Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "Rotating unbalance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotating unbalance is the uneven distribution of mass around an axis of rotation. A rotating mass, or rotor, is said to be out of balance when its center of mass (inertia axis) is out of alignment with the center of rotation (geometric axis). Unbalance causes a moment which gives the rotor a wobbling movement characteristic of vibration of rotating structures.

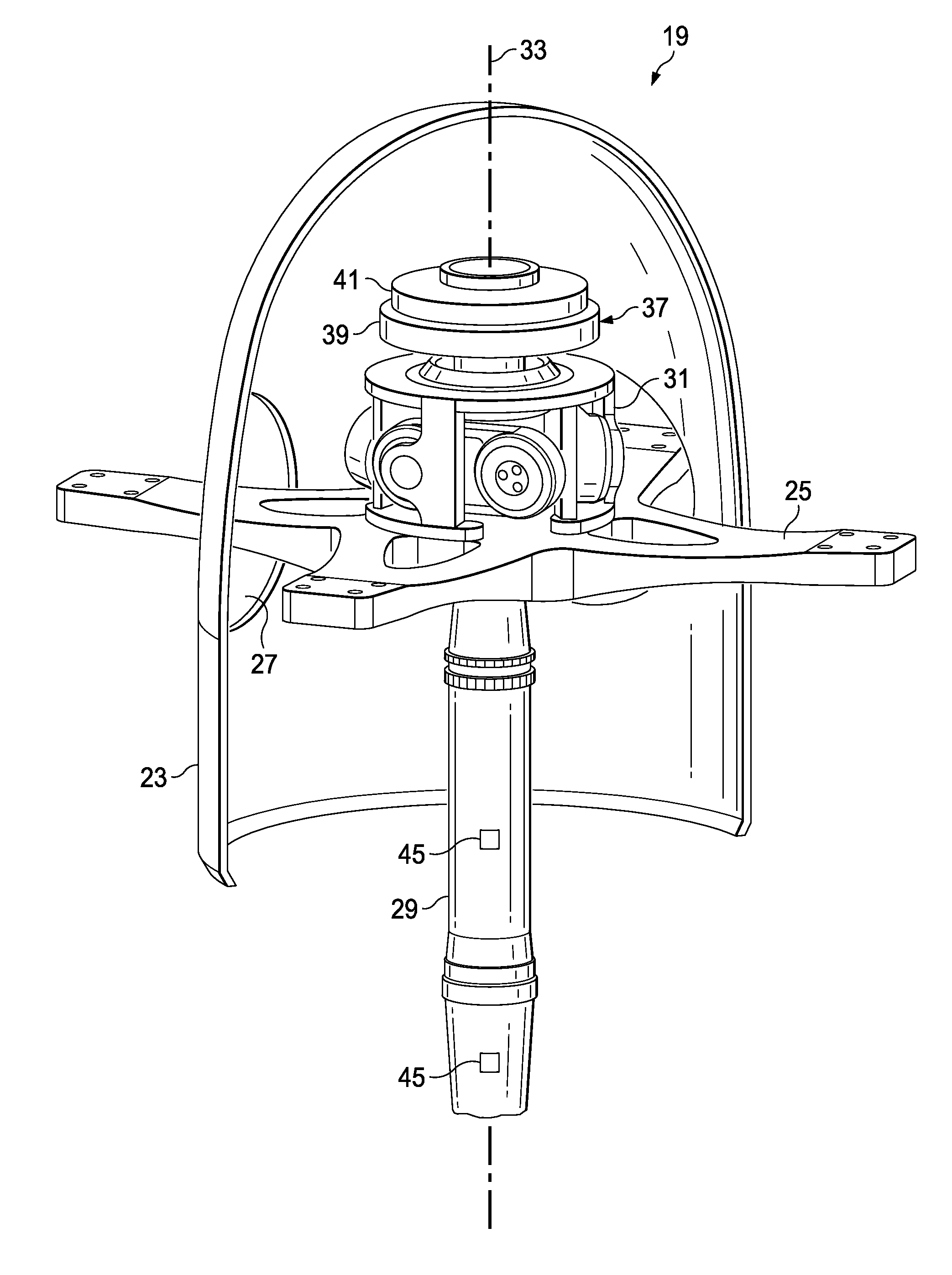

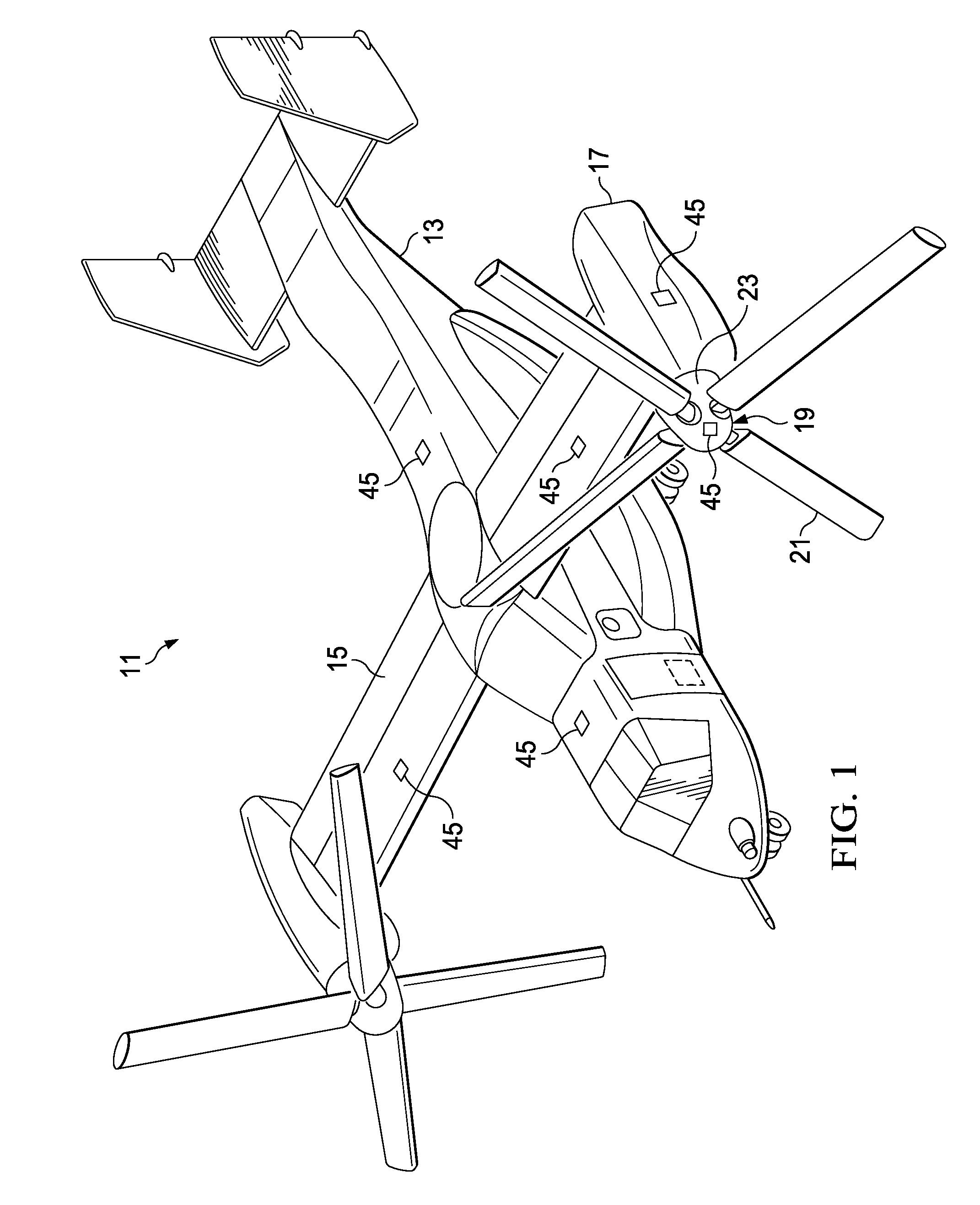

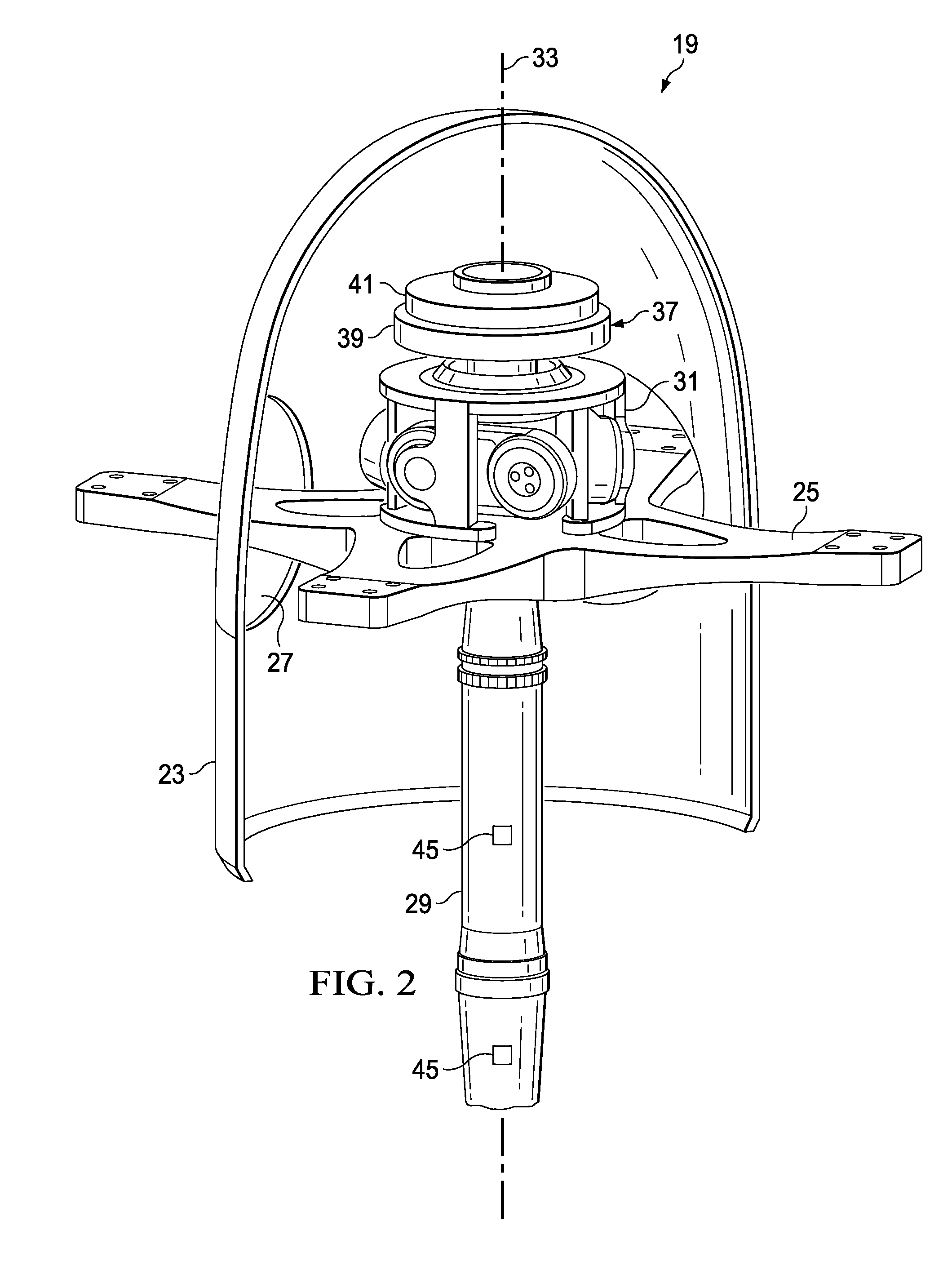

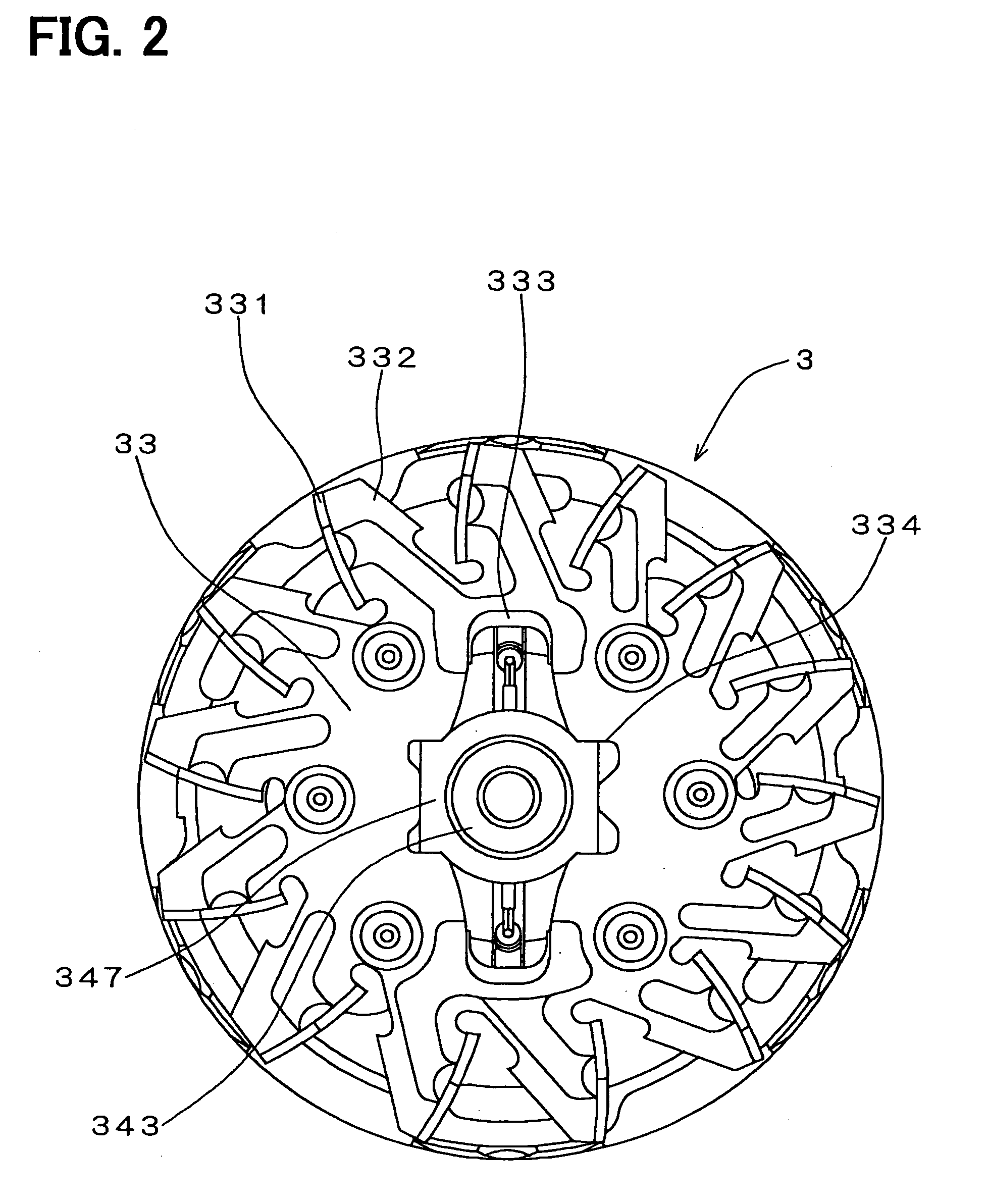

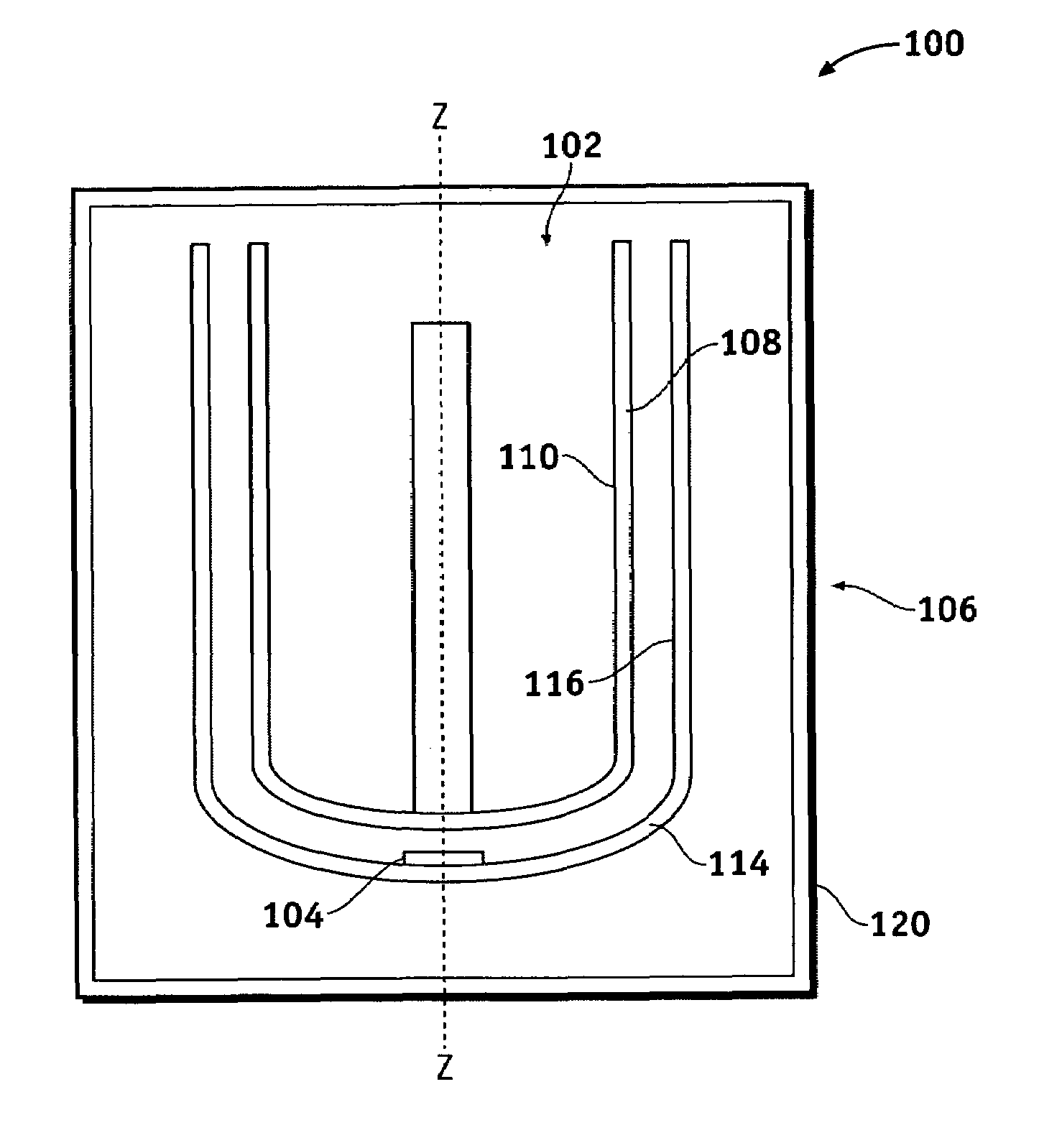

Active vibration control system with non-concentric revolving masses

ActiveUS20150203196A1Digital data processing detailsNavigation instrumentsVibration attenuationControl system

A vibration control system for a rotor hub provides vibration attenuation in an aircraft by reducing the magnitude of rotor induced vibratory. The system can include a force generating device attached to a rotor hub which rotates along with the rotor at the rotational speed of the rotor. Vibratory shear force is generated by rotating unbalanced weights each about an axis non-concentric with the rotor hub axis at high speed to create large centrifugal forces. The rotational speed of the weights can be a multiple of the rotor rotational speed to create shear forces for canceling rotor induced vibrations. The amplitude of the generated shear force is controlled by indexing the positions of the unbalanced weights relative to each other, while the phase of the shear force is adjusted by equally phasing each weight relative to the rotor.

Owner:BELL HELICOPTER TEXTRON INC

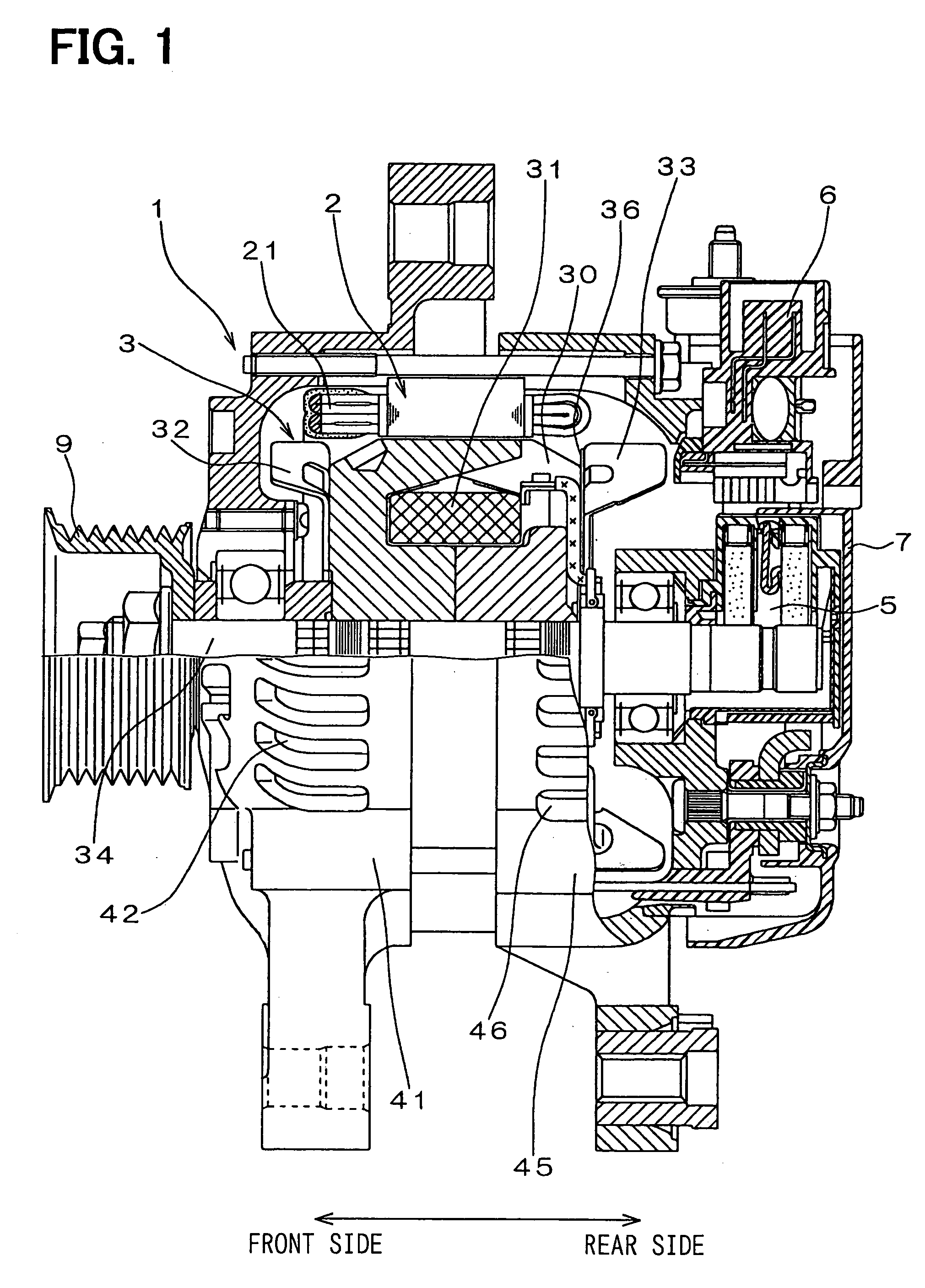

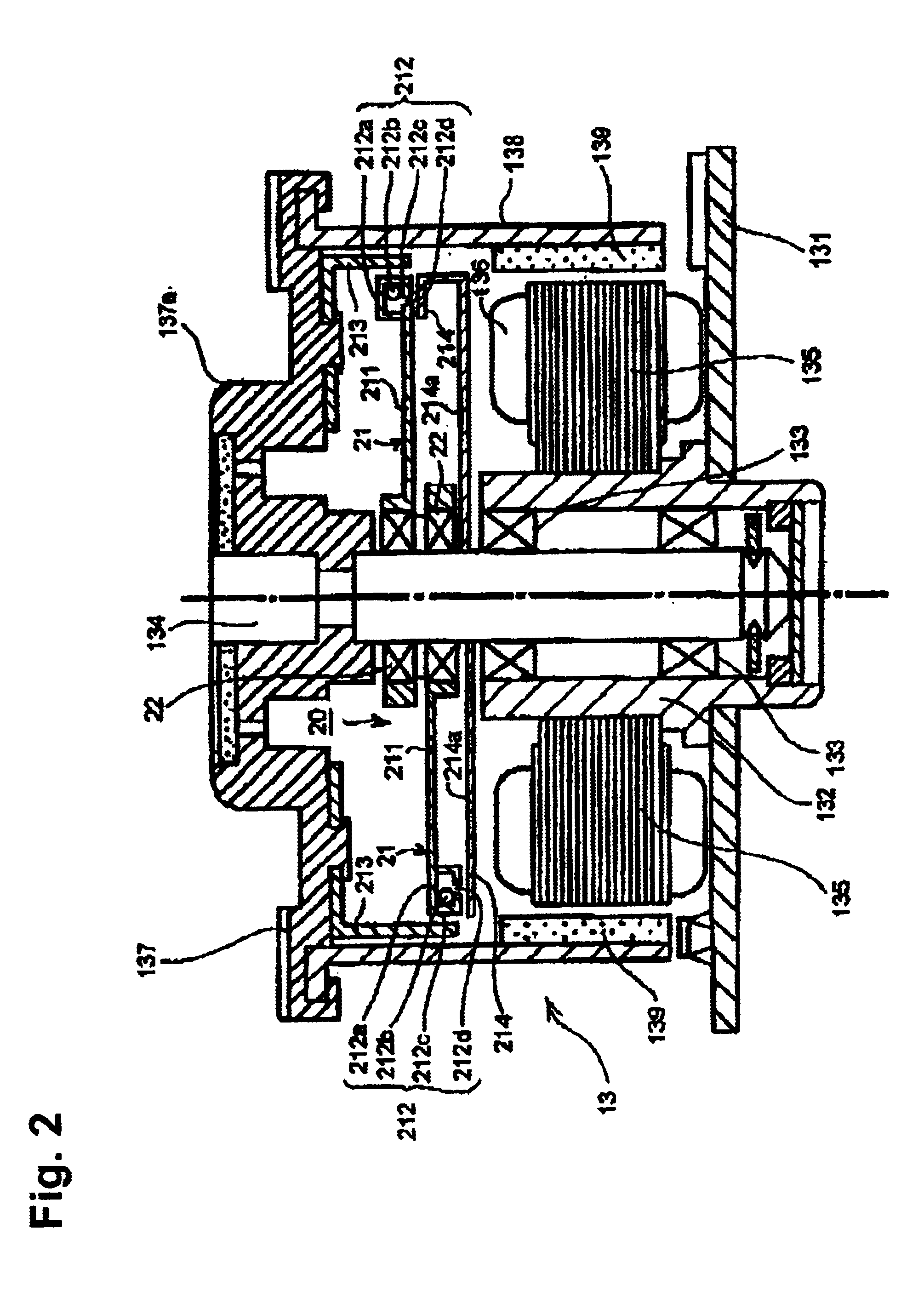

Automotive alternator having cooling fan coupled to rotor shaft

ActiveUS20050285459A1Firmly connectedSimple processRotary current collectorMagnetic circuit rotating partsAlternatorEngineering

An alternator for use in an automobile includes a stator supported between a front housing and a rear housing, and a rotor connected to a rotor shaft and rotatably supported inside the stator. A cooling fan is positioned at an end of a pole core of the rotor. The cooling fan is coupled to the rotor shaft by engaging edges of a center opening of the cooling fan with a non-circular flange formed on the rotor shaft. The cooling fan is correctly positioned relative to the rotor shaft, without using a jig, both in the radial direction and in the rotational direction of cooling fan. Noises and vibrations due to rotational imbalance of the cooling fan are suppressed.

