Washing machine

A washing machine and washing tank technology, applied in the field of washing machines, can solve the problems of low washing capacity, failure to wash, and entanglement of fabrics, etc., and achieve the effect of improving ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

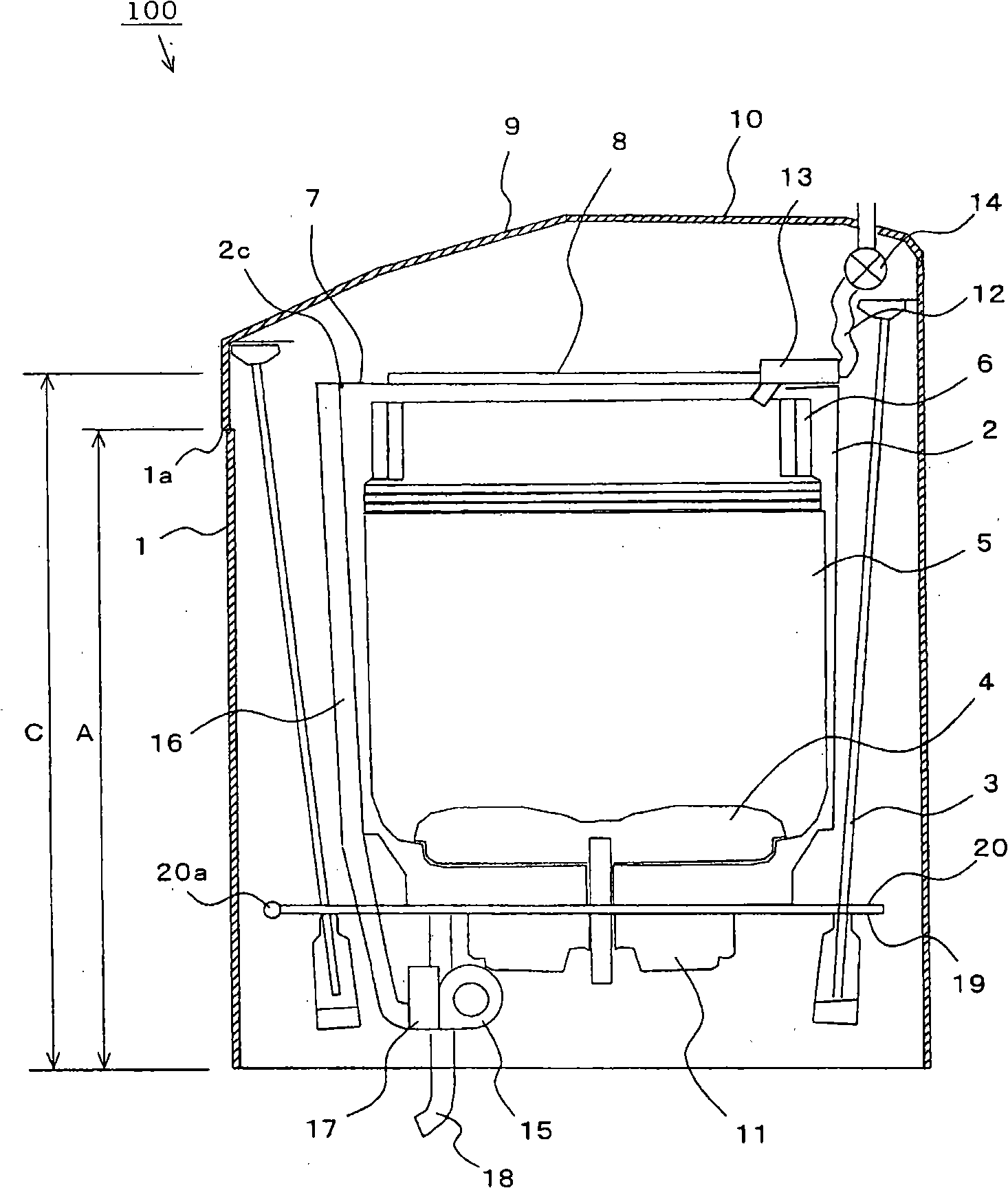

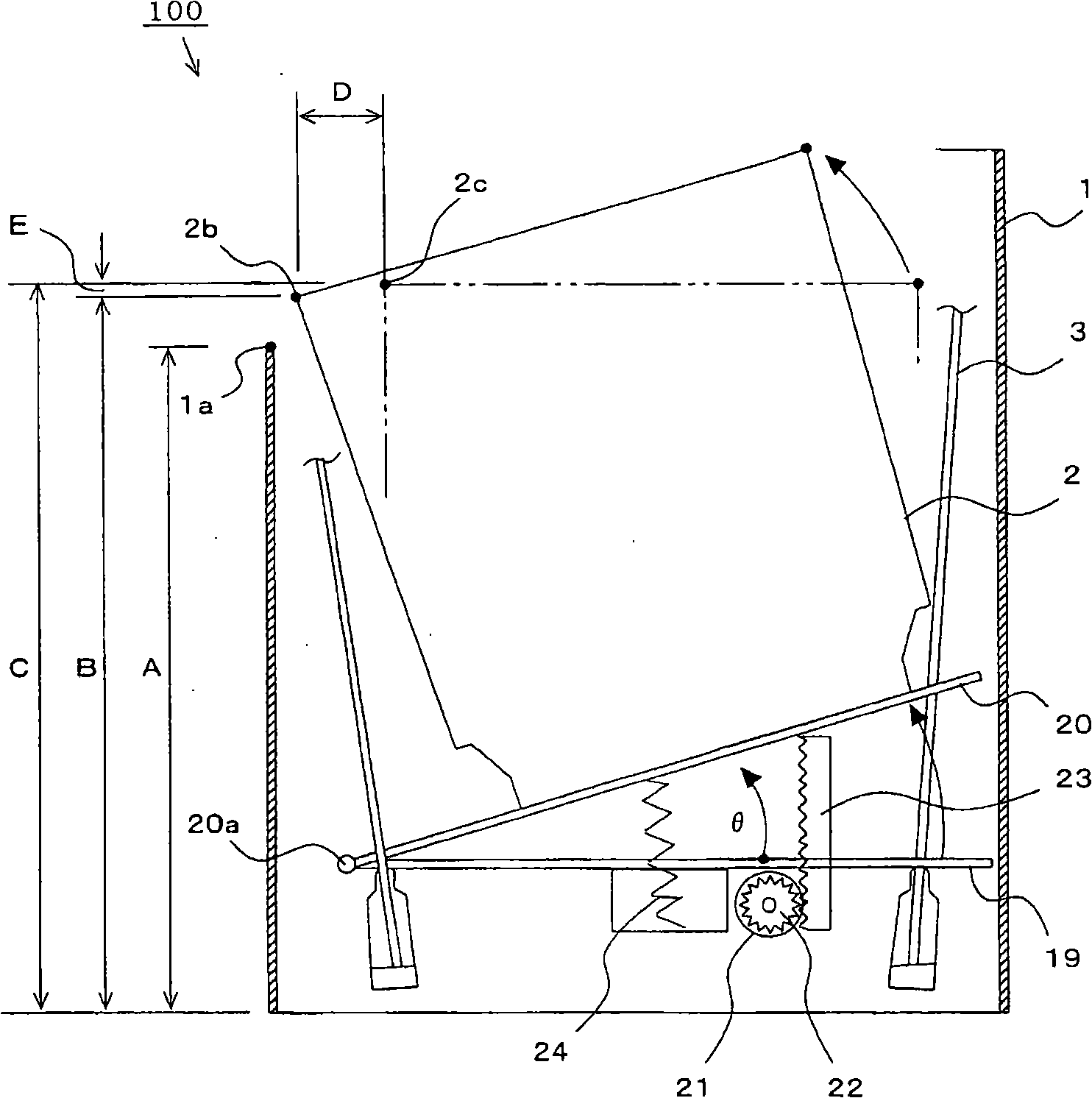

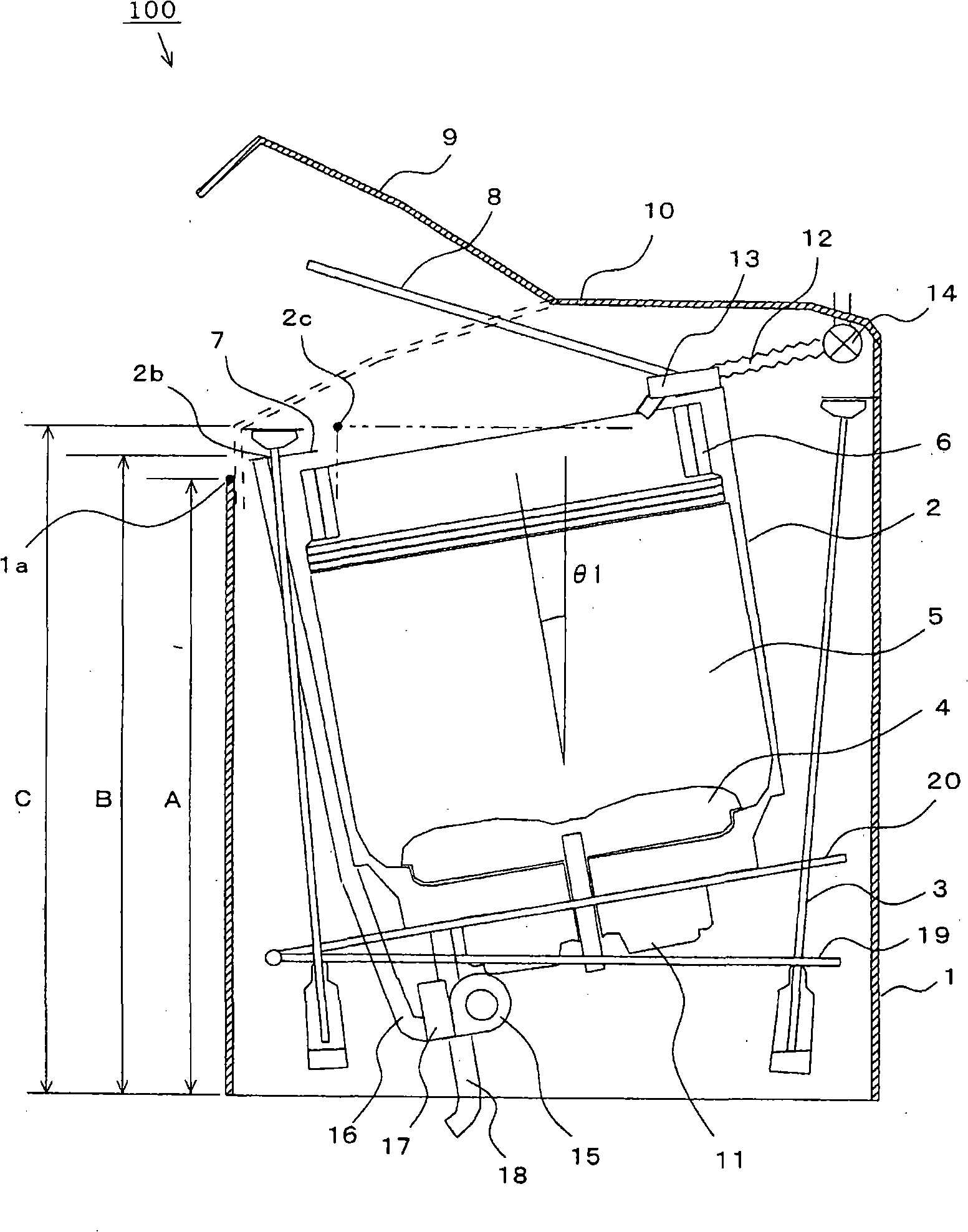

[0043] figure 1 It is a side sectional view of the washing machine concerning embodiment of this invention. In the drawings, since each structural component is schematically shown, the dimensions are not correct. In particular, the thickness of a member formed of a thin plate is exaggerated for easy viewing. In addition, the same code|symbol is attached|subjected to the same part in each figure, and description of a part is abbreviate|omitted.

[0044] (washing machine)

[0045] figure 1It is a side sectional view of the washing machine concerning embodiment of this invention. exist figure 1 In the washing machine 100, a series of washing, rinsing, dehydrating, and drying steps are performed, and washing is performed in a state in which the washing tub is tilted (a state in which the rotation axis is inclined relative to the vertical direction) as described later. In the course and the drying course, the rinsing course and the dehydration are performed in a state where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com