Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74 results about "Thermosipho" patented technology

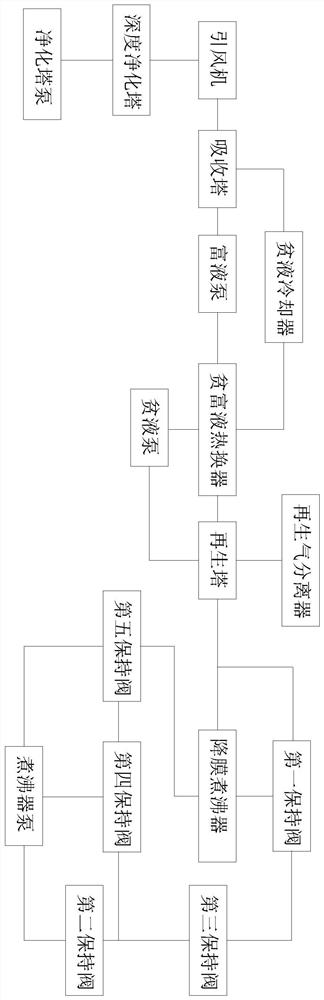

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosiphon (or thermosyphon) is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces.

Thermo siphon chiller refrigerator for use in cold district

InactiveUS20050284169A1Mechanical apparatusCompression machines with non-reversible cycleIceboxProcess engineering

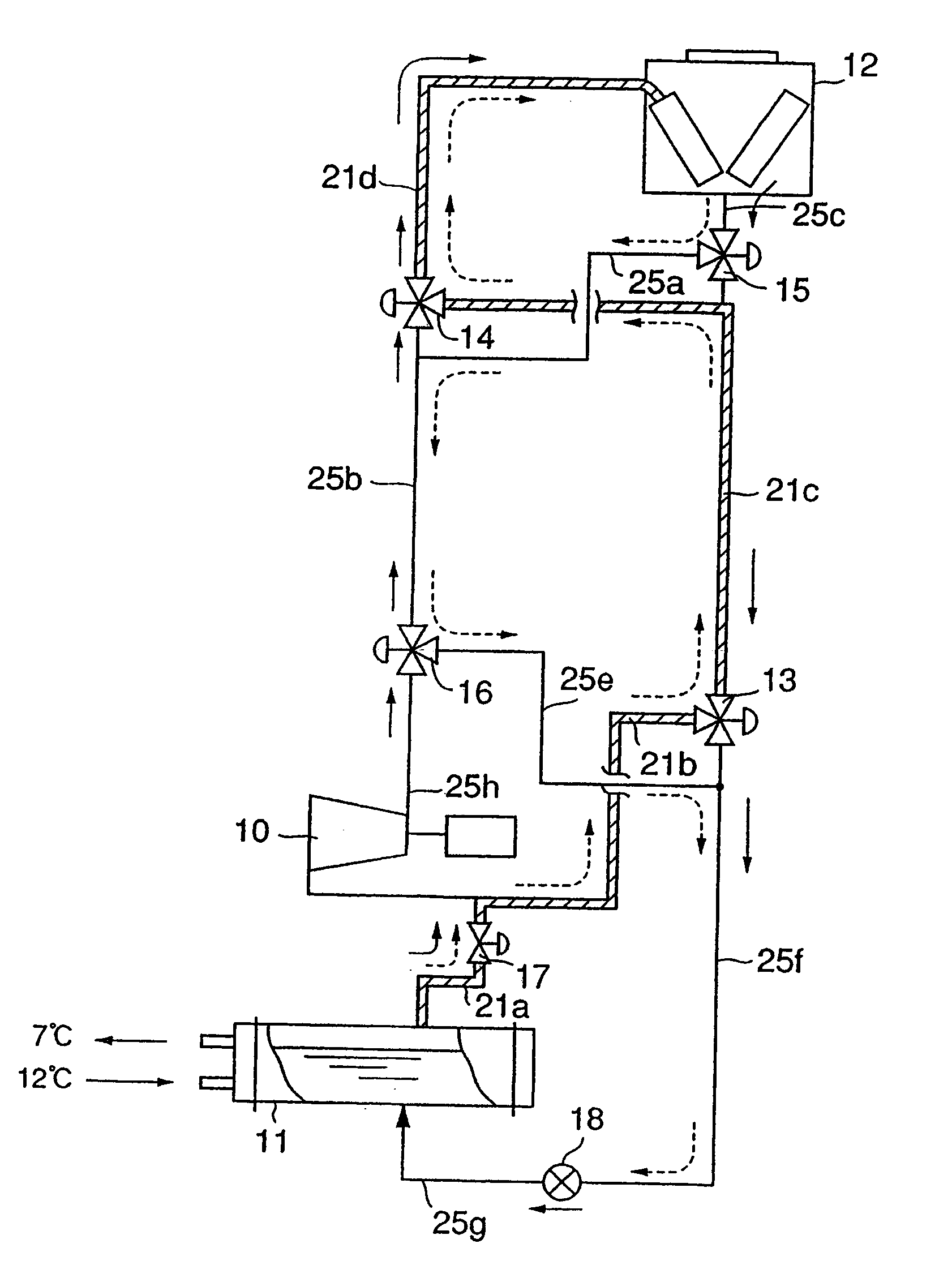

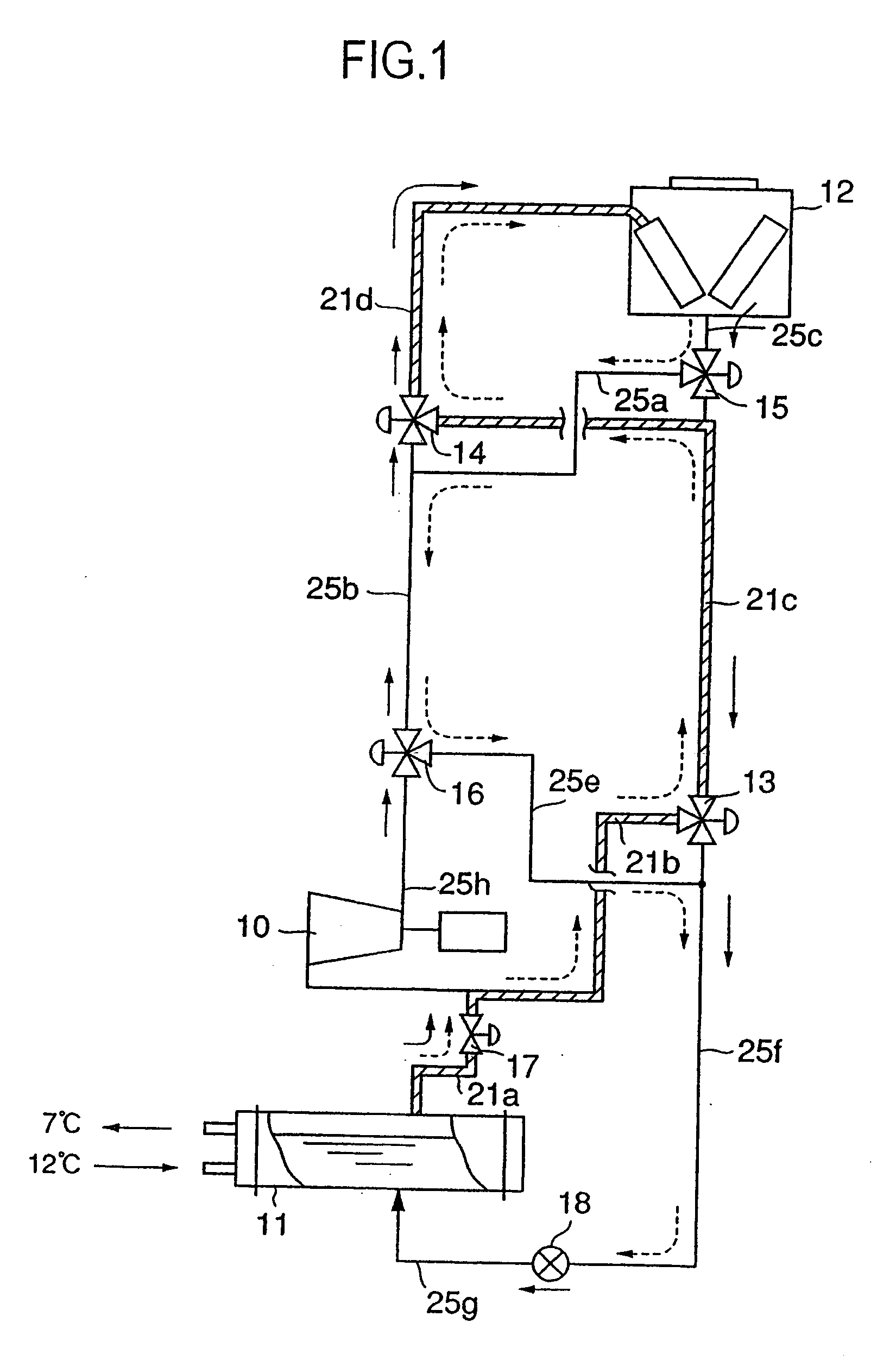

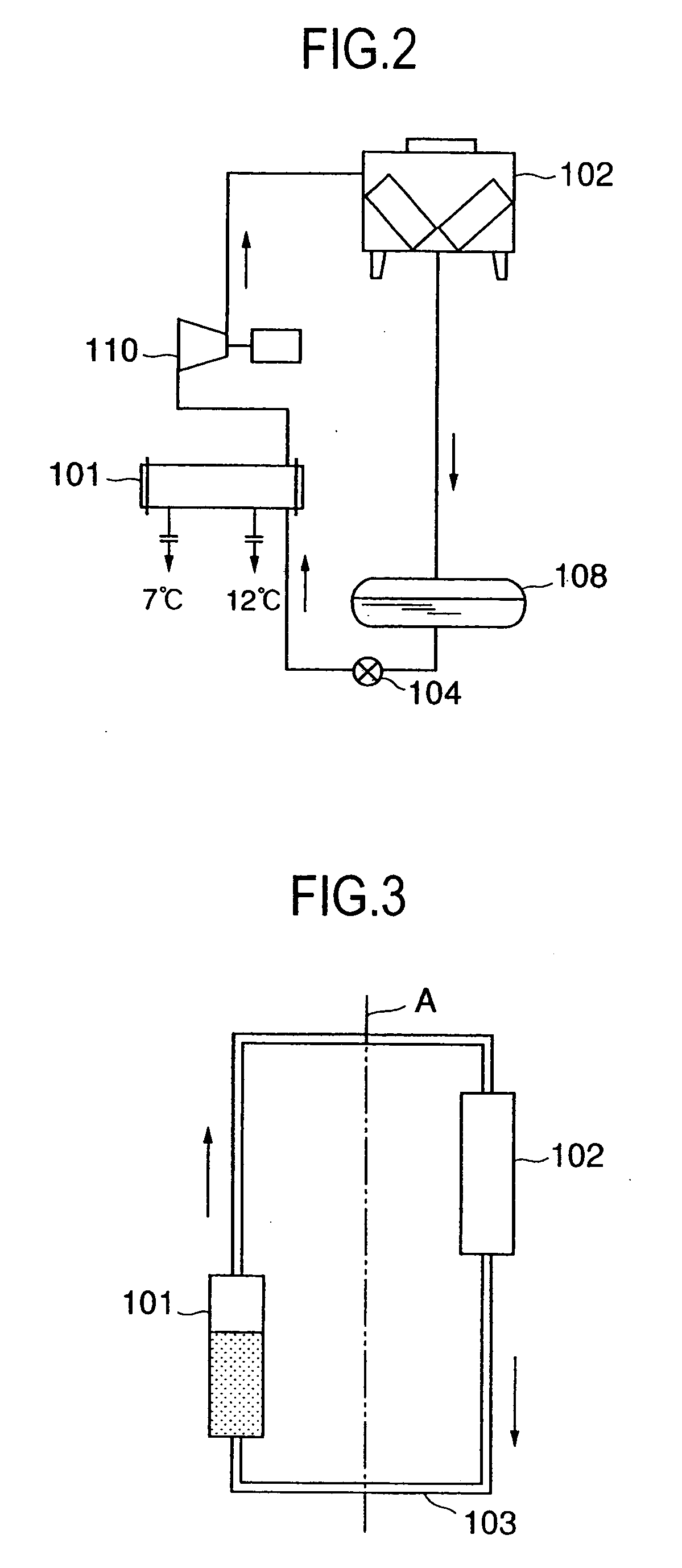

In order to provide a thermo-siphon chiller refrigerator for use in cold districts which performs natural refrigerant-circulation refrigerating cycle and also can perform a forced refrigerant-circulation refrigerating cycle when outside air temperature is high by using an indoor heat exchanger, an outdoor heat exchanger, and a compressor, and combining them with refrigerant piping, the thermo-siphon chiller refrigerator for use in cold districts of the invention has a compressor (10) additionally installed to a natural refrigerant-circulation refrigerating system comprising an outdoor heat exchanger (12), an indoor heat exchanger (11) located at a position lower than that of the outer heat exchanger (12), and an expansion valve (18). When the refrigerating capacity of the natural refrigerant circulation refrigerating system is not sufficient, the additional compressor (10) is operated to perform a forced refrigerant-circulation cycle i.e. a vapor compression refrigerating cycle.

Owner:MAYEKAWA MFG CO LTD

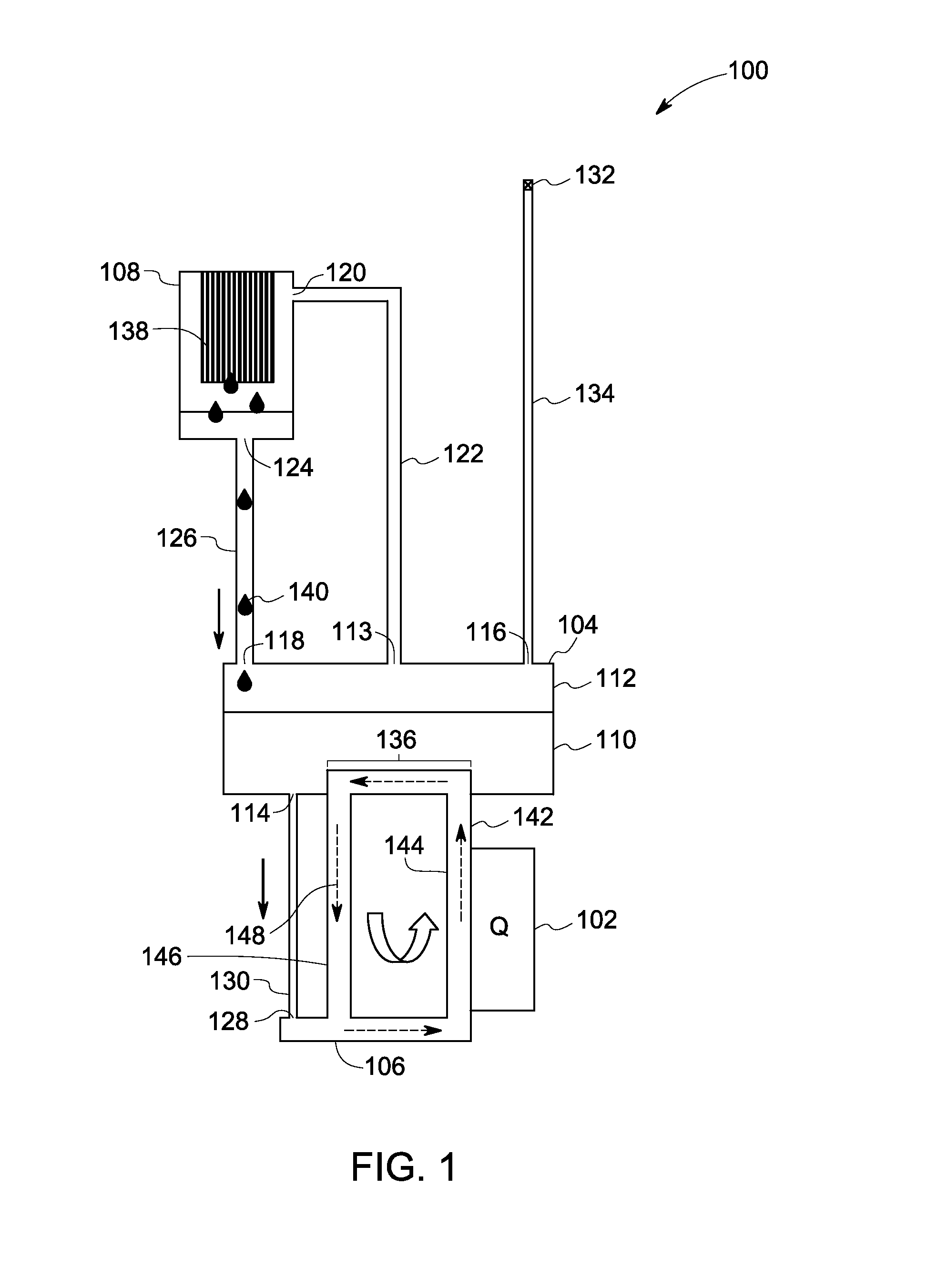

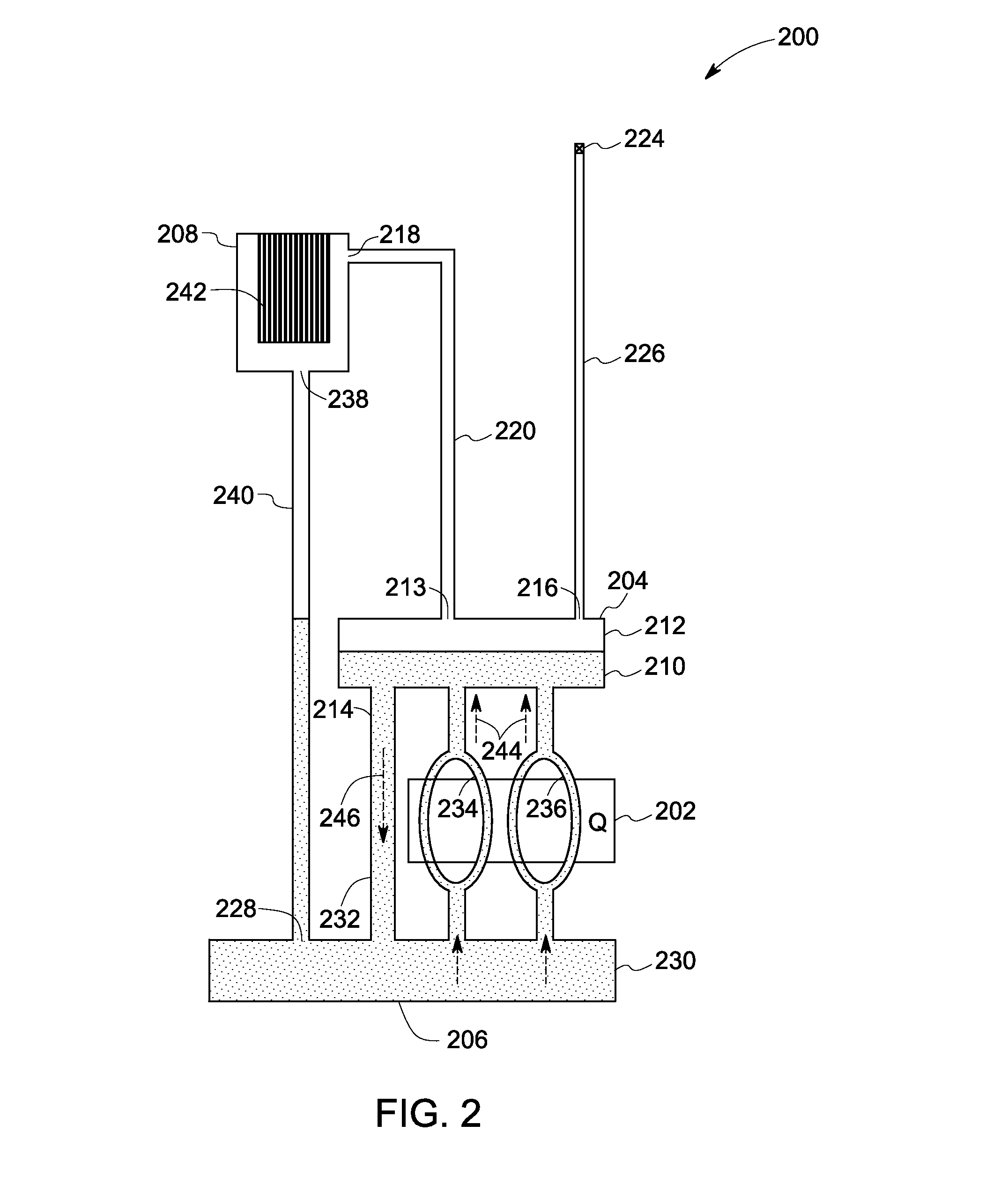

Thermosiphon cooling system and method

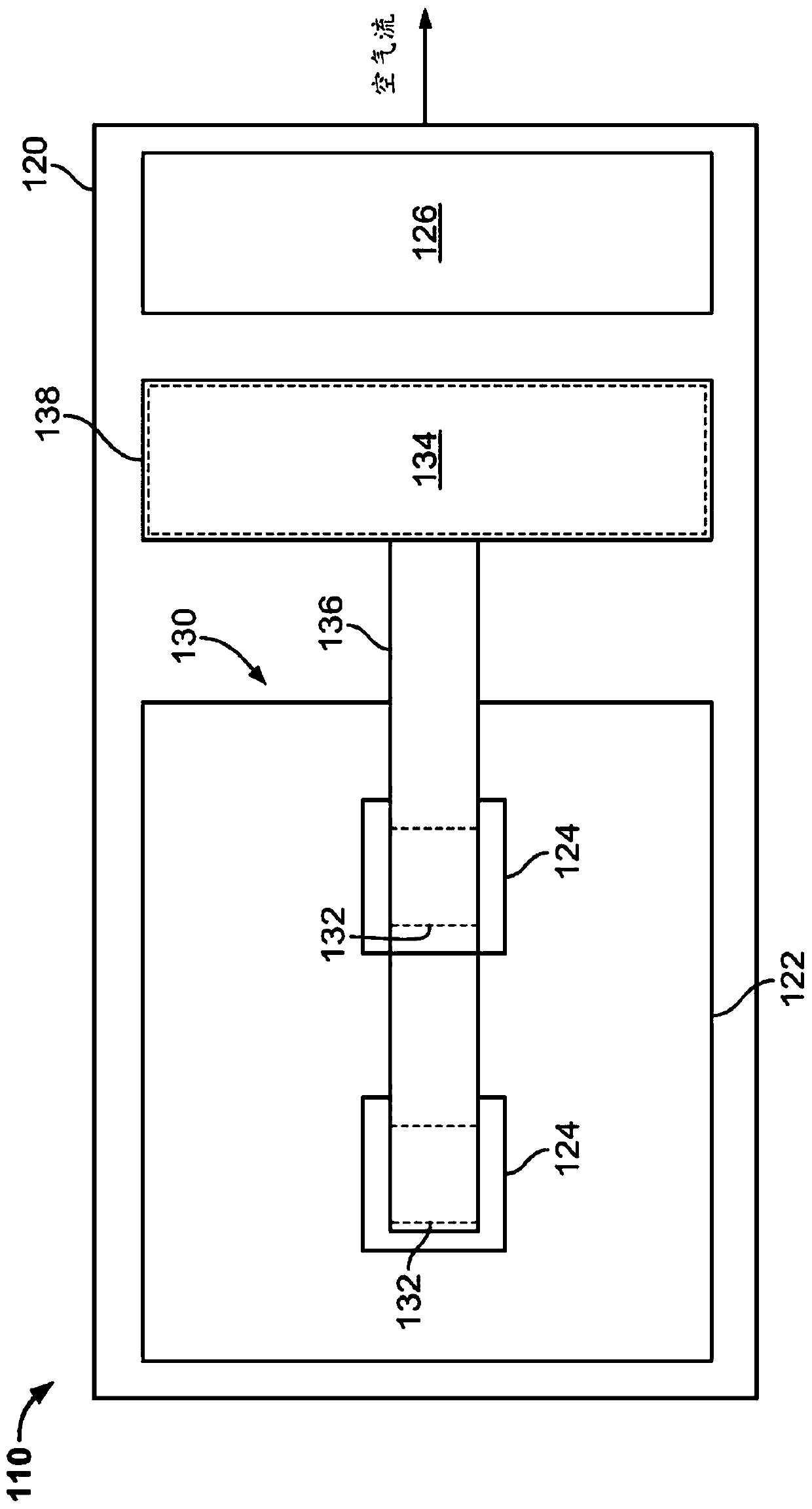

ActiveUS20130160975A1Magnetic measurementsSolid-state devicesNuclear engineeringVolumetric Mass Density

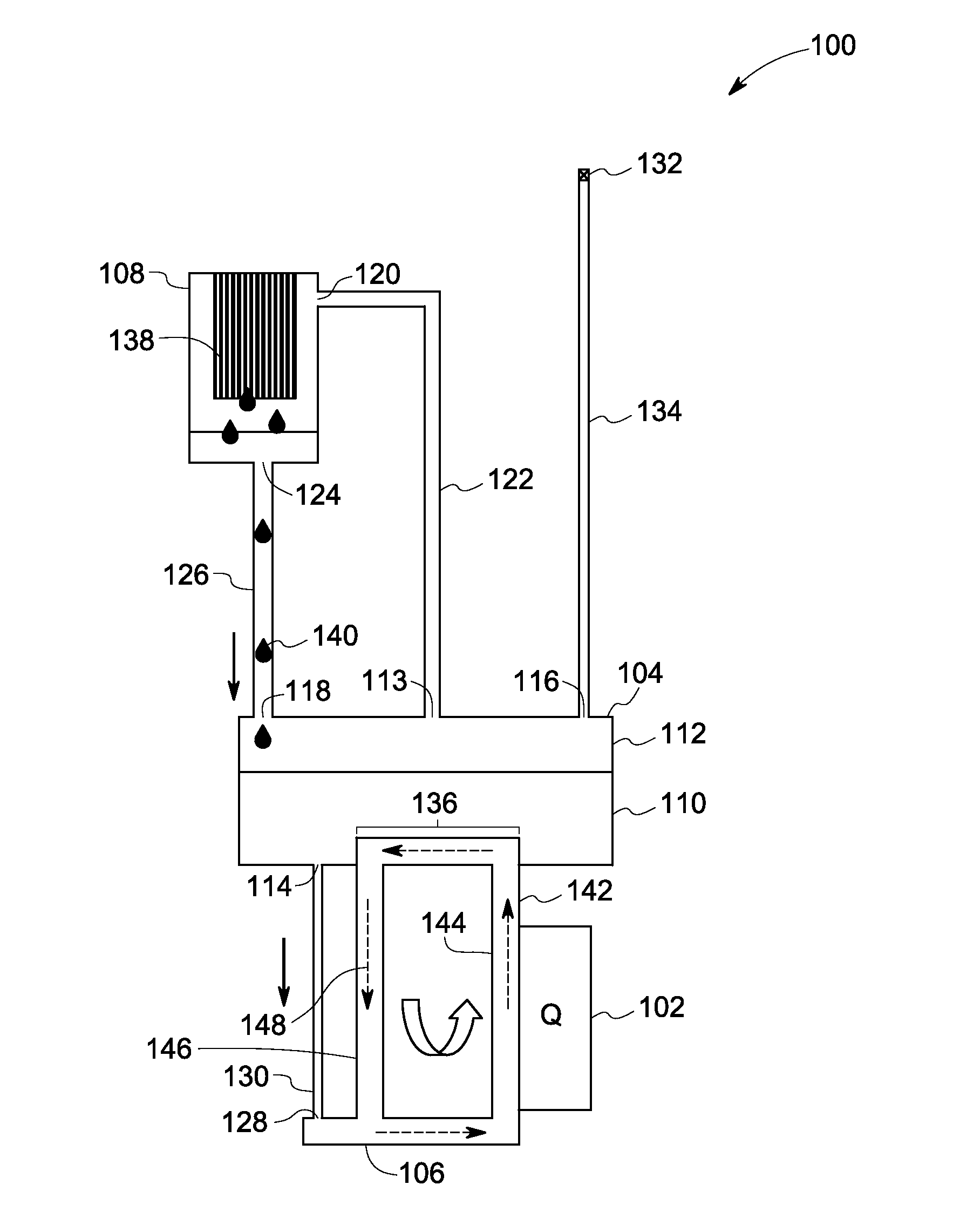

A thermosiphon cooling system is presented. One embodiment of the thermosiphon cooling system includes a reservoir having a first portion configured to store a liquid coolant. The thermosiphon cooling system also includes a tubing unit coupled to the reservoir and disposed adjacent to at least one superconducting unit to be cooled and configured to receive the liquid coolant from the first portion of the reservoir, and circulate the received liquid coolant within the tubing unit to dissipate heat generated by the at least one superconducting unit. The received liquid coolant is circulated within the tubing unit by varying a density of the received liquid coolant at different portions of the tubing unit.

Owner:GENERAL ELECTRIC CO

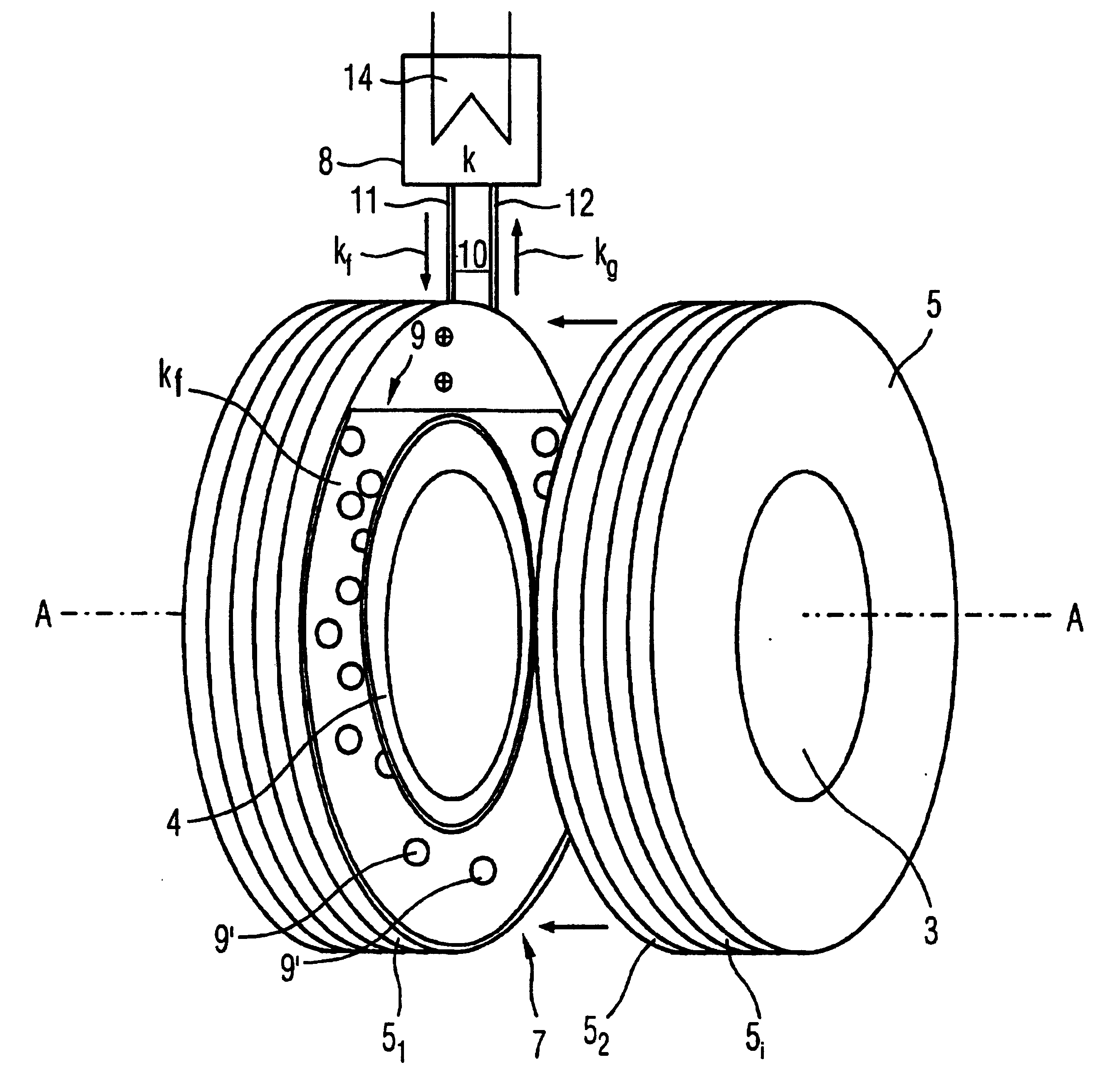

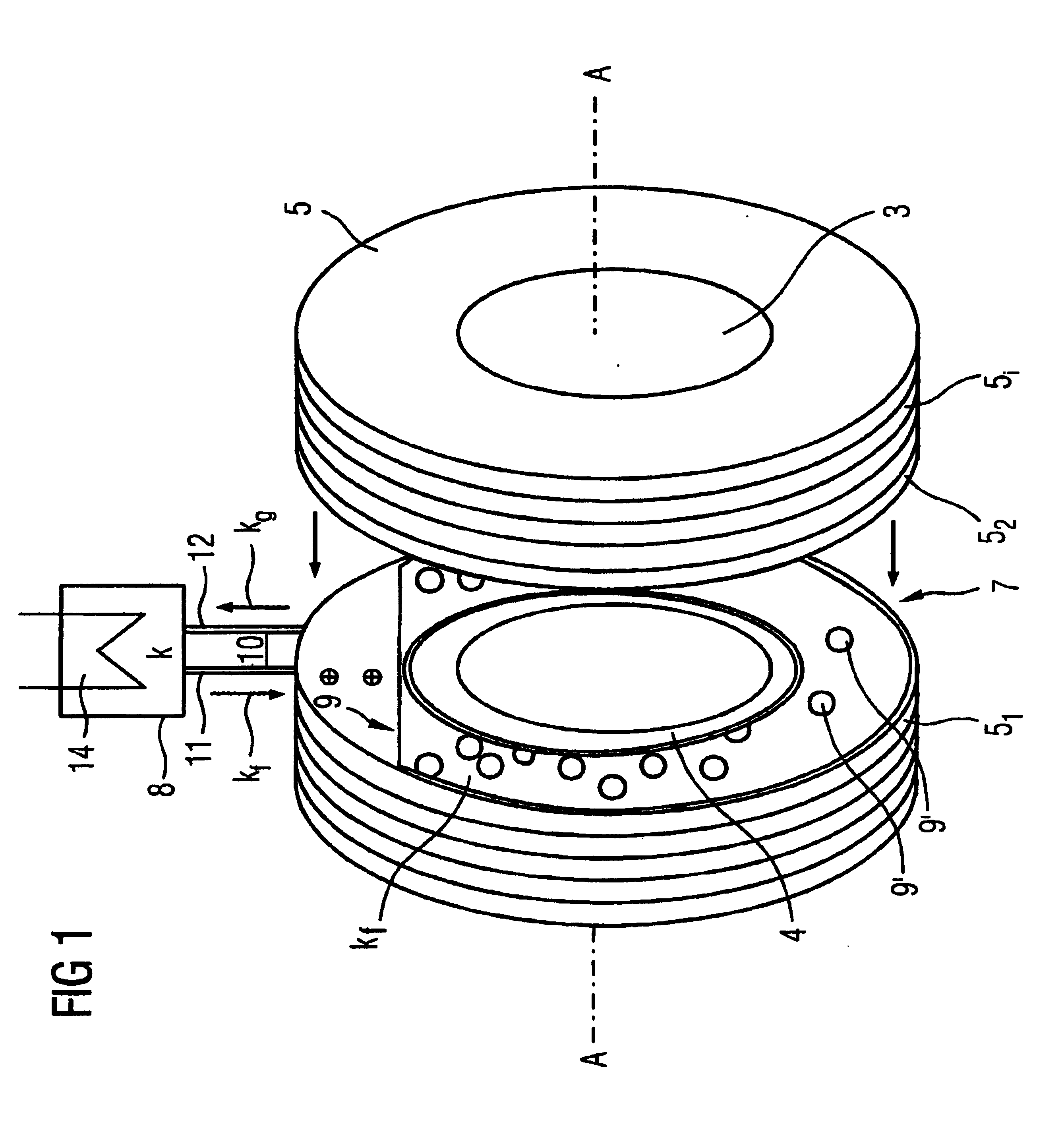

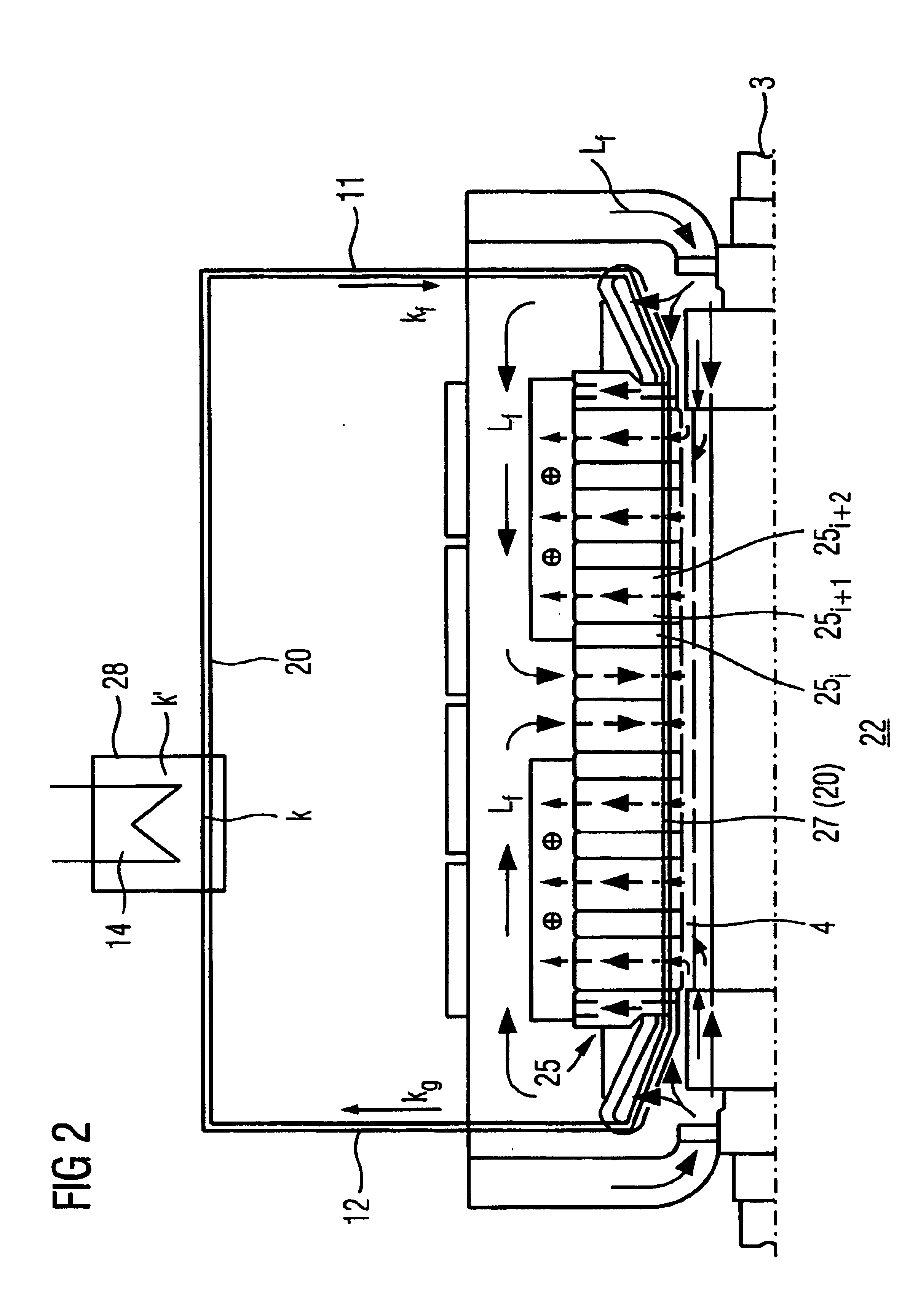

Electric motor comprising a stator cooling unit

InactiveUS20050156470A1Simple processReduce air volumeManufacturing dynamo-electric machinesIndirect heat exchangersEngineeringThermosipho

A fixed stator is arranged around a rotatably mounted rotor in an electric motor that includes at least one cooling unit to which parts of the stator which are to be cooled are thermally coupled by a line system in which a cooling agent circulates according to a thermosyphon effect. The stator parts to be cooled can be arranged in the inner region of a stator housing which is integrated into the line system. The electric motor can be provided with a heating device to maintain the pressure in the inner region when the motor is stopped.

