Swirling spreader for solid fuel fired spreader stoker boilers

A solid fuel and spreader technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of expensive auxiliary fuel, increase the production cost of sugarcane processing, etc., and achieve the effect of obvious lateral distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

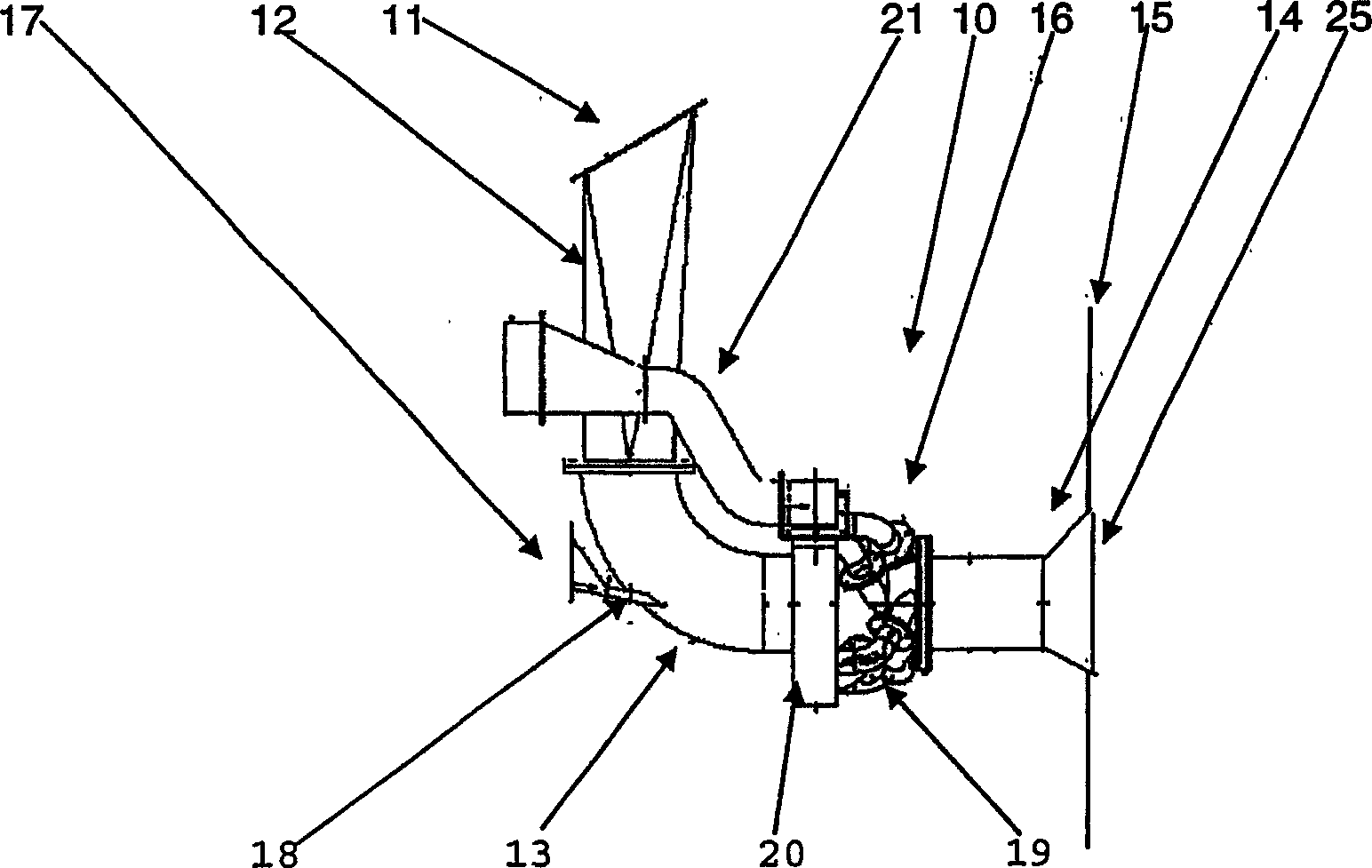

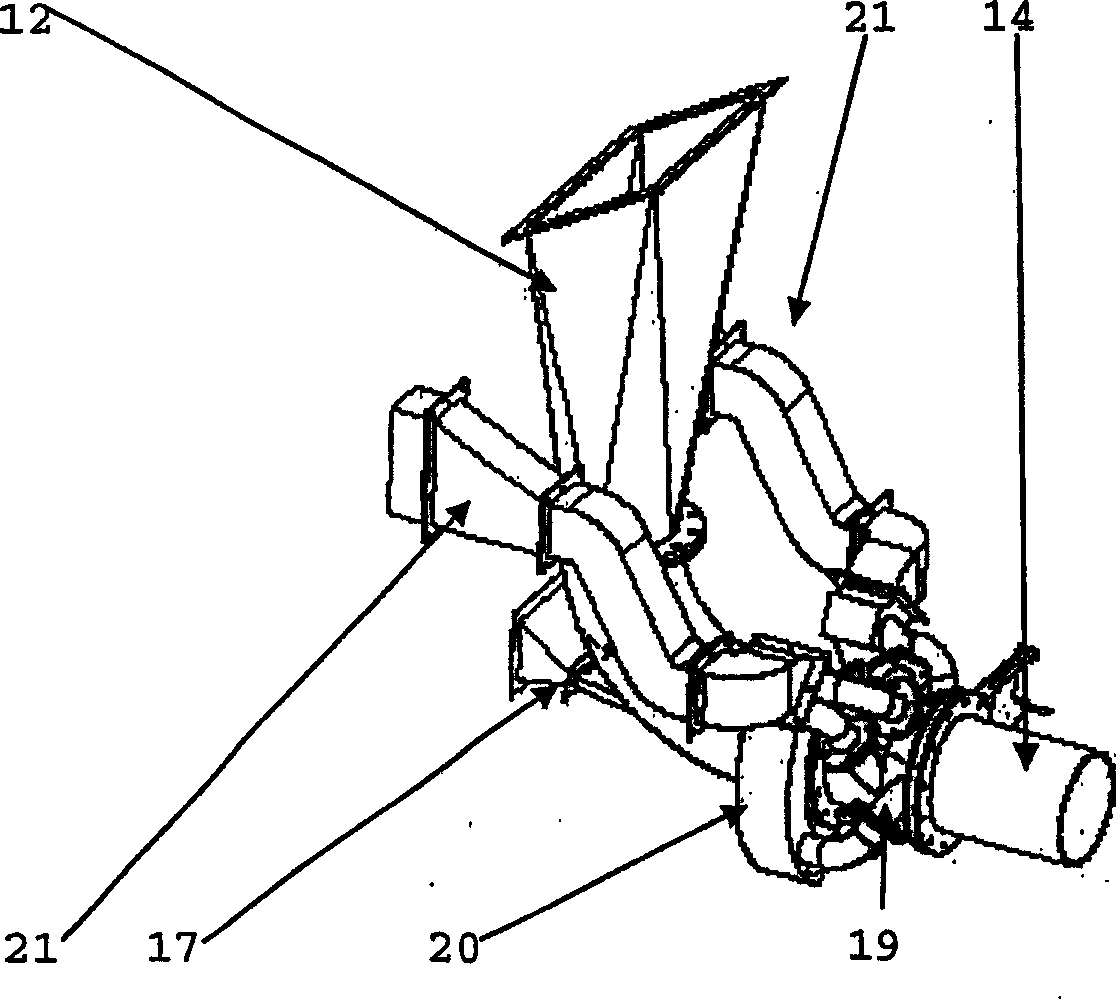

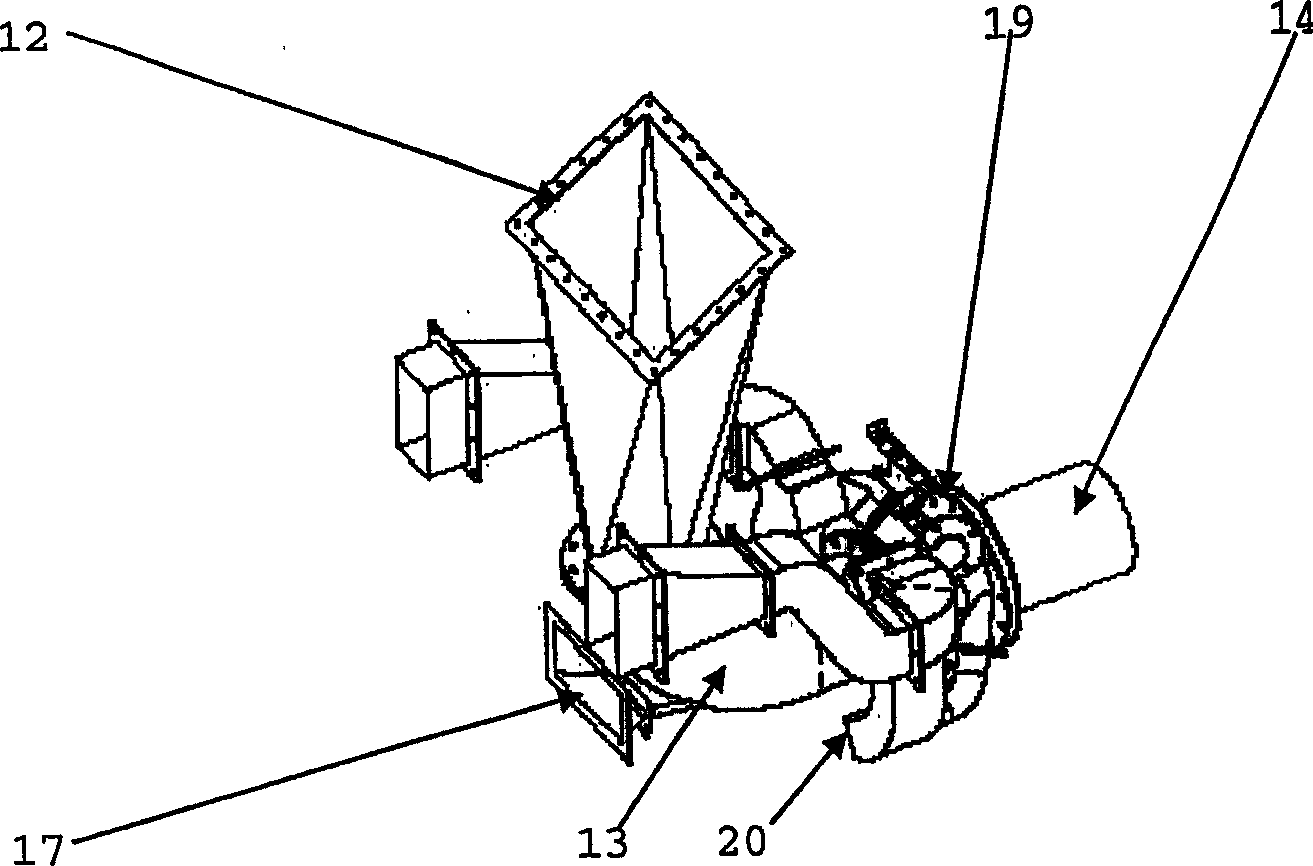

[0077] See attached drawings and see first figure 1 , figure 1 Showing a first embodiment of the invention, this figure shows a side view of a spreader 10 according to one embodiment of the invention. The spreader 10 comprises an upper inlet 11 forming part of a chute 12, a main body in the form of a cylindrical member 13, an outlet 14 through a side wall 15 of the boiler, and an outlet 14 through which the bagasse is pushed through the spreader from the upper inlet 11 through the outlet 14. A vortex motion is applied to a device 16 on the bagasse.

[0078] The chute 12 is generally generally rectangular when viewed in plan, but may be of any desired size and have other shapes if desired.

[0079] The chute has an open top including the inlet 11 . Bagasse or other solid fuel enters the chute 12 through the inlet 11 . If bagasse is used, a bagasse feeder (not shown) is typically provided to supply bagasse into the chute 12 . The bagasse flows down from the chute 12 under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com