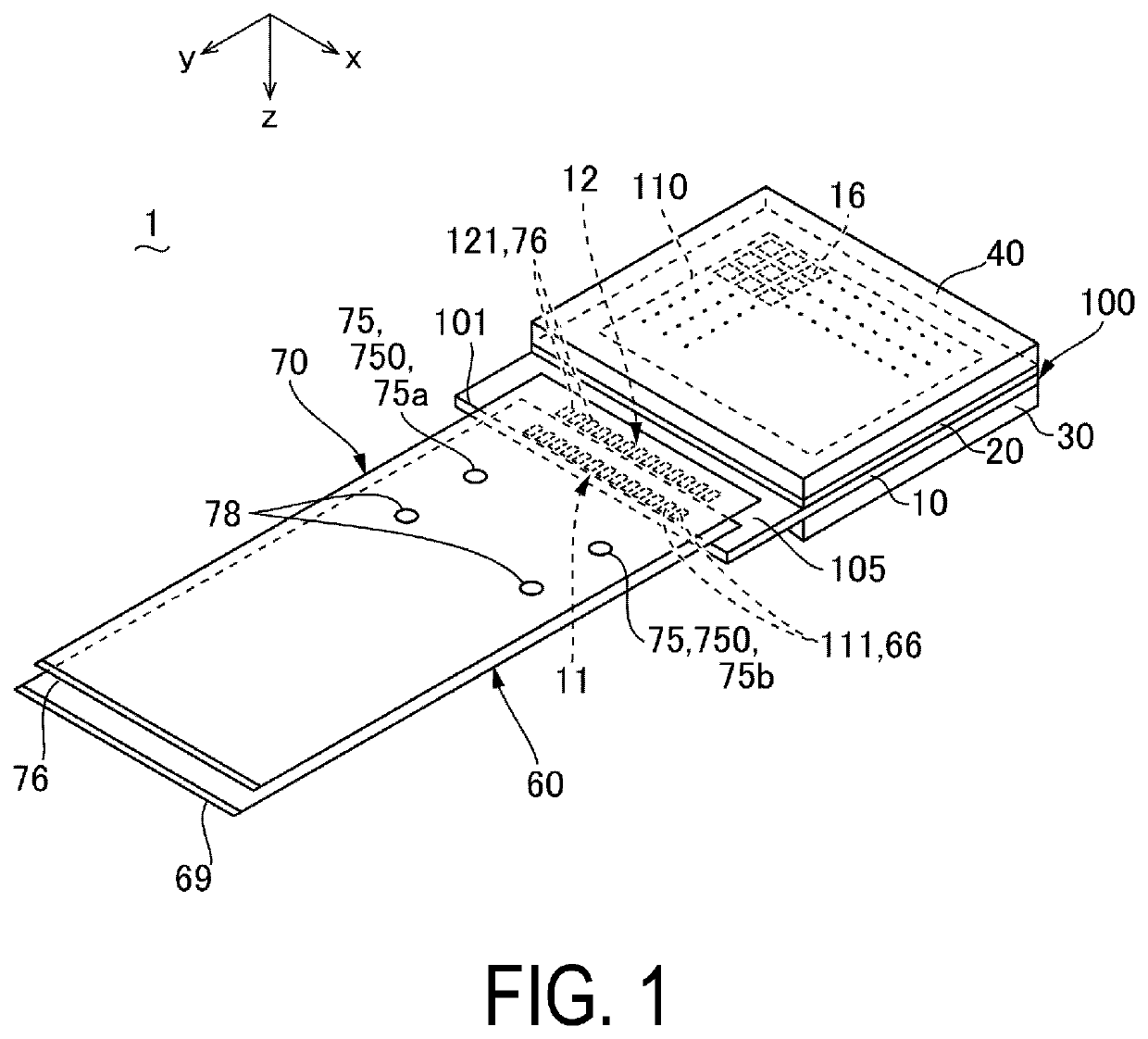

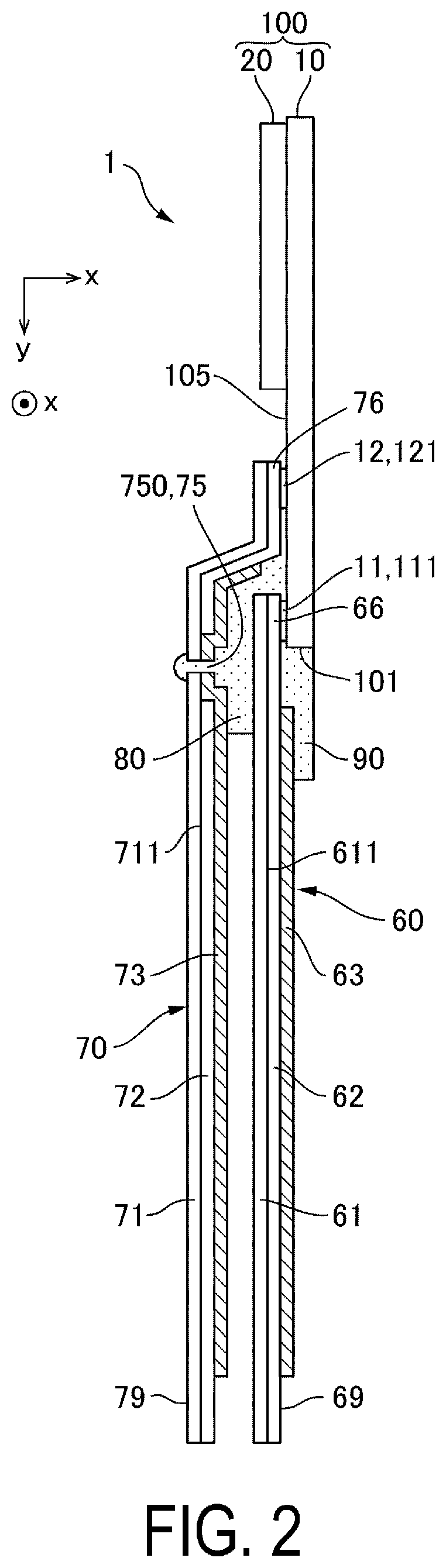

An antenna module of the present disclosure includes a control substrate having a flat plate shape and configured to house or mount a semiconductor element; a frame substrate bonded to an upper surface of the control substrate via bonding members and exposing a center portion of the upper surface of the control substrate; and an antenna substrate having a flat plate shape, bonded to an upper surface of the frame substrate via the bonding members so as to face the control substrate, and provided with a plurality of antenna patterns disposed along a main surface of the antenna substrate. The frame substrate includes a frame main body and a crosspiece. Between the frame main body / the crosspiece and the control substrate as well as the antenna substrate, projecting portions that come into contact with the opposing control substrate, frame substrate, and antenna substrate are provided at a fixed height.

