Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258results about "Housing manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

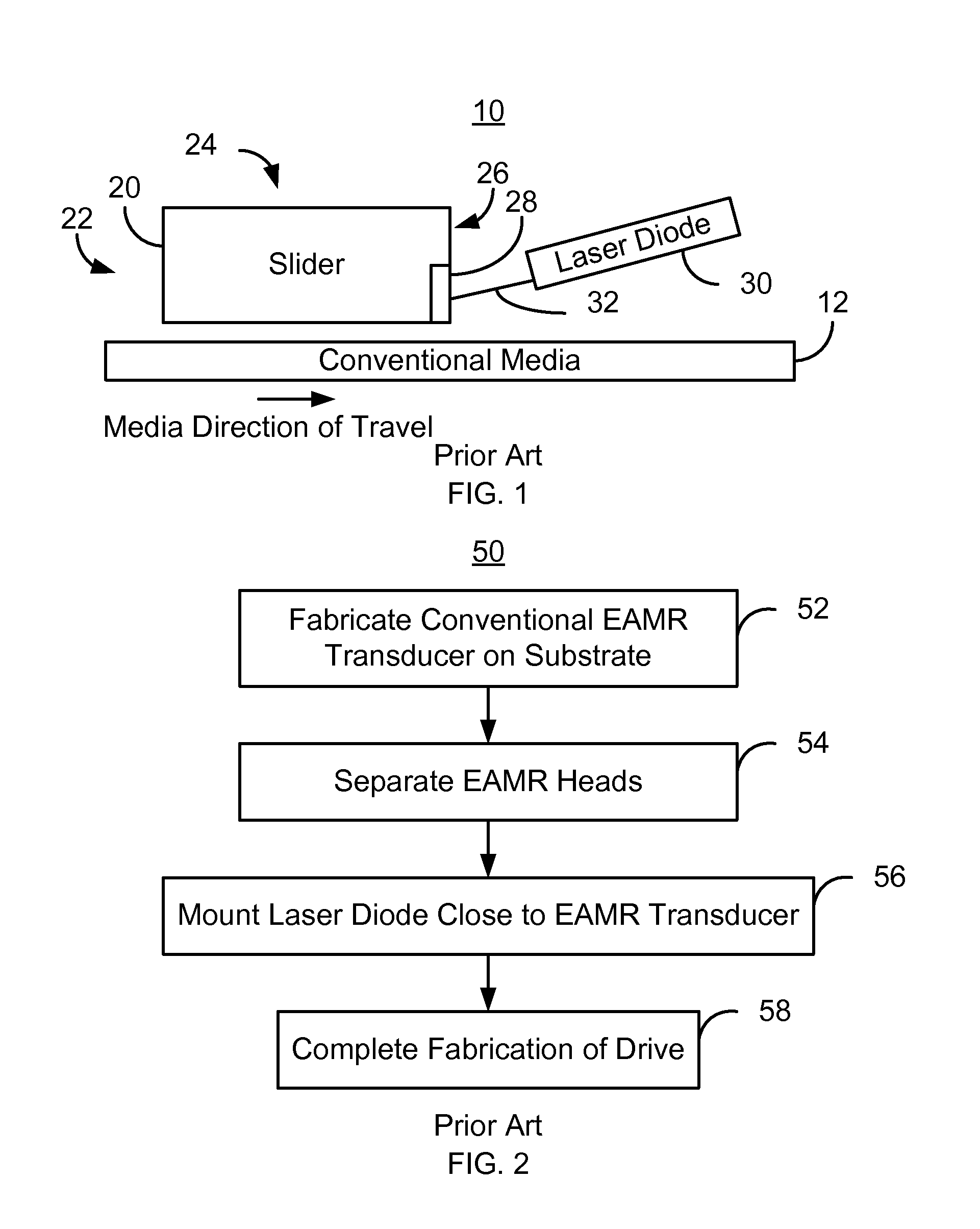

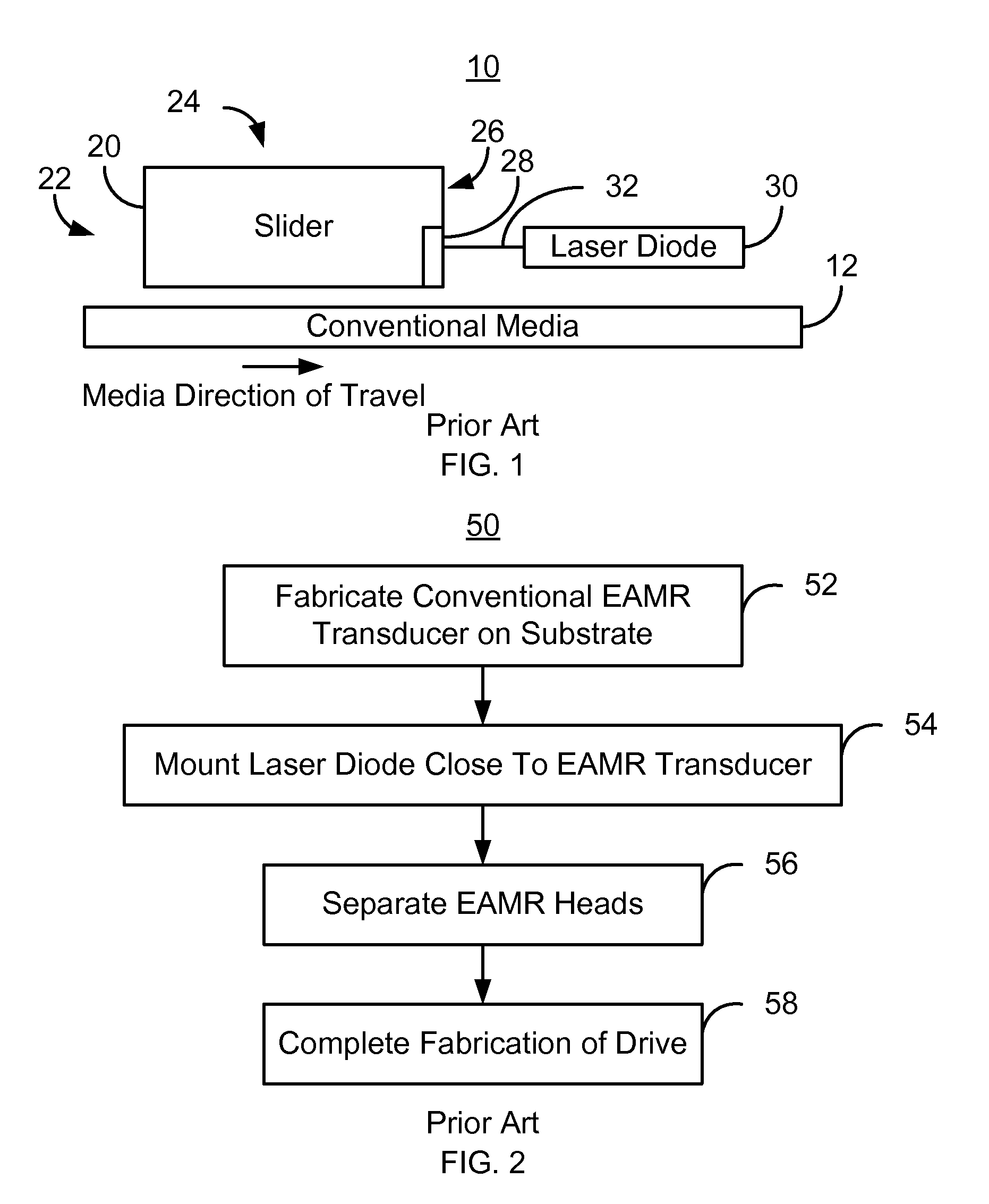

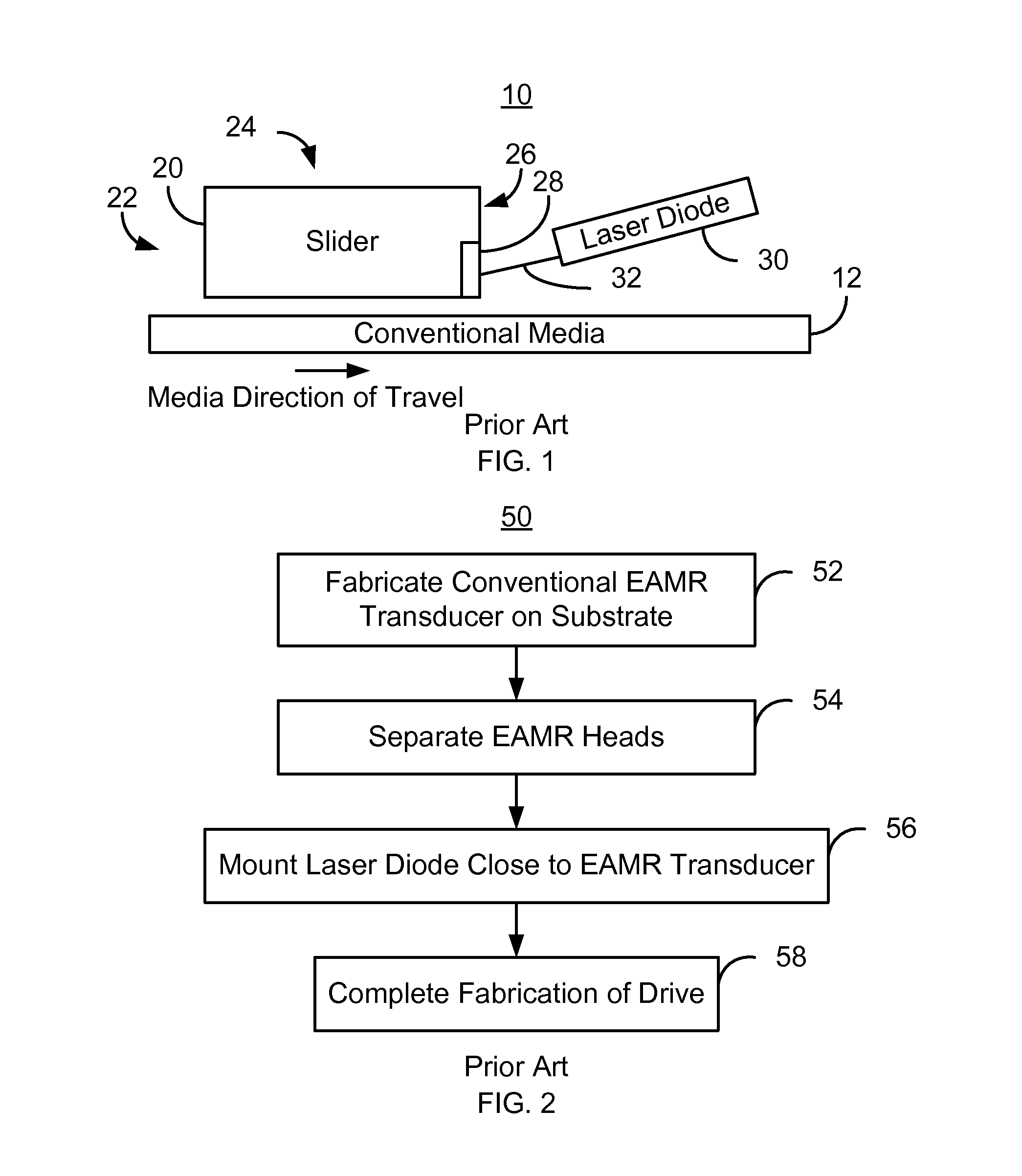

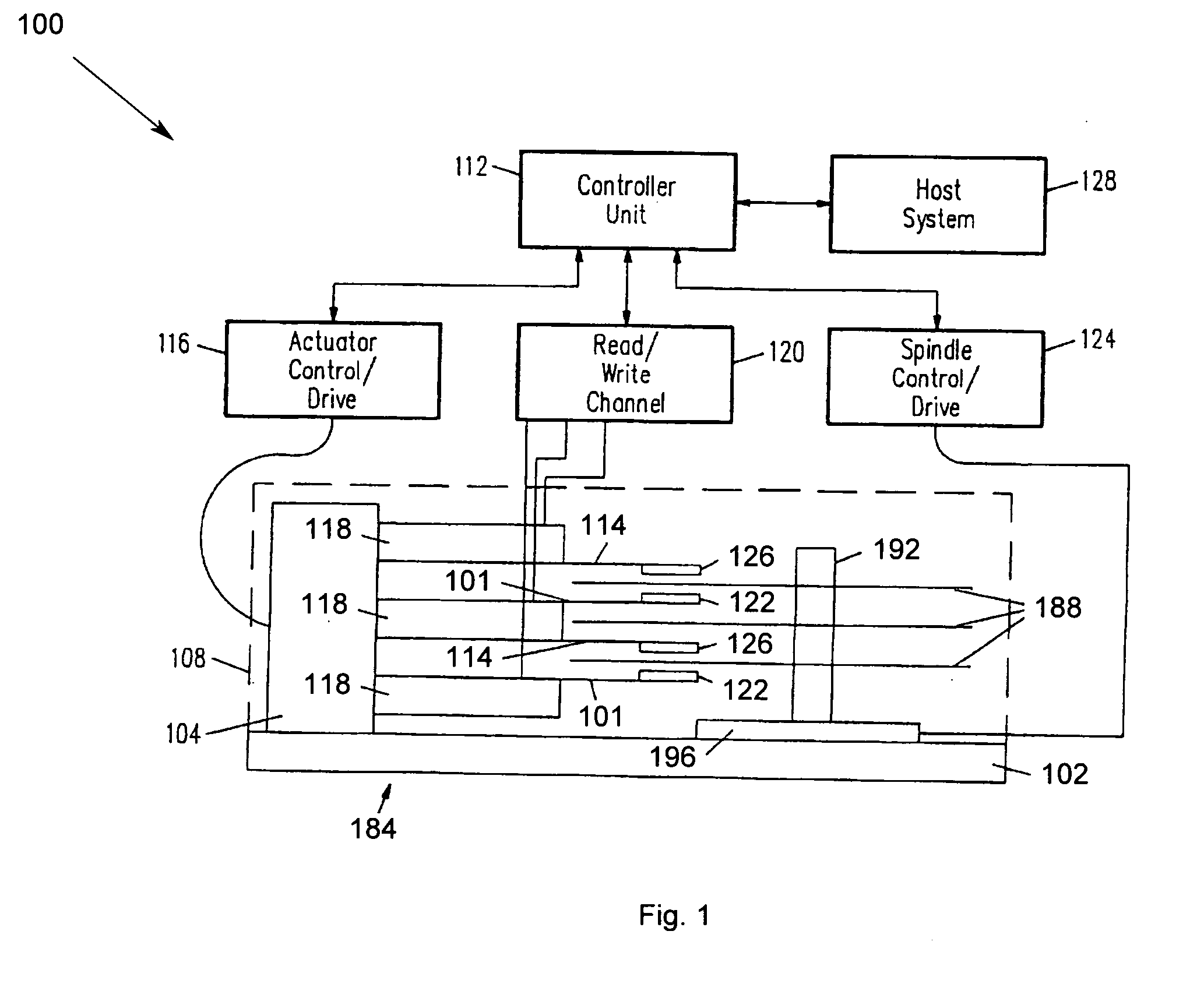

Method for providing an energy assisted magnetic recording (EAMR) head

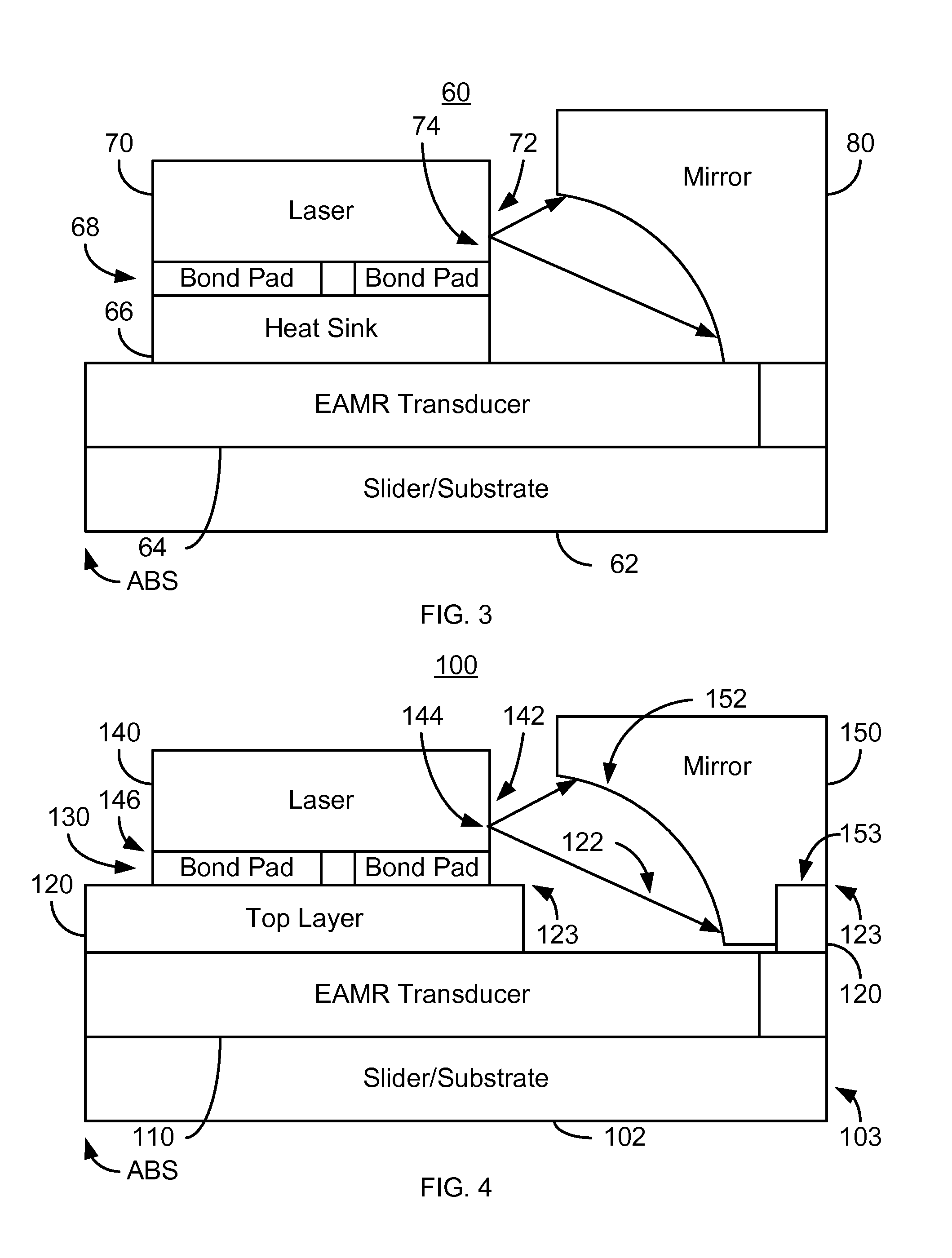

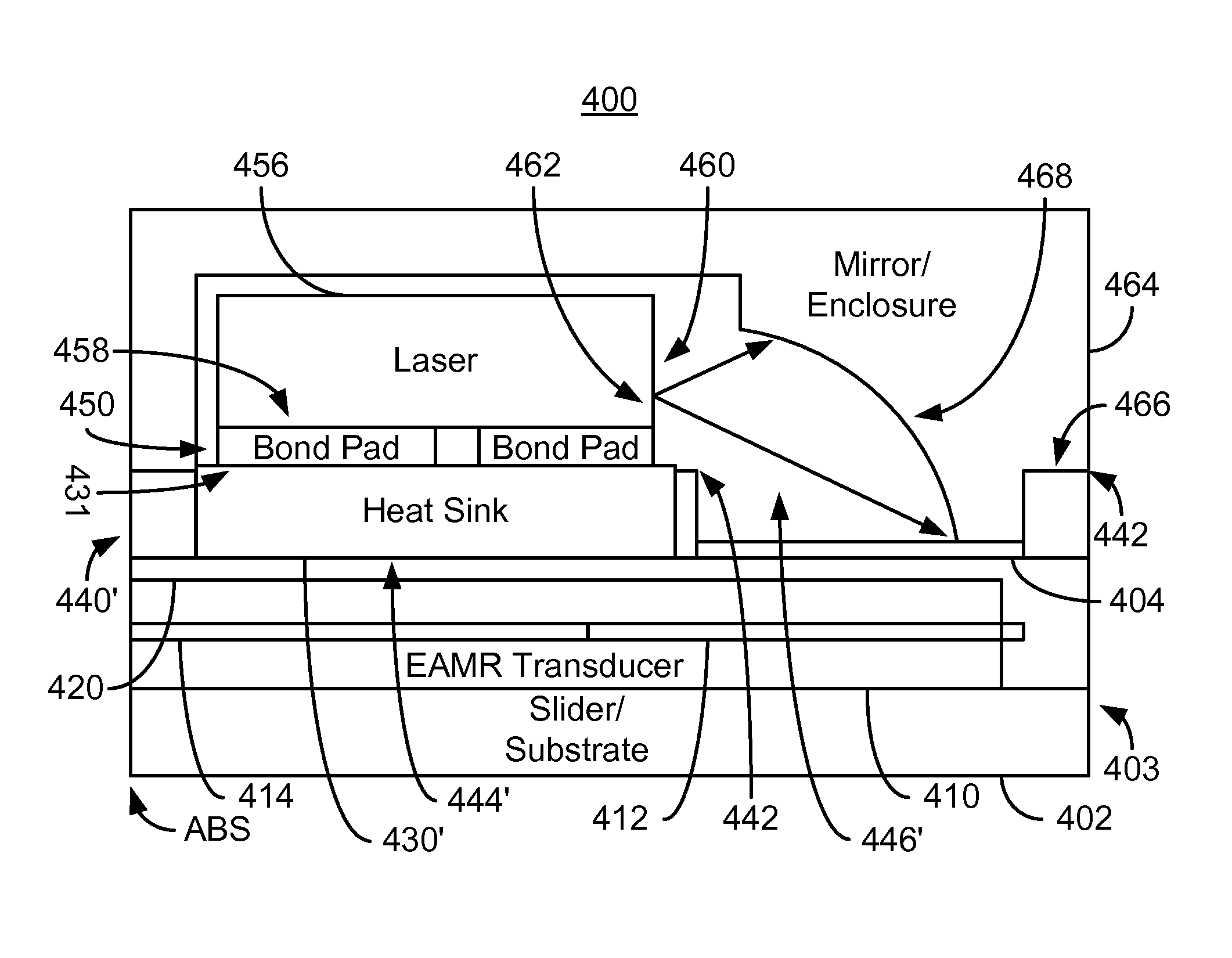

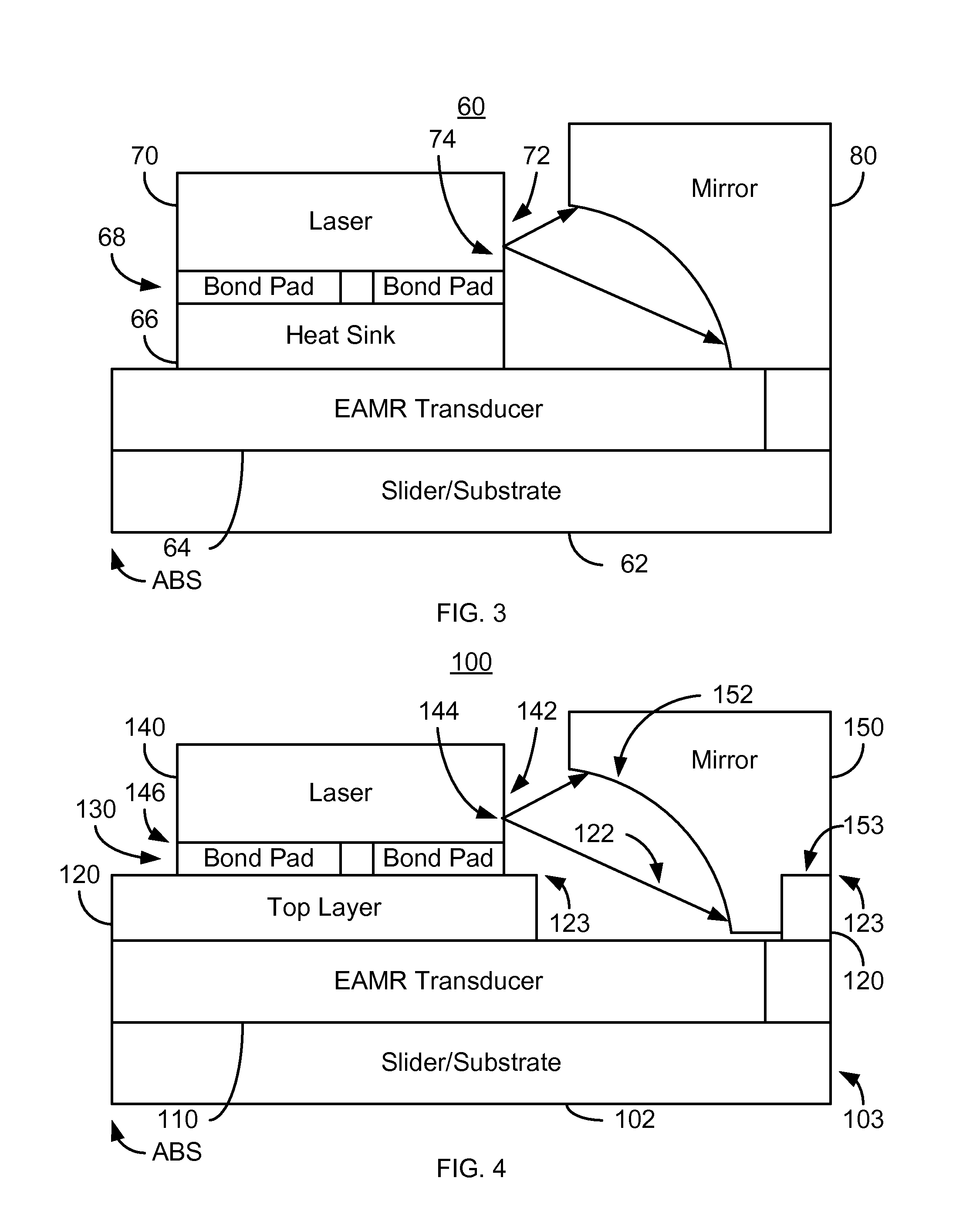

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The method and system include providing a slider, an EAMR transducer coupled with the slider, and a top layer on the slider. The top layer includes a mirror well therein and has a substantially flat top surface. The method and system further includes providing a laser including a light-emitting surface and providing a mirror optically coupled with the laser. The laser is coupled to the top surface of the top layer external to the mirror well. The mirror has a bottom surface and a reflective surface facing the light-emitting surface of the laser. A portion of the bottom surface of the mirror is affixed to the top surface of the top layer. A portion of the mirror resides in the mirror well.