Owner:DENSO CORP

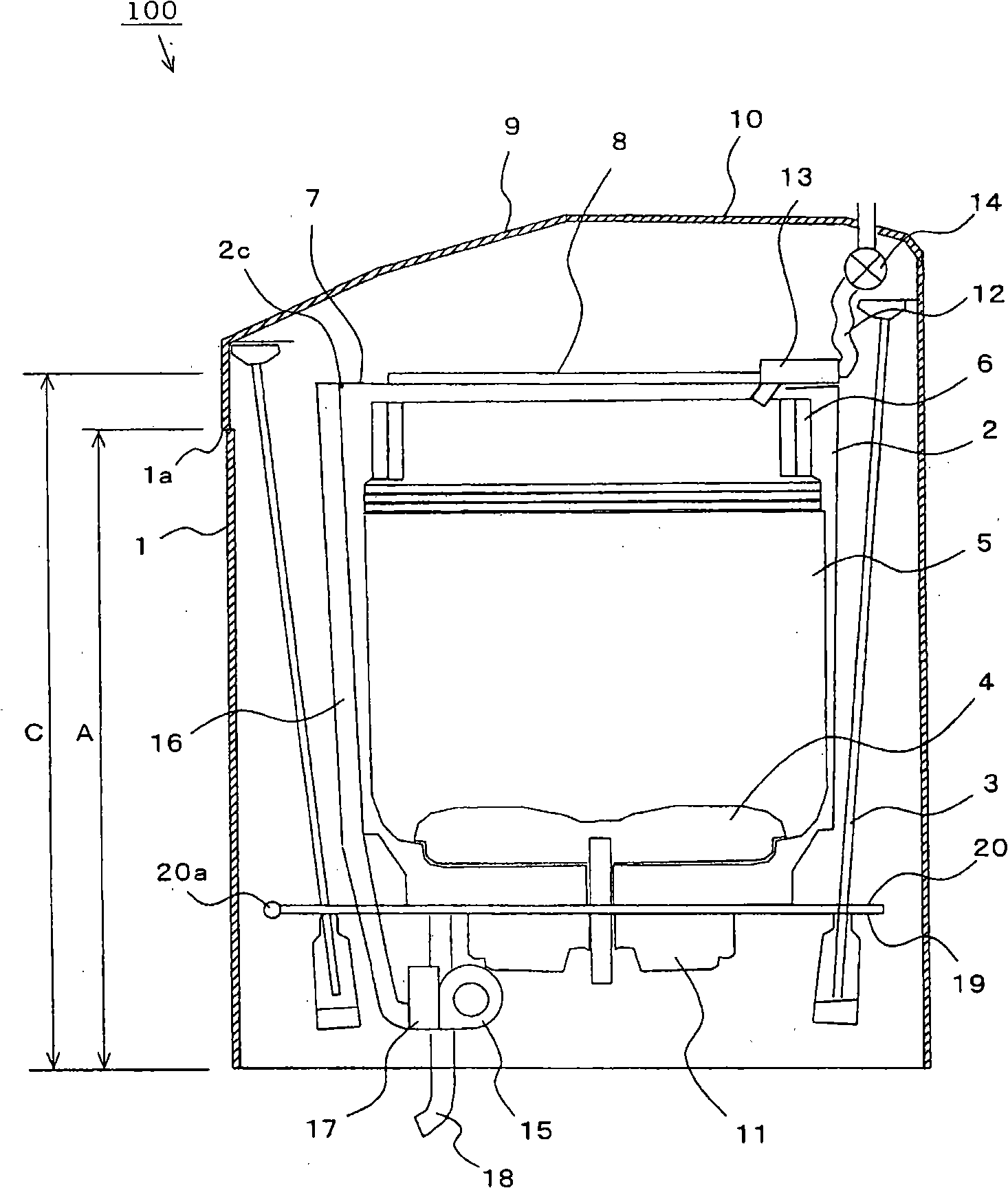

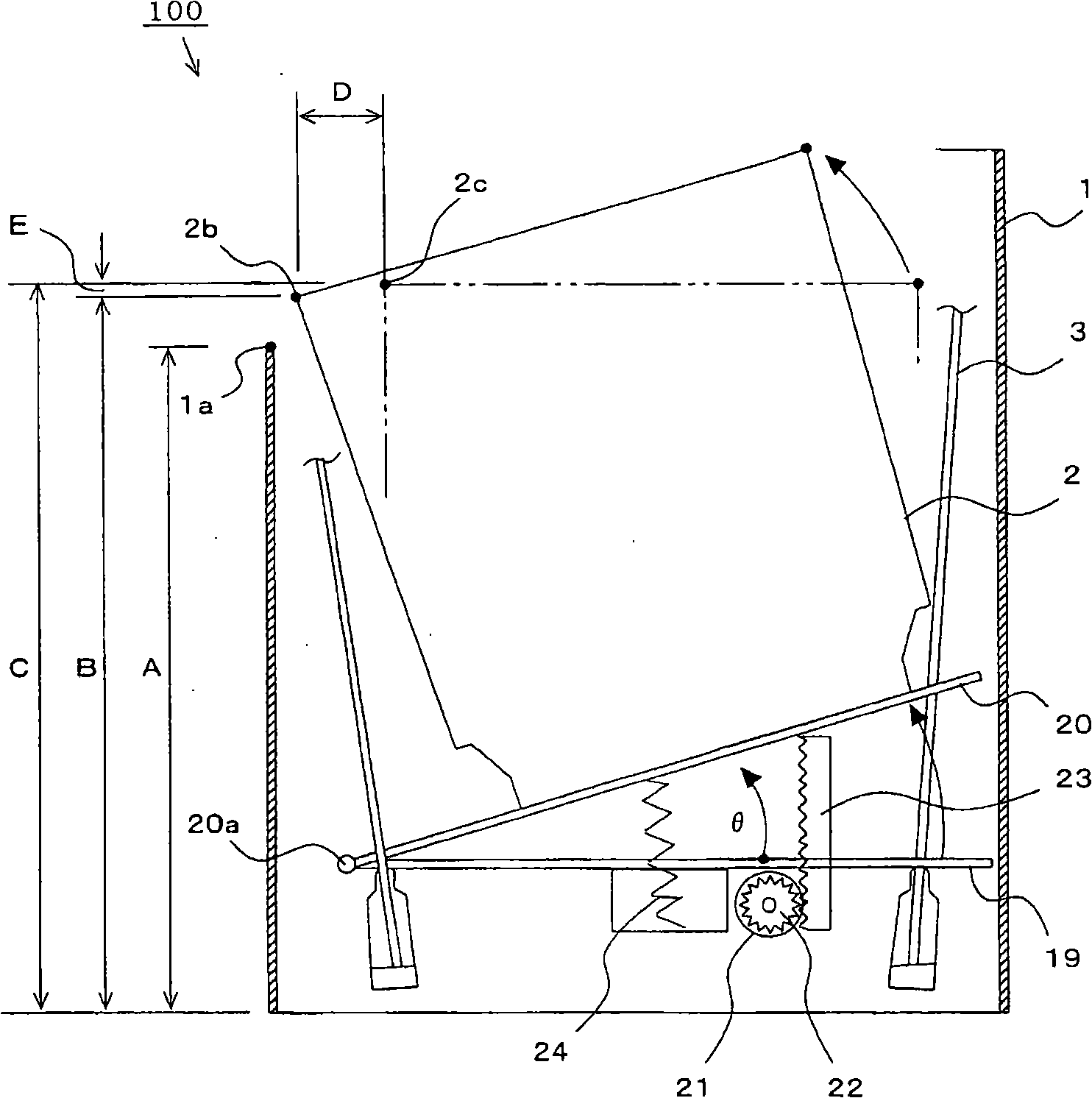

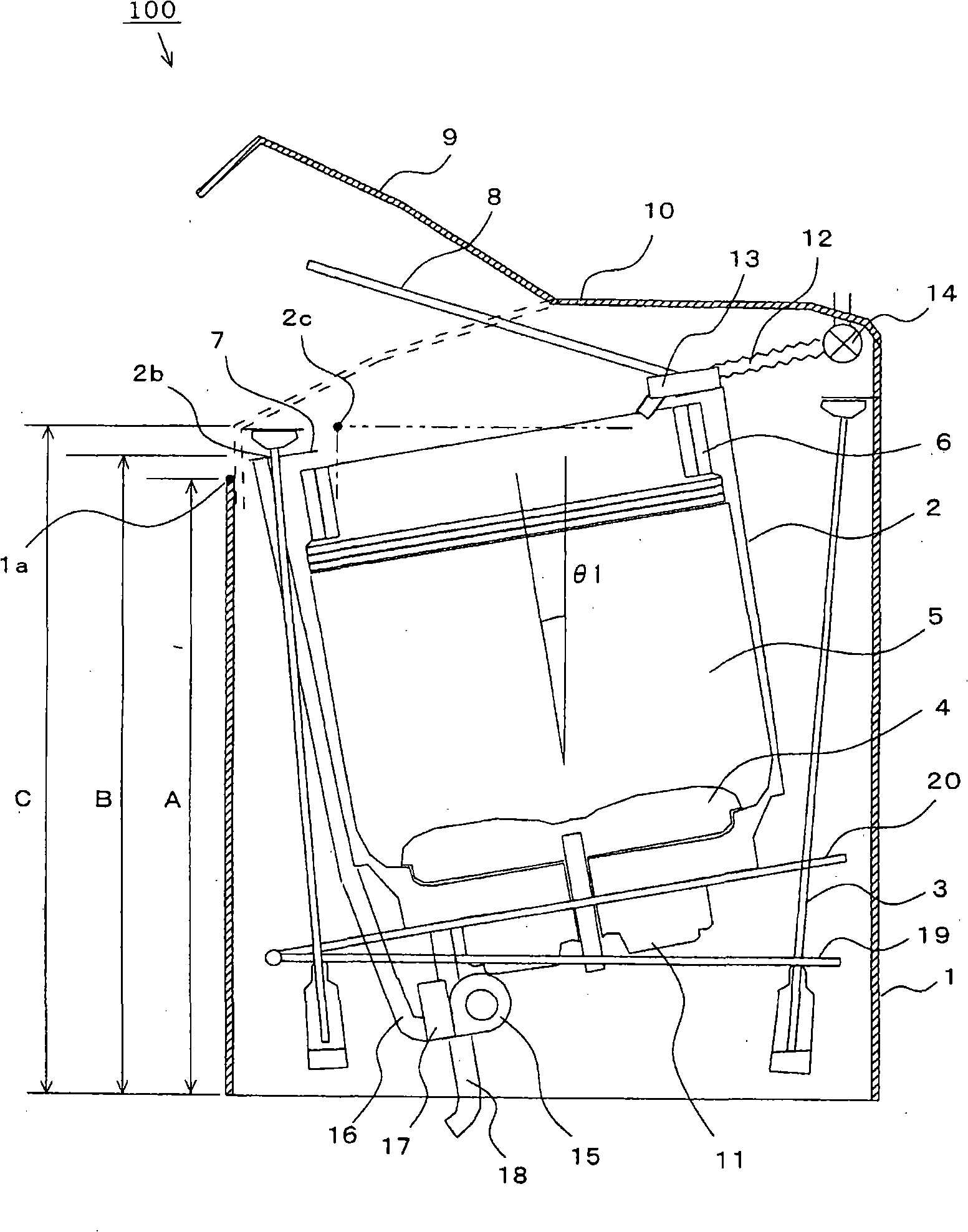

Washing machine

InactiveCN101356309AHave the following effectEasy to take out the jobOther washing machinesControl devices for washing apparatusSupport pointWater tanks

A washing machine which ensures good cleaning performance and drying performance, prevents the rotational unbalance of a washing tank during drying, and is easy to use. The washing machine comprises a housing (1), a washing tank disposed in a water tank (2), an inclining means for inclining the washing tank with an inclining supporting point (20a) as a supporting point, and a control means, the inclining angle of the washing tank being able to be changed according to the steps of charging clothes through taking out washed and dehydrated clothes. For example, a mechanism is provided that allows the clothes to be washed with the washing tank inclined, to be dehydrated with the washing tank erected, and to be taken out with the washing tank inclined. In addition, the volume of charged clothes is detected, and, based on the result of the detection, an inclination angle during a washing step is determined or a washing step is carried out in an erected state. Further, an inclination angle is changed during a washing step for stepwise inclining or for continuous reciprocating inclining.

Owner:MITSUBISHI ELECTRIC CORP +1

System and method for predicting rotational imbalance

InactiveUS7409738B2Reliable predictionOther washing machinesControl devices for washing apparatusCountermeasureAccelerometer

Owner:NORTH STAR INNOVATIONS

Axial water pressure plunger pump with easy maintenance

InactiveCN101832243AAchieve balanceBalance overturning momentPositive displacement pump componentsPositive-displacement liquid enginesDynamic balanceReciprocating motion

The invention relates to an axial water pressure plunger pump with easy maintenance, belonging to the field of water pumps, in particular to an axial water pressure plunger pump with a cylinder body and flat valve seat separate structure. The plunger pump comprises a pump body, a main shaft disk, a cylinder body, a flat valve seat and a rear end cover in sequence, wherein the main shaft disk drives a plunger to make reciprocating movement in the cylinder bore of the cylinder body; a plunger sleeve being in contact with the plunger covers in the cylinder bore; an annular rubber-plastic seal capable of realizing oil and water separation is arranged at the inner side of the plunger sleeve; the upper part in the pump body is lubricated by oil, and the lower part thereof is lubricated and cooled by water; the cylinder body and the flat valve seat are connected by bolts; the cylinder bore in the cylinder body is through front and back; the plunger sleeve and the rubber-plastic seal are arranged in the cylinder bore from the side of the flat valve seat; a tilting tray-sliding boot working structure is adopted in the middle of the main shaft disk; and the main shaft disk is provided with an upper couple disk, a lower couple disk and a balance weight disk. The invention solves the problem that the rubber=-plastic seal realizing the oil and water separation in the high-pressure water pump has serious friction loss and is hard to replace, meanwhile realizes the static balance and the dynamic balance of the main shaft disk and relieves the cylinder body swing caused by the unbalanced quality in the rotation of the main shaft disk.

Owner:BEIJING UNIV OF TECH

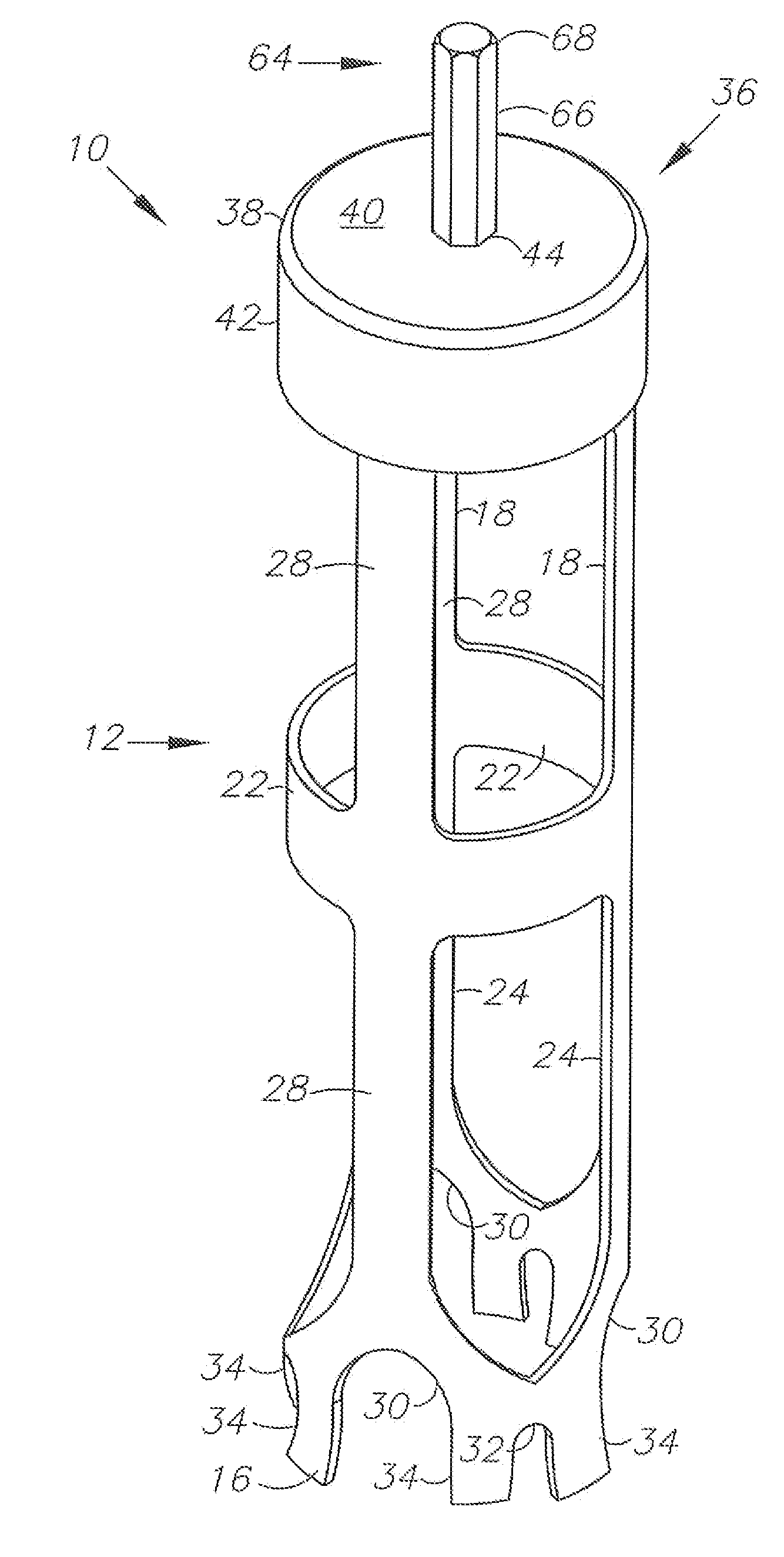

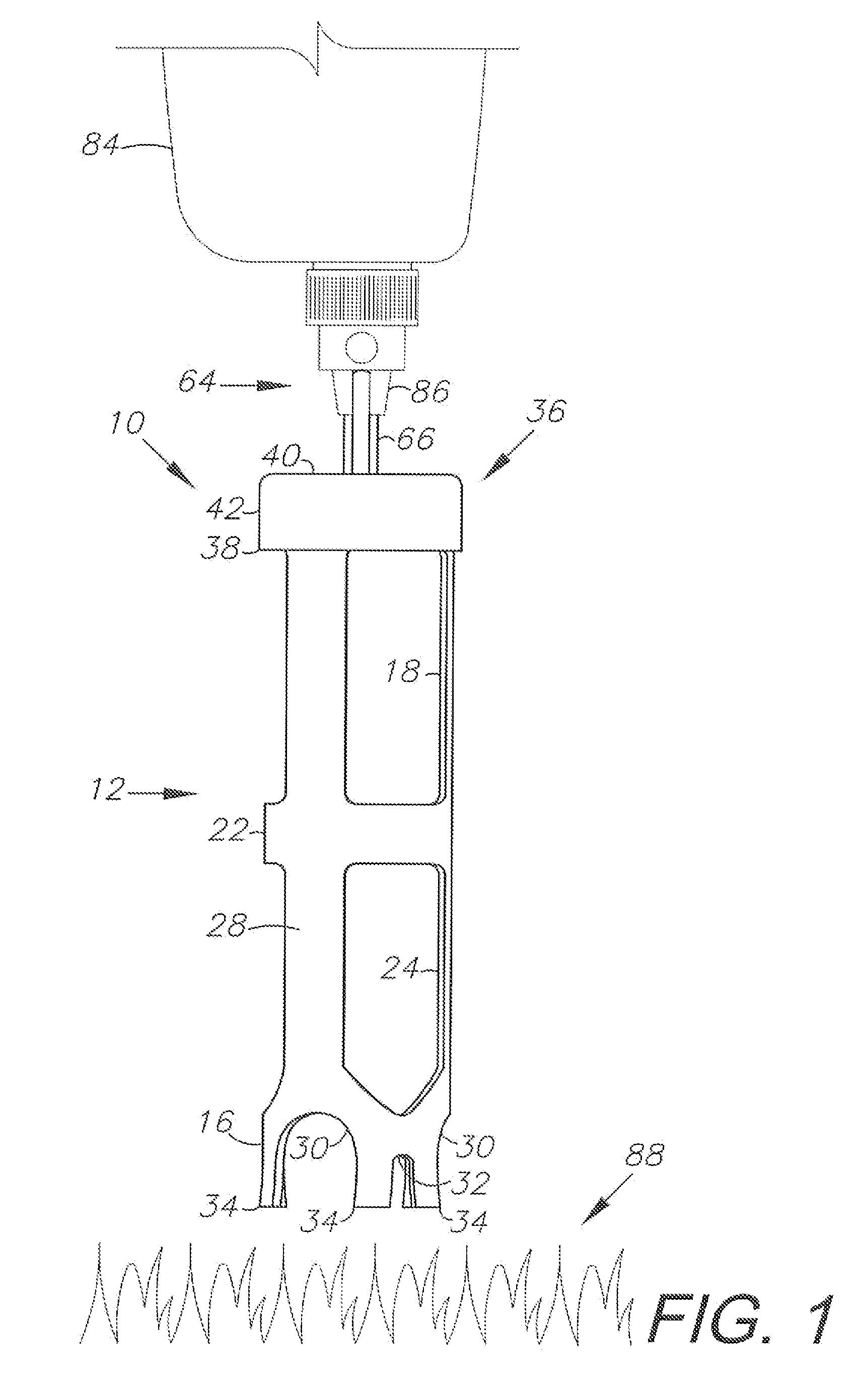

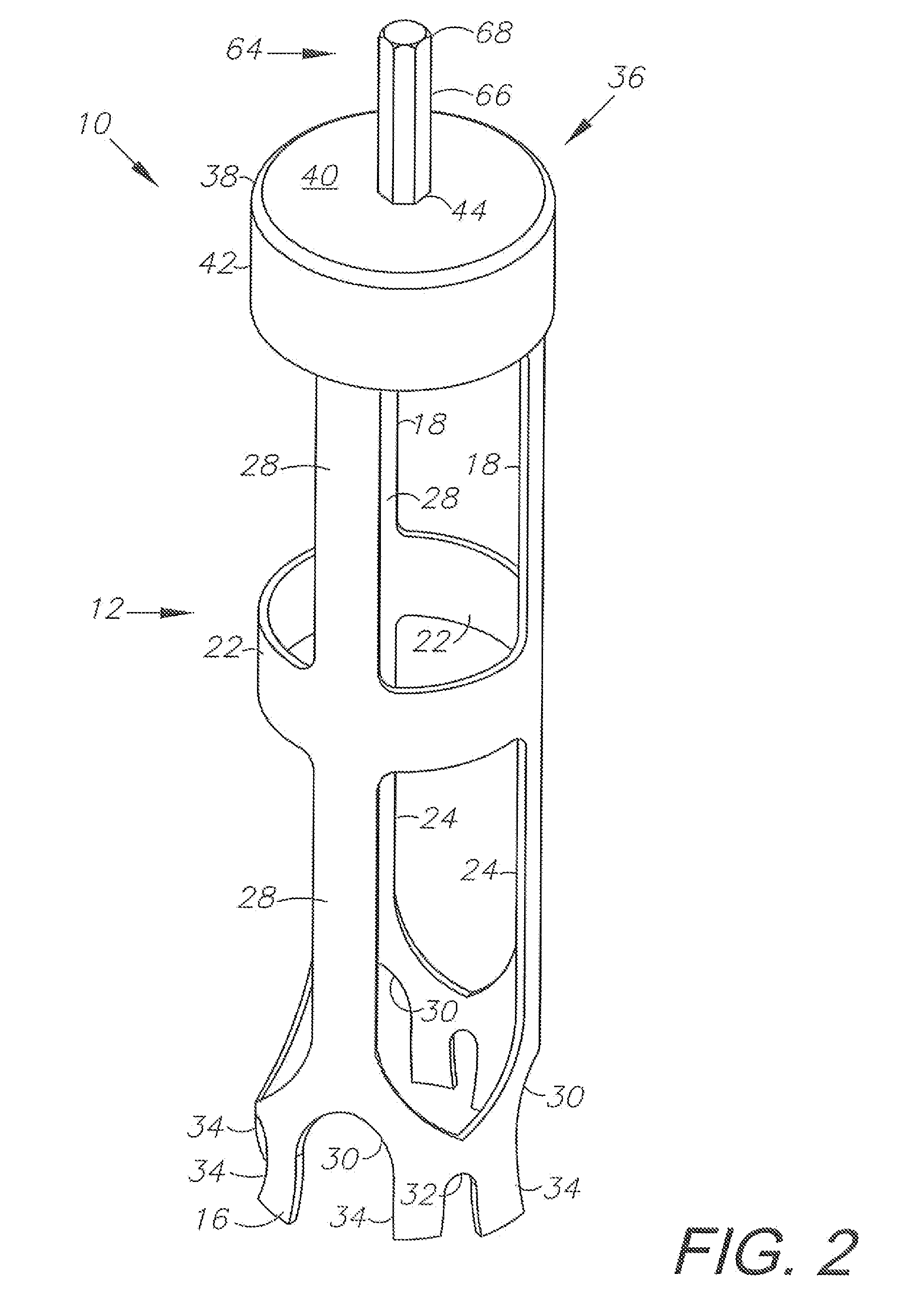

Tubular soil auger and manufacturing method

ActiveUS20100243332A1Increase speedReduce shakingDrill bitsMetal-working drilling toolsRotational axisEngineering

A soil auger for creating smooth-walled cylindrical holes in the earth is provided for use with a drill. The auger has a central rotational axis with a tubular body that is open at a bottom cutting end, and enclosed at a top end by a cap assembly. The cap assembly has a top wall and a bottom wall. The top and bottom walls have apertures aligned with the central rotational axis for receiving a shaft in alignment therewith, and for attachment to a drill. The distance between the top wall and bottom wall compared to the overall length of the assembled auger determines the minimum height of the cap assembly to minimize the rotational imbalance of the auger during use for a given body length. A method of manufacturing the auger is provided using precision cutting tools to create apertures in the body and to maintain concentricity of the auger components.

Owner:PAXTON FR

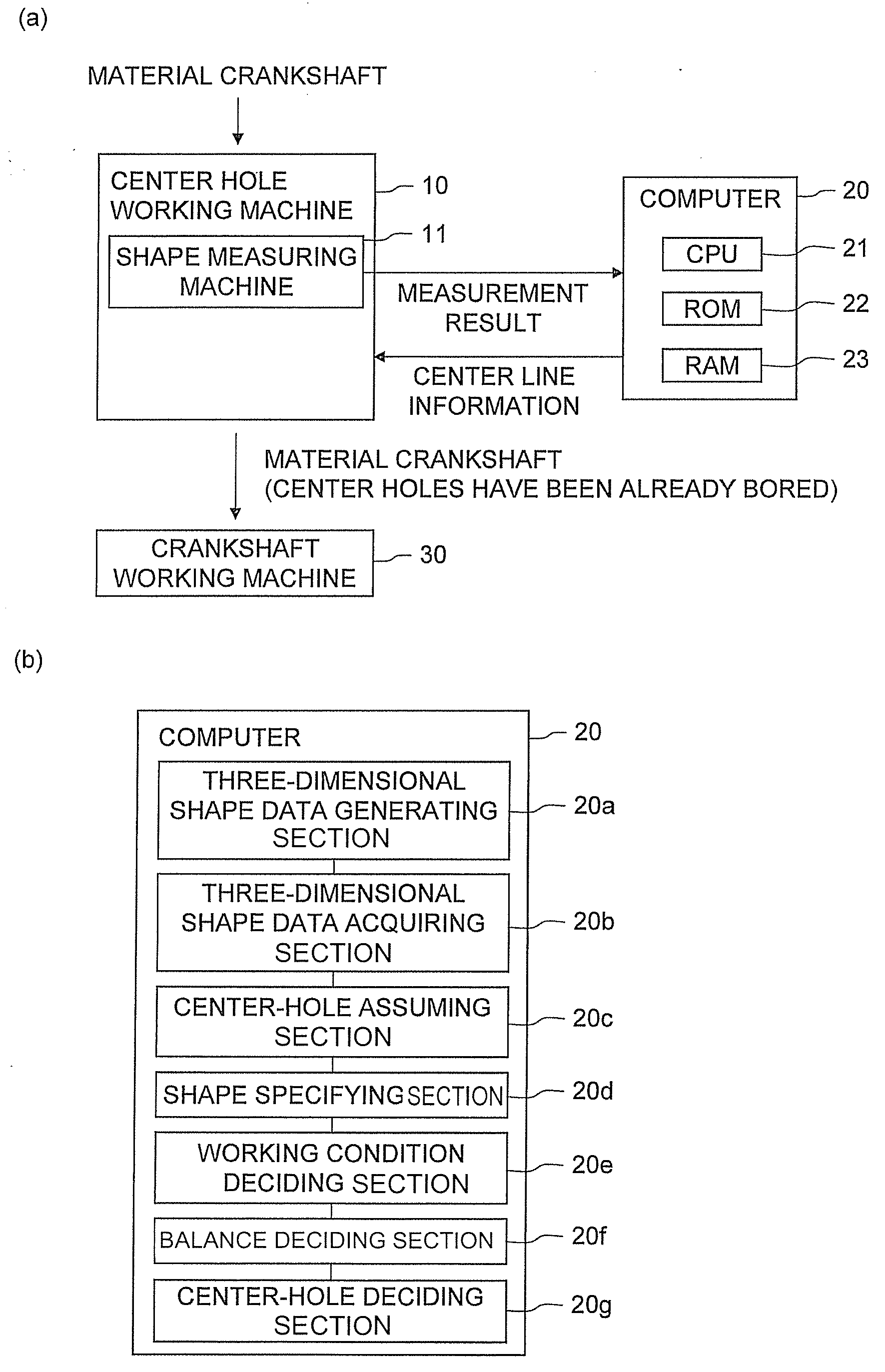

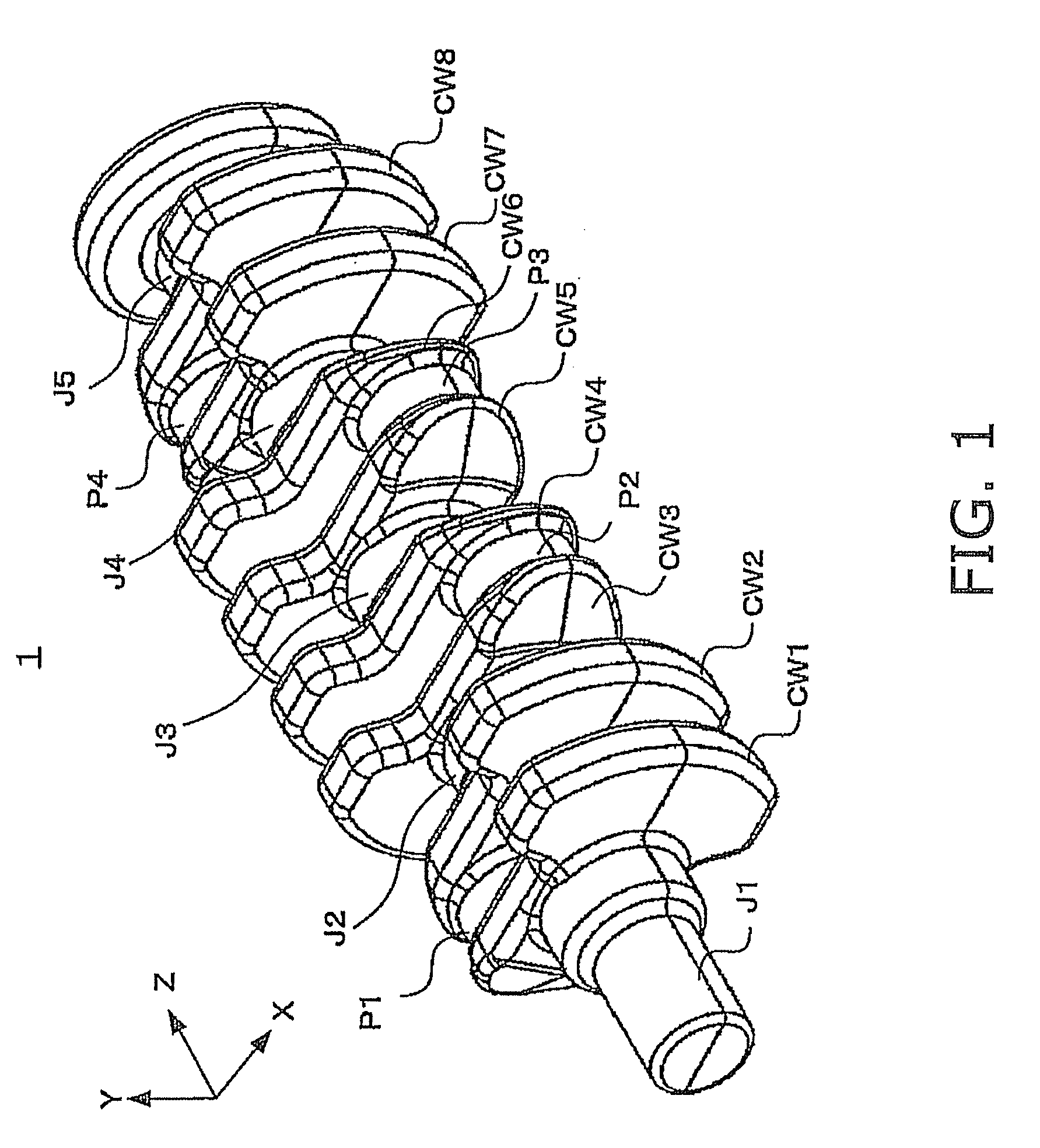

Processing apparatus, center-hole working system, center-hole position deciding program, and center-hole position deciding method

ActiveUS20100179675A1Reduce necessityEasily and properly decidingStatic/dynamic balance measurementMeasurement/indication equipmentsThree dimensional shapeEngineering

A processing apparatus includes a three-dimensional shape data acquiring section, a tentative center-hole position determining section, a shape simulating section, a balance deciding section, and a center-hole deciding section. The tentative center-hole position determining section is configured to determine a tentative position of the center holes based on the three-dimensional shape data. The shape simulating section is configured to obtain a simulated shape of the material crankshaft after a working is simulated for the material crankshaft based on the tentative position of the center holes as a reference. The balance deciding section is configured to decide whether a rotational imbalance amount in the simulated shape is within a predetermined allowable range. The center-hole deciding section is configured to decide the tentative position as an actual boring position of the center holes when the rotational imbalance amount is within the predetermined allowable range.

