Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114 results about "Single class" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single class means they're using a test that only checks one type of drug - for example, it might check for opiates or barbiturates or amphetamines, but not all 3 at once. My doctor uses single class when he's testing to make sure people are taking their meds and multiple class when he's testing to see...

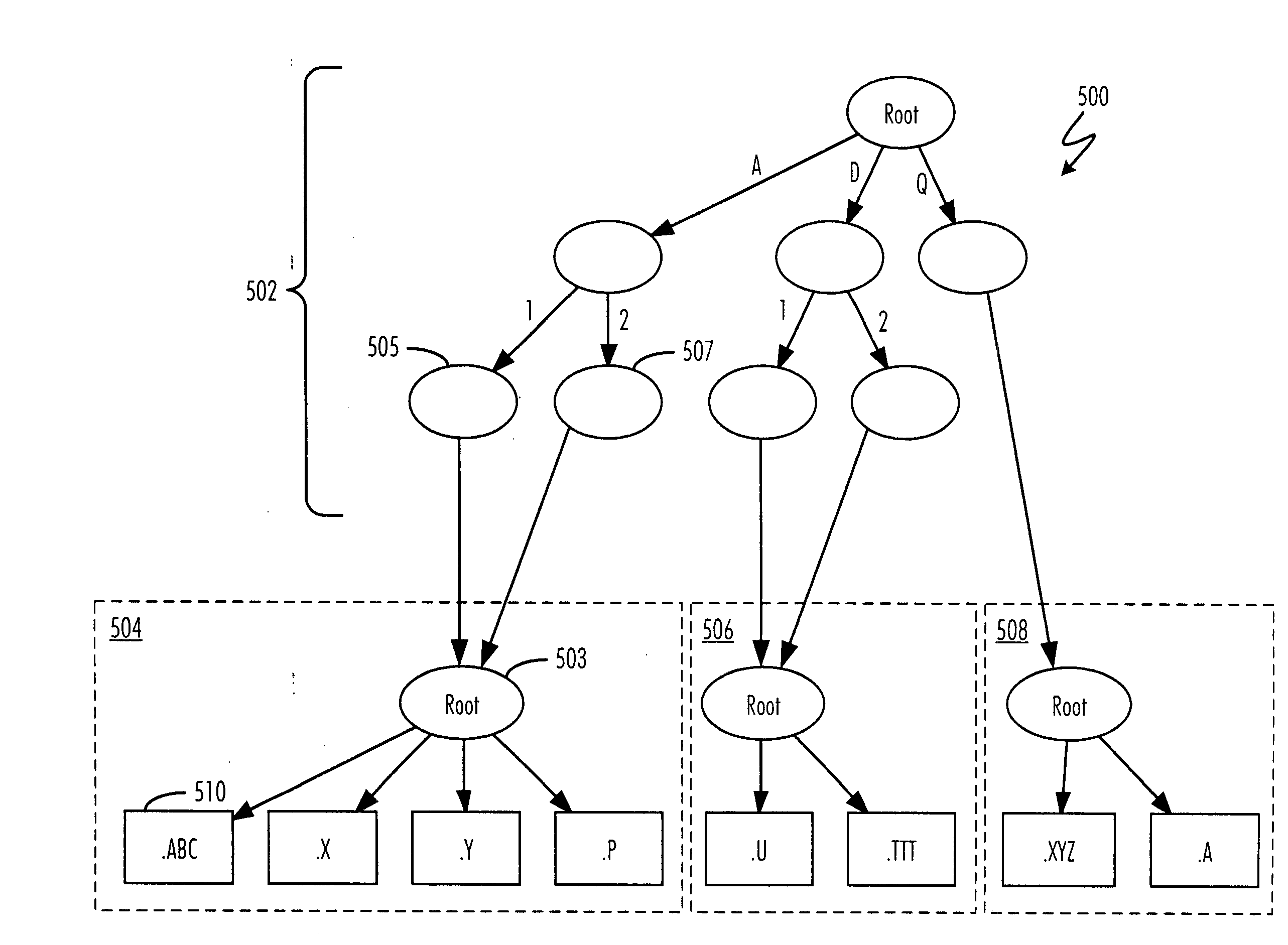

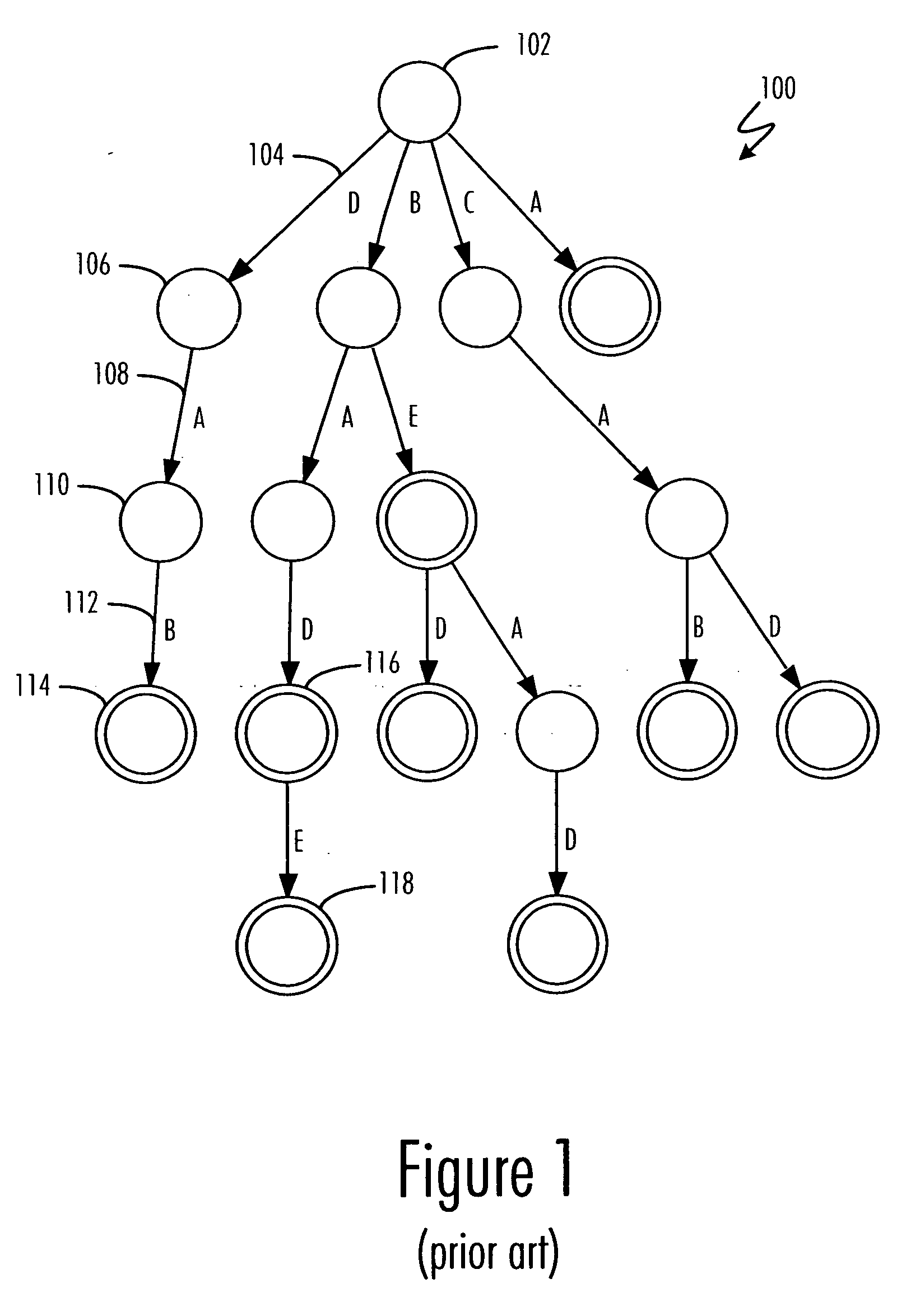

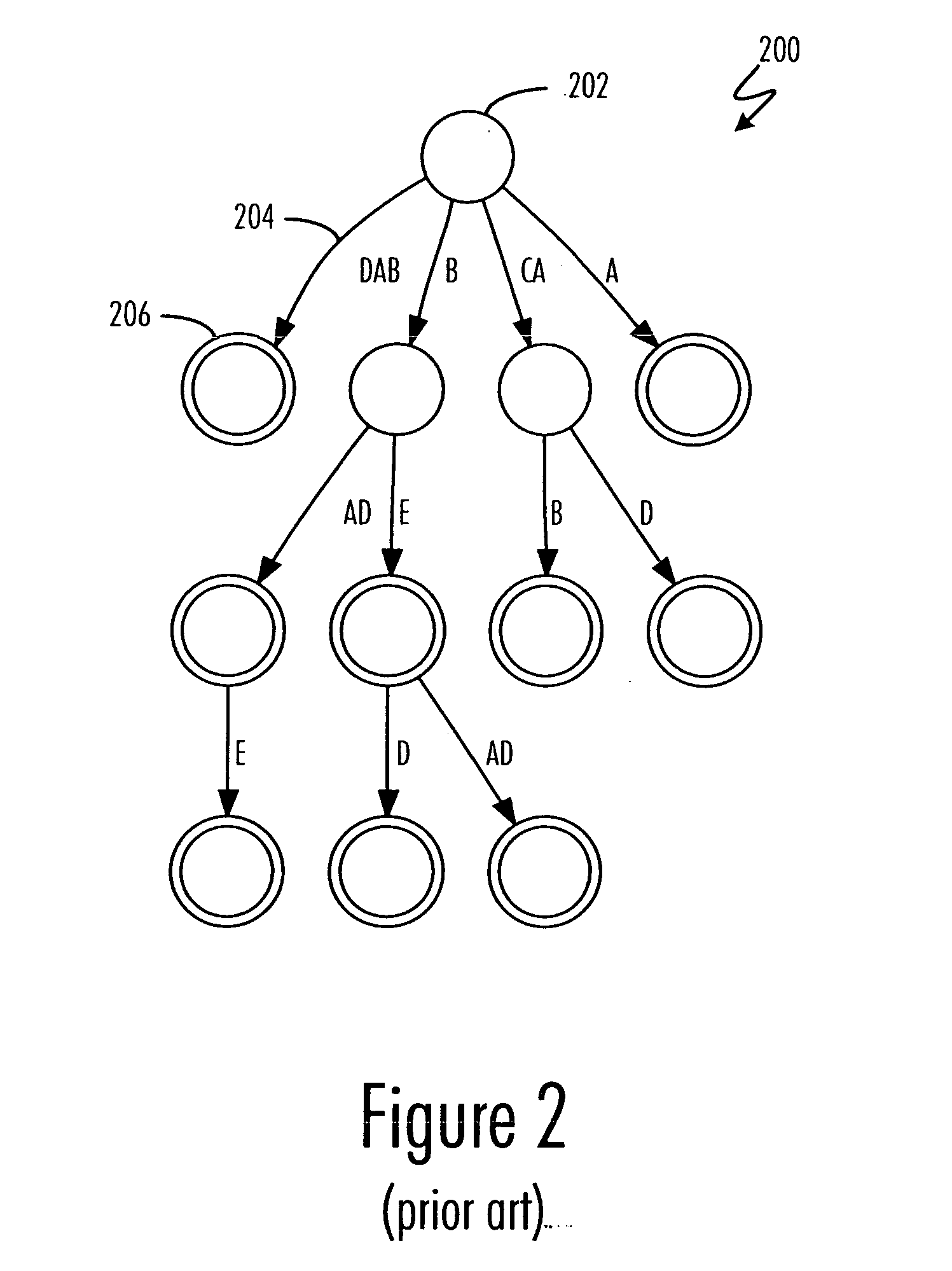

Method and apparatus for efficient storage of hierarchical signal names

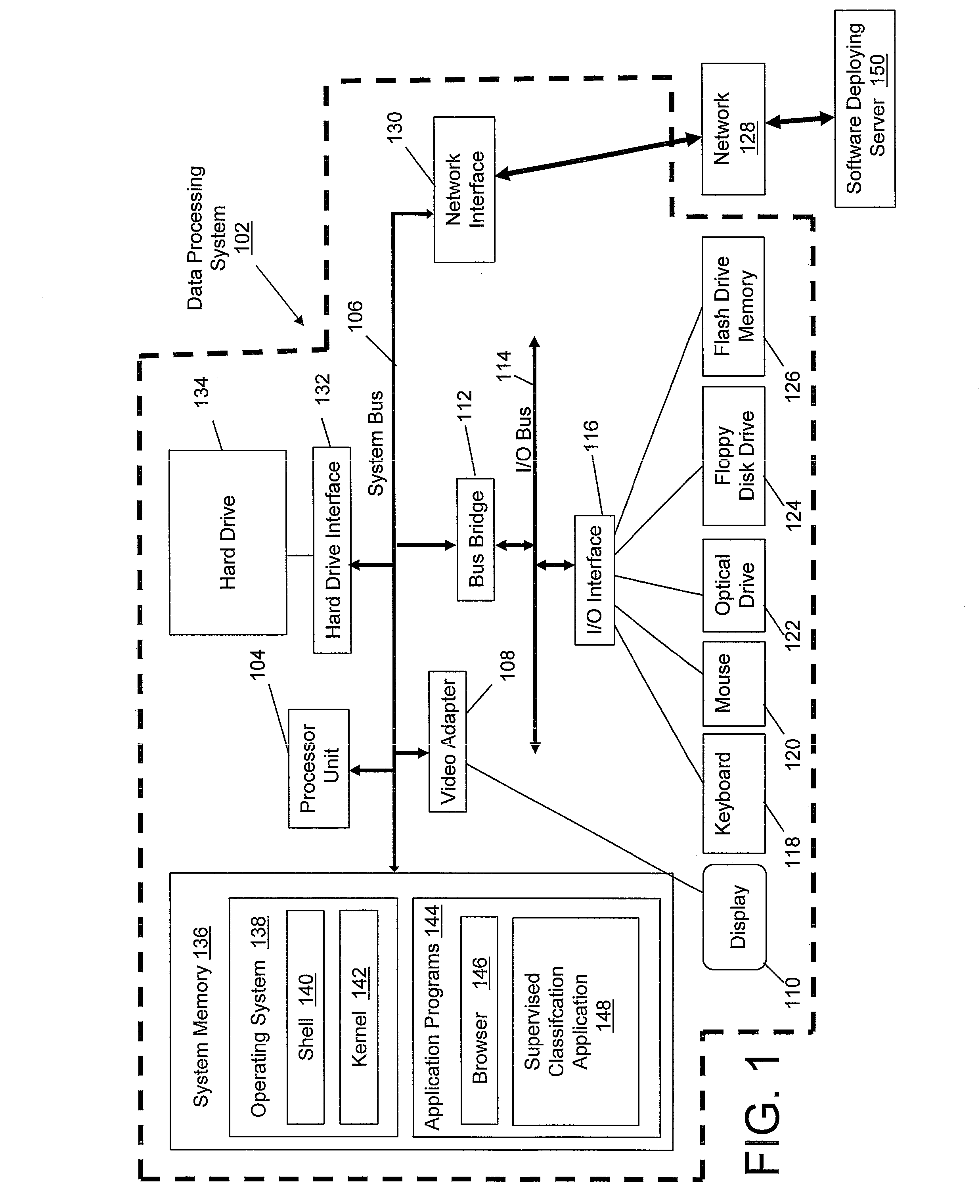

InactiveUS20070198566A1Efficient storageMinimize memory useDigital data processing detailsCAD circuit designData processing systemTheoretical computer science

A method, computer program product, and data processing system for efficiently storing a set of hierarchically-specified names in a modular hardware design are disclosed. In accordance with a preferred embodiment of the present invention, a data structure for storing the names is built from a master trie. The master trie is used to store names of instances of modules contained within the design. The node in the master trie corresponding to a particular instance name is associated with an additional trie (“class trie”) corresponding to the class of module to which that instance belongs. In this additional trie are stored the names of the individual signals associated with that class of module. Where there are multiple instances of the same class of module within a design, each instance name may be associated with a single class trie storing each of the individual signal names associated with that class of module.

