Preparation of zeolite/mullite composite hollow microsphee by using fly-ash hollow imcrobead

The technology of hollow microbeads and hollow microspheres is applied in molecular sieves and alkali exchange compounds, inorganic chemistry, non-metallic elements, etc., and can solve the problems of insufficiency of economical and simple methods, unpractical zeolite, waste of energy, etc. High utilization rate and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

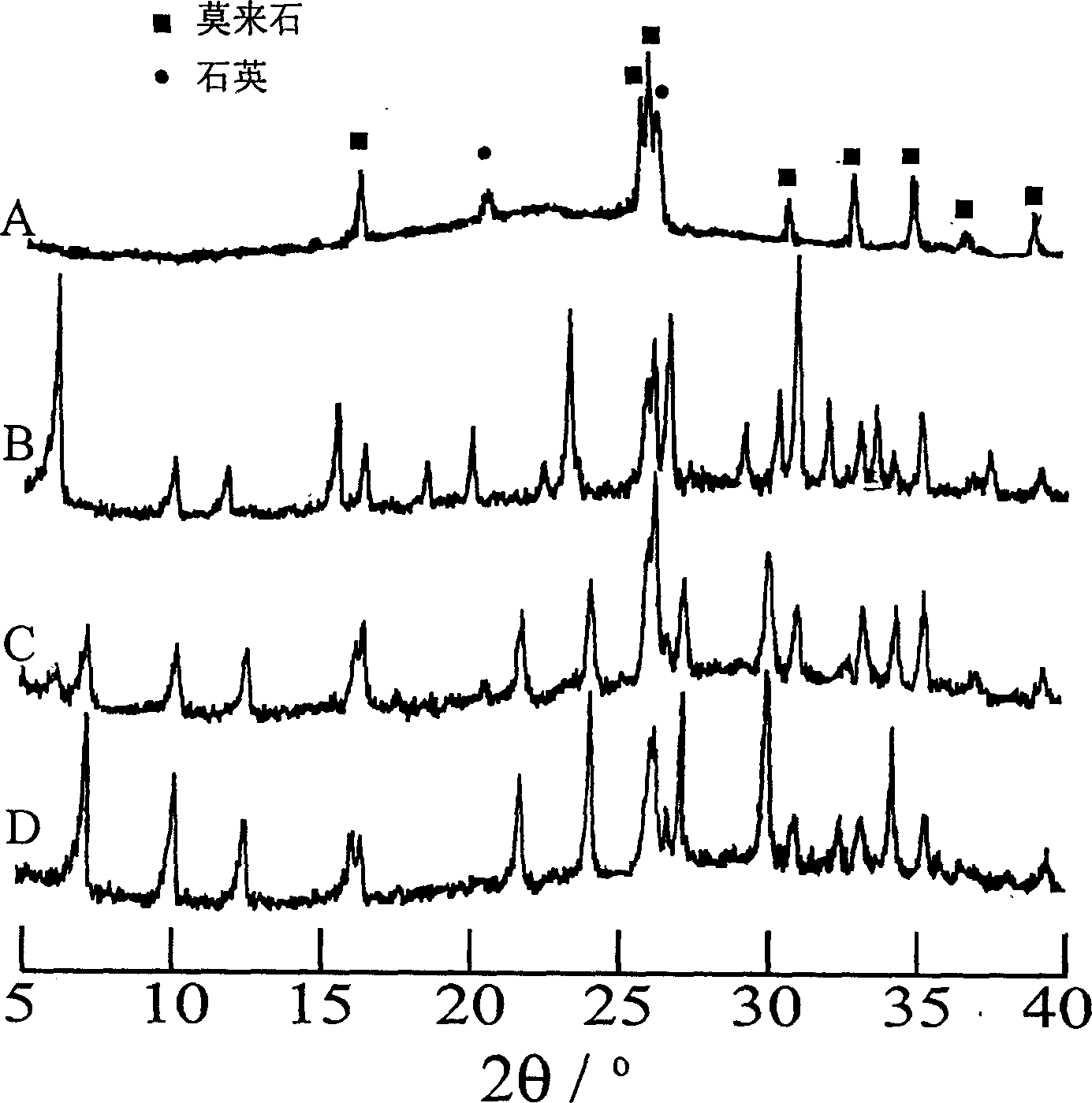

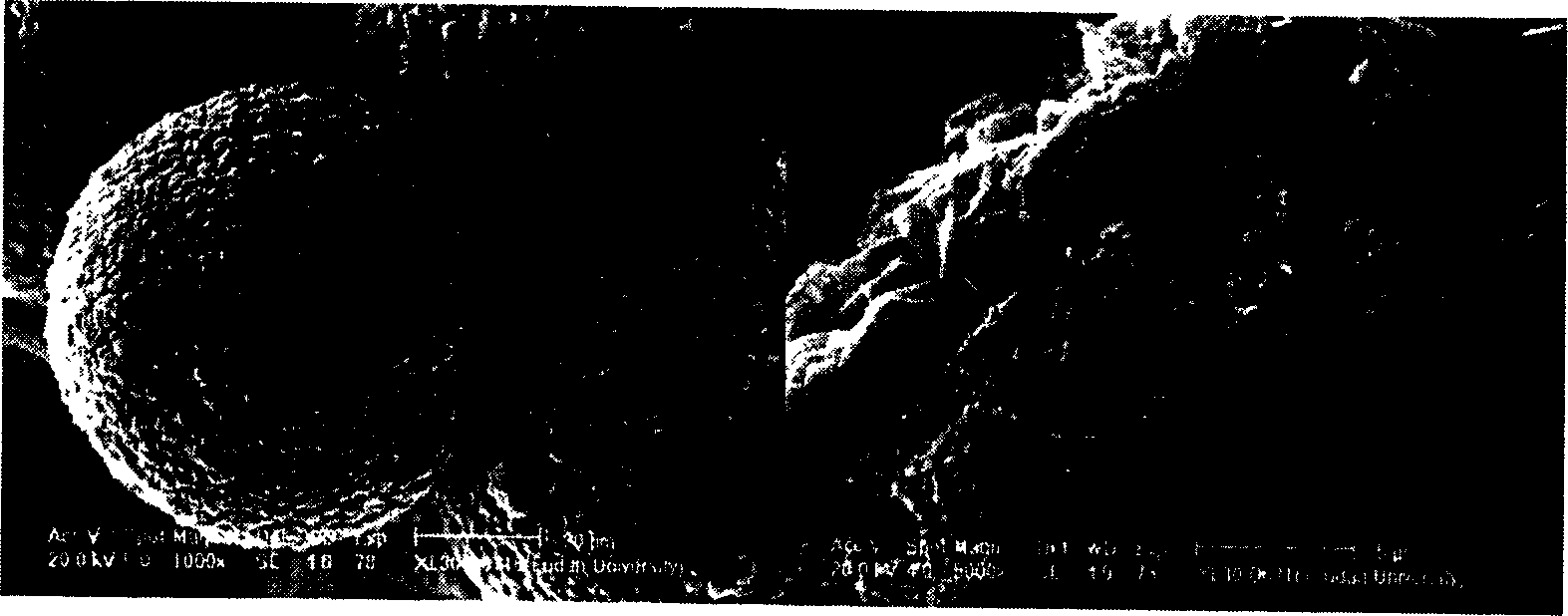

[0023] Fly ash hollow microspheres (containing SiO2) provided by Henan Fly Ash Research Center 2 56.21%, Al 2 o 3 29.45%, the main crystal phase is mullite and quartz, select the hollow microspheres with a diameter of less than 100μm as an example), firstly adsorb a layer of FAU seed crystals with a size of about 100nm, and put 0.08g of fly ash hollow microspheres adsorbed with FAU seeds Mix it with 1ml of 2M NaOH solution and put it into a 15ml polytetrafluoroethylene-lined reaction kettle, seal it and crystallize at 100°C for 48 hours, wash and dry to obtain a sample, and XRD (Rigaku D / max-IIA x-ray powder Diffractometer) and SEM (Philips XL 30 Scanning Electron Microscope) characterization detection, XRD spectrum and SEM figure are shown in the accompanying drawings.

example 2

[0025] The LTA seed crystal with a size of about 200nm is used instead of the FAU seed crystal, and the other experimental procedures are the same as above, and the XRD spectrum and SEM image are shown in the attached figure.

example 3

[0027] With 1ml of aluminum-containing solution (NaOH:NaAlO 2 :H 2 O=9:1:250 molar ratio) replaces NaOH solution, and other experimental steps are with example 2, and XRD spectrum and SEM figure are shown in accompanying drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com