Ignition powder, preparation method and application thereof, and airbag gas generator

An ignition powder and container technology, applied in the generation of compressed gas, ignition agent, vehicle safety arrangement, etc., can solve the problem of inability to meet the requirements of burning speed, low detonation heat that cannot meet the requirements of high heat of ignition powder, low sensitivity of aluminum powder, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] The ignition agent raw material comprises the following components in mass percent content:

[0117]

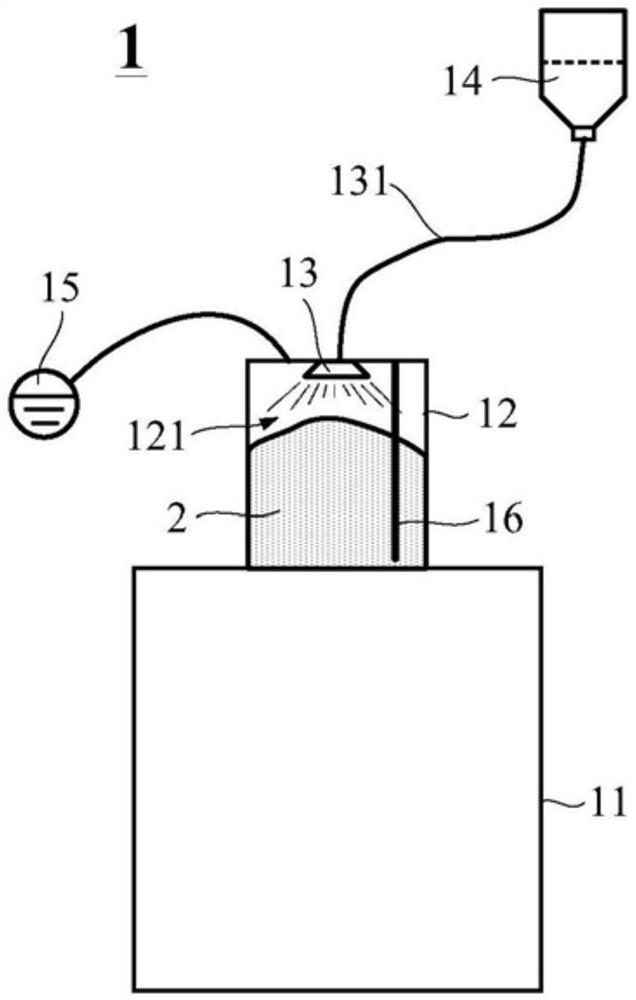

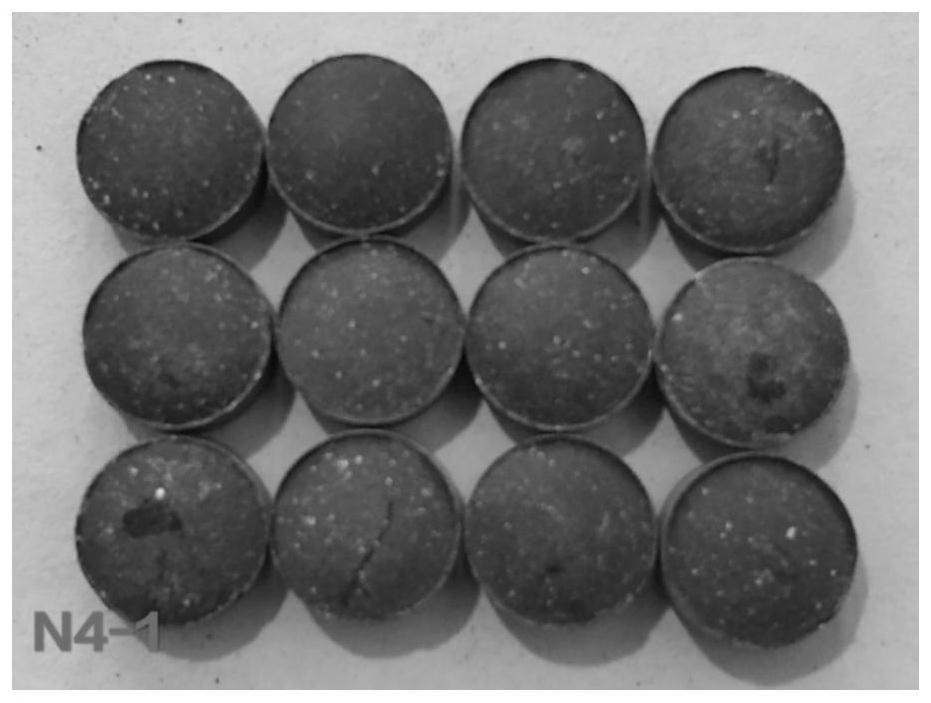

[0118] After the above-mentioned components are weighed, they are pressed into discs with a diameter of 5.0 mm and a thickness of 2.2 to 3.7 mm by wet granulation and a rotary tablet press. The specific preparation method is: pass potassium perchlorate, guanidine nitrate, copper oxide, basic copper nitrate and titanium powder through figure 1 After the mixing system shown, add distilled water with 8% of the total mass of raw materials and mix for 5 minutes. The process of adding water is intermittent spraying. The spraying time is 3s, the intermittent time is 3s, and the spraying rate is 2ml / s to obtain the first material; The first material passes through a 10-purpose screen to obtain the second material; the second material is dried until the water content is less than 0.5% of the total mass of the second material, and the third material is obtained through a 10-p...

Embodiment 2

[0120] The ignition agent raw material comprises the following components in mass percent content:

[0121]

[0122] After the above-mentioned components are weighed, they are pressed into discs with a diameter of 5.0 mm and a thickness of 2.2 to 3.7 mm by wet granulation and a rotary tablet press. The specific preparation method is: pass potassium perchlorate, guanidine nitrate, copper oxide, basic copper nitrate and titanium powder through figure 1 After the mixing system shown, add distilled water with 8% of the total mass of raw materials and mix for 5 minutes. The process of adding water is intermittent spraying. The spraying time is 3s, the intermittent time is 3s, and the spraying rate is 2ml / s to obtain the first material; The first material passes through a 20-mesh screen to obtain the second material; the second material is dried until the moisture content is less than 0.5% of the total mass of the second material, and the third material is obtained through a 10-p...

Embodiment 3

[0124] The ignition agent raw material comprises the following components in mass percent content:

[0125]

[0126]

[0127] After the above-mentioned components are weighed, they are pressed into discs with a diameter of 5.0 mm and a thickness of 2.2 to 3.7 mm by wet granulation and a rotary tablet press. The specific preparation method is: pass potassium perchlorate, guanidine nitrate, copper oxide, basic copper nitrate and magnesium powder through figure 1 After the mixing system shown, add distilled water with 8% of the total mass of raw materials and mix for 5 minutes. The process of adding water is intermittent spraying. The spraying time is 3s, the intermittent time is 3s, and the spraying rate is 2ml / s to obtain the first material; The first material is passed through a 10-mesh screen to obtain the second material; the second material is dried until the water content is less than 0.5% of the total mass of the second material, and the third material is obtained t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com