Owner:IBM CORP

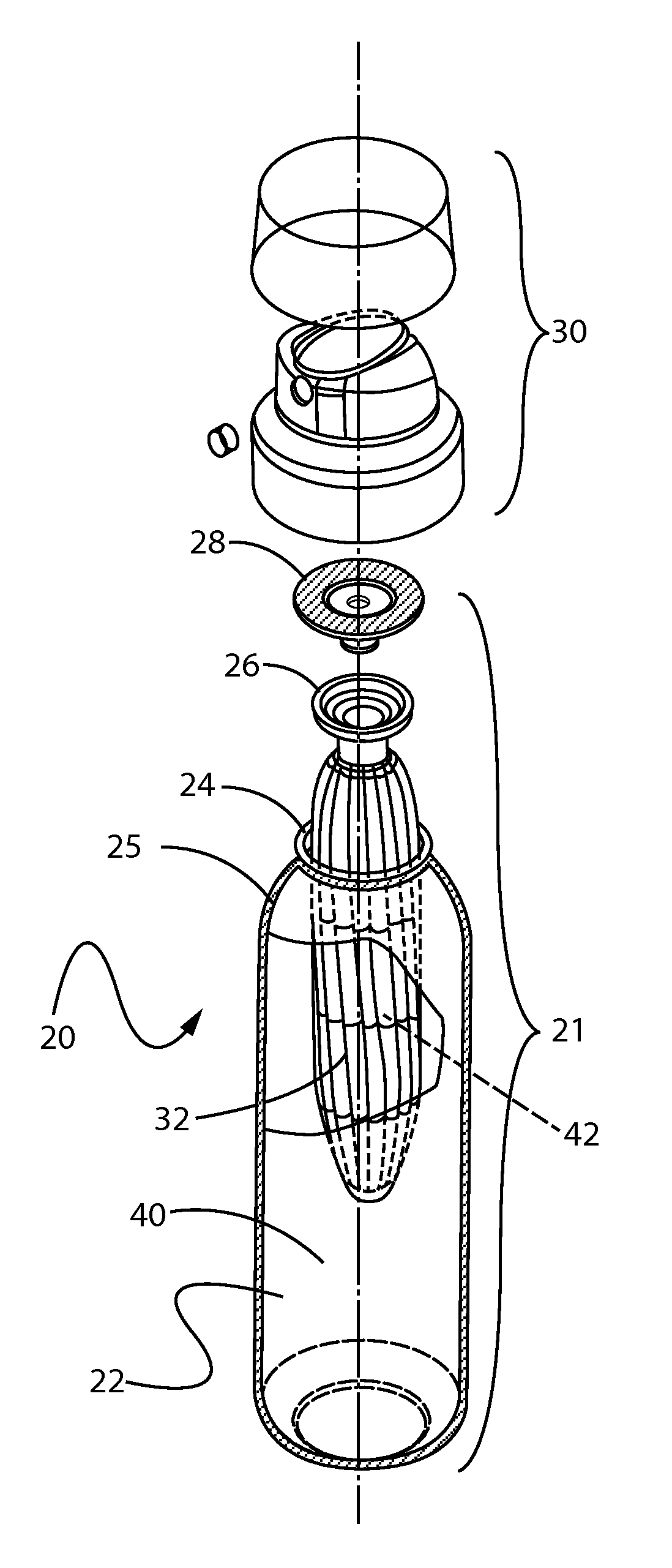

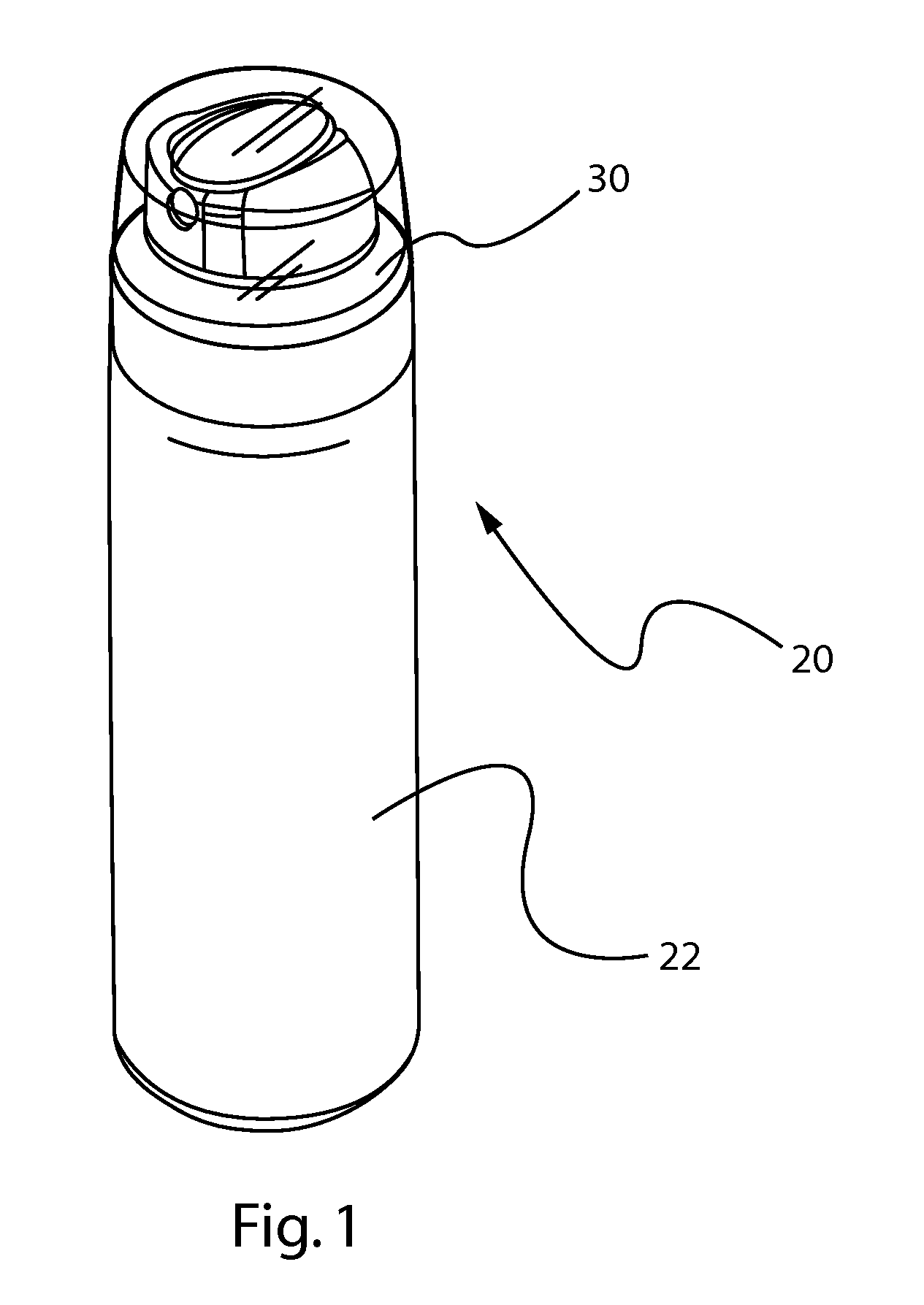

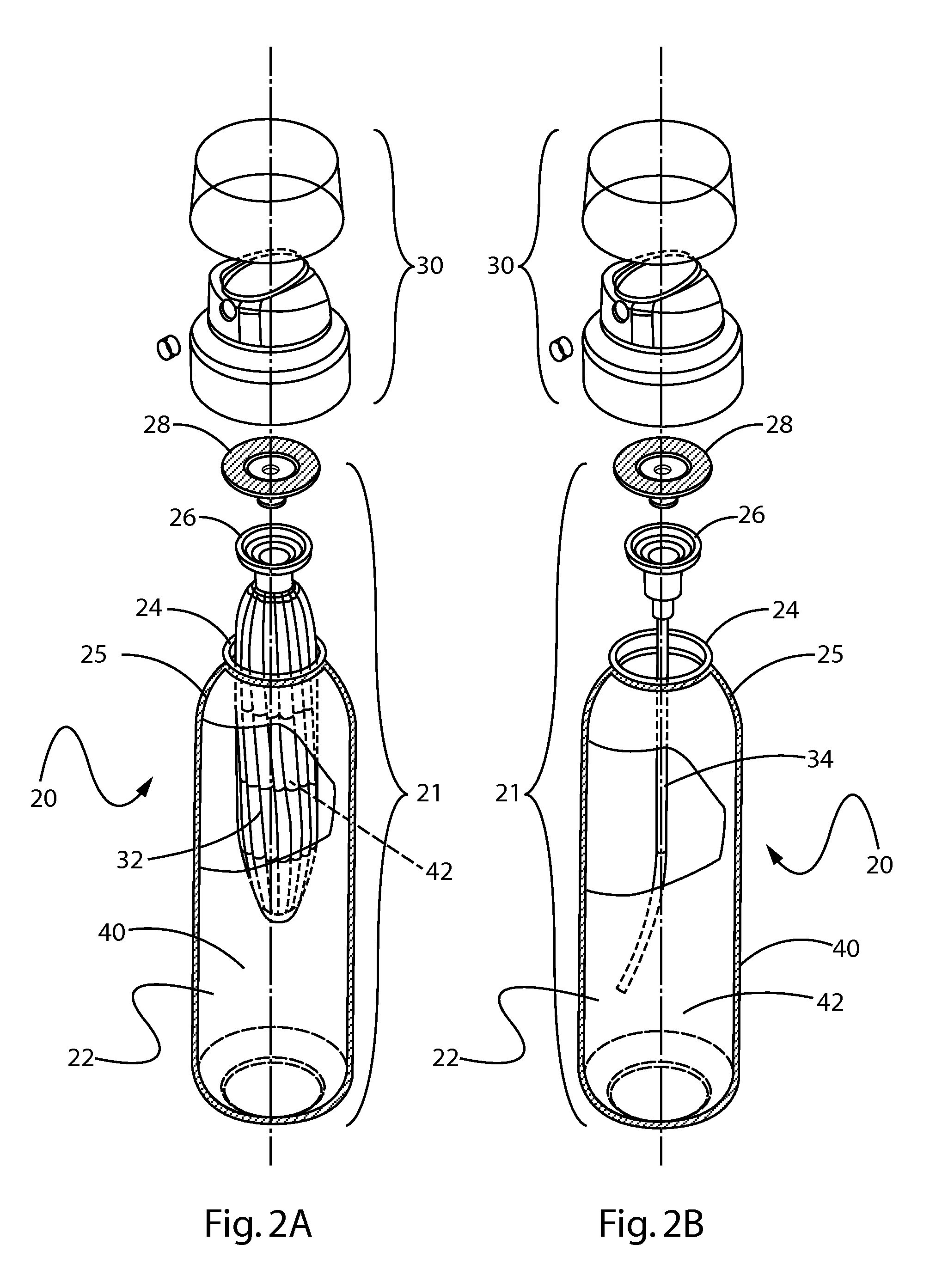

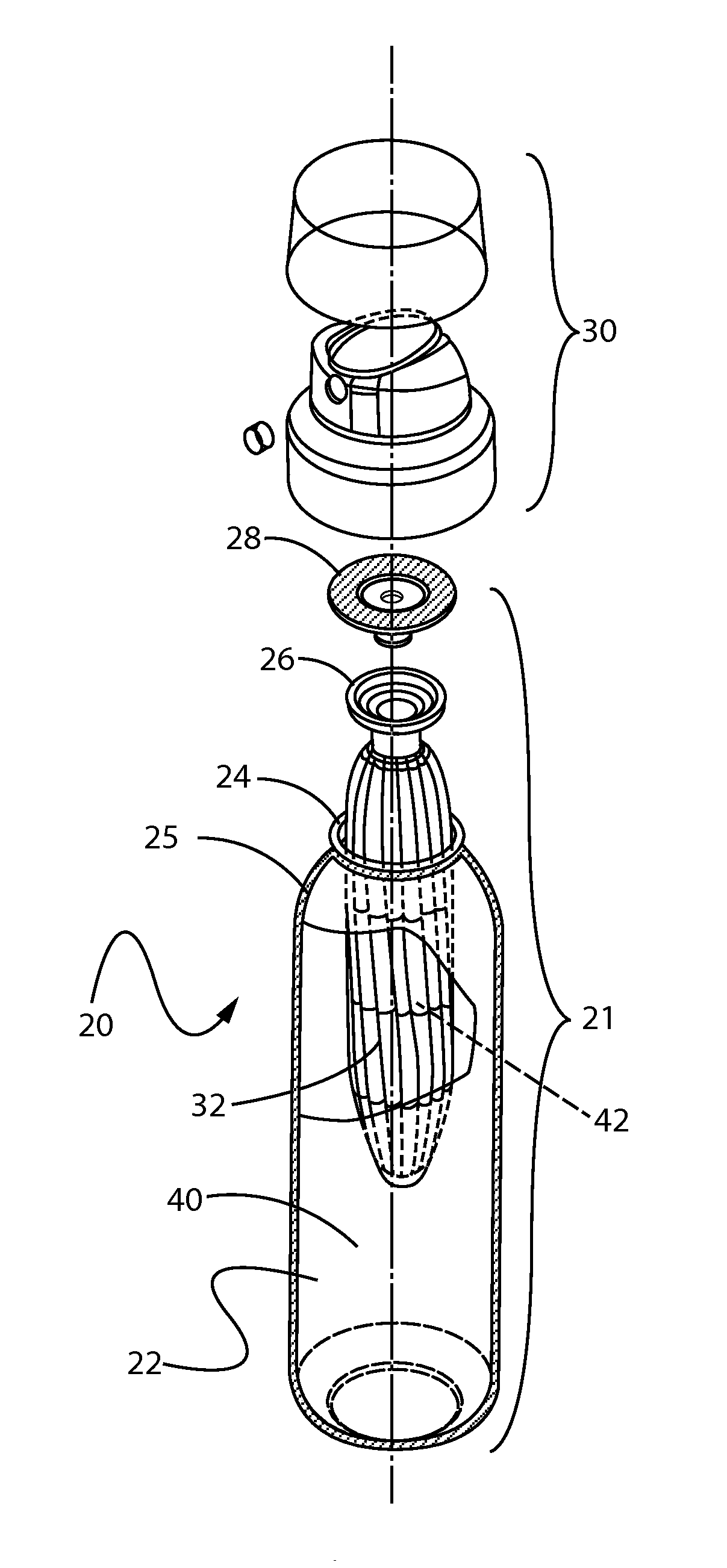

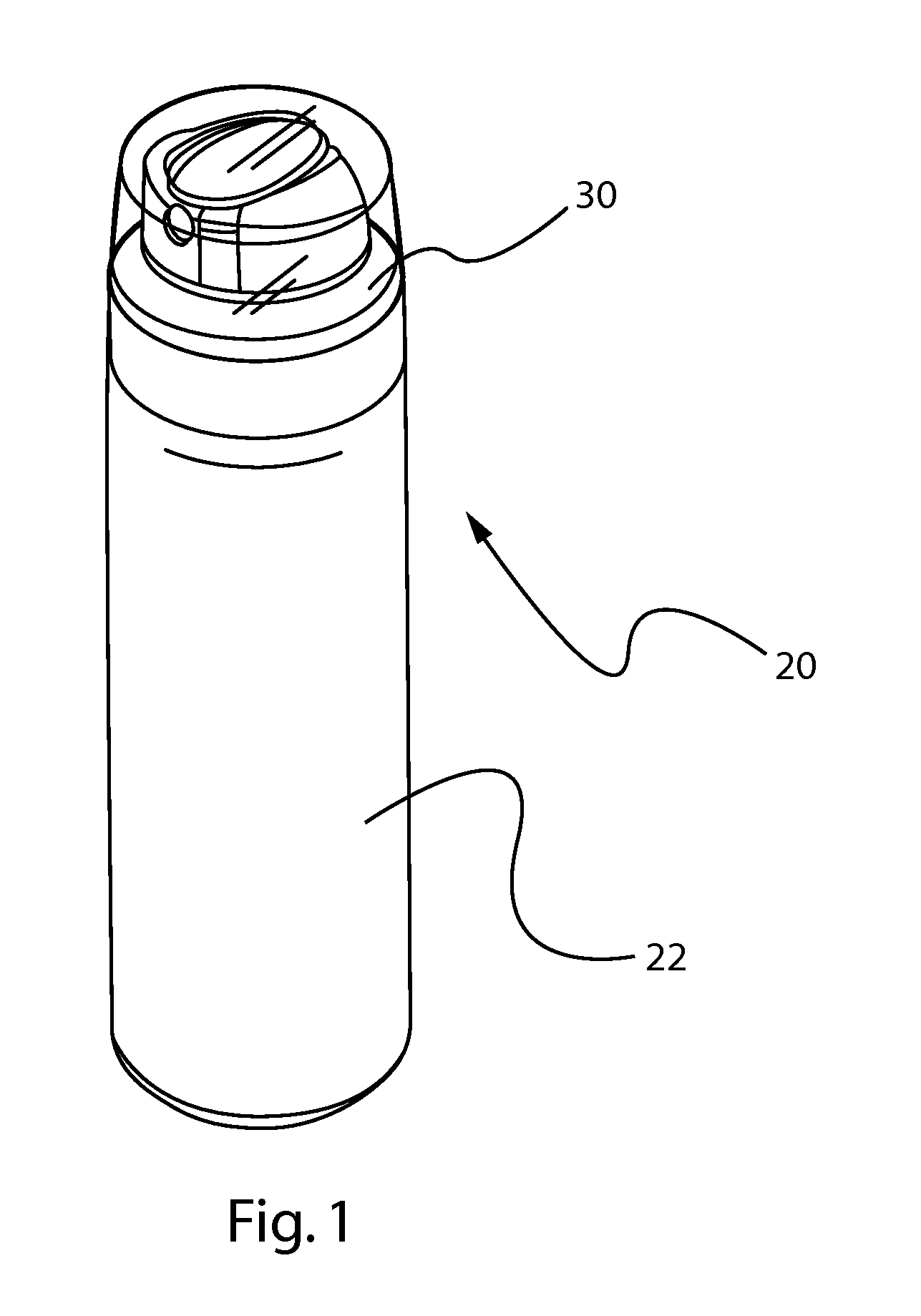

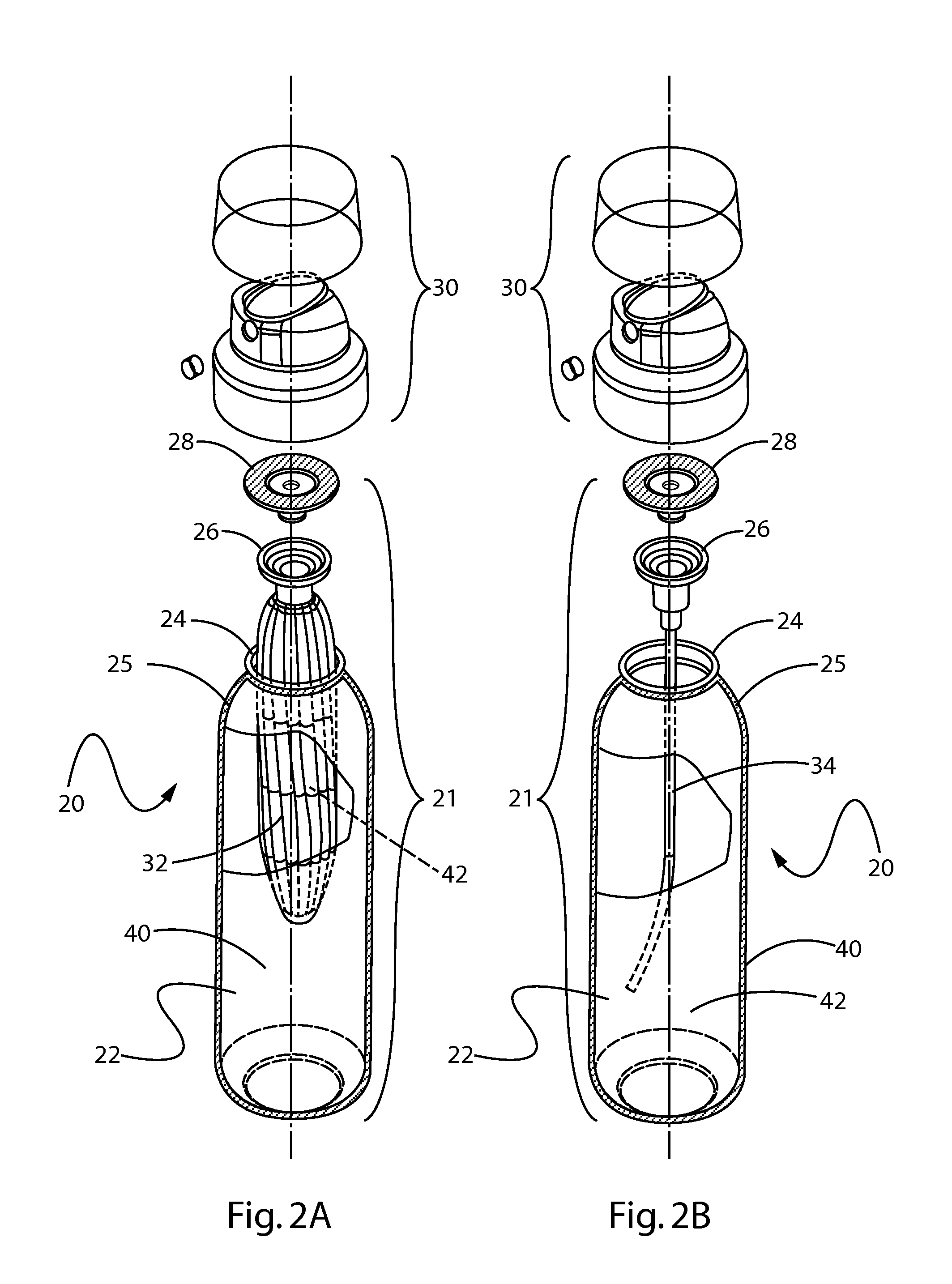

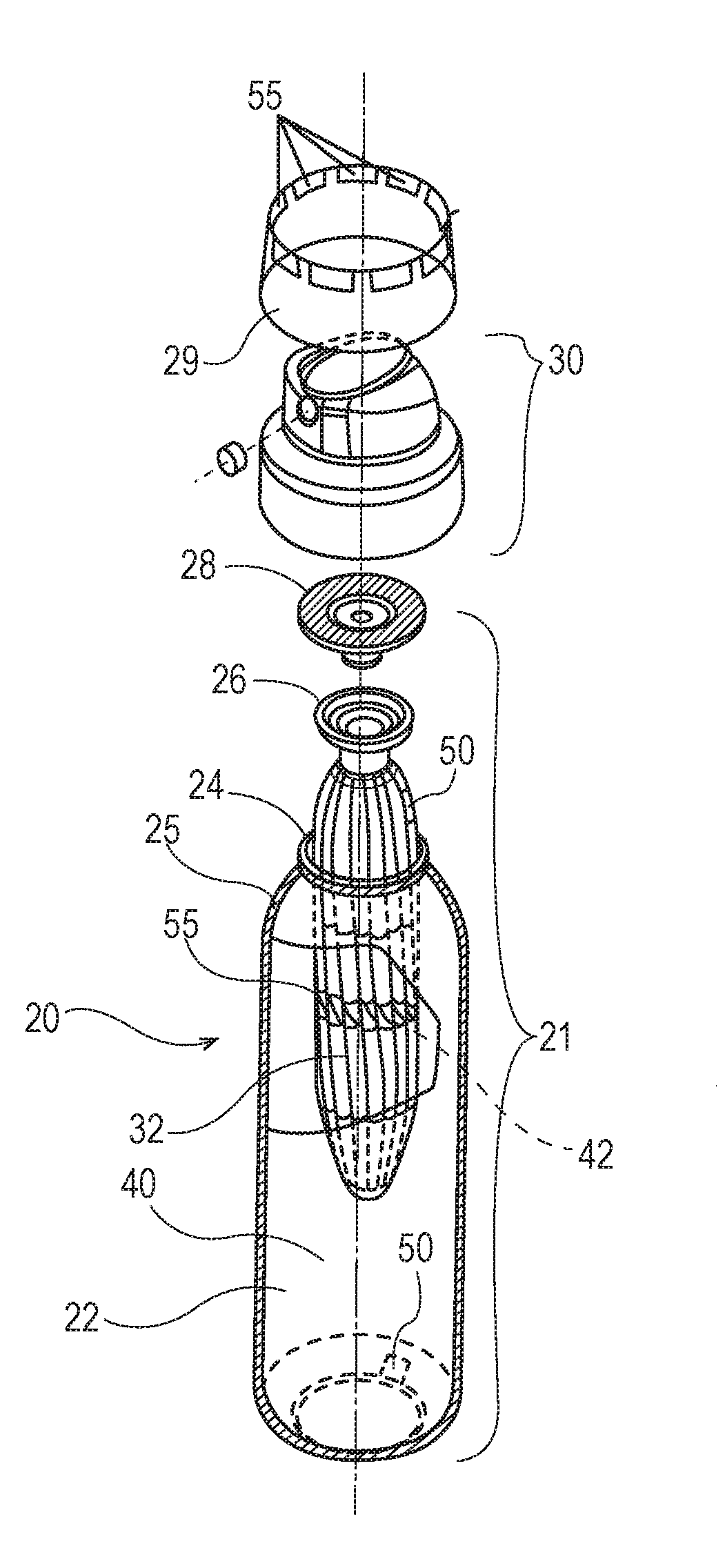

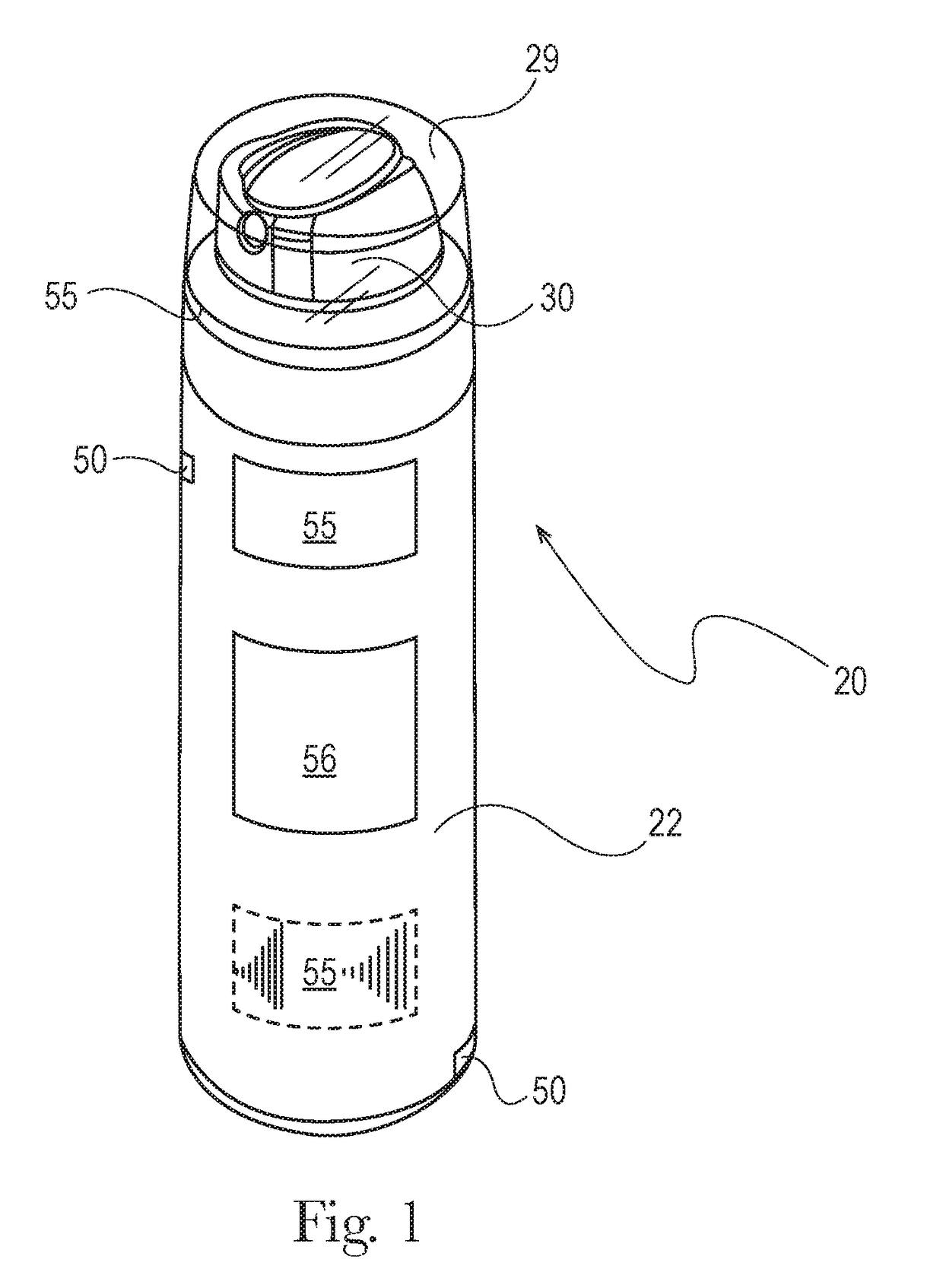

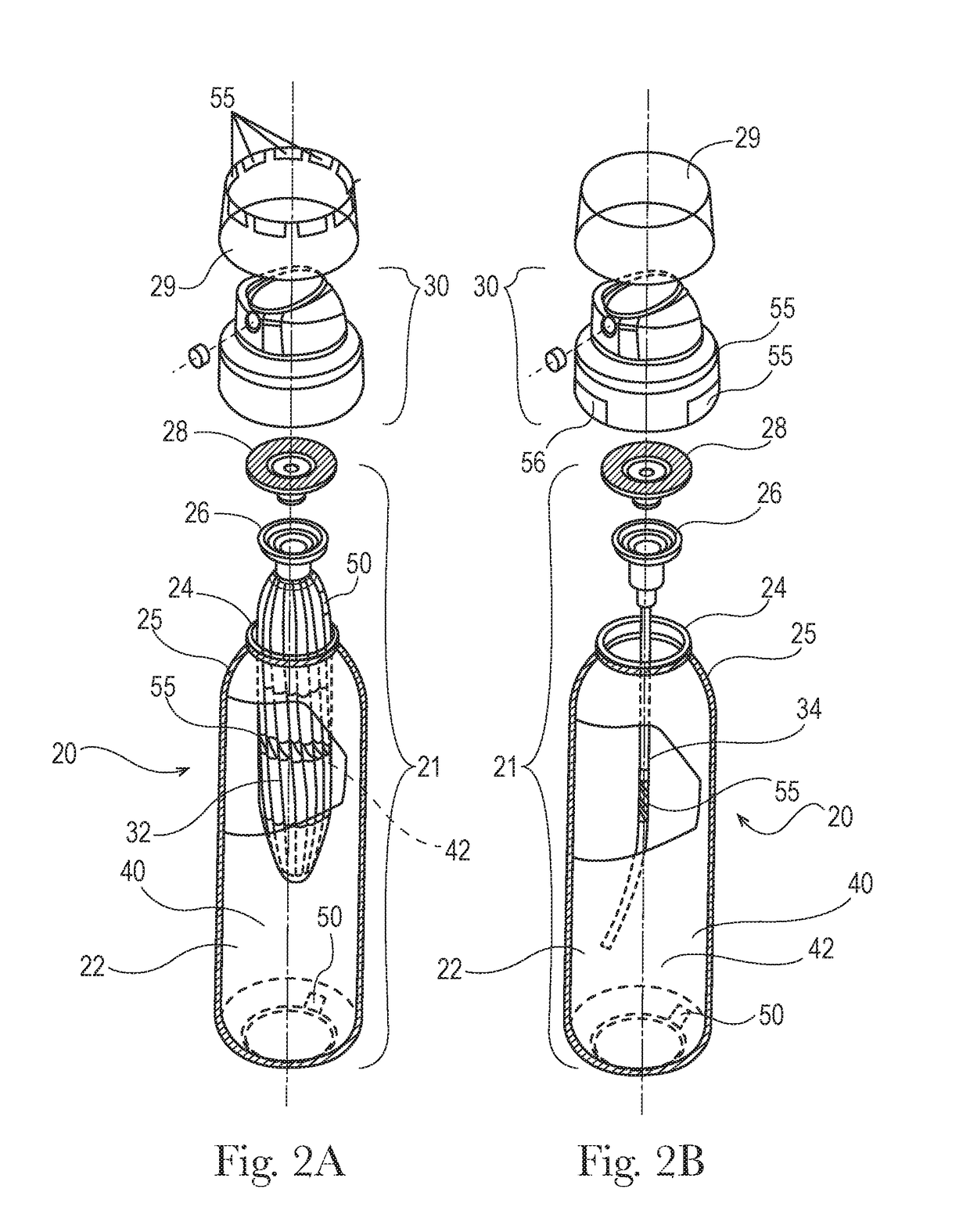

Recyclable plastic aerosol dispenser

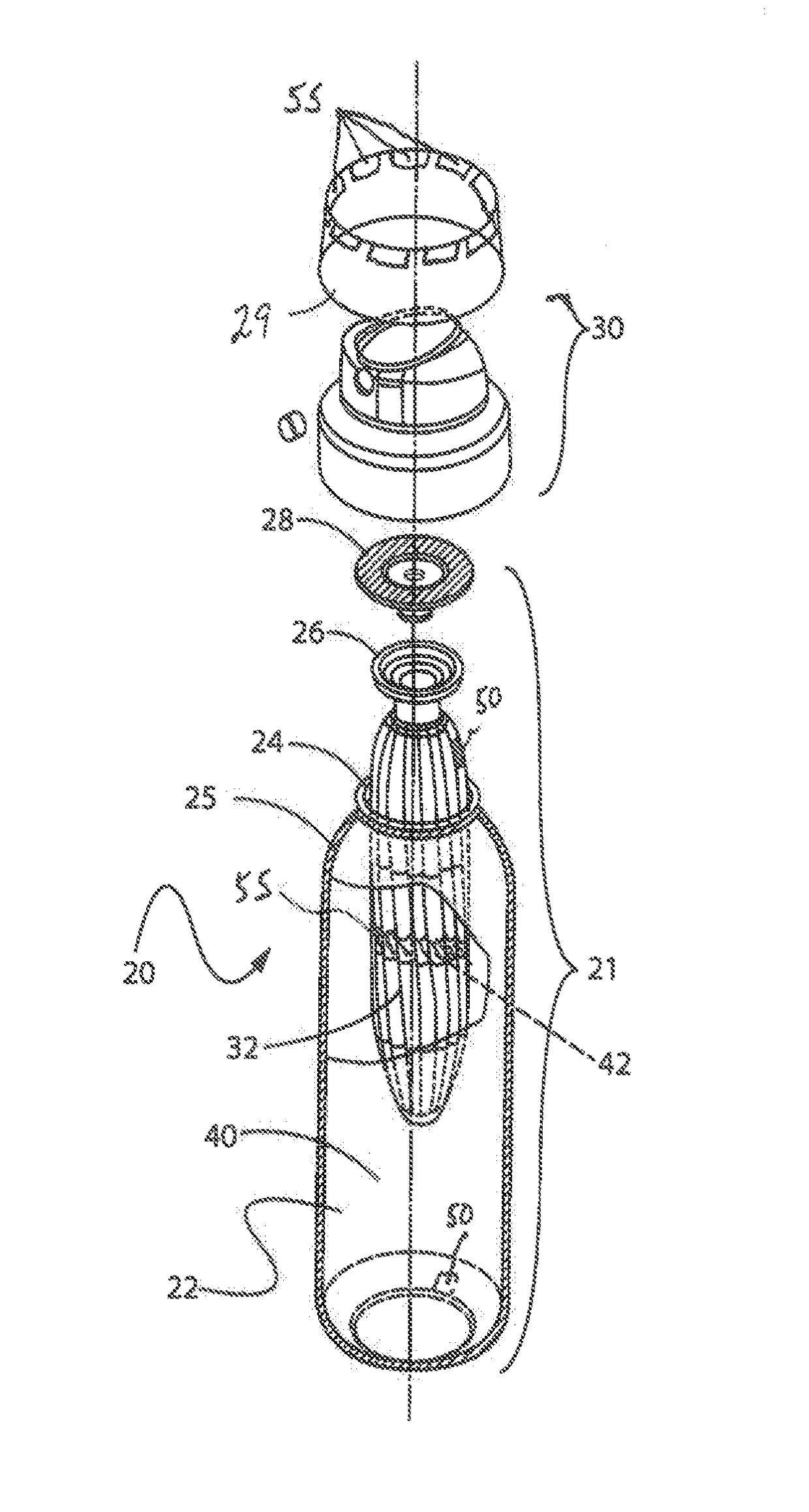

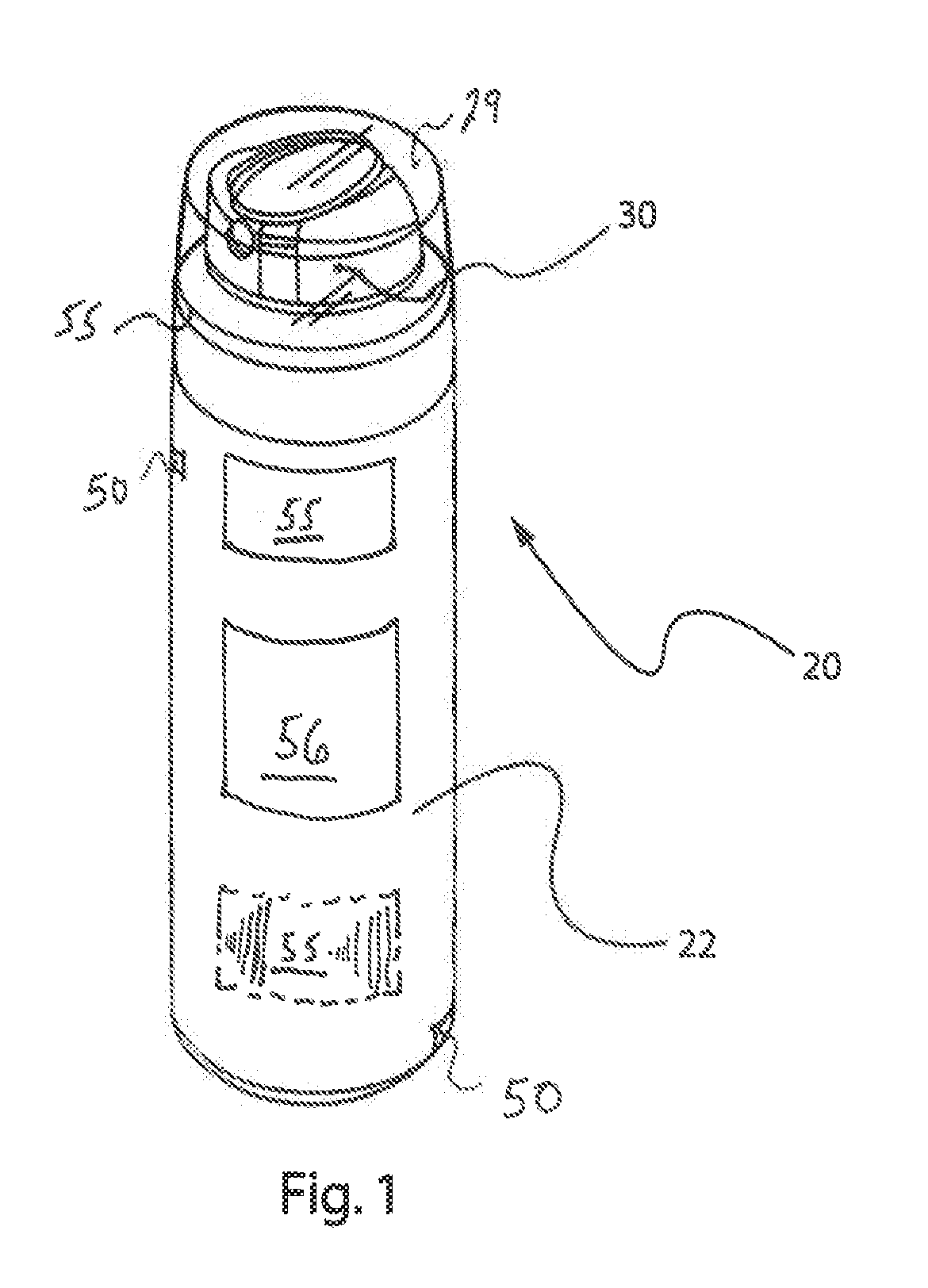

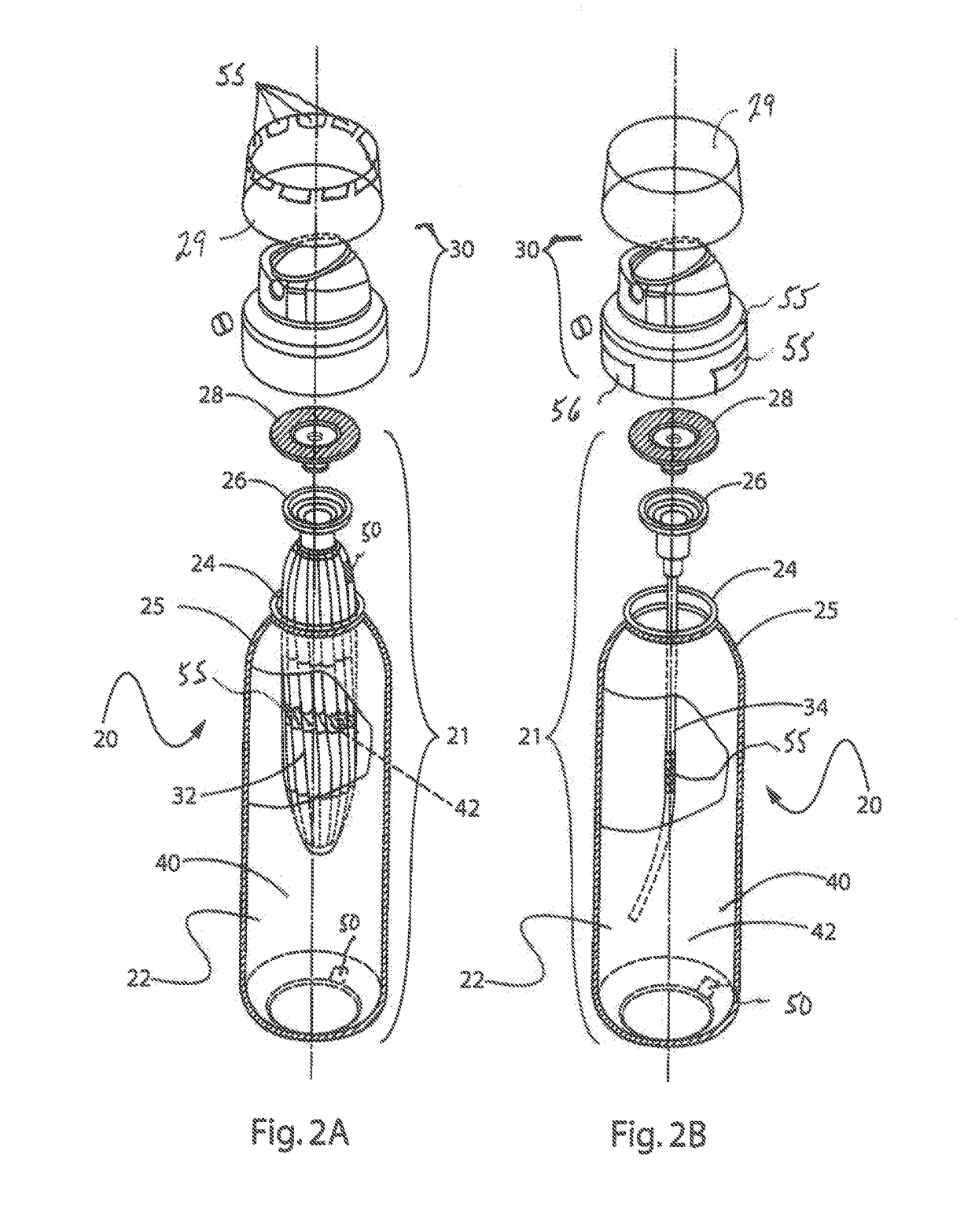

An aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials with no flammable product / propellant present.

