Inner Layer Monitoring Structure of Multilayer Printed Circuit Board

A multi-layer printing and circuit board technology, applied in the directions of printed circuit components, other printed circuit components, circuit inspection/identification, etc. Reflect and other problems to achieve the effect of accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

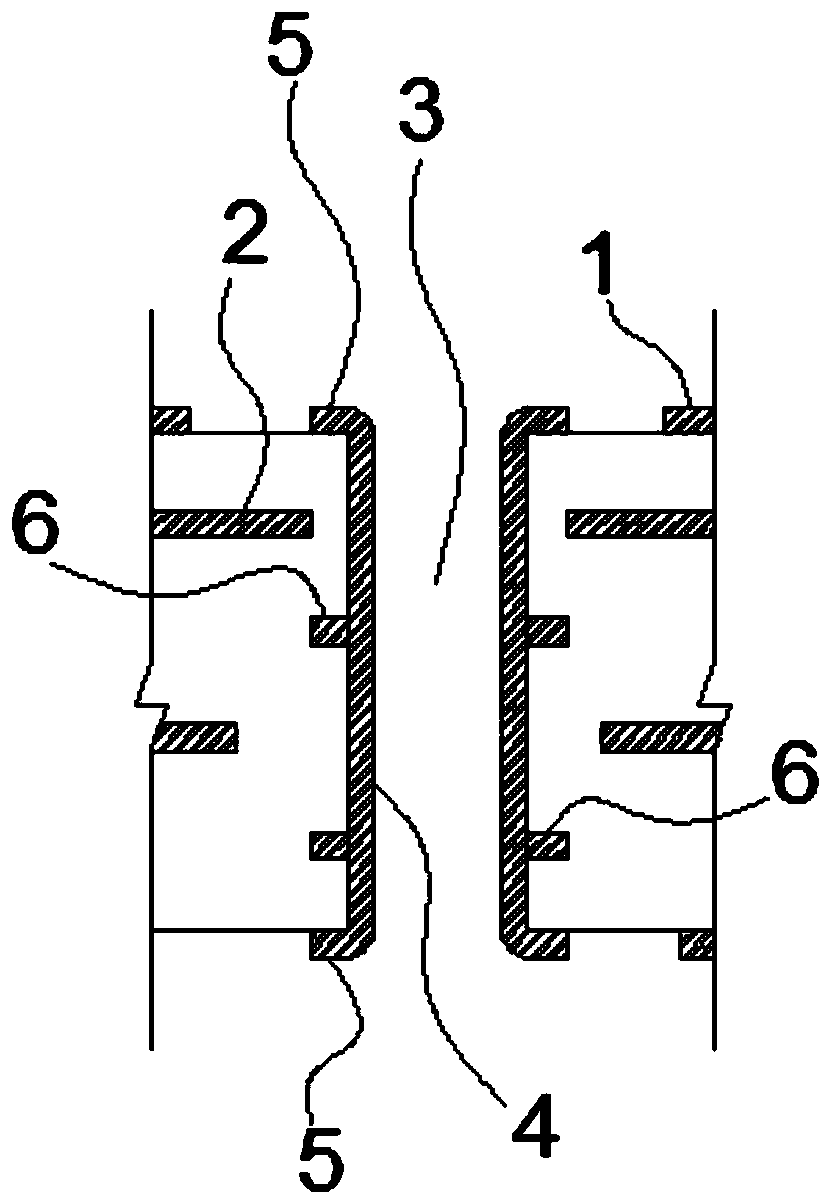

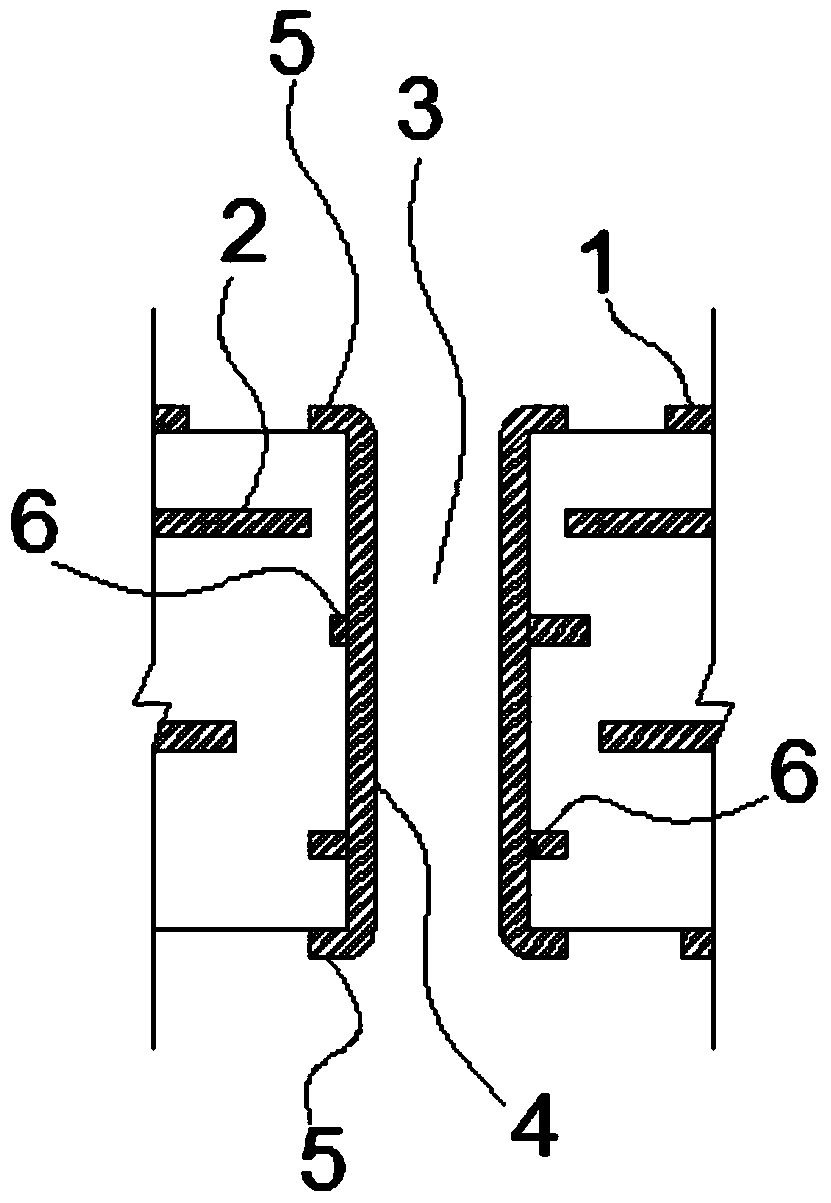

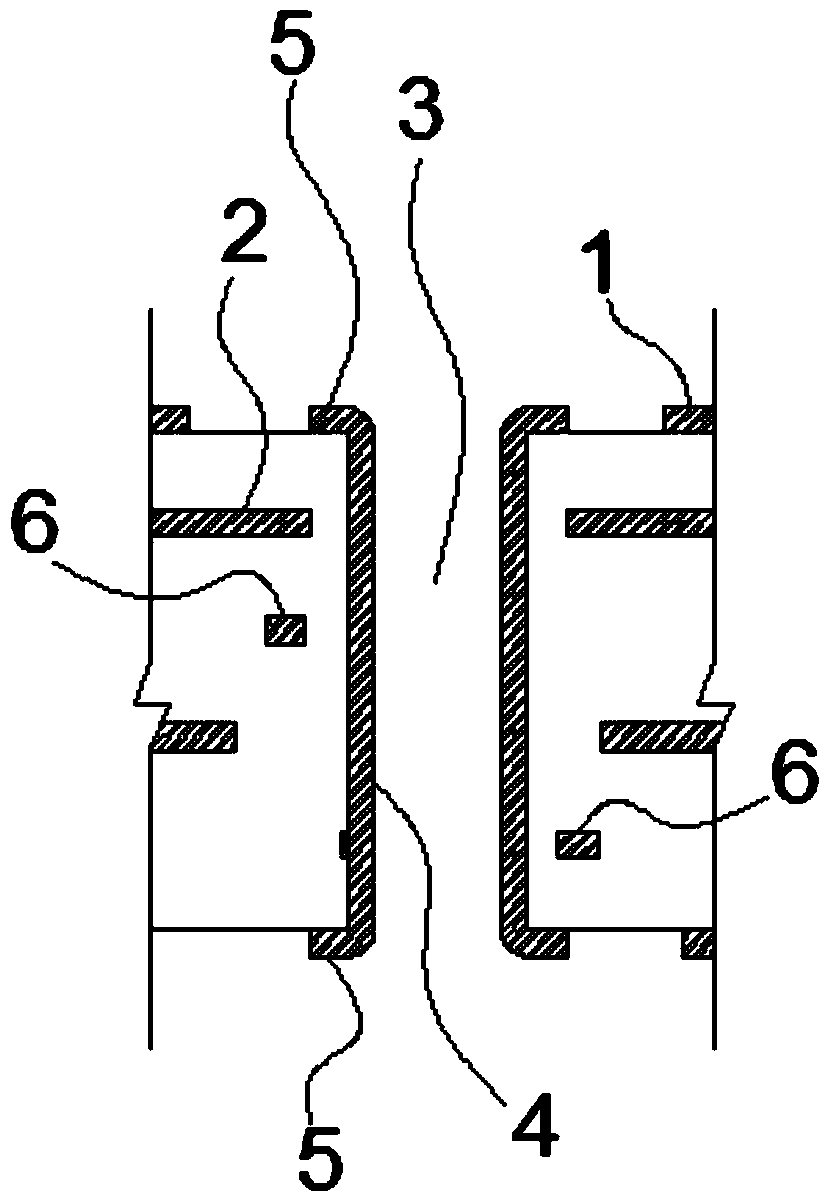

[0020] Embodiment: a kind of multilayer printed circuit board inner layer monitoring structure, the longitudinal stacking structure of the working piece of multilayer printed wiring board has outer layer 1 and multilayer inner layer 2, and the plane layout of the working piece of multilayer printed wiring board is A plurality of single pieces of circuit boards are arranged, and the edge of the working piece has several slicing holes 3, the slicing holes are through holes through the inner layer and the outer layer, and the inner surface of the slicing holes is covered with copper skin 4. The outer layer of the working sheet and the outer periphery of the slicing hole are provided with an outer copper ring 5, the outer copper ring is connected to the copper skin in the slicing hole, and the inner layer of the working sheet is located at the slicing hole. An inner layer copper ring 6 is arranged on the periphery of the hole, and the inner layer copper ring is connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com