Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Open grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

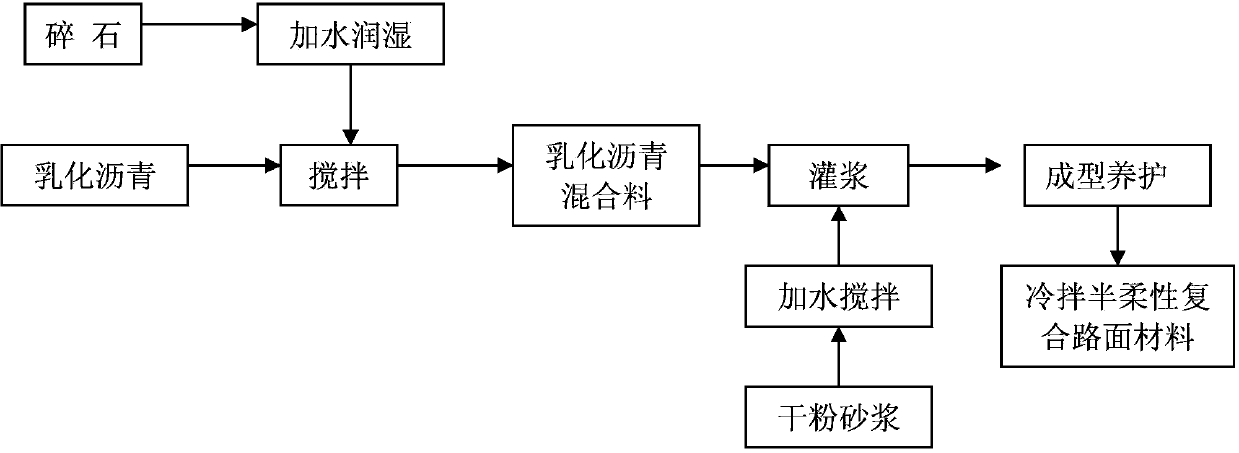

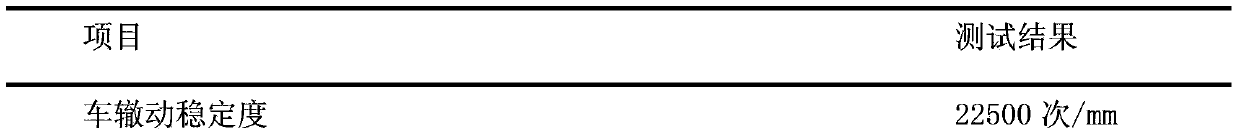

Cold-mix semi-flexible composite pavement material and preparation method thereof