Owner:THE PROCTER & GAMBLE COMPANY

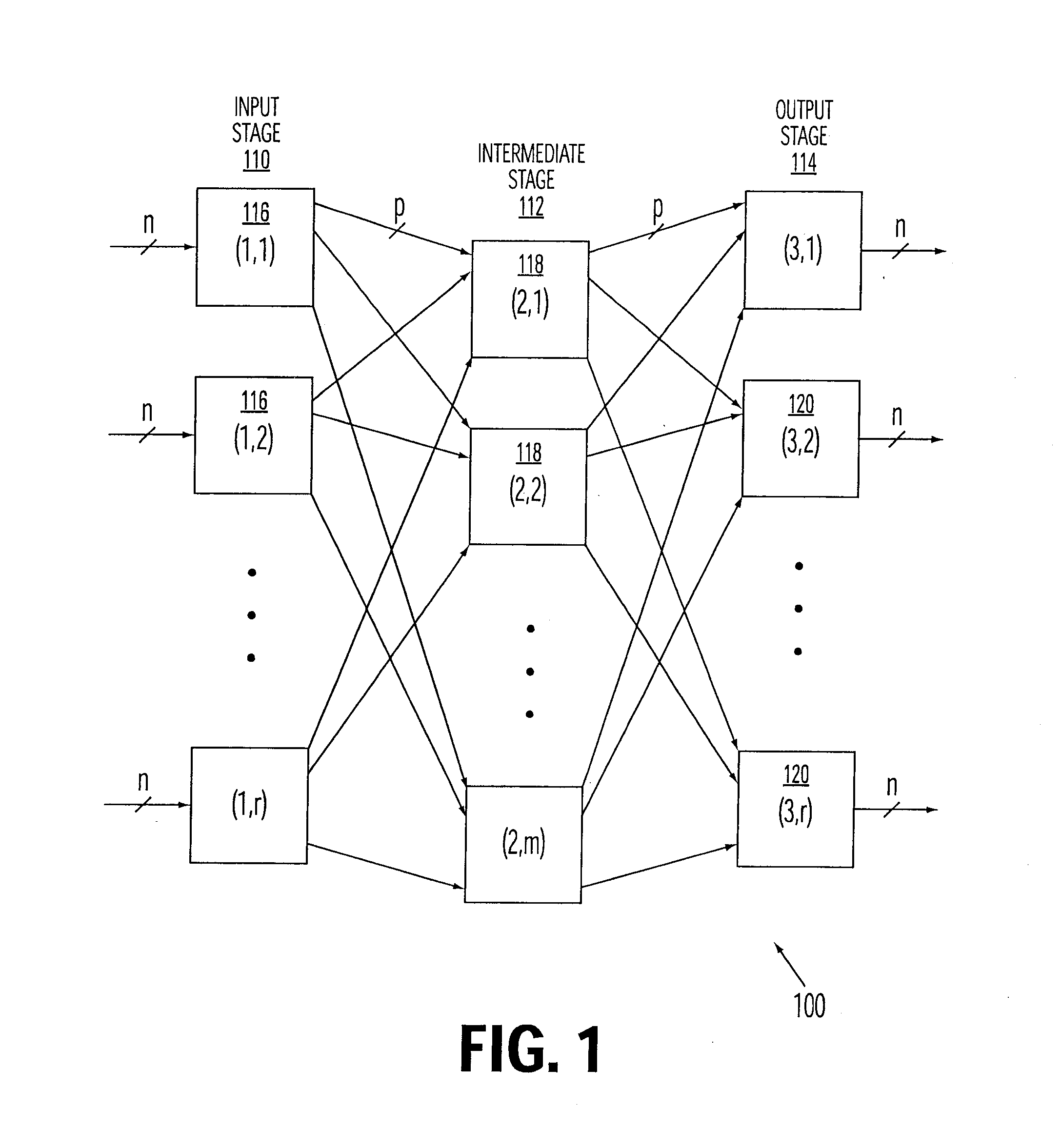

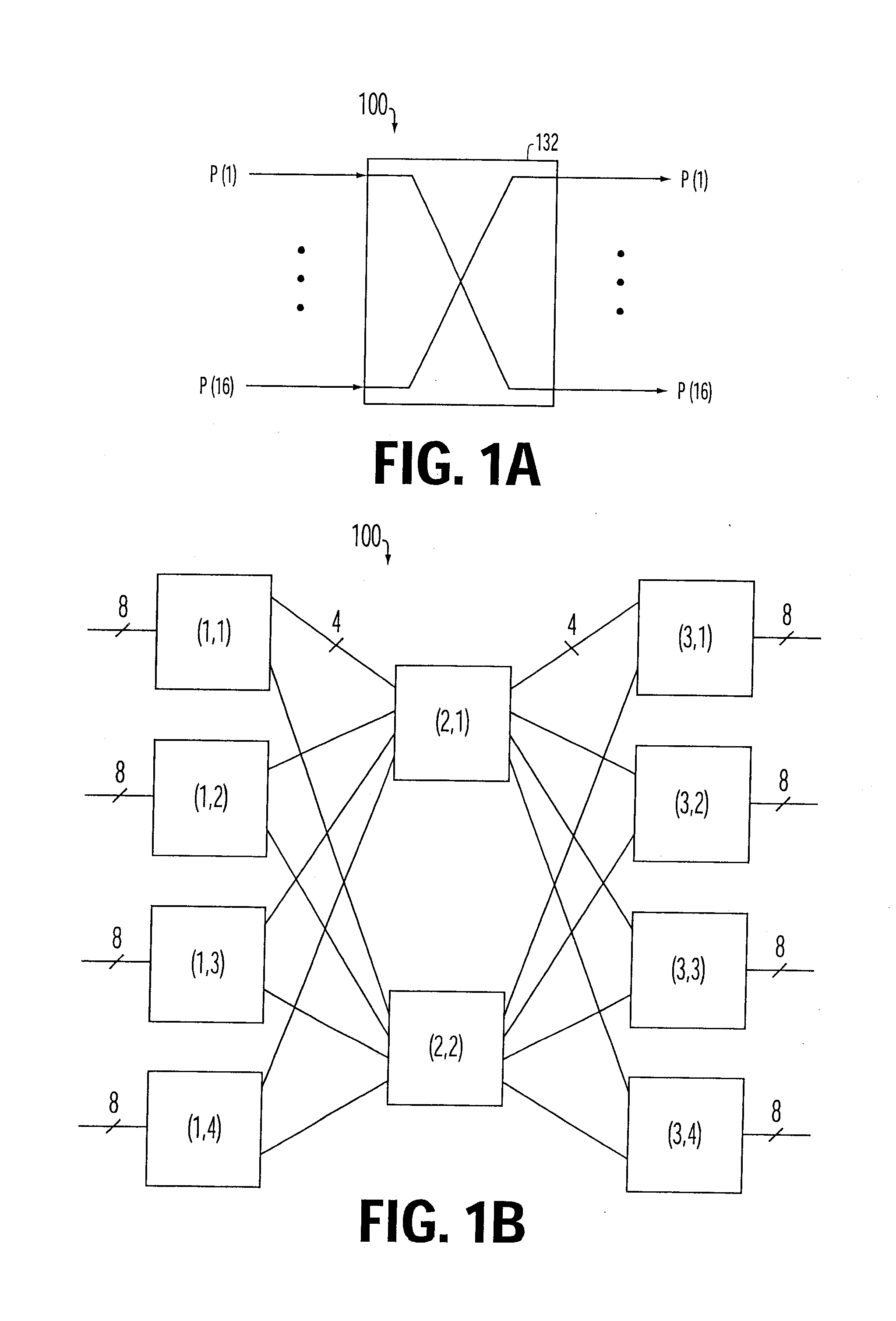

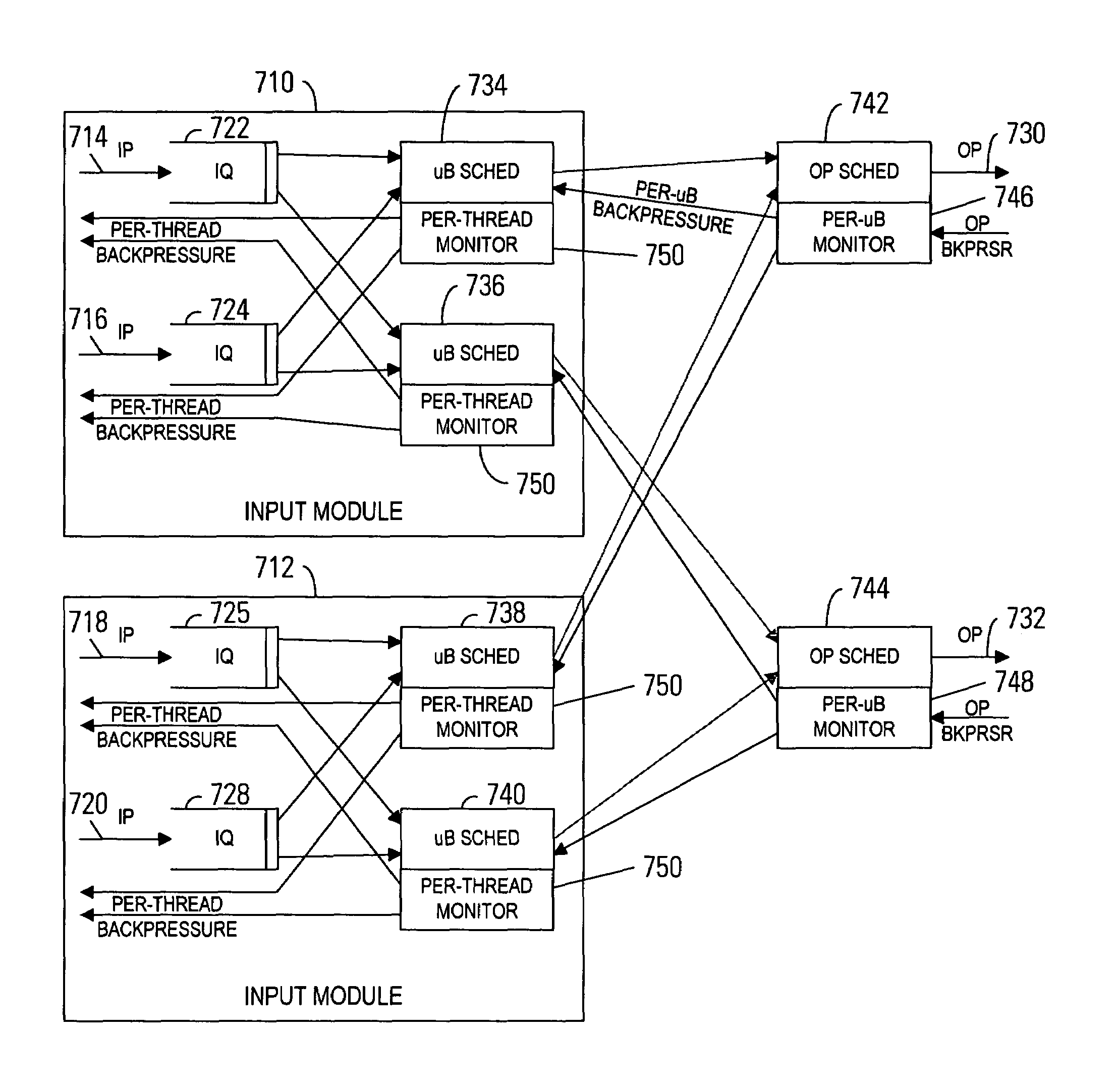

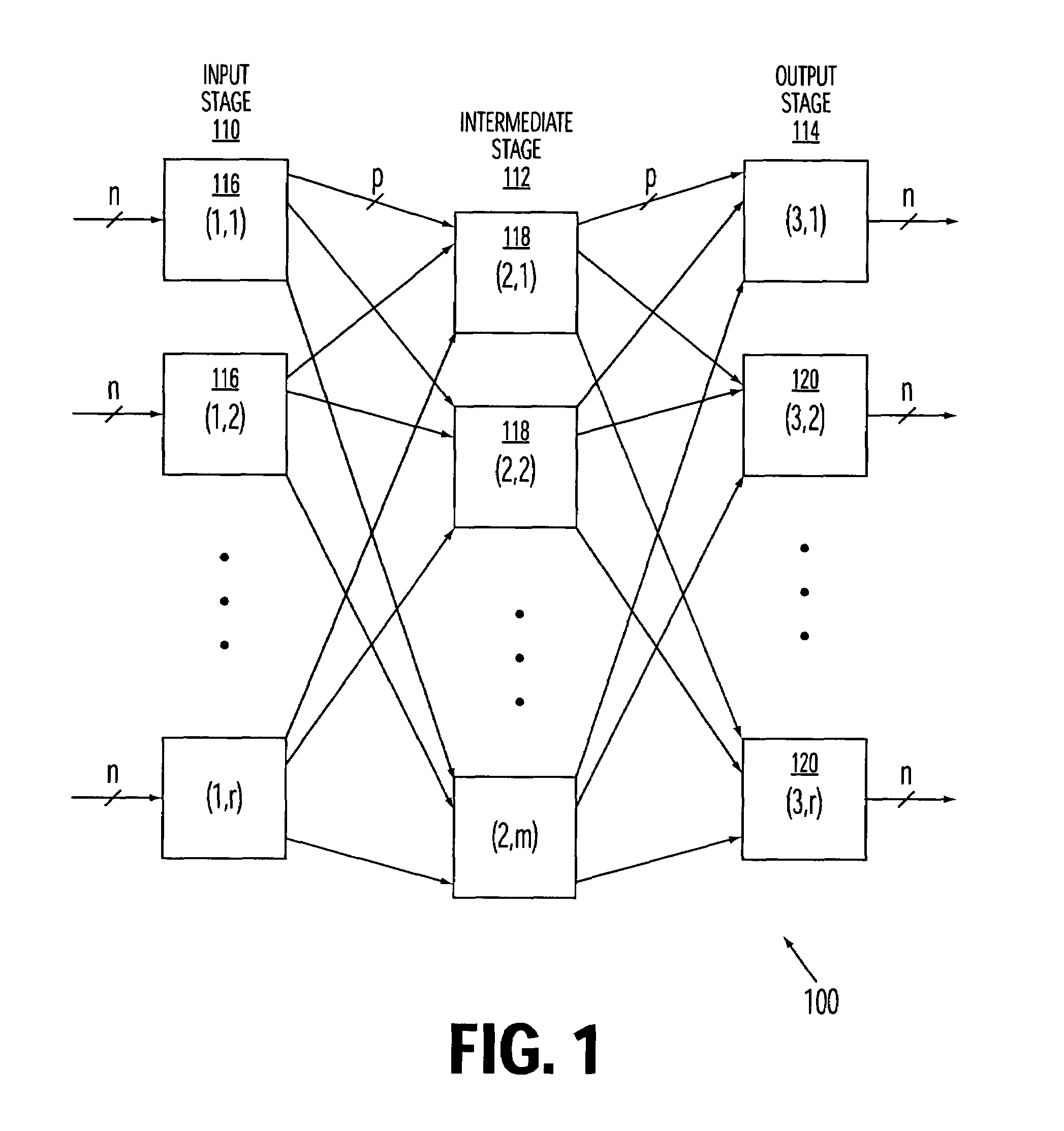

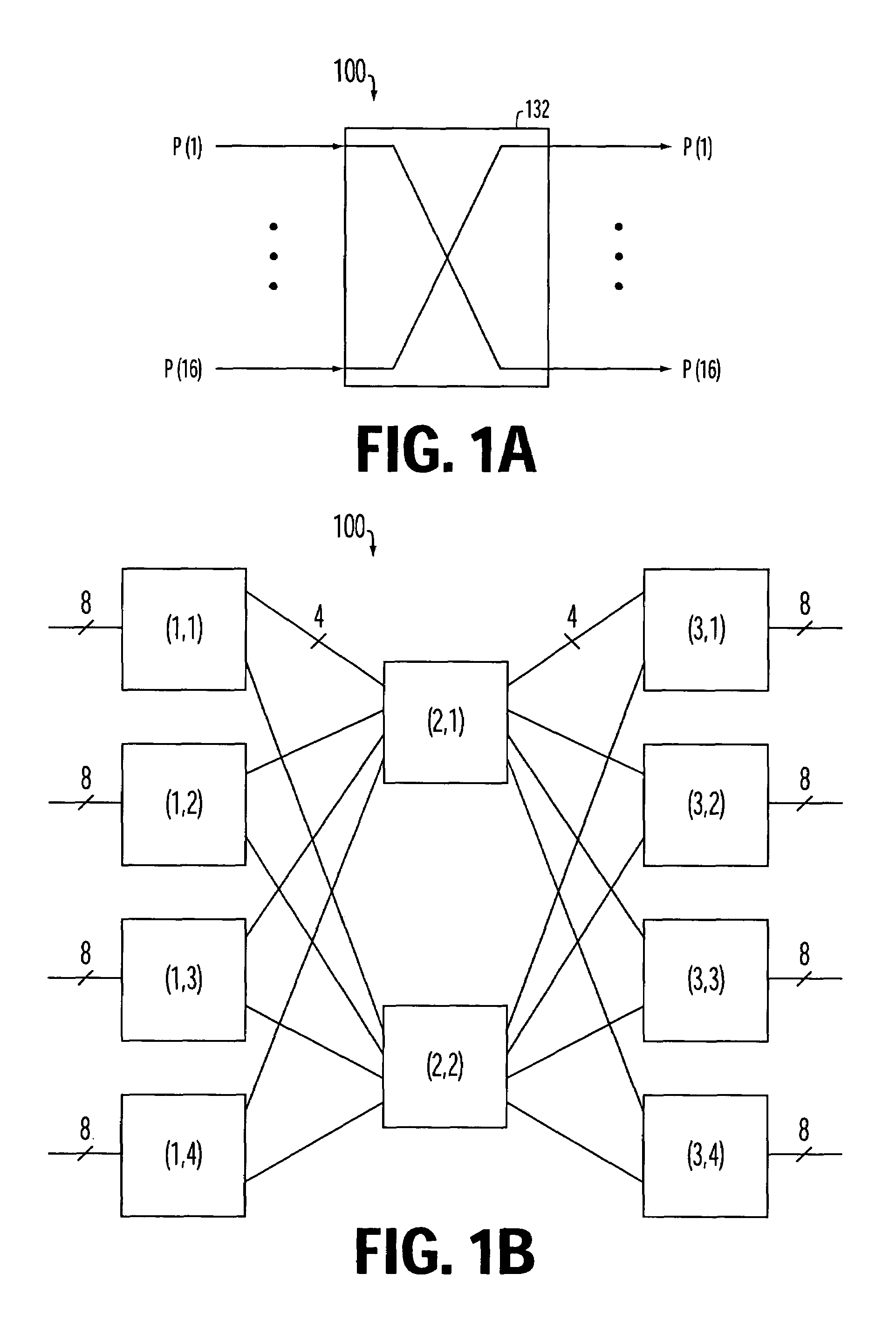

Backpressure mechanism for switching fabric

InactiveUS20080212472A1Reduce transmissionSimple processError preventionFrequency-division multiplex detailsDistributed computingPacket switching

Roughly described, a packet switching fabric contains a separate queue scheduler for each combination of an input module and a fabric output port. The schedulers may also be specific to a single class of service. Each queue scheduler schedules its packets without regard to state of other input queues and without regard to packets destined for other output ports. In an aspect, the fabric manages per-flow bandwidth utilization of output port bandwidth capacity by monitoring the same and asserting backpressure toward the queue scheduler for any thread that is exceeding its bandwidth allocation. In another aspect, a switching fabric uses leaky buckets to apply backpressure in response to overutilization of downstream port capacity by particular subflows. In another aspect, a switching fabric includes a cascaded backpressure scheme.

Owner:INTEL CORP

Backpressure mechanism for switching fabric

InactiveUS7426185B1Reduce transmissionSimple processError preventionFrequency-division multiplex detailsDistributed computingPacket switching

Owner:INTEL CORP

Recyclable plastic aerosol dispenser

An aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials with no flammable product / propellant present.

Owner:THE PROCTER & GAMBLE COMPANY

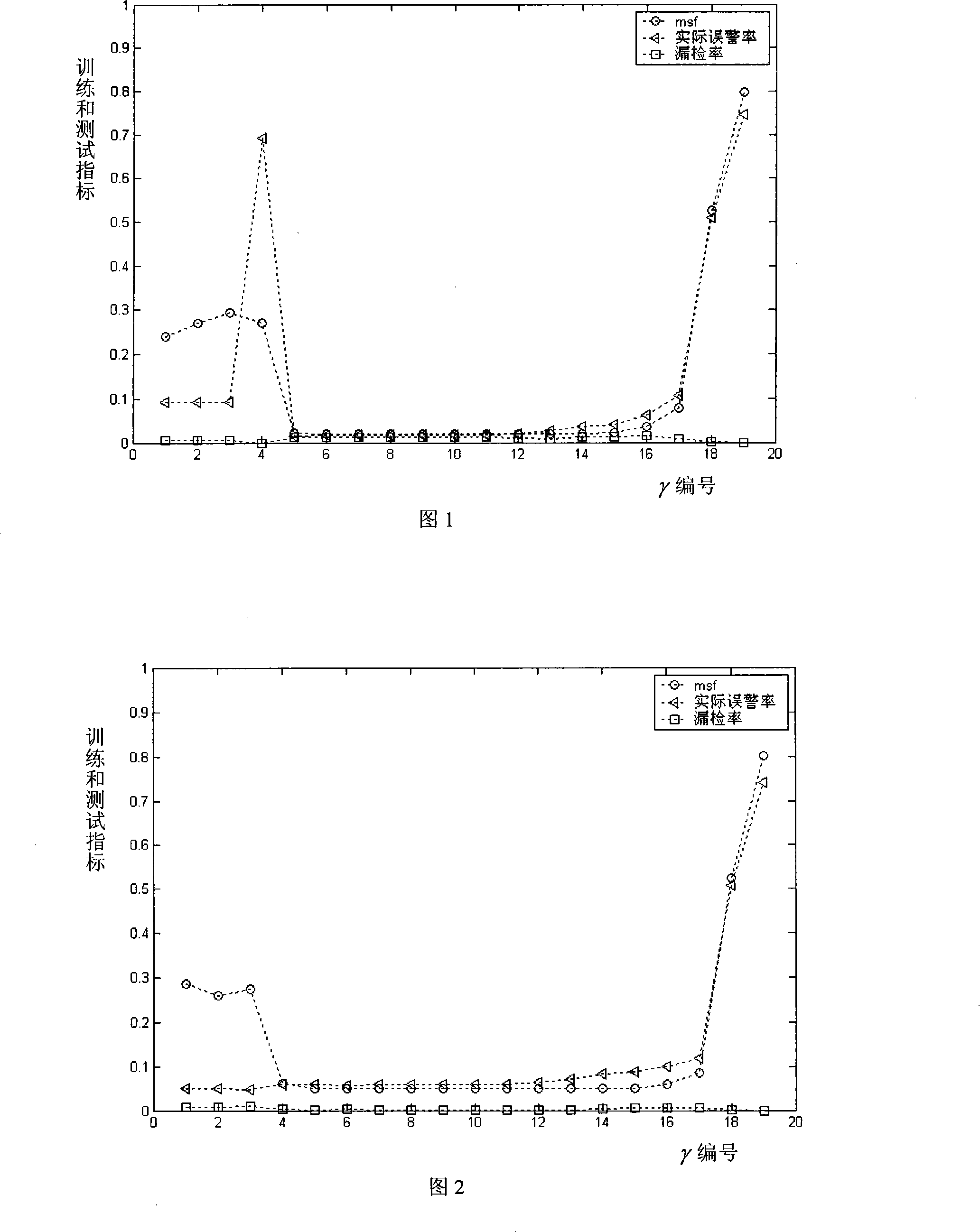

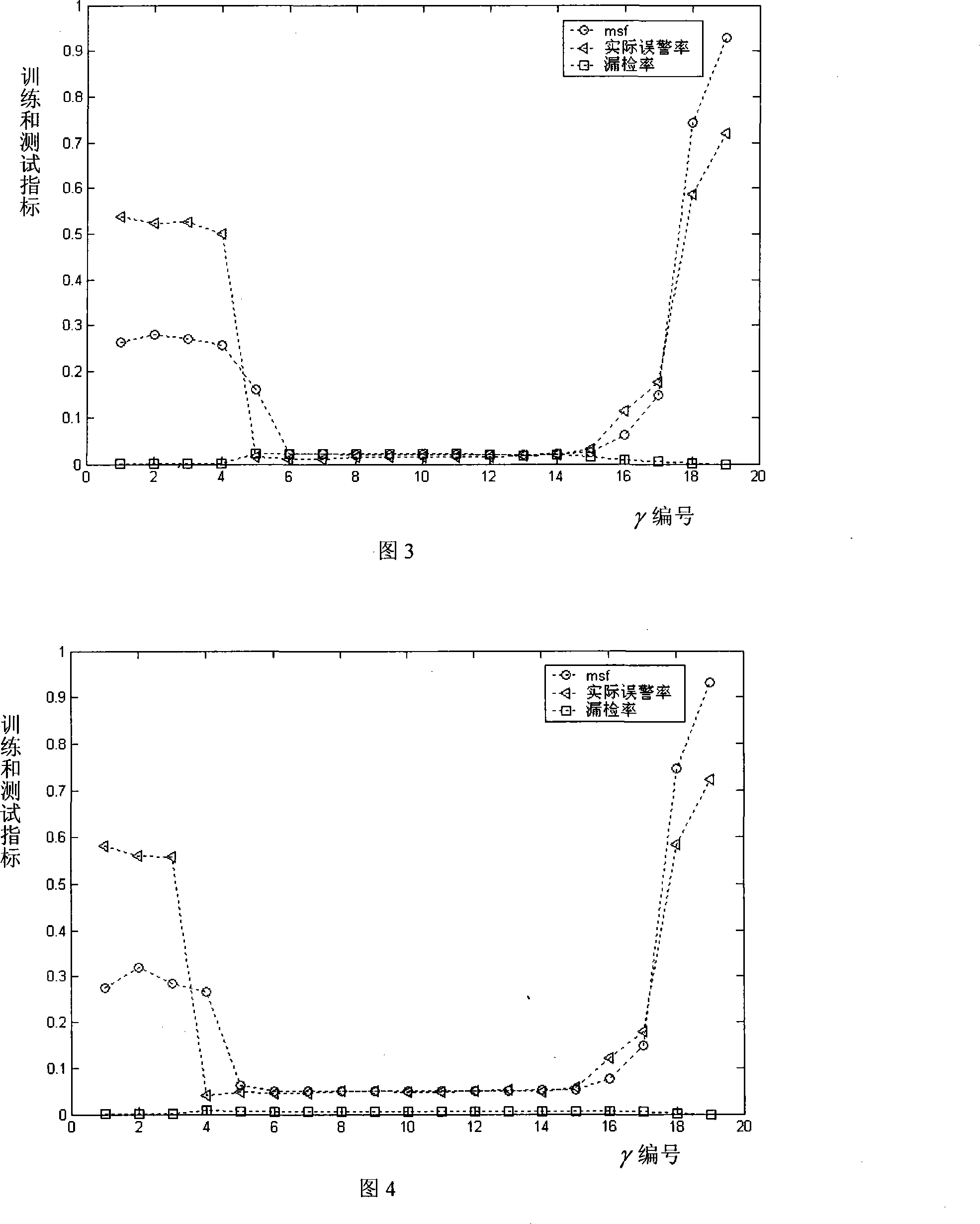

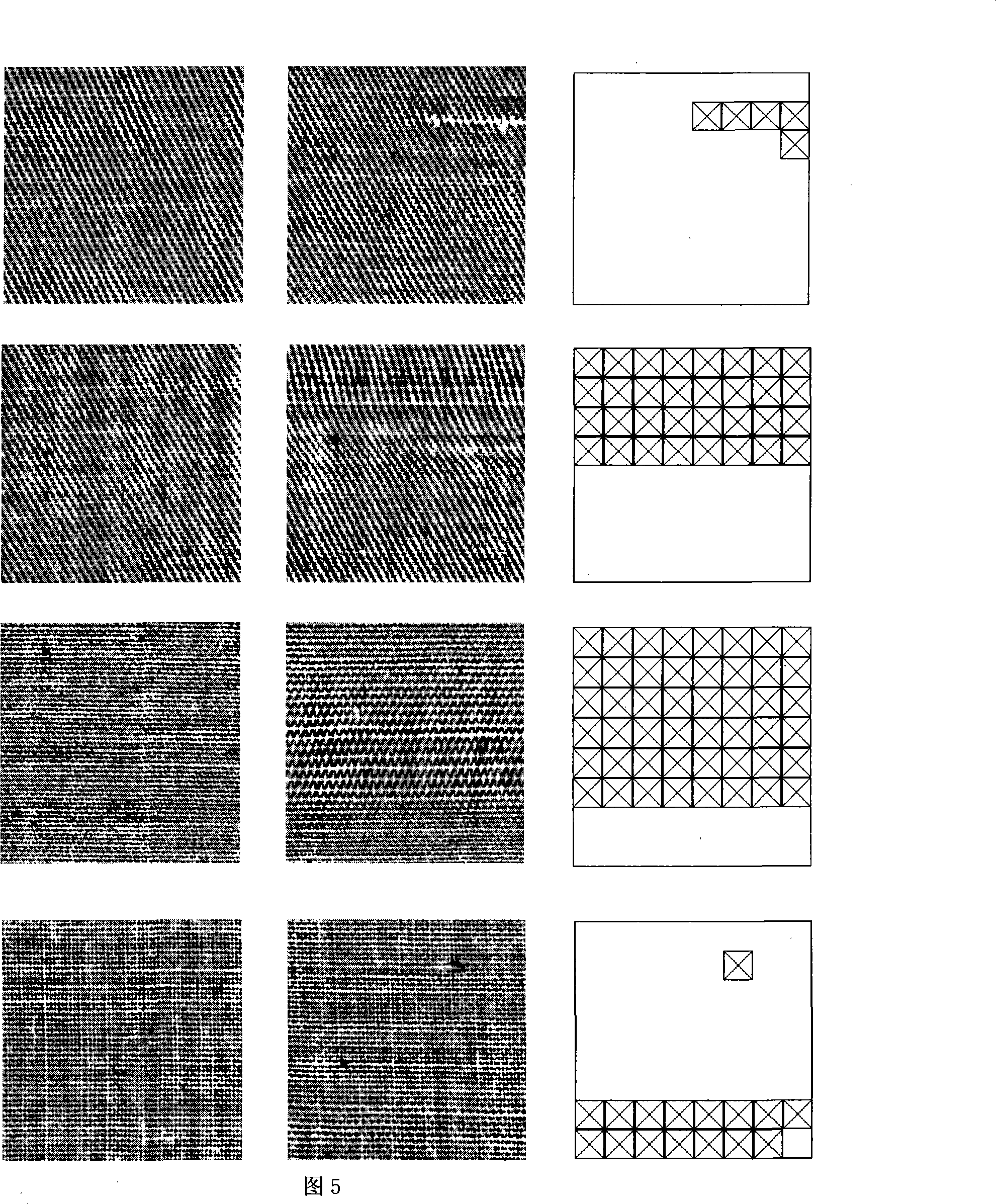

Fabric flaw automatic detection method based on Support Vector data description theory

InactiveCN101216436AControl false alarm rateReduce false alarm rateOptically investigating flaws/contaminationOne-class classificationData description

The invention belongs to the field of automatic detection and control of textile quality and particularly relates to a method for automatically detecting defects of textiles based on support vector data description theory. The automatic textile defect detection based on computer vision is a more difficult one-class classification task in real world. In the invention, support vector data description (SVDD) of the advanced one-class classification method is applied in the textile defect detection field for the first time to obviate the problems present in textile defect detection of conventional two-class classification support vector machine, which is difficult to collect representative defect samples completely and at larger number and further fails to effectively train the detector. Additionally, the invention provides a robust new method for solving the optimization problem of parameters, in particular to scale parameter of gauss kernel function, related in SVDD training. The automatic textile defect detection system based on SVDD can prospectively and conveniently control false alarm rate (false detection rate) in practice and can obtain lower miss ratio at lower false alarm rate.

Owner:DONGHUA UNIV

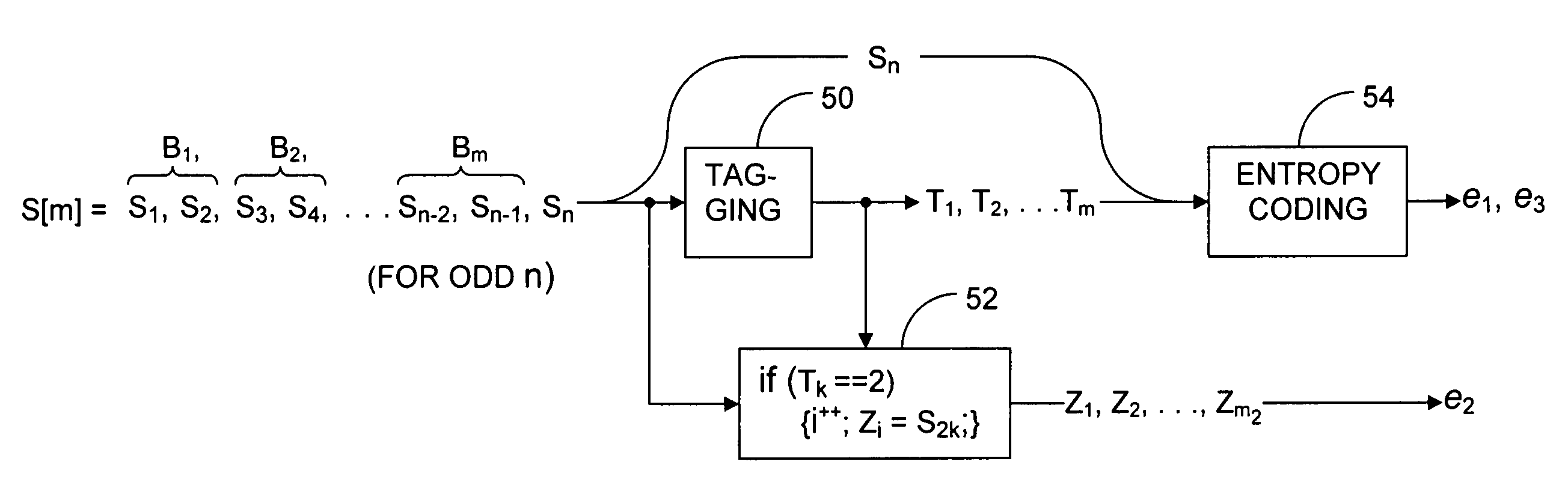

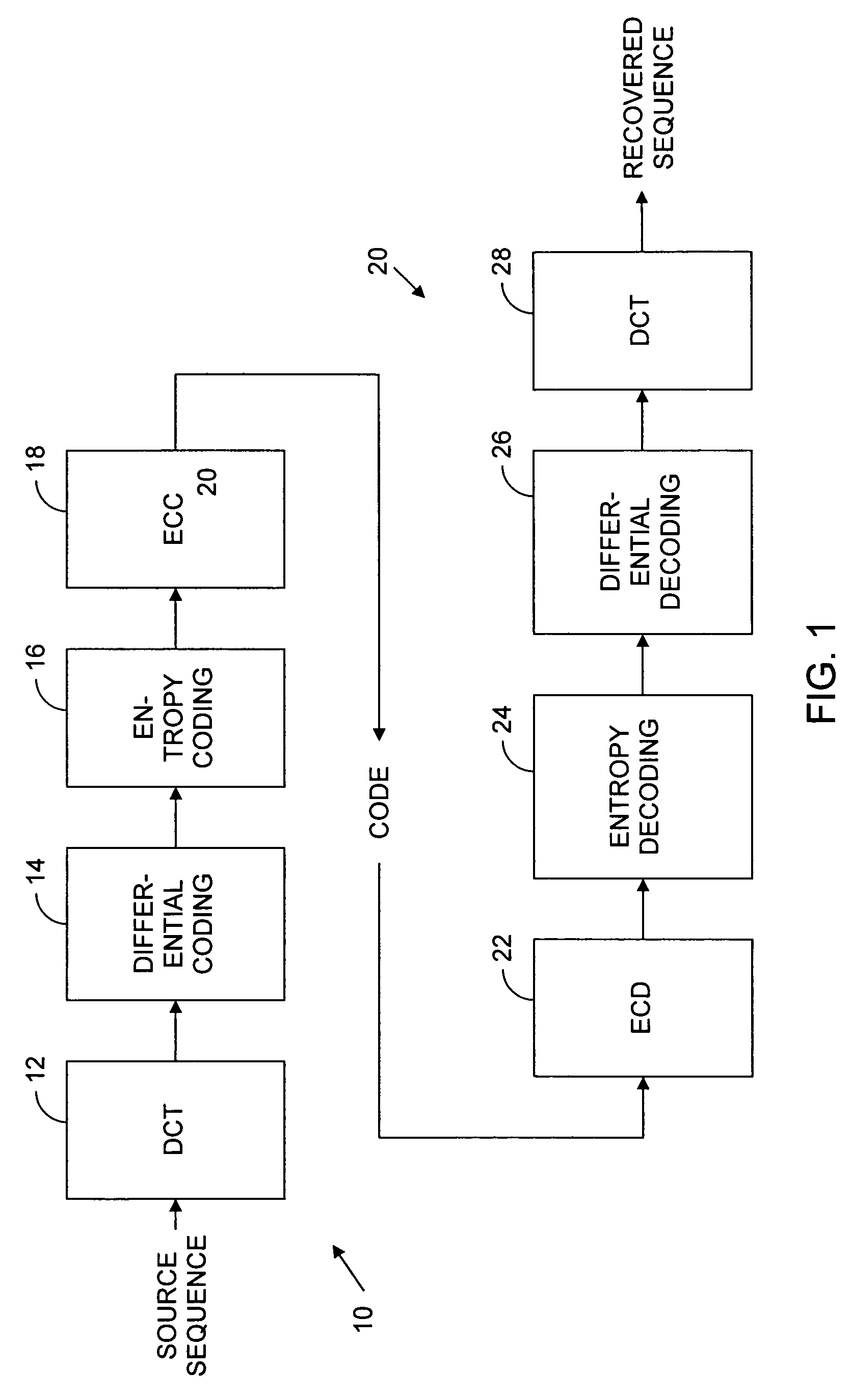

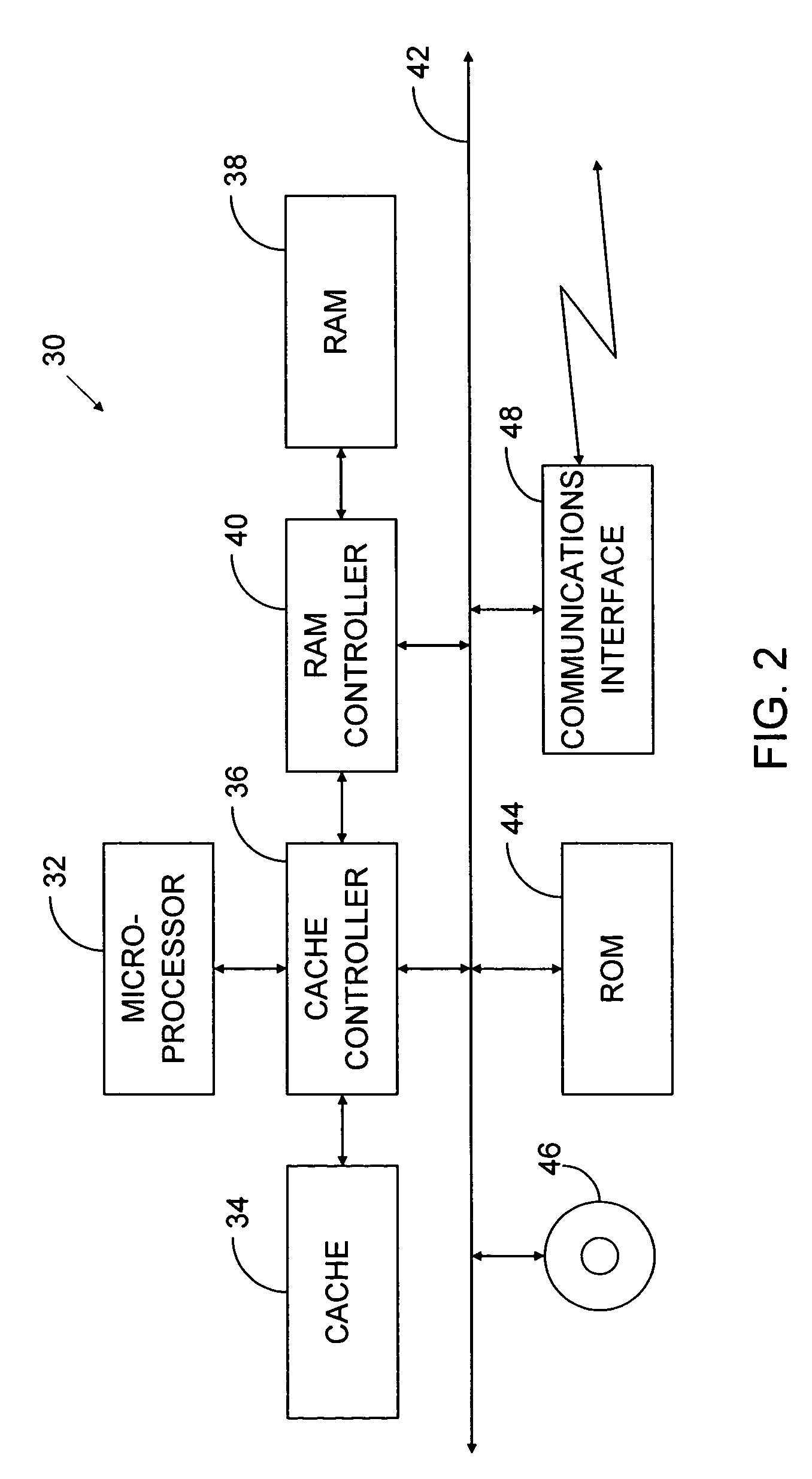

Modeling for enumerative encoding

Entropy encoders and decoders employ an entropy-pump operation. The entropy-pump operation includes classifying blocks of the input sequence's symbols in accordance with the probabilities of occurrence of those blocks' values. Entropy coding an output component that represents the sequence of classes to which the blocks belong tends to be profitable, because that component has an entropy density less than that of the input sequence. In contrast, little opportunity for compression tends to be lost by not entropy encoding an output component that represents the values of the blocks that belong to single class, because those values' probabilities of occurrence are similar.