Owner:KYOCERA CORP

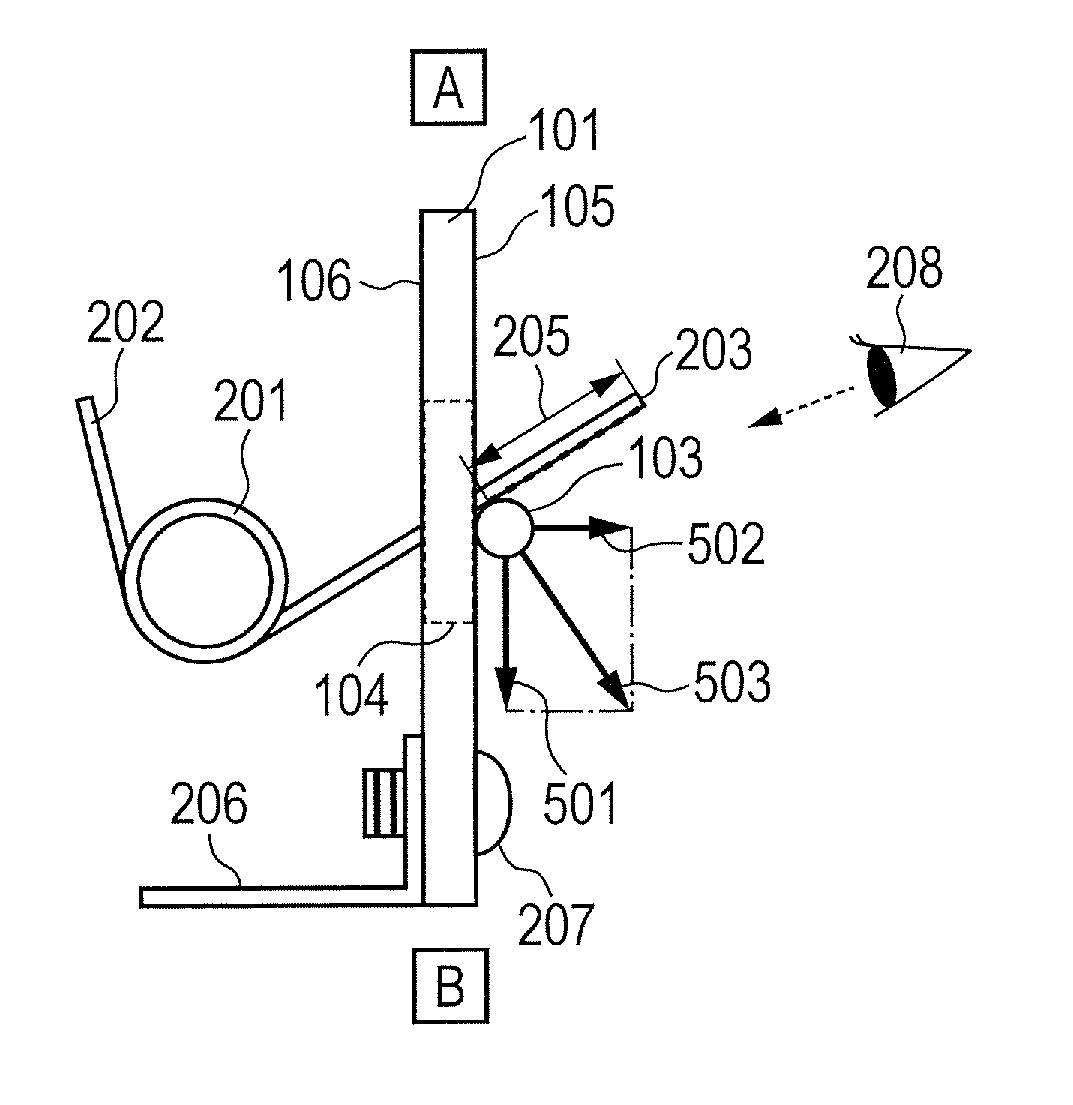

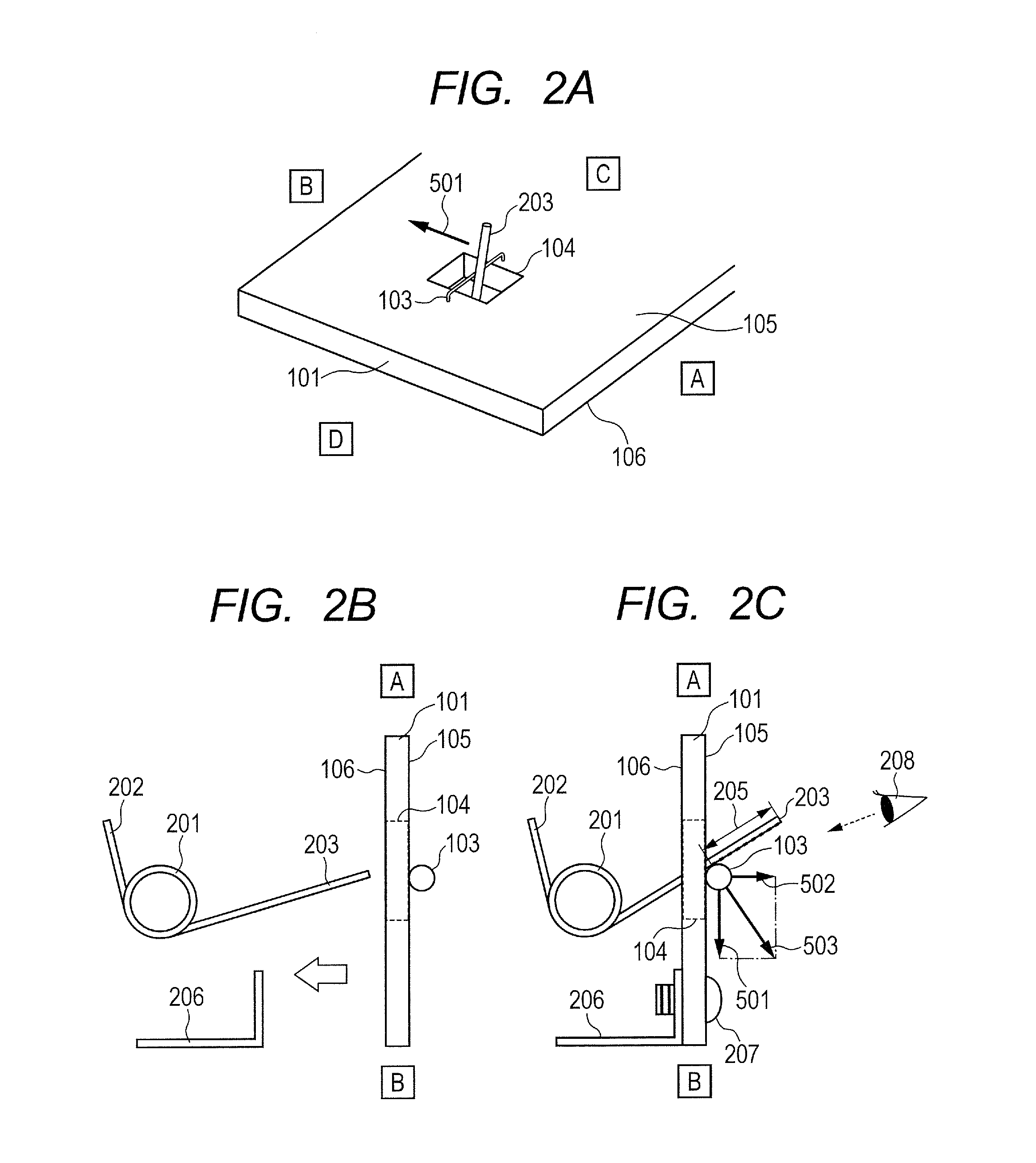

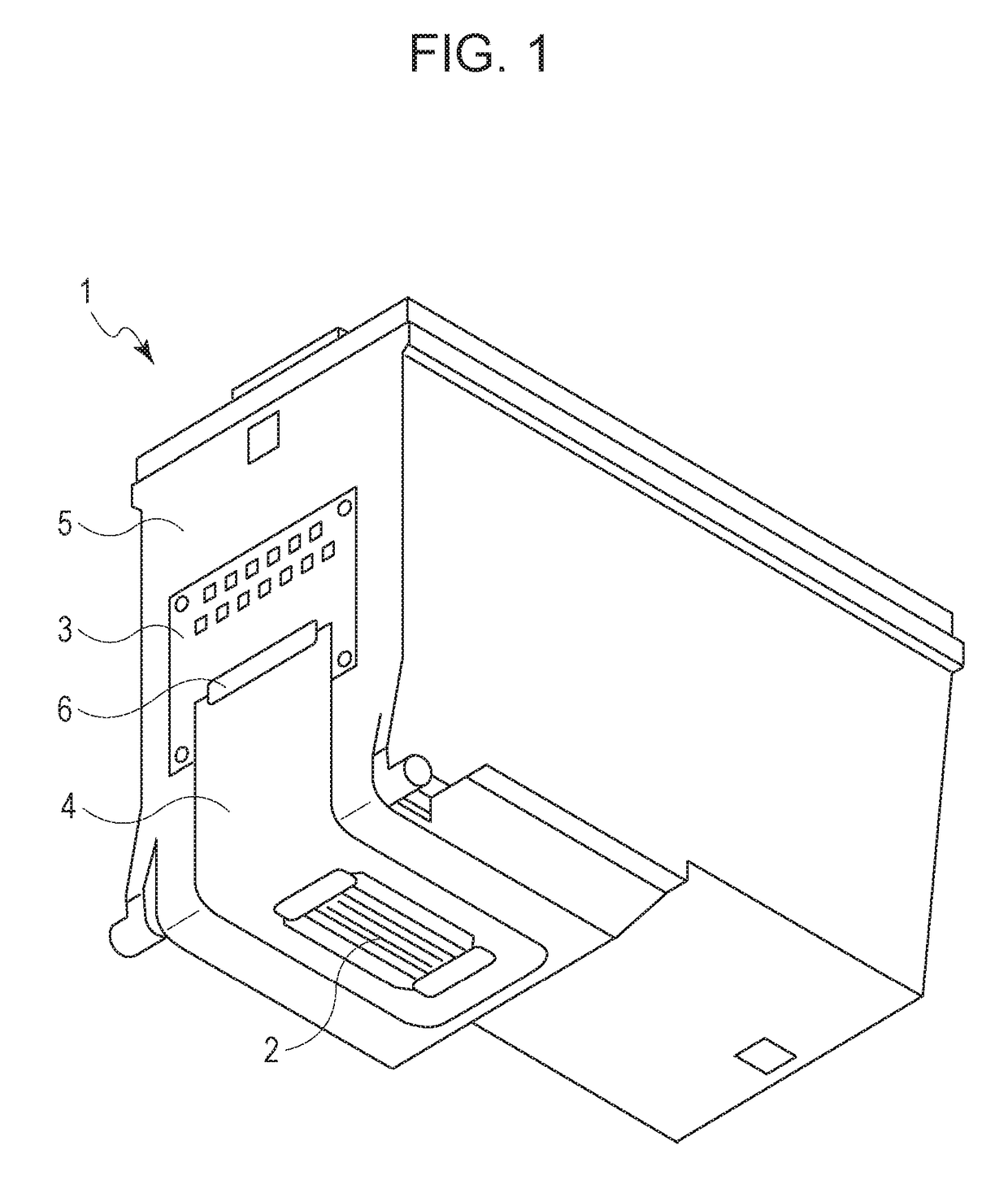

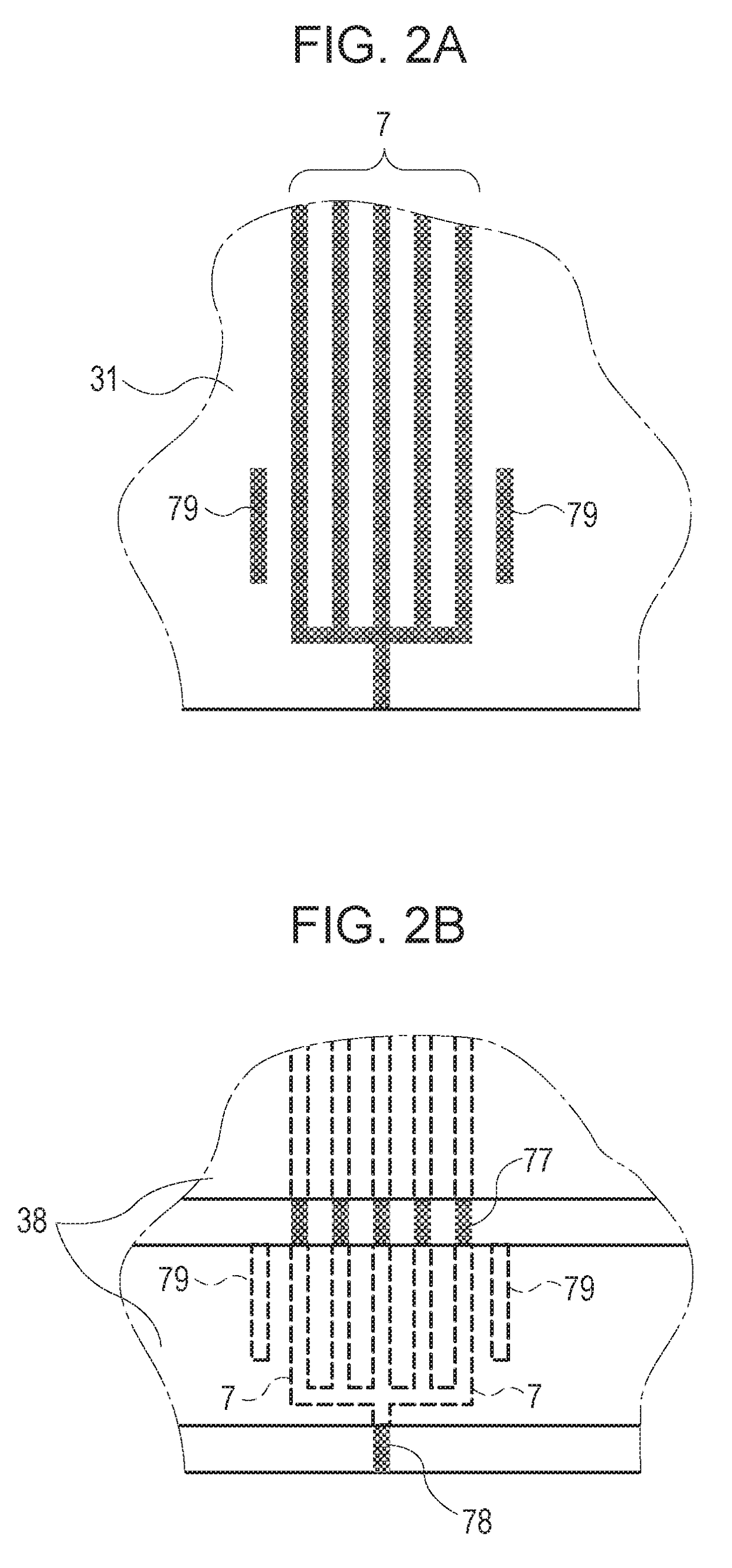

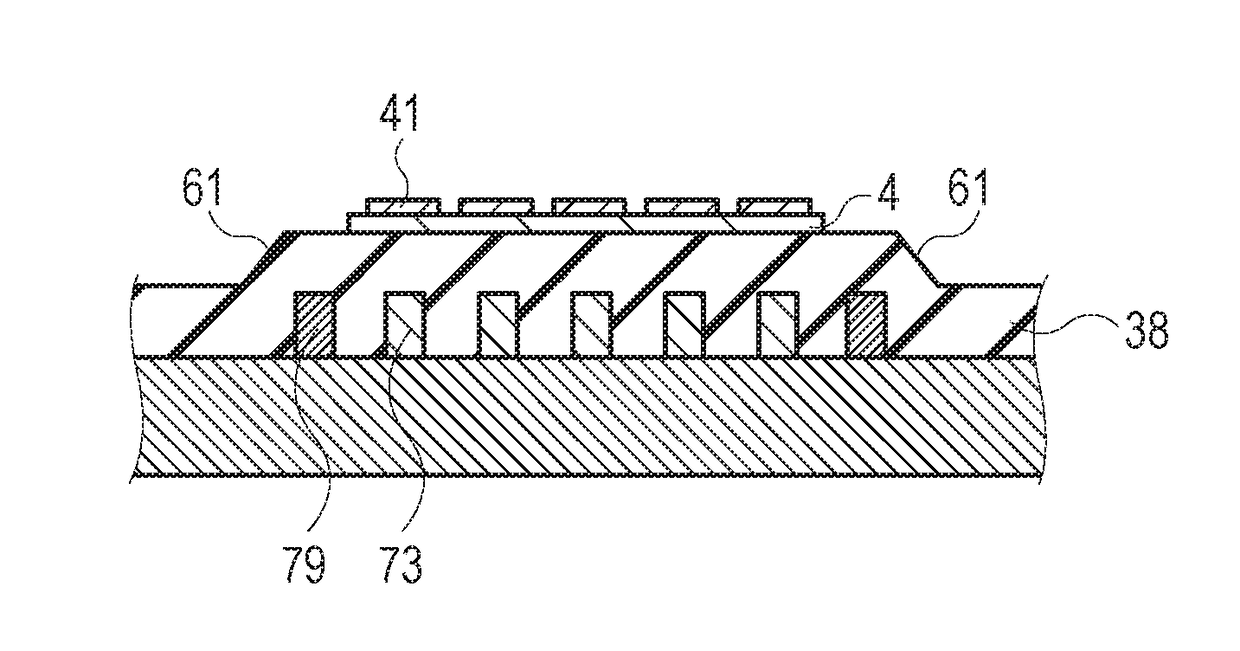

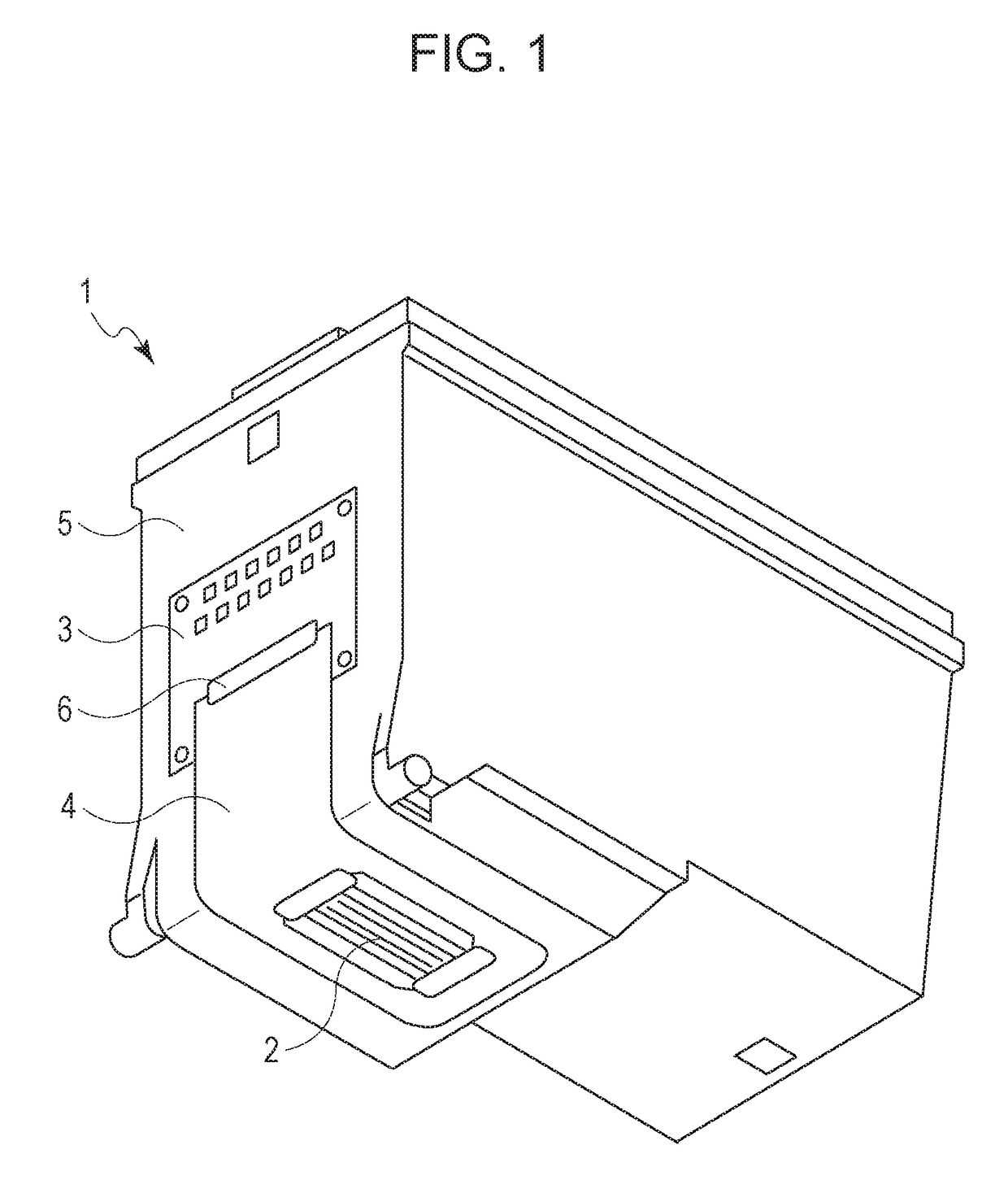

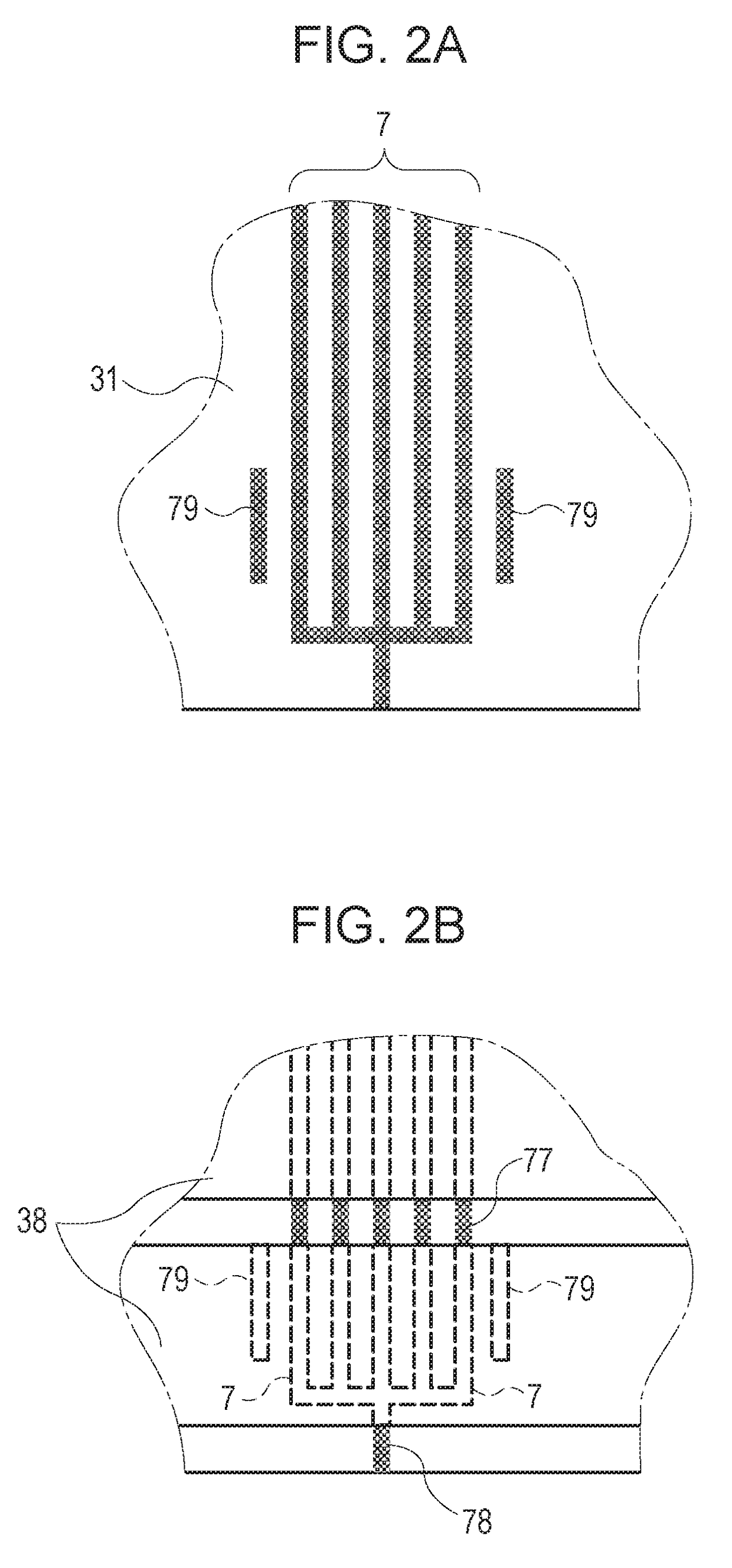

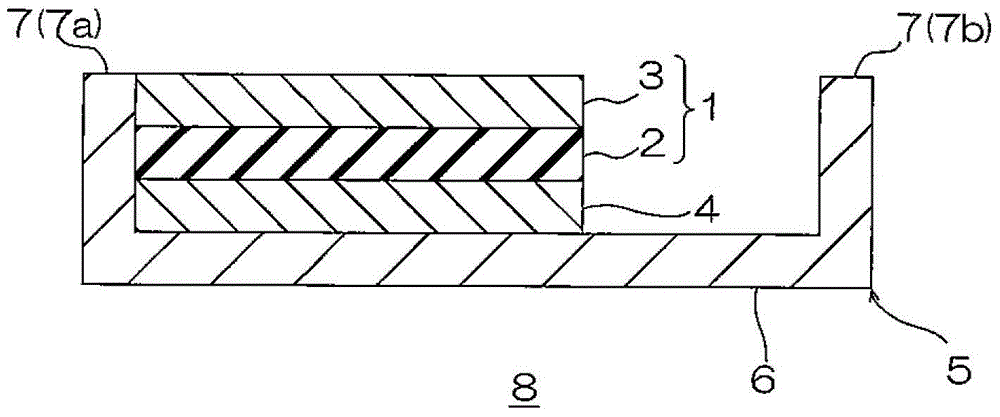

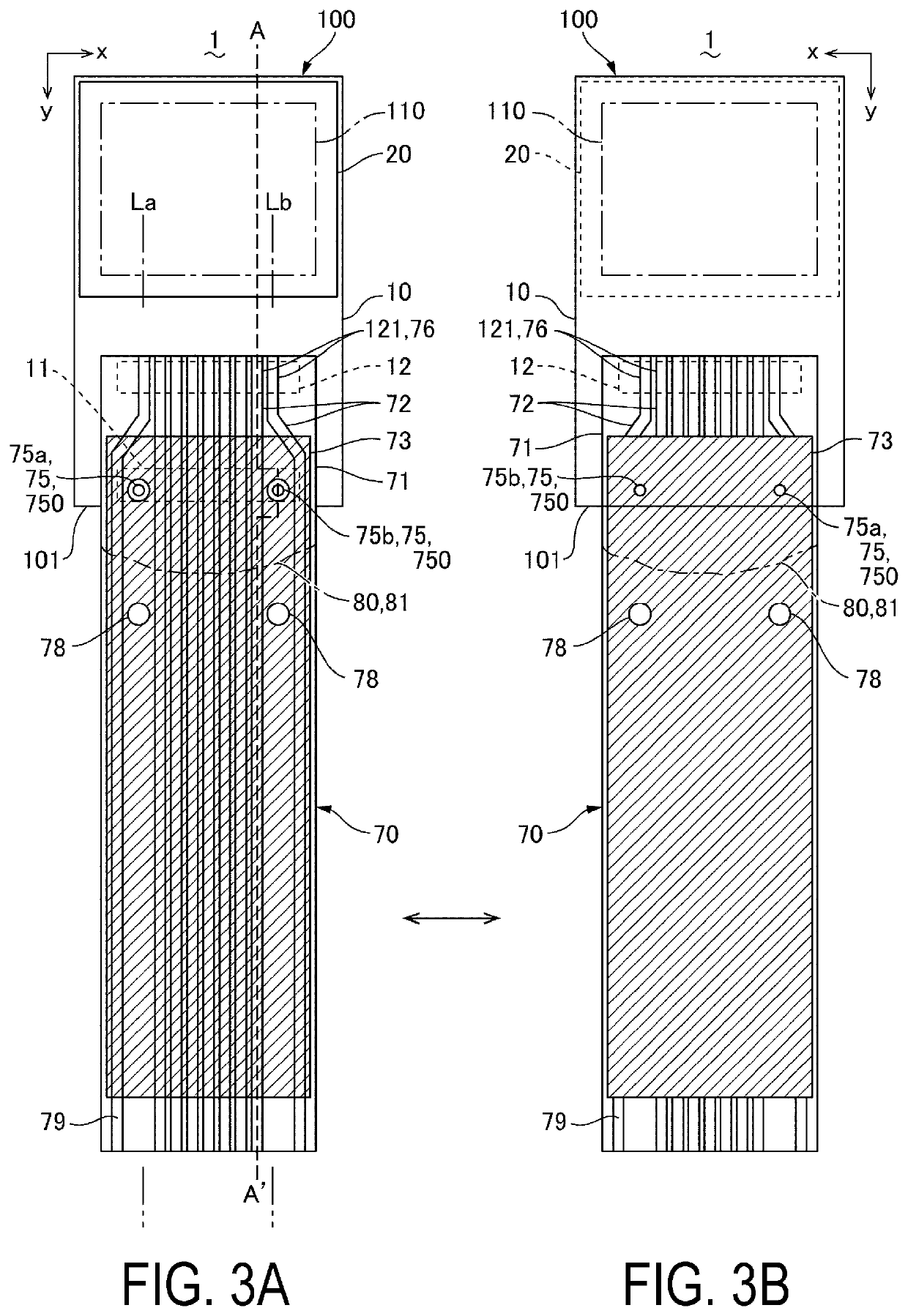

Liquid discharge head

InactiveUS20170142826A1Suppress inclinationReduce decreaseCircuit fluid transportConductive pattern formationEngineeringPrinted circuit board

A liquid discharge head includes an element substrate to which an electric signal is supplied, an electrical wiring board that is connected to the element substrate and that is capable of supplying the electric signal to the element substrate, and a printed circuit board that includes a wiring line and an insulating layer covering the wiring line and that is capable of supplying the electric signal to the element substrate via the wiring line. A protruding structure that has a thickness approximately equal to a thickness of the wiring line and that is covered with the insulating layer is disposed along the wiring line on the printed circuit board, and a portion of the electrical wiring board is bonded to a portion of the insulating layer located on the wiring line disposed on the printed circuit board.