Owner:WESTERN DIGITAL TECH INC

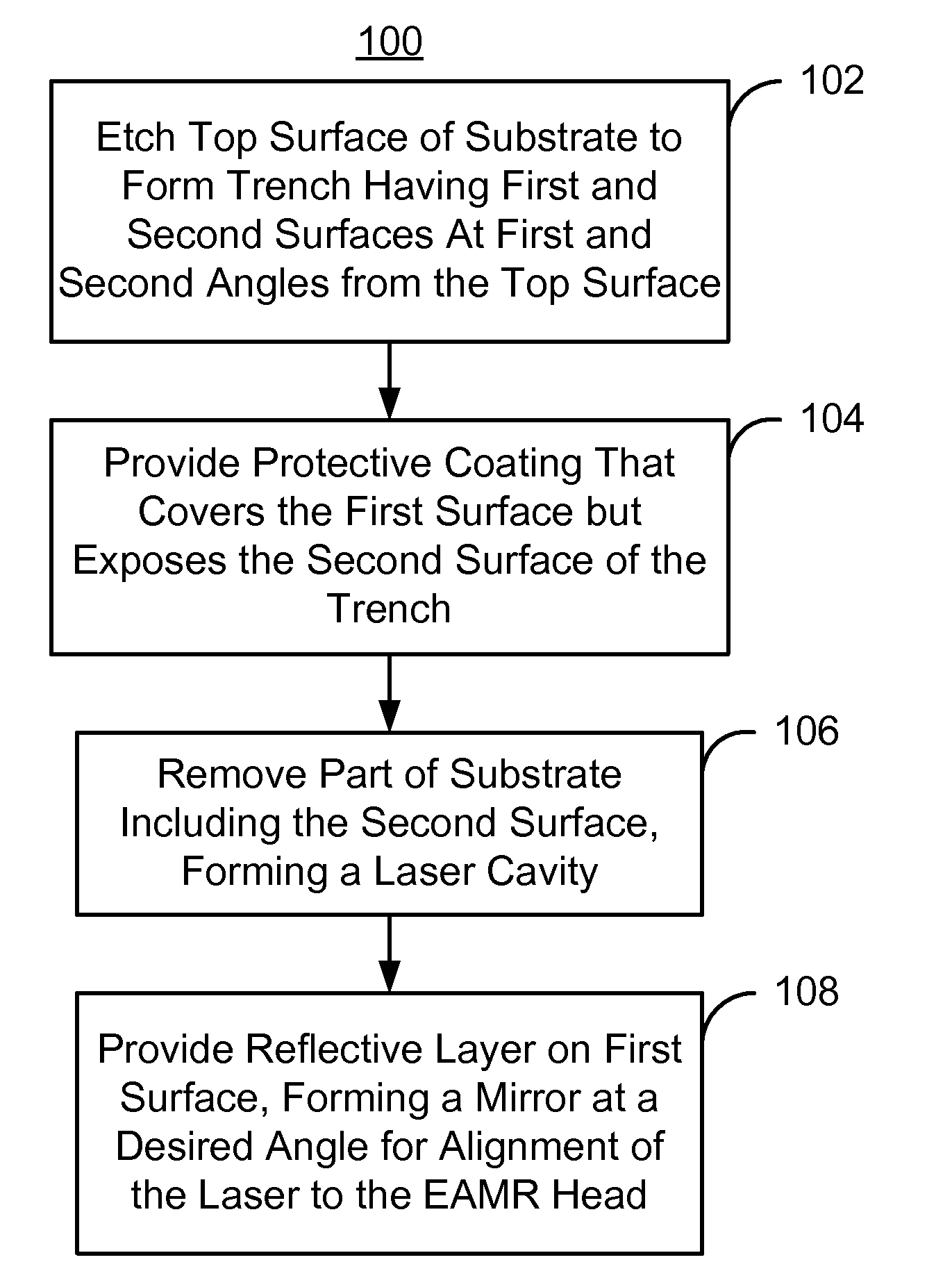

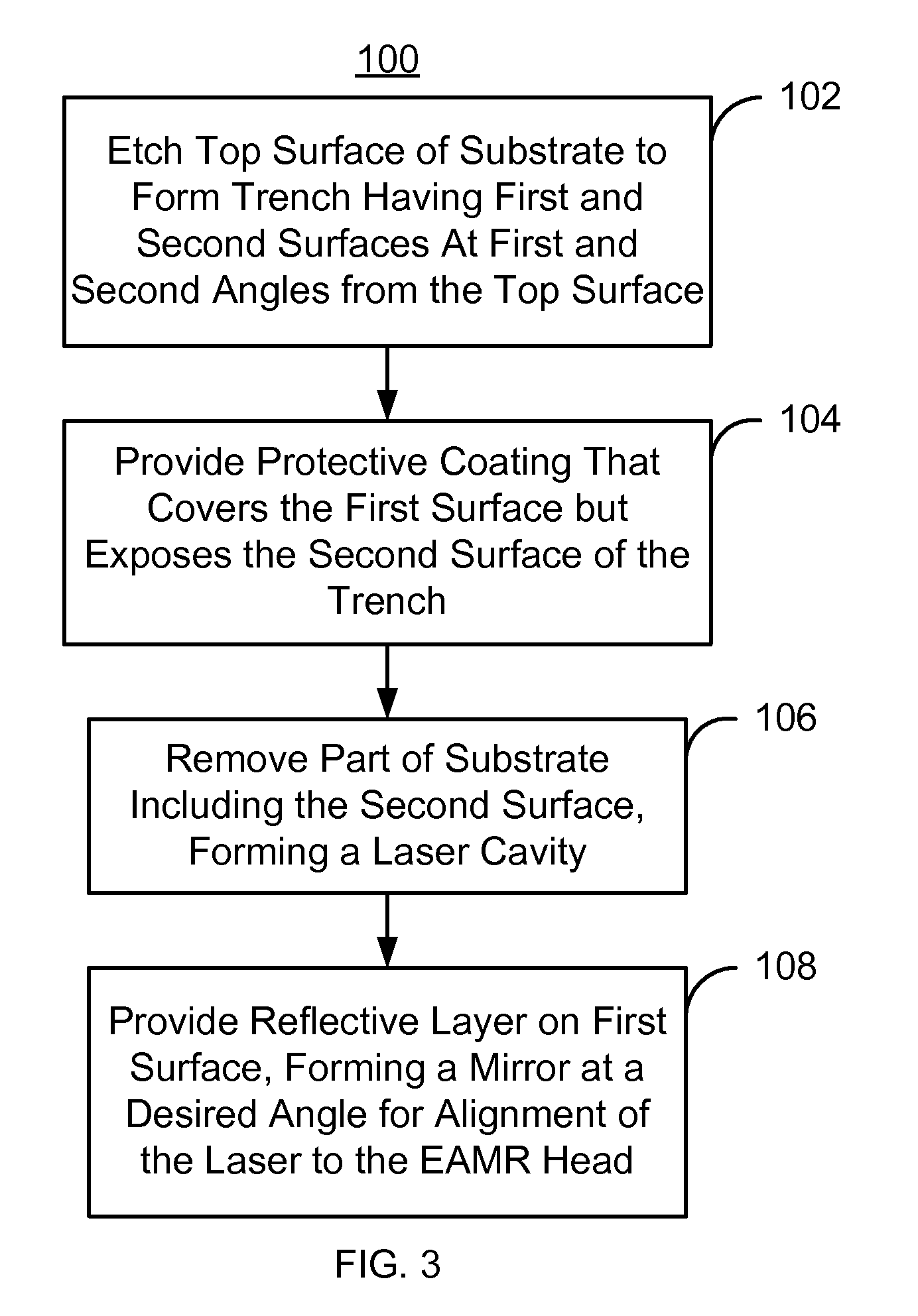

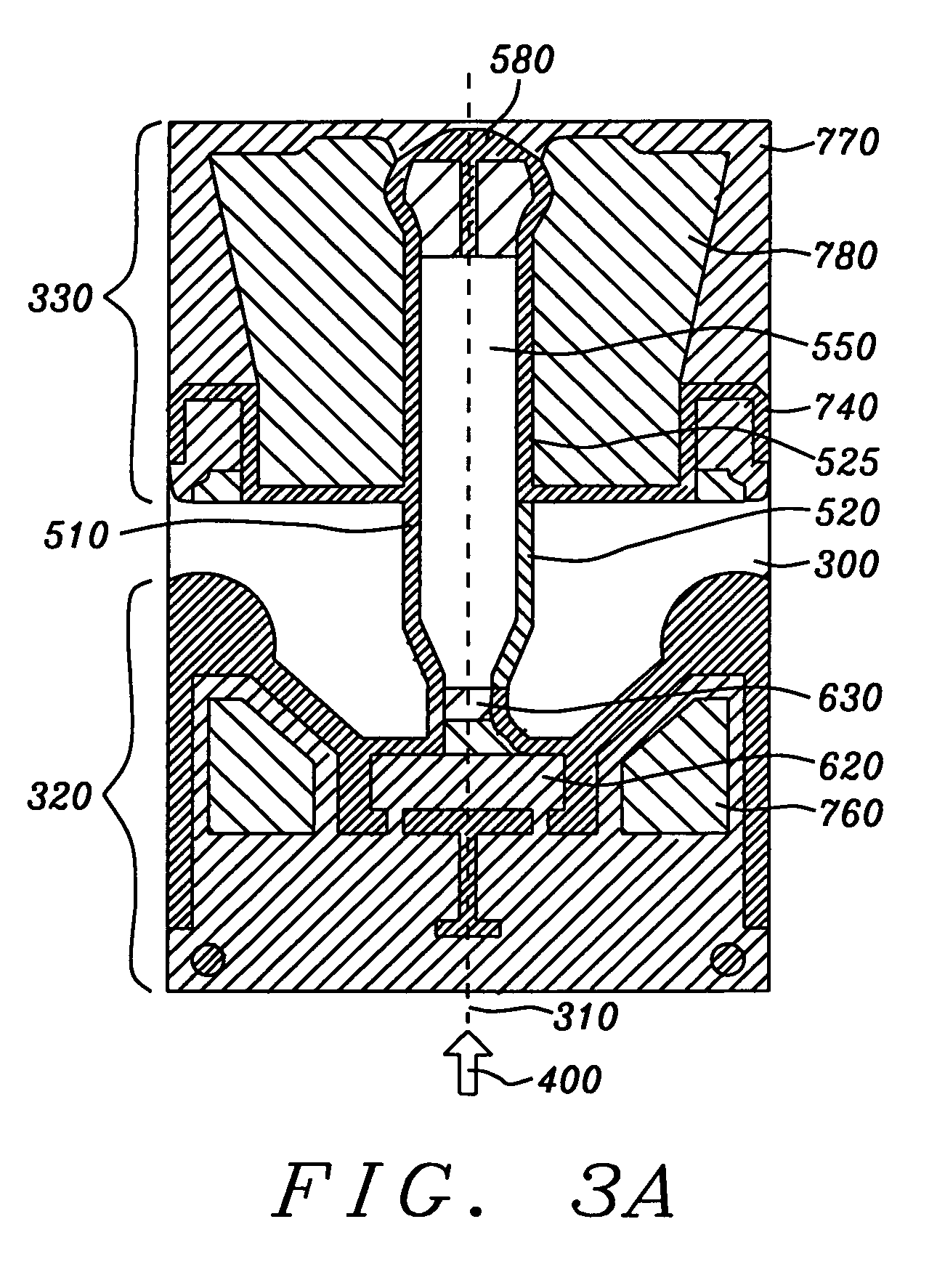

Method and system for providing a laser cavity for an energy assisted magnetic recording head

A method for providing a capping layer configured for an energy assisted magnetic recording (EAMR) head including at least one slider. The method comprises etching a substrate having a top surface using an etch to form a trench in the substrate, the trench having a first surface at a first angle from the top surface and a second surface having a second angle from the top surface. The method further comprises providing a protective coating exposing the second surface and covering the first surface, removing a portion of the substrate including the second surface to form a laser cavity within the substrate configured to fit a laser therein, and providing a reflective layer on the first surface to form a mirror, the cavity and mirror being configured for alignment of the laser to the laser cavity and to the mirror and for bonding the laser to the laser cavity.

Owner:WESTERN DIGITAL TECH INC

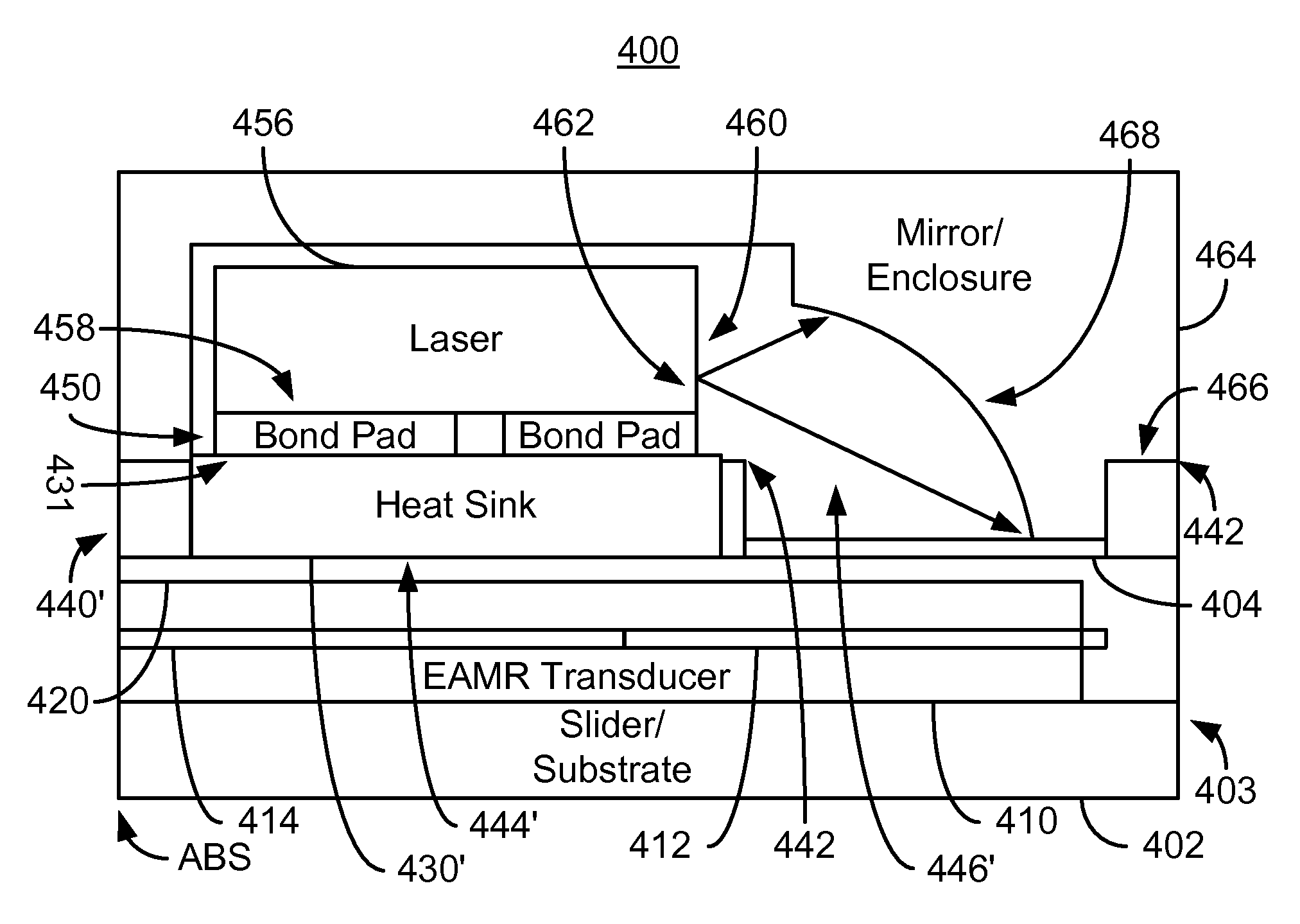

Method and system for providing an energy assisted magnetic recording head

A method and system for providing an energy assisted magnetic recording (EAMR) head are described. The method and system include providing a slider, an EAMR transducer coupled with the slider, and a top layer on the slider. The top layer includes a mirror well therein and has a substantially flat top surface. The method and system further includes providing a laser including a light-emitting surface and providing a mirror optically coupled with the laser. The laser is coupled to the top surface of the top layer external to the mirror well. The mirror has a bottom surface and a reflective surface facing the light-emitting surface of the laser. A portion of the bottom surface of the mirror is affixed to the top surface of the top layer. A portion of the mirror resides in the mirror well.

Owner:WESTERN DIGITAL TECH INC

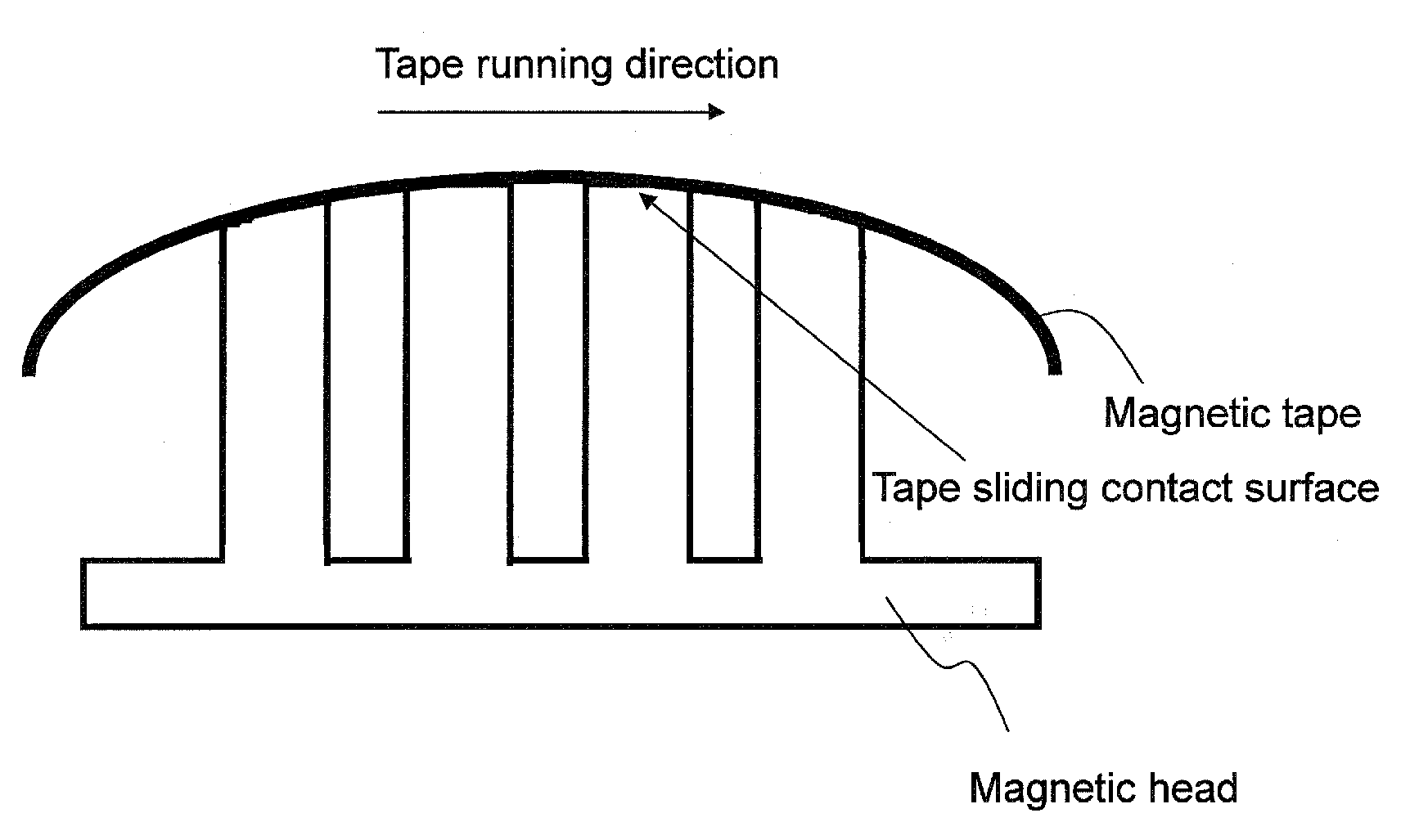

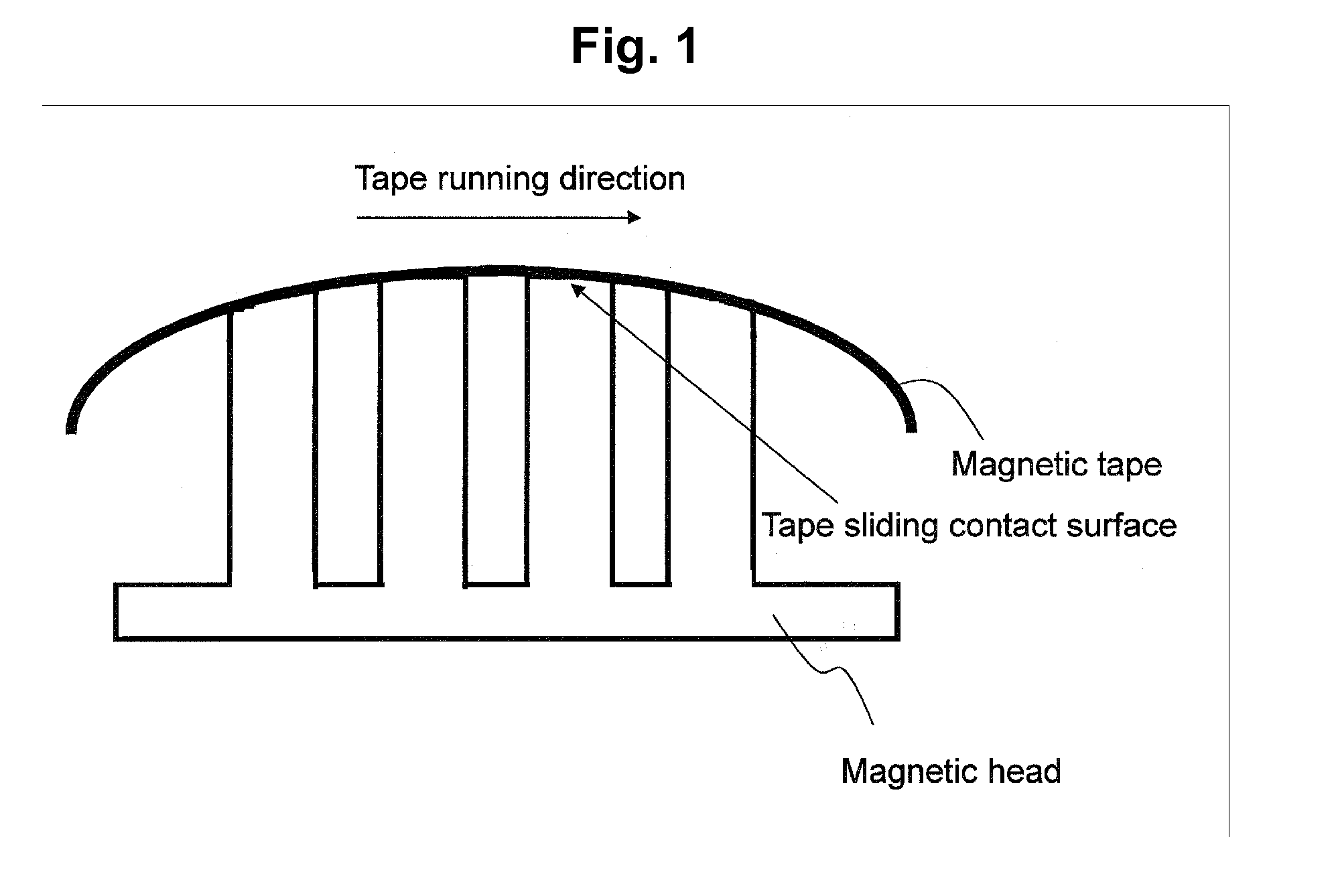

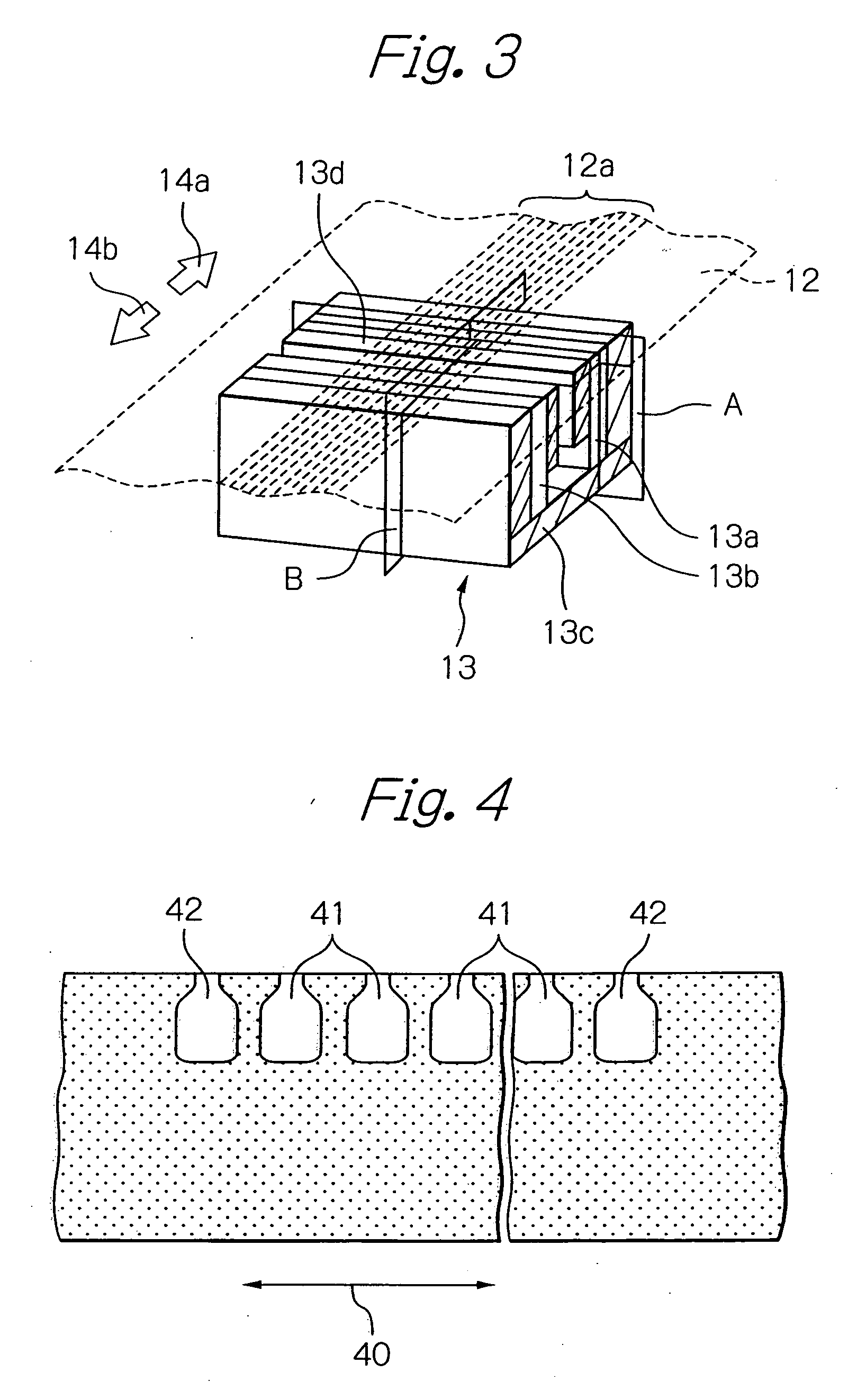

Magnetic head and method of manufacturing the same, linear tape drive apparatus, and magnetic recording and reproduction method

InactiveUS20100073816A1Excellent characteristicsImprove stabilityElectrical transducersRecord information storageMagnetic tapeImage View

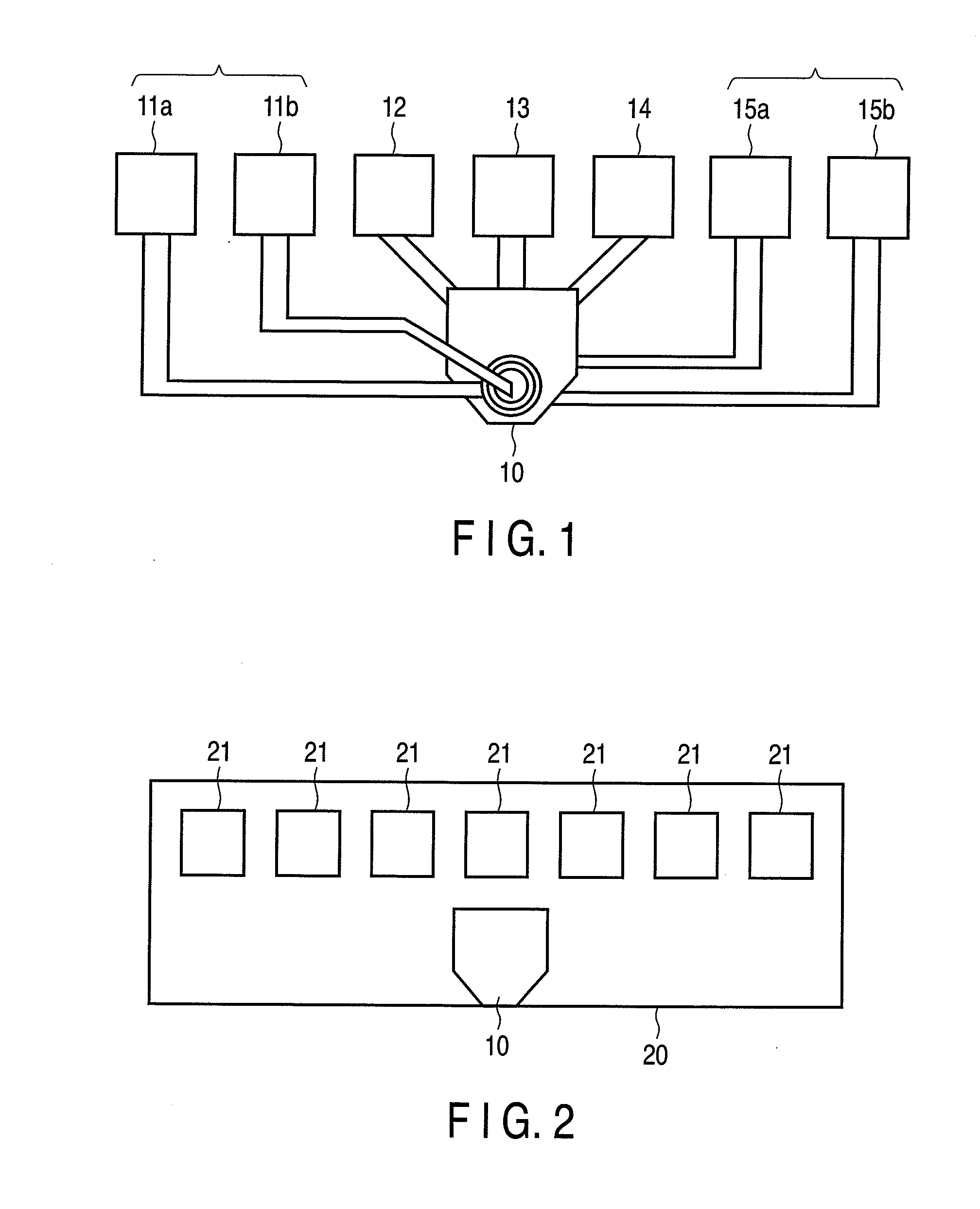

An aspect of the present invention relates to a magnetic head employed in a linear tape drive in the form of a sliding-contact linear tape drive. The magnetic head comprises multiple indentations that are observed in a surface topographic image viewed by a scanning probe microscope on a surface (sliding contact surface) of sliding contact with a magnetic tape, and the multiple indentations satisfy (1) to (4) below:(1) an average area of the indentations in the sliding contact surface ranges from about 0.2 μm2 to about 1.0 μm2;(2) a standard deviation of an area of the indentations ranges from about 0.5 μm2 to about 2.0 μm2;(3) an area ratio of the indentations in the sliding contact surface ranges from about 20 percent to about 50 percent; and(4) an average depth of the indentations is equal to or greater than about 15 nm.