Owner:SIEMENS AG

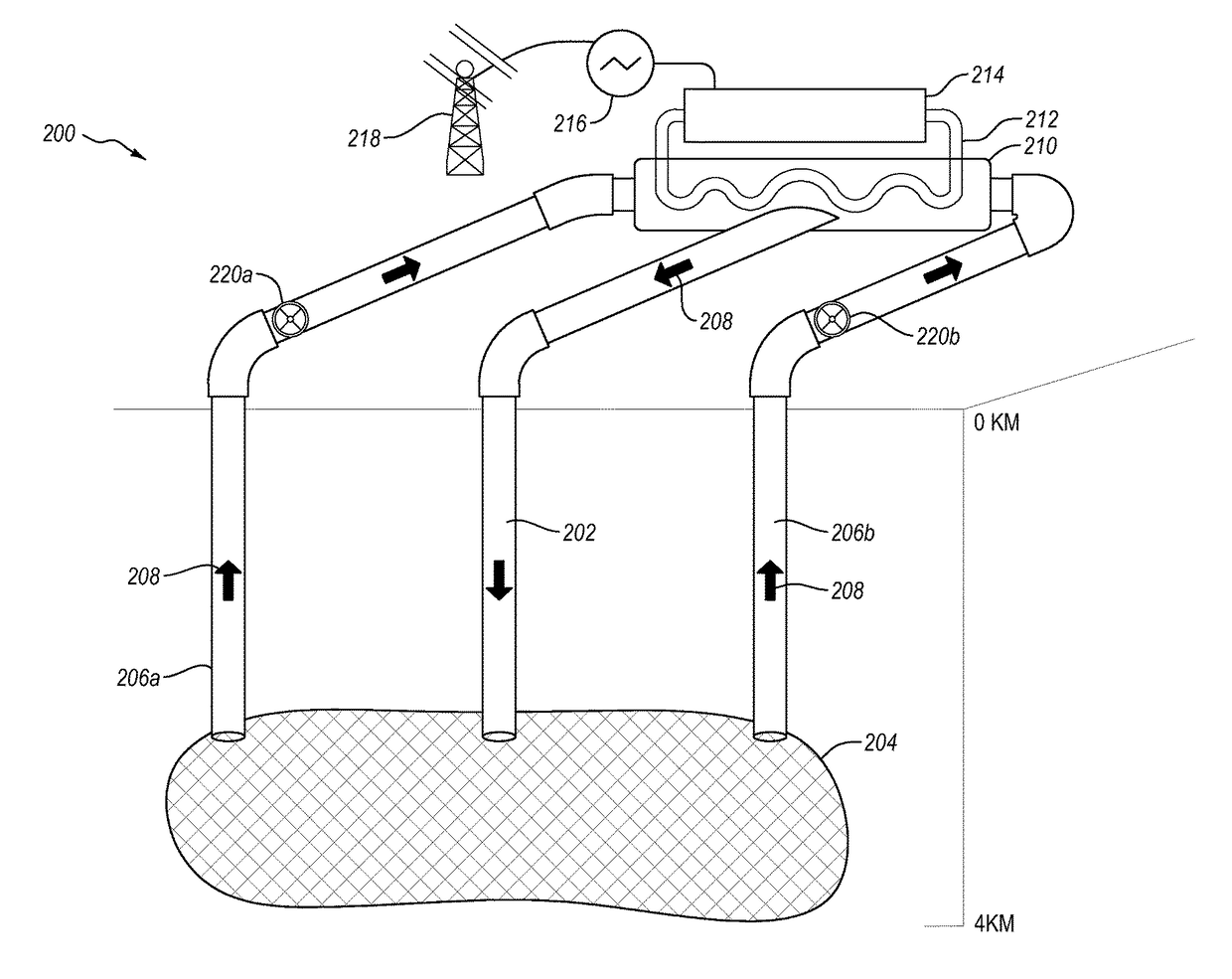

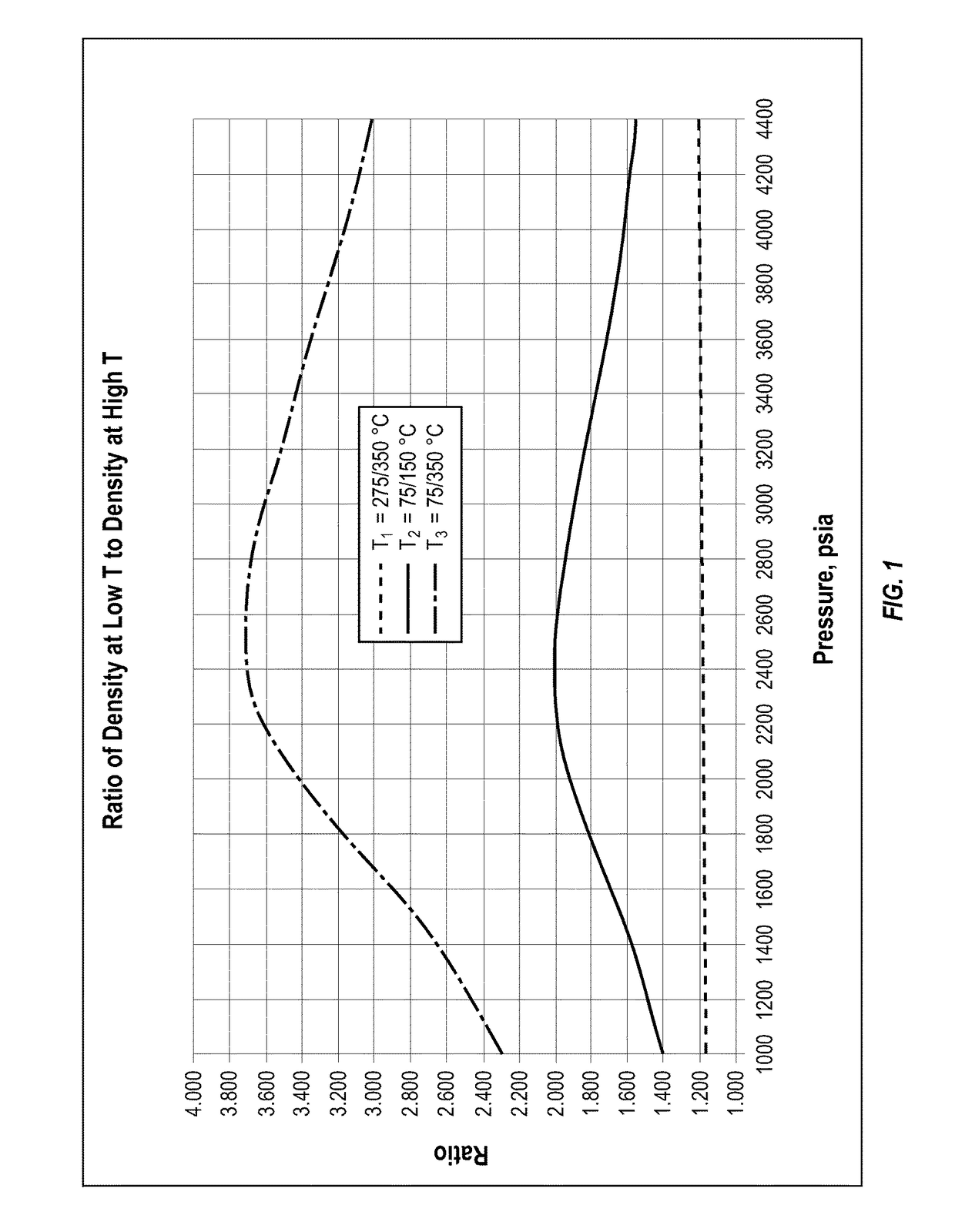

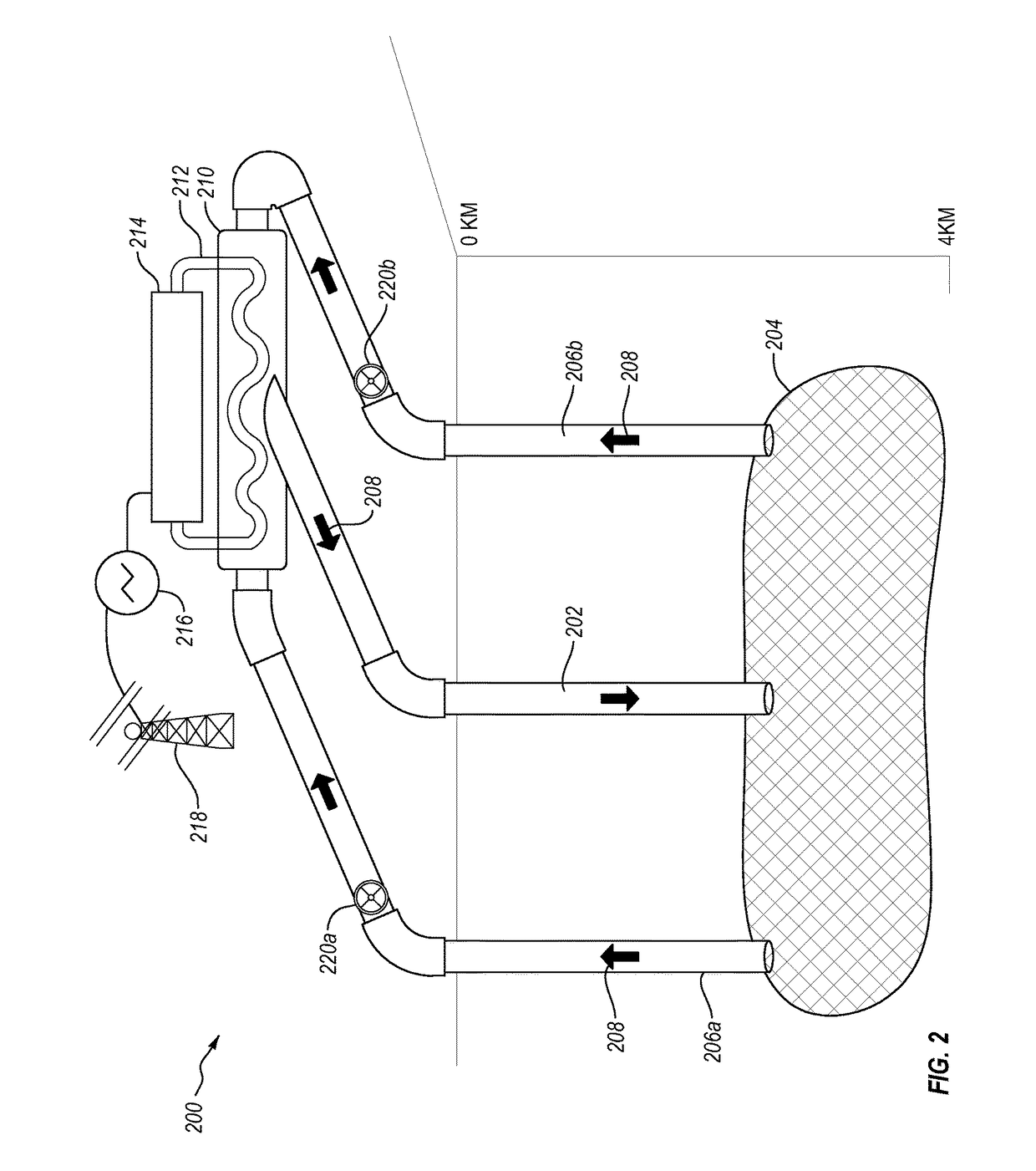

Thermosiphoning supercritical CO2 in geothermal energy production

ActiveUS9803626B1Minimize and eliminate needThermosiphoning is maximizedOther heat production devicesGeothermal energy generationInjection wellGeothermal energy

Methods for thermalsiphoning supercritical CO2 within a geothermal formation includes providing a geothermal energy system that includes an underground hot rock reservoir, a production well, and an injection well that together form a fluid path suitable for circulating supercritical CO2. The supercritical CO2 flows by thermosiphoning. Thermosiphoning is maximized by maintaining a pressure between 1400-4000 psia, an injection temperature in a range from 50-200 C and a production temperature in a range from 150-600 where injection temperature and the production temperature differ by at least 50° C.

Owner:GREENFIRE ENERGY

Thermosyphon Heat Recovery

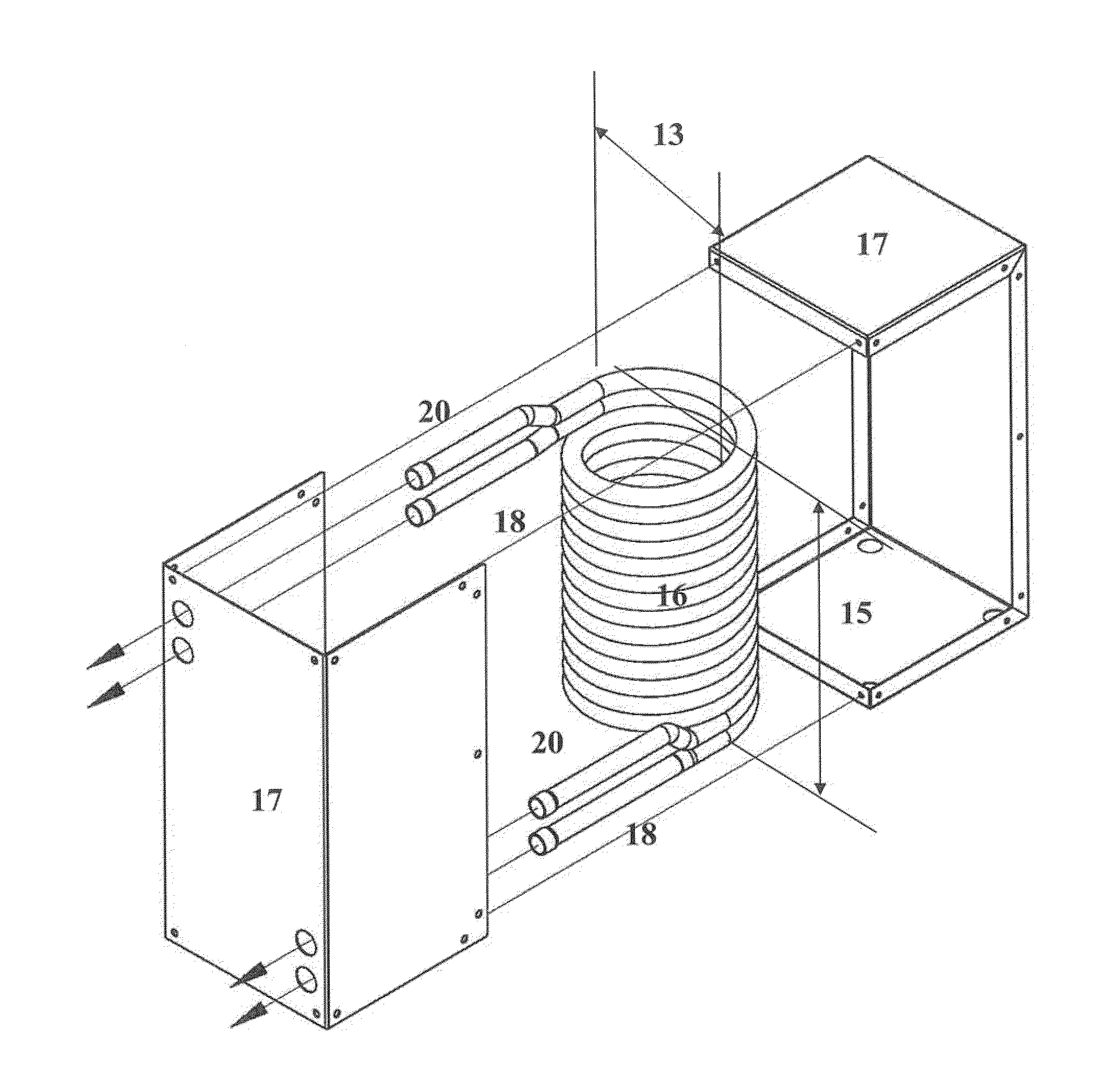

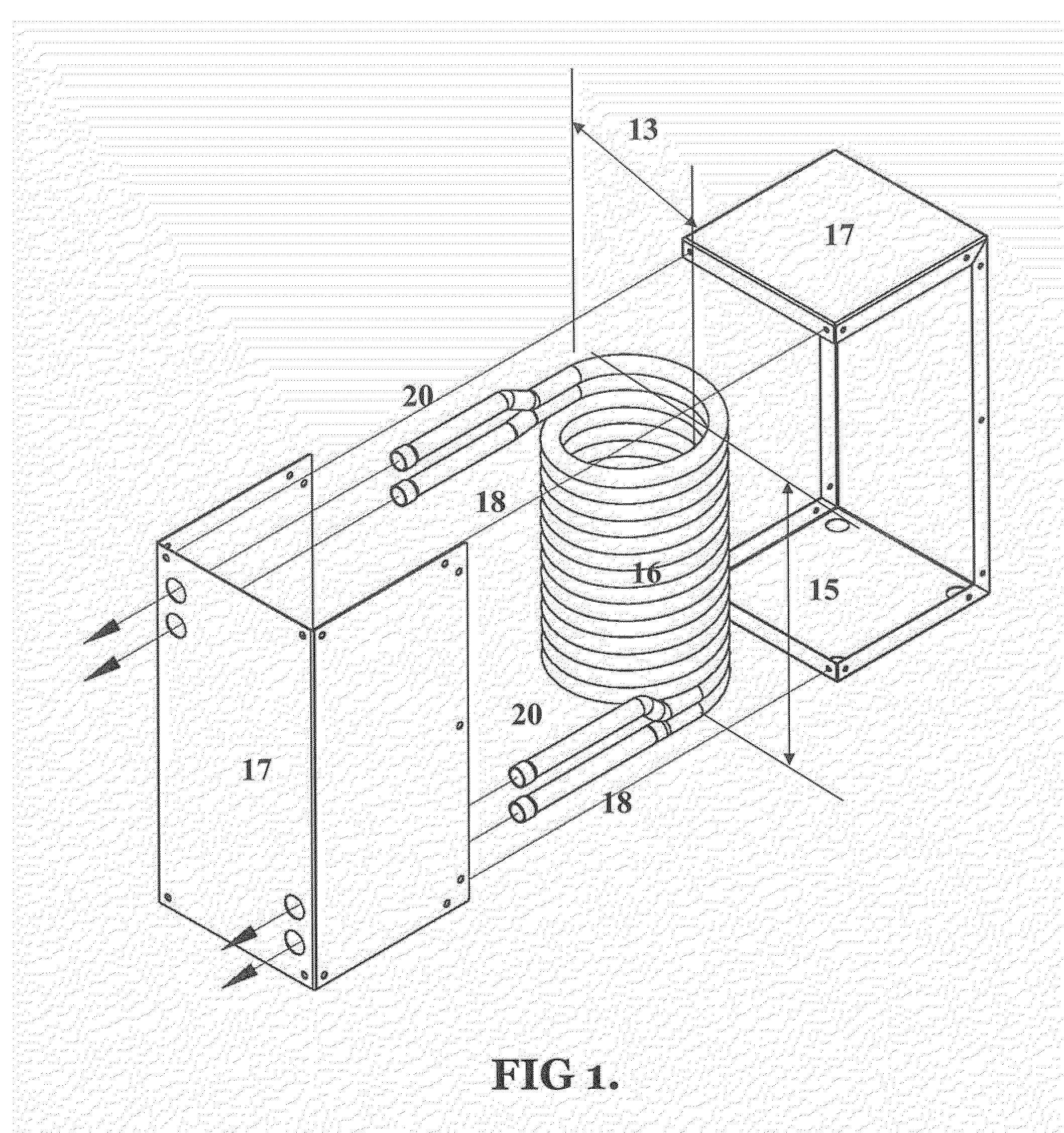

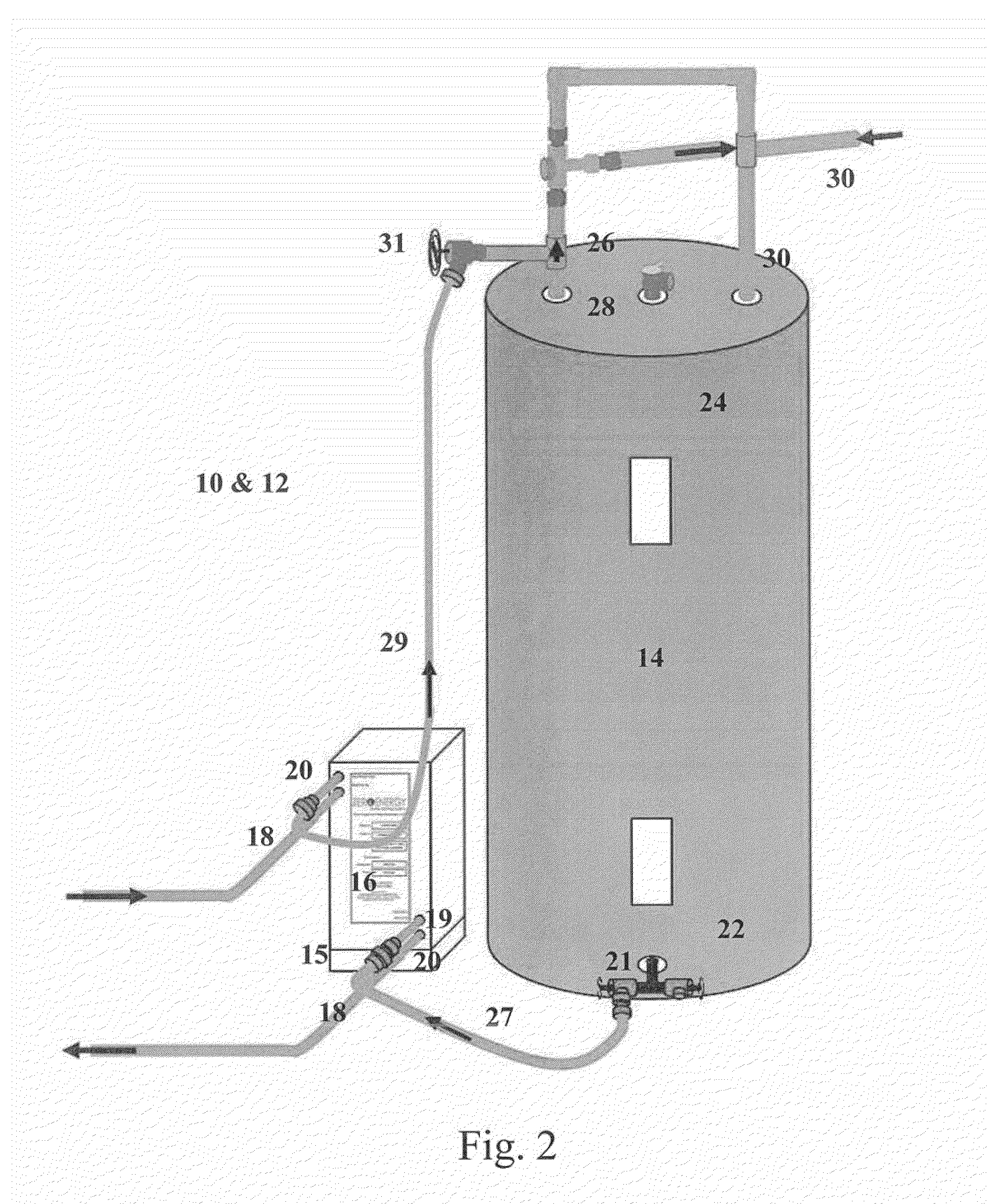

ActiveUS20120261102A1Easy to installEasy to mergeFluid heatersHeat recovery systemsEngineeringRefrigerant

A thermosyphonic heat recovery unit for thermosyphonic heat transfer of heat from a hotter first fluid to a cooler second fluid comprising a heat exchanger including a first fluid conduit and a second fluid conduit, optimized means for connecting fluids to the two conduits to optimize heat transfer and fluid flow, a pressurized cold fluid input and hot fluid output, whereby the second fluid thermosyphonically flows through said second conduit as the first fluid flows through said first conduit. Said system having an optimized heat exchanger tube-on tube spirally wound, with wind direction to take advantage of the Coriolus force effect, for optimized refrigerant and other fluid turbulence and therefore optimized heat transfer, and optimum location of said heat exchanger and sizes of connecting tubes to minimize refrigerant friction related pressure loss, and to optimize heat transfer, refrigerant flow and thermosyphonic second fluid flow through said heat exchanger.

