Polyphase material each ingredient phase content test method

A technology of multi-phase materials and testing methods, applied in the direction of testing material hardness, preparation of test samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

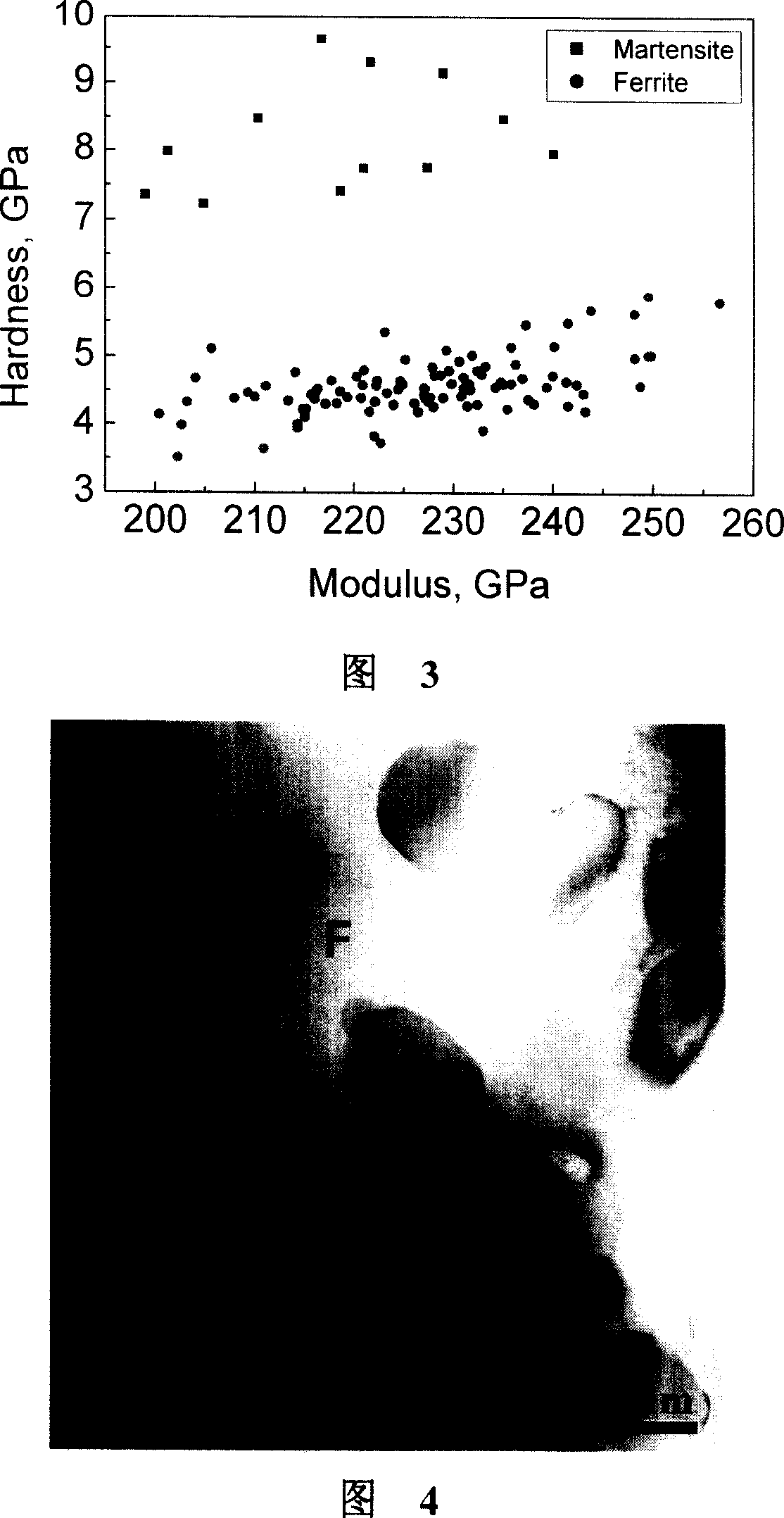

[0043] The multiphase material tested is a ferrite-martensite dual-phase steel, and the average grain diameters of ferrite and martensite are 3.0 μm and 1.3 μm, respectively. A test area was randomly selected on the sample, and 120 indentation tests were performed. The 120 indentation points constituted a 12×10 rectangular grid with a pitch of 5 μm. During the test, the Berkovich diamond indenter was used, and the radius of curvature of the tip was -1 .

[0044] After the test, 120 hardness-Young's modulus data pairs were obtained, and the scatter diagram is shown in Figure 2. It can be seen from the figure that the 12 points with higher hardness values gather into a group, indicating that 12 points fall on the harder martensite phase in the dual-phase steel during the test; the remaining 108 points with lower hardness values gather into a group, It shows that 108 points fell on the softer ferrite phase in the dual phase steel during the test. It can be concluded that th...