Owner:1STWORKS CORP

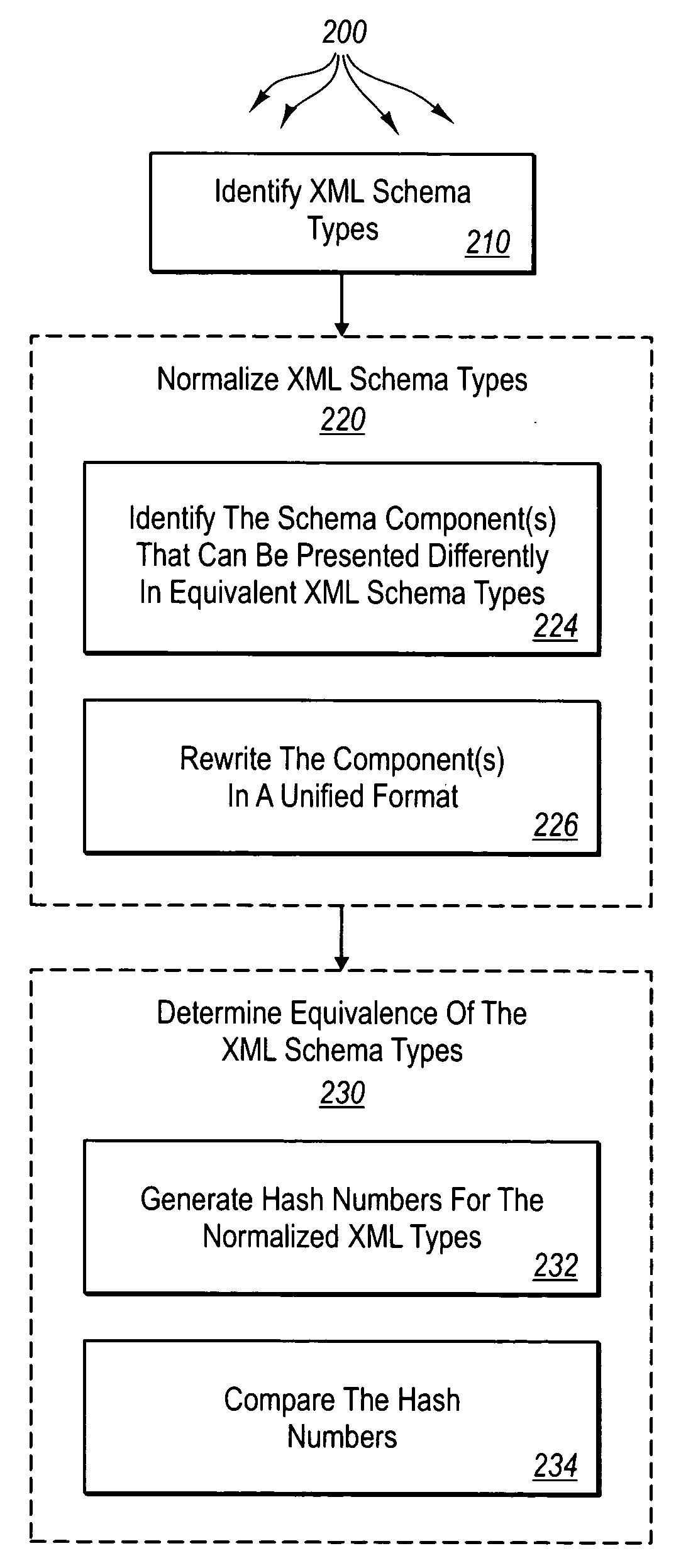

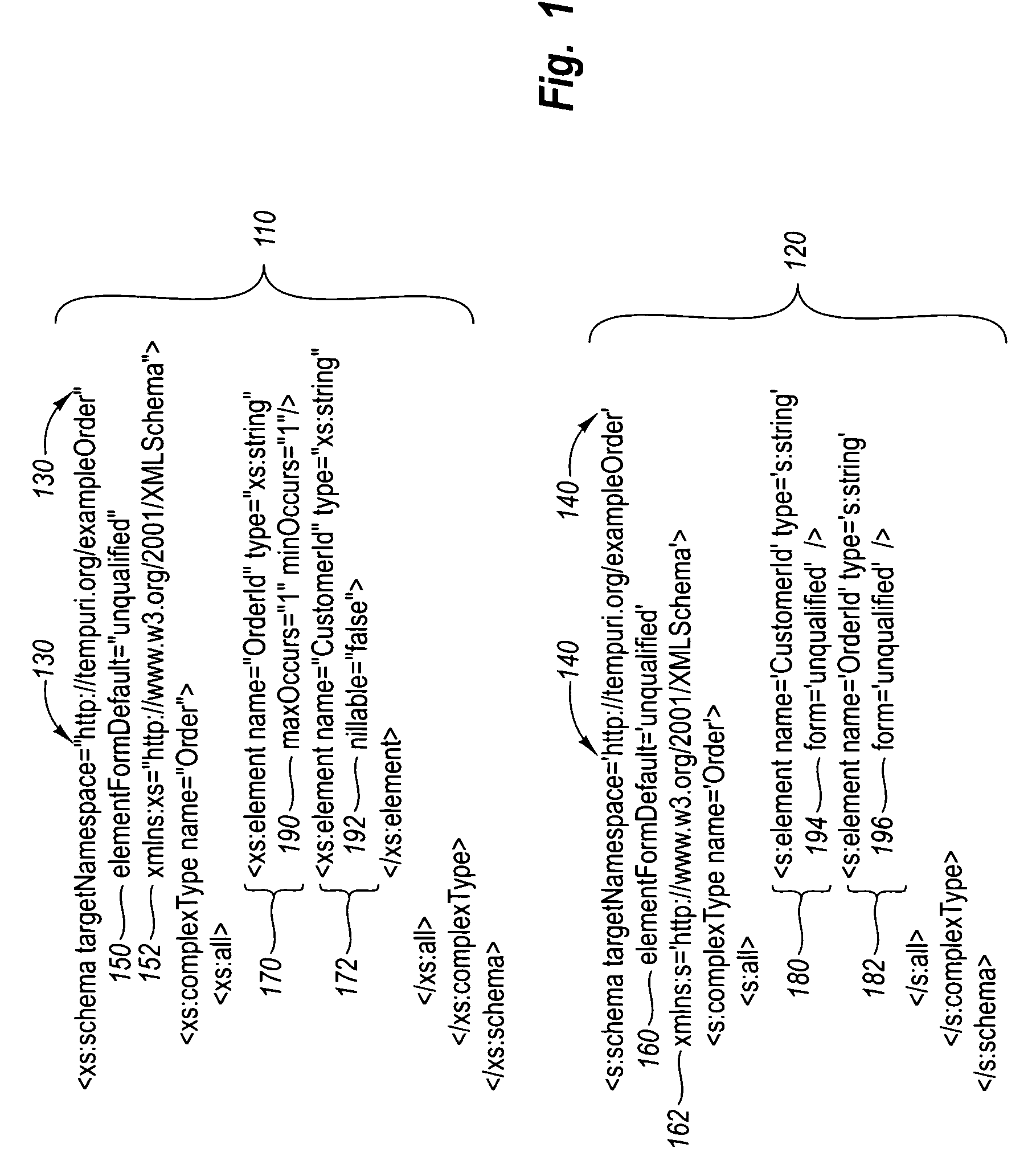

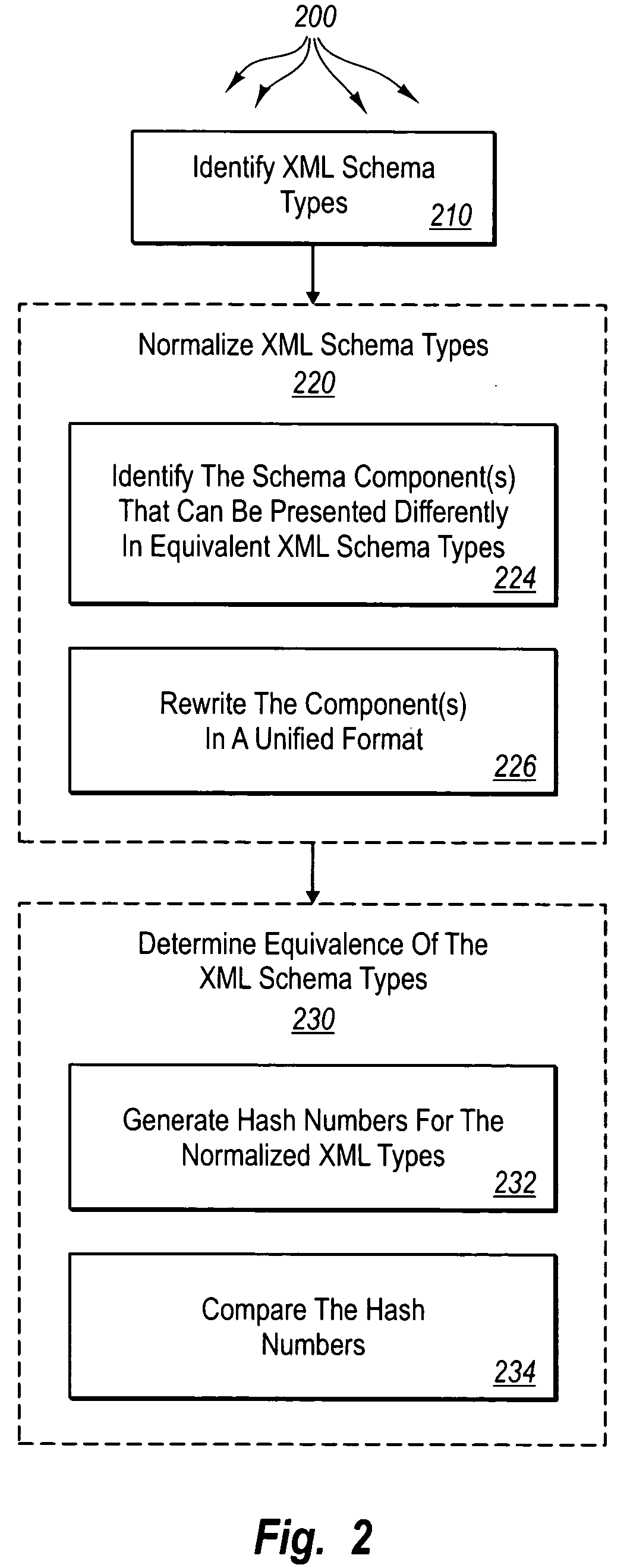

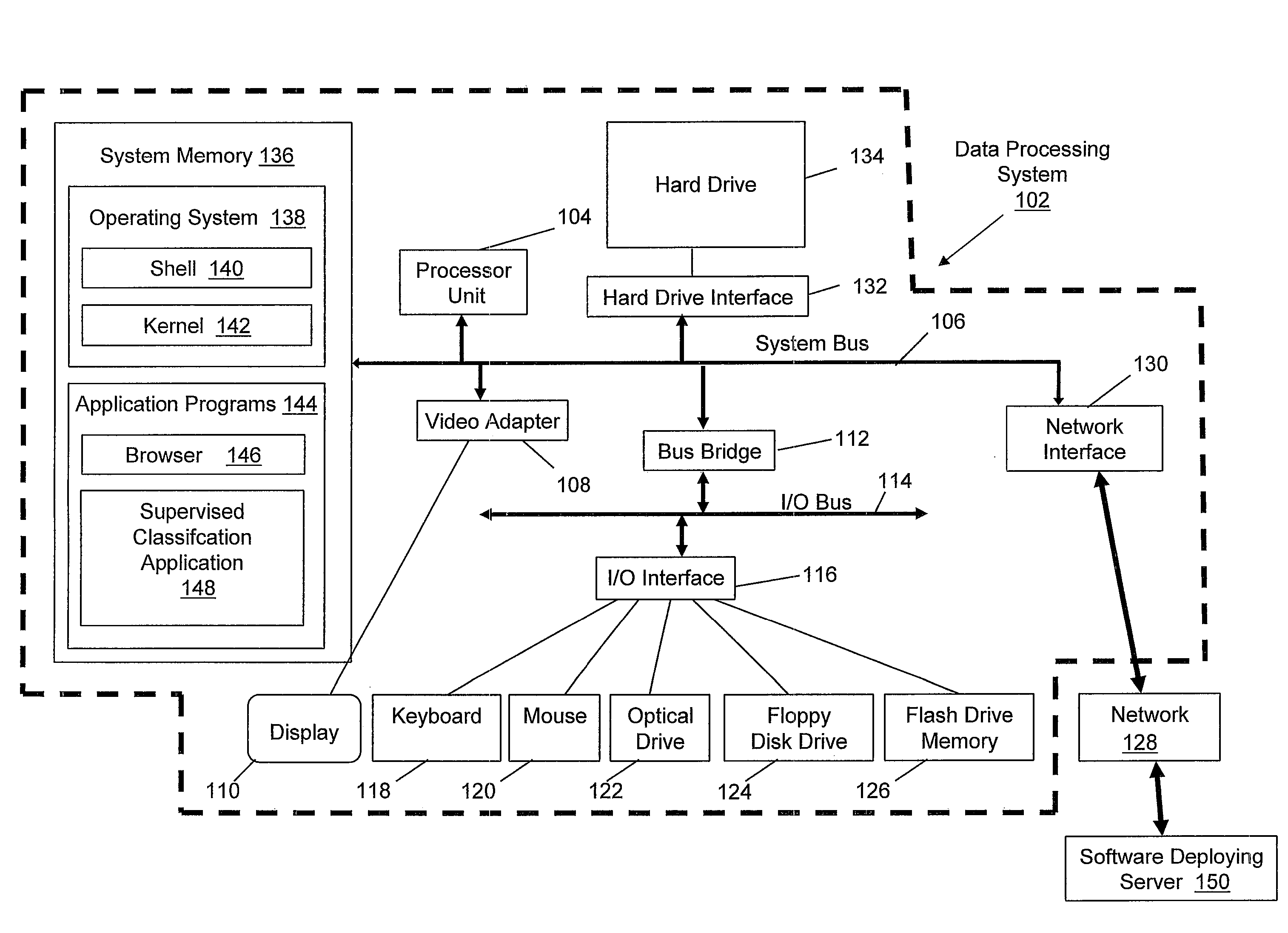

Determining XML schema type equivalence

InactiveUS20050192990A1Natural language data processingSpecial data processing applicationsXML schemaUnified system

XML schema types can be identified and compared for equivalence so as to avoid unnecessary and undesirable creation of multiple classes for equivalent schema types. XML schema types having the same name are identified and normalized according to a unified system for representing schema types. The step for normalizing schema types can include any writing and / or rewriting at least a portion of the schema types into a common unifying format so that they can be compared. Once the schema types have been normalized, they are then compared for equivalence. One technique for comparing the schema types is to create and compare hash numbers of all or only selected portions of the normalized schema types. Equivalent schema types can then be indexed to share a single class, thereby avoiding the creation of multiple classes for equivalent schema types.

Owner:MICROSOFT TECH LICENSING LLC

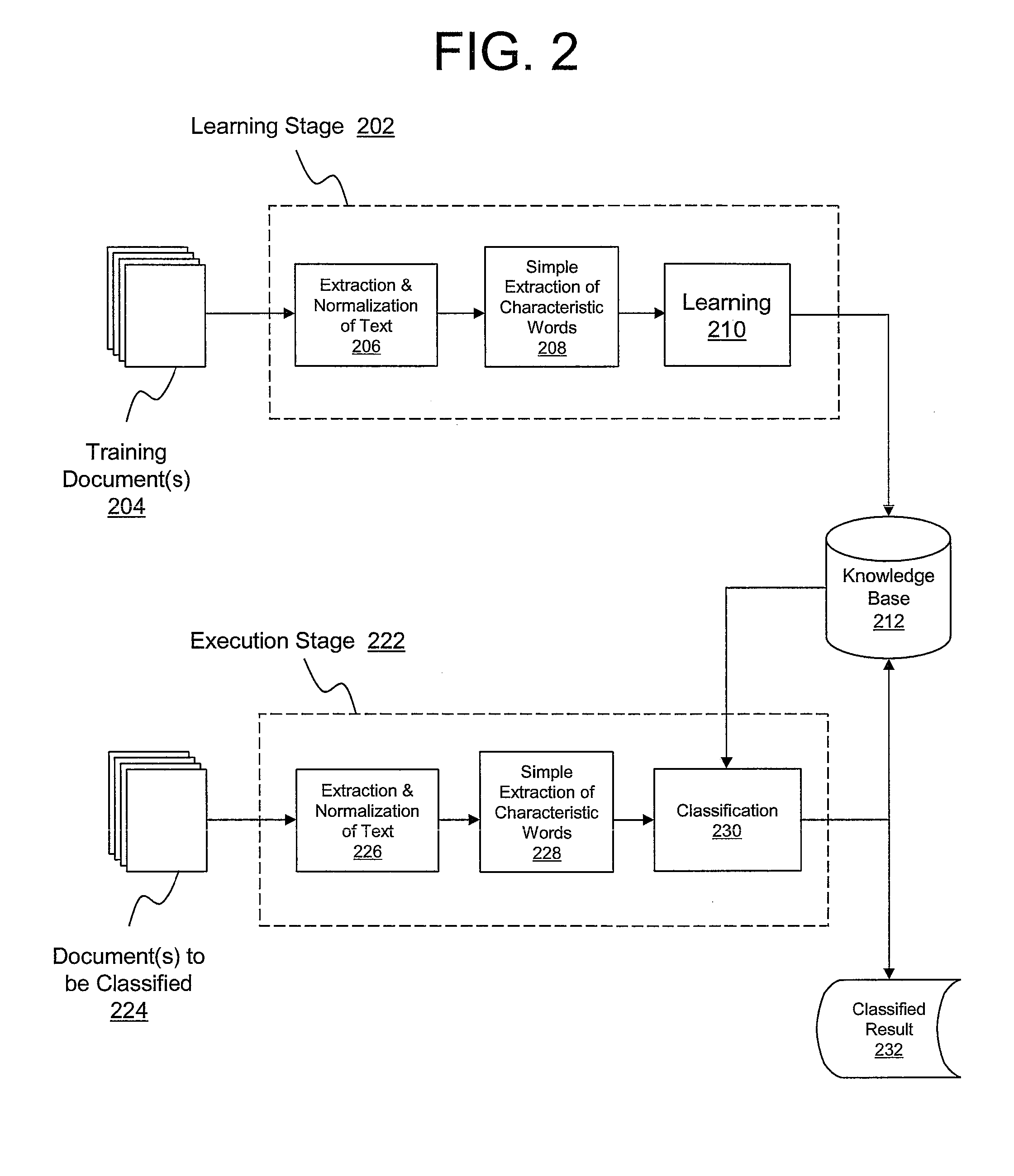

Computer-based method and system for efficient categorizing of digital documents

InactiveUS20090094178A1Digital data information retrievalDigital computer detailsOne step predictionDocumentation

A method, system and computer-readable medium are presented for computer-based supervised classification of digital documents that can exclusively identify an optimal category for the single class model by dividing a calculated score of each category into groups (thresholds can be automatically decided from the knowledge base) and can further predict whether it will be subjected to human examination and whether feedback learning should be performed.

Owner:IBM CORP

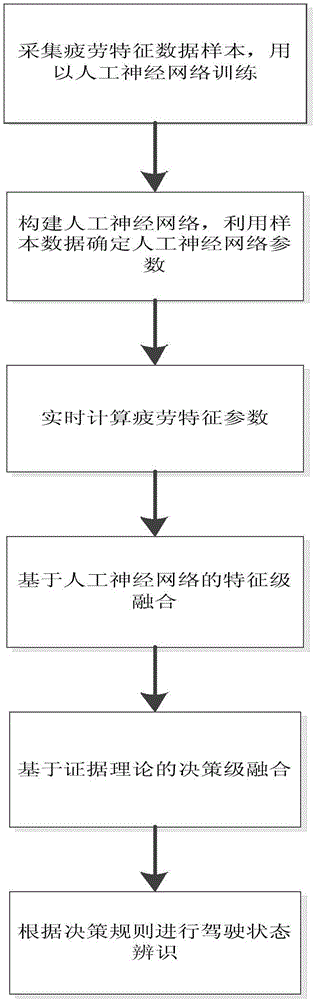

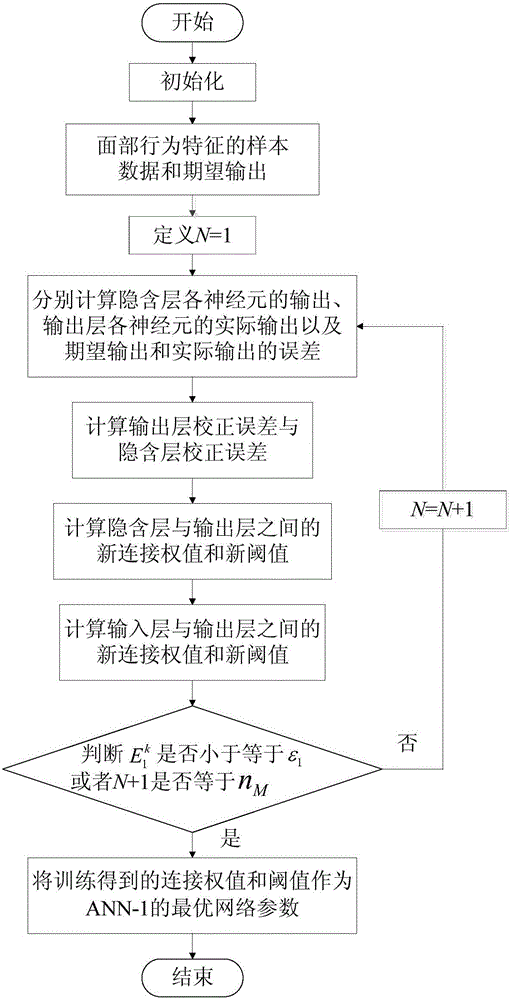

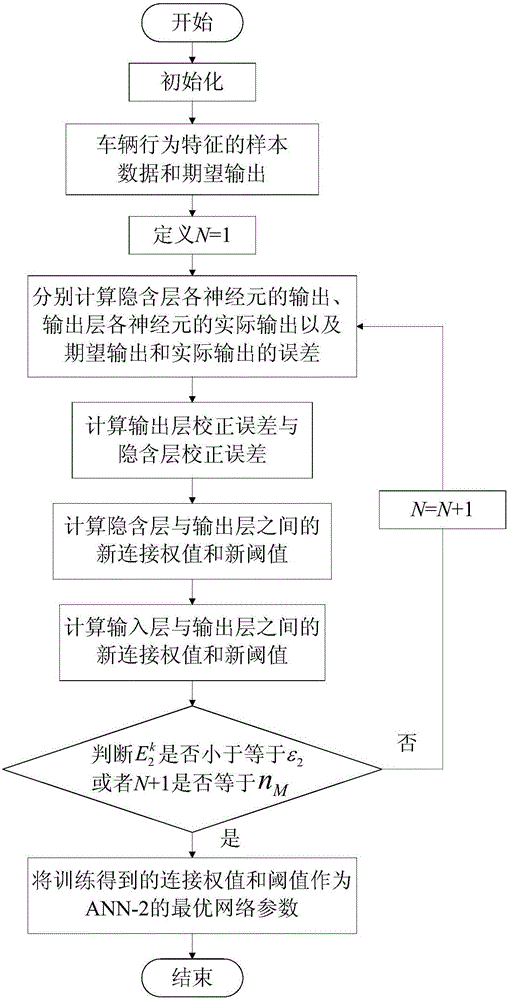

Fatigue driving evaluation method based on artificial nerve network and evidence theory

ActiveCN105139070AMeasuring fatigue driving statusOvercome limitationsBiological neural network modelsNerve networkDependability

The invention discloses a fatigue driving evaluation method based on an artificial nerve network and an evidence theory, comprising the steps of: collecting a fatigue characteristic data sample; building an artificial nerve network, and utilizing sample data to determine artificial nerve network parameters; calculating fatigue characteristic parameters in real time; performing characteristic grade fusion based on the artificial nerve network; performing decision grade fusion based on a D-S evidence theory; and performing driving state identification according to decision rules. The fatigue driving evaluation method overcomes limitations of a fatigue driving evaluation method based on a single class characteristic or a single information source characteristic, reduces a false drop rate and a miss rate, improves fatigue driving evaluation reliability and accuracy, and is suitable for fatigue driving fatigue real-time evaluation occasions of high accuracy and strong robustness.

Owner:DEEPBLUE TECH (SHANGHAI) CO LTD

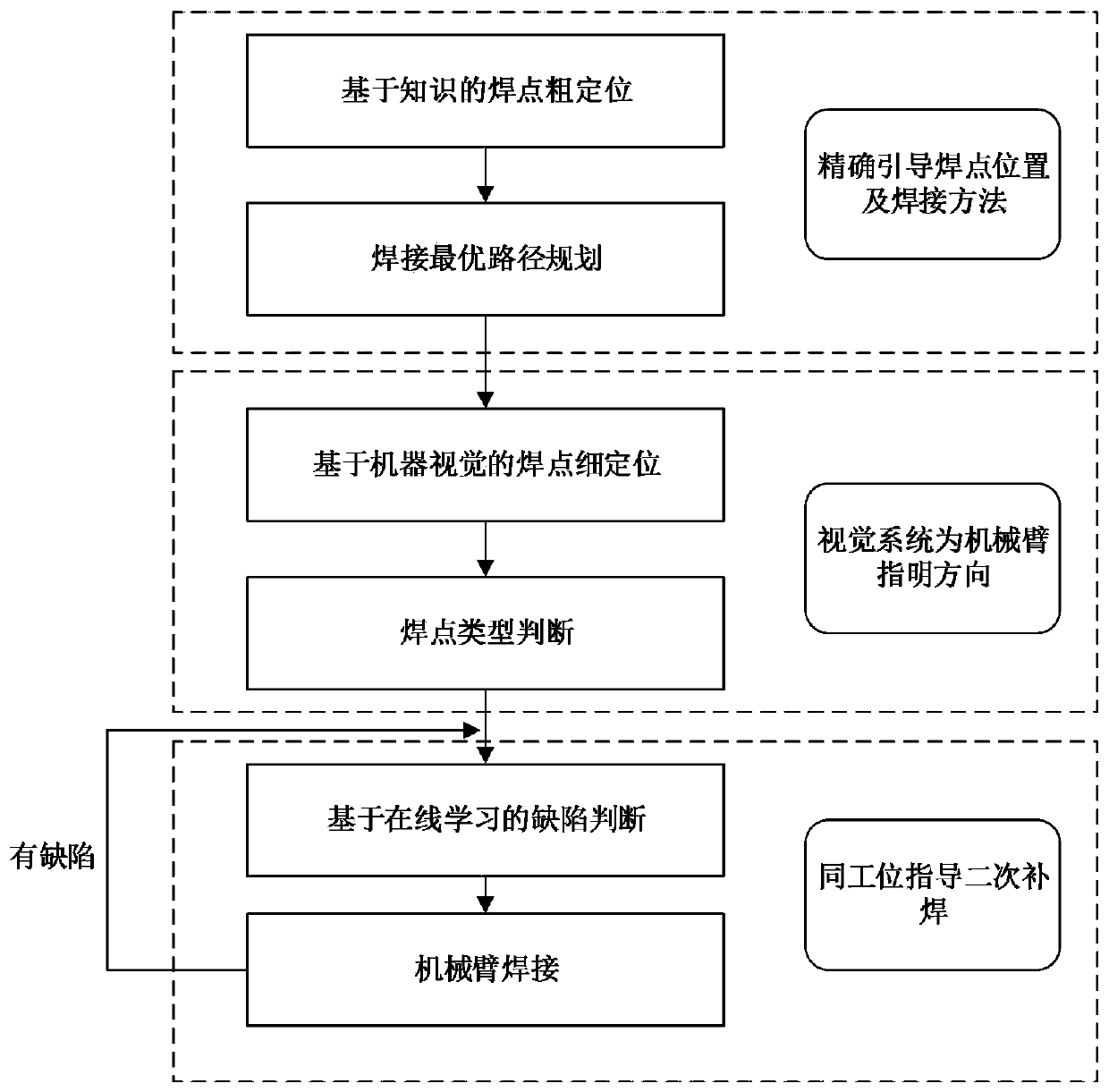

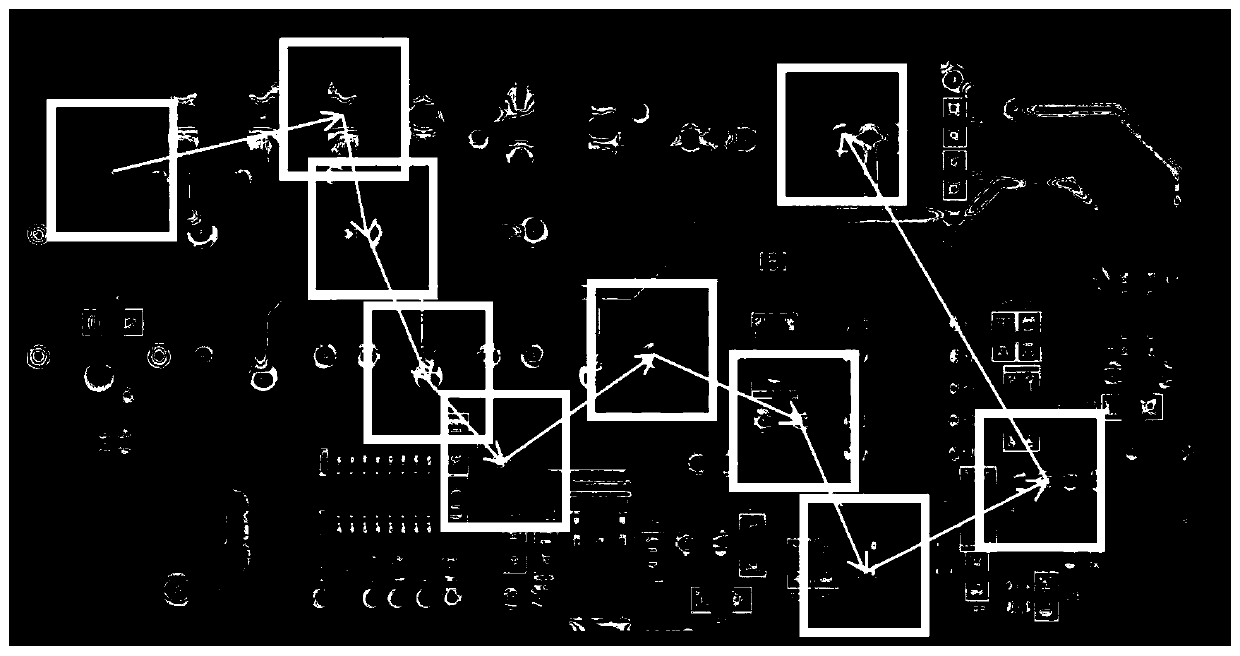

Automatic welding and defect detection method based on self-learning

ActiveCN110636715AIncrease productivityEasy to detectPrinted circuit assemblingOptically investigating flaws/contaminationMachine visionRobotic arm

The invention discloses an automatic welding and defect detection method based on self-learning. The method provided by the invention comprises the steps that 1 knowledge-based coarse welding spot positioning is used, and the optimal welding path is planned to provide a vision system and a robotic arm with a running direction; 2 fine positioning of welding spots is carried out based on machine vision, and the types of welding spots are judged; the robotic arm is accurately guided to find the location of welding spots, so as to implement targeted automatic welding; and 3 welding spot defect detection based on online deep reinforcement learning is used to automatically detect welding spot defects and determine the type, so as to provide basis and guidance for secondary repair welding at thesame station. According to the invention, a path planning algorithm is used to optimize the welding path of a camera and the robotic arm to improve the production efficiency; a deep neural network which fuses multi-layer features is used to facilitate the detection of many small target scenes with welding spots; for a single type of target, the weight of coordinate loss is improved, and the positioning accuracy is improved; and threshold filtering is carried out on the results, which filters out interference targets, and improves the recognition accuracy.