Owner:OLIVE TREE PATENTS 1

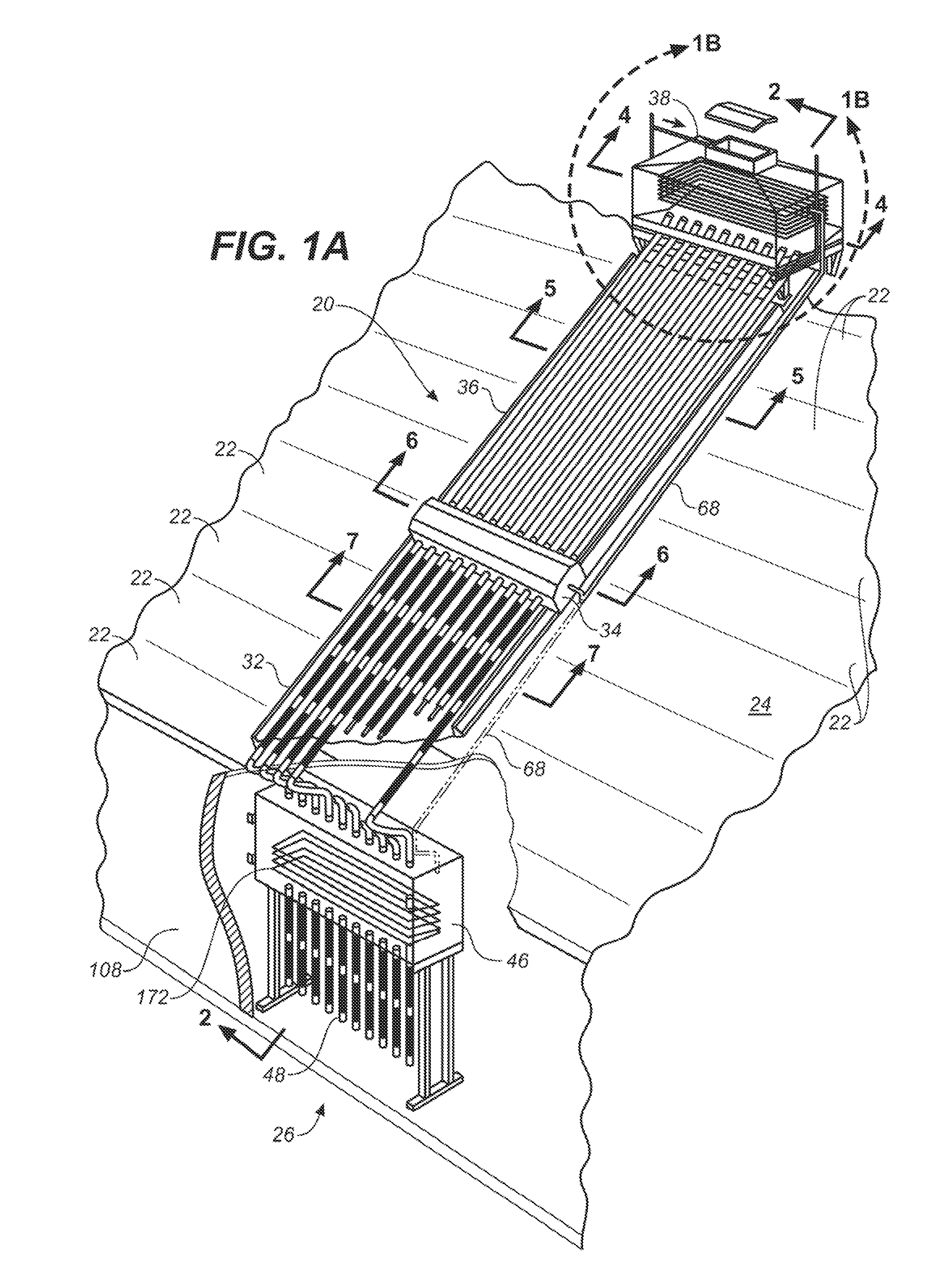

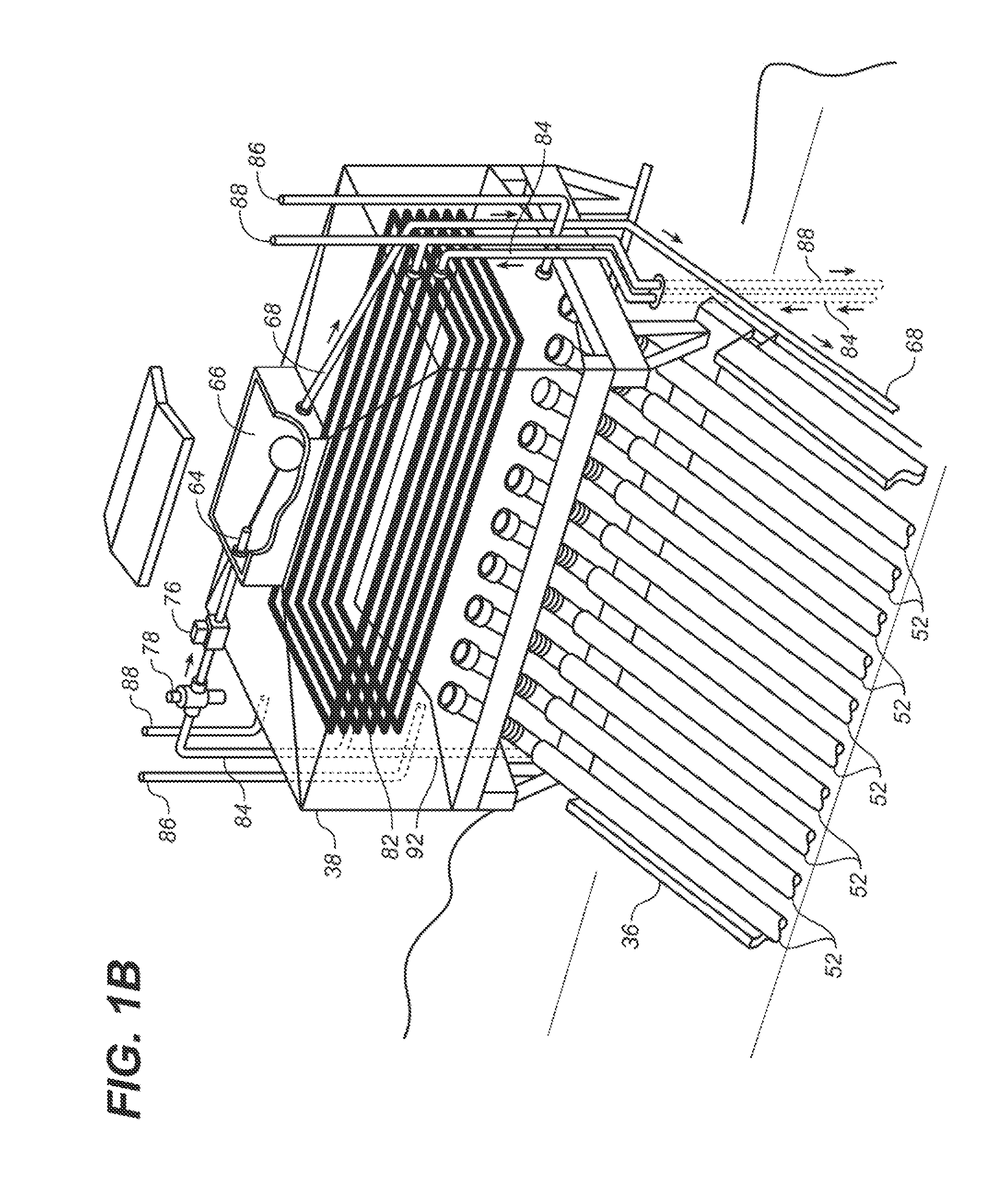

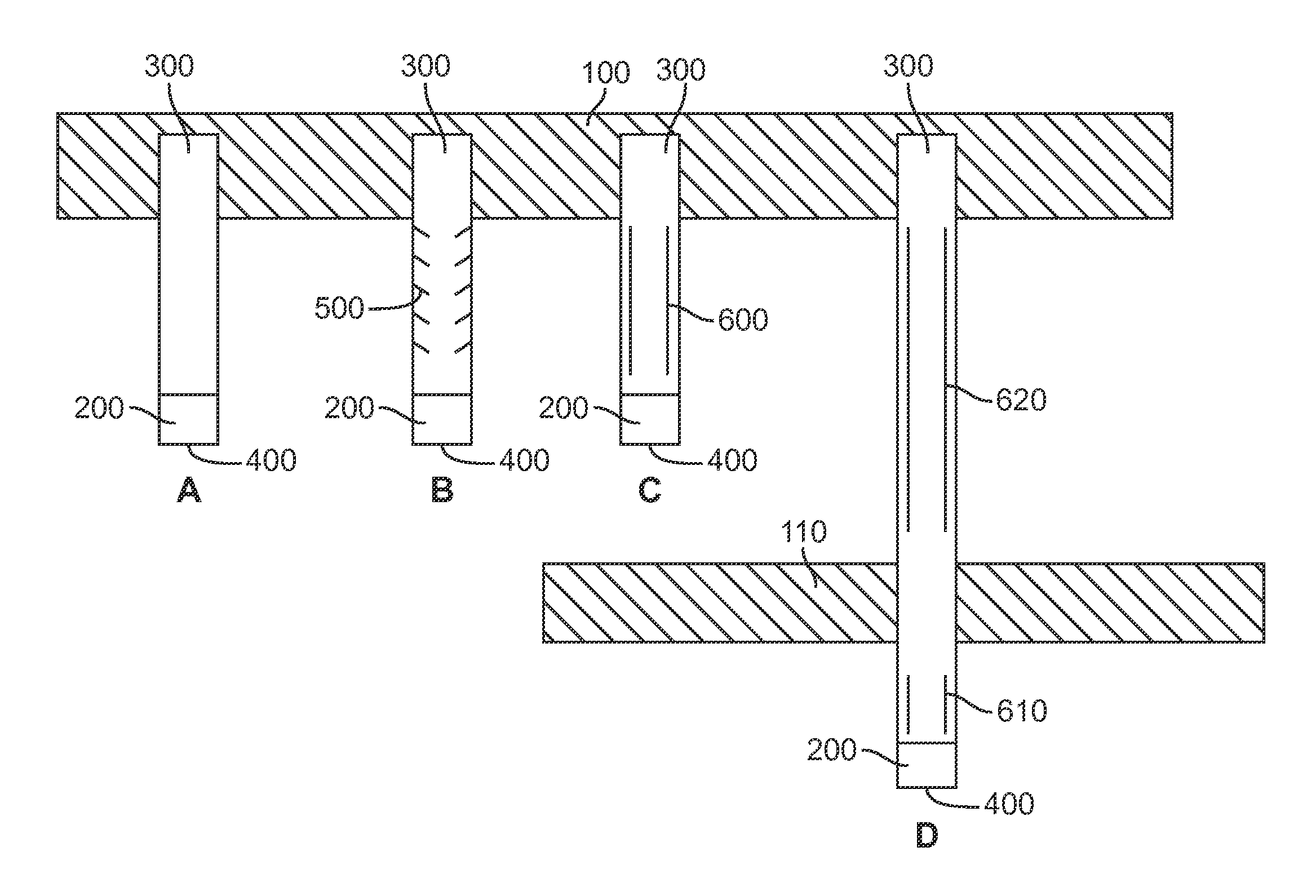

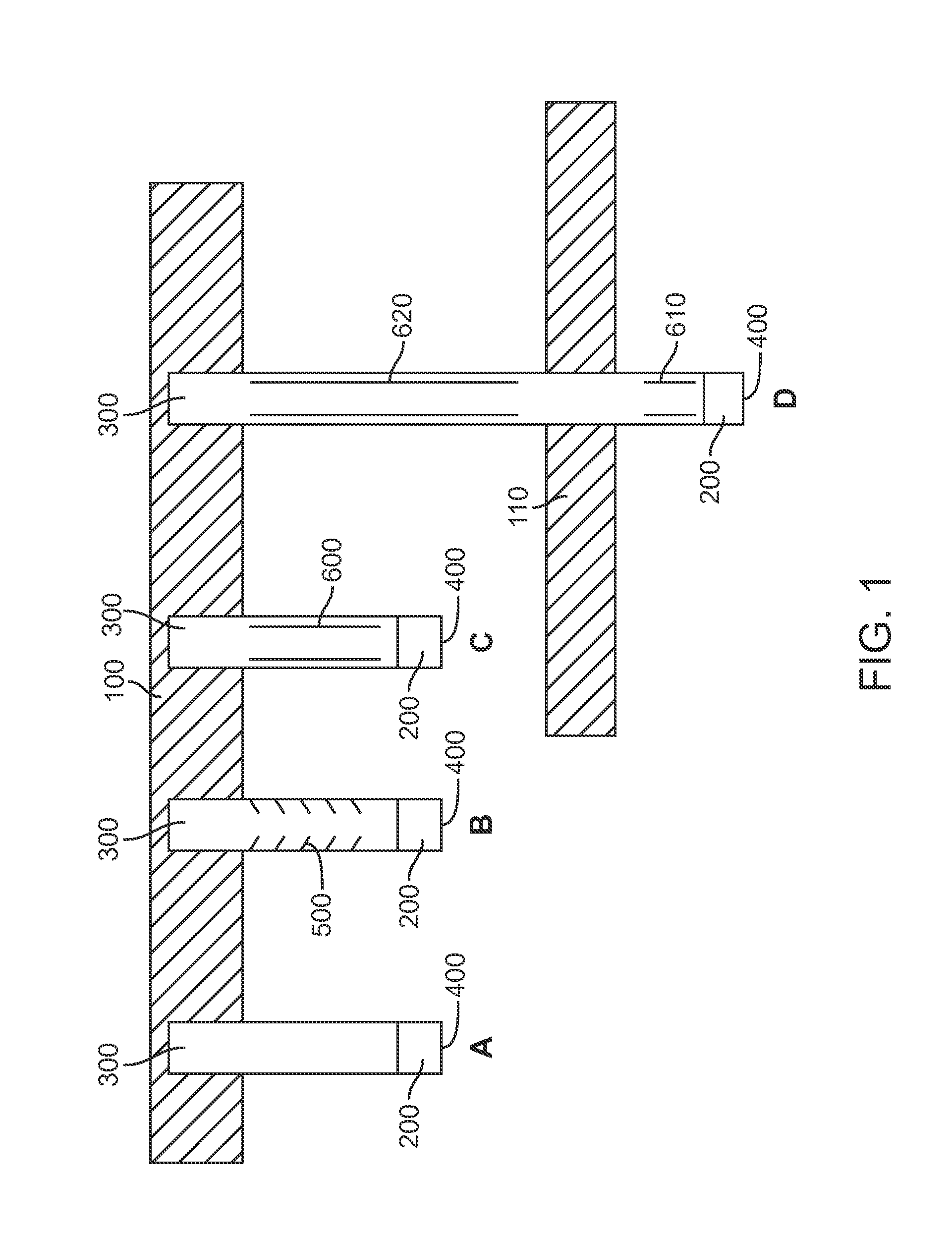

Coaxial tube solar heater with nighttime cooling

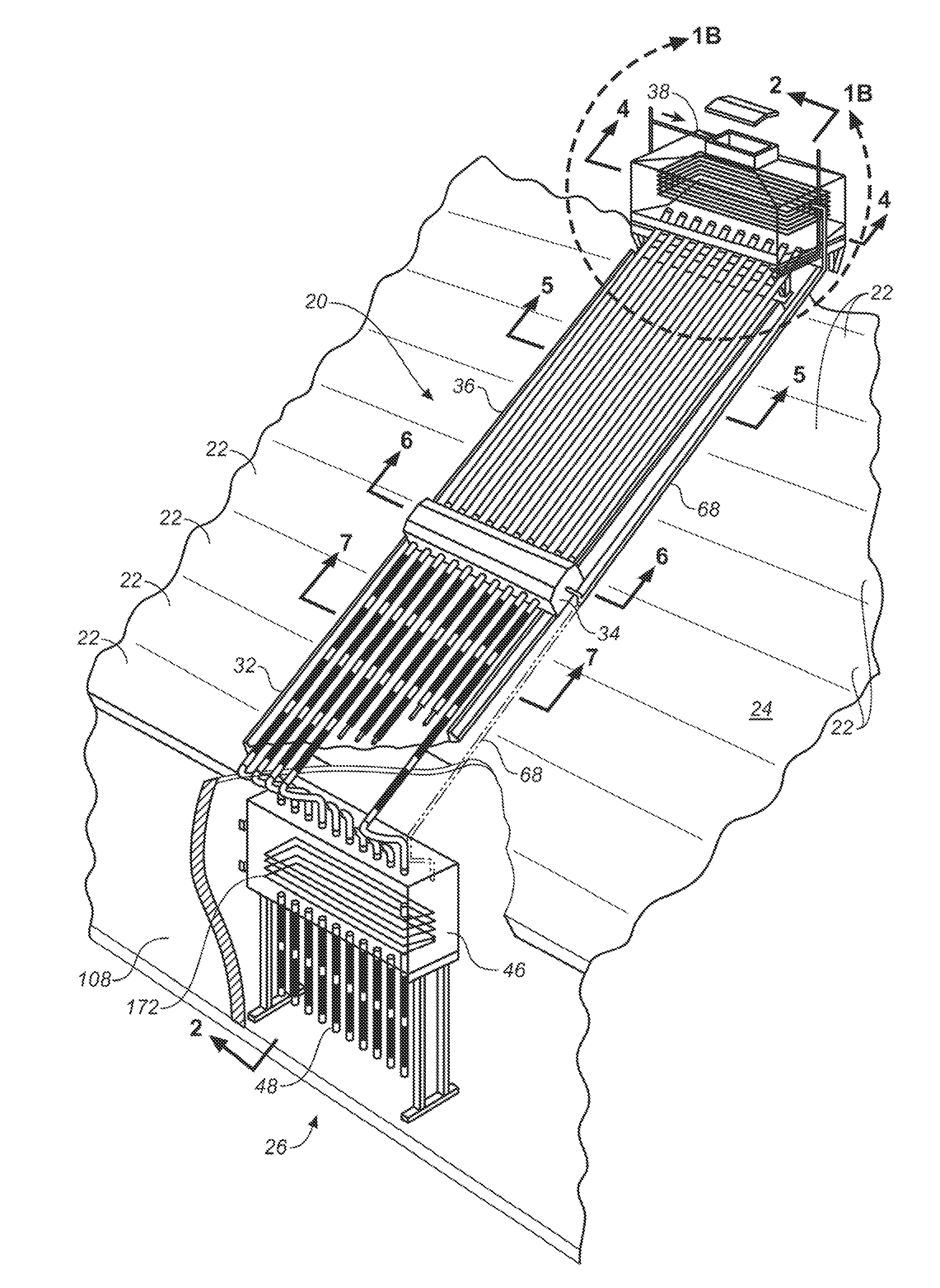

InactiveUS20120227730A1Improve the immunityImprove efficiencySolar heating energyCentral heating with accumulated heatCoaxial cableWater storage tank

Disclosed is a solar water-heating-and-cooling system (20) that included a collector array panel (32, 36) having thermosyphon coaxial heating / cooling tubes (52). The disclosed system (20) avoids damaging the collector array panel (32, 36) by filling the tubes (52): 1. only when environmental conditions ensure that damage won't occur,—and / or 2. using a filling method that ensures that damage won't occur. Thermosyphon coaxial heating / cooling tubes (52) disclosed herein may be open both at their upper and lower ends. Tubes (52) that are open at their, lower end enables capturing radiative cooling of liquid present within the tubes (52). A cold water storage tank (46) and cold radiator array (48) included in the water-heating-and-cooling system (20) permits preserving and using the radiative ‘cooling. Also disclosed are coaxial tubes (104, 106) that enable simpler and easier installation of the system (20), and also provide a less architecturally intrusive system (20).

Owner:TEOH SIANG TEIK

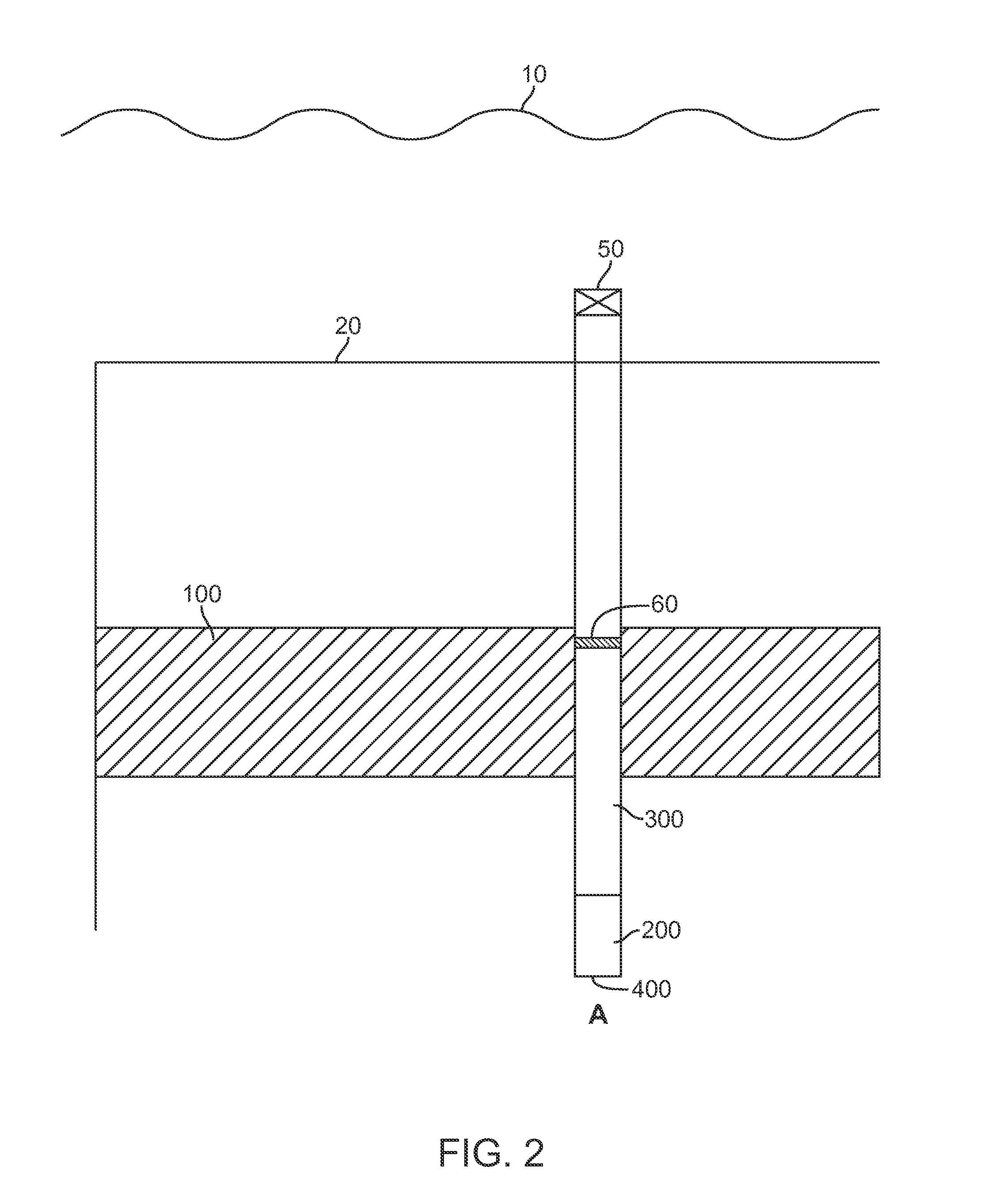

Enhancing Production of Clathrates by Use of Thermosyphons

ActiveUS20140041872A1Increase productionConstructionsInsulationThermodynamicsHydrocotyle bowlesioides

A method and system for initiating hydrocarbon production from a reservoir are provided. This method and system utilize thermosyphons. The system and method utilize one or more sealed, elongated, hollow tubular containers supported in earth in a geothermal heat zone below the reservoir and extending upwardly therefrom into the reservoir. The containers comprise (a) a bottom portion in the geothermal heat zone below the reservoir; (b) a top portion within the reservoir; and (c) being partially filled with a liquid that evaporates in the bottom portion forming a vapor and transferring heat via convective flow of the vapor to the top portion, the heat being dissipated at the top portion into the surrounding reservoir as the vapor condenses back into liquid and flows downward to the bottom portion. The reservoir can be a natural gas hydrate reservoir.

Owner:CHEVROU USA INC

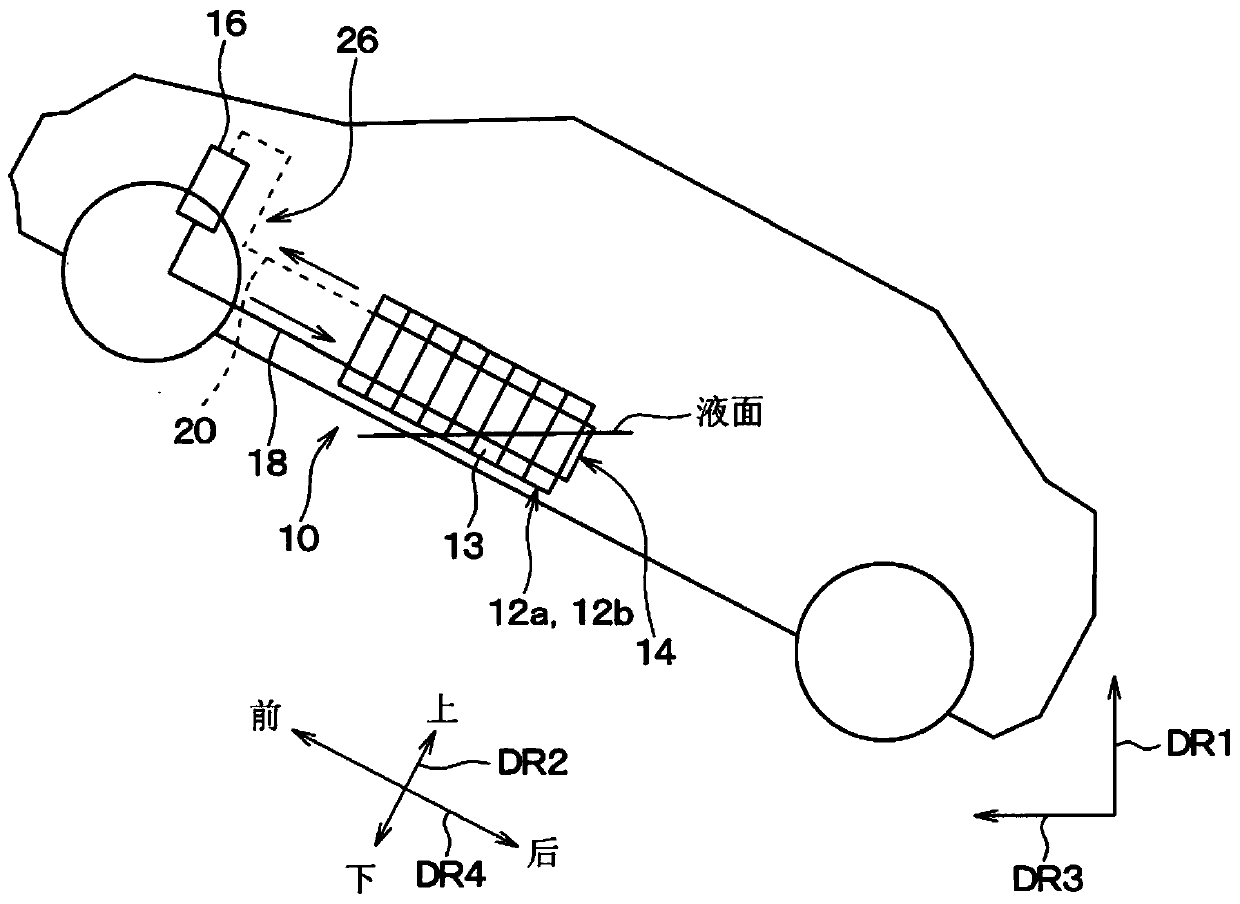

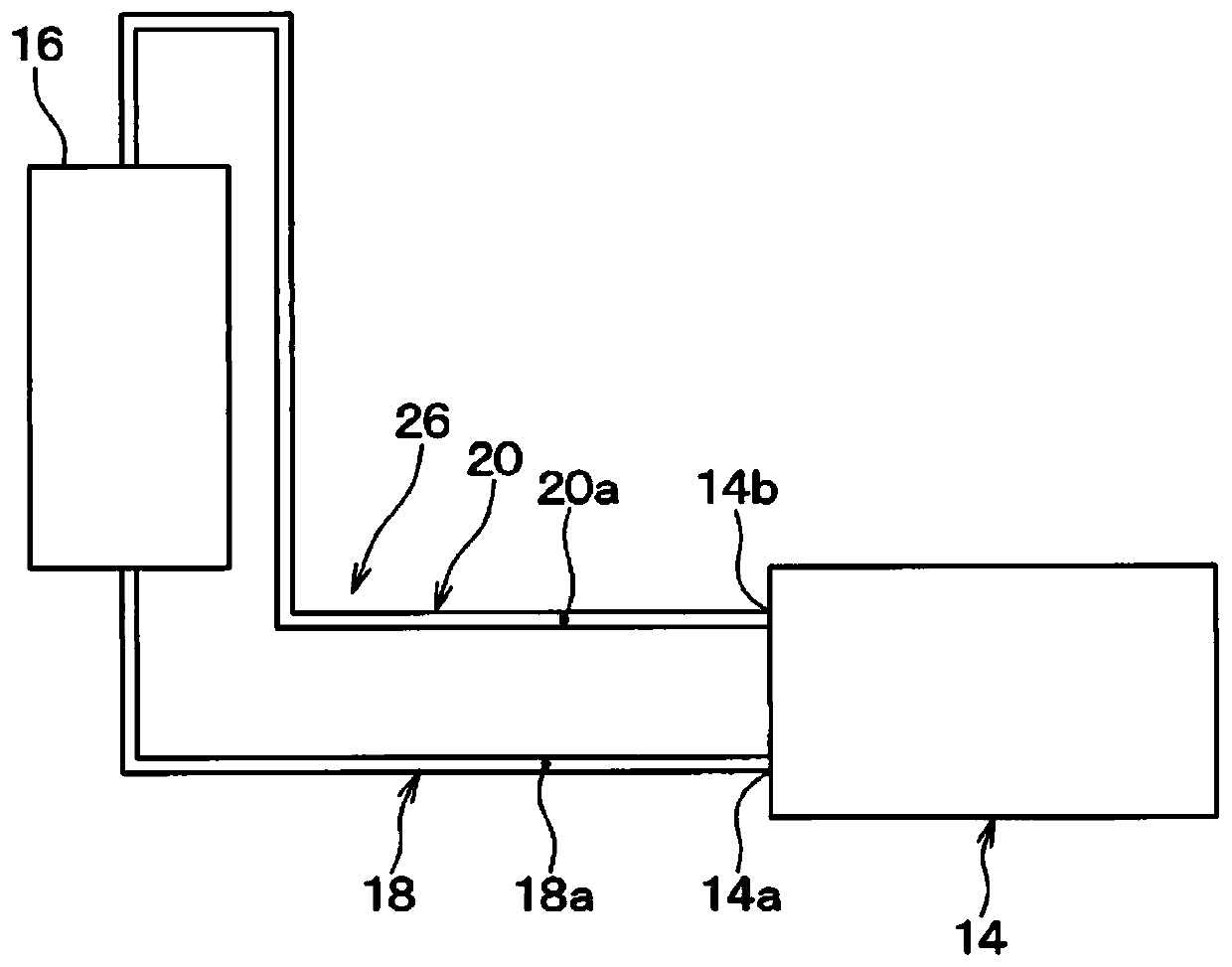

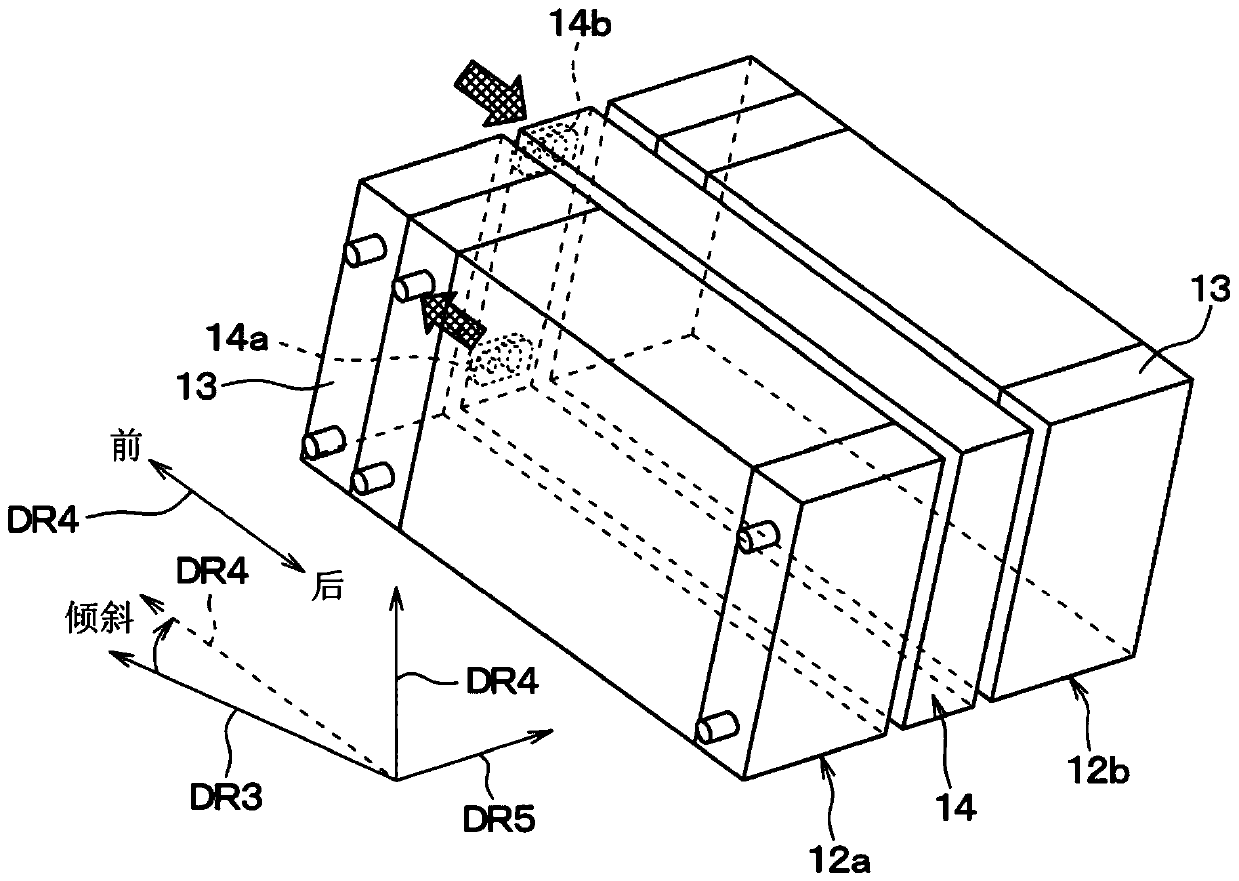

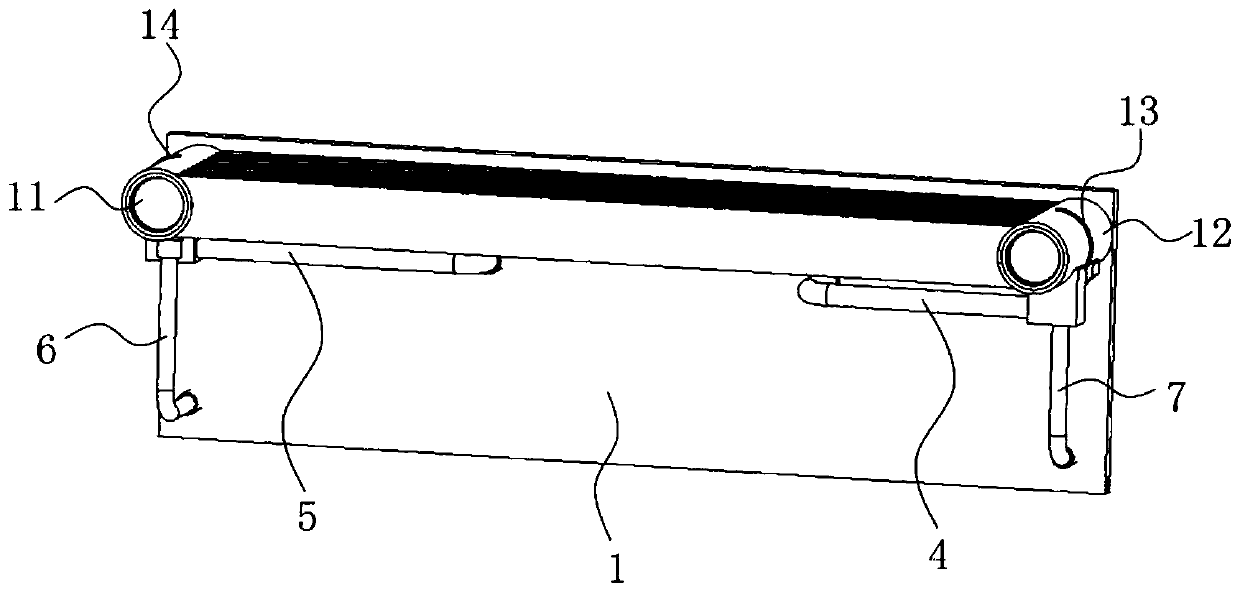

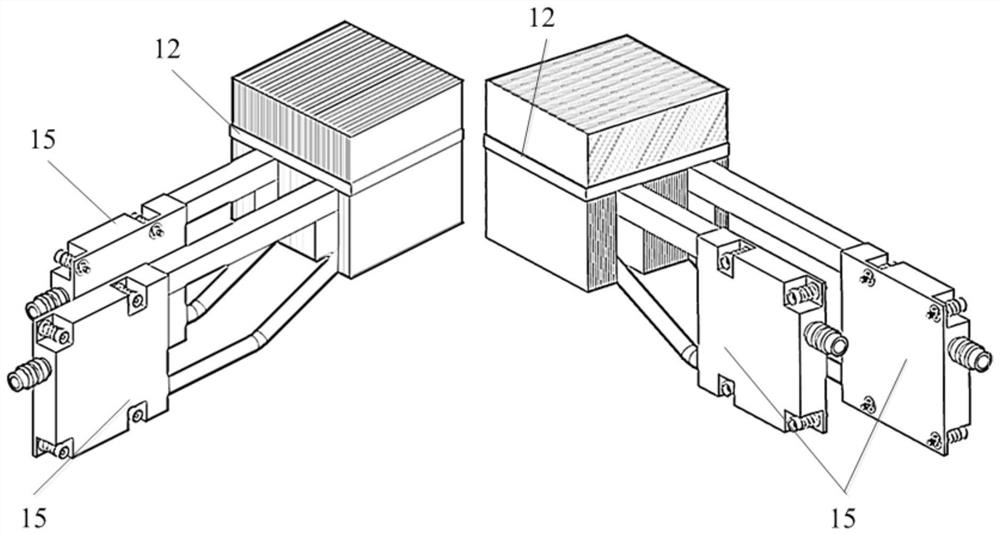

Cooler and thermosyphon

This cooler, together with a condenser (16) that condenses a gas-phase coolant and discharges a liquid-phase coolant, constitutes a thermosyphon that causes a coolant to circulate. The cooler comprises: first channel forming parts (60a, 60b, 60c) that form a supply channel (70) through which the liquid-phase coolant from the condenser flows; second channel forming parts (60a, 43, 60b, 44) that form evaporation channels (61a, 61b) that have coolant inlets (64a, 64b) that communicate with the supply channel, that are formed to extend upward from the coolant inlets, and that cause the liquid-phase coolant to evaporate through heat exchange between cooling targets (12a, 12b) and the liquid-phase coolant that flows in from the supply channel via the coolant inlets, thereby causing the gas-phasecoolant to be generated; and third channel forming parts (60a, 60b, 45) that form a discharge channel (71) through which the gas-phase coolant from the evaporation channels flows toward the condenser. The coolant inlets are located below a vertical center part of the supply channel.

