Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Solid fuel fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

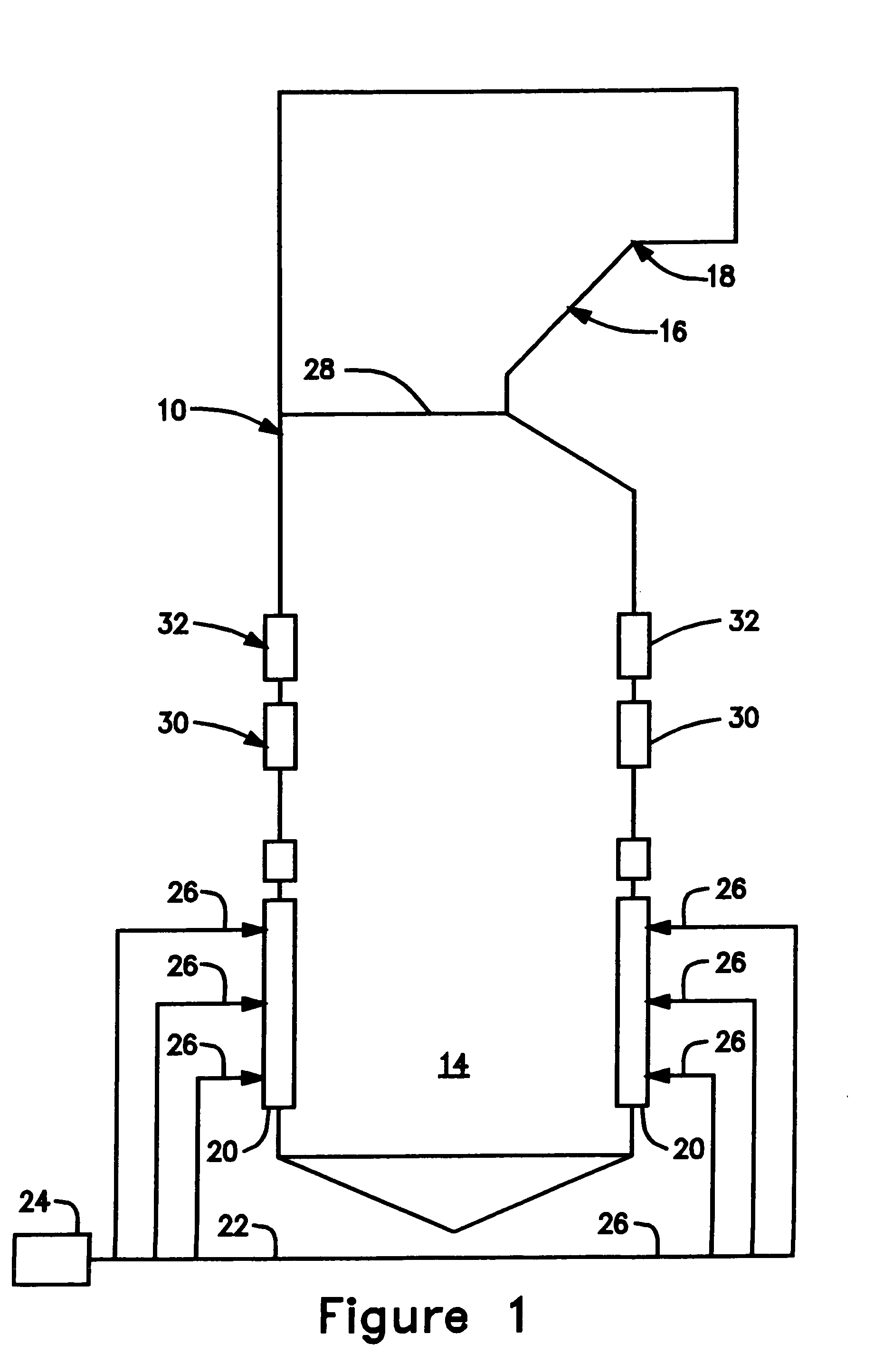

Production of hydrogen and removal and sequestration of carbon dioxide from coal-fired furnaces and boilers

InactiveUS7282189B2Increase ratingsValue maximizationOrganic chemistryNitrogen compoundsHydrogenProcess engineering

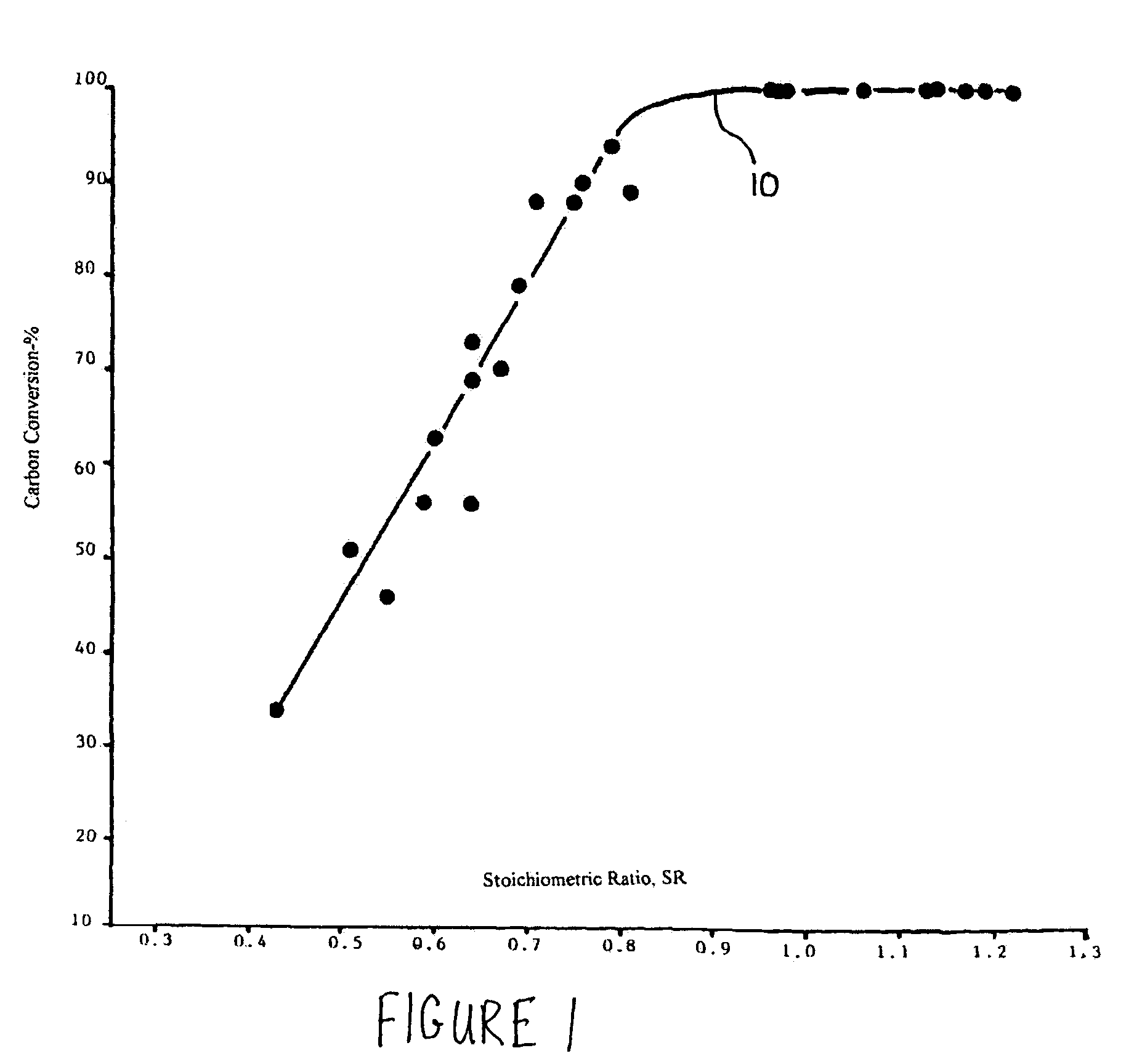

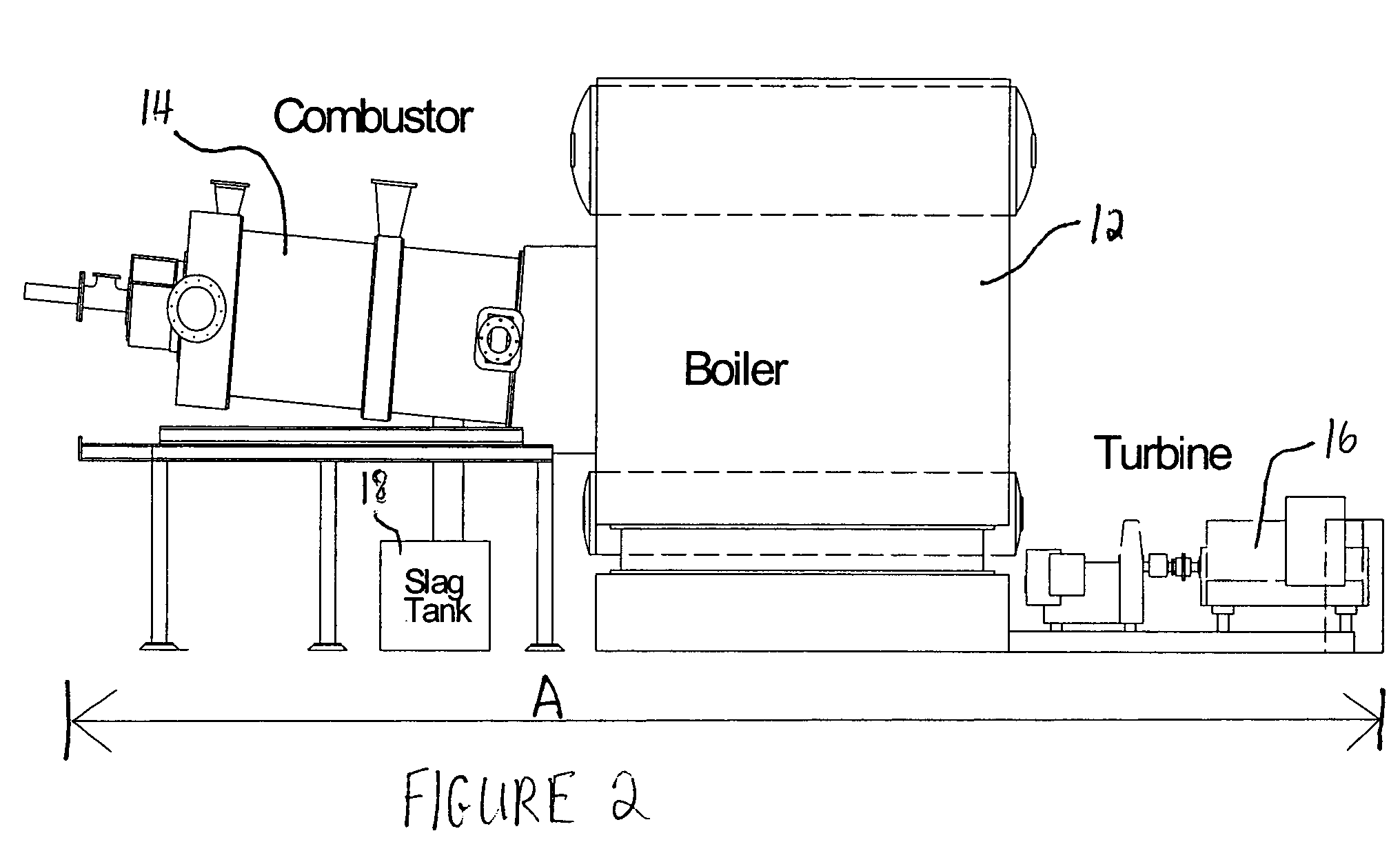

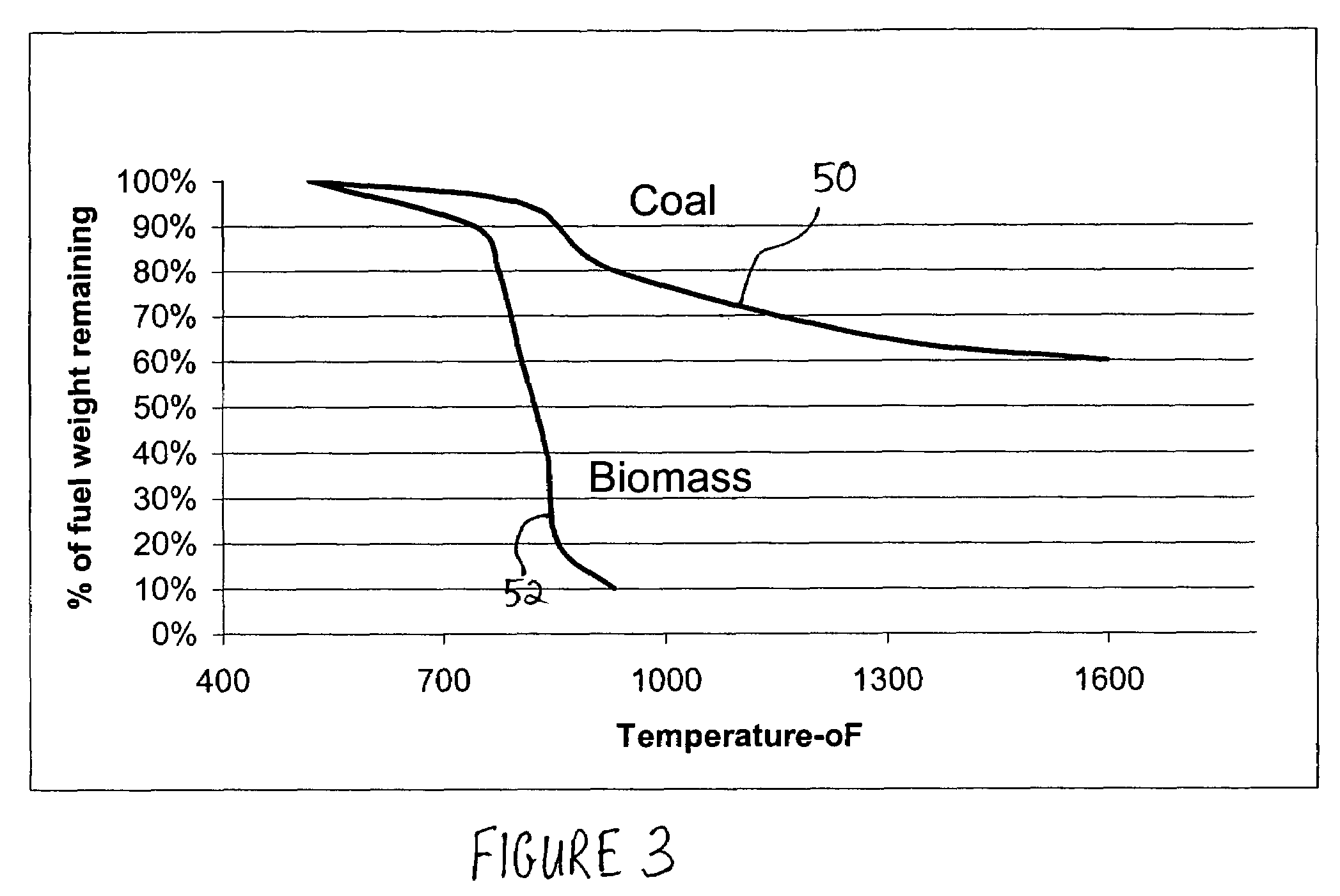

Methods for reducing and eliminating carbon dioxide from the emissions of solid fuel fired power plants, particularly coal fired power plants, and to sequester the carbon dioxide, typically by using existing equipment. In some embodiments, the methods involve pyrolyzing the solid fuel to remove volatile matter and using the volatile matter to produce hydrogen. Additionally, the methods may involve burning the solid fuel or pyrolized solid fuel at very fuel rich stoichiometric conditions. Sequestration may include the production of a carbon dioxide-containing solution and the pumping of the solution into the ground, particularly in areas high in limestone.