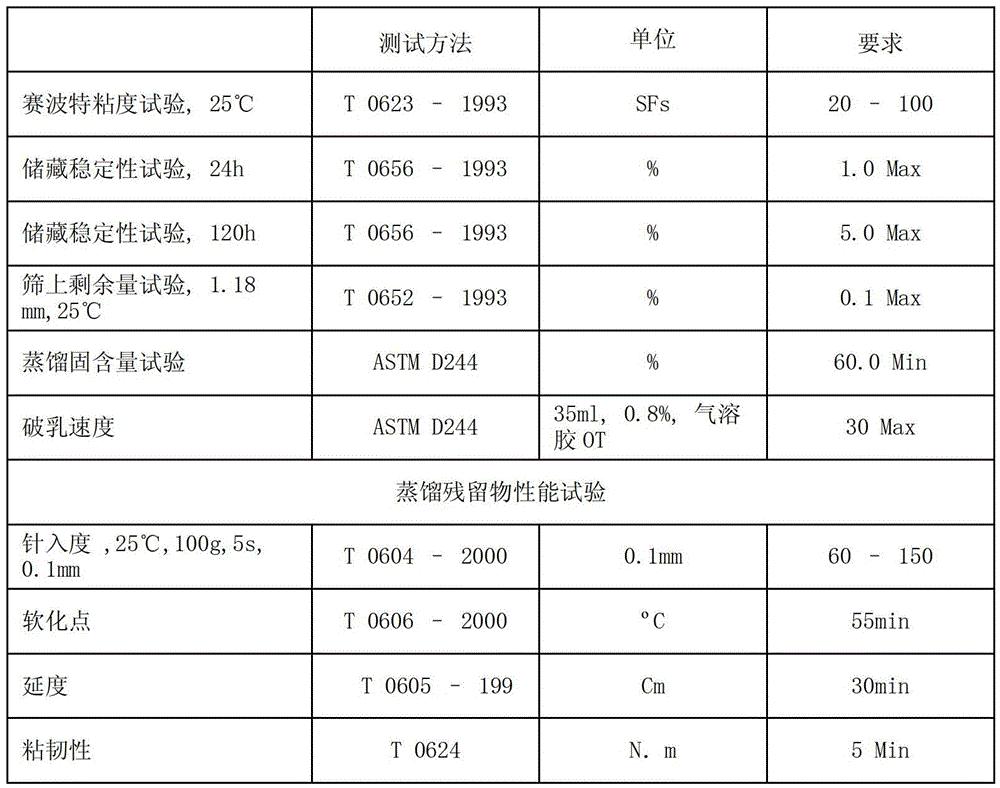

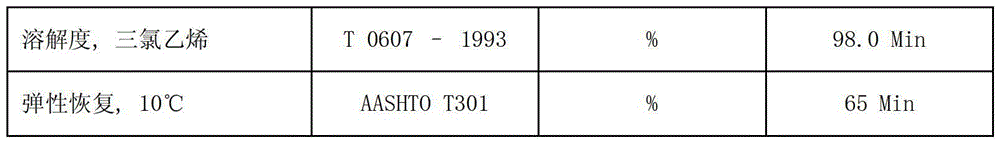

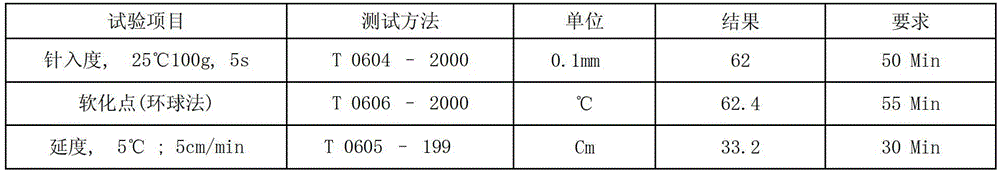

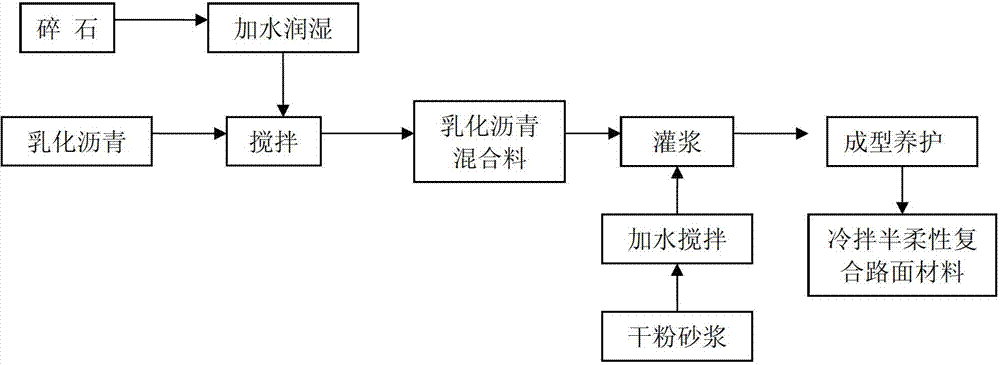

The invention discloses a semi-flexible composite pavement material and belongs to the technical field of modern pavements. The semi-flexible composite pavement material comprises the following components in percentage by weight: 65%-75% of gravels or gravel mixtures, 15%-20% of self-made dry powder cement mortar, 3%-8% of emulsified asphalt, 2%-5% of mineral powder and 5%-10% of water. The cold-mix semi-flexible composite pavement material disclosed by the invention is simple and convenient in construction process without using construction machine and equipment used for large-scale production, is mixed and formed at normal temperature without being heated; the subsequent grouting procedure also can be carried out at the normal temperature, thereby saving the energy; and the cold-mix semi-flexible composite pavement material disclosed by the invention has the advantages of energy conservation and environment friendliness. The invention also discloses a preparation method of the semi-flexible composite pavement material. According to the preparation method, the cement mortar is grouted into large-gap open-graded emulsified asphalt mixtures.