Owner:DENSO CORP

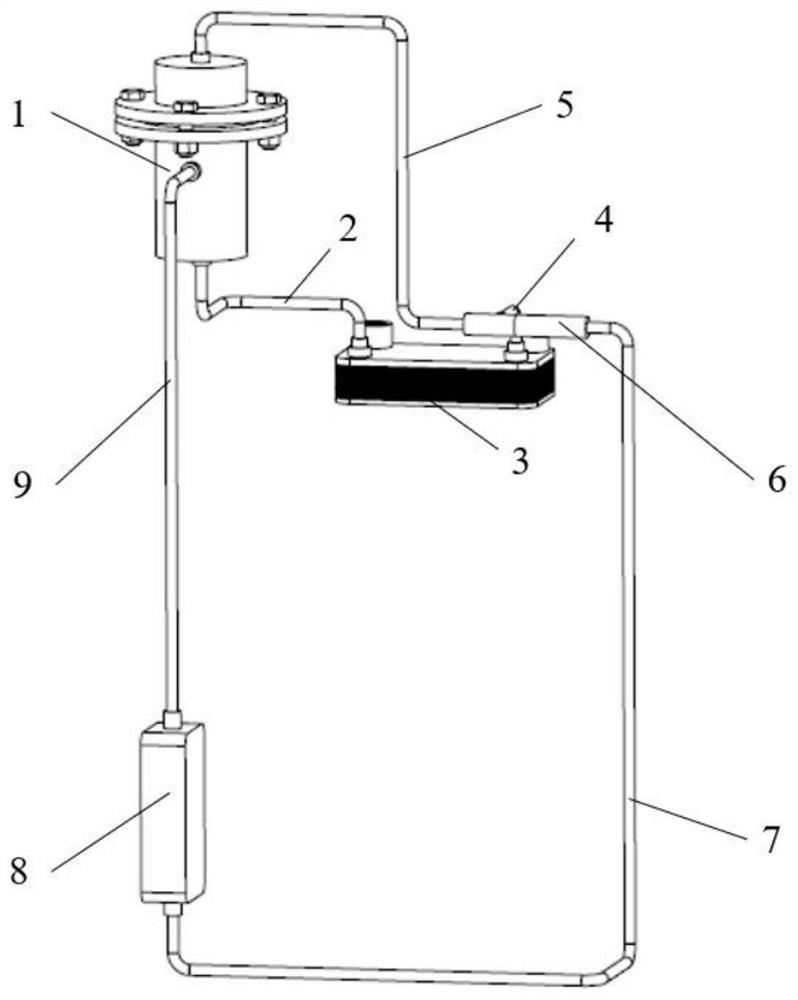

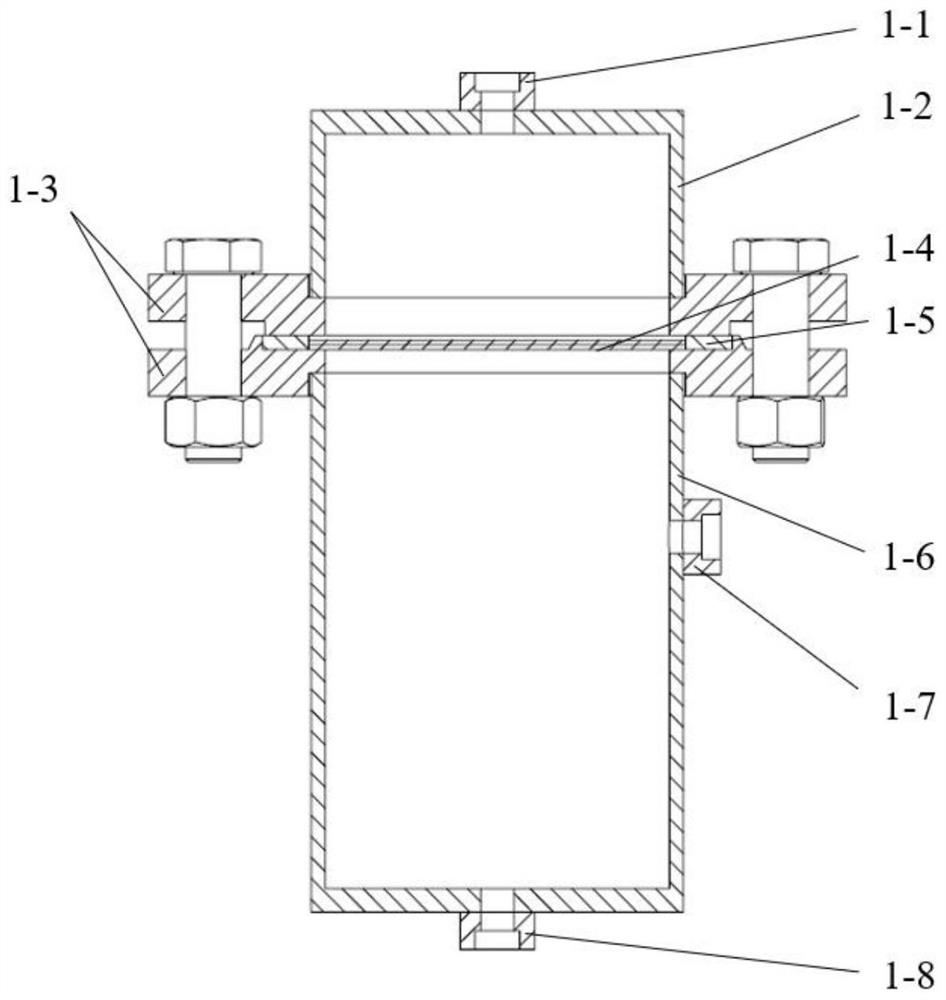

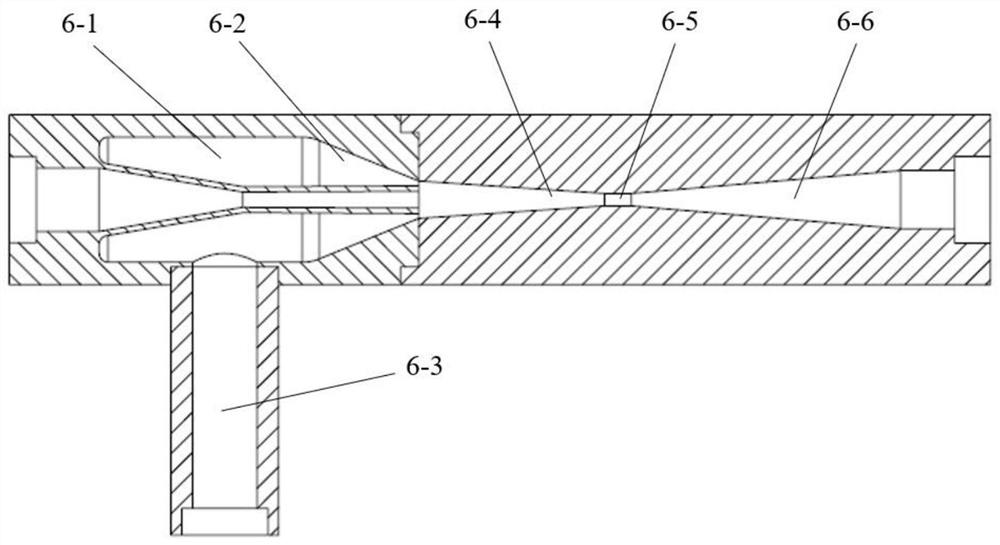

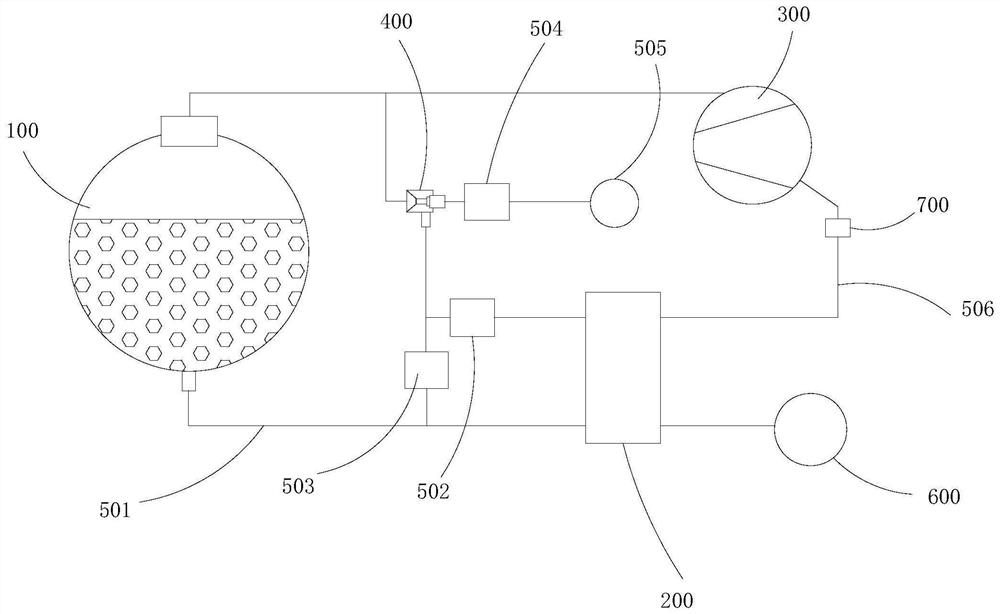

Self-driven thermosyphon loop heat dissipation device coupled with gas-liquid two-phase flow jet pump

ActiveCN113357946AImprove cooling effectGuaranteed uptimeIndirect heat exchangersCooling/ventilation/heating modificationsVapor–liquid separatorThermosipho

A self-driven thermosyphon loop heat dissipation device coupled with a gas-liquid two-phase flow jet pump comprises a gas-liquid separator, a cooler, the gas-liquid two-phase flow jet pump and an evaporator which are sequentially connected to form a loop, wherein a liquid outlet of the gas-liquid separator is connected with an inlet of the cooler through a first liquid section; an outlet of the cooler is connected with a liquid inlet of the gas-liquid two-phase flow jet pump through a second liquid section, a steam outlet of the gas-liquid separator is connected with a steam inlet of the gas-liquid two-phase flow jet pump through a first steam section, and an outlet of the gas-liquid two-phase flow jet pump is connected with an inlet of the evaporator through a third liquid section; an outlet of the evaporator is connected with an inlet of the gas-liquid separator through a second steam section; and the vertical height of the gas-liquid separator is larger than the position of the cooler and the position of the gas-liquid two-phase flow jet pump, the vertical height of the cooler and the vertical height of the gas-liquid two-phase flow jet pump are larger than the position of the evaporator, and the evaporator is vertically arranged. According to the self-driven thermosyphon loop heat dissipation device, a flowing pressure head in a loop can be remarkably improved, so that the heat dissipation capacity of the thermosyphon loop is enhanced, operation is more stable, and noise generated in the working process is small.

Owner:SHANGHAI JIAO TONG UNIV

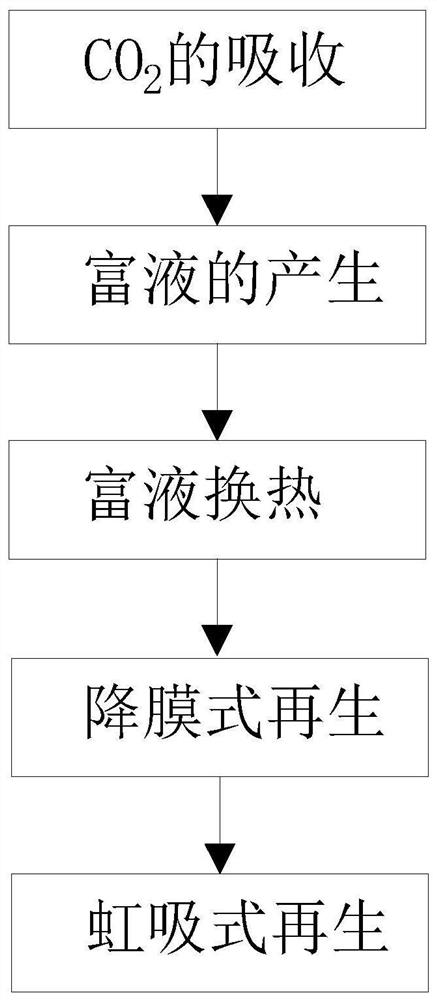

Novel flue gas CO2 capture system regeneration process

InactiveCN112774401AReduce in quantityReduce engineering investment costGas treatmentDispersed particle separationProcess equipmentCo2 absorption

The invention discloses a novel flue gas CO2 capture system regeneration process which comprises the following steps of: S1, CO2 absorption: flue gas subjected to desulfurization, denitrification and dust removal enters a deep purification tower, the flue gas is pressurized by an induced draft fan and then enters an absorption tower, a barren liquor absorbent is added into the absorption tower, the barren liquor absorbent is in countercurrent contact with the flue gas, and CO2 absorption is completed; S2, generation of rich liquid: the barren liquor absorbent reacts with carbon elements in the flue gas in the absorption tower to form rich liquid, the rich liquid is discharged through the bottom of the absorption tower, and gas is discharged from a tail gas discharge port in the top of the absorption tower; S3, rich liquid heat exchange; S4, falling film type regeneration; and S5, siphoning type regeneration. A falling film type boiler is mainly adopted to replace a conventional thermosyphon type boiler, top spraying falling film type regeneration and boiler bottom liquid inlet syphon type regeneration can be achieved through technological process switching, two regeneration technologies are achieved through one set of technological equipment, the number of equipment is reduced, and the engineering investment cost is saved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

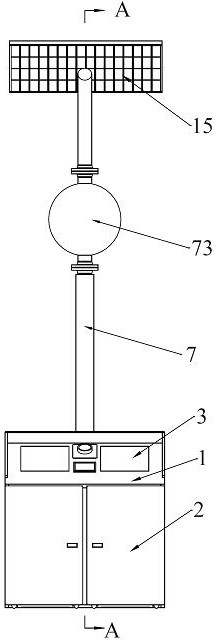

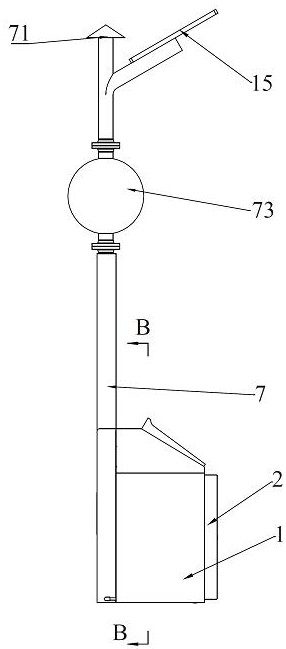

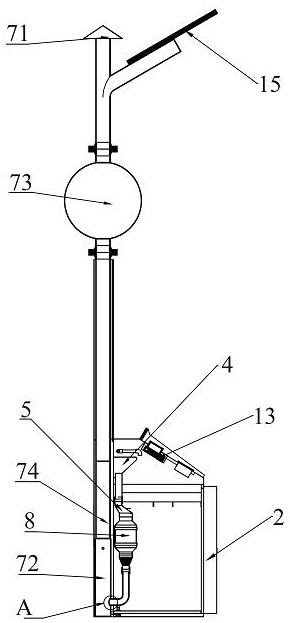

Low-energy-consumption automatic deodorization garbage can cover, garbage can and use method of garbage can

PendingCN113353487AReduced specific gravity due to thermal expansionTo achieve the purpose of deodorizationGlass recyclingRefuse receptaclesThermodynamicsEngineering

The invention discloses a low-energy-consumption automatic deodorization garbage can cover. The garbage can cover comprises a can cover body provided with an inner cavity for containing a garbage can, an air suction piece and an emptying piece, wherein the can cover body is provided with a garbage can transfer opening and a feeding opening, the garbage can transfer opening is provided with a transfer door, and the feeding opening is provided with a feeding door; the air suction piece is arranged in the inner cavity and communicates with the first end part of an exhaust pipe; and the emptying pipe is communicated with the second end part of the exhaust pipe and comprises a high-position emptying port, a heating pipe section and a peculiar smell treatment pipe section, and the high-position emptying port is used for exhausting rising hot air of the heating pipe section. When a fan is not started, the low-energy-consumption automatic deodorization garbage can cover heats the air in the heating pipe section, gas is heated to expand, the specific gravity is reduced, the gas floats upwards, a thermosyphon system is formed, the emptying pipe is in a vacuum state, and peculiar smell gas in the garbage can cover is forced to float upwards through the air suction piece, the exhaust pipe and the emptying pipe and is deodorized through the peculiar smell treatment pipe section. The invention further discloses a garbage can comprising the low-energy-consumption automatic deodorization garbage can cover and a using method of the garbage can.

Owner:JIANGYIN LIANYE BIOTECHOLOGY

Production method for device temperature control device and filling method for working fluid

InactiveCN109690220AEasy and safe to fillCompression machines with non-reversible cycleSemiconductor/solid-state device detailsTemperature controlEquipment temperature

A production method for a device temperature control device, including: connecting a filling port (36) for a circuit (10) and a container (45) housing a working fluid in a gas phase; and filling the working fluid into the circuit (10). The circuit (10) constitutes a thermosiphon-type heat pipe and circulates the working fluid. During filling, the working fluid inside the circuit (10) is cooled bya cooling source (21). The internal pressure of the circuit (10) is made lower than the internal pressure of the container (45), by reducing the internal temperature of the circuit (10) to below the internal temperature of the container (45).

Owner:DENSO CORP

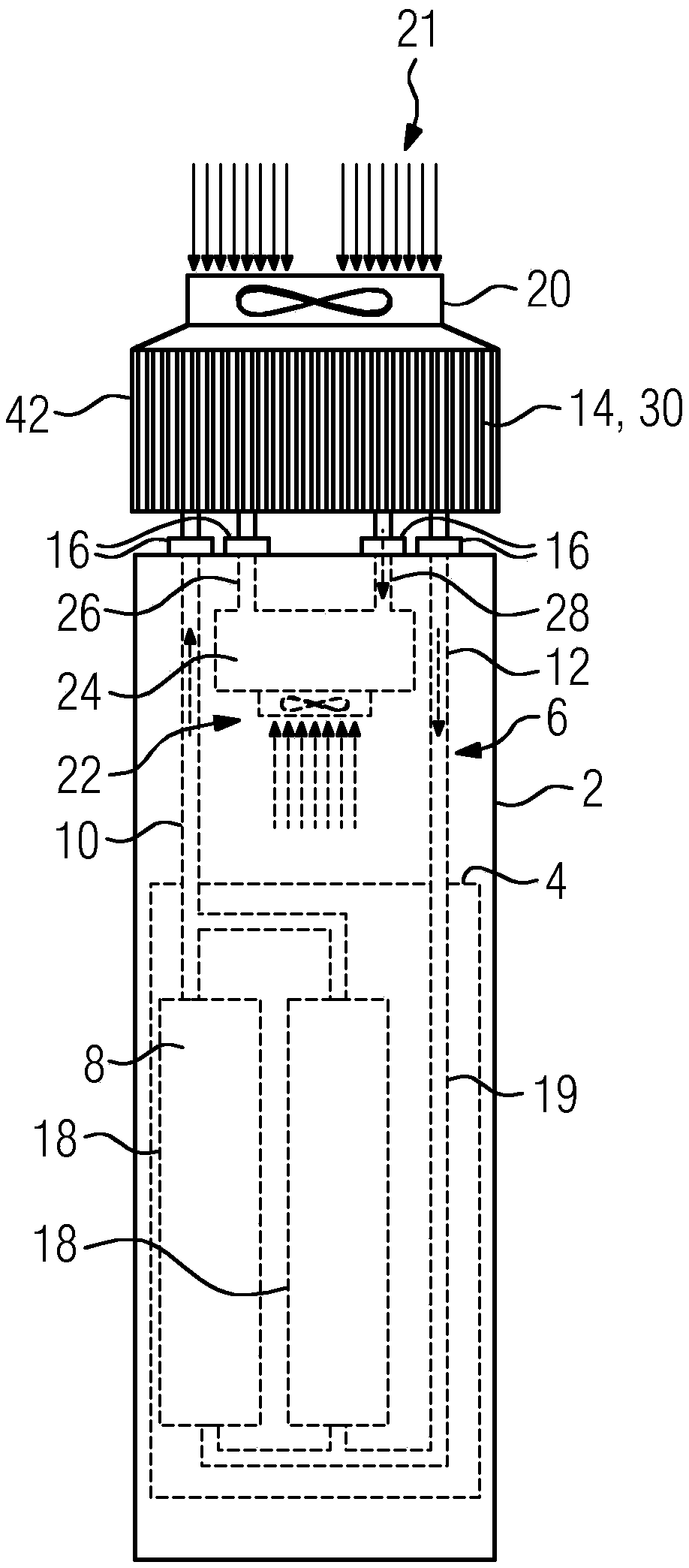

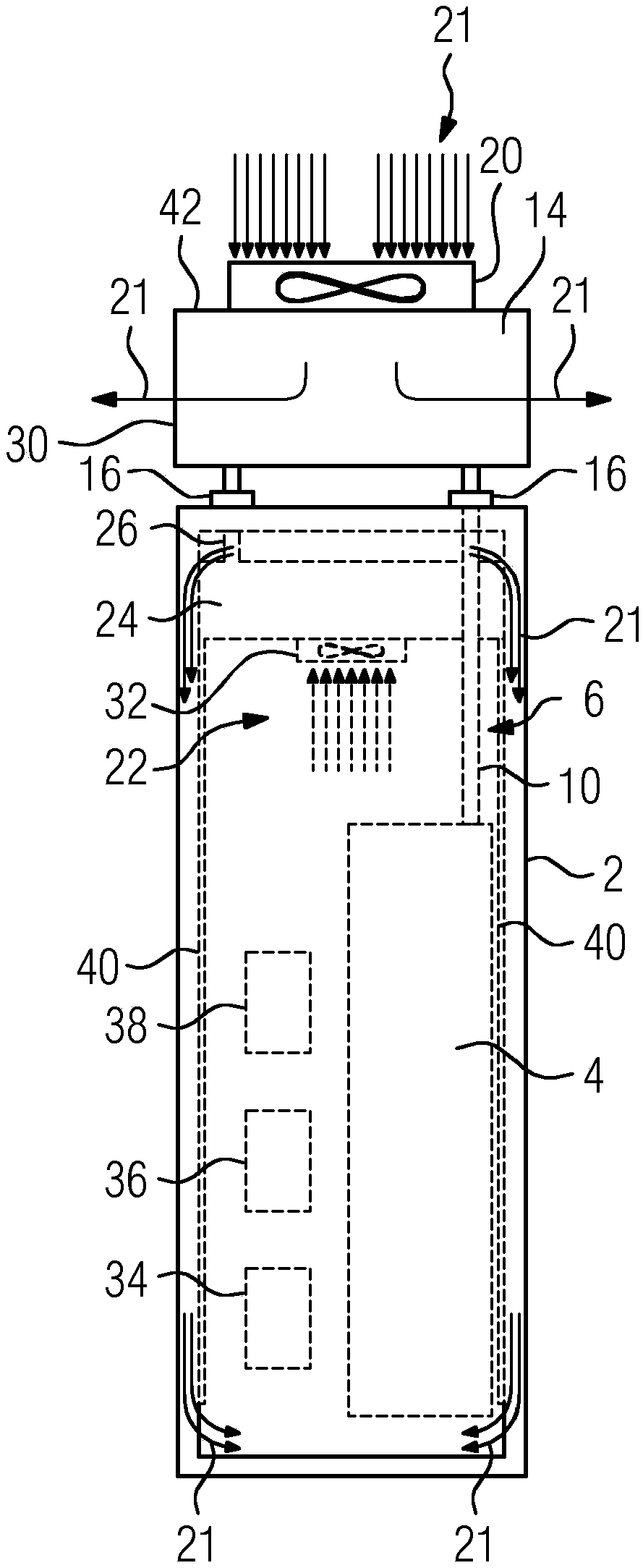

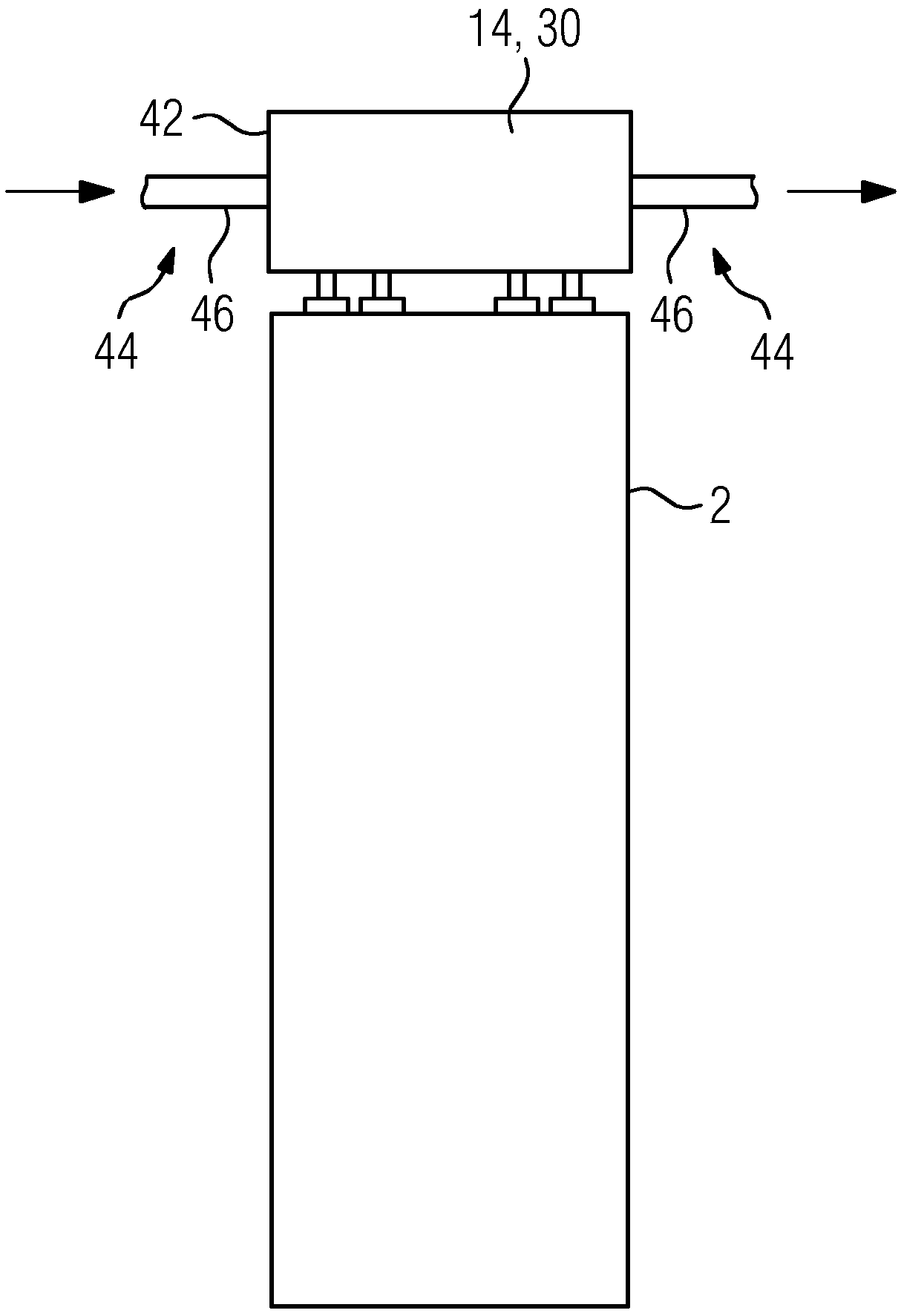

Switchgear cabinet comprising a closed housing and a cooling device

ActiveCN109690763AHigh densityHigh power lossSemiconductor/solid-state device detailsSolid-state devicesEngineeringSwitchgear

The invention relates to a switchgear cabinet comprising a closed housing and a cooling device for cooling electrical and / or electronic operating means (4, 34, 36, 38) that can be arranged inside thehousing (2), said switchgear cabinet comprising a first closed cooling circuit (6). The first cooling circuit (6) contains a first cooling medium for removing heat produced during the operation of atleast one of the operating means (4) from the housing (2). The first cooling circuit (6) is connected to a first heat-transfer medium (8, 18) arranged inside the housing (2), for transferring the heatfrom the at least one of the operating means (4) to the first cooling medium, and outside the housing (2), to a second heat-transfer medium (14) for giving off the heat to an outer cooling medium. The second heat-transfer medium (14) is arranged above the first heat-transfer medium (8, 18). The first cooling circuit (6), the first cooling medium and the first and second heat-transfer media (8,18;14) are designed to carry out the heat transport according to the two-phase thermosyphon principle.

Owner:SIEMENS AG

Thermosyphon heat dissipation device

PendingCN111174613AReduce space consumptionSmall temperature differenceIndirect heat exchangersEngineeringThermosipho

The invention provides a thermosyphon heat dissipation device. A first condensing unit and a second condensing unit are arranged, a first right flow collecting cavity and a first left flow collectingcavity of the first condensing unit and a second left flow collecting cavity and a second right flow collecting cavity of the second condensing unit are perpendicular to and fixedly arranged close toan evaporator, therefore, the space occupation of the thermosyphon heat dissipation device in the vertical direction is reduced; a first steam pipe communicates with the first right flow collecting cavity of the first condensing unit and a right steam pipe connecting hole formed in the evaporator, and a second steam pipe communicates with the second left flow collecting cavity of the second condensing unit and a left steam pipe connecting hole formed in the evaporator; and compared with the mode that only one flow collecting pipe used for collecting steam is arranged on one side of the evaporator, the technical scheme can reduce a stroke difference between the steam from the left side area and the steam in the right side area of a sealed containing cavity of the evaporator to the collecting cavities, and then the temperature difference between the left side and the right side of the evaporator is reduced, and the temperatures of the left and right sides of the bottom of the evaporatorare relatively uniform.

Owner:SHENZHEN ZHIHAN THERMAL TRANSMISSION TECH CO LTD

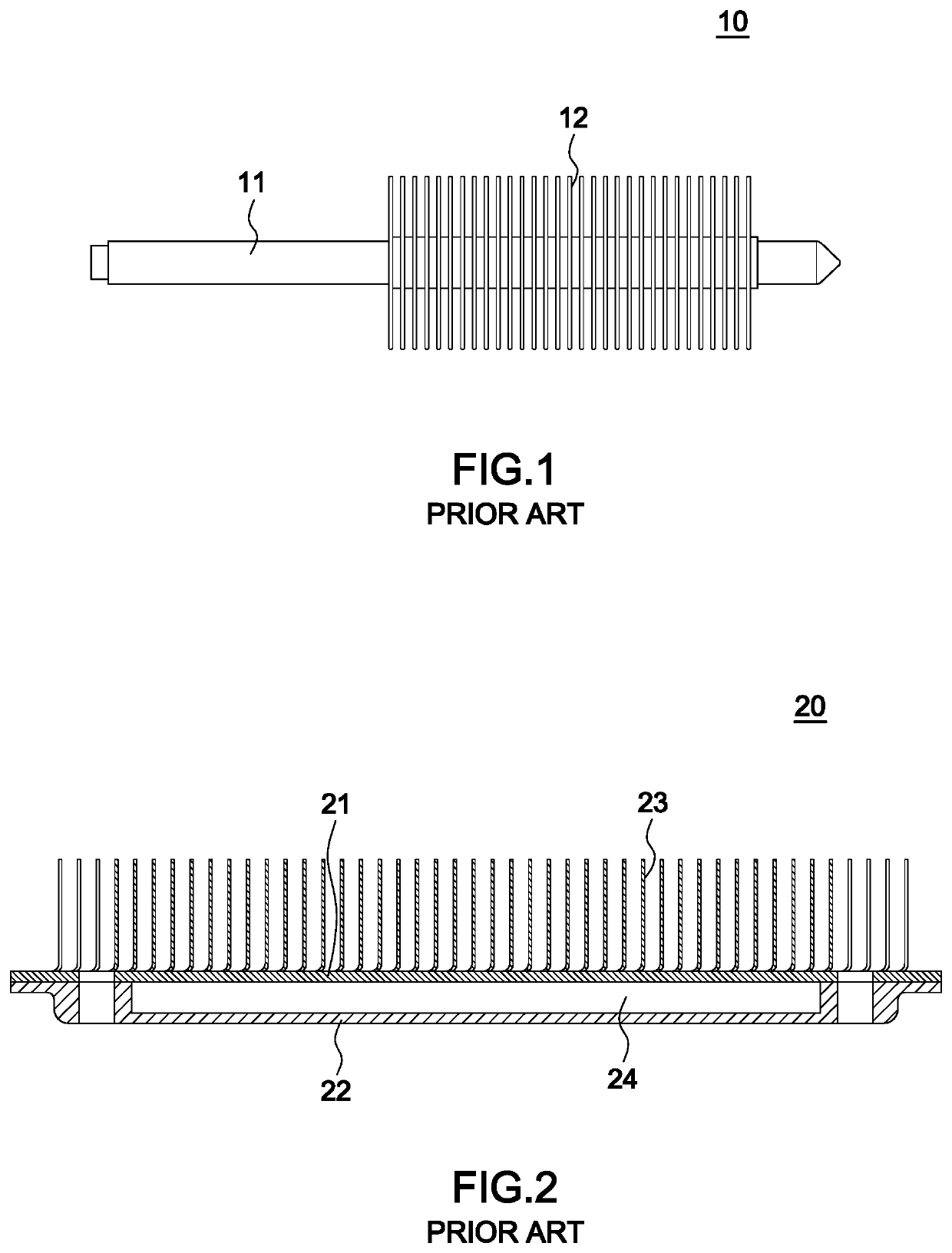

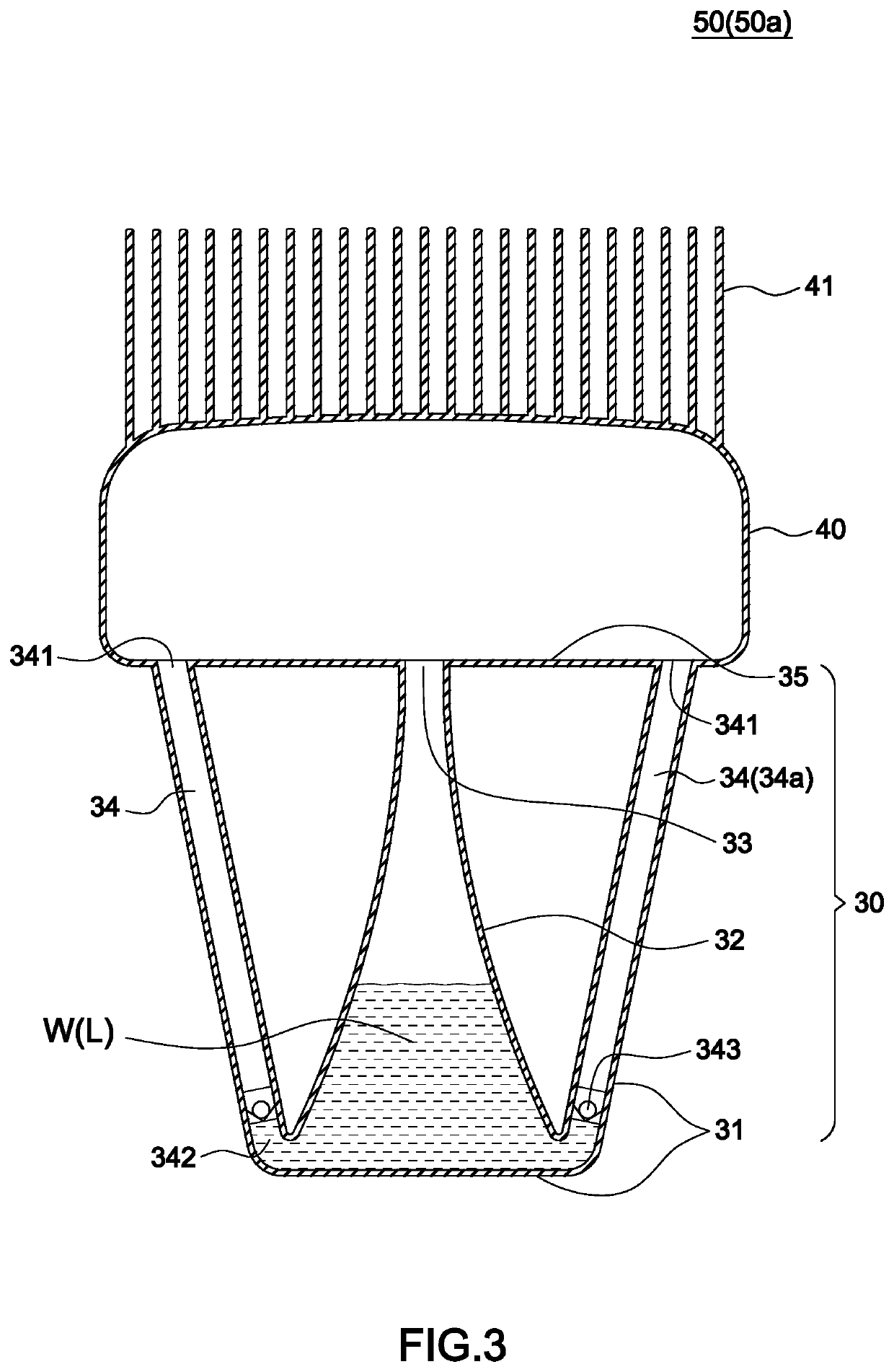

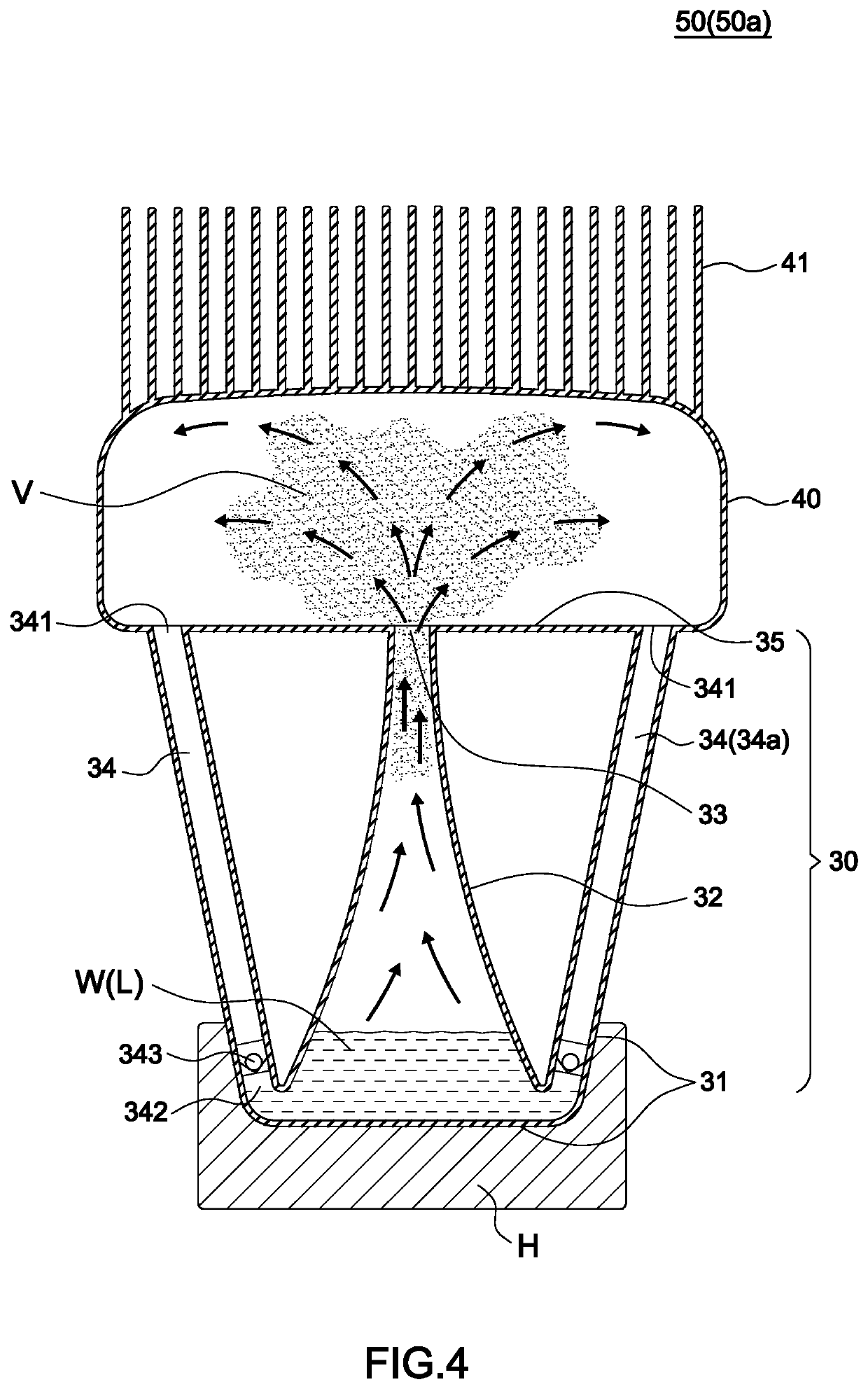

Heat dissipating module with micro-passages

PendingUS20200328137A1Improve cooling effectLess side effectsSemiconductor/solid-state device detailsSolid-state devicesVaporizationBoyle's law

A heat dissipating module with micro-passages includes a heat dissipating cavity connecting to a top of a heat absorbing cavity to form a distance from a heat source. When a working fluid in the heat absorbing cavity absorbs the thermal energy and is vaporized, the vapor would flow up to a vapor guiding space due to thermosyphon effect and principles of Boyle's Law, and then the vapor is projected and spread rapidly and evenly to the heat dissipating cavity through a projecting exit. Then the vapor is condensed into liquid and become the working fluid again by heat exchange. The condensed liquid then drips down and flows back to the heat absorbing cavity via micro-passages, forming a cycle of phase change of the working fluid for operation of heat dissipation.

