Self-driven thermosyphon loop heat dissipation device coupled with gas-liquid two-phase flow jet pump

A gas-liquid two-phase flow and heat dissipation device technology, which is applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve problems such as limited heat exchange capacity and enhanced heat dissipation capacity of thermosiphon loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

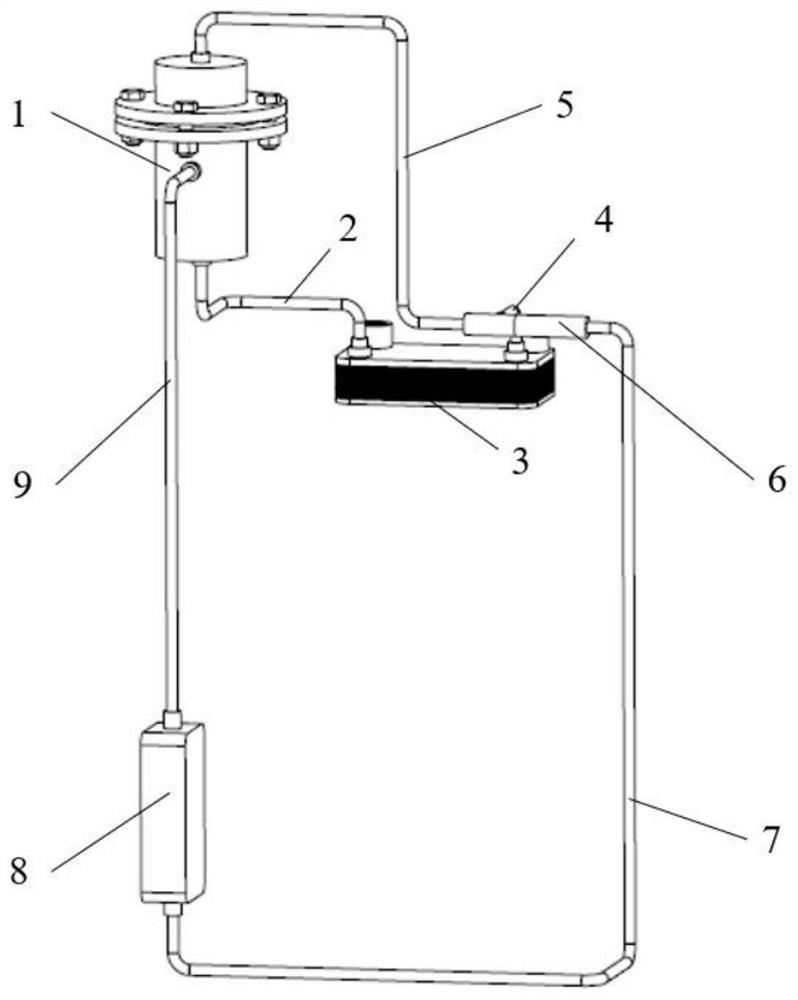

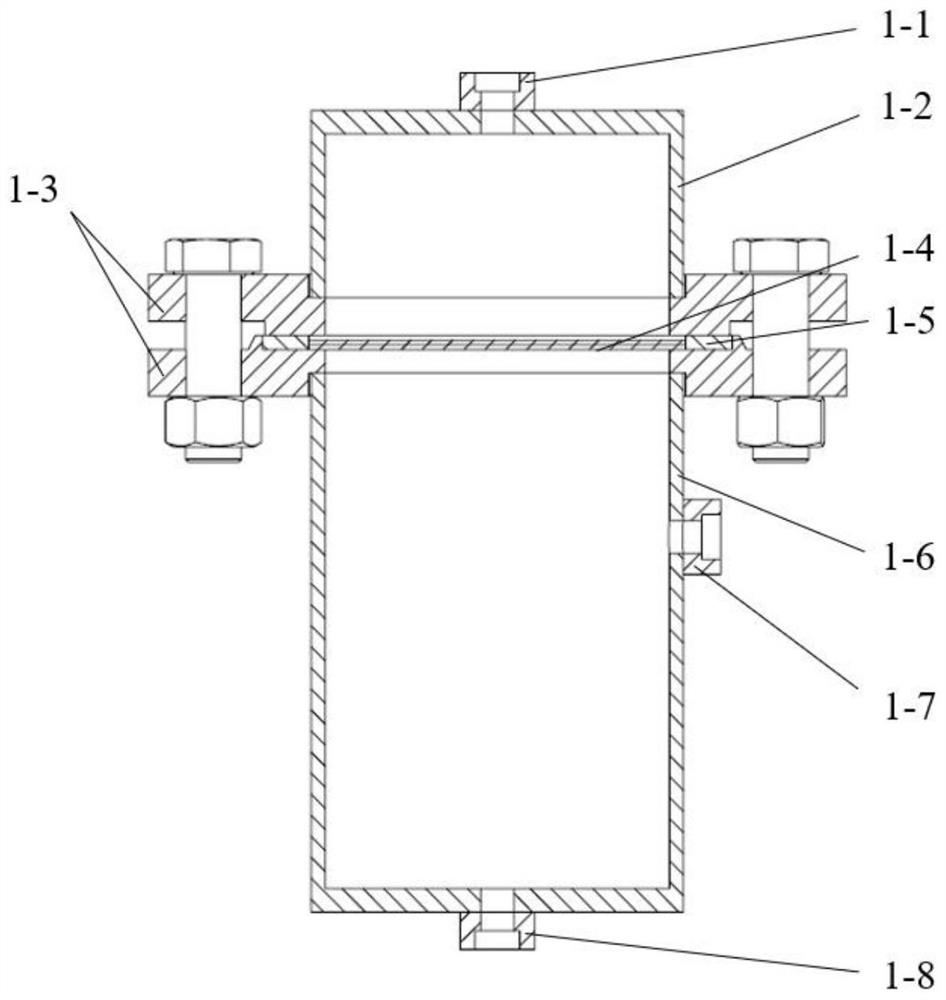

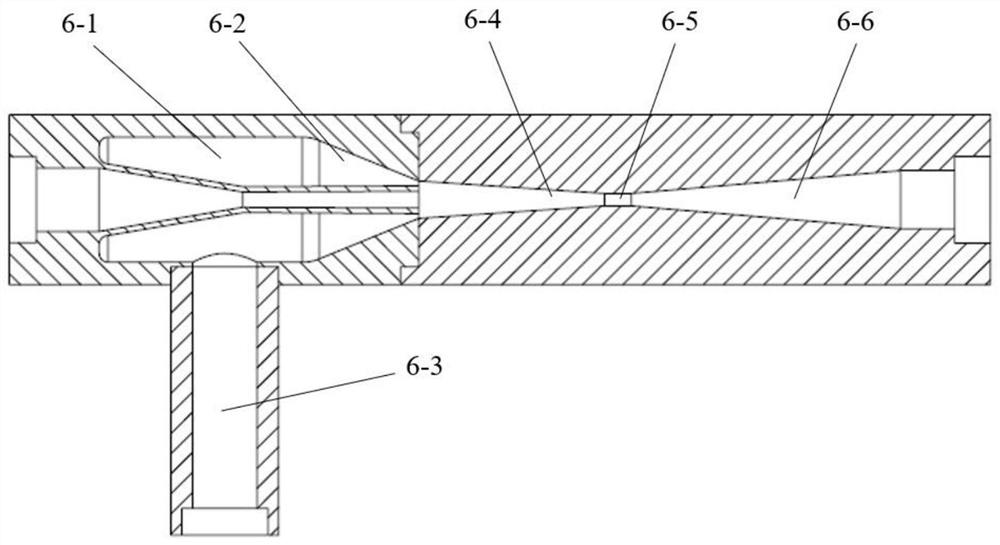

[0021] Such as figure 1 As shown, this embodiment relates to a self-driven thermosiphon circuit cooling device coupled with a gas-liquid two-phase flow ejector pump, including: a gas-liquid separator 1, a cooler 3, a gas-liquid two-phase flow ejector pump 6 and Evaporator 8, wherein: the upper outlet 1-1 of the gas-liquid separator 1 is connected to the steam nozzle 6-1 of the gas-liquid two-phase flow injection pump 6 through the first steam section 5; the lower outlet 1 of the gas-liquid separator 1 -8 is connected to the inlet of the cooler 3 through the first liquid section 2; the outlet of the cooler 3 is connected to the drainage pipe 6-3 of the gas-liquid two-phase flow injection pump 6 through the second liquid section 4; the gas-liquid two-phase flow injection The expansion section 6-6 of the pump 6 is connected to the inlet of the evaporator 8 through the third liquid section 7; the outlet of the evaporator 8 is connected to the side inlet 1-7 of the gas-liquid separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com