Production method for device temperature control device and filling method for working fluid

A technology for temperature adjustment devices and working fluids, which can be used in lighting and heating equipment, refrigerators, refrigeration and liquefaction, etc., and can solve problems such as unoptimized containers and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

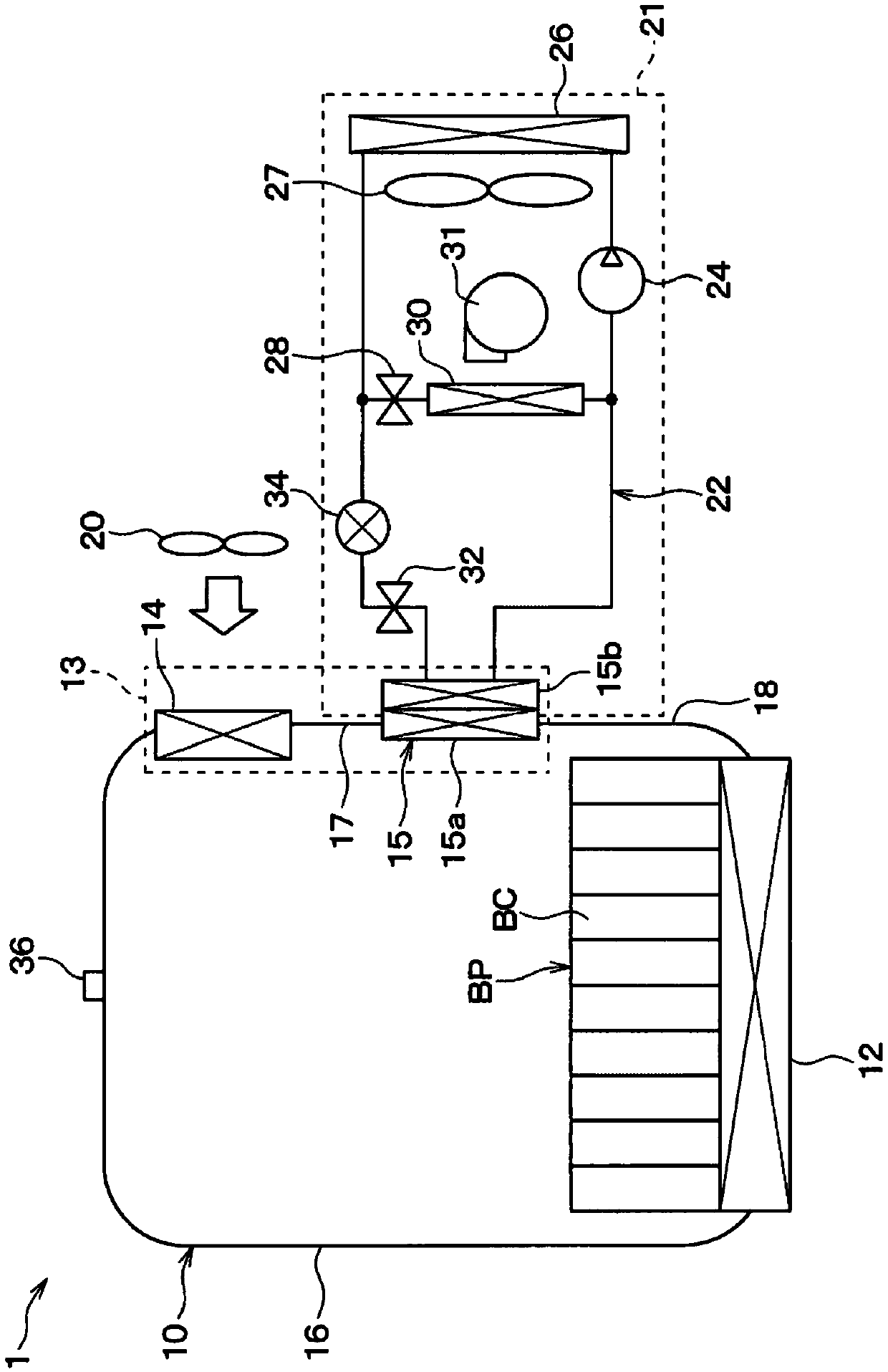

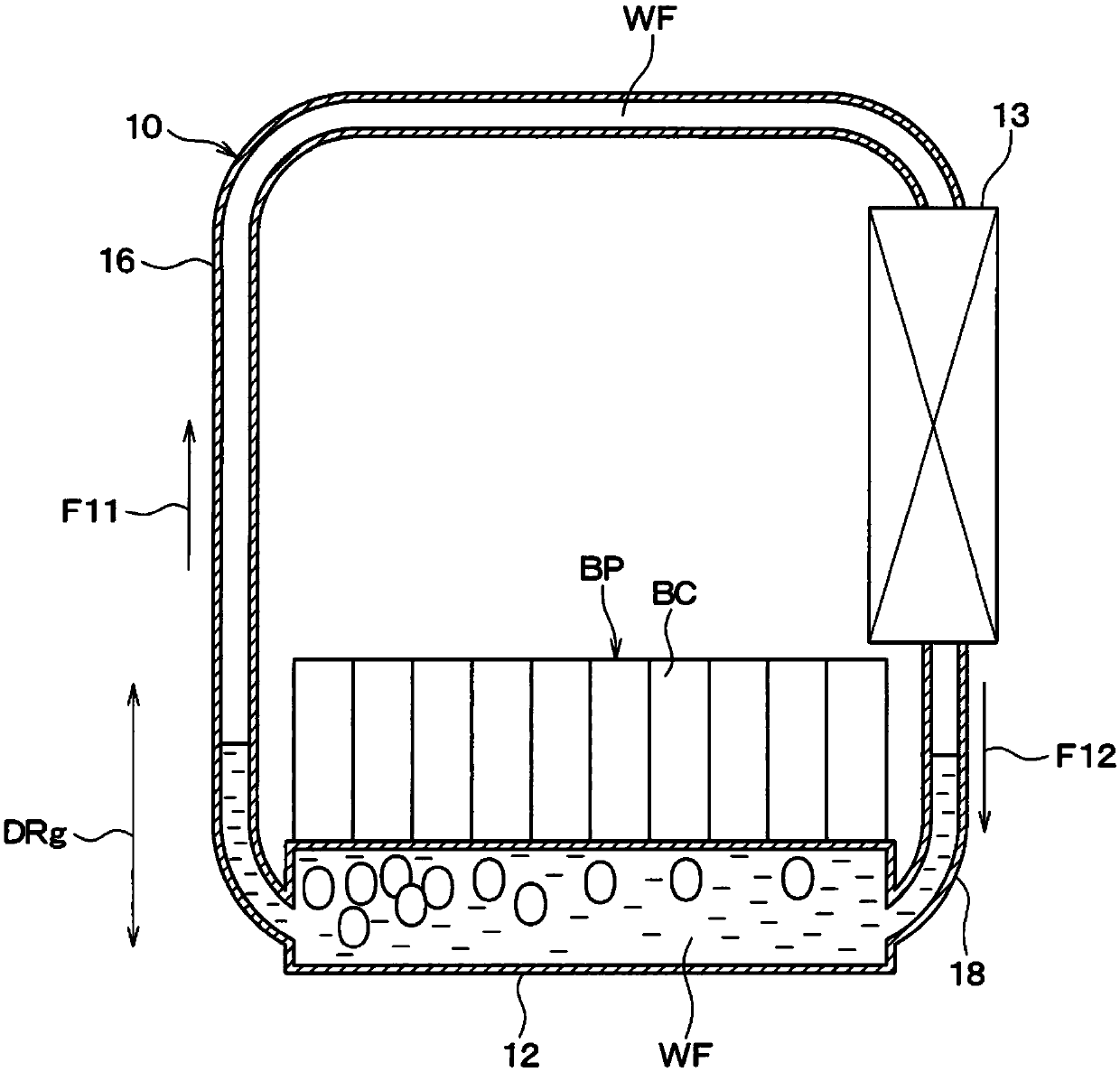

[0054] figure 1 The device temperature adjustment device 1 of the illustrated embodiment cools the battery pack BP mounted on the vehicle to adjust the battery temperature of the battery pack BP as the temperature adjustment target device. As a vehicle equipped with the equipment temperature control device 1, an electric vehicle or a hybrid vehicle that uses the battery pack BP as a power source and can be driven by a traveling motor (not shown) is assumed.

[0055] The battery pack BP is composed of a laminate in which a plurality of rectangular parallelepiped battery cells BC are stacked. The plurality of battery cells BC constituting the battery pack BP are electrically connected in series. Each battery cell BC constituting the battery pack BP is constituted by a secondary battery (for example, a lithium ion battery, a lead battery) that can be charged and discharged. In addition, the battery cell BC is not limited to a rectangular parallelepiped shape, and may have other sha...

no. 2 approach

[0110] Such as Figure 8 As shown, the condensing unit 13 for equipment in this embodiment is different from the first embodiment. The other structure of the device temperature adjustment device 1 is the same as that of the first embodiment.

