A method of producing SO2 sorbent that is suitable for use to desulfurize combustion gases

A technology of burning gas and production methods, which is applied in the direction of lime production, separation methods, chemical instruments and methods, etc., and can solve problems such as uncontrollable lime quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

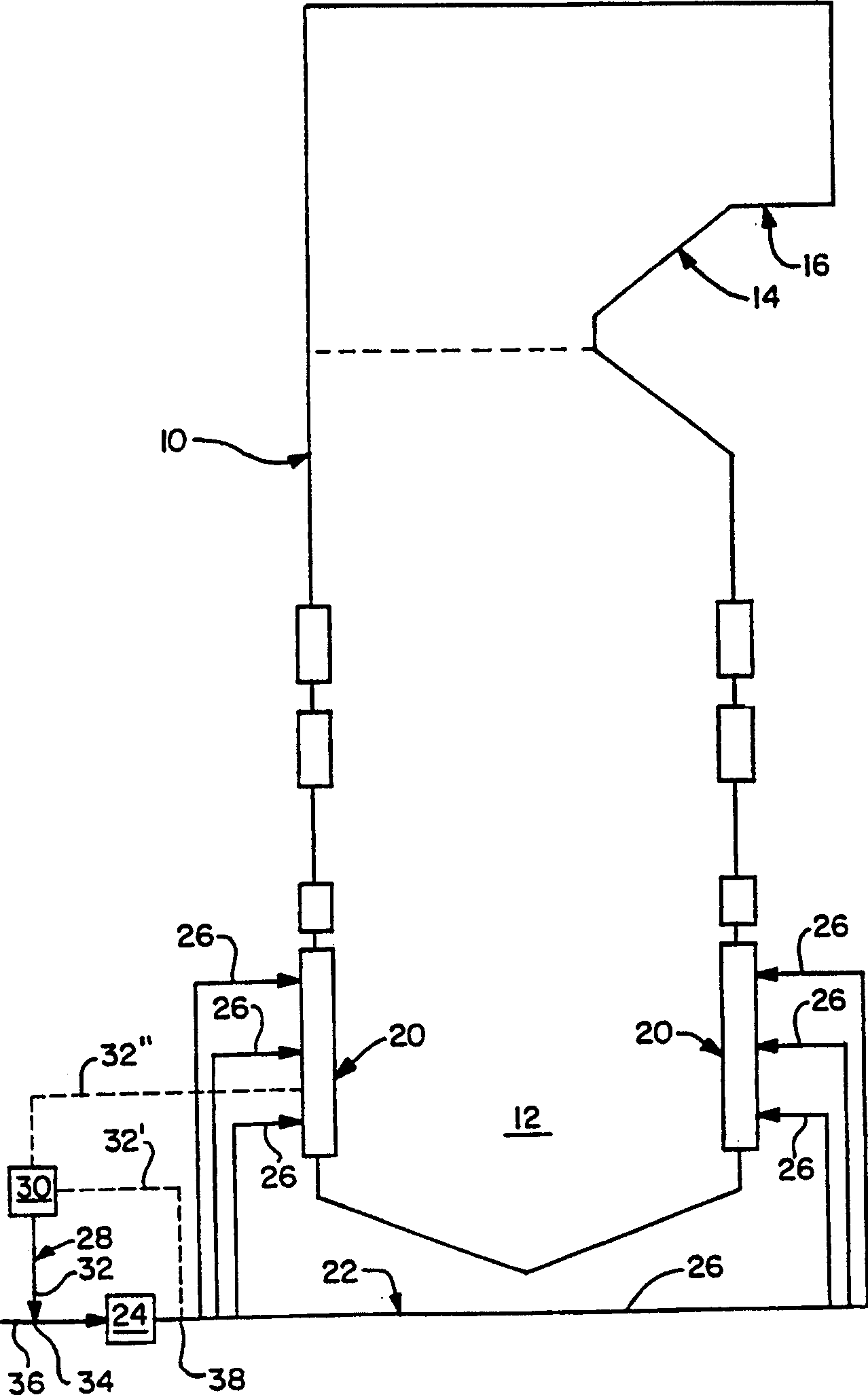

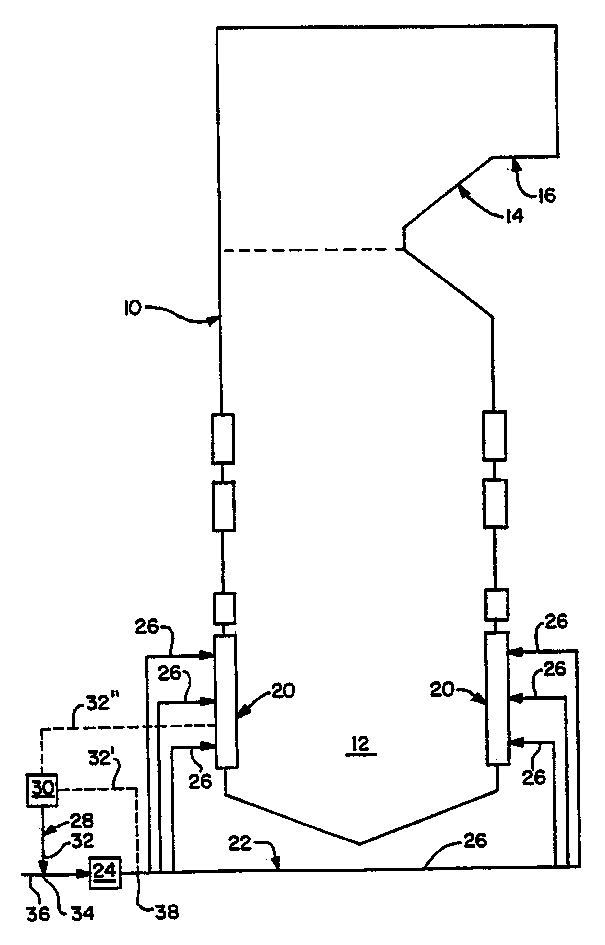

[0043] see figure 1 , shows a conventional solid fuel steam generator, generally designated by numeral 10. Since the structure and mode of operation of conventional solid fuel steam generators are known to those skilled in the art, no figure 1 The illustrated conventional solid fuel steam generator 10 is described in detail. However, for a better understanding of the conventional solid fuel steam generator 10, it can be used to implement the present invention to produce SO suitable for combustion gas desulfurization 2 For the absorbent, it suffices to describe in detail the components of the above-described solid fuel steam generator 10 of the present invention. For a detailed description of the structure and mode of operation of a conventional solid fuel steam generator 10, reference may be made to prior art US4719587, issued to F.J. Berte on January 12, 1988 and assigned to the same assignee as the present applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com