Owner:FUJIFILM CORP

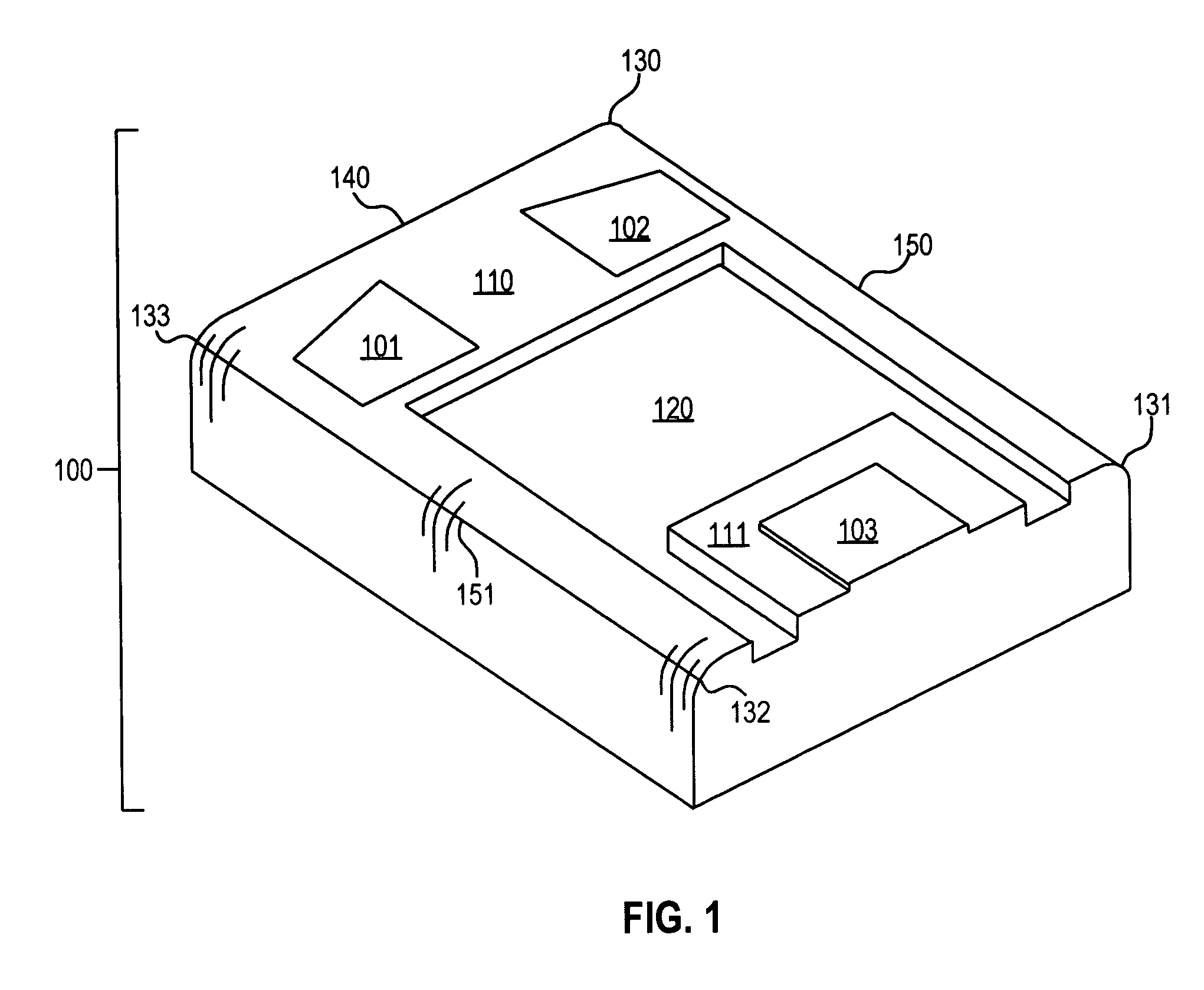

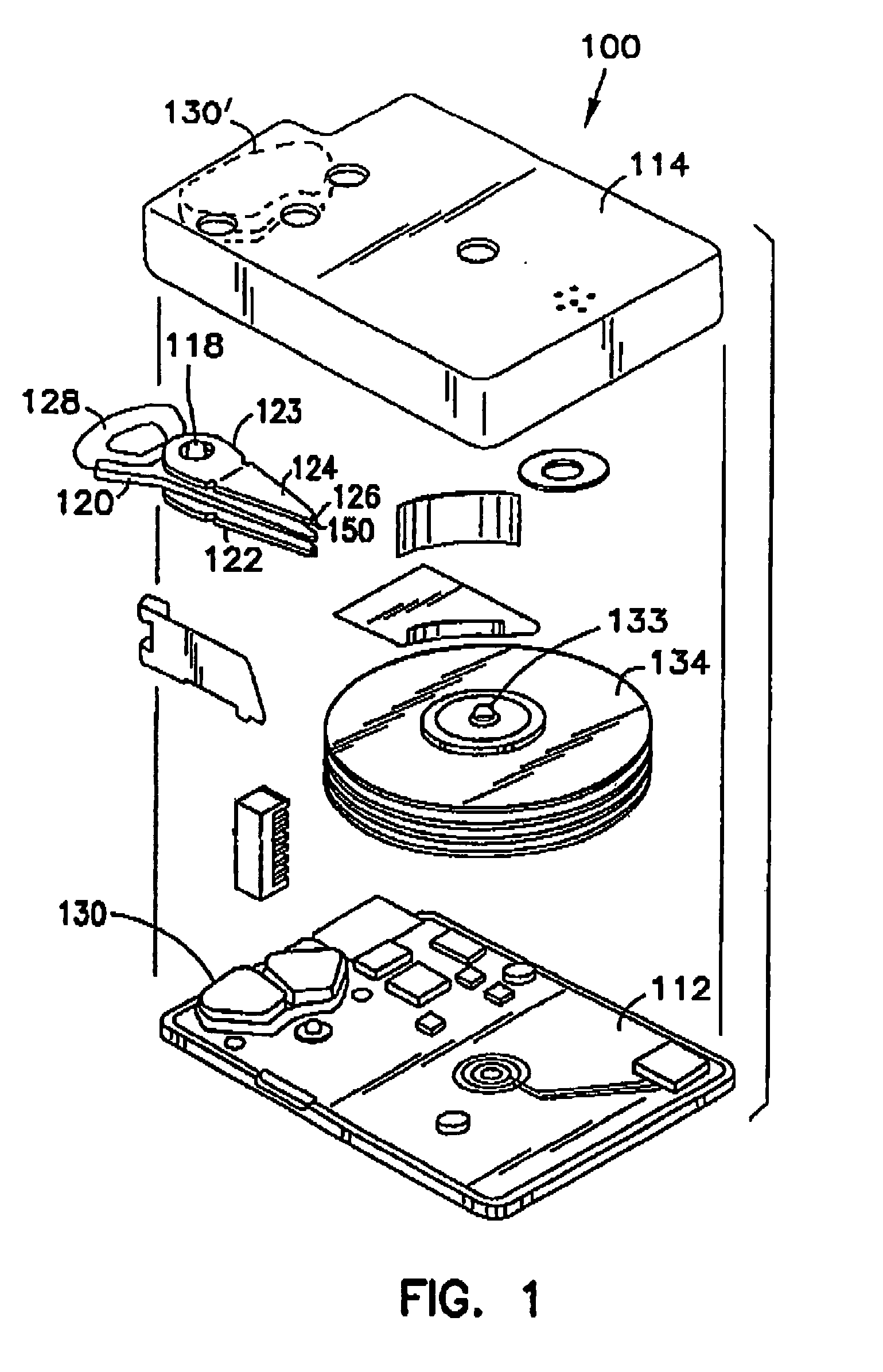

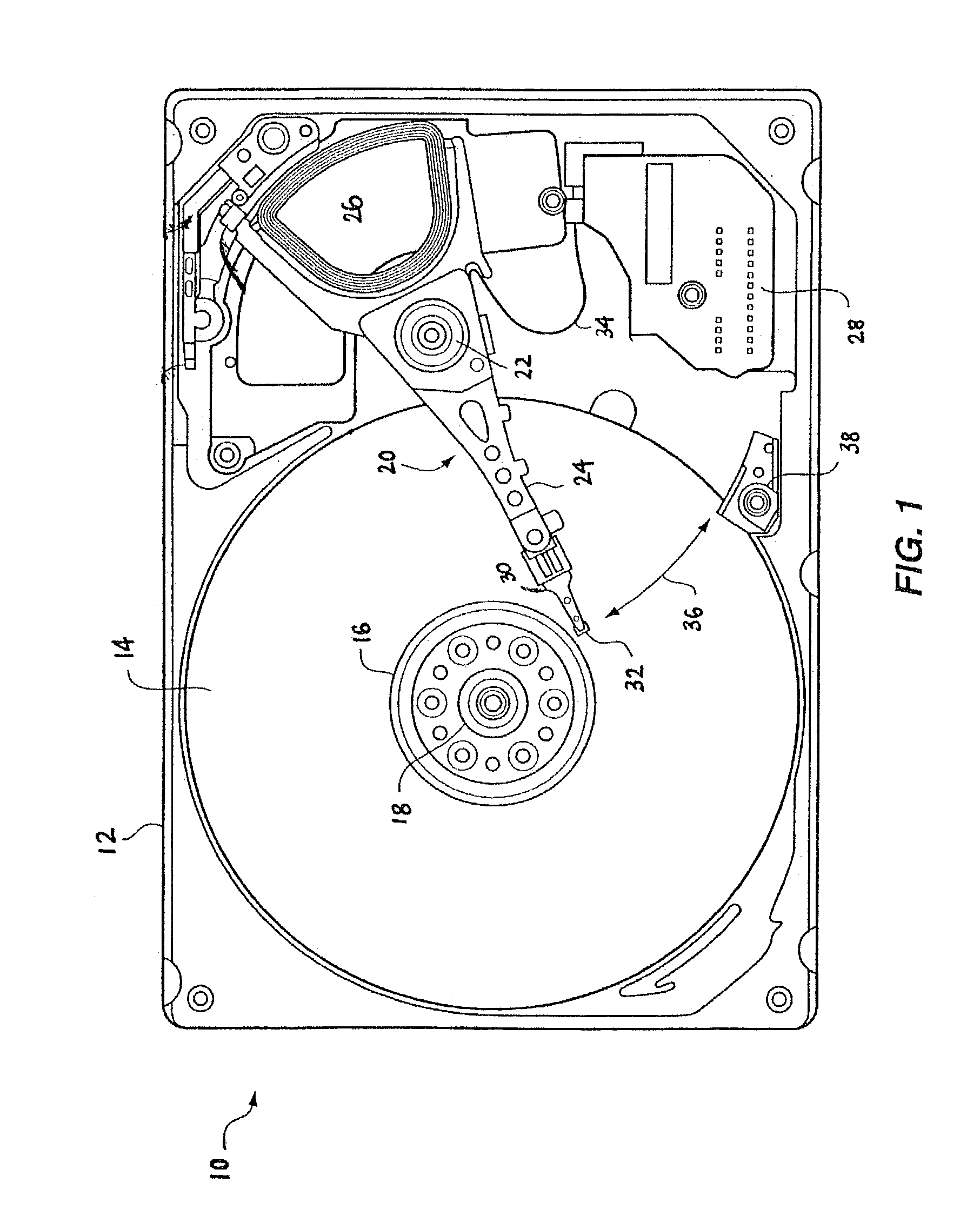

Disk drive cover with top and bottom layers electrically grounded with first and second flaps and method of manufacturing the same

InactiveUS7385784B1Apparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionEngineeringMechanical engineering

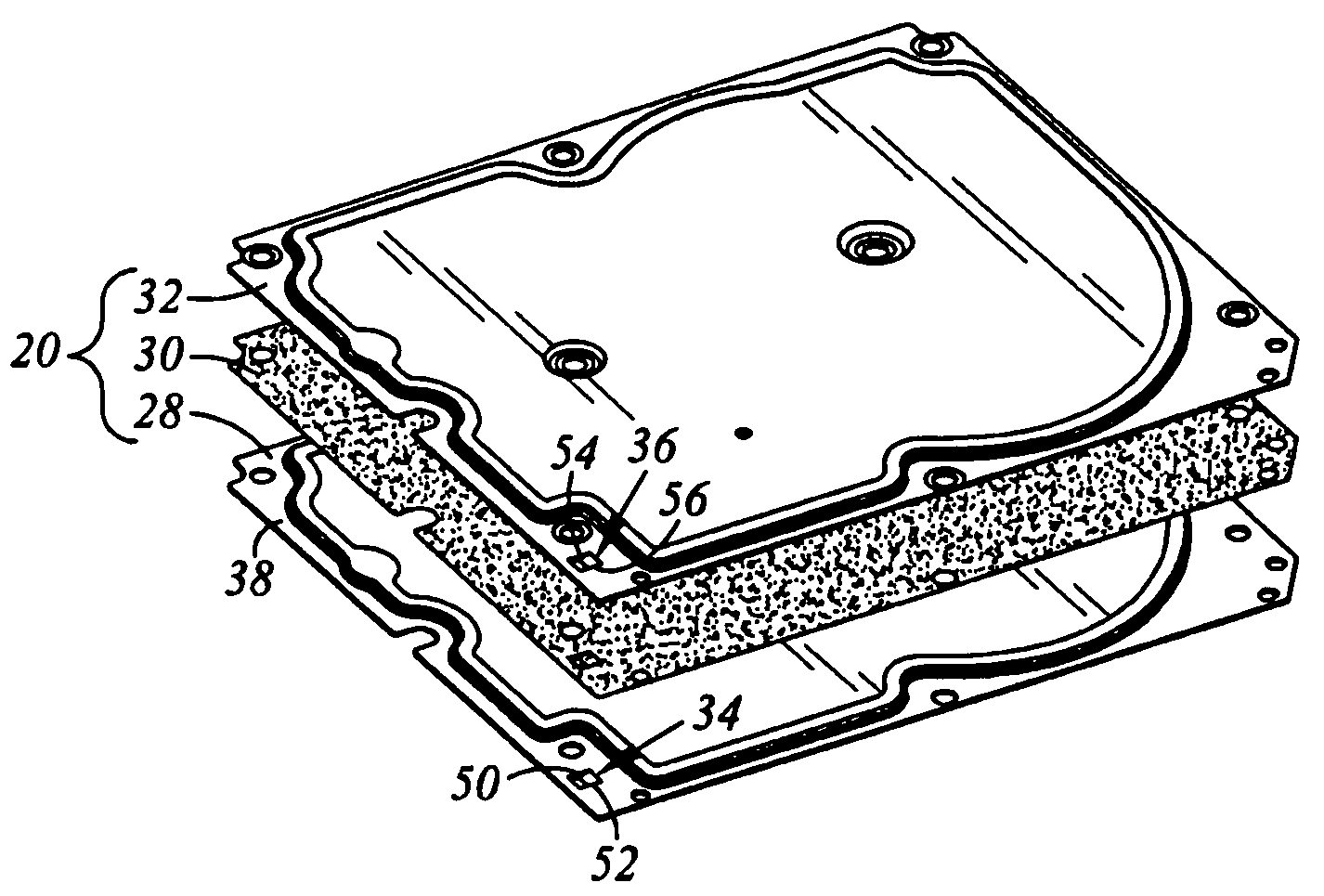

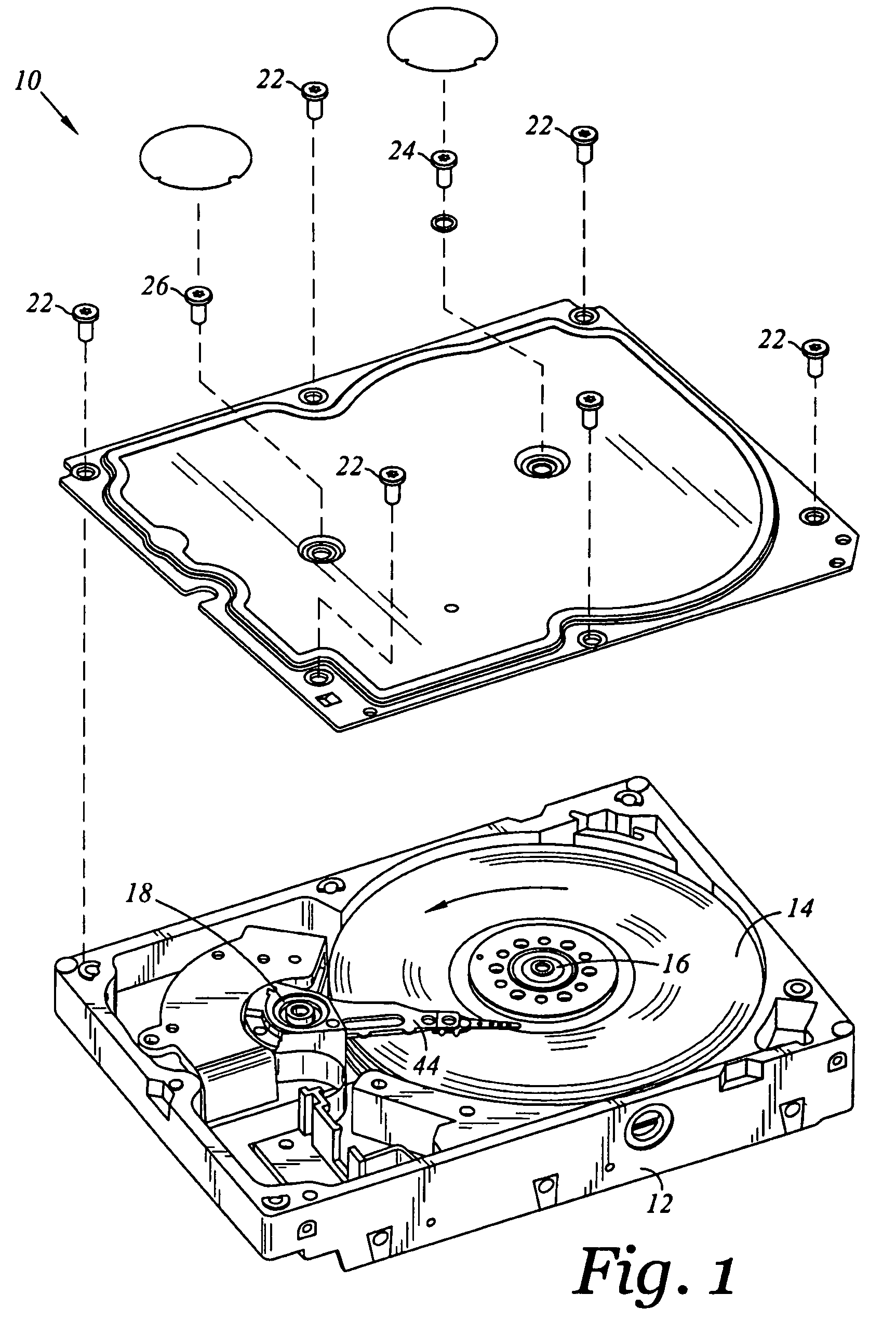

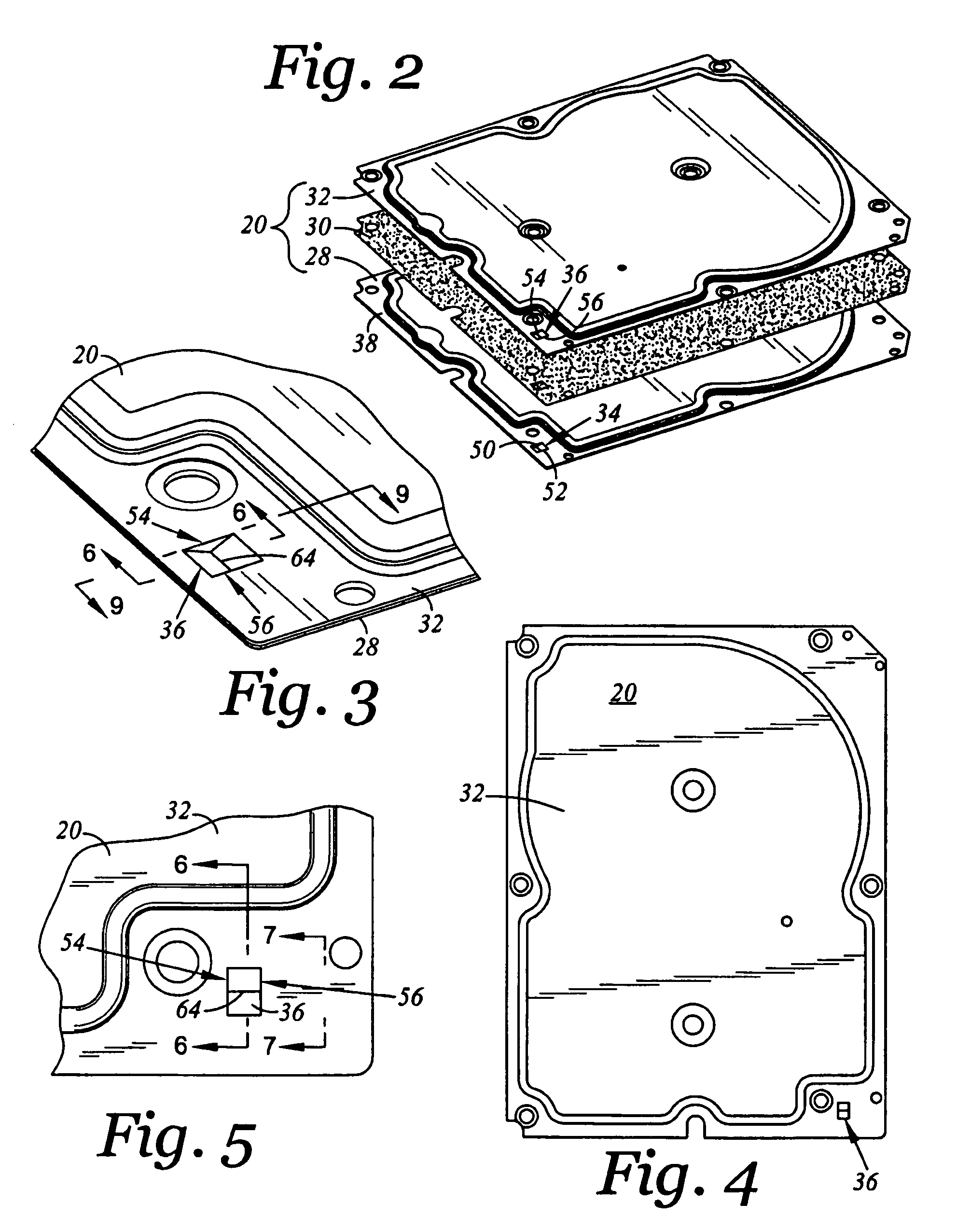

There is provided a disk drive cover. The disk drive cover includes a bottom layer including a metallic bottom layer body and a first flap formed in the bottom layer body. The first flap defines an exposed inner body edge of the bottom layer body. The disk drive cover further includes a damping layer. The disk drive cover further includes a top layer including a metallic top layer body and a second flap. The second flap is formed in the top layer body with the second flap extending into the bottom layer adjacent the first flap. The second flap defines an exposed second flap edge. The second flap edge is disposed in mechanical communication with the exposed inner body edge for electrically grounding the top and bottom layers.

Owner:WESTERN DIGITAL TECH INC

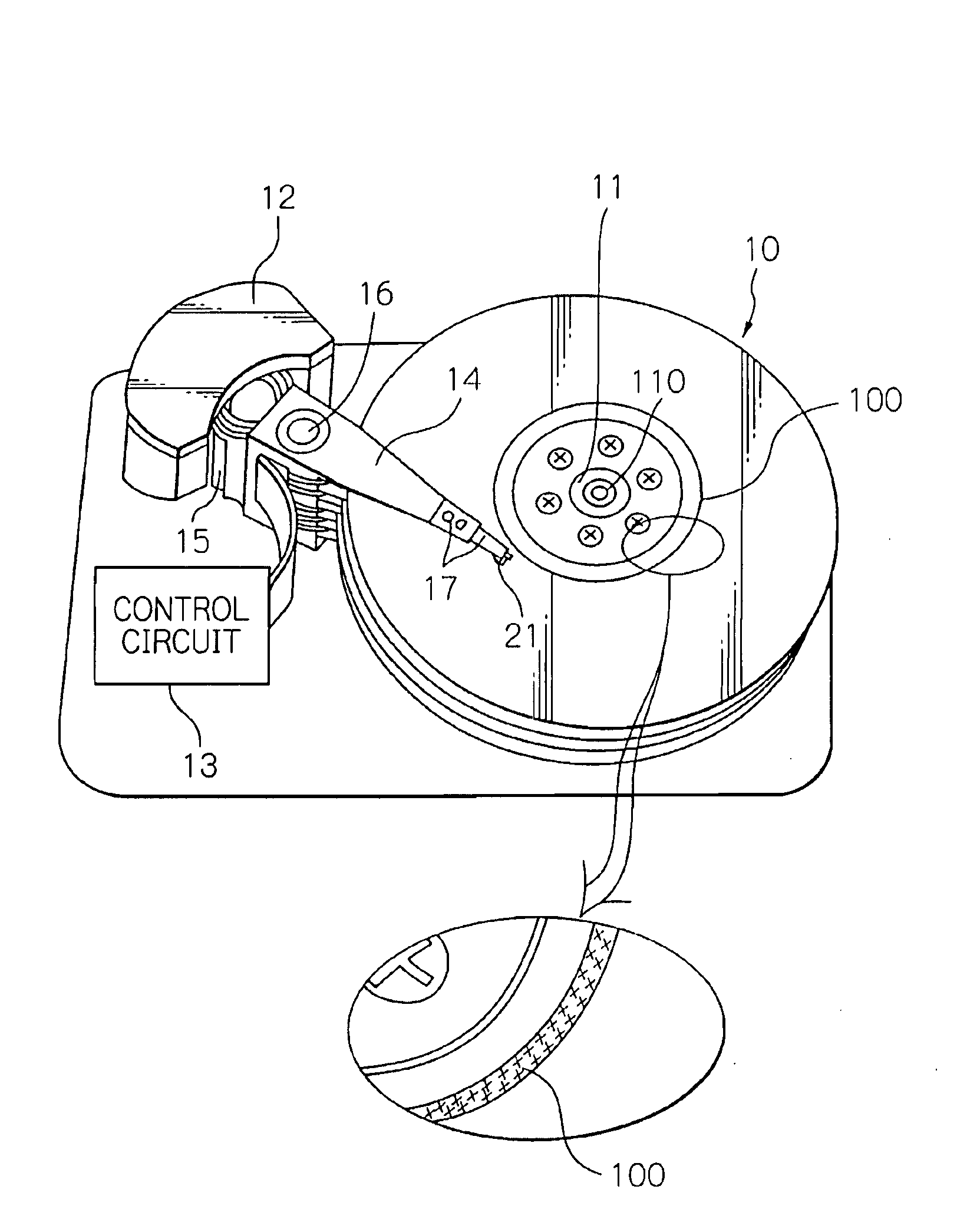

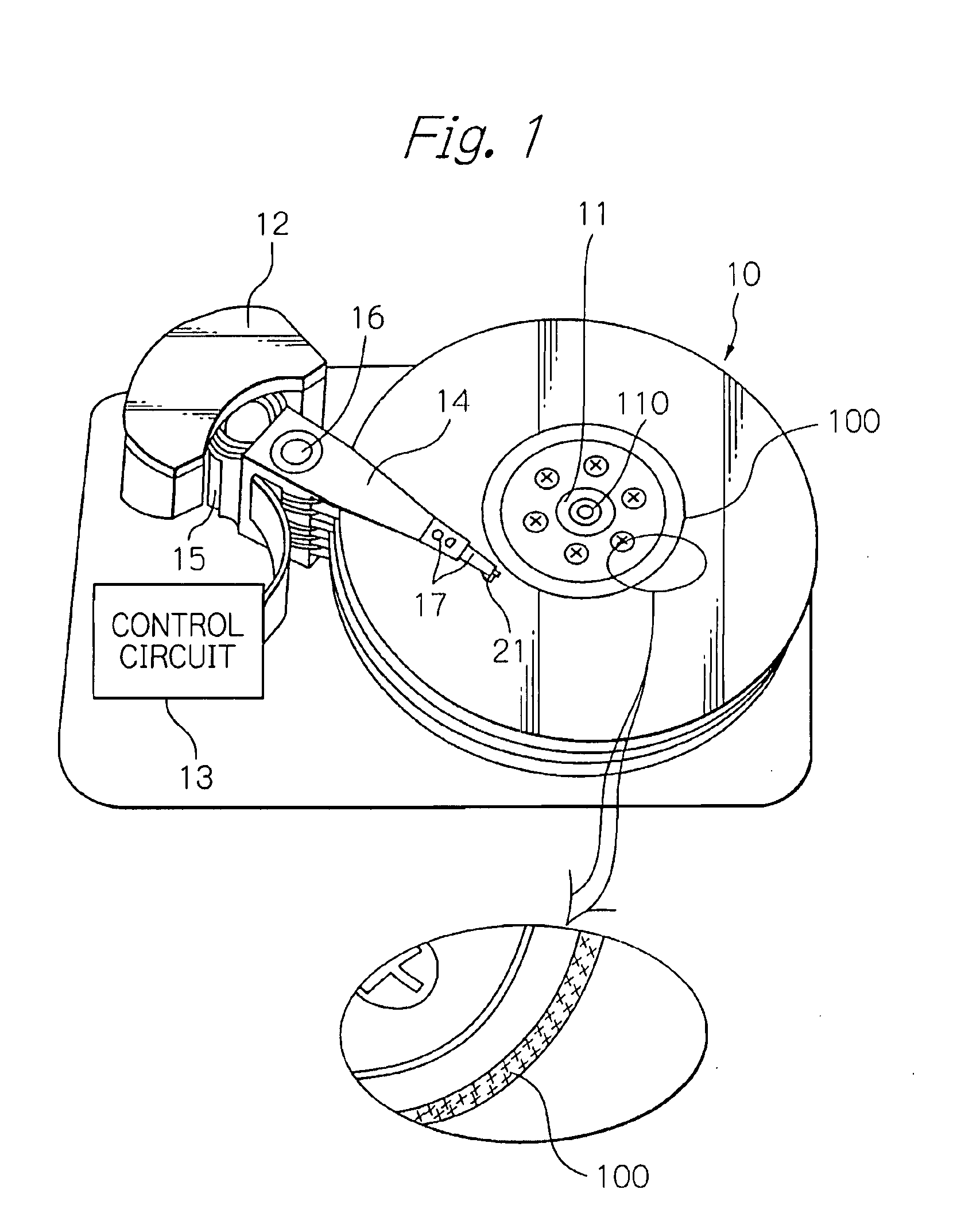

Magnetic head and disk drive with high-frequency assisted writing

InactiveUS20090059418A1Driving/moving recording headsRecord information storageEngineeringFlying height

According to one embodiment, a magnetic head having a head slider which holds a magnetic head unit including a heat-generating element for controlling the flying-height and a high-frequency oscillator for performing high-frequency assisted writing, and on which terminals connected to the magnetic head elements are used in the smallest number required. Terminals are mounted on the head slider and are connected to the magnetic head unit. The terminals include at least one current-supplying terminal that is connected to the heat-generating element serving to control the flying height and to the high-frequency oscillator.