Owner:CANON KK

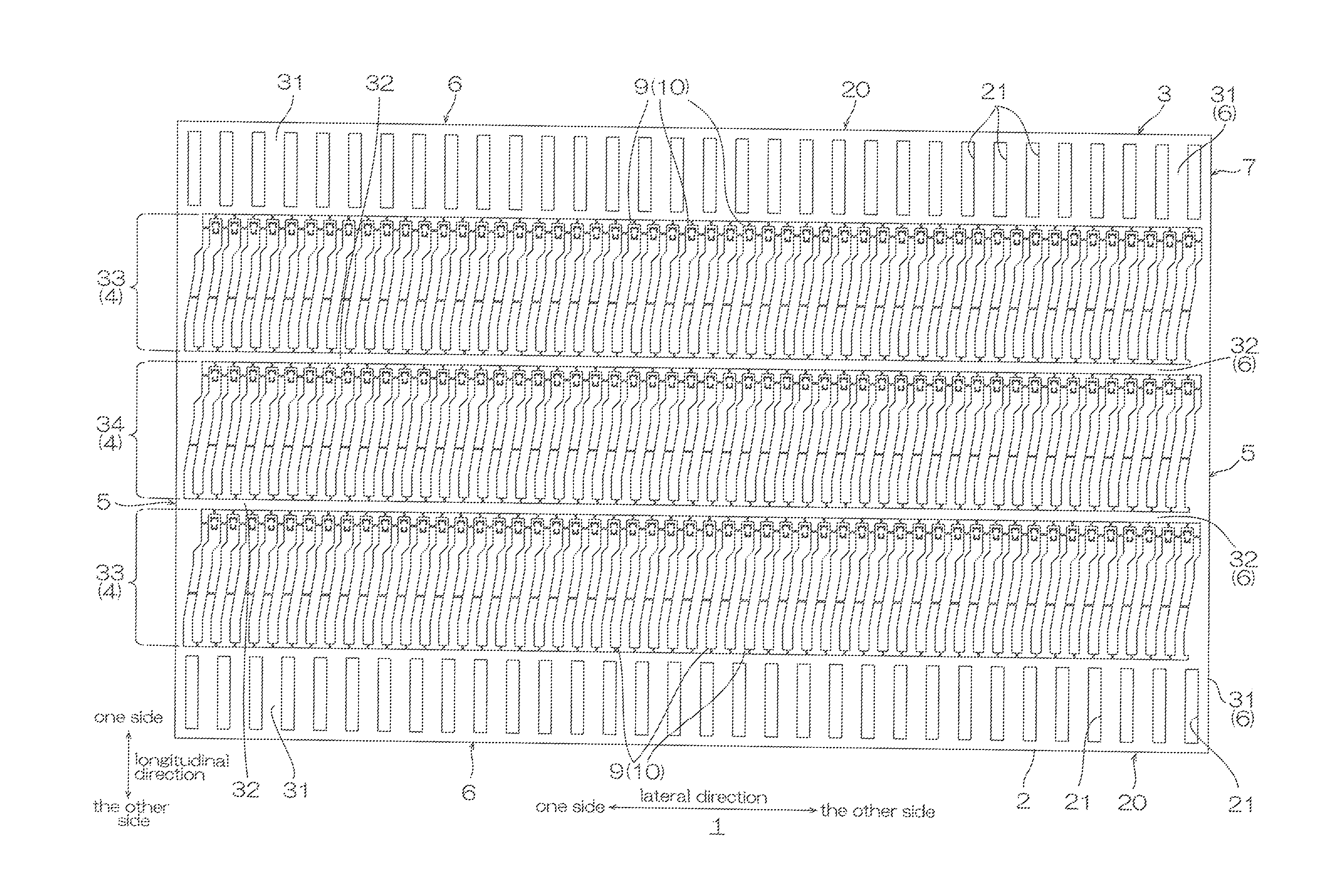

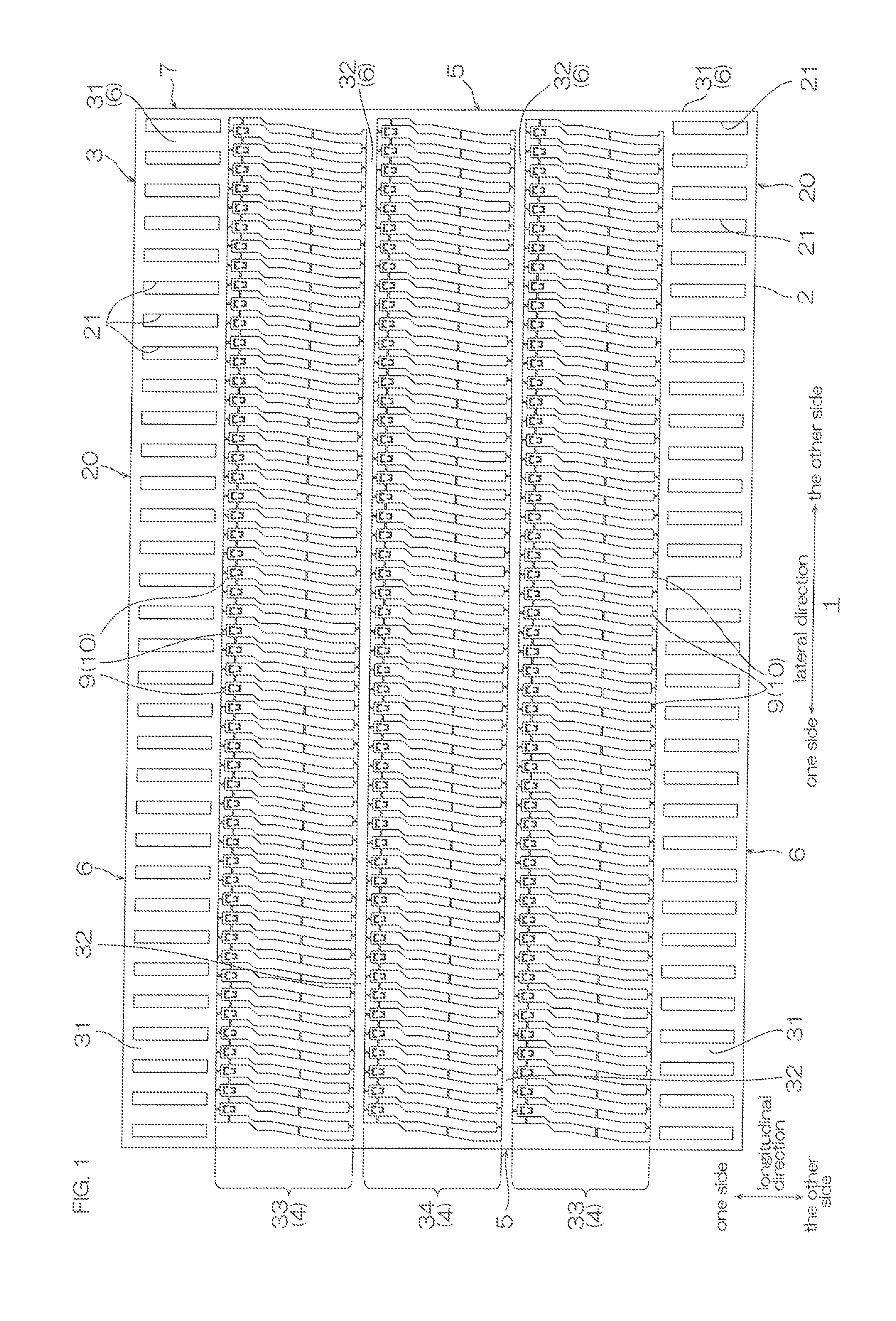

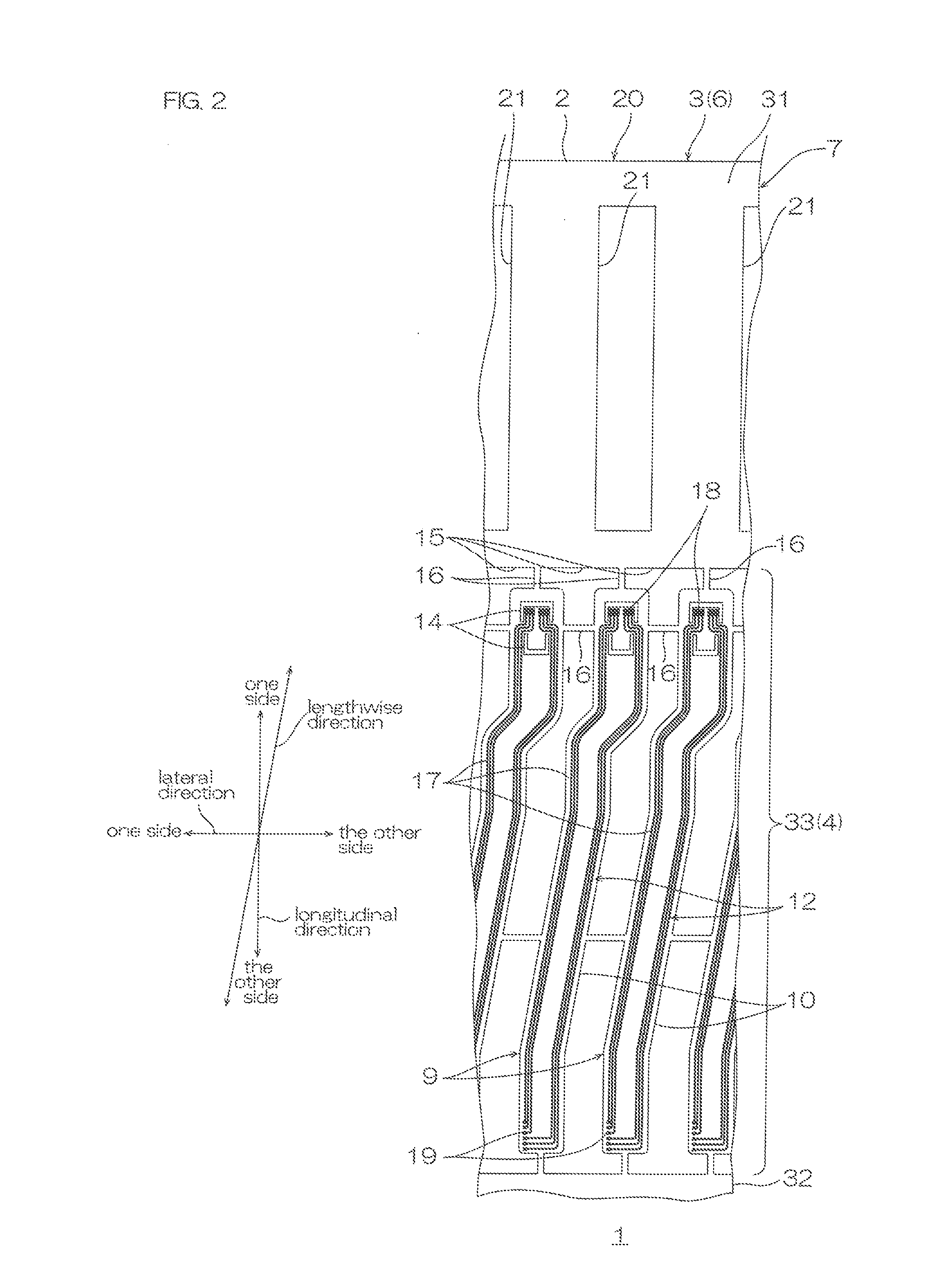

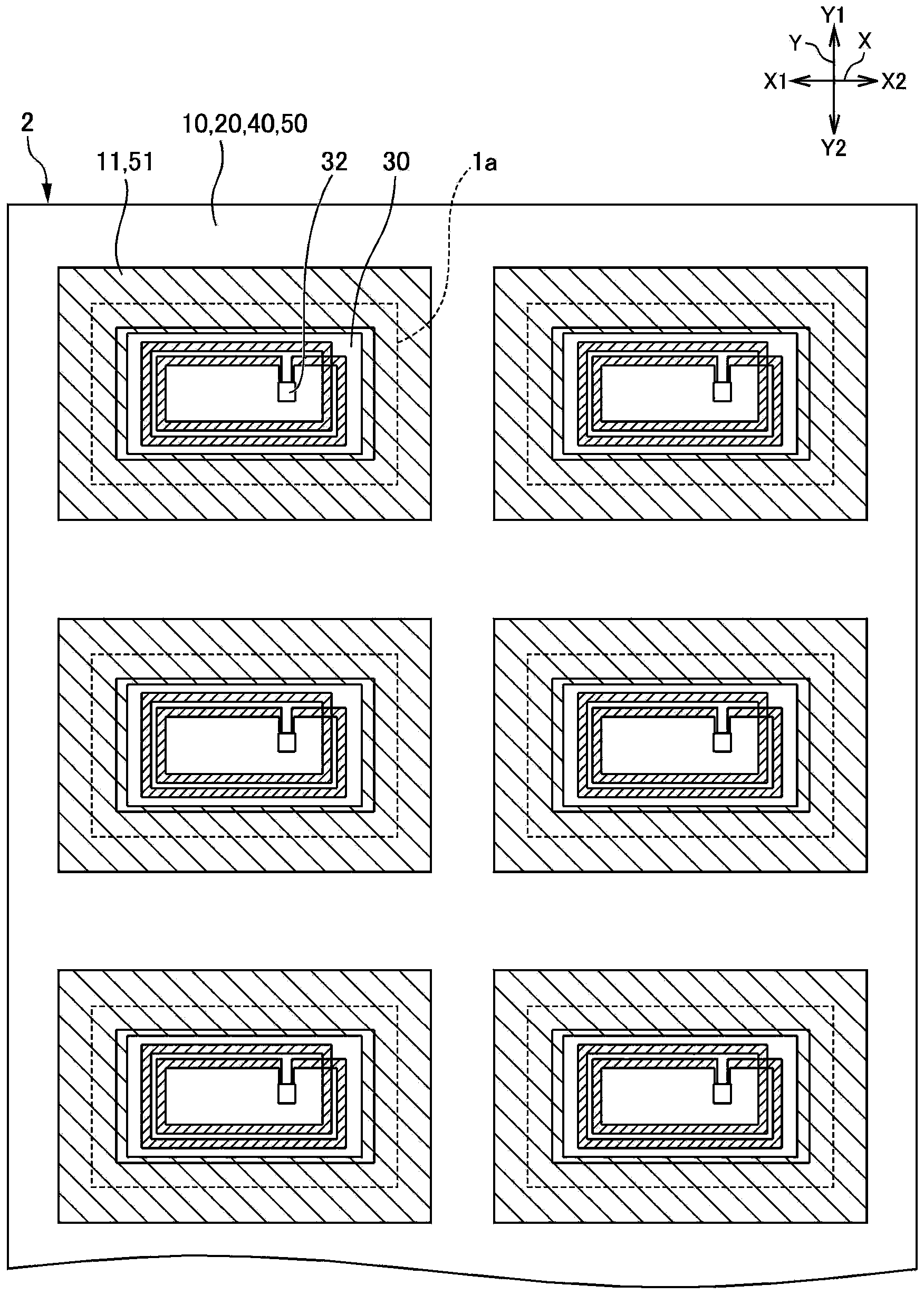

Suspension board with circuit assembly sheet

ActiveUS20150216039A1Reduce stiffnessAvoid assemblyElectrical connection between head and armFlexible printed circuitsMechanical engineering

A suspension board with circuit assembly sheet includes an assembly provided region provided with a plurality of suspension boards with circuits at spaced intervals to each other along one direction and a margin region provided at least at one side in a crossing direction with respect to the one direction of the assembly provided region. In the assembly provided region, a first opening portion is provided between the suspension boards with circuits that are adjacent to each other and in the margin region, a fragile portion is provided.

Owner:NITTO DENKO CORP

Card and card production method

ActiveCN104145280AImprove appearance qualityCircuit arrangements on support structuresAdhesivesComputer science