Owner:KOMATSU NTC LTD

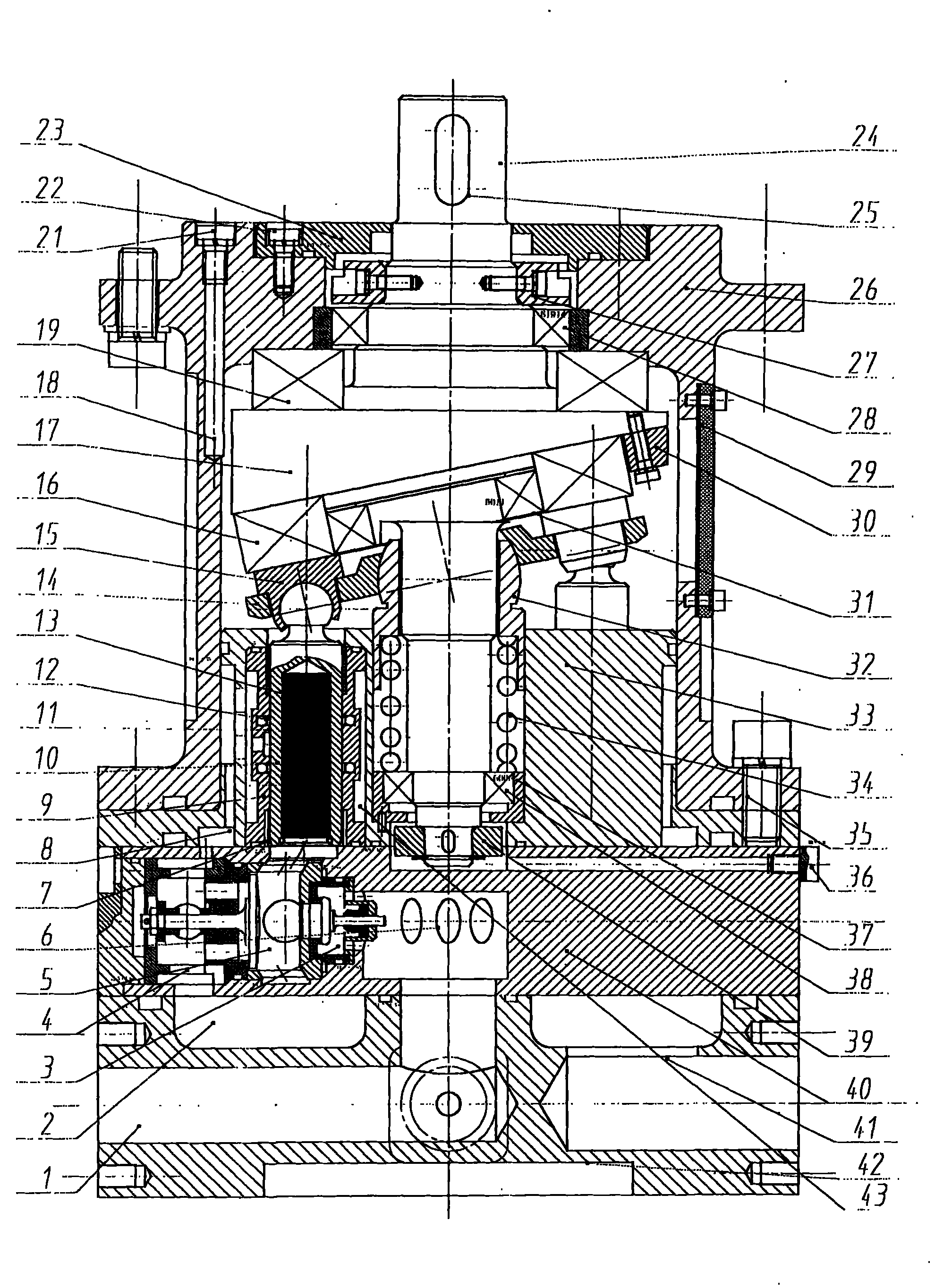

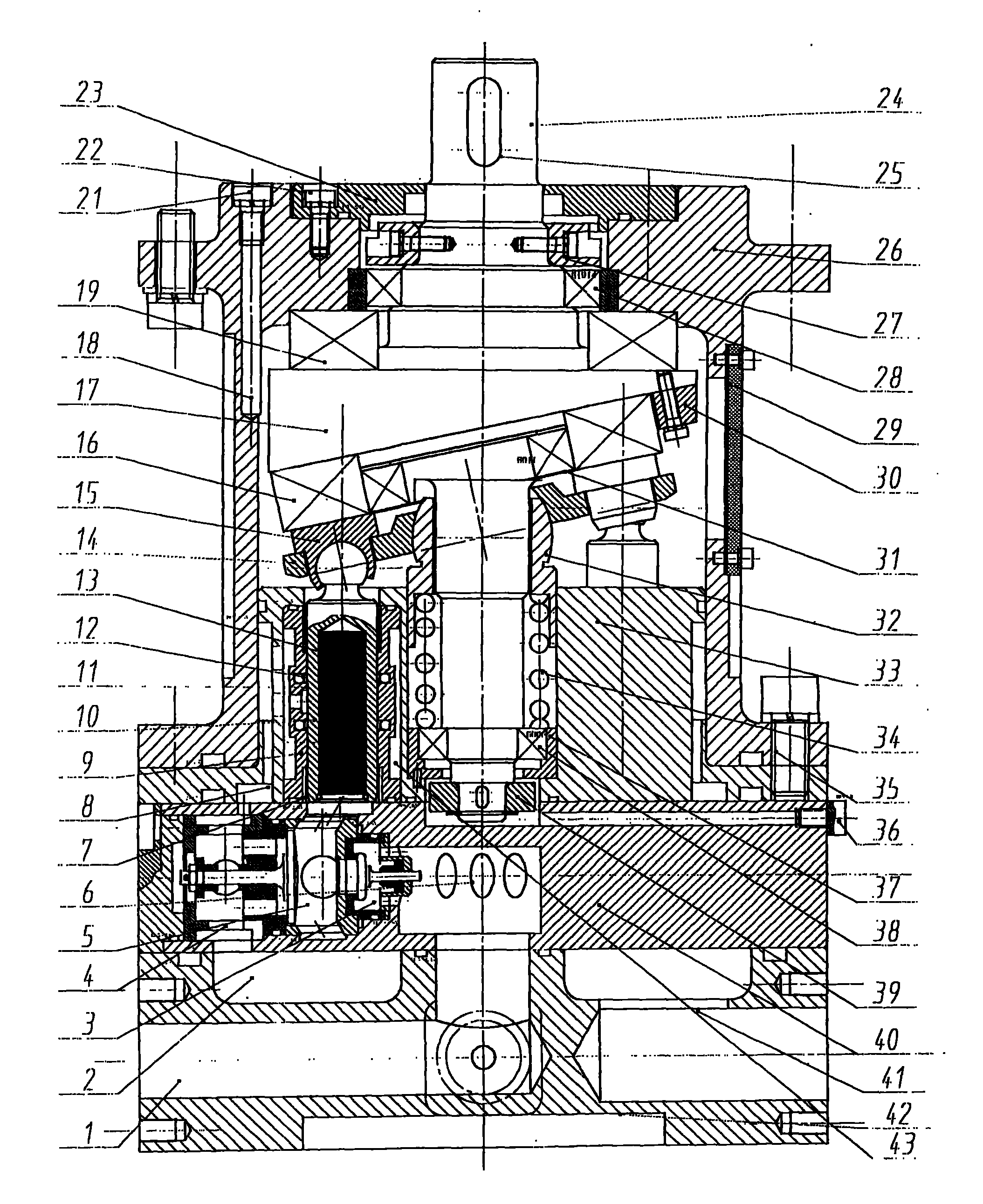

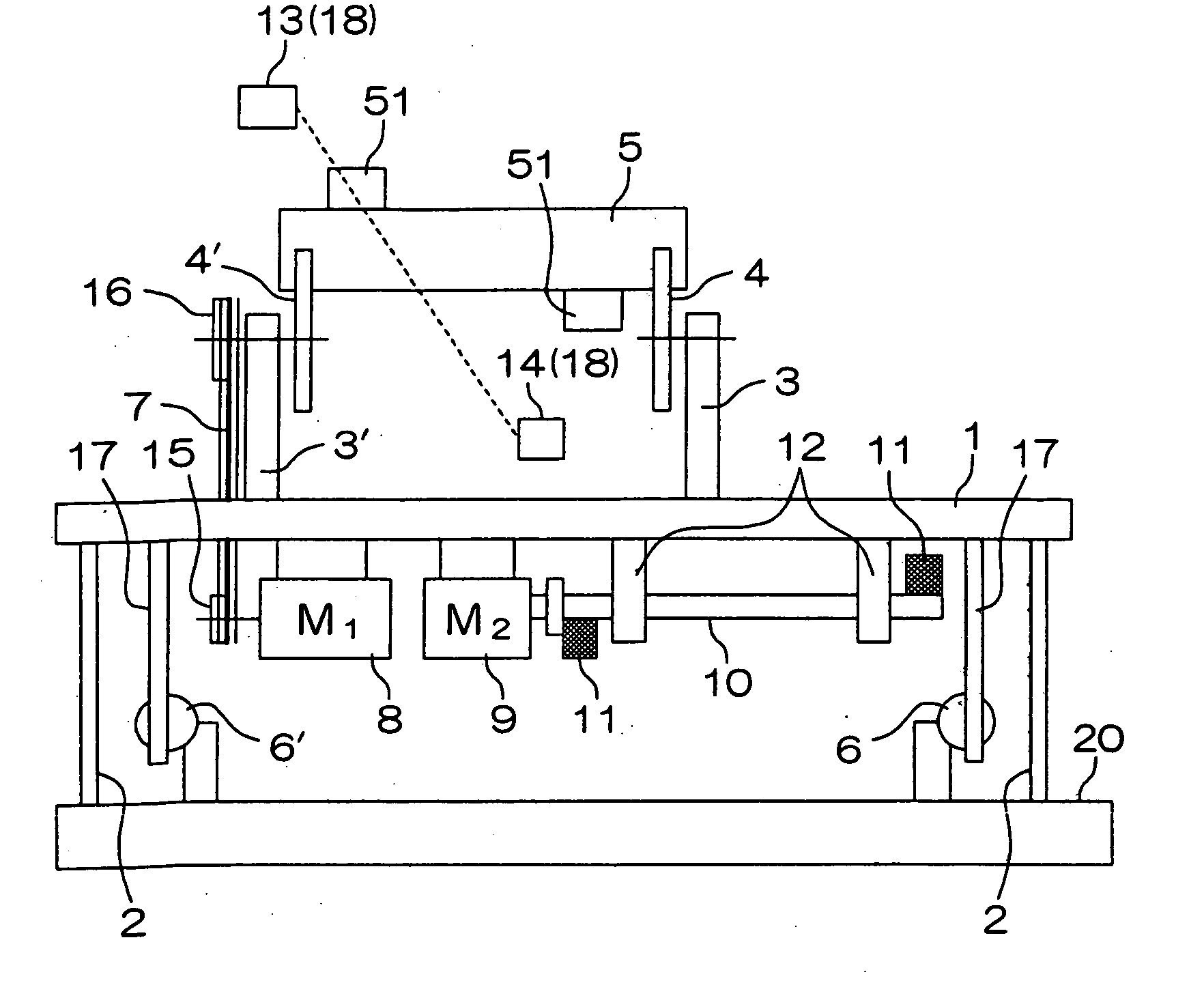

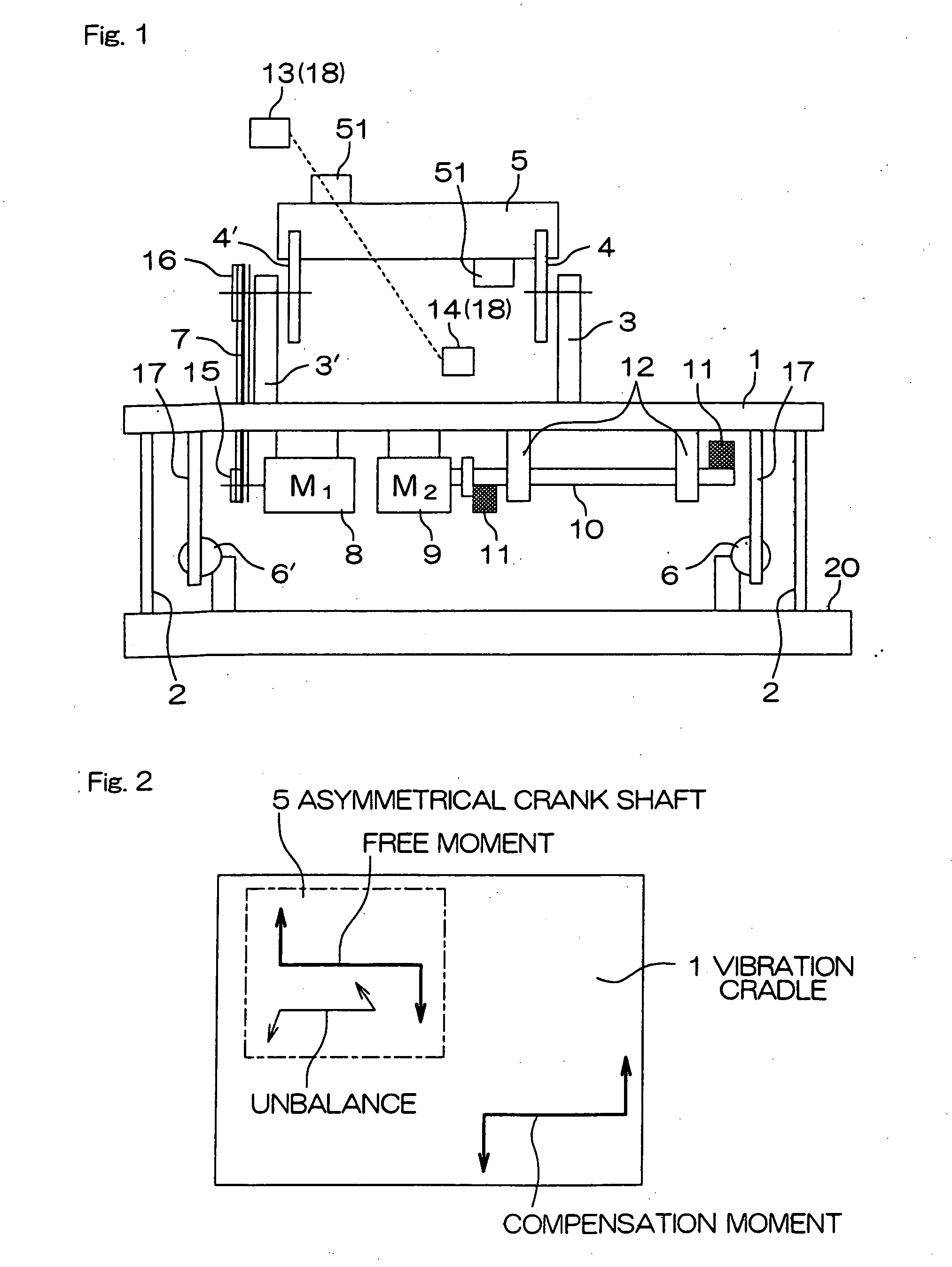

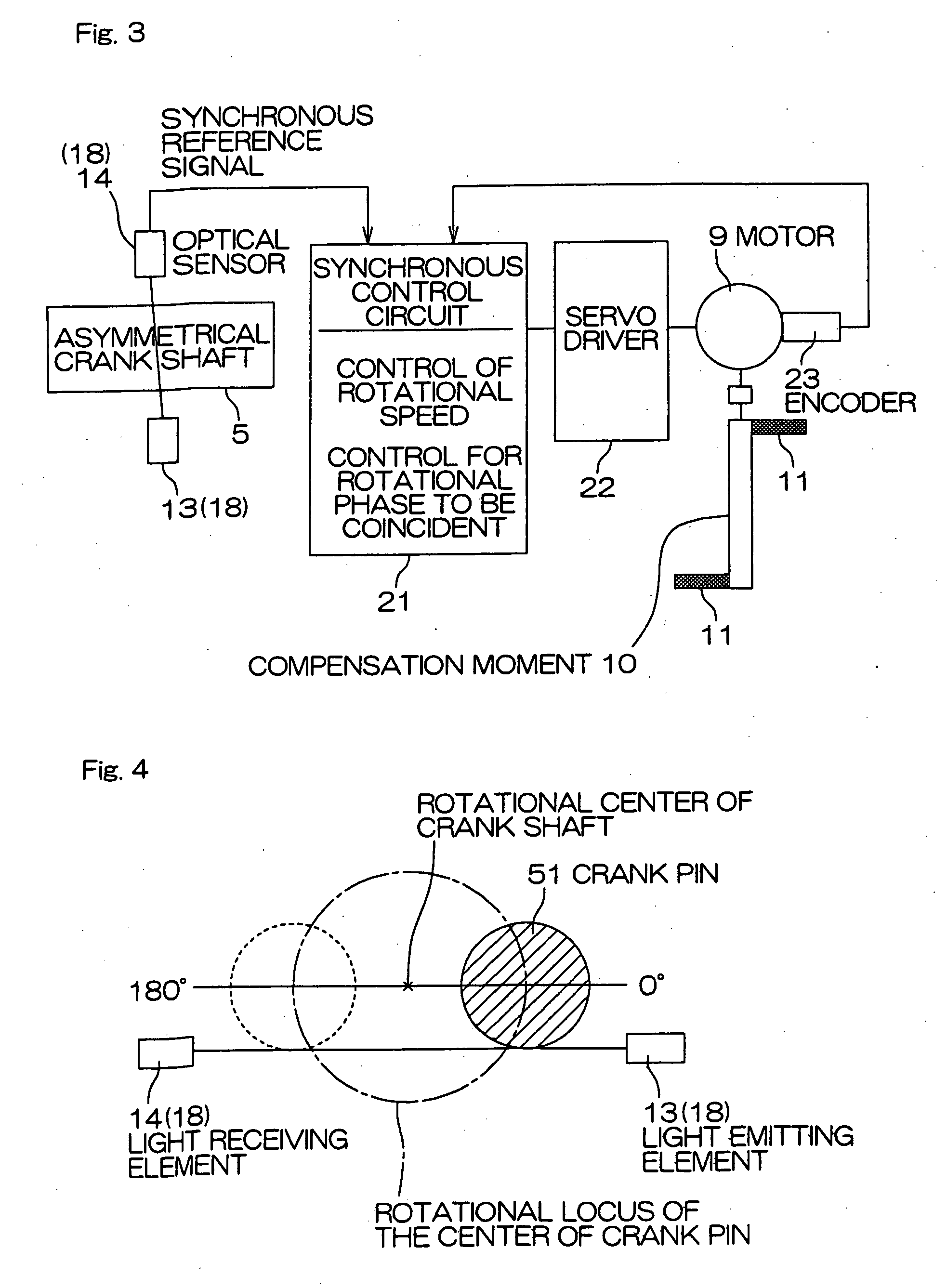

Dynamic balance testing machine

InactiveUS20060010976A1Improve machine reliabilityImprove reliabilityStatic/dynamic balance measurementSynchronous motorDynamic balance

A dynamic balance testing machine is provided with mechanical arrangements for canceling out a free moment of an asymmetrical crank shaft and capable of accurately measuring a rotating unbalance of the asymmetrical crank shaft. A compensation rotational shaft 10 having a compensation weights 11 for canceling out a free moment of a crank shaft 5 as a test piece is provided on a vibration cradle 1. The compensation rotational shaft 10 is rotated by a synchronous motor 9 other than a synchronous motor 8 for rotating the crank shaft 5. The synchronous motor 9 is rotated based on a reference signal detected by an optical sensor 18 (13, 14) in such a manner that the synchronous motor 9 is synchronously rotated with the rotation of the crank shaft.

Owner:NAGAHAMA SEISAKUSHO

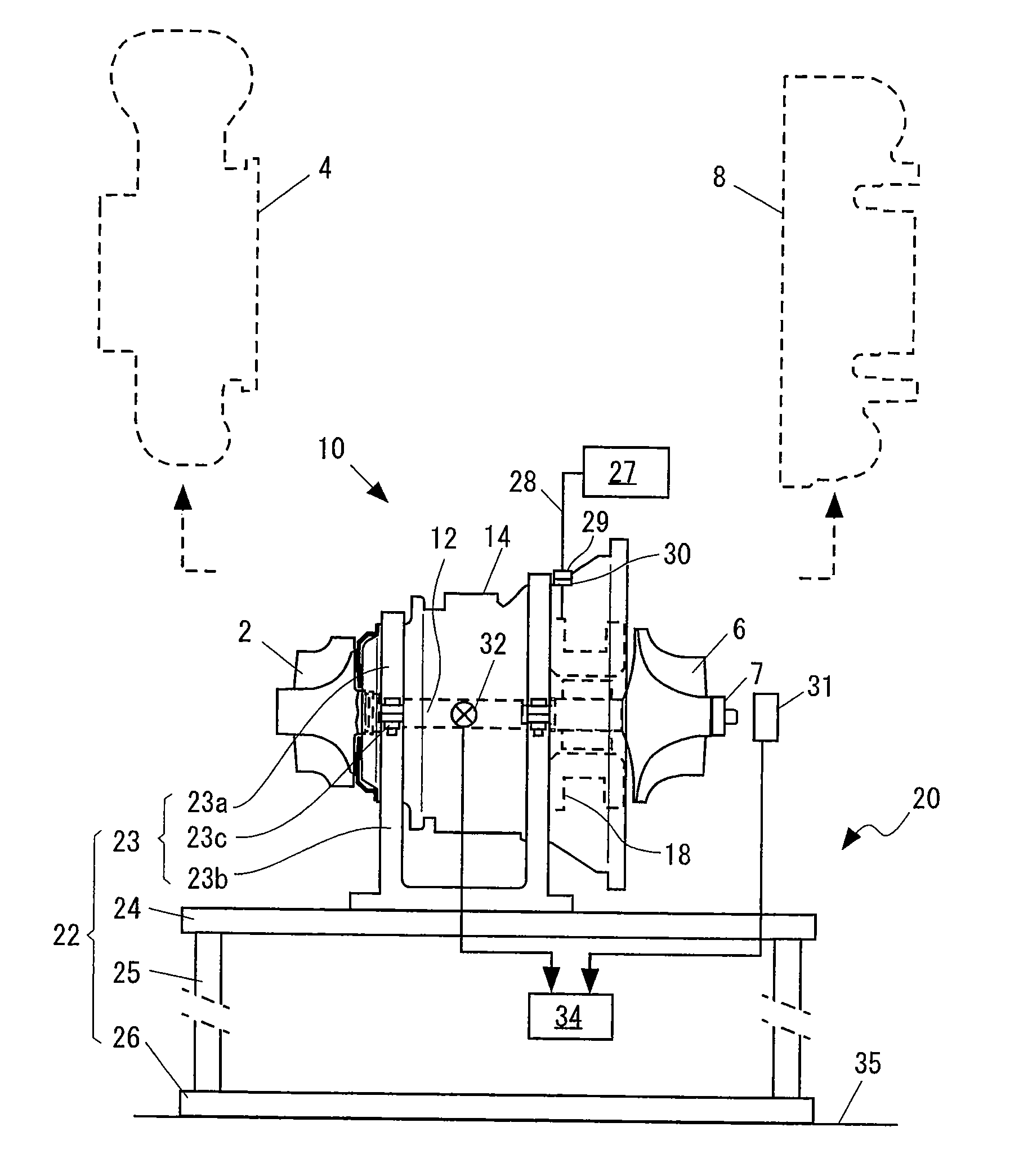

Method and apparatus for balancing an electrically assisted turbocharger rotor

InactiveUS20090183556A1Improve balanceRotation balance testing apparatus simple and compactInternal combustion piston enginesBlade accessoriesElectricityImpeller

A rotation is corrected by rotationally driving a supercharger rotor (a turbine impeller (2), a compressor impeller (6) and a shaft (12)) by an electric motor (18) in a state of detaching a turbine housing (4) and a compressor housing (8), and detecting data necessary for correcting the rotation inbalance of a motor-driven supercharger (10). Further, the electric motor (18) is driven by using a dedicated motor driver (27) supplying a larger electric power than a power supply of an acceleration assisting motor driver.

Owner:IHI CORP

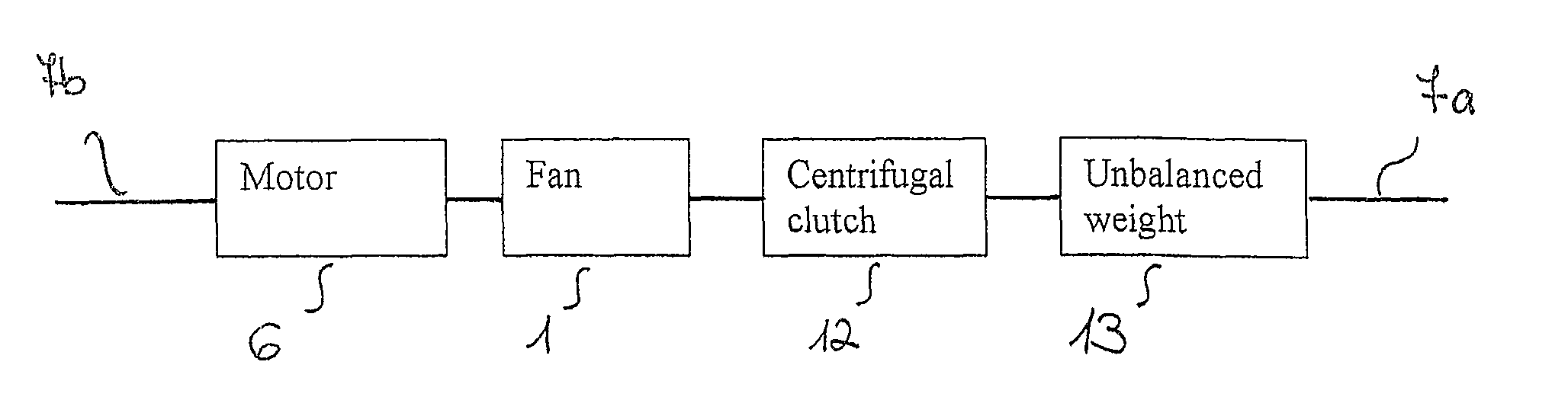

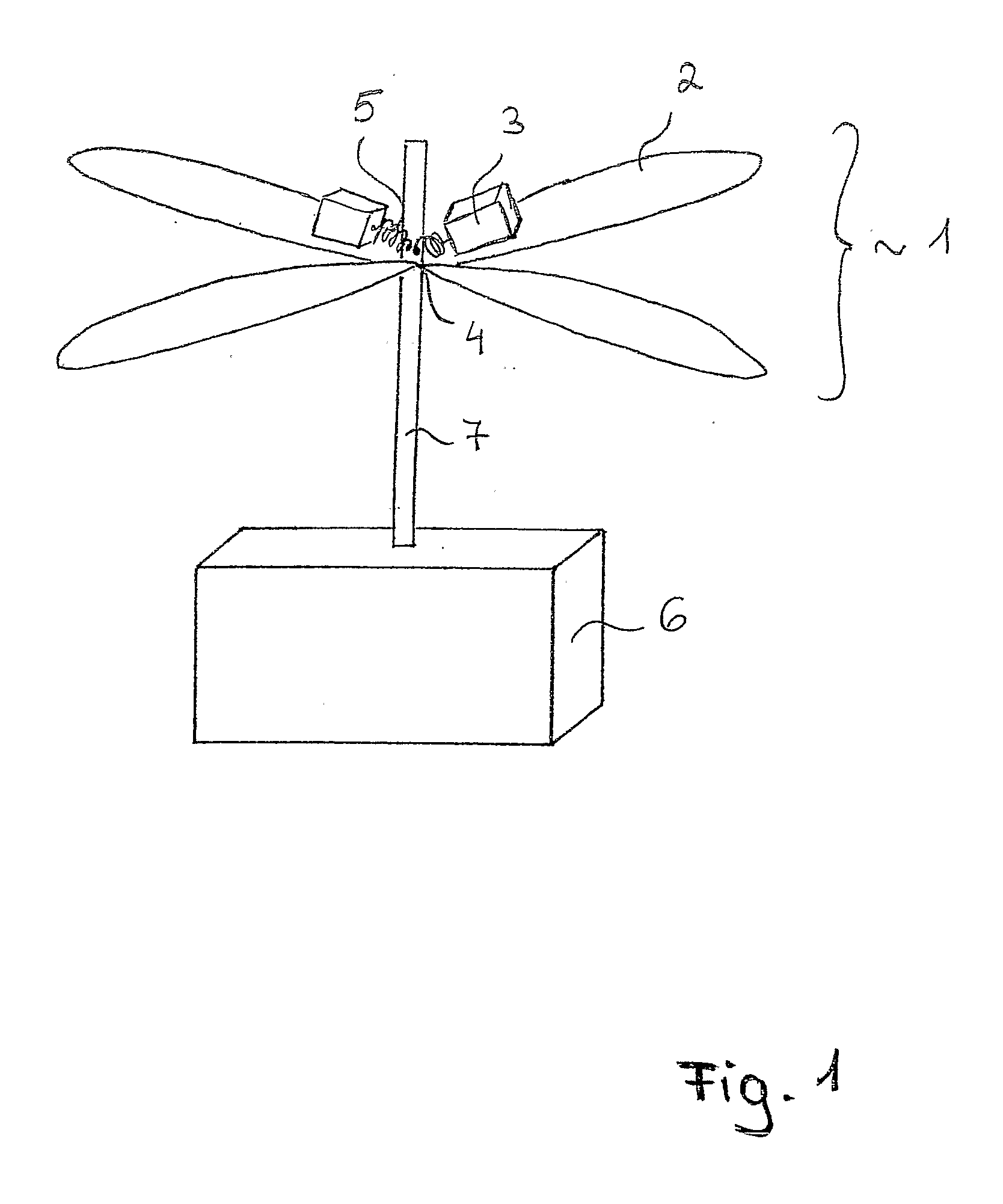

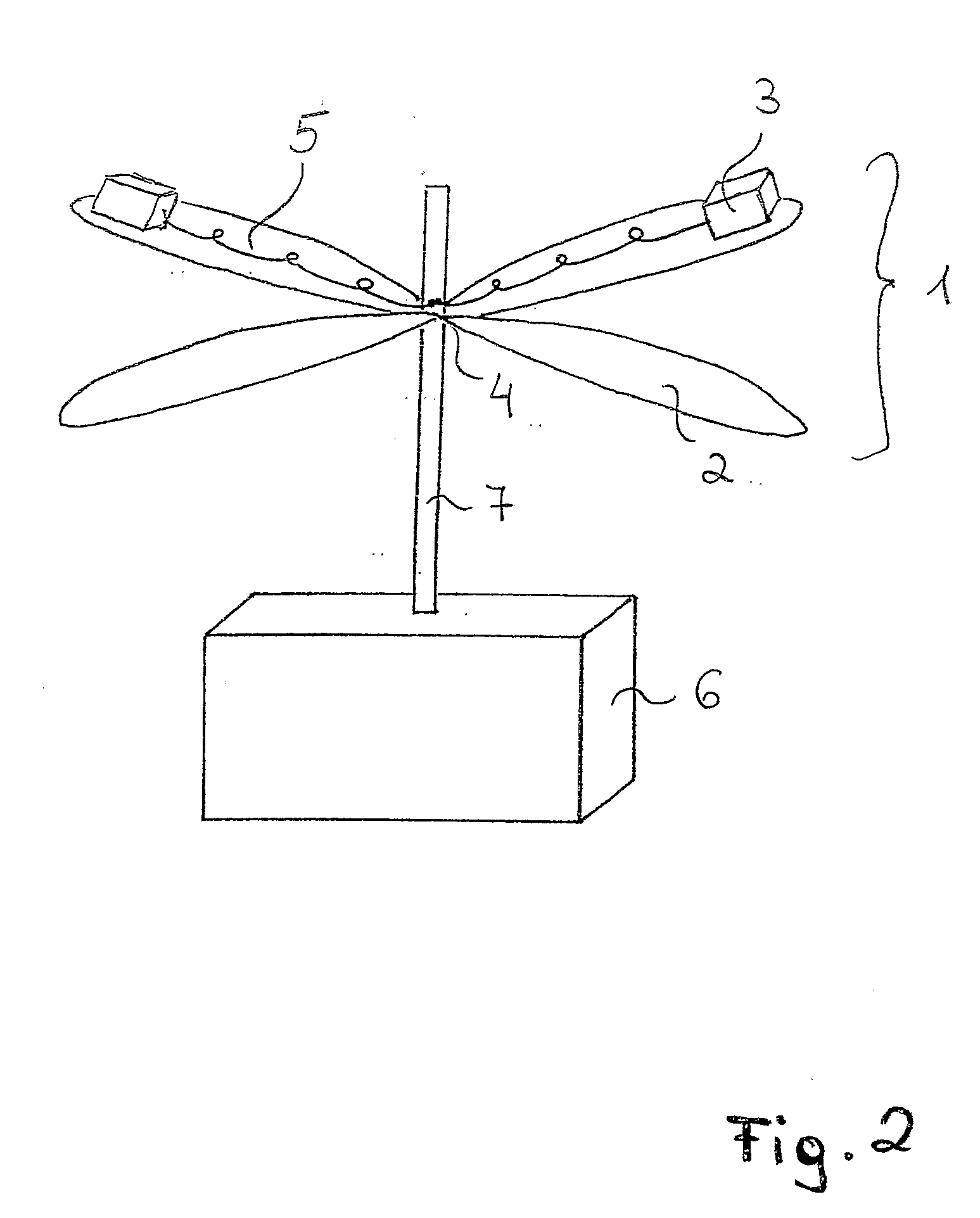

Cooling system for a mobile terminal for wireless communication

InactiveUS7880586B2Easy to implementLow heat generationWeather/light/corrosion resistanceFrequency-division multiplex detailsTelecommunicationsComputer terminal

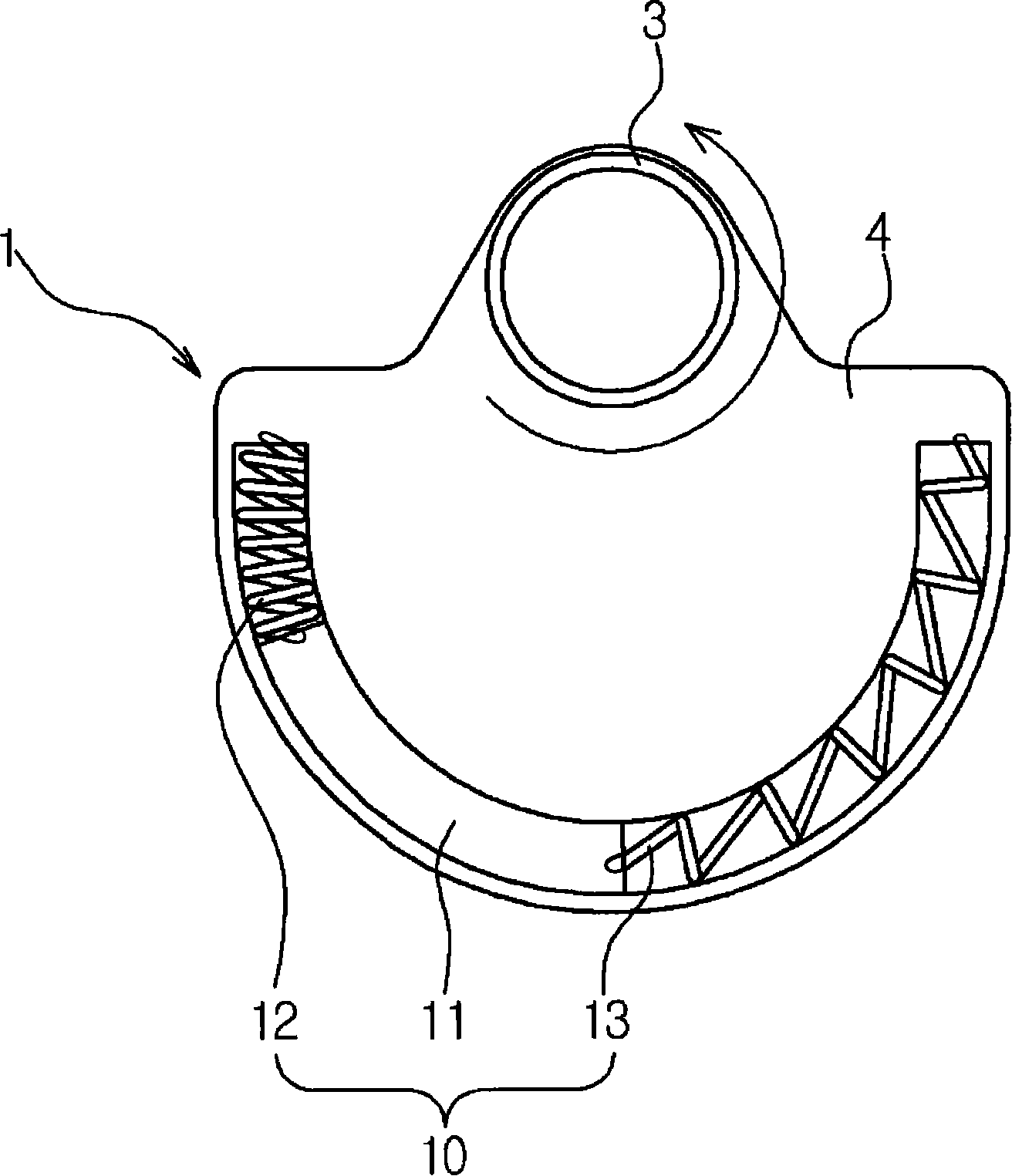

The present invention relates to a cooling system for a mobile terminal for wireless communication comprising a rotating fan (1) for reducing the heat generated by the mobile terminal and at least one weight (3) for causing an unbalance of the rotation of the fan (1) in order to cause vibration of the fan, whereby said weight is activated when the rotational speed of the fan (1) exceeds a predefined level.