Owner:浙江固路交通科技有限公司

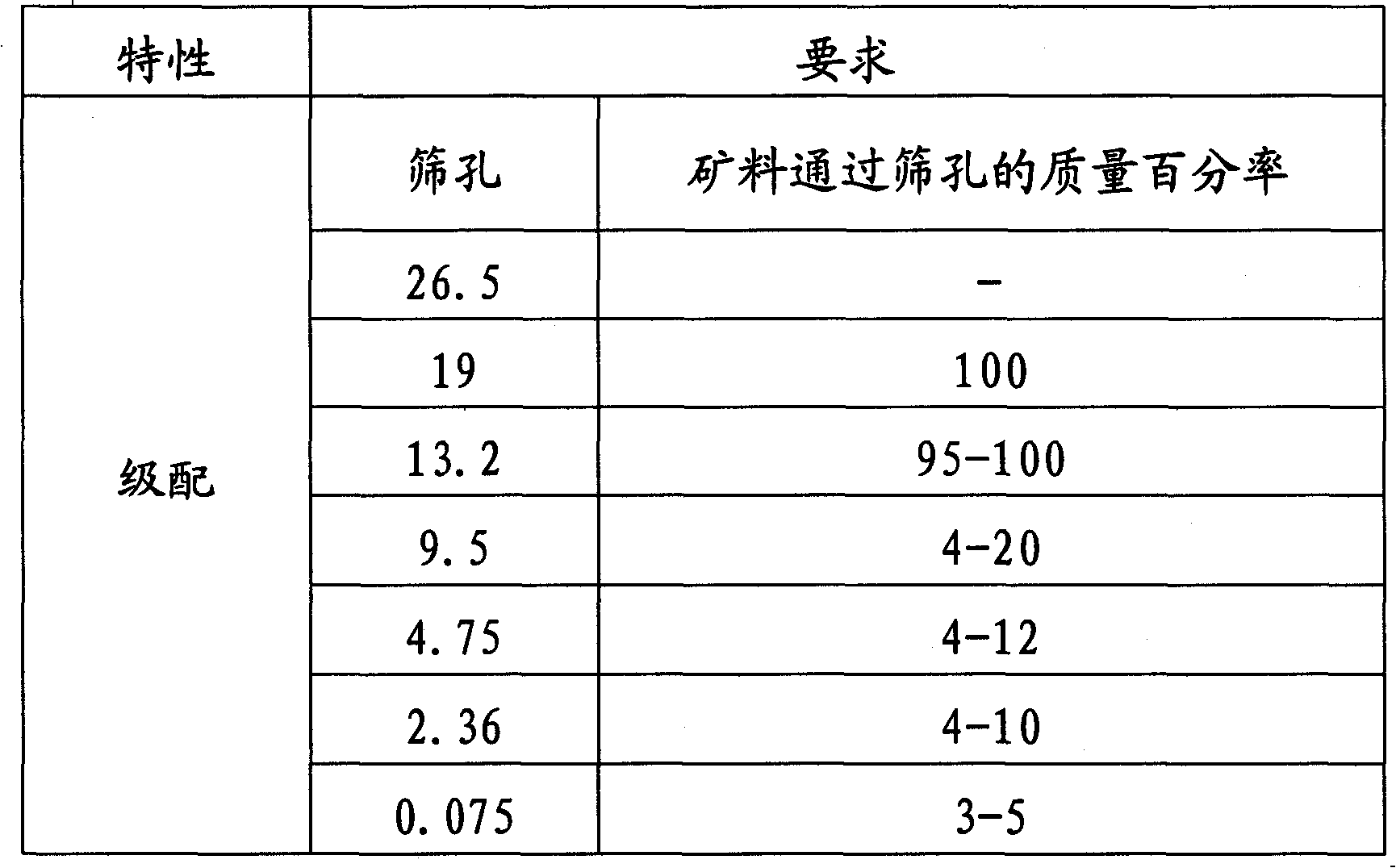

Self-inflow type semi-flexible composite pavement and construction method thereof