Owner:DAI NIPPON PRINTING CO LTD

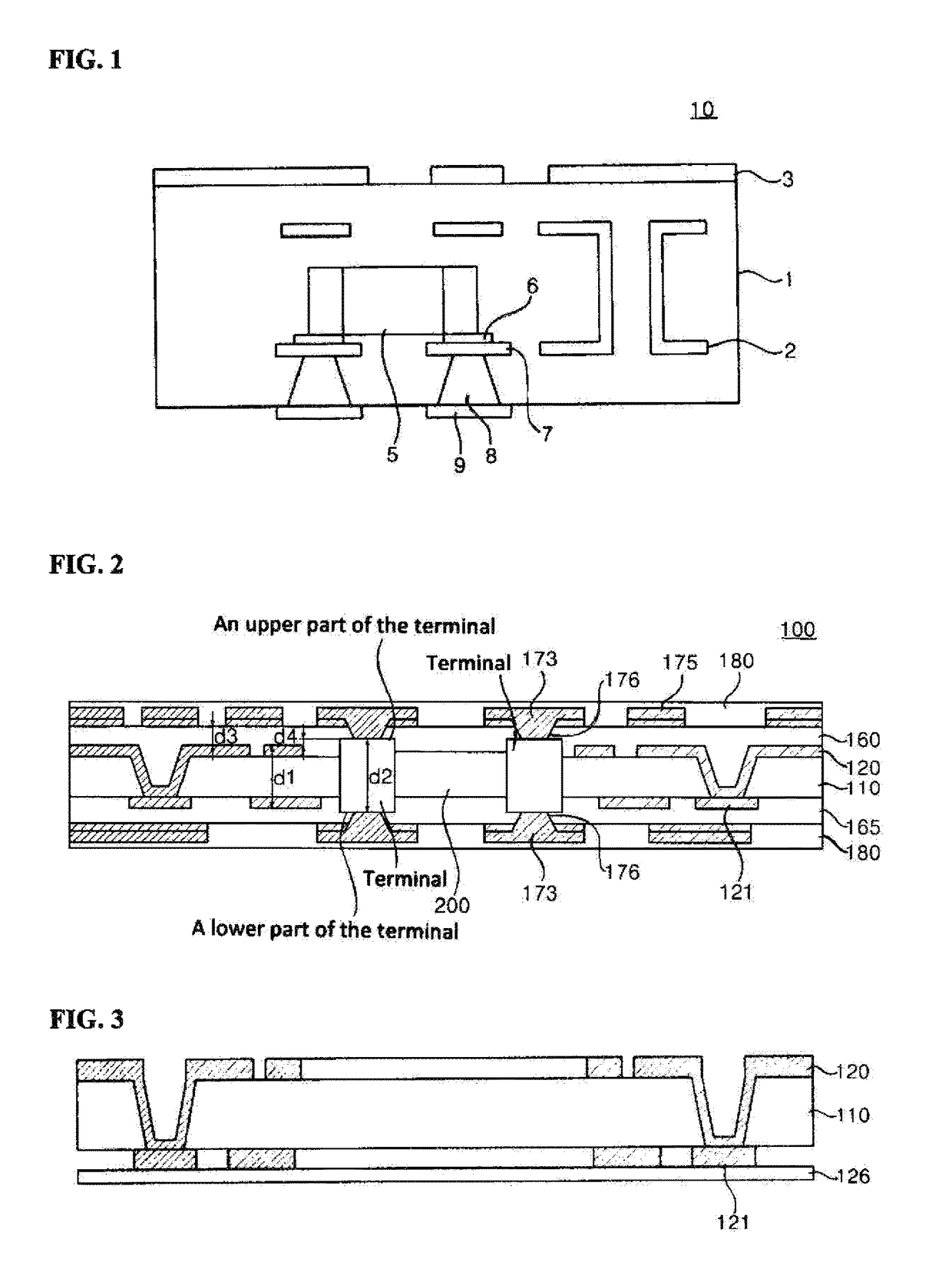

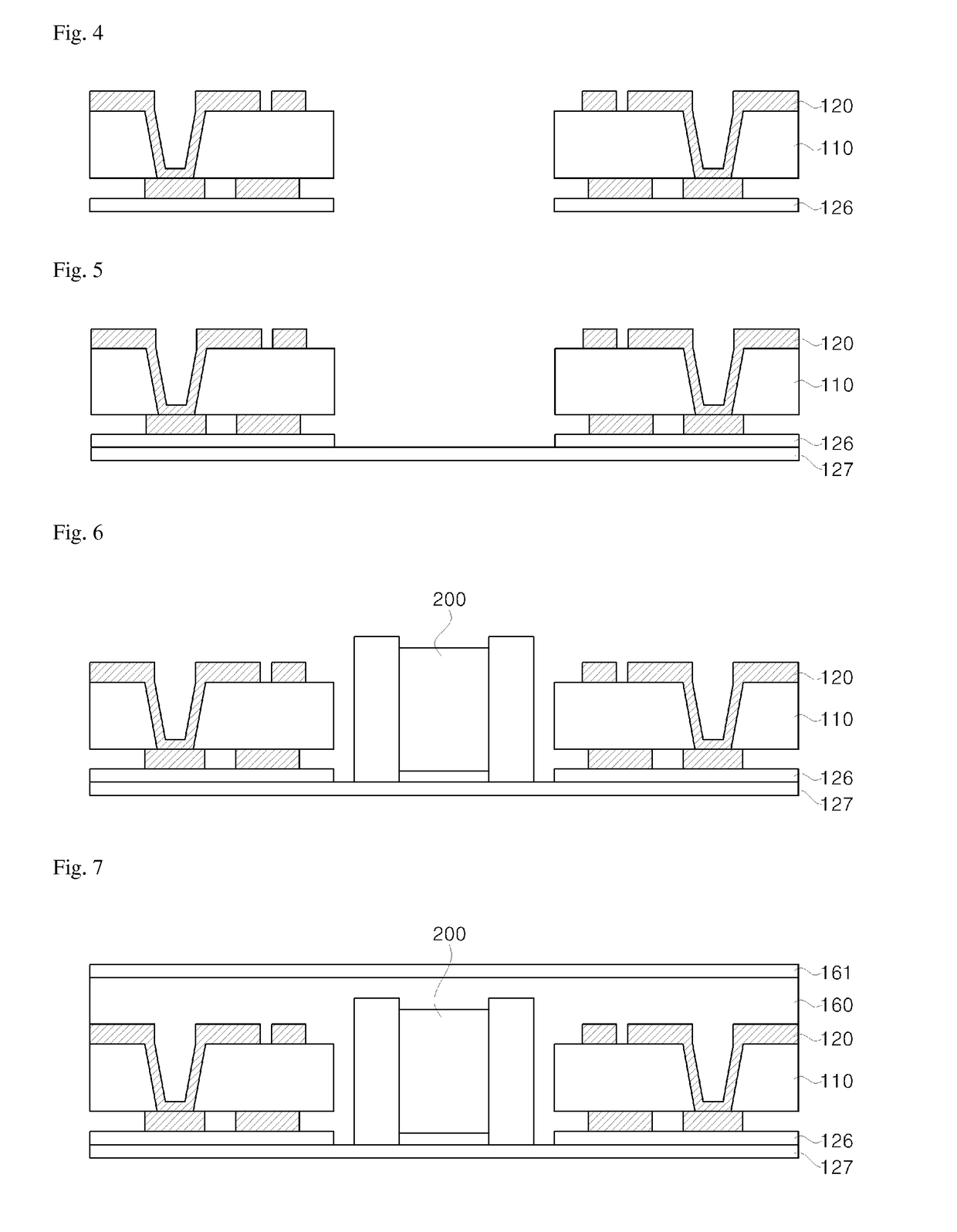

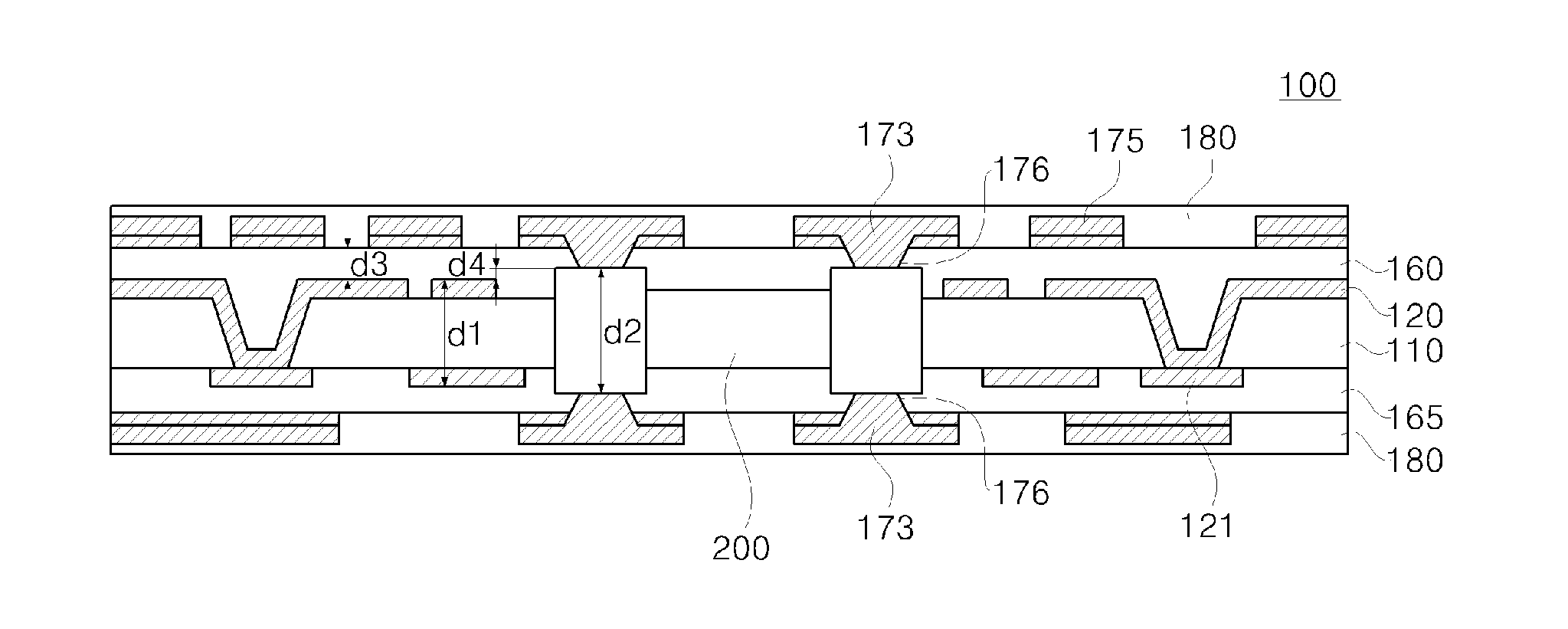

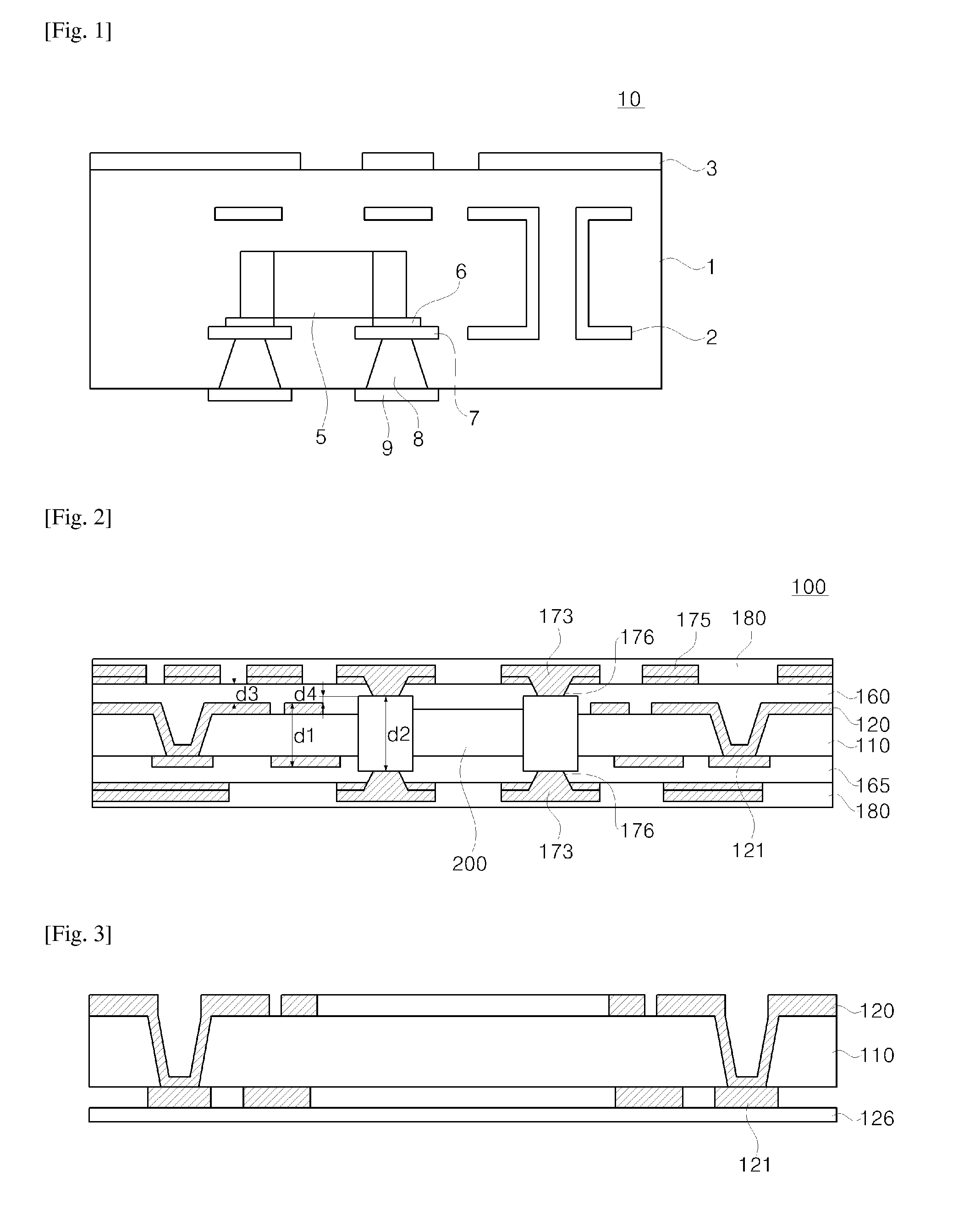

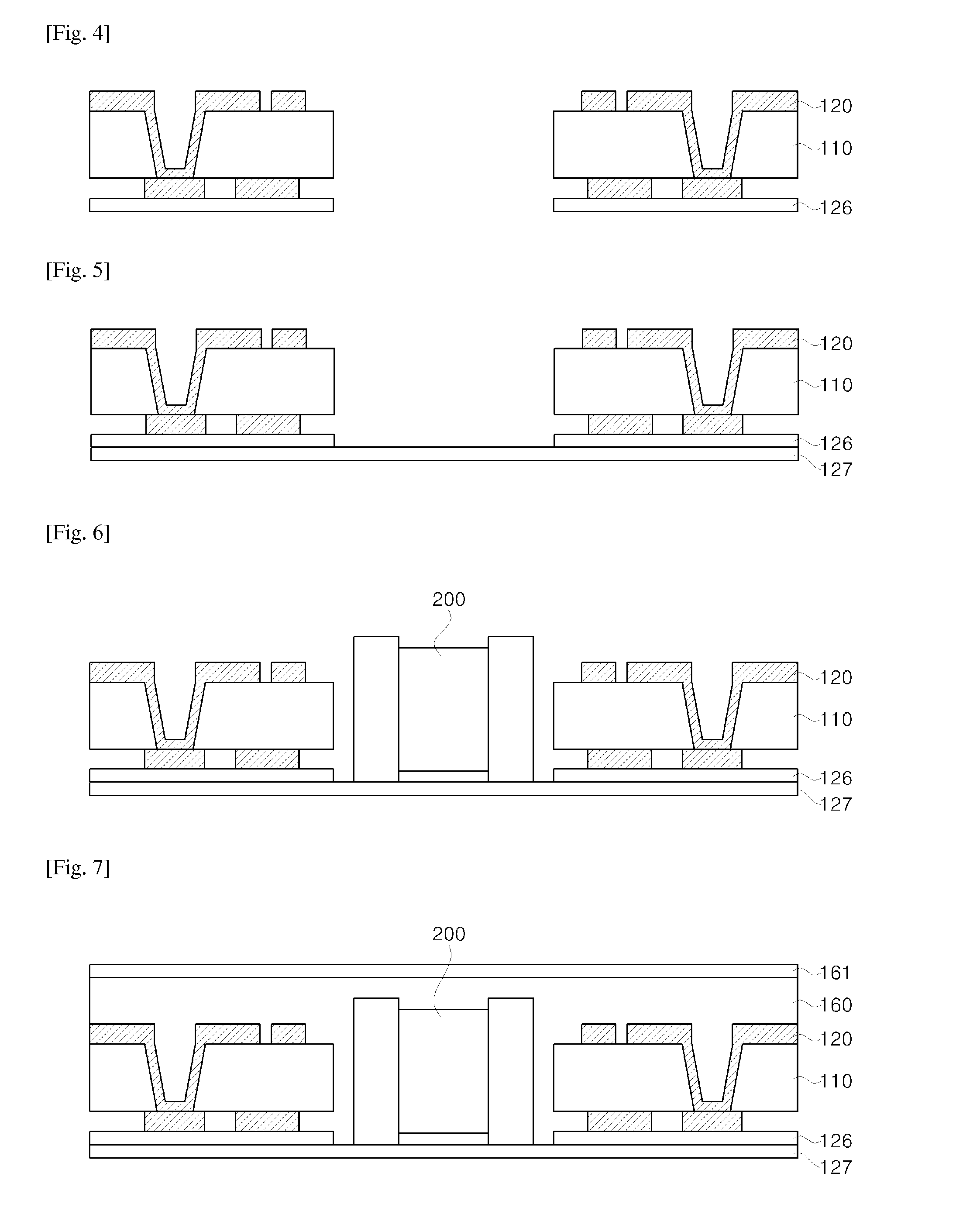

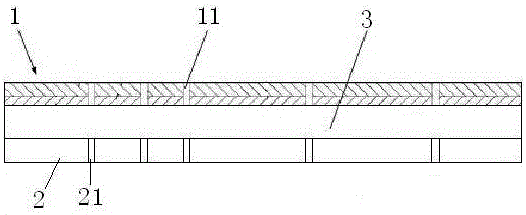

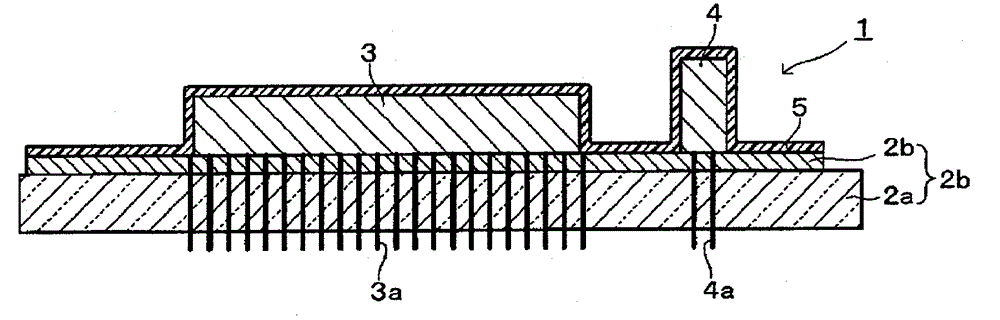

Printed circuit board and method of manufacturing the same

InactiveUS9661759B2Desired thicknessDielectric materialsConductive pattern formationEngineeringPrinted circuit board

Provided is a printed circuit board, including: a core substrate including an internal circuit pattern on an upper surface or a lower surface; electronic devices which are formed to pass through the core substrate; an external insulating layer which covers the internal circuit pattern and the electronic devices; and an external circuit pattern which is formed on an upper surface of the external insulating layer, wherein a lower surface of the electronic devices protrudes from the lower surface of the core substrate to a lower part. Accordingly, in the embedded printed circuit board in which the electronic devices are embedded, when the electronic devices are mounted, because the insulating layer is formed regardless of a thickness of the electronic devices, the printed circuit board having a desired thickness regardless of the thickness of the electronic devices can be formed.

Owner:LG INNOTEK CO LTD

Method of making a microelectronic device

ActiveUS9781833B2Side-by-side/stacked arrangementsSemiconductor/solid-state device detailsEngineeringConductive materials

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

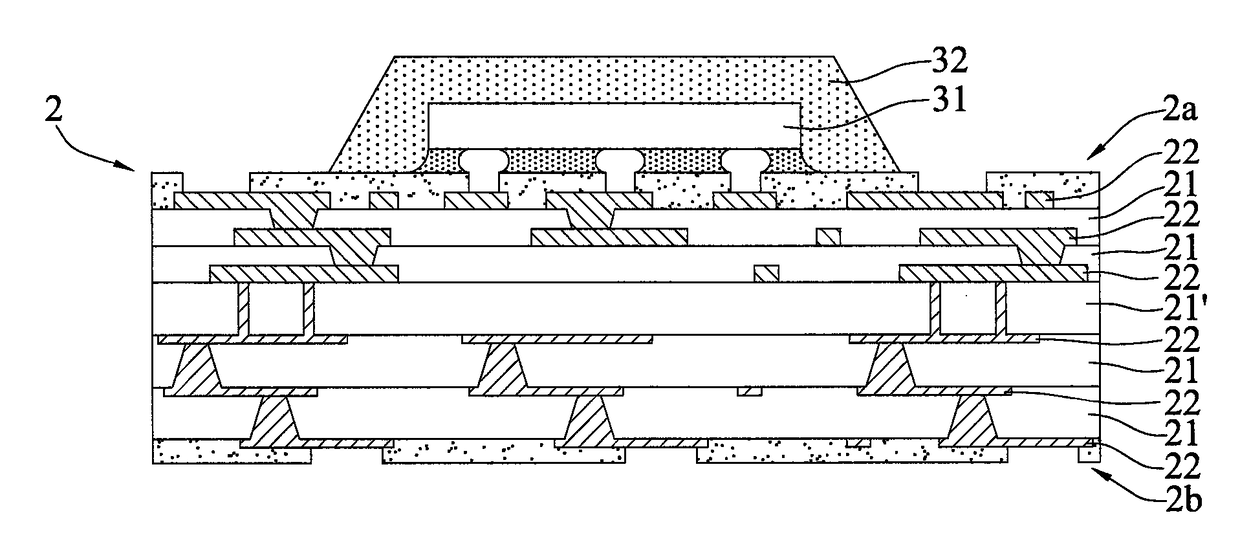

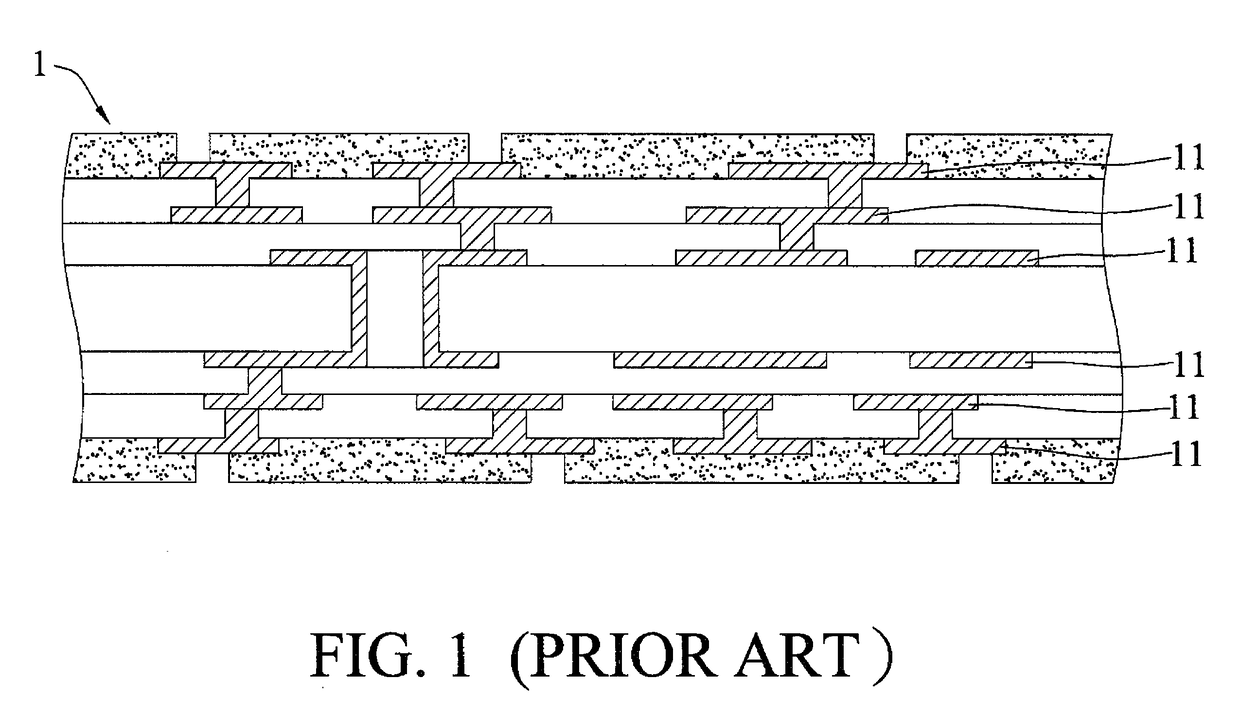

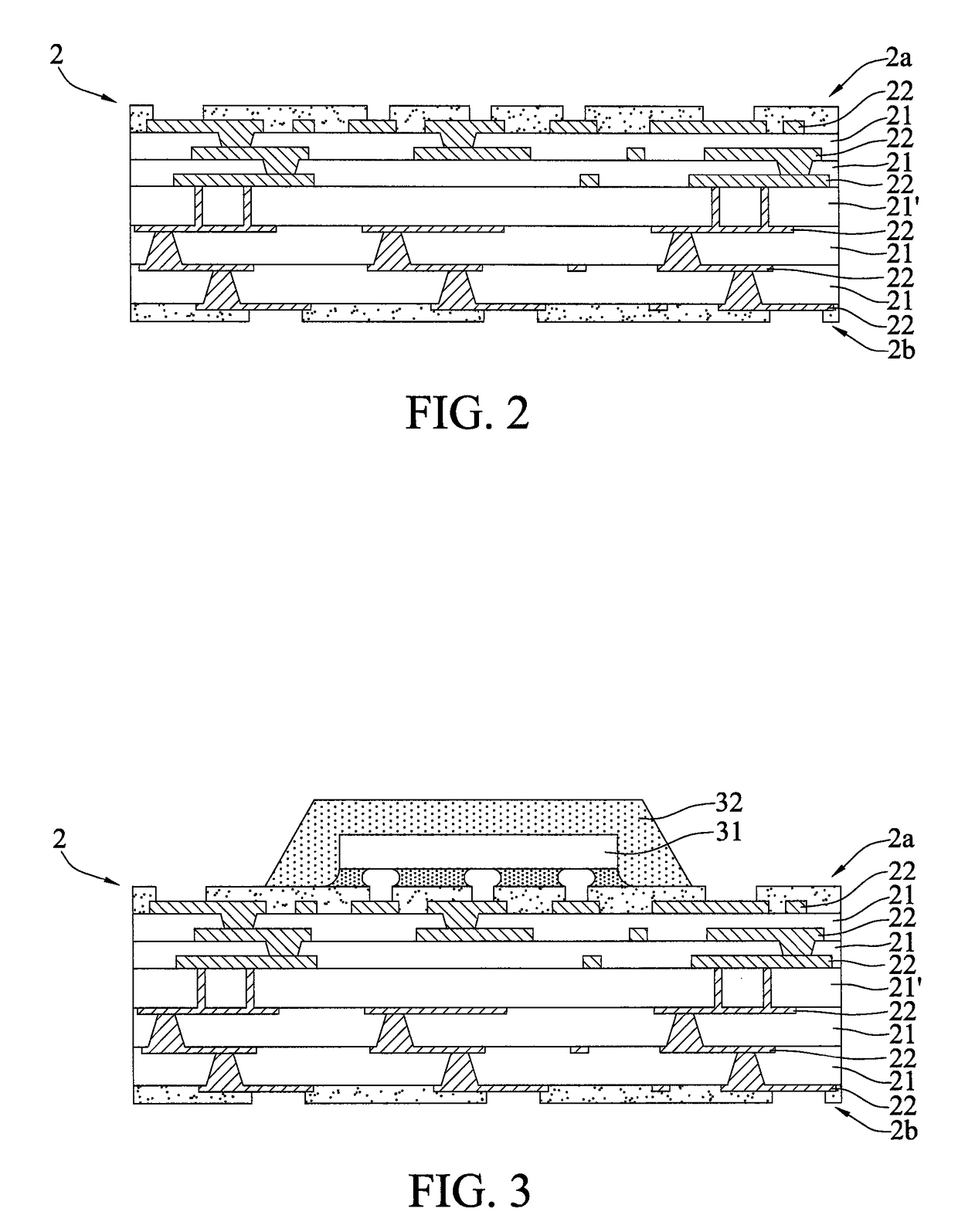

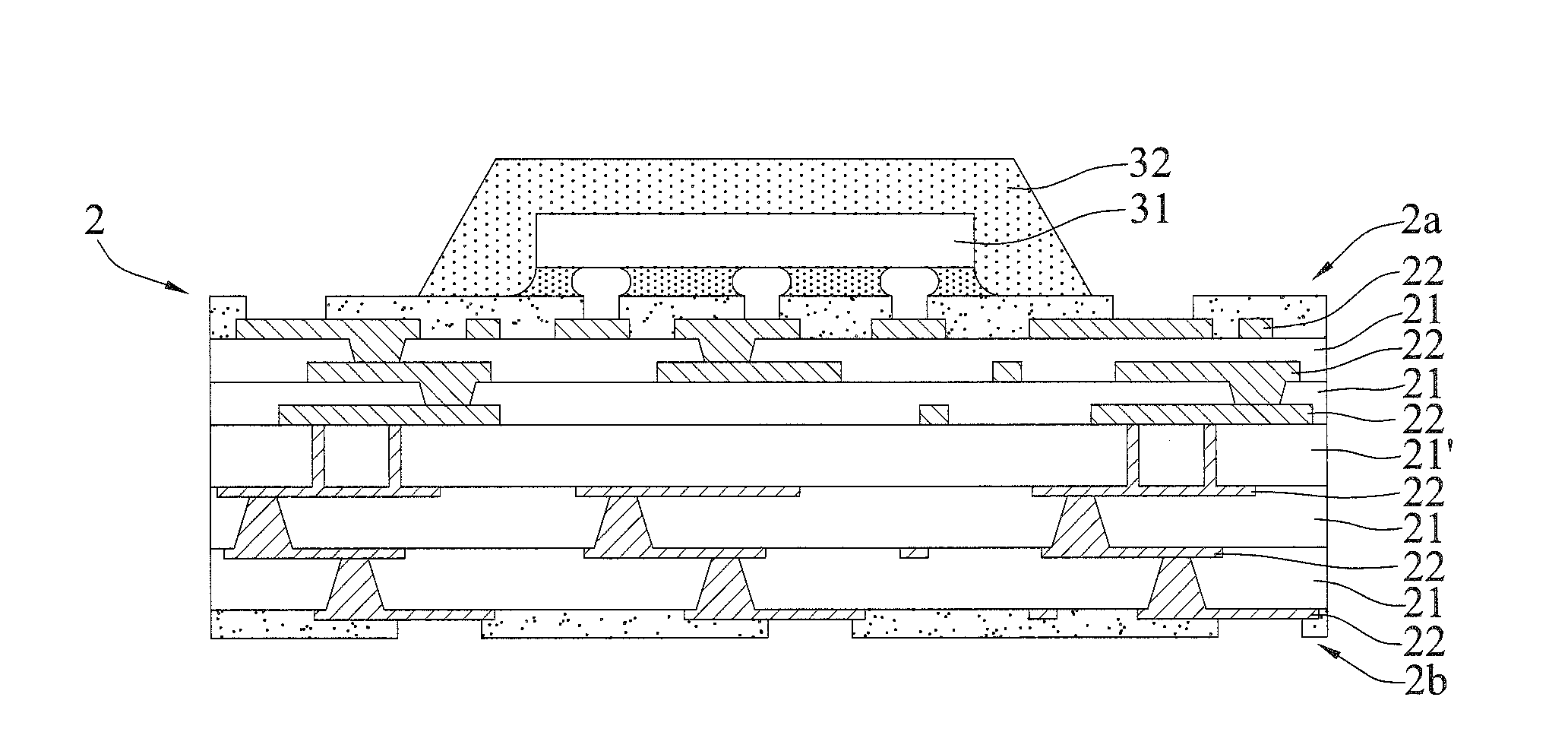

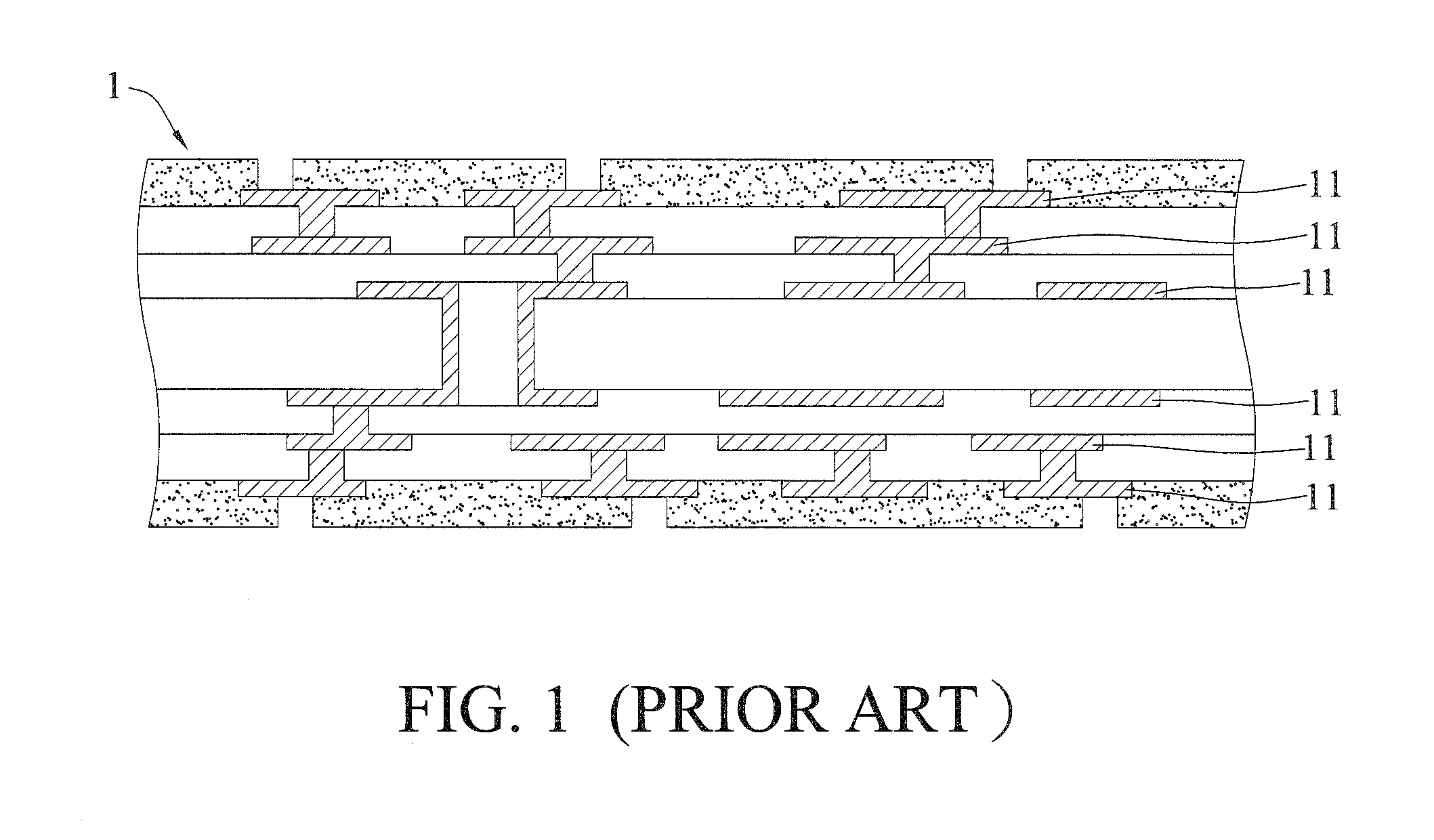

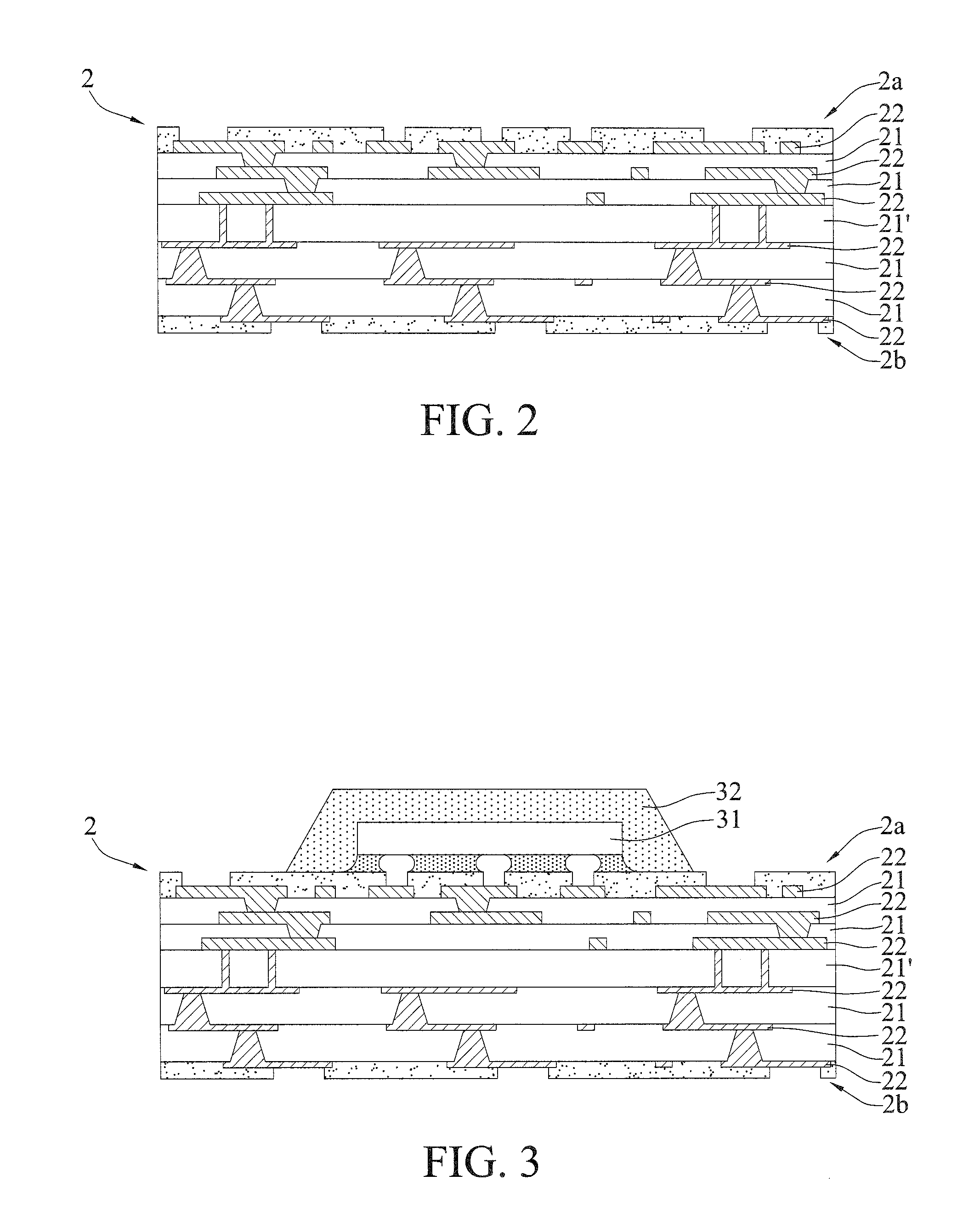

Package substrate and structure

ActiveUS9900996B2Improve rigidityReduce warpageSolid-state devicesMultilayer circuit manufactureDielectric layer

A package substrate is provided, which includes a plurality of dielectric layers and a plurality of circuit layers alternately stacked with the dielectric layers. At least two of the circuit layers have a difference in thickness so as to prevent warpage of the substrate.