Owner:SONY ERICSSON MOBILE COMM AB

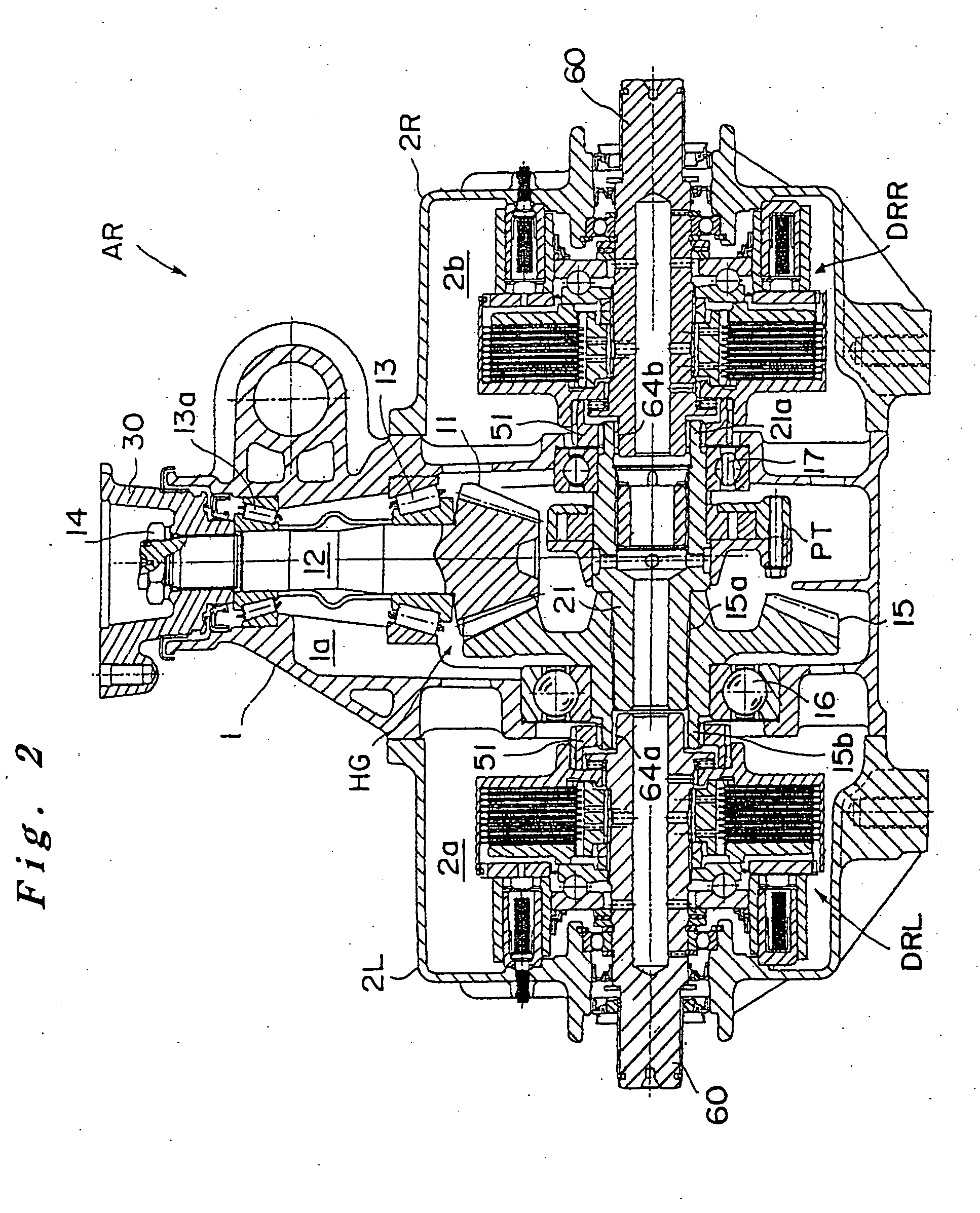

Apparatus and method for testing rotational balance of crankshaft

InactiveUS6840104B2Improve automationAccurate measurementMaterial analysis using sonic/ultrasonic/infrasonic wavesFlow propertiesEngineeringCentrifugal force

Measurement is made of centrifugal force produced on a crankshaft to be tested that is being rotated about its rotation axis, to provide centrifugal force variation information of the crankshaft. Also, measurement is made of errors in respective rotational phases of crankpins of the crankshaft about rotation axes of the crankpins. Dummy information, comprising rotational unbalance data representative of rotational unbalance components to be removed from the centrifugal force variation information of the crankshaft, is created using the measured errors in the respective rotational phases. Then, an initial rotational unbalance value of the crankshaft is determined, using the dummy information and the centrifugal force variation information of the crankshaft.

Owner:HONDA MOTOR CO LTD +1

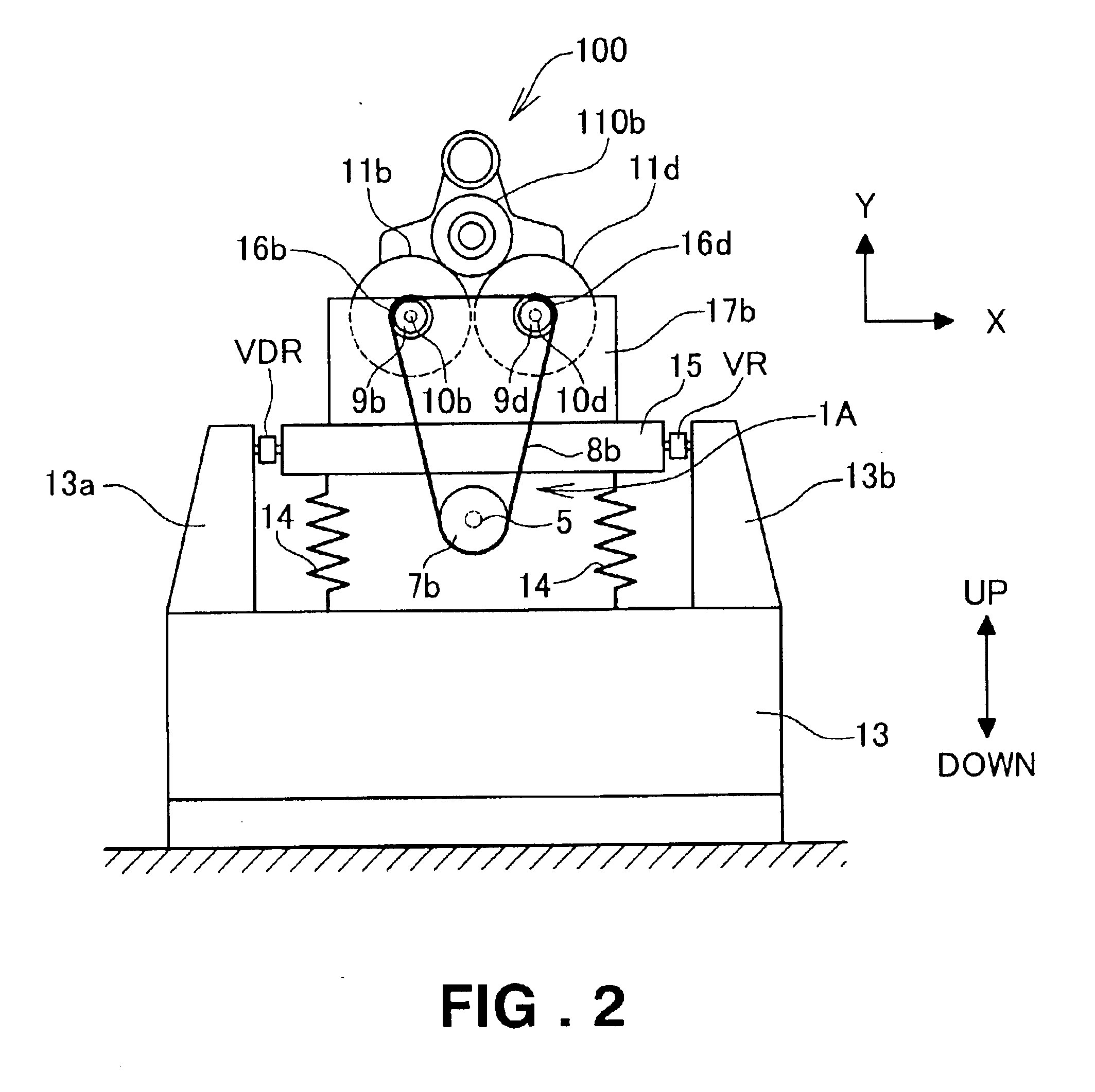

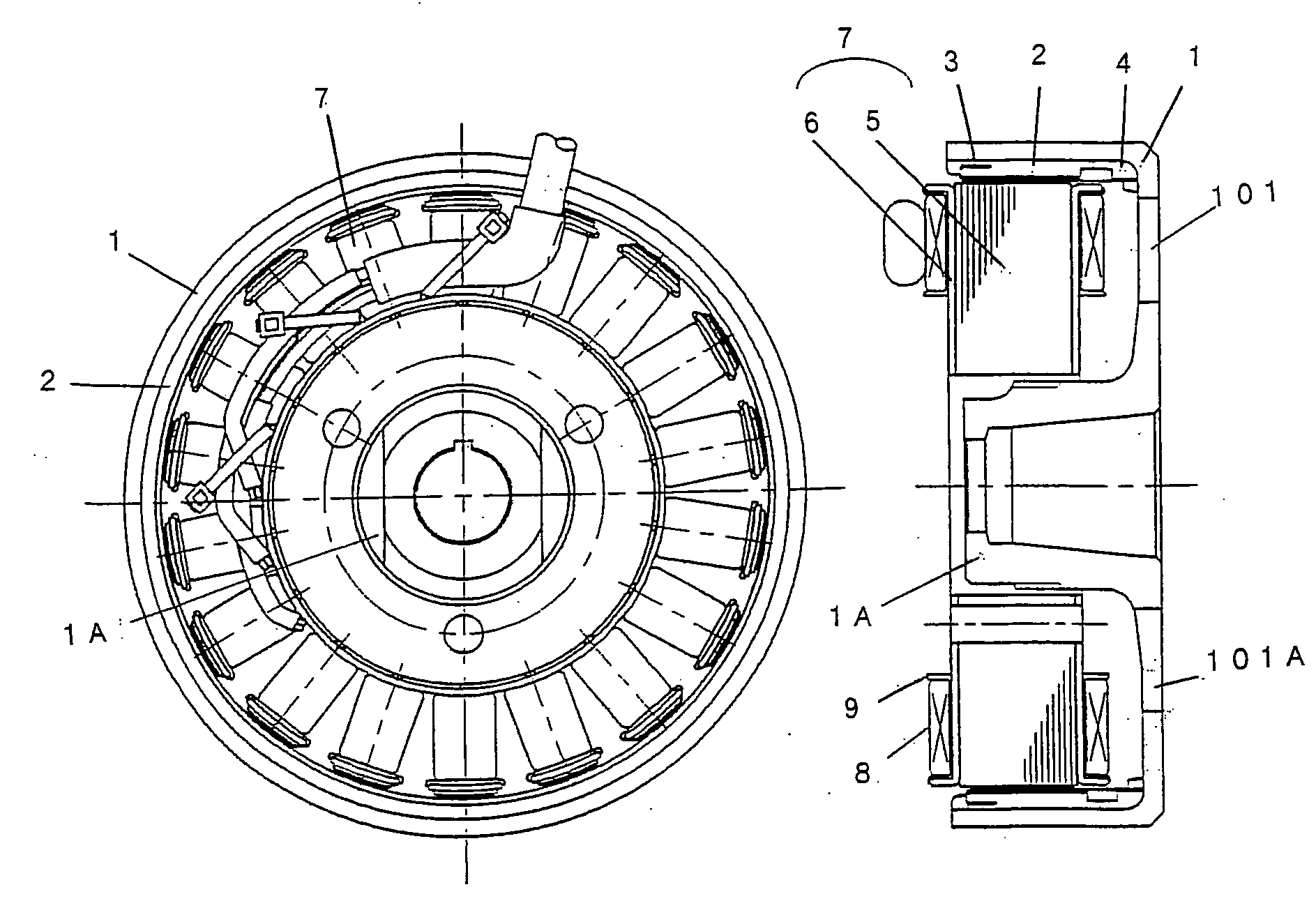

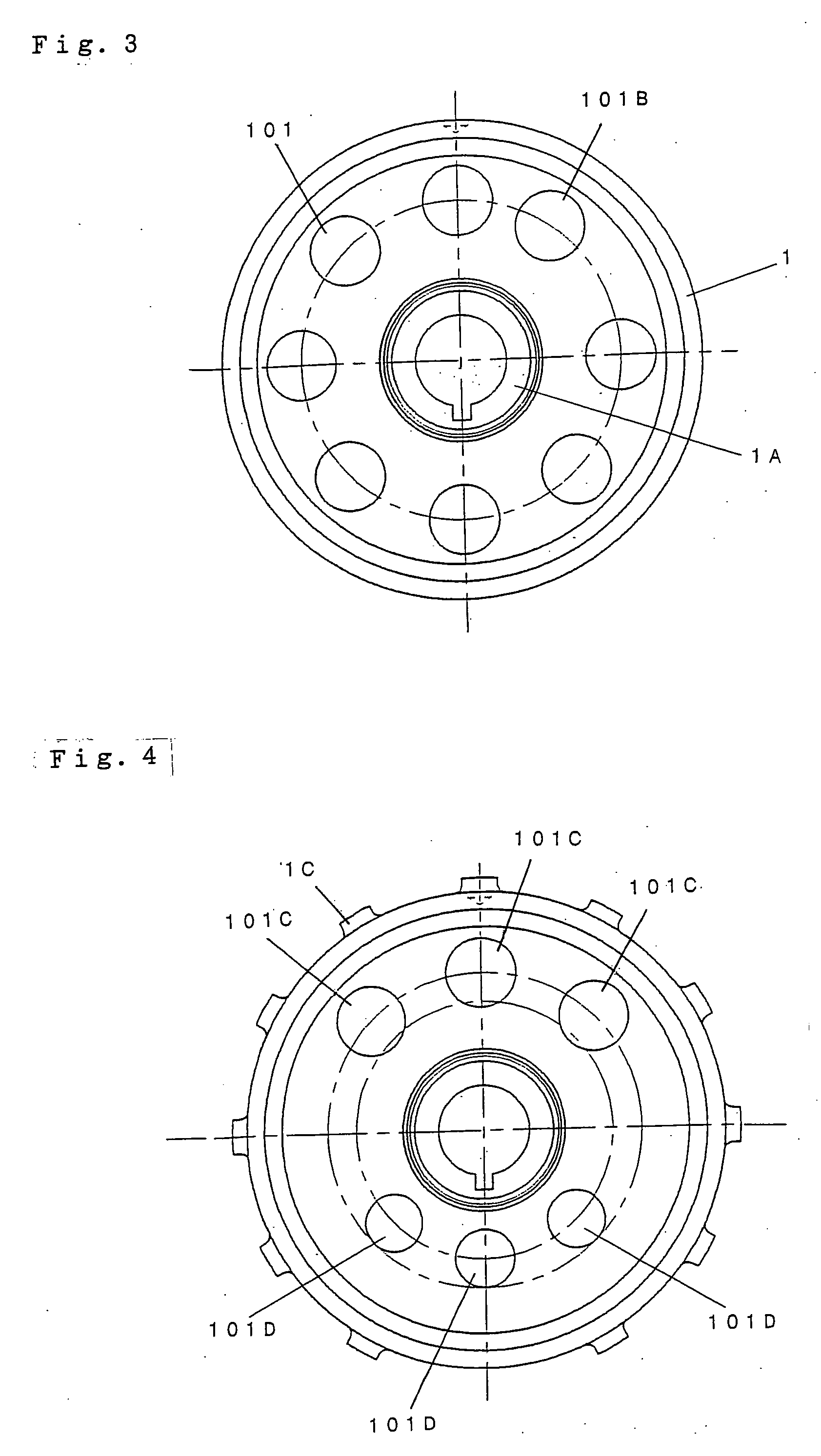

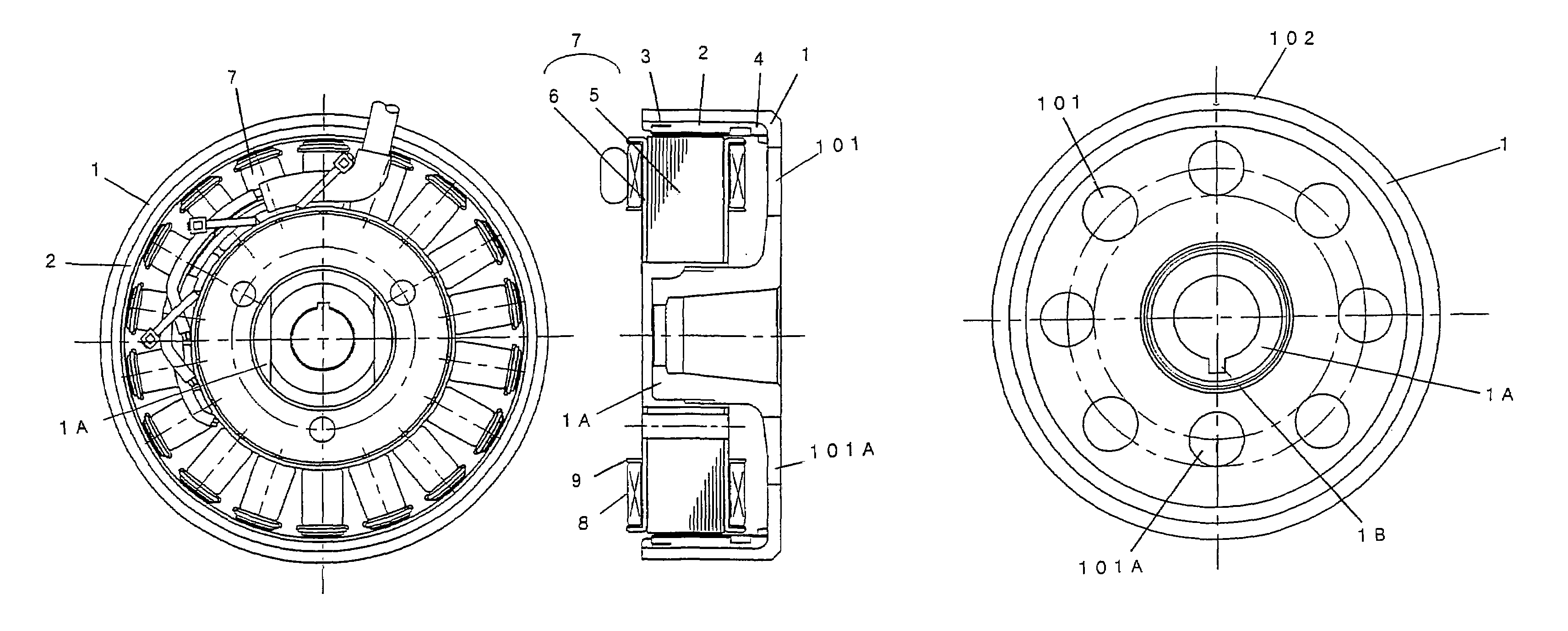

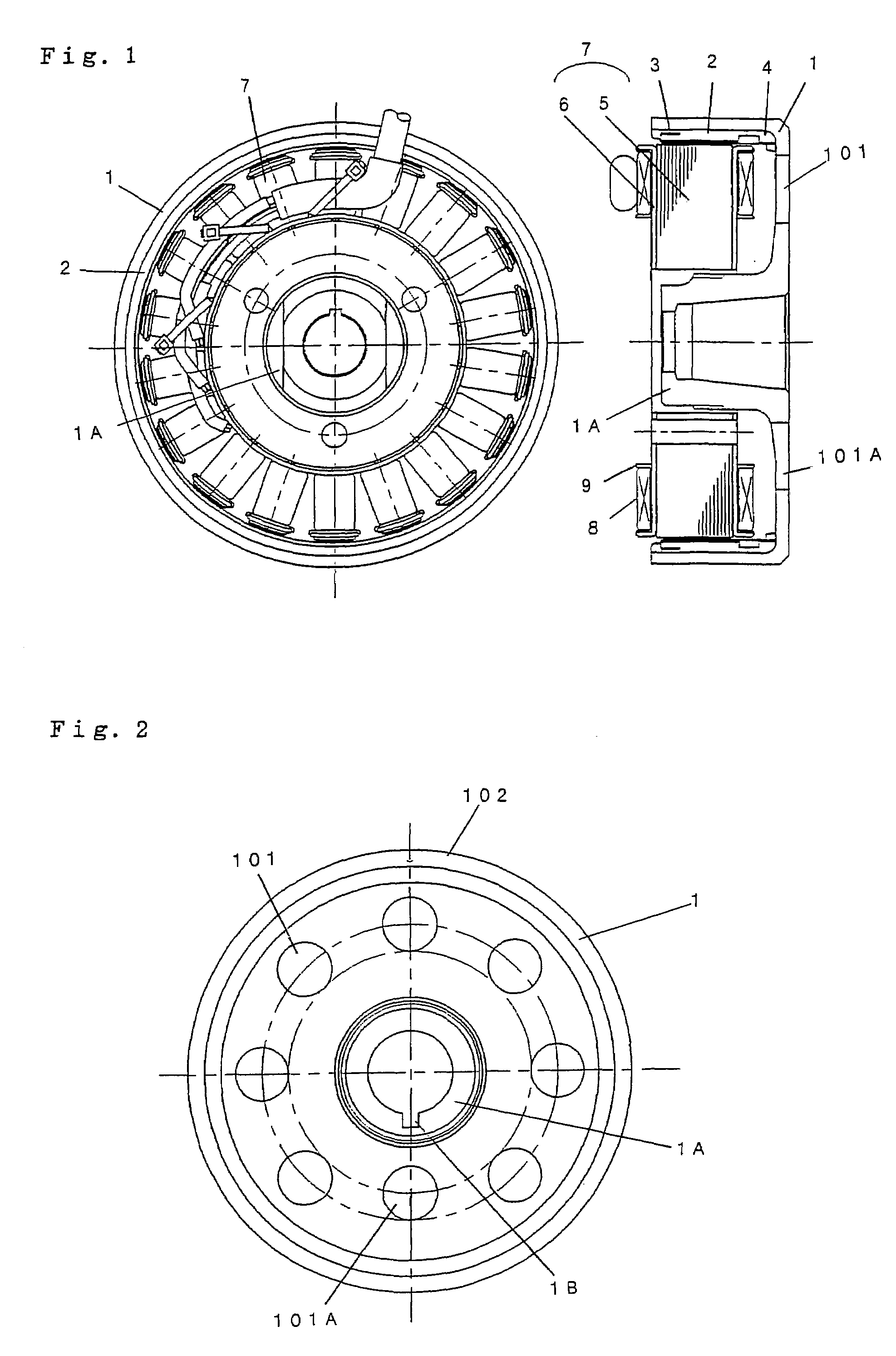

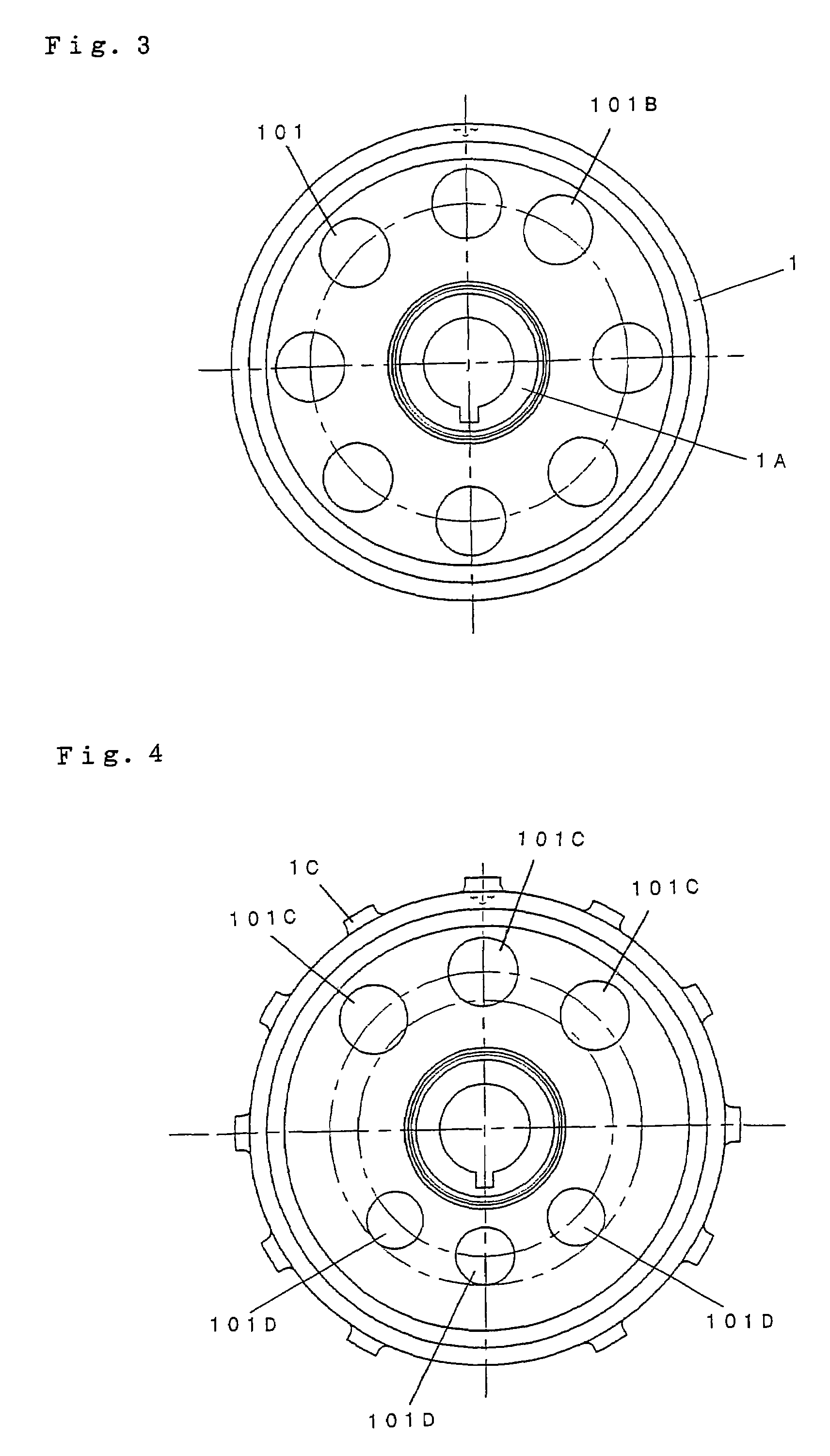

Permanent-magnet generator

ActiveUS20070108851A1Increase the number ofReduce in quantityMagnetic circuit rotating partsManufacturing dynamo-electric machinesEngineeringFlywheel

A permanent-magnet generator is provided that has a bowl-shaped fly wheel integrally formed with a boss part by casting or hot forging, and that enables improvement in the quantity of rotation imbalance and significant reduction in the quantity of balance correction processing (drilling), which is necessary in a later process. The permanent-magnet generator has a bowl-shaped fly wheel produced by casting or hot forging, having a circumferential wall part and a bottom wall part, and having a boss part for supporting a rotating shaft, the boss part being integrally formed at the center of the bottom wall part. The plural vents are arranged substantially circularly with spacing from each other in the bottom wall part of the fly wheel, and a key groove for coupling with the rotating shaft is provided at a part of the boss part. The arrangement of at least one of the plural vents is made unequal in order to reduce the quantity of rotation imbalance including that of the key groove.