Owner:HANGZHOU DIANZI UNIV

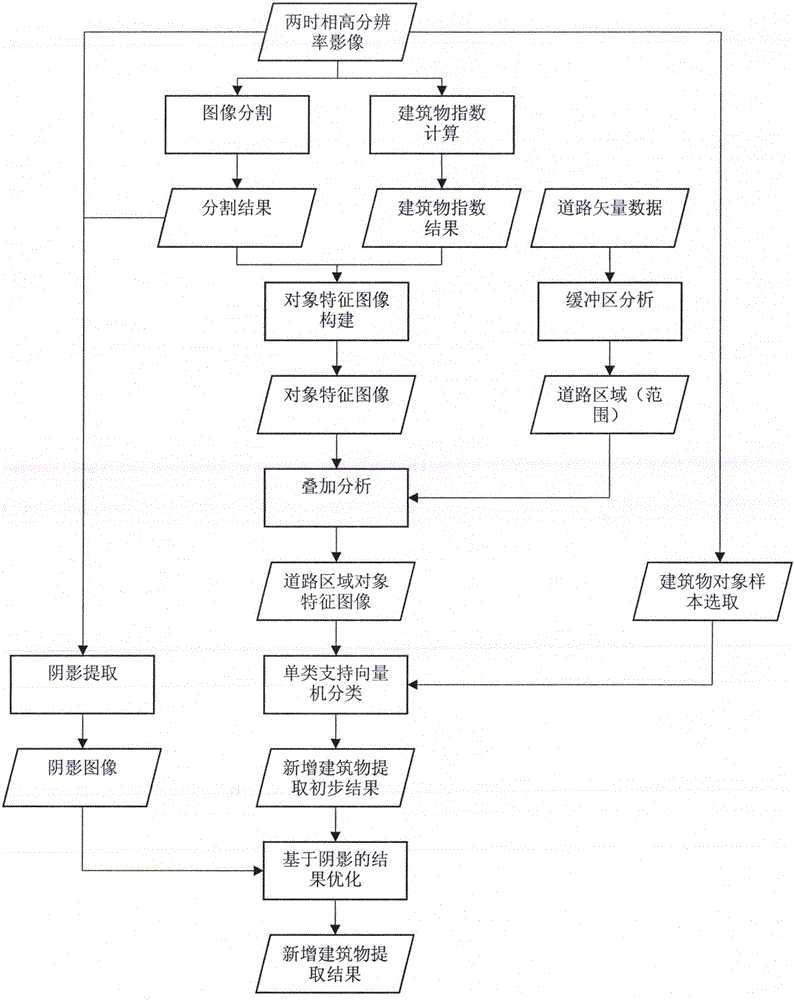

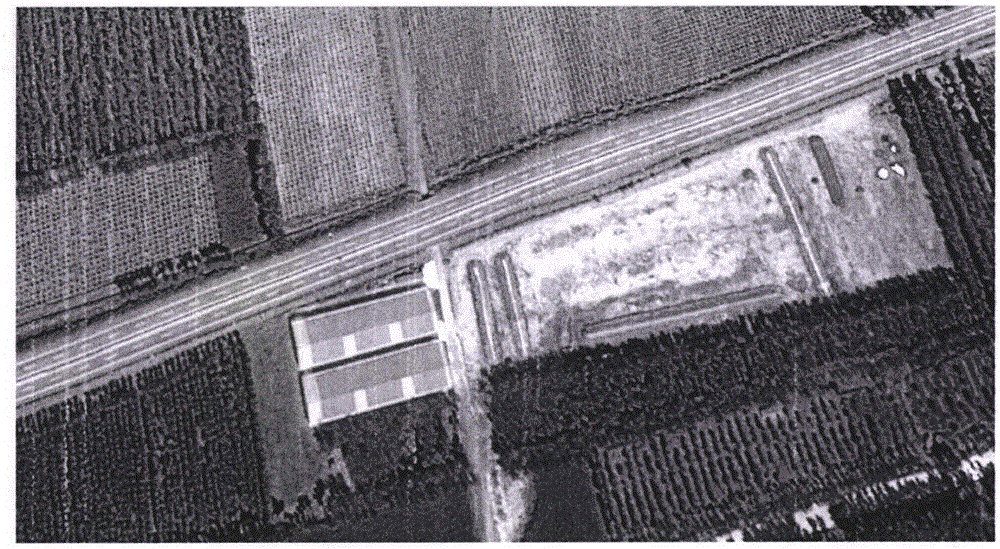

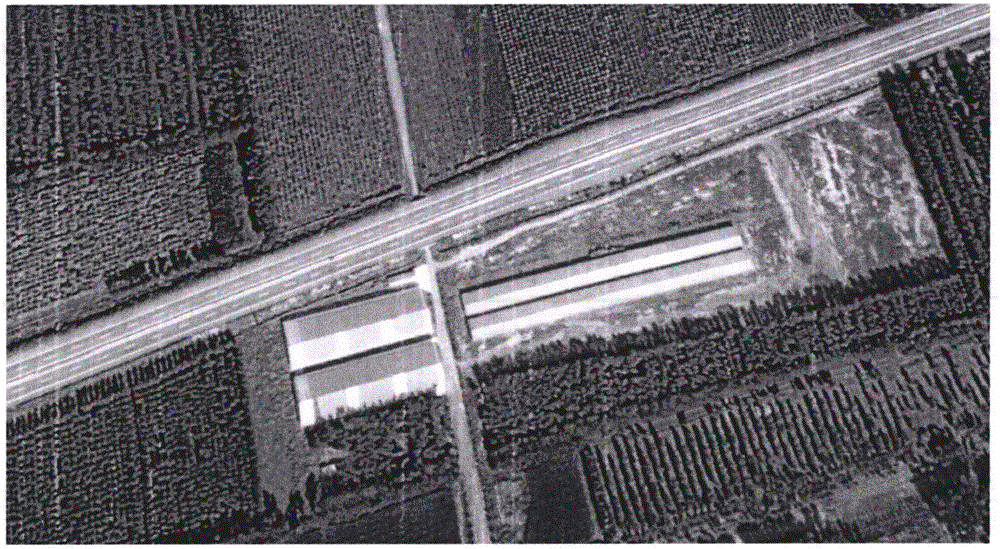

High-resolution image-based road region building change extraction method

ActiveCN106683112AAvoid interferenceImage enhancementImage analysisVisual interpretationClassification methods

The invention relates to a high-spatial resolution remote sensing image-based road region building change extraction method and device. According to the method and device, an object-oriented image processing strategy is adopted, the spectral information and spatial information (including structural indexes and spatial relationships) of images are comprehensively utilized, and a single-class classification method is adopted. In order to avoid interference (spectral similarity) on extracted results caused by ground feature classes except road regions, it is required that existing road information such as an existing road vector diagram, is provided in advance; the existing road vector diagram is adopted to extract a road region range; and newly increased buildings are extracted within the road region range. With the high-spatial resolution remote sensing image-based road area building change extraction method and device provided by the invention, time for a traditional method to obtain newly increased buildings such as illegal buildings by using image visual interpretation can be greatly decreased, efficiency can be improved, and human resources can be saved. The method and device can be used for road maintenance and monitoring business operation systems.

Owner:国交空间信息技术(北京)有限公司 +1

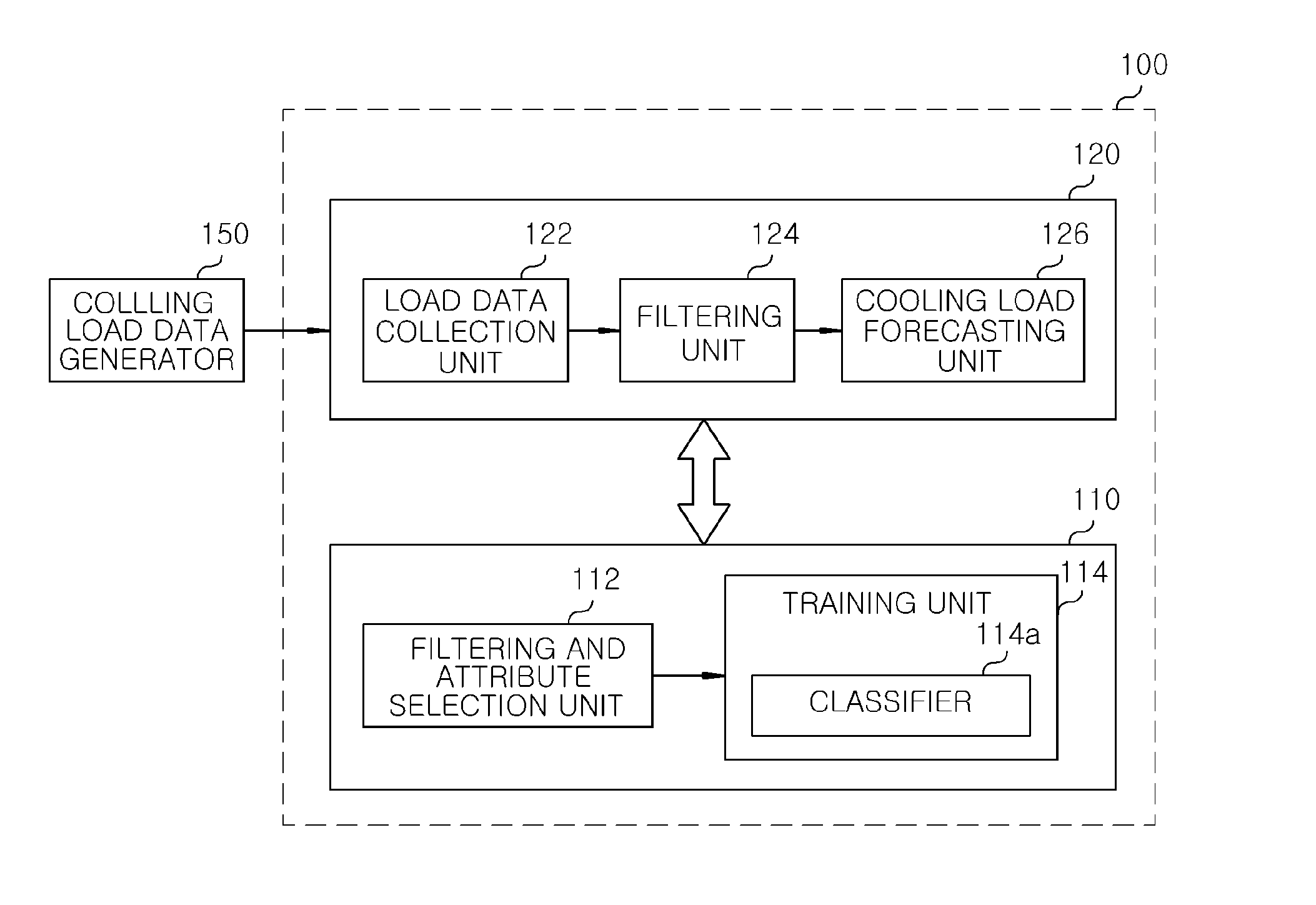

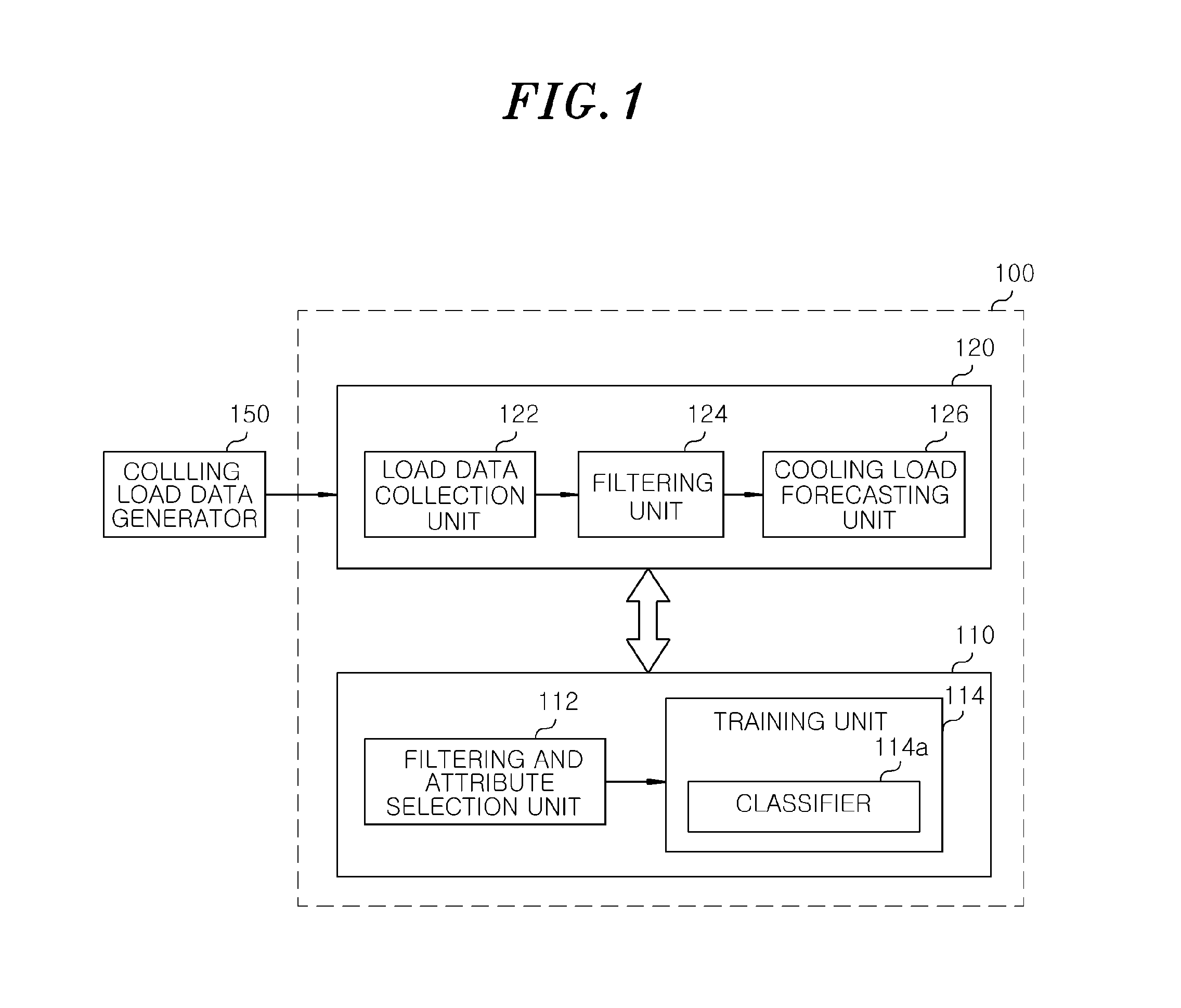

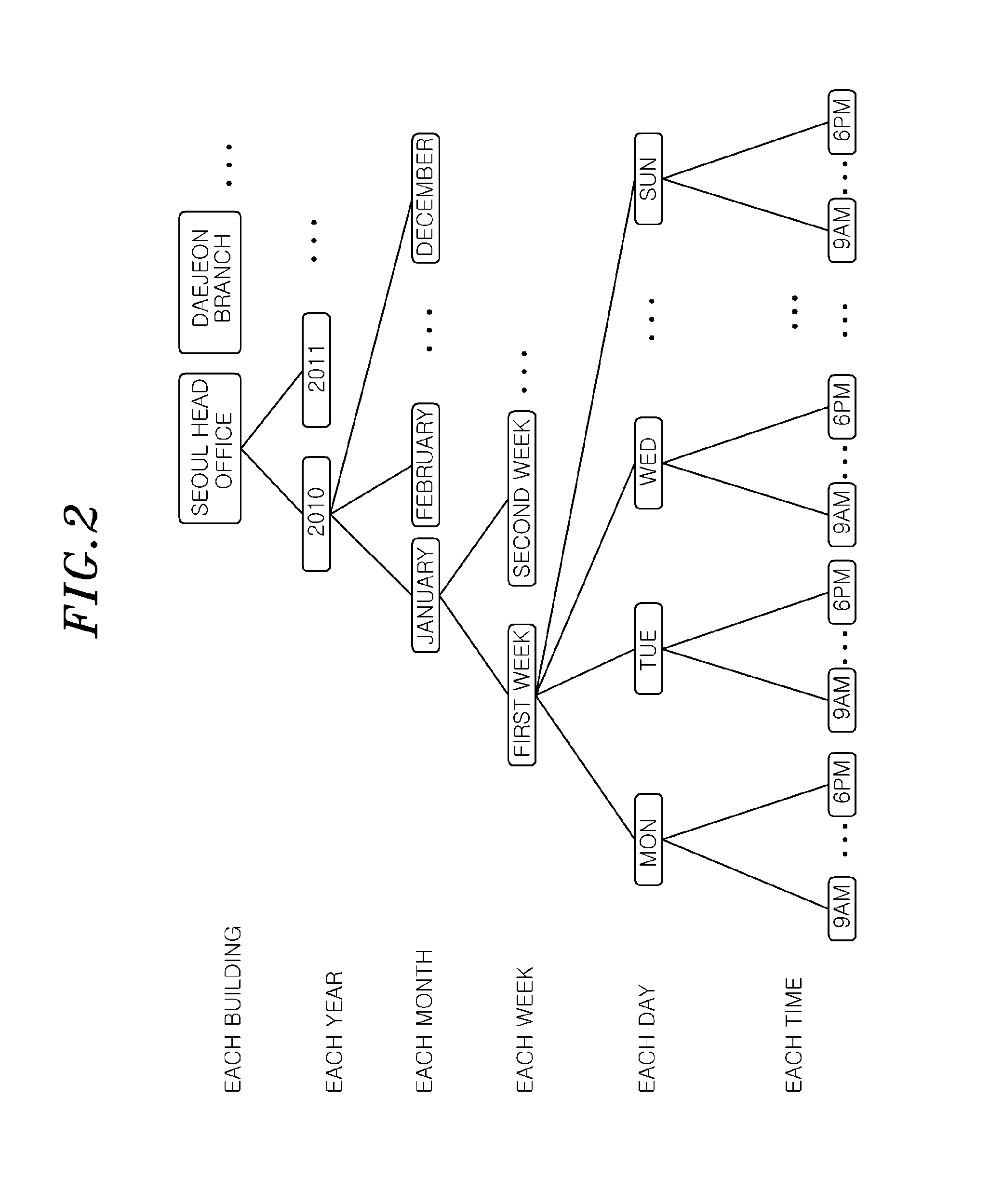

Apparatus and method for forecasting energy consumption

An apparatus for forecasting energy consumption includes a load data collection unit to collect low level data related to energy load data. The apparatus includes a filtering / attribute selection unit to eliminate duplicated attributes from attributes of low level data to produce an optimal attribute set. The apparatus includes a training unit produces a multi-class in which a plurality of single classes is hierarchically coupled in at least two levels and creates training data used for forecasting the energy consumption based on the produced multi-class. The apparatus includes a forecasting unit calculates the energy consumption to be forecasted on a basis of the real-time low level data, the multi-class and the training data. Therefore, it is possible to contribute to the progressive expansion and update of a cooling load forecasting system.

Owner:ELECTRONICS & TELECOMM RES INST

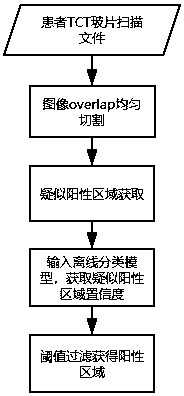

Cervical cancer TCT digital section data analysis method based on ResNet

ActiveCN108334909AReduce the cost of manual identificationLow costCharacter and pattern recognitionPattern recognitionMedical diagnosis

The invention discloses a cervical cancer TCT digital section data analysis method based on ResNet. The method comprises the steps of obtaining a TCT slide scanning image of a patient, and uniformly dividing the TCT slide scanning image to obtain multiple image blocks which are uniformly cut; inputting the image blocks to an automatic coder to extract features, further inputting the extracted features into a single-class SVM classifier, and extracting image blocks belonging to a positive region; preprocessing the extracted image blocks, inputting the processed image blocks to a trained ResNetclassification model, obtaining the lesion confidence coefficients of the image blocks, presetting confidence coefficient threshold values, and determining the image blocks of which the lesion confidence coefficients are higher than the confidence coefficient threshold values as the positive region. By means of the cervical cancer TCT digital section data analysis method based on ResNet, cervicalcancer TCT digital section image data is detected. Compared with a traditional cervical cancer detection method, the disclosed cervical cancer TCT digital section data analysis method can save the image medical diagnosis time and cost, and improve the diagnosis and treatment accuracy.

Owner:NANJING ILUVATAR COREX TECH CO LTD (DBA ILUVATAR COREX INC NANJING)

Semi-supervised intrusion detection method combining improved Grey Wolf algorithm

ActiveCN108520272ABalanced Global ExplorationBalance local development capabilitiesCharacter and pattern recognitionArtificial lifeSupport vector machineData set

The invention discloses a semi-supervised intrusion detection method combining the improved grey wolf algorithm, and belongs to the technical field of network information security. The method can effectively avoid the defect that the basic GWO algorithm is prone to premature convergence, and balance the global exploration and local development ability of the GWO algorithm; and the cloud GWO algorithm is used to optimize the K-means algorithm to mark data having similar features, and realization of generation of the large-scale accurate mark training data set is realized on the basis of manually marking the data in a small amount. The proportion of unmarked data and marked data is provided, the phenomenon of "under-fitting" and "over-fitting" of the model is avoided, and the detection accuracy of the model is ensured. The optimized semi-supervised learning method is combined with the cloud GWO algorithm to optimize parameters of a single-class support vector machine model. Compared withthe unilateral optimization, the invention achieves higher detection precision.

Owner:JIANGNAN UNIV

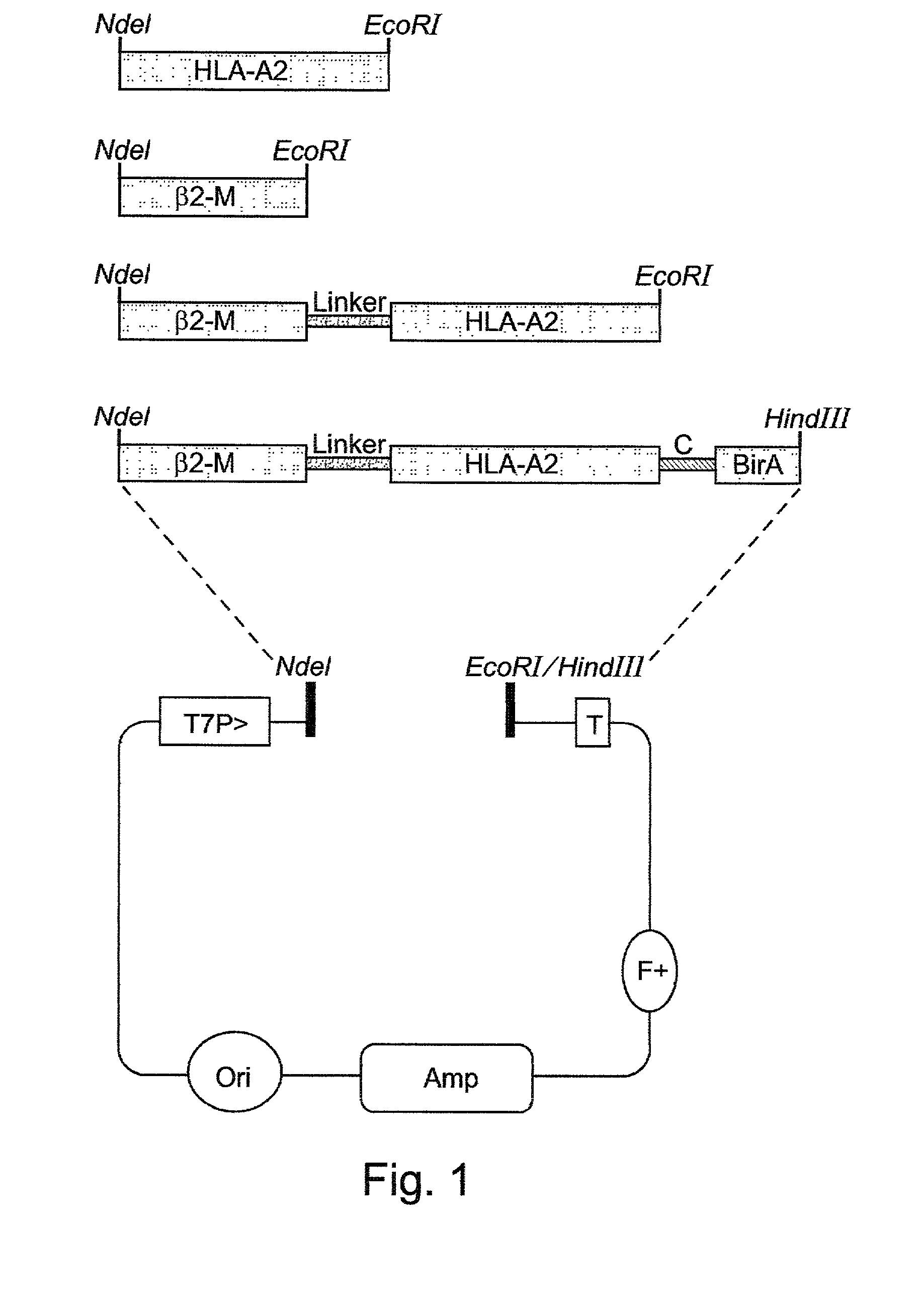

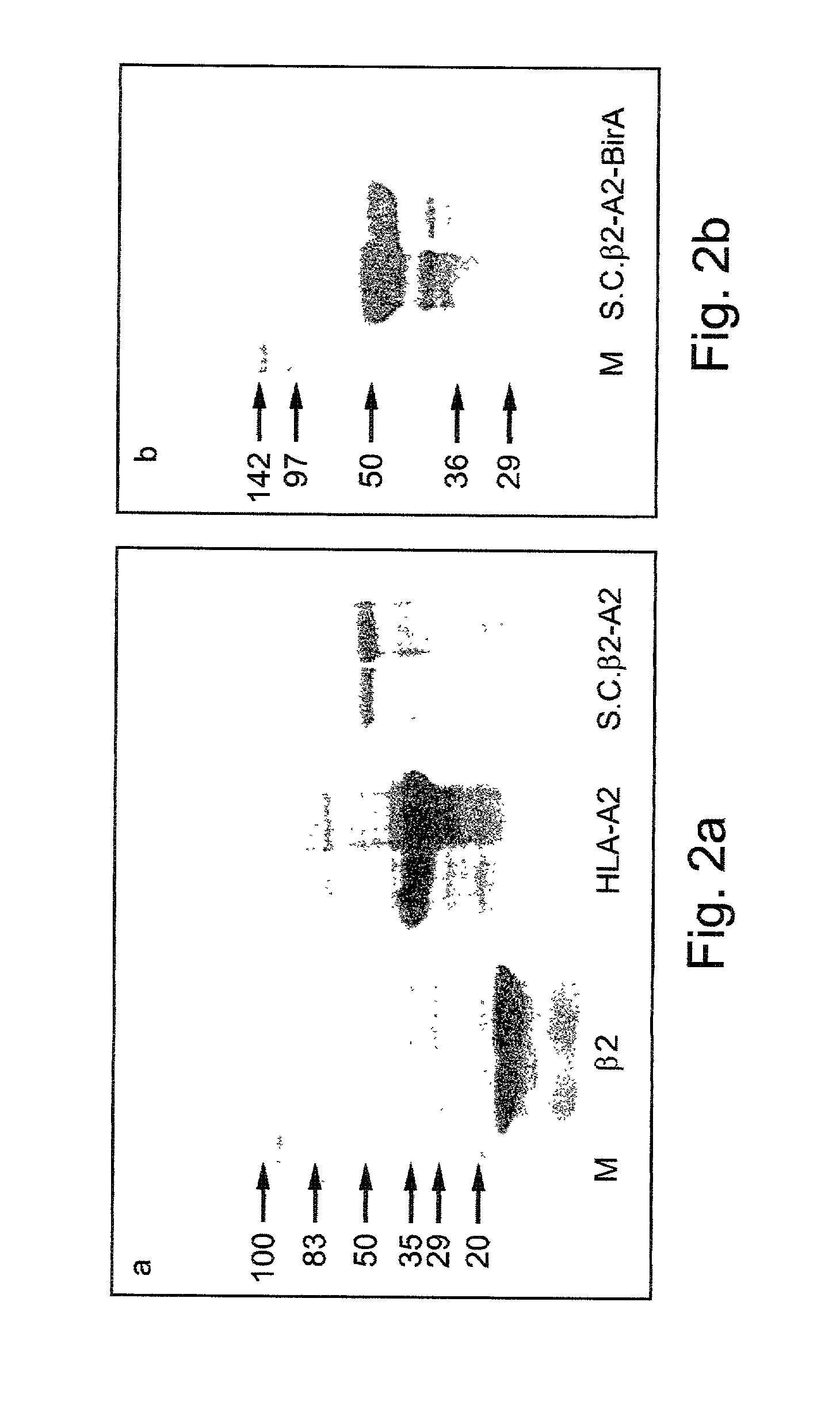

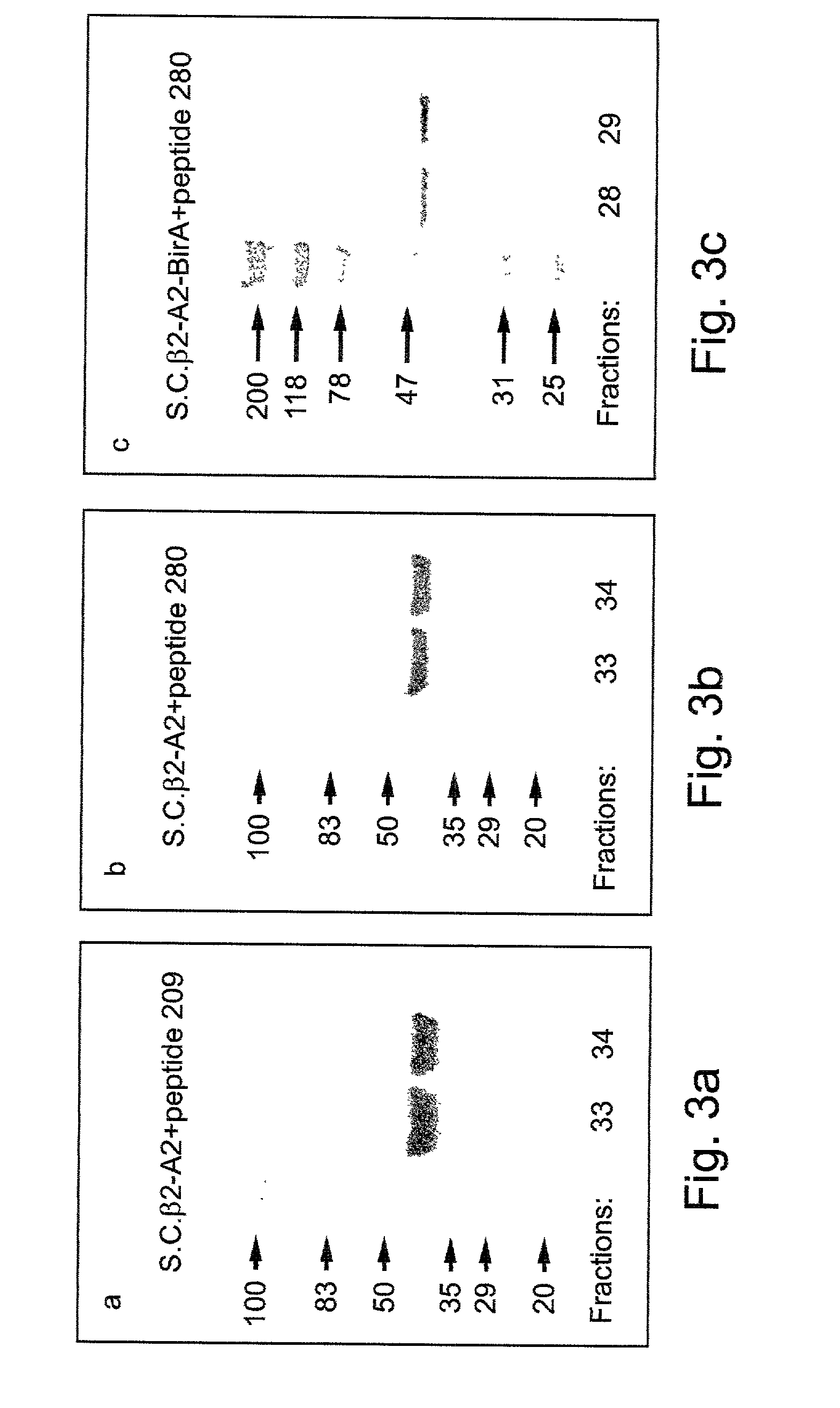

Single chain class I major histo-compatibility complexes

A recombinant polypeptide and nucleic acid constructs capable of expressing the recombinant polypeptide are provided. The recombinant polypeptide comprises a chimeric polypeptide including an antigenic peptide being capable of binding a human MHC class I, a functional human beta-2 microglobulin and a functional human MHC class I heavy chain.