Owner:KK TOSHIBA

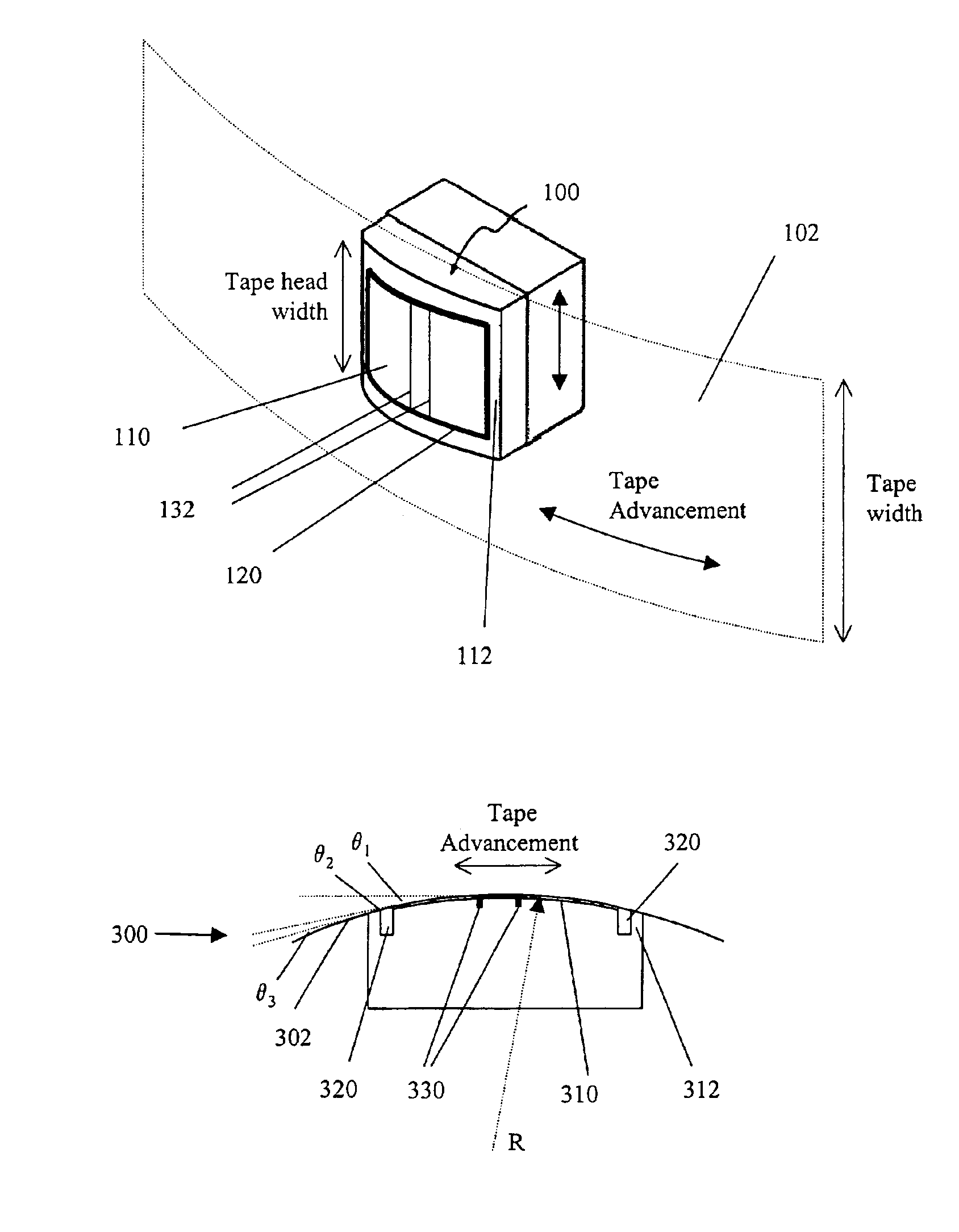

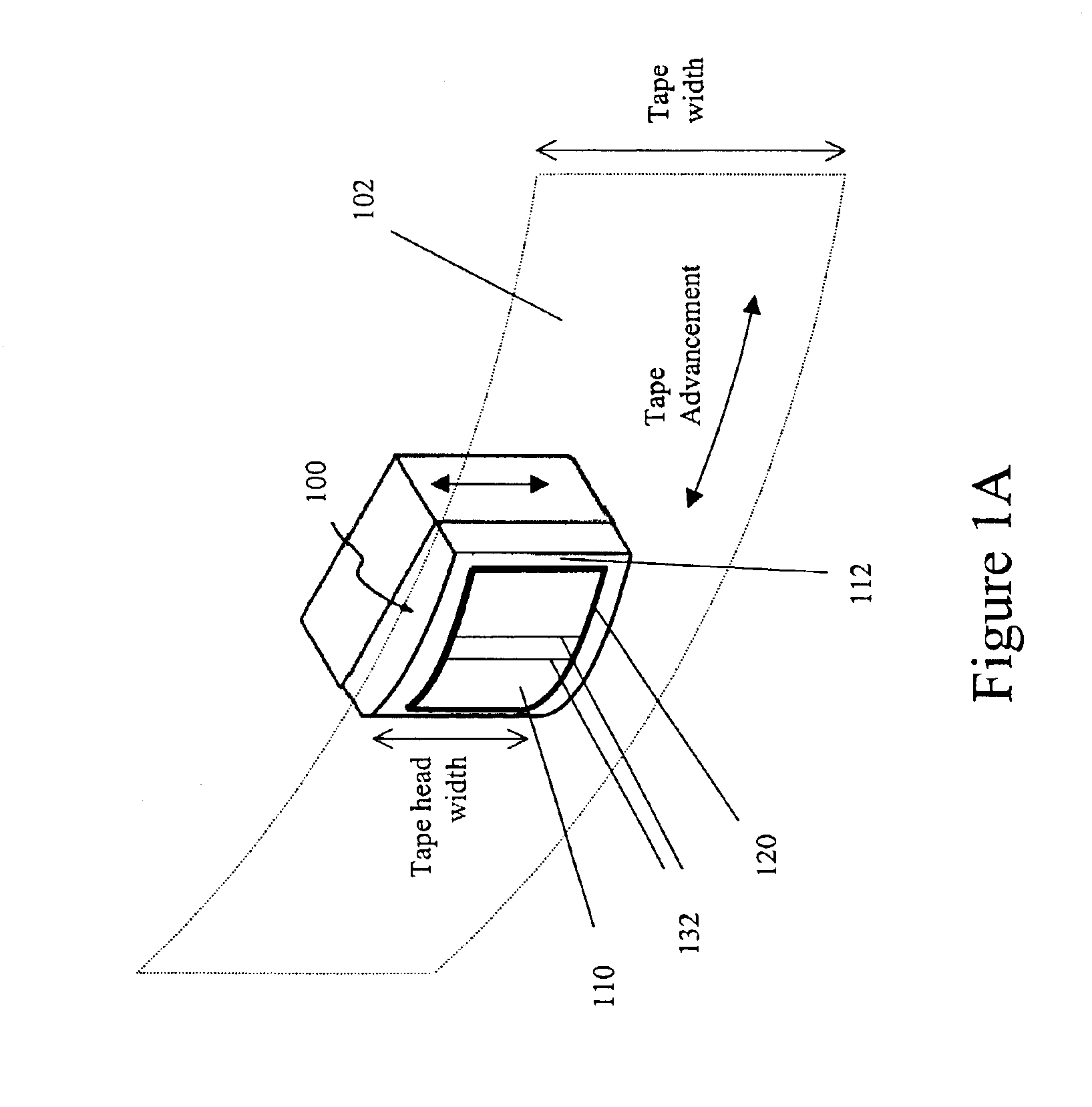

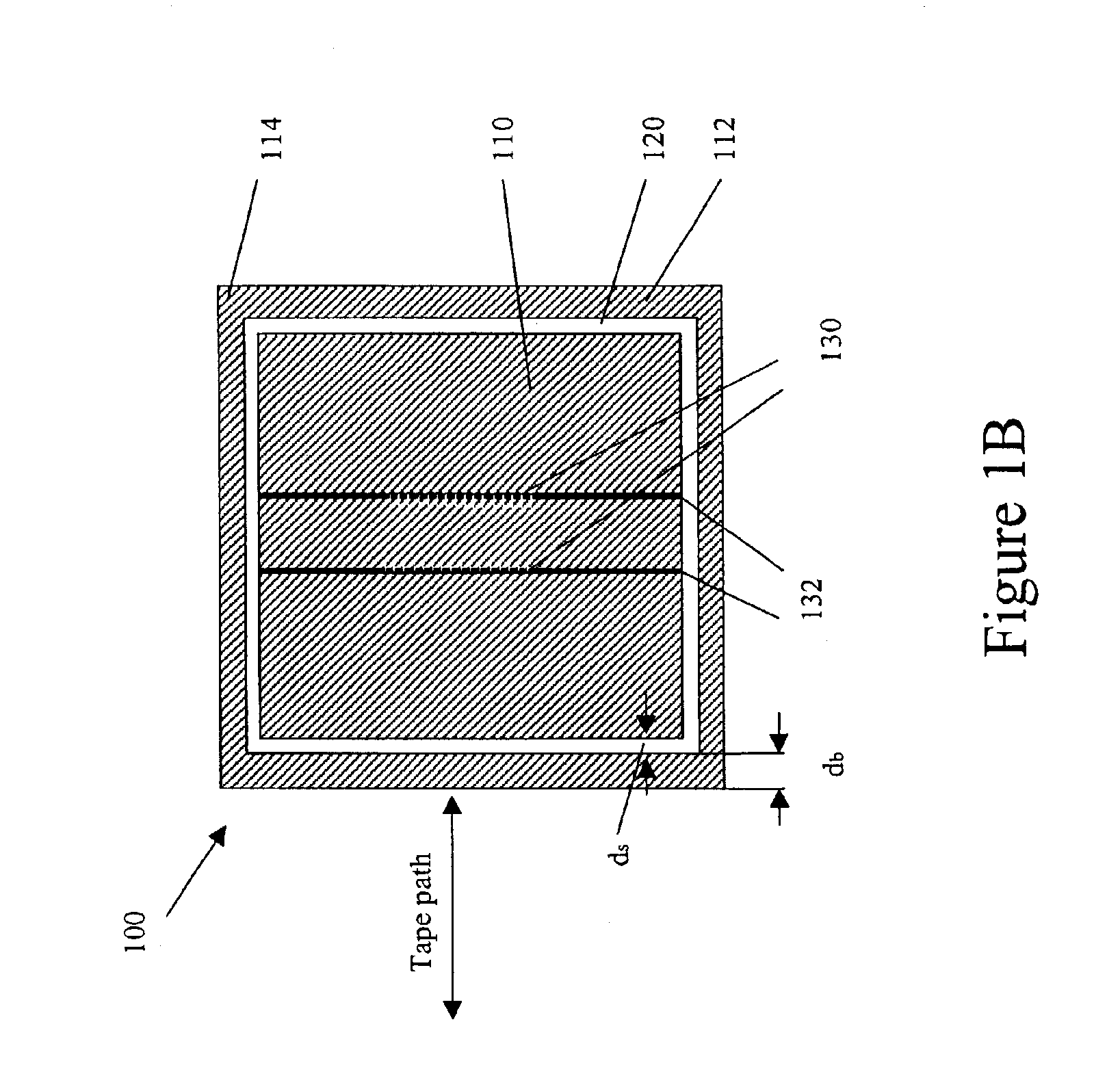

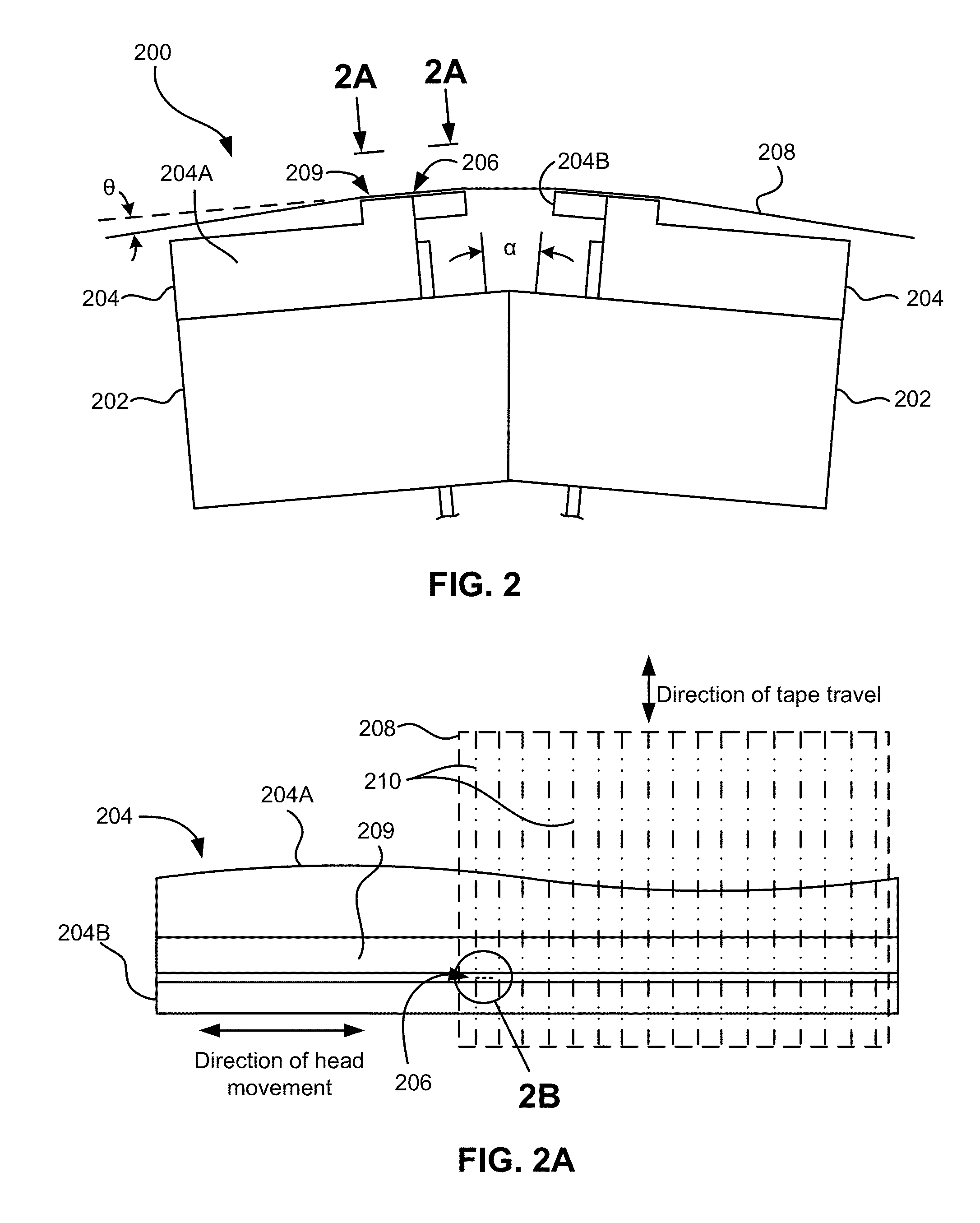

Tape head with thin support surface and method of manufacture

According to one aspect, an exemplary method of manufacturing a magnetic head assembly with a predetermined wrap angle is described. The method includes removing a portion of a magnetic head support surface to create a slot transverse to a direction the media advances and at least partially separating a major support surface having an active device region and a thin support surface. The method further includes removing a portion of the thin support surface such that the height of at least a portion of the thin support surface is reduced relative to the major support surface. The height may be reduced to achieve a predetermined wrap angle between the media and the major support surface of the head assembly.

Owner:QUANTUM CORP

Methods for hardening amorphous dielectric films in a magnetic head and other structures

A method in one embodiment includes exposing a side of a dielectric layer to a beam of charged particles for converting an amorphous component of at least a portion of a dielectric layer to a crystalline state, wherein the side of the dielectric layer of extends between adjacent layers. Another method includes forming a dielectric overcoat on a media facing side of a plurality of thin films, the thin films having at least one transducer formed therein; and exposing at least a portion of the overcoat to a beam of charged particles for converting an amorphous component of the dielectric overcoat of the thin films to a crystalline state. Another method includes forming a thin film dielectric layer above a substrate; and exposing the dielectric layer to a beam of charged particles for converting an amorphous component of at least a portion of the dielectric layer to a crystalline state.

Owner:GLOBALFOUNDRIES INC

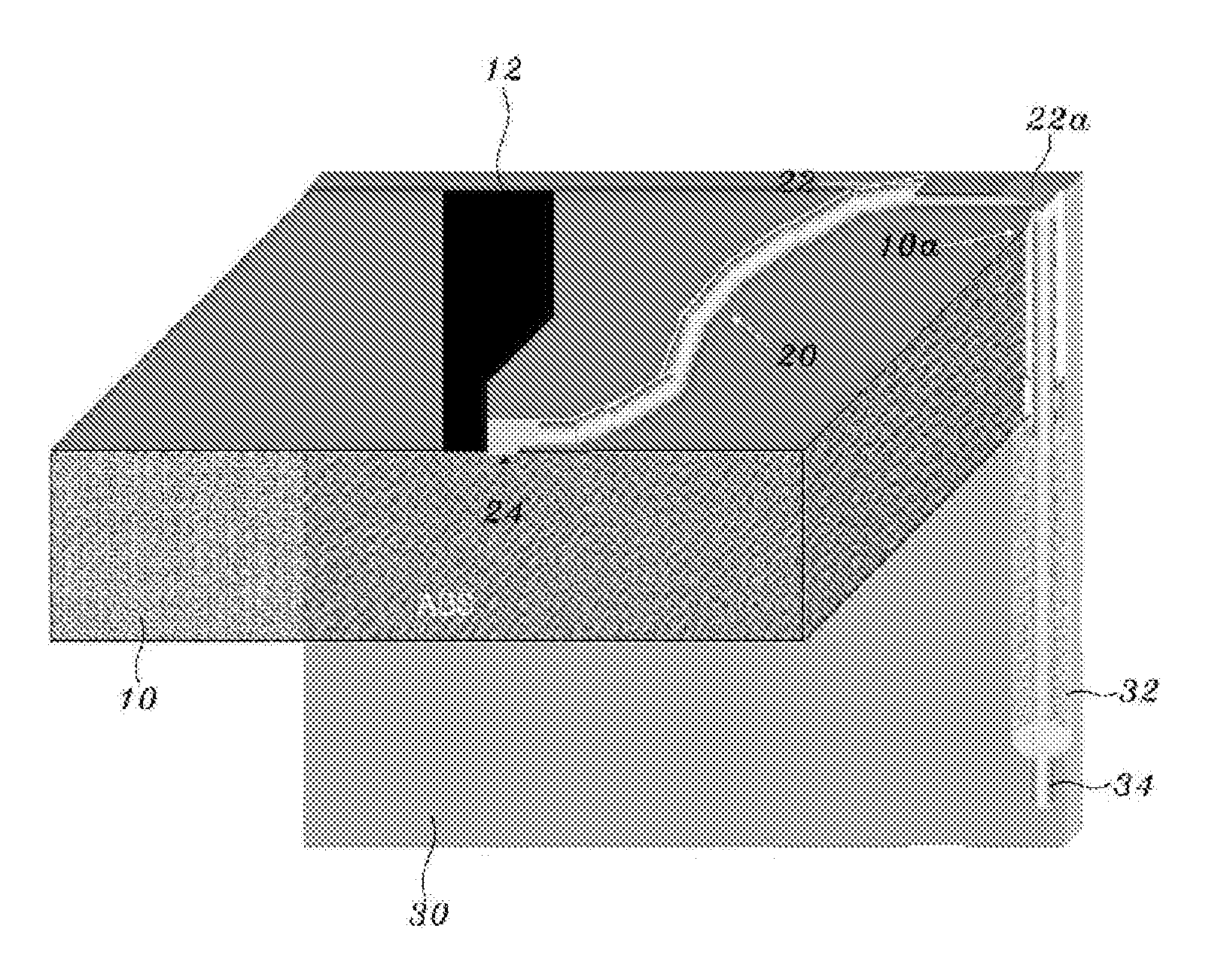

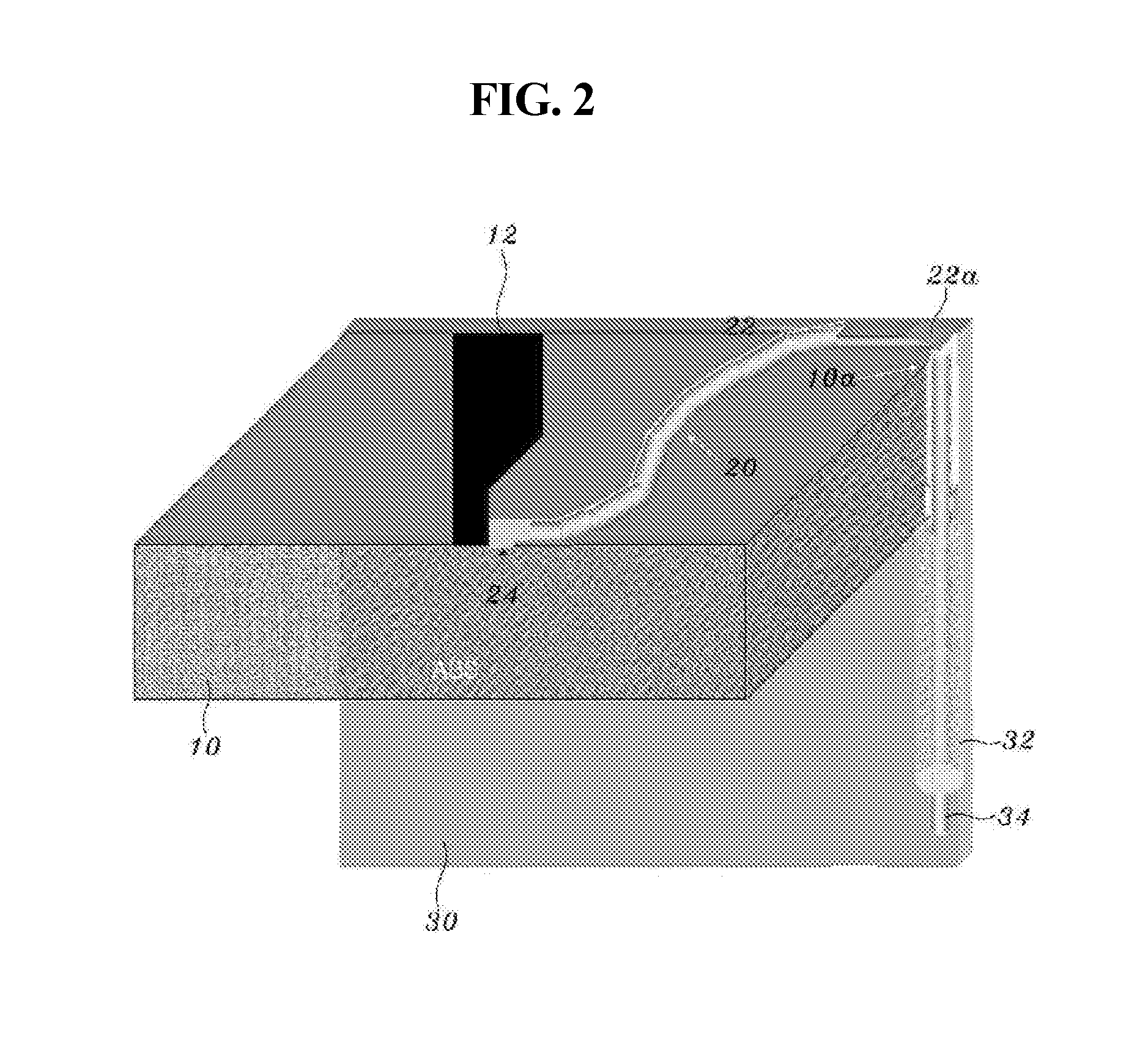

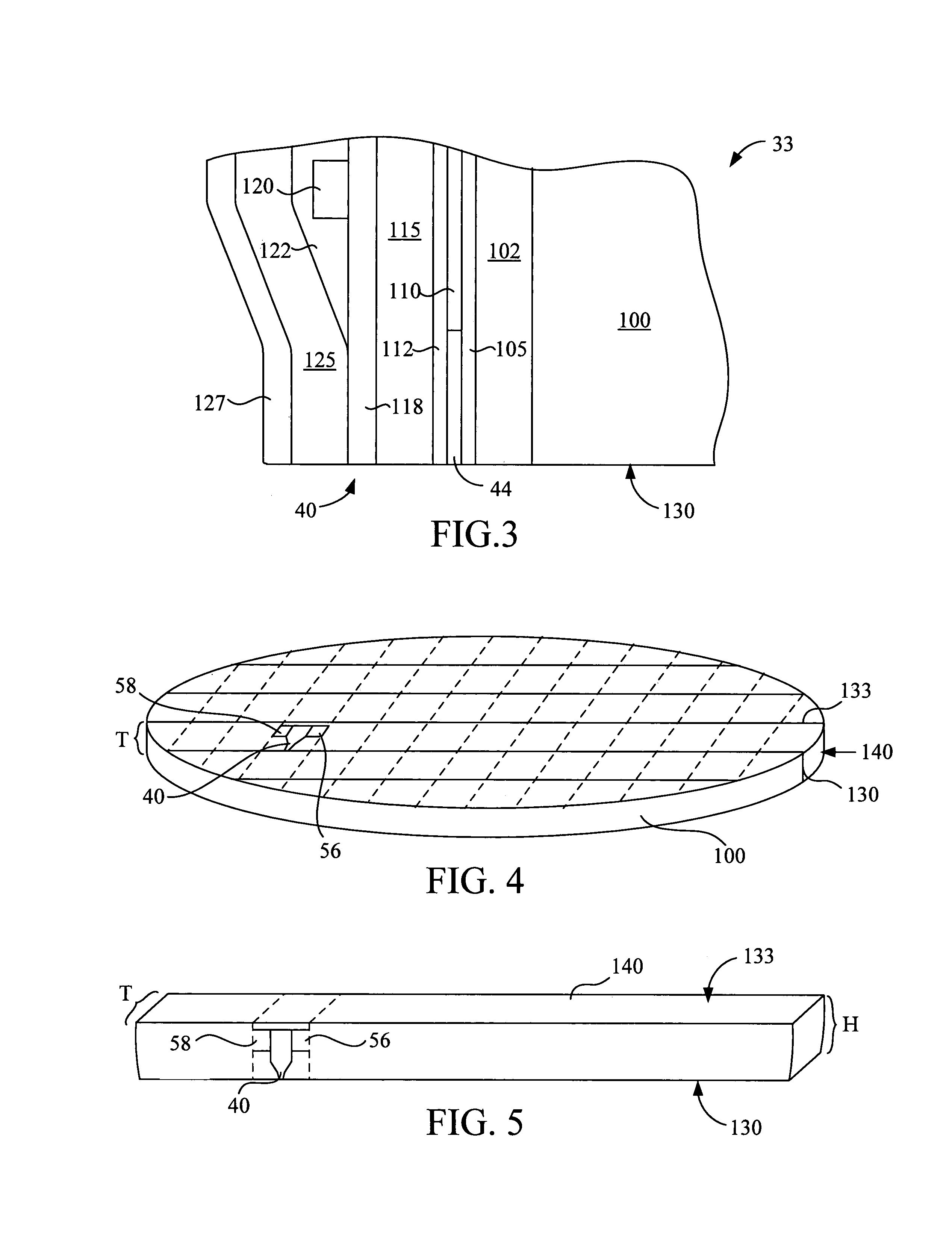

Structure for light coupling in heat-assisted magnetic recording

InactiveUS20080181560A1Easy to installSmall sizeRecord information storageRecording/reproducing/erasing methodsFiberHeat-assisted magnetic recording

A light-coupling structure in a type of heat-assisted magnetic recording is provided, the structure not needing a separate additional slider or a suspension arm through reduction in variation amounts of coupling due to vibrations, and being realized as a high efficient, low-cost structure with compact size. The light-coupling structure in a type of heat-assisted magnetic recording (HAMR) includes: a waveguide having, at its one end, a mirror part inclined at a certain angle; a slider having one of a groove provided along a width direction of one side thereof contacting the waveguide and a via hole provided along a width direction of one side thereof contacting the waveguide; and a fiber butt-connected to the waveguide by means of a connector provided parallel with the slider.

Owner:SAMSUNG ELECTRONICS CO LTD

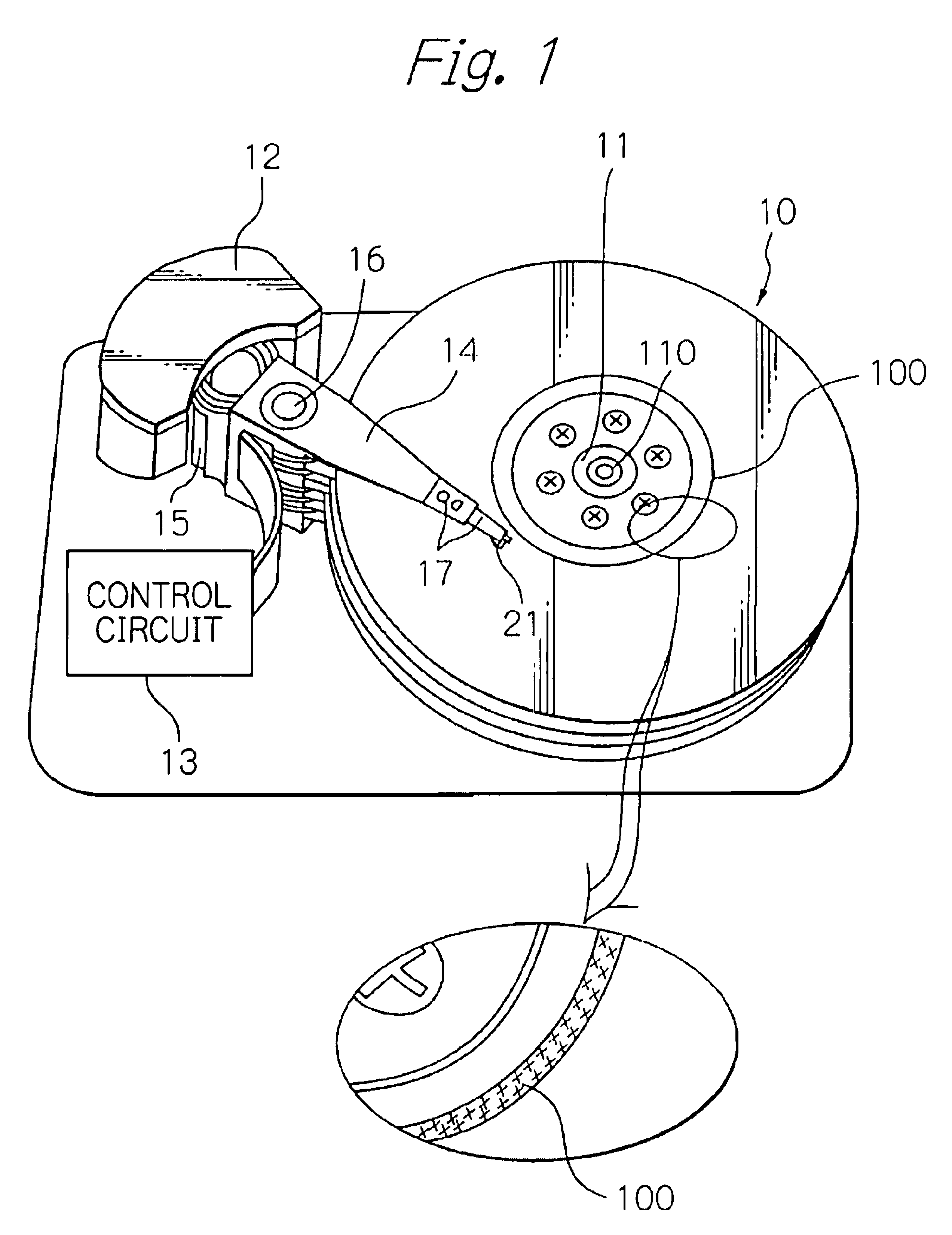

Laser cutting method for forming magnetic recording head sliders

A method for cutting a ceramic wafer to form individual sliders for use in supporting the read / write heads in magnetic recording disk drives uses multiple parallel scans of a pulsed laser to ablate the ceramic material. After the wafer has been cut into individual rows, a pulsed laser beam is directed to that surface of the row that will become the disk sides of the sliders (i.e., the sides of the sliders that will face the disks in the disk drive). The laser is pulsed as the laser spot is moved along a first scan line across the surface of the wafer row to form a generally V-shaped trench. The laser spot is then moved in a direction generally perpendicular to the first scan line a distance less than the laser beam diameter, and then pulsed while the laser spot is scanned along a second line generally parallel to the first scan line. This slight offset of the laser beam during the second scan blends the edges of the wafer surface at the trench to remove protrusions formed at those edges by the first laser scan. The laser is then moved to the other side of the first scan line a distance less than the laser beam diameter and a third scan is made to blend the other edge. One of more subsequent laser scans can be made along the first scan line to either cut deeper or to cut completely through the wafer row to completely separate the sliders.