[0111] The facility temperature control device 1 includes an air-cooled condenser 14 as the condensing unit 13 for facilities. The condenser 14 is a heat exchanger that exchanges heat between the working fluid and the blowing air blown to the condenser 14. The condenser 14 is selectively blown with external air and cold air lower than the external air as blowing air. The cold air is generated by the refrigeration cycle device 21. The cold air is cooling air that cools the working fluid.

[0112] Specifically, the facility temperature adjustment device 1 includes a switching device 51 that selectively switches between outside air and cold air as the blowing air to be blown to the condenser 14. The switching device 51 includes a duct 511 th...

no. 3 approach

[0122] Such as Picture 9 As shown, the condensing unit 13 for equipment of this embodiment is different from the first embodiment. The other structure of the device temperature adjustment device 1 is the same as that of the first embodiment.

[0123] The facility temperature control device 1 includes a water-cooled condenser 61 as the facility condensing unit 13 and a cooling water circuit 62 that circulates cooling water. Cooling water is a cooling liquid containing water. Coolant is a liquid heat medium used to transport heat. For example, use antifreeze, water, etc. as cooling water. The condenser 61 is a heat exchanger that condenses the working medium of the equipment fluid circuit 10 by performing heat exchange between the working medium and the cooling water of the cooling water circuit 62. The condenser 61 has a working fluid side heat exchange part 61 a through which the working fluid of the equipment fluid circuit 10 flows, and a cooling water side heat exchange par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com