Owner:TECHNION RES & DEV FOUND LTD

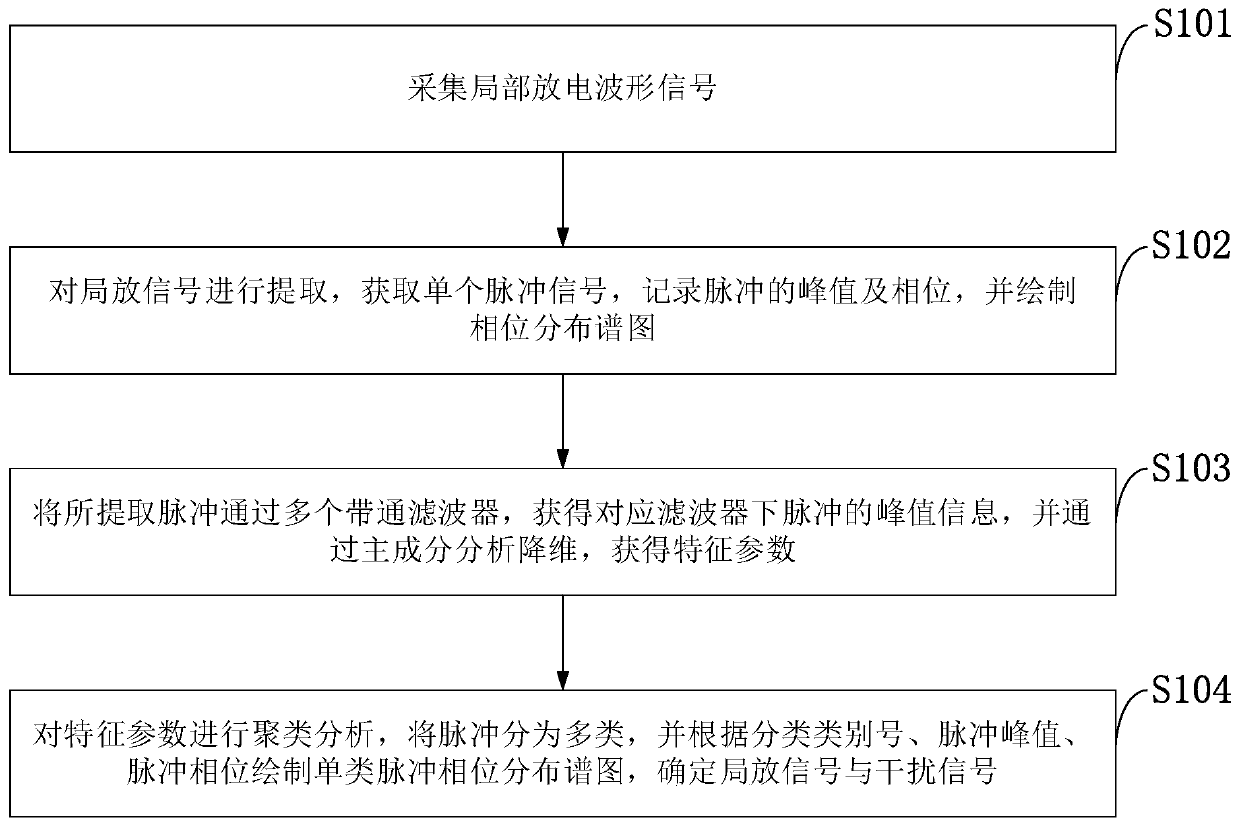

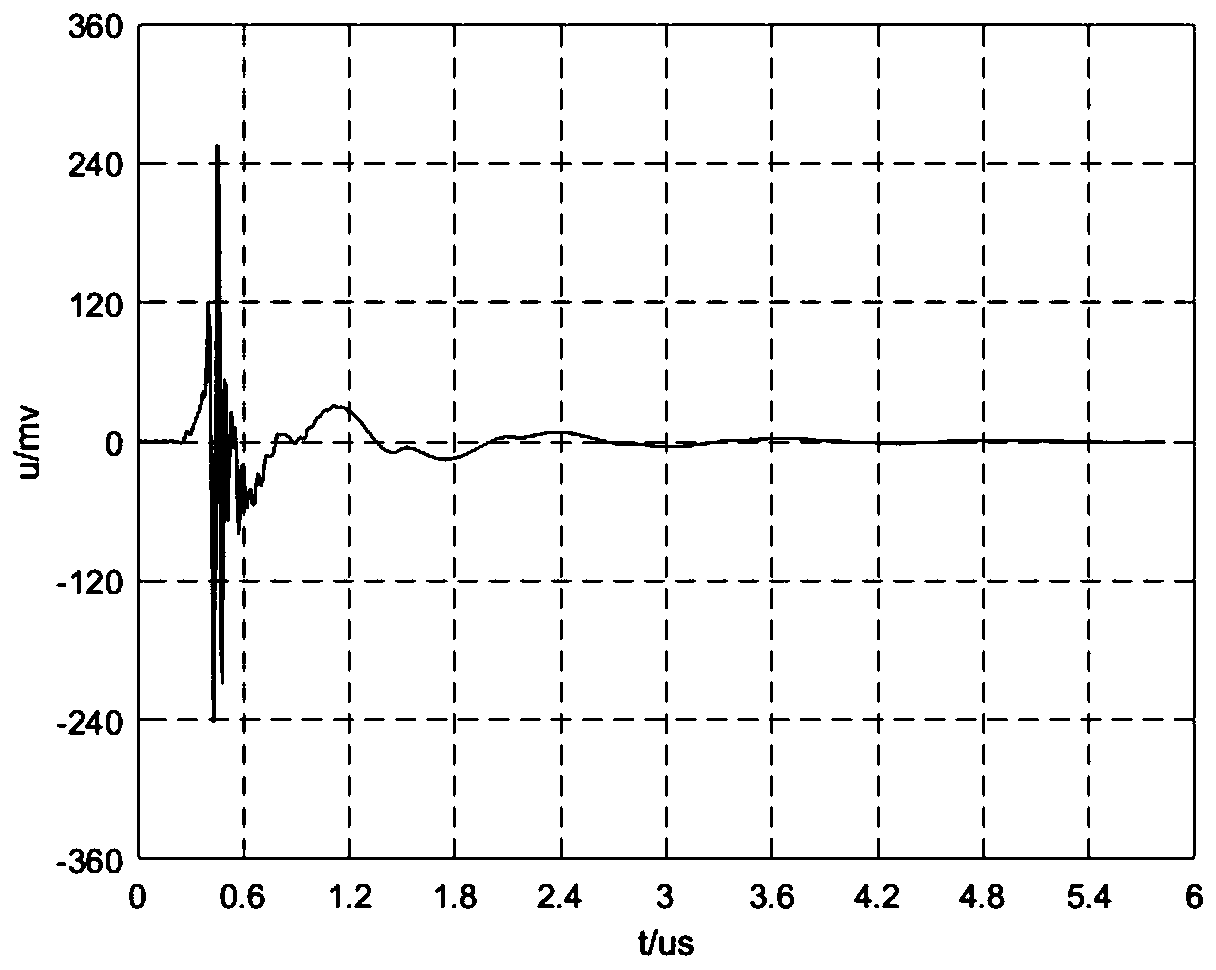

Signal and noise separation method for partial discharge signal and information data processing terminal

ActiveCN109901031AWill not cause duplicate fetchesEfficient and accurate extractionTesting dielectric strengthCharacter and pattern recognitionBandpass filteringPrincipal component analysis

The invention belongs to the technical field of high voltage electrical equipment partial discharge detection and discloses a signal and noise separation method for a partial discharge signal and an information data processing terminal. A partial discharge waveform signal is collected; the partial discharge signal is extracted, a single pulse signal is acquired, a peak value and the phase of the pulses are recorded, and a phase distribution spectrum is drawn; for the extracted pulses, through multiple band pass filters, the down pulse peak value information of the corresponding filters is obtained, through principal component analysis and dimension reduction, characteristic parameters are obtained; the characteristic parameters are subjected to clustering analysis, the pulses are classified into multiple categories, a single-class pulse phase distribution spectrum is drawn according to the classification category number, the pulse peak value and the pulse phase, and the PD signal and the interference signal are determined. The method is advantaged in that the method can extract various pulse waveforms efficiently and accurately, utilizes the peak information under the multiple bandpass filters as a feature vector, can fully reflect the pulse waveform information and improves precision of separation of the interference signal and the partial discharge signal.

Owner:XIDIAN UNIV

Aerosol dispenser having a safety valve

ActiveUS20180244460A1Catastrophic explosionPackage recyclingSpraying apparatusPlastics industryMicrowave oven

A method of warming food dispensable from an aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials suitable for eating in a microwave oven. Consumer products, such as food, contained in the aerosol dispenser may be heated in a microwave oven prior to dispensing. Upon dispensing, food retains residual heat, and is suitable for eating or further cooking. Other heated products in the aerosol dispenser may be comfortably applied to the skin, used as air freshener, used for cleaning, etc. The aerosol dispenser may have indicia indicating the aerosol dispenser is suitable for microwave heating. The aerosol dispenser can have indicia indicating the aerosol dispenser is suitable for heating in a microwave oven. The indicia may be thermochromic, indiciating when a desired temperature has been reached. The aerosol dispenser can have a safety valve, to safely relieve product and / or propellant pressure upon overpressurization in a microwave oven. The safety valve may be single use or reusable.

Owner:THE PROCTER & GAMBLE COMPANY

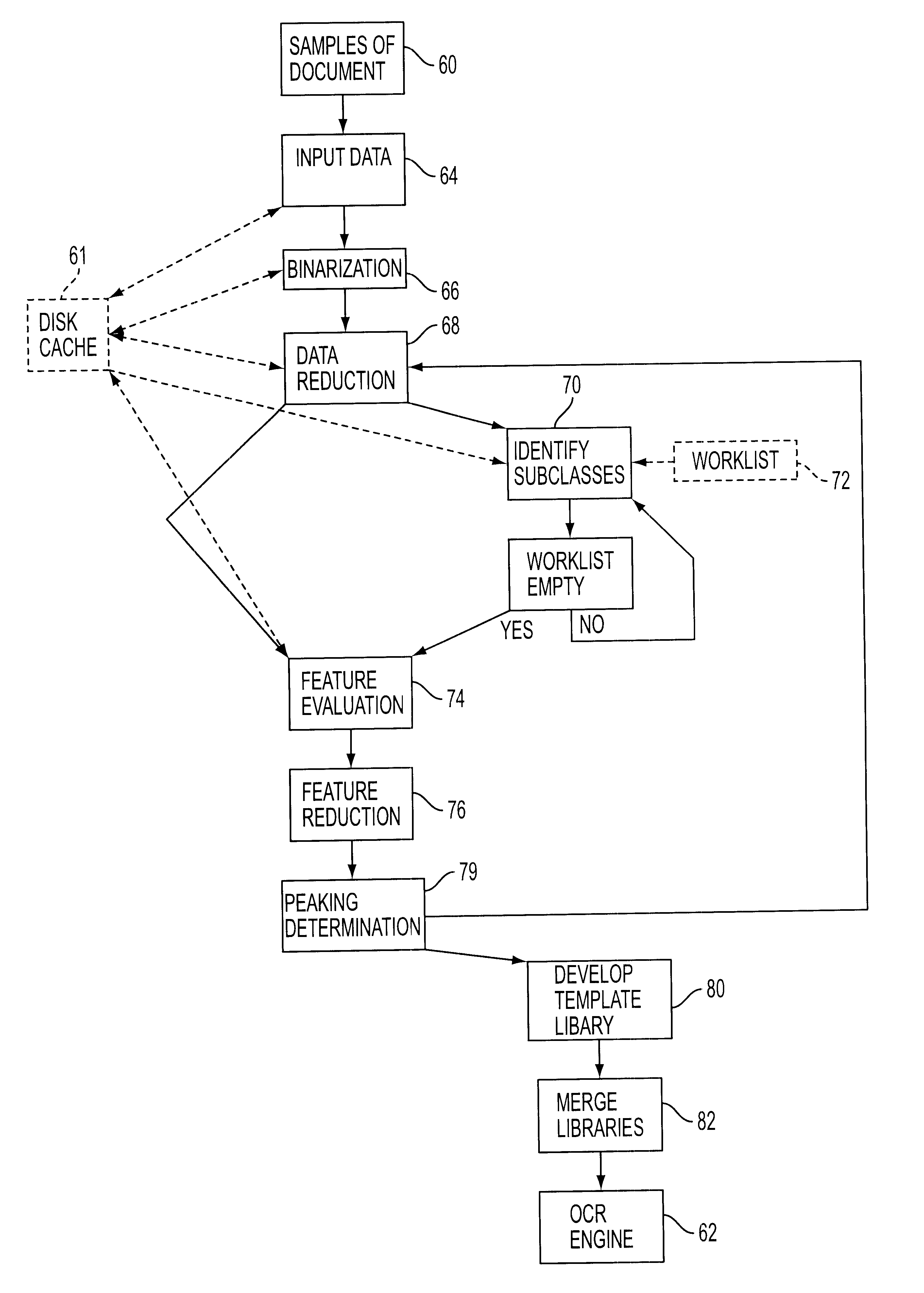

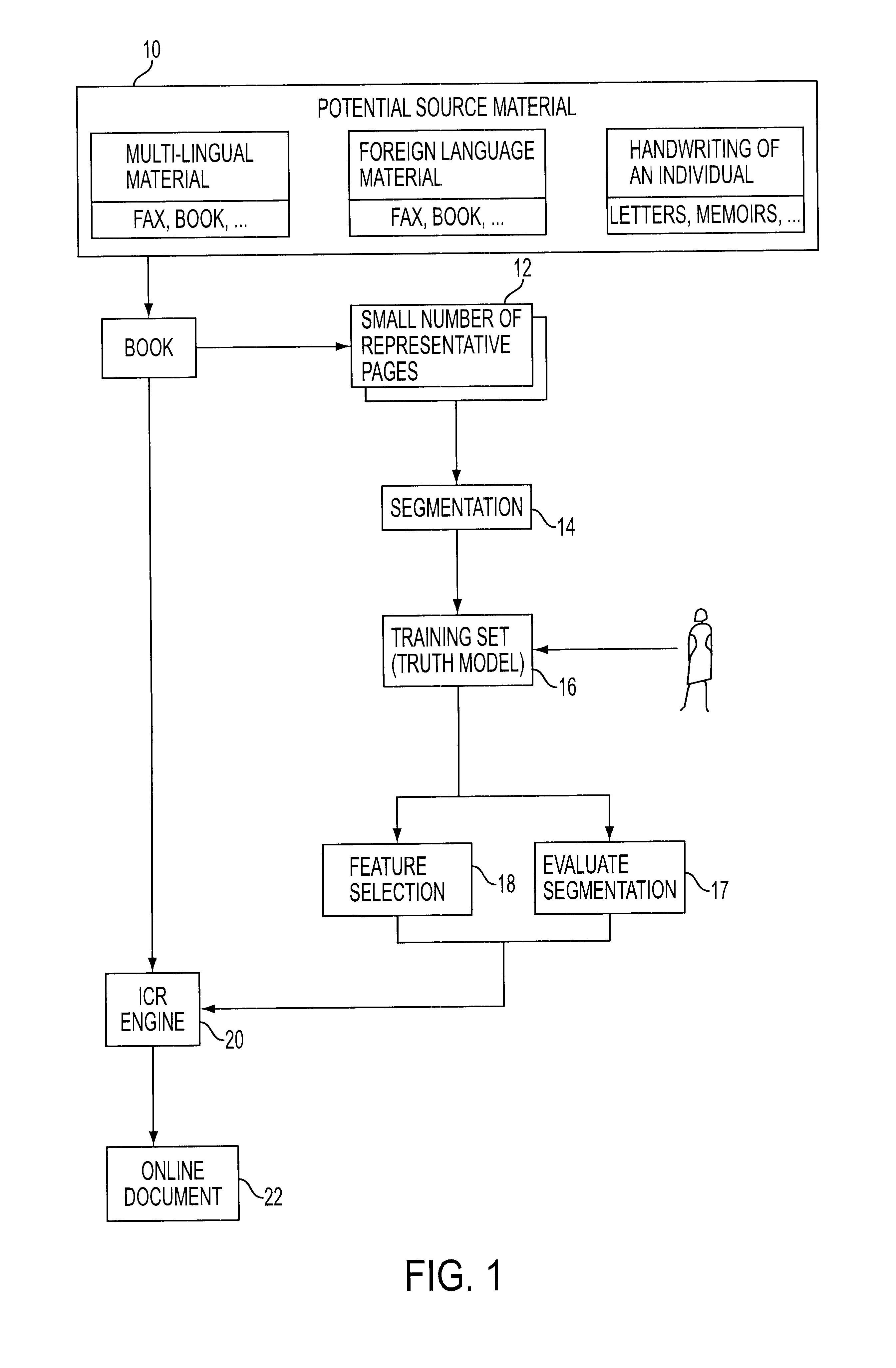

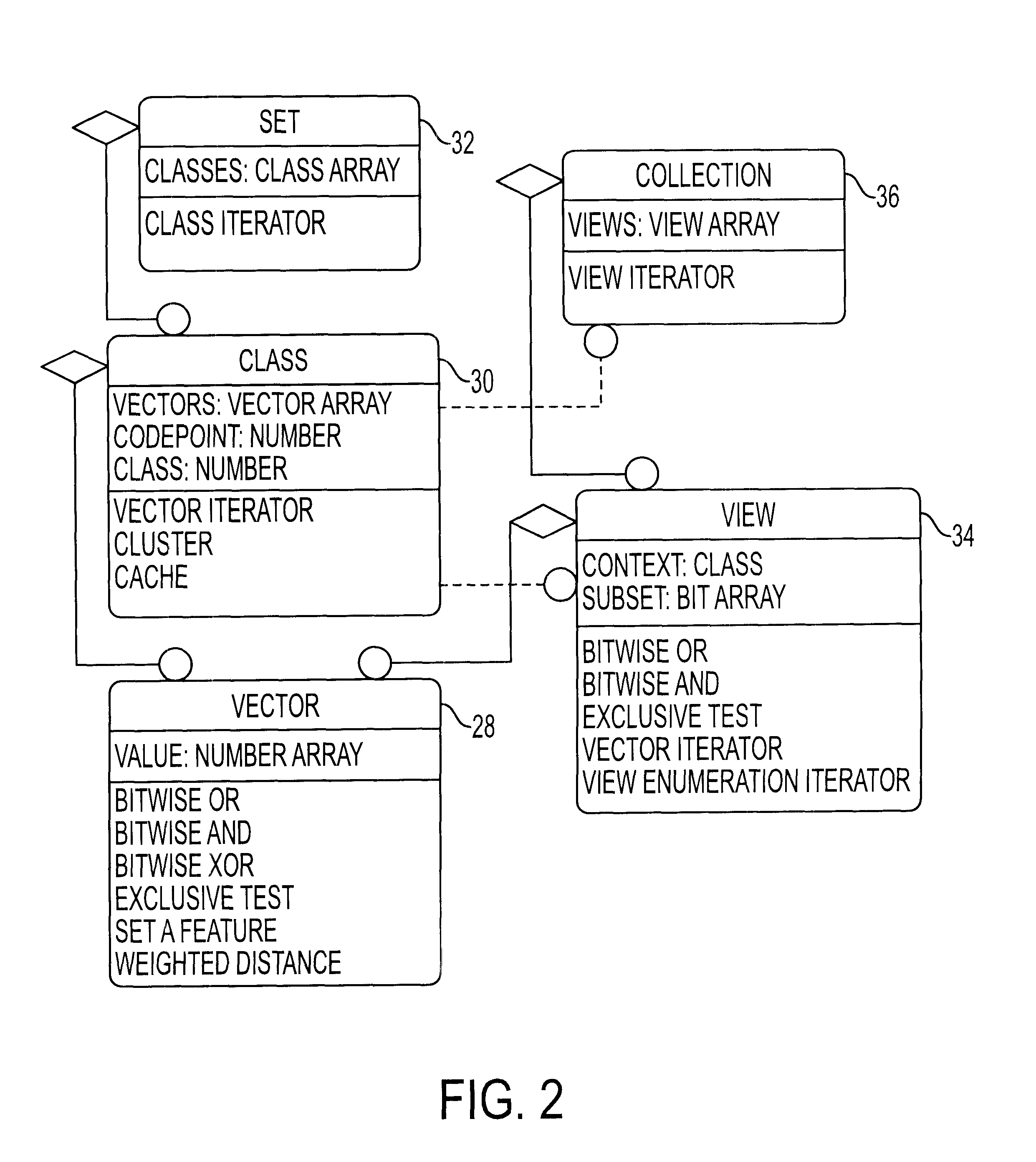

Automatic method for developing custom ICR engines

A computer automated feature selection method based upon the evaluation of hyper-rectangles and the ability of these rectangles to discriminate between classes. The boundaries of the hyper-rectangles are established upon a binary feature space where each bit indicates the relationship of a real feature value to a boundary within the minimum and maximum values for the feature across all samples. Data reduction combines the binary vector spaces so that the number of samples within a single class is within a range which is computationally feasible. Identification of subclasses identifies maximal subsets of S+ which are exclusive against S-. Feature evaluation determines within a single subclass the contribution of each feature towards the ability to discriminate the subclass from S-. The base algorithm examines each feature, dropping any feature which does not contribute towards discrimination. A pair of statistics are generated for each remaining feature. The statistics represent a measure of how many samples from the class are within the subclass and a measure of how important each feature is to discriminating the subclass from S-. The values for each subclass are then combined to generate a set of values for the class. These class feature metrics are further merged into metrics evaluating the features contribution across the entire set of classes. Feature reduction determines which features contribute the least across the entire set of classes.

Owner:LOCKHEED MARTIN CORP +1

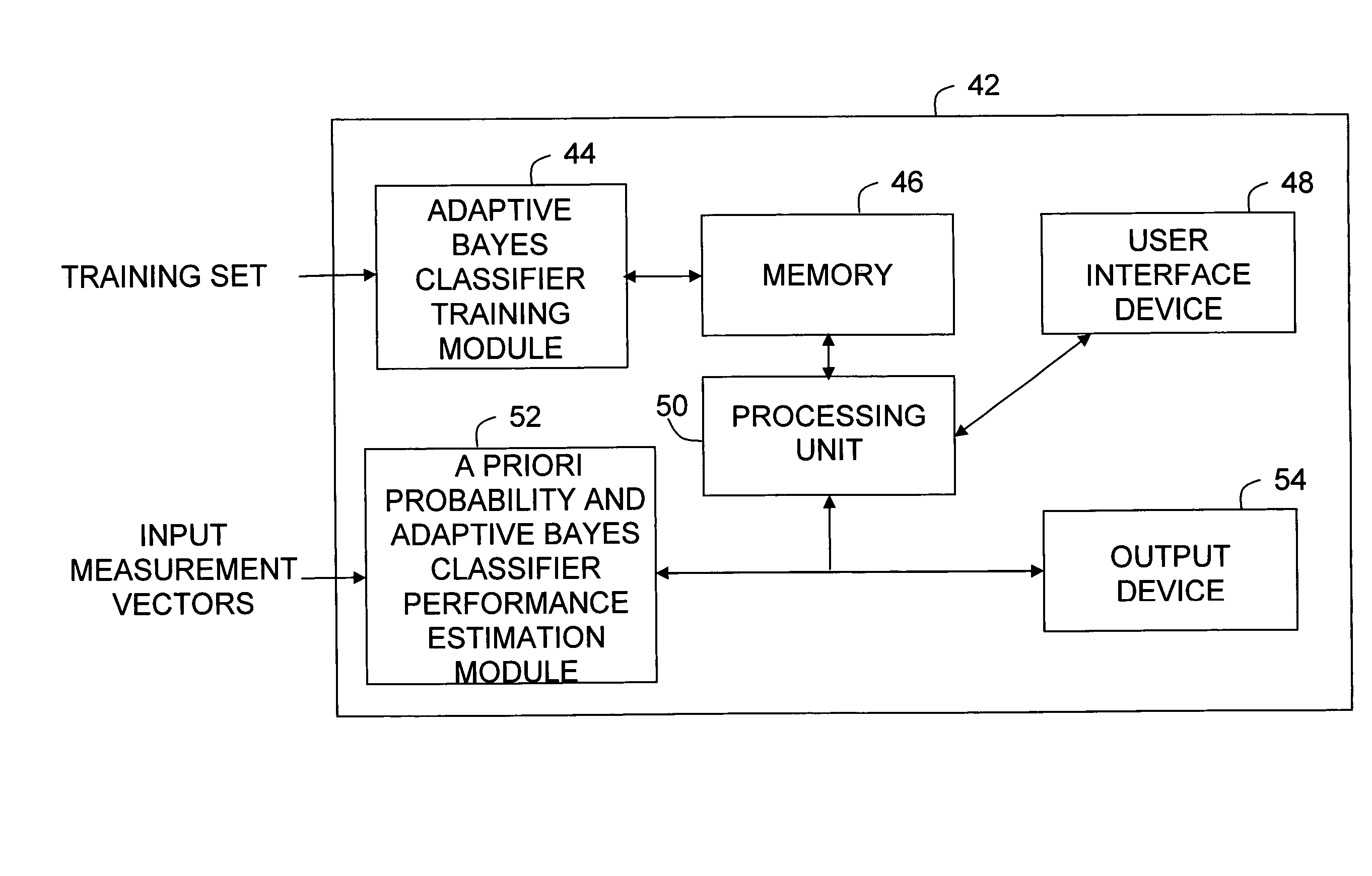

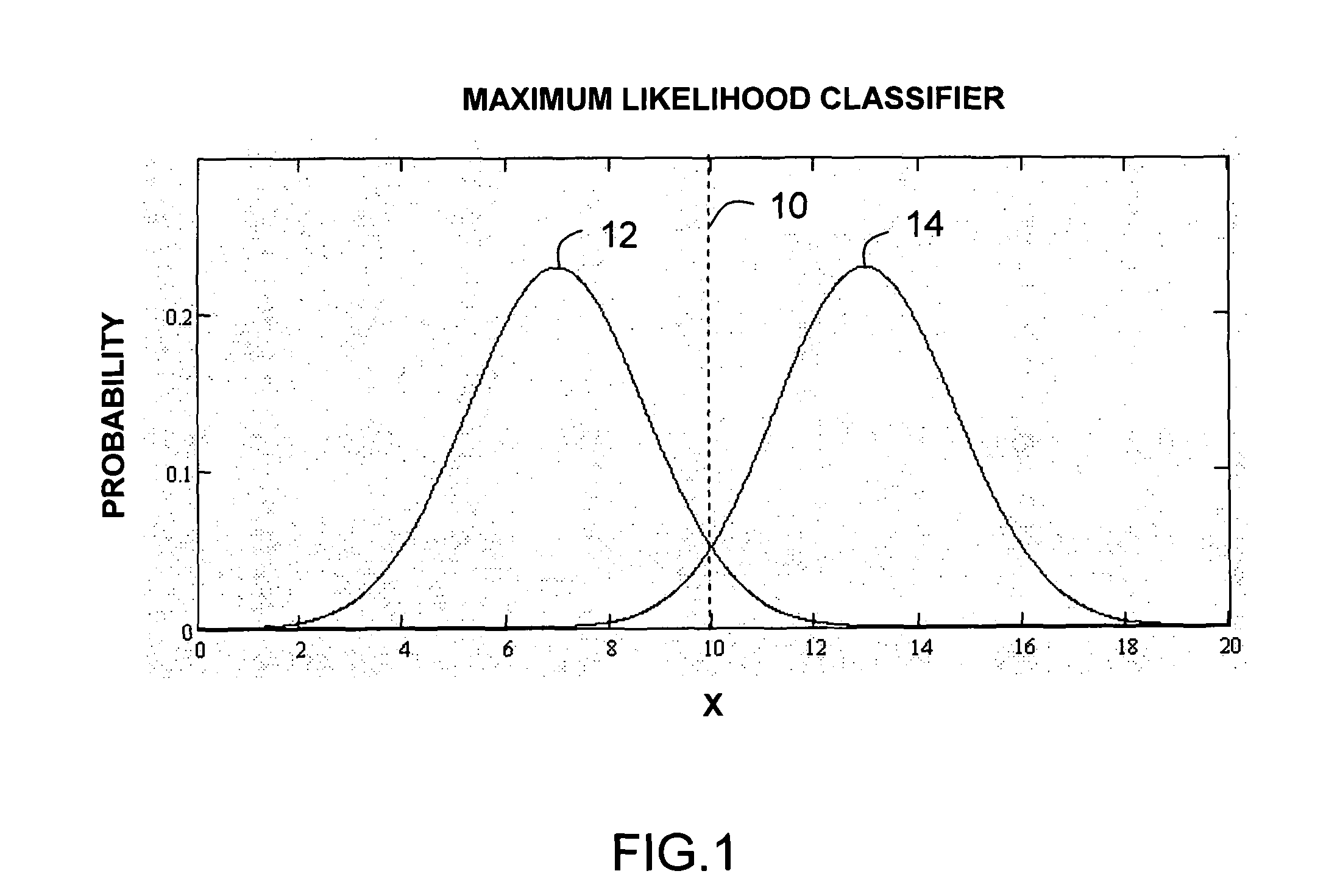

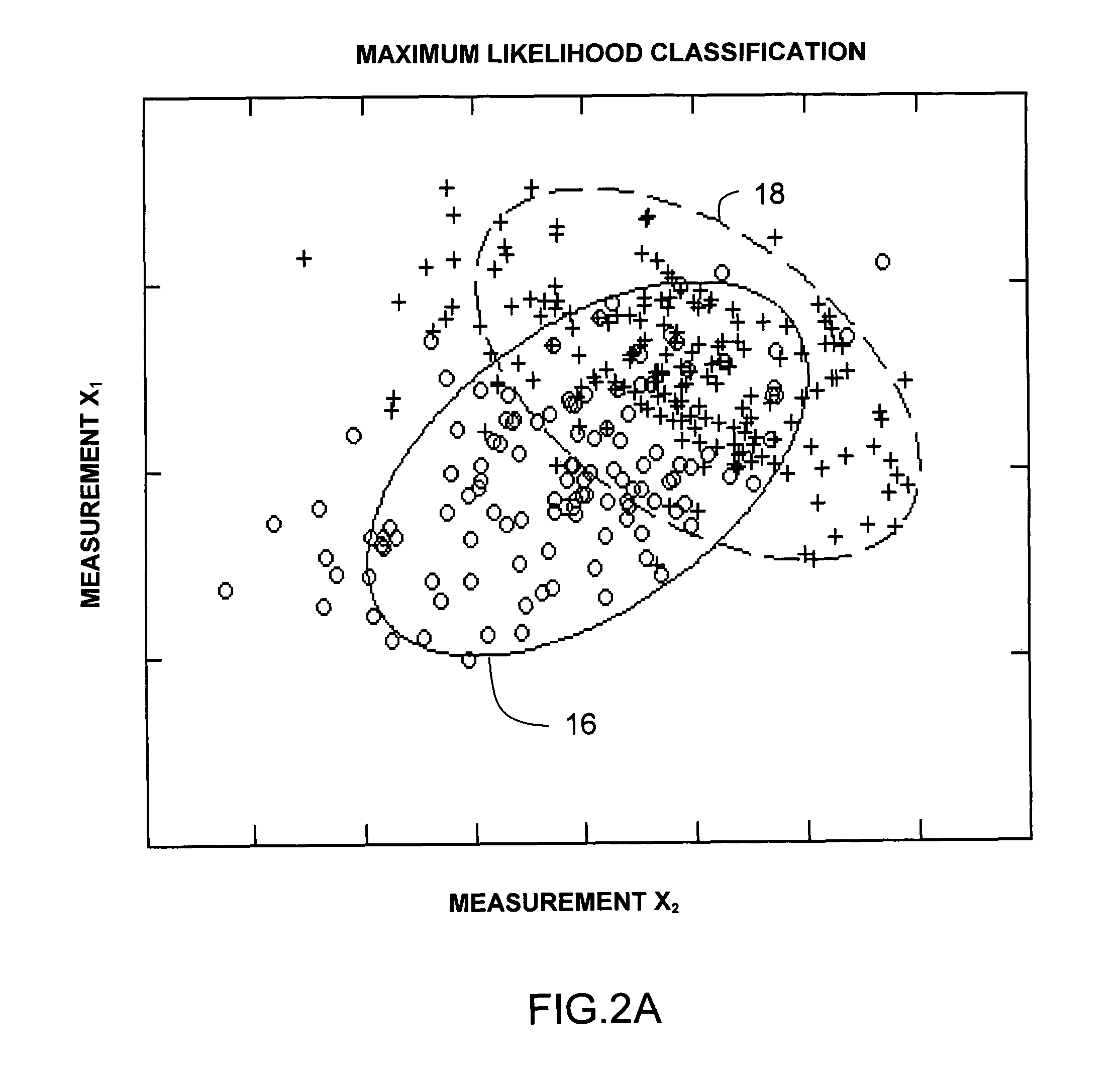

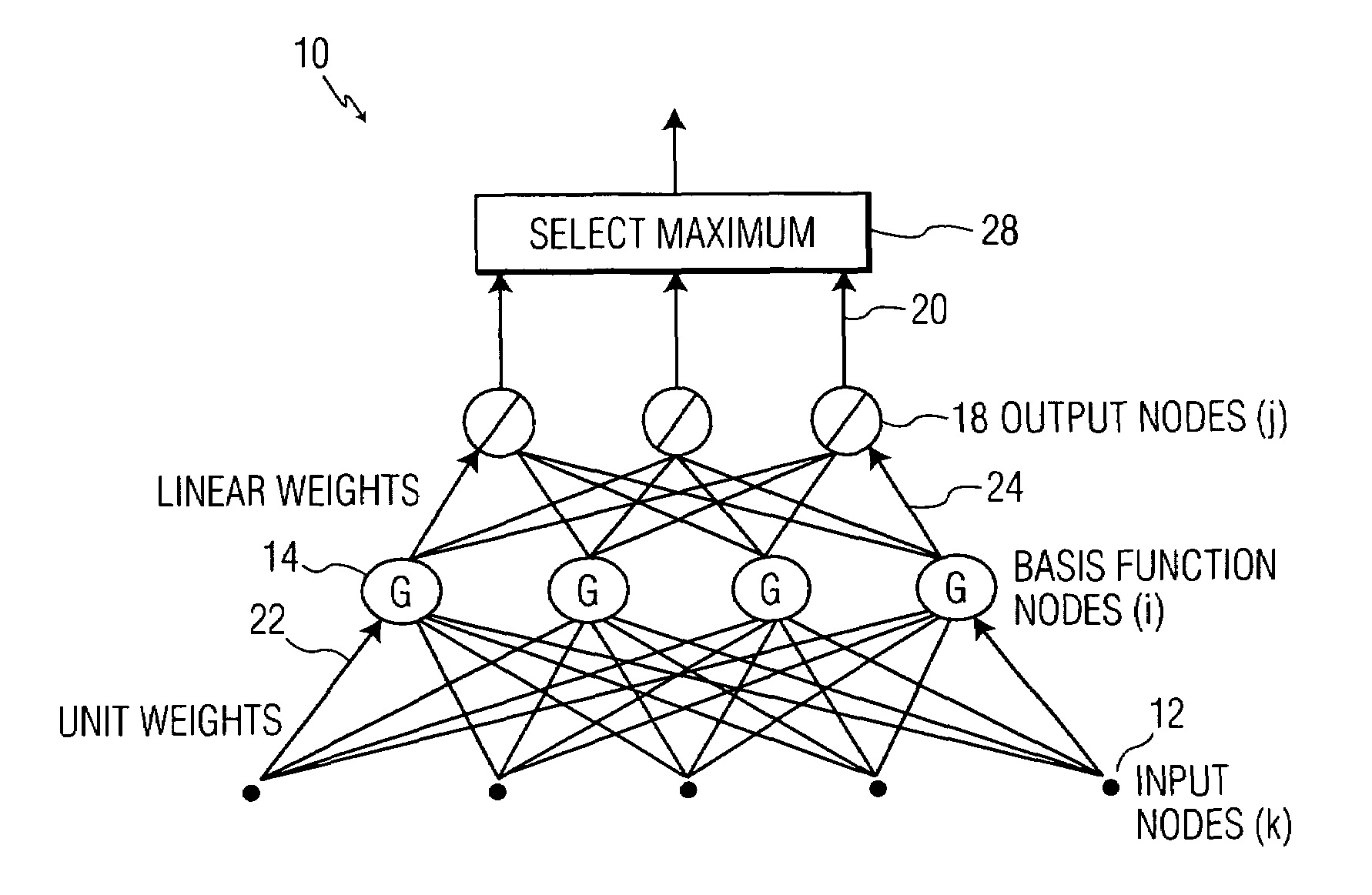

Priori probability and probability of error estimation for adaptive bayes pattern recognition

InactiveUS7979363B1Minimum errorImprove classification accuracyDigital computer detailsProbabilistic networksData setAlgorithm

A system and method for estimating the a priori probability of a class-of-interest in an input-data-set and a system and method for evaluating the performance of the adaptive Bayes classifier in classifying unlabeled samples from an input-put-data-set. The adaptive Bayes classifier provides a capability to classify data into two classes, a class-of-interest or a class-other, with minimum classification error in an environment where a priori knowledge, through training samples or otherwise, is only available for a single class, the class-of-interest. This invention provides a method and system for estimating the a priori probability of the class-of-interest in the data set to be classified and evaluating adaptive Bayes classifier performance in classifying data into two classes, a class-of-interest and a class-other, using only labeled training samples, or otherwise, from the class-of-interest and unlabeled samples from the data set to be classified.