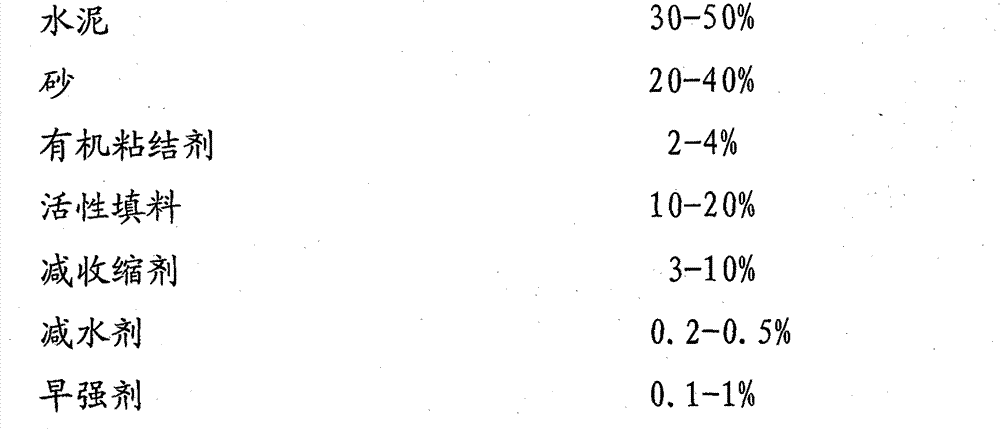

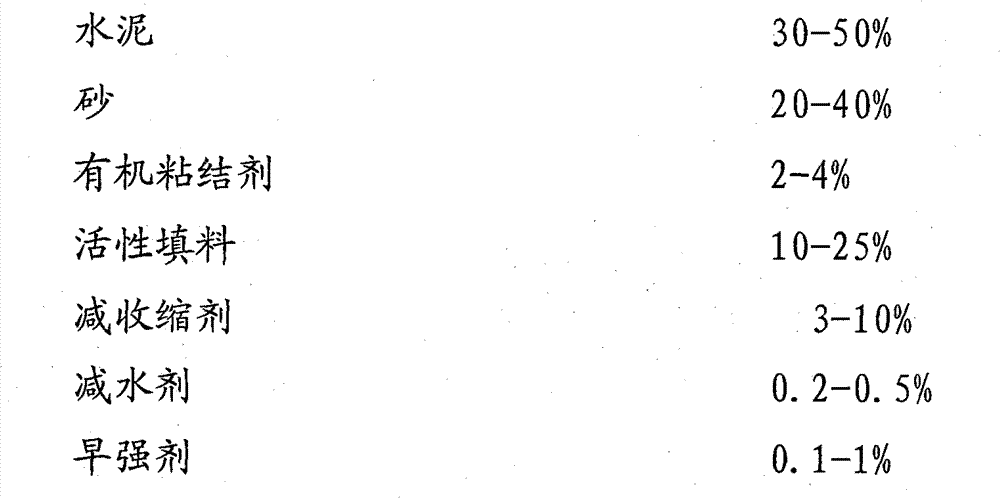

The invention relates to a semi-flexible composite pavement of which mixed cement slurry can automatically flow in holes of an asphalt mixture in a construction process. The composite pavement comprises an open-graded macro-porous asphalt mixture structure layer and pavement mortar which is filled in the holes of the macro-porous asphalt mixture, wherein the pavement mortar comprises 30 to 50 percent cement, 20 to 40 percent of sand, 2 to 4 percent of organic binder, 10 to 20 percent of active filler, 3 to 10 percent of shrinkage reducer, 0.2 to 0.5 percent of water reducer, 0.1 to 1 percent of early strength agent and water in an amount of 20 to 28 percent based on the total weight of all the components of the pavement mortar. The composite pavement of the invention has the advantages of high compression strength, short maintenance time, smoothness, compactness, seamlessness, skid resistance, wear resistance, crack resistance, durability and convenient construction. The invention also provides a construction method of the semi-flexible composite pavement. The method comprises the steps of base pavement treatment, open-graded asphalt mixture paving, on-spot pavement mortar stirring and grouting, maintenance and the like. In the construction method of the invention, the mortar is automatically filled in the holes of the asphalt mixture according to the gravity per self and high workability and fluidity, so influences which are caused by adopting vibration paving on asphalt frameworks are avoided.