Owner:SILICONWARE PRECISION IND CO LTD

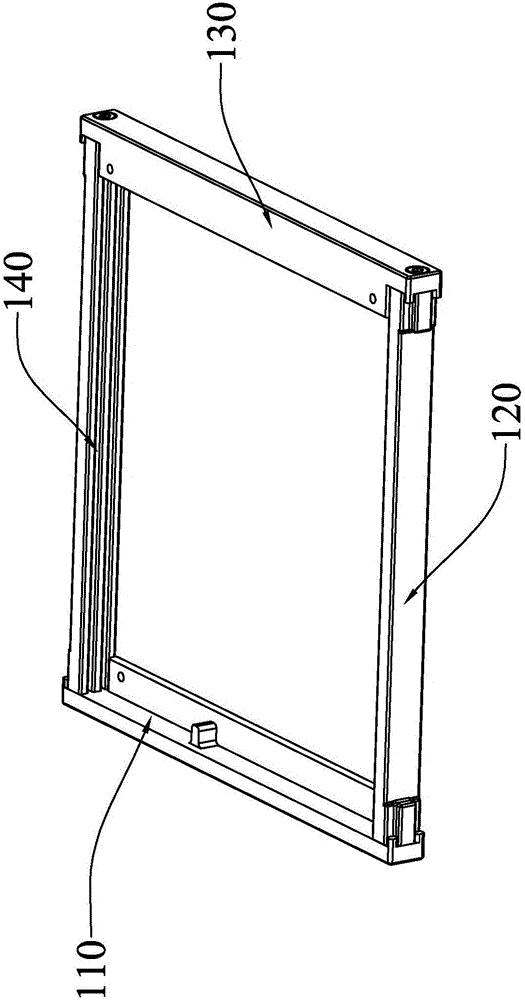

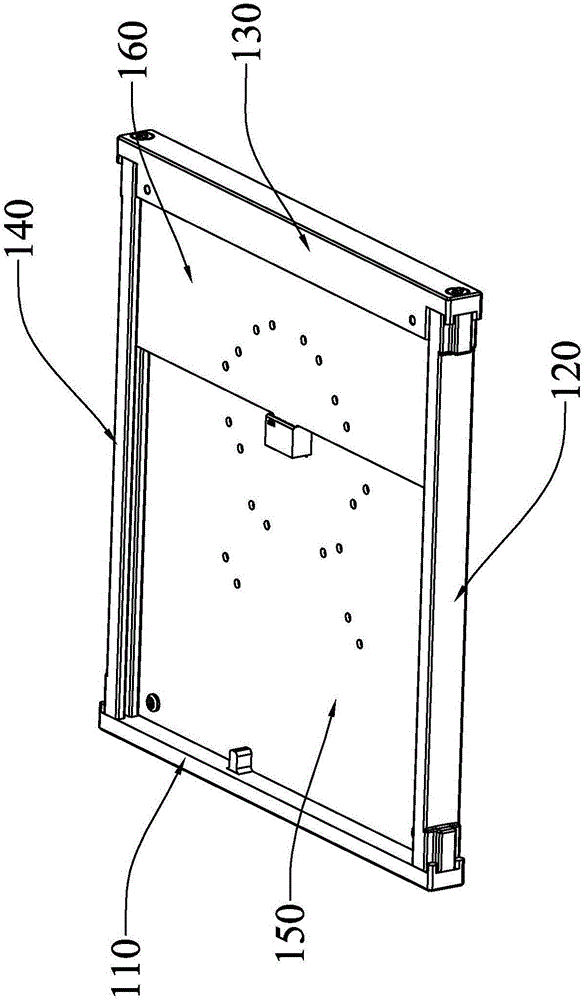

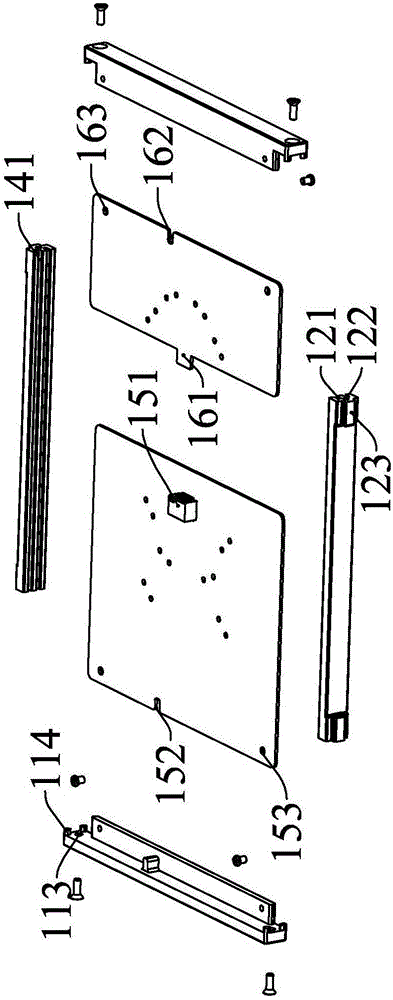

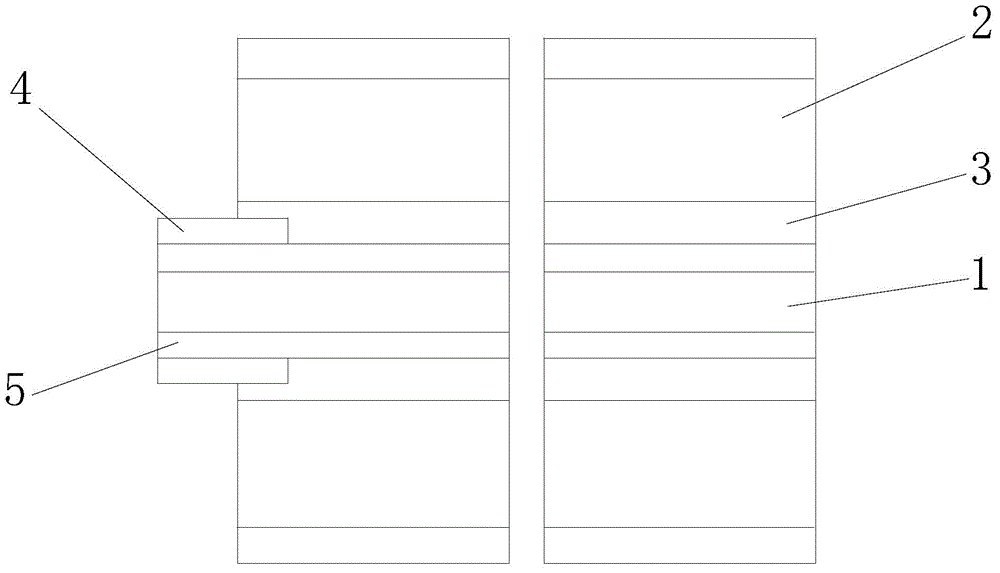

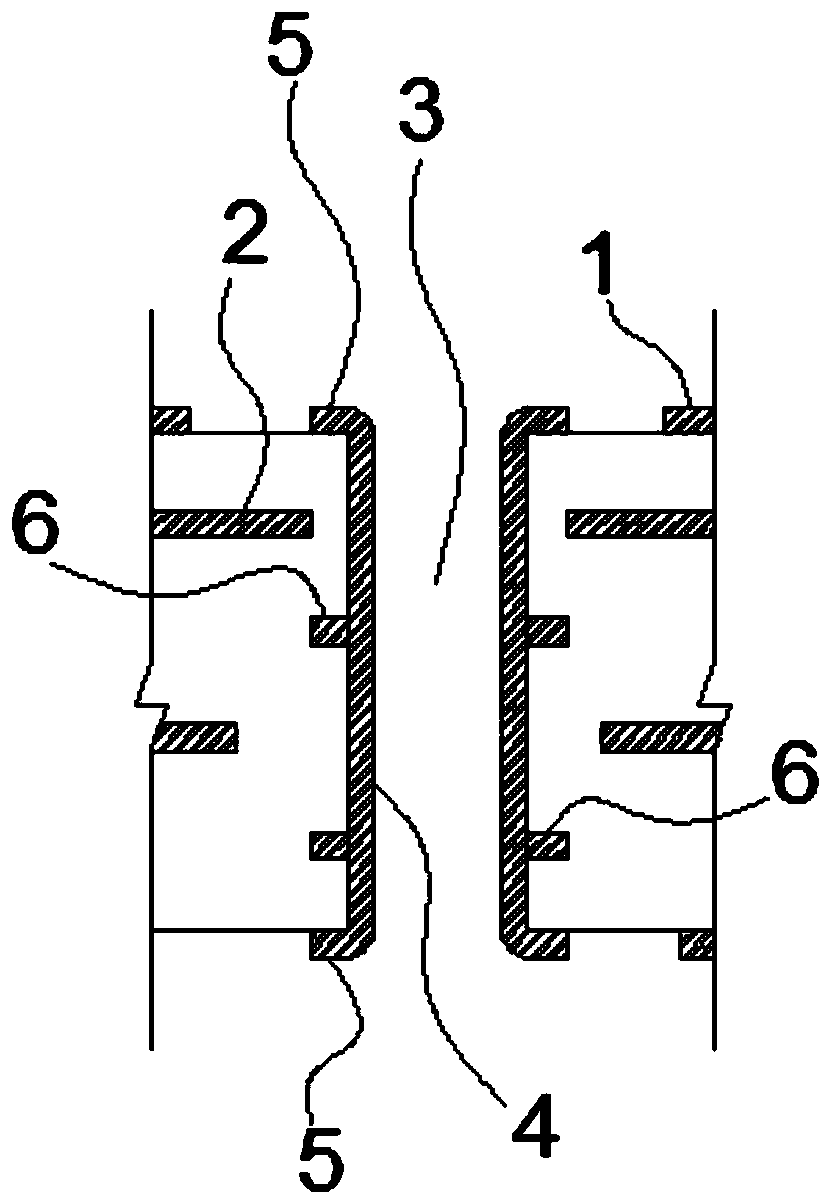

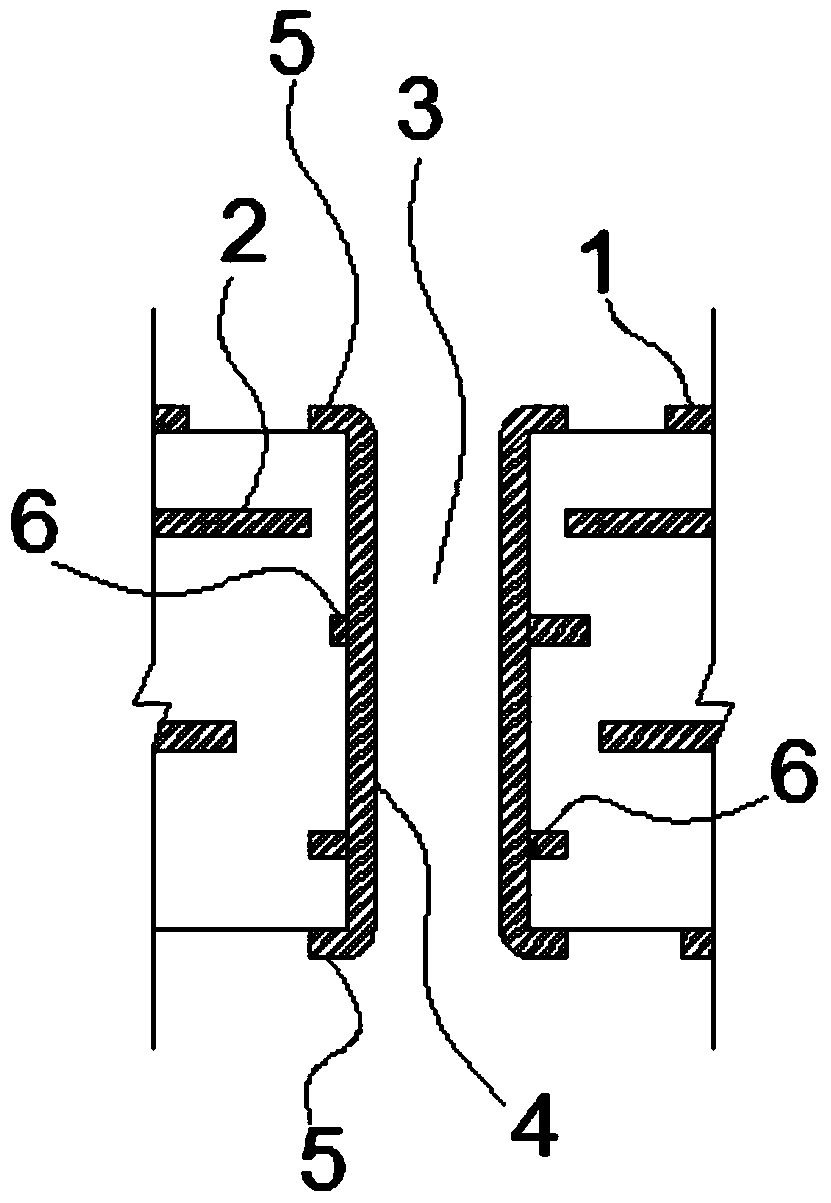

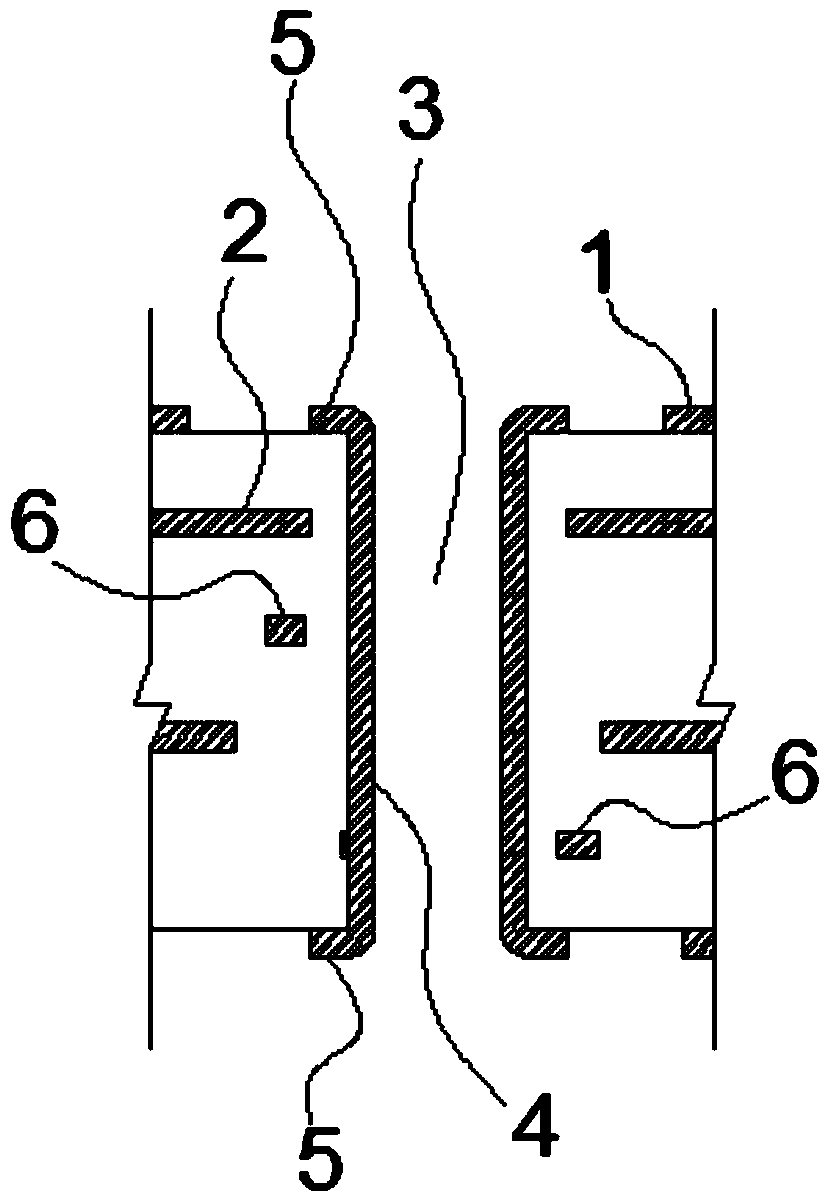

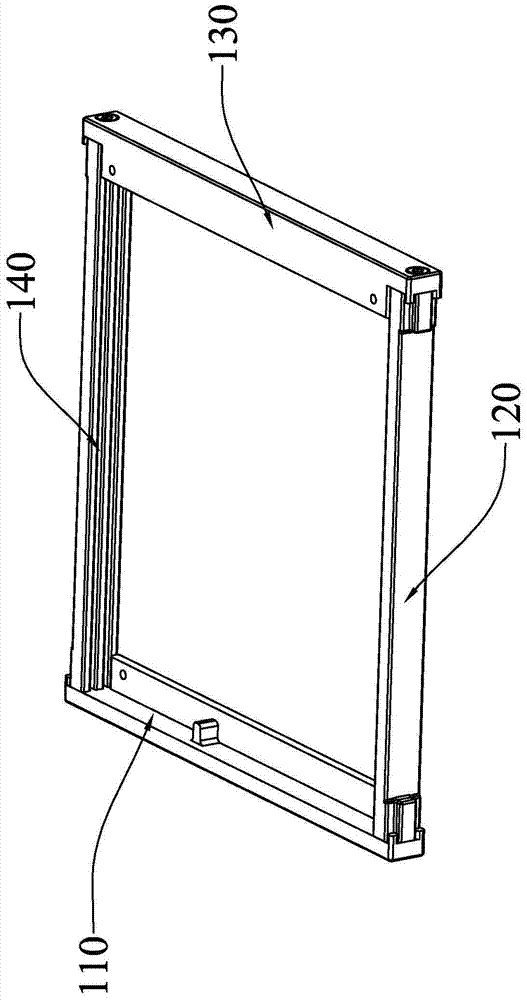

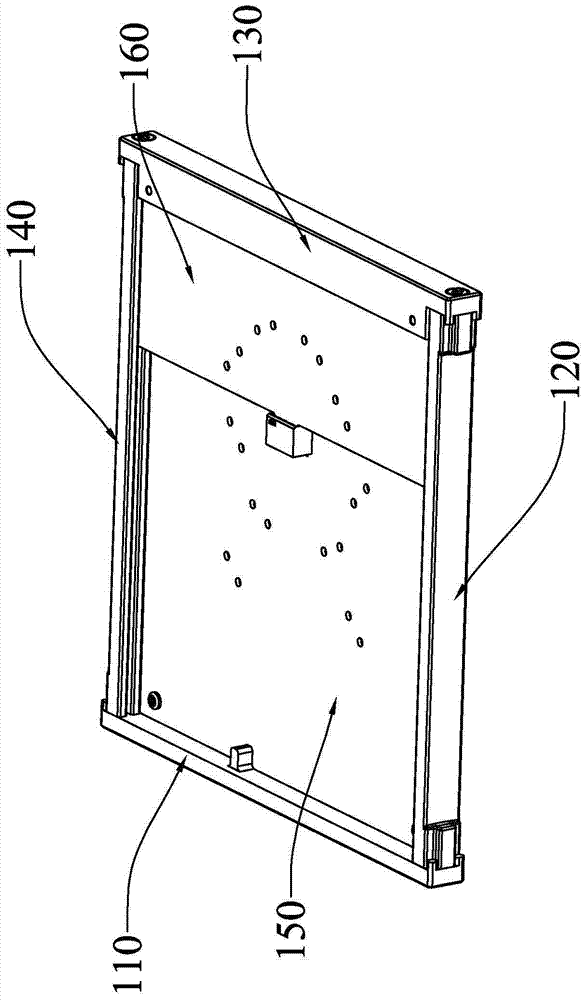

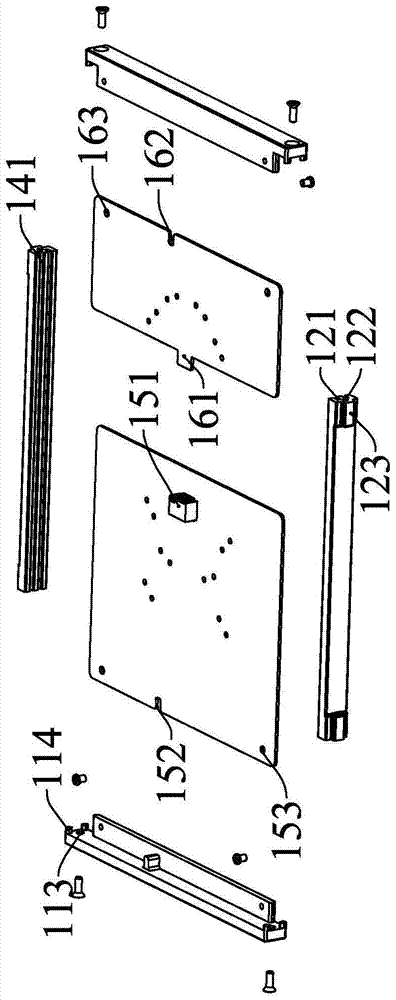

Fixing device for assisting butt joint of PCBs

ActiveCN105101631AEasy to assembleStable structurePrinted circuits structural associationsOther printed circuit detailsButt jointEngineering

The invention provides a fixing device for assisting butt joint of PCBs. The fixing device comprises a first transverse frame, a first vertical frame, a second transverse frame and a second vertical frame which are sequentially connected in a head-tail mode to form a sealed frame and are mutually detachable. One side, facing the inner part of the sealed frame, of the first transverse frame is provided with a first fixing part for fixing a PCB; one side, facing the inner part of the sealed frame, of the second transverse frame is provided with a second fixing part for fixing the other PCB; one side, facing the inner part of the sealed frame, of the first vertical frame is provided with at least one first sliding groove for supporting side edges of the PCBs; and one side, facing the inner part of the sealed frame, of the second vertical frame is provided with second sliding grooves with the same number as the first sliding grooves and positions of the first sliding grooves and the second sliding grooves are mutual corresponding. The frames in head-tail connection are adopted for fixing the PCBs, the size of the frame is controlled to enable two or more PCBs to be in accurate butt joint, each spare part is fixed by adopting a bolt, the device is simple to assemble, the structure is firm, and the application range is wide.