Owner:MITSUBISHI ELECTRIC CORP

Automotive alternator having cooling fan coupled to rotor shaft

ActiveUS7057315B2Firmly connectedSimple processRotary current collectorMagnetic circuit rotating partsAlternatorEngineering

An alternator for use in an automobile includes a stator supported between a front housing and a rear housing, and a rotor connected to a rotor shaft and rotatably supported inside the stator. A cooling fan is positioned at an end of a pole core of the rotor. The cooling fan is coupled to the rotor shaft by engaging edges of a center opening of the cooling fan with a non-circular flange formed on the rotor shaft. The cooling fan is correctly positioned relative to the rotor shaft, without using a jig, both in the radial direction and in the rotational direction of cooling fan. Noises and vibrations due to rotational imbalance of the cooling fan are suppressed.

Owner:DENSO CORP

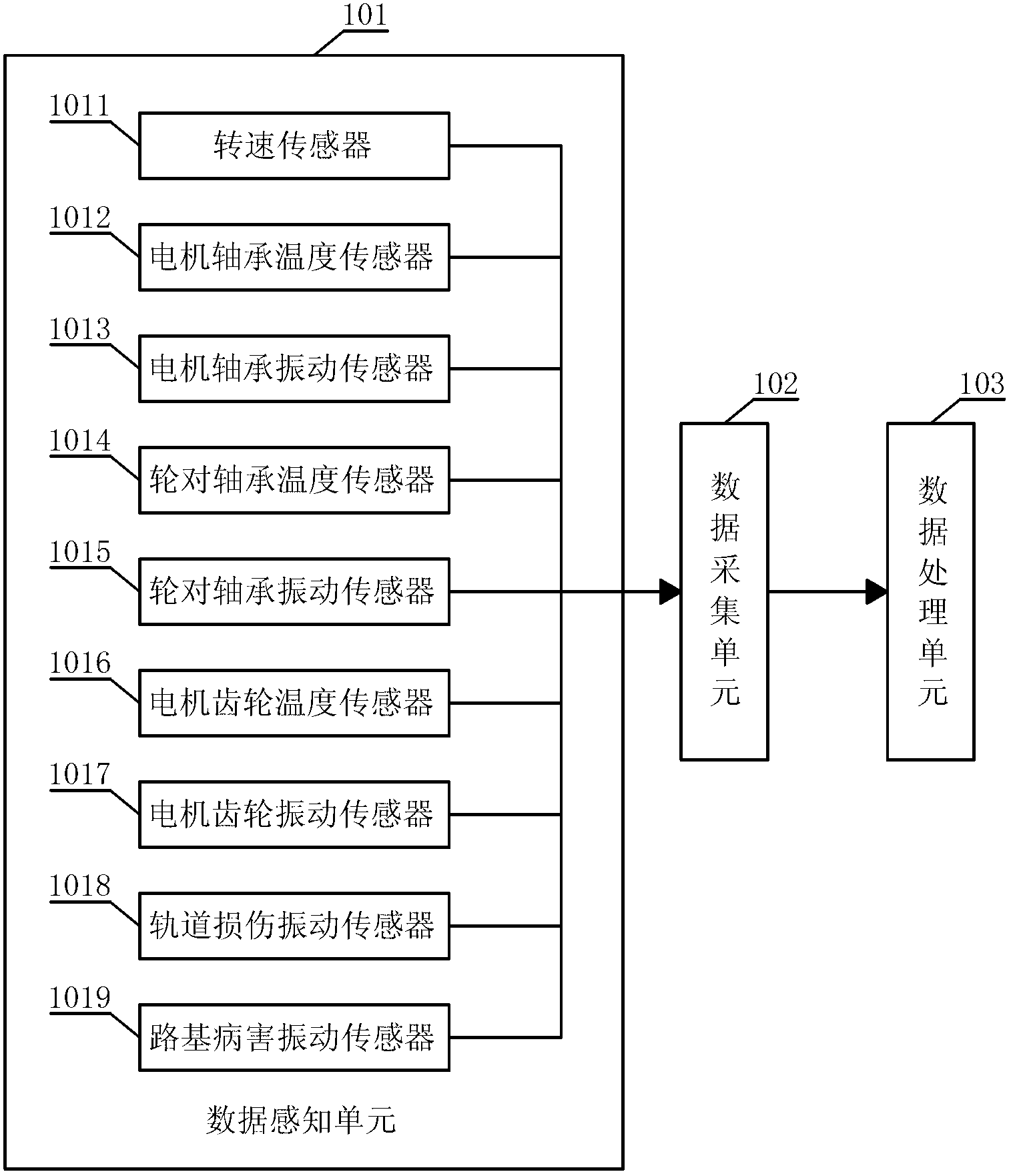

Railway dynamic detection system

ActiveCN102798413ATroubleshooting cannot be fully diagnosedSolve the low detection efficiencyMeasurement devicesBogieEngineering

The invention discloses a railway dynamic detection system, comprising a data aware unit, a data acquiring unit, and a data processing unit. The system can complete fault real-time diagnosis of unbalanced rotation and misaligned rotation of a bogie wheel shaft, real-time monitoring of working conditions of a wheel set traction motor bearing of the bogie, a bogie wheel set bearing, and transmission gears of a traction motor when a rolling stock is in an operating state, and the system can diagnosis faults which is possible to occur in real time. Meanwhile, using real-time transmission characteristic of vibration, through obtaining vibrating impulse signals generated by railway track damage when the rolling stock is operating, and vibrating impulse signals generated by railway subgrade defects when the rolling stock is operating, the system monitors the railway track damage and subgrade defects. Compared with conventional railway detection systems, the system not only can comprehensively diagnosis the rolling stock's faults, but also has high detection efficiency.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

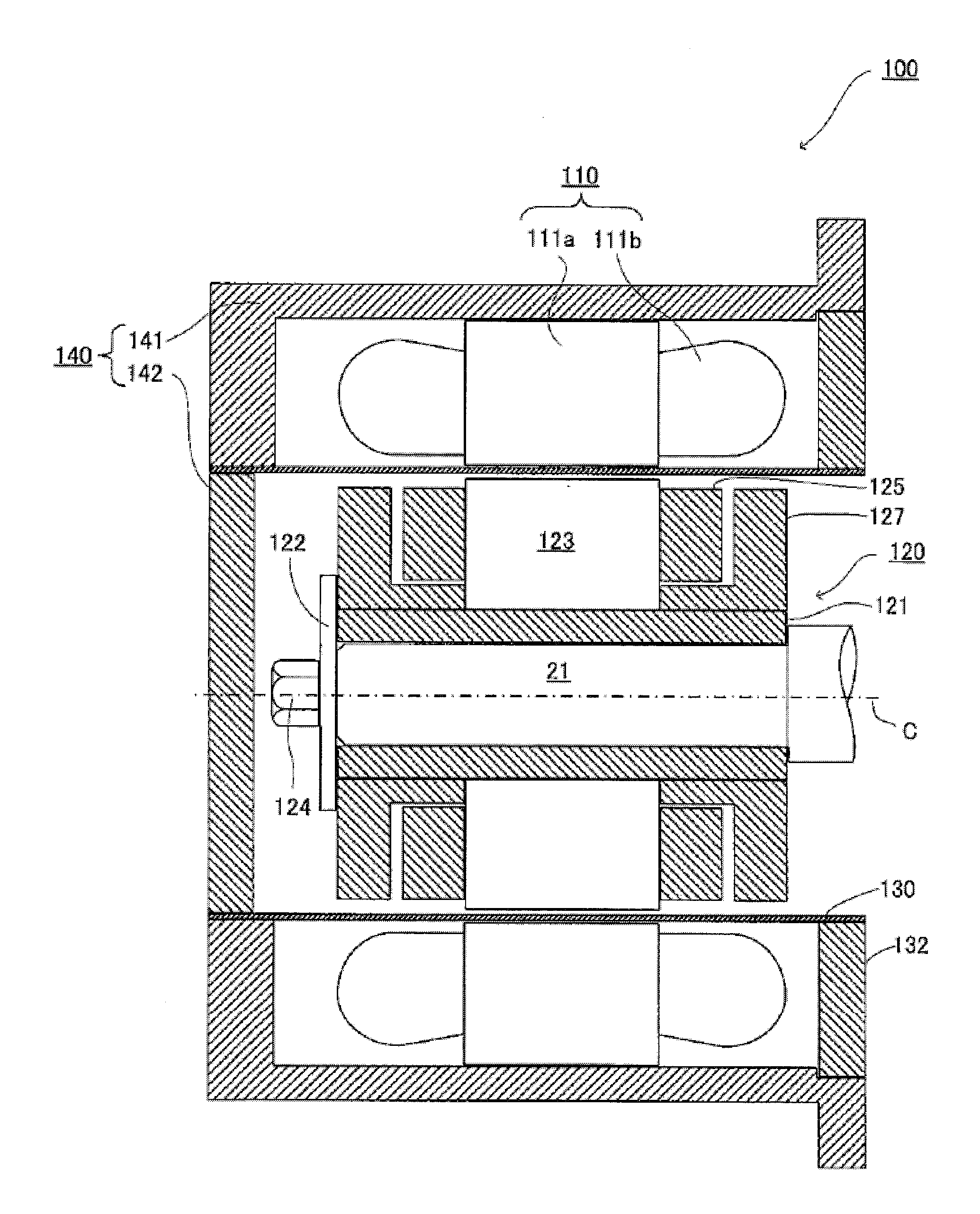

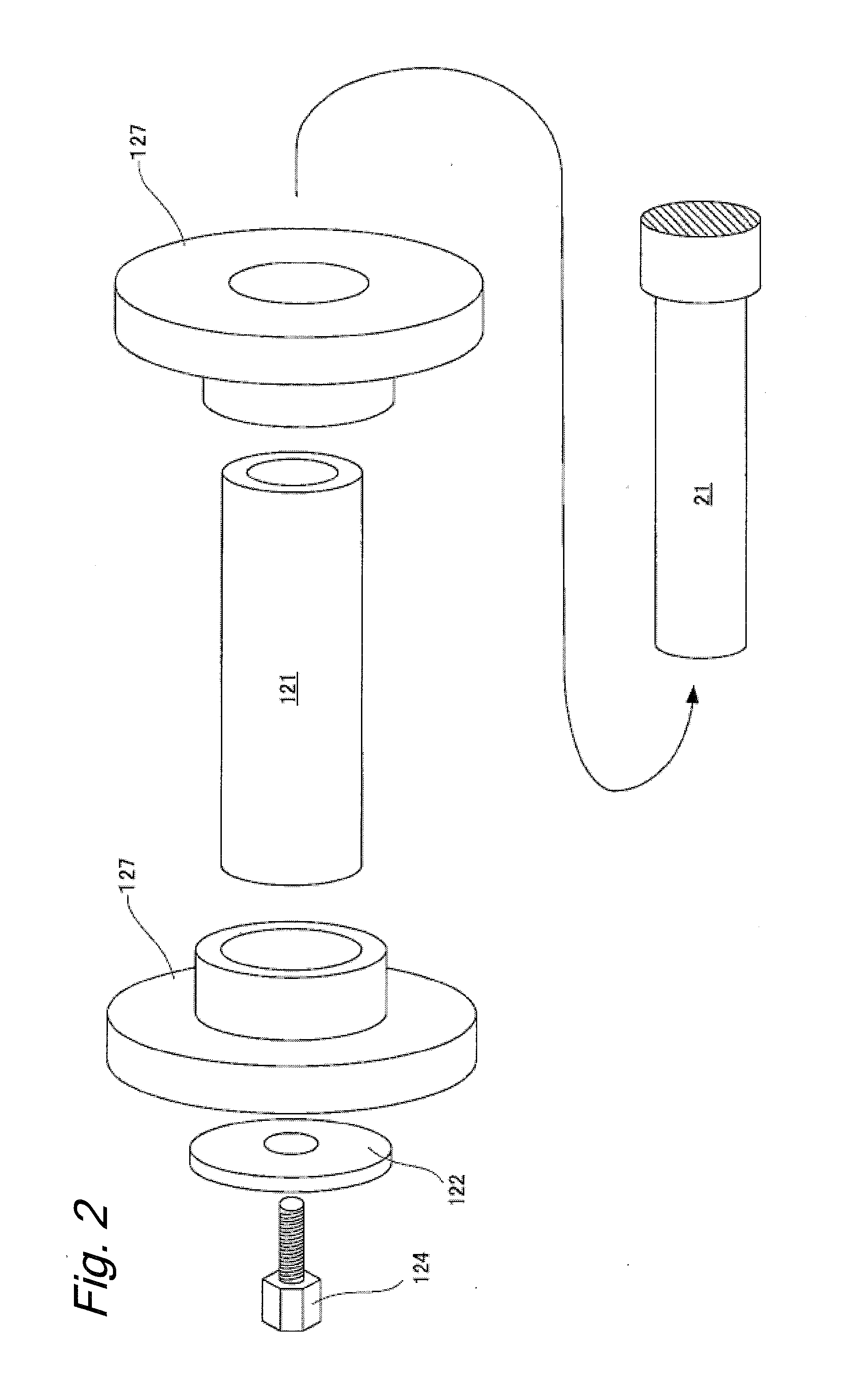

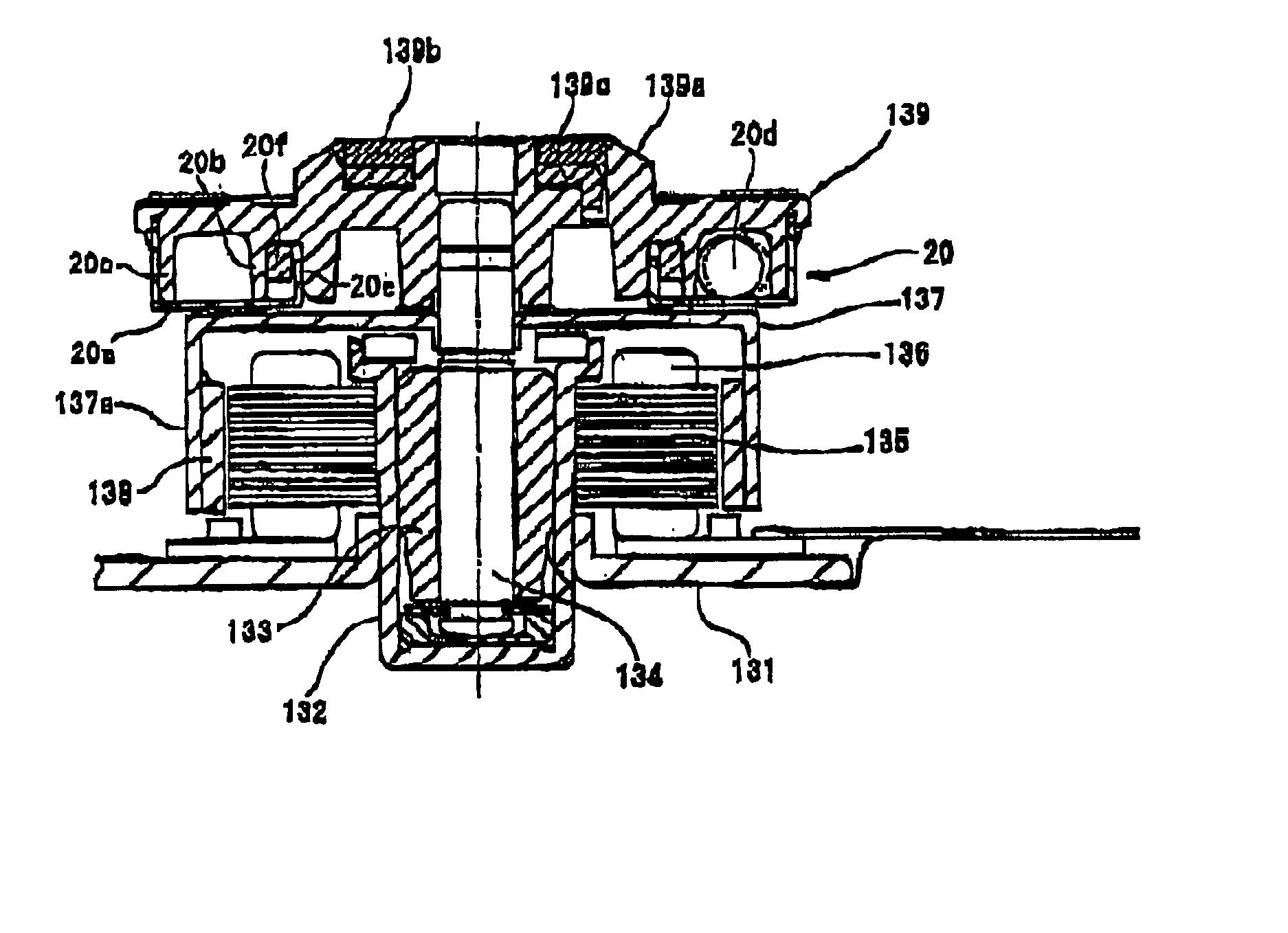

Vacuum pump motor and vacuum pump including same

ActiveUS20140056733A1Improve performanceSuperiority in mechanical designCorrosion preventionPump controlVacuum pumpElectric motor

In order to provide a vacuum pump motor which is free from rotation imbalance, there is provided a vacuum pump motor 10 which is connected directly to a pump main shaft 21 of a vacuum pump 20, including a motor rotor 120 which is attached directly or indirectly to the pump main shaft 21 and balance rings 127 which are attached directly or indirectly to the pump main shaft 21 at ends thereof which are spaced apart from end portions of a rotor core 123, wherein the balance rings 127 contain a material having anticorrosion properties.

Owner:EBARA CORP

Spindle clamp

ActiveUS20120279286A1Improve balance qualityRigid characteristicStatic/dynamic balance measurementMaterial removalEngineering

The invention relates to a balancing device, having a measuring system for determining the rotational unbalance of a test object, comprising a spindle unit with a spindle, which is intended to hold the test object and rotate it at a test rotational speed, and a spindle mounting, by which the spindle unit is movably anchored on the machine base, such that the spindle unit can oscillate in a predetermined measuring direction as a result of the unbalance forces occurring during the measurement operation, and at least one sensor, which upon rotation of the spindle detects at least one unbalance characteristic variable occurring in the measuring direction, and a material removal system for balancing the test object by material removal in a predetermined site. The measuring system and the material removal system are designed such that material can be removed when the test object is held in the spindle.

Owner:FRANZ HAIMER MASCHINENBAU KG

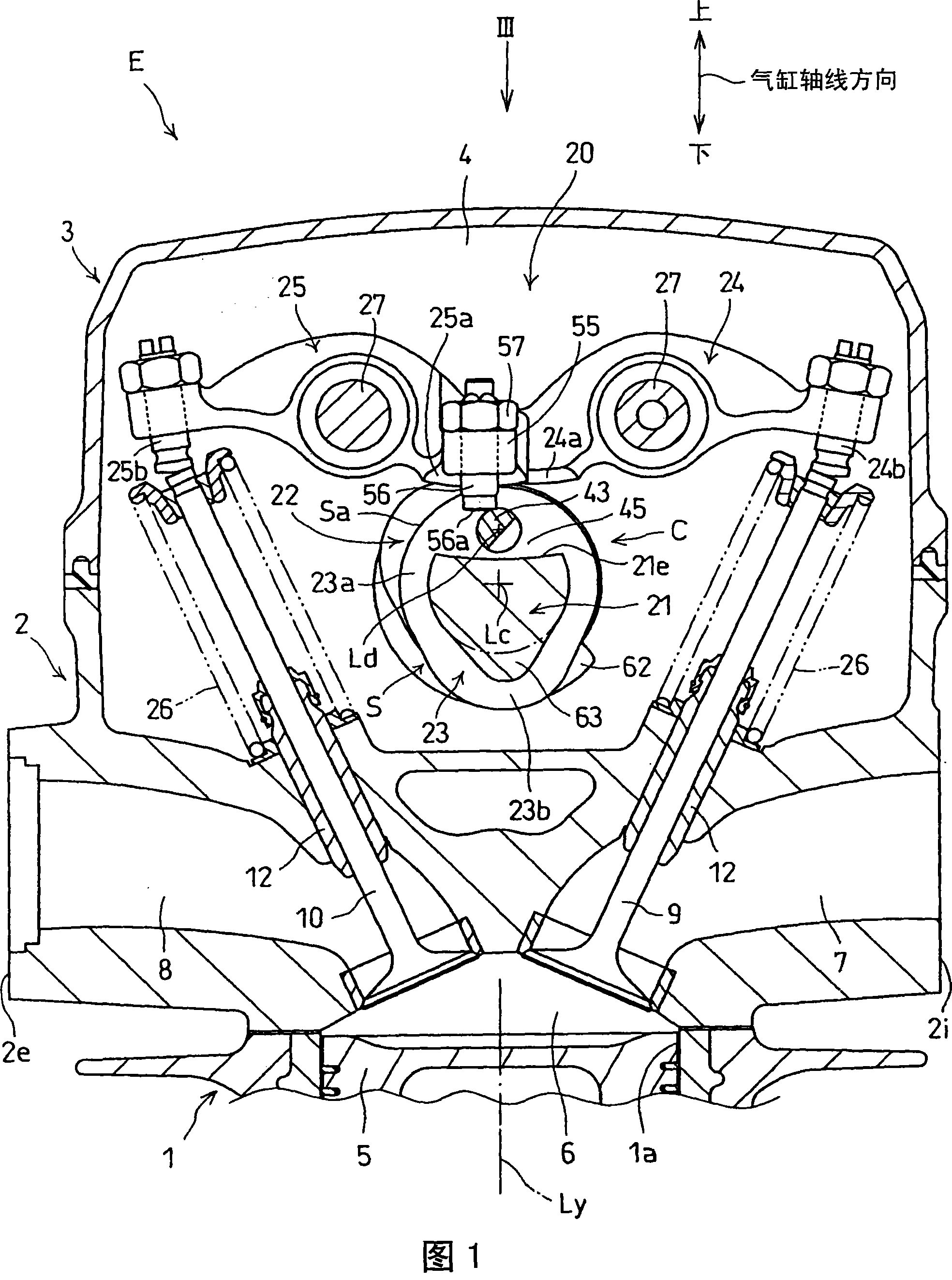

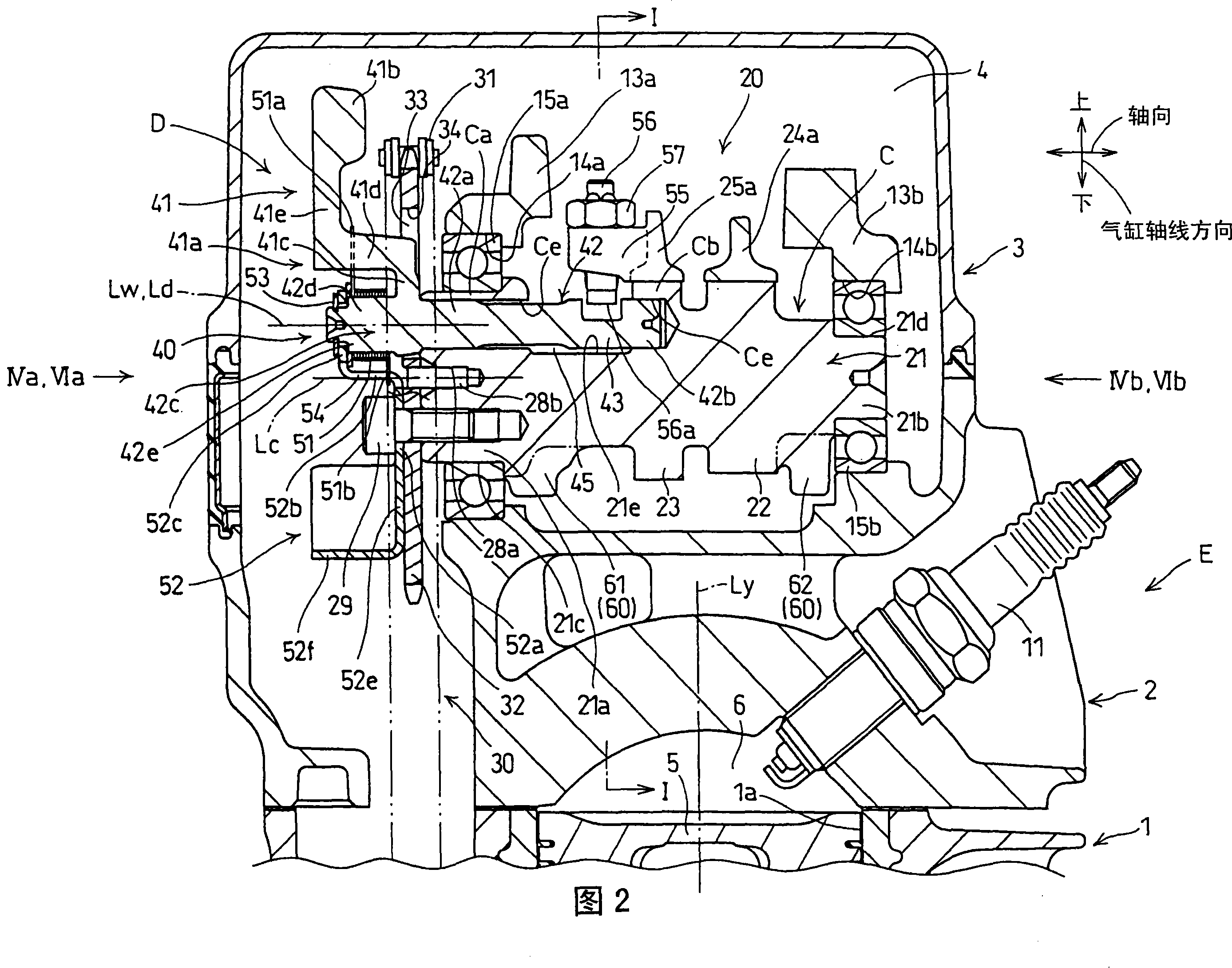

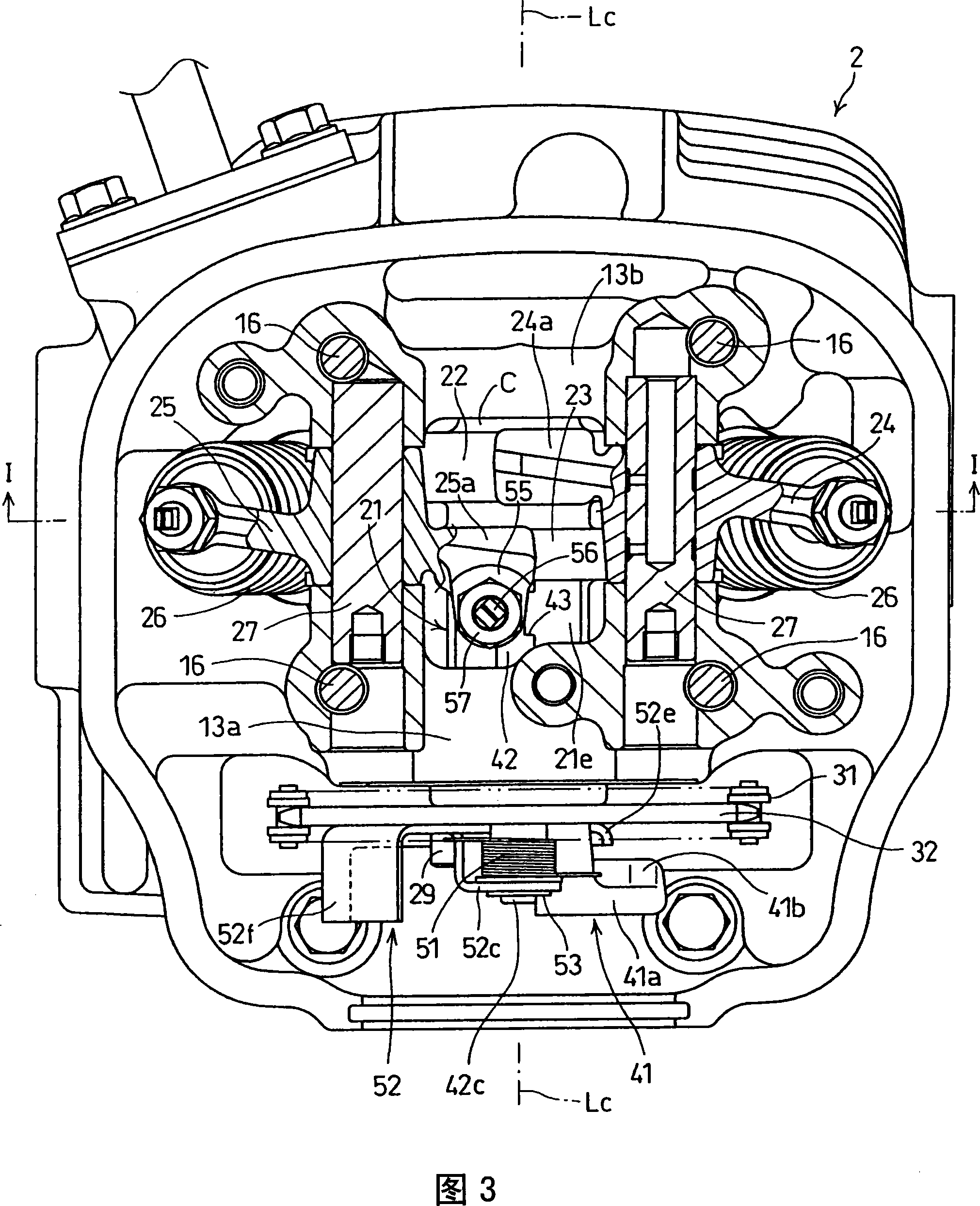

Internal-combustion engine with decompressor

ActiveCN101187320AVibration suppressionReduce vibrationValve arrangementsMachines/enginesCombustionLow speed

The present invention provides an internal combustion engine (E) provided with a decompression device, which reduces rotational imbalance of a camshaft by the decompression device and improves the opening and closing accuracy of engine valves by the valve cam. It includes: a centrifugal load (41) swingably supported on the camshaft of the valve device (20), a decompression device (D) having a decompression cam (43) driven by the swinging centrifugal load (41) . The decompression cam (43) occupies the decompression position where the engine valve is opened during the compression stroke in which the compression pressure in the combustion space should be lowered when the centrifugal load (41) occupies the low-speed side position when the engine is started, and the centrifugal load (41) ) After the engine that occupies the high-speed side position is started, it occupies the decompression release position that does not open the engine valve. A balance load (60) for reducing rotational imbalance of the camshaft caused by a centrifugal load (41) occupying a high-speed side position is provided on the camshaft. The balance load (60) is composed of a plurality of load portions (61, 62, 52e) spaced apart from each other in the axial direction of the camshaft (C).