Owner:WESTERN DIGITAL TECH INC

Top bond pad for transducing head interconnect

InactiveUS7929248B2Electrical connection between head and armFluid-dynamic spacing of headsEngineeringMechanical engineering

Owner:SEAGATE TECH LLC

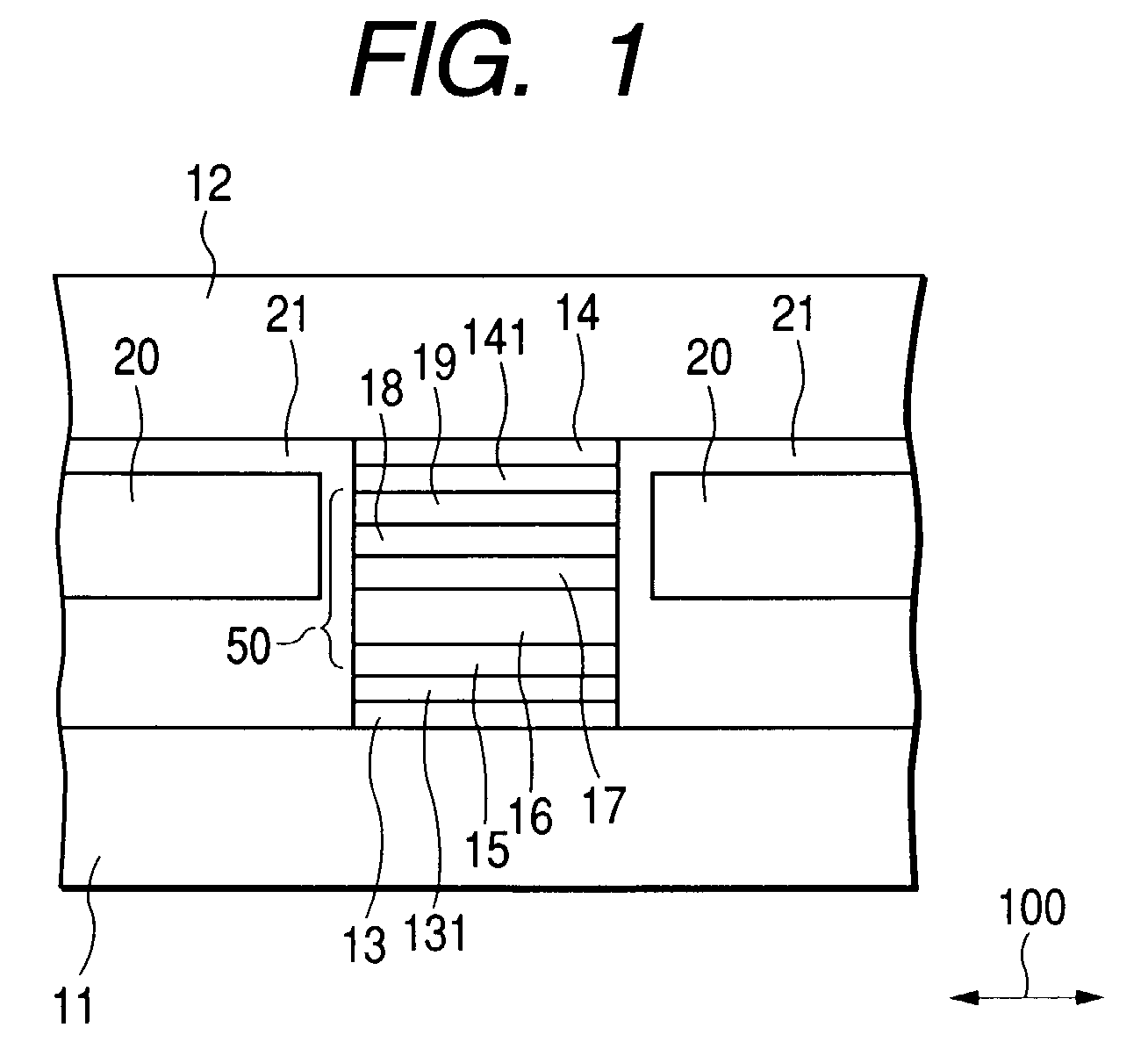

CPP-type magnetic head with less deformation and a magnetic recording/reproducing system using the same

InactiveUS7031119B2High yieldIncrease productionNanomagnetismNanoinformaticsShear modulusMagnetic reluctance

A high output, magnetoresistive head with a CPP structure is disclosed which reduces or prevents deformation near the air bearing surface of the read element portion layer at the time of air bearing surface processing. In the CPP structure magnetoresistive head, the deformation near the air bearing surface as a result of mechanical polishing during the air bearing surface processing can be reduced by forming deformation prevention layers having a higher shear modulus than a first ferromagnetic layer, and a second ferromagnetic layer between a magnetoresistive film and at least one of a lower shield layer and an upper shield layer.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

Magnetic head with electro-lapping guide

InactiveUS7149061B2Improve accuracyHigh precision machiningManufacture head surfaceElectrical transducersEngineeringInductor

A thin-film includes an inductive element and a first and second magneto-resistive effect elements in which the first and second magneto-resistive effect elements are arranged in proximity to each other on a substrate, and one surface of the substrate perpendicular to the surface formed with the first and second magneto-resistive effect elements constitutes a slider surface, thereby providing appropriate hight of the magneto-resistive effect elements.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

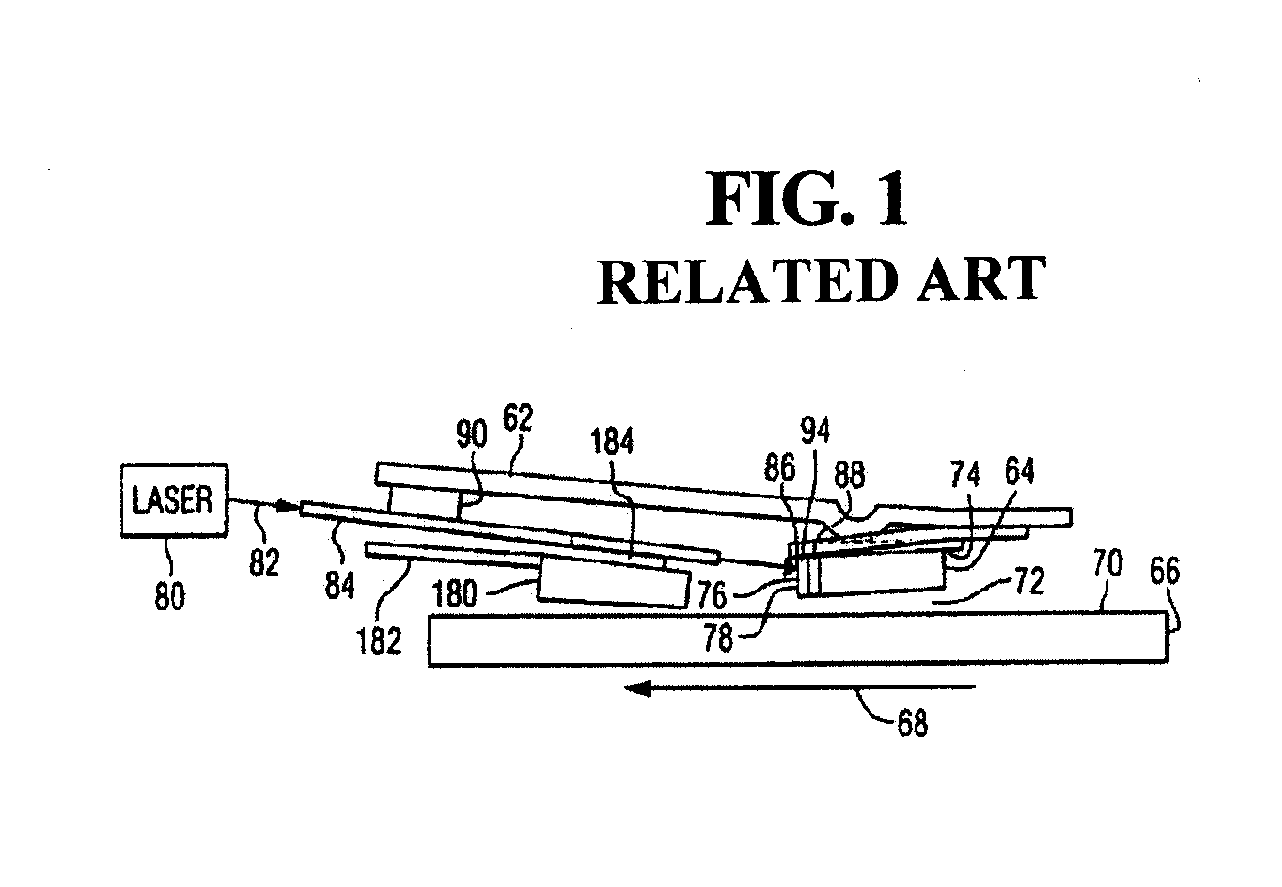

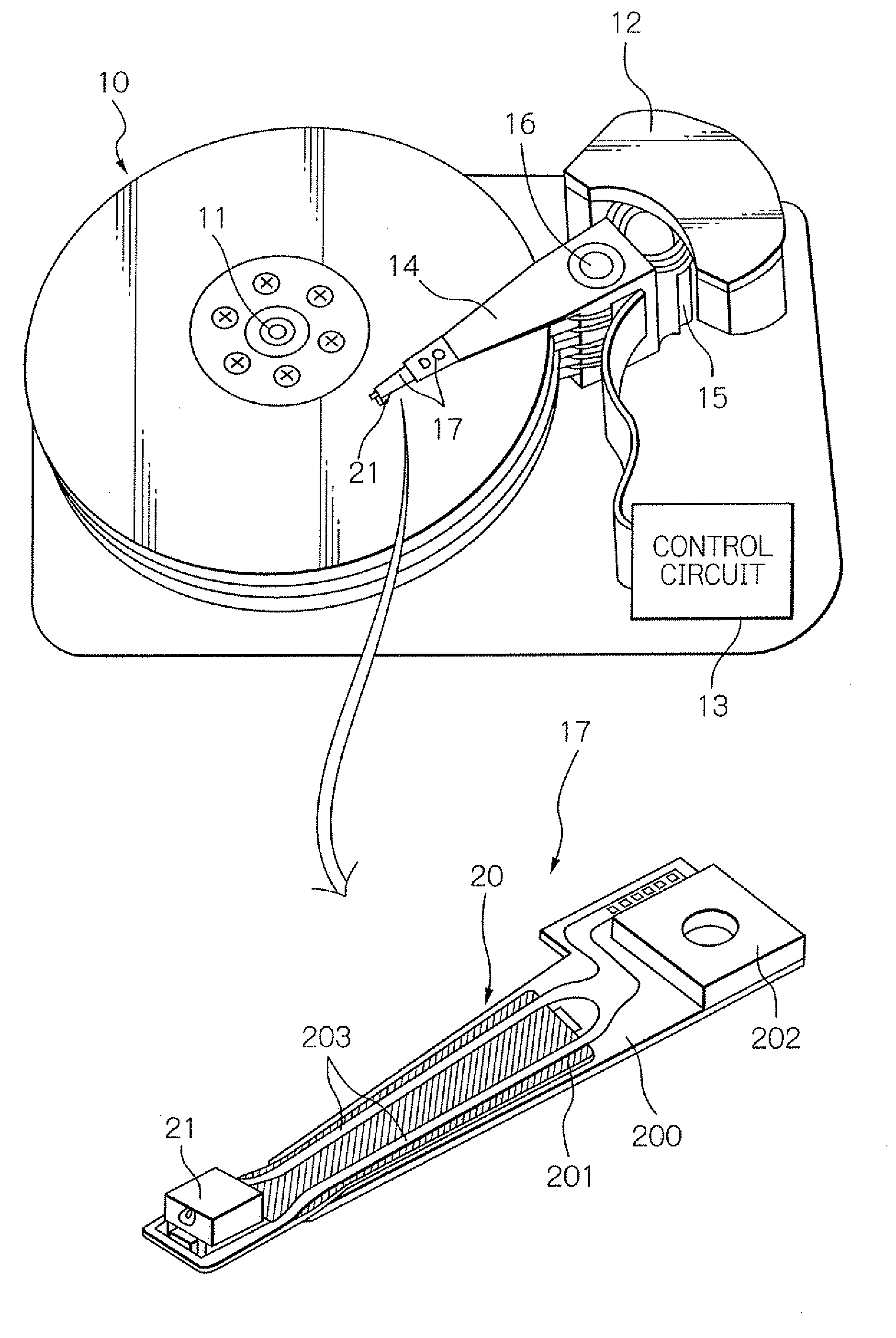

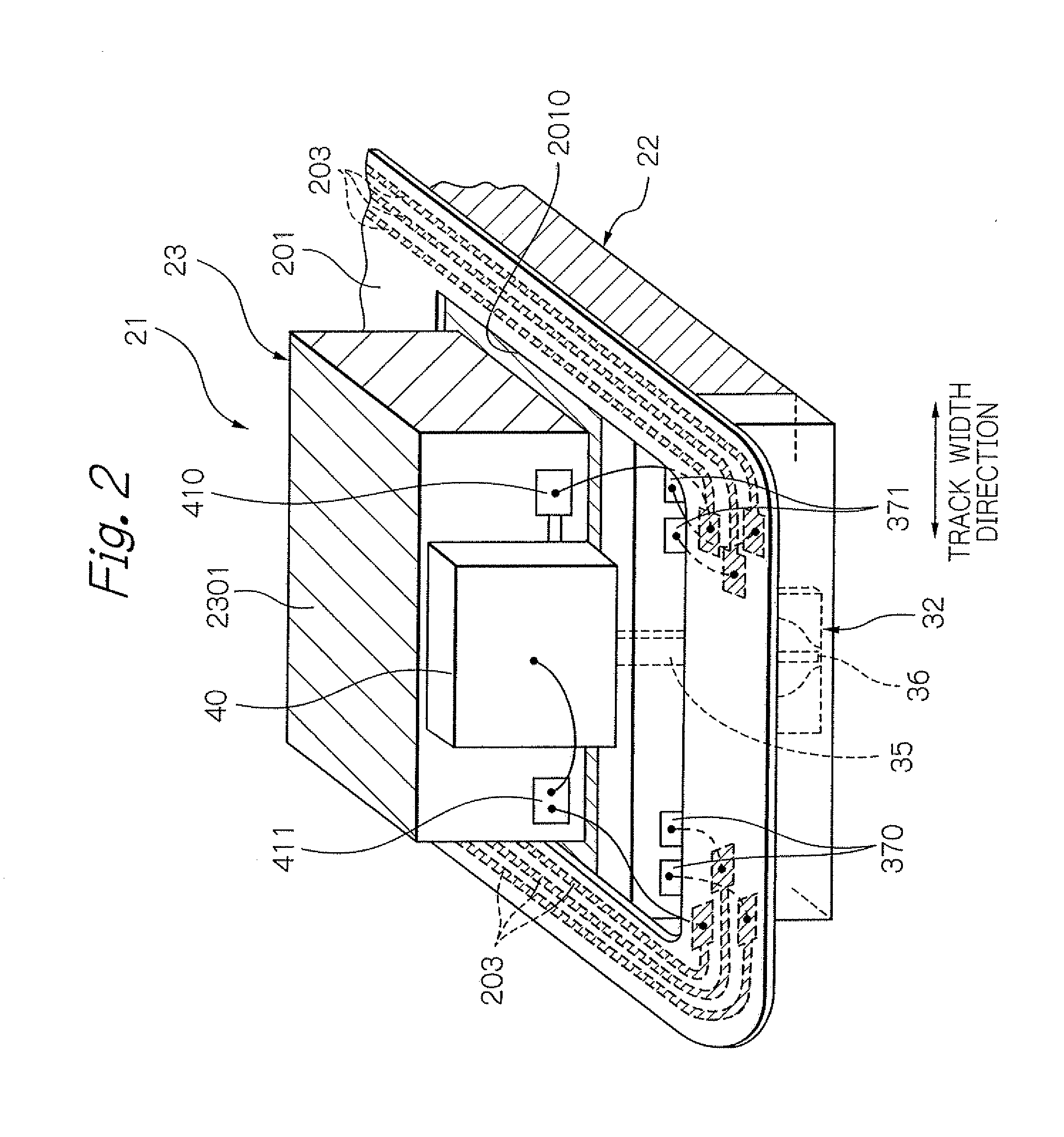

Heat-assisted magnetic recording head constituted of slider and light source unit, and manufacturing method of the head

ActiveUS20100085846A1High precision alignmentImprove manufacturing yieldElectrical transducersArm with optical waveguideHeat-assisted magnetic recordingEngineering

Provided is a method for manufacturing a heat-assisted magnetic recording head, capable of joining a light source unit and a slider with a sufficiently high alignment accuracy. In the method, the unit including a light source is joined to the slider including a head part. First, at least one marker provided on the head-part end surface is set so that the distance from the waveguide incident center to the marker end is substantially equal to the distance from the light-emission center of the light source to the end surface of the light source. After that, the unit and slider are relatively moved while keeping the unit in surface contact with the slider, and the relative positions are set so that the end of the marker coincides with, or is at a distance within an acceptable range from, the edge of the surface of the light source.

Owner:TDK CORPARATION

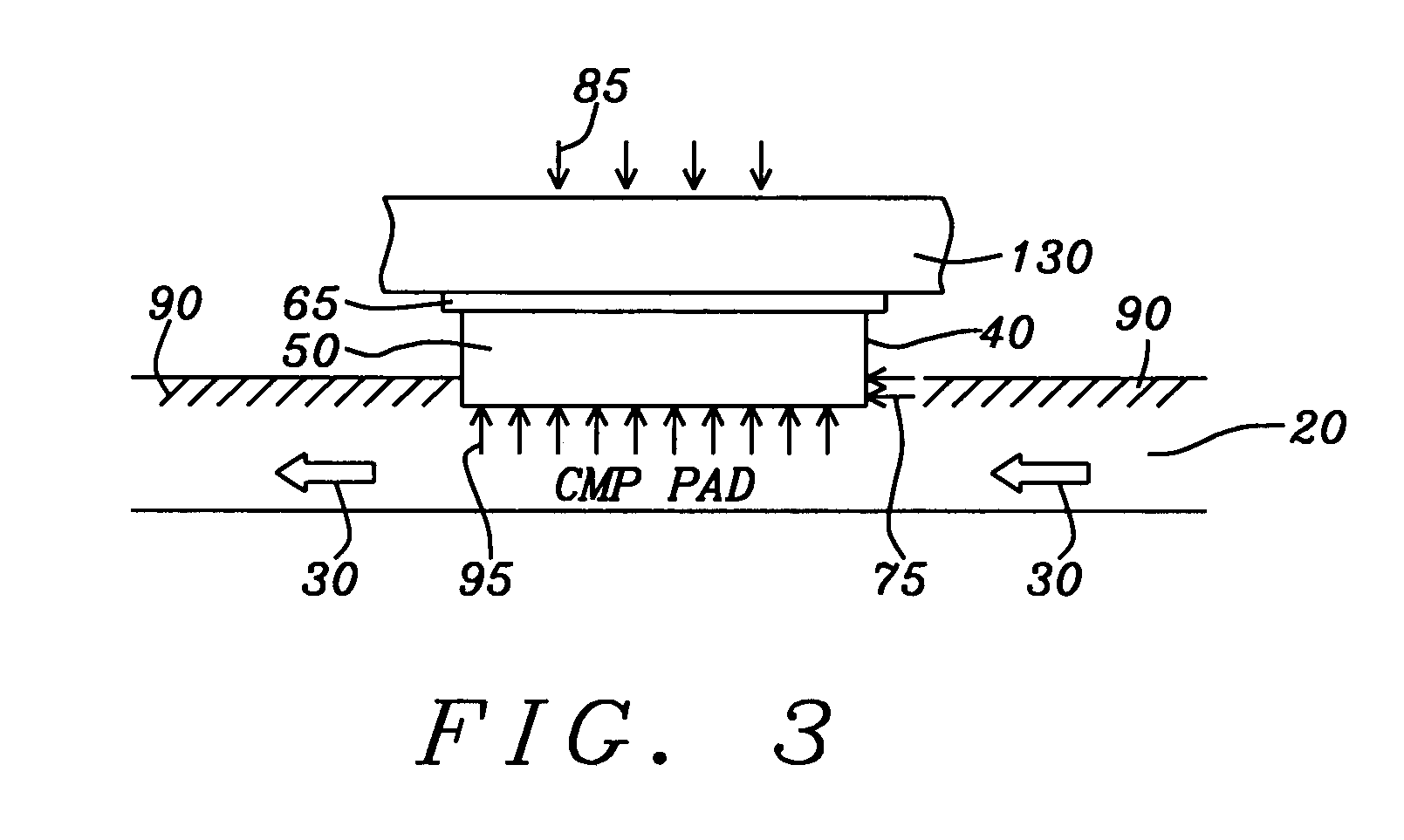

Method for controlling overcoat recession in a magnetic thin film head

InactiveUS20070109686A1Surface softeningSlightly wornSemiconductor/solid-state device manufacturingFluid-dynamic spacing of headsHard disc driveEngineering

The overcoat of a slider (alumina) is recessed relative to the slider ABS by a non-abrasive CMP process sufficiently to prevent thermal protrusion of the overcoat during subsequent slider use in a hard disk drive. The CMP process involves the oscillatory and rotational compressional contact between the ABS surface of the slider and a polymerically pre-treated compliant pad that is sprayed by an aqueous alkali lubricating solution having a pH between about 9 and 10. The overcoat is thereby also softened by the lubricating solution and removed by the compressional contact and no use of abrasives is required.

Owner:SAE MAGNETICS (HK) LTD

Thin-film magnetic head with heating portion and protrusion adjustment portion and manufacturing method of head

ActiveUS20080094755A1Easy to writeImprove reading characteristicRecord information storageFluid-dynamic spacing of headsFlying heightElectrical and Electronics engineering

The present invention provides a thin-film magnetic head which surely improves the writing and reading characteristic with reducing the flying height and surely handles the contact or collision with the magnetic recording medium.A thin-film magnetic head is provided, which includes, an substrate with ABS; a read or write head element provided on an element-formed surface of the substrate; at least one protrusion adjustment portion whose end reaches a slider end surface on the ABS side, which provides on an element-formed surface of the substrate; at least one heating portion provided rear at least one protrusion adjustment portion viewed from the slider end surface on the ABS side.

Owner:TDK CORPARATION

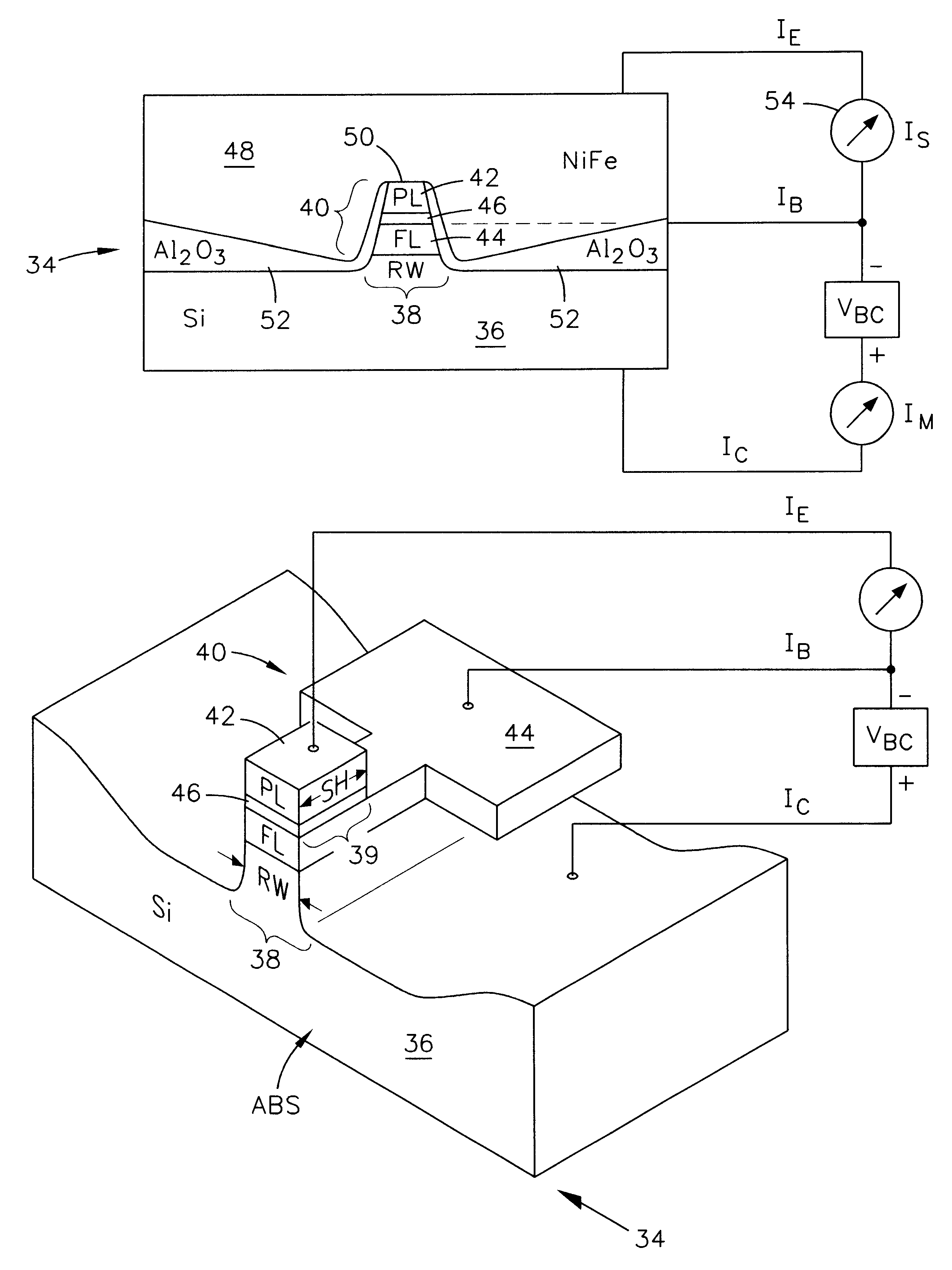

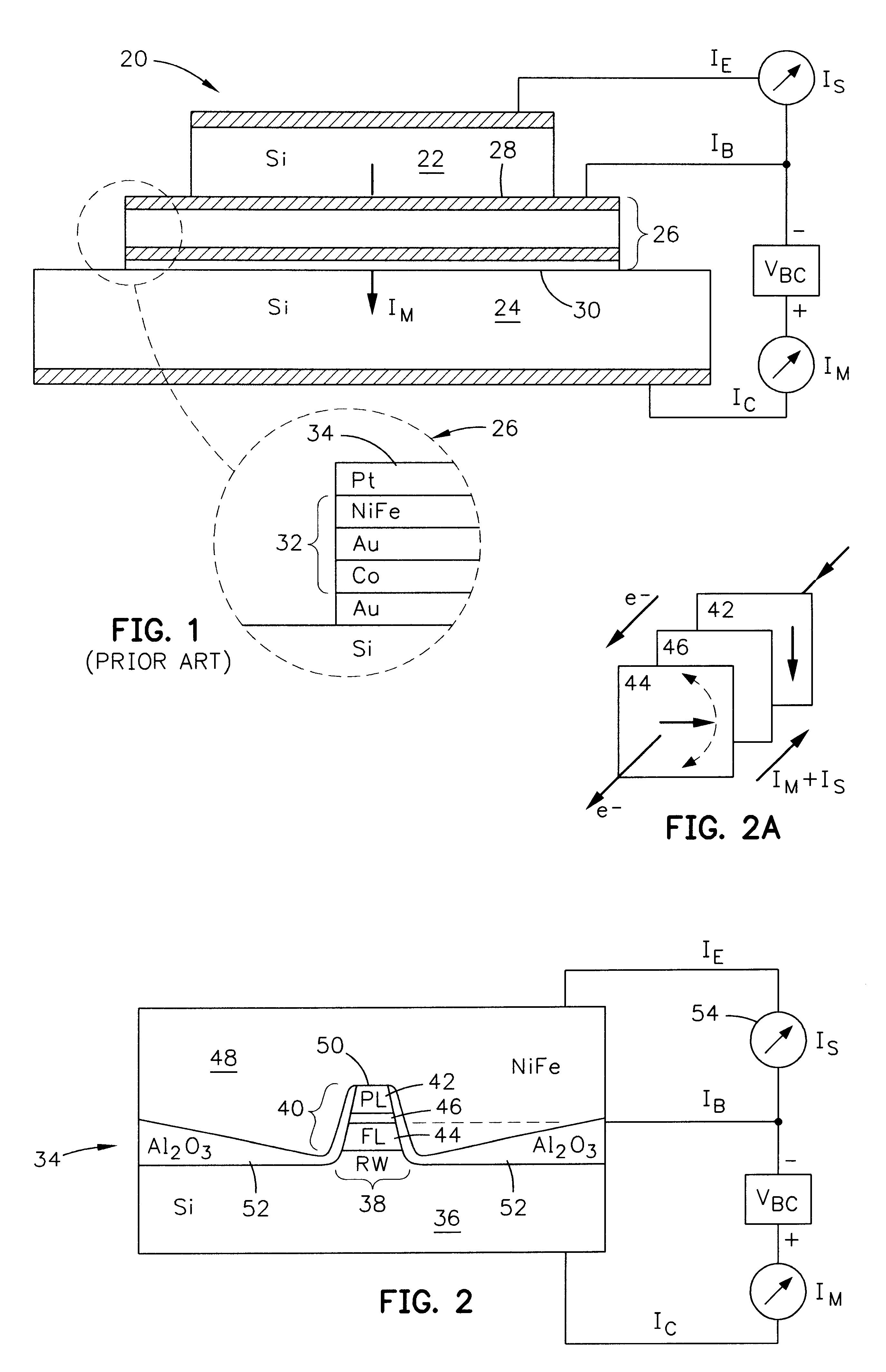

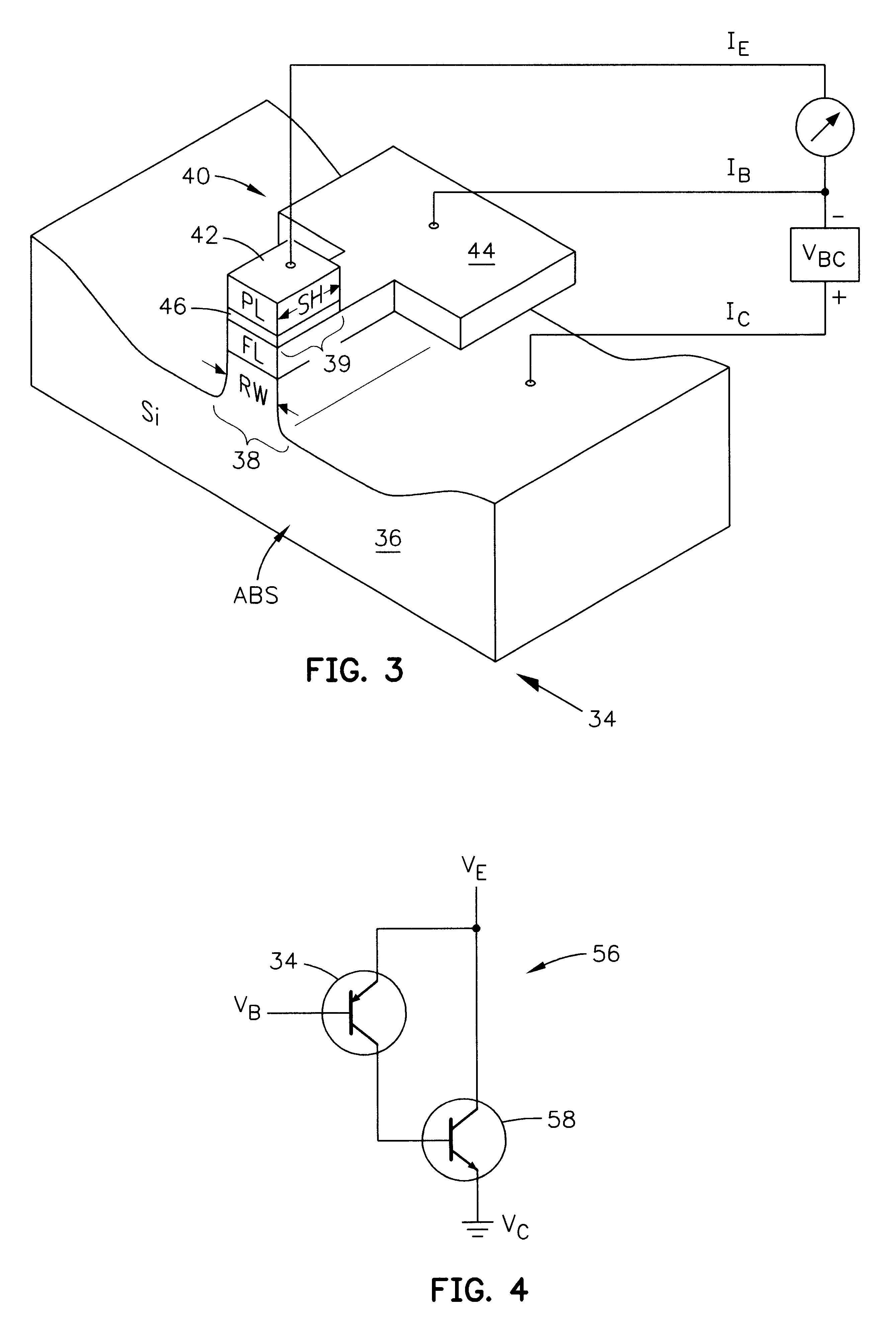

Semiconductor slider with an integral spin valve transistor structure and method for making same without a bonding step

