Rotationally Balanced Camshaft Assembly

a camshaft and rotational balance technology, applied in the direction of valve details, valve arrangements, valve drives, etc., can solve the problems of unfavorable rotational balance, camshaft assembly, etc., and achieve the effect of zero balan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

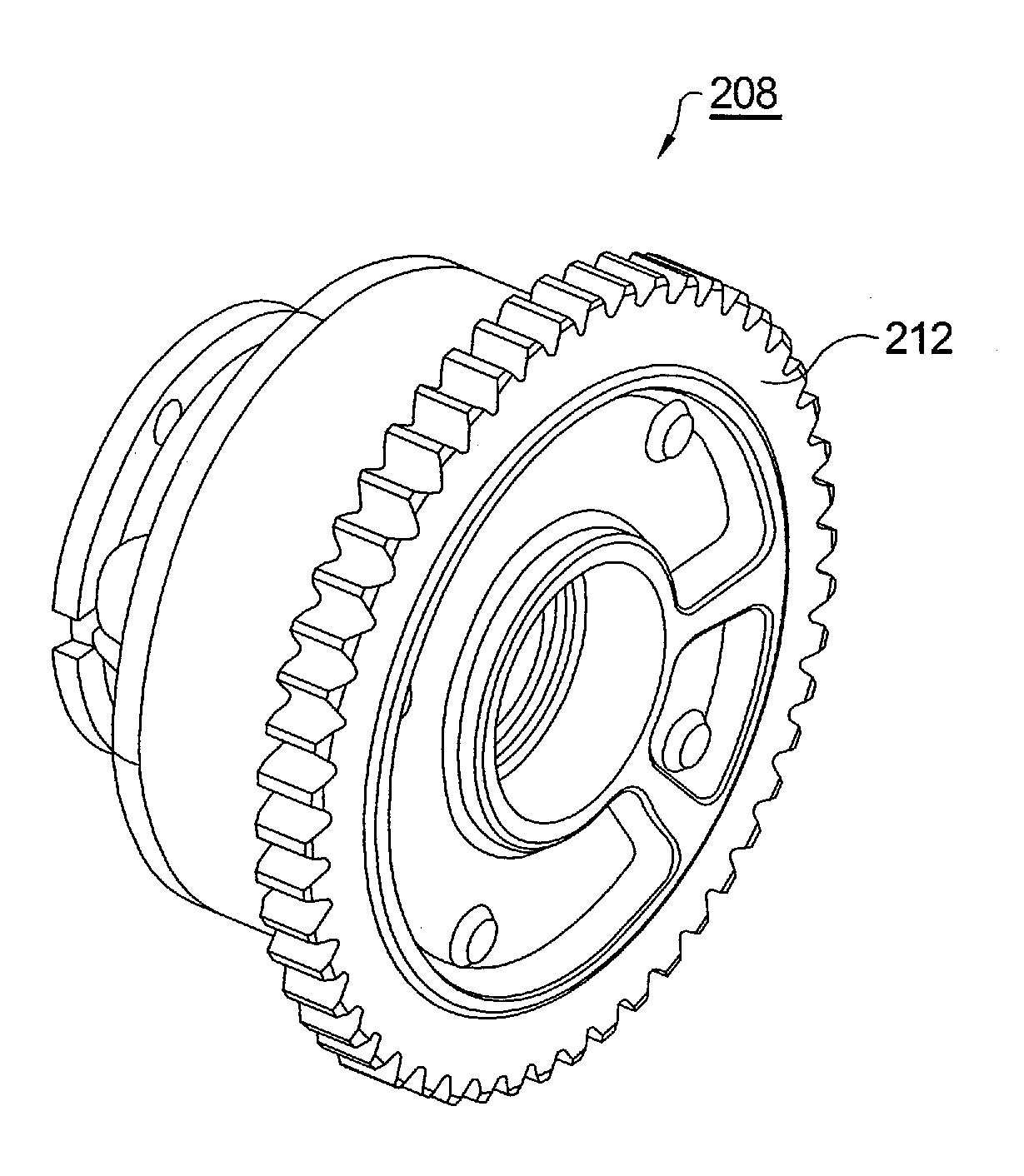

[0018]The object of the present invention is to rotationally balance (zero-balance) a camshaft assembly using components within the camshaft assembly, preferably by intentional imbalancing of an incorporated camshaft phaser assembly. Re-balance can be accomplished using any of the non-functional areas of such components and / or by adding material as counterweights. Both adding mass features and removing mass can affect imbalance and a combination of the two can be used to achieve the end result. A secondary objective of the present invention is to accomplish the abovementioned without an increase in part count, complexity, or cost. Because of its relatively large mass and diameter, the camshaft phaser assembly is a preferred site for creation of such component imbalance.