Owner:MINTER THOMAS CECIL

System and method of face recognition using proportions of learned model

InactiveUS7308133B2Image analysisCharacter and pattern recognitionClassification methodsImaging data

A system and method for classifying facial image data, the method comprising the steps of: training a classifier device for recognizing one or more facial images and obtaining corresponding learned models the facial images used for training; inputting a vector including data representing a portion of an unknown facial image to be recognized into the classifier; classifying the portion of the unknown facial image according to a classification method; repeating inputting and classifying steps using a different portion of the unknown facial image at each iteration; and, identifying a single class result from the different portions input to the classifier.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

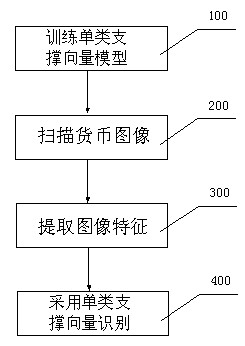

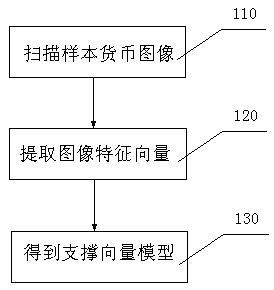

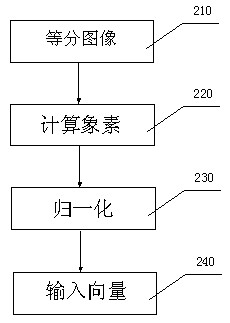

Method and device for examining money

InactiveCN102110323AHigh precisionImprove reliabilityPaper-money testing devicesCharacter and pattern recognitionFeature vectorSupport vector machine

The invention relates to a method and a device for examining money. The method for examining money comprises the following steps: training a single-class support vector model: according to a collected money image vector, carrying out algorithm training to obtain a single-class support vector and a vector model; scanning money images: scanning the images for preliminarily-examined money; extracting an image characteristic vector: processing a money image pixel characteristic into a standard matrix conforming to the input of the support vector machine, and extracting the money image characteristic vector; and identifying by a single-class classifier: calculating the extracted money image characteristic vector by the single-class support vector model, and judging the fact or fiction of the money according to a calculation result. According to the method and the device for examining money, the money is examined and identified by the single-class support vector model. Money examining technology with high precision and high reliability can be realized by the method and the device for examining money.

Owner:SHENZHEN YIHUA COMP

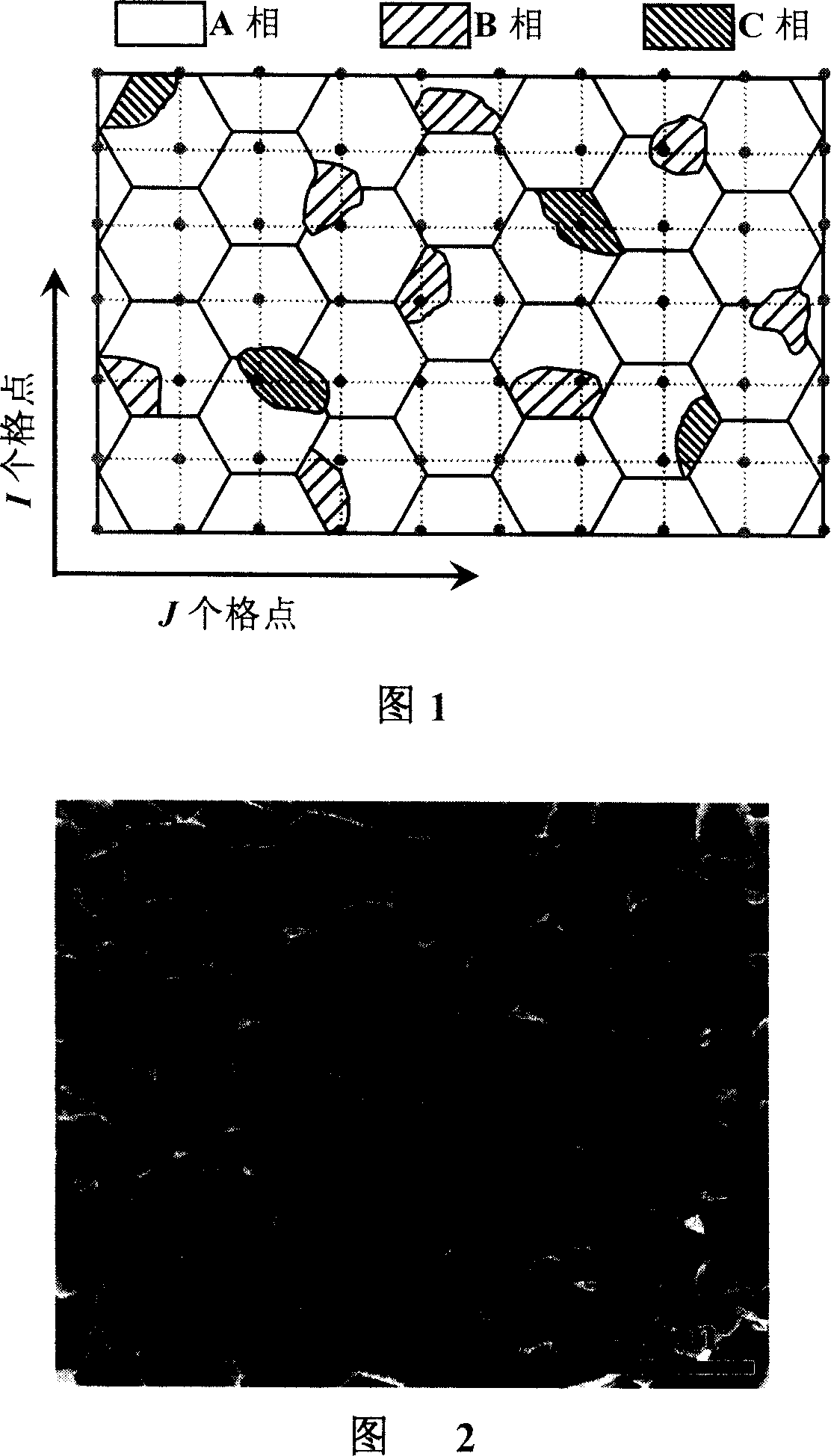

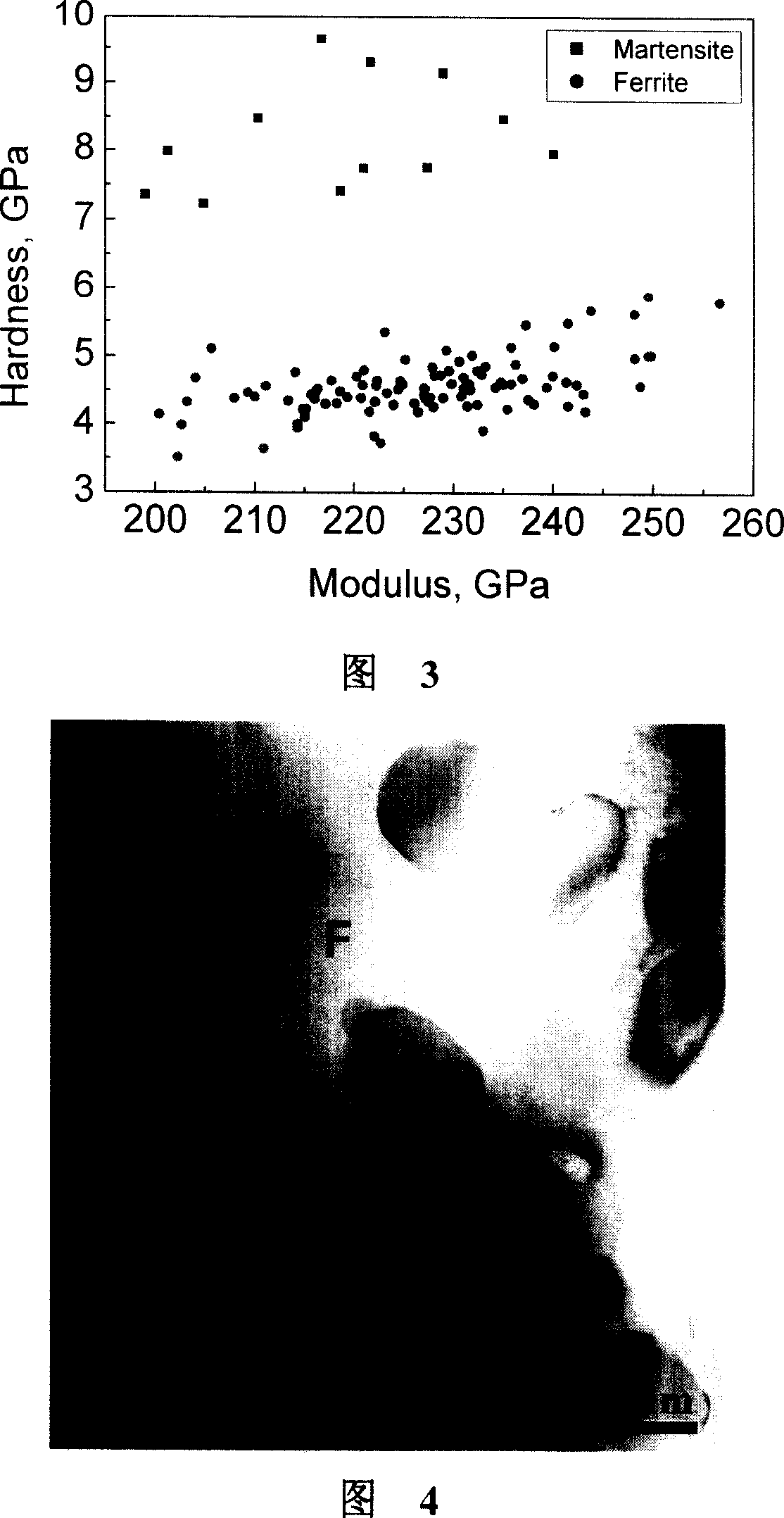

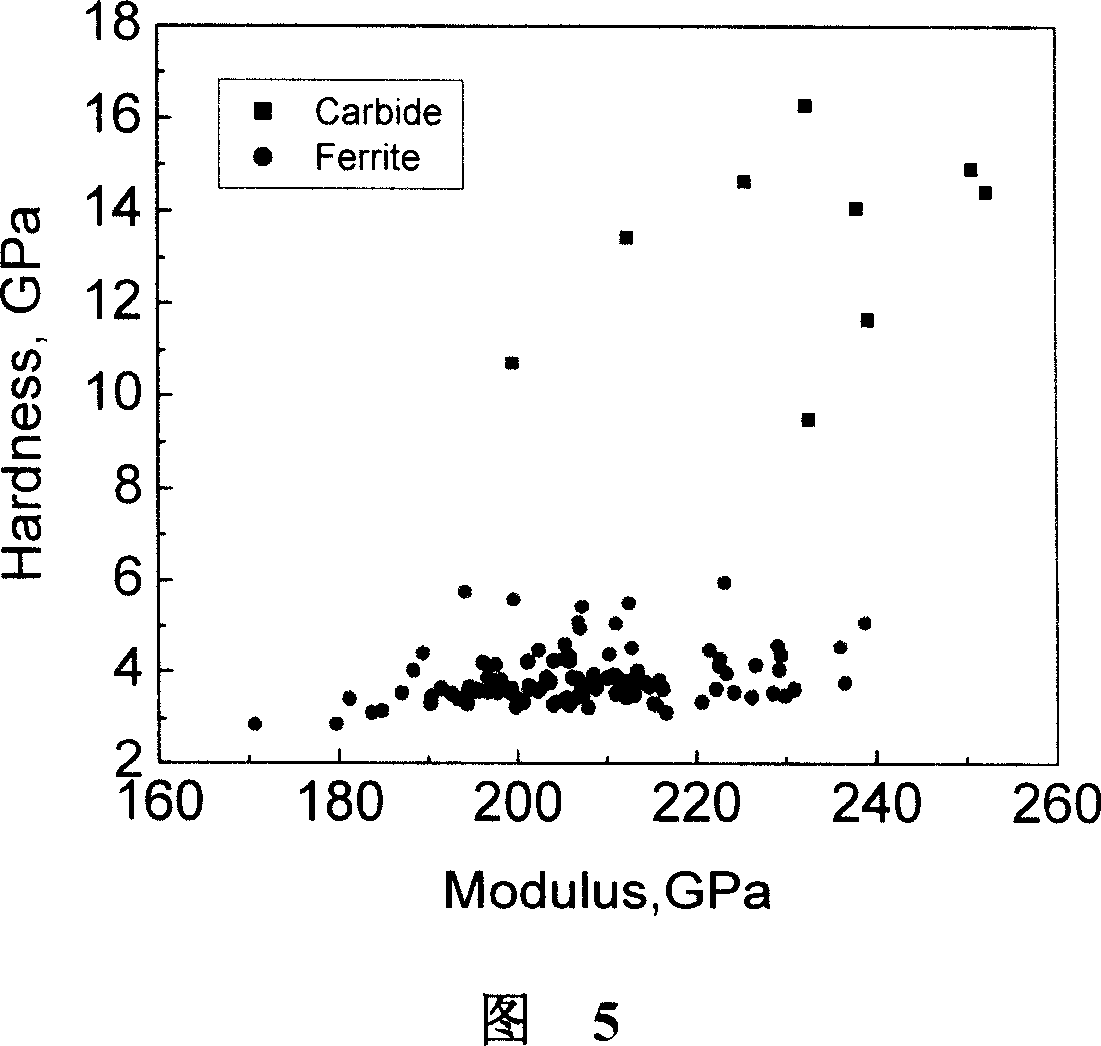

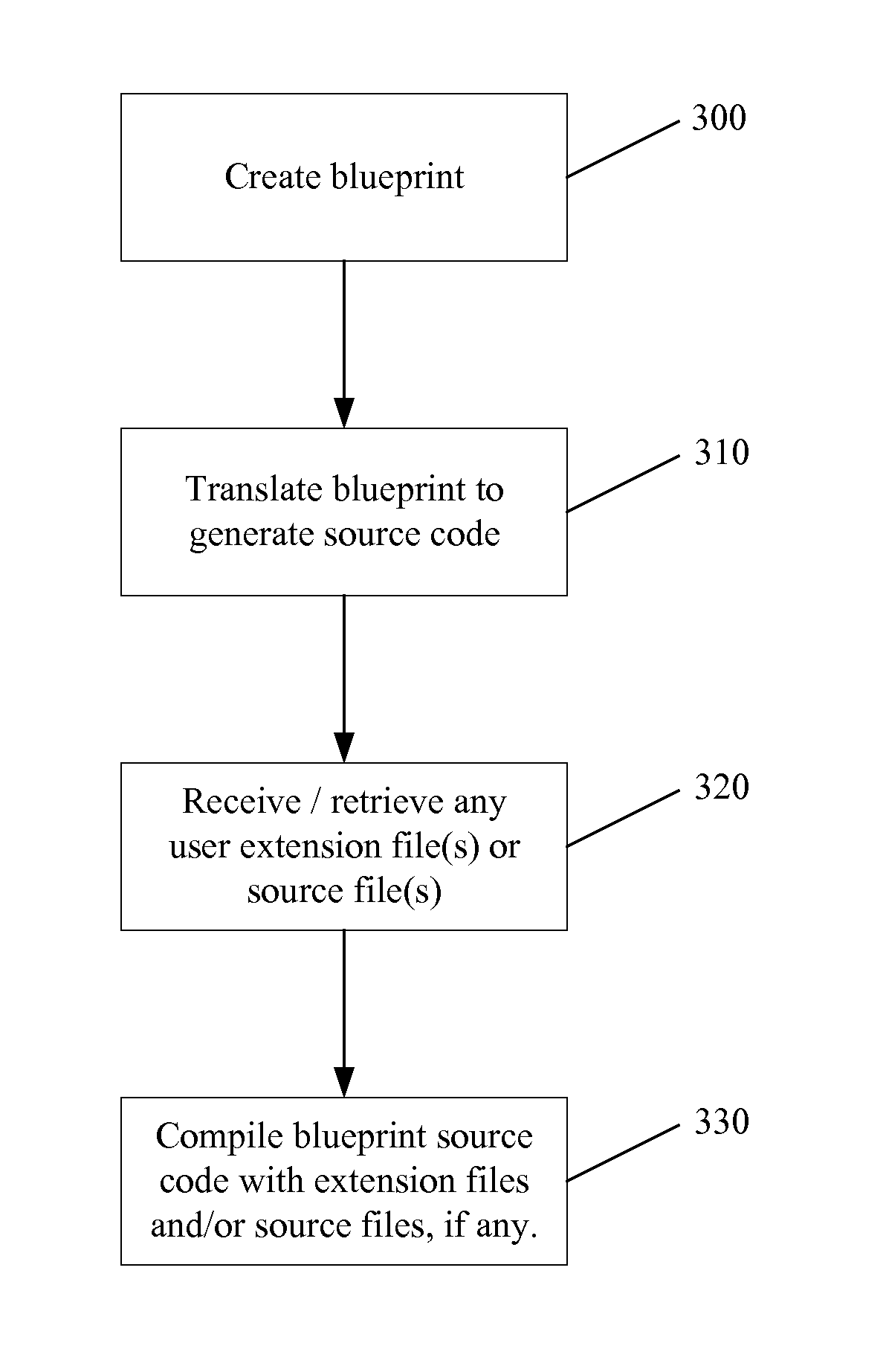

Polyphase material each ingredient phase content test method

ActiveCN101144765ASimple requirementsEliminate the effects ofPreparing sample for investigationInvestigating material hardnessMethod testAdditive ingredient

The invention discloses a nanometer press in testing method of the content of each constituent phase in heterogeneous material. The method tests the content of each constituent phase in the heterogeneous material by using the nanometer press in technology and the microindent characteristic, therefore, the invention has a substantive difference with other methods which are used to test the content of each constituent phase in the heterogeneous material. The method can achieve the testing of three parameters of the content of each constituent phase, the hardness and the Young modulus synchronously, to estimate the drop point of the press in testing each time (the press in point is positioned on which phase of the heterogeneous material), to get the content of each phase. The method of the invention is not only suitable for the heterogeneous materials of metal, macromolecule and ceramics, etc. which are combined by multi-class of different materials, but also suitable for the heterogeneous material which is combined by different phases in single-class material.

Owner:BAOSHAN IRON & STEEL CO LTD

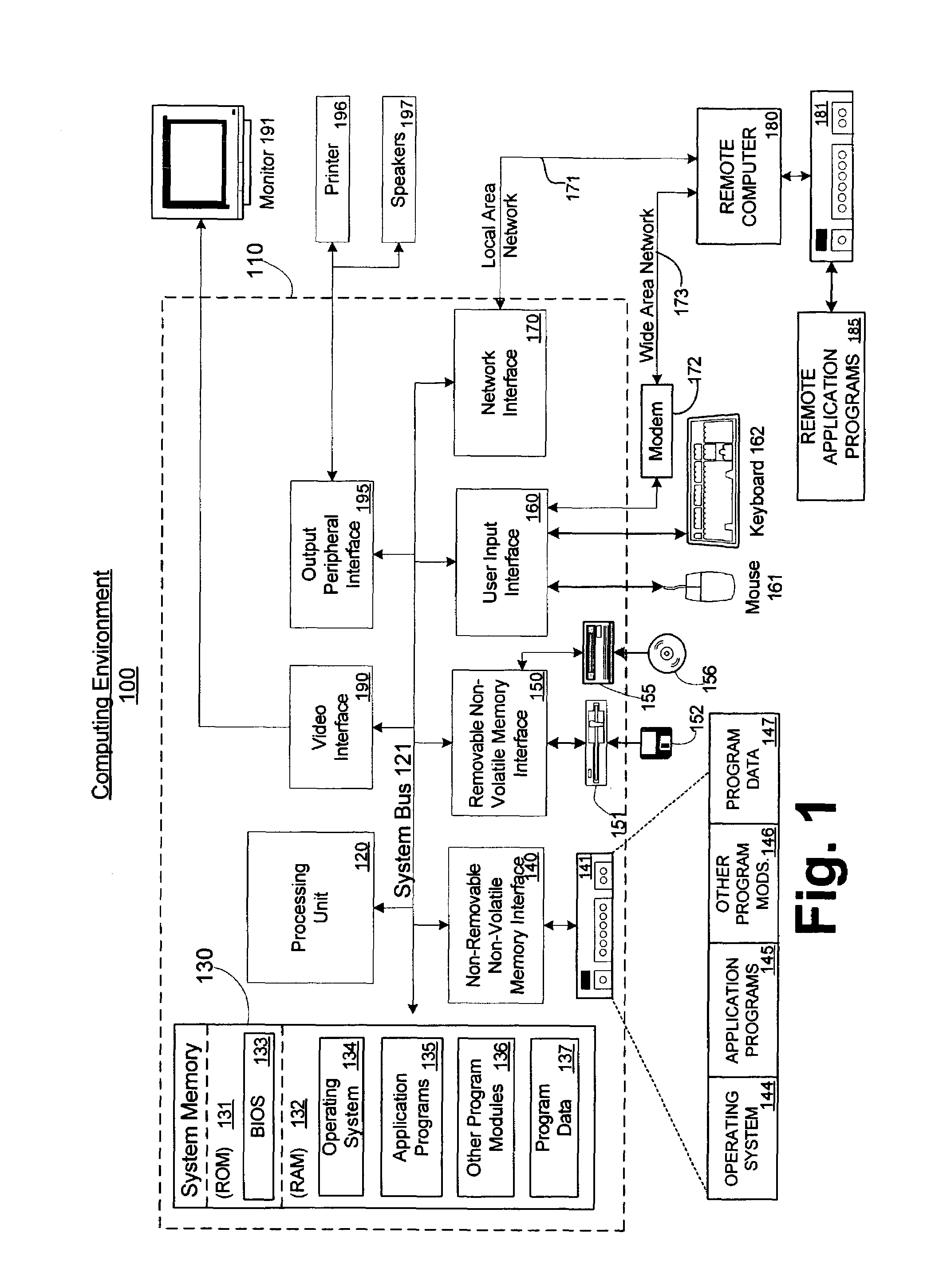

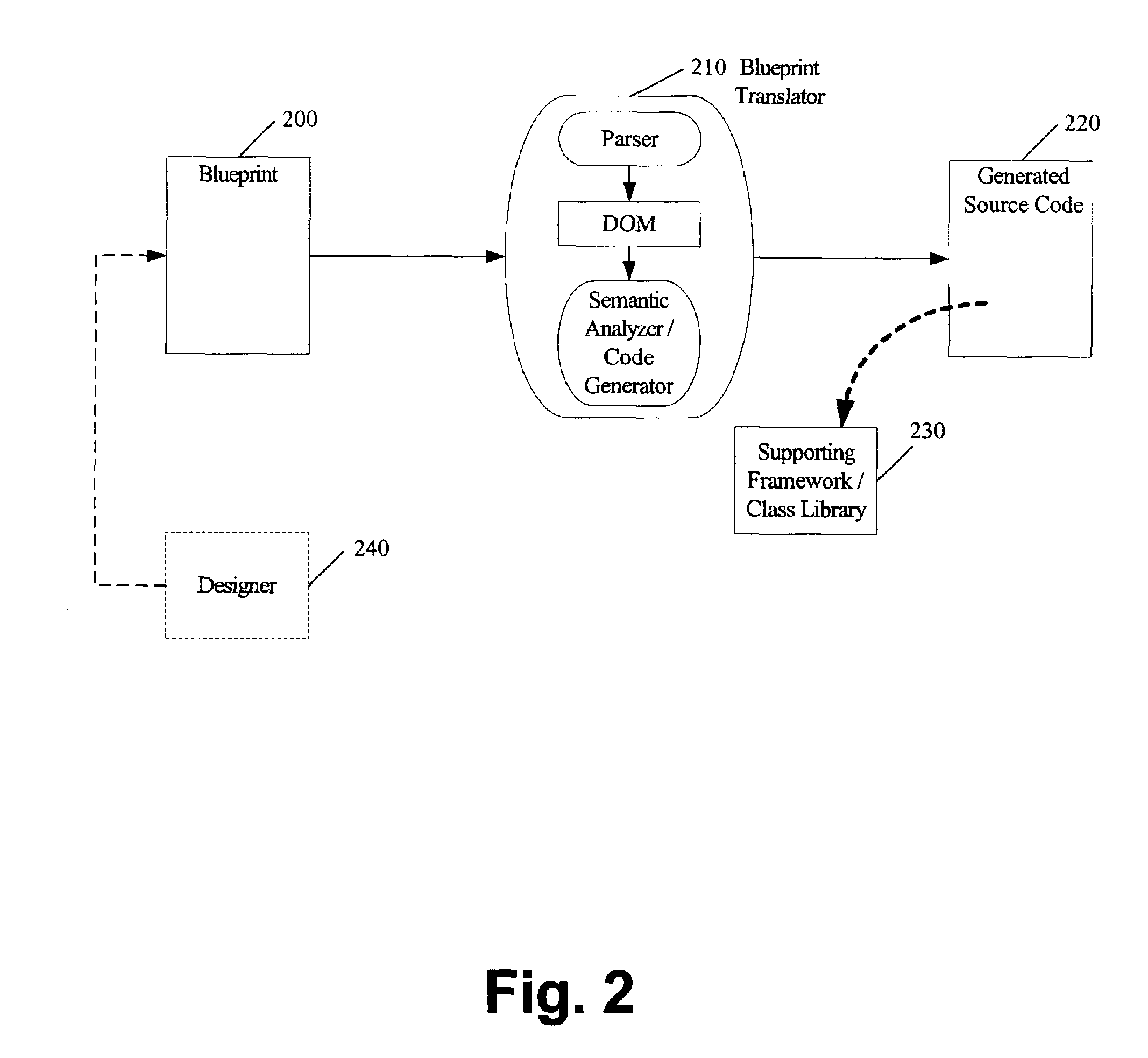

Code blueprints

A blueprint is described that provides a framework for writing a code generator. A blueprint translator translates the blueprint into one or more classes with source code. The newly generated code can then be compiled. If the user wishes to add additional functionality to a generated class, this is done in a separate source file. At compilation time, the compiler combines the generated class with the user's additions, as if they were written in a single class. Later, if the blueprint is ever changed, the generated code can safely be updated without overwriting the user's additions. Alternately, the user can embed his desired additions or changes directly into the blueprint (embedded code). In this manner, should the blueprint ever be re-compiled, the user's changes will still be present. The partial classes technique can be used in conjunction with the embedded code technique.