InactiveUS6870717B2Minimizing sensitivityNanoinformaticsHeads using thin filmsSingle processSchottky barrier

A semiconductor slider including an integral spin valve transistor (SVT) having a read width of 250 nm or less disposed on a monolithic semiconductor substrate, useful in magnetic data storage applications. The monolithic slider may also include other magnetic and semiconductor transistor structures and is fabricated in a single process using standard thin-film processing steps. The SVT includes a sensor stack having a top surface and including a first ferromagnetic (FM) layer in contact with and forming a Schottky barrier at the monolithic semiconductor substrate, a FM shield layer disposed over the sensor stack and in electrical contact with the top surface thereof, a SVT emitter terminal coupled to the FM shield, a SVT collector terminal coupled to the substrate and a SVT base terminal coupled to the first FM layer. The sensor stack may include a spin valve (SV) stack or a tunnel valve (TV) stack, for example.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

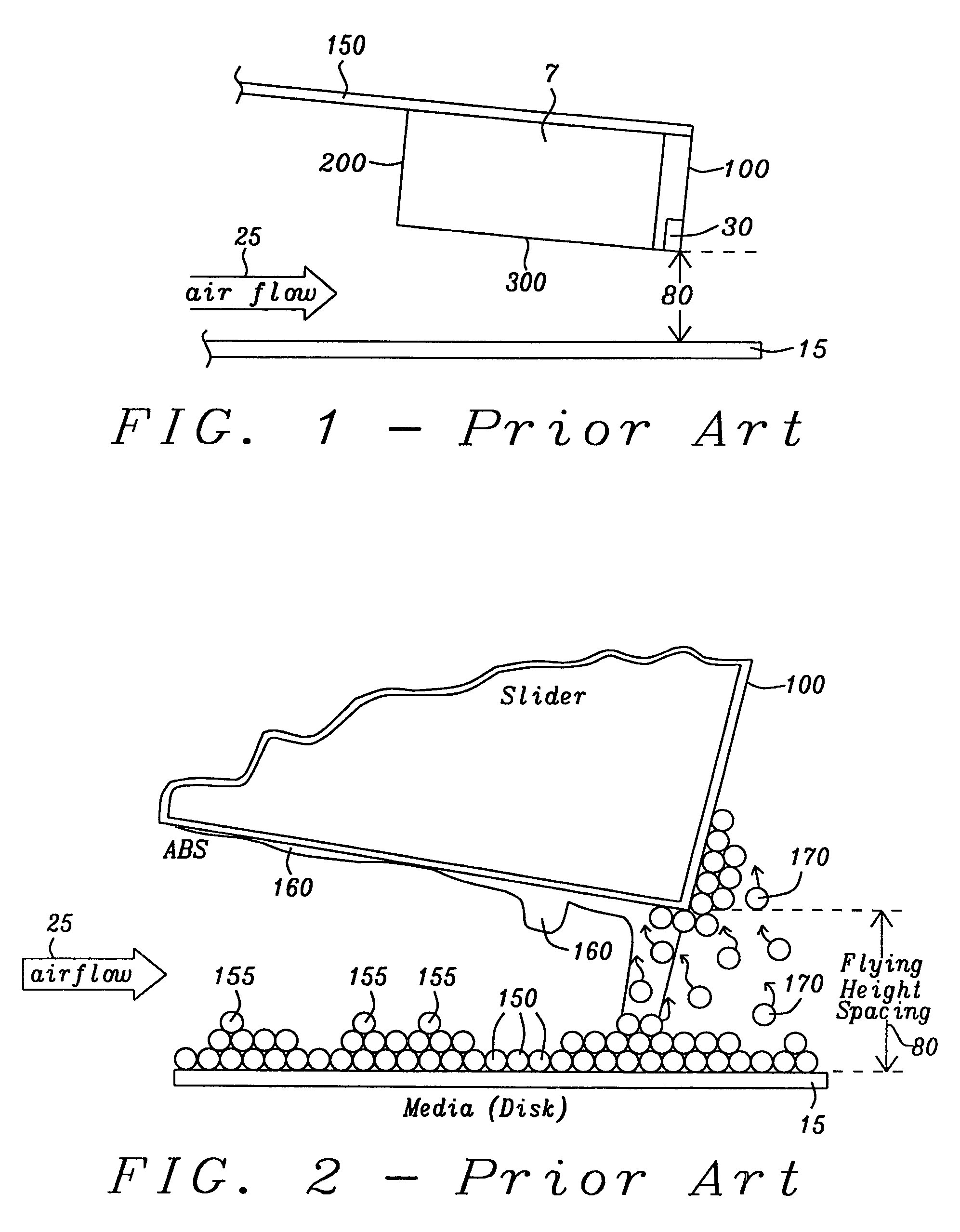

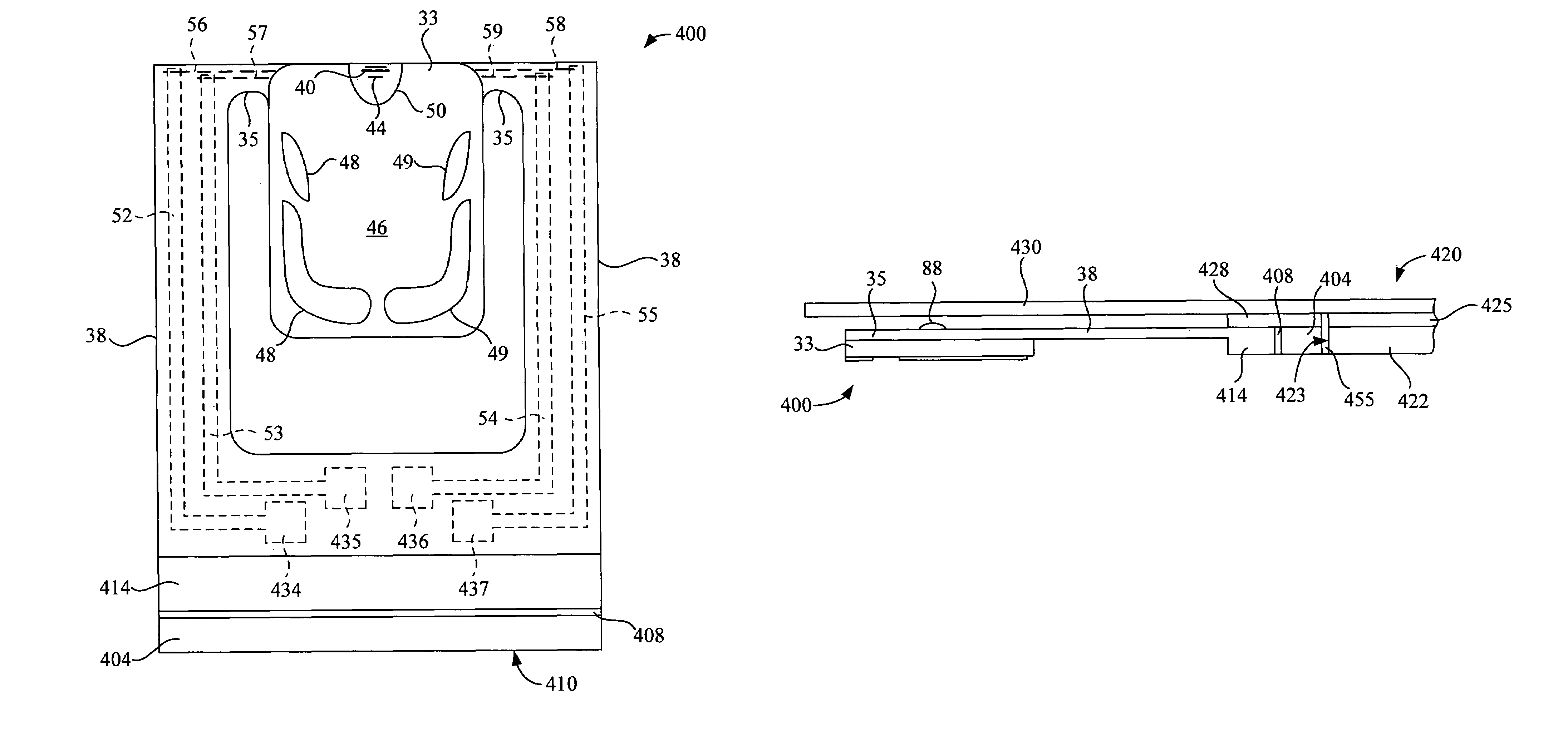

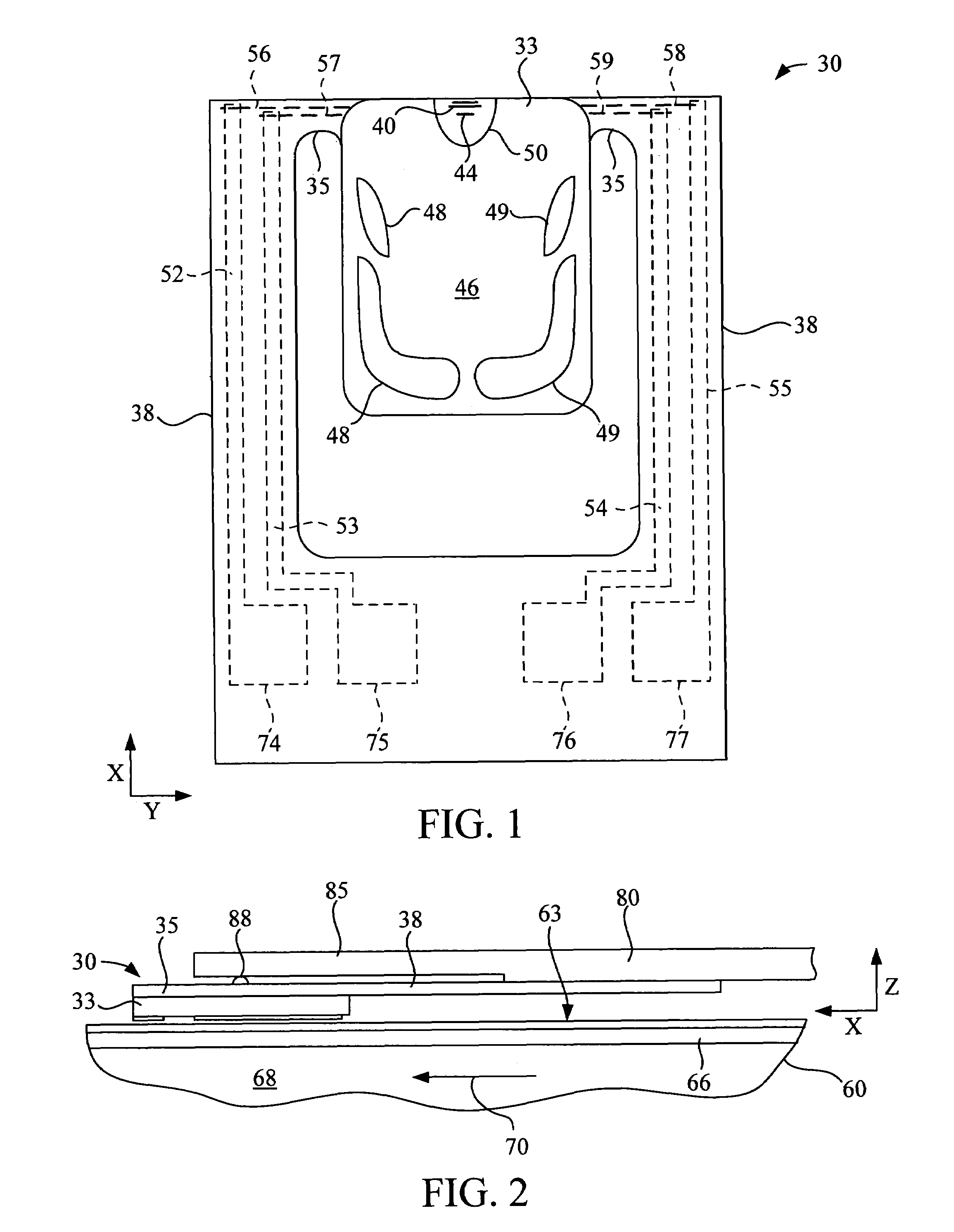

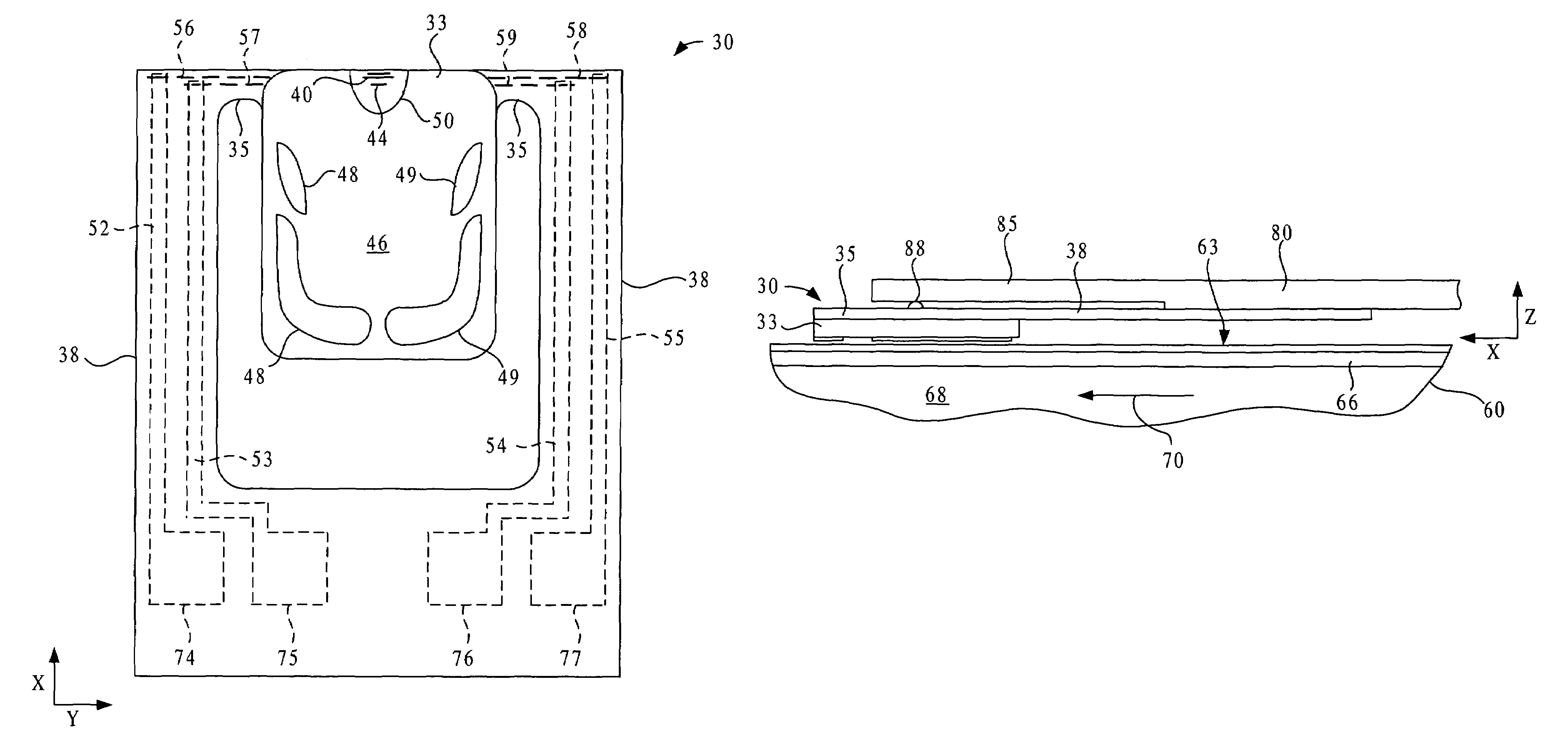

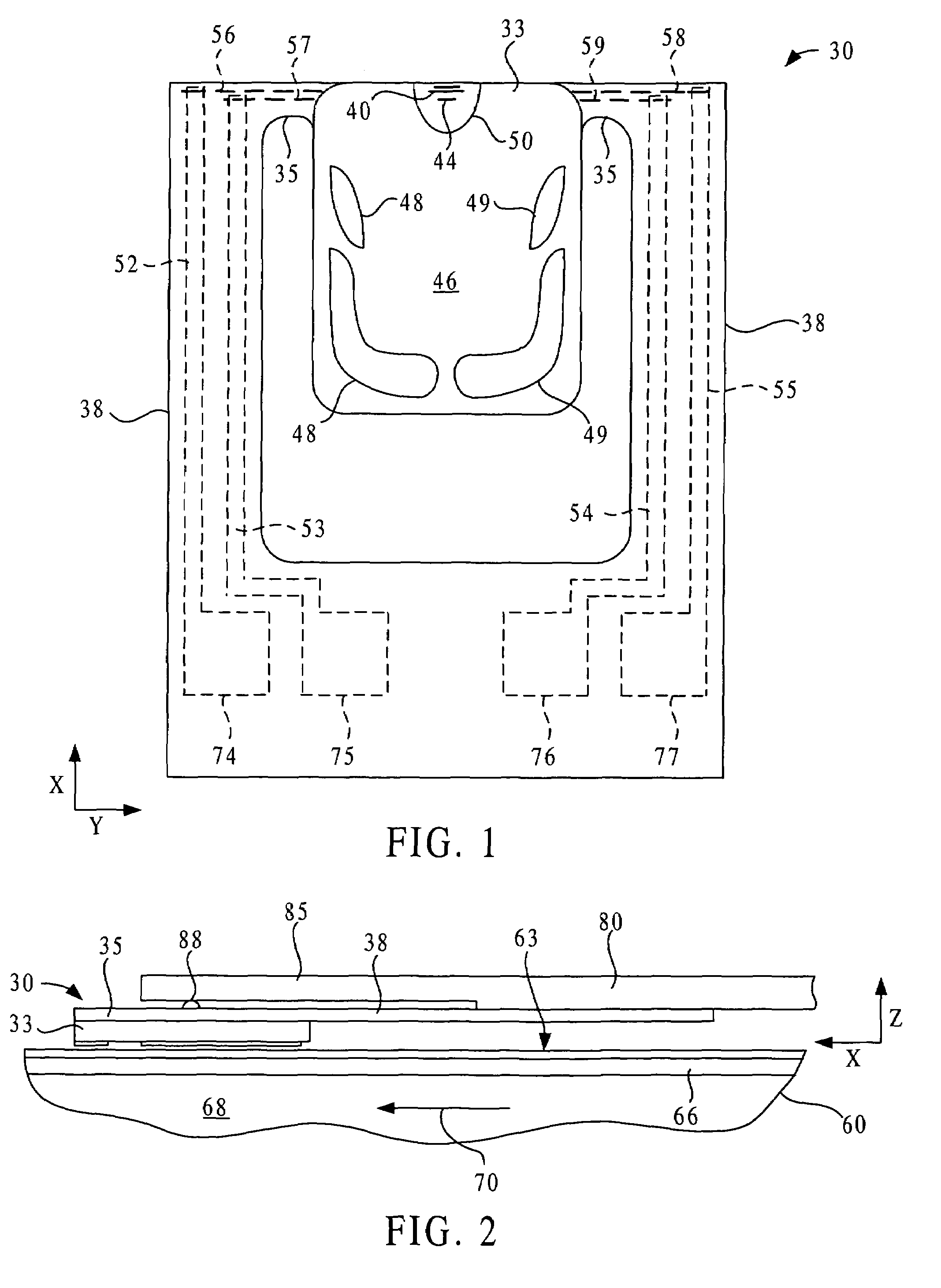

Air-bearing slider design for sub-nanometer clearance in hard disk drive (HDD)

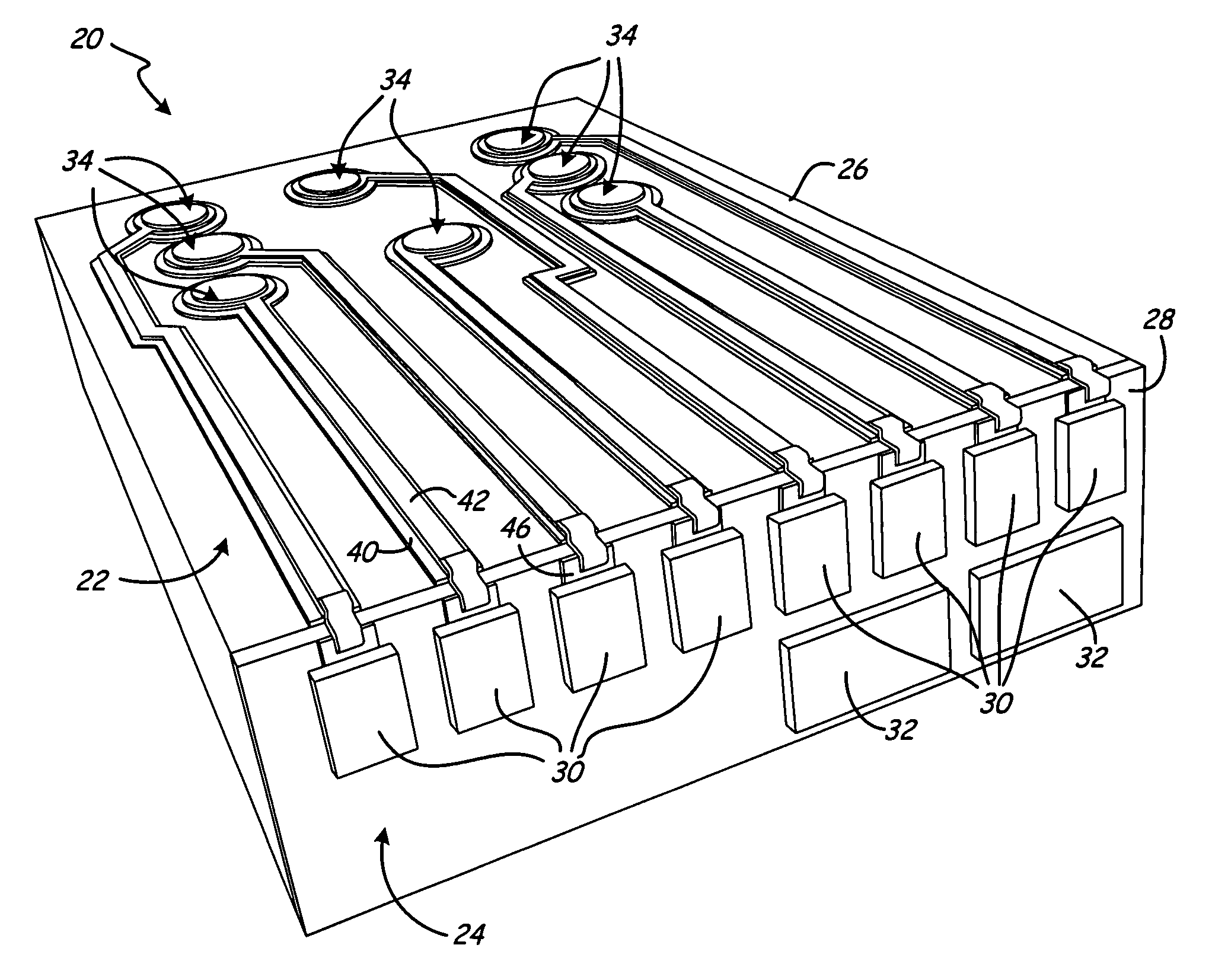

ActiveUS8184405B1Eliminate the problemReduce sensitivityDisposition/mounting of recording headsRecord information storageHard disc driveAir bearing

A slider is formed by a three-step ion milling process with an ABS topography that provides aerodynamic stability at sub-nanometer flying heights. The ABS design significantly eliminates the accumulation of lubricant and removes whatever lubricant does accumulate by use of a shallow dam at the trailing edge. In addition, a junction between a down-track channel and a cross-track channel directs airflow towards a center pad in which a transducer is embedded so that the pressure at the pad is enhanced even under high altitude conditions. The slider ABS is divided into two portions by a transverse deep air channel, but the channel is bridged by the cross-track channel which crosses the deep air channel with sides of unequal height. This dual height bridge allows variations in skew angle to be compensated so that pressure variations across the disk tracks are significantly reduced.

Owner:HEADWAY TECH INC +1

Stable encapsulant fluid capable of undergoing reversible diels-alder polymerization

An encapsulant fluid is provided comprising a mixture of a diene-containing compound and a dienophilic compound. At least one of the diene-containing and the dienophilic compounds is protected so that the compounds do not substantially react with each other at room temperature. The diene-containing and the dienophilic compounds undergo a reversible Diels-Alder polymerization reaction at a polymerization temperature above room temperature to form a solid debondable polymeric encapsulant. Also provided are methods for forming slider assemblies and methods for patterning a slider surface using the encapsulant.

Owner:WESTERN DIGITAL TECH INC

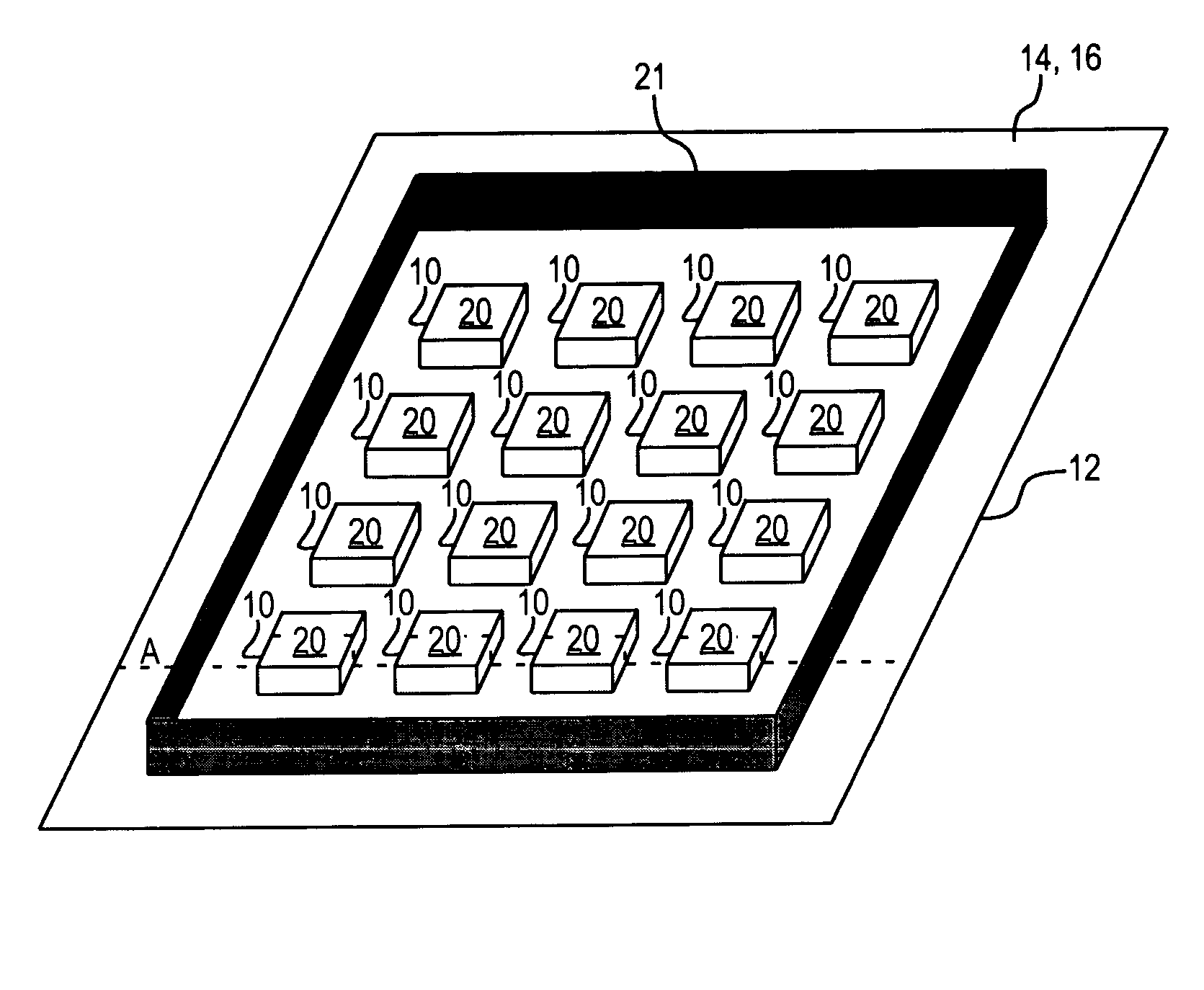

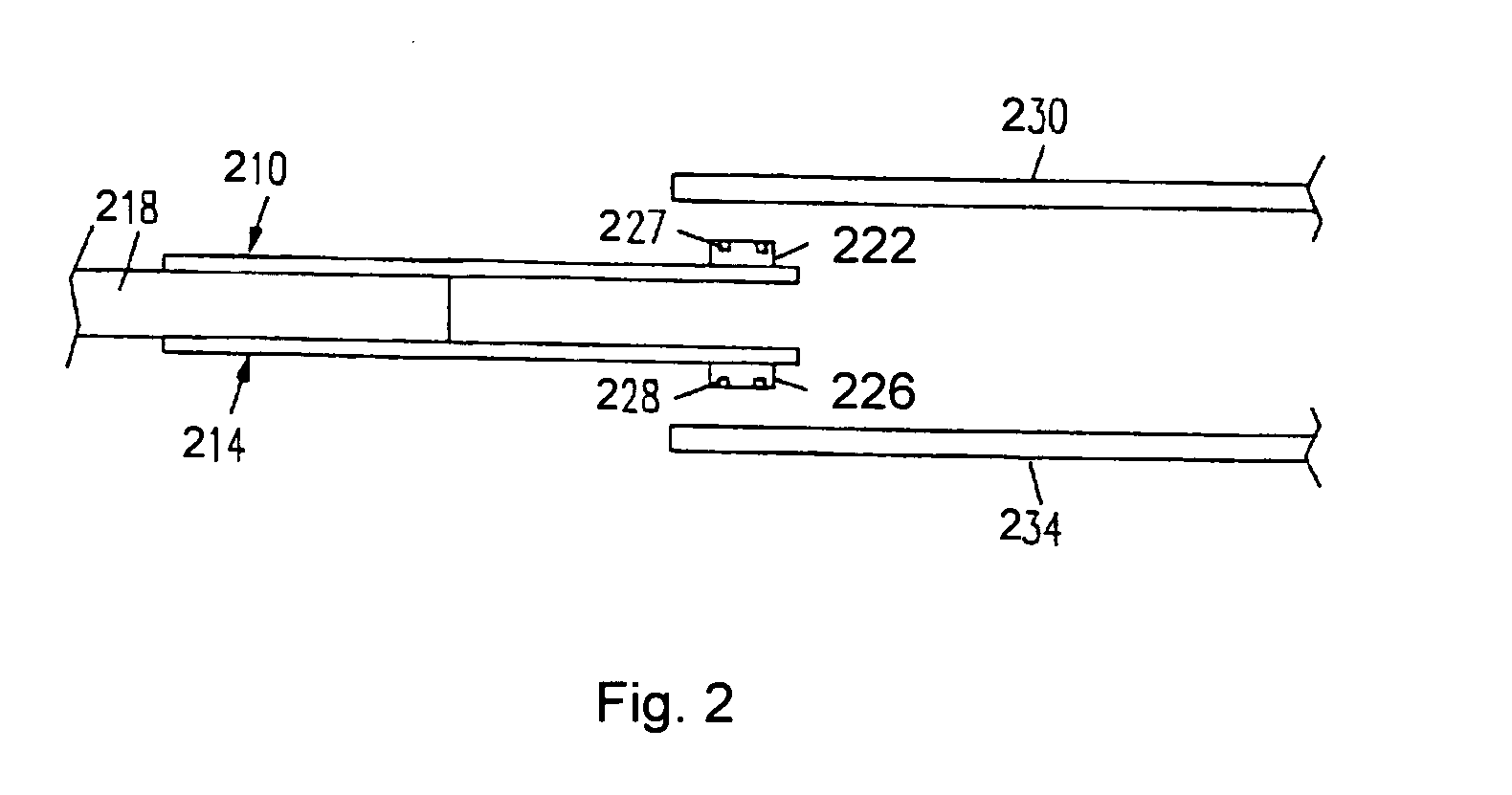

Electromagnetic heads, flexures, gimbals and actuators formed on and from a wafer substrate

InactiveUS7684158B1Improve accuracyHigh track densityElectrical connection between head and armRecord information storageAccess timePiezoelectric actuators

Devices for reading or writing electromagnetic information include a wafer substrate piece disposed between an electromagnetic transducer and an electrostrictive or piezoelectric actuator. The substrate piece is shaped as a rigid body adjoining the transducer and as a flexible element connecting the body and the actuator. To fabricate, at least one electrostrictive layer and many transducers are formed on opposite sides of a wafer that is then cut into rows containing plural transducers. The rows are processed from directions generally normal to the wafer surface upon which the transducers were formed, by removing material to form a head, flexures and a media-facing surface on the head. Conductive leads are formed on a back surface of flexures connecting the transducer with drive electronics. The flexures are aligned with forces arising from interaction with the media surface and from seeking various tracks, reducing torque and dynamic instabilities and increasing actuator access time.