Embodiment 2

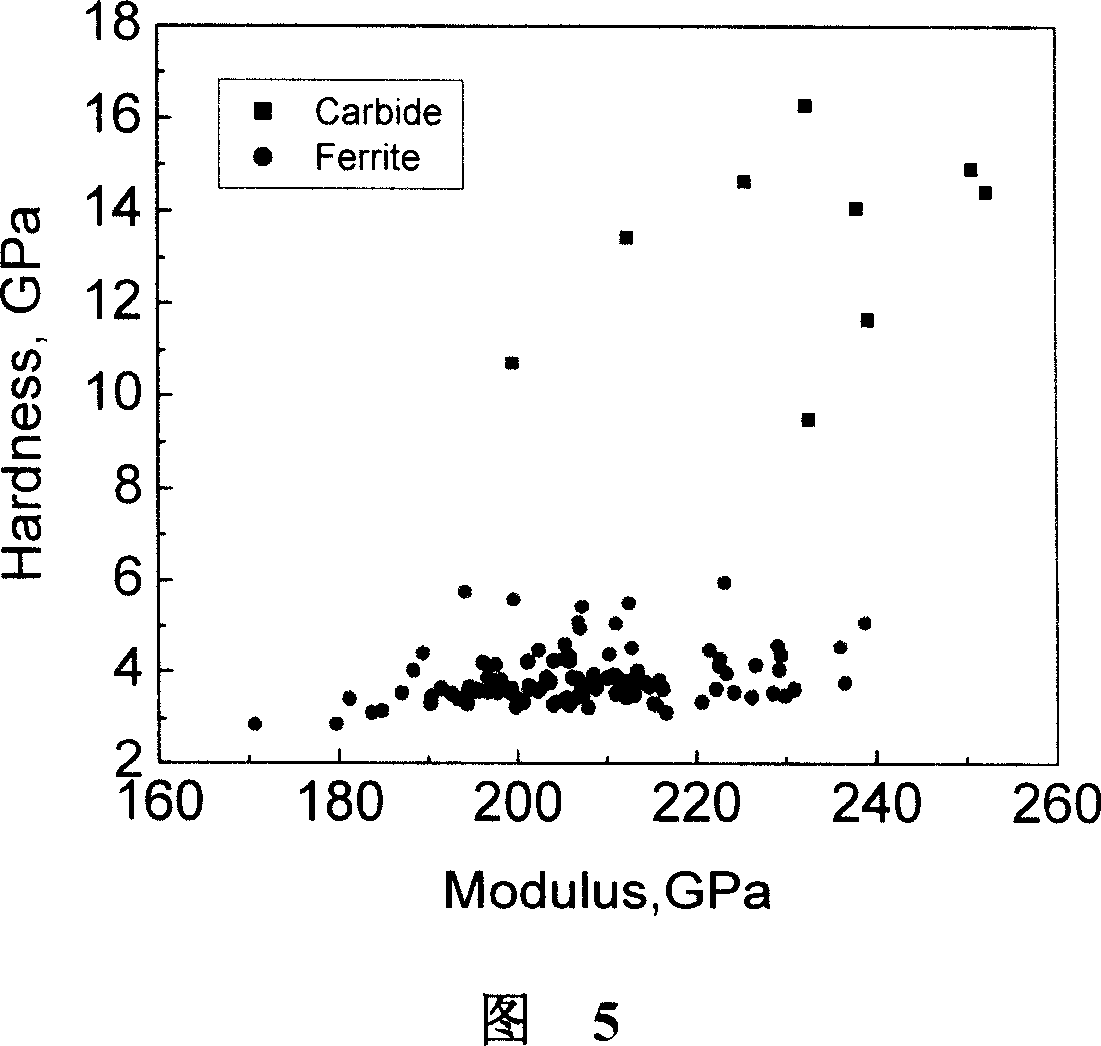

[0047] The multiphase material tested is a ferrite-carbide dual-phase steel, and the average diameter of carbide particles is 0.5 μm. Three test areas were randomly selected on the sample, and 40 indentation tests were performed on each area. The 40 indentation points constituted an 8×5 rectangular grid with a pitch of 5 μm. During the test, a Berkovich diamond indenter was used, the radius of curvature of the tip was 1 .

[0048] After the test, 120 hardness-Young's modulus data pairs were obtained, and these data were summarized in a scatter diagram, as shown in Figure 3. It can be seen from the figure that 9 points with higher hardness values are gathered into a group, indicating that 9 points fall on the harder carbide particles in the dual-phase steel during the test; the remaining 111 points with lower hardness values are gathered into a group, indicating that During the test, 111 points fell on the softer ferrite phase in the dual phase steel. It can be concluded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius of curvature | aaaaa | aaaaa |

| Average grain diameter | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com