Owner:HONDA MOTOR CO LTD

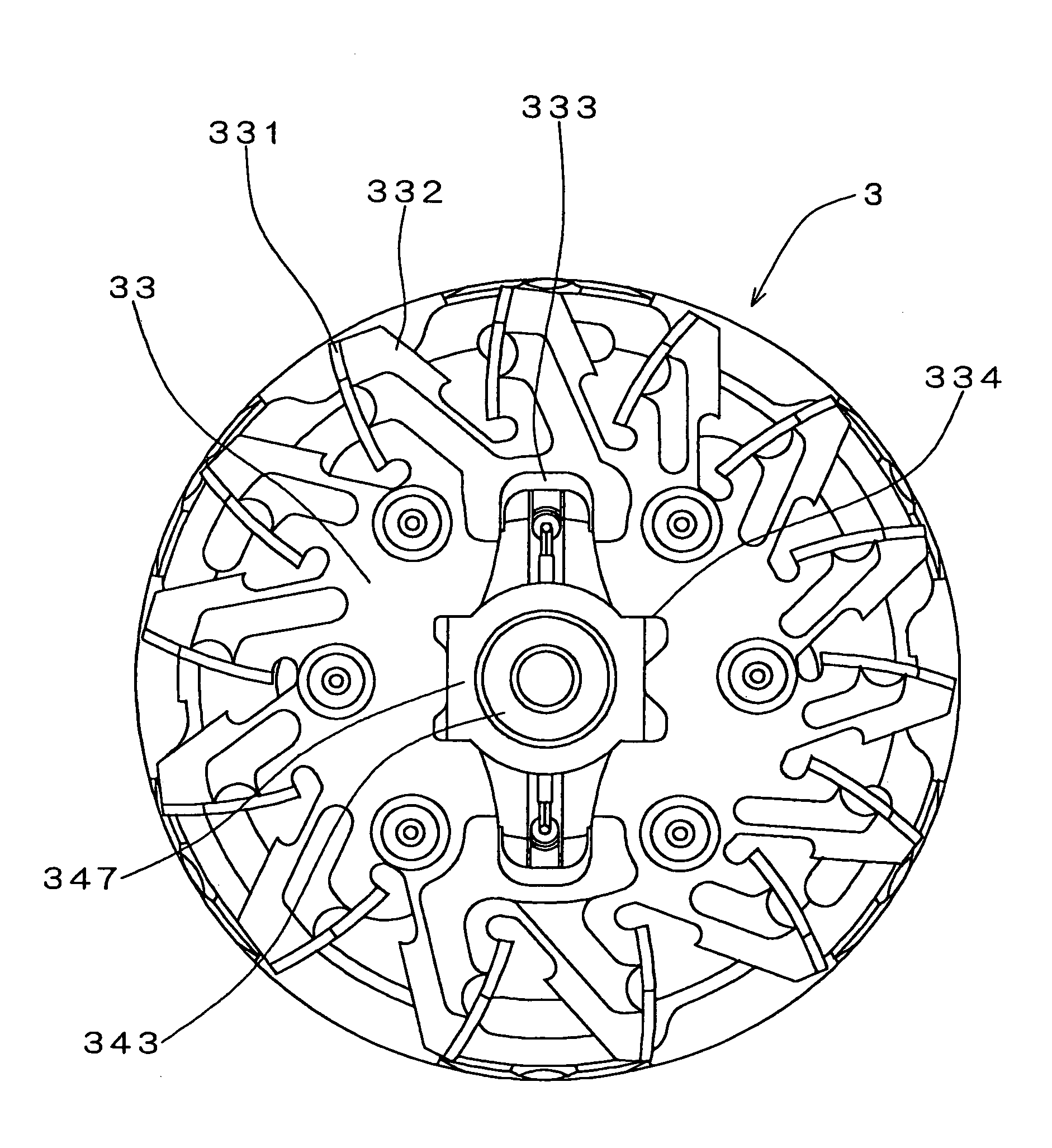

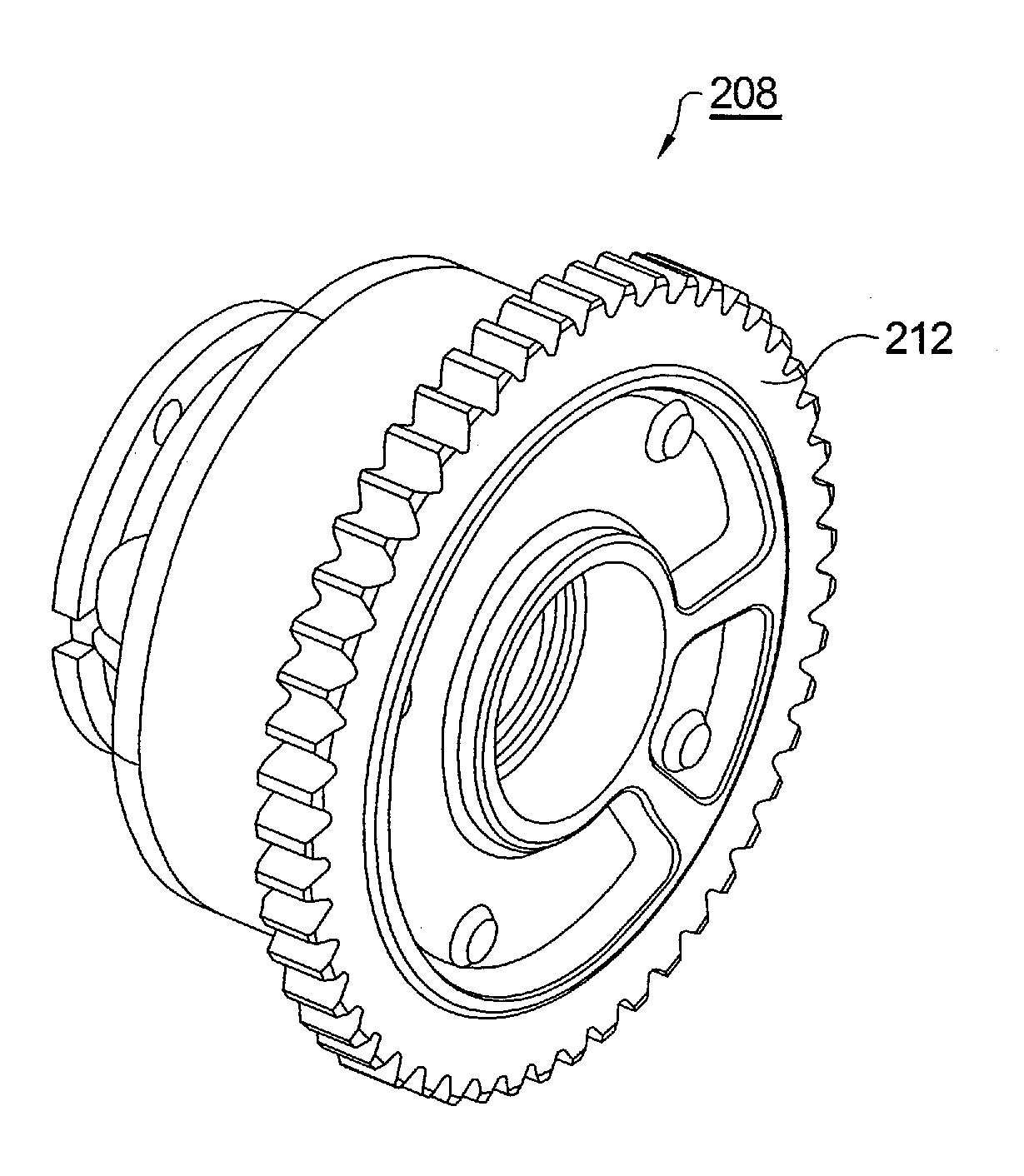

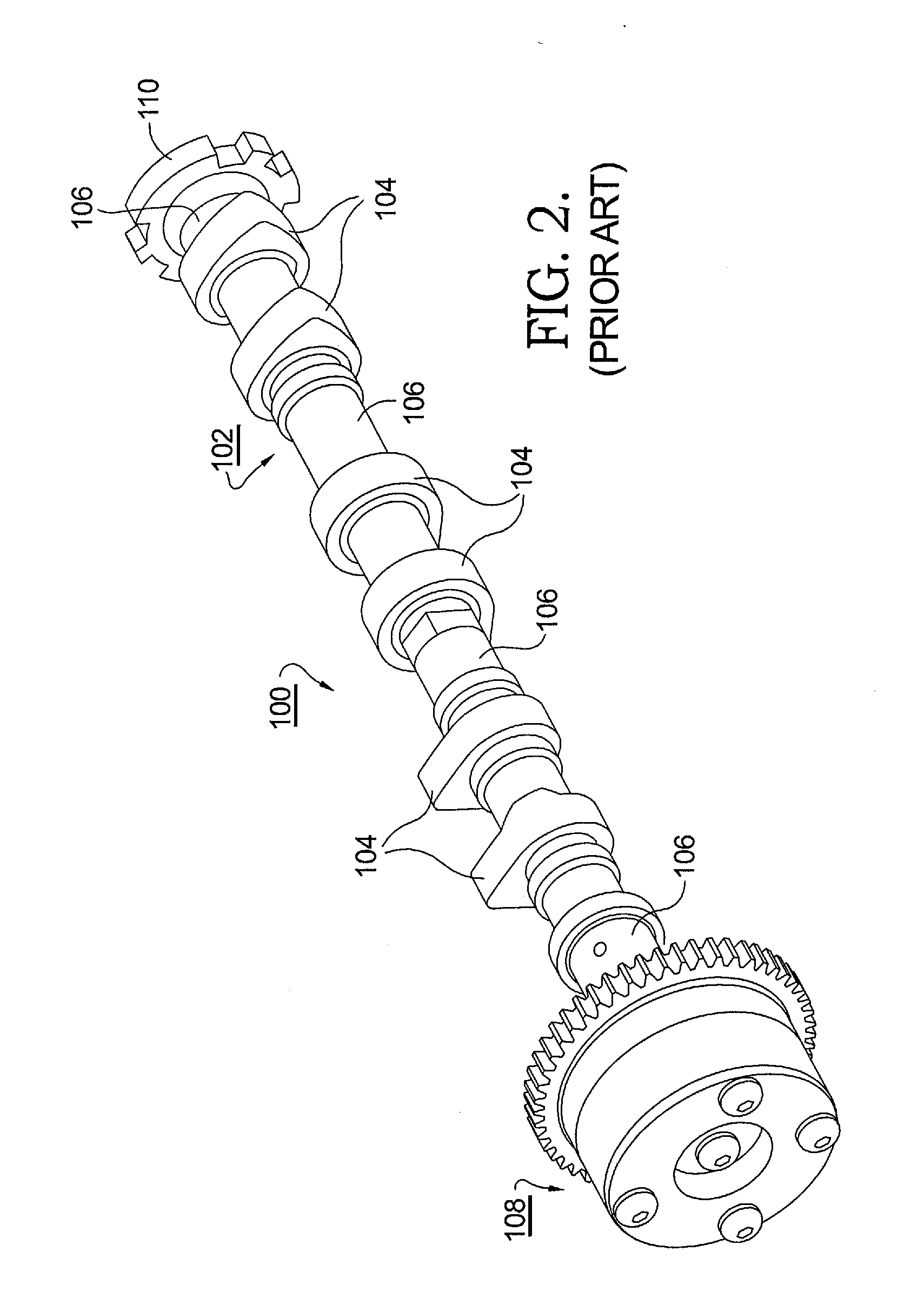

Rotationally Balanced Camshaft Assembly

A method for intentionally imbalancing one or more mass elements of a camshaft assembly to provide overall rotational balance to the assembly, also referred to herein as “zero balance”. Such intentional imbalance may be imparted to any element of a camshaft assembly. In a currently-preferred embodiment, one or more components of an improved camshaft phaser assembly are manufactured as rotationally unbalanced, either by intentionally forming an unbalanced component such as a sprocket wheel having added material or by removing non-functional material from an otherwise standard component. Because the camshaft phaser assembly has a unique and fixed angular relationship to the camshaft, zero balance can be readily and repeatedly achieved for all camshaft assemblies by correct manufacture of parts without requiring separate balancing for each individual camshaft assembly as manufactured.

Owner:DELPHI TECH INC

Permanent-magnet generator

ActiveUS7531931B2Increase the number ofReduce in quantityMagnetic circuit rotating partsManufacturing dynamo-electric machinesEngineeringFlywheel

A permanent-magnet generator is provided that has a bowl-shaped fly wheel integrally formed with a boss part by casting or hot forging, that reduces rotational imbalance and the quantity of balance correction processing such as drilling. The permanent-magnet generator has a bowl-shaped fly wheel produced by casting or hot forging, having a circumferential wall part and a bottom wall part, and having a boss part for supporting a rotating shaft, the boss part being integrally formed at the center of the bottom wall part. The plural vents are arranged substantially circularly in the bottom wall part of the fly wheel, and a key groove for coupling with the rotating shaft is provided at a part of the boss part. The arrangement of at least one of the plural vents is made unequal in order to reduce rotational imbalance including that caused by the key groove.

Owner:MITSUBISHI ELECTRIC CORP

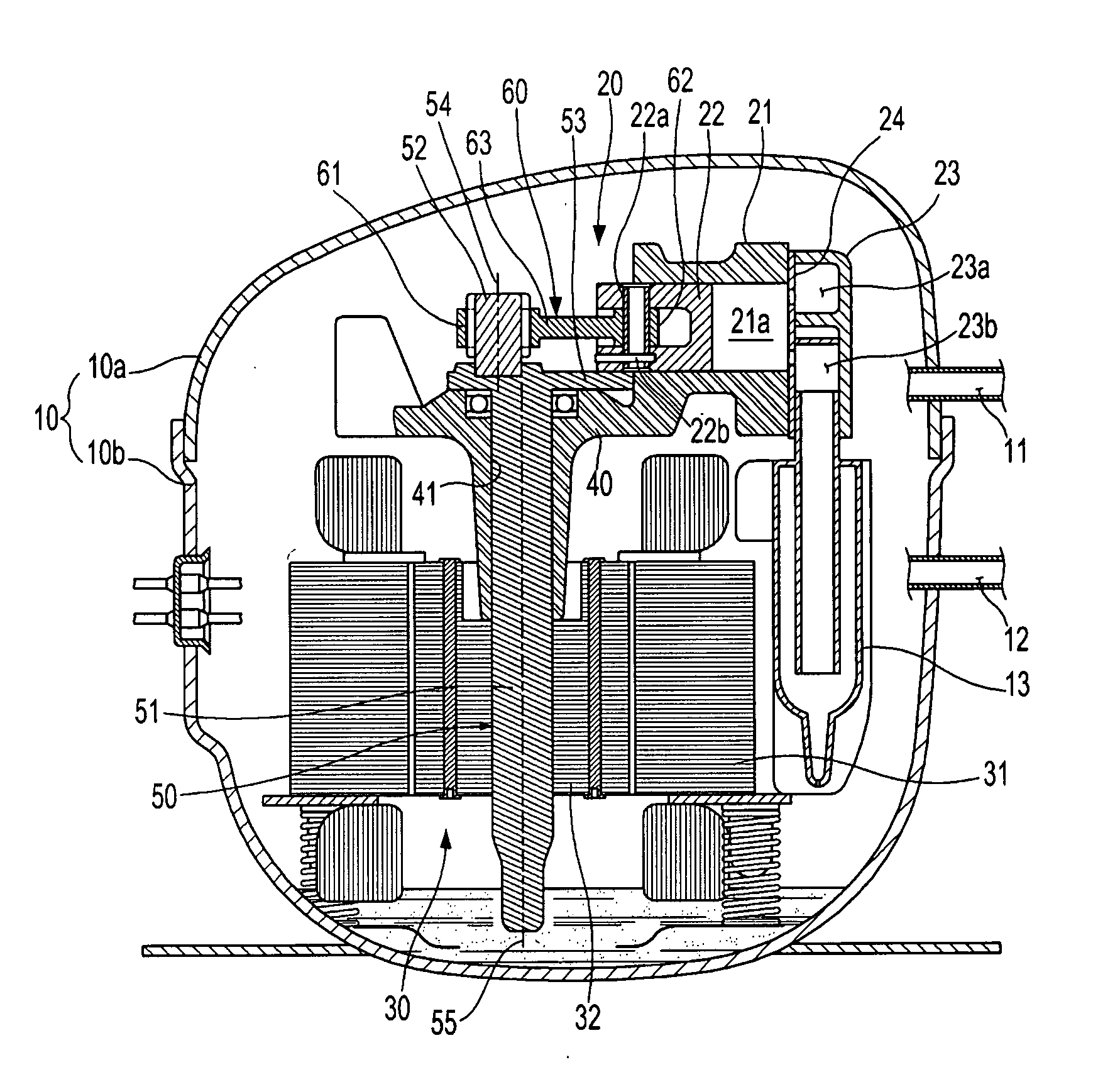

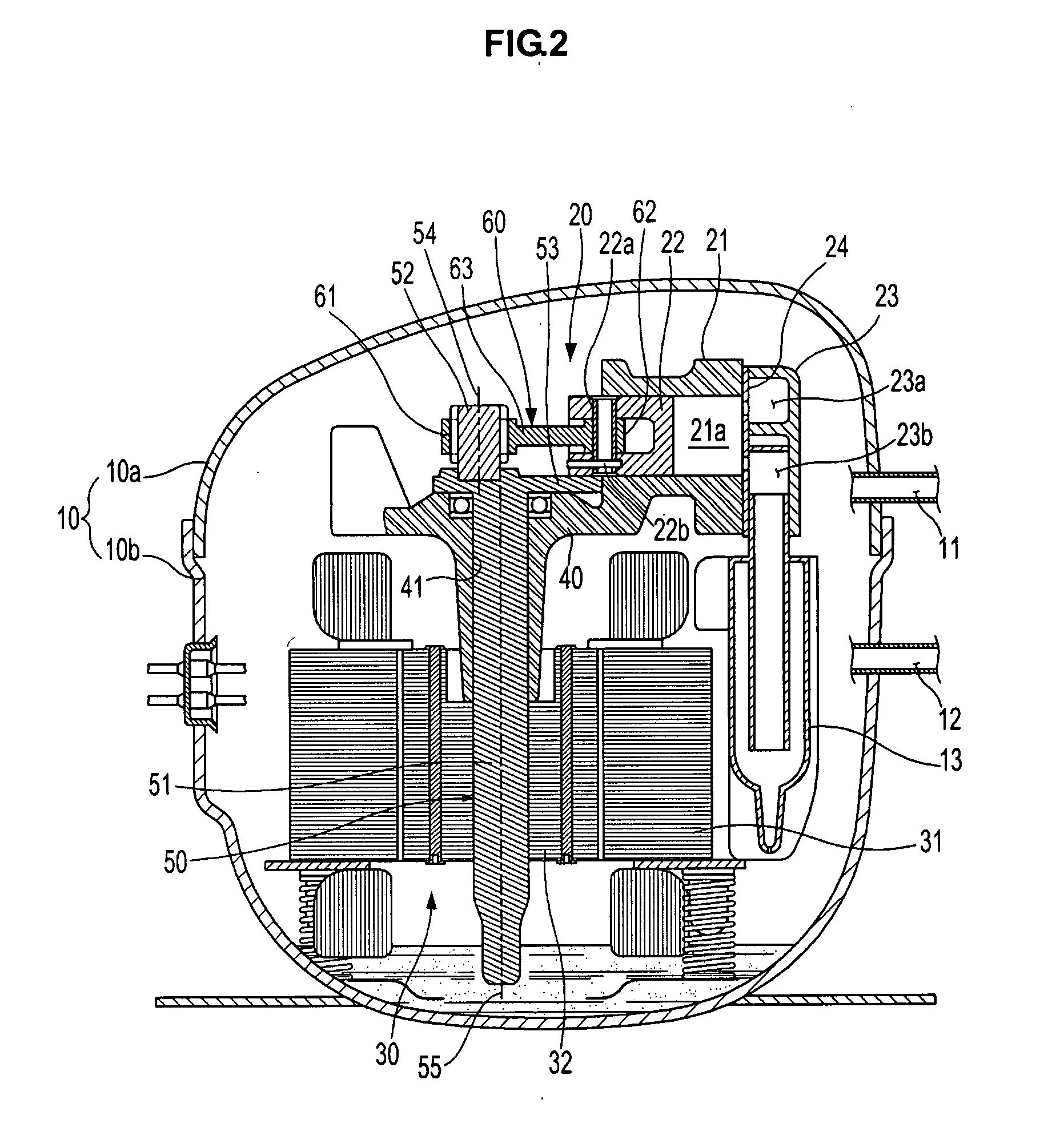

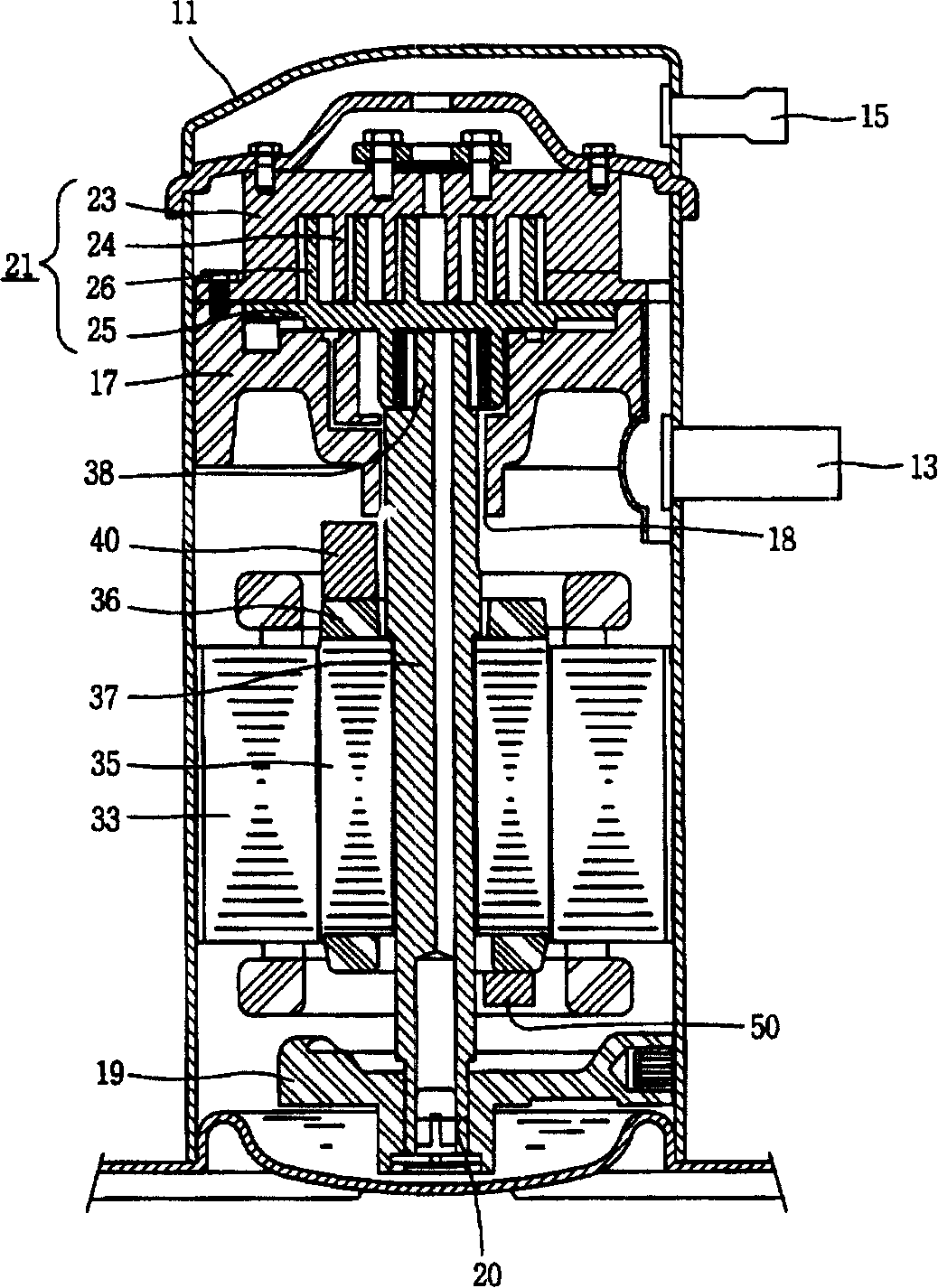

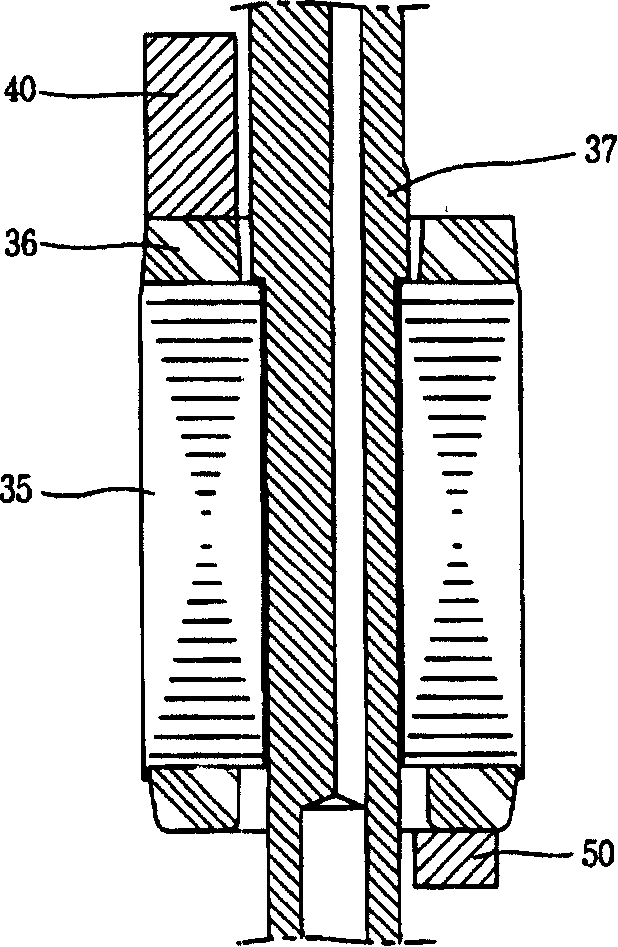

Hermetic compressor

A hermetic compressor with a connecting rod that can be assembled with a crankshaft and a piston while the piston is in a cylinder integrally formed with a frame. The hermetic compressor includes the frame formed with a hollow portion, a drive unit disposed on the frame, a cylinder integrally formed with the frame, the piston disposed within the cylinder, a crankshaft, and a connecting rod. The piston linearly reciprocates within the cylinder. The crankshaft has a main shaft portion adapted to rotate by a drive force of the drive unit, an eccentric shaft portion provided at one end of the main shaft portion, and a weight balance portion provided between the main shaft portion and the eccentric shaft portion. The main shaft portion is rotatably supported in the hollow portion. The eccentric shaft portion is positioned eccentrically relative to the main shaft portion. The weight portion is adapted to compensate for a rotating imbalance caused by the eccentric shaft portion. The eccentric shaft portion is fabricated separately from the crankshaft and rotatably coupled to the weight balance portion. The connecting rod couples the eccentric shaft portion and the piston. The connecting rod is formed to convert a rotating motion of the crankshaft into the linearly reciprocating motion of the piston.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Crankshaft of reciprocal compressor

InactiveCN101205960APrevent disengagementInertia force compensationPositive displacement pump componentsElastic componentEngineering

The invention relates to a crank for a reciprocated compressor. The proposal of the invention is to provide a crank for a reciprocated compressor, wherein, the unbalance rotation of the crank can be compensate quickly no matter what the rotation direction when the crank rotates towards two directions. Therefore, the crank for a reciprocated compressor provided by the invention can rotate towards any one of two directions in the drive of a driving unit; one end of the crank is provided with an eccentric shaft which is connected with a piston through a ram; and the lower part of the eccentric shaft is provided with a balance hammer which is used for compensating the unbalance rotation caused by the eccentric shaft. The balance hammer is provided with a weight balancing device which comprises a moving component moved along the rotation direction of the crank and provided with a predetermined quality, and a pair of elastic component for elastically supporting the two ends of the moving component.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

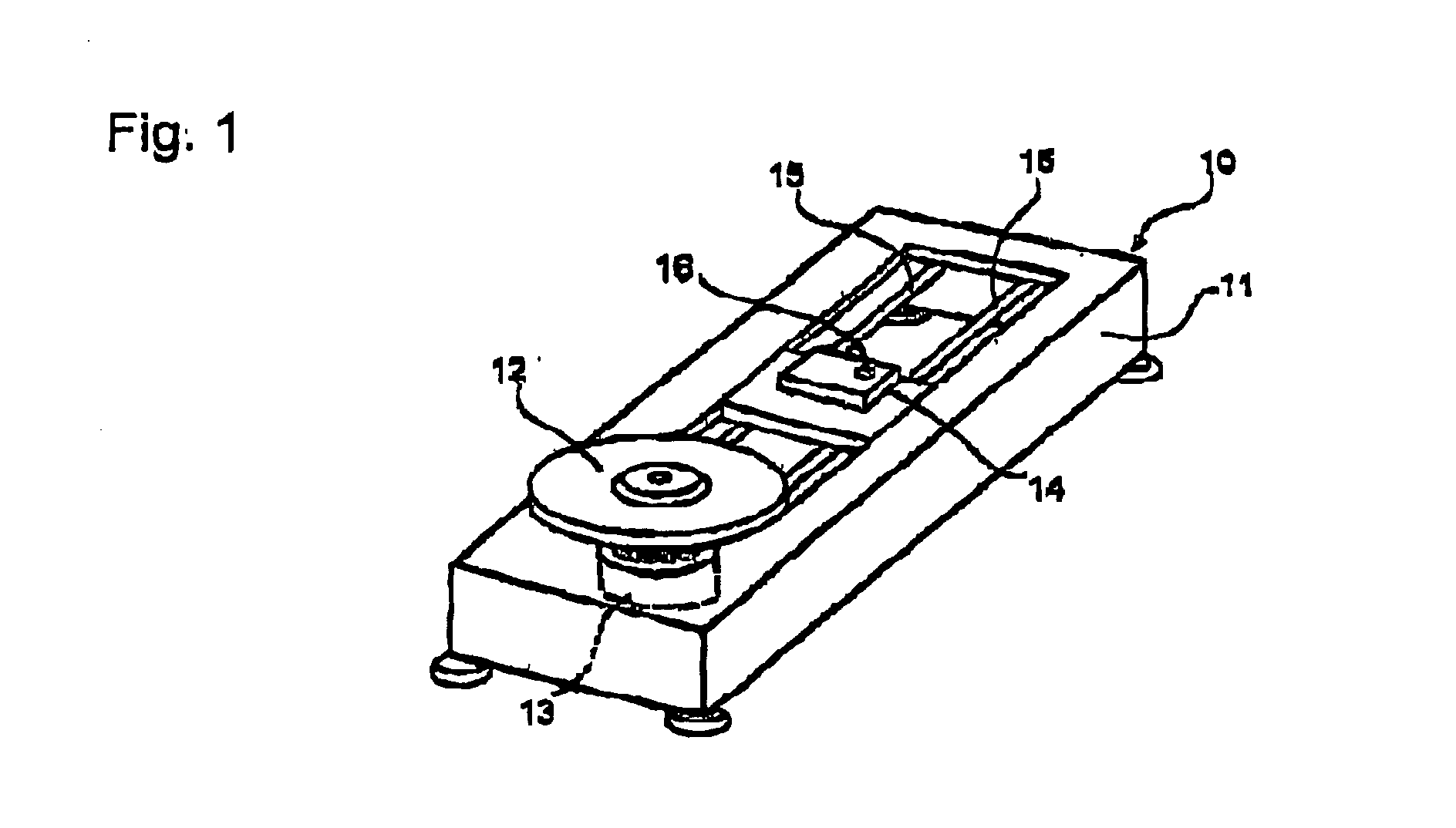

Rotary drive device

InactiveUS20030117935A1Avoid noiseMore balancedRotating vibration suppressionDisposition/mounting of recording headsLow speedCentrifugal force

A rotary drive device includes a plurality of balancing balls that are held to a holding magnet during low speed rotation, including when a rotary body starts. The balancing balls move outward in the radial direction away from the holding magnet by a centrifugal force applied to the plurality of balancing balls as a result of the rotation of the rotary body. Each of the balancing balls is moved into a position that negates a rotational unbalance of the rotary body to achieve a balancing effect. The number of effective revolutions, at which point the plurality of balancing balls that is attracted to the holding magnet begins to move outward in the radial direction away from the holding magnet as the number of revolutions of the rotary body increases, is smaller than the number of resonant revolutions of the rotary body.

