Circuit board

A circuit board and circuit technology, applied in the directions of printed circuit, multilayer circuit manufacturing, printed circuit manufacturing, etc., can solve the problems of increasing production process and cost, affecting the passage of light, imaging alignment deviation, etc., and achieving easy positioning welding Forming, the effect of reducing production processes and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

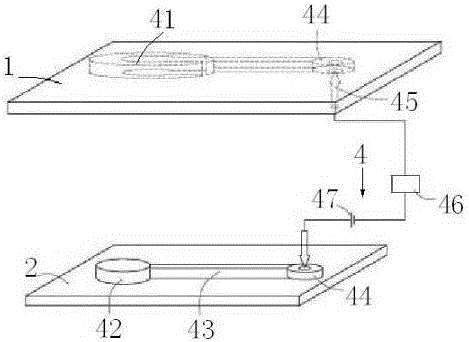

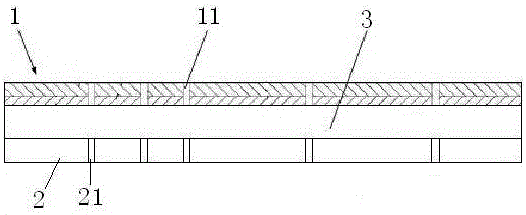

[0014] refer to figure 1 , 2 , a circuit board, including a first circuit board 1, a second circuit board 2, an adhesive layer 3 is coated between the first circuit board 1 and the second circuit board 2, specifically, a hot-pressing soldering method is adopted The first circuit board 1 and the second circuit board 2 are consolidated together with an adhesive layer 3 to form a circuit board. Further, the first circuit board 1 is provided with a plurality of first positioning connection holes 11, and the second circuit board 2 A number of second positioning connection holes 21 are opened on the top, and a positioning device 4 is installed on the first circuit board 1 and the second circuit board 2. The positioning device 4 includes an external power terminal 41, an internal power terminal 42, a connecting rod 43, and a positioning device. Block 44, connecting wire 45, current indicating meter 46, power supply 47, external energizing terminal 41 and internal energizing terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com