Owner:ZAUDERER BERT

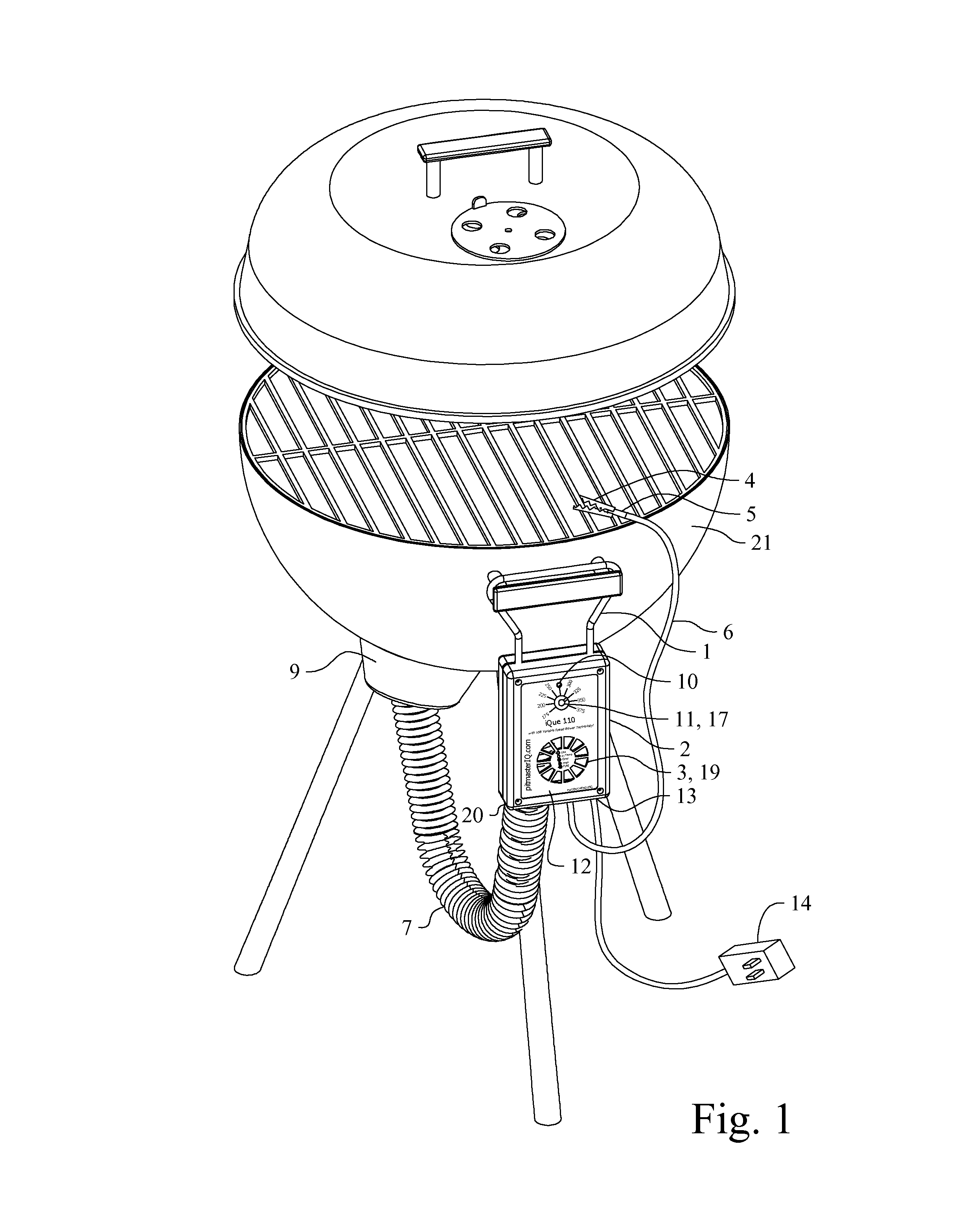

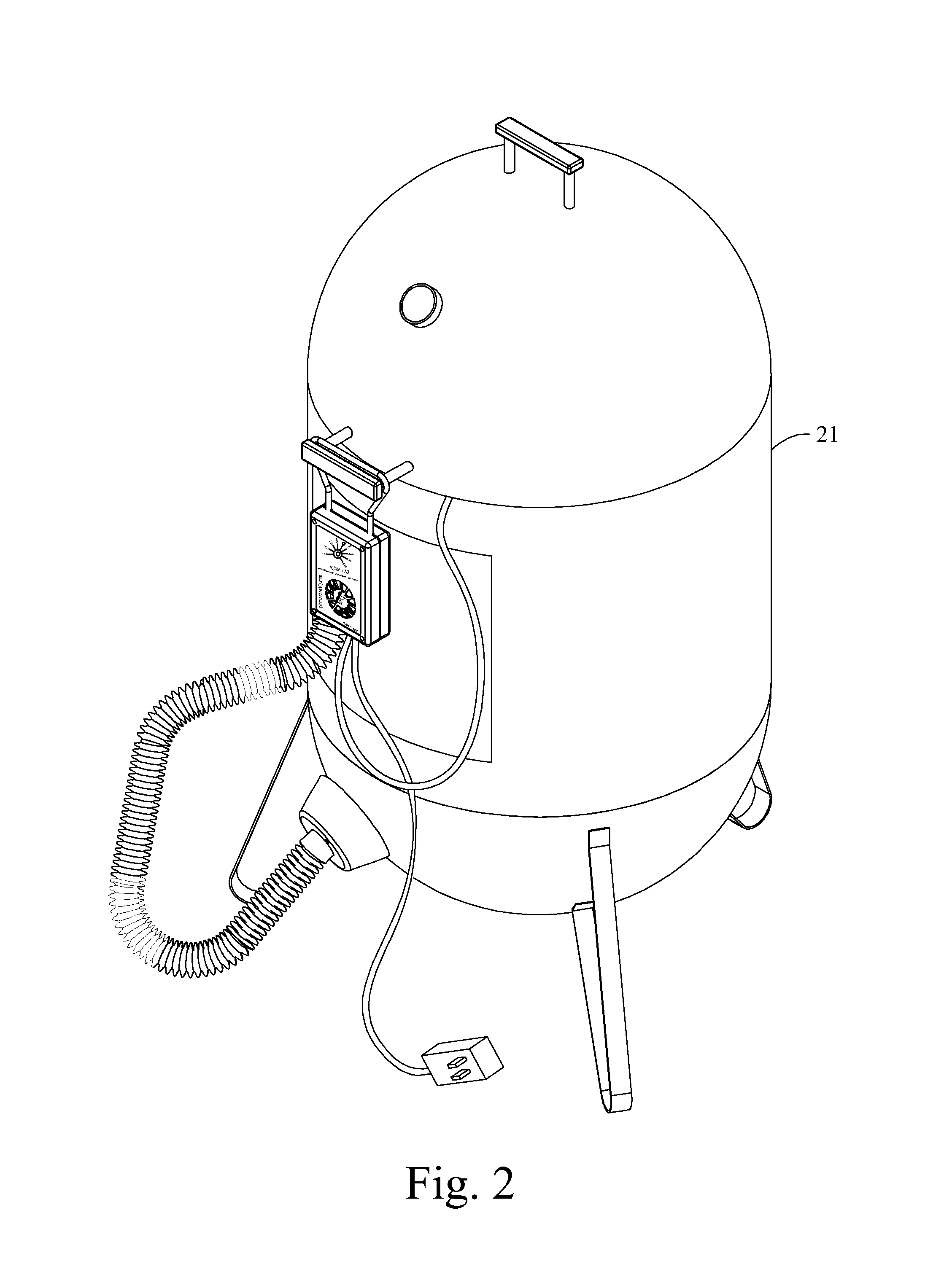

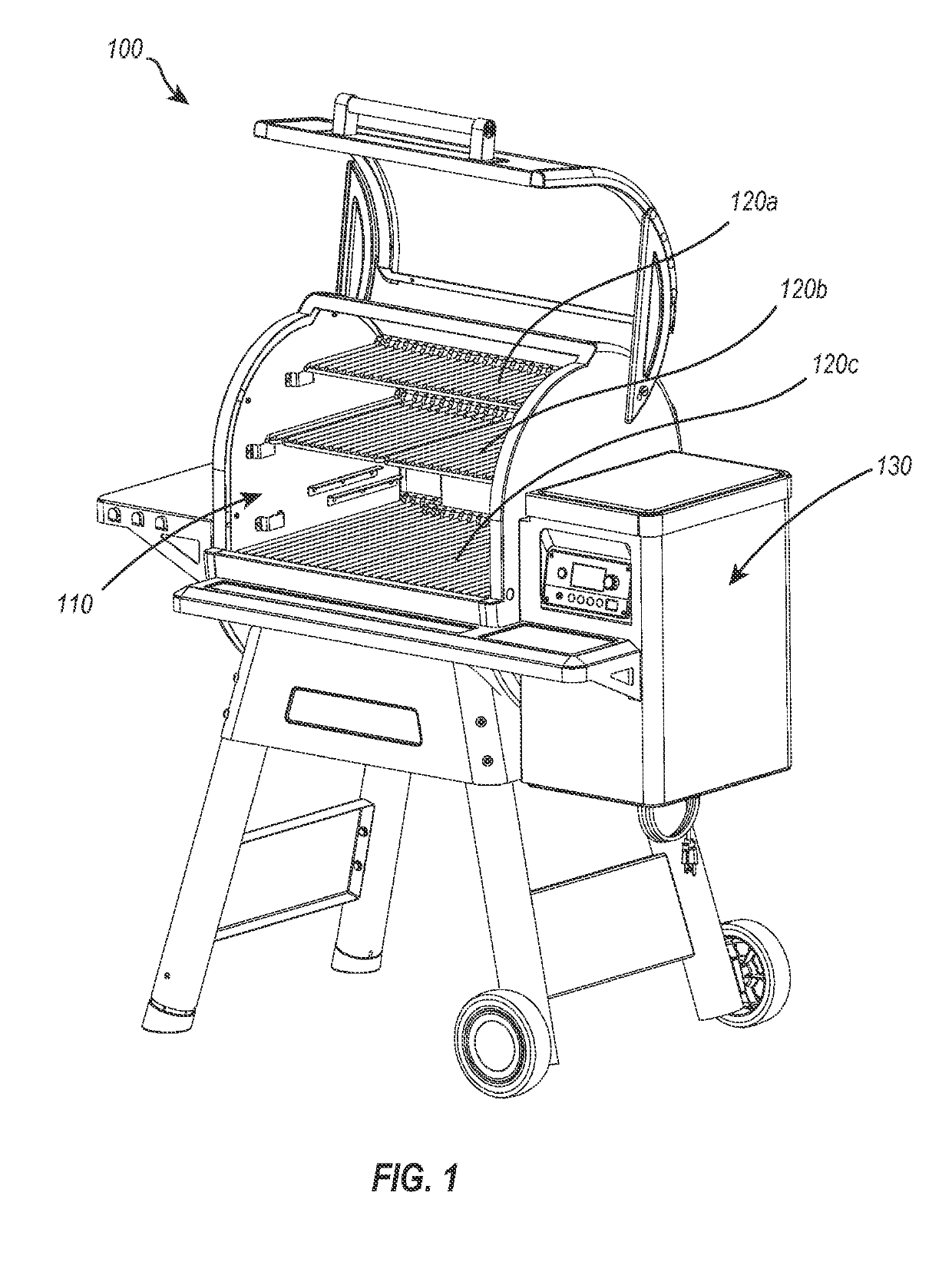

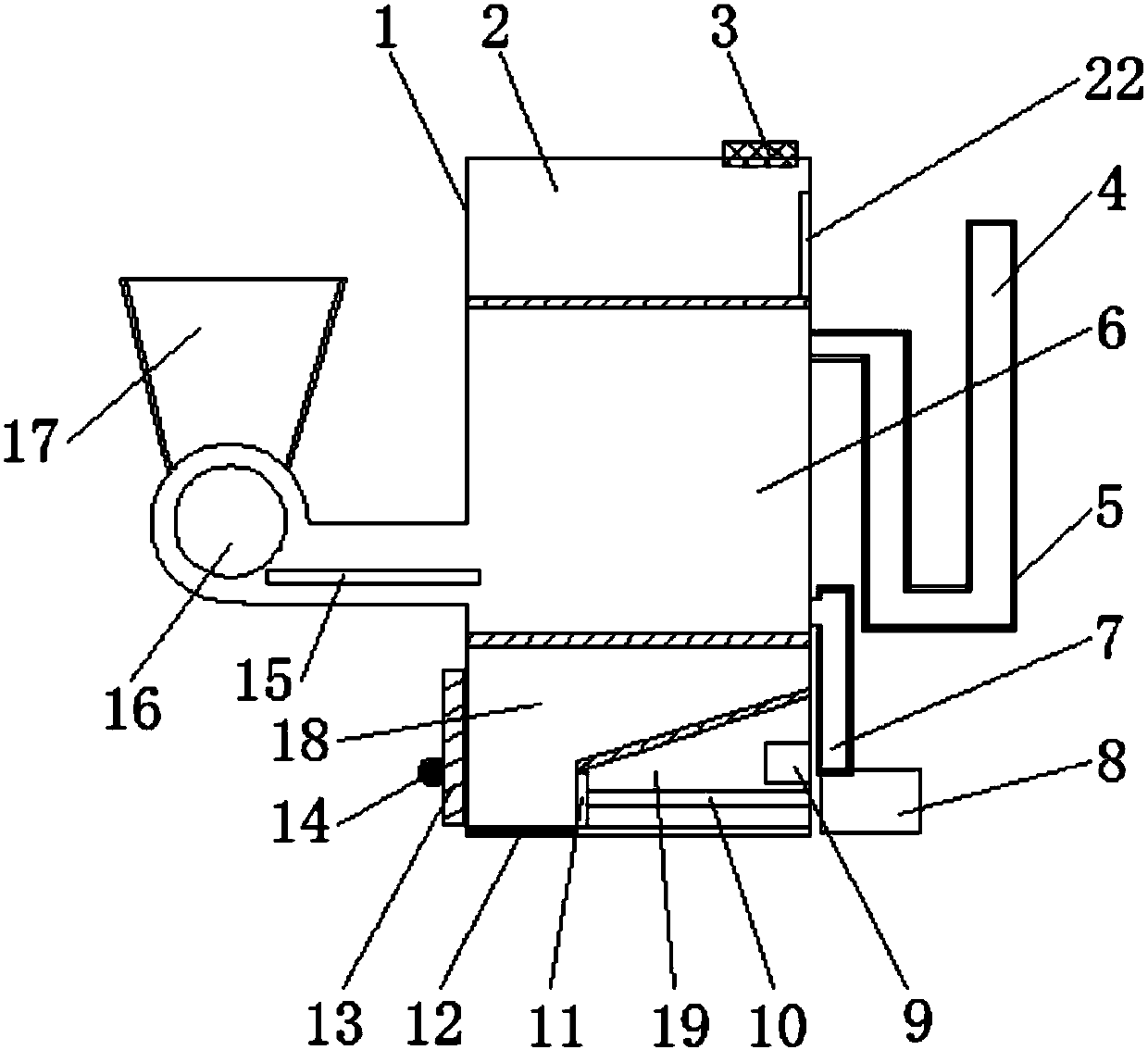

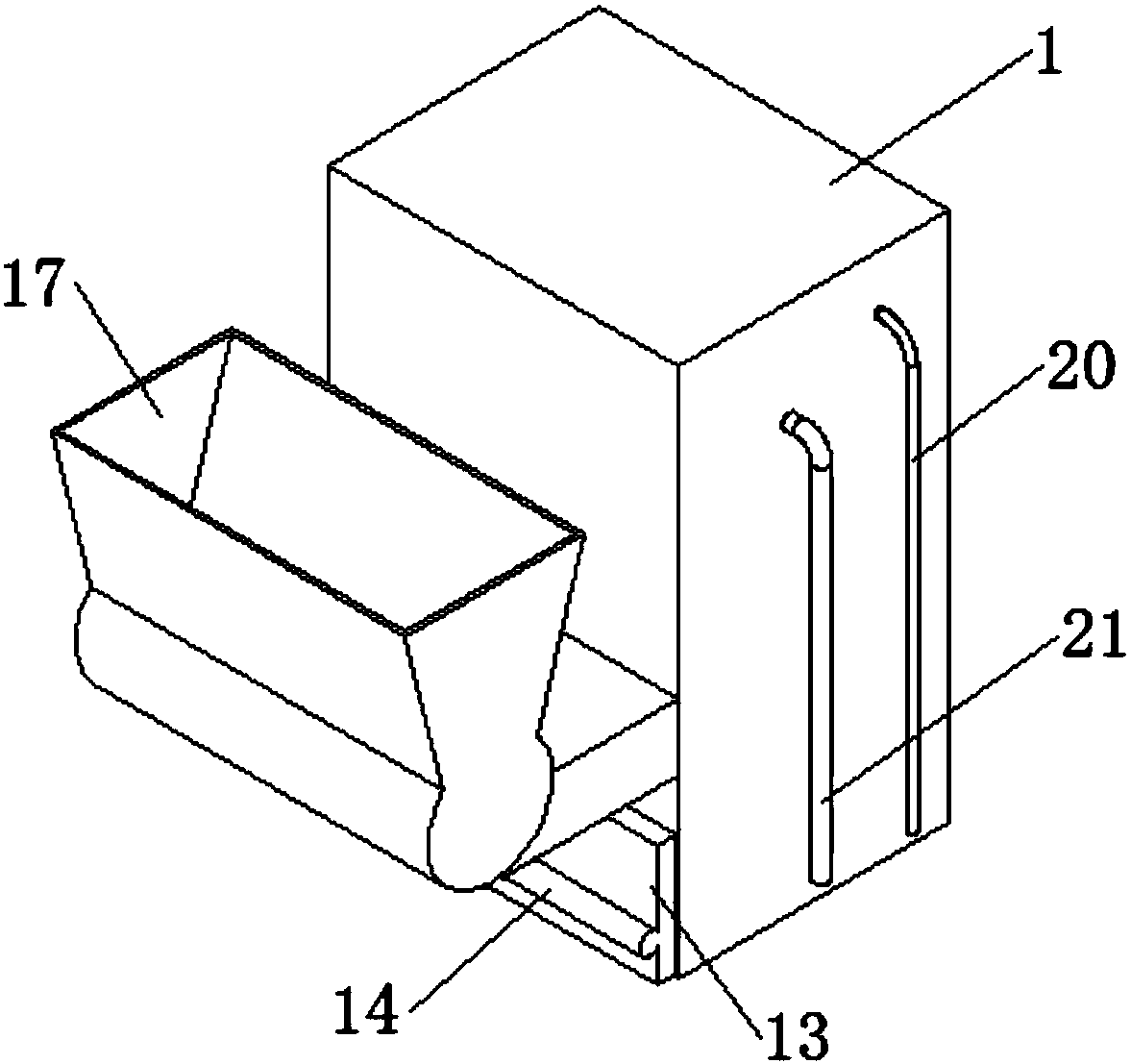

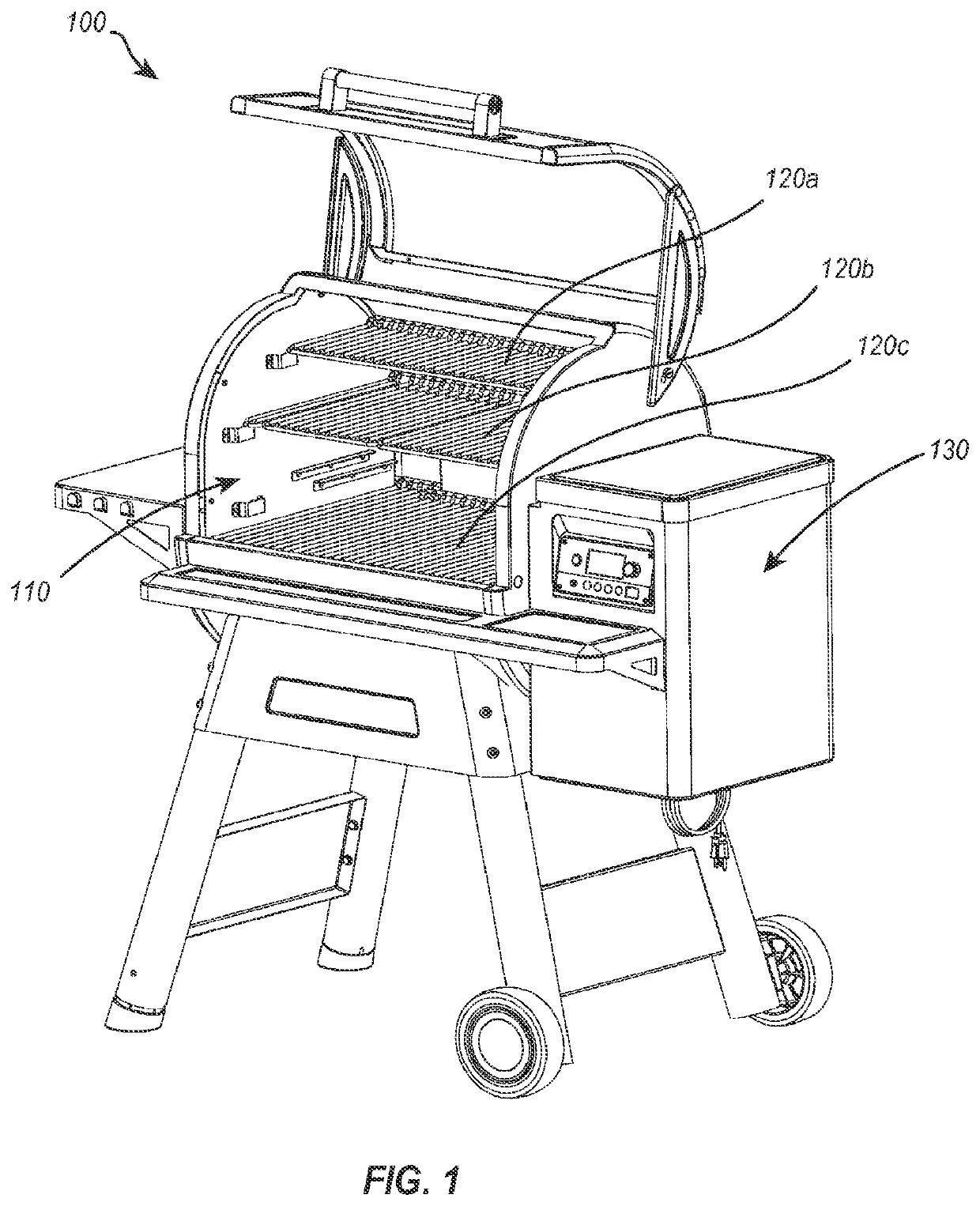

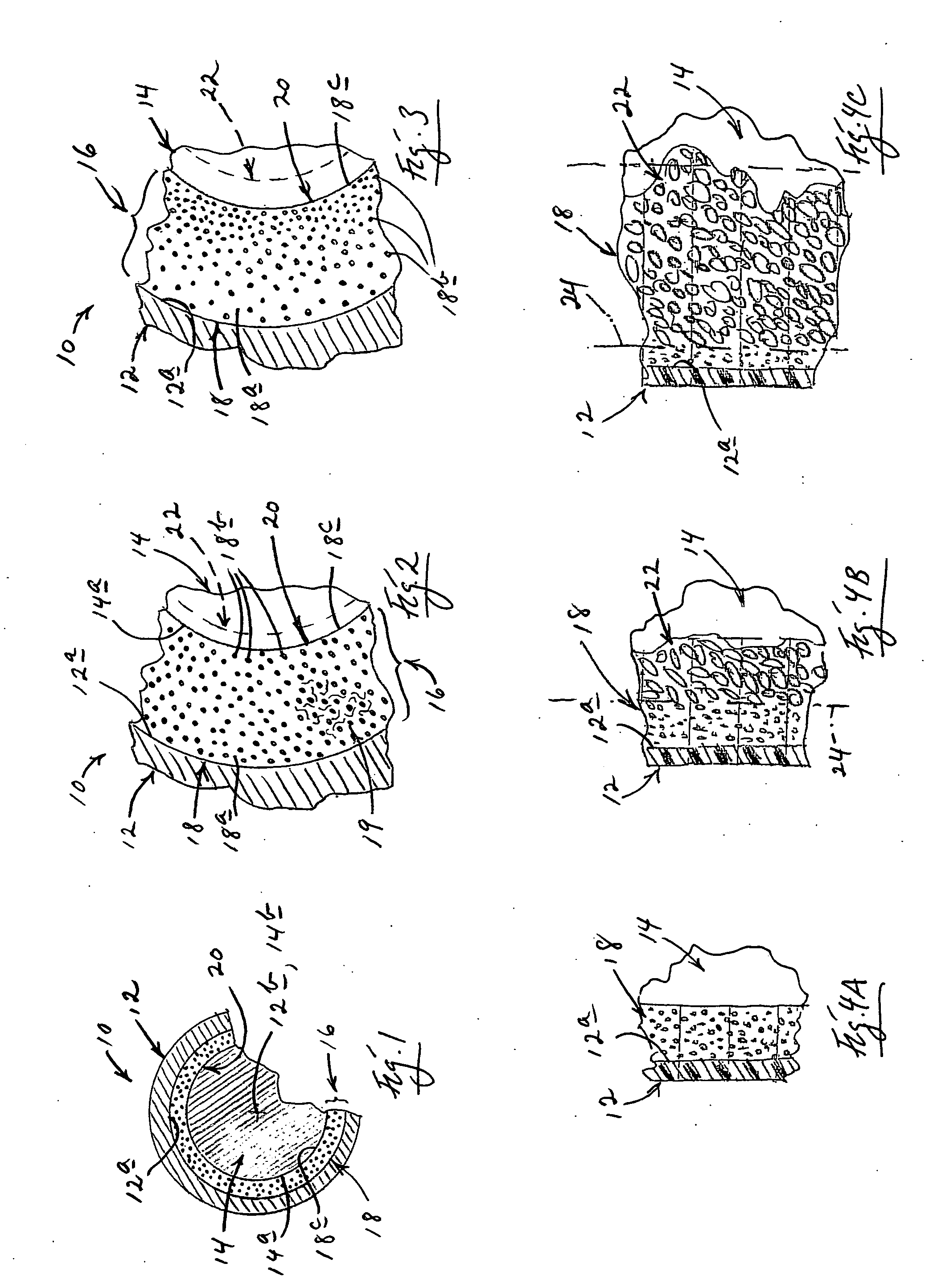

Automatic temperature control device for solid fuel fired food cooker

ActiveUS8800542B1The process is simple and easy to understandQuick installationDomestic stoves or rangesBoiling over preventionTemperature controlCore component

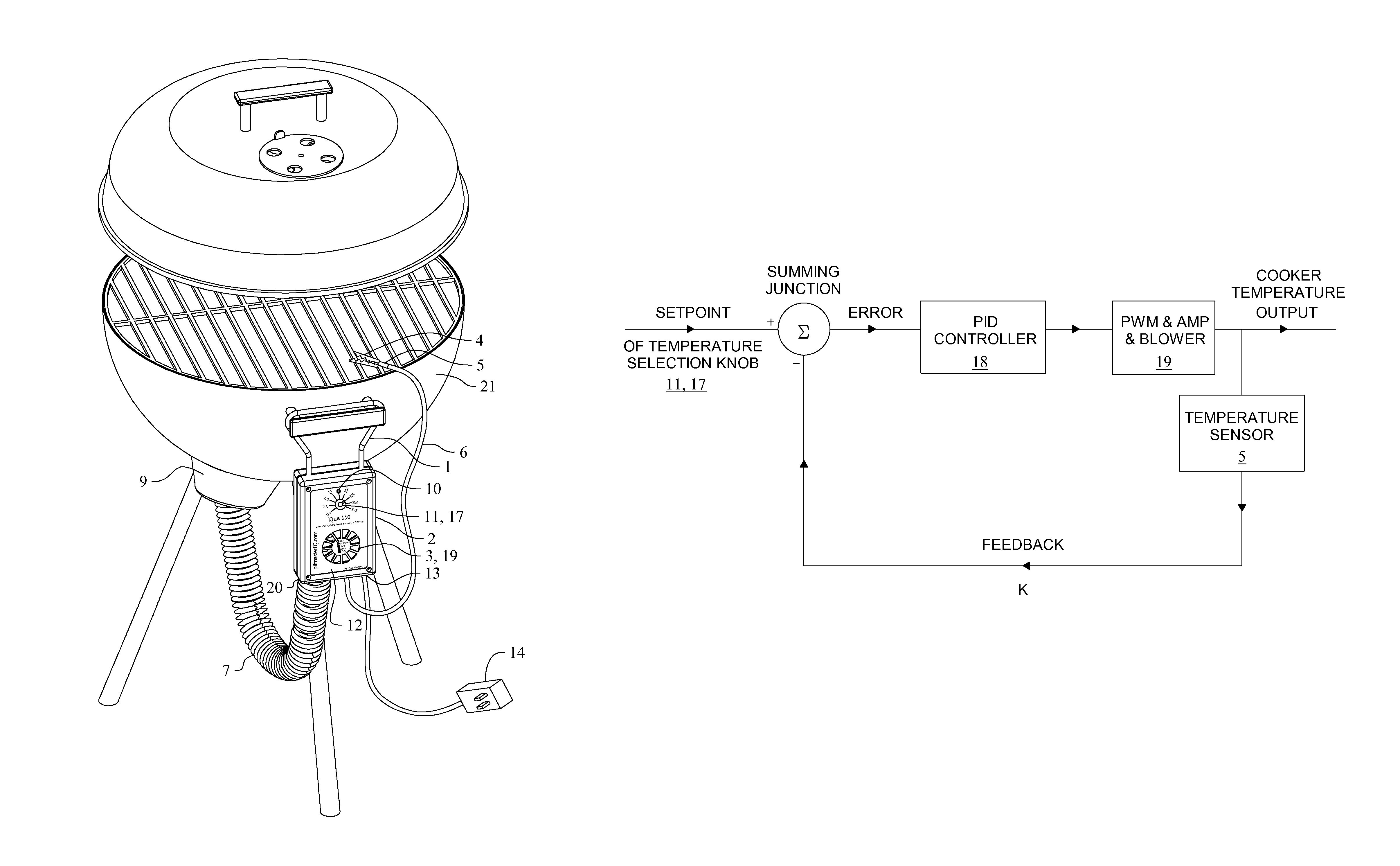

An automatic temperature control device for solid fuel fired food cooker fueled by wood, charcoal, or other solid fuels which is capable of operation with any type of cooker without utilization of different sized blowers and conserves solid fuel usage. The present invention serves to regulate cooking temperature by controlling or optimizing the amount of combustion air reaching the fuel. The present invention also allows an outdoor barbecue grill or smoker of any reasonable size to be retrofitted with the invention in order to allow a chef to cook foods at stable and precise temperatures. The core components of the invention are an air blower to provide combustion air to the burning fuel, an electronic controller to control the amount of air delivered by the air blower via a unique algorithm embedded within the electronic controller, a temperature sensor to sense the temperature inside of the cooker in the vicinity of the cooking food and provide feedback to the electronic controller, and an air tube and air manifold to get or direct the combustion air from the air blower inside the blower box to the burning fuel inside the cooker. Alternative embodiments utilize an automatic damper connected with said electronic controller whereby convection air currents may be precisely controlled.

Owner:KENNINGTON JOHN MATTHEW

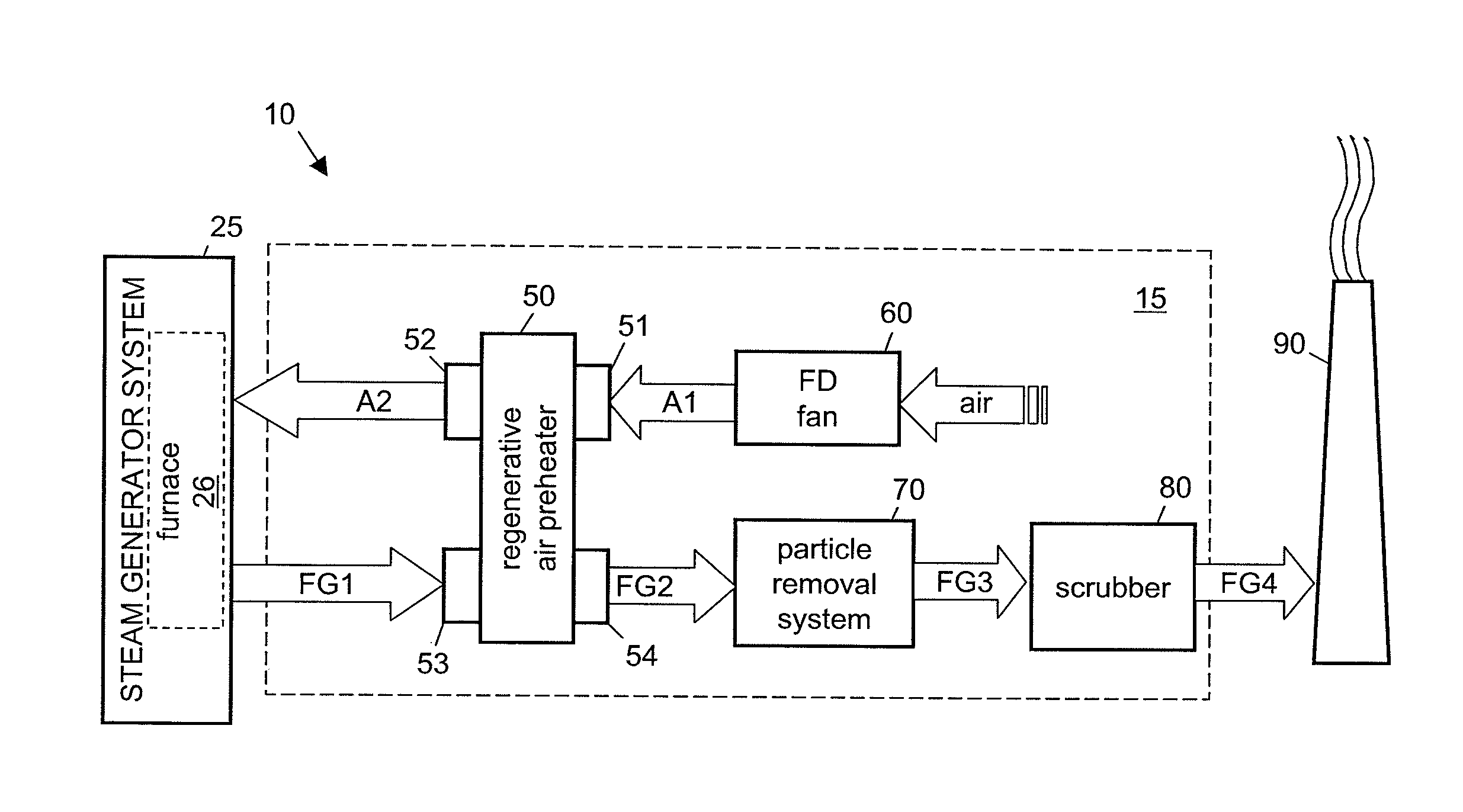

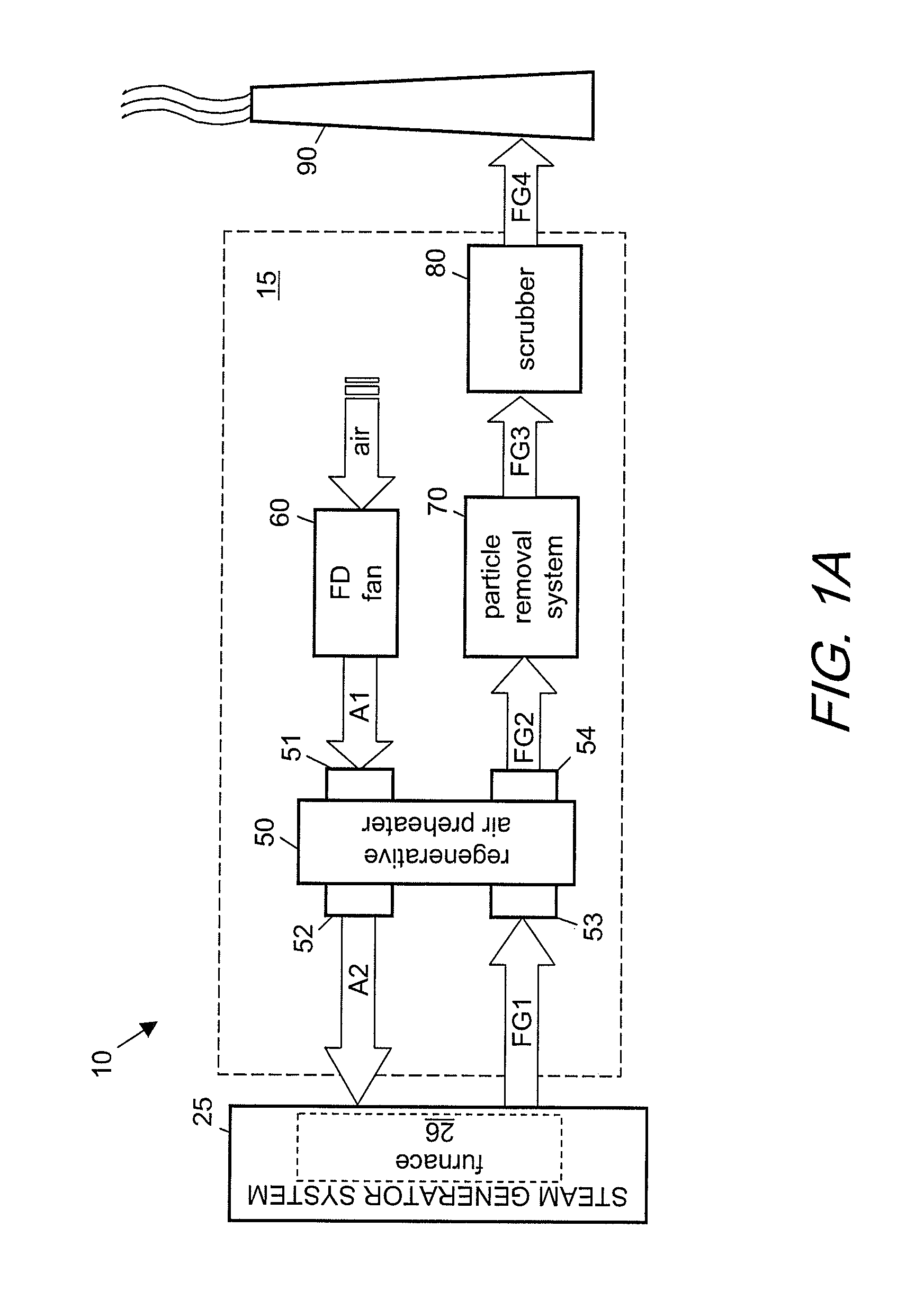

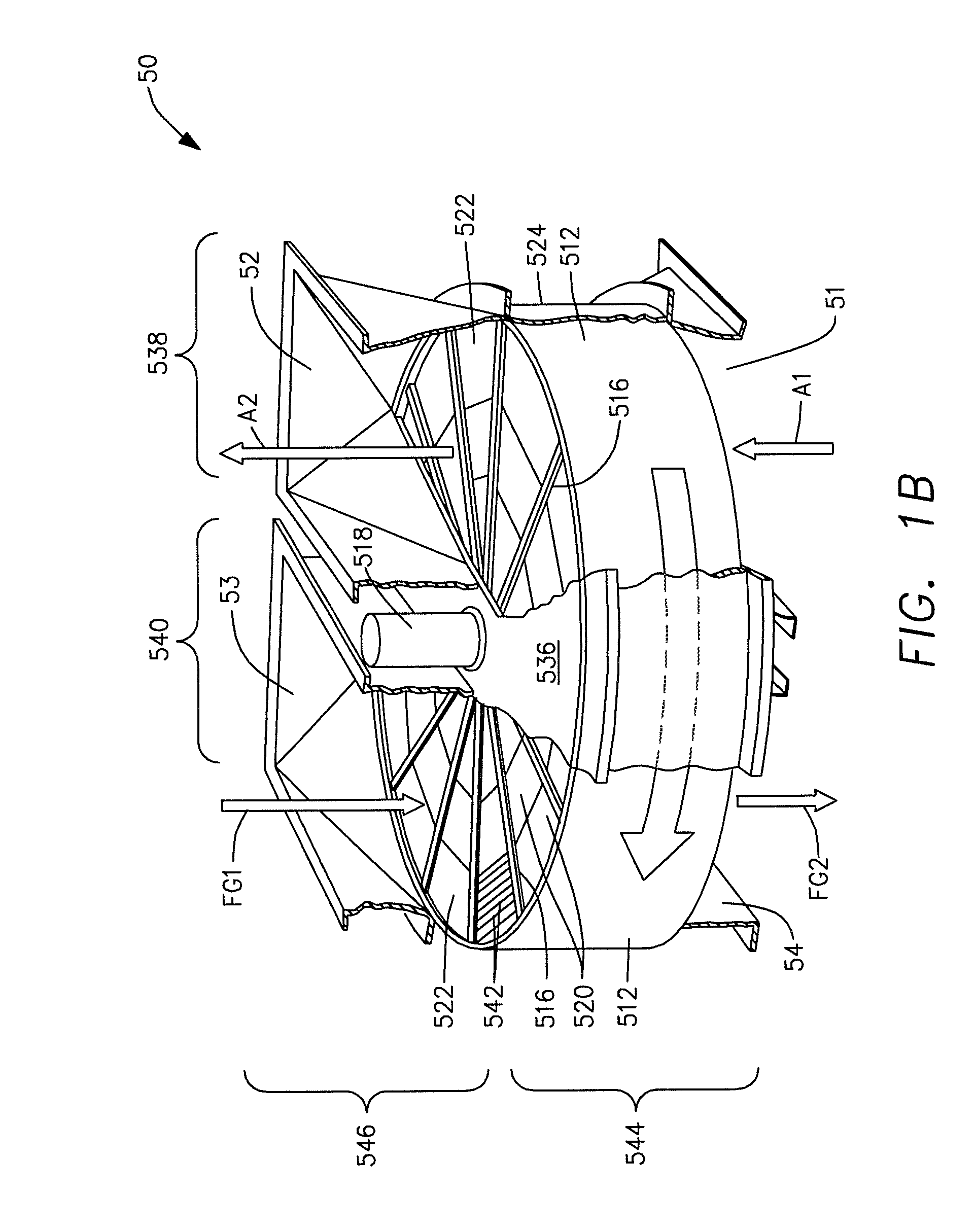

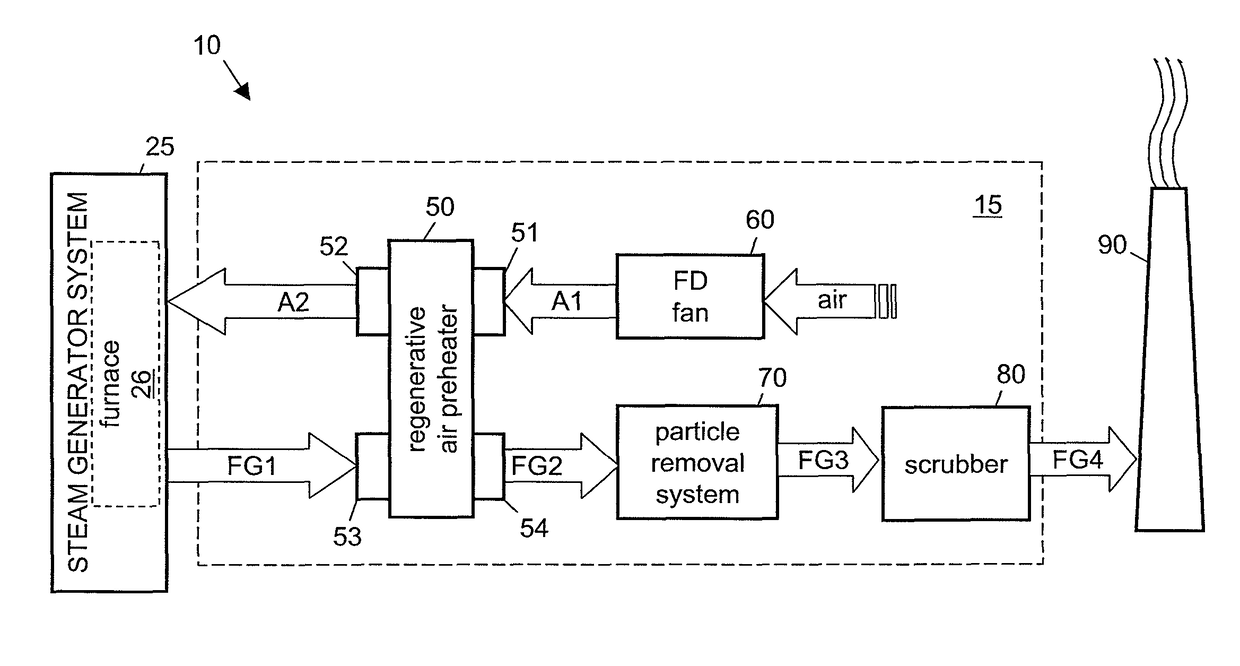

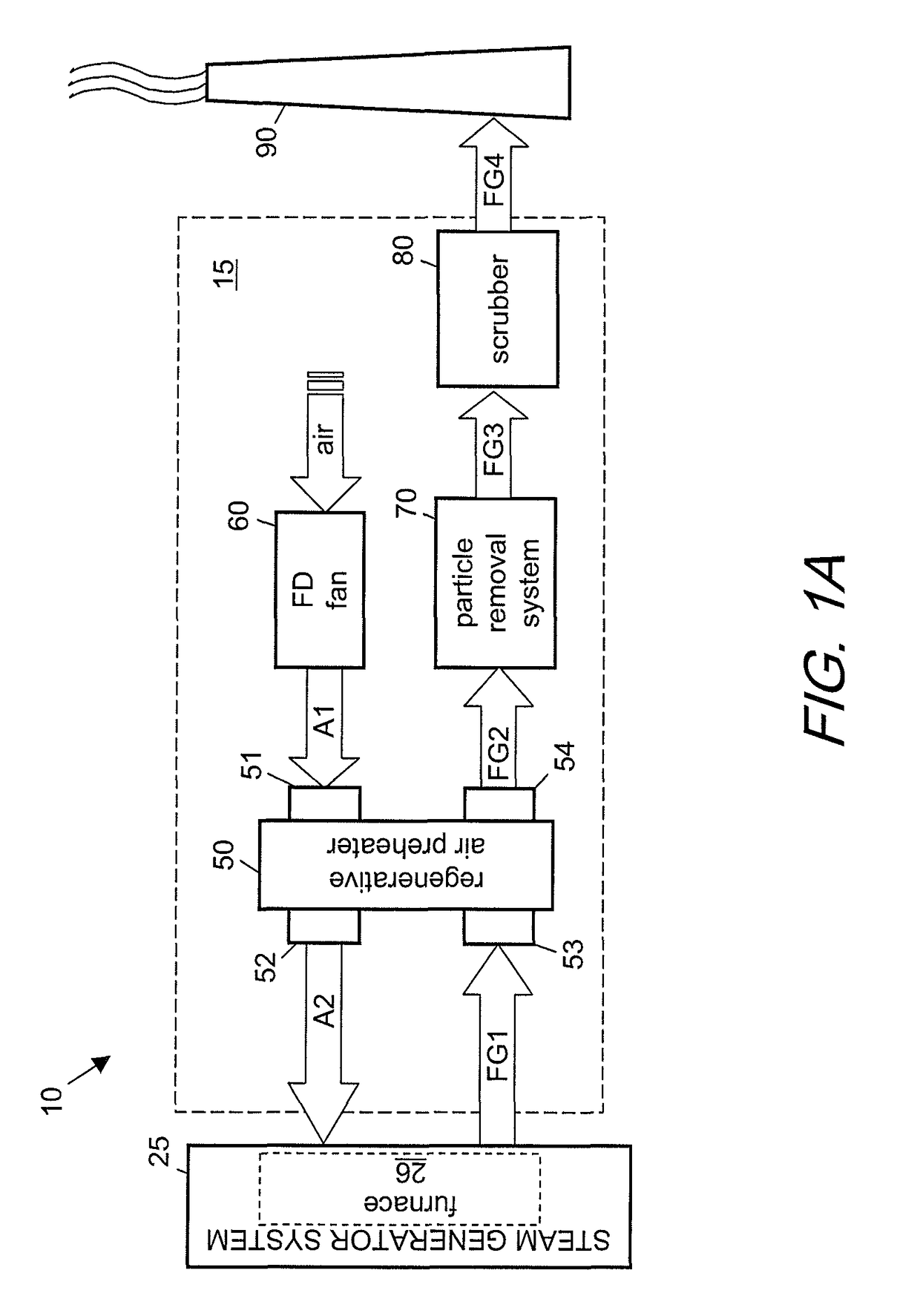

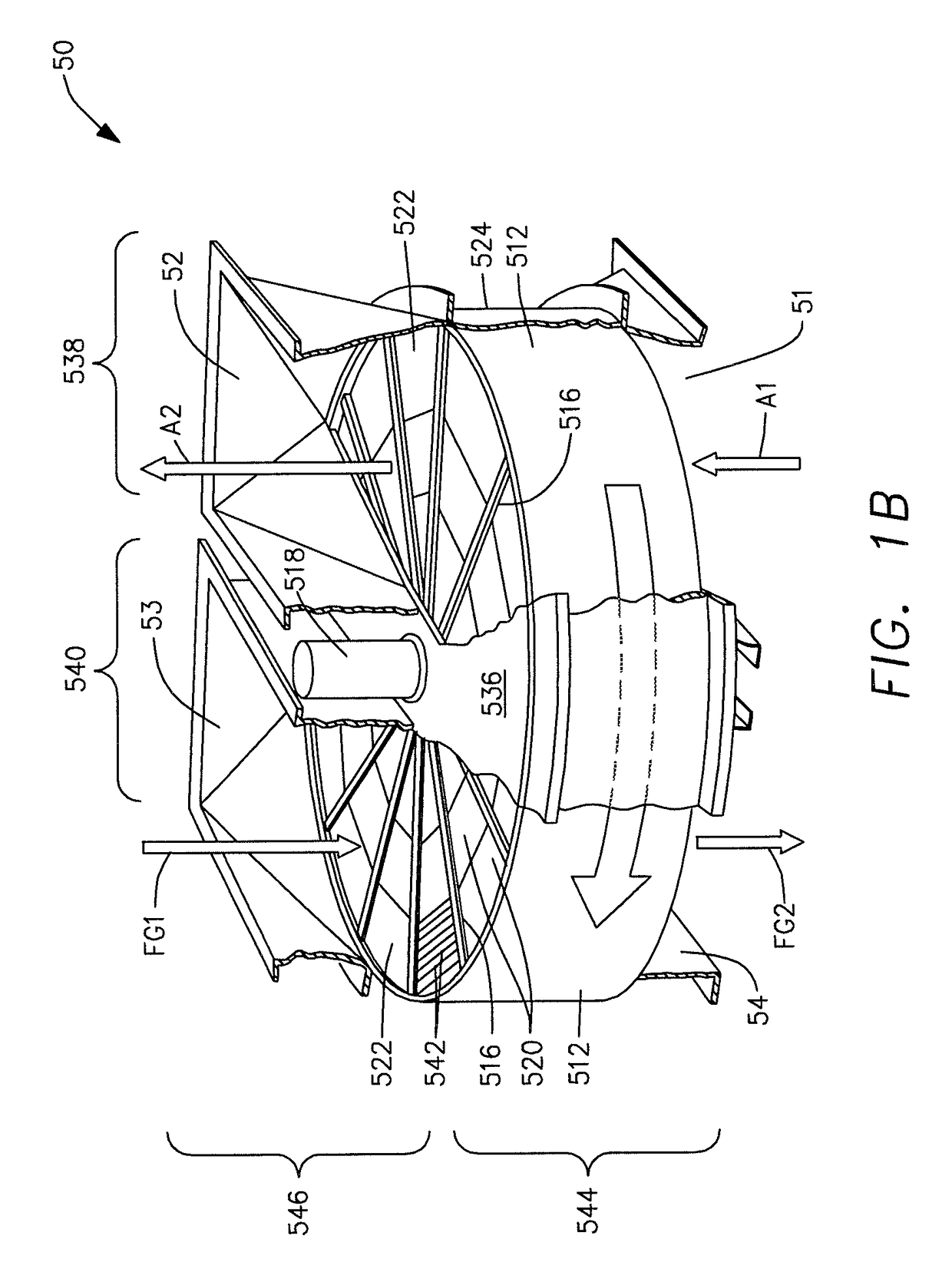

Exhaust processing and heat recovery system

InactiveUS20110073023A1Reduce accumulationImprove thermal efficiencyBurnersBlast furnace detailsThermal energyAir preheater

A thermally efficiency regenerative air preheater 250 extracts more thermal energy from the flue gas exiting a solid fuel fired furnace 26 by employing an alkaline injection system 276. This mitigates acid fouling by selectively injecting different sized alkaline particles 275 into the air preheater 250. Small particles provide nucleation sites for condensation and neutralization of acid vapors. Large particles are injected to contact and selectively adhere to the heat exchange elements 542 and neutralize liquid acid that condenses there. When the deposit accumulation exceeds a threshold, the apparatus generates and utilizes a higher relative percentage of large particles. Similarly, a larger relative percentage of small particles are used in other cases. Mitigation of the fouling conditions permits the redesign of the air preheater 250 to achieve the transfer of more heat from the flue resulting in a lower flue gas outlet temperature without excessive fouling.