Owner:JAI LONG PING TANG TECH

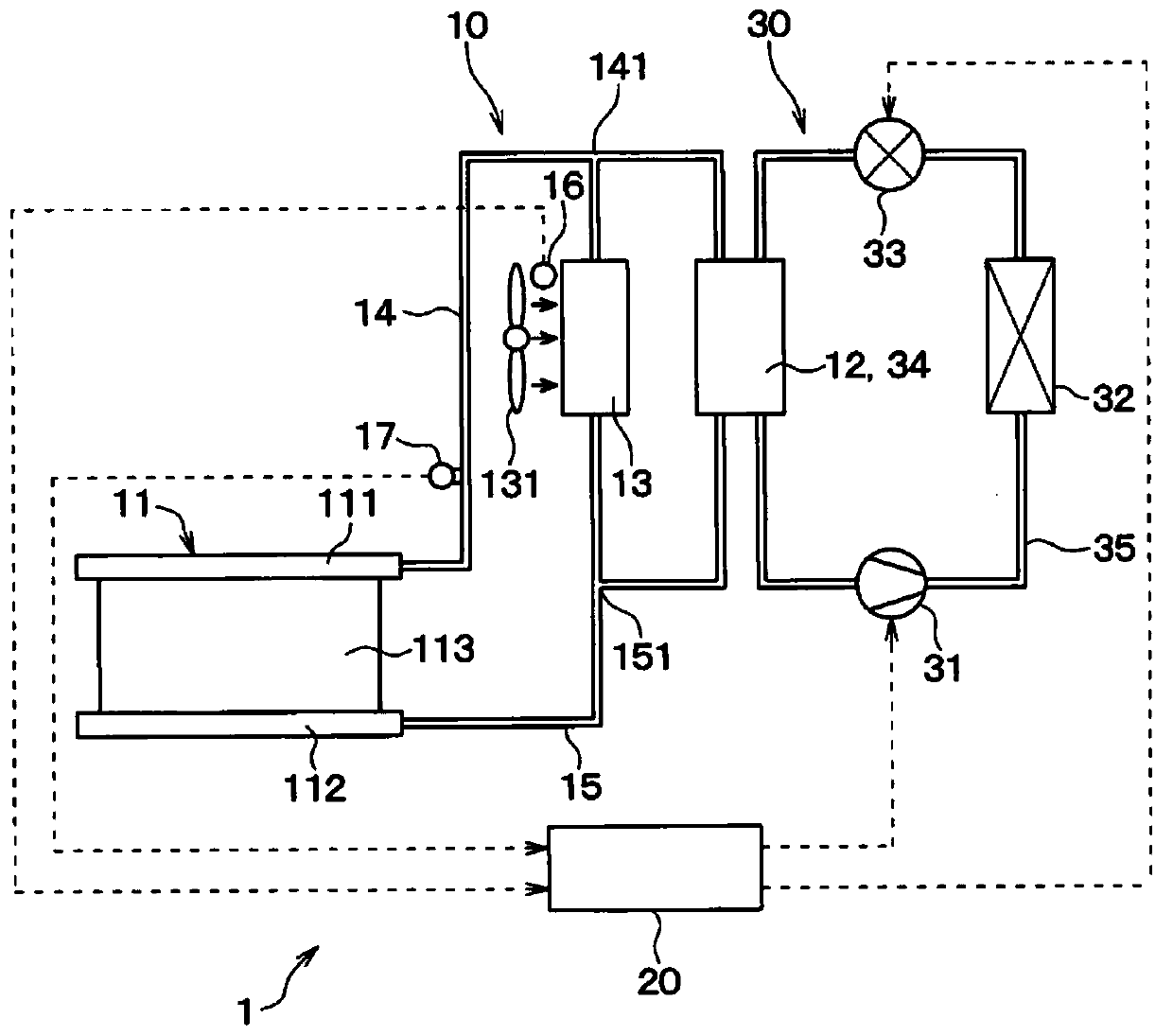

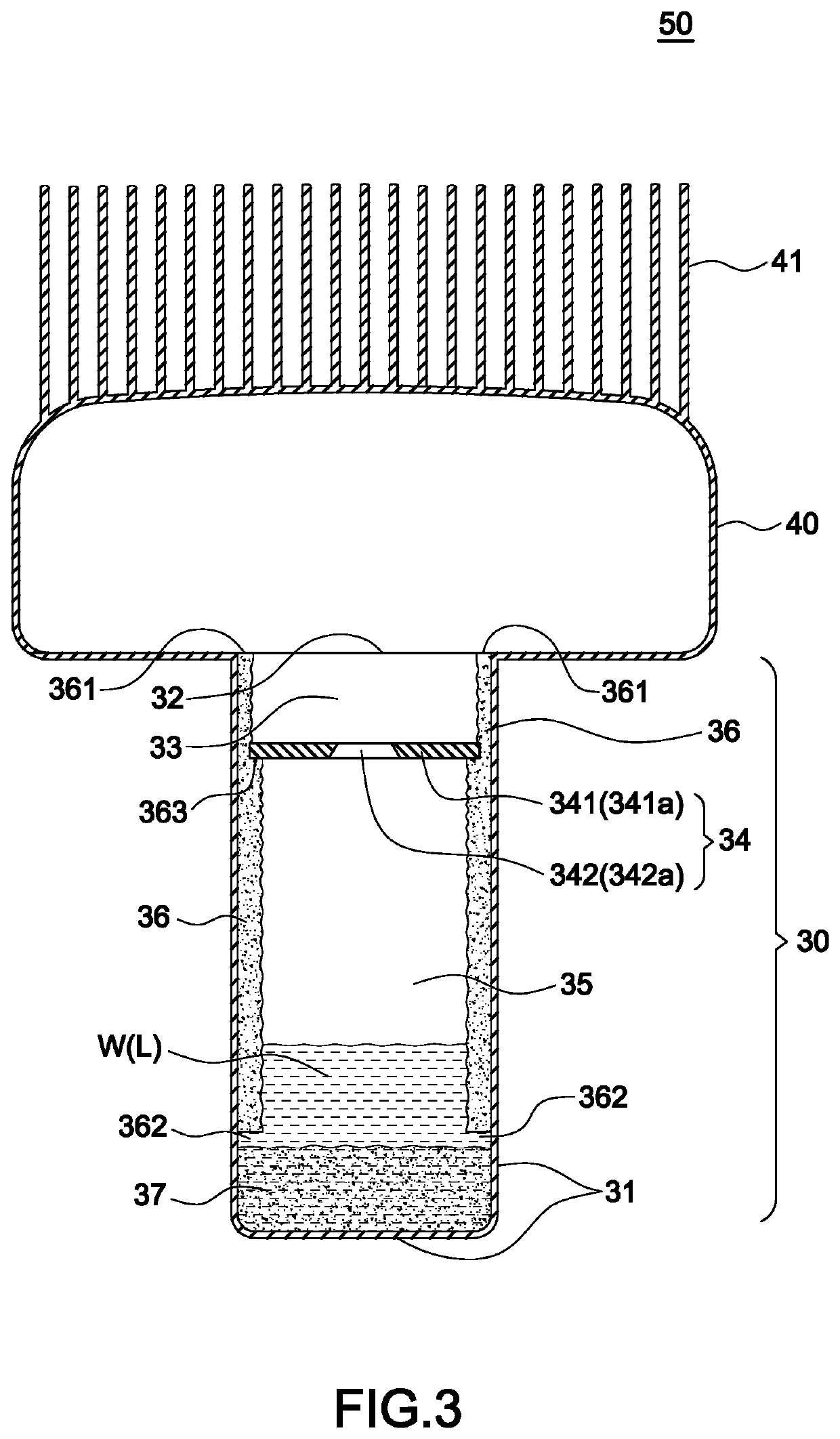

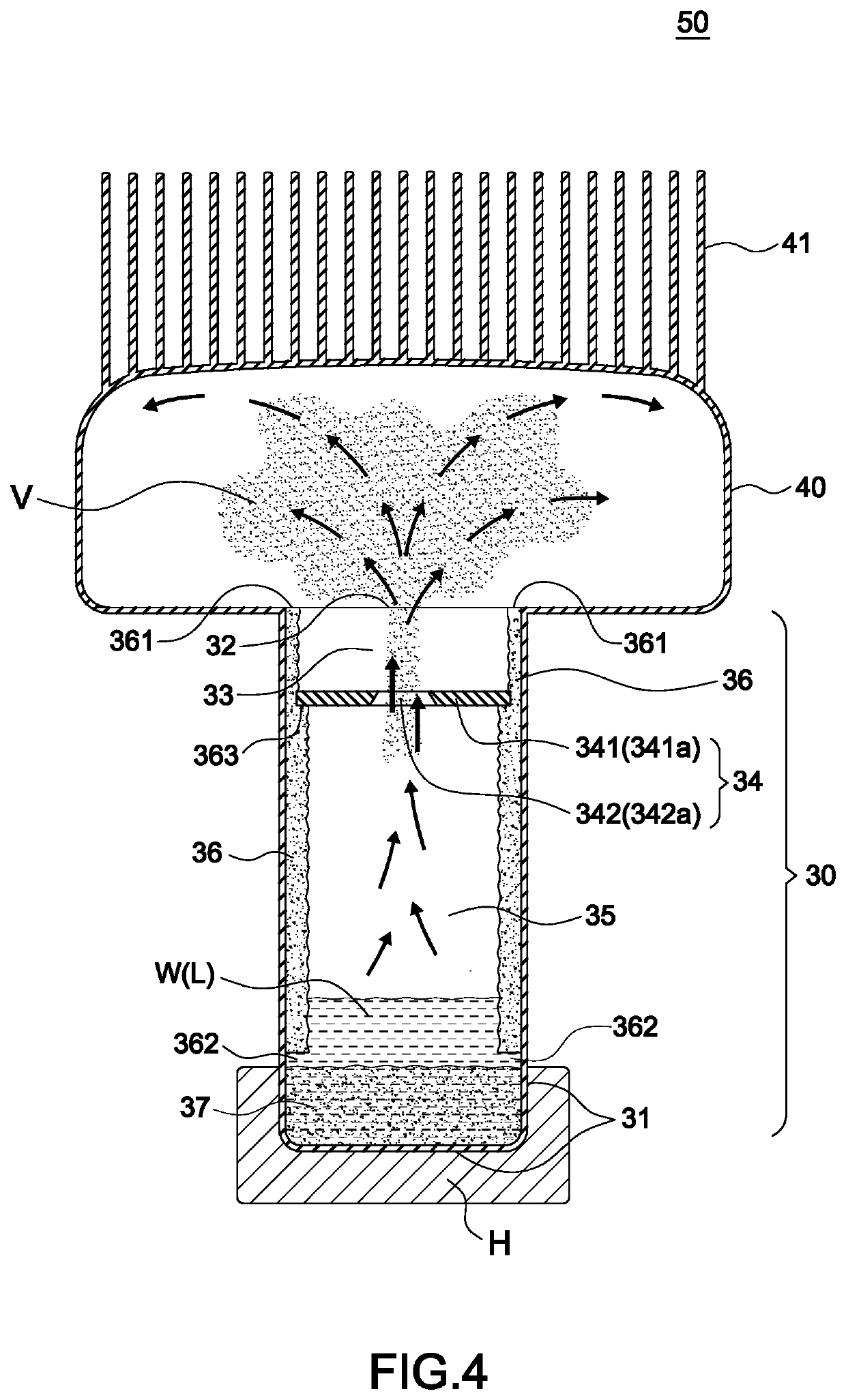

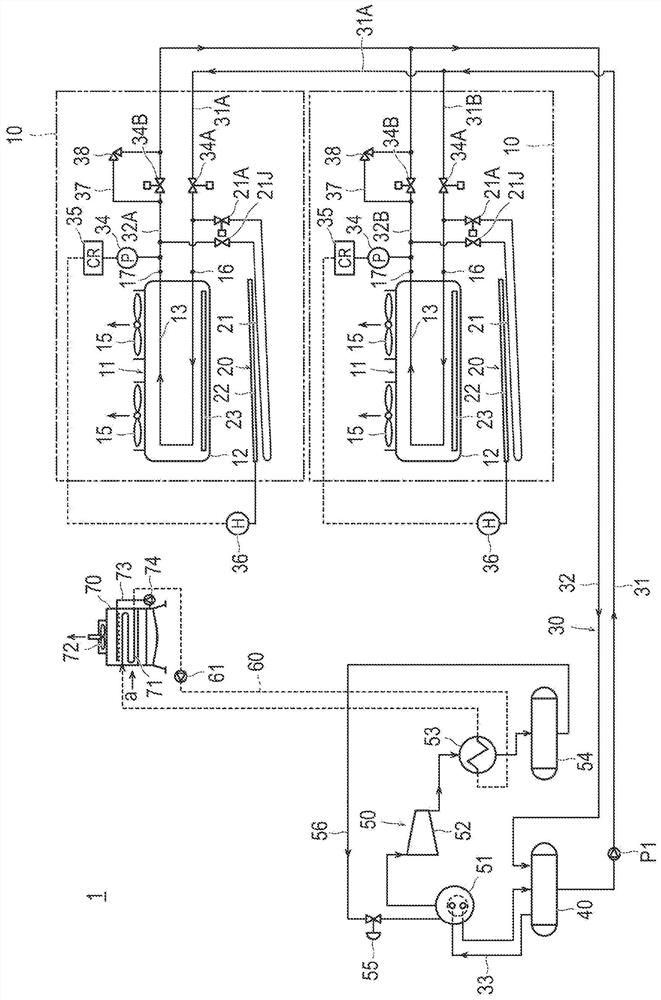

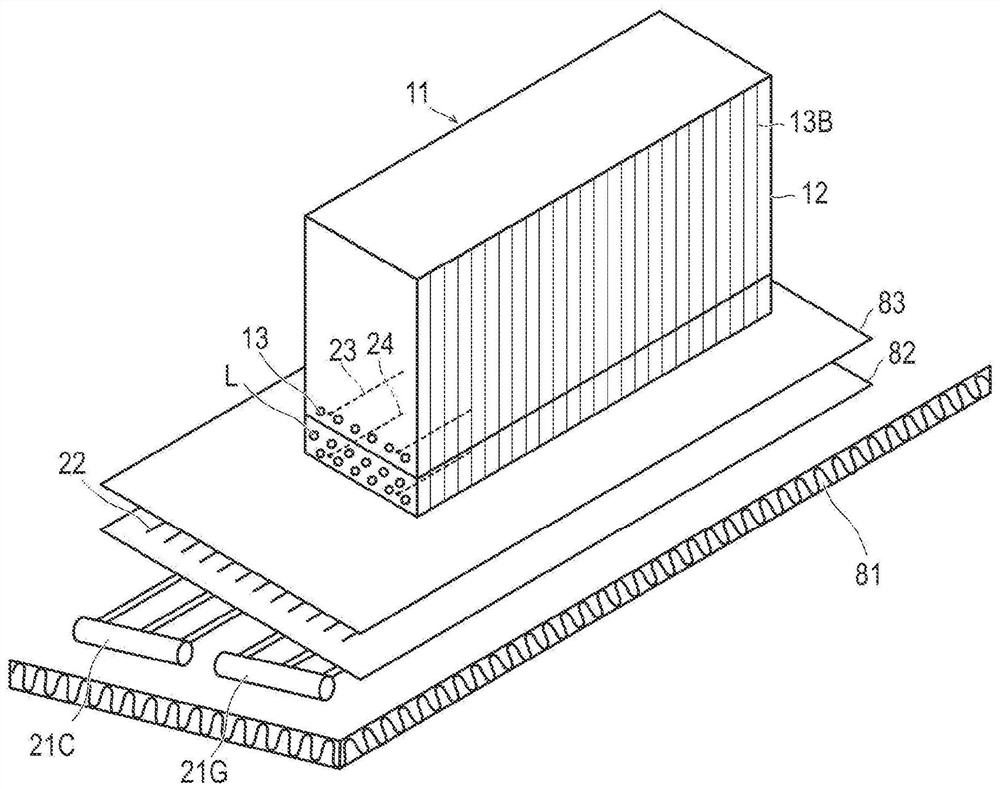

Equipment cooling device

InactiveCN111295555AReduce consumptionAir-treating devicesCompression machines with non-reversible cycleWorking fluidHydraulic fluid

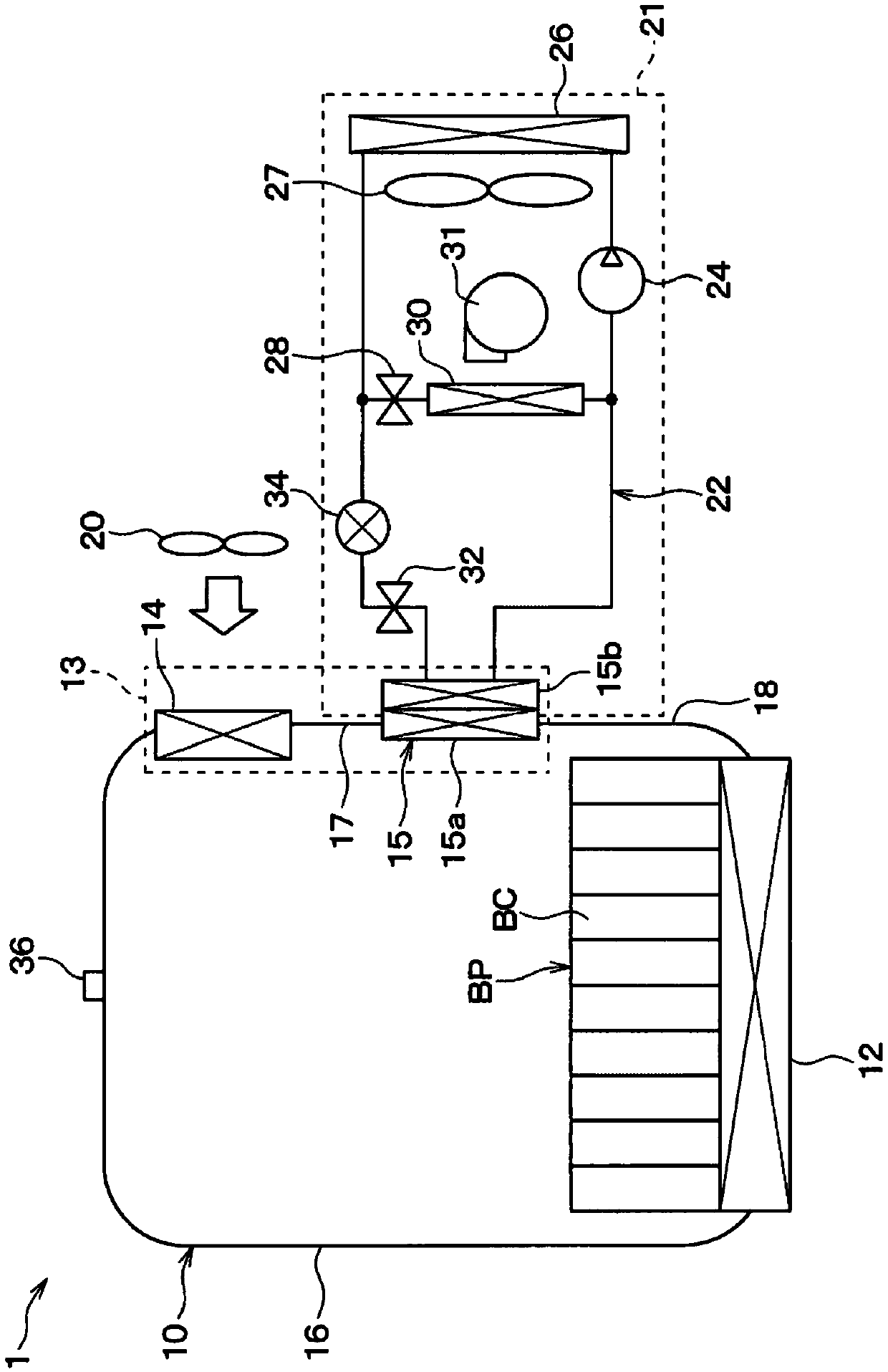

A cooler (11) cools target equipment (2) by using latent heat from vaporization of a hydraulic fluid. A cold heat source-type heat exchanger (12) uses the cold heat of a low-temperature, low-pressurerefrigerant circulating through a freezing cycle (30), radiates heat from hydraulic fluid that has vaporized in a cooler (11), and condenses the hydraulic fluid. An air cooled heat exchanger (13) usescold heat of external air, radiates heat from hydraulic fluid that has vaporized in the cooler (11), and condenses the hydraulic fluid. The cooler (11), the cold heat source-type heat exchanger (12),and the air cooled heat exchanger (13) are connected by a gas pipe (14) and a liquid pipe (15). An external air temperature detection unit (16) detects external air temperature. A saturation temperature detection unit (17) detects the saturation temperature of hydraulic fluid circulating through a thermosiphon circuit (10). Heat radiation amount adjustment units (18, 20, 31, 33, 38, 41, 321, 322)adjust the amount of heat radiation from the hydraulic fluid flowing through the cold heat source-type heat exchanger (12), such that the saturation temperature of the hydraulic fluid is higher thanthe external air temperature.

Owner:DENSO CORP

Heat dissipating module with three-dimensional structure

InactiveUS20200326130A1Improve cooling effectLess side effectsSemiconductor/solid-state device detailsIndirect heat exchangersVaporizationBoyle's law

A heat dissipating module with three-dimensional structure includes a heat dissipating cavity connecting to a top of a heat absorbing cavity to form a distance from a heat source. When a working fluid in the heat absorbing cavity absorbs the thermal energy and is vaporized, the vapor would flow up to a vapor guiding space due to thermosyphon effect and principles of Boyle's Law, and then the vapor is projected and spread rapidly and evenly to the heat dissipating cavity through a projecting exit. Then the vapor is condensed into liquid and become the working fluid again by heat exchange. The condensed liquid then drips down and flows back to the heat absorbing cavity via micro-passages, forming a cycle of phase change of the working fluid for operation of heat dissipation.

Owner:JAI LONG PING TANG TECH

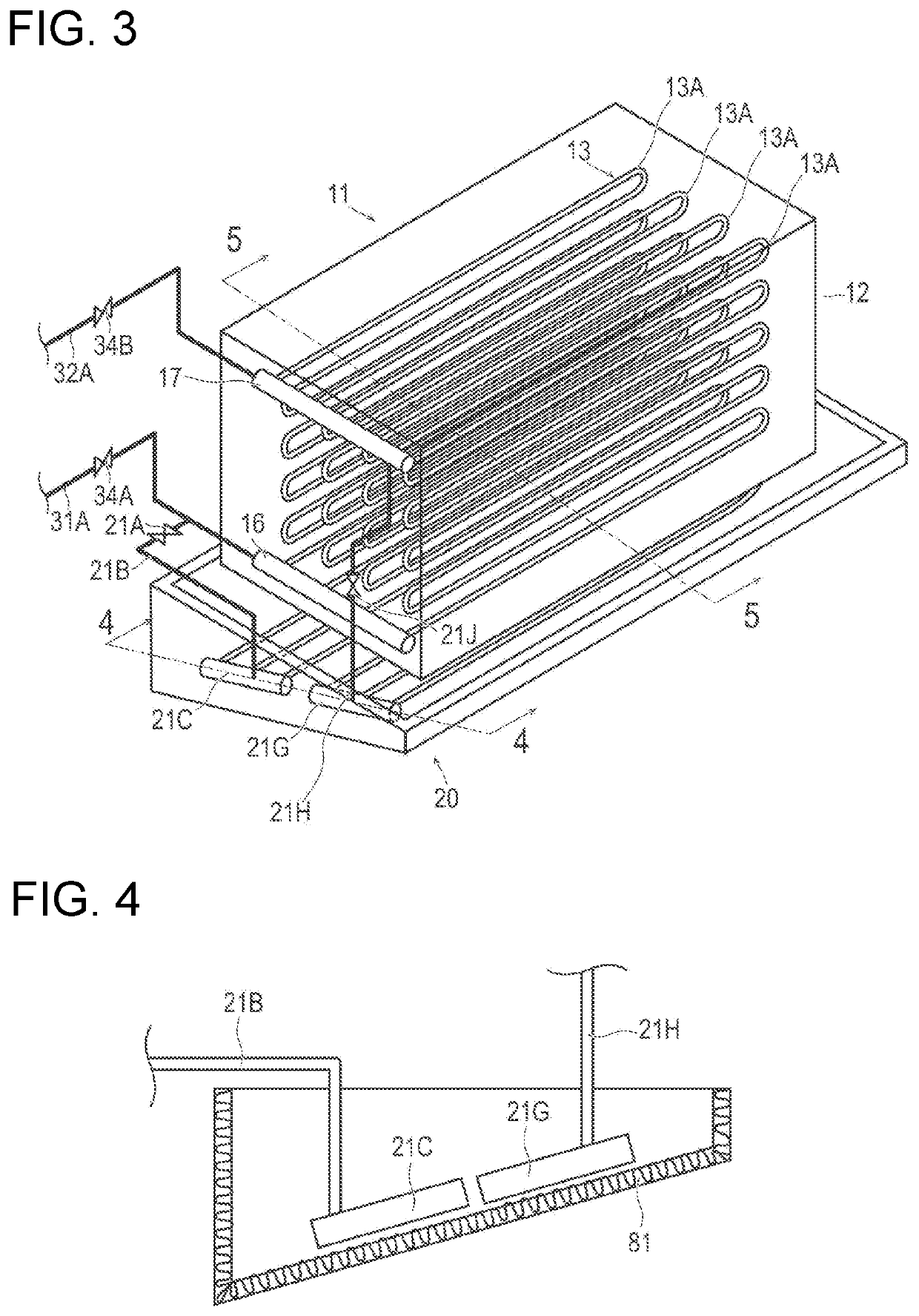

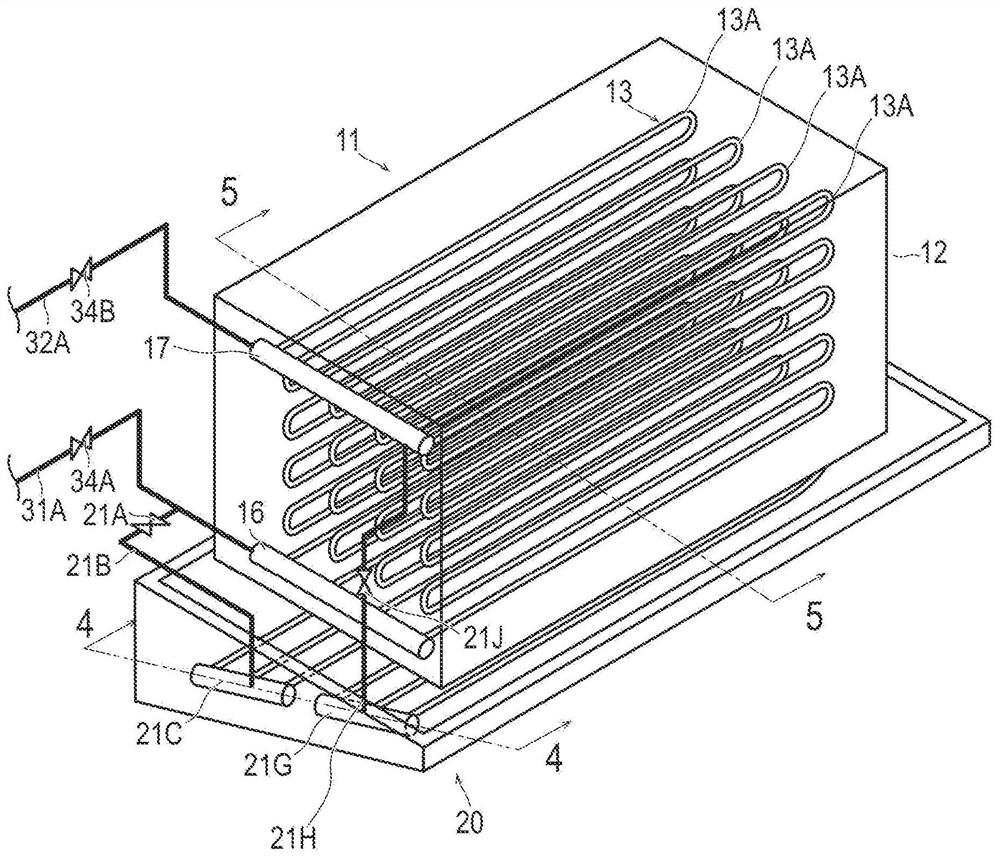

Defrost system

InactiveUS20210262721A1Prevent icicleAvoid it happening againMechanical apparatusCorrosion preventionRefrigerantMechanical engineering

To provide a defrost system capable of preferable defrosting and prevention of generation of icicles on a casing without installing a brine circuit. A defrost system includes a thermosiphon defrost circuit that is provided by being branched from a circulation line, in which, at the time of defrosting, a CO2 refrigerant staying inside a fin-tube heat exchanger repeats a two-phase change of a gaseous form and reliquefaction, and which forms a CO2 circulation path together with the fin-tube heat exchanger; electromagnetic opening / closing valves and that are closed at the time of defrosting and set the CO2 circulation path to a closed circuit; and a first electric heater arranged above the thermosiphon defrost circuit so as to be adjacent to the thermosiphon defrost circuit, and naturally circulates the CO2 refrigerant in the closed circuit at the time of defrosting.

Owner:MAYEKAWA MFG CO LTD

Defrost system

ActiveCN113631876AAvoid it happening againMechanical apparatusCorrosion preventionEngineeringRefrigerant

To provide a defrost system that can satisfactorily defrost without the introduction of a brine circuit and that can prevent the formation of icicles in a casing. A defrost system 20 comprises: a thermosiphon defrost circuit 21 provided so as to branch off from a circulation line 30 and to form a CO2 circulation path with a fin tube heat exchanger 13 containing a CO2 refrigerant which, during a defrosting operation, repeatedly undergoes a two-phase change between a gaseous state and re-liquefaction; an electromagnetic opening / closing valve 34A, 34B that closes during a defrosting operation to make the CO2 circulation path a closed circuit; and a first electric heater 22 disposed above the thermosiphon defrost circuit so as to be adjacent thereto. The defrost system 20 allows the CO2 refrigerant to naturally circulate around the closed circuit during the defrosting operation.

