Pulverized solid fuel nozzle tip

A technology of solid fuel and nozzle head, which is applied in the direction of gas fuel burner, combustion using block fuel and liquid fuel, burner burning powder fuel, etc., and can solve problems such as reverse flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

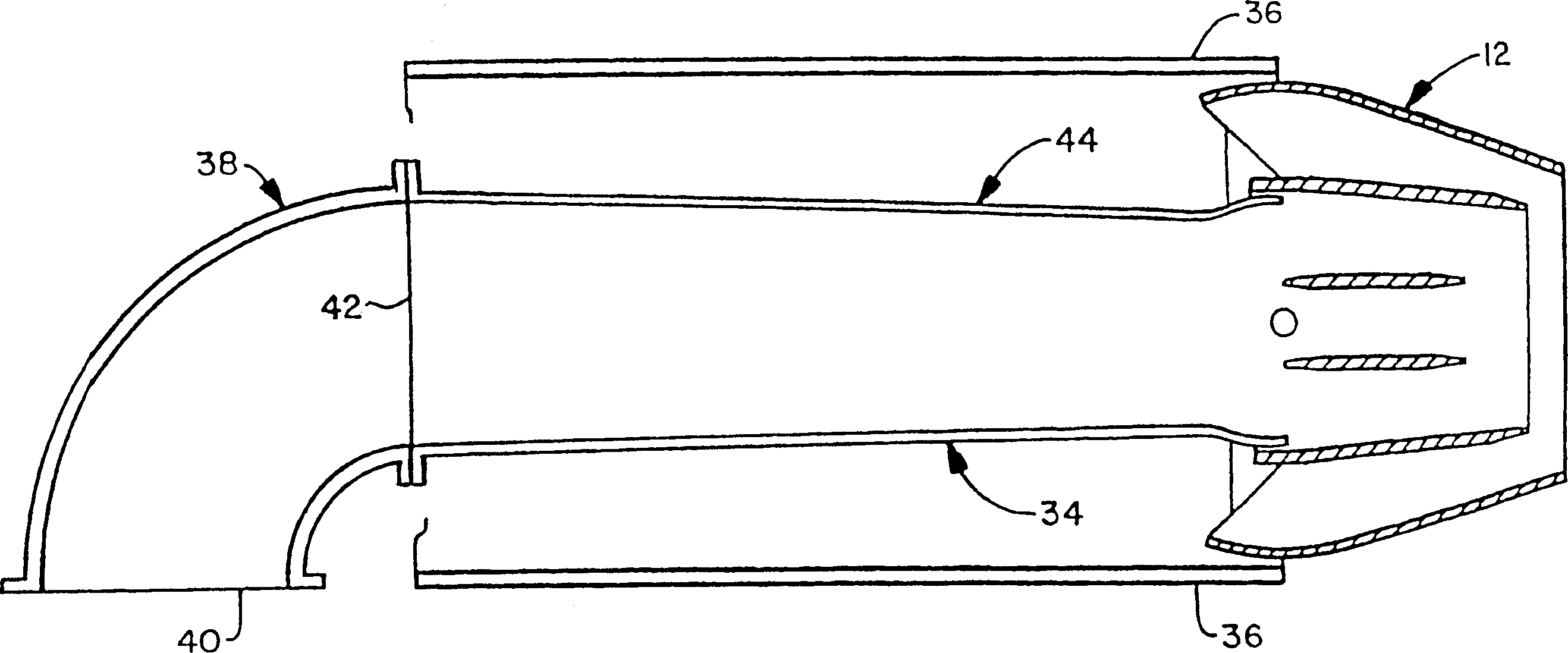

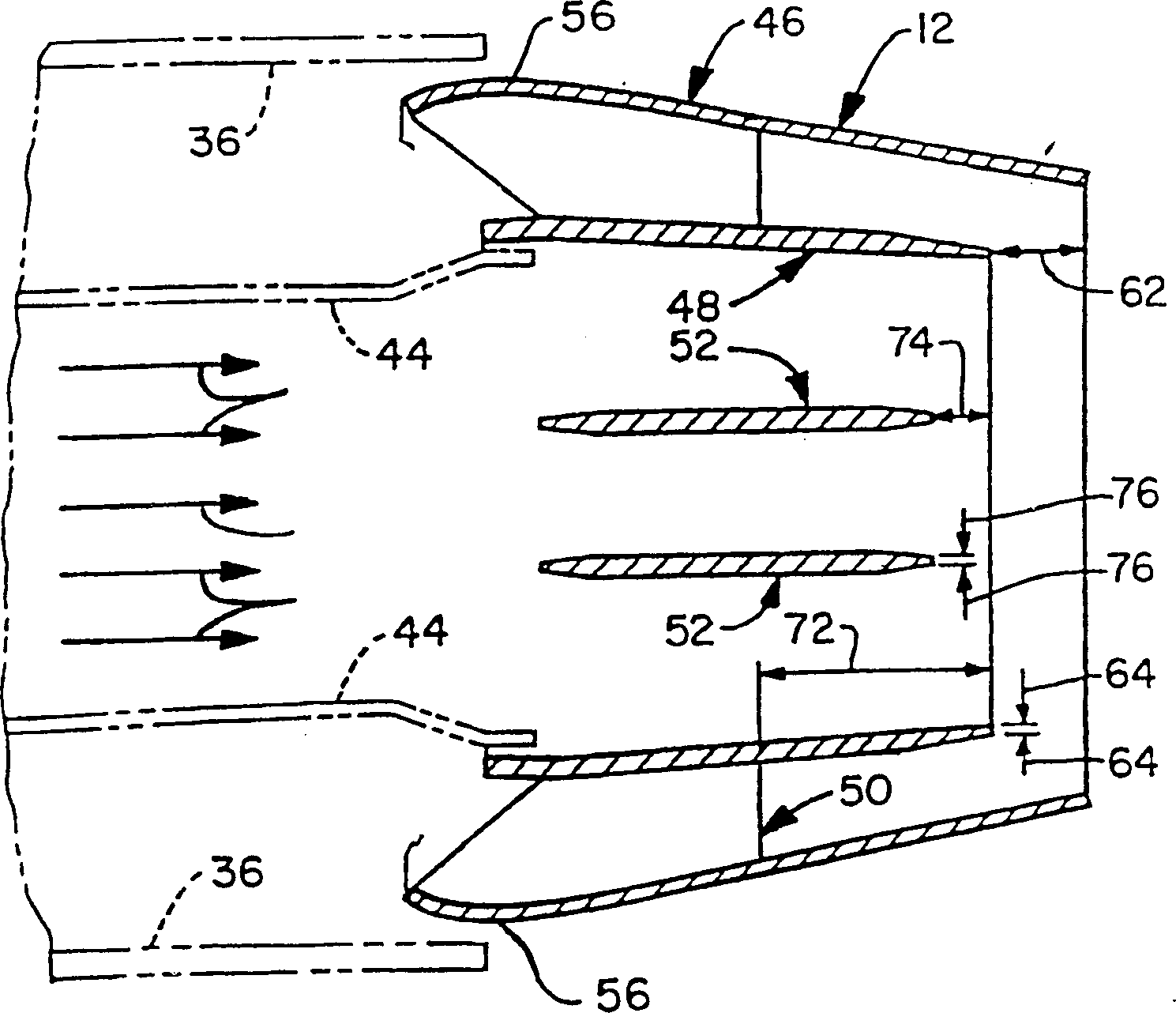

[0042] The pulverized solid fuel nozzle 34 may be mounted in the fuel chamber 36 using any conventional form of mounting means suitable for such purpose. Reference attached figure 2 It will be well understood that the pulverized solid fuel nozzle 34 is included in figure 2 The elbow portion generally indicated by reference numeral 38 in the figure 2 Not described in, the elbow is designed at one end of the figure 2 Indicated by reference numeral 40, it is connected with the pulverized solid fuel delivery pipe 26. The other end of rib-shaped portion 38 is represented by numeral 42, with reference to figure 2 It can be seen that by applying any conventional form of fastening means suitable for such purpose, the attachment to figure 2 On the longitudinally extending portion indicated generally by reference numeral 44. The length of the longitudinally extending portion 44 is such that it substantially corresponds to the depth of the fuel chamber 36 . The pulverized solid fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com