Owner:SHENZHEN FASTPRINT CIRCUIT TECH +1

Dust-proof, antifouling and anti-static HDI flexible circuit board and processing technology thereof

InactiveCN106255312ASolve static electricityEffective fitFlexible printed circuitsHigh voltage circuit adaptationsCopper platingFlexible circuits

The invention discloses a dust-proof, antifouling and anti-static HDI flexible circuit board, which comprises a circuit board body, wherein one end of the circuit board body is a connector, and the other end is a golden finger; the circuit board body comprises a first anti-static PET protective film, a first covering film, a first conductive layer, a substrate, a second conductive layer, a second covering film and a second anti-static PET protective film; the substrate is arranged in the middle of the circuit board body, the first conductive layer is adhered to the upper side of the substrate by using a transparent adhesive, and the second conductive layer is adhered to the lower side of the substrate by using a transparent adhesive; the first conductive layer is provided with deposited and plated copper, and the covering films are arranged on the deposited and plated copper; the first anti-static PET protective film is adhered on the first covering film; and a blind hole penetrates the first conductive layer, the substrate and the second conductive layer in sequence. The anti-static PET protective films of the HDI flexible circuit board are made of a transparent and flexible material, can effectively adhere to the board surfaces without being in contact with external air, do not generate static electricity and dust, do not break down a chip of a circuit on the circuit board, and can achieve the dust-proof, antifouling and anti-static effects.

Owner:昆山蒂梵尼智能家居有限公司

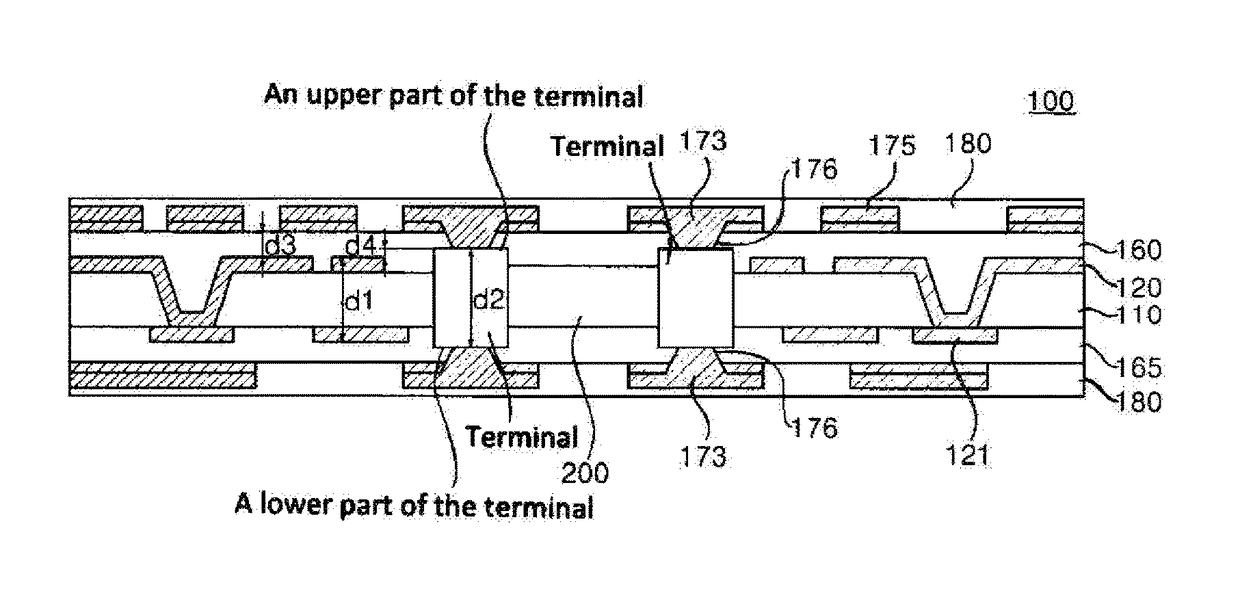

Printed circuit board and method of manufacturing the same

InactiveUS20150062846A1Desired thicknessDielectric materialsConductive pattern formationEngineeringPrinted circuit board

Provided is a printed circuit board, including: a core substrate including an internal circuit pattern on an upper surface or a lower surface; electronic devices which are formed to pass through the core substrate; an external insulating layer which covers the internal circuit pattern and the electronic devices; and an external circuit pattern which is formed on an upper surface of the external insulating layer, wherein a lower surface of the electronic devices protrudes from the lower surface of the core substrate to a lower part. Accordingly, in the embedded printed circuit board in which the electronic devices are embedded, when the electronic devices are mounted, because the insulating layer is formed regardless of a thickness of the electronic devices, the printed circuit board having a desired thickness regardless of the thickness of the electronic devices can be formed.

Owner:LG INNOTEK CO LTD

Electronic device and method for manufacturing electronic device

ActiveUS10034380B2Efficient preparationLow costFinal product manufactureInsulating layers/substrates workingElectrical conductorEngineering

Owner:MURATA MFG CO LTD

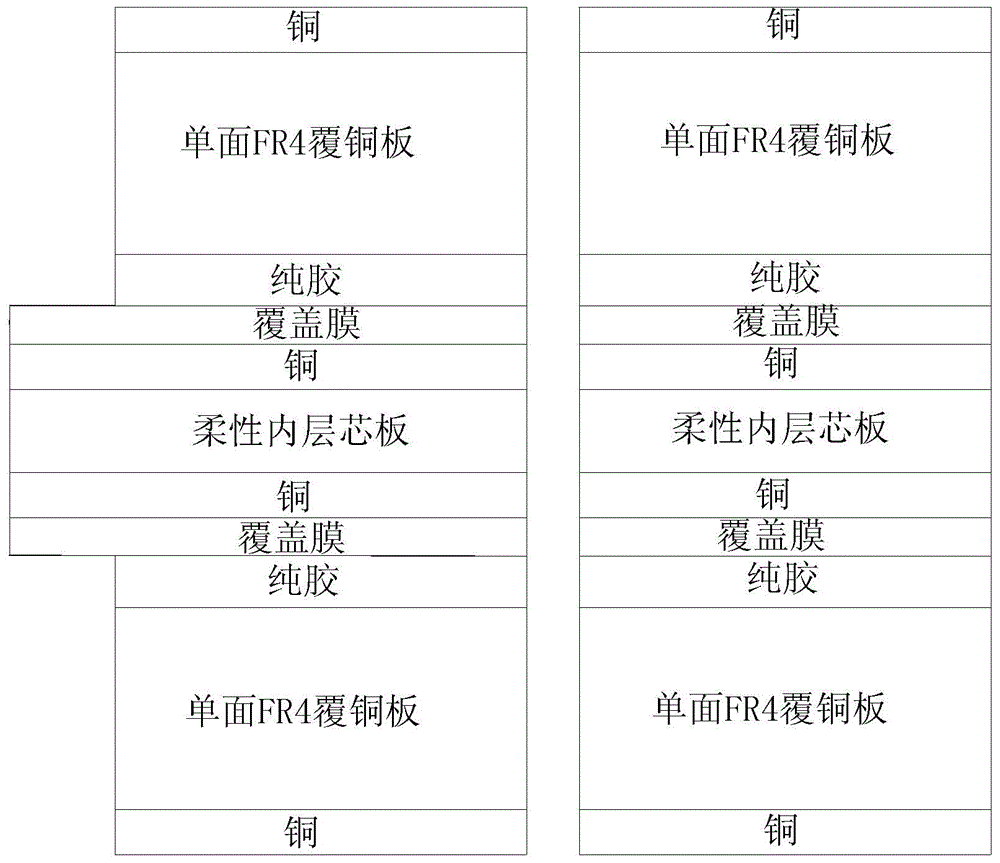

Laminar structure of flexible and rigid PCBs less than four in layer number

InactiveCN104470198AConsistent erosion rateTroubleshoot faultsPrinted circuit manufactureOther printed circuit detailsEngineeringCopper

The invention discloses a laminar structure of flexible and rigid PCBs less than four in layer number. The laminar structure comprises flexible inner layer core boards, single-side FR4 copper-clad plates, pure gum and covering films. According to the laminar structure, the flexible inner layer core boards serve as centers, the upper side and the lower side of each flexible inner layer core board are each sequentially provided with the corresponding single-side FR4 copper-clad plate and the corresponding pure gum from outside to inside, and the covering films are only arranged on the upper side and the lower side of the outer edge part of each flexible inner layer core board and extend inwards by a certain distance. The laminar structure has the advantages that after the covering films, at flexible PCBs, of rigid PCBs are removed, the fretting rates of liquid medicine are basically identical during gum residue removal, and the problem of hole copper faultage is solved; in the lamination process, the pure gum is injected to the spaces between lines, the thicknesses of pure gum layers between inner layer copper sides and FR4 decrease, the drilling pollution probability is reduced during drilling, and the problem of plating nodules is solved. The defects are solved, so that the yield of products is greatly increased, raw materials are saved, production cost is lowered, and production efficacy is improved.

Owner:ZHENJIANG HUAYIN PRINTED CIRCUIT BOARD

Antenna module

ActiveUS10965013B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringStructural engineering

An antenna module of the present disclosure includes a control substrate having a flat plate shape and configured to house or mount a semiconductor element; a frame substrate bonded to an upper surface of the control substrate via bonding members and exposing a center portion of the upper surface of the control substrate; and an antenna substrate having a flat plate shape, bonded to an upper surface of the frame substrate via the bonding members so as to face the control substrate, and provided with a plurality of antenna patterns disposed along a main surface of the antenna substrate. The frame substrate includes a frame main body and a crosspiece. Between the frame main body / the crosspiece and the control substrate as well as the antenna substrate, projecting portions that come into contact with the opposing control substrate, frame substrate, and antenna substrate are provided at a fixed height.

Owner:KYOCERA CORP

Circuit board

InactiveCN106211562AEasy to tack weld into shapeReduce production capacityInspection/indentification of circuitsMultilayer circuit manufacturePower flowElectrical and Electronics engineering

The invention discloses a circuit board. The circuit board comprises a first circuit board body and a second circuit board body. The portion between the first circuit board body and the second circuit board body is coated with a bonding layer, a positioning device is positioned and installed on the first circuit board body and the second circuit board body, and the first circuit board body is in contact with the second circuit board body to form a cut-off circuit with the positioning device. The positioning device comprises an external energizing terminal, an internal energizing terminal, connecting rods, positioning blocks, a communication wire, a current indicating gauge and a power source; the external energizing terminal and the internal energizing terminal are fixedly connected with the connecting rods and the positioning blocks to form two sections to be matched with a positioning module; the positioning blocks are connected with the current indicating gauge and the power source through the communication wire to form a circuit. According to the circuit board, the space position of the circuit board is accurately positioned through the positioning device, later positioning, welding and forming are easy, and therefore the production process and the cost are reduced.

Owner:苏州良基电子科技有限公司

Package substrate and structure

ActiveUS20150237717A1Improve rigidityReduce warpageSolid-state devicesPrinted circuit manufactureEngineeringDielectric layer

A package substrate is provided, which includes a plurality of dielectric layers and a plurality of circuit layers alternately stacked with the dielectric layers. At least two of the circuit layers have a difference in thickness so as to prevent warpage of the substrate.

Owner:SILICONWARE PRECISION IND CO LTD

Liquid discharge head

InactiveUS9950512B2Conductive pattern formationElectrical connection printed elementsEngineeringElectric signal

A liquid discharge head includes an element substrate to which an electric signal is supplied, an electrical wiring board that is connected to the element substrate and that is capable of supplying the electric signal to the element substrate, and a printed circuit board that includes a wiring line and an insulating layer covering the wiring line and that is capable of supplying the electric signal to the element substrate via the wiring line. A protruding structure that has a thickness approximately equal to a thickness of the wiring line and that is covered with the insulating layer is disposed along the wiring line on the printed circuit board, and a portion of the electrical wiring board is bonded to a portion of the insulating layer located on the wiring line disposed on the printed circuit board.

Owner:CANON KK

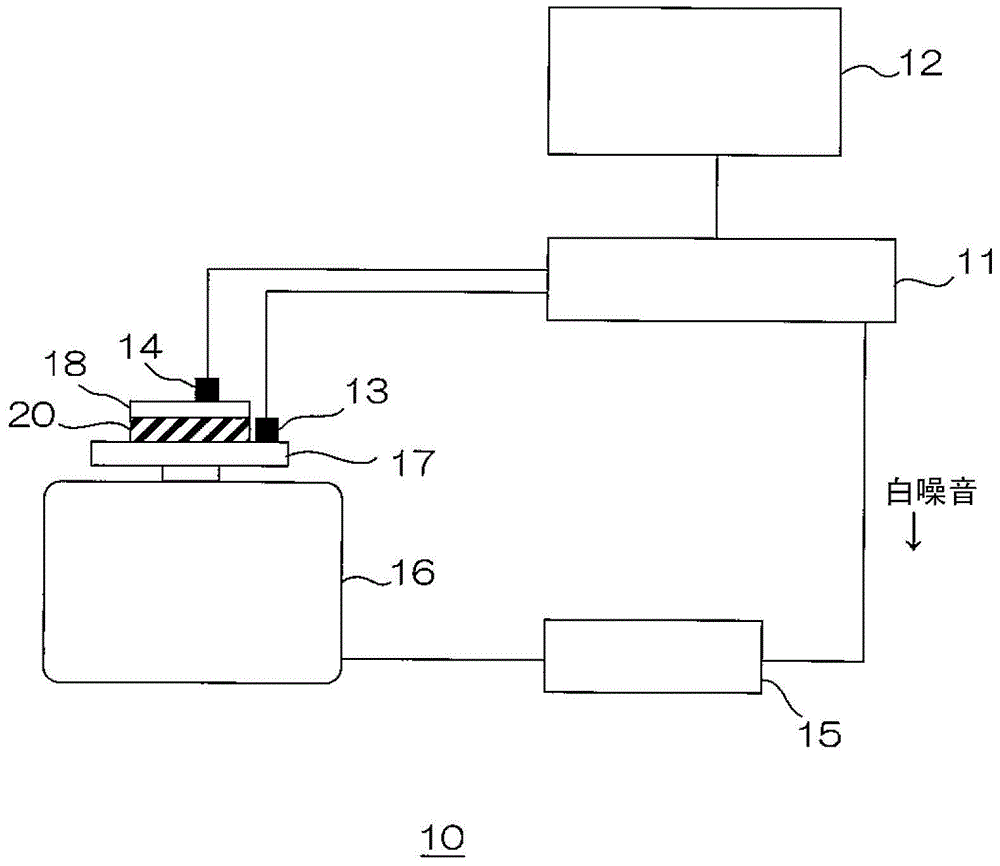

Vibration-proof Material, Vibration-proof Structure, And Vibration-proof Method

InactiveCN104059302ALess corrosiveImprove the anti-vibration effectPorous dielectricsNon-rotating vibration suppressionCrystallographySulfur

A vibration-proof material is obtained by foaming a rubber composition containing an ethylene-propylene-diene rubber. The content ratio of a sulfur atom calculated based on the measurement result of a fluorescent X-ray measurement, based on mass, is 1000 ppm or less and the vibration-proof material has a Young's modulus at 23° C. of 6.0×105 Pa or less.

Owner:NITTO DENKO CORP

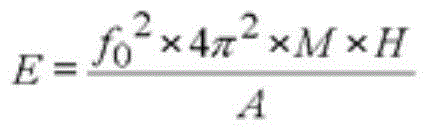

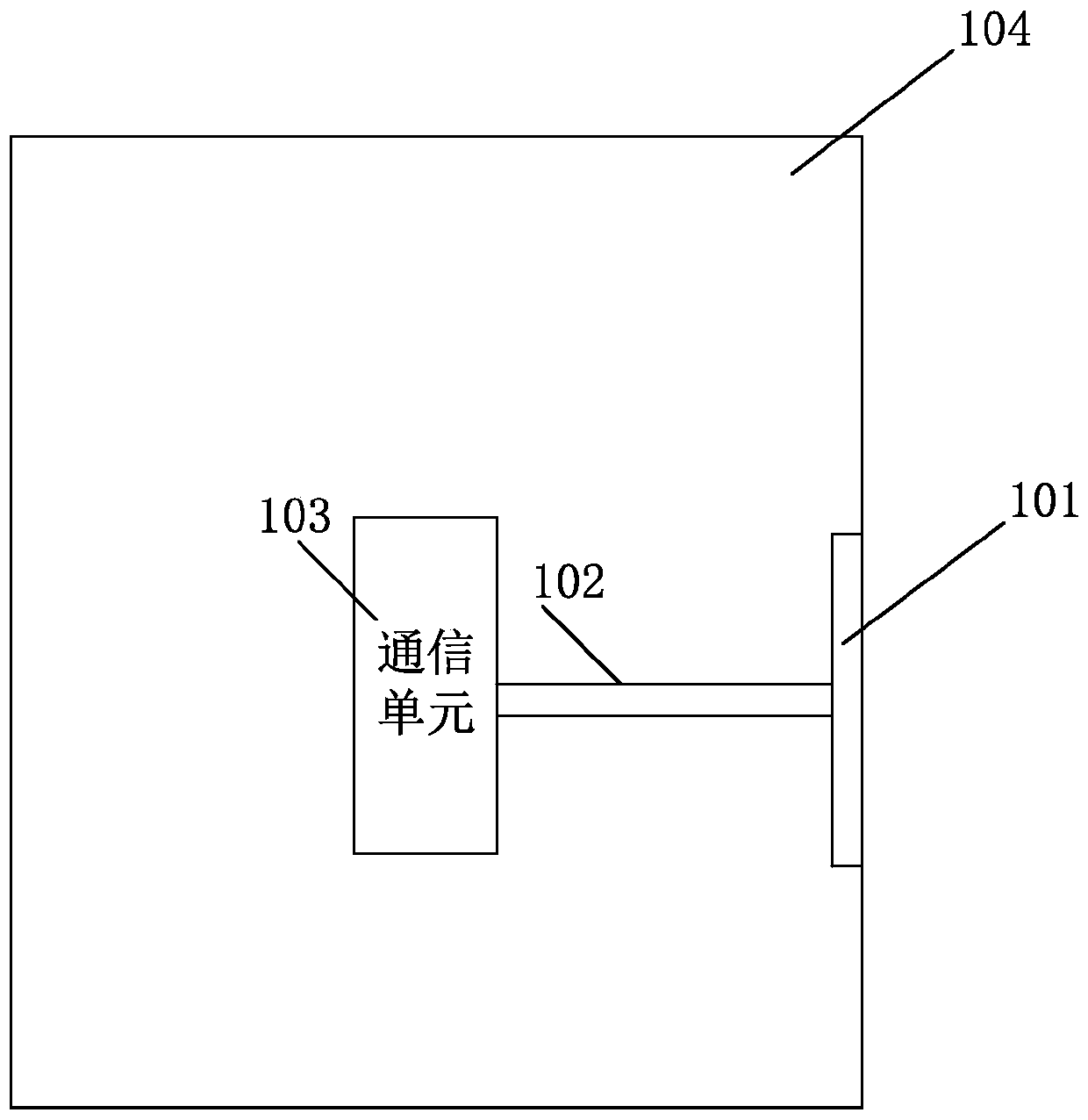

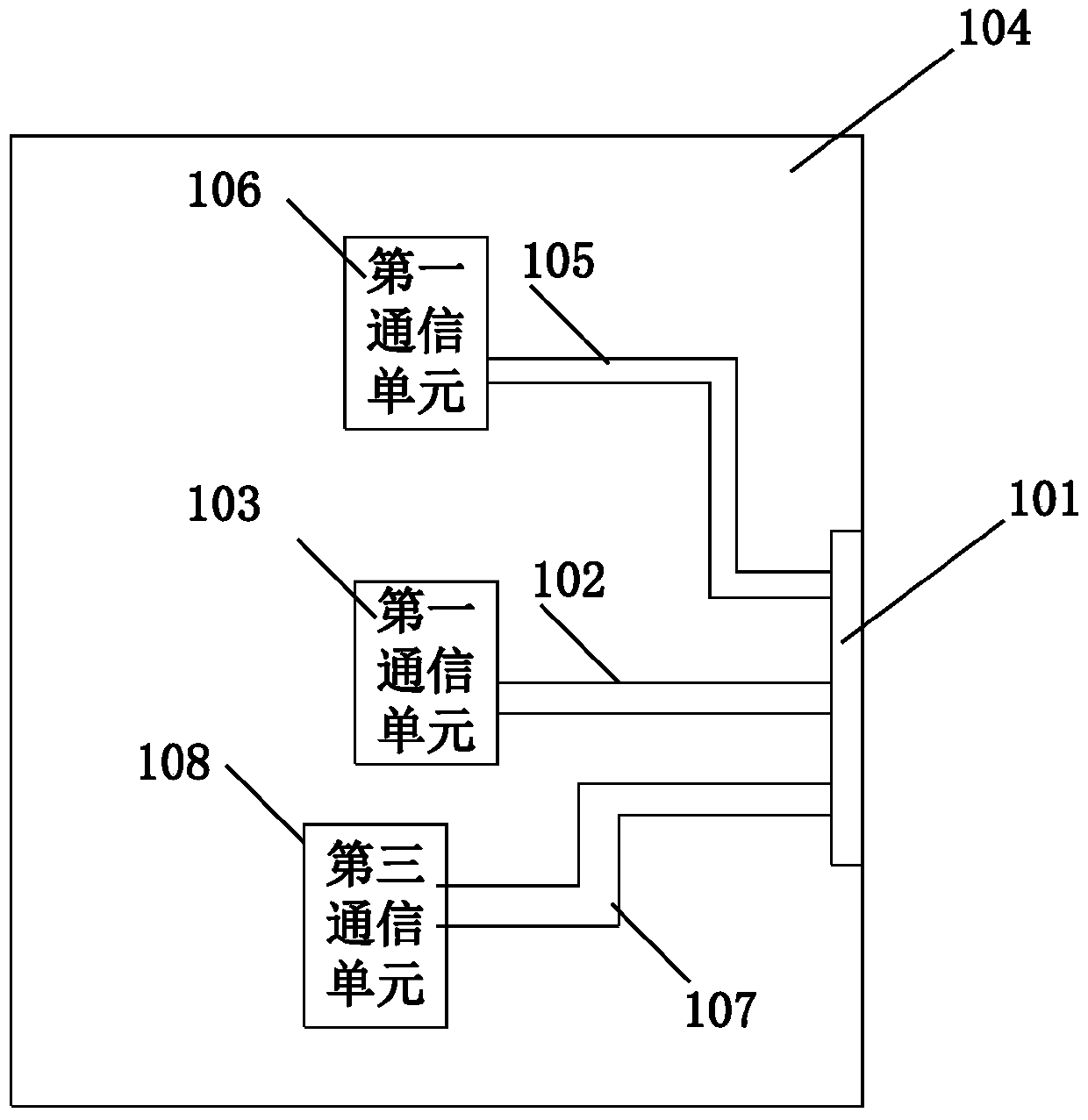

Circuit board and manufacturing method thereof

ActiveCN105072804BReduce continuityHigh speedLithography/patterningElectrical connection printed elementsElectricityTransmission quality