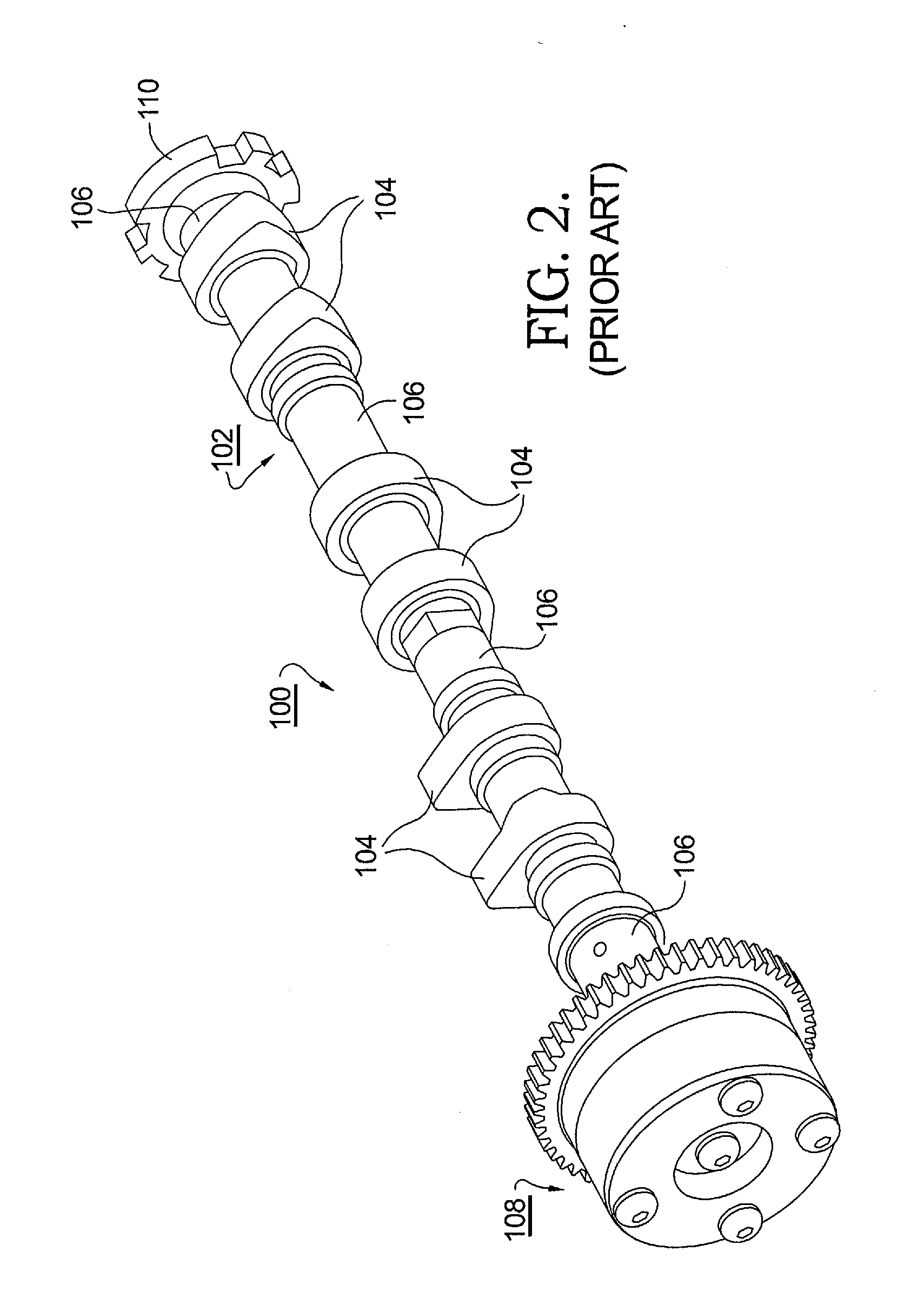

[0019]Referring to FIG. 1, a typical prior art vane-type camshaft phaser assembly 10 includes a pulley or sprocket wheel (pulley / sprocket) 12 for engaging a timing chain or belt (not shown) operated by an engine crank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com