Owner:MAYEKAWA MFG CO LTD

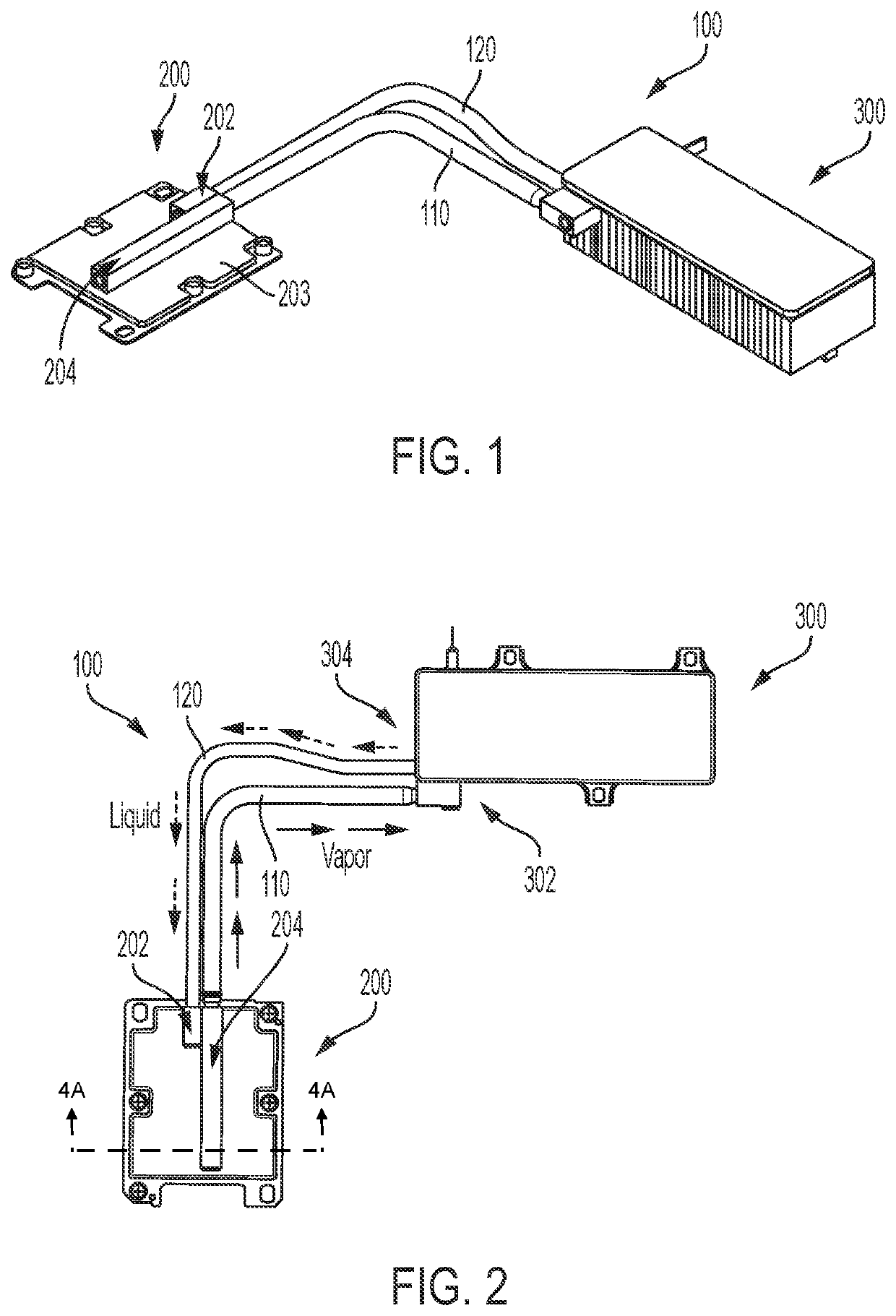

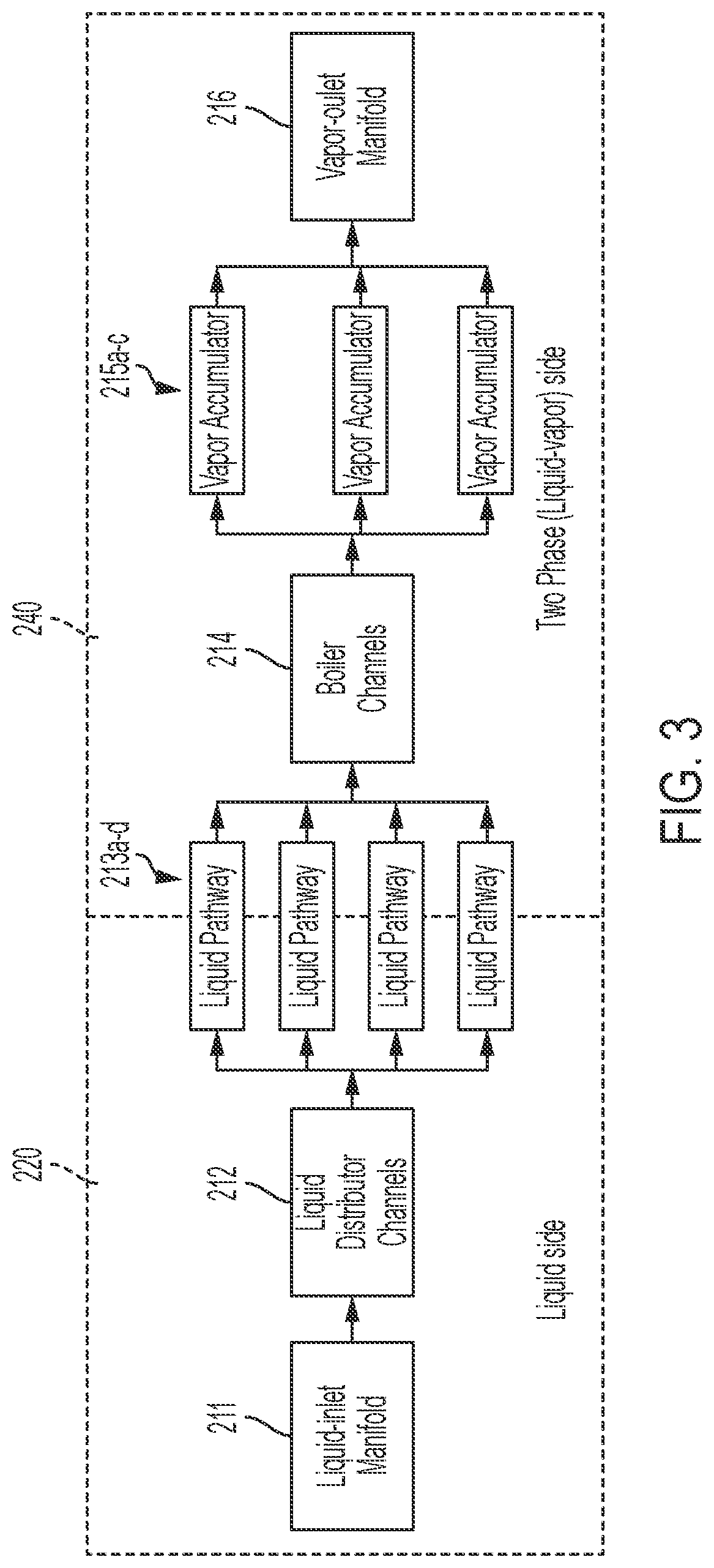

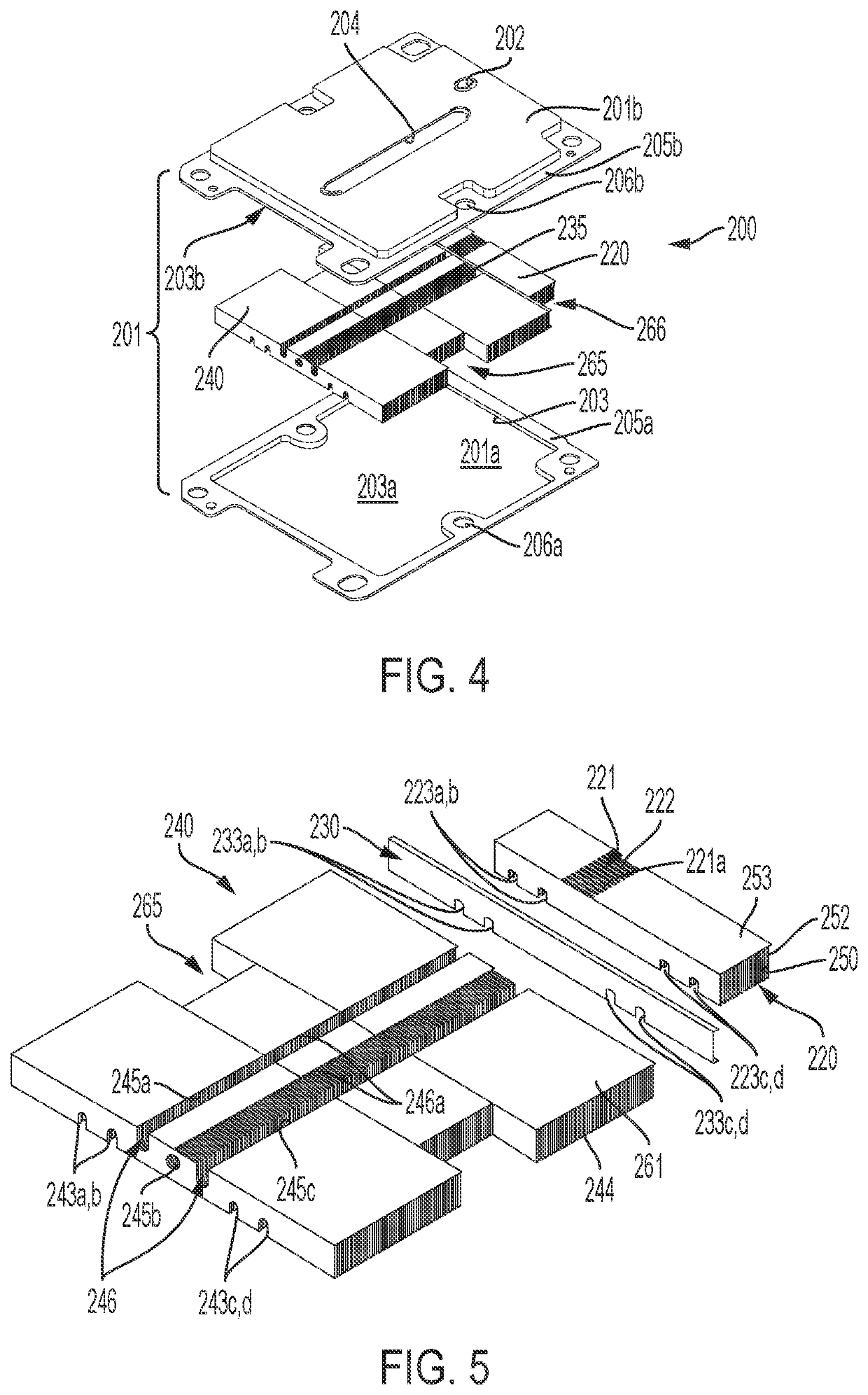

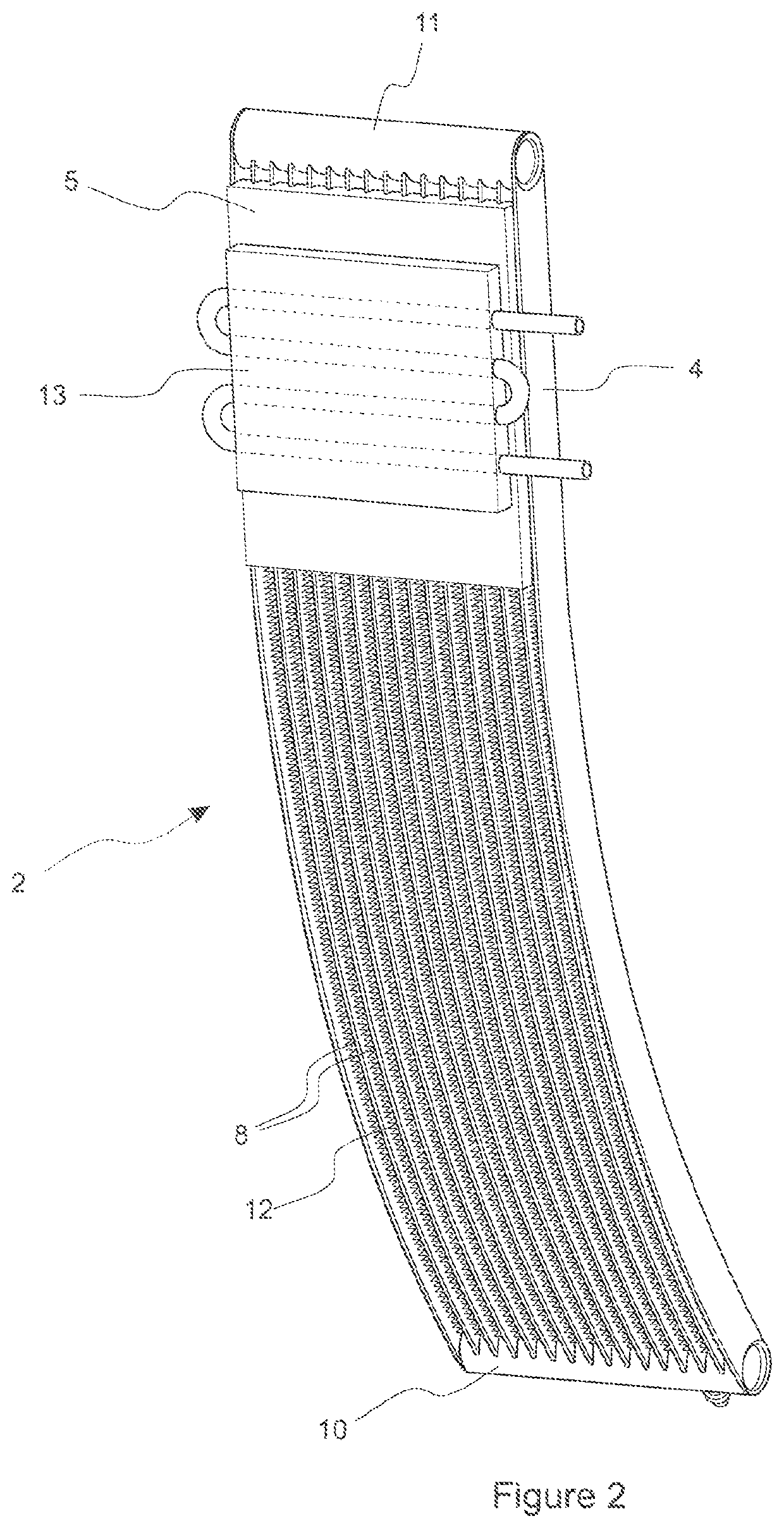

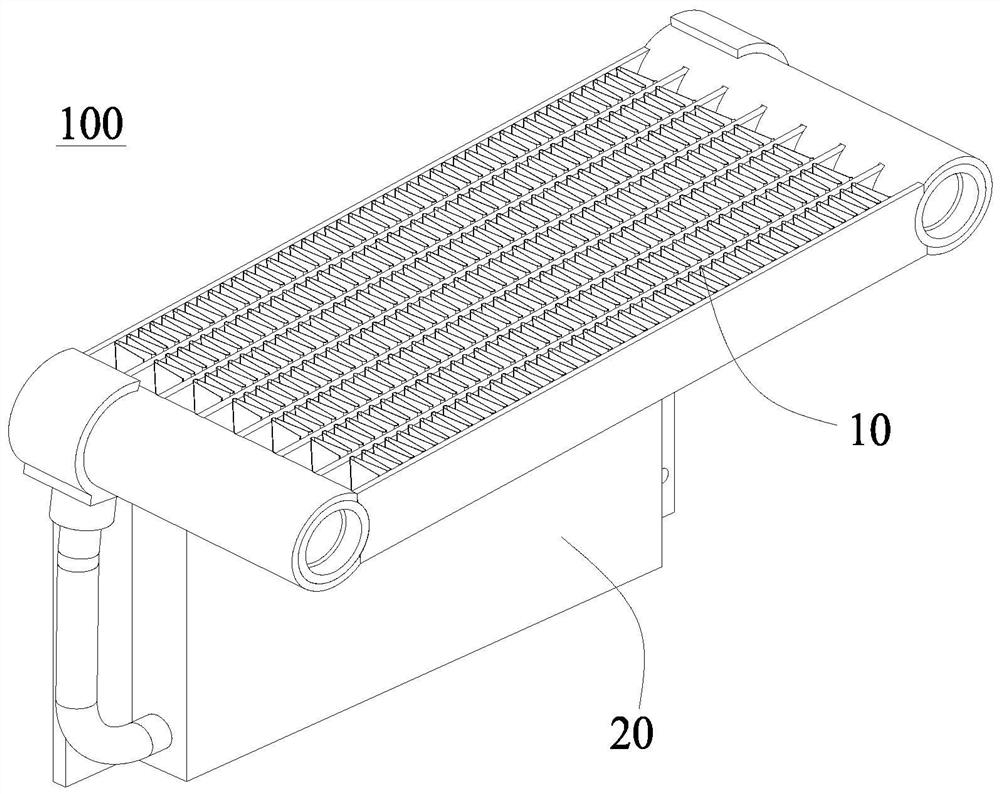

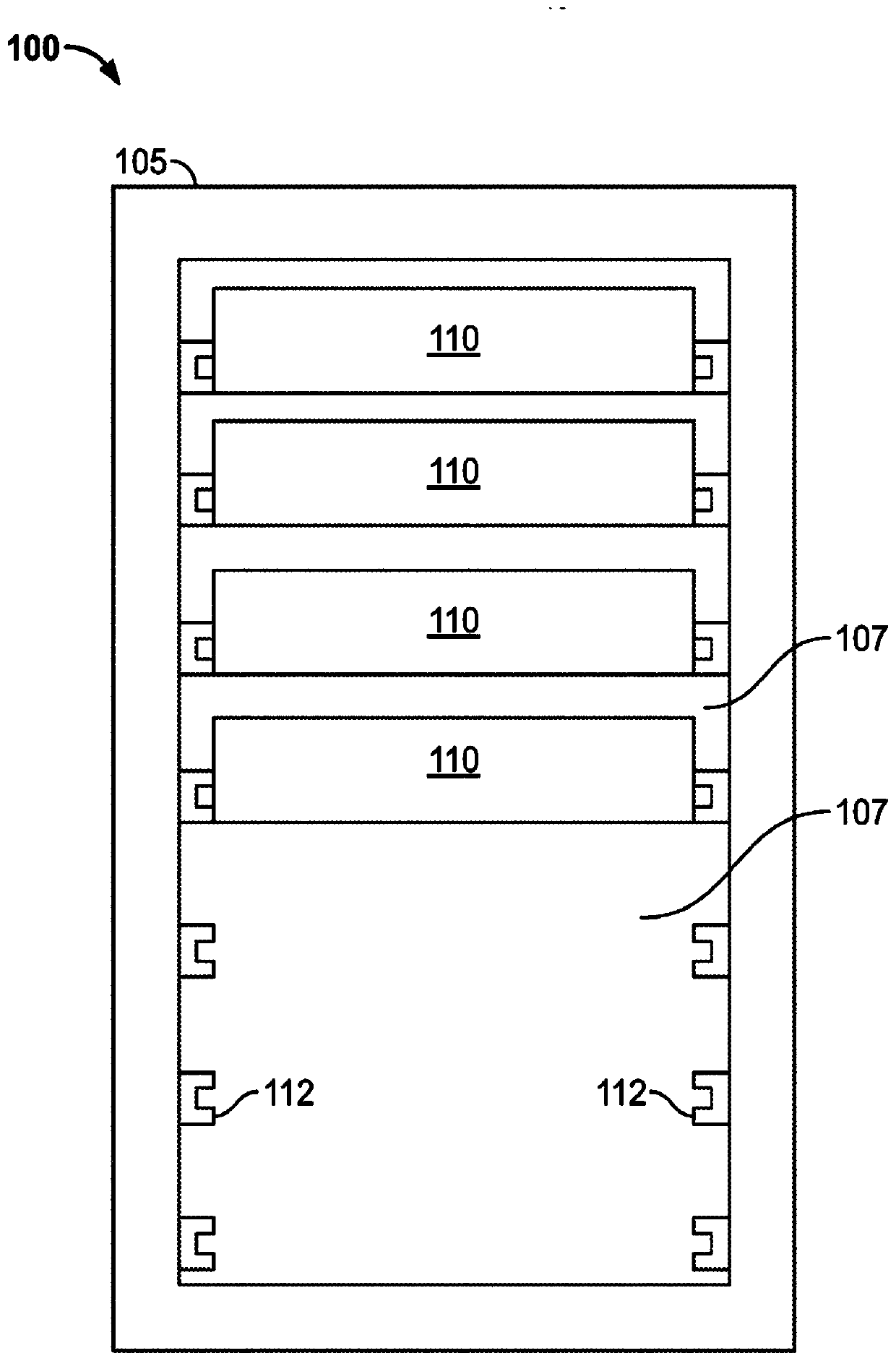

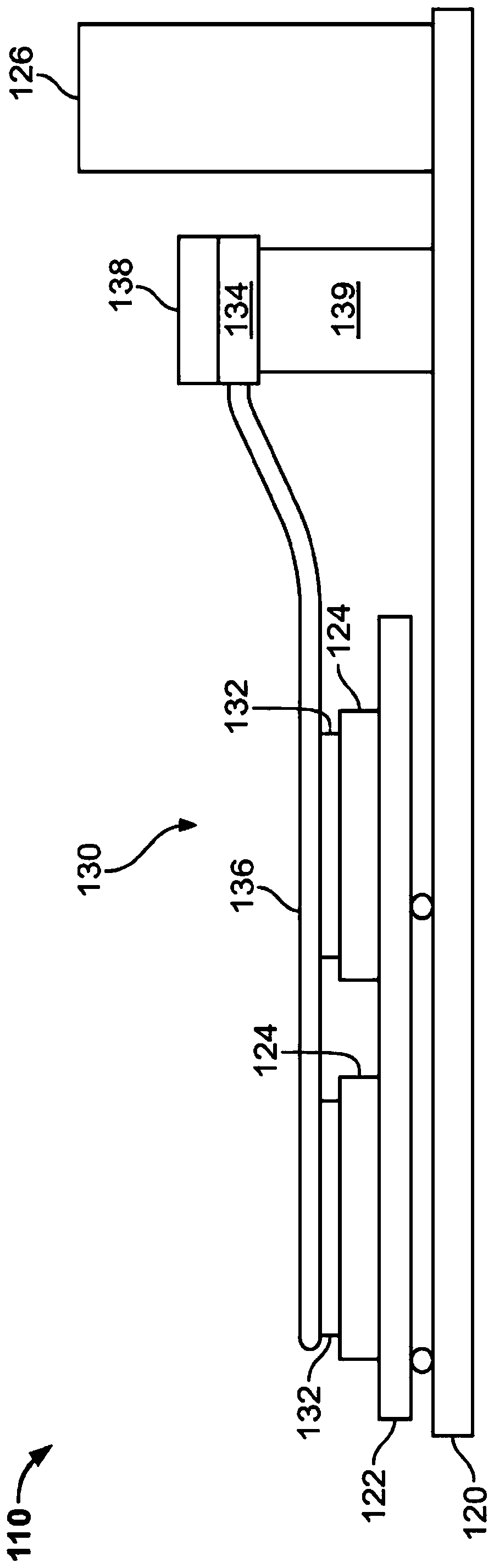

Loop thermosyphon devices and systems, and related methods

PendingUS20220142001A1Reduce thermal resistanceAdequate flowIndirect heat exchangersModifications using liquid coolingHeat transmissionLiquid cooling system

A loop thermosyphon can combine the best of heat-pipes and traditional liquid-cooling systems that include a mechanical pump. A disclosed heat-transfer device includes a first heat-transfer component and a second heat-transfer component fluidly coupled with each other by a first conduit and a second conduit. A first manifold is positioned in the first heat-transfer component and defines a first plurality of liquid pathways. The first manifold fluidly couples with the first conduit. A second manifold is also positioned in the first heat-transfer component and defines a second plurality of liquid pathways fluidly coupled with and extending from the first plurality of liquid pathways. The second manifold further defines a plurality of boiling channels, a plurality of accumulator channels and a vapor manifold. The boiling channels extend transversely relative to and are fluidly coupled with the second plurality of liquid pathways. The plurality of accumulator channels extends transversely relative to and are fluidly coupled with the plurality of boiling channels. The vapor manifold is configured to collect vapor from one or more of the plurality of boiling channels, one or more of the plurality of accumulator channels, or both. The first heat-transfer component further defines an outlet fluidly coupling the vapor manifold with the second conduit. Electrical devices incorporating such a heat-transfer device also are disclosed, as well as associated methods.

Owner:DEEIA INC

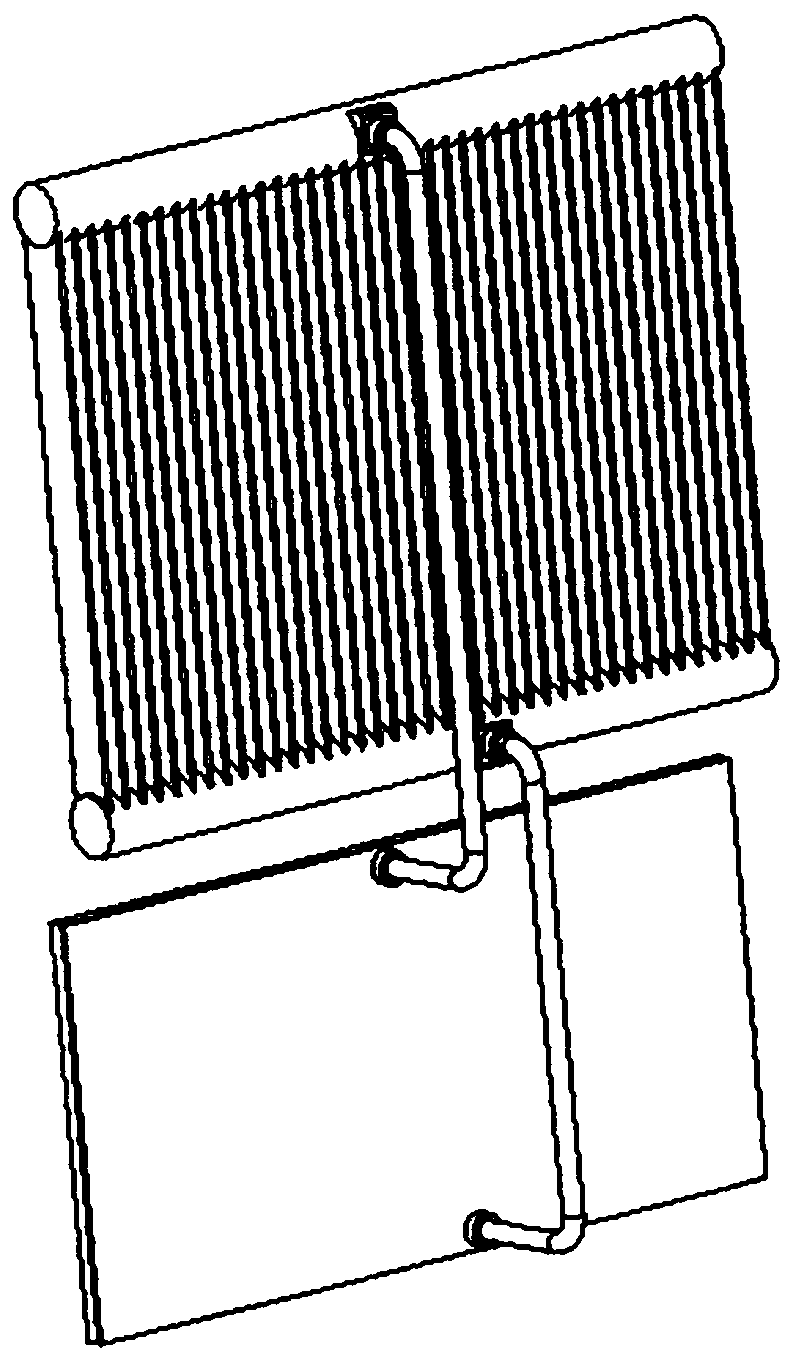

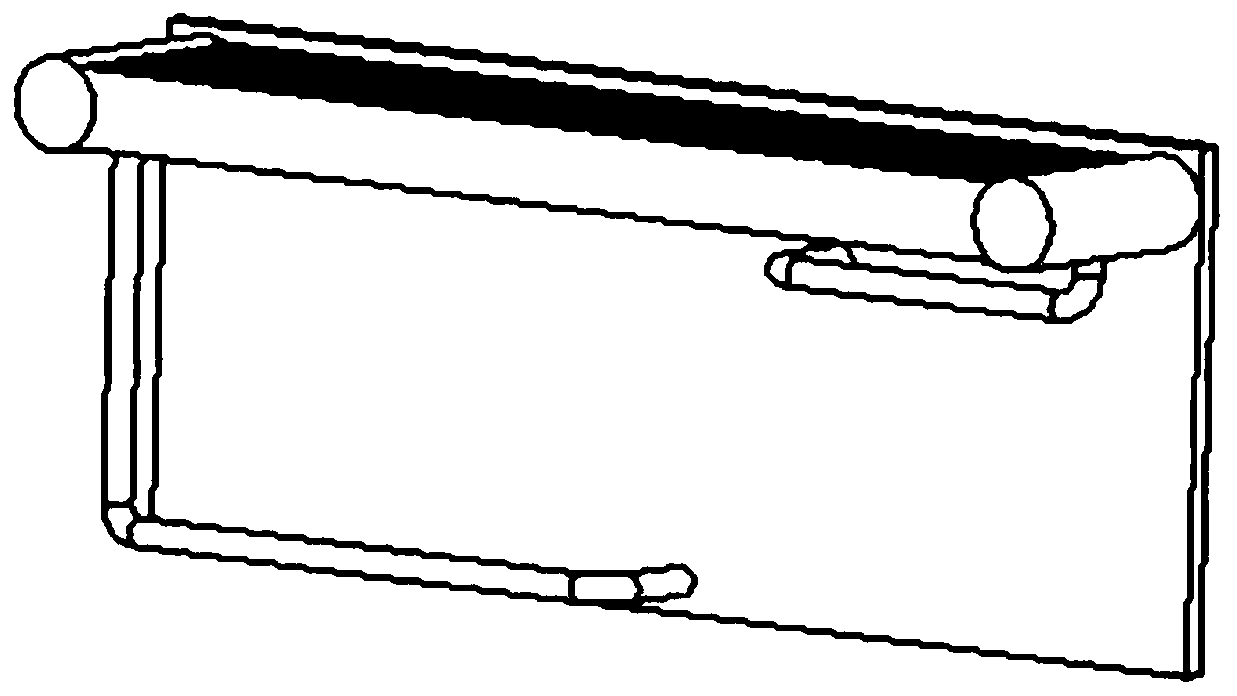

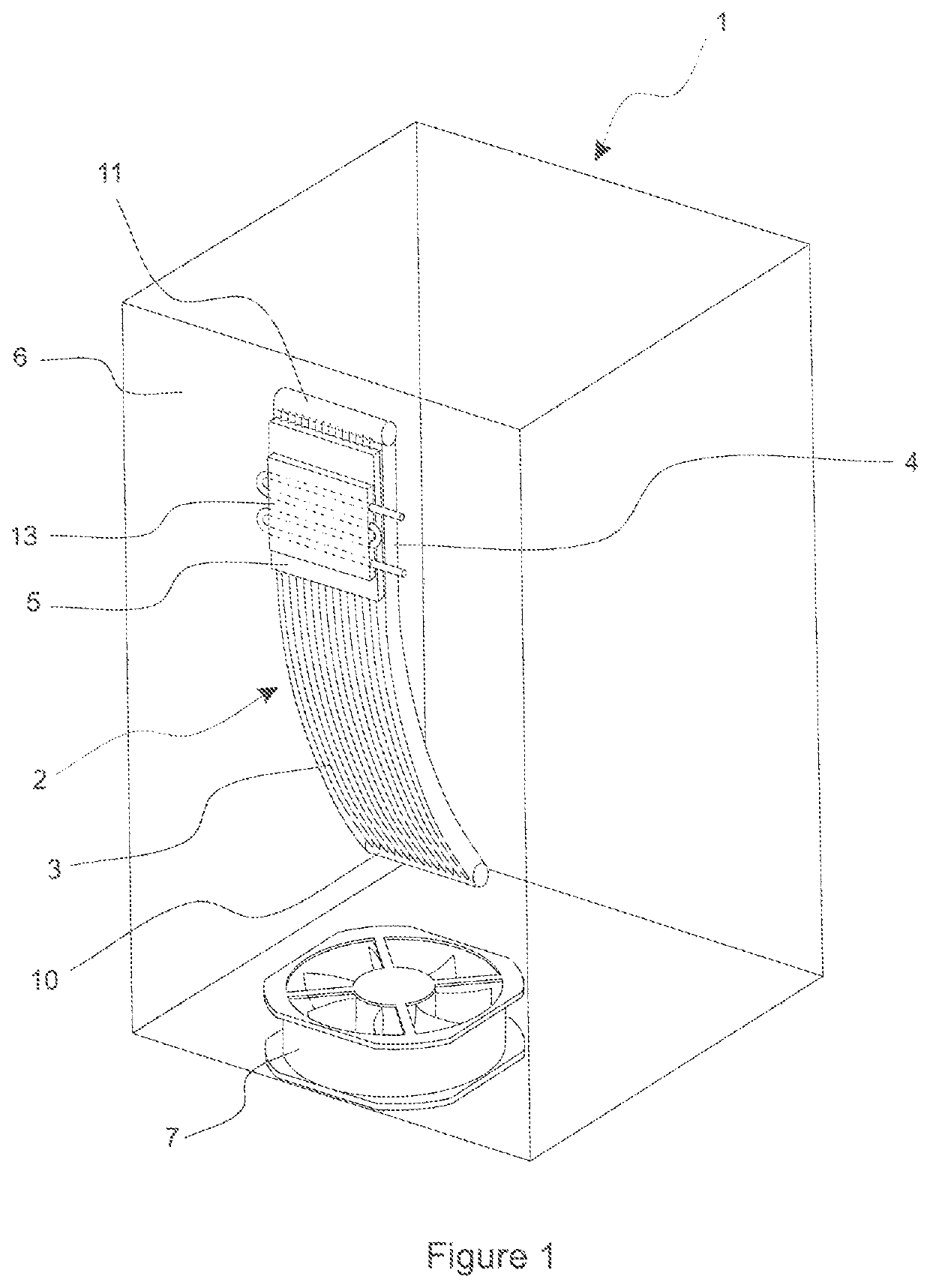

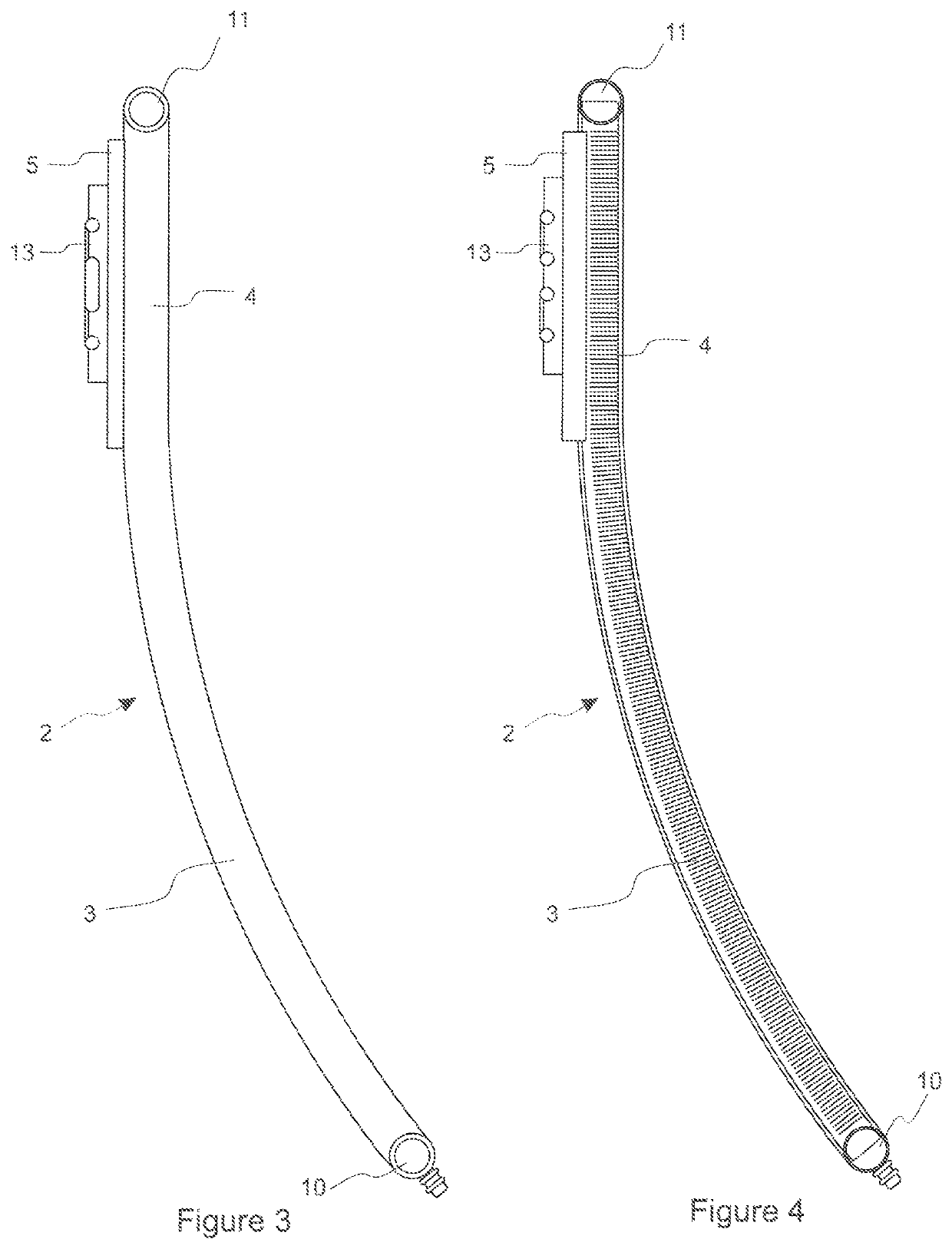

Arrangement for cooling a closed cabinet

ActiveUS10634434B2Easy to installEasy maintenanceDomestic cooling apparatusStationary conduit assembliesHeat flowCondenser (heat transfer)

An arrangement for cooling a closed, sealed cabinet (1), comprising a thermosiphon heat exchanger (2) disposed inside the cabinet (1) and having an evaporator (3) and a condenser (4) for circulating a working fluid between the evaporator (3) and the condenser (4) in a closed loop, wherein the working fluid evaporated in the evaporator (3) by heat flows to the condenser (4) for cooling and the condensed working fluid flows back to the evaporator (3). The evaporator (3) is exposed to hot air flow generated inside the cabinet (1), and a heat transfer element (5) is attached to the condenser (3) in a sealed manner through a cabinet wall (6) for transferring heat to the outside of the cabinet (1).

Owner:ABB (SCHWEIZ) AG

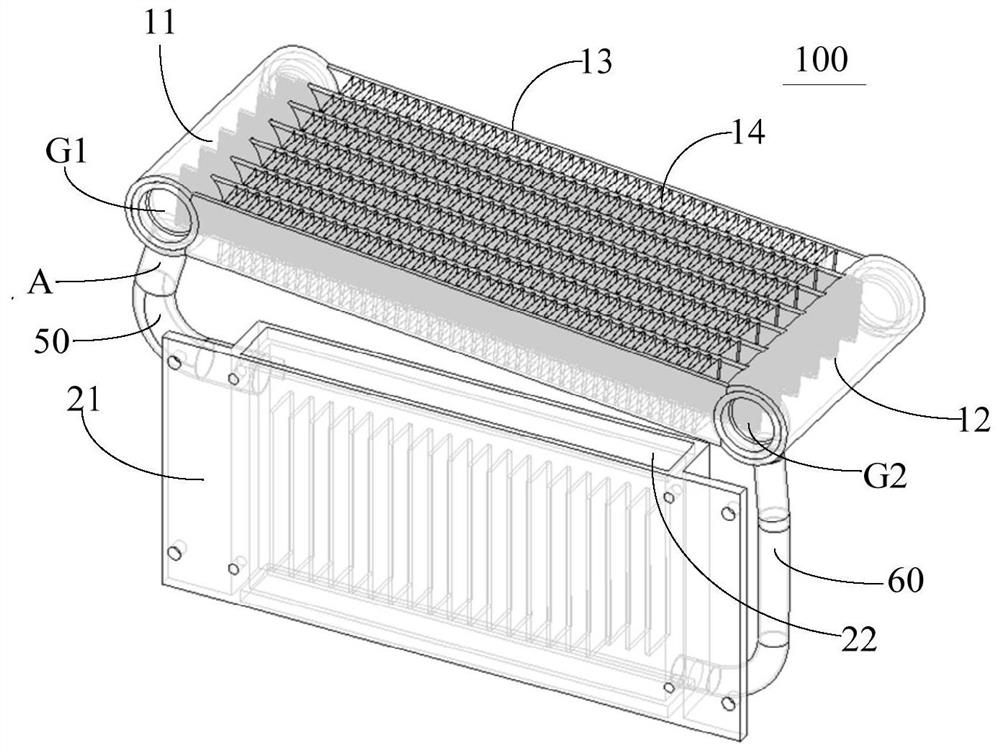

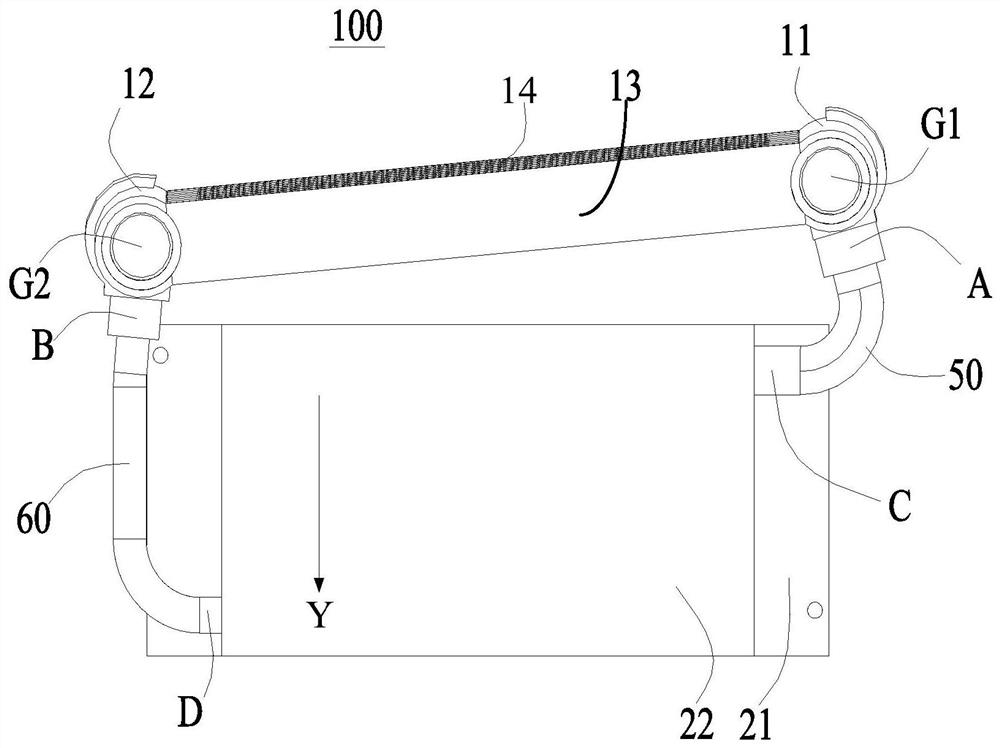

Thermosiphon heat exchanger

ActiveUS20210041180A1Avoid wastingCorrosion preventionStationary conduit assembliesEngineeringMechanical engineering

A thermosiphon heat exchanger includes a chassis, an evaporation assembly and a condensation assembly. The chassis has an internal circulation chamber and an external circulation chamber separated from each other. The evaporation assembly is disposed in the internal circulation chamber. The condensation assembly is disposed in the external circulation chamber and horizontally positioned higher than the evaporation assembly, and the condensation assembly is coupled to the evaporation assembly by plural separated loops.

