Method and device for combustion of solid fuel

一种燃料、燃烧器的技术,应用在燃烧方法、燃烧粉末燃料的燃烧器、燃烧的空气/燃料供给等方向,能够解决火焰温度高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

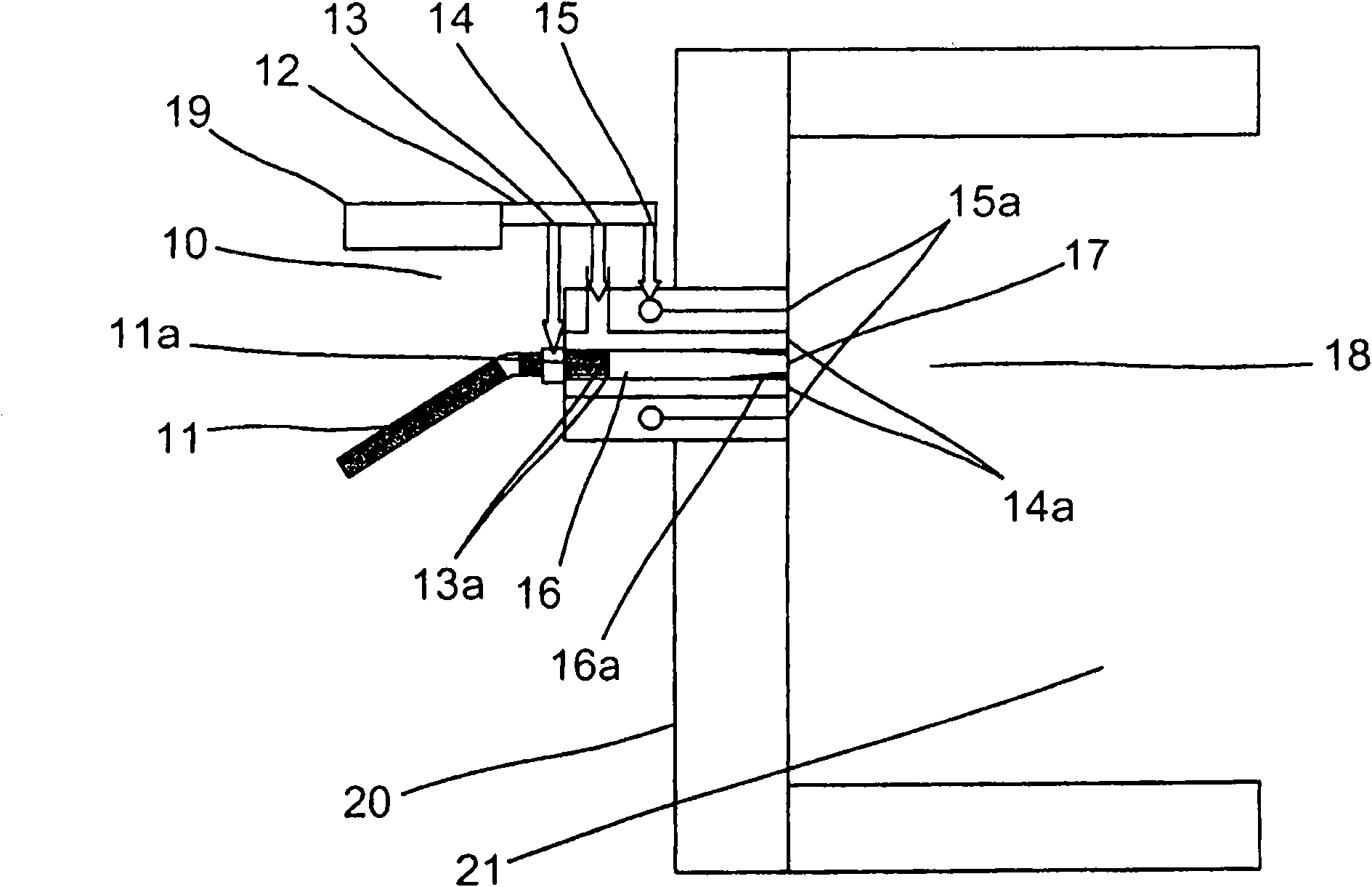

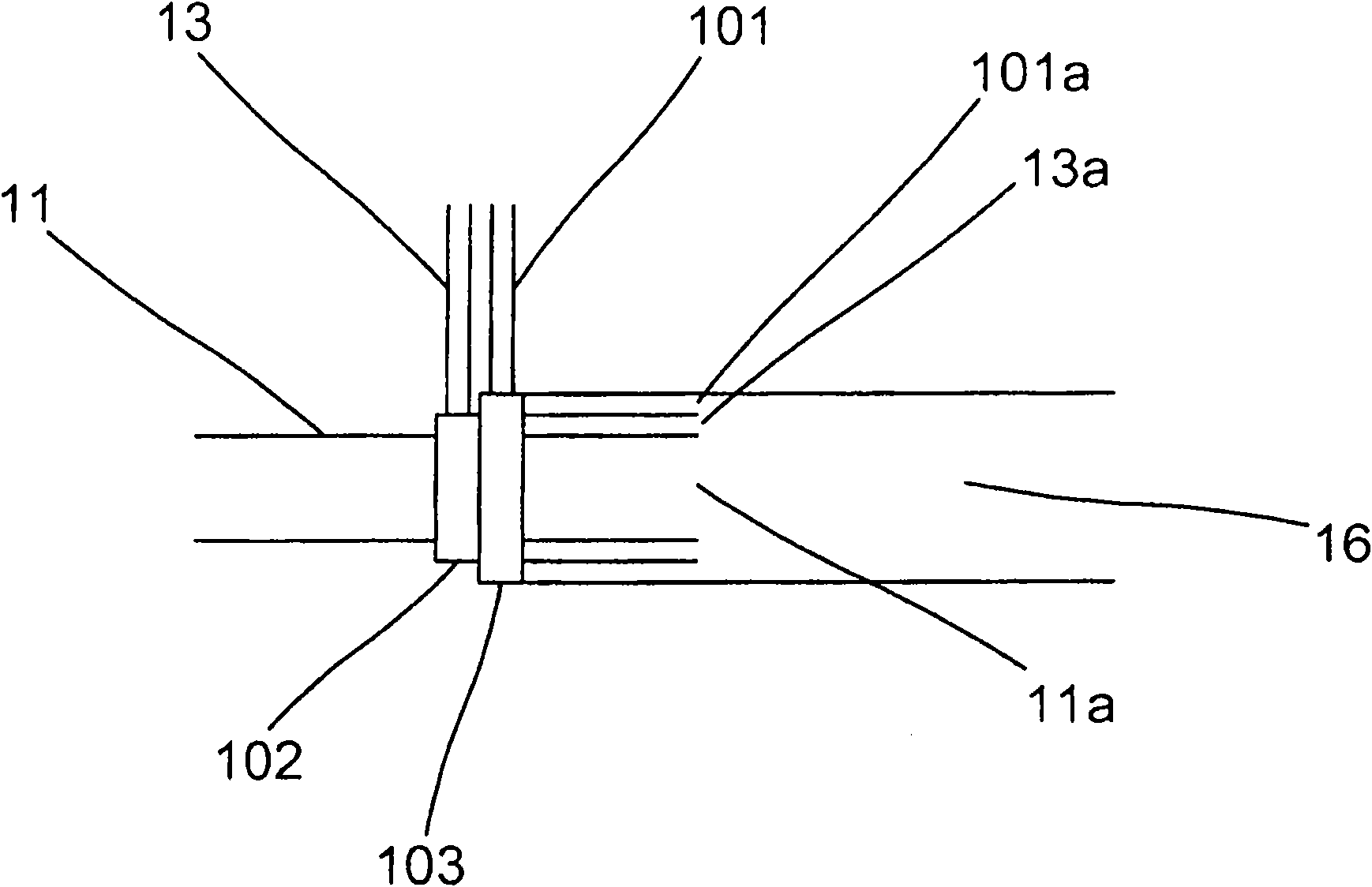

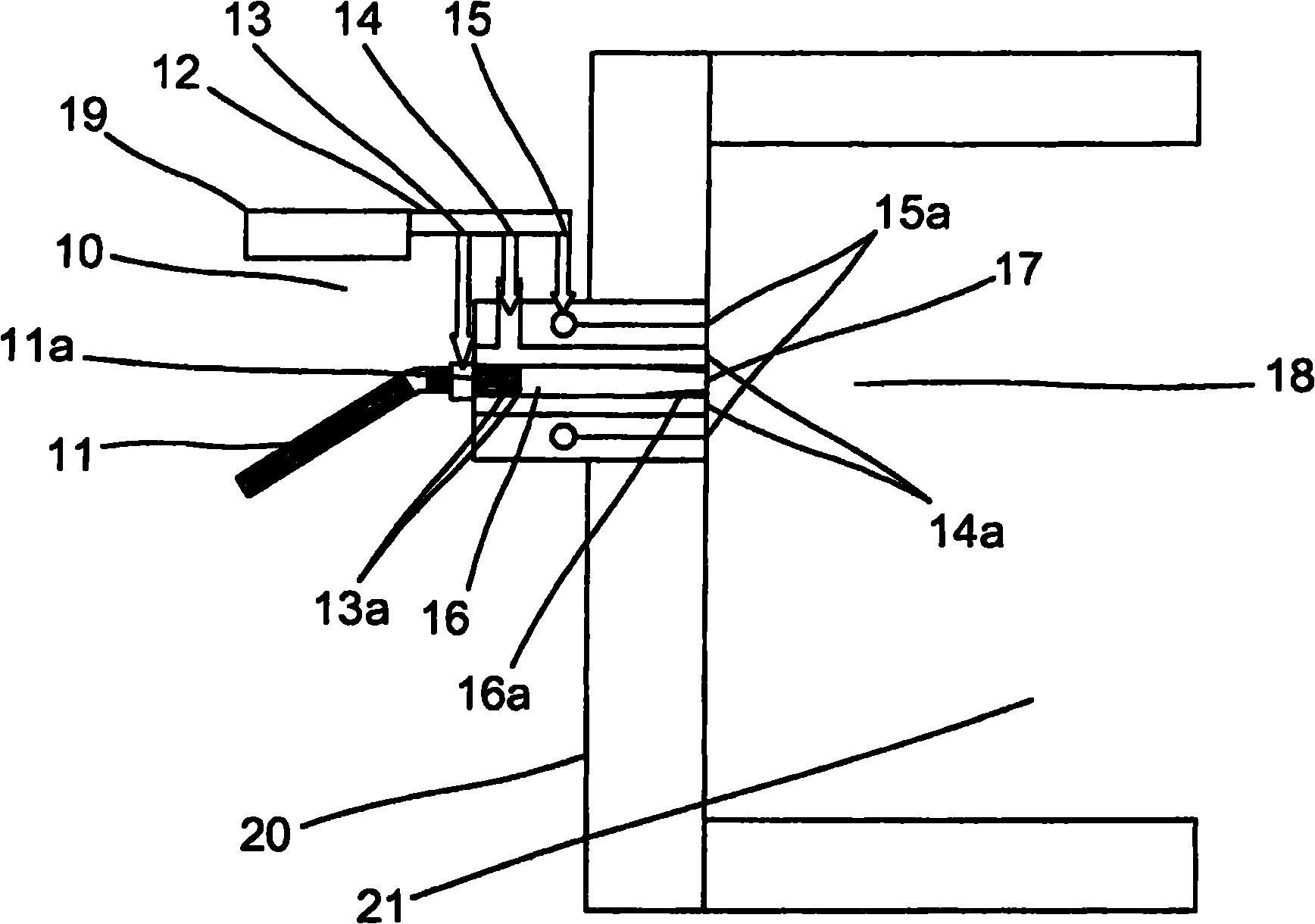

[0013] figure 1 A burner arrangement 10 according to the invention is shown which is suitable for carrying out the method according to the invention. The burner arrangement 10 is mounted on a furnace wall of an industrial furnace 20 and is oriented such that the combustion space 18 associated with the burner arrangement 10 is arranged within the heating space 21 of the furnace 20 . The industrial furnace 20 can be used to heat various materials such as glass, steel, non-ferrous metals, and ceramic materials. Furthermore, the burner arrangement according to the invention can also be used, for example, in heating plants, power stations or thermal power plants, where the heat from the burner arrangement 10 is used, for example, as municipal heating and / or converted into electricity.

[0014] A screw feeder or corresponding form of feeding means 11 is provided to feed a predetermined amount of solid phase fuel, such as pulverized coal, to the inlet port 11 a provided in the burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com