Owner:MICROSOFT TECH LICENSING LLC

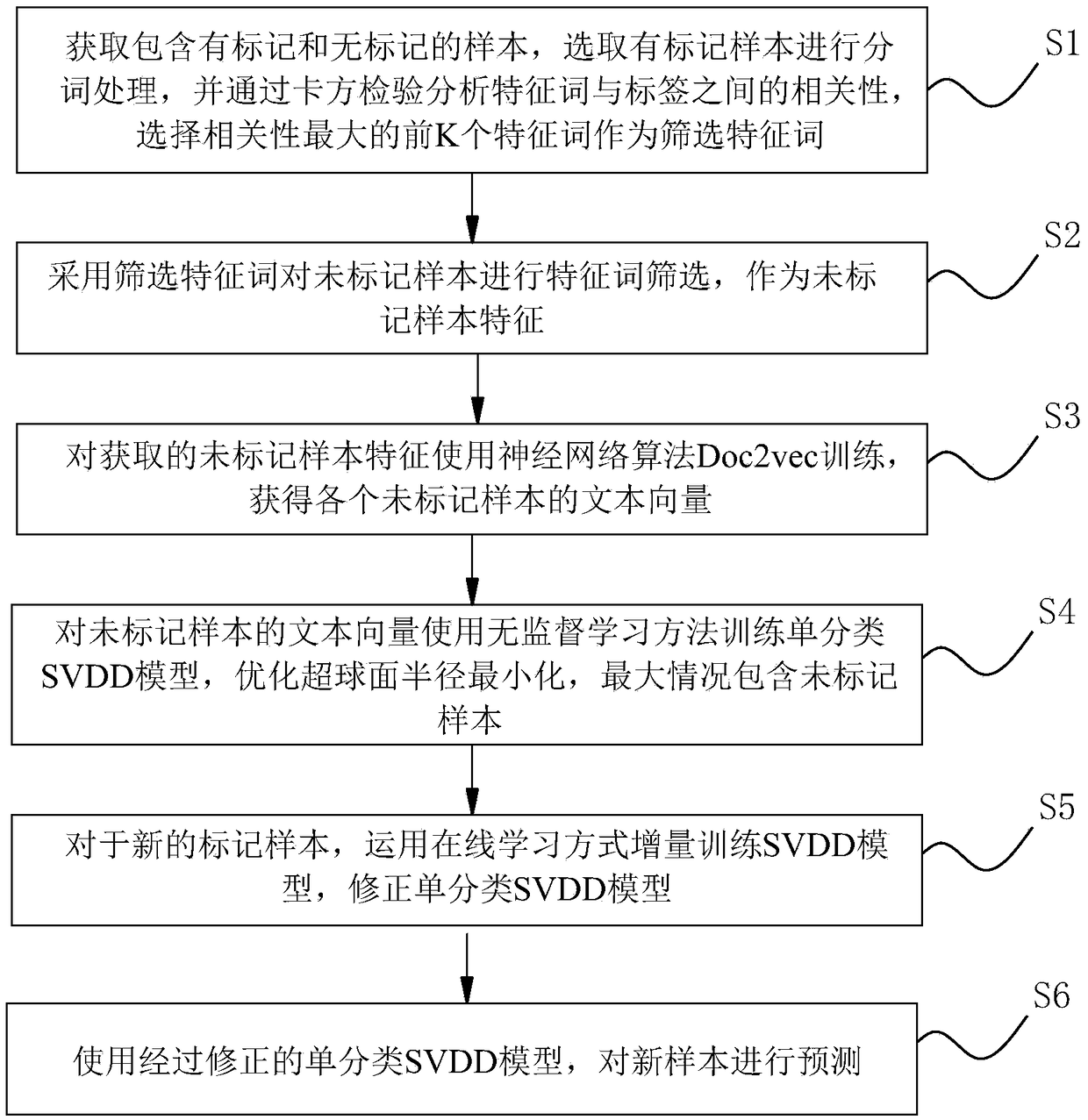

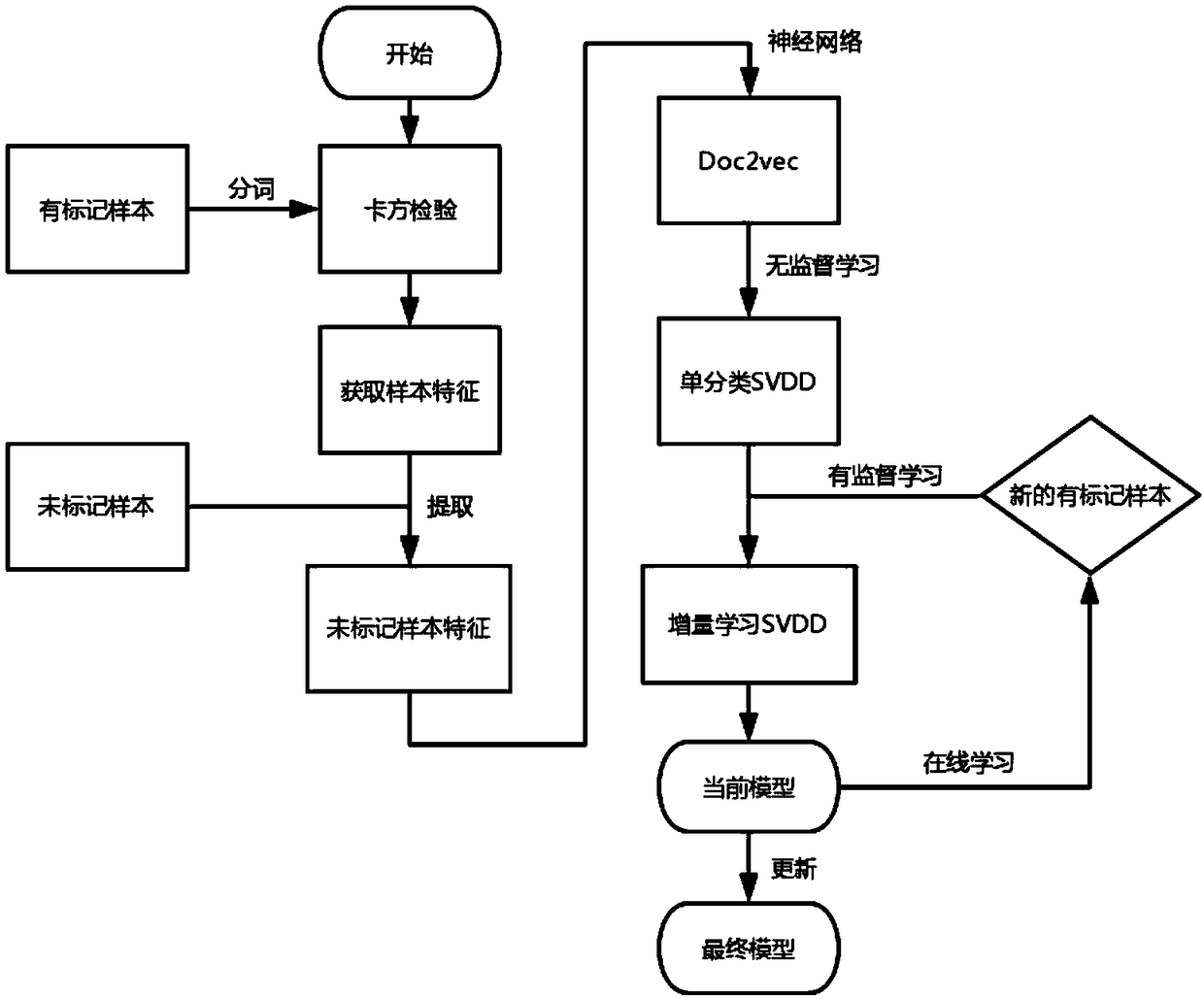

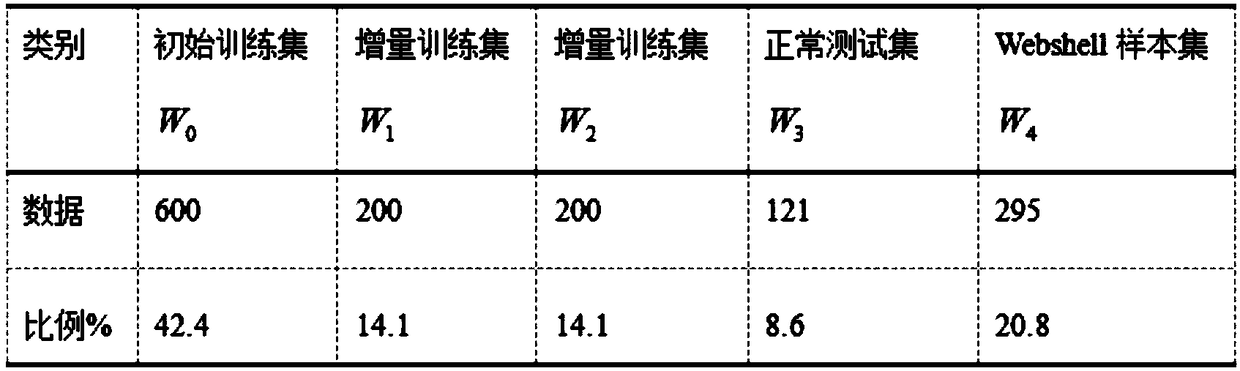

Webshell detection method and apparatus based on deep learning and semi-supervised learning

ActiveCN108833409AShow wellImprove performancePlatform integrity maintainanceTransmissionHypersphereSupervised learning

The invention provides a Webshell detection method and apparatus based on deep learning and semi-supervised learning. The method comprises the following steps: obtaining original training samples, selecting labeled samples to perform word segmentation processing, analyzing the correlation between feature words and labels by chi-square test, and selecting the previous K feature words with the strongest correlation as screening feature words; performing feature word screening on unlabeled samples by using the screening feature words to serve as unlabeled sample features; training the obtained unlabeled sample features by using a neural network algorithm to obtain text vectors of the unlabeled samples; training a single-class SVDD model by using an unsupervised method, and optimizing a hypersphere radius to the minimum, wherein the maximum case comprises the unlabeled samples; and for a new labeled sample, performing incremental training on the SVDD model by using an online learning method to correct the single-class SVDD model; and applying the latest model to the prediction of new samples. By adoption of the Webshell detection method and apparatus provided by the invention, the missing report rate and the false reporting rate of the traditional webshell detection can be effectively improved.

Owner:BEIJING WANGSIKEPING TECH

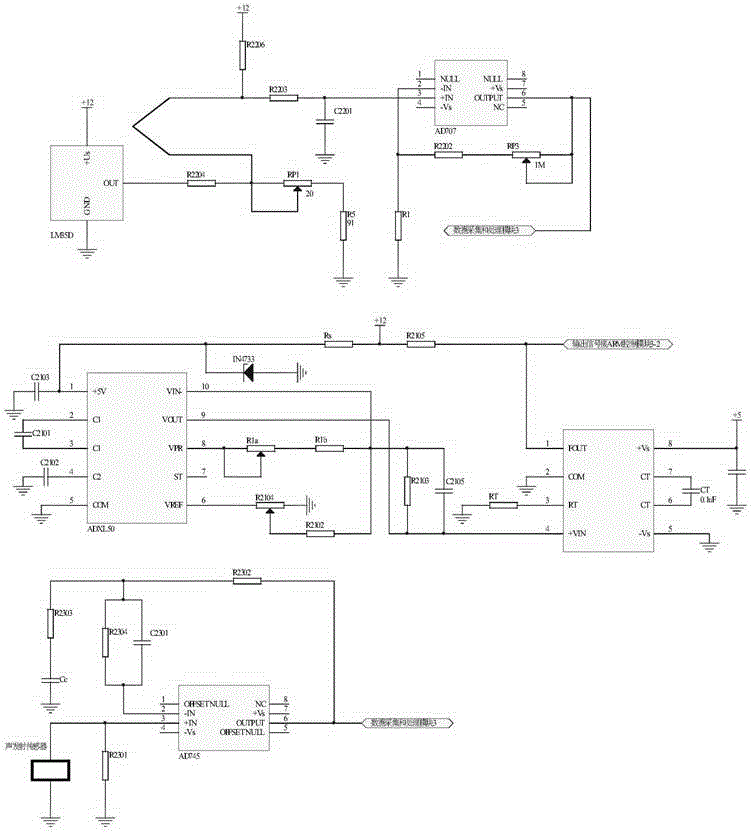

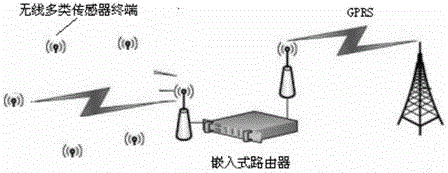

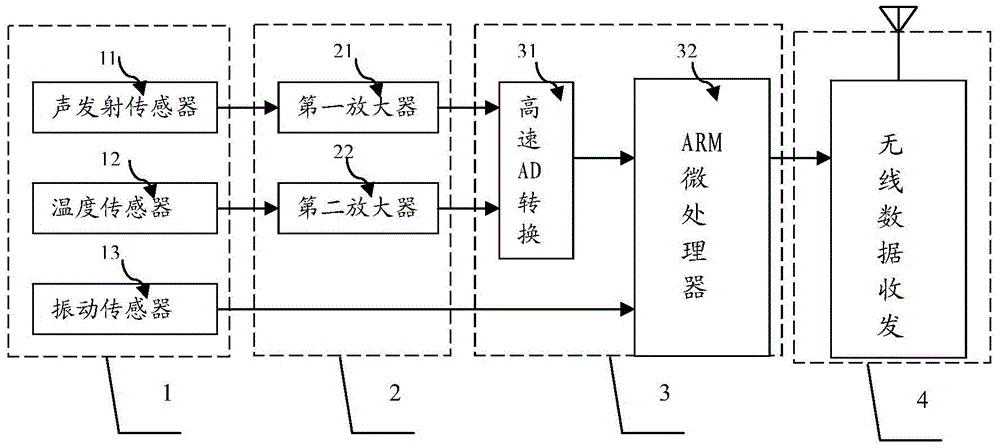

Wind turbine generator gear case remote monitoring device

InactiveCN104019917AOvercoming the shortcomings of using a single type of vibration sensor measurementVersatileSubsonic/sonic/ultrasonic wave measurementThermometers using electric/magnetic elementsTransceiverWireless data

The invention discloses a wind turbine generator gear case remote monitoring device. The wind turbine generator gear case remote monitoring device comprises wireless multiclass sensor terminals, an embedded router and a GPRS data transceiver terminal, wherein the wireless multiclass sensor terminal comprise integrated sound emission, vibration and temperature multiclass sensor modules, amplification modules, data acquisition and processing modules and wireless data transceiver modules. During monitoring, the multiple wireless multiclass sensor terminals are distributed on monitoring points of a wind turbine generator gear case, the wireless multiclass sensor terminals detect temperature, vibration and sound emission data of the monitoring points in real time, and the data is sent to the GPRS data transceiver terminal through the embedded router and is remotely transmitted to a data analysis processing computer of a main station. The wind turbine generator gear case remote monitoring device employs digitalization, modularization and radio transmission technologies, solves problems of over-long connection wire, complex mounting and difficult maintenance of a traditional wired monitoring device, and further solves a problem of single-class measurement existing in the traditional monitoring device employing a vibration sensor.

Owner:HARBIN INST OF TECH

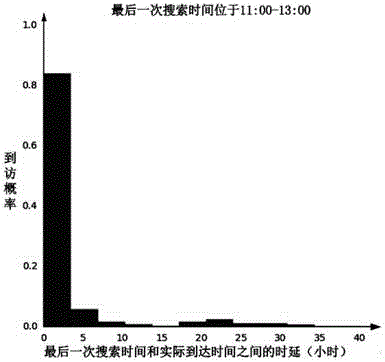

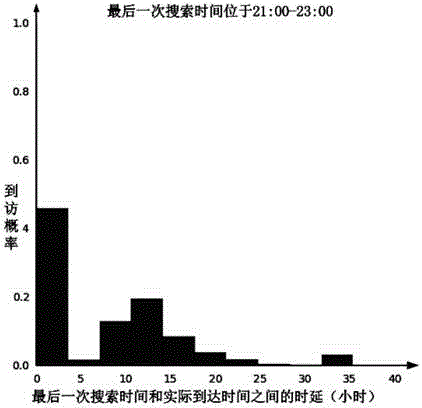

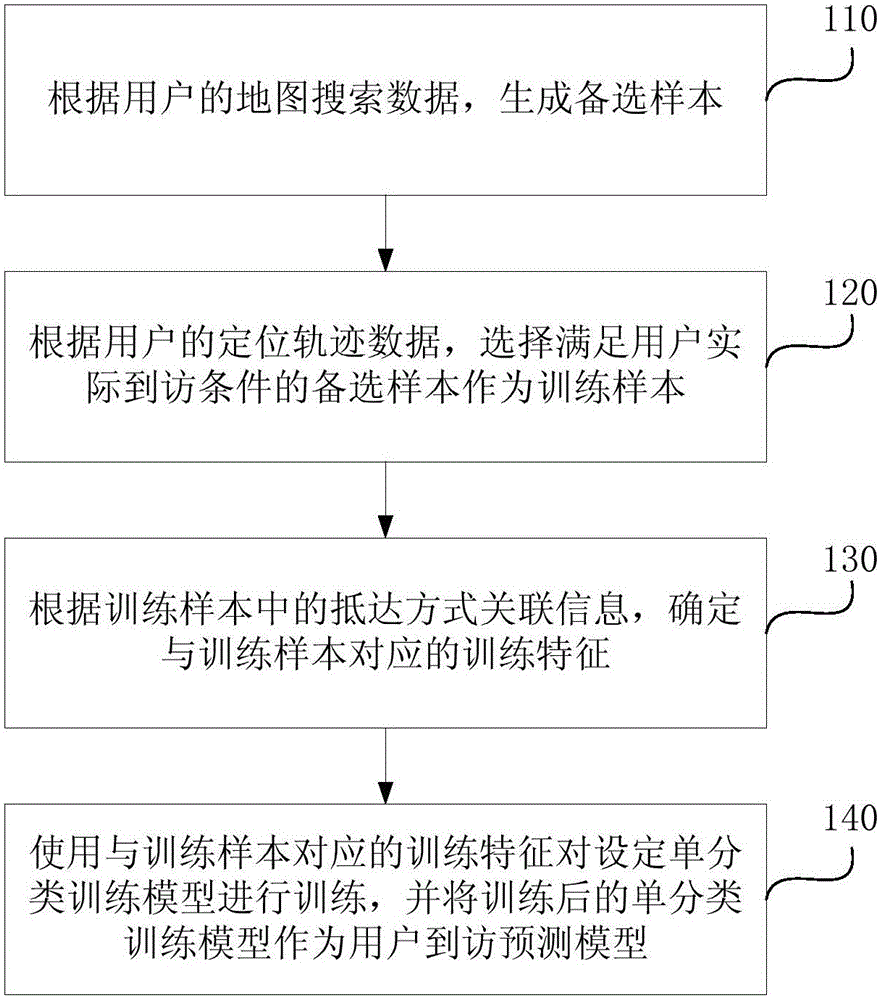

User visiting prediction model establishment and user visiting prediction method and apparatus

ActiveCN106055607AOptimizing Visit Prediction TechnologyImprove accuracySpecial data processing applicationsMachine learningSingle class

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

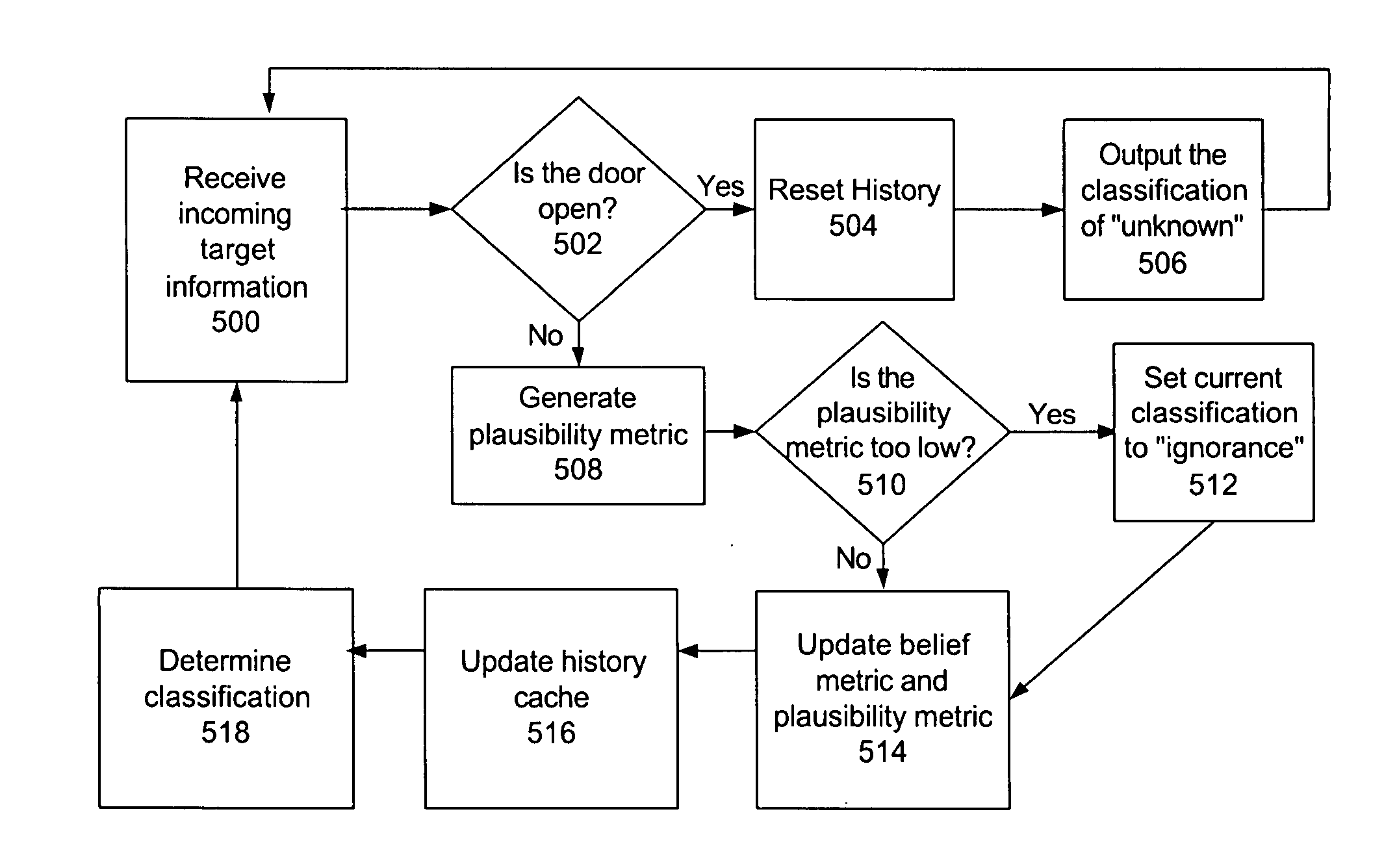

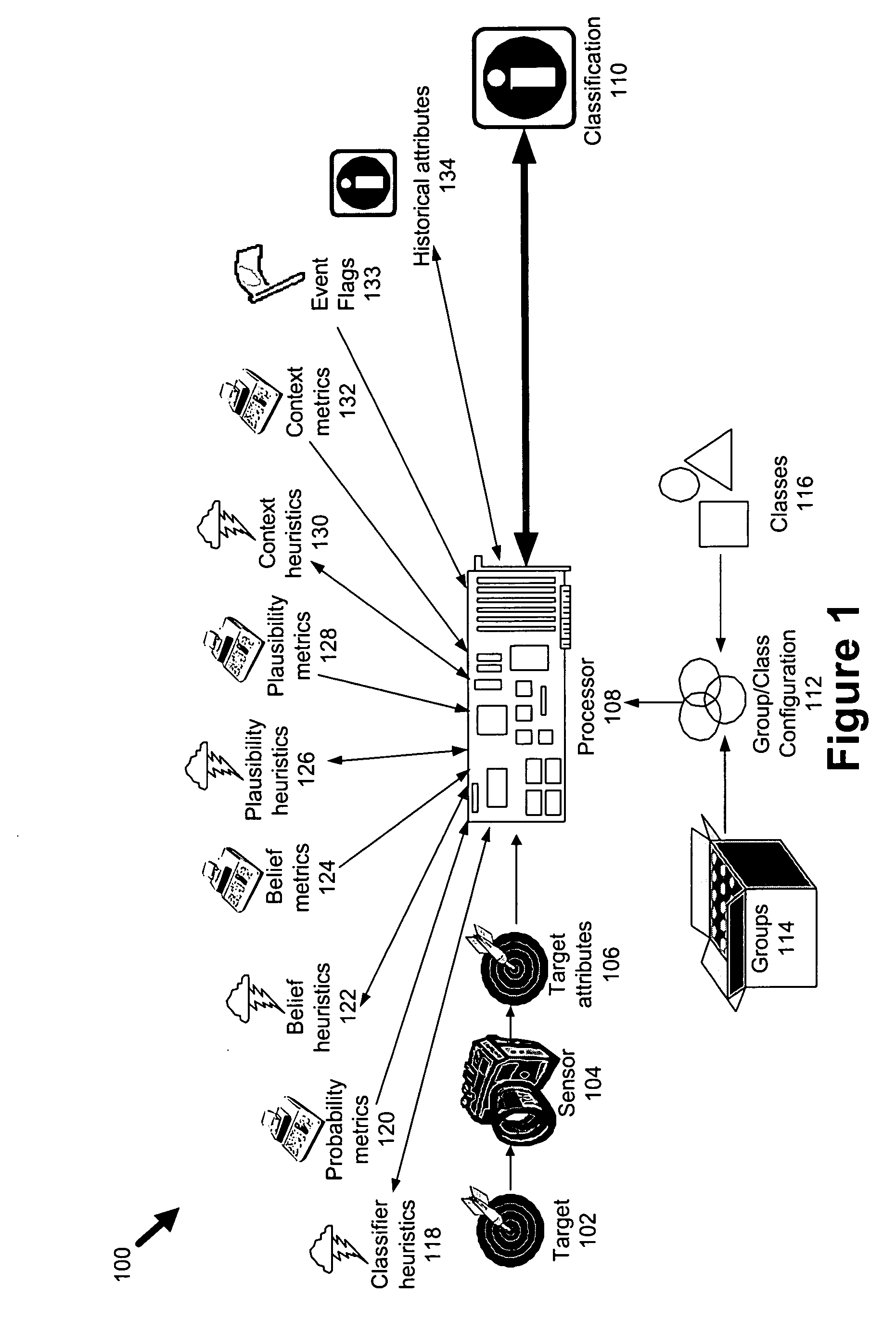

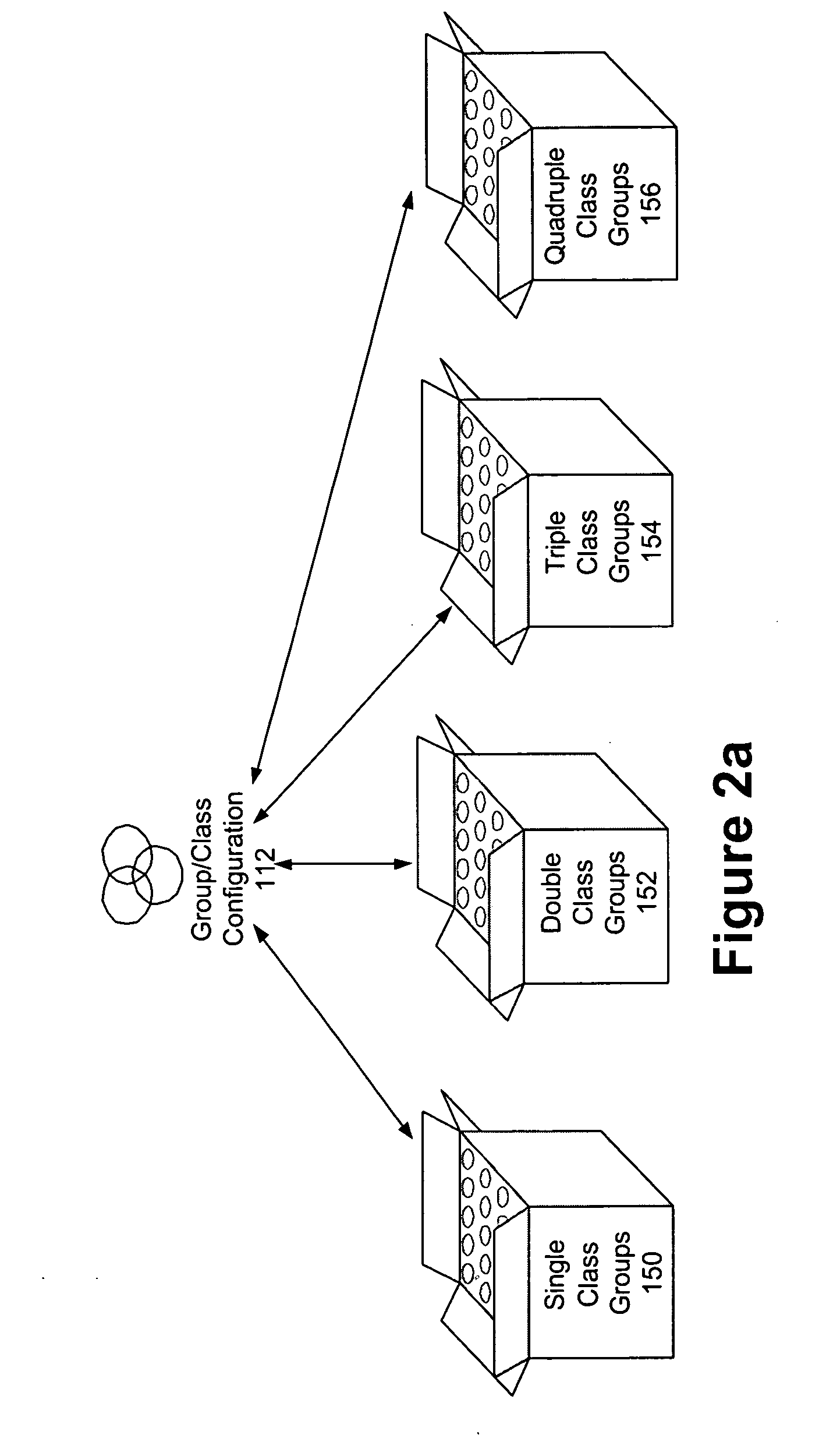

System or method for classifying target information captured by a sensor

InactiveUS20050177290A1Enhance decision of selectionFacilitate decision-makingElectric devicesDigital data processing detailsInformation captureMachine learning

The disclosure describes a system and method for classifying information relating to target attributes that are captured by a sensor (collectively “classification system”). A wide variety of sensors, classification categories (including potentially classes and groups of classes), targets, and purposes can influence the processing performed by the classification system. The classification system is not forced to arbitrarily identify a single class as the appropriate classification if two or more classes cannot be adequately distinguished from one another given the particular target attributes and processing results. The classification system can generate a classification relating to a group of classes, with the group including one, two, or even more than two classes, if such a conclusion is appropriate. Historical attributes, environmental factors, relevant events and the plausibility of transitions from one class to another, can be incorporated into the classification process.

Owner:EATON CORP

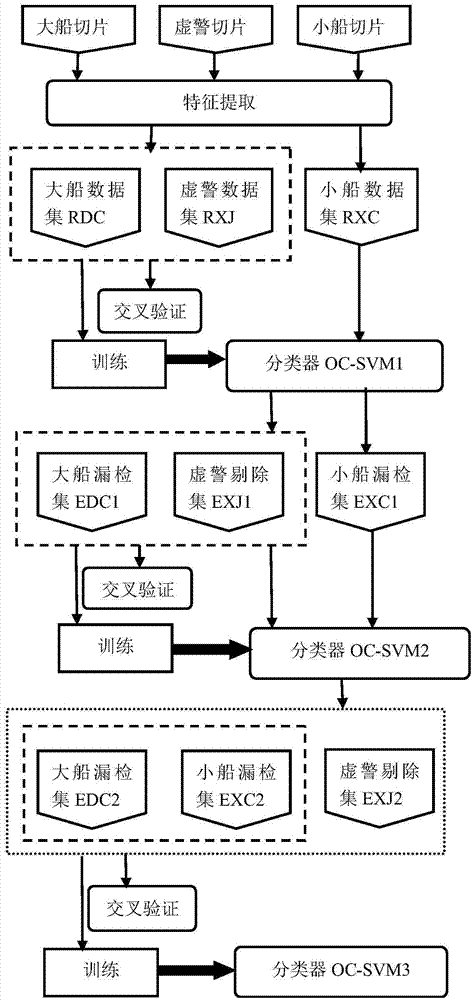

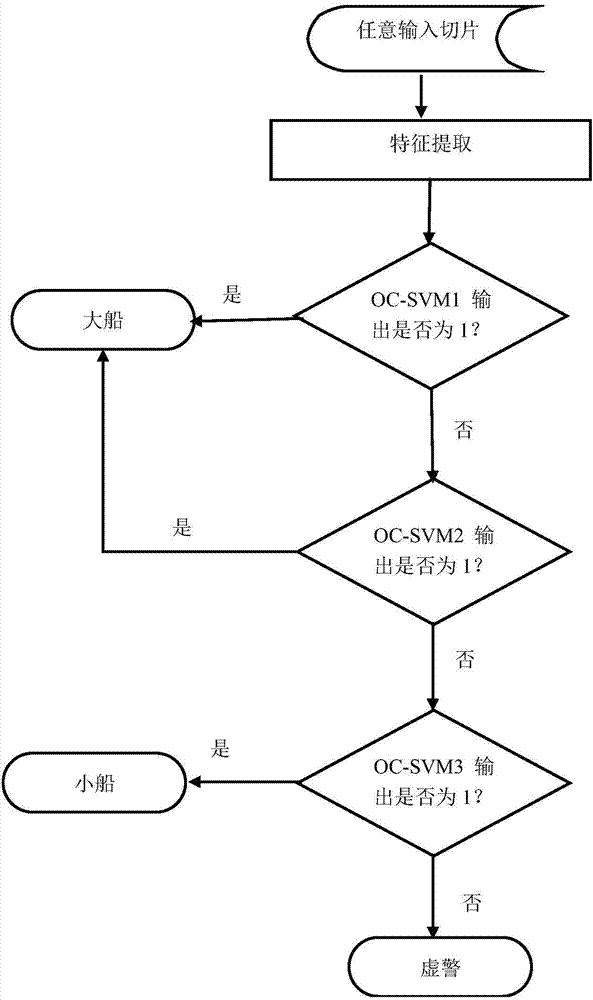

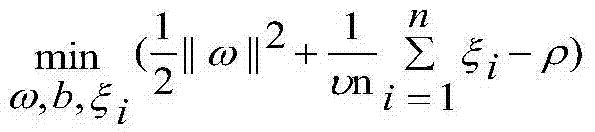

Layering single-class ship target false alarm eliminating method based on intra-class difference

ActiveCN104268570AQuick checkImprove detection rateCharacter and pattern recognitionData setFeature data

The invention discloses a layering single-class ship target false alarm eliminating method based on the intra-class difference. The method includes the steps that an optical remote sensing image is divided into a large ship slice, a small ship slice and a false alarm slice, a first-layer classifier is established based on large ship feature data, and a large ship to which great attention is paid in ship detection can be basically recognized through the first-layer classifier; when features of the large ship are obvious, the large ship can be detected through primary detection, and therefore the purpose of rapid large ship detection can be achieved; a large ship data set missing detection is trained, so that a second-layer classifier is formed, when the large ship is not recognized through the first-layer classifier, the large ship easily missing detection can be detected through the second-layer classifier, and therefore the detection probability can be increased; through screening of the first-layer classifier and the second-layer classifier, data with the large ship features in a small ship data set are eliminated, the data with the obvious small ship features are kept, a small ship mistakenly-distributed set is formed, and the detection probability of a small ship is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heating of products in an aerosol dispenser and aerosol dispenser containing such heated products

PendingUS20170166391A1Avoid explosionPackage recyclingLiquid dispensingPlastics industryMicrowave oven

A method of warming food dispensable from an aerosol dispenser. The aerosol dispenser is made from materials which can go into a single recycling stream having a single class of materials, as defined by the Society of the Plastics Industry, and particularly may exclusively comprise Class 1 materials suitable for eating in a microwave oven. Consumer products, such as food, contained in the aerosol dispenser may be heated in a microwave oven prior to dispensing. Upon dispensing, food retains residual heat, and is suitable for eating or further cooking. Other heated products in the aerosol dispenser may be comfortably applied to the skin, used as air freshener, used for cleaning, etc. The aerosol dispenser may have indicia indicating the aerosol dispenser is suitable for microwave heating. The aerosol dispenser can have indicia indicating the aerosol dispenser is suitable for heating in a microwave oven. The indicia may be thermochromic, indicating when a desired temperature has been reached. The aerosol dispenser can have a safety valve, to safely relieve product and / or propellant pressure upon overpressurization in a microwave oven. The safety valve may be single use or reusable.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com