Owner:XIAOMI INC

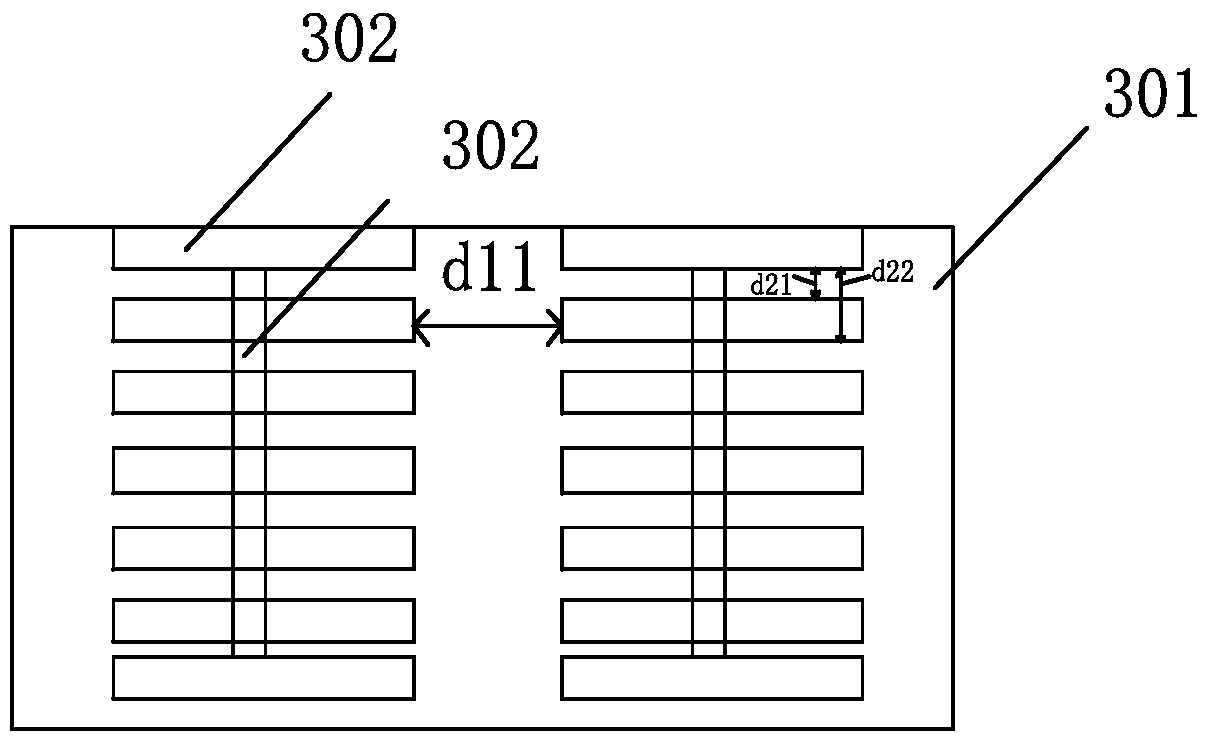

Inner Layer Monitoring Structure of Multilayer Printed Circuit Board

ActiveCN105101624BAccurateInspection/indentification of circuitsOther printed circuit detailsCopperPrinted circuit board

Owner:竞陆电子(昆山)有限公司

Printed circuit board and display device including the same

ActiveUS10624210B2Improve efficiencyImprove straightnessPrinted circuit groundingCross-talk/noise/interference reductionInsulation layerDisplay device

A printed circuit board and a display device are provided. The printed circuit board includes a plurality of insulation layers; at least one metal layer between the plurality of insulation layers; and a fixing member fixed to a surface of one of the at least one metal layer and passing through an outermost one of insulation layers to protrude to the outside.

Owner:LG DISPLAY CO LTD

Room-temperature-curable polyorganosiloxane composition and electric/electronic apparatus

InactiveCN104487519ALow viscosityGood spreadabilityCoatingsThin material handlingSilane compoundsCross-link

This room-temperature-curable polyorganosiloxane composition contains, for every 100 parts by mass of a polyorganosiloxane (A) comprising (A1) 10-80 parts by mass of an alkoxysilyl group end-blocked polyorganosiloxane and (A2) 90-20 parts by mass of a partial hydrolysis condensate (having 10-200 Si atoms) of a silane compound represented by the general formula R4 bSi(OR5)4-b, (B) 0.1-15 parts by mass of a silane compound or partial hydrolysis condensate thereof (having at least 1 and less than 10 Si atoms) as a cross-linking agent, and (C) 0.1-15 parts by mass of an organic titanium compound as a curing catalyst. The present invention forms a cured coating film having low viscosity, favorable coating properties without a solvent, and superior scratch resistance.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

A fixing device for auxiliary pcb board docking

ActiveCN105101631BEasy to assembleStable structurePrinted circuits structural associationsOther printed circuit detailsButt jointEngineering

The invention provides a fixing device for assisting butt joint of PCBs. The fixing device comprises a first transverse frame, a first vertical frame, a second transverse frame and a second vertical frame which are sequentially connected in a head-tail mode to form a sealed frame and are mutually detachable. One side, facing the inner part of the sealed frame, of the first transverse frame is provided with a first fixing part for fixing a PCB; one side, facing the inner part of the sealed frame, of the second transverse frame is provided with a second fixing part for fixing the other PCB; one side, facing the inner part of the sealed frame, of the first vertical frame is provided with at least one first sliding groove for supporting side edges of the PCBs; and one side, facing the inner part of the sealed frame, of the second vertical frame is provided with second sliding grooves with the same number as the first sliding grooves and positions of the first sliding grooves and the second sliding grooves are mutual corresponding. The frames in head-tail connection are adopted for fixing the PCBs, the size of the frame is controlled to enable two or more PCBs to be in accurate butt joint, each spare part is fixed by adopting a bolt, the device is simple to assemble, the structure is firm, and the application range is wide.

Owner:SHENZHEN FASTPRINT CIRCUIT TECH +1

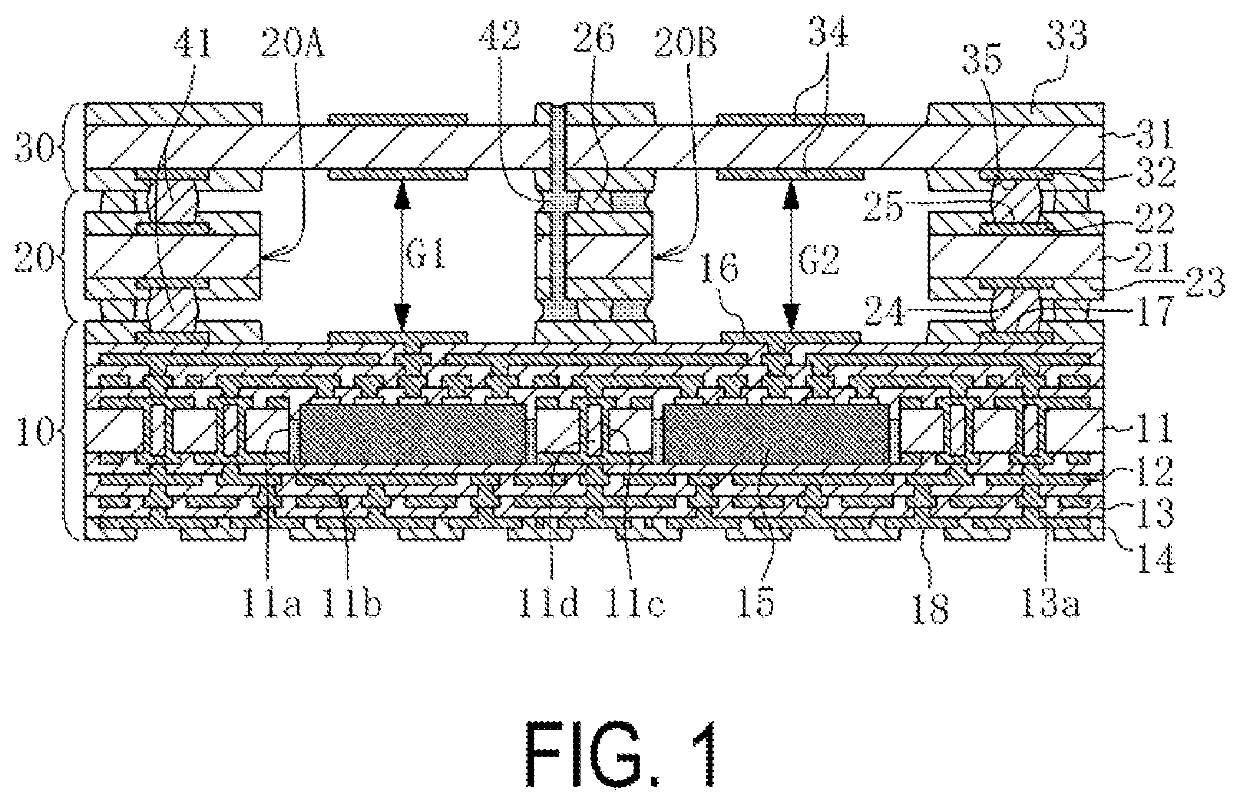

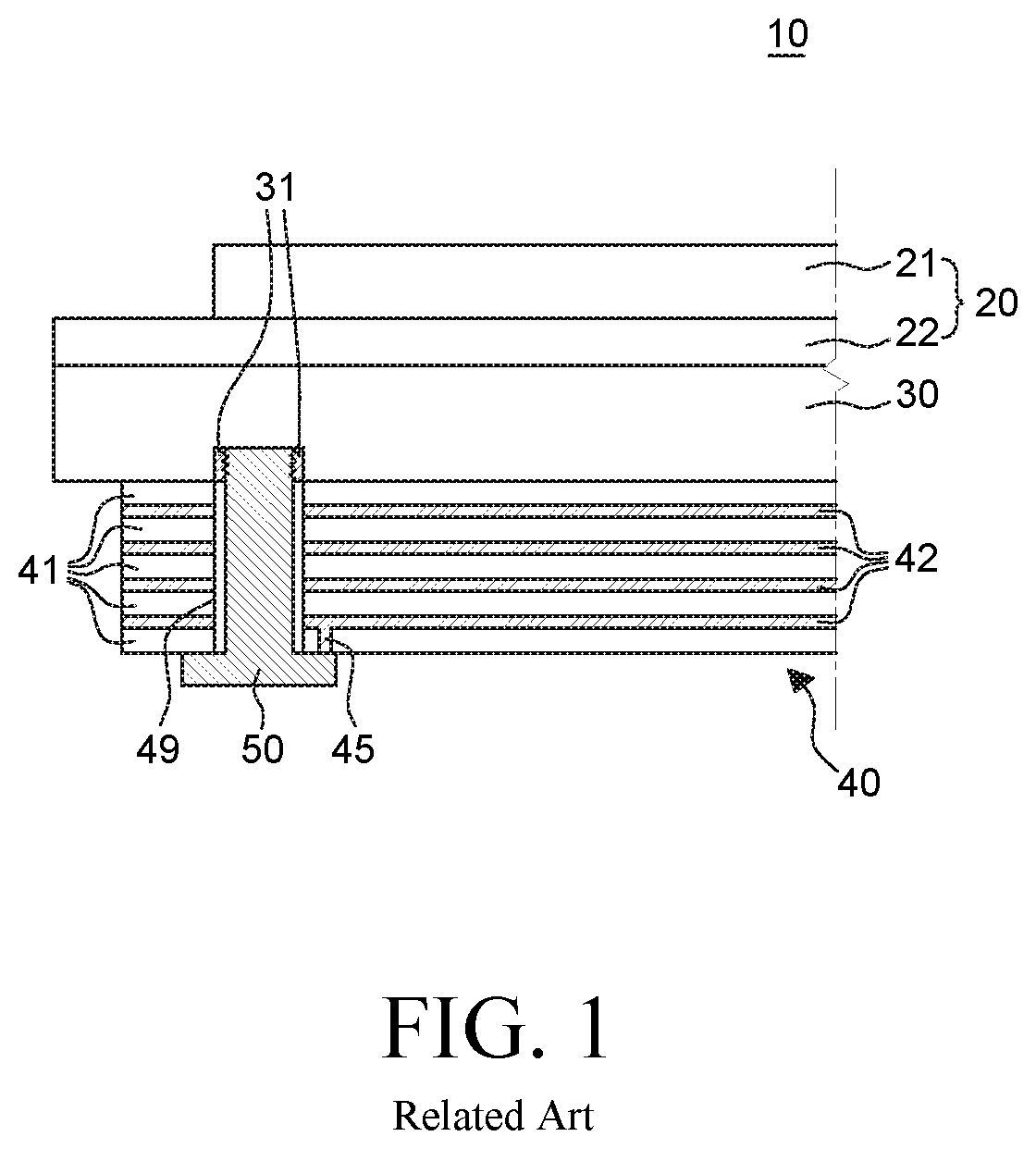

Method for manufacturing electrical connection assembly

ActiveUS10804622B2Low melting pointPrinted circuit assemblingContact member assembly/disassemblyElectrical conductorElectrical connection