Owner:DELTA ELECTRONICS INC

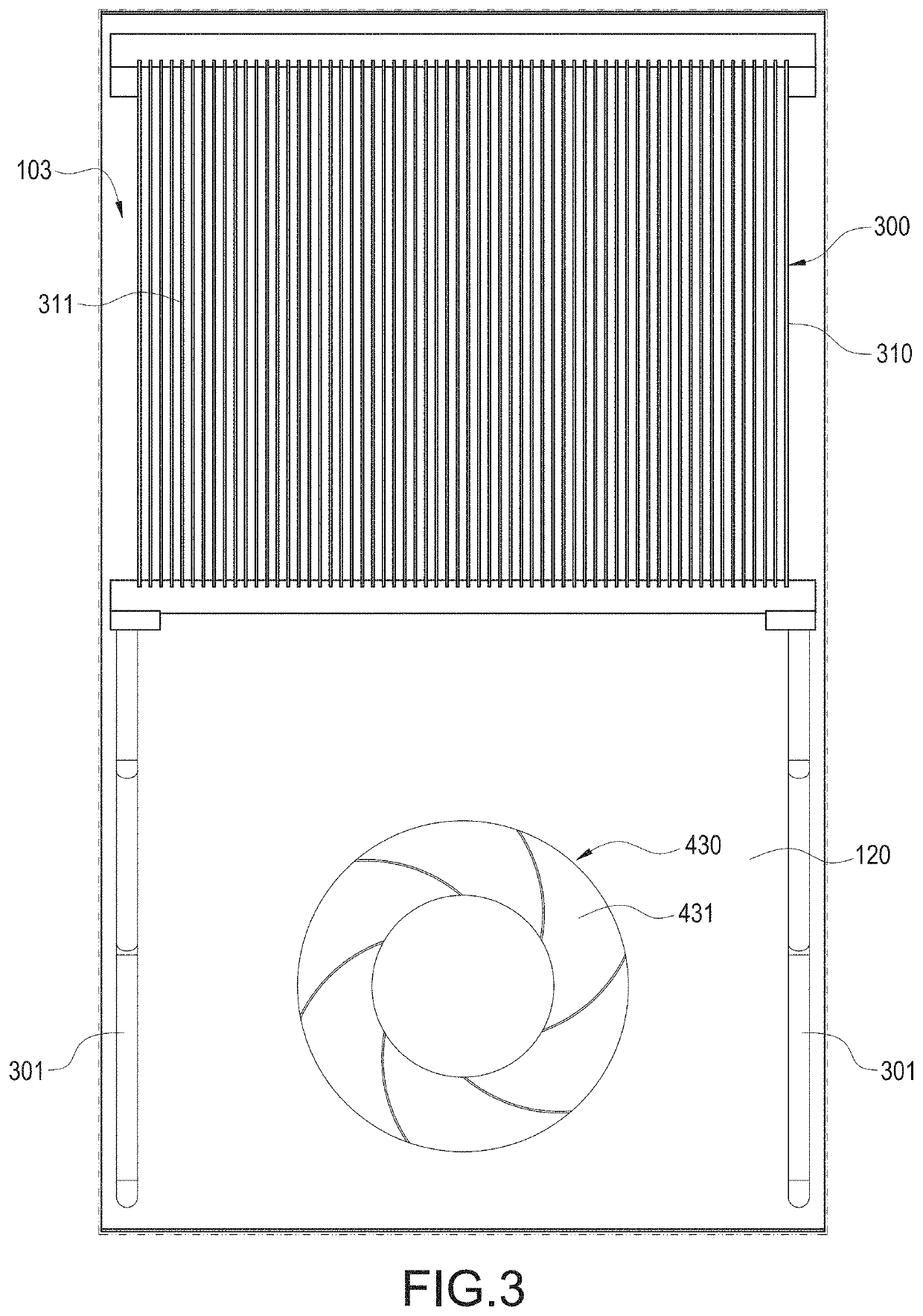

Split type thermosyphon phase change radiator and industrial control equipment

PendingCN112867364AImprove exchange capacityImprove cooling effectIndirect heat exchangersCooling/ventilation/heating modificationsThermosiphoHeat spreader

The invention provides a split type thermosyphon phase change radiator and industrial control equipment. The split type thermosyphon phase change radiator comprises a condenser and an evaporator. According to the technical scheme, in order to improve the heat exchange effect of the evaporator, ab evaporation cavity is formed in the evaporator and provided with a first area, a second area and a third area which communicate with one another, the first area communicates with the air outlet, the second area communicates with a liquid return opening, and a closed loop is formed. After the evaporator is tightly attached to a heating device, heat of the heating device is absorbed through a heat conduction structure and / or a flow guide structure in the third area, so that the physical state of the phase change medium in the evaporation cavity is changed, specifically, the phase change medium is vaporized in the third area to form high-temperature gas, and the high-temperature gas enters the condenser through the first area and the gas outlet in sequence; and the liquid flows back to the second area through the liquid outlet and the liquid return opening, so that the heat dissipation effect of the evaporator is improved.

Owner:SUZHOU INOVANCE TECH CO LTD

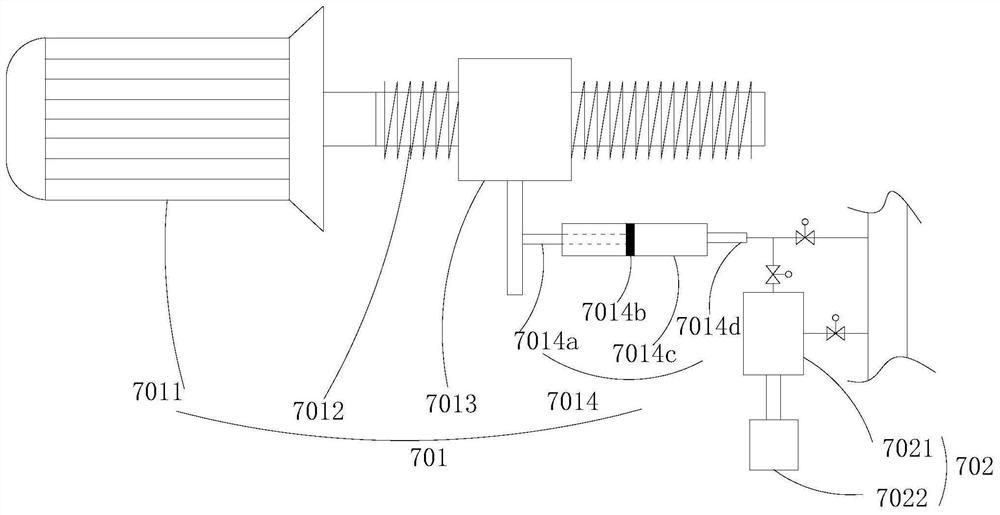

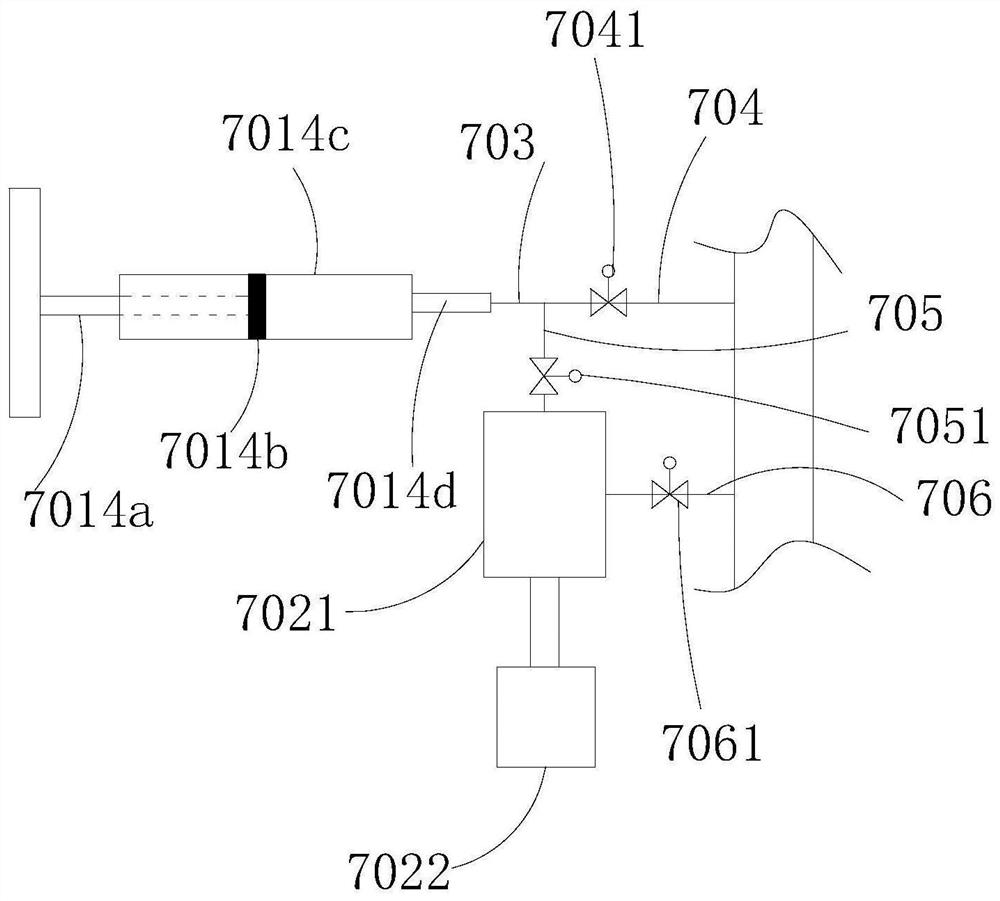

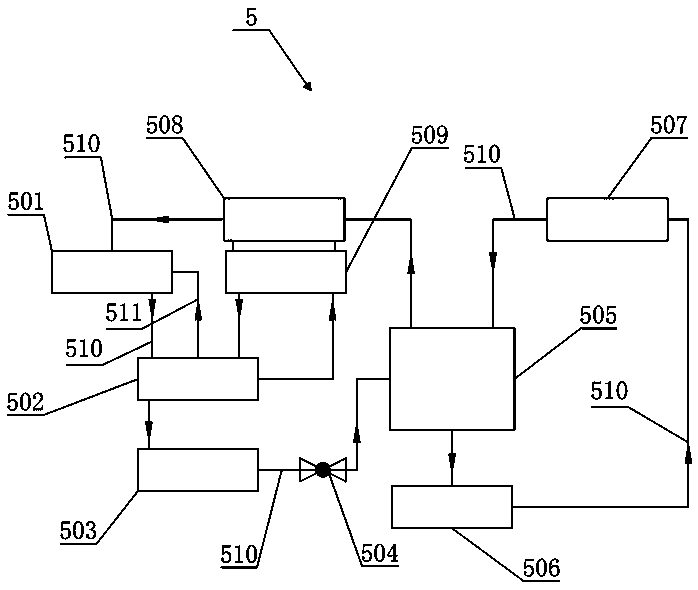

Ejecting thermosyphon multifunctional oil return device for heat pump unit

PendingCN112923605AImprove performanceViscosity real-time feedbackCompressorRefrigeration safety arrangementEngineeringRefrigerant

The invention relates to an ejecting thermosyphon multifunctional oil return device for a heat pump unit. The ejecting thermosyphon multifunctional oil return device comprises an evaporator, a cooling heat exchanger, a compressor and an ejector. The evaporator is sequentially connected with the cooling heat exchanger and the compressor through a refrigerant liquid inlet pipeline; the ejector is respectively connected to the evaporator and the compressor through pipeline connection; the cooling heat exchanger is connected with an oil tank and further connected with the ejector through a cooling electromagnetic valve; a bypass electromagnetic valve is arranged between the ejector and the refrigerant liquid inlet pipeline, and the ejector is further connected with a condenser gas pipeline through a condensed gas electromagnetic valve; and a lubricating oil detection device is arranged on the cooling oil pipe between the compressor and the cooling heat exchanger. Oil temperature control and system oil return are achieved at the same time, the cost can be reduced, and the compressor efficiency and the system performance are improved; and lubricating oil entering the compressor is detected online through a viscosity detection device, so that the temperature of the lubricating oil entering the compressor is adjusted in time, and the lubricating effect of the lubricating oil is guaranteed.

Owner:一冷豪申新能源(上海)有限公司

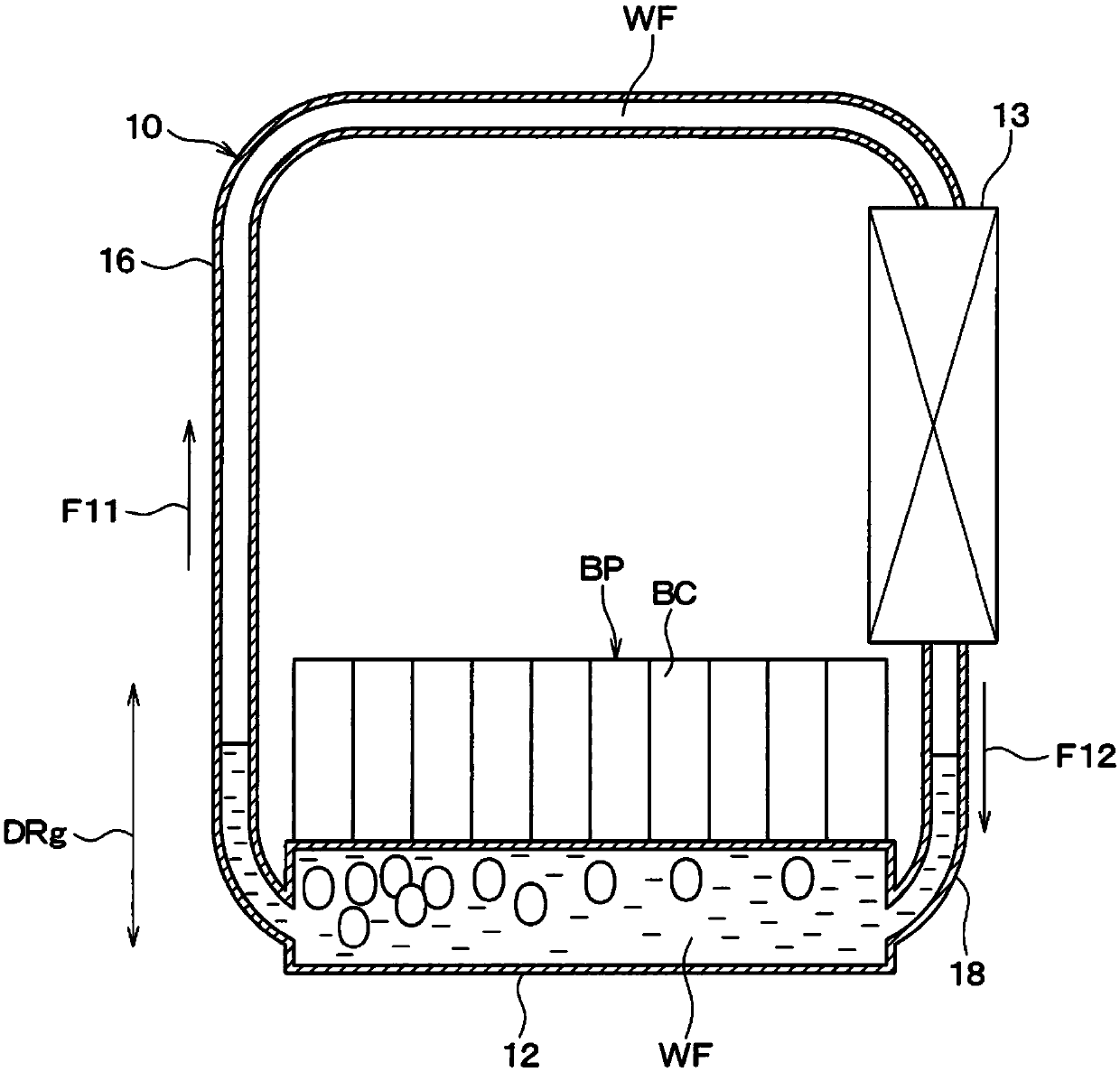

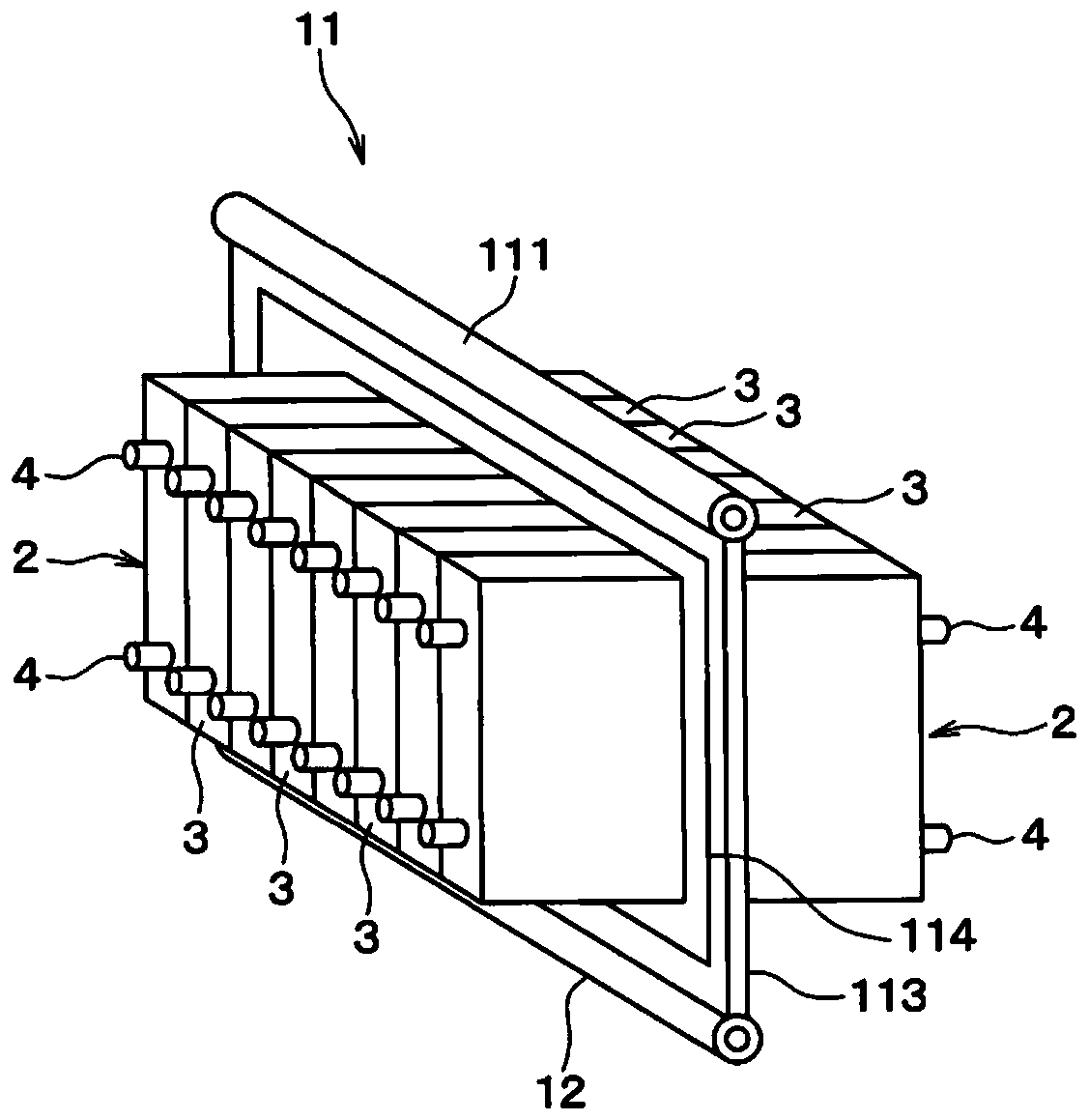

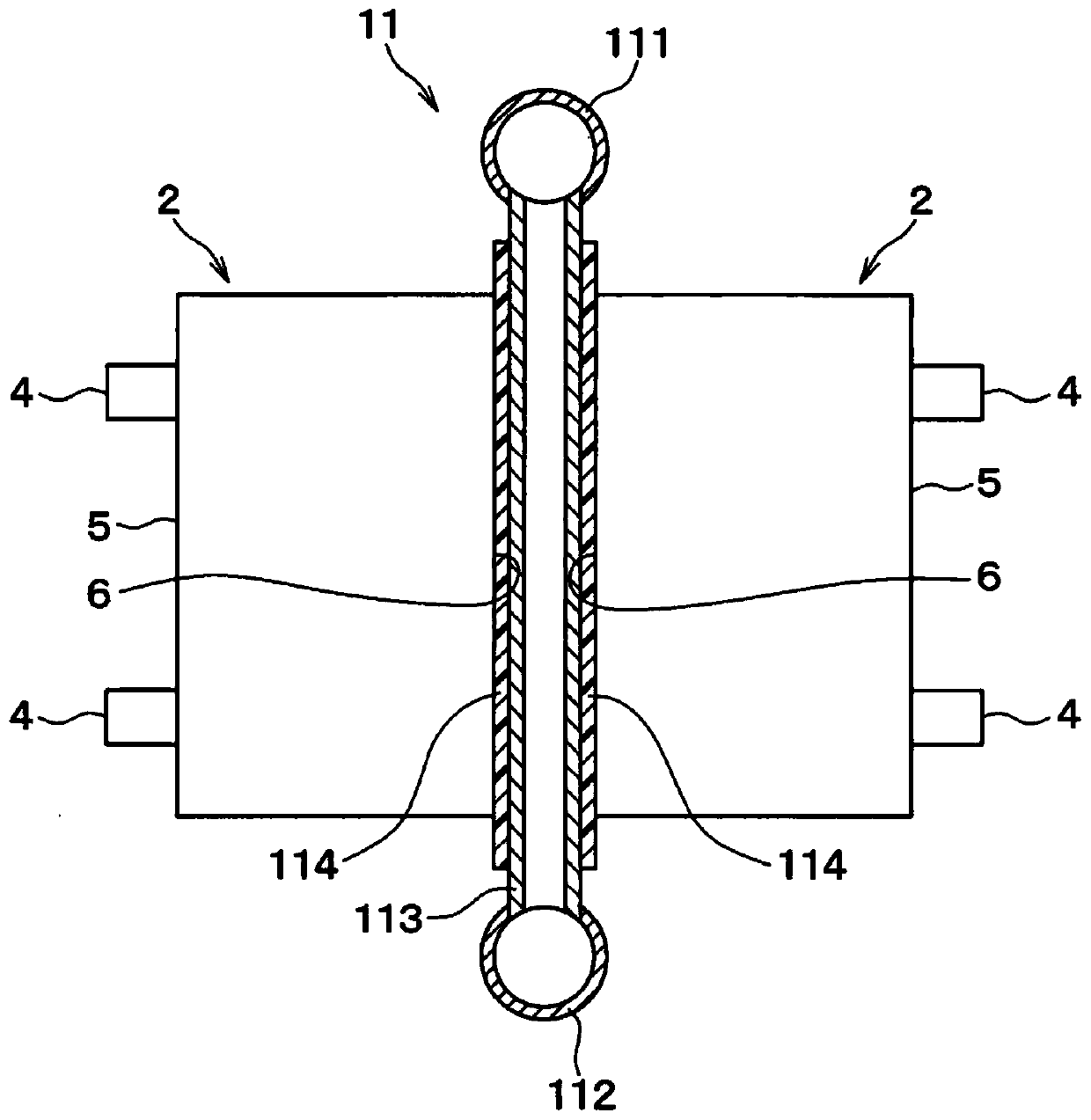

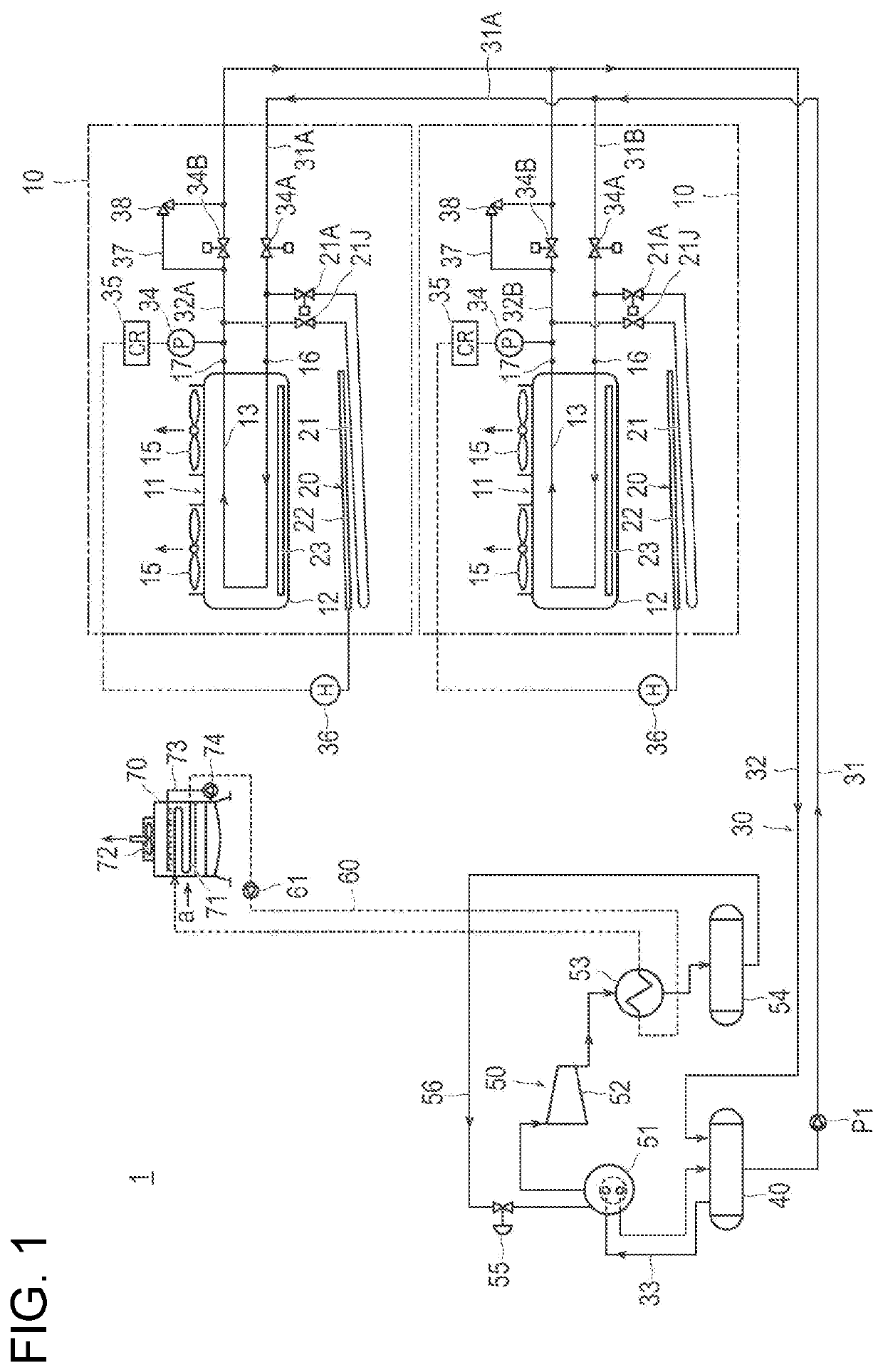

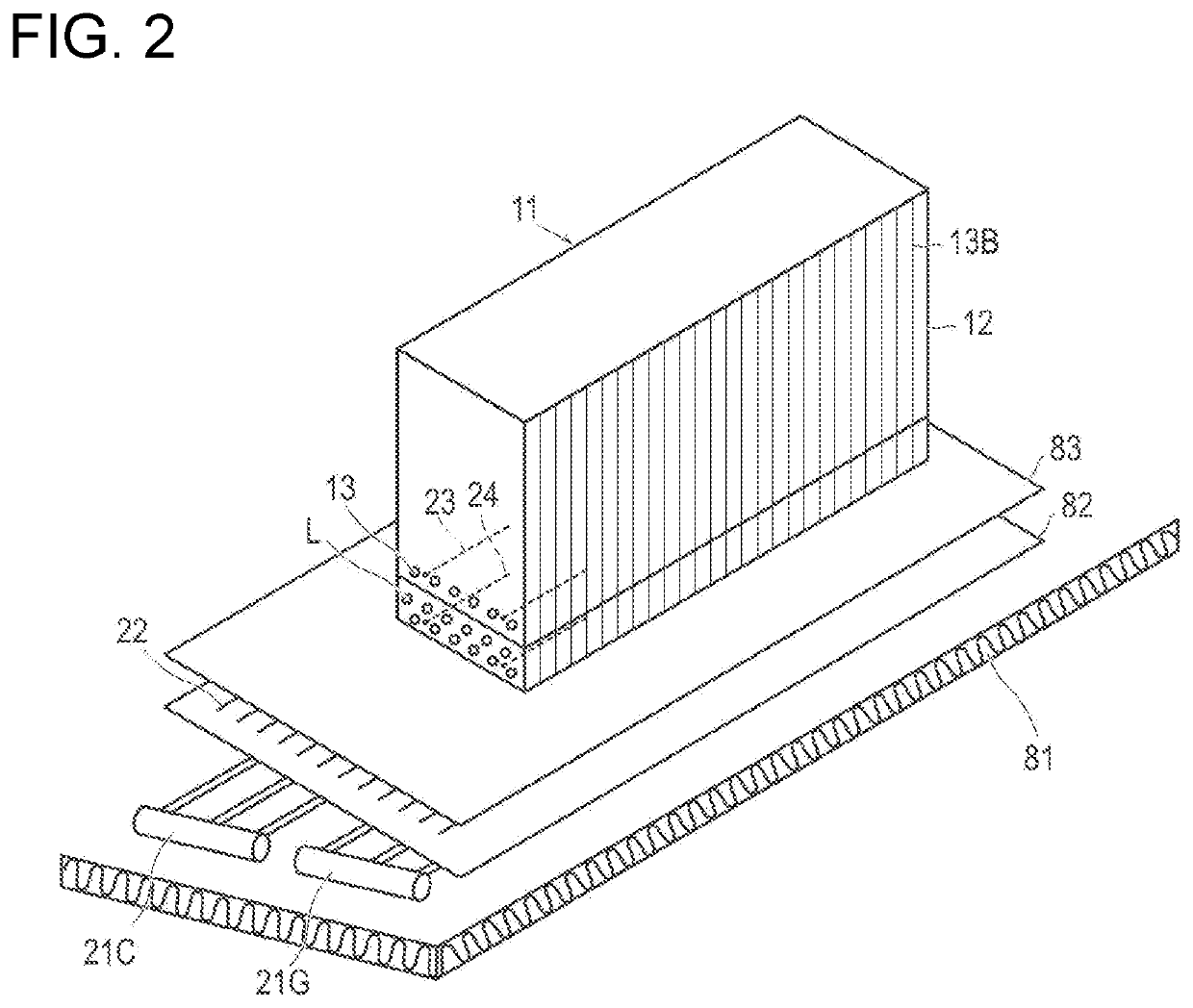

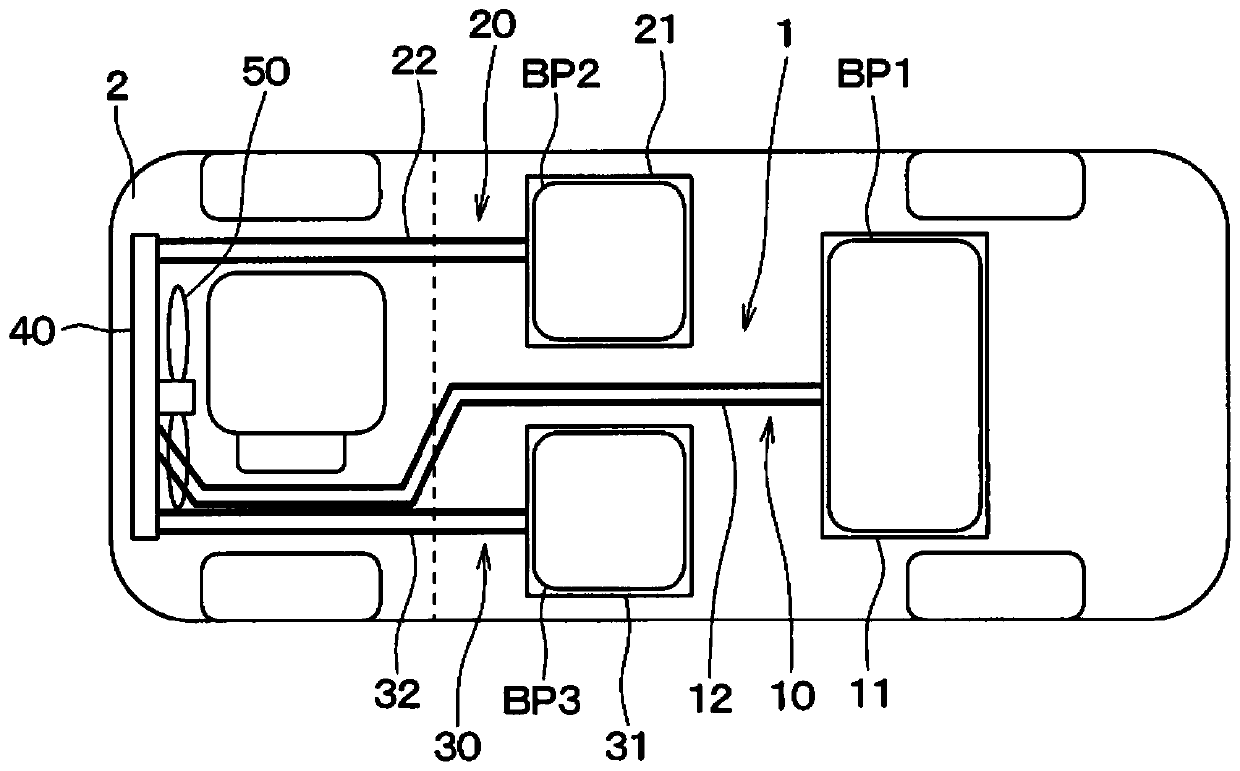

Equipment temperature regulator

InactiveCN109716051BReduce in quantityIncrease carrying capacitySemiconductor/solid-state device detailsSolid-state devicesTemperature controlWorking fluid

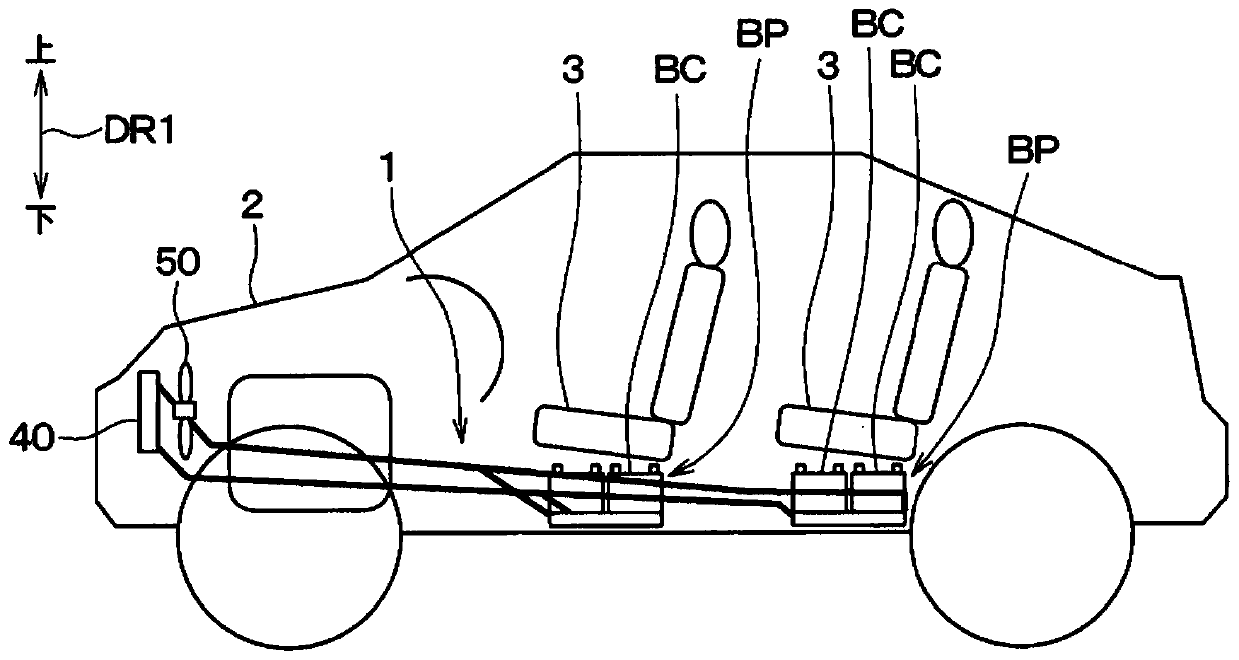

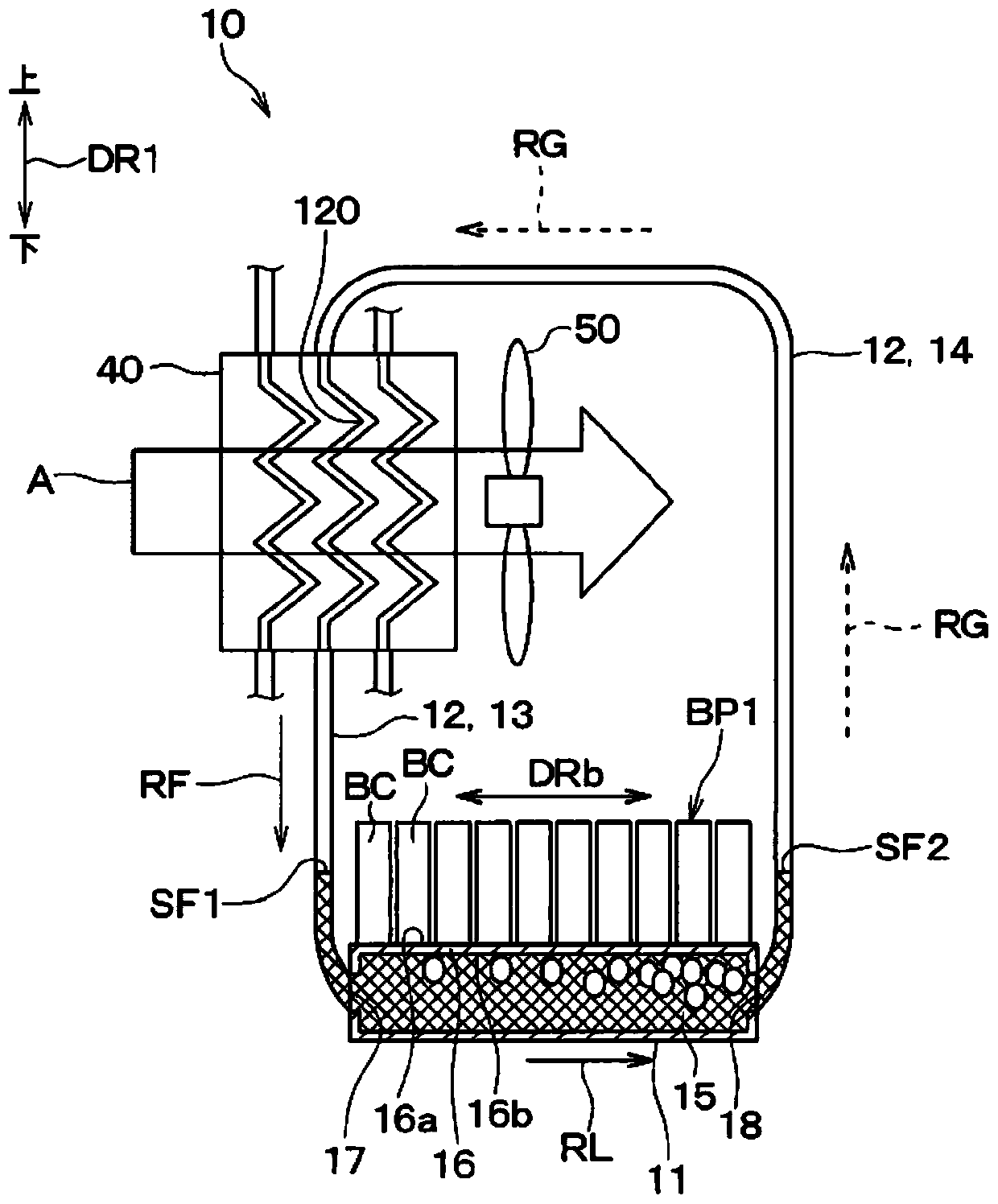

The present invention provides a device temperature regulator using a plurality of thermosiphon circuits capable of reducing the number of parts and improving vehicle mountability and vehicle mountability. The first thermosyphon circuit (10) has a first evaporator (11) and a first passage (12) through latent heat of evaporation of the working fluid evaporated by absorbing heat from the first object device (BP1) To cool the first object device (BP1), the first passage communicates with the first evaporator (11). The second thermosiphon circuit (20) includes a second evaporator (21) that evaporates the working fluid evaporated by absorbing heat from the second object device (BP2) and a second passage (22). The second object device (BP2) is cooled by latent heat, and the second passage (22) communicates with the second evaporator (21). The main condenser (40) has a first heat exchange part (120) provided in the first passage (12) and a second heat exchange part (220) provided in the second passage (22), and is configured to conduct the following fluids: Heat exchange: the working fluid flowing in the first heat exchanging part (120), the working fluid flowing in the second heat exchanging part (220), and a prescribed cooling and heating supply medium.