Owner:LAUER MARK A

Thin-film magnetic head with heating portion and protrusion adjustment portion, head gimbal assembly equipped head, magnetic recording/reproducing apparatus equipped HGA, and manufacturing method of head

ActiveUS7974046B2Improve featuresReduce the overall heightRecord information storageFluid-dynamic spacing of headsFlying heightBiomedical engineering

The present invention provides a thin-film magnetic head which surely improves the writing and reading characteristic with reducing the flying height and surely handles the contact or collision with the magnetic recording medium.A thin-film magnetic head is provided, which includes, an substrate with ABS; a read or write head element provided on an element-formed surface of the substrate; at least one protrusion adjustment portion whose end reaches a slider end surface on the ABS side, which provides on an element-formed surface of the substrate; at least one heating portion provided rear at least one protrusion adjustment portion viewed from the slider end surface on the ABS side.

Owner:TDK CORPARATION

Electromagnetic heads, flexures, gimbals and actuators formed on and from a wafer substrate

InactiveUS7248444B1Improve accuracyHigh track densityElectrical connection between head and armRecord information storageAccess timePiezoelectric actuators

Devices for reading or writing electromagnetic information include a wafer substrate piece disposed between an electromagnetic transducer and an electrostrictive or piezoelectric actuator. The substrate piece is shaped as a rigid body adjoining the transducer and as a flexible element connecting the body and the actuator. To fabricate, at least one electrostrictive layer and many transducers are formed on opposite sides of a wafer that is then cut into rows containing plural transducers. The rows are processed from directions generally normal to the wafer surface upon which the transducers were formed, by removing material to form a head, flexures and a media-facing surface on the head. Conductive leads are formed on a back surface of flexures connecting the transducer with drive electronics. The flexures are aligned with forces arising from interaction with the media surface and from seeking various tracks, reducing torque and dynamic instabilities and increasing actuator access time.

Owner:LAUER MARK A

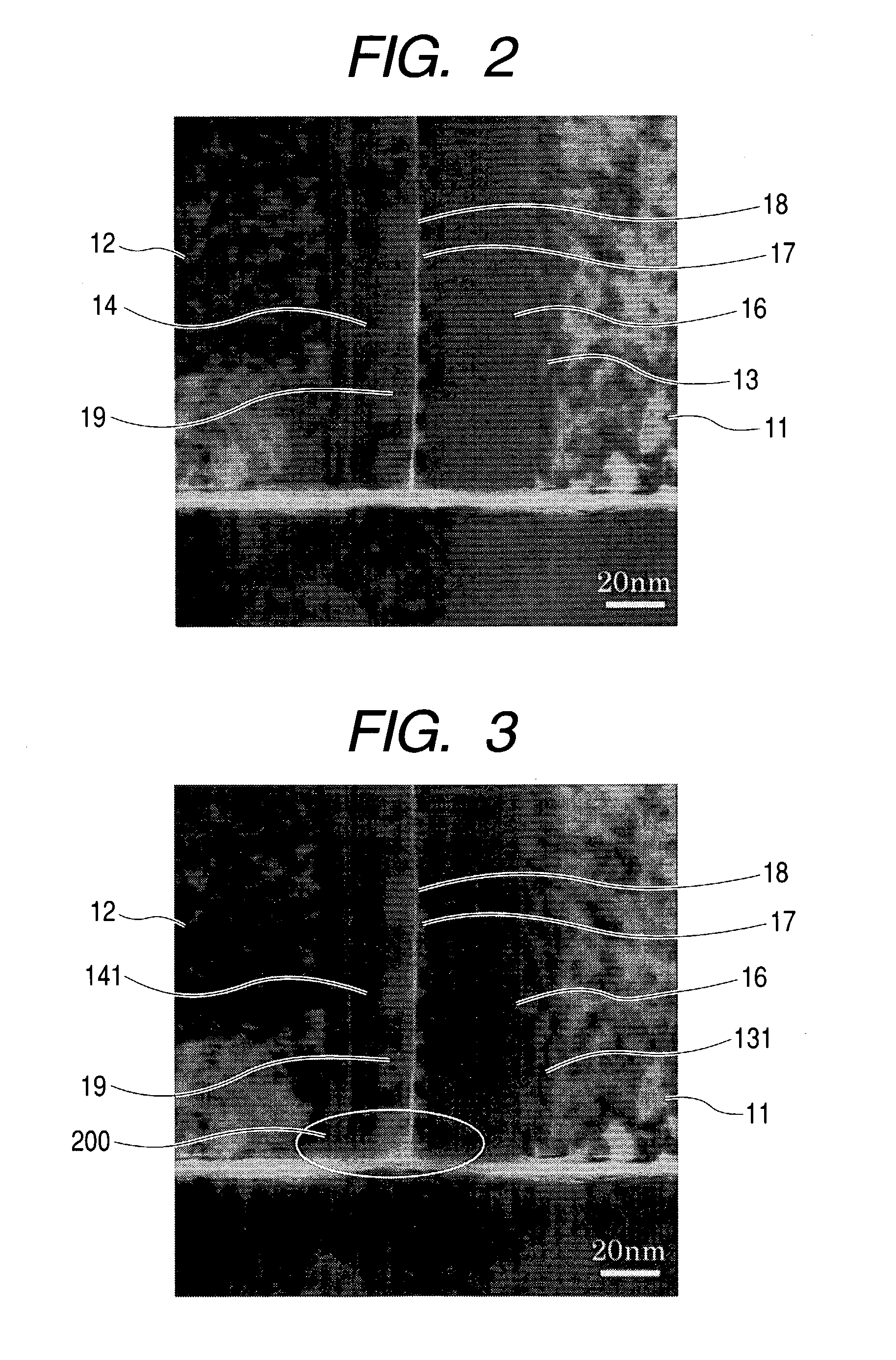

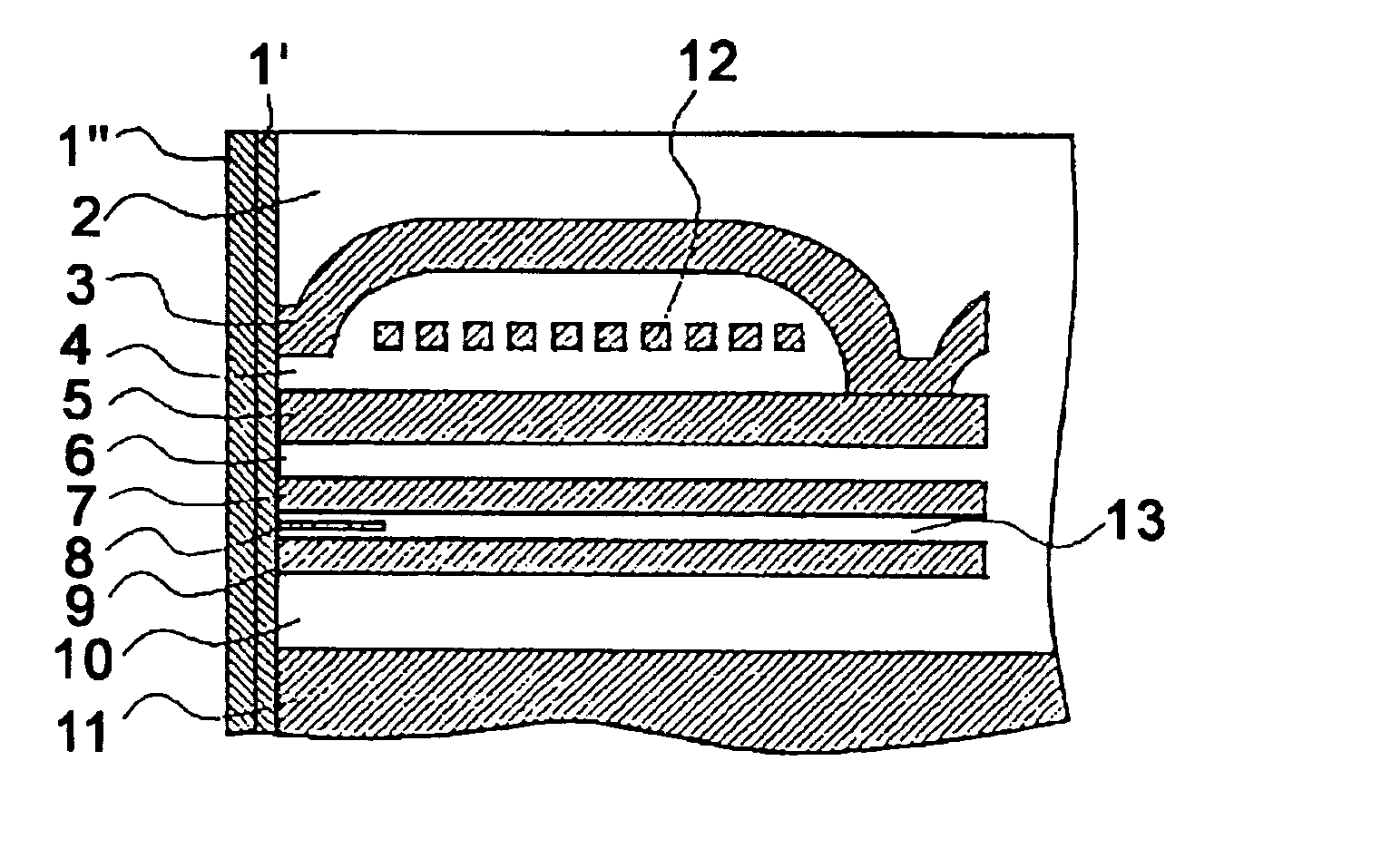

Thin-film magnetic head, method for producing the same and magnetic disk device using the same

InactiveUS20040052004A1Improve corrosion resistanceImprove wear resistanceNanomagnetismManufacture head surfaceVolumetric Mass DensityTotal thickness

A magnetoresistive thin-film magnetic head with high corrosion resistance for recording medium having massive capacity is provided by providing a protective film having a thickness of 40 Å or less. Since the distance between the head and the medium is remarkably reduced, the film is suitable for a recording medium having high-packing density. The magnetoresistive type thin-film magnetic head is provided, wherein the following layers are formed on at least the surface of the head facing a recording medium: (A) a lower layer composed of a thin film having the composition represented by the formula selected from the group consisting of: formula (i): SiCXHYOZNWFTBUPV (where X=0.5-26, Y=0.5-13, Z=0-6, W=0-6, T=0-6, U=0-1 and V=0-1, in terms of atomic ratio), and formula (ii): SiHYOZNWFTBUPV (where Y=0.0001-0.7, Z=0-6, W=0-6, T=0-6, U=0-1 and V=0-1); and (B) an upper layer composed of a diamond-like thin film having the composition represented by the following formula: CHaObNcFdBePf (where a=0-0.7, b=0-1, c=0-1, d=0-1, e=0-1 and f=0-1), and the total thickness of the lower layer and the upper layer is 40 Å or less. Also provided are a method for producing the same, and a magnetic head device using the same.