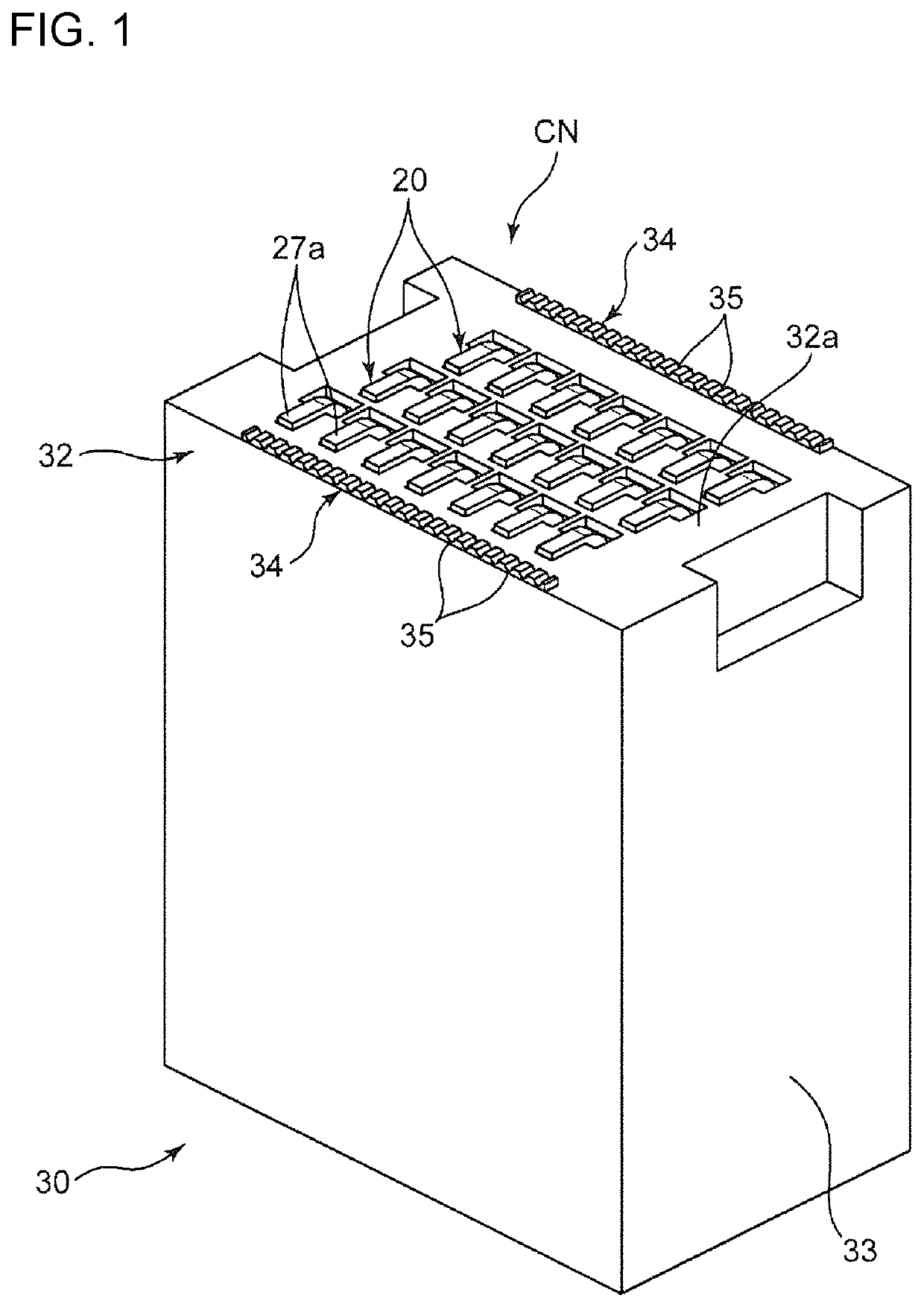

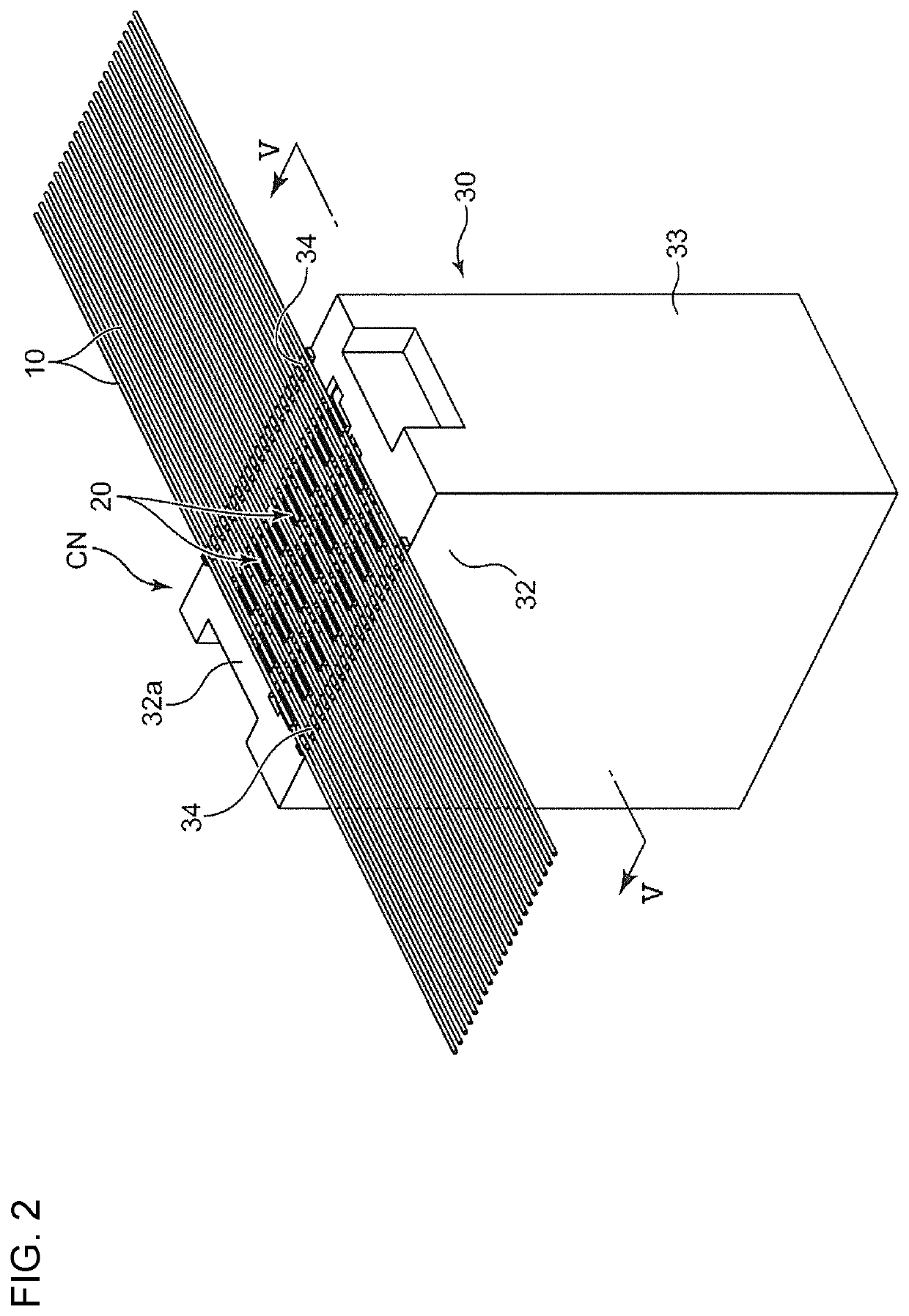

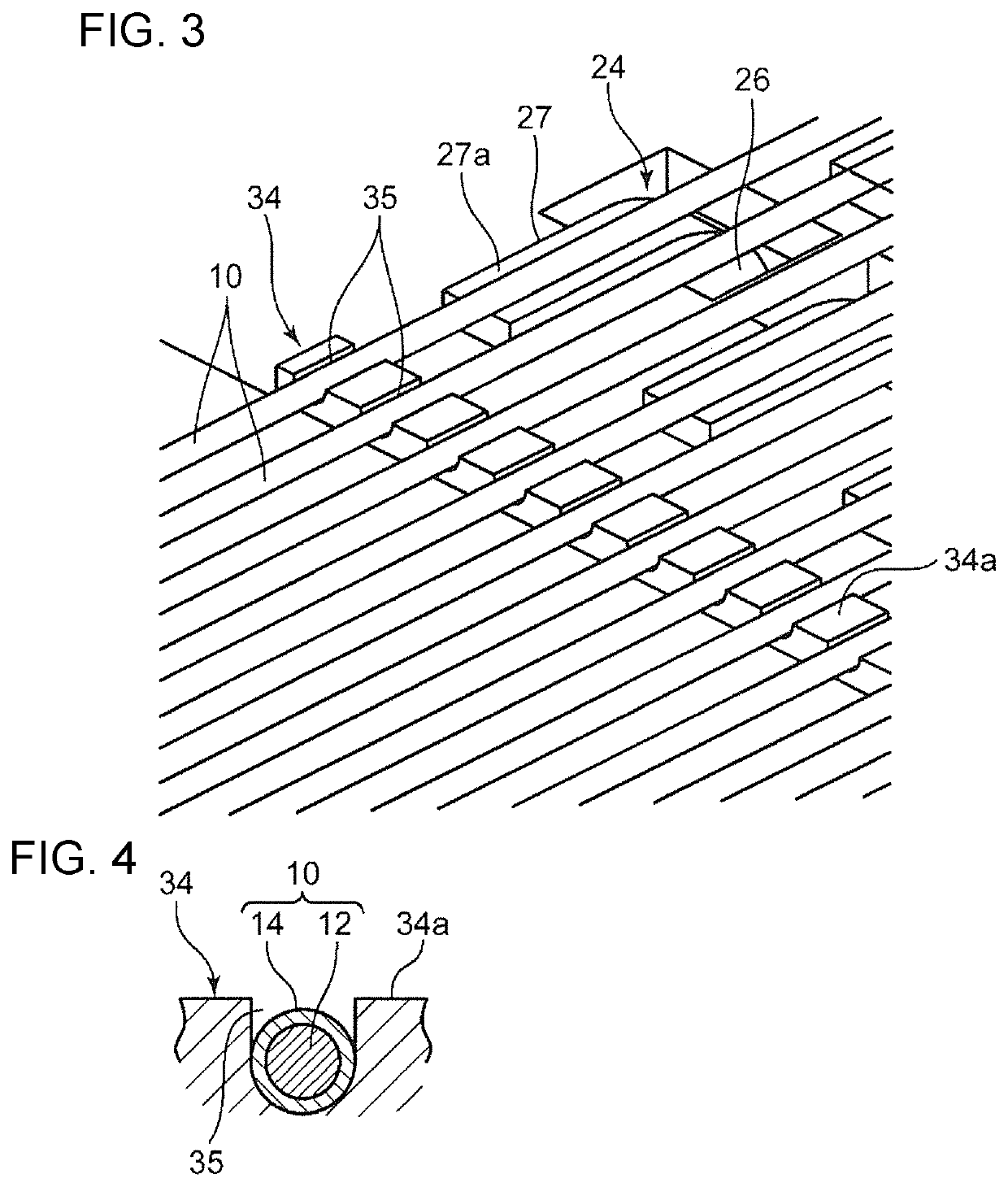

A method is provided for manufacturing an electrical connection assembly includes preparing a connector (CN) in which each terminal (20) has a conductor connection surface (27a) exposed from an insulating housing (30), bringing parts of conductors and the conductor connection surfaces (27a) corresponding thereto into contact and connecting both while tension is applied to a wiring material (10). The method further includes fixing the wiring material (10) to the insulating housing (30) by bringing the wiring material (10) and the insulating housing (30) into contact with each other at the fixing positions separated in the longitudinal direction of the wiring material (10) from the parts to be connected and solidifying the fixing portions (34) of the insulating housing (30) after melting the fixing portions at the fixing positions.

Owner:AUTONETWORKS TECH LTD +2

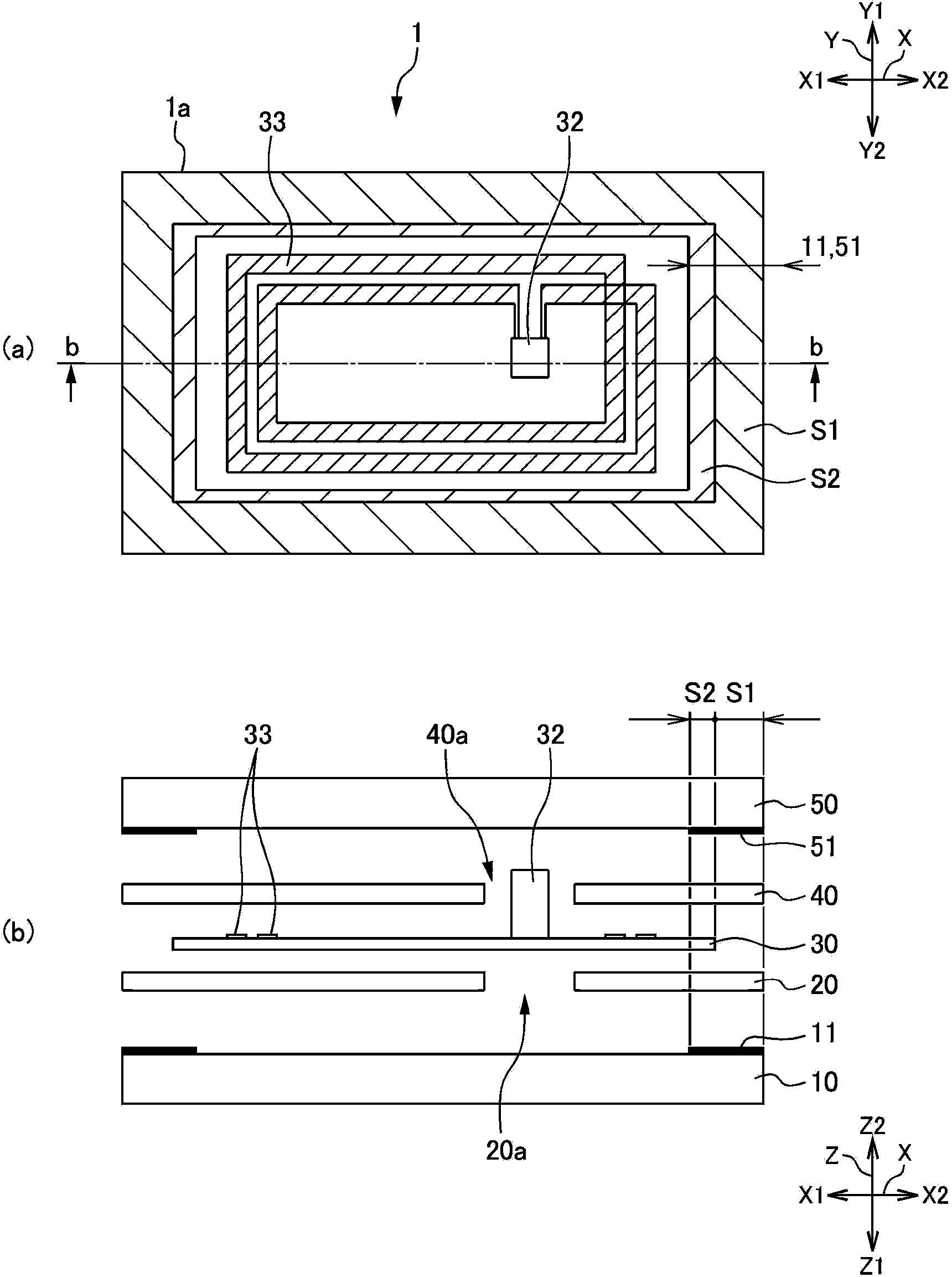

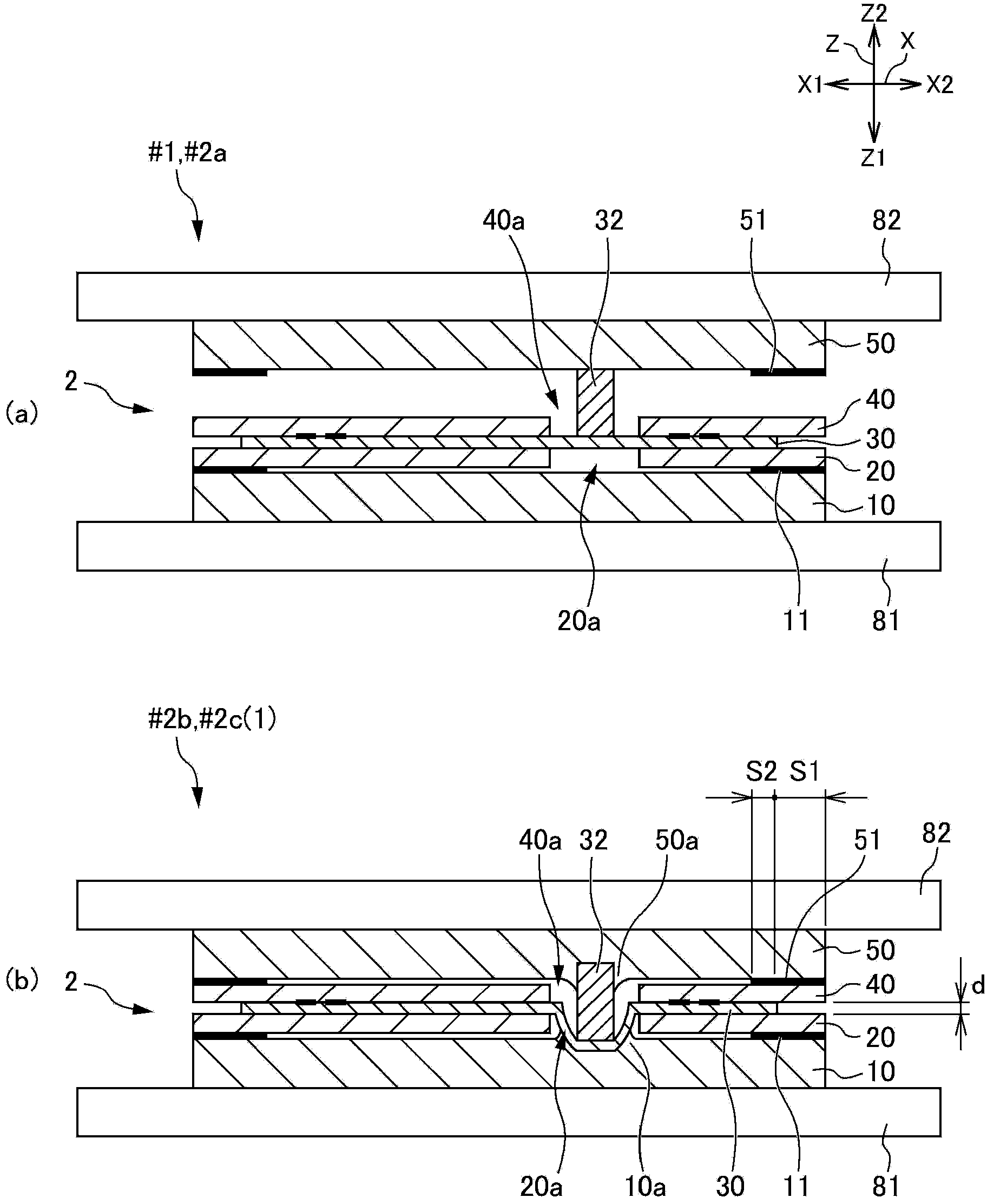

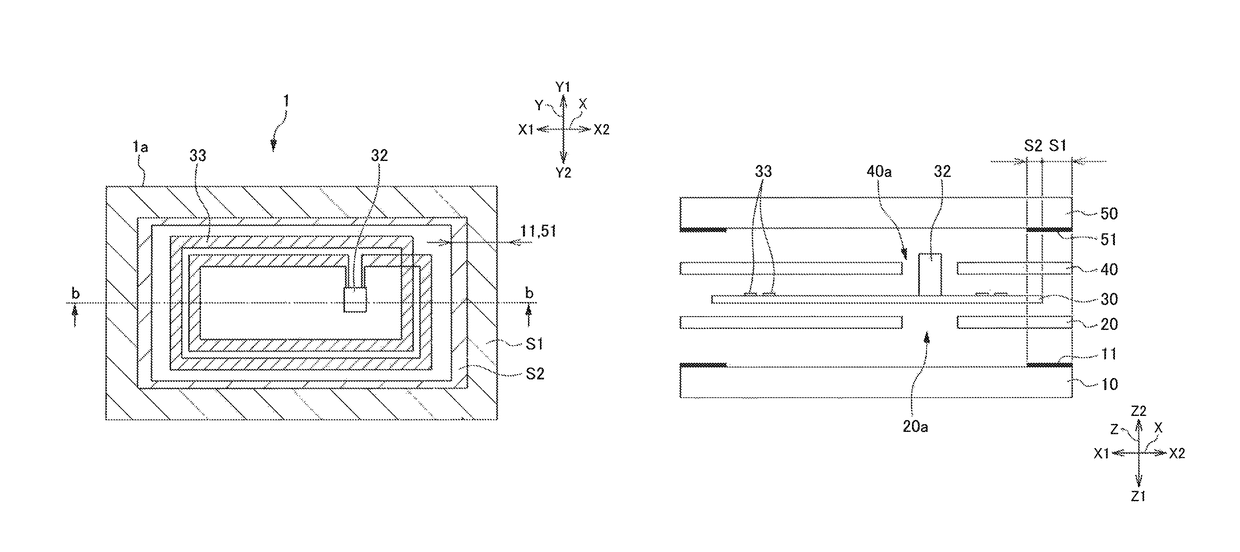

Card and card production method

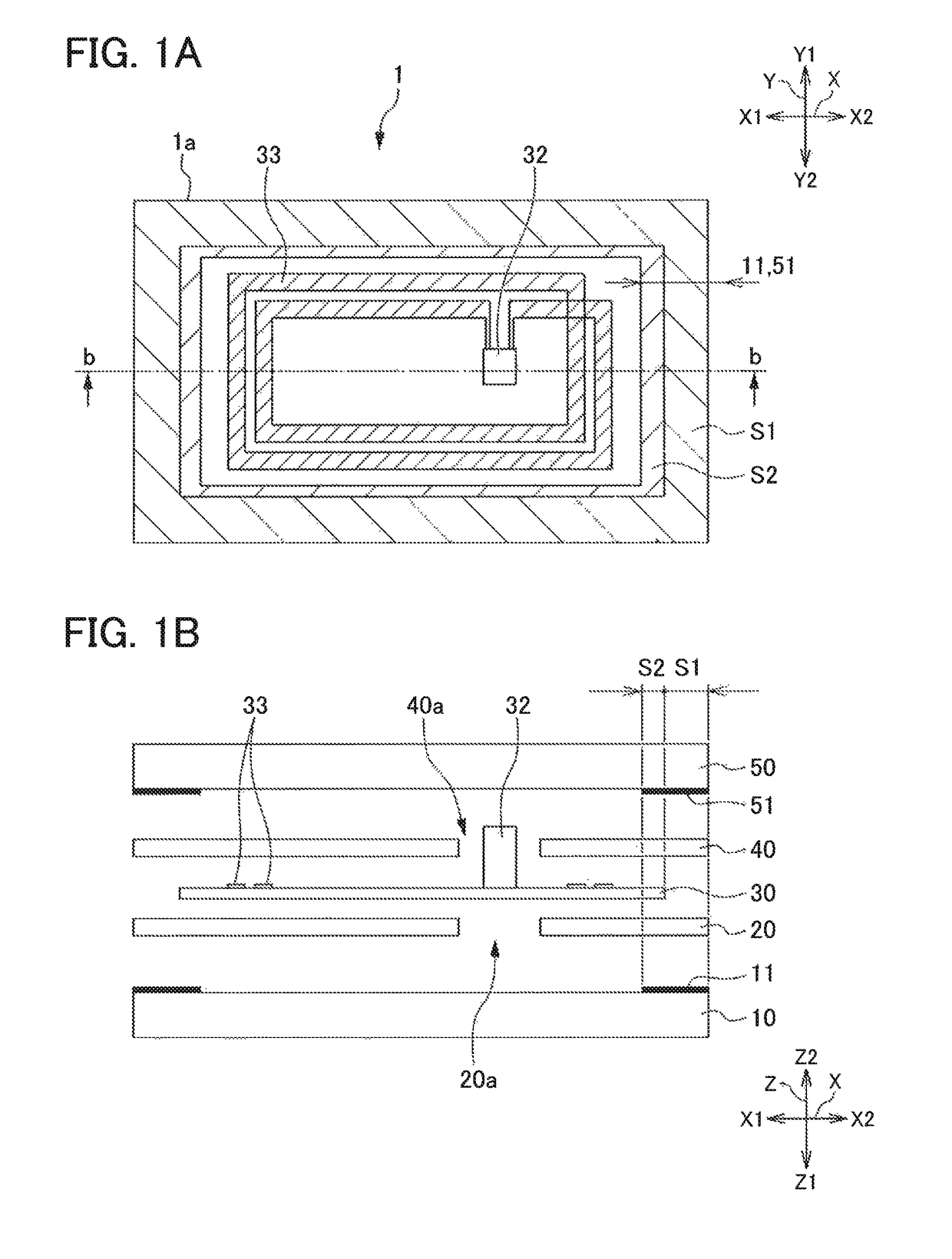

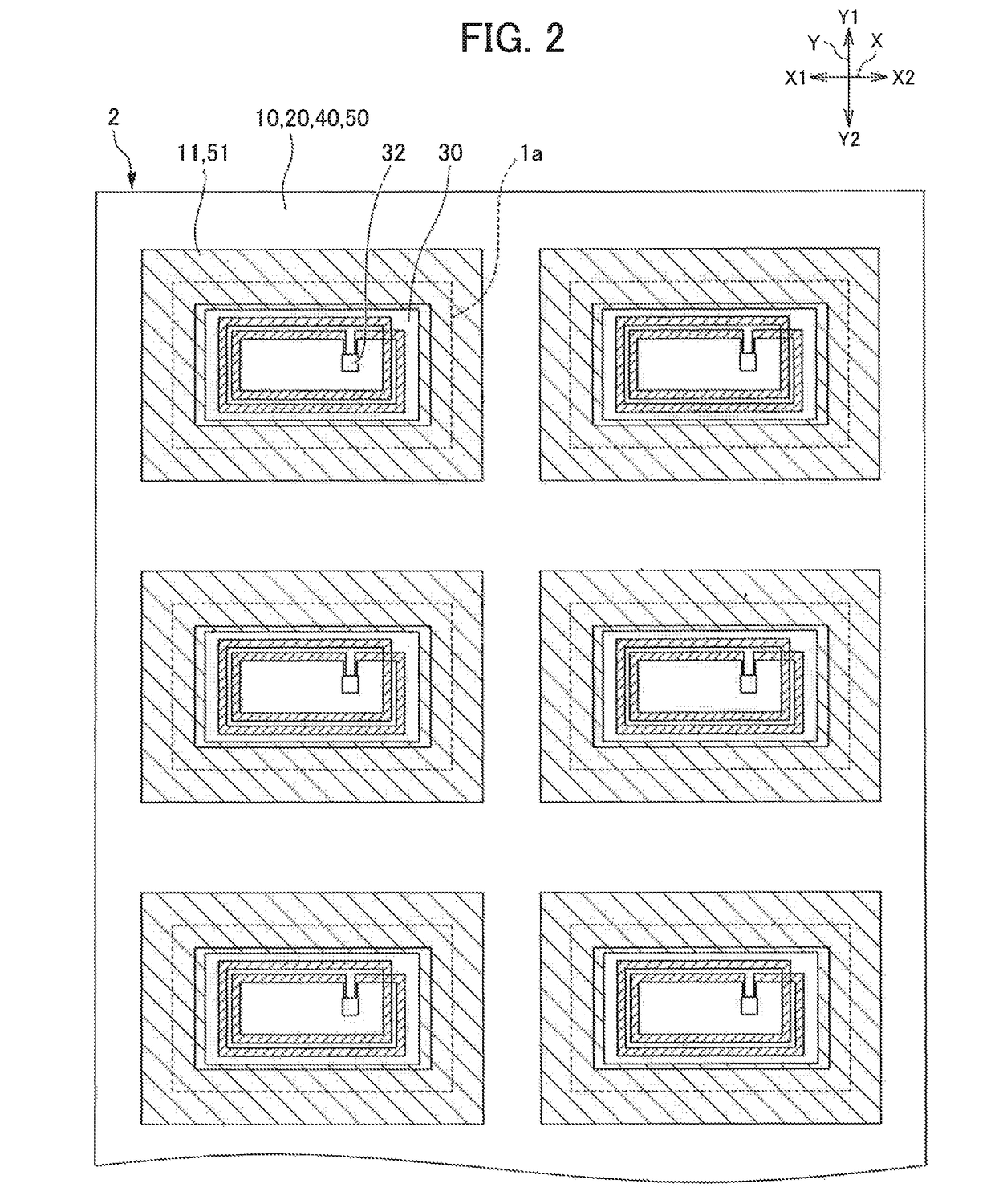

To provide a card capable of improving external appearance, and a card production method. A card (1) is provided with: a module substrate (30); a lower layer (10) and an upper layer (50) arranged above and below the module substrate (30), the layers having an outline larger than the outline of the module substrate (30); and thickness adjustment layers (11, 51) for adjusting the thickness in a substrate outward region (S1), the thickness adjustment layers being provided between the lower layer (10) and the upper layer (50) and to the substrate outward region (S1) further outward than the outline of the module substrate (30), and being provided by printing to at least one layer among the layers that form the card (1).

Owner:DAI NIPPON PRINTING CO LTD

Electro-optical device and electronic apparatus

Owner:SEIKO EPSON CORP

Popular searches

Printed circuit non-printed electric components association Casings/cabinets/drawers details Semiconductor/solid-state device manufacturing Cell component details Non-metallic protective coating application Printed element electric connection formation Semiconductor devices Circuit susbtrate materials Electrical components Emergency protective devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com