Owner:ALSTOM ENERGY TECH AG

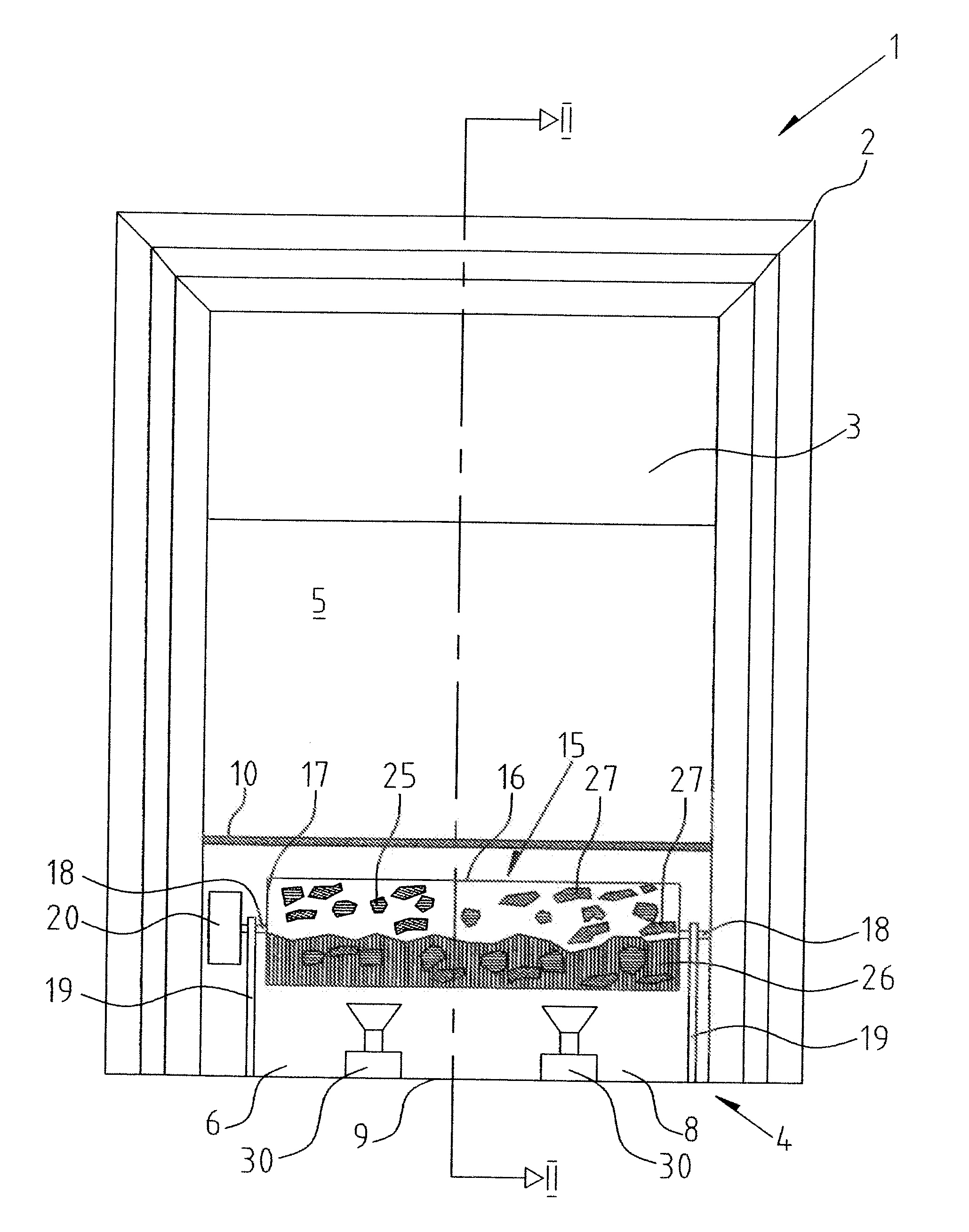

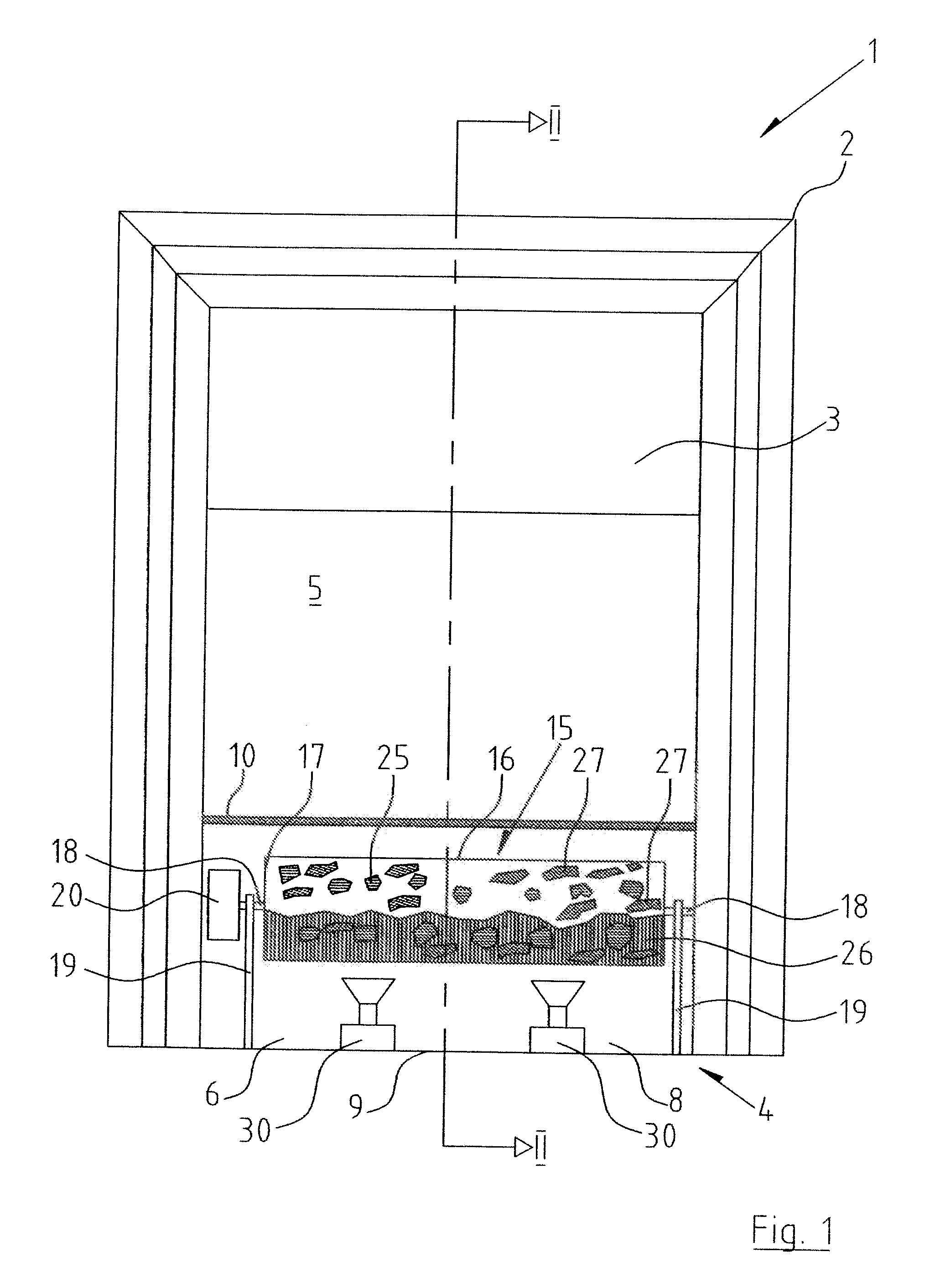

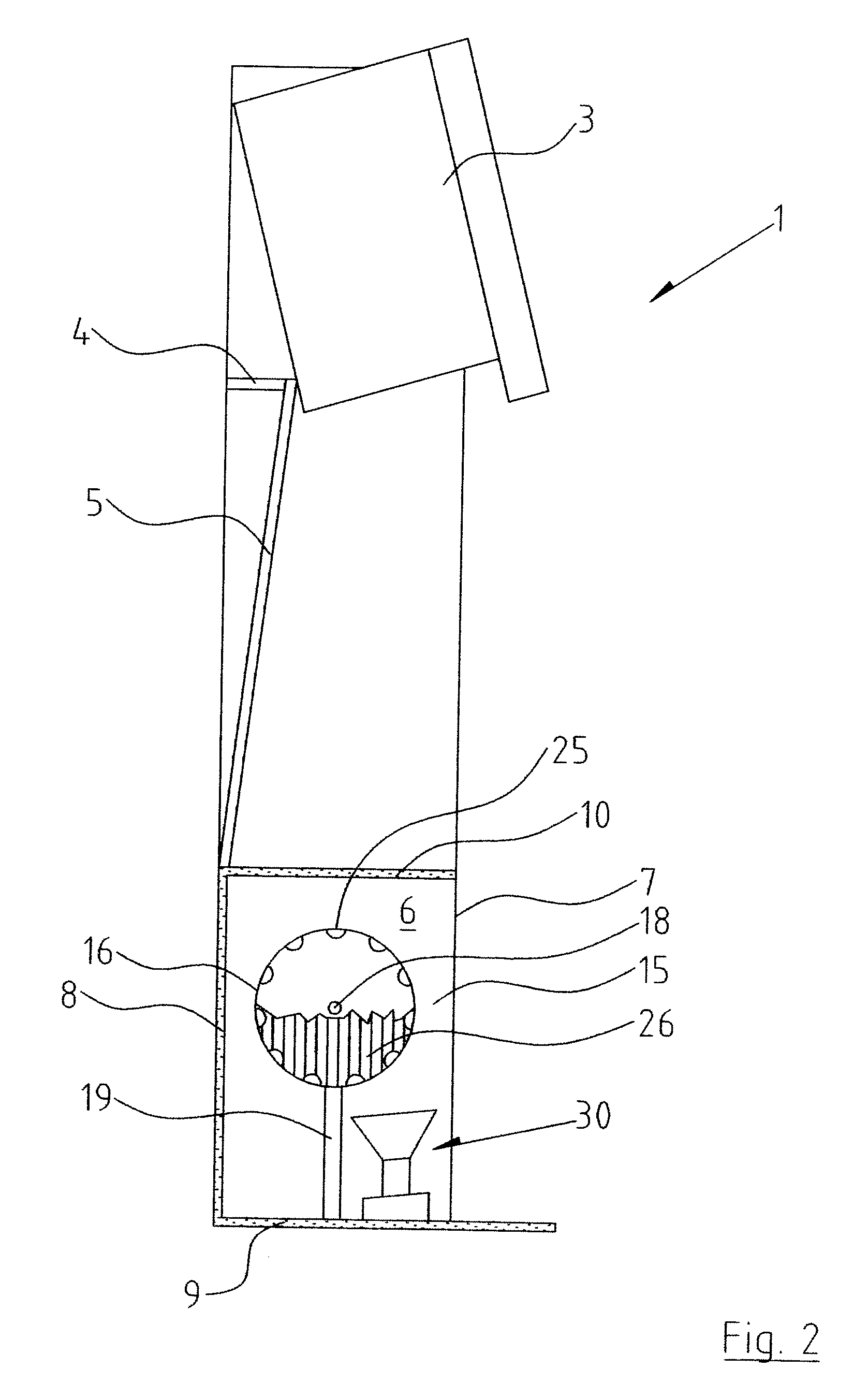

Flame effect apparatus

InactiveUS20090074390A1Domestic stoves or rangesLighting and heating apparatusEngineeringFrosted glass

Apparatus for simulating a solid fuel flame includes a frame within which is mounted a screen. An enclosure is mounted below the screen having a frosted glass refractor panel forming a top wall of the enclosure. A cylindrical container is rotatably mounted within the enclosure. A motor rotates the container on a support. The container is partially filled with a red or brown coloured liquid. Lamps or LED's within the enclosure are operable to shine light through the coloured liquid in the container and through the refractor panel onto the screen. Movement of the coloured liquid, which may be enhanced by internal projections in the container, causes flickering of the light projected onto the screen to give a flame effect simulating a solid fuel fire.

Owner:POWER PATRICK VIRGILIUS +2

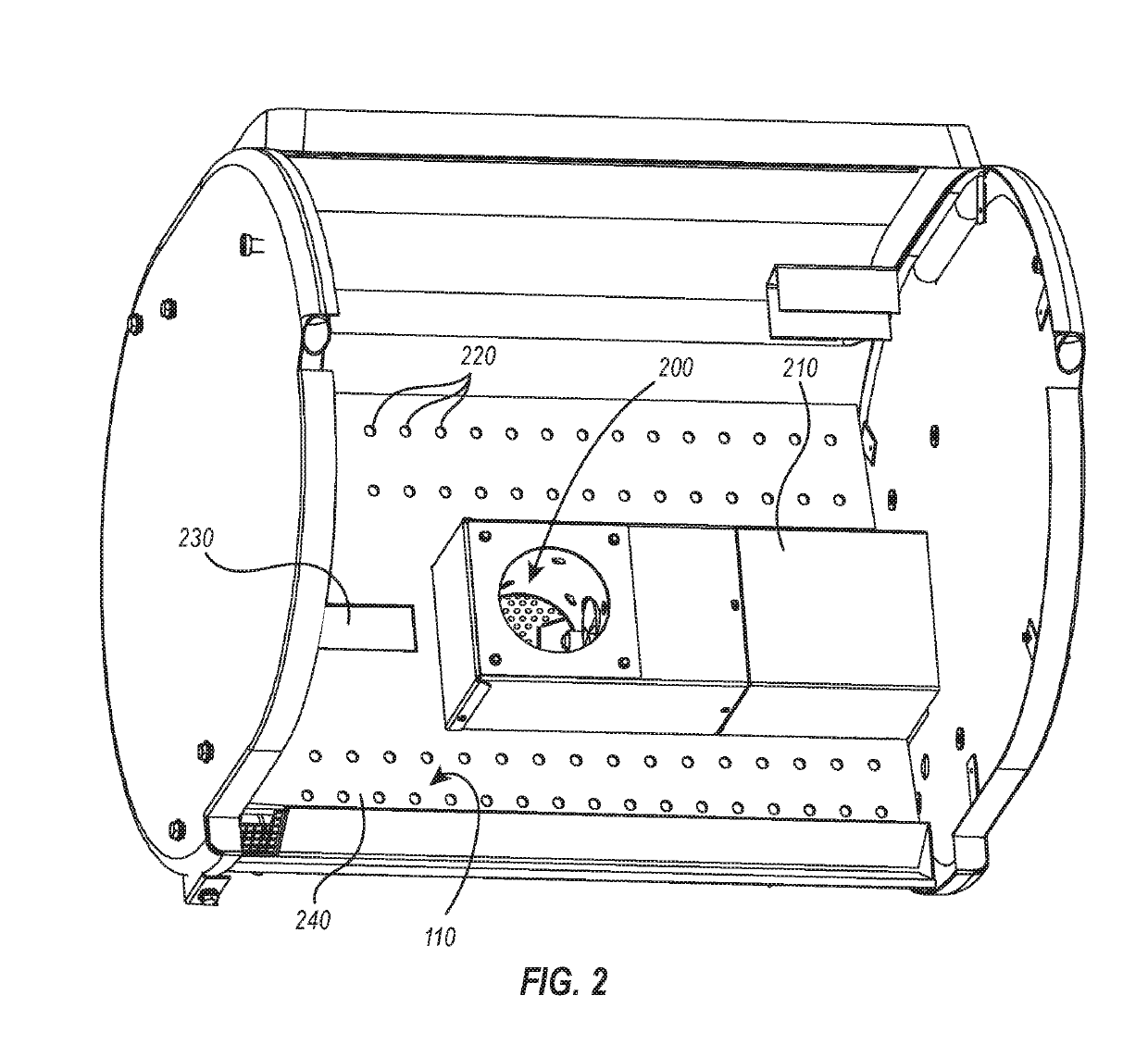

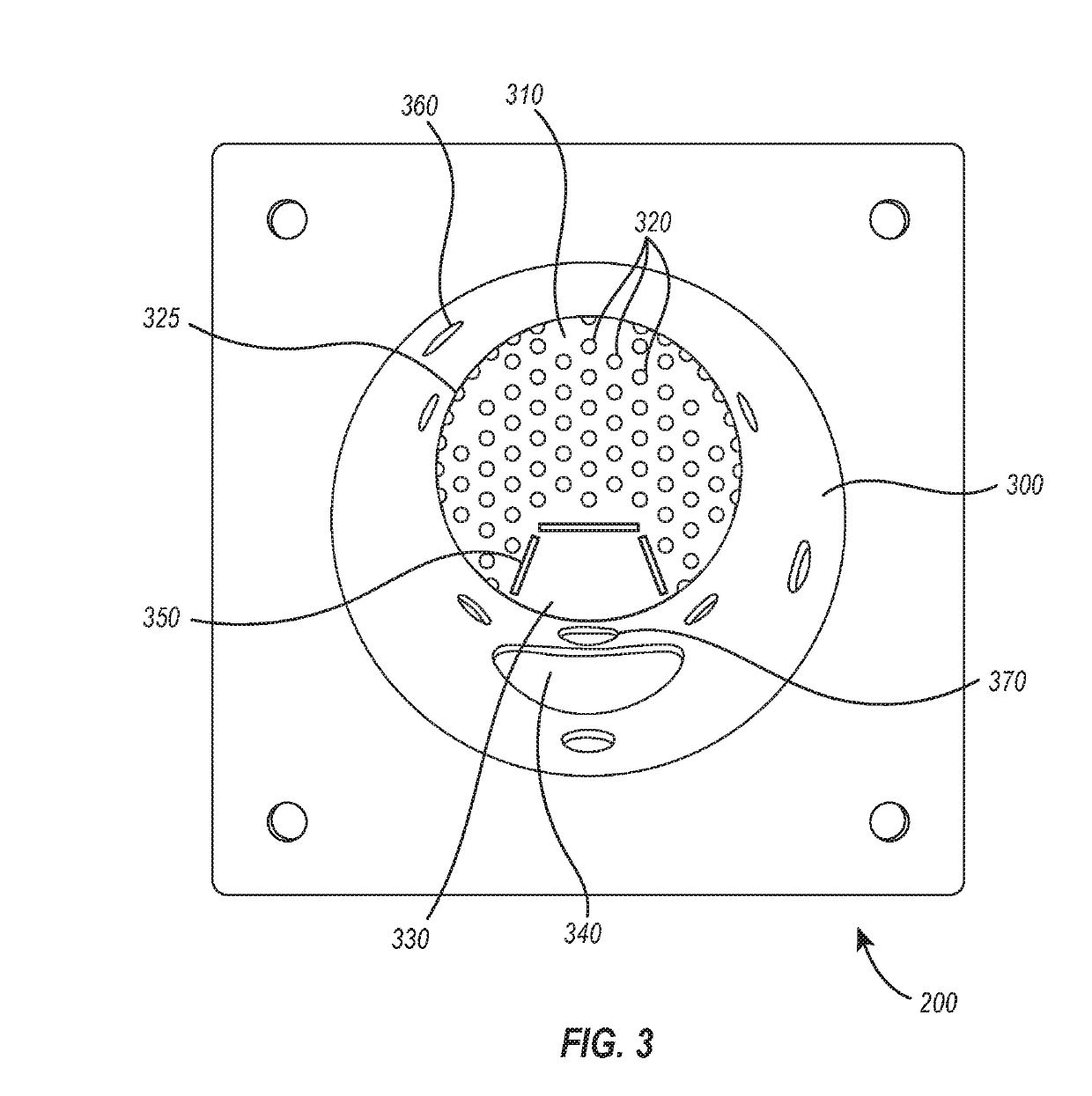

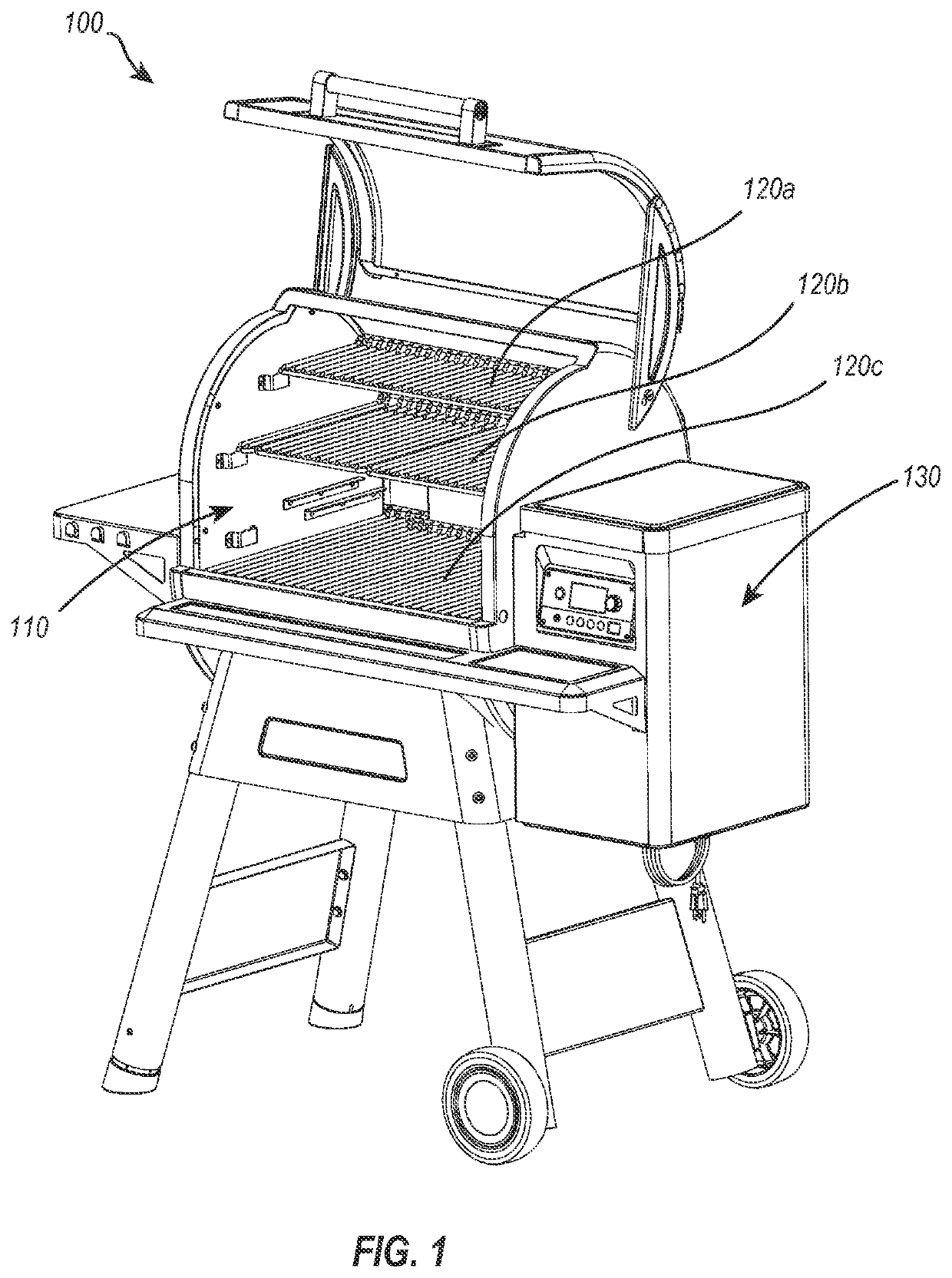

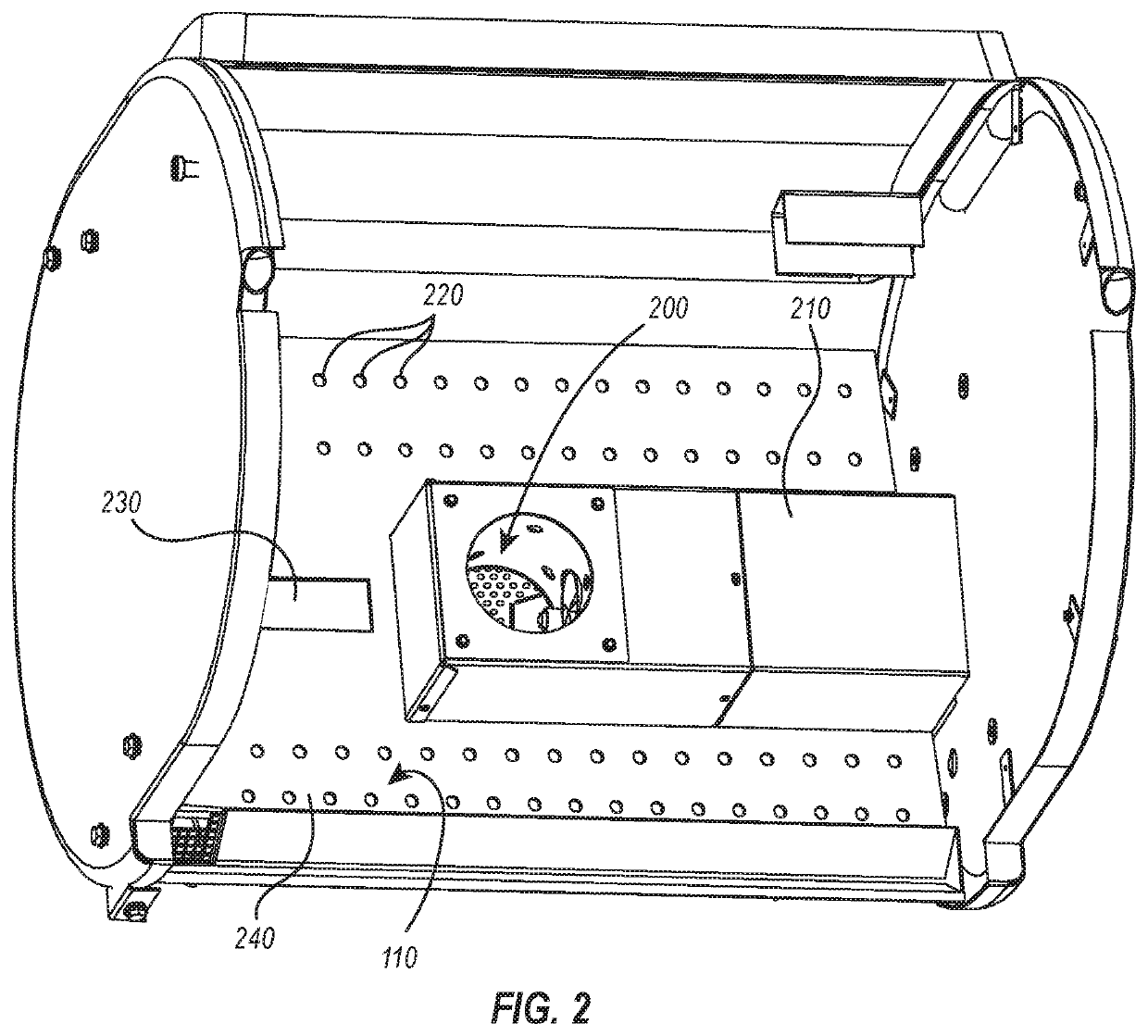

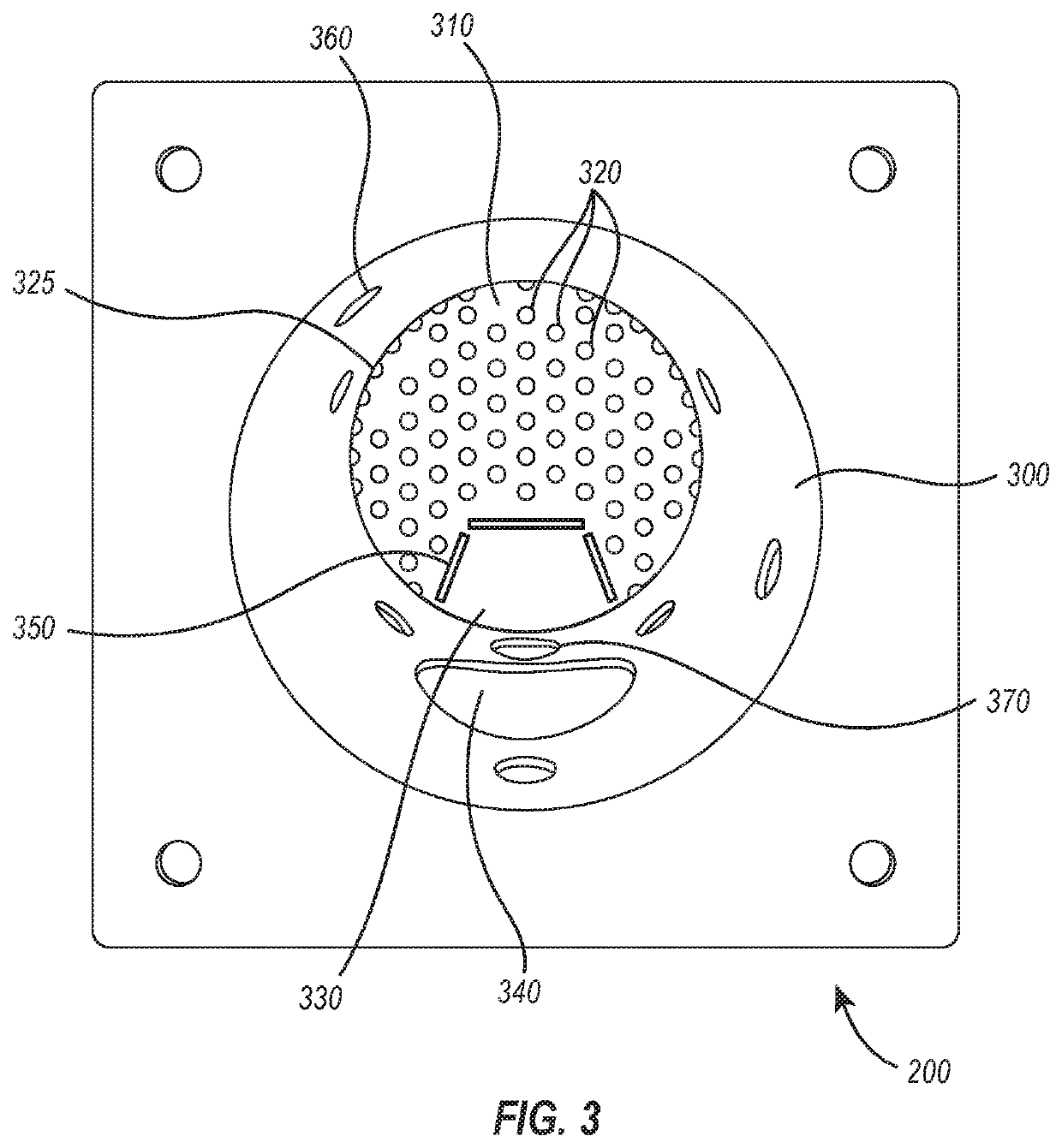

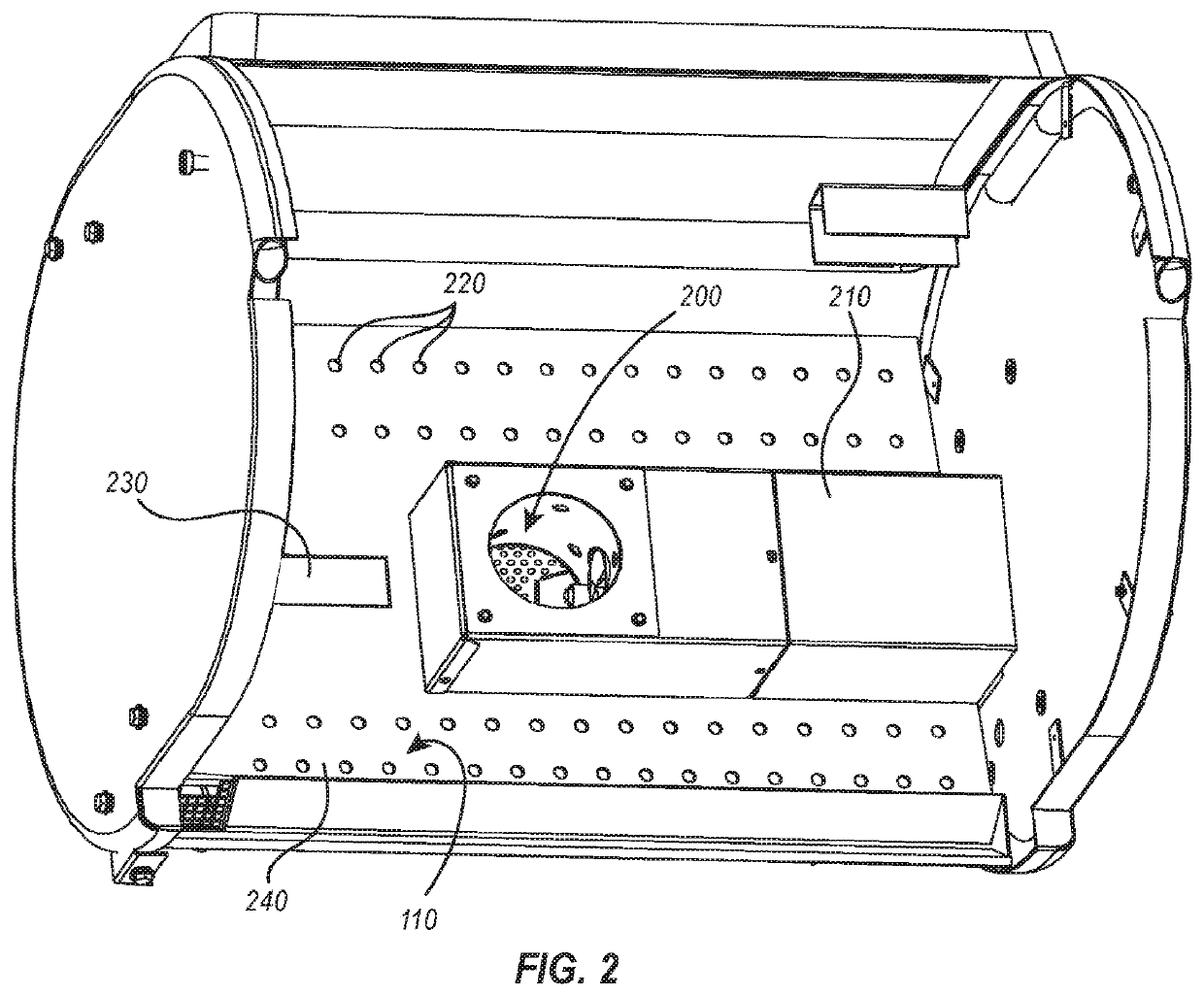

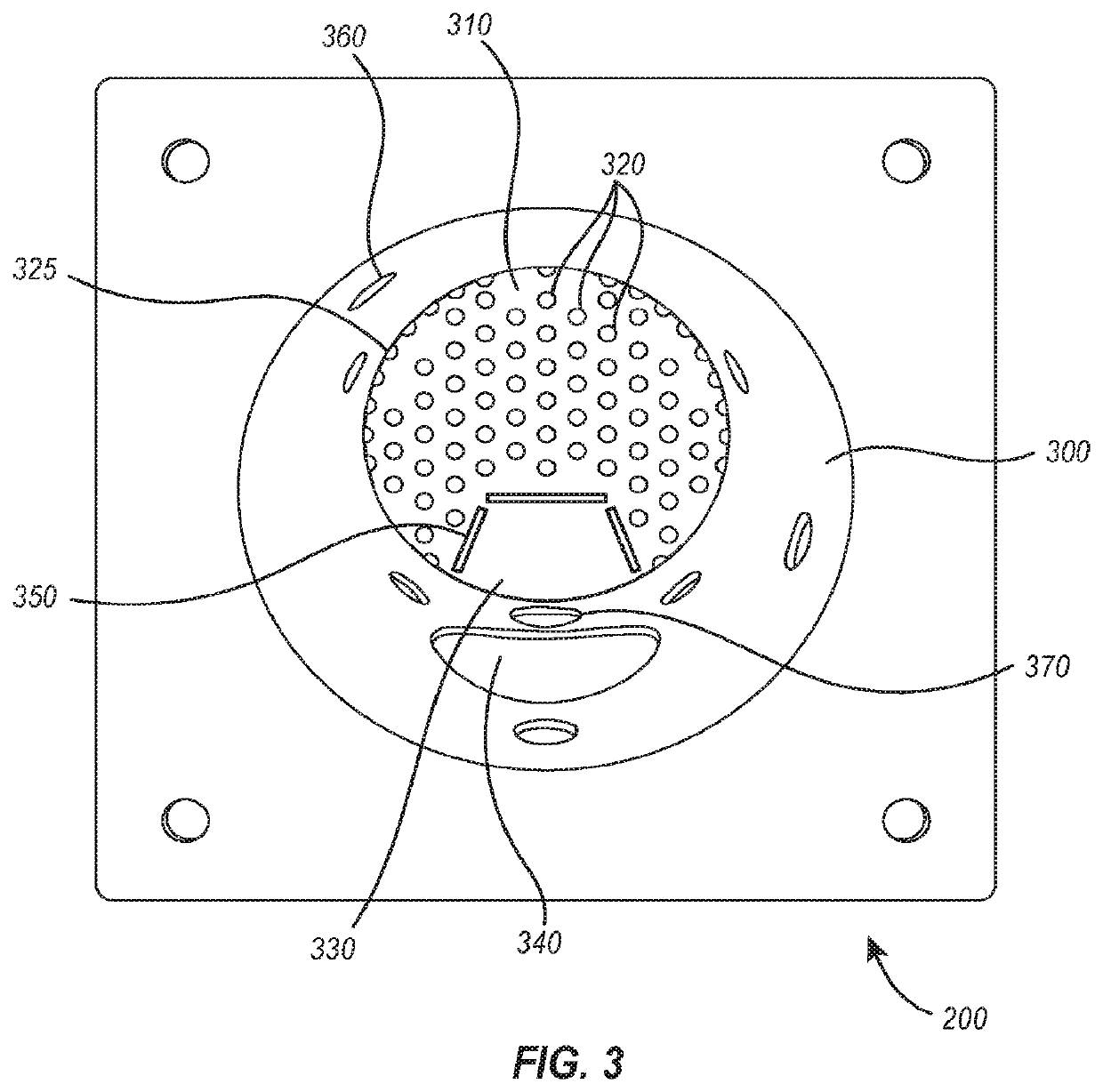

Self-cleaning grill

ActiveUS20190293295A1Lower performance requirementsReduce effortDomestic stoves or rangesLighting and heating apparatusEngineeringHeating element

A firepot for a grilling device comprises one or more walls at least partially forming an outer boundary of the firepot. The firepot is structurally configured to hold at least partially ignited solid fuel. The firepot also comprises a floor defining, at least in part, a lower end of the firepot. The floor comprises one or more holes extending through the floor. Additionally, a portion of the one or more walls form a solid fuel delivery opening that comprises a solid fuel portal through which solid fuel is deliverable to an interior of the firepot. A heating element mount is positioned to hold a heating element within the interior of the firepot.