Owner:SANKYO SEIKI MFG CO LTD

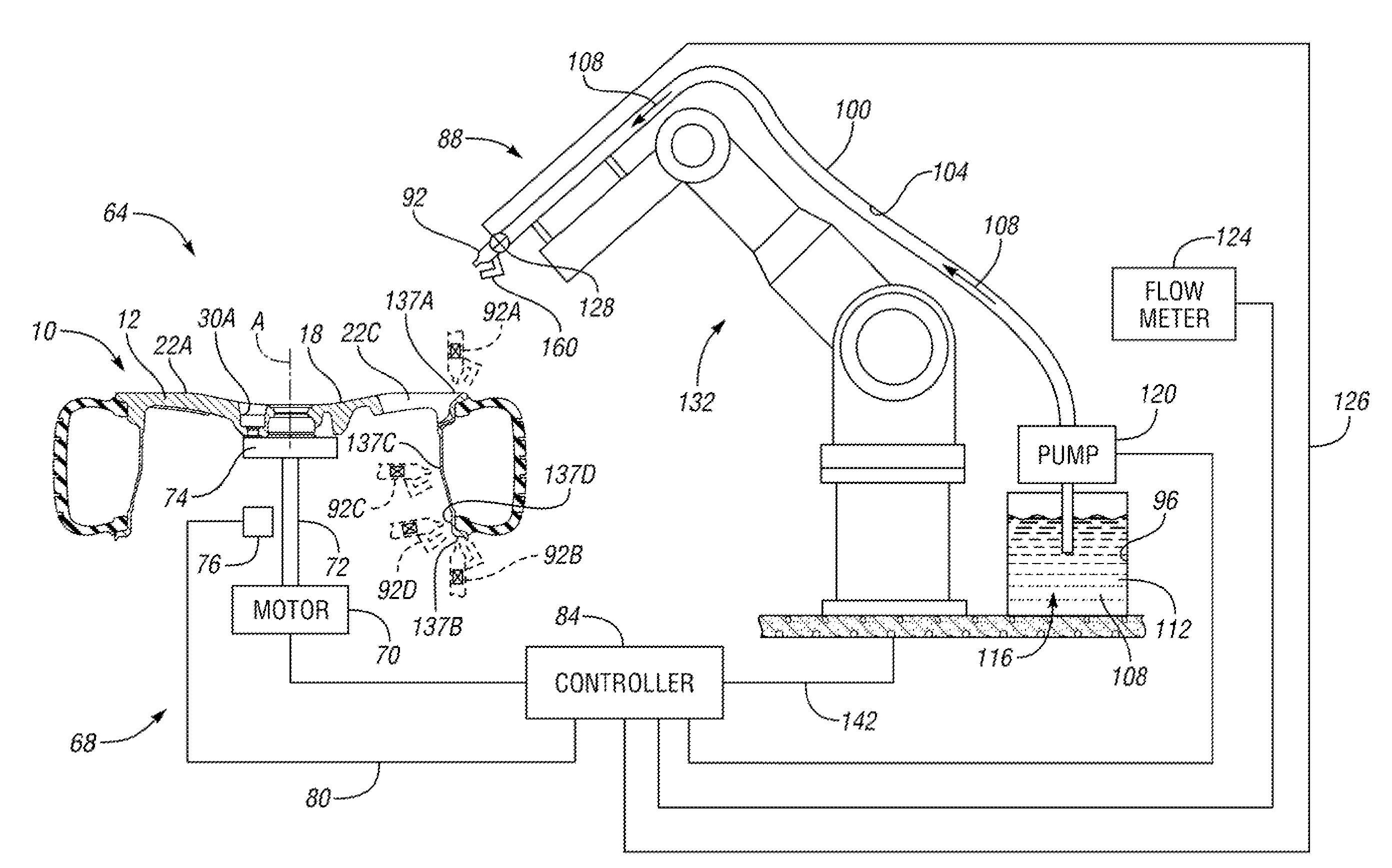

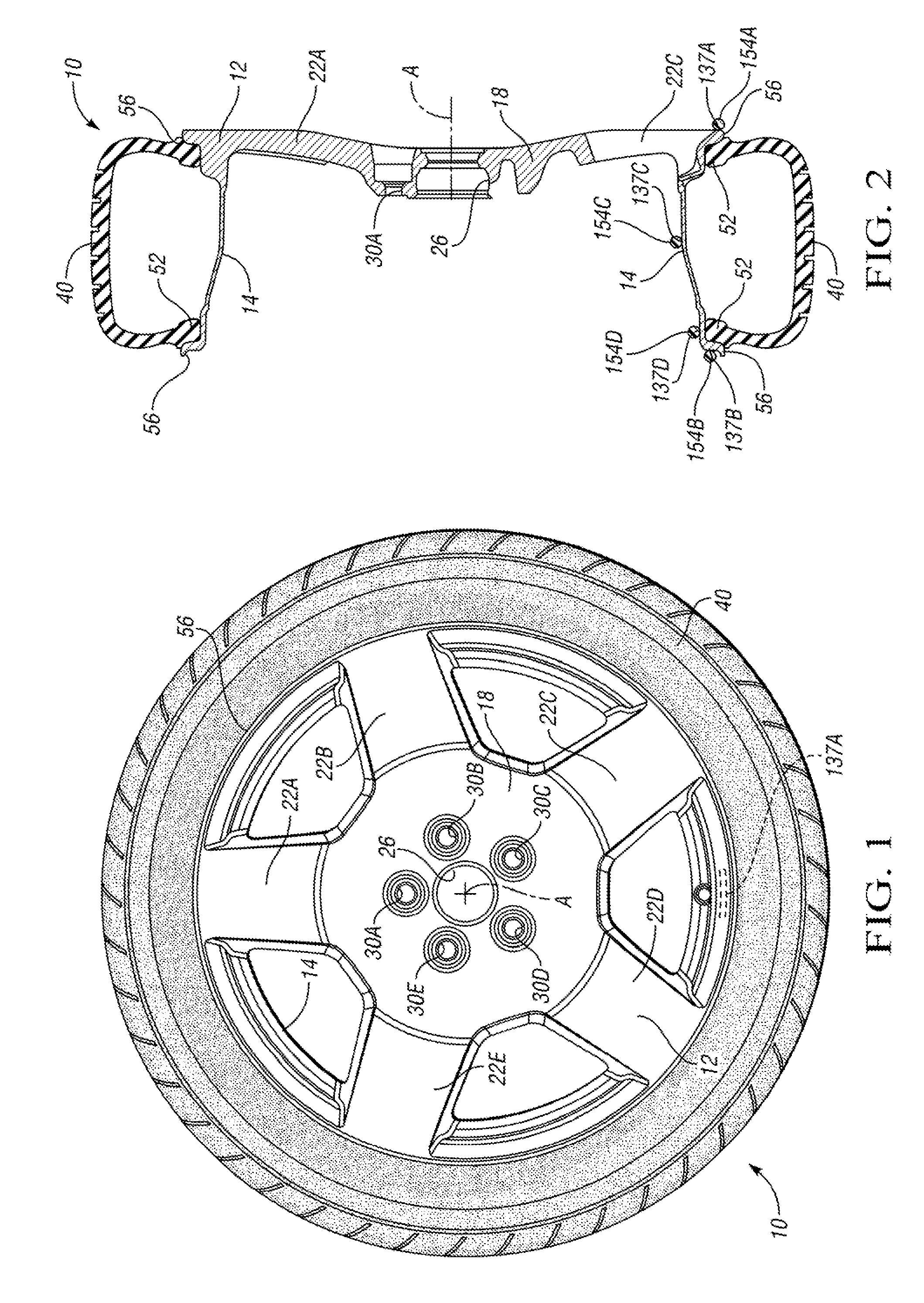

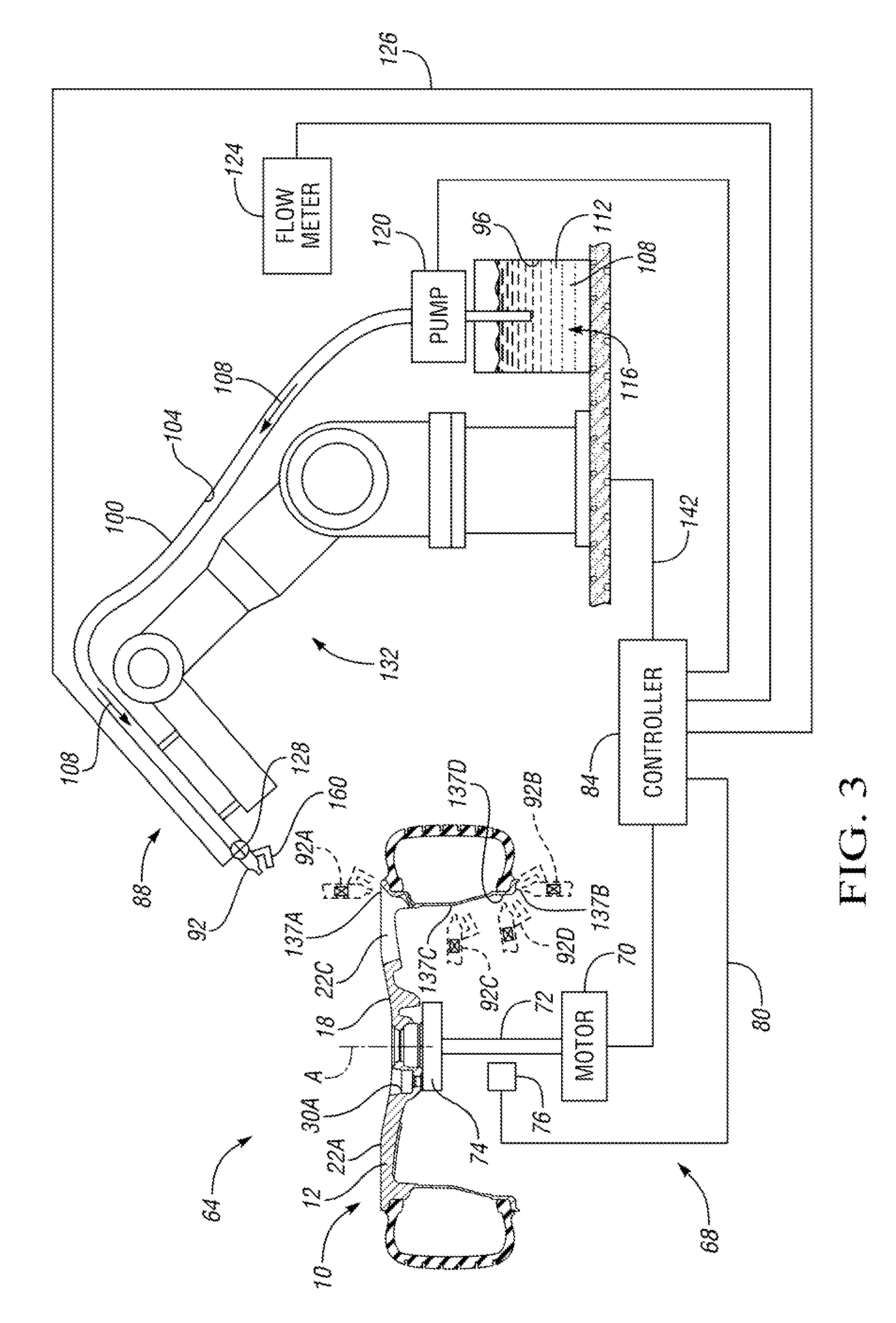

Wheel Balancing Method and Apparatus

InactiveUS20080196496A1Reduce in quantityAccurate balanceStatic/dynamic balance measurementAutomationRotating unbalance

A method for balancing a wheel and tire assembly includes providing a wheel and tire assembly characterized by a rotational imbalance, and applying a fluid to the wheel and tire assembly thereby to correct the rotational imbalance. The use of a liquid to correct a rotational imbalance facilitates the automation of a balancing operation. Accordingly, another method is provided that includes determining a quantity of mass to be applied to a wheel and tire assembly to correct a rotational imbalance, and commanding an apparatus to dispense an amount of a fluid having the quantity of mass to be dispensed from a nozzle. A corresponding apparatus is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

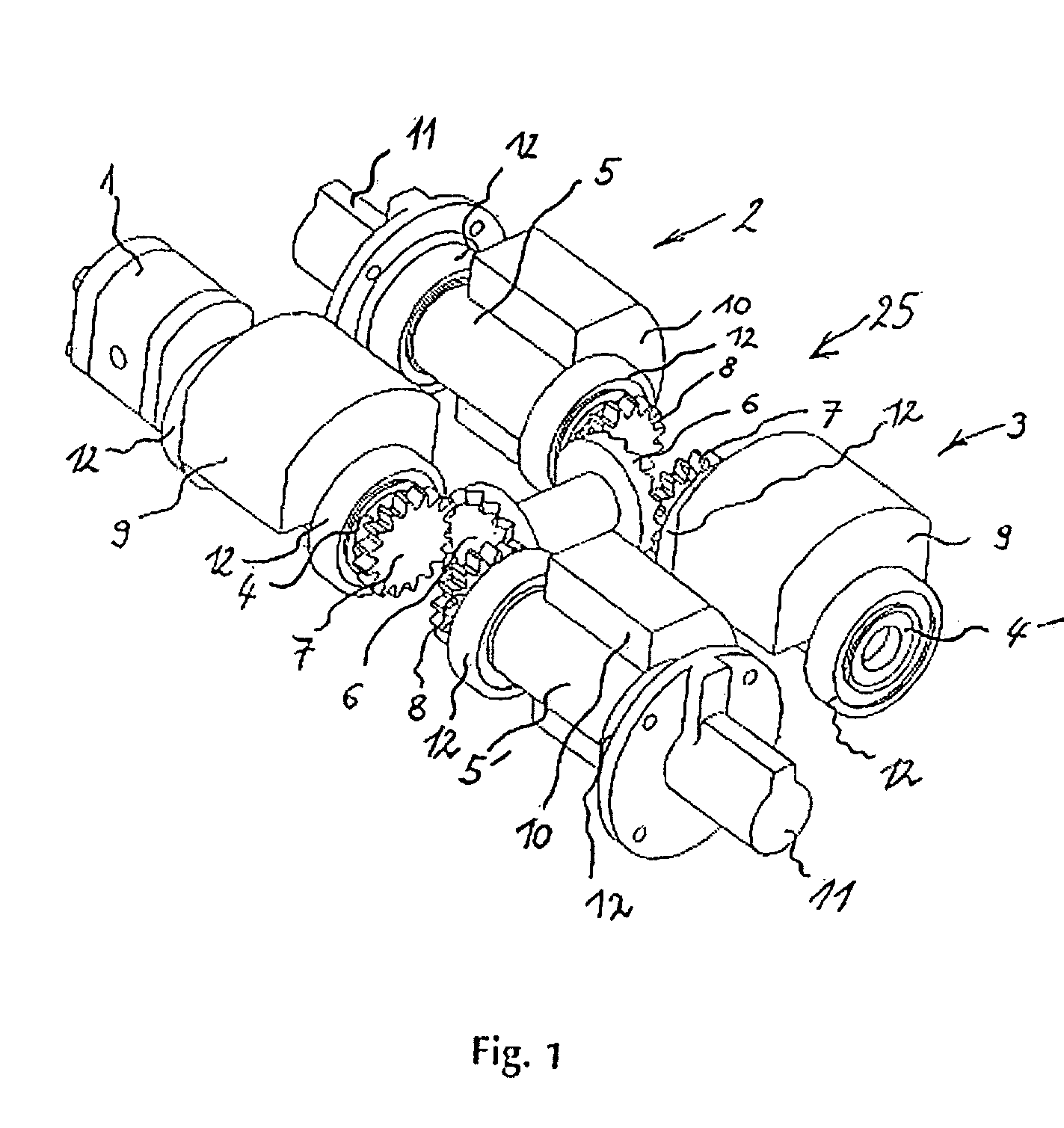

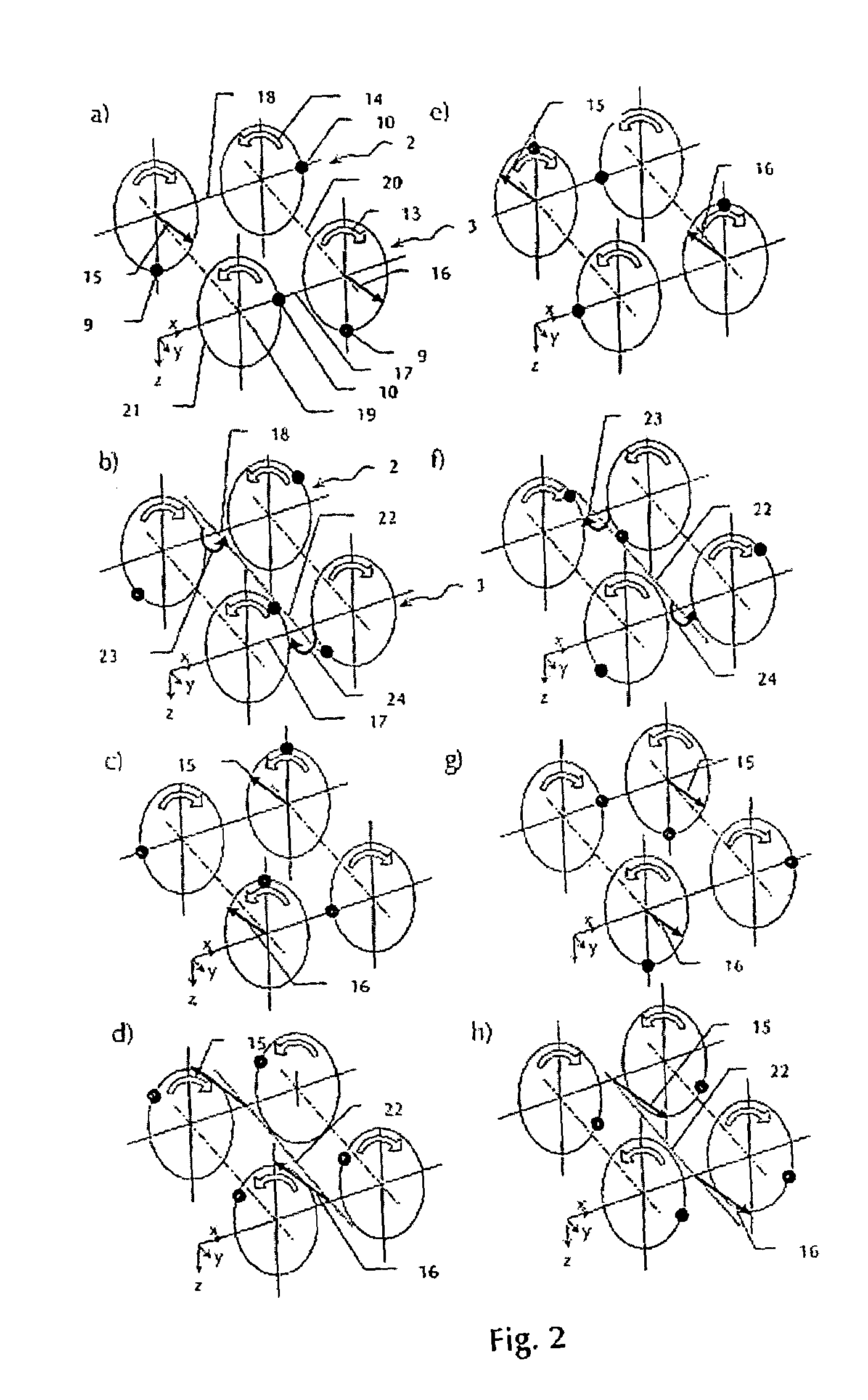

Oscillation generating device

The invention relates to an oscillation generating device for use in a soil compacter with a tipping moment compensation device. A second unbalance shaft pair with oppositely rotating unbalance shafts is arranged adjacent to a first unbalance shaft pair as a tipping moment compensation device. Diagonally opposite unbalance shafts rotate in the same direction. In this way, centrifugal forces and torques on the two unbalance shaft pairs reciprocally cancel each other out so that no tipping moment occurs parallel to the axes of rotation of the unbalances.

Owner:BOMAG +1

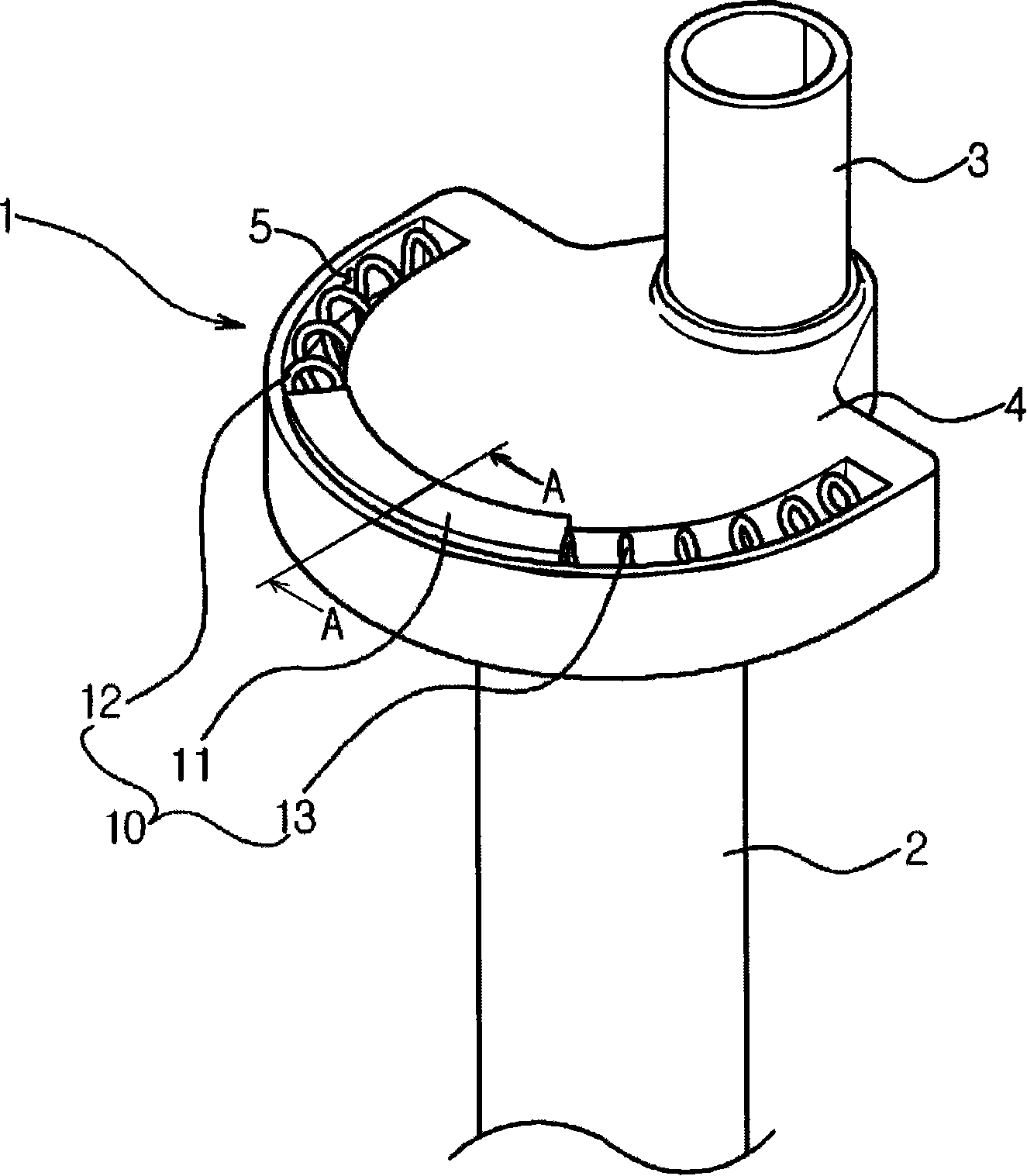

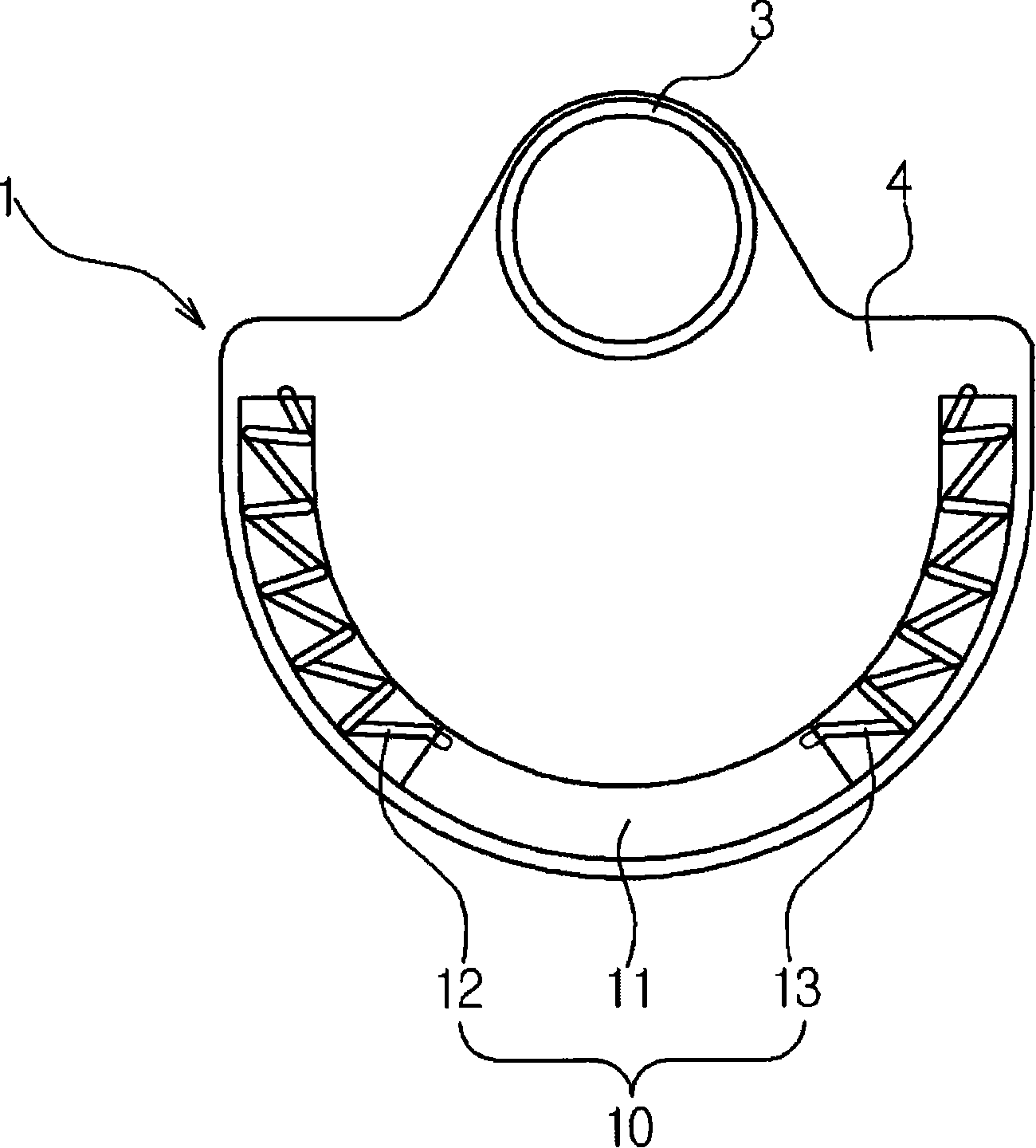

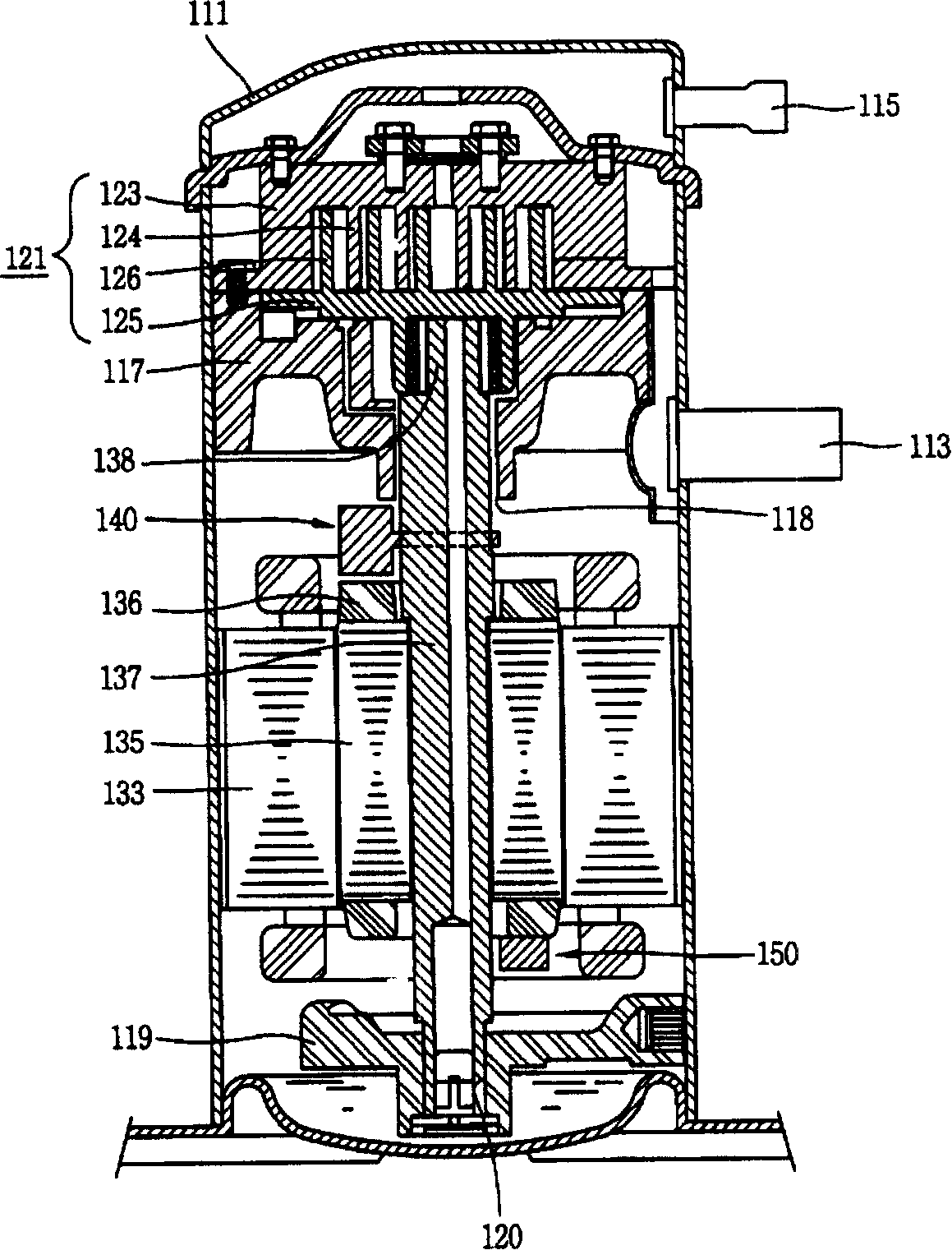

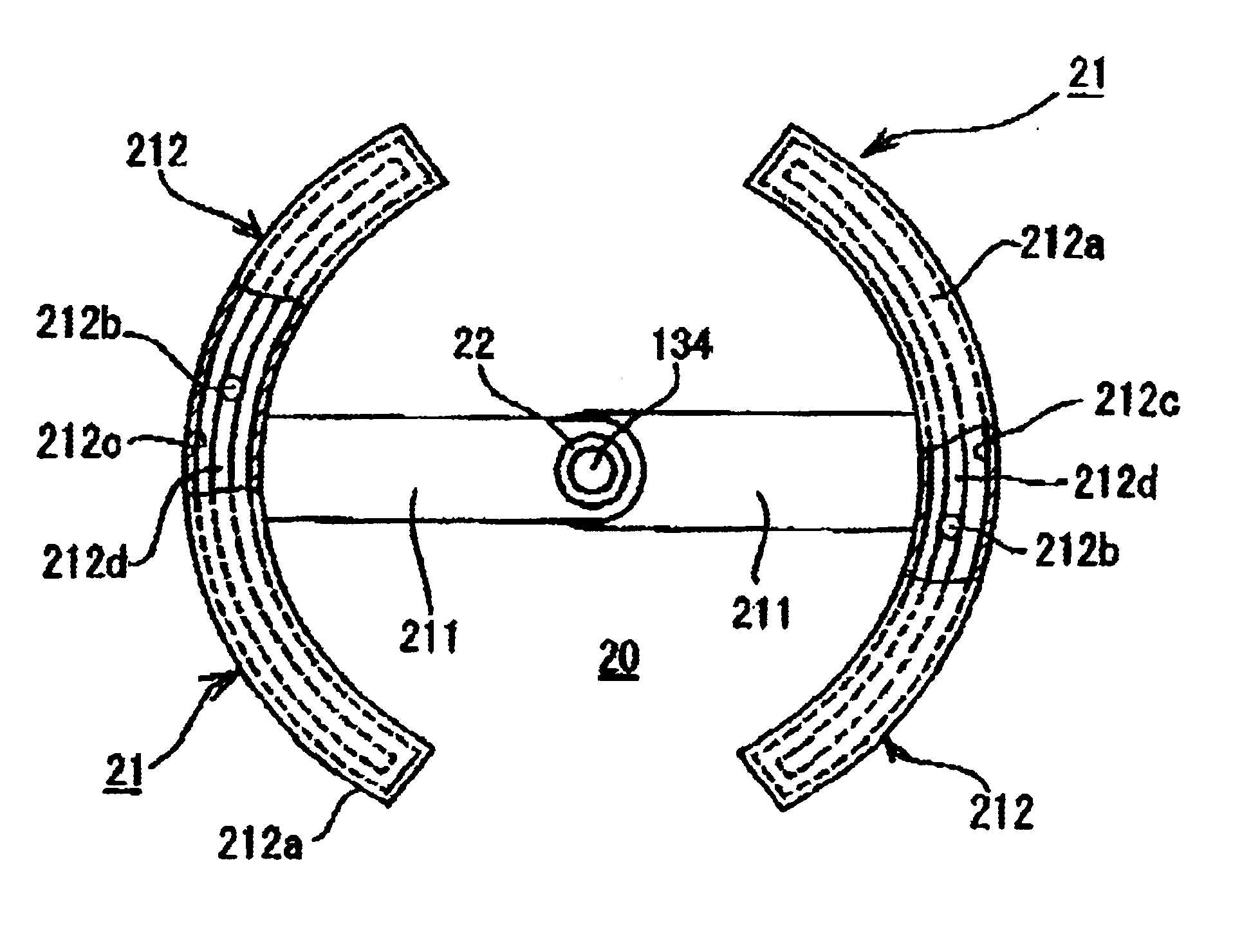

Rotation balance device of enclosed scroll compressor

InactiveCN101205912AReduce support loadSmooth rotationRotary piston pumpsRotary piston liquid enginesRotational axisEngineering

The invention discloses a rotary balance device of a hermetic scroll compressor, which belongs to an arc engagement rotary piston pump. The invention comprises a drive motor which is arranged inside a shell to generate rotary force; a compression mechanism part which is arranged on a rotational axis of the drive motor and combined with an eccentric part to compress refrigerant; at least more than one balance device which are arranged to counterbalance the rotary imbalance generated on the eccentric part while the rotational axis conducts the rotary motion, wherein, the balance device comprises a main body part which has appointed weight and a combining part which leads the main body part to be combined on the rotational axis, moreover, the balance device is combined with the rotational axis. Therefore, stators of the invention can stably rotate, and the performance loss of the motor can be avoided, thereby providing the compressor with higher reliability.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Automatic balancing apparatus

An automatic balancing apparatus may be mounted in a rotator body such as a spindle motor having a rotary shaft defining an axis of rotation. The automatic balancing apparatus has a plurality of balancing members rotatable about the axis of rotation in a non-contact manner. Each of the balancing members has a balance action section spaced a distance in a radial direction from the axis of rotation and a connection section that rotatably couples the balance action section to the axis of rotation. The balance action section has a mass that effects a balance correction action to cancel a rotational unbalance of the rotator body when the rotator body rotates at a rotational speed that exceeds a resonant rotational speed CR thereof. The connection section has a mass that substantially does not affect the balance correction action compared to the balance action section.