Owner:DENSO CORP

Thermosiphon, data center cooling system and method

ActiveCN107567723BDigital data processing detailsSemiconductor/solid-state device detailsFluid phaseCondenser (heat transfer)

A thermosyphon comprising: a condenser; an evaporator comprising a fluid channel and a heat transfer surface defining a plurality of fluid paths in the fluid channel extending through the fluid channel, the The evaporator is configured to be thermally coupled to one or more heat-generating electronic devices; and a delivery member fluidly coupling the condenser and the evaporator, the delivery member including a liquid conduit, the liquid conduit Extending through the delivery member to deliver a liquid phase of a working fluid into the fluid paths, the delivery member further includes a surface to vertically surround the plurality of fluid paths.

Owner:GOOGLE LLC

Thermosiphon system

PendingCN113405387AEasy to disassemble and transportEasy to useIndirect heat exchangersEngineeringControl theory

A thermosyphon system includes an evaporator, a condenser, and a pipeline assembly. The evaporator comprises an evaporator inlet and an evaporator outlet. The condenser comprises a condenser inlet and a condenser outlet. The evaporator and the condenser are detachably connected through the pipeline assembly. The pipeline assembly comprises a first pipeline connected with the evaporator inlet, a second pipeline connected with the evaporator outlet, a third pipeline connected with the condenser inlet, a fourth pipeline connected with the condenser outlet and a first valve assembly connected with the second pipeline and the third pipeline. The first valve assembly can control whether the second pipeline is connected or disconnected or not, and the first valve assembly can also control whether the third pipeline is connected or disconnected or not. Compared with the prior art, the evaporator and the condenser are detachably connected through the pipeline assembly, and therefore maintenance is easy.

Owner:浙江酷灵信息技术有限公司

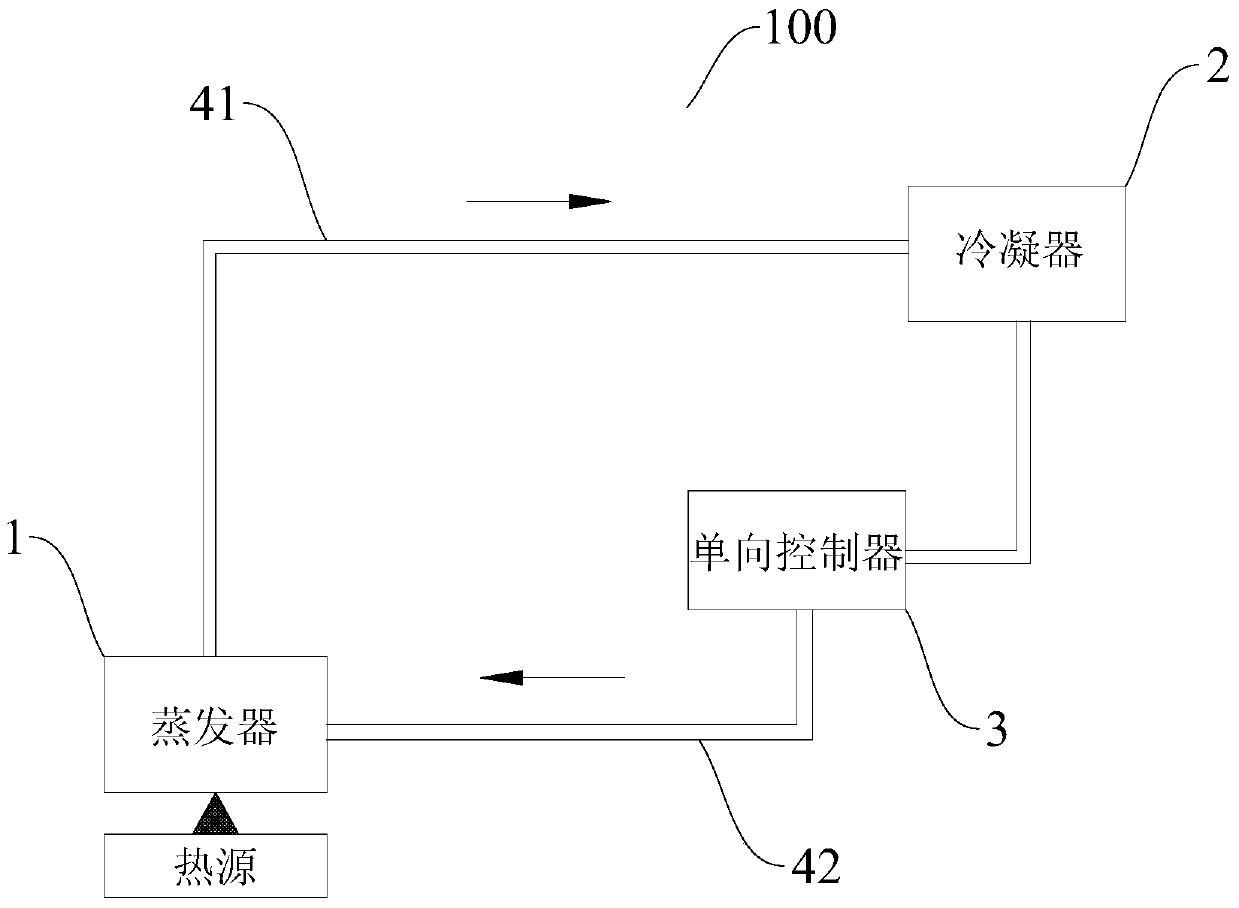

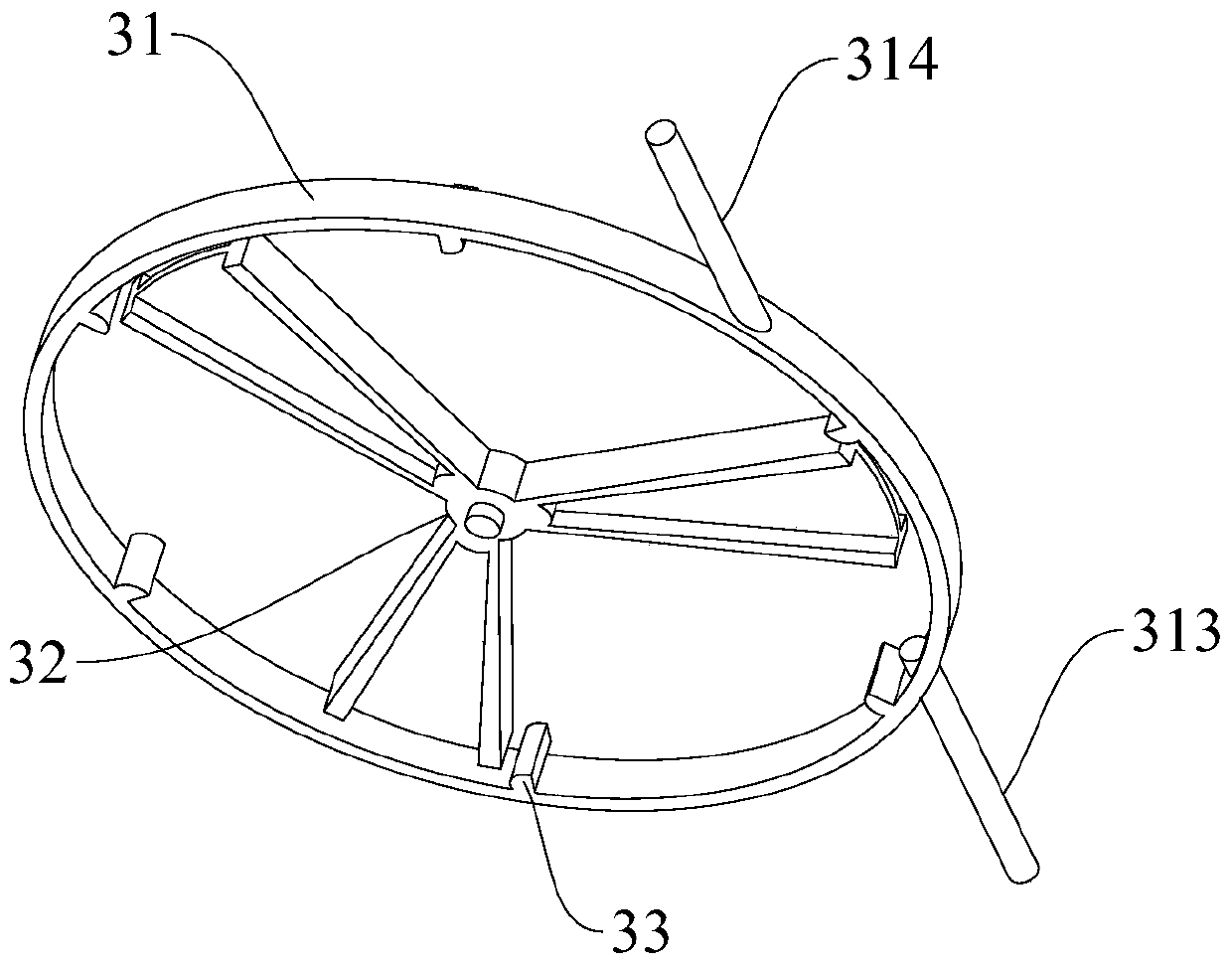

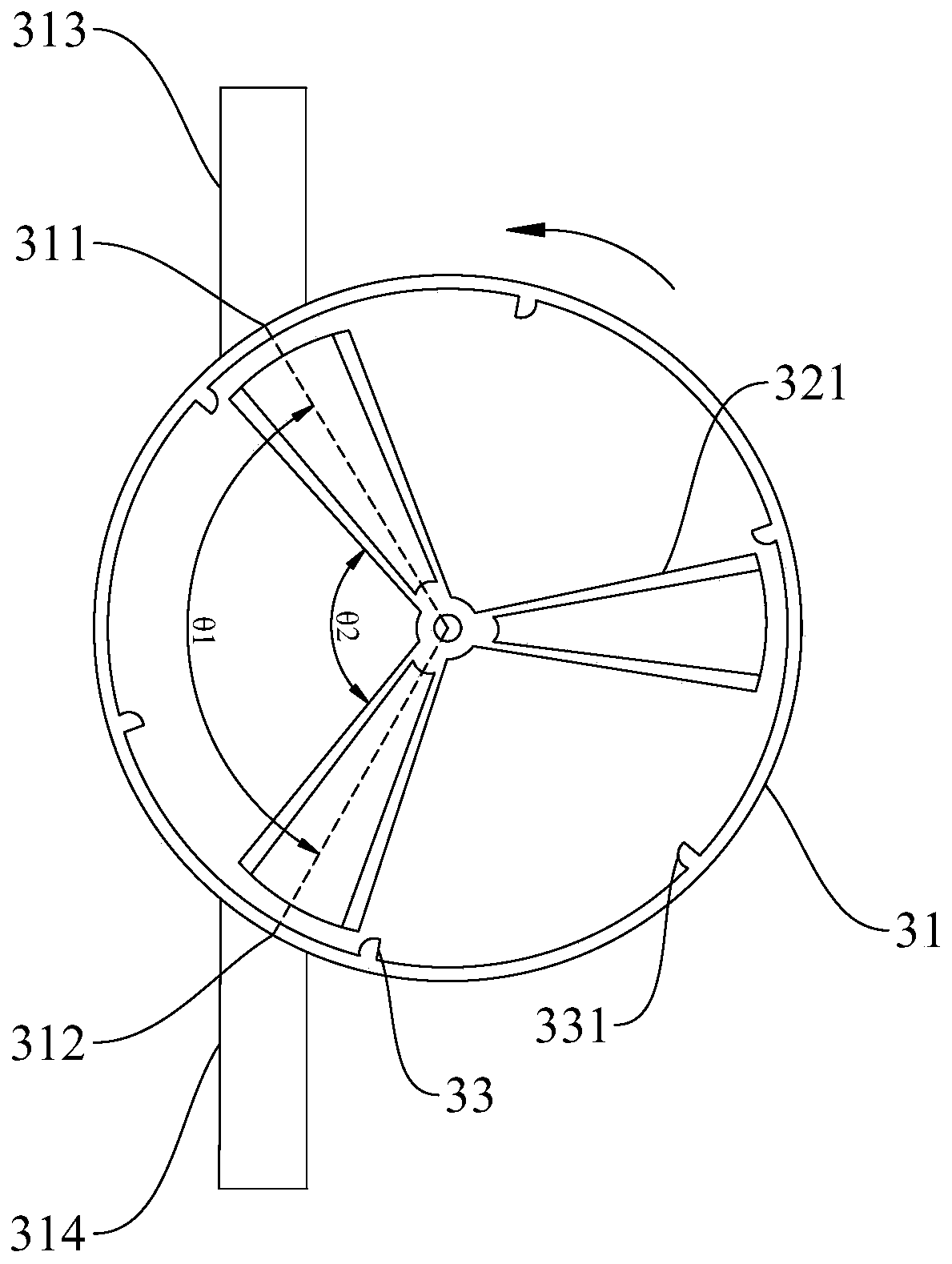

Thermosiphon system and fluid one-way controller

InactiveCN106288541BWork lessGuaranteed work efficiencyMechanical apparatusFluid circulation arrangementEngineeringThermosipho

The invention discloses a thermosiphon system and a fluid one-way controller. The thermosiphon system has a fluid used for heat exchange. The thermosiphon system includes: an evaporator, a condenser and a fluid one-way controller. The fluid flows through the evaporator for heat exchange; the condenser is in fluid communication with the evaporator through a first flow path and is in fluid communication with the evaporator through a second flow path; the fluid one-way controller is set on the second flow path and configured to unidirectionally deliver the fluid to the evaporator. According to the thermosiphon system of the present invention, by setting the fluid one-way controller on the second flow path, the condensation in the condenser can smoothly flow to the evaporator, so that the thermosiphon system can work normally, and the work of the thermosiphon system is guaranteed efficiency.

Owner:光宇清源(香港)有限公司

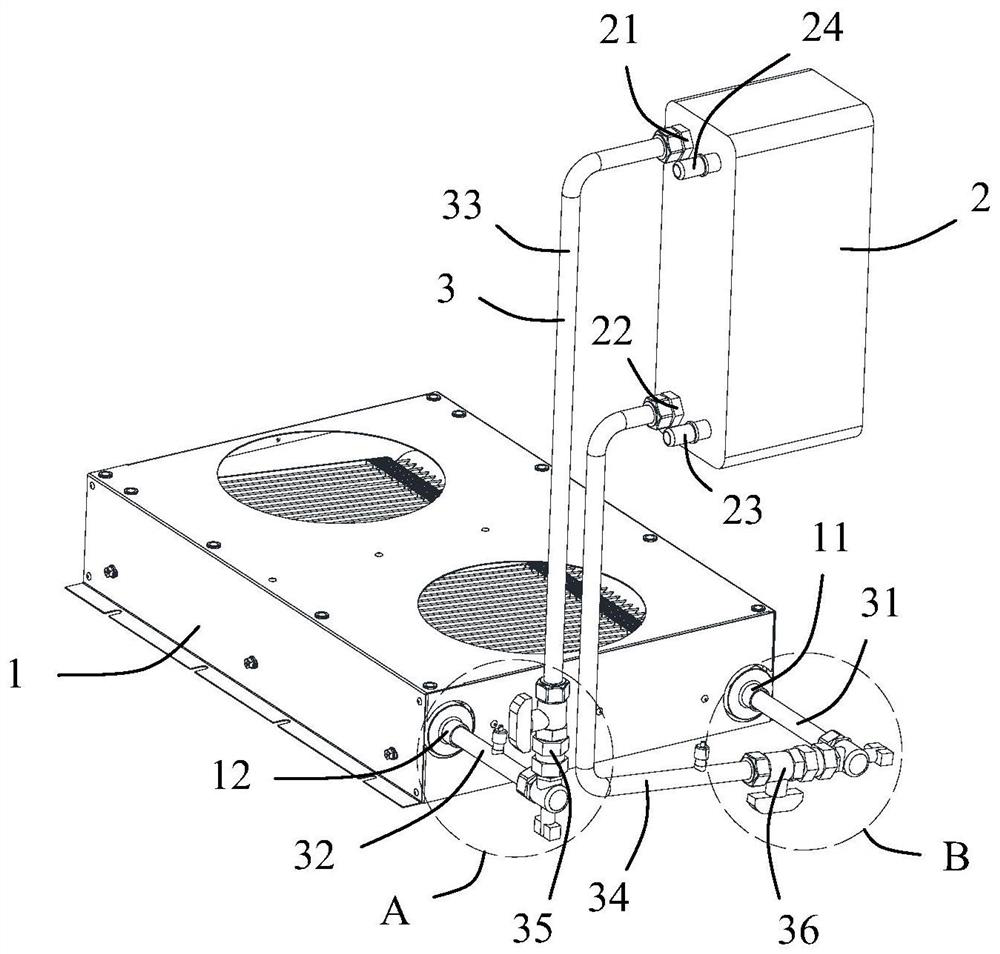

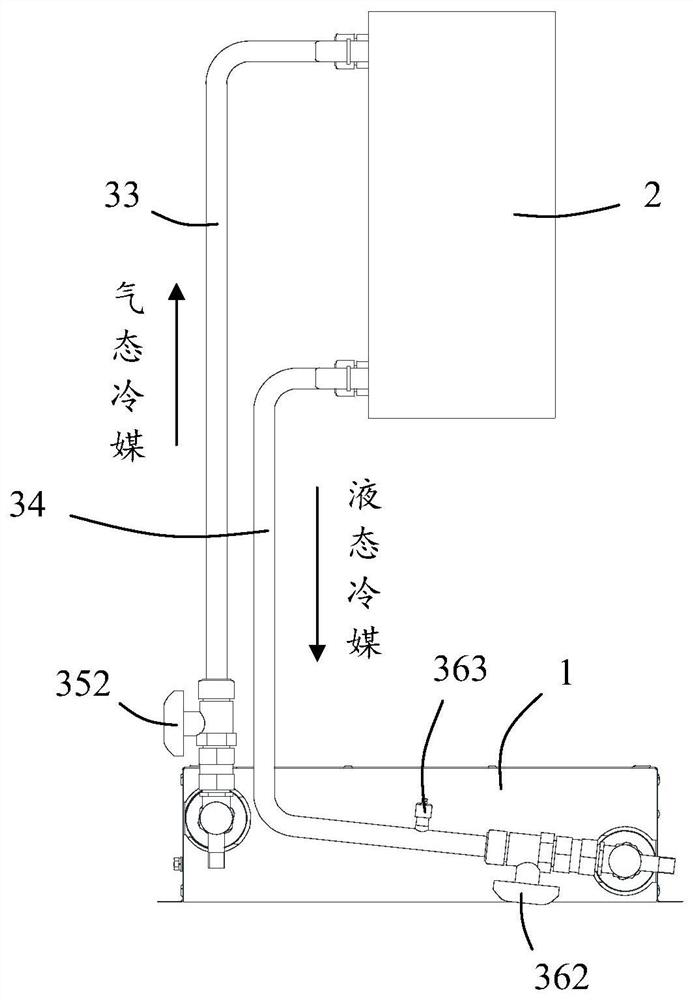

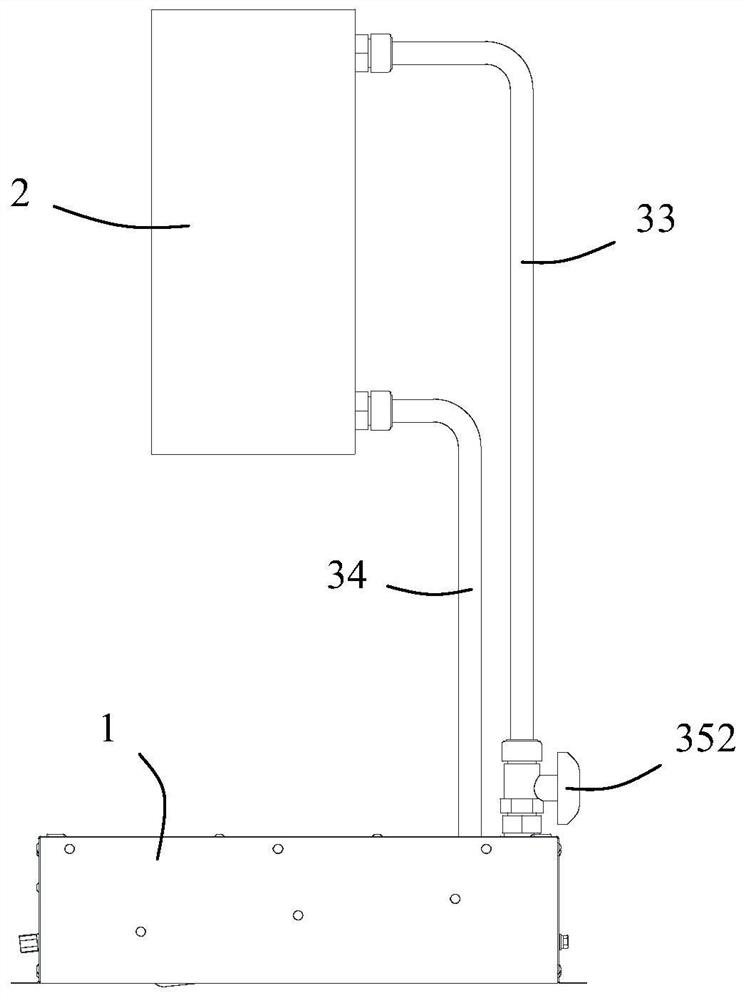

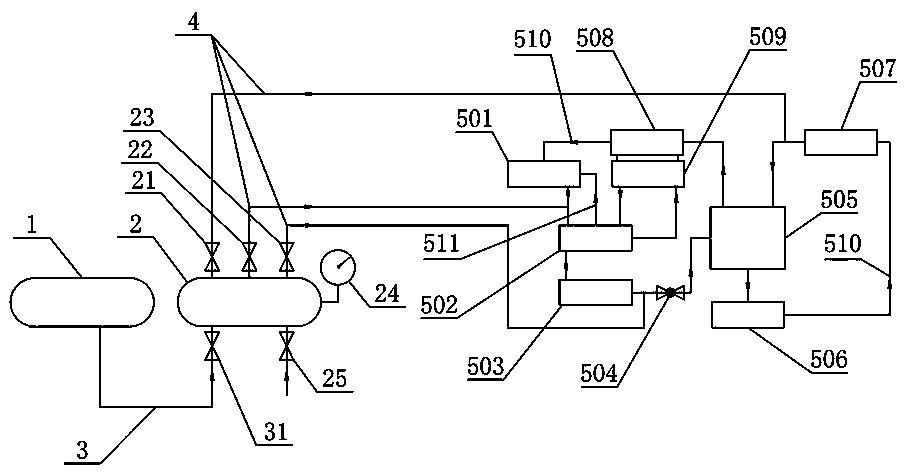

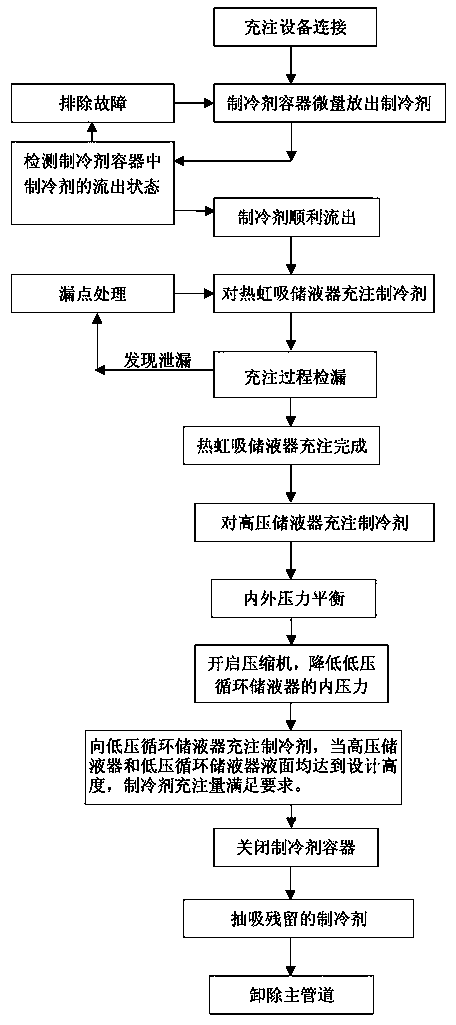

Refrigerant charging method for thermosiphon oil cooling refrigeration system

The invention discloses a refrigerant filling method for a thermosyphon oil cooling refrigeration system. The thermosyphon oil cooling refrigeration system is filled with a refrigerant by adopting filling equipment mainly composed of a refrigerant container, a distribution station, a main pipeline and three distribution pipelines; a refrigerant inlet valve is arranged on the main pipeline, and thedistribution station is provided with a first refrigerant outlet valve, a second refrigerant outlet valve, a third refrigerant outlet valve and a pressure gauge; the first refrigerant outlet valve, the second refrigerant outlet valve and the third refrigerant outlet valve are sequentially connected to a pipeline between an evaporator and a low-pressure circulating liquid storage device, a pipeline between a condenser and a thermosyphon liquid storage device, and a pipeline between a high-pressure liquid storage device and a throttle valve through the three distribution pipelines correspondingly; and one end of the main pipeline is connected to the refrigerant container, and the other end of the main pipeline is connected with the distribution station. The refrigerant filling method has the advantages that the filling equipment which is simple in structure and convenient to operate is adopted, safety and reliability are achieved, the procedure is clear, and the filling efficiency is high.

Owner:SINOHYDRO BUREAU 8 CO LTD

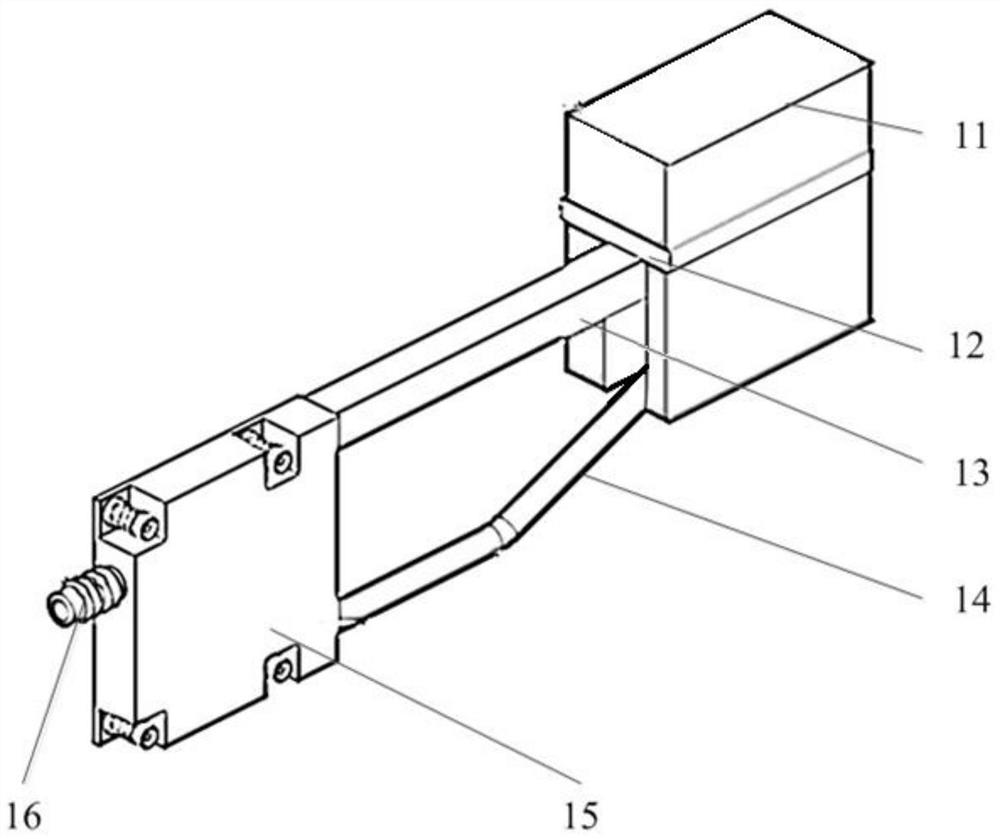

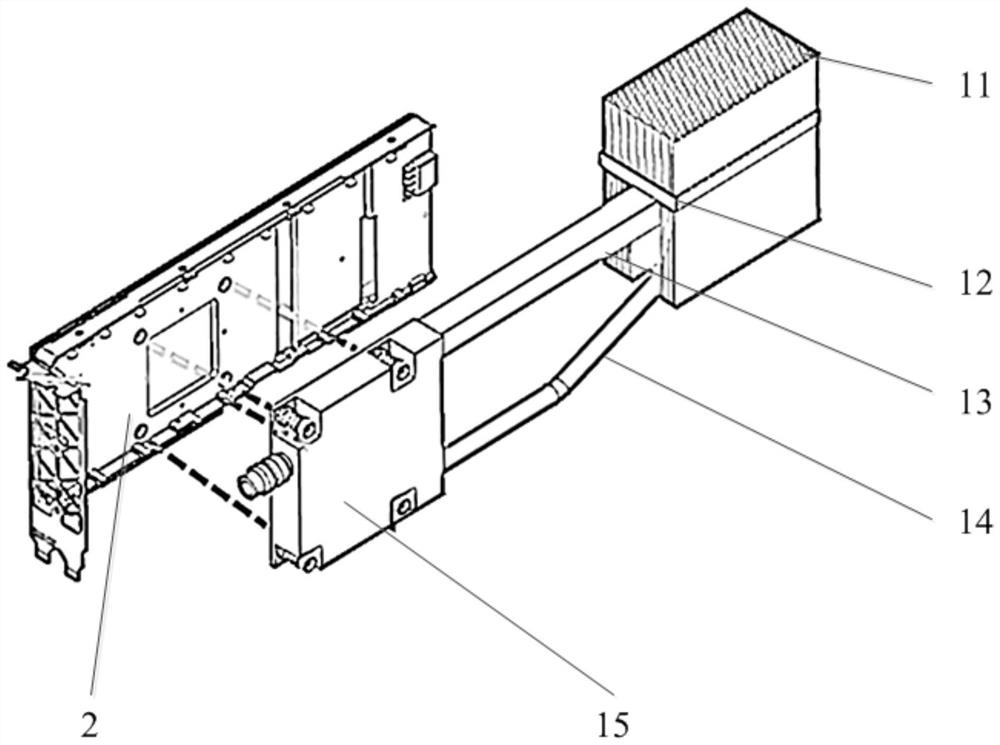

GPU heat dissipation device and server

PendingCN114281177AImprove cooling effectReduce power consumptionDigital data processing detailsEngineeringGraphics processing unit

The invention discloses a GPU (Graphics Processing Unit) heat dissipation device and a server. The GPU heat dissipation device comprises a GPU chip; the thermosyphon radiator comprises radiating fins, an evaporator and a condenser, the evaporator and the condenser are connected through a gas pipe and a liquid pipe to form a circulation structure, and the radiating fins are connected to the side portion of the condenser. The evaporator is attached to the GPU chip; the cooling fan is arranged on one side of the cooling fins and used for cooling the cooling fins. According to the GPU heat dissipation device, the GPU chip is connected with the evaporator of the thermosiphon heat dissipation device, the heat dissipation effect on the GPU chip is achieved through the siphon effect of the thermosiphon heat dissipation device on heat, and the heat dissipation effect on the GPU chip is achieved through the heat dissipation effect of the thermosiphon heat dissipation device. The power consumption of the server and even the machine room can be reduced, and the overall cost is saved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com