Automatic welding and defect detection method based on self-learning

An automatic welding and defect detection technology, applied in optical testing defects/defects, measuring devices, scientific instruments, etc., can solve the problems of high automation, self-learning and self-evolution of intelligent welding production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

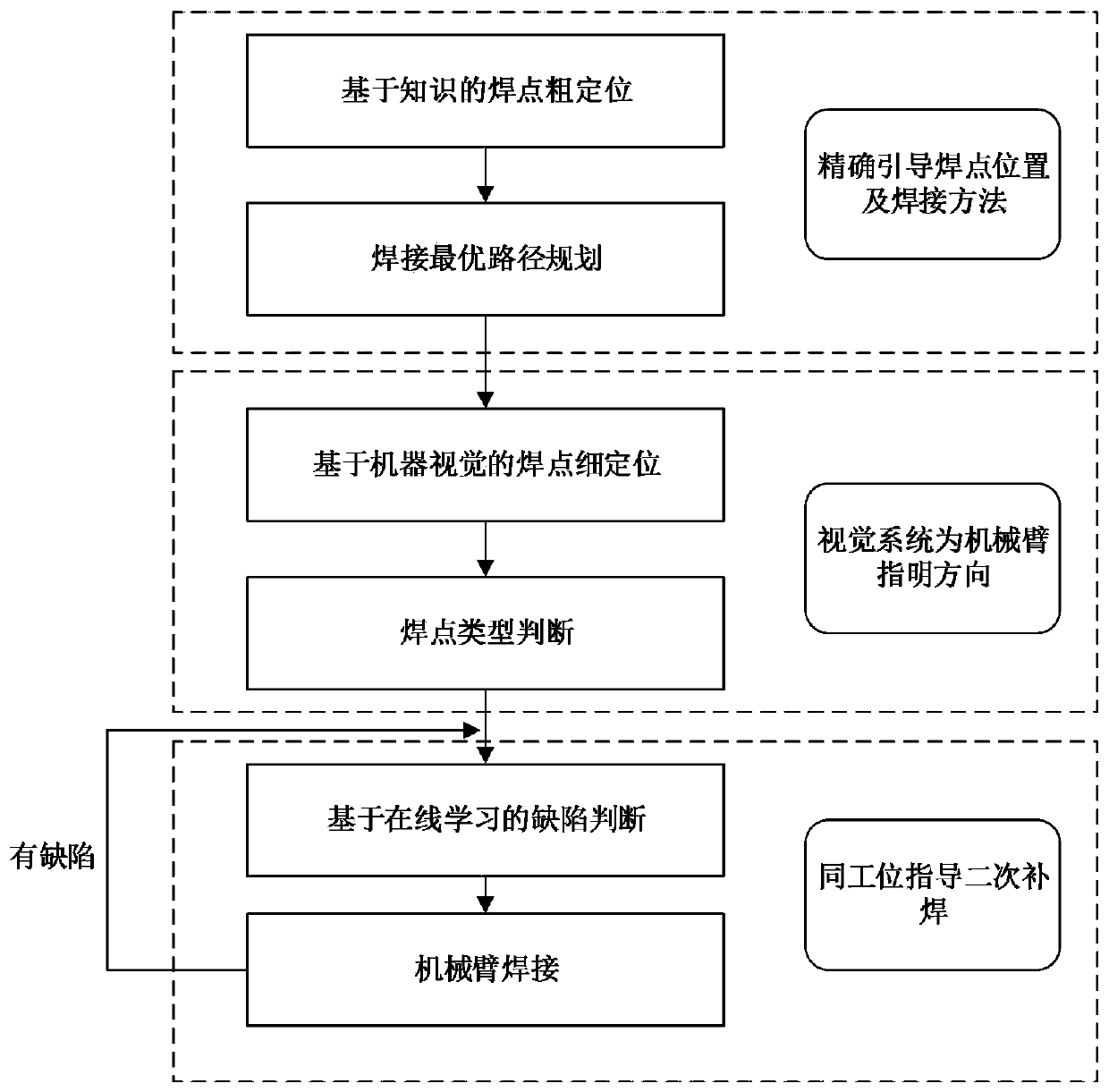

[0076] In order to meet the flexible welding production requirements of PCB non-standard components and realize intelligent automatic welding in the true sense, the present invention proposes an automatic welding and defect detection method and system based on self-learning.

[0077] In order to achieve this goal, the technical solution of the present invention comprises the following steps:

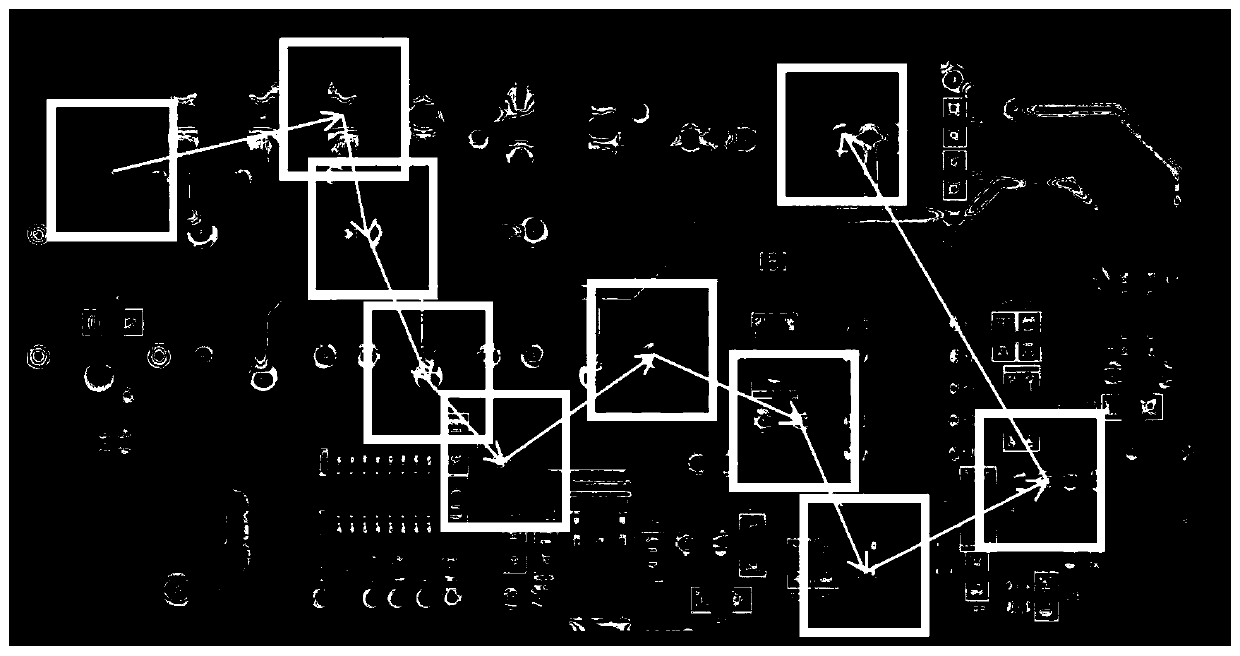

[0078] Step 1, use knowledge-based rough positioning of solder joints, plan the optimal welding path, and provide running directions for the vision system and robotic arm.

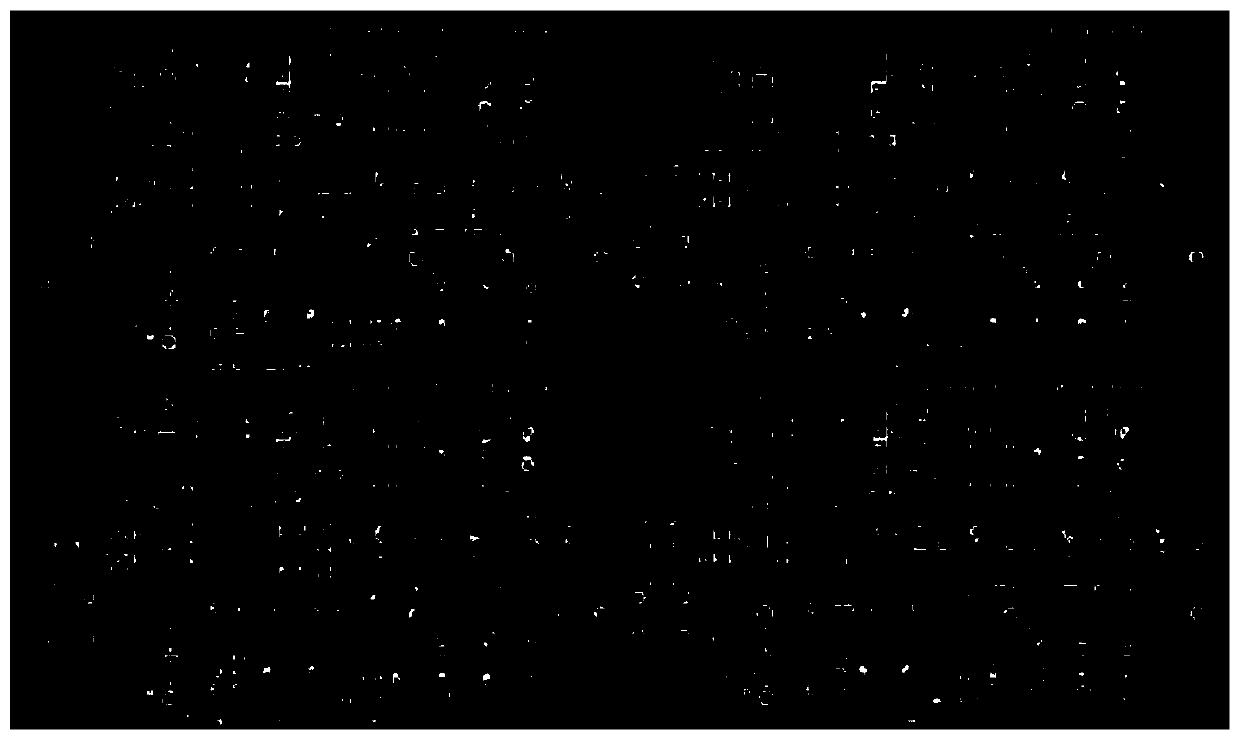

[0079] Step 2, based on the fine positioning of solder joints based on machine vision, and judge the type of solder joints, accurately guide the robotic arm to find the position of the solder joints, and implement targeted automatic welding.

[0080] Step 3, adopt the solder joint defect detection based on online deep reinforcement learning, automatically detect the solder joint defect and judge the type, and provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com