Owner:SANKYO SEIKI MFG CO LTD

Cooling System for a Mobile Terminal for Wireless Communication

InactiveUS20080002361A1Easy to implementLow heat generationWeather/light/corrosion resistanceFrequency-division multiplex detailsTelecommunicationsComputer terminal

The present invention relates to a cooling system for a mobile terminal for wireless communication comprising a rotating fan (1) for reducing the heat generated by the mobile terminal and at least one weight (3) for causing an unbalance of the rotation of the fan (1) in order to cause vibration of the fan, whereby said weight is activated when the rotational speed of the fan (1) exceeds a predefined level.

Owner:SONY ERICSSON MOBILE COMM AB

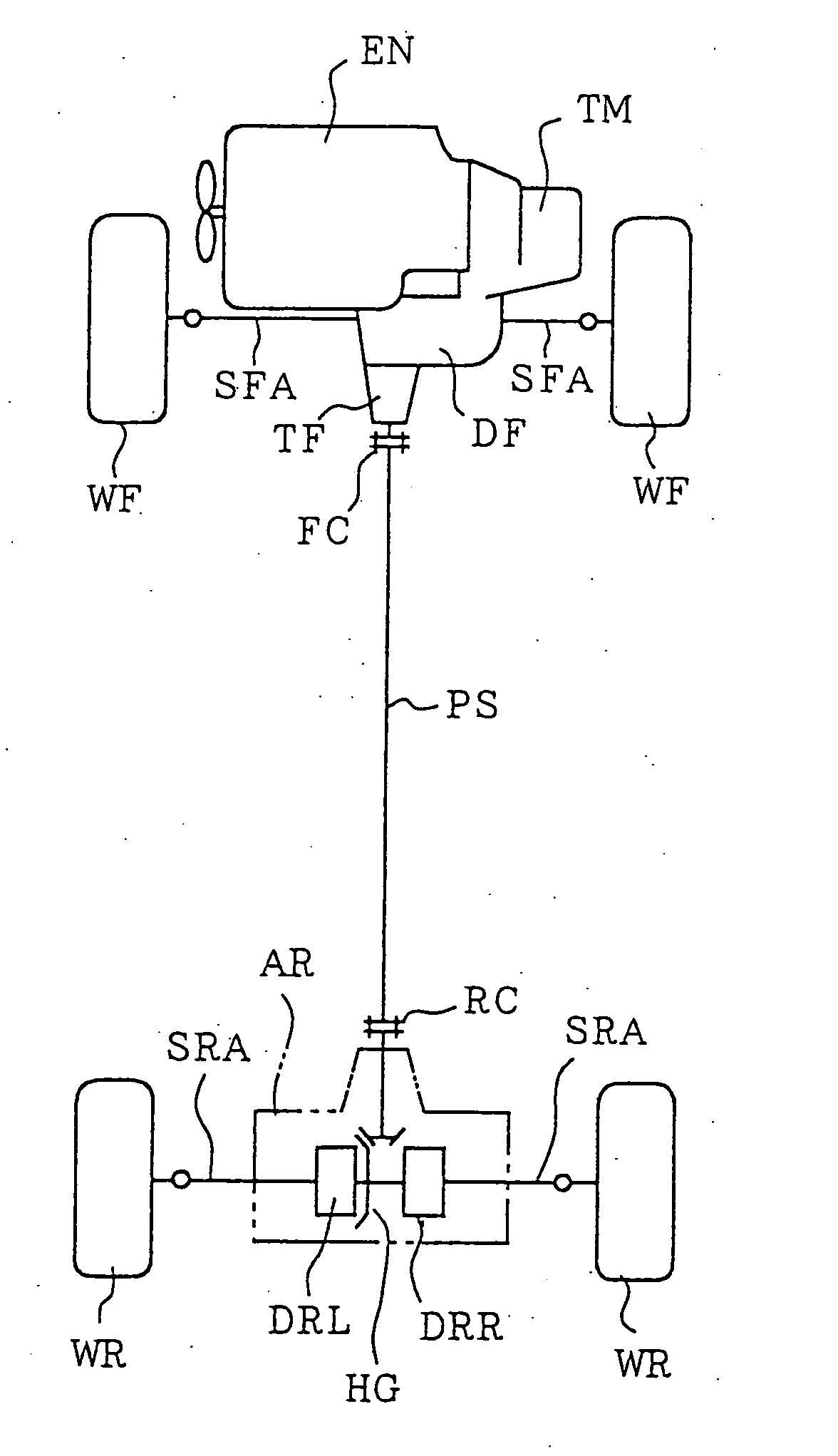

Coupling structure and coupling method for power transmission

ActiveUS20050126285A1Sure easyIncrease awarenessYielding couplingSlip couplingElectric power transmissionDrive shaft

According to the present invention, a first mark for indicating the direction of the rotational unbalance of a propeller shaft is provided on the propeller shaft while a second mark for indicating the direction of the rotational unbalance of a companion flange is provided on the companion flange, which is to be connected to the propeller shaft at a rotation-transmitting device. One of the directions of the rotational unbalances indicated by the first mark and the second mark is set as a direction along which the rotating mass becomes larger while the other is set as a direction along which the rotating mass becomes smaller, and one of the first mark and the second mark is provided over an angular region with a predetermined angle around an axis.

Owner:HONDA MOTOR CO LTD

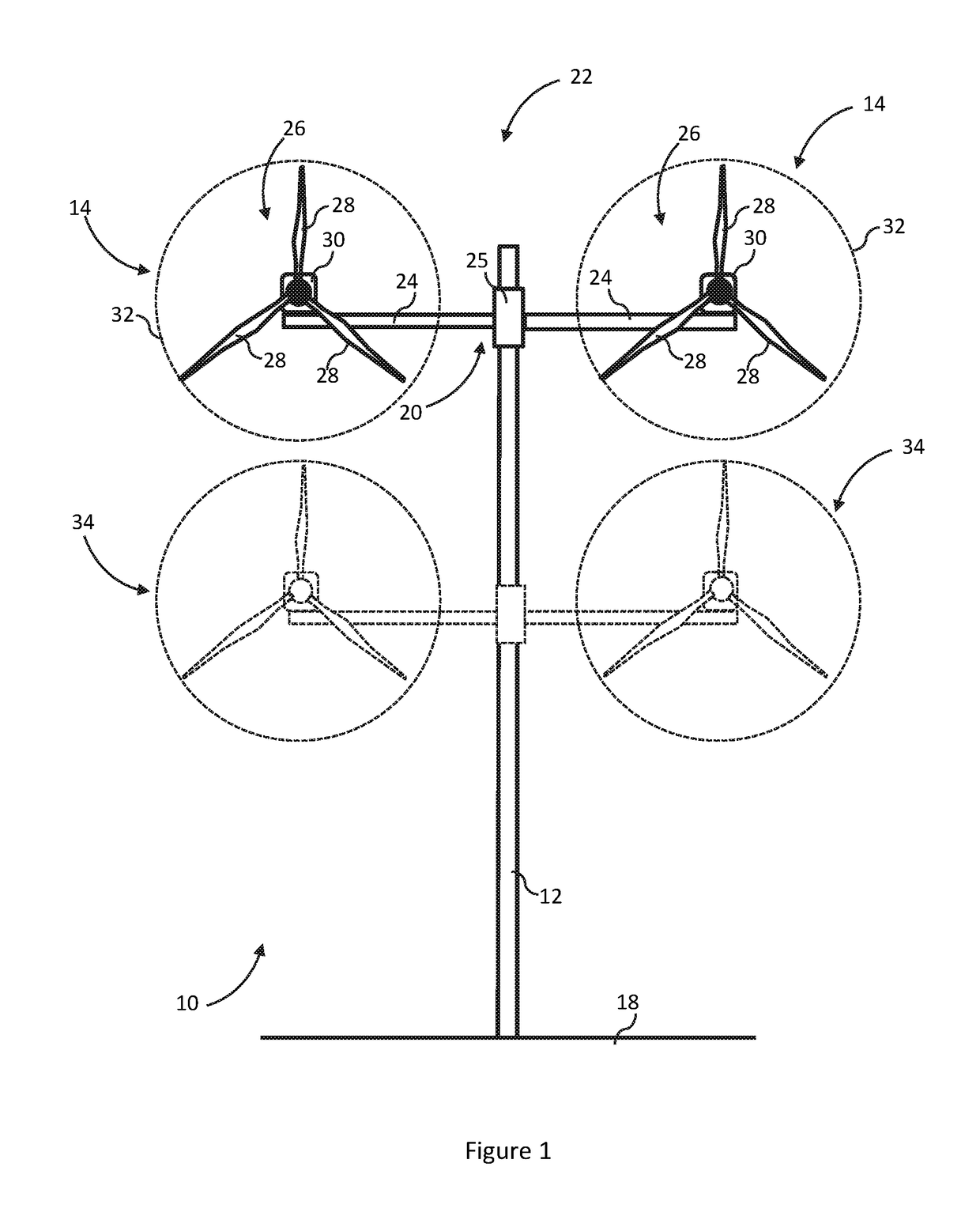

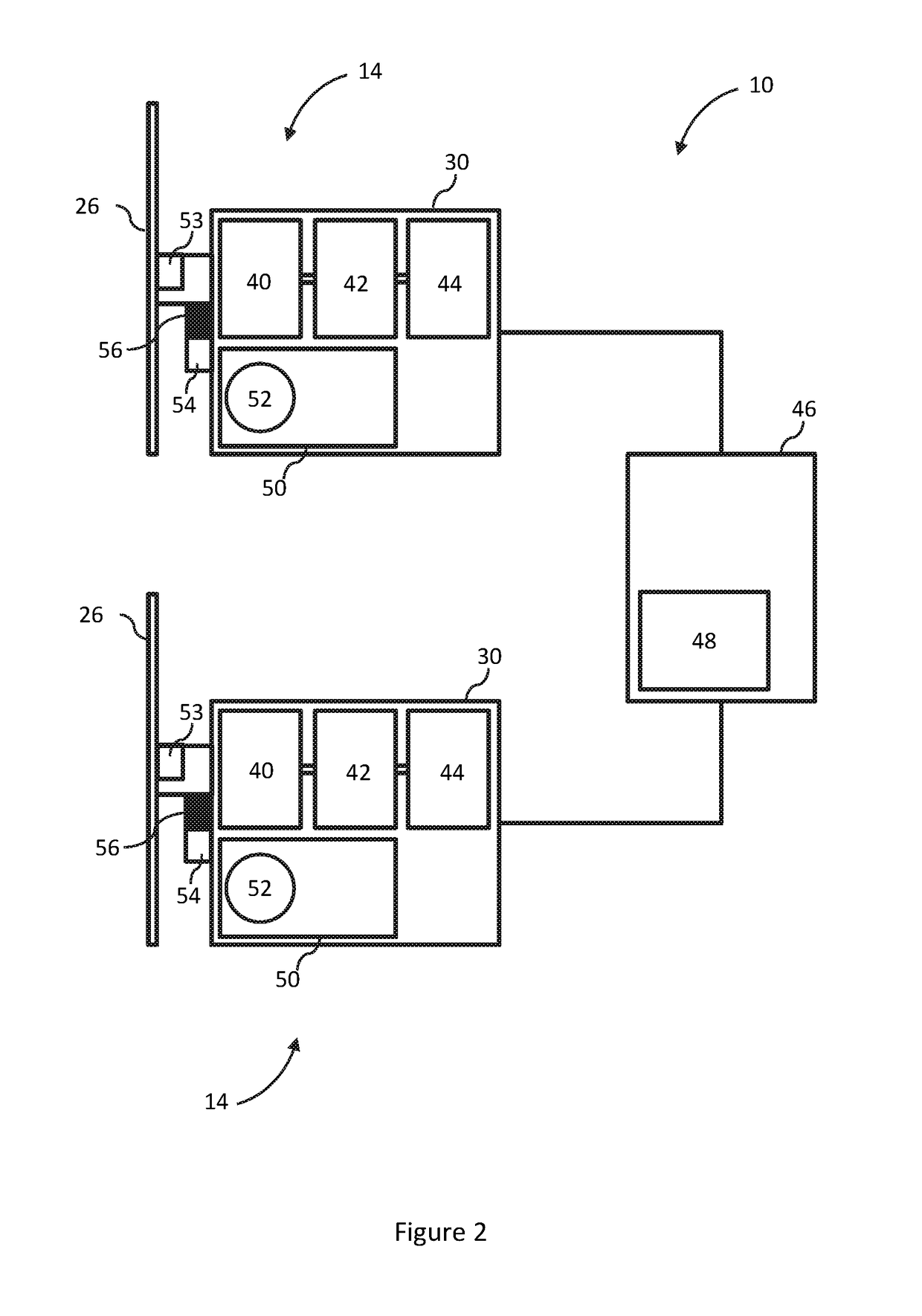

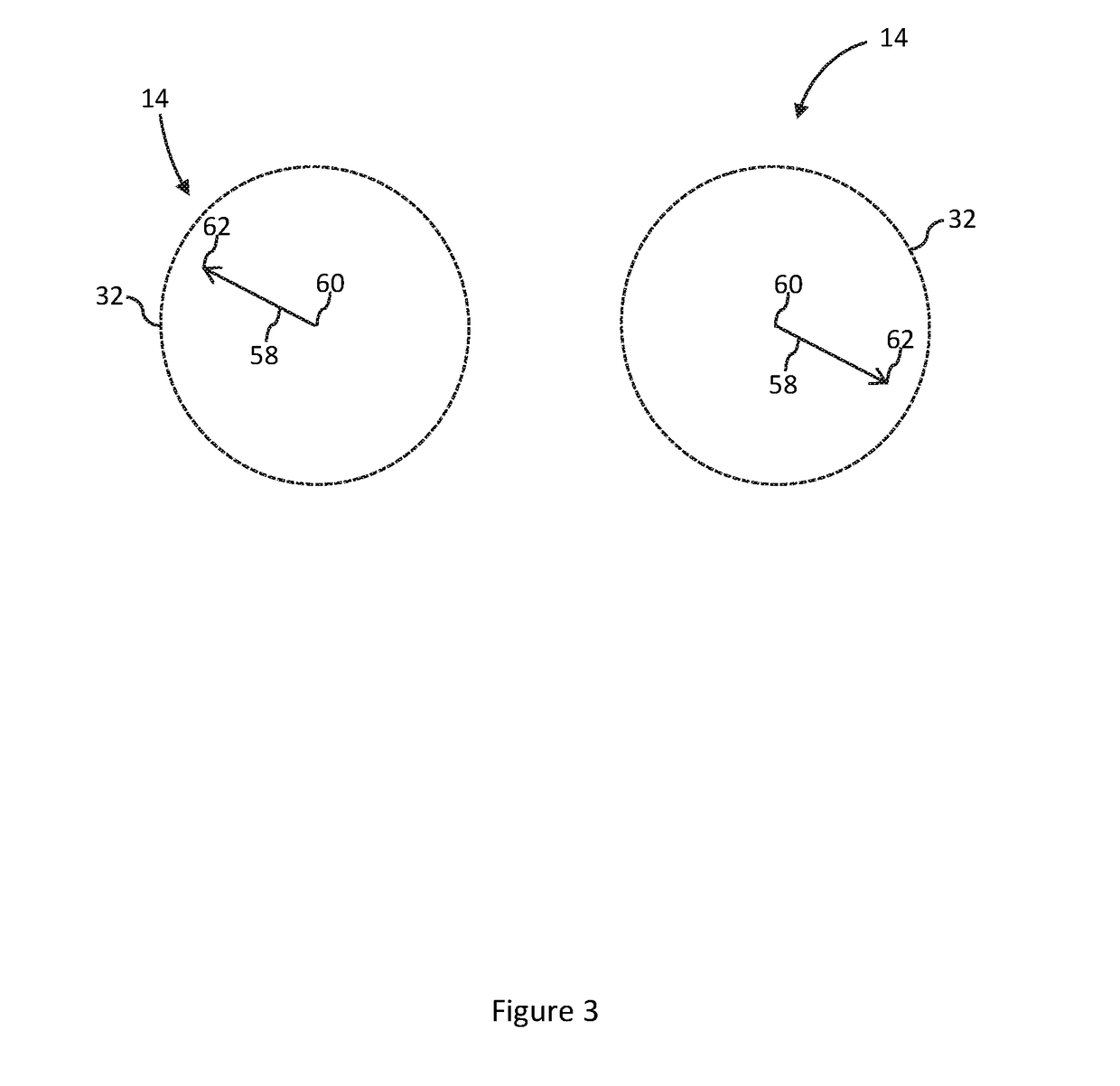

Multi-rotor turbine arranged for coordinated rotational speeds

ActiveUS20180347544A1Reduce oscillationEasy to operateProgramme controlRotational speed controlTowerTurbine

A wind turbine system is described comprising a plurality of wind turbine modules, each including a rotor, mounted to a support structure including a tower. In use, each rotor has an associated rotating unbalance that defines an unbalance vector. The wind turbine system includes control means configured to coordinate the rotational speeds of the plurality of rotors to attenuate oscillations of the support structure caused by the rotating unbalance of the rotors. Also described is a method of controlling such a wind turbine system. The method comprises coordinating the rotational speeds of the plurality of rotors to attenuate oscillations of the support structure caused by the rotating unbalance of the rotors.

Owner:VESTAS WIND SYST AS

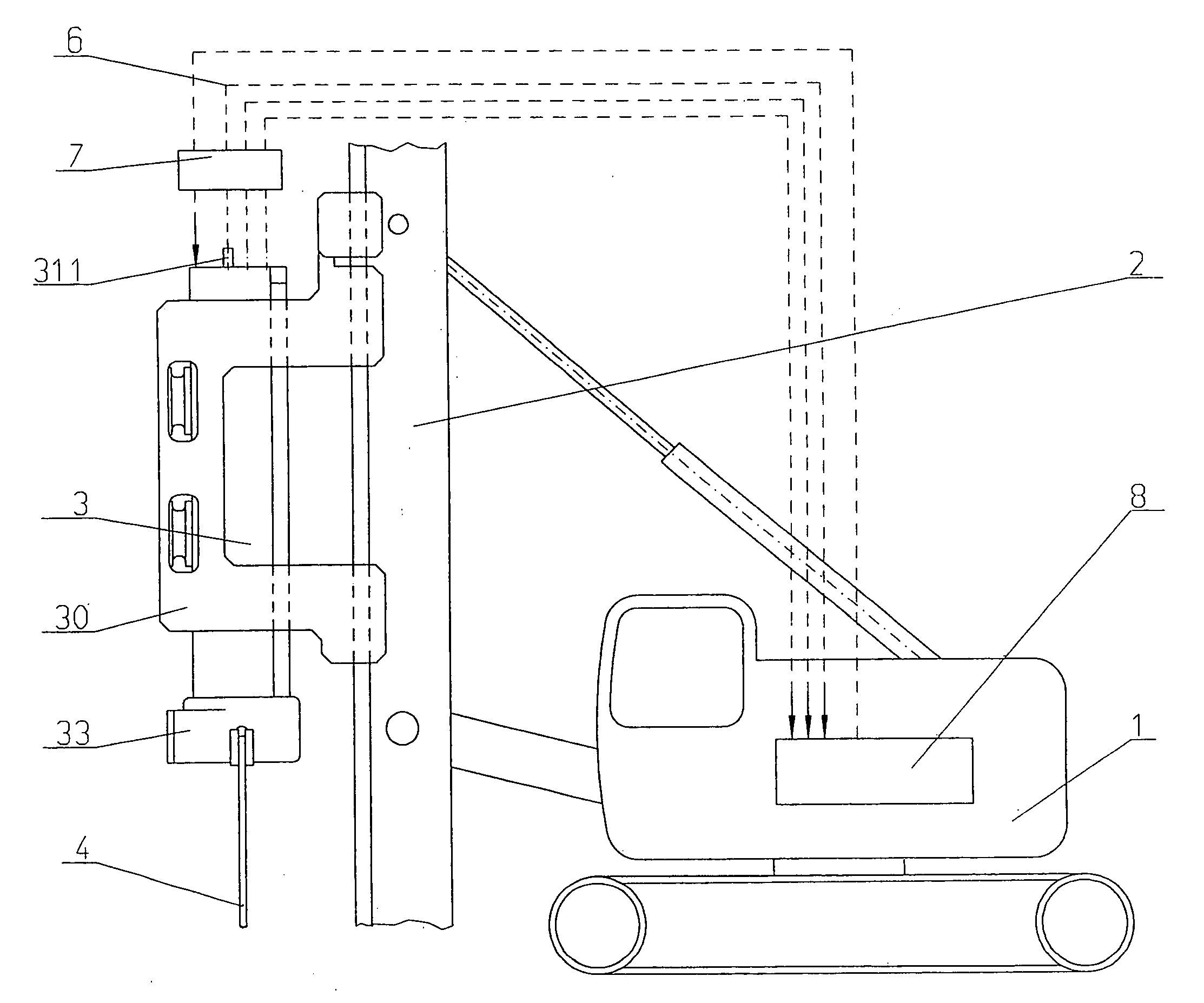

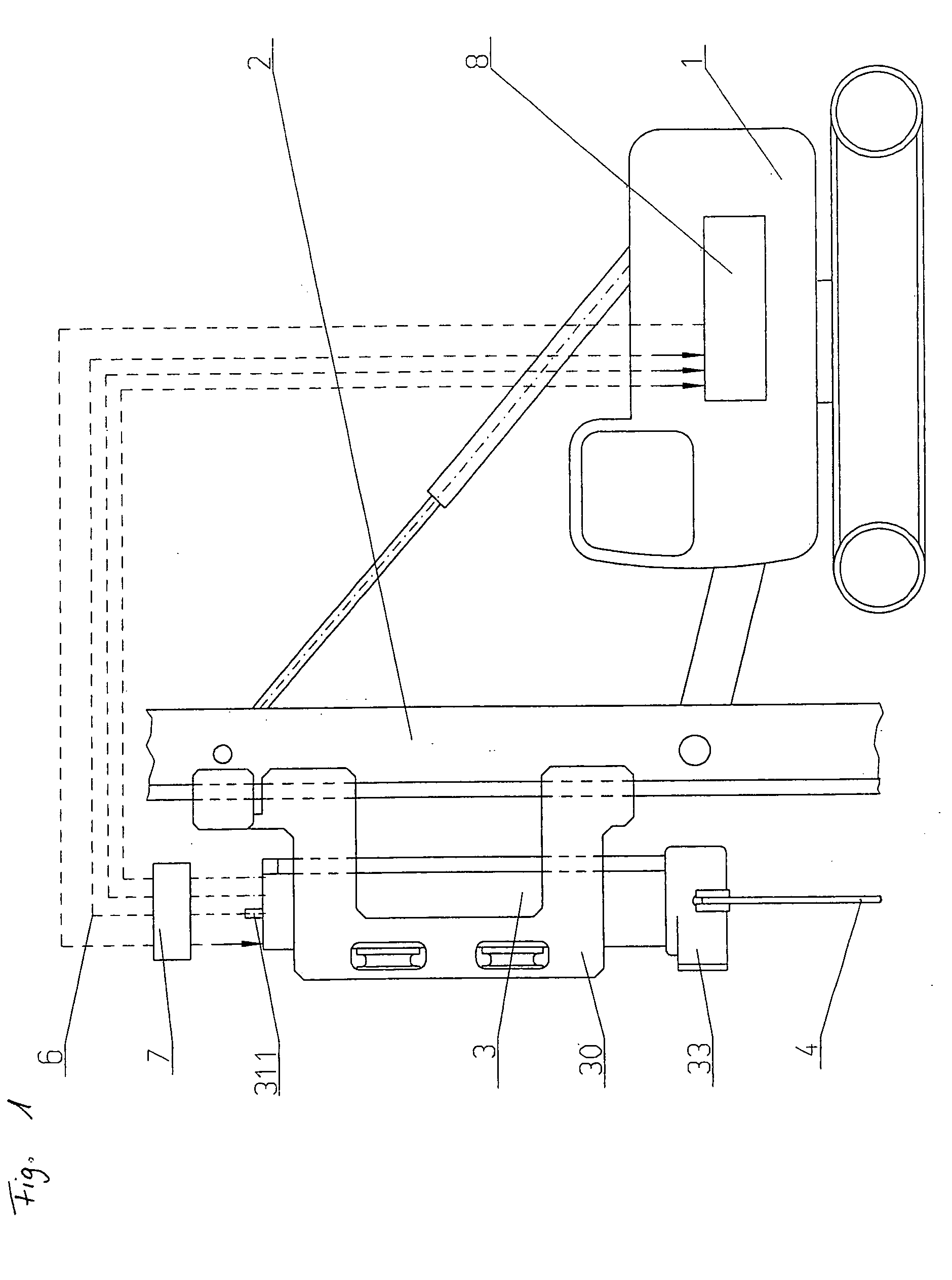

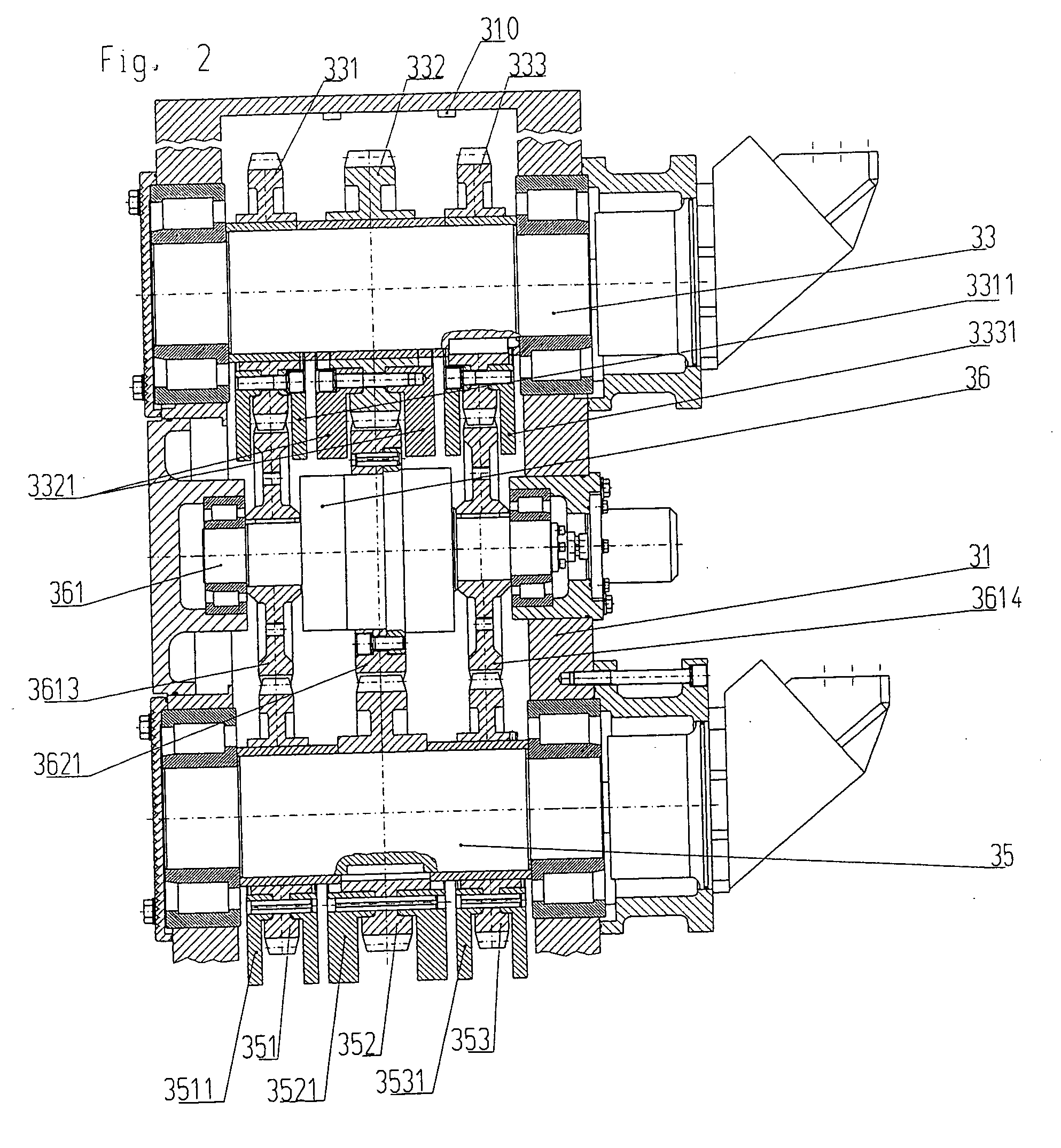

Vibration generator for a vibration pile driver

InactiveUS20090146514A1Possible to detectRelieve pressureMechanical vibrations separationMechanical energy handlingClassical mechanicsAngular acceleration

A vibration generator has rotatable imbalance masses disposed on at least two shafts, in which means for adjusting the rotational position of the imbalance masses relative to one another are disposed. There is at least one sensor for determining the angular acceleration of the rotating imbalance masses. The sensors may also determine acceleration of the vibration generator. There is a module for determining the angular acceleration of the rotating imbalance masses on the basis of the measurement values determined by the sensors. A vibration pile driver for introducing elements to be pile-driven into the ground, and drawing them from the ground, as well as for compacting ground material, contains one of the aforementioned vibration generators.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com