Owner:广东龙湖科技股份有限公司

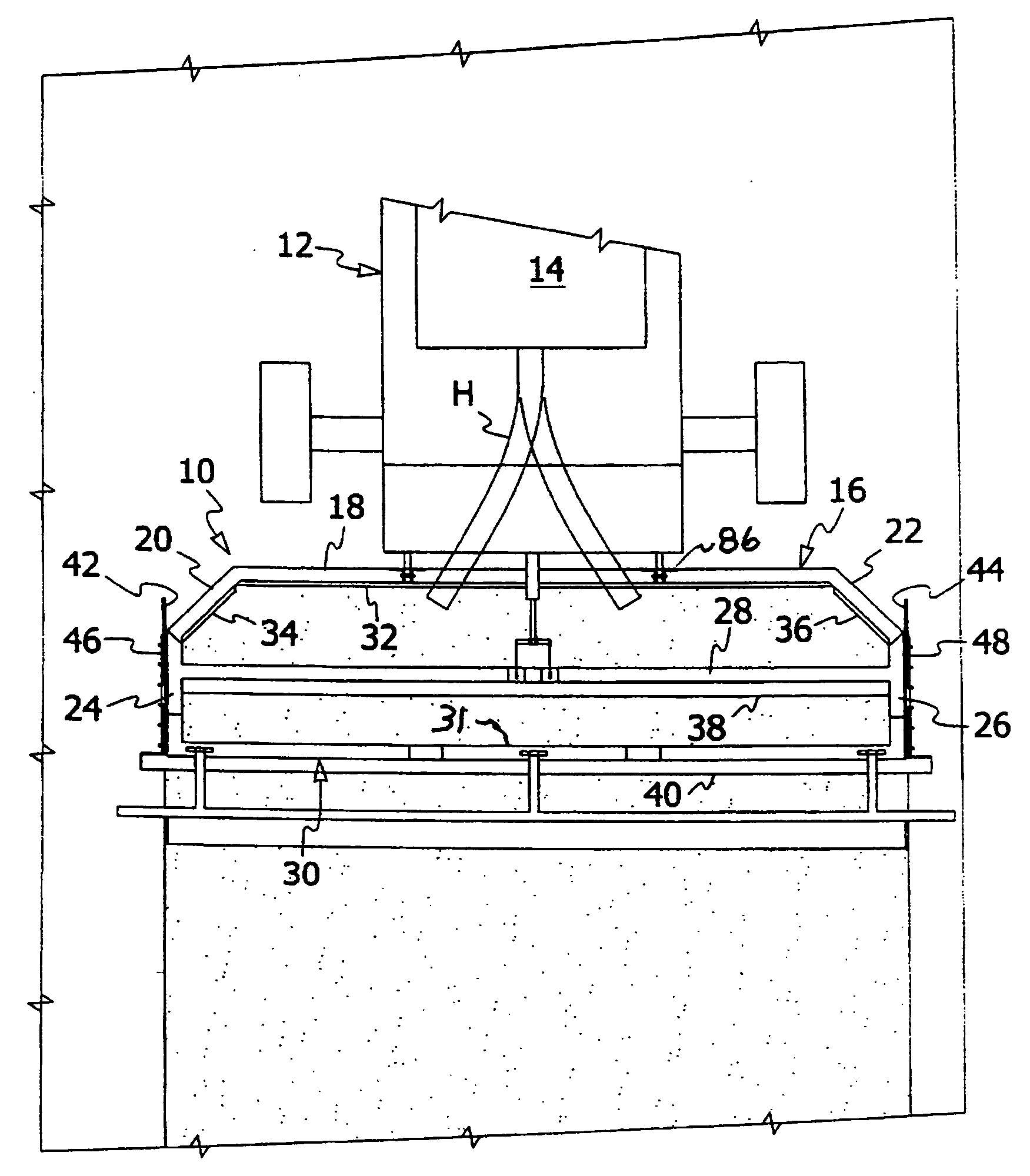

