A solid fuel gasification incineration boiler

A solid fuel and boiler technology, applied in fluidized bed boilers, incinerators, combustion methods, etc., can solve the problems of increasing the cost of flue gas treatment, limited waste treatment capacity, and large changes in calorific value, reducing ignition start-up costs, The effect of reducing ignition oil consumption, high temperature and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

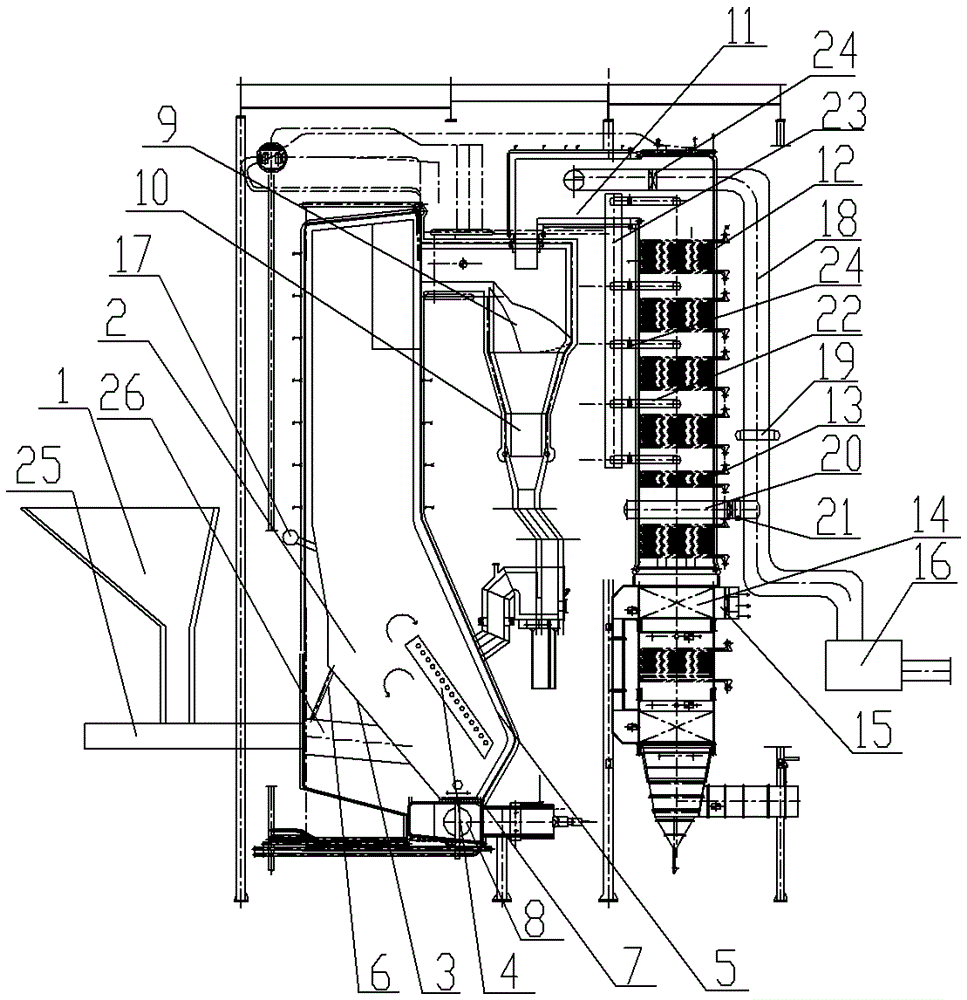

[0014] See figure 1 As shown, a solid fuel gasification incineration boiler includes a feed hopper 1, the feed hopper 1 is connected to a furnace 2, and the furnace 2 includes a front arch 3, a first rear arch 4, and a second rear arch 5 arranged obliquely in sequence. The inner walls of the arch 3, the first rear arch 4, and the second rear arch 5 are poured with thick wear-resistant castables, and gaps and steel mesh are arranged inside the castables to facilitate heating of the castables. The front arch 3 is provided with ventilation holes 6, and the first The inside of the rear arch 4 is supported by cold air pipes. Through eccentric support, the temperature of the fire surface is increased to promote combustion. The cold air with adjustable flow is introduced into the interior, and the temperature is maintained by controlling the flow rate. The height of the first rear arch 4 is lower than that of the front arch 3 and the height of the second rear arch 5, the front arch 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com