Owner:TDK CORPARATION

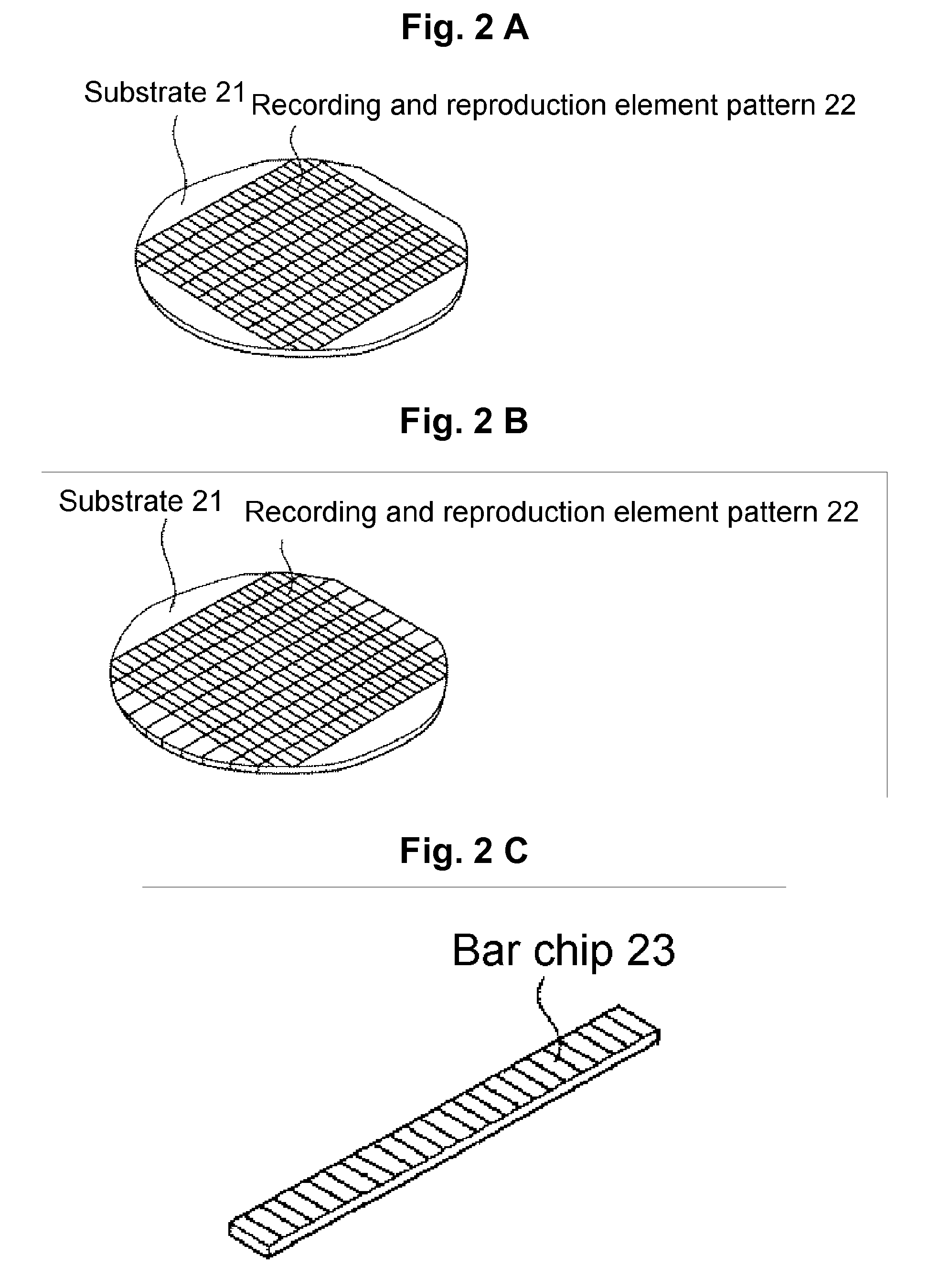

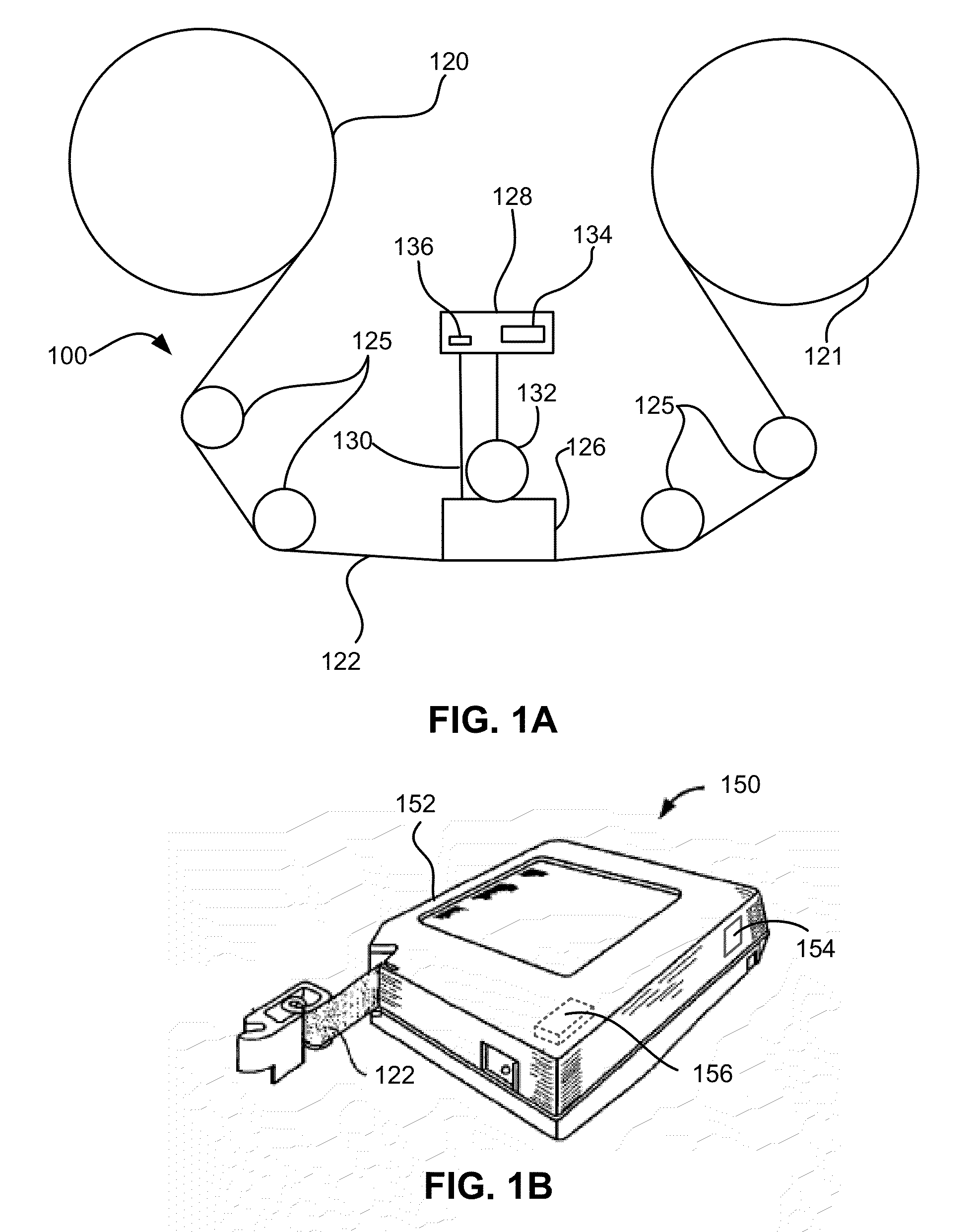

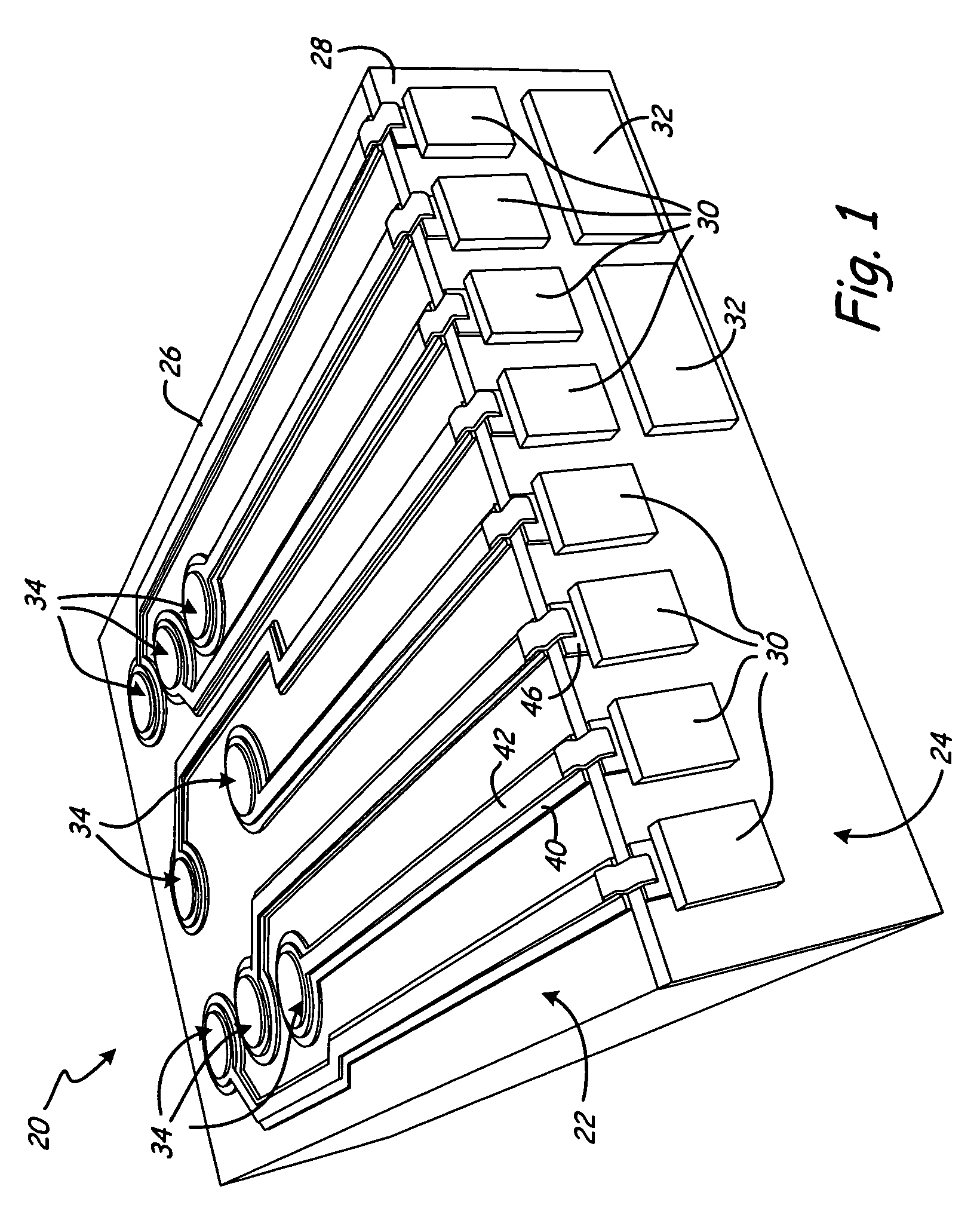

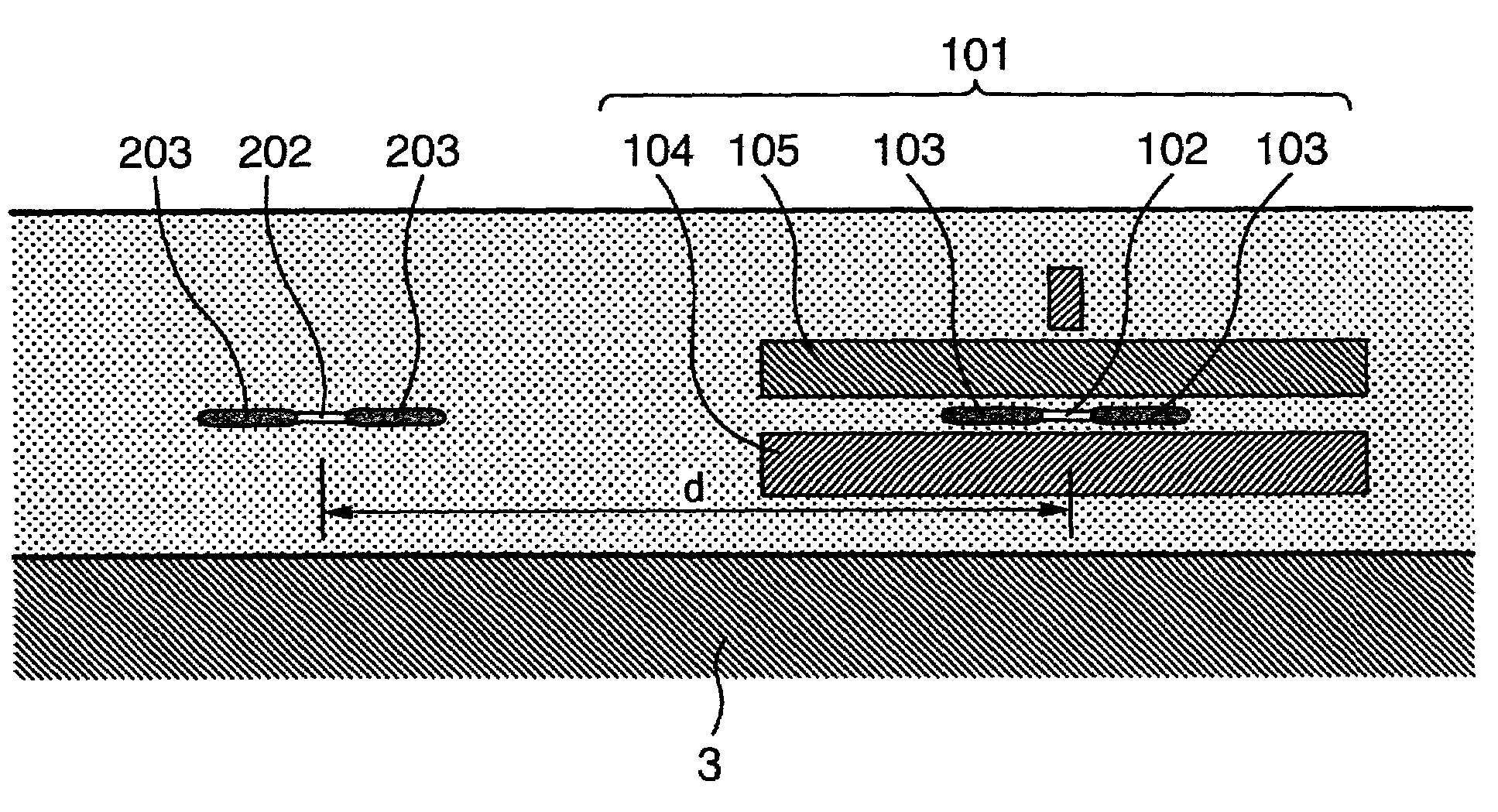

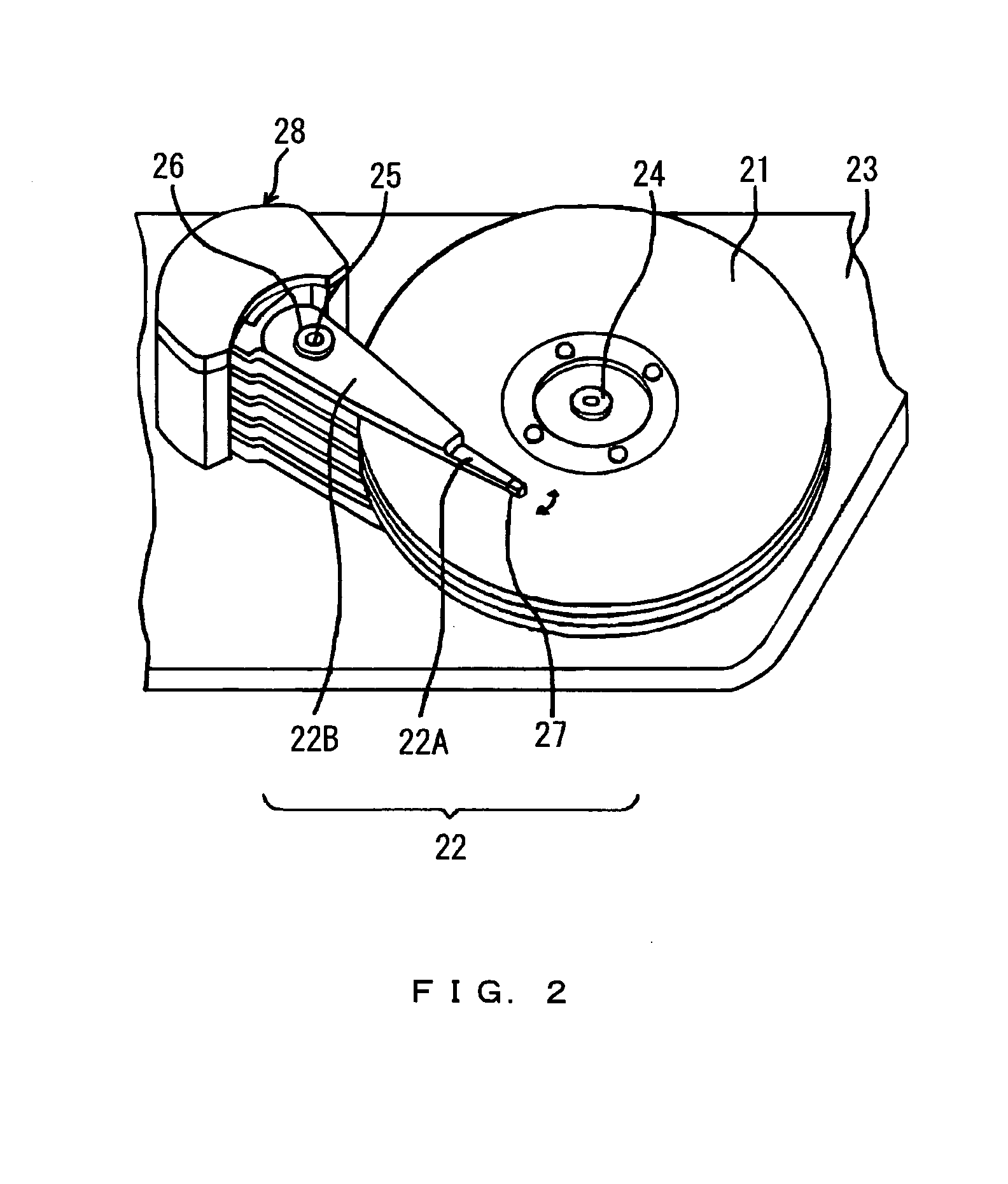

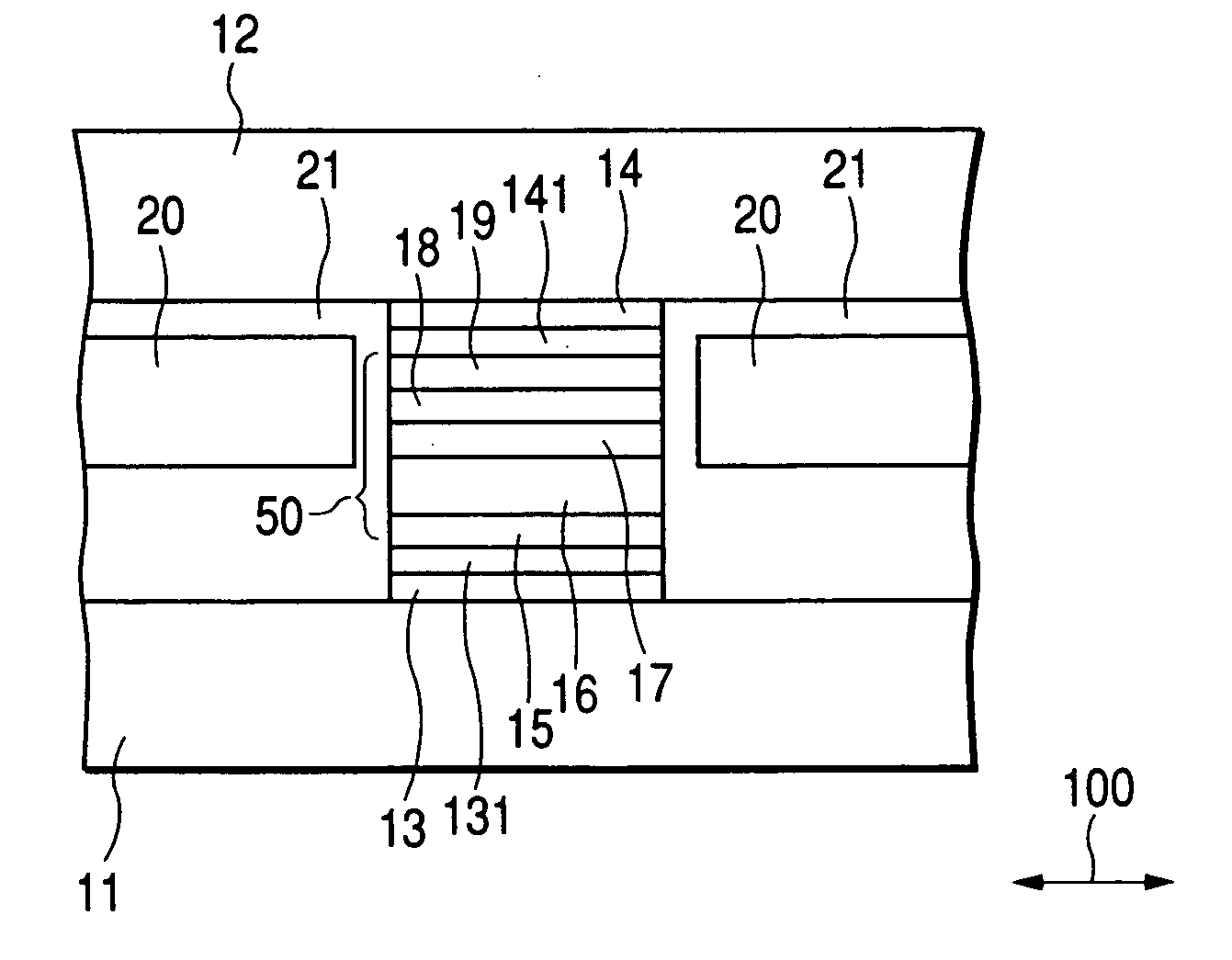

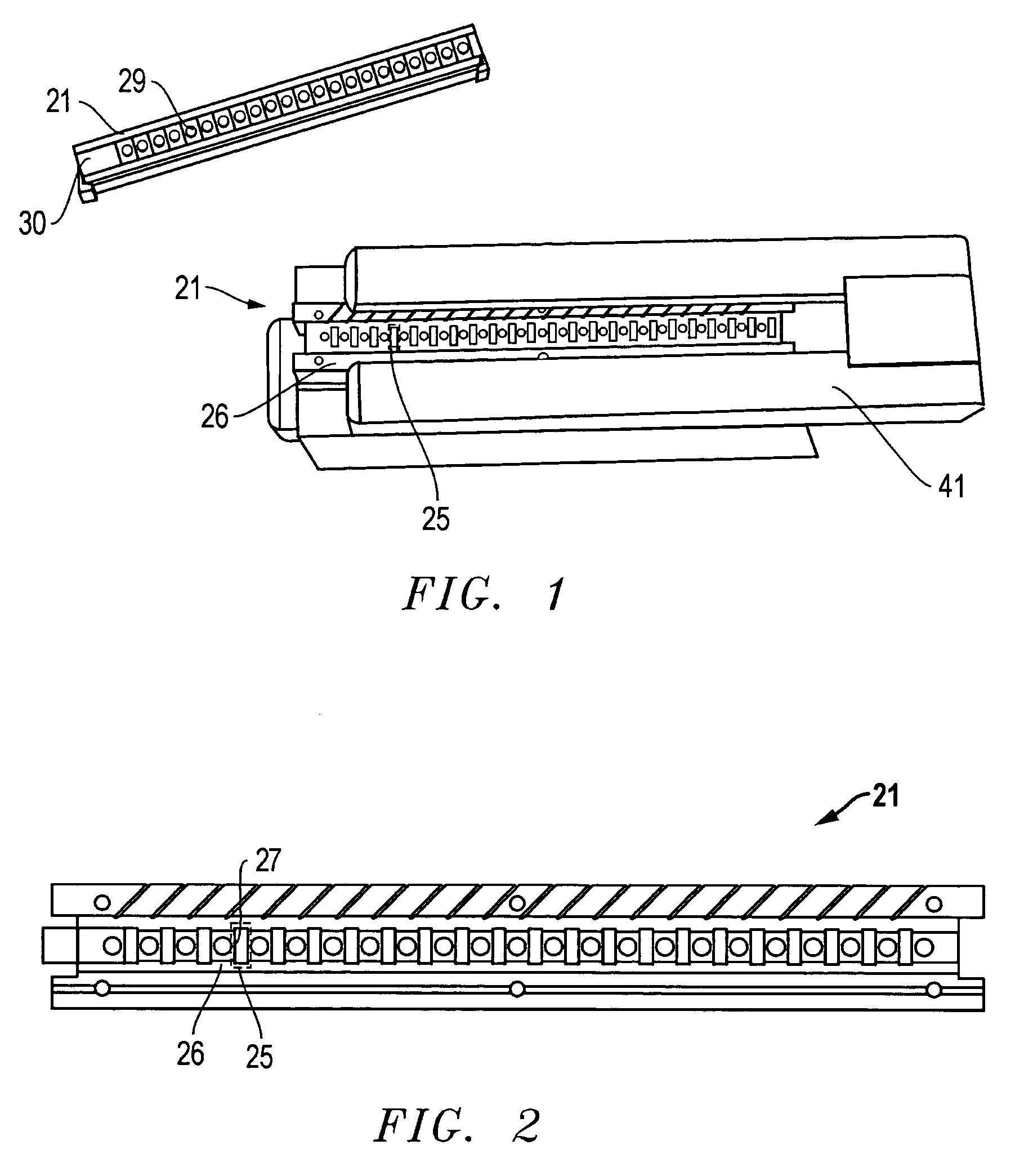

Multi-channel thin-film magnetic head, magnetic tape drive apparatus with the multi-channel thin-film magnetic head and manufacturing method of multi-channel thin-film magnetic head

InactiveUS20100149685A1Smooth rideStable travelManufacturing heads with multiple gapsDecorative surface effectsTectorial membraneMagnetic tape

Owner:TDK CORPARATION

Negative thermal expansion dielectrics for thermal pole tip protrusion compensation

InactiveUS7102853B2Low deposition rateEasy to controlConstruction of head windingsHeads using thin filmsDielectricTransducer

A slider having a magnetic read / write head and including, a base coat, a reader element having a transducer, a writer element, the writer element including at least one conductive coil, the coil being electrically insulated by a composition which has a negative coefficient of thermal expansion, and an overcoat.

Owner:SEAGATE TECH LLC

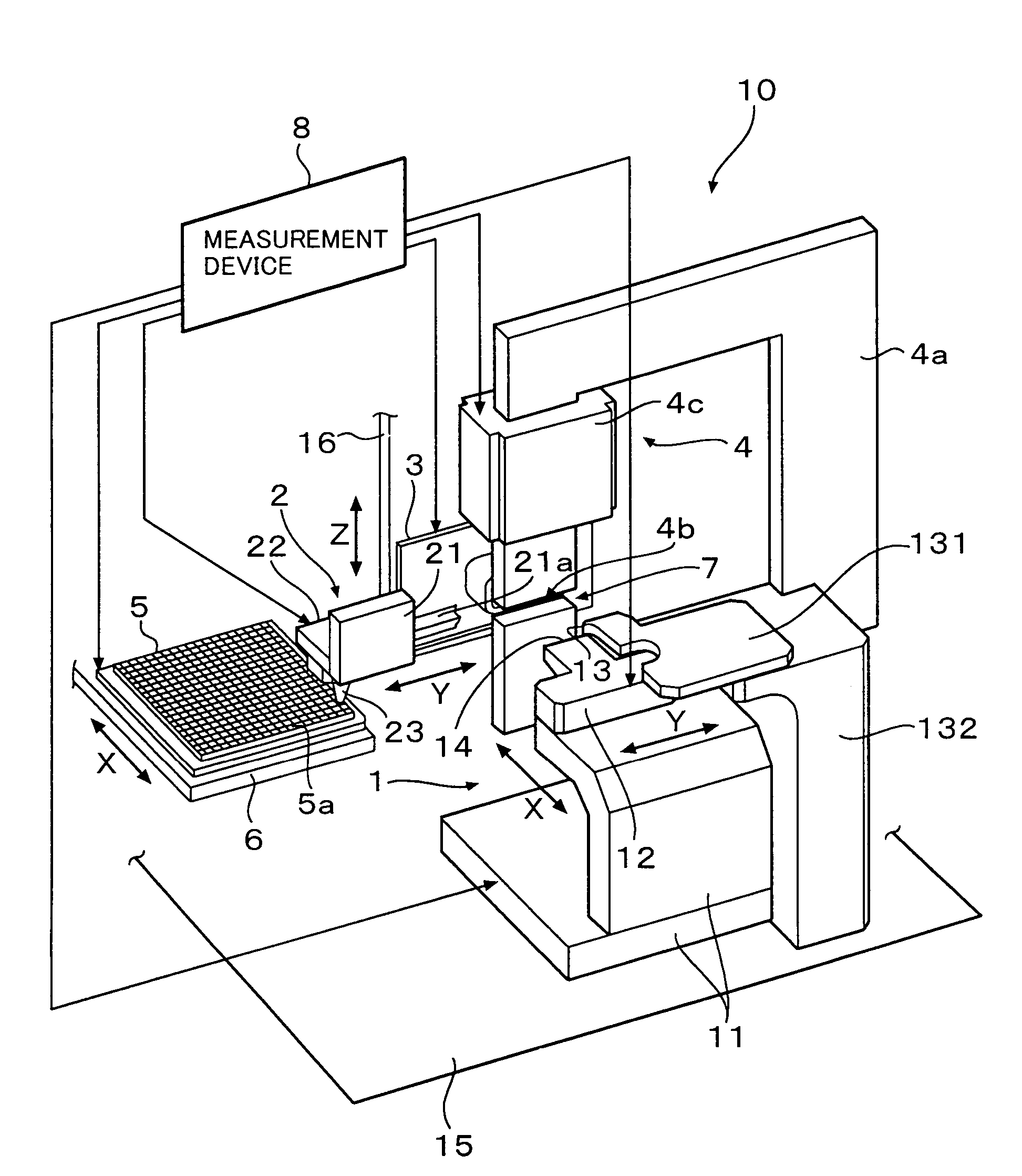

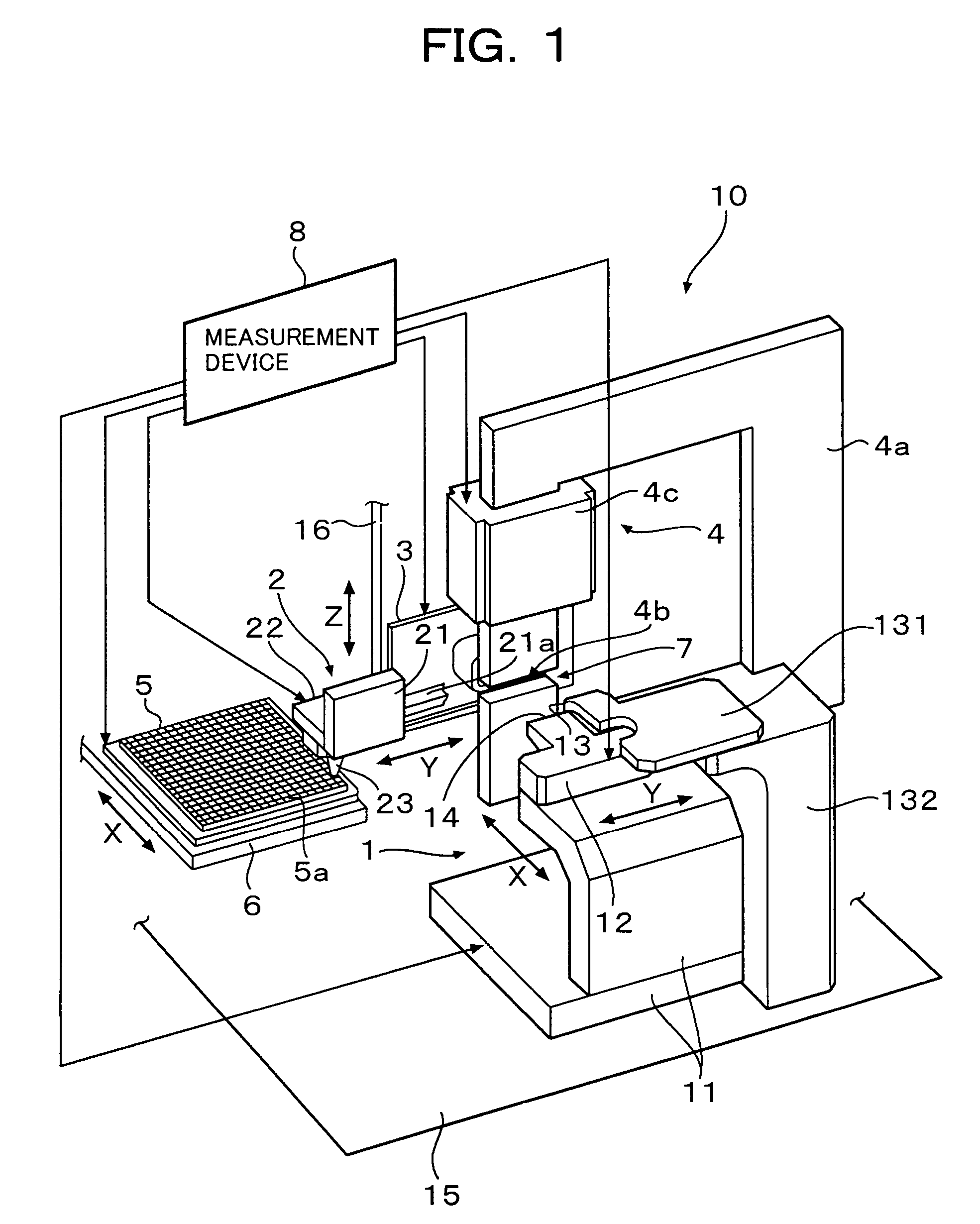

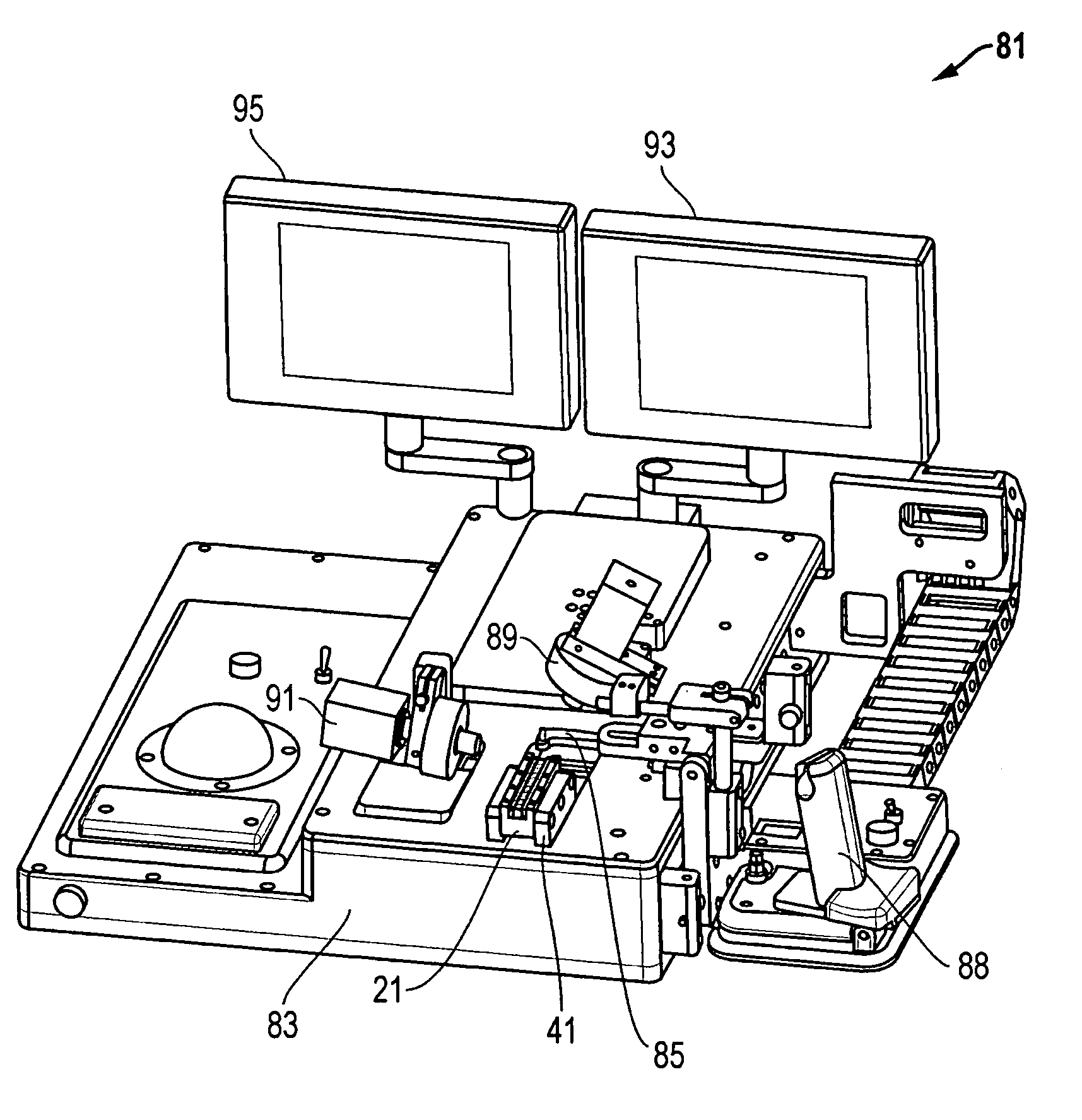

Magnetic head slider testing apparatus and magnetic head slider testing method

ActiveUS7355393B2Suppress leakageRecord information storageMagnetic property measurementsEngineeringInductance

Owner:HITACHI HIGH-TECH CORP

Magnetic head and magnetic recording/reproducing system

InactiveUS20060109592A1High yieldIncrease productionNanomagnetismNanoinformaticsShear modulusMagnetic reluctance

A high output, magnetoresistive head with a CPP structure is disclosed which reduces or prevents deformation near the air bearing surface of the read element portion layer at the time of air bearing surface processing. In the CPP structure magnetoresistive head, the deformation near the air bearing surface as a result of mechanical polishing during the air bearing surface processing can be reduced by forming deformation prevention layers having a higher shear modulus than the first ferromagnetic layer, and a second ferromagnetic layer between a magnetoresistive film and at least one of a lower shield layer and an upper shield layer.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Slider with bonding pads opposite the air bearing surface and method for producing the same

InactiveUS20060044689A1Reduce eliminateElectrical connection between head and armRecord information storageBonding processEngineering

A slider having bonding pads opposite an air bearing surface and a method for producing the same is disclosed. Bonding pads are formed on the side of a slider assembly opposite the air bearing surface (ABS) to allow electrical probing devices on the slider while applying pressure to the slider during the lapping process and to allow a flip chip bonding process of the slider to the suspension thereby reducing or eliminating the need to bend wires and attach to the end of the slider body.

Owner:WESTERN DIGITAL TECH INC

Method for reducing pole and alumina recession on magnetic recording heads

InactiveUS6949004B1Reduced magnetic spacing lossReduce pollutionNanomagnetismNanoinformaticsDiamond-like carbonTransducer

A manufacturing process for reducing magnetic spacing loss in a magnetic recording head. The recession of the transducer relative to the substrate at the air bearing surface is decreased by applying a coating of sacrificial material such as diamond-like carbon to the upper surfaces of the substrate, the transducer, and the encapsulation material such as alumina prior to final kiss lapping. The recession due to the alumina being softer than the substrate is greatly reduced since the DLC is kiss-lapped.

Owner:MAXTOR

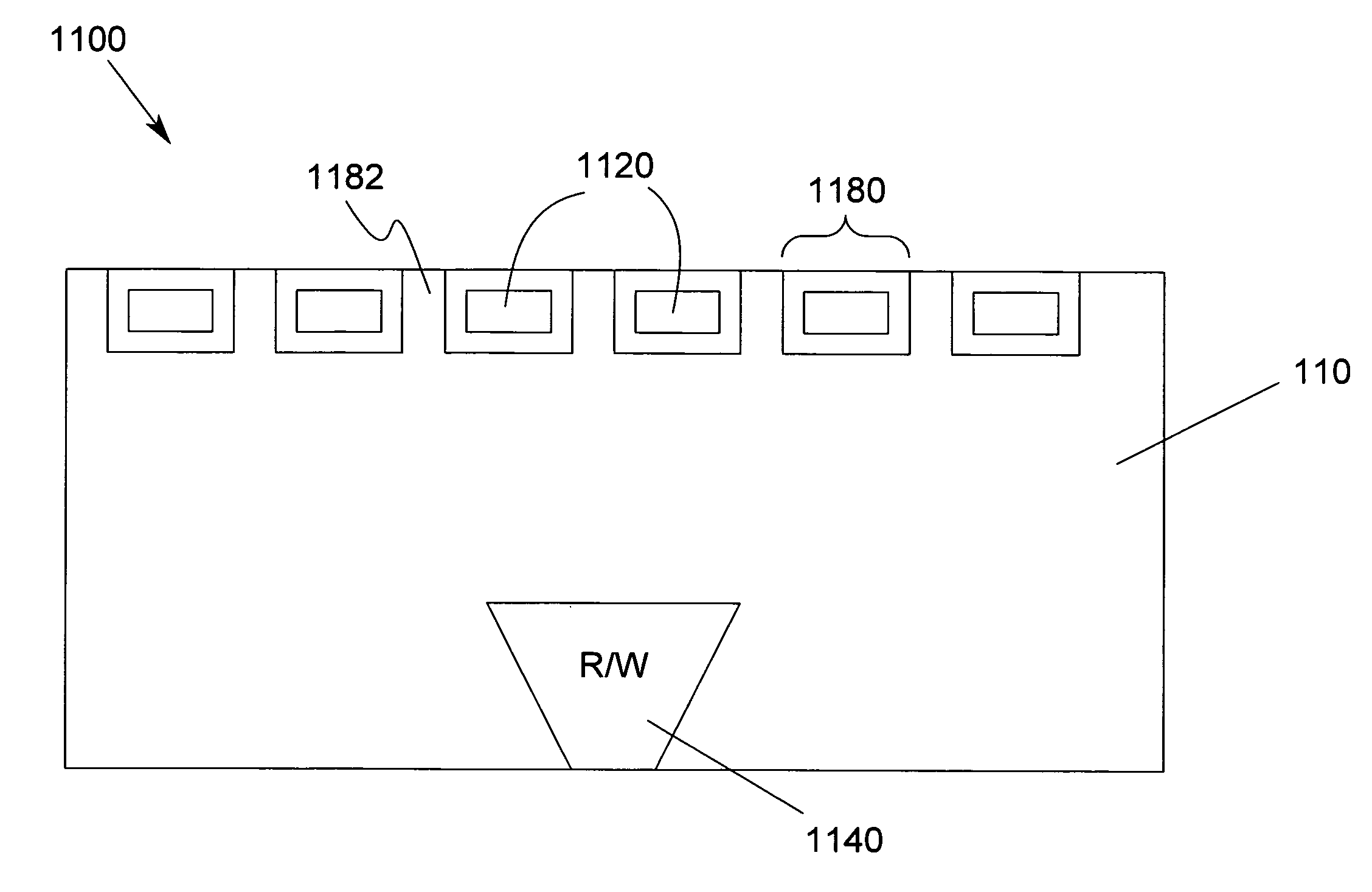

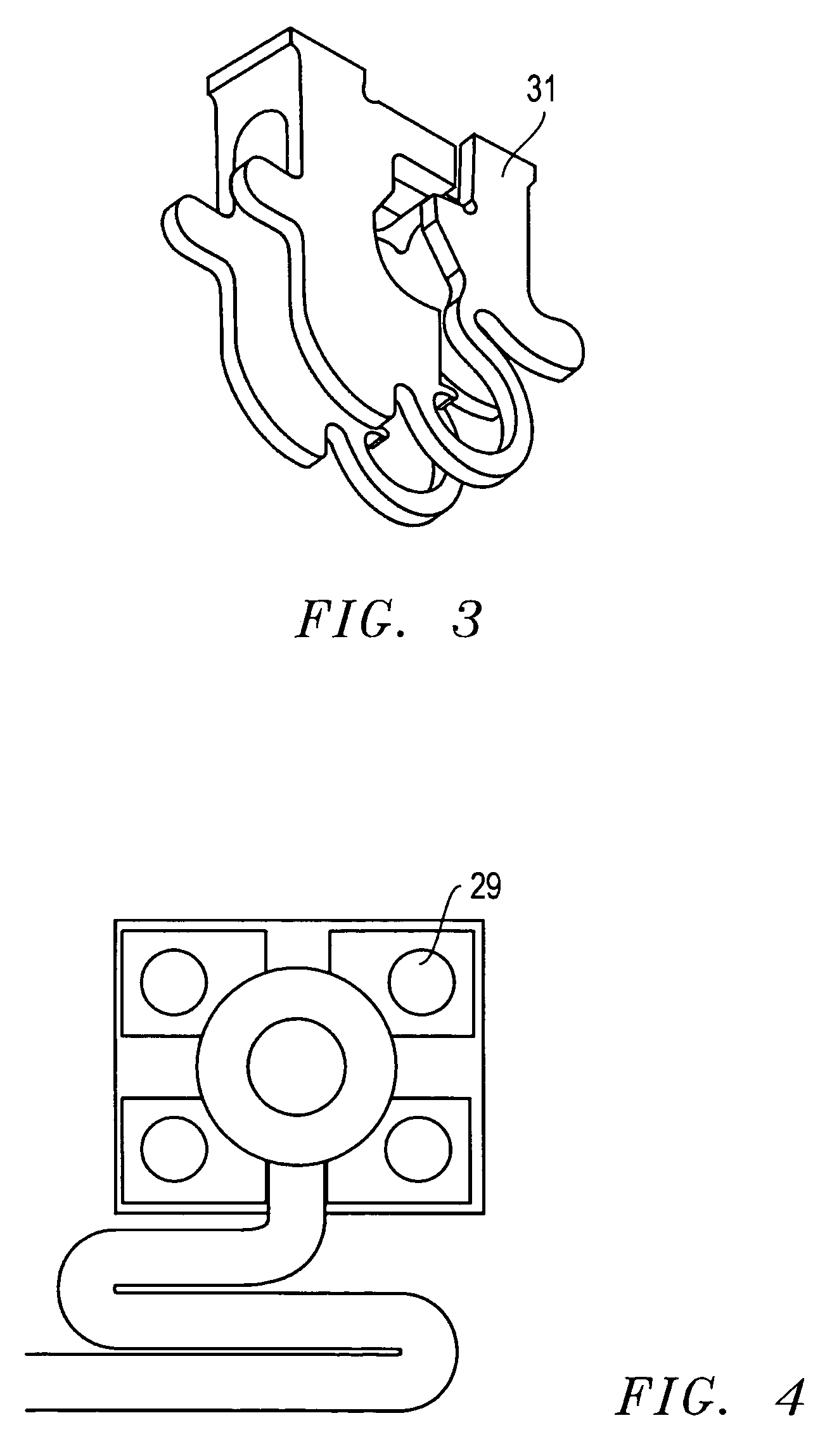

System, method, and apparatus for handling and testing individual sliders in a row-like format in single slider processing systems

InactiveUS7049809B2Avoid damageEasy dischargeElectronic circuit testingRecord information storageElectricityEngineering

A device for handling and testing individual sliders in a row-like format utilizes an elongated, row-like holder having a series of small pockets, each of which receives a single slider. After the sliders enter the holder, a clamp is moved to a closed position to retain the sliders in the holder. The holder is placed in a test fixture such that permanently mounted probes precisely engage the small pads on the sliders for multiple testing purposes. Enlarged probe pads on the test fixture are electrically interconnected with the probes to provide an operator with easy access to the slider pads. The sliders are tested in a row-like format, side by side, to reduce handling-induced electrostatic discharge and mechanical damage.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Popular searches

Manufacture unitary devices of plural heads Manufacture of flux-sensitive heads Mounting head within housing Optical articles Galvano-magnetic device manufacture/treatment Thin material handling Casings/cabinets/drawers details EMI or RFI carrier shielding Hermetically-sealed casings Cooling/ventilation/heating modifications

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com