Owner:TRAEGER PELLET GRILLS LLC

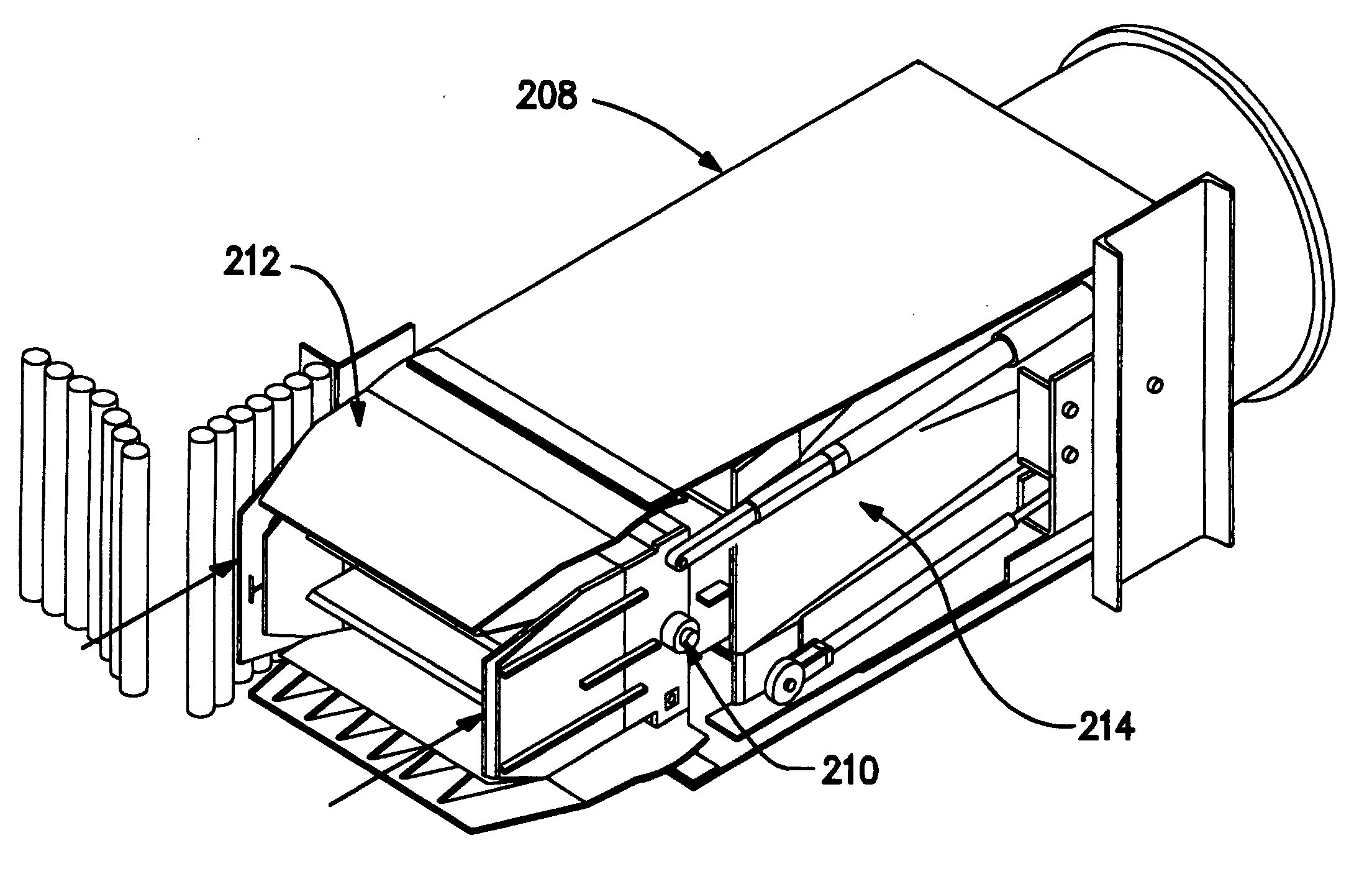

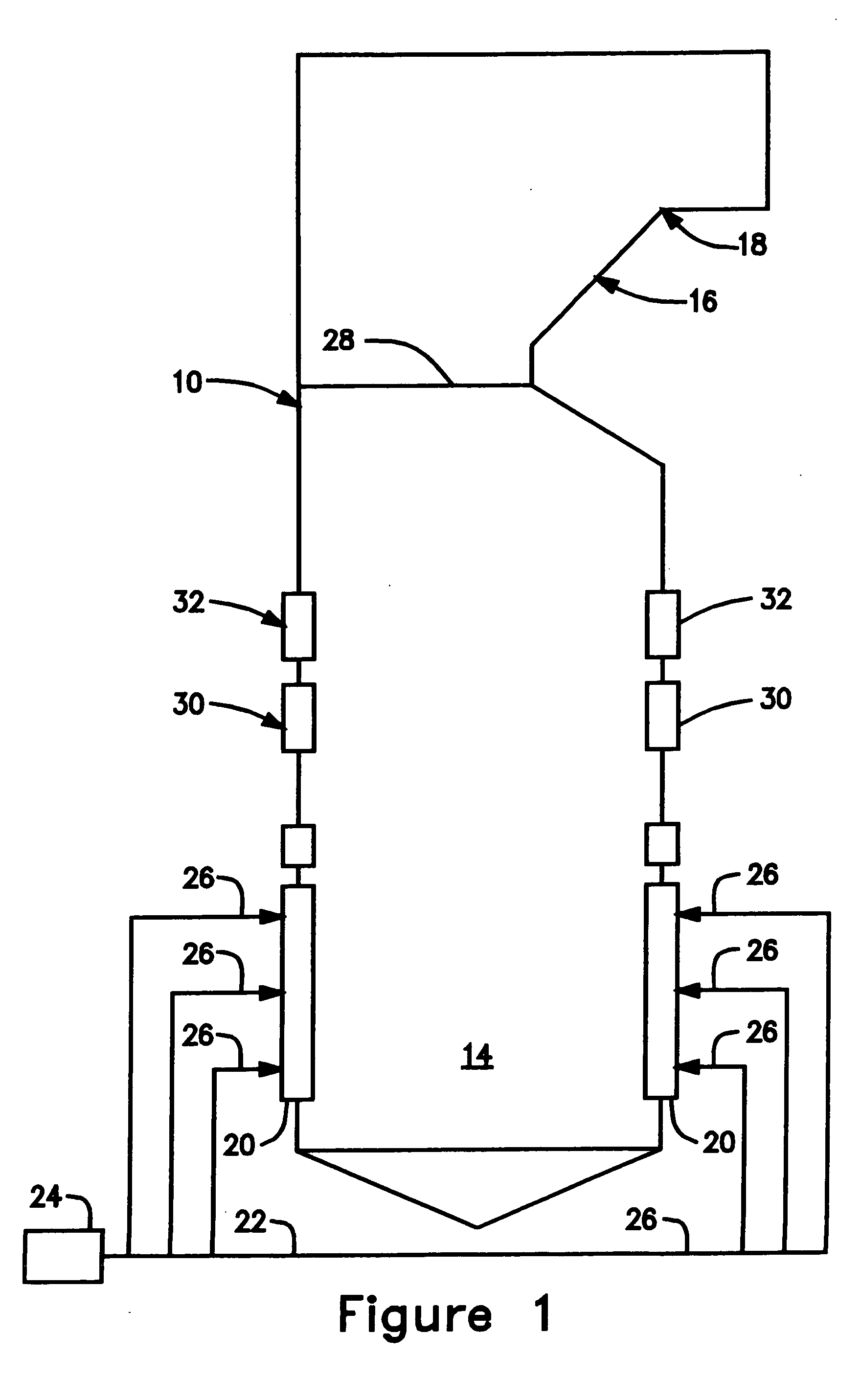

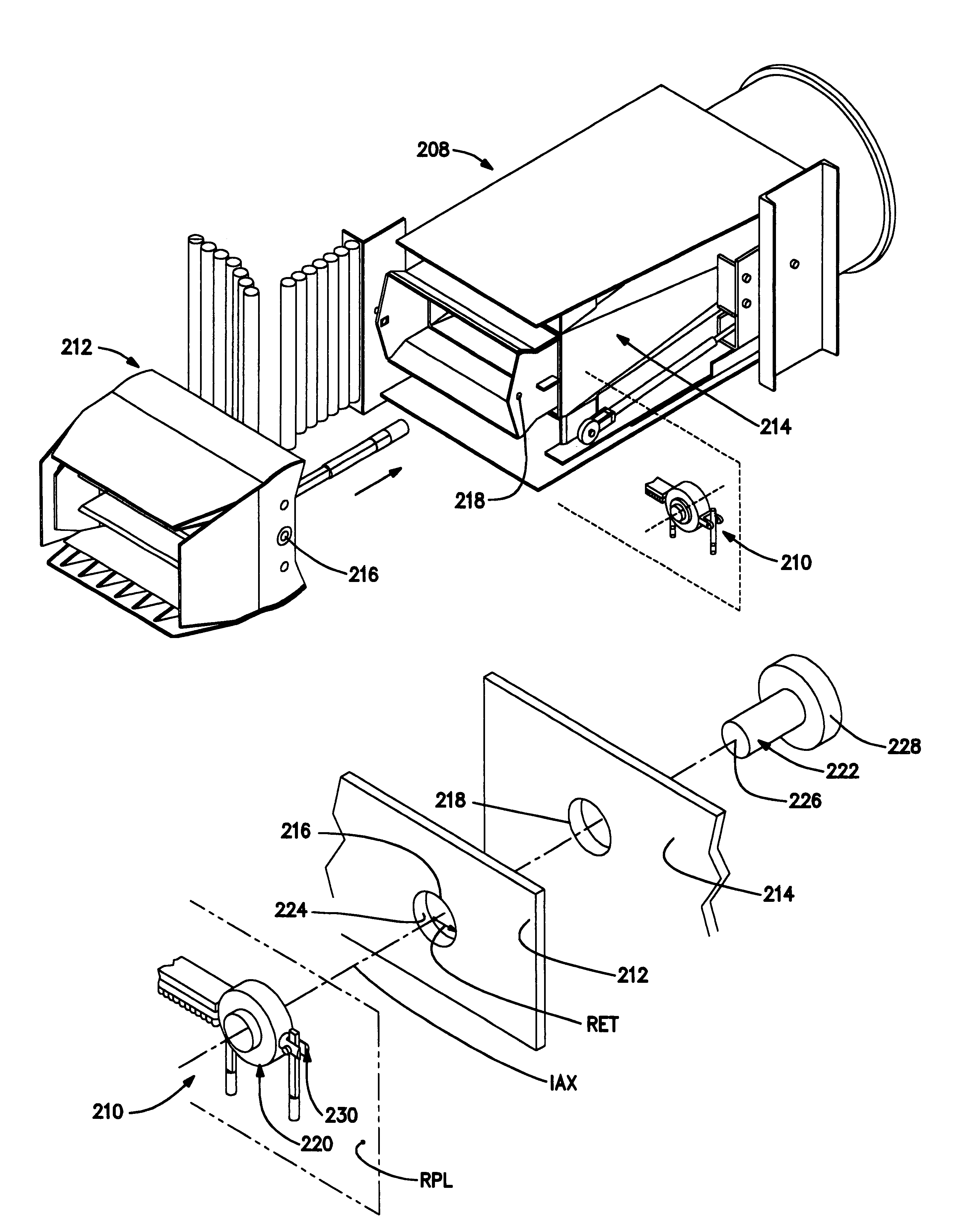

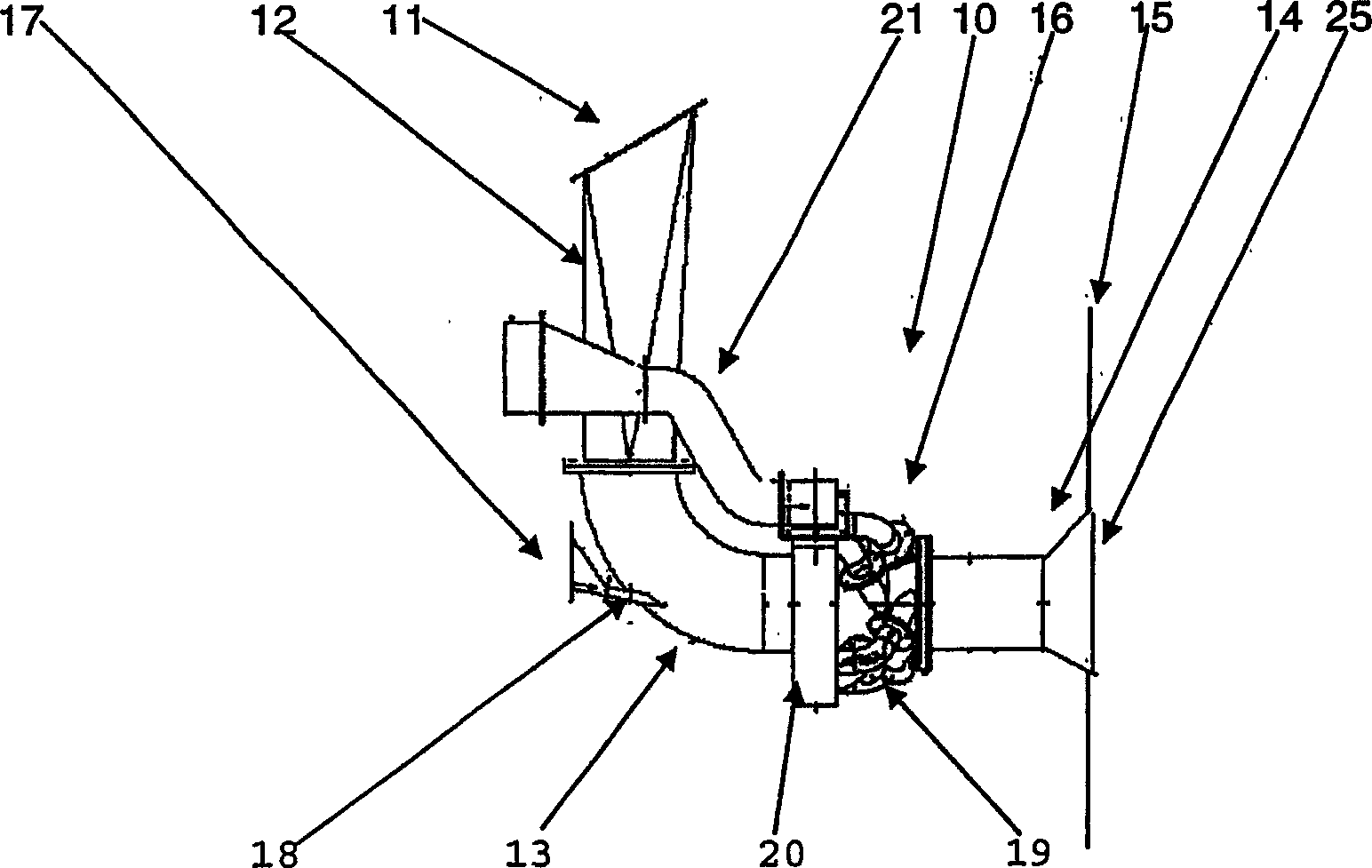

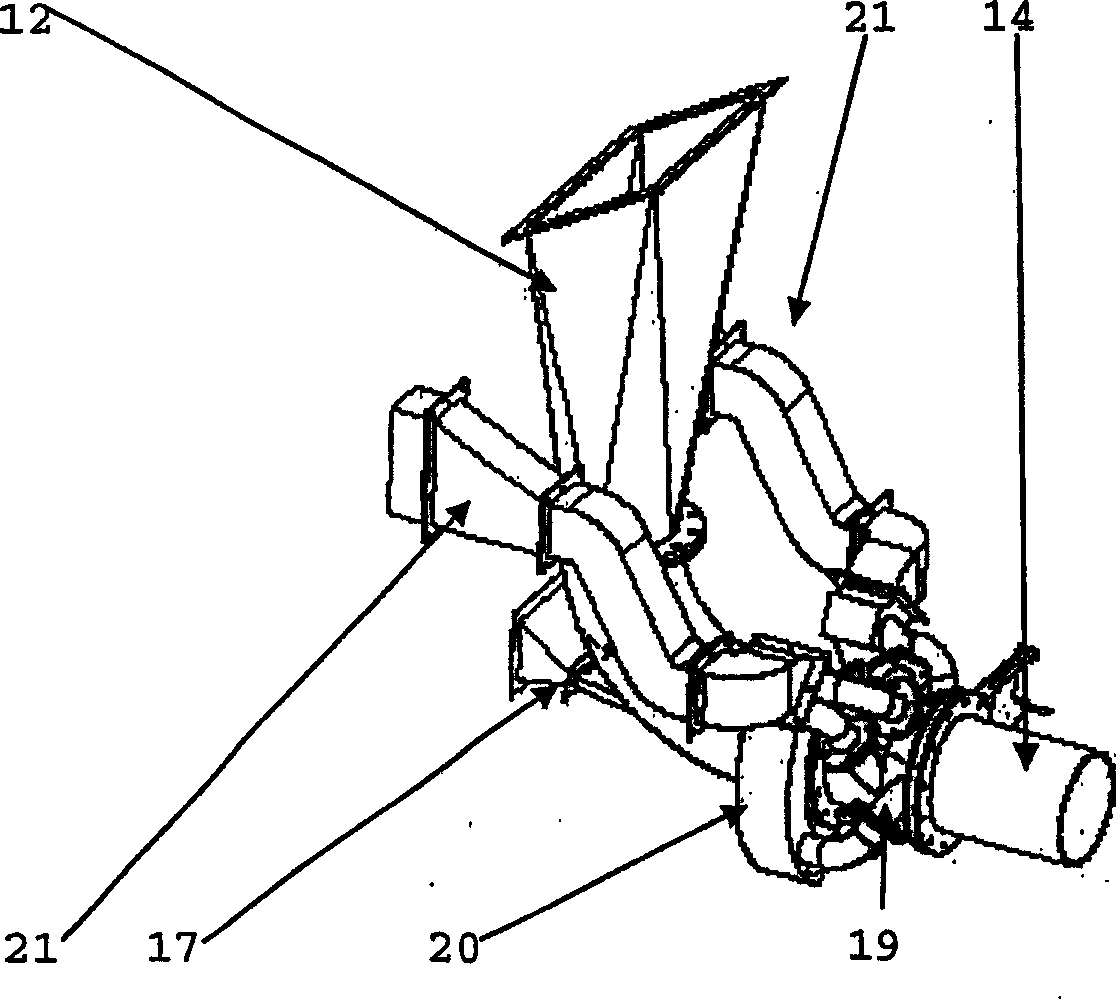

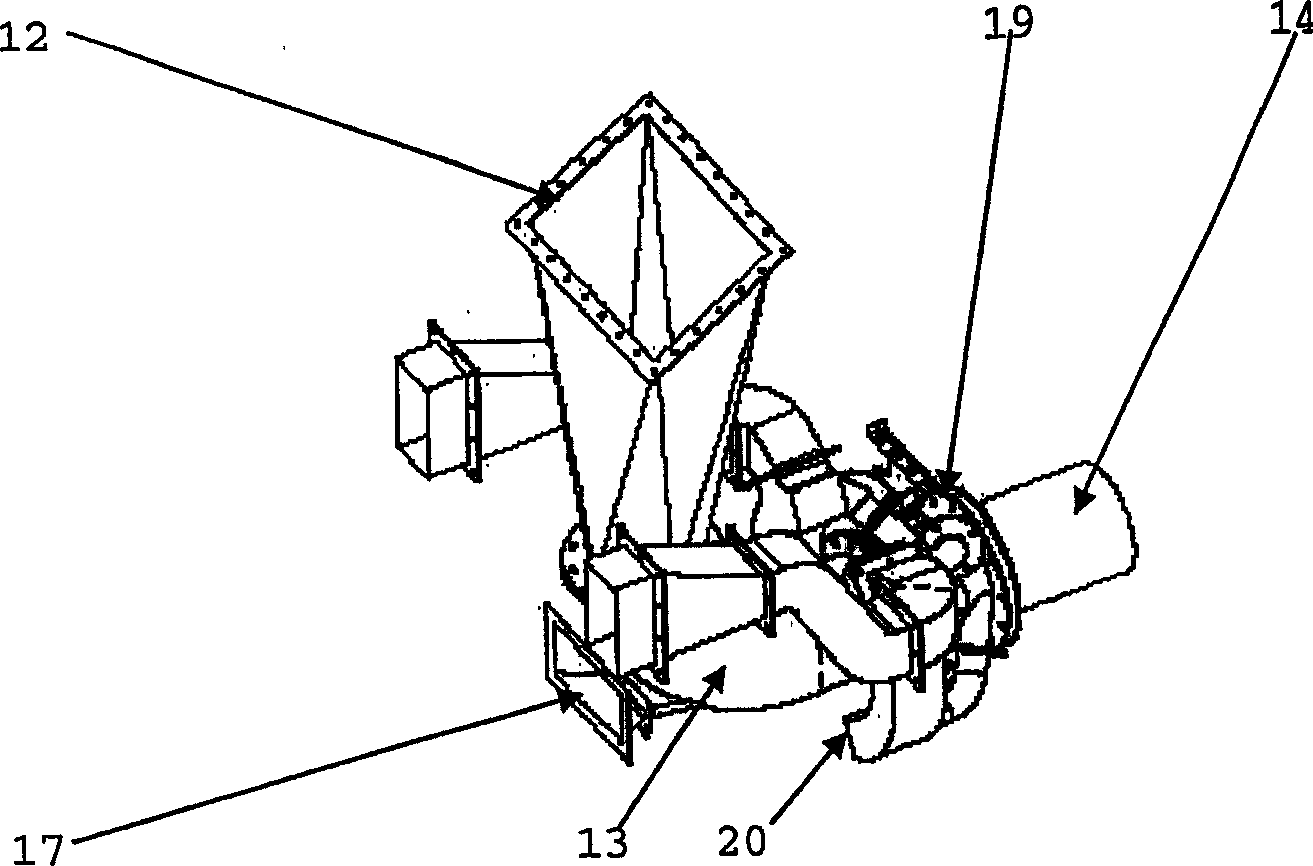

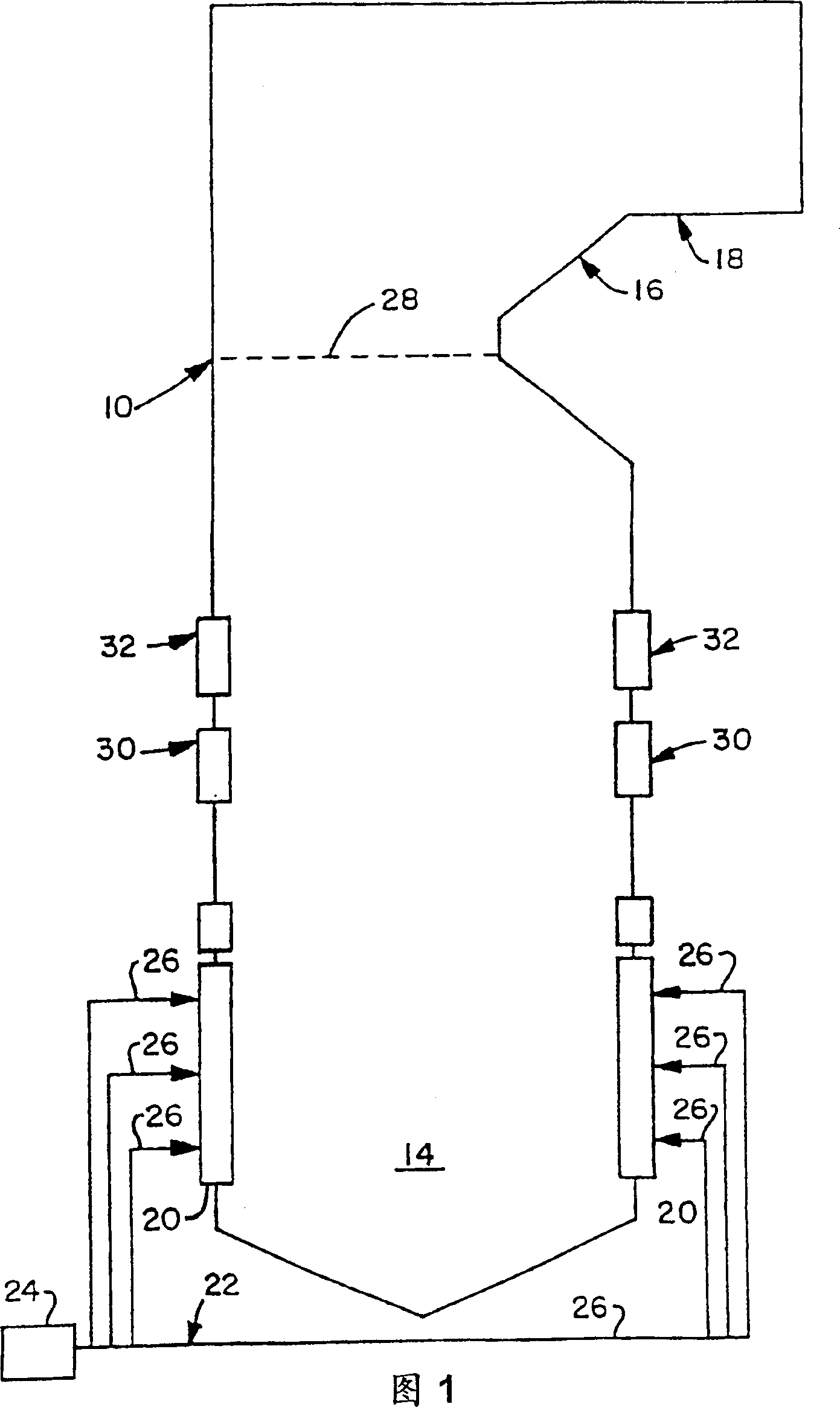

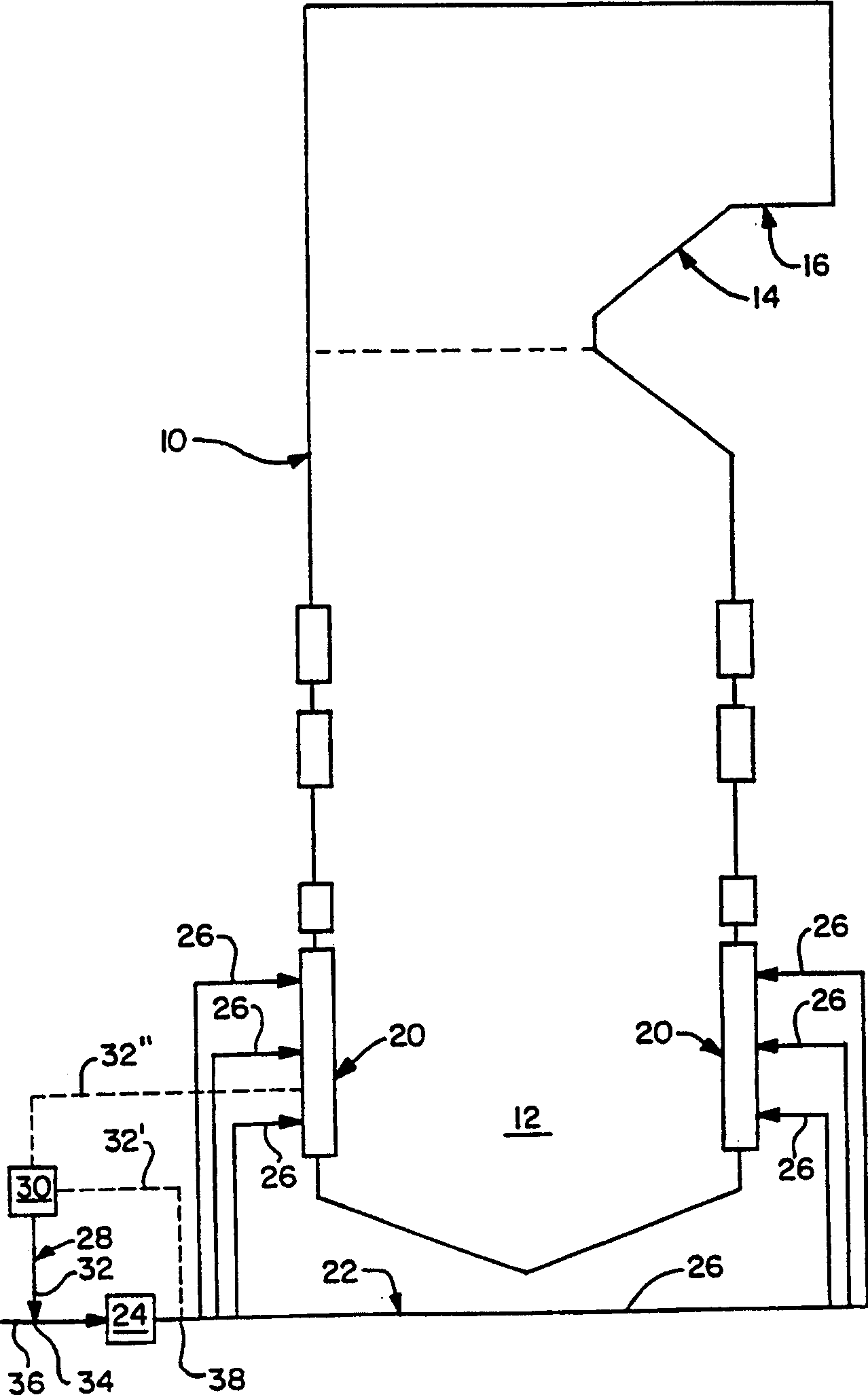

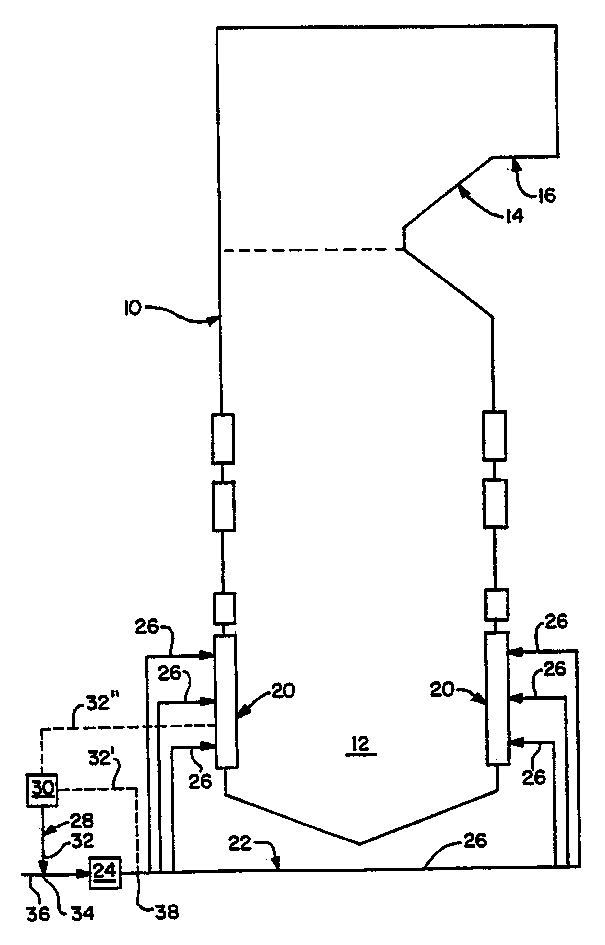

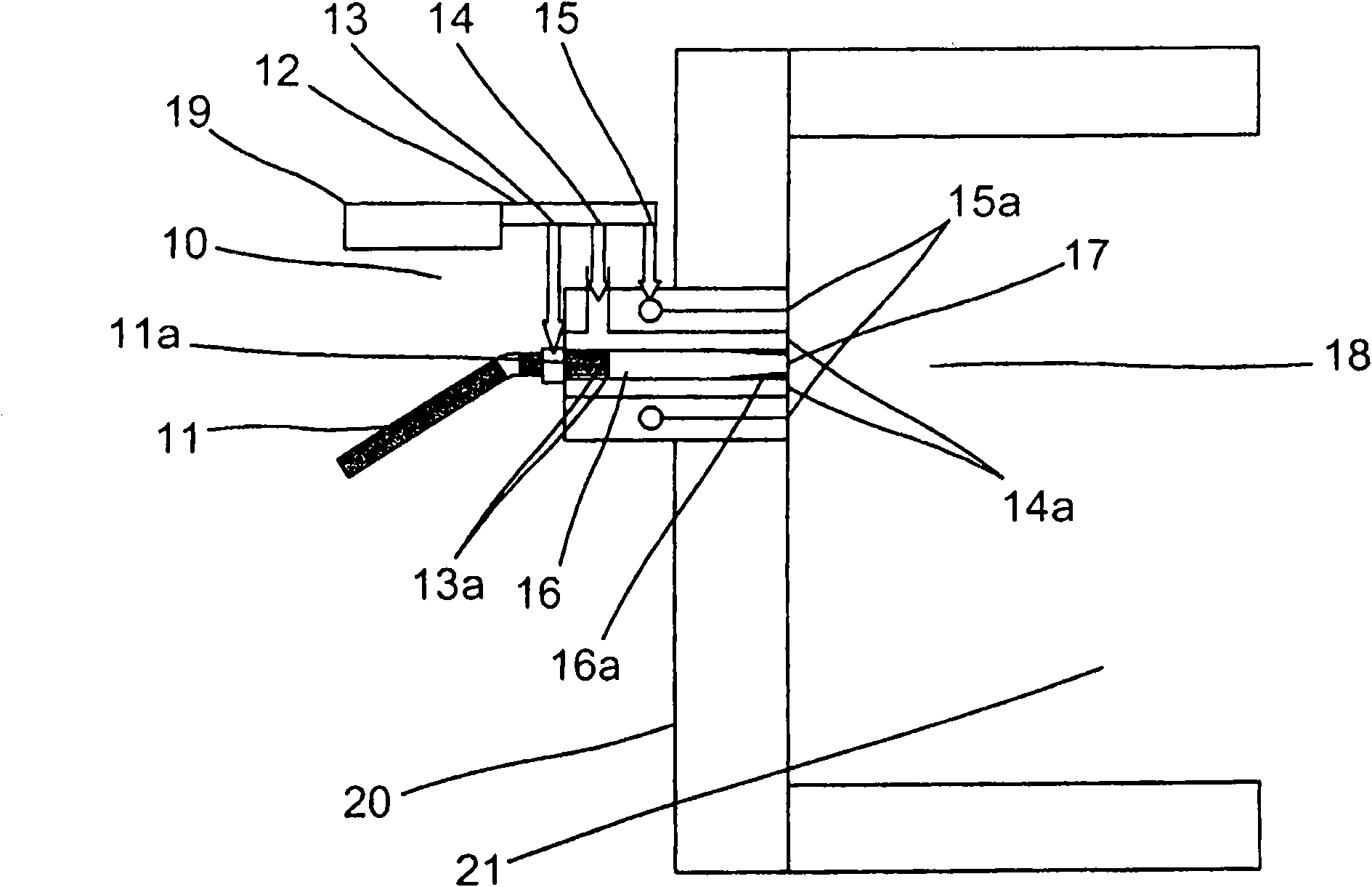

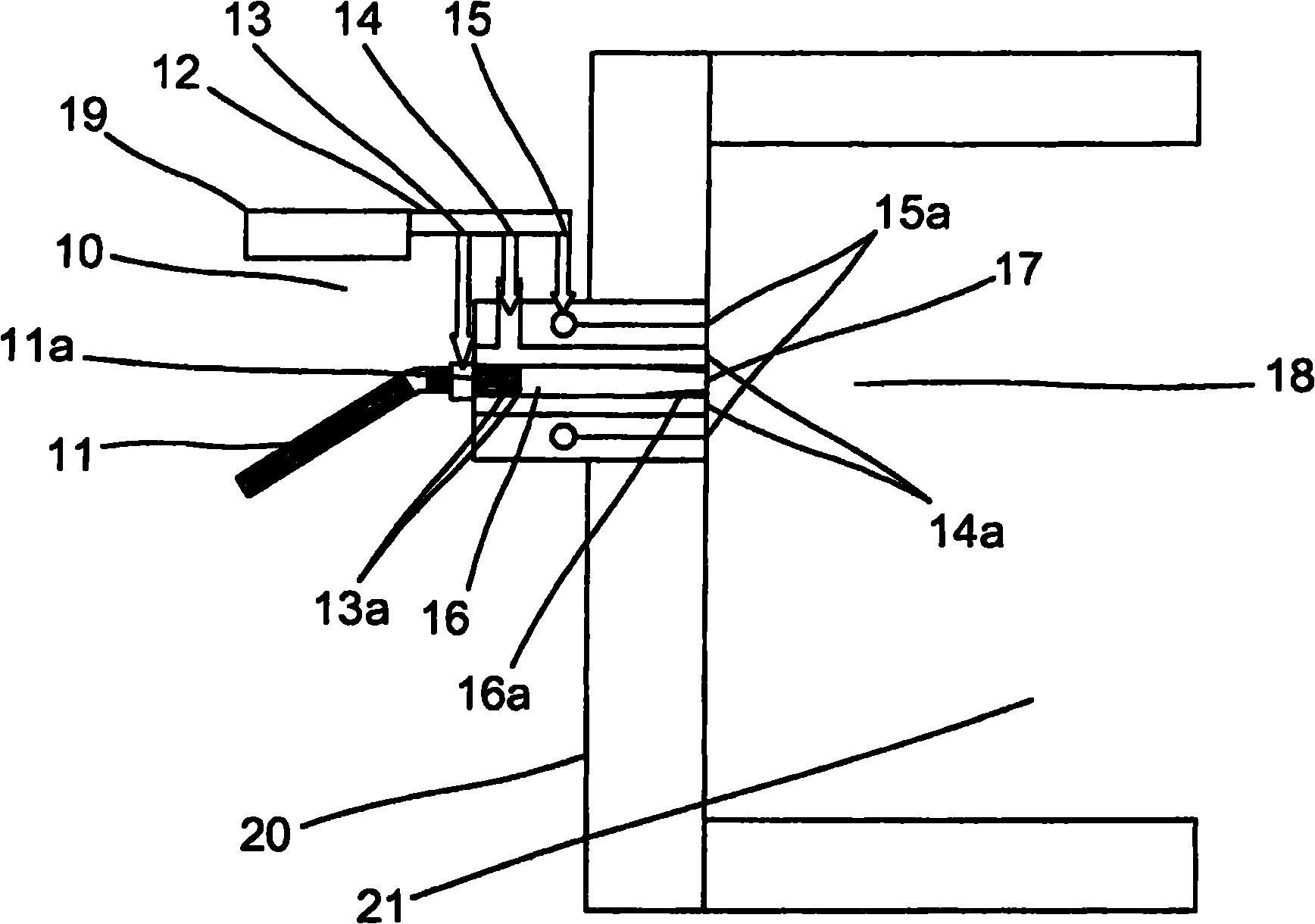

Fuel nozzle for a fossil fuel fired combustion arrangement

ActiveUS20050235888A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoalFossil fuel

A pivot mounting apparatus 210 is provided for pivotally mounting to one another the coal nozzle tip 212 and coal nozzle body 214 of a pulverized solid fuel nozzle 208 of a pulverized solid fuel-fired furnace 10. The pivot mounting apparatus 210 includes a latch interconnecting assembly 220 that includes a pin 222 for insertion in a traversing movement through an insertion passage 224 which passes through both the through hole 216 of the coal nozzle tip 212 and the through hole 218 of the coal nozzle body 214 upon the mutually facing positioning of respective sides of the coal nozzle tip 212 and the coal nozzle body 214 with one another with their respective through holes 216, 218 both co-axial with an insertion axis IAX.

