Igniter, ignition device and ignition method

An ignition device and igniter technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as oxygen breakthrough, wellbore explosion, uneven heating of oil layers, etc., and achieve the best temperature resistance and durability The effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

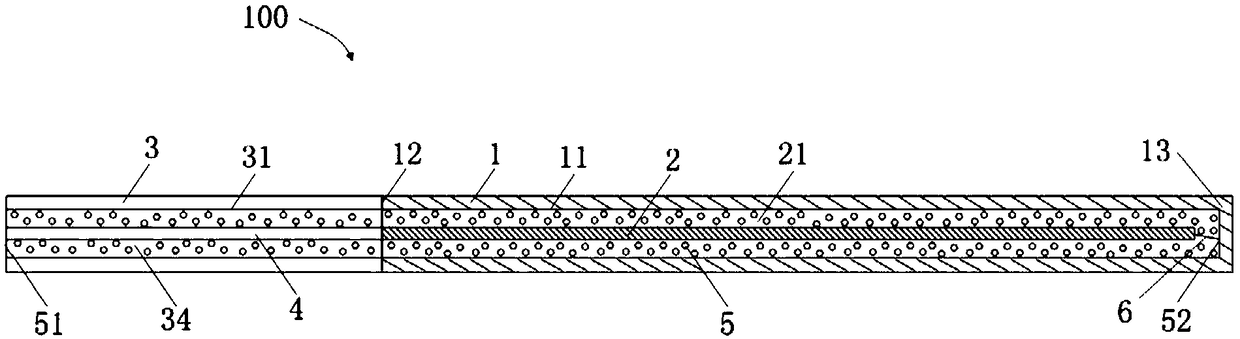

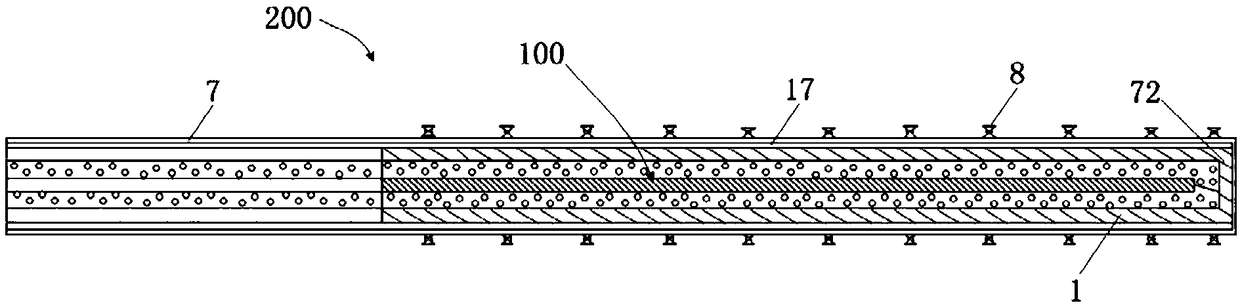

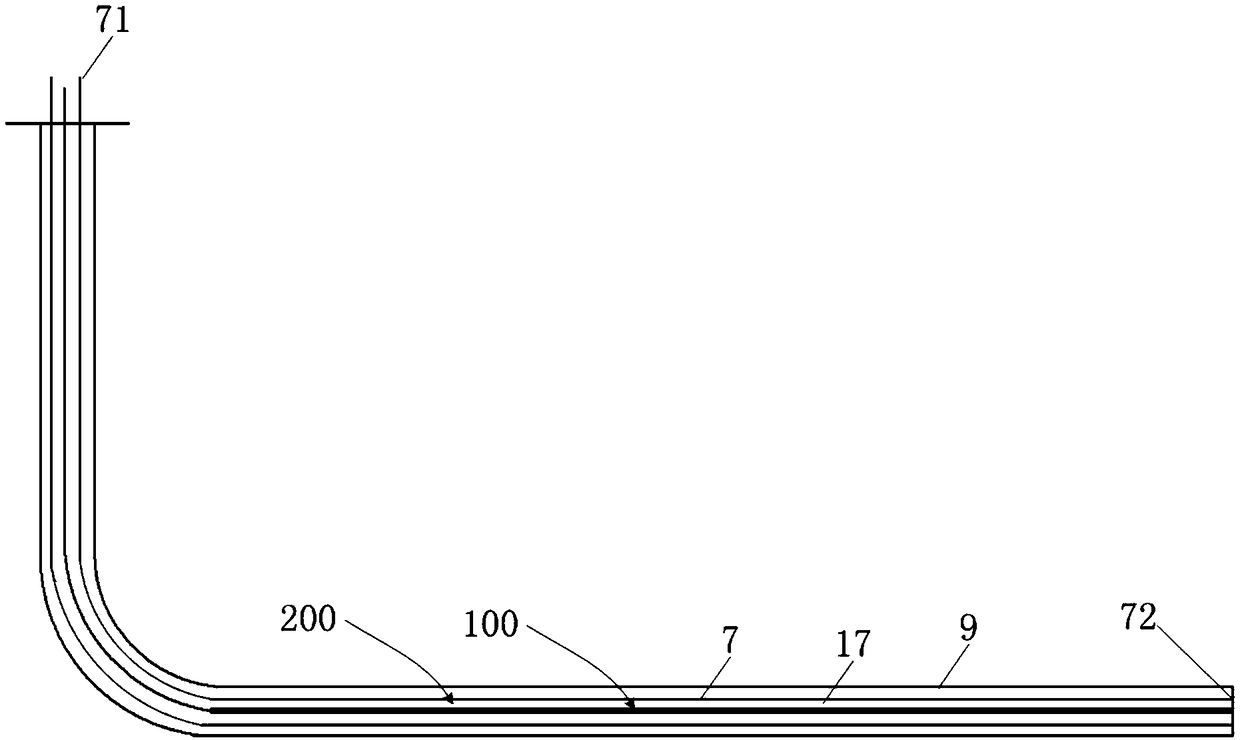

Embodiment Construction

[0051] To clarify, when a component is said to be "set on" another component, it can be directly on the other component or there can be an intervening component as well. When a component is said to be "connected" to another component, it can be directly connected to the other component or there may be a centered component at the same time. As used herein, the terms "vertical", "horizontal", "left", "right" and similar expressions are for the purpose of illustration only and do not represent the only embodiment.

[0052]Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the technical field to which this application belongs. The terminology used herein in the description of the application is only for the purpose of describing specific embodiments, and is not intended to limit the application. As used herein, the term "and / or" includes any and all combinations of one or more of the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com