Owner:GENERAL ELECTRIC TECH GMBH

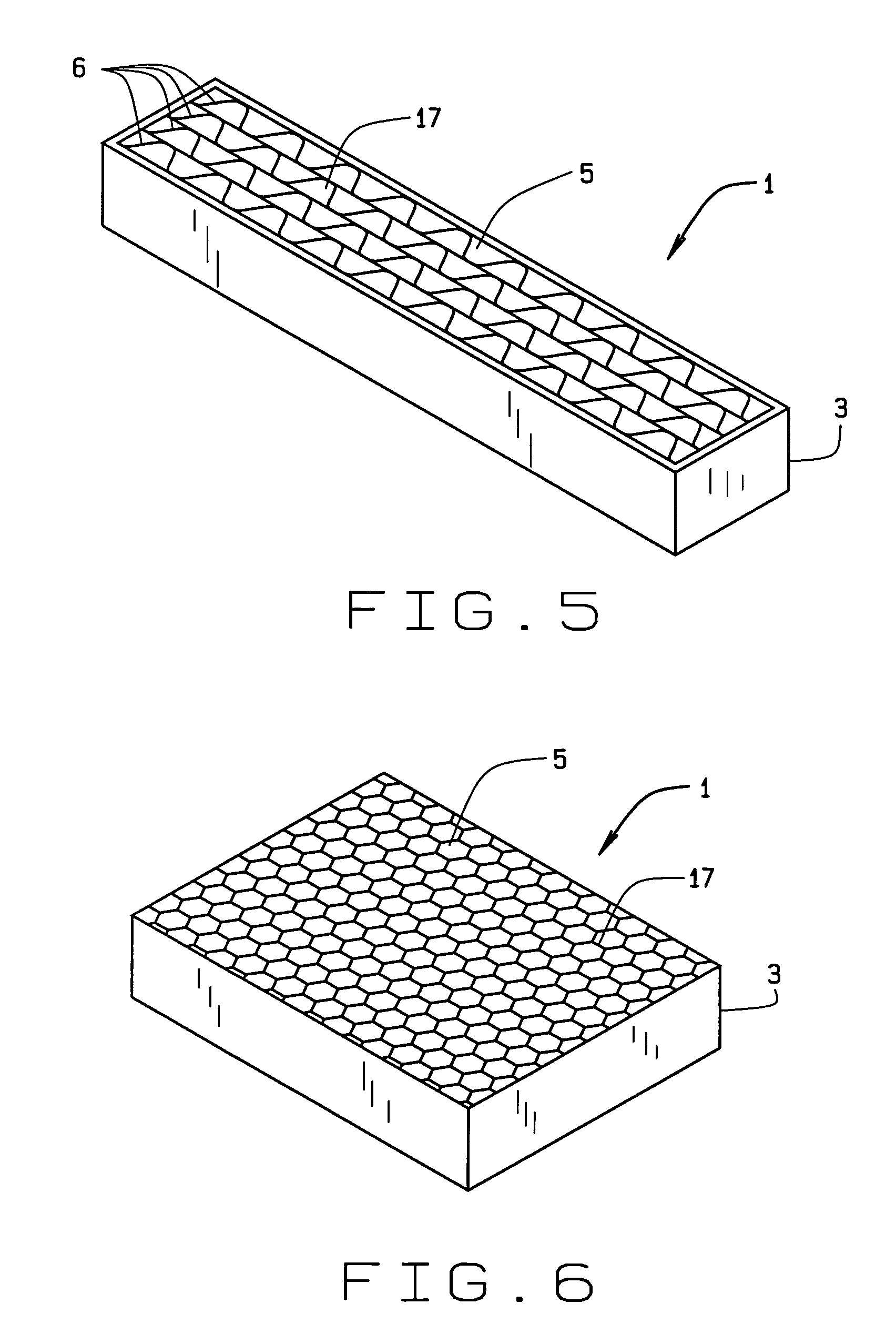

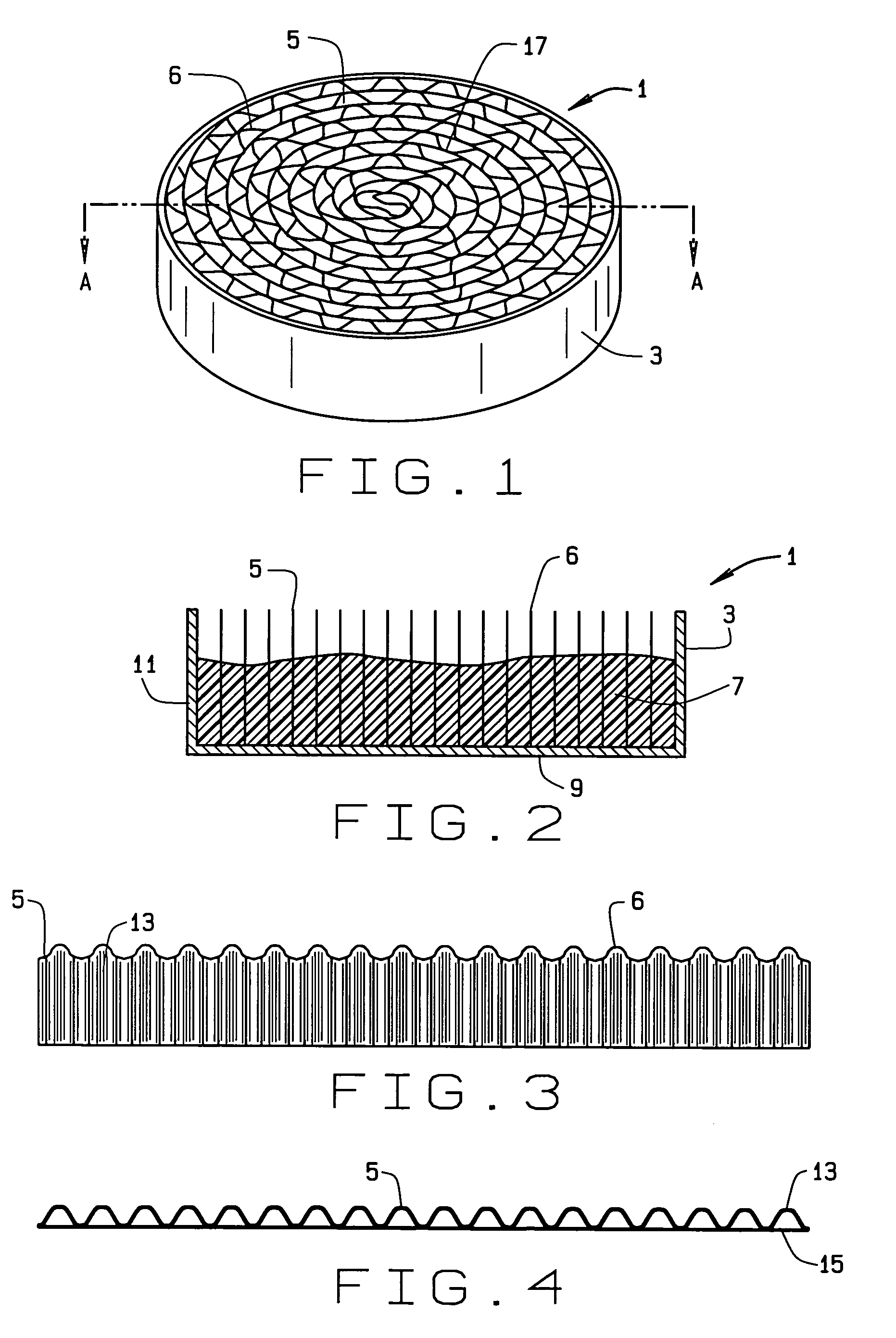

Solid fuel fire starter

The present invention is a solid fuel fire starter having a wicking element made of corrugated cardboard with an exposed top end for ignition by a flame source, a non-combustible housing surrounding the wicking element, the housing defining an open end for exposing the top end of the wicking element; and a paraffin wax reservoir within the housing integrally molded with the wicking element so that the wicking element conveys the paraffin wax by capillary action up into a flame.

Owner:SCHWEICKHARDT JANE H +1

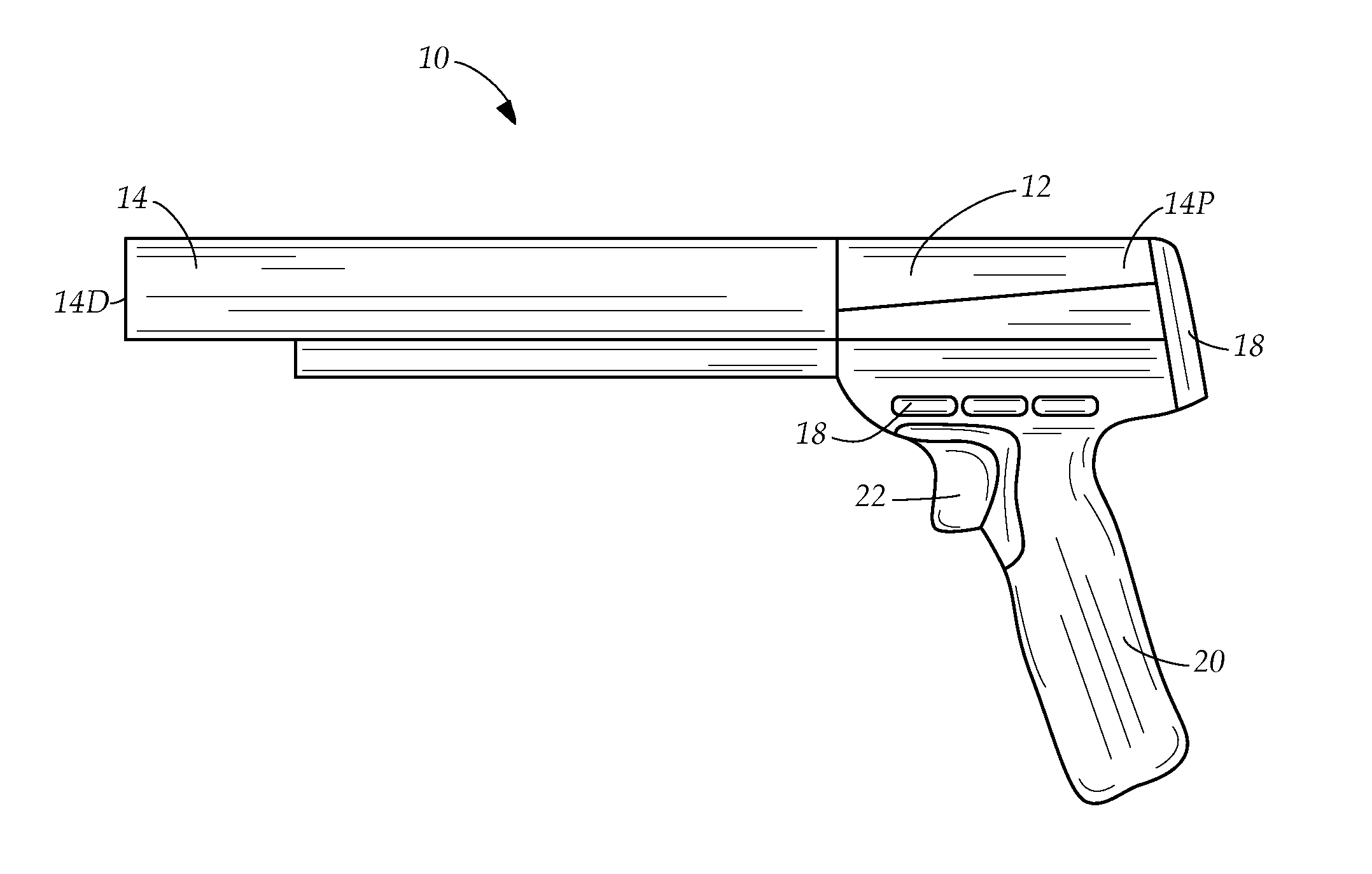

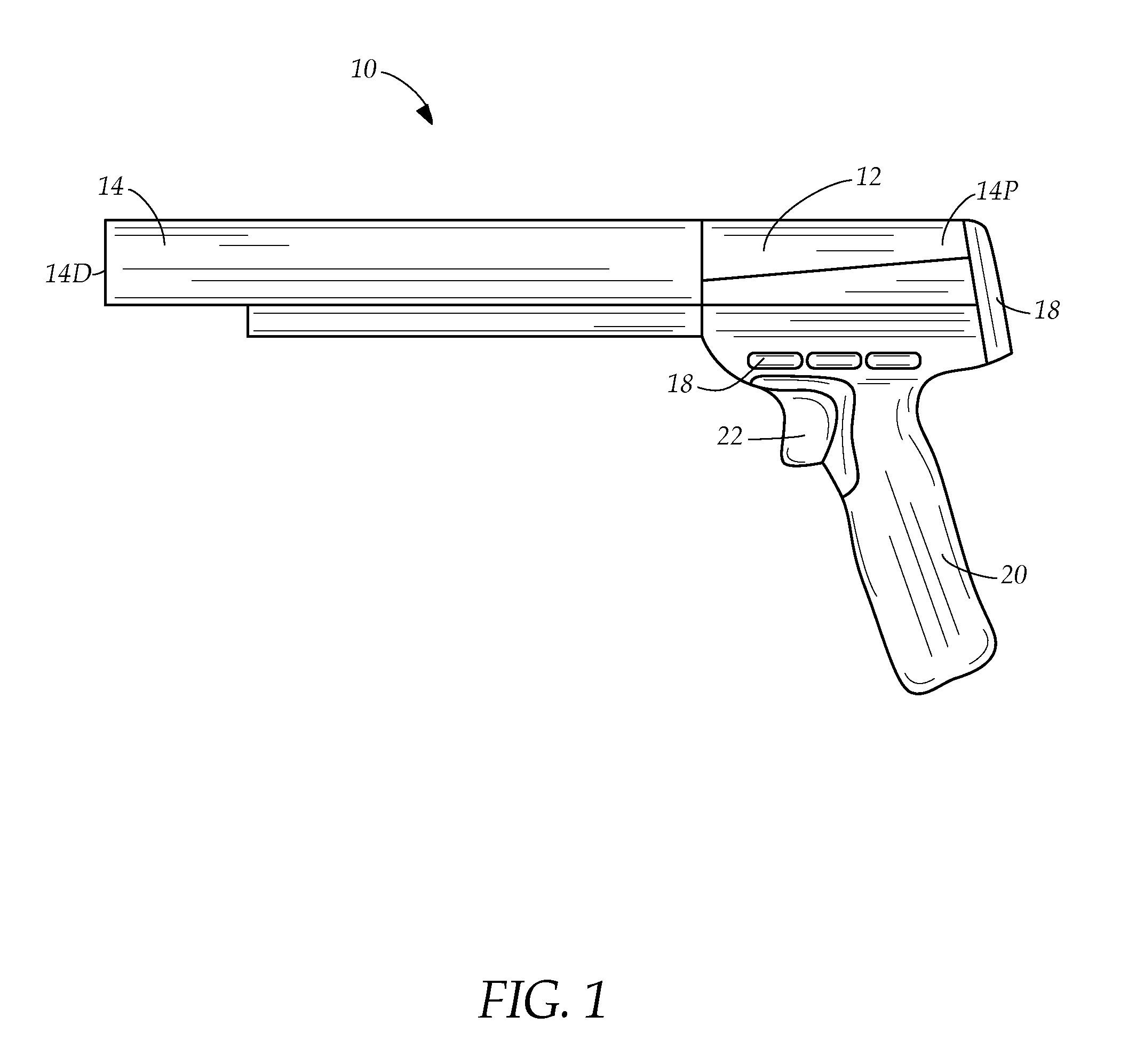

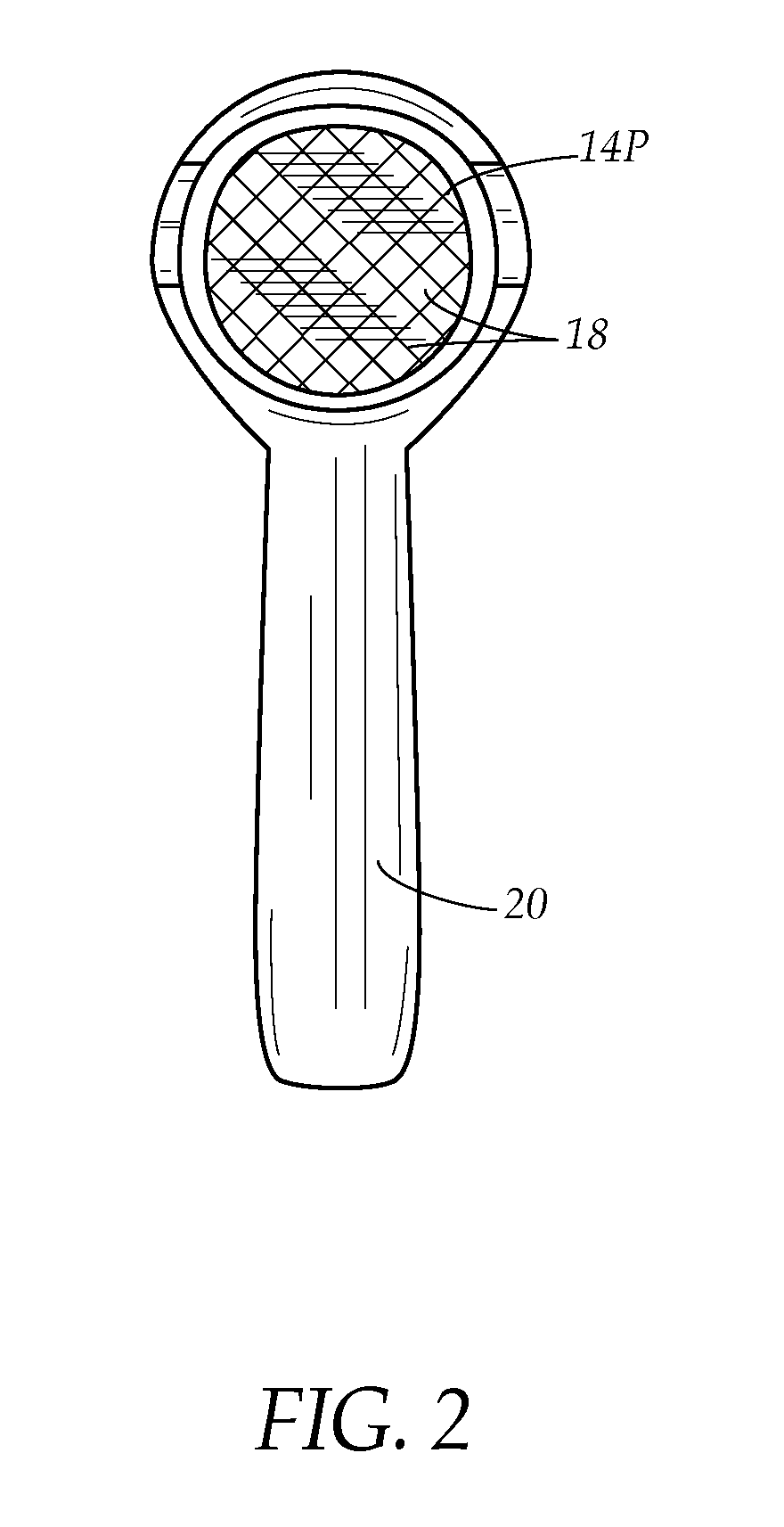

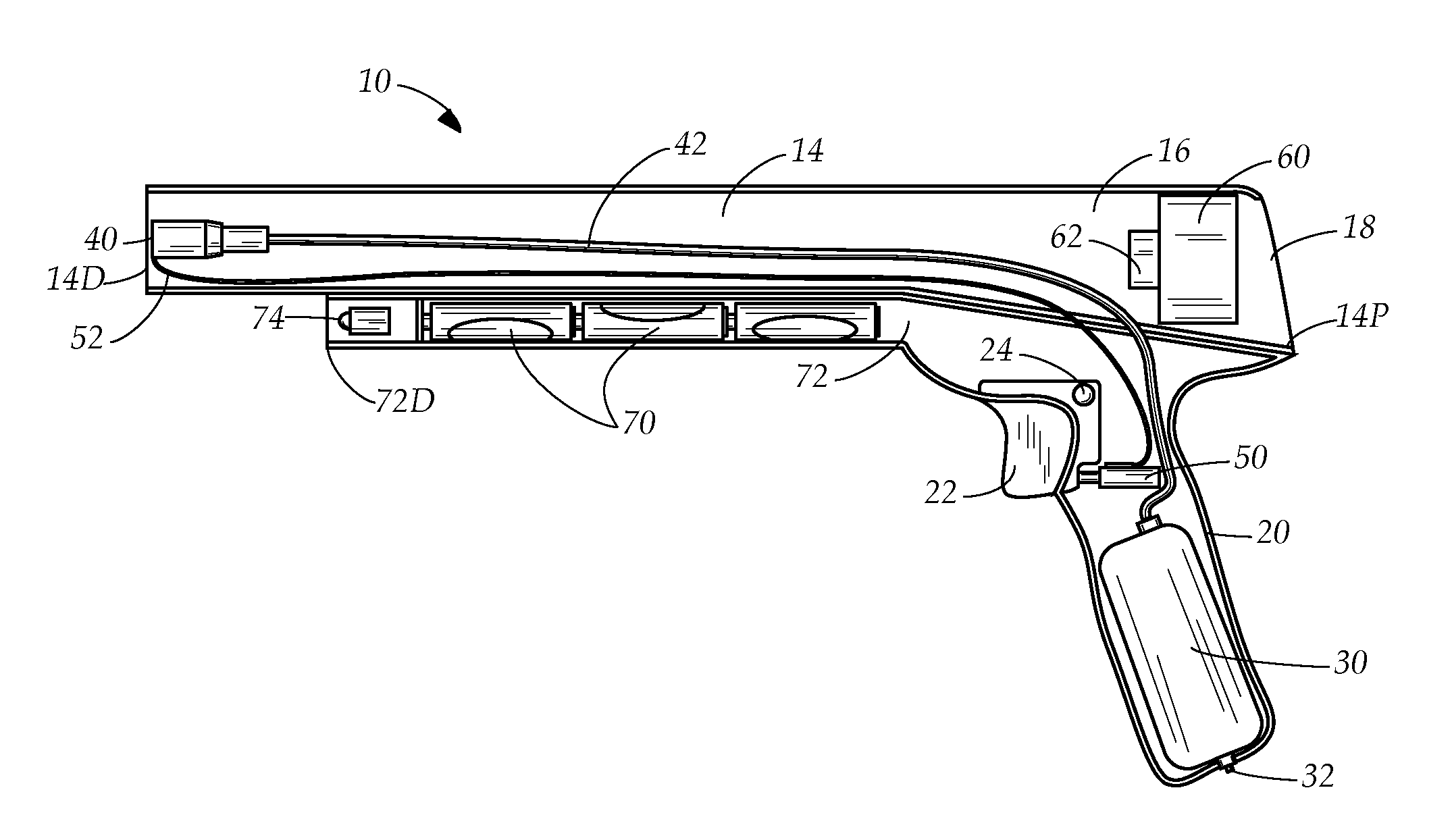

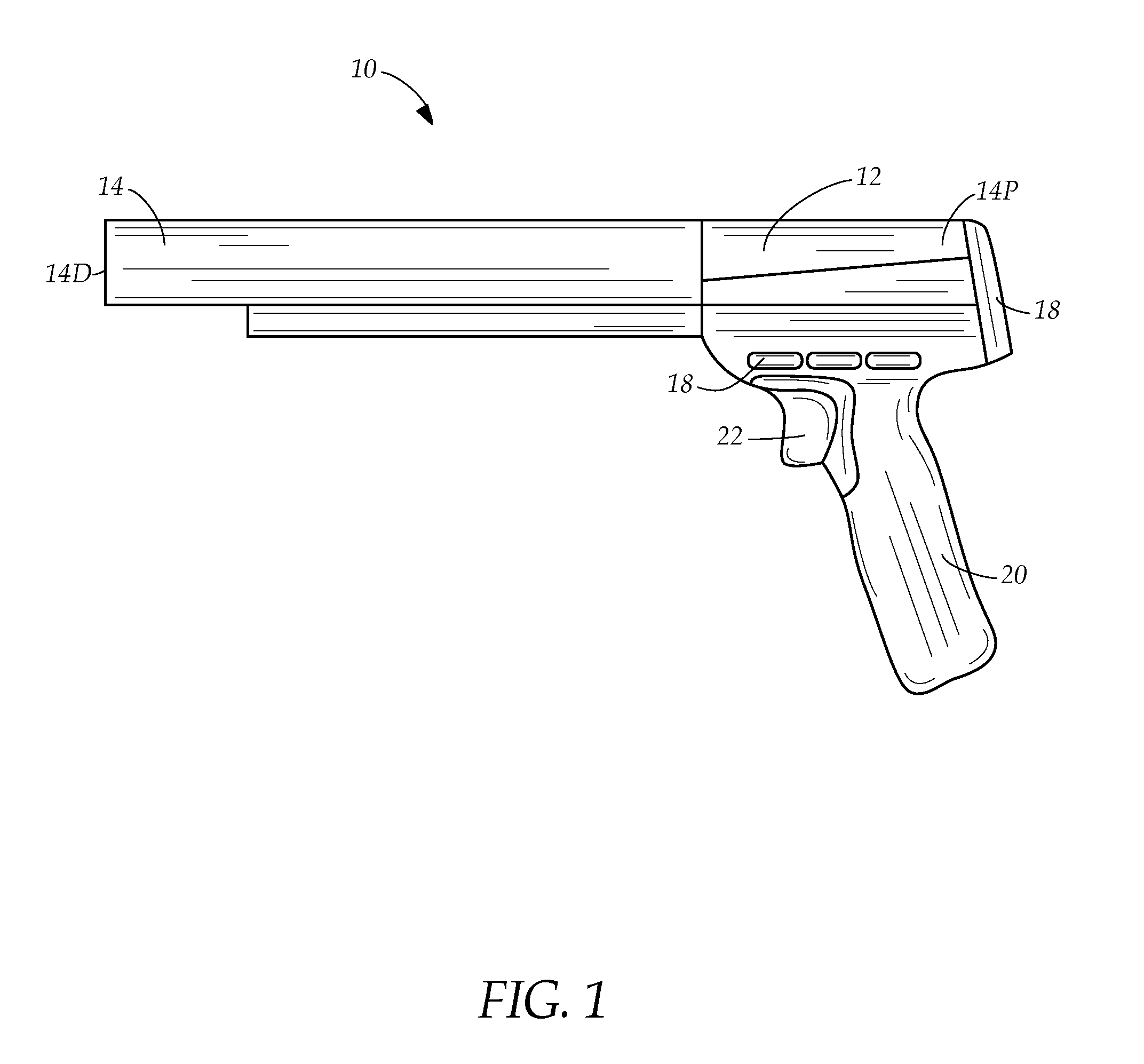

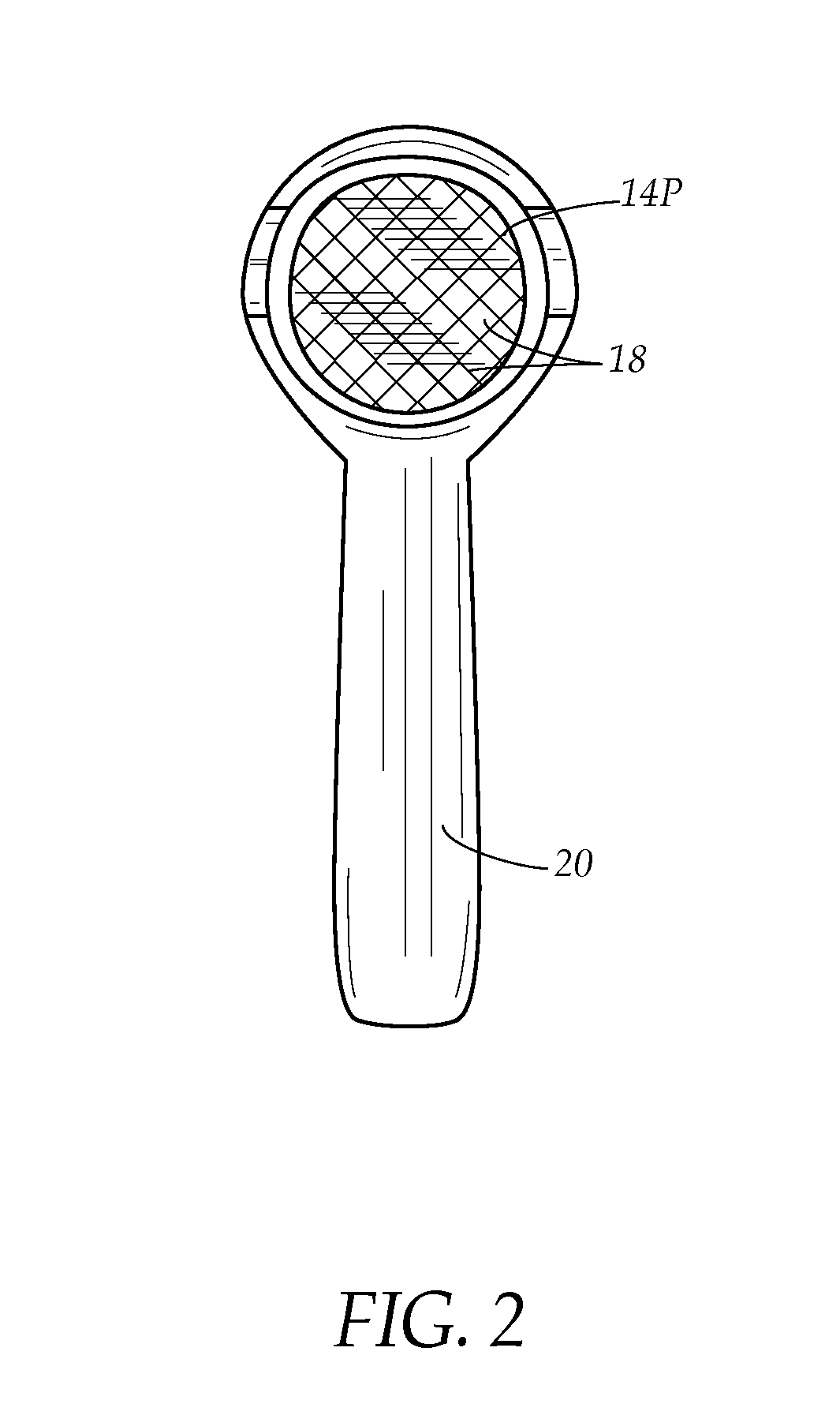

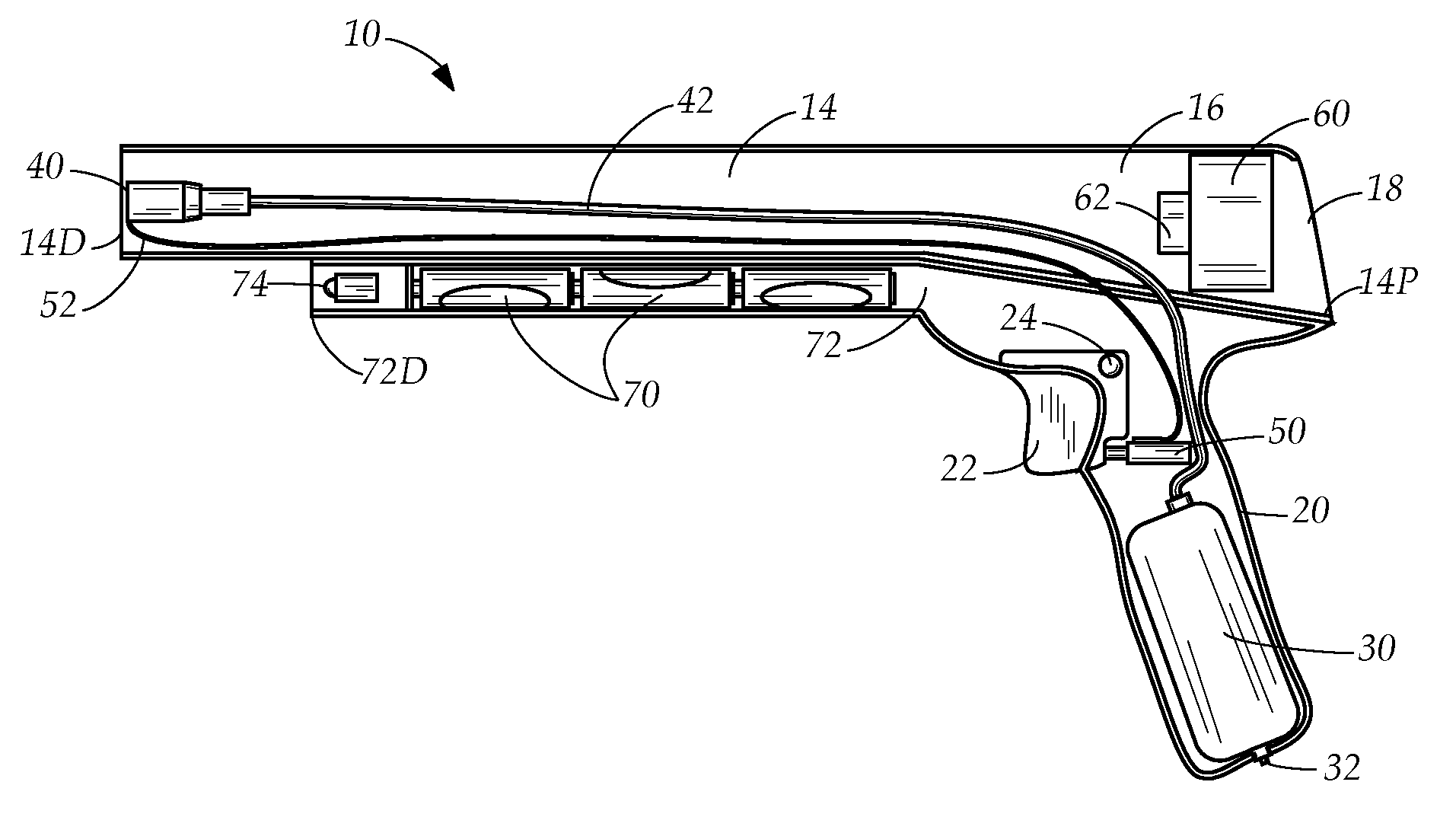

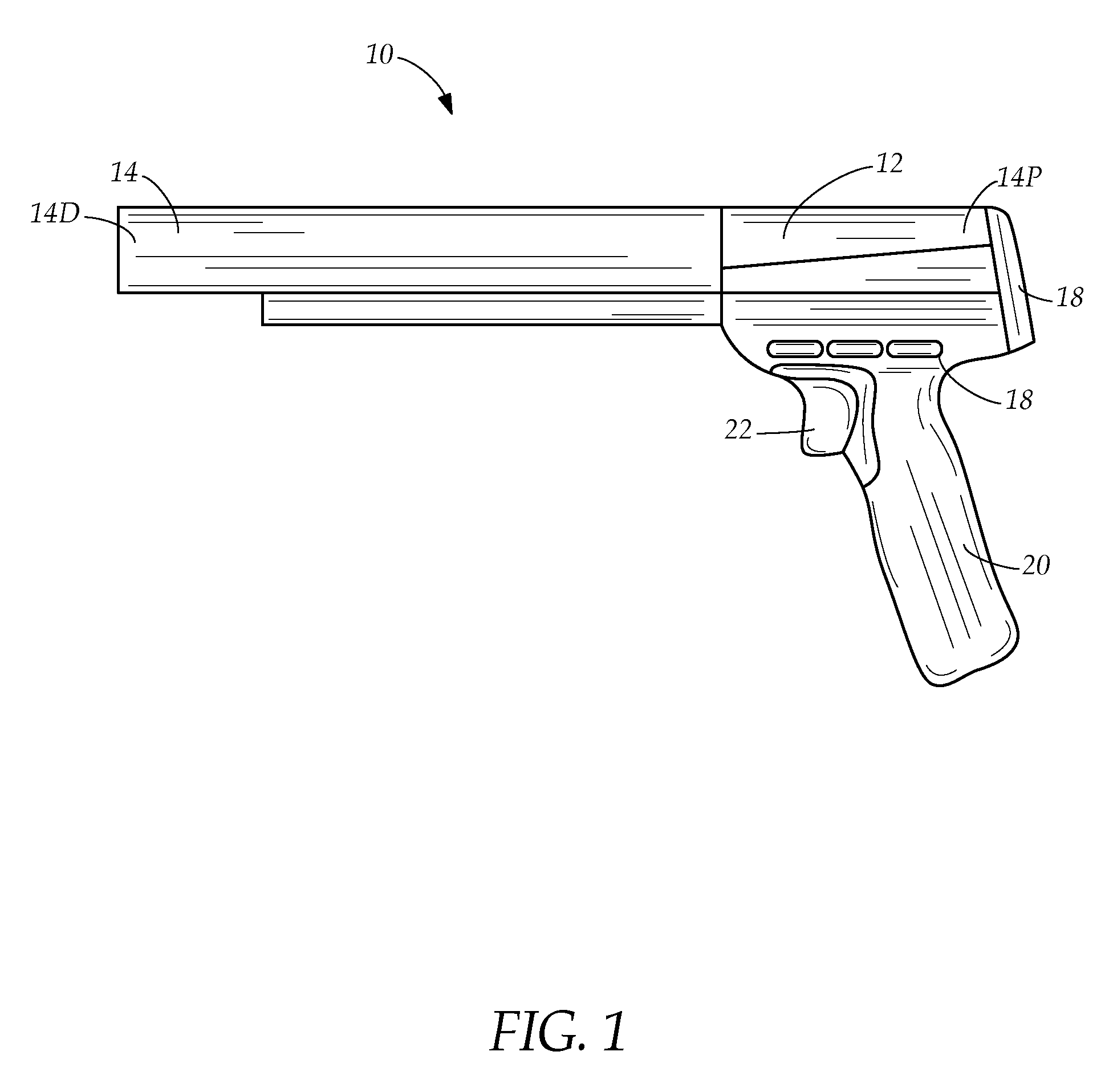

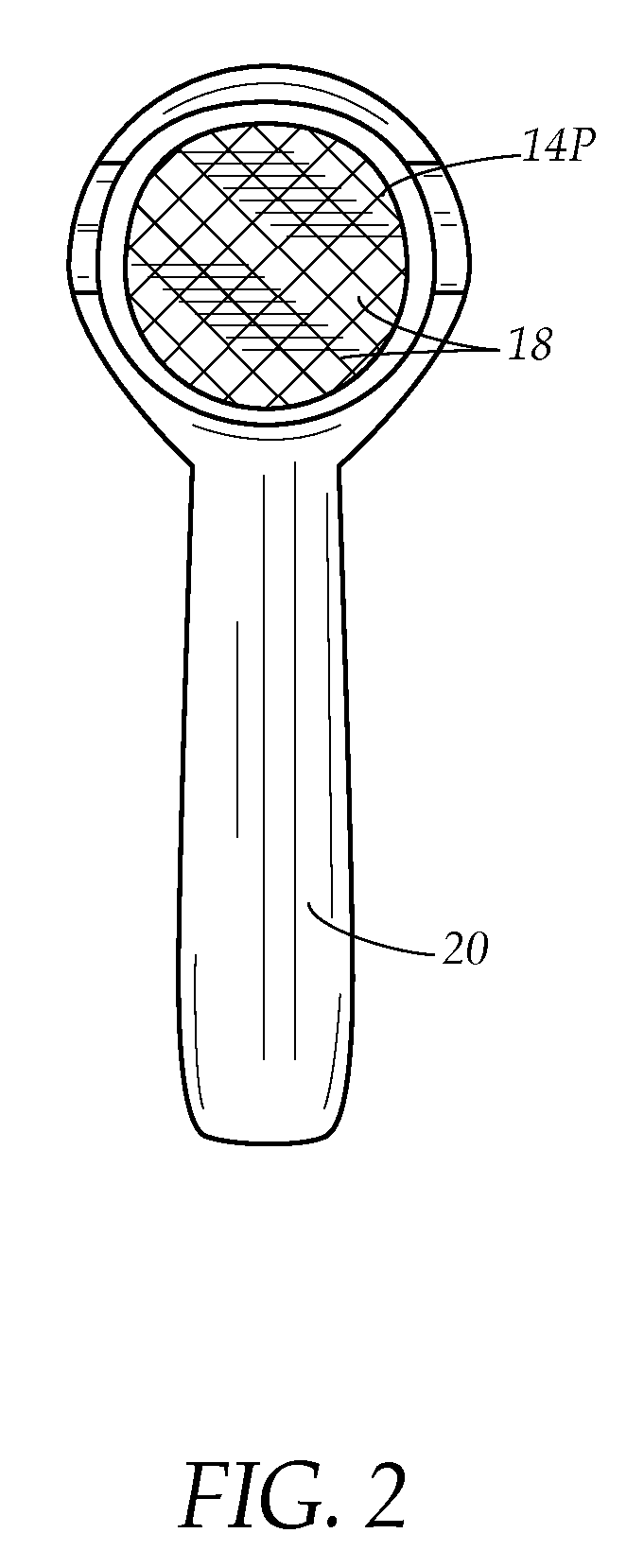

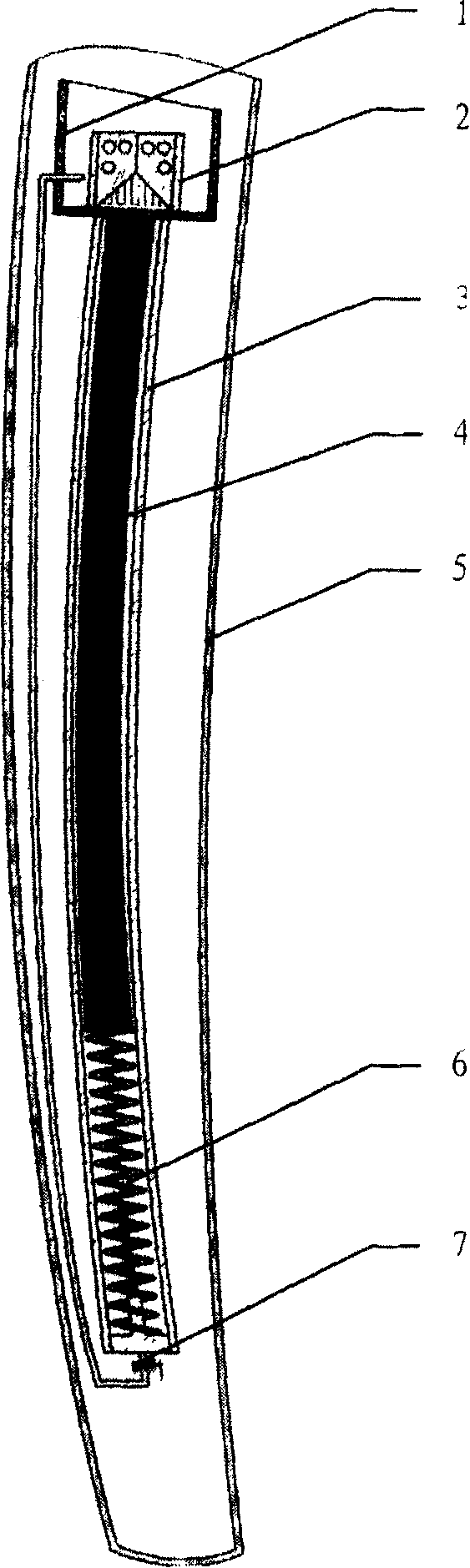

Air fire lighter

ActiveUS8851885B2Easy portabilityEasy to storeDomestic stoves or rangesIncandescent ignitionAirflowFire spread

An air fire lighter having fuel, an igniter and a ducted fan for igniting a solid fuel fire. The fuel travels through the fire lighter to a collar at a distal end of the fire lighter, transforming into a vapor that is ignited by an igniter. As the solid fuel begins to glow at the initiation of the fire, the fan is activated, shutting off the vapors from the fuel. The fan blows air through a chamber onto the fire, causing the fire to spread throughout the solid fuel, establishing and spreading the fire through an ignition period. The chamber has a volume and ducting for providing optimal airflow to the fire. The fan is battery-operated. The lighter is lightweight and compact with a swiveling handle that adjusts for optimal placement of the lighter for addressing the solid fuel, folding for portability and storage.

Owner:INFORA

Solid fuel fire starter

The present invention is a solid fuel fire starter having a wicking element made of corrugated cardboard with an exposed top end for ignition by a flame source, a non-combustible housing surrounding the wicking element, the housing defining an open end for exposing the top end of the wicking element; and a paraffin wax reservoir within the housing integrally molded with the wicking element so that the wicking element conveys the paraffin wax by capillary action up into a flame.

Owner:SCHWEICKHARDT JANE H +1

Method for reducing violence of accidental explosions in solid fuel rocket motors and other energetic devices

InactiveUS20060032562A1Reduce violencePrevent crashExplosive chargesNuclear energy generationEngineeringEnergetic material

A method and system for reducing the violence of an accidental explosive reaction of an energetic material, the method comprising: (a) obtaining a solid energetic material configured for use within an energetic device, the energetic material comprising at least one void formed therein; and (b) filling at least a portion of the at least one void with an inert, incompressible material configured to mechanically stabilize the energetic material to prevent the void from collapsing and the surface area of the energetic material from increasing in the event of an insult tending to damage the energetic the material. In one exemplary embodiment, the inert, incompressible material is configured to temporarily modify the energetic device, meaning that the inert, incompressible material is configured to be removably inserted or otherwise applied to the energetic device.

Owner:UNIV OF UTAH RES FOUND

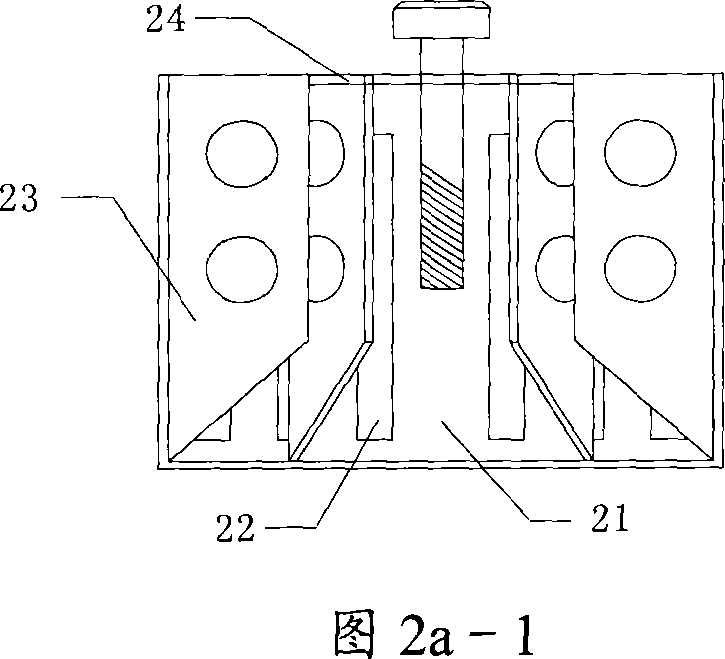

Fuel nozzle for a fossil fuel fired combustion arrangement

ActiveUS6959653B1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringMechanical engineering

A pivot mounting apparatus 210 is provided for pivotally mounting to one another the coal nozzle tip 212 and coal nozzle body 214 of a pulverized solid fuel nozzle 208 of a pulverized solid fuel-fired furnace 10. The pivot mounting apparatus 210 includes a latch interconnecting assembly 220 that includes a pin 222 for insertion in a traversing movement through an insertion passage 224 which passes through both the through hole 216 of the coal nozzle tip 212 and the through hole 218 of the coal nozzle body 214 upon the mutually facing positioning of respective sides of the coal nozzle tip 212 and the coal nozzle body 214 with one another with their respective through holes 216, 218 both co-axial with an insertion axis IAX.

Owner:GENERAL ELECTRIC TECH GMBH

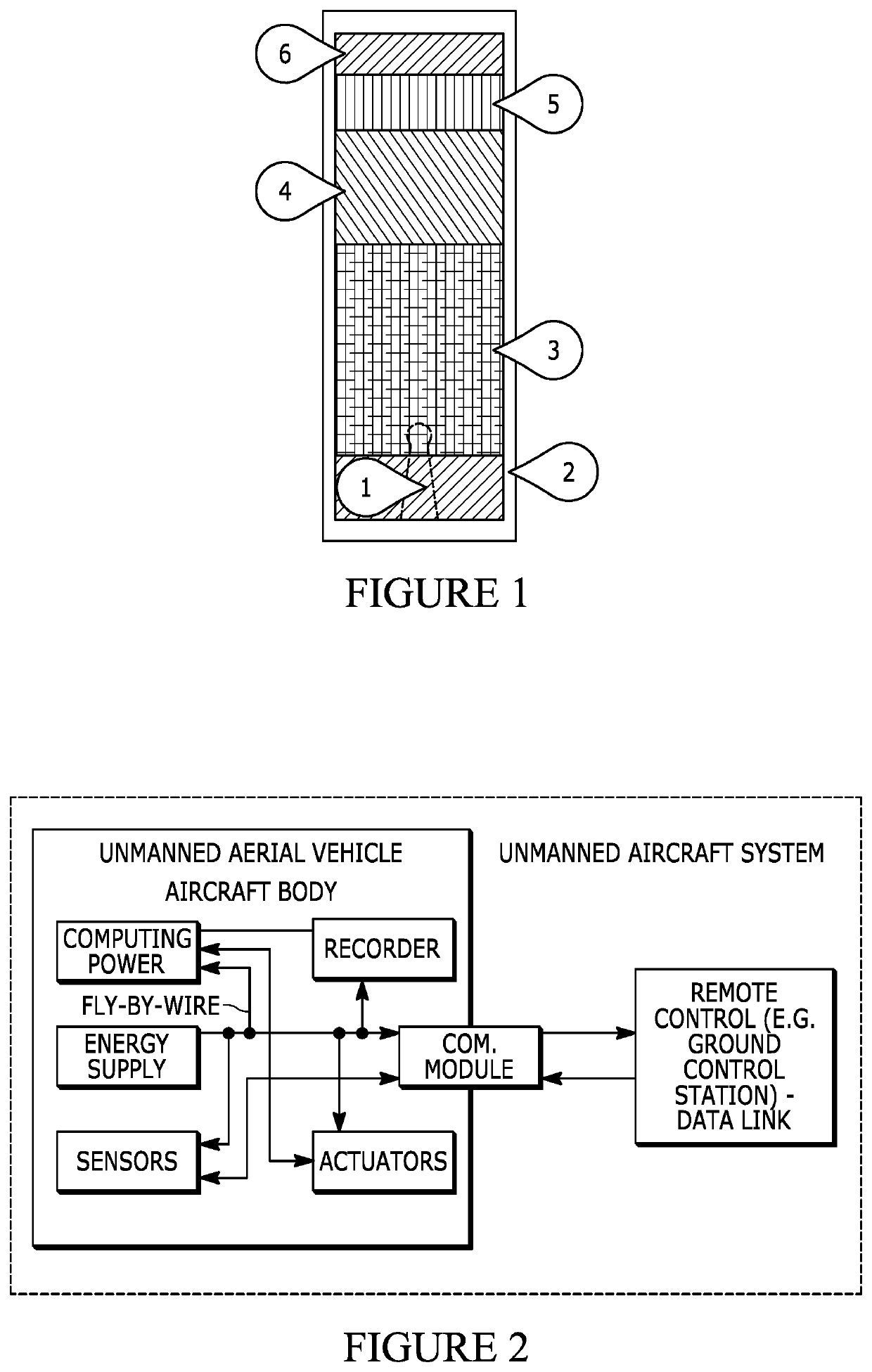

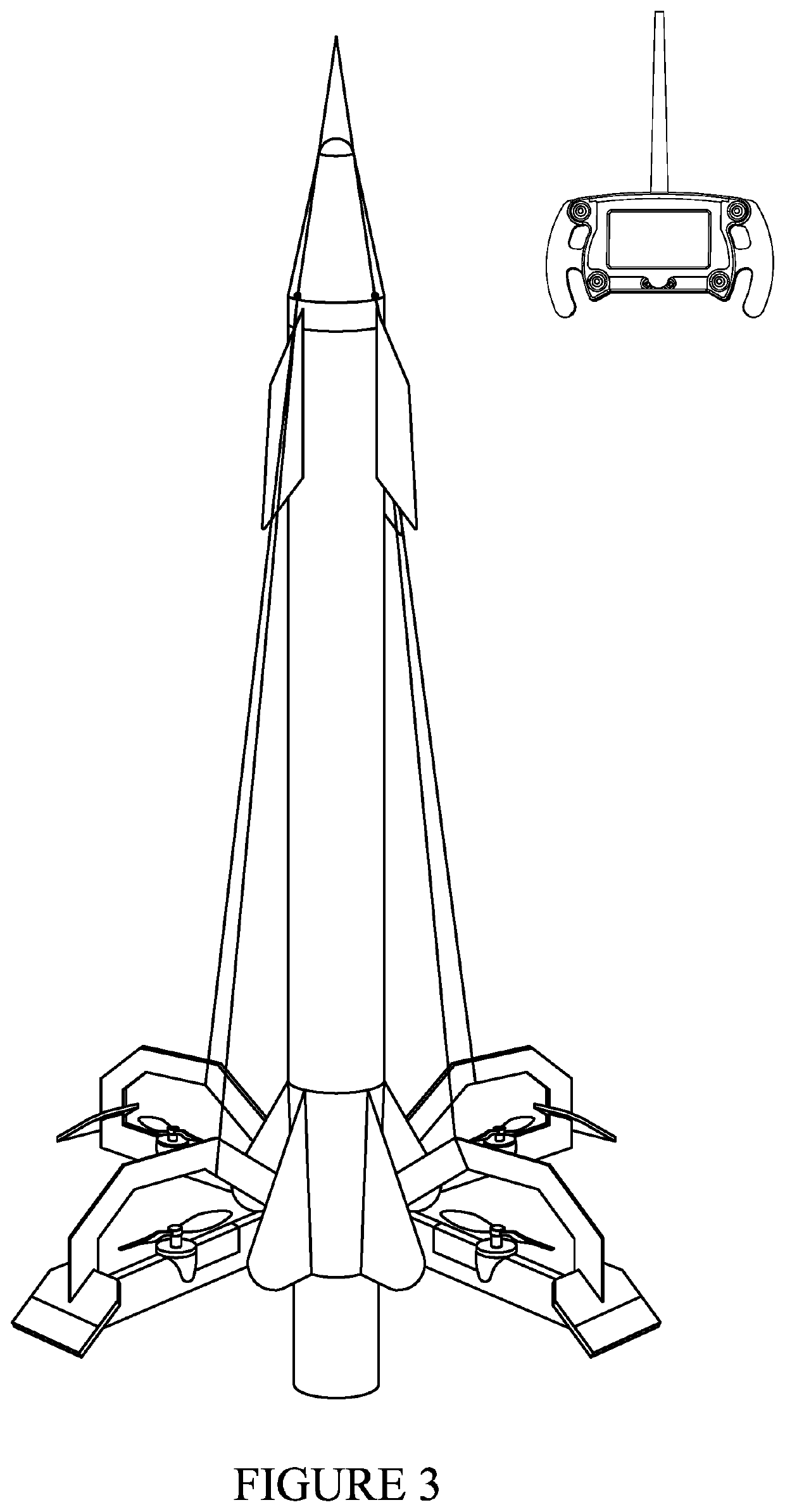

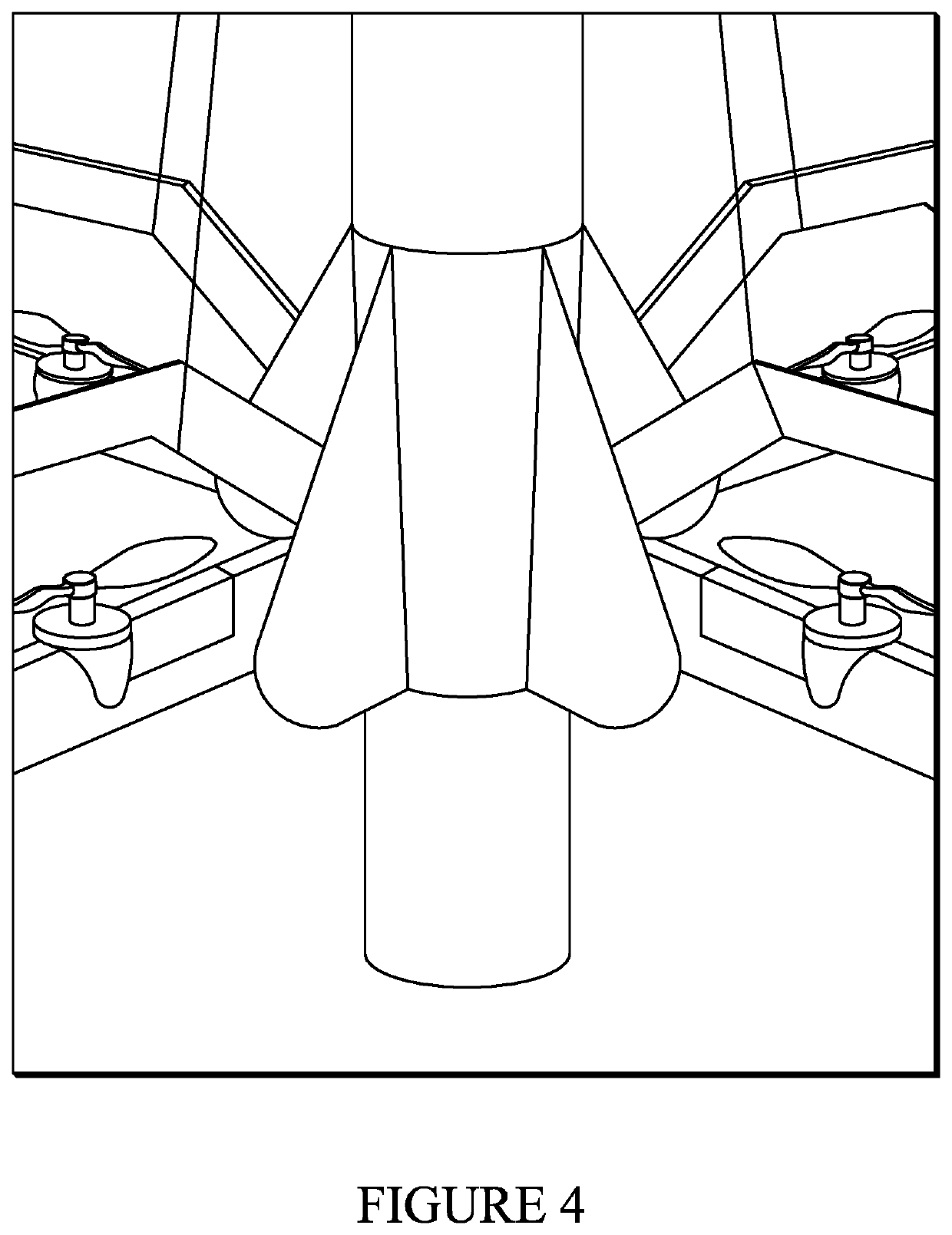

Rocket propelled drone

PendingUS20210031913A1Comparable and good performanceGood power to weight ratio power to ratioRocket type power plantsConvertible aircraftsFlight vehicleUncrewed vehicle

Disclosed is a remotely controlled wireless drone which employs a solid fuel rocket engine to propel it quickly to a desired or location. More specifically, an unmanned vehicle including a fuselage and a propulsion unit engaged with the fuselage, the propulsion unit being operable to bring the unmanned vehicle to a desired altitude or location, generally during a launch stage. The fuselage also includes multiple rotors pivotally engaged with the fuselage and a rotor positioning system operable to pivot the multiple rotors between stowed and deployed positions. The stowed position of the propellers minimizes drag and instability during the launch stage, and the deployed position allows the multiple rotors to control the position and altitude of the unmanned vehicle after the fuel of the rocket engine is spent. Submersible / amphibious and other embodiments are also described.

Owner:MARTEL RANDY

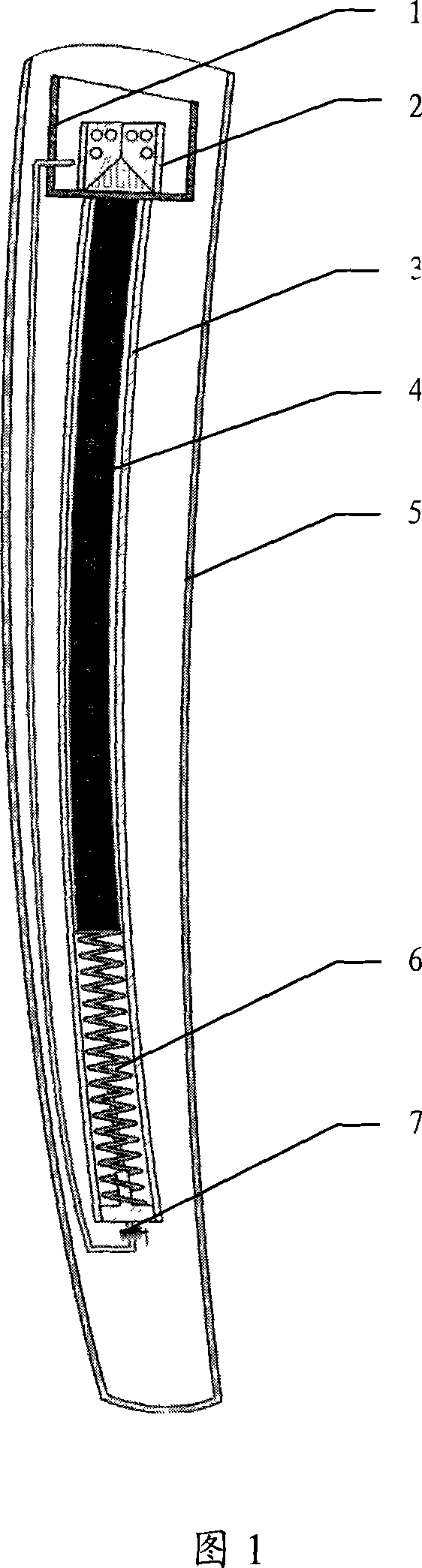

Solid fuel torch

This invention discloses a solid fuel torch which cracks the problems as instable burning, short-time burning, light-color flame and low visibility when the torch is under low temperature, voltage and heavy wind. The torch includes the fuel bin that loads the solid or gel fuel, the burning unit that connects to the top of the fuel bin. The side wall of the burning unit has holes and the inside sets heat-feedback unit of which the bottom attaches to the fuel. The pusher which connects to the bottom of fuel bin pushes the fuel forward the burning unit. The structure of multi-hole and heat-feedback can keep the continue burning and improve the flame burning thickness when the torch is under heavy wind, low temperature and voltage so as to improve the flame color and visibility and satisfy many displaying function.

Owner:AEROSPACE HI TECH HLDG GROUP

Air fire lighter

ActiveUS20140147796A1Easy portabilityEasy to storeDomestic stoves or rangesIncandescent ignitionAirflowFire spread

An air fire lighter having fuel, an igniter and a ducted fan for igniting a solid fuel fire. The fuel travels through the fire lighter to a collar at a distal end of the fire lighter, transforming into a vapor that is ignited by an igniter. As the solid fuel begins to glow at the initiation of the fire, the fan is activated, shutting off the vapors from the fuel. The fan blows air through a chamber onto the fire, causing the fire to spread throughout the solid fuel, establishing and spreading the fire through an ignition period. The chamber has a volume and ducting for providing optimal airflow to the fire. The fan is battery-operated. The lighter is lightweight and compact with a swiveling handle that adjusts for optimal placement of the lighter for addressing the solid fuel, folding for portability and storage.

Owner:INFORA

Environment-friendly type biomass solid fuel combustion boiler

InactiveCN107726296ABurn fullyEasy to collectFuel supply regulationSolid fuel combustionCombustion chamberThermal efficiency

The invention discloses an environment-friendly biomass solid fuel combustion boiler, which comprises a boiler body, which is divided into a heating water tank, a combustion chamber, a waste material chamber and an equipment room from top to bottom in sequence, and the left end of the combustion chamber is provided with a feed A hob is set at the bottom of the feed hopper, and the feed hopper communicates with the combustion chamber through a conveyor belt, the waste chamber is separated from the equipment chamber by an inclined partition, and a push plate is arranged at the lowest end of the partition, the The push plate is connected to the main body of the boiler through a telescopic rod, and a pressure sensor is installed at the bottom of the waste chamber, an electric control gate is installed at the outlet of the lower end of the waste chamber, a chimney is installed at the upper end of the combustion chamber, and the lower end of the combustion chamber is connected to the blower through an air intake pipe , This environmentally friendly biomass solid fuel combustion boiler adopts automatic feeding, the output temperature is adjustable, the heat utilization rate is high, and it is easy to use.

Owner:成都汇鲤科技有限公司

Exhaust processing and heat recovery system

InactiveUS9598742B2Reduce accumulationImprove thermal efficiencyBurnersUsing liquid separation agentAir preheaterThermal energy

Owner:ALSTOM ENERGY TECH AG

Air Fire Lighter

InactiveUS20150226430A1Easy portabilityEasy to storeDomestic stoves or rangesFuel lightersAirflowFire spread

An air fire lighter having fuel and a ducted axial fan for igniting a solid fuel fire. The fuel travels through the fire lighter to a distal end of the fire lighter and is ignited by an igniter. The flame is applied to solid fuel. As the solid fuel begins to glow at the initiation of the fire, the fan is activated, shutting off the vapors from the fuel. The fan blows air through a chamber onto the fire, causing the fire to spread throughout the solid fuel, establishing and spreading the fire through an ignition period. The chamber has a volume and ducting for providing optimal airflow to the fire. The fan is battery-operated. A further example embodiment of the air fire lighter has a pair of chamber barrels, a first barrel for the gaseous fuel and a second barrel housing the axial fan.

Owner:INFORA

Self-cleaning grill

ActiveUS11181276B2Lower performance requirementsReduce effortDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

A firepot for a grilling device comprises one or more walls at least partially forming an outer boundary of the firepot. The firepot is structurally configured to hold at least partially ignited solid fuel. The firepot also comprises a floor defining, at least in part, a lower end of the firepot. The floor comprises one or more holes extending through the floor. Additionally, a portion of the one or more walls form a solid fuel delivery opening that comprises a solid fuel portal through which solid fuel is deliverable to an interior of the firepot. A heating element mount is positioned to hold a heating element within the interior of the firepot.

Owner:TRAEGER PELLET GRILLS LLC

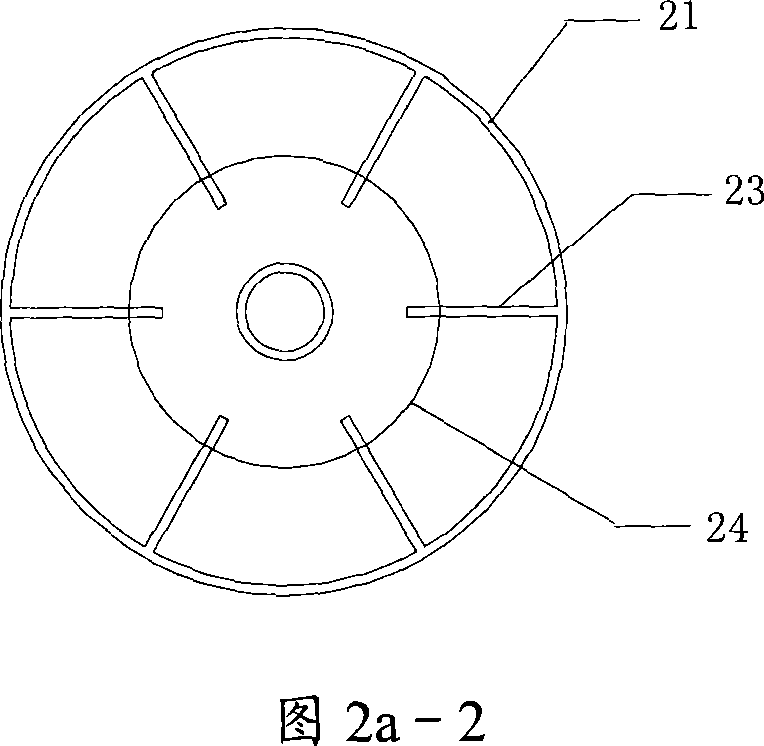

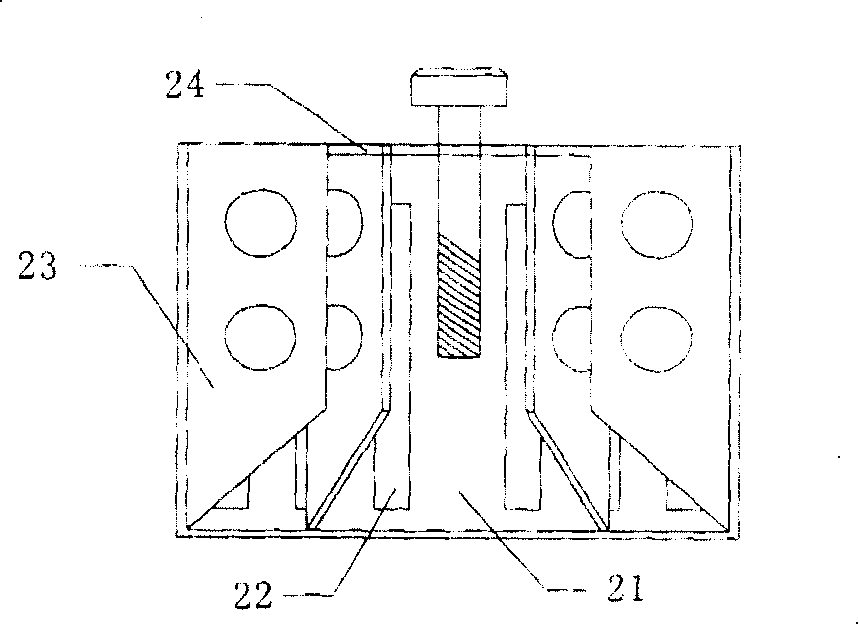

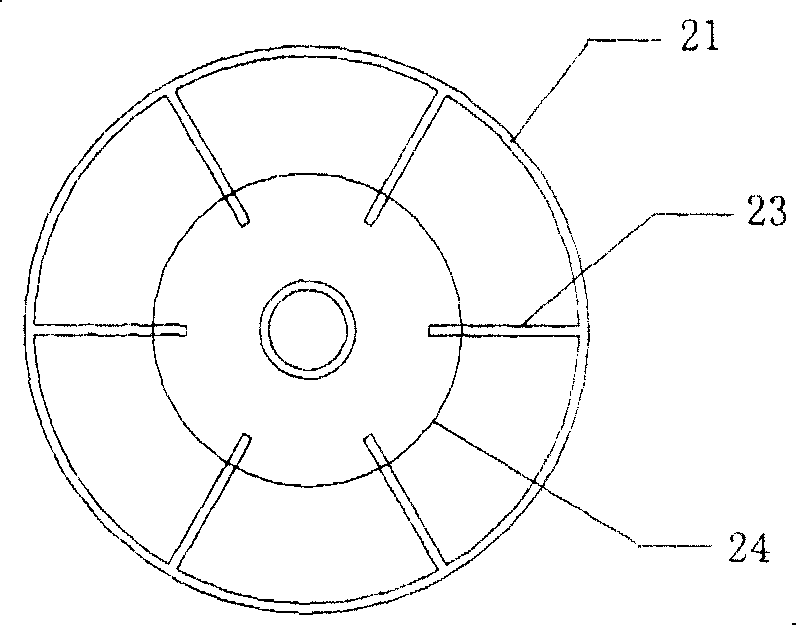

Swirling spreader for solid fuel fired spreader stoker boilers

InactiveCN1612994APowerful vortex motionObvious lateral distributionIncinerator apparatusLump/pulverulent fuel feeder/distributionEngineeringMechanical engineering

An apparatus to pass a solid fuel into a furnace, the apparatus compries: an inlet to allow the fuel to pass into the apparatus, an outlet to allow the fuel to pass out of the apparatus, a main body portion between the inlet and the outlet, means to propel the fuel through the apparatus, and, means to impart a swirling motion to the fuel prior to the fuel passing through the outlet. The apparatus can be used as a swirler spreader to propel bagasse into a boiler / furnace.

Owner:SUGAR RES

Self-cleaning grilling devices

PendingUS20220082262A1Lower performance requirementsReduce effortMeat/fish preservationDomestic stoves or rangesThermodynamicsEngineering

A firepot for a grilling device comprises one or more walls at least partially forming an outer boundary of the firepot. The firepot is structurally configured to hold at least partially ignited solid fuel. The firepot also comprises a floor defining, at least in part, a lower end of the firepot. The floor comprises one or more holes extending through the floor. Additionally, a portion of the one or more walls form a solid fuel delivery opening that comprises a solid fuel portal through which solid fuel is deliverable to an interior of the firepot. A heating element mount is positioned to hold a heating element within the interior of the firepot.

Owner:TRAEGER PELLET GRILLS LLC

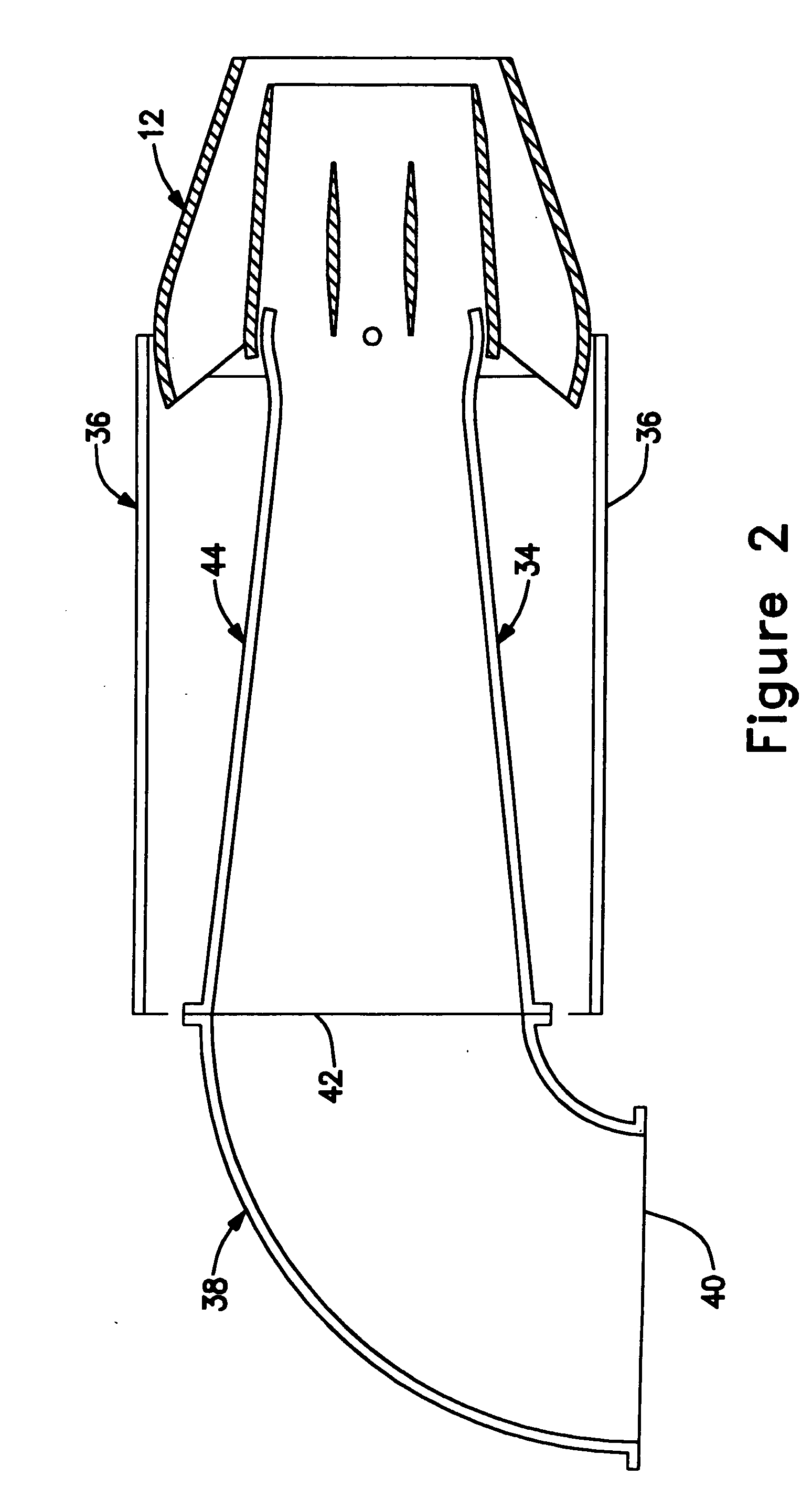

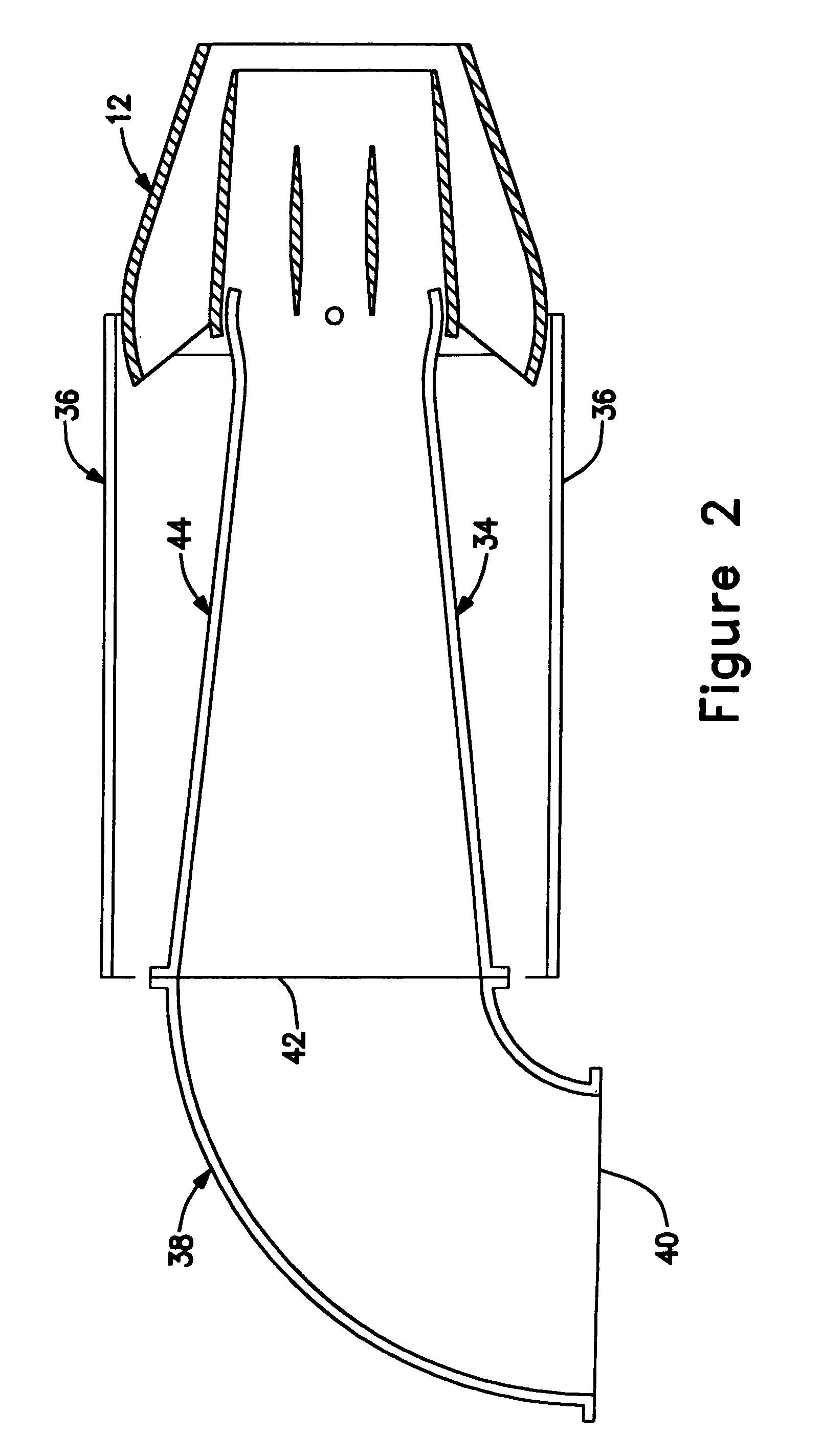

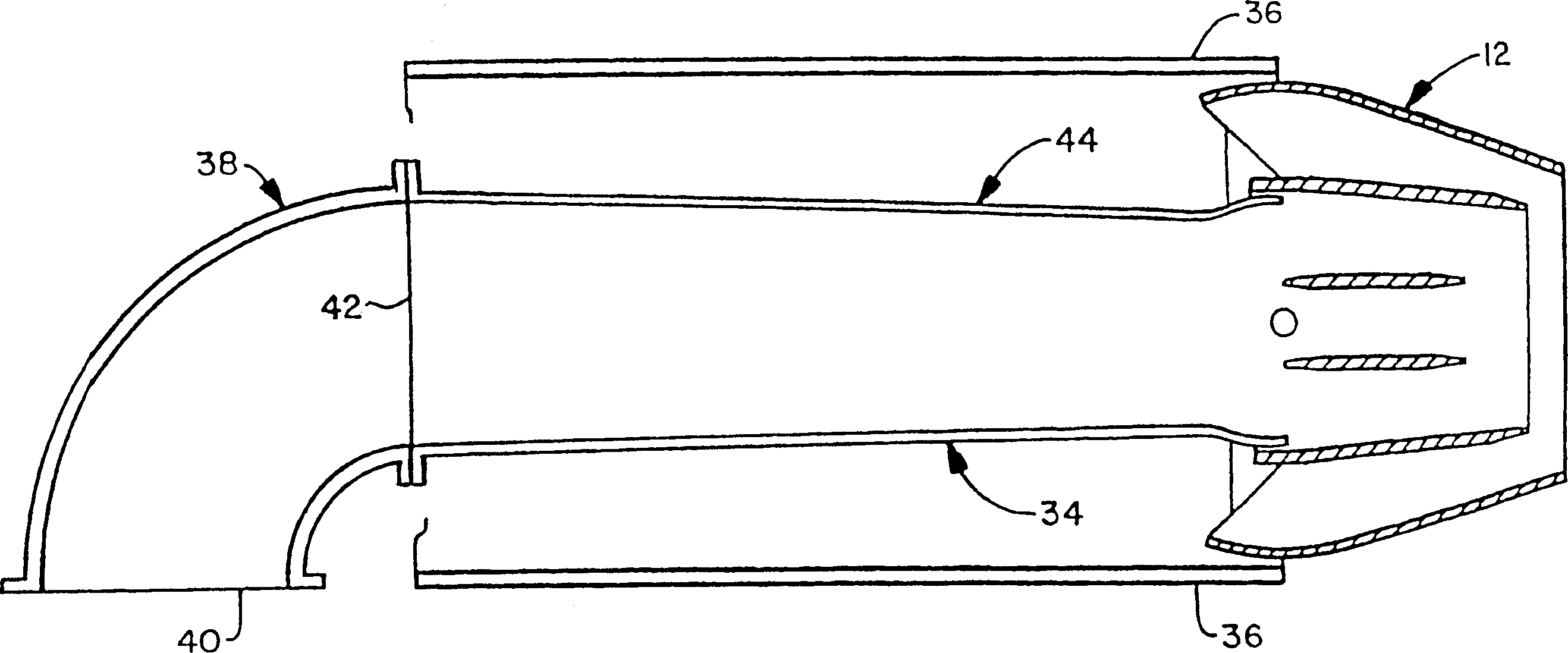

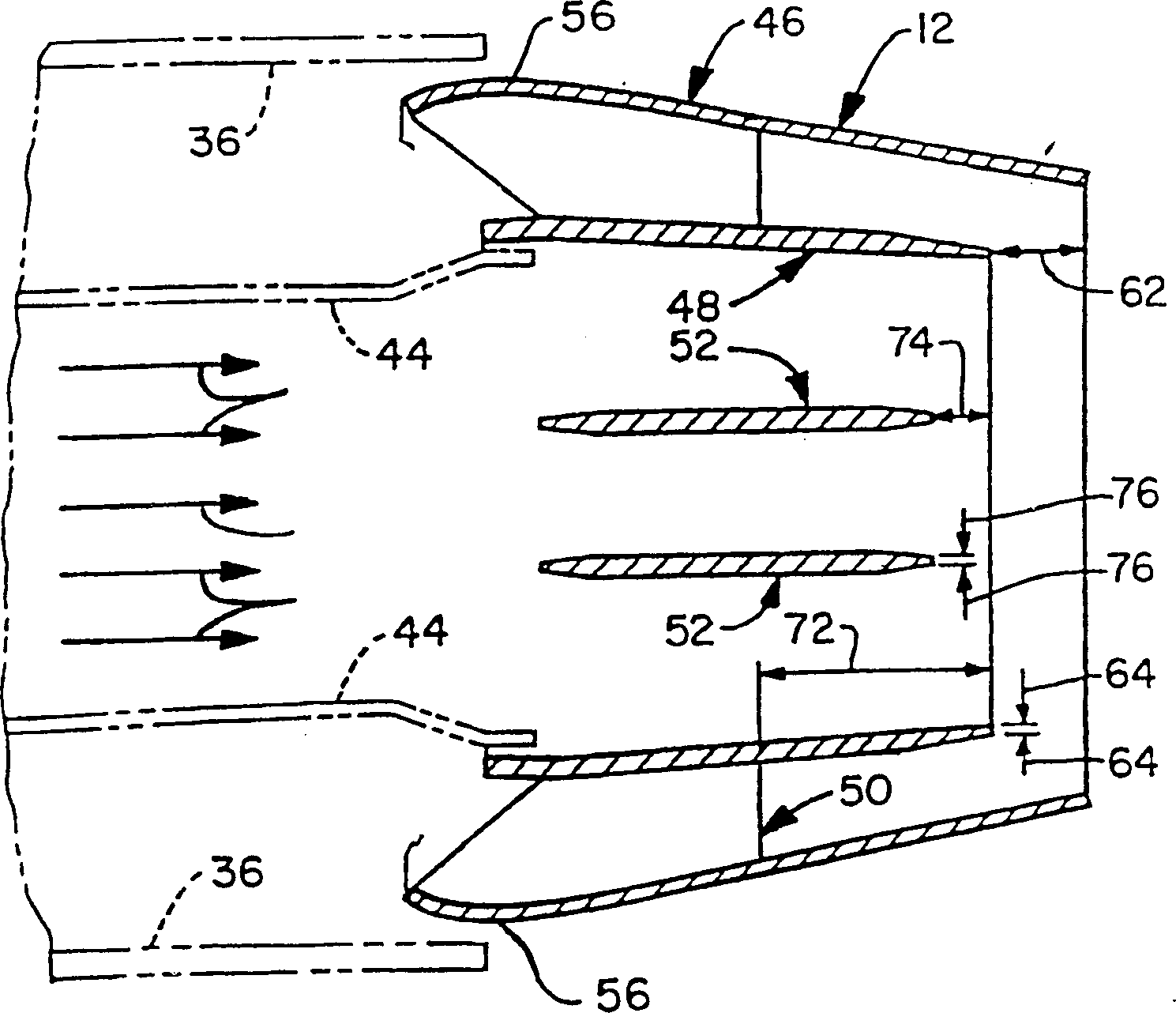

Pulverized solid fuel nozzle tip

InactiveCN1104589CUniform ignitionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelParticulatesExit plane

A minimum recirculation flame control (MRFC) solid fuel nozzle tip (12) that is particularly suited to being cooperatively associated with a pulverized solid fuel nozzle (34) of a firing system of the type employed in a pulverized solid fuel-fired furnace (10). The MRFC solid fuel nozzle tip (12) when so employed is operative to minimize low and negative, i.e., recirculation, velocity regions of the exit plane of the MRFC solid fuel nozzle tip (12), and to reduce available deposition surface on the MRFC solid fuel nozzle tip (12), and to vary the nozzle tip (12) / solid fuel nozzle (34) thermal conditions to keep the 'hot' solid fuel particulate matter from depositing on available metal platework surface of the MRRC solid fuel nozzle tip (12). The MRFC solid fuel nozzle tip (12) includes fuel air shroud means (46), primary air shroud means (48) located within the fuel air shroud means (46), fuel air shroud support means (50) operative for supporting the primary air shroud means (48) relative to the fuel air shroud means (46), and splitter plate means (52) mounted in supported relation within the primary air shroud means (48).

Owner:GENERAL ELECTRIC TECH GMBH

A method of producing SO2 sorbent that is suitable for use to desulfurize combustion gases

InactiveCN1300234A"roasting" to avoidGuaranteed dwell timeDispersed particle separationLime productionSorbentEngineering

A method of producing SO2 sorbent that is suitable for use to effect therewith the desulfurization of combustion gases wherein the SO2 sorbent that is produced from the use of the present invention is limestone particles that have been injected into the burner region (12) of a conventional solid fuel-fired steam generator (10) and that have been subjected to 'deadburning' therein thereby creating unreactive lime particles therefrom.

Owner:ABB ALSTOM POWER INC

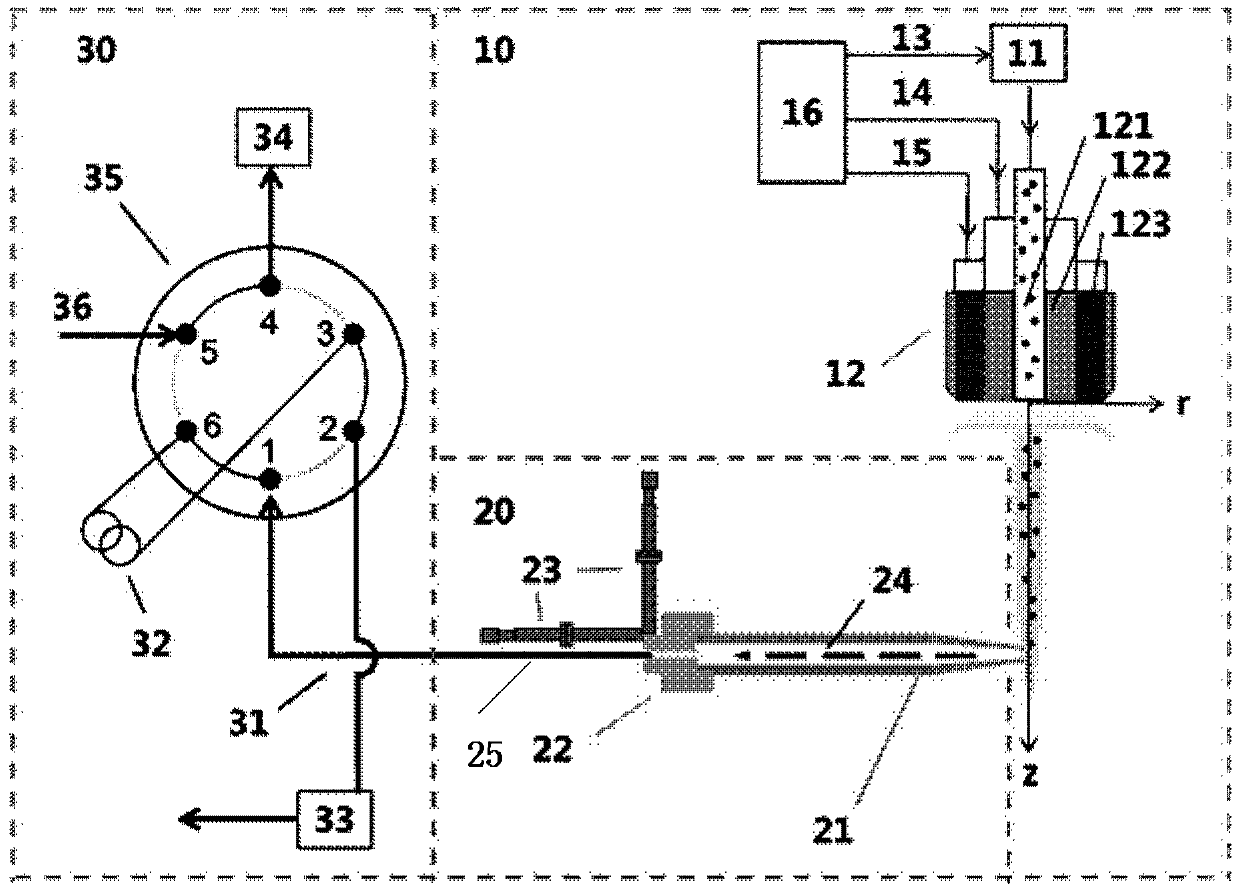

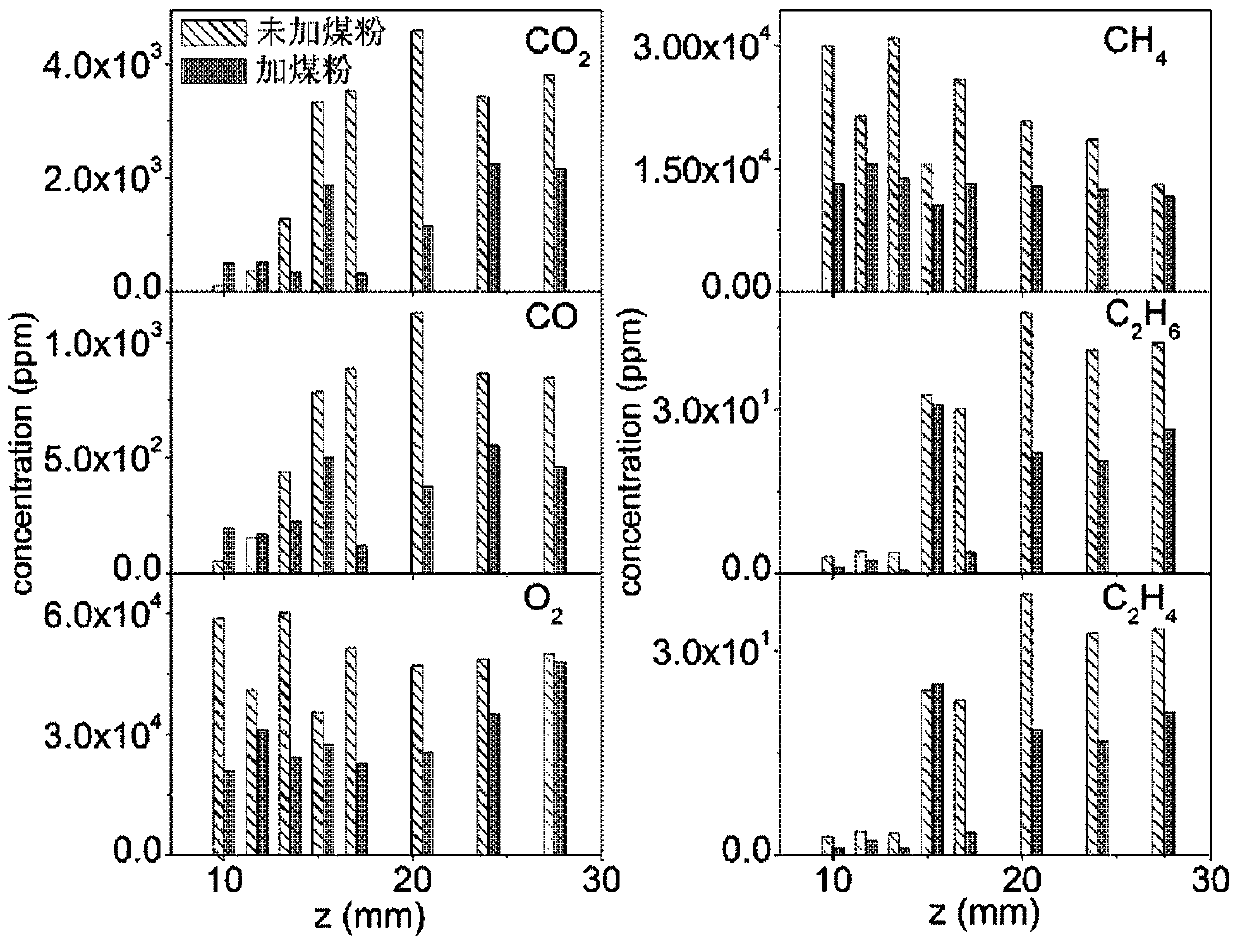

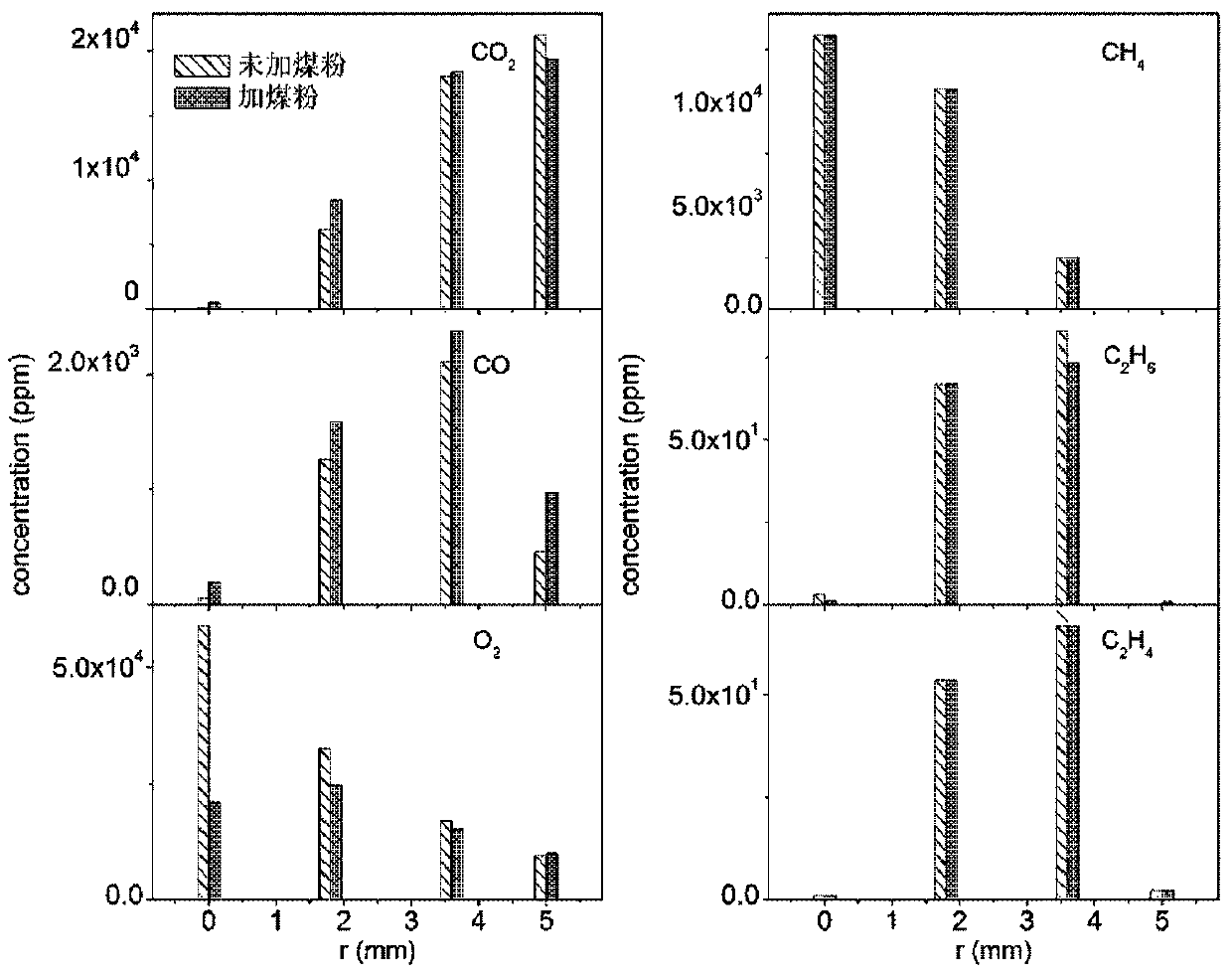

Device for online detection of solid fuel combustion products at different spatial locations

ActiveCN106093282BRich and precise spatial distribution informationUnderstand the chemical reaction mechanism of combustionChemical analysis using combustionComponent separationPolycyclic aromatic hydrocarbonChemical reaction

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

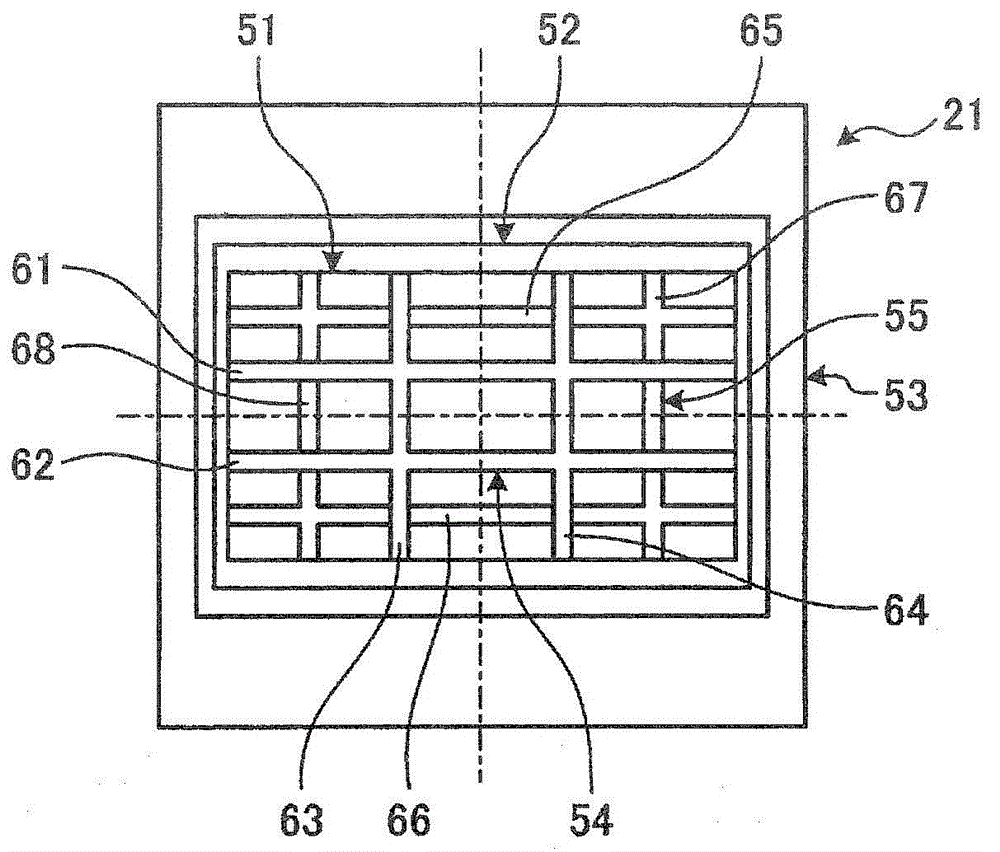

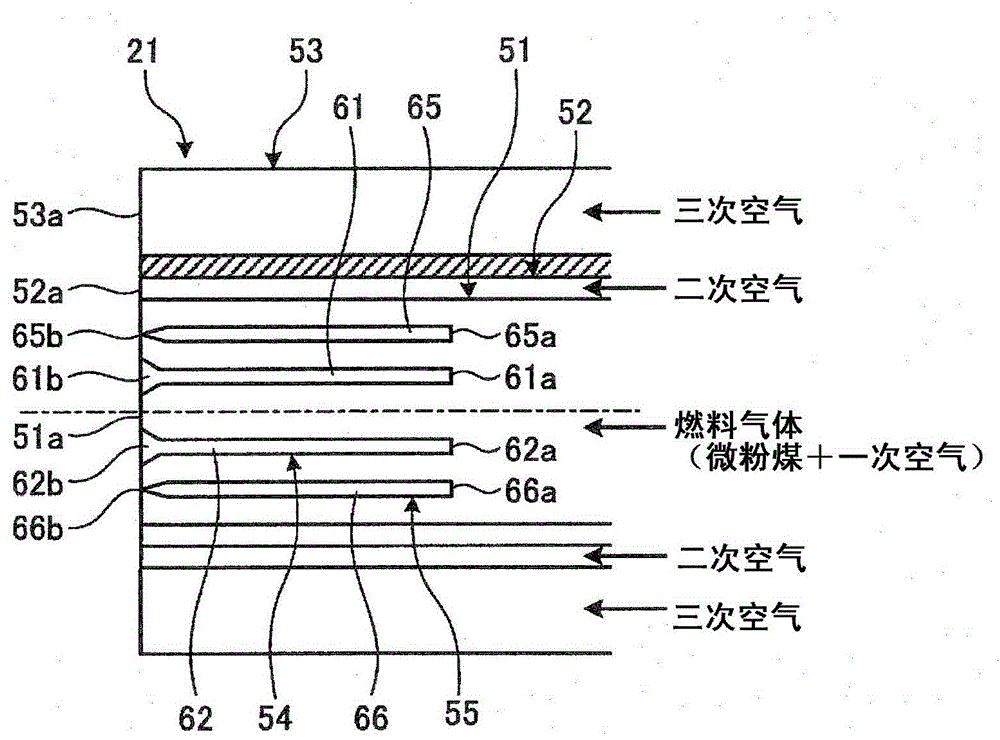

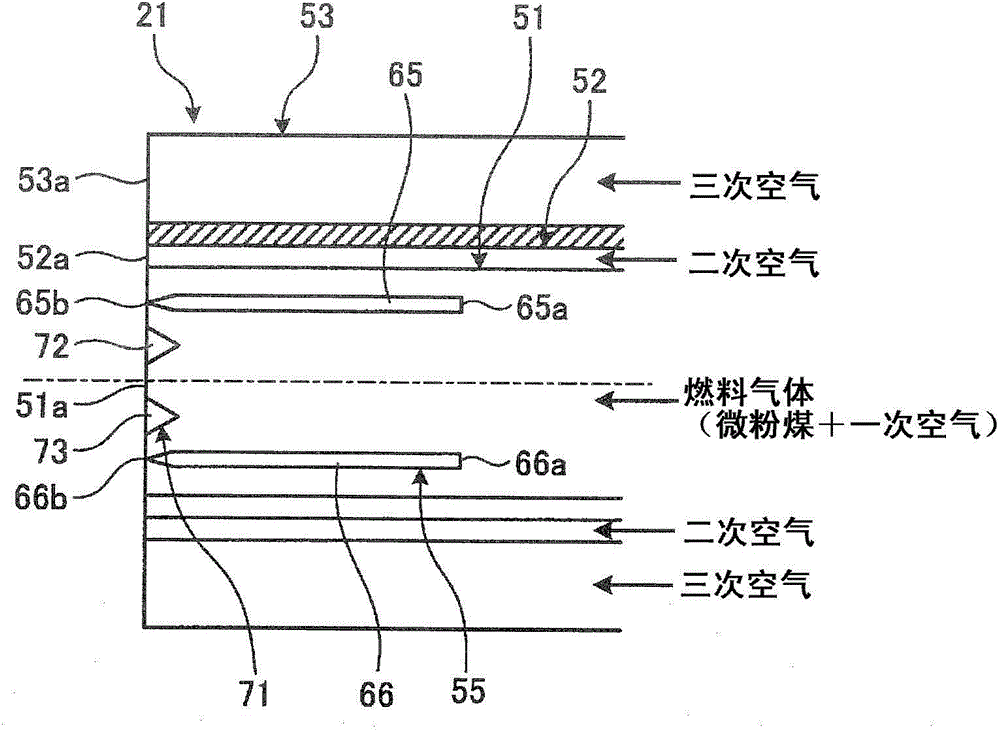

Burner, solid fuel burner and solid fuel boiler, boiler and method of operating the boiler

ActiveCN103443543BProper circulationAppropriate circulationBurner safety arrangementsAir supply regulationCombustorFuel gas

Provided are a burner, a burner burning solid fuel, a boiler burning solid fuel, a boiler, and a method for operating the boiler. The burner is provided with a fuel nozzle (51) capable of blowing fuel gas mixed with pulverized coal and primary air. and a secondary air nozzle (52) capable of blowing secondary air from the outside of the fuel nozzle (51), and a flame stabilizer (51) is set on the axial center side of the front end of the fuel nozzle (51), and the fuel nozzle A straightening member (55) is provided between the inner wall surface of (51) and the flame stabilizer (54), thereby realizing proper flow of fuel gas mixed with solid fuel and air.

Owner:MITSUBISHI HEAVY IND LTD

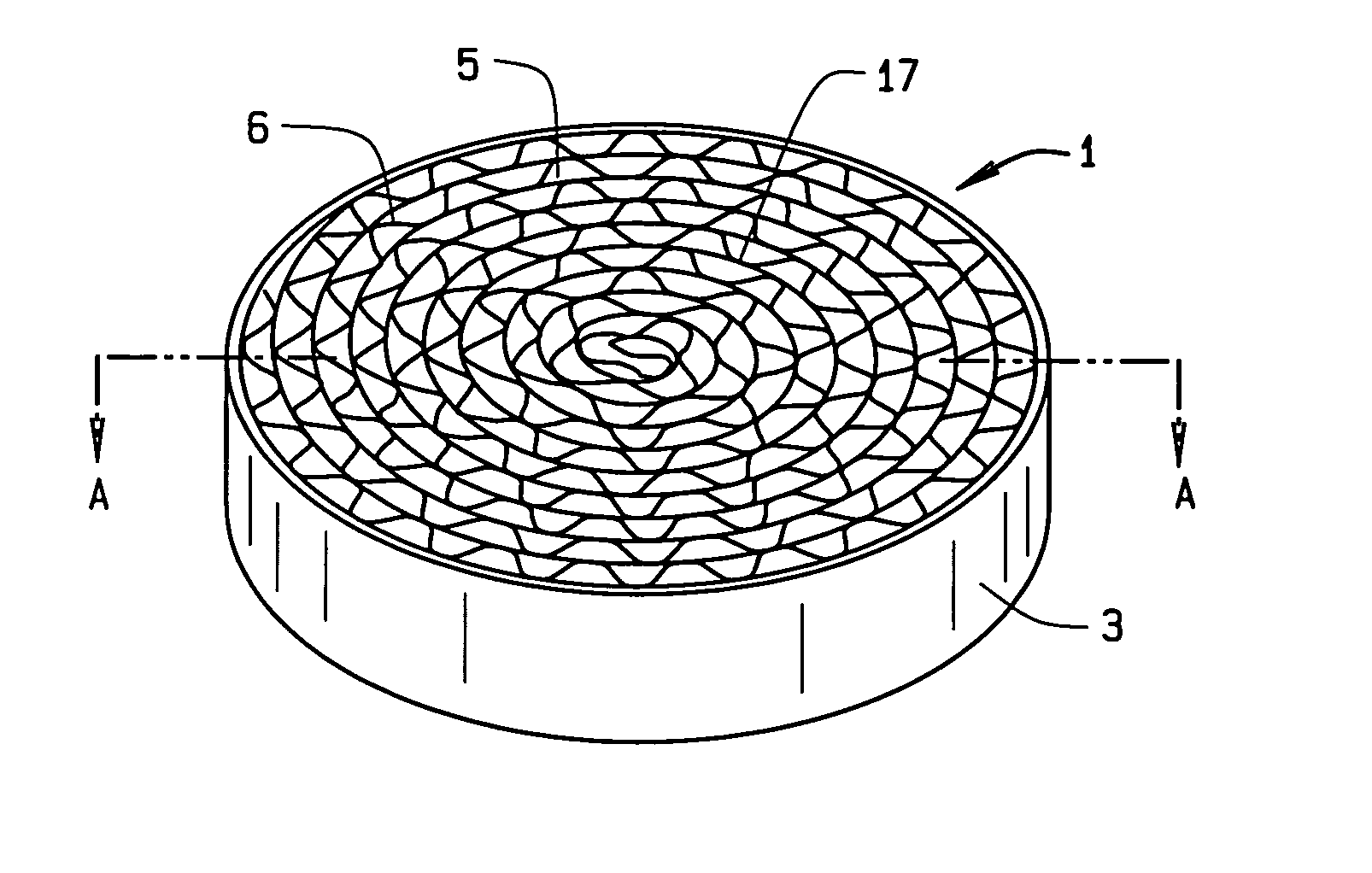

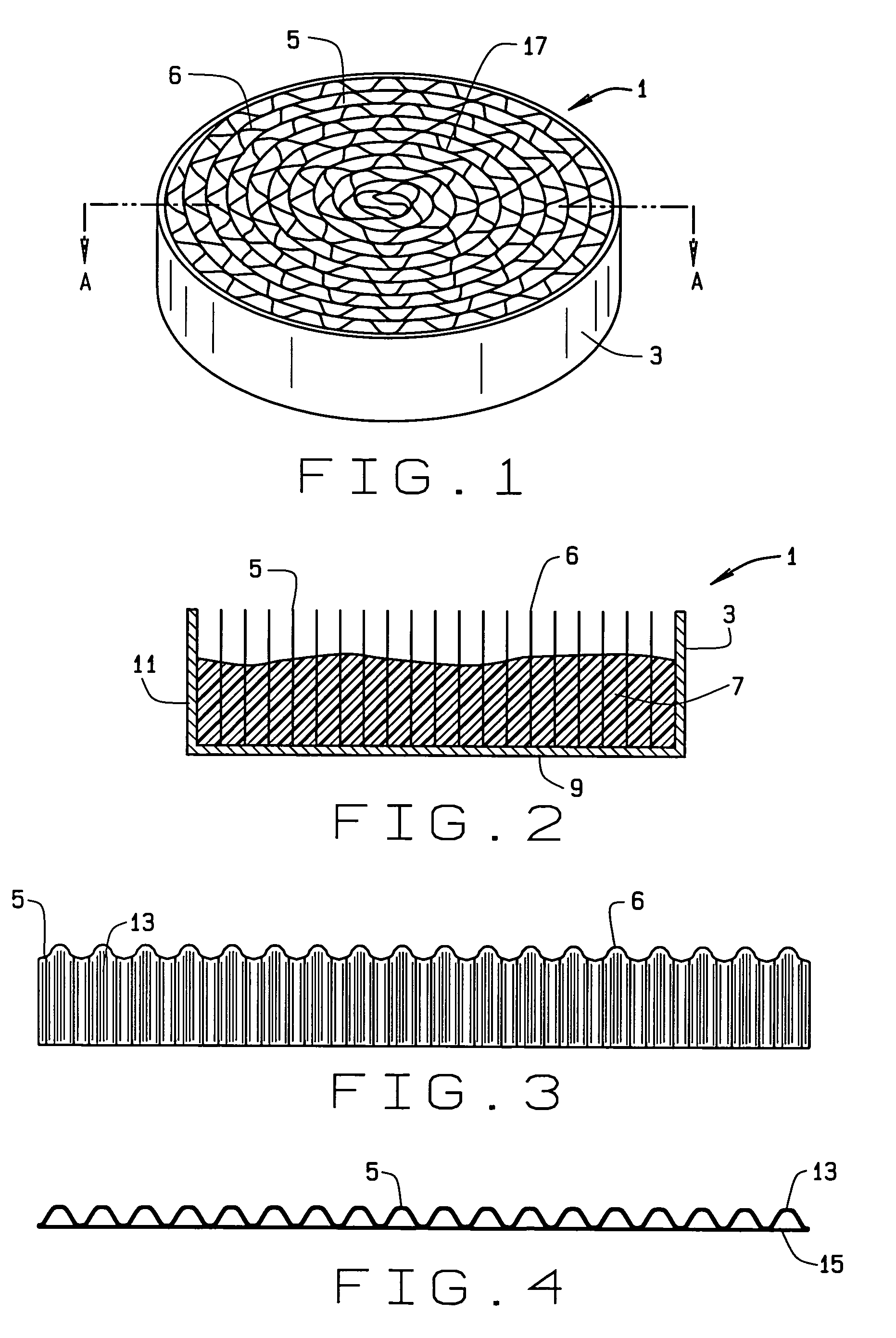

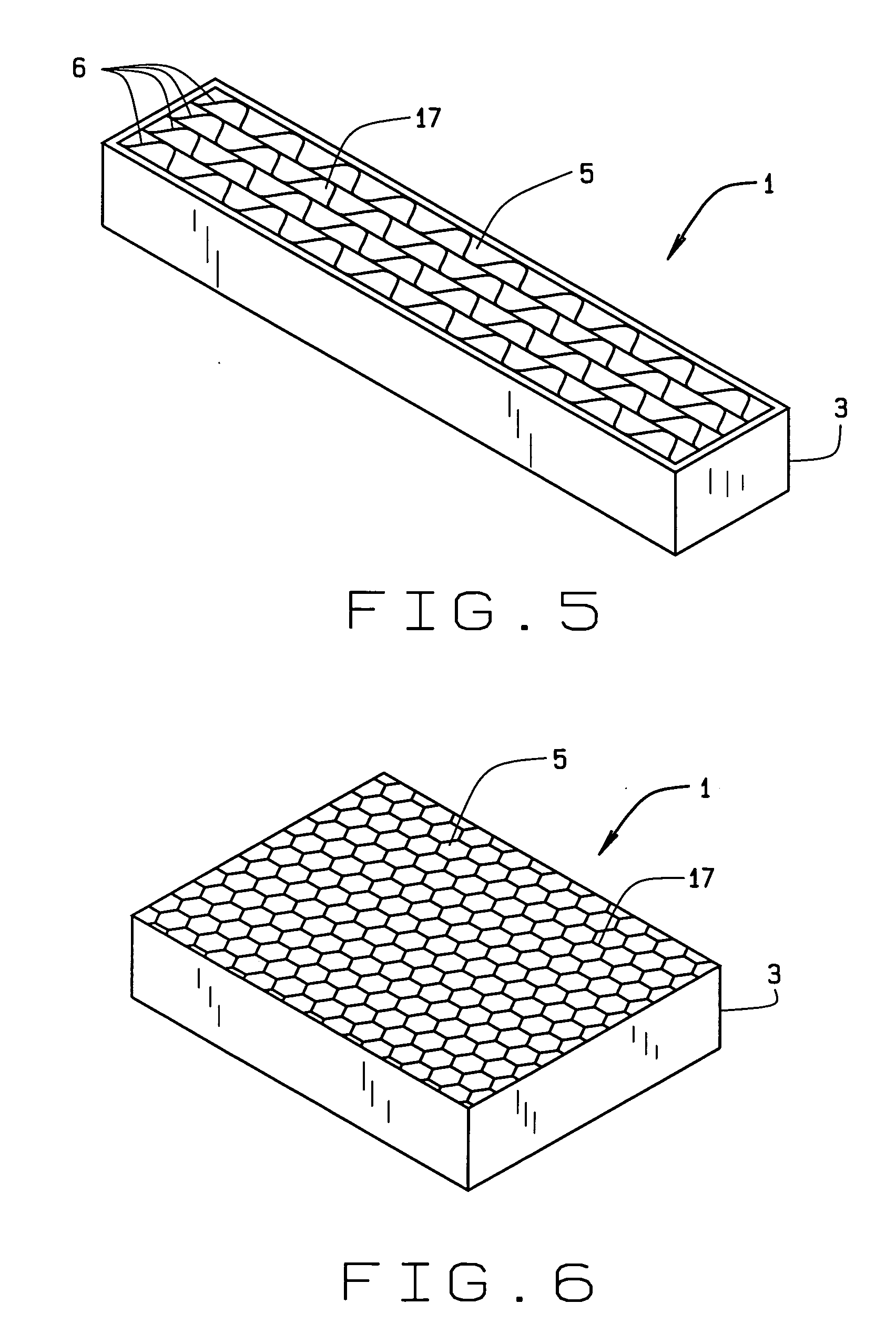

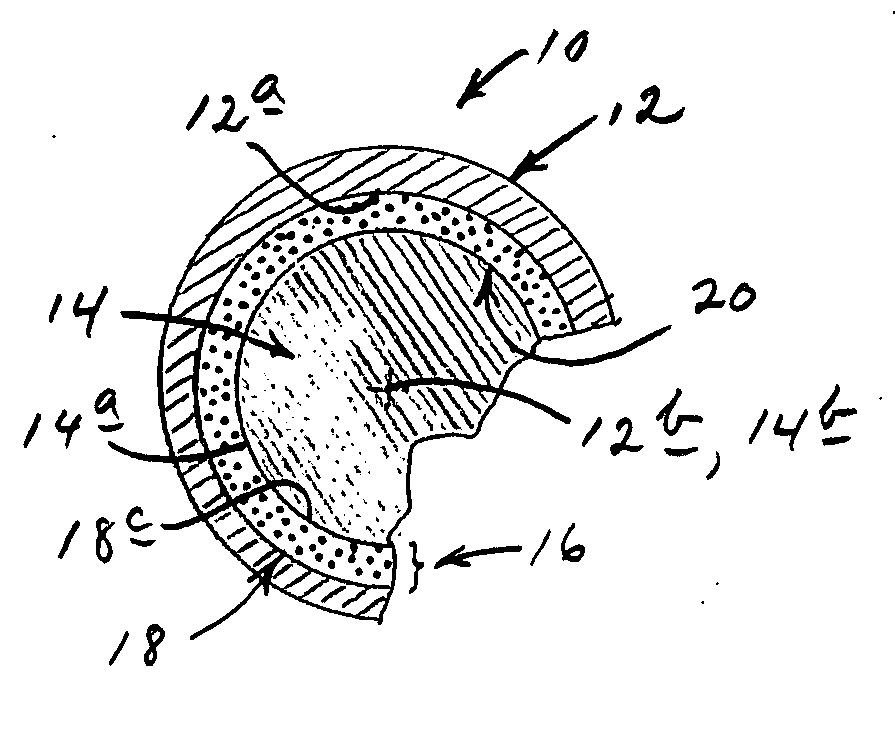

Solid-fuel-combustion fire-insulation interface with adjacent container-wall

A solid-fuel rocket assembly including an elongate fuel container having a long axis, and an inner surface spaced outwardly from, and generally circumsurrounding, that axis, and a continuous, elastomeric, heat-insulative, intumescence-behavior jacket adhered to the container's inner surface and defining a central chamber for receiving an elongate body of solid fuel. This structure implements a method for minimizing, in a solid-fuel rocket, heat damage to the wall of a solid-fuel container during burning of contained solid fuel including the steps of (a) producing dual-interface, continuous-presence, heat-insulative barriering in the zone existing between the container and burning fuel, with such barriering being characterized by (1) interfacially following any heat-produced deformations in the container wall, and (2) interfacially confronting the burning fuel with a tendency for intumescence-driven barrier-thickening.

Owner:OHNSTAD THOMAS S +2

Solid fuel torch

This invention discloses a solid fuel torch which cracks the problems as instable burning, short-time burning, light-color flame and low visibility when the torch is under low temperature, voltage and heavy wind. The torch includes the fuel bin that loads the solid or gel fuel, the burning unit that connects to the top of the fuel bin. The side wall of the burning unit has holes and the inside sets heat-feedback unit of which the bottom attaches to the fuel. The pusher which connects to the bottom of fuel bin pushes the fuel forward the burning unit. The structure of multi-hole and heat-feedback can keep the continue burning and improve the flame burning thickness when the torch is under heavy wind, low temperature and voltage so as to improve the flame color and visibility and satisfy many displaying function.

Owner:AEROSPACE HI TECH HLDG GROUP

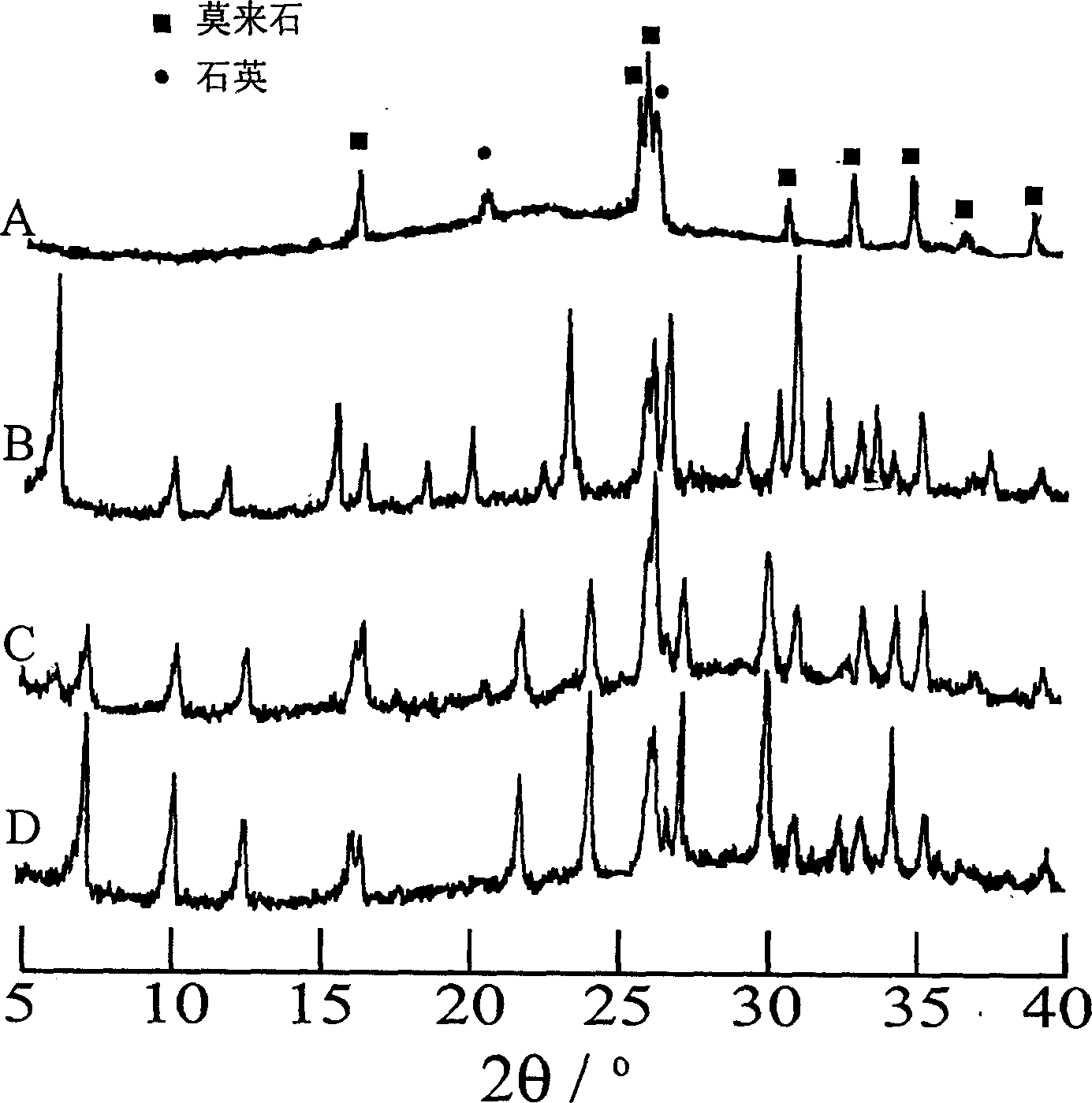

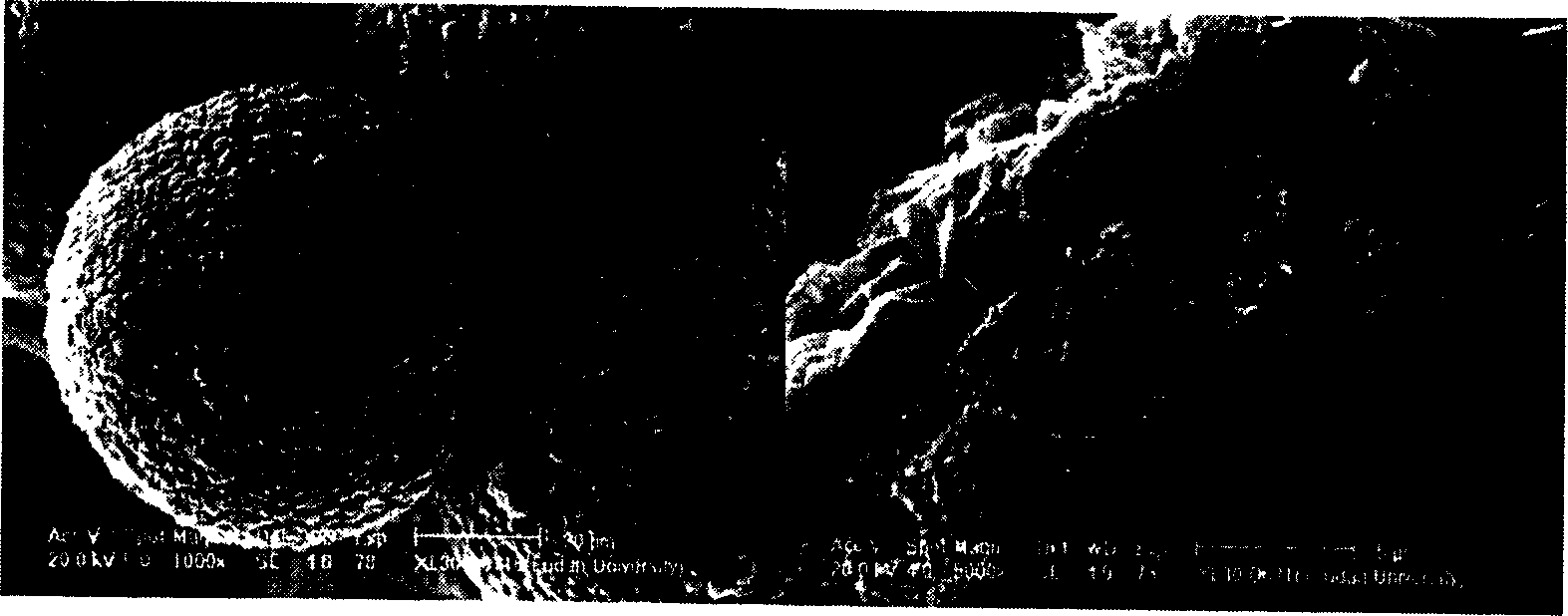

Preparation of zeolite/mullite composite hollow microsphee by using fly-ash hollow imcrobead

InactiveCN1202996CIncrease profitImprove conversion rateMolecular-sieve and base-exchange compoundsMicrosphereMullite

Owner:FUDAN UNIV

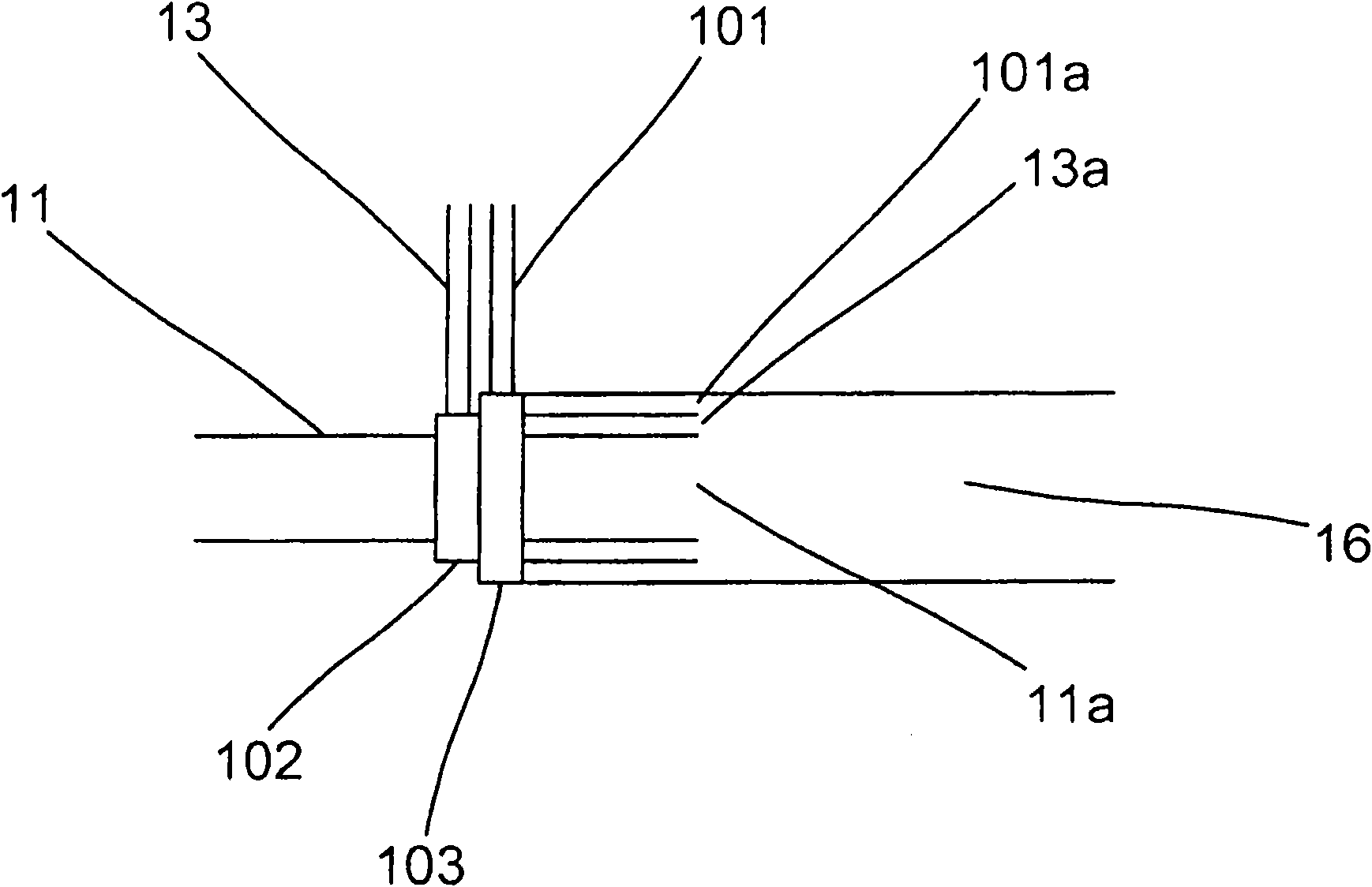

Method and device for combustion of solid fuel

InactiveCN102016421AFuel feeding arrangementsPulverulent fuel combustion burnersCombustorEngineering

Method for combusting a solid phase fuel, where the fuel is caused, by the help of a non-pneumatic feeding means (11), to be fed to an inlet opening (lla) in a burner device (10), where the burner device (10) is caused to comprise a first inlet (13a) for the oxidant through which an oxidant is caused to flow via a first supply conduit (13). The invention is characterised in that the first inlet (13a) for oxidant is caused to be arranged in the form of a first opening arranged by the inlet opening, through which the oxidant is caused to flow out, through a burner pipe (16) and out through a burner orifice (17) to a combustion space (18), so that the oxidant by ejector action causes the fuel to be conveyed through the burner pipe and out through the burner orifice (17), and in that water vapour is added to the oxi not dant before the oxidant reacts with the fuel.

Owner:AGA AB

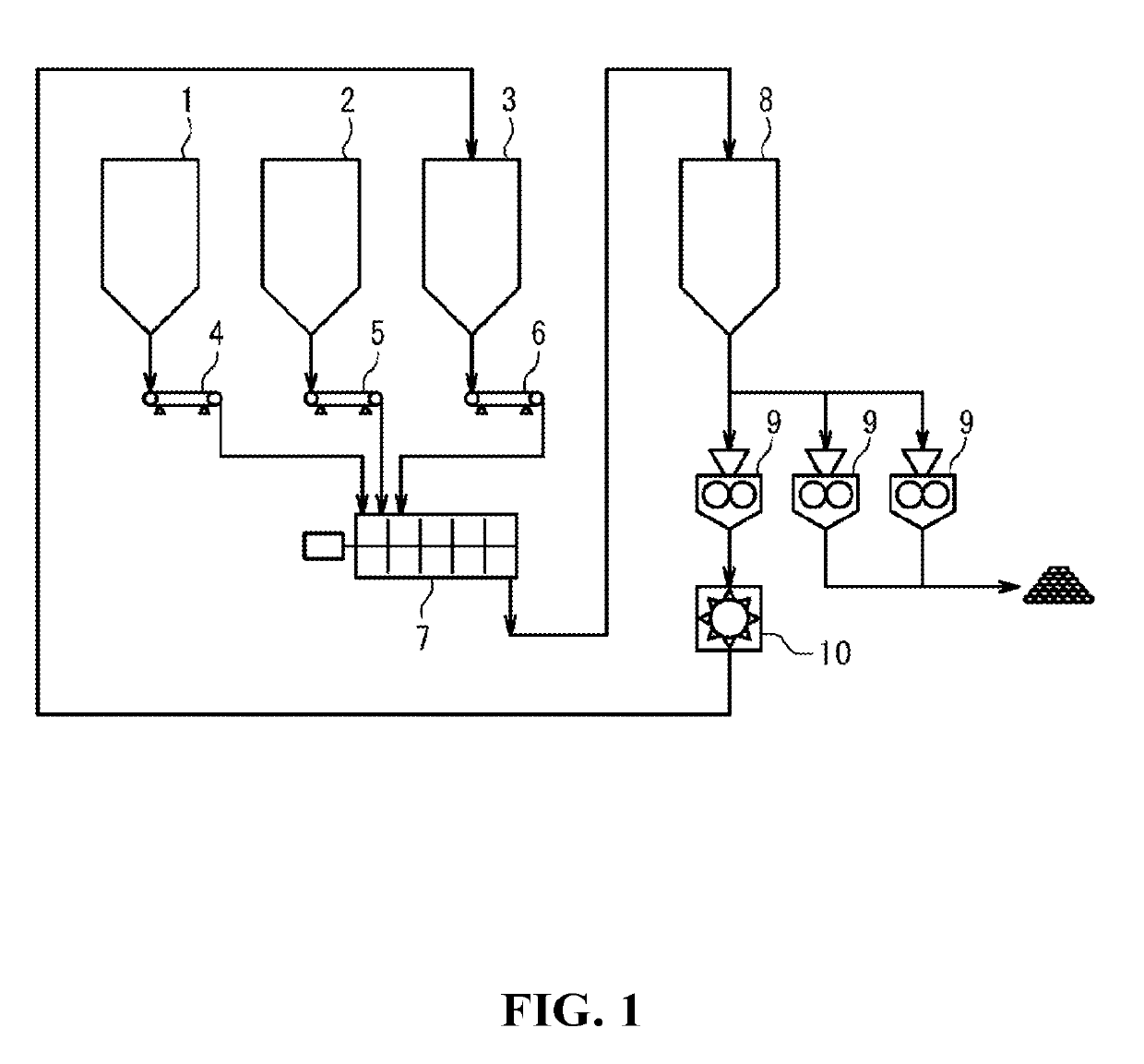

Production method of solid fuel

Provided is a method that produces a solid fuel having a relatively high strength from a powder fuel. The method includes: blending a coal-derived powder fuel with a pulverized fuel having a greater mean particle diameter than the coal-derived powder fuel to obtain a mixture; compression-molding the mixture to obtain a solid fuel; and pulverizing a part of the solid fuel, in which the part of the pulverized solid fuel is used as the pulverized fuel in the blending. A blending proportion of the pulverized fuel with respect to the blending mixture is preferably at least 5 mass % and at most 50 mass %. A cohesive fine coal having a superior cohesive property to the coal-derived powder fuel is preferably further blended in the blending. A blending proportion of the cohesive fine coal with respect to the blending mixture is preferably at least 5 mass % and at most 30 mass %.

Owner:KOBE STEEL LTD

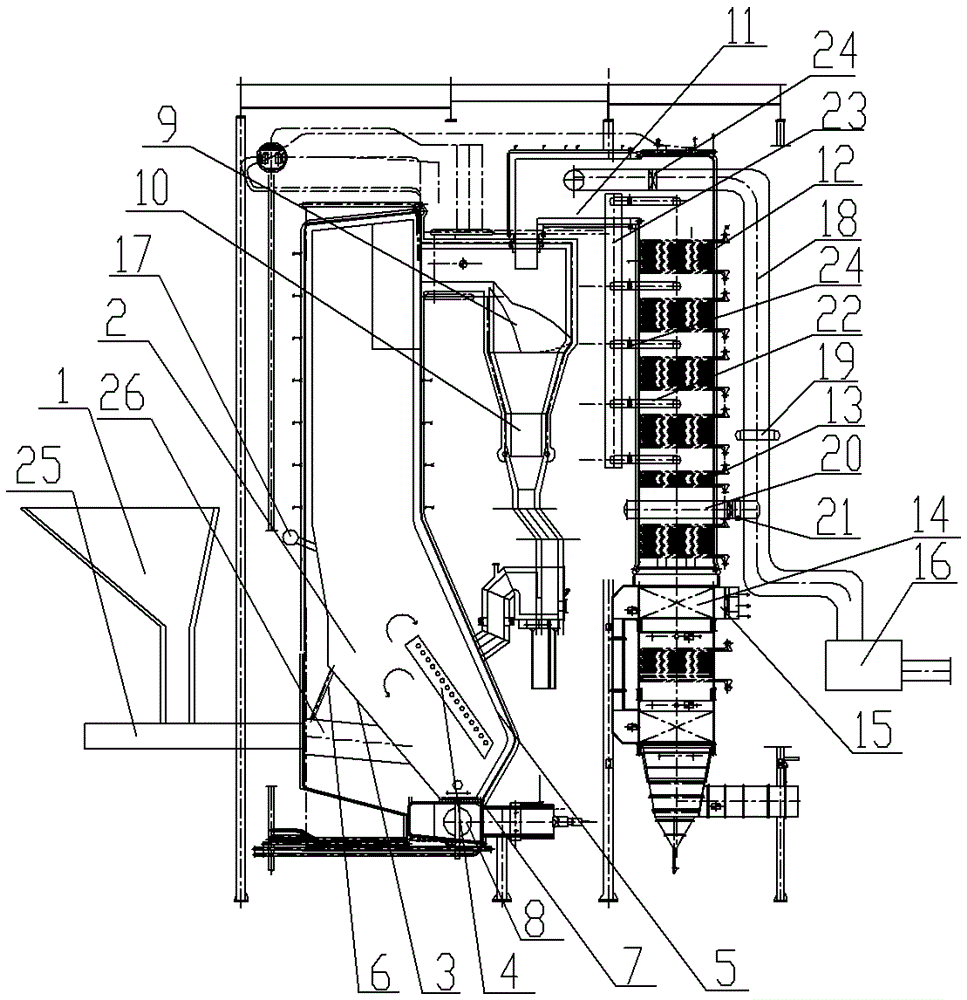

A solid fuel gasification incineration boiler

ActiveCN104791807BHigh thermal efficiencyReduce consumptionIncinerator apparatusFluidised bed boilersParticulatesEngineering

Owner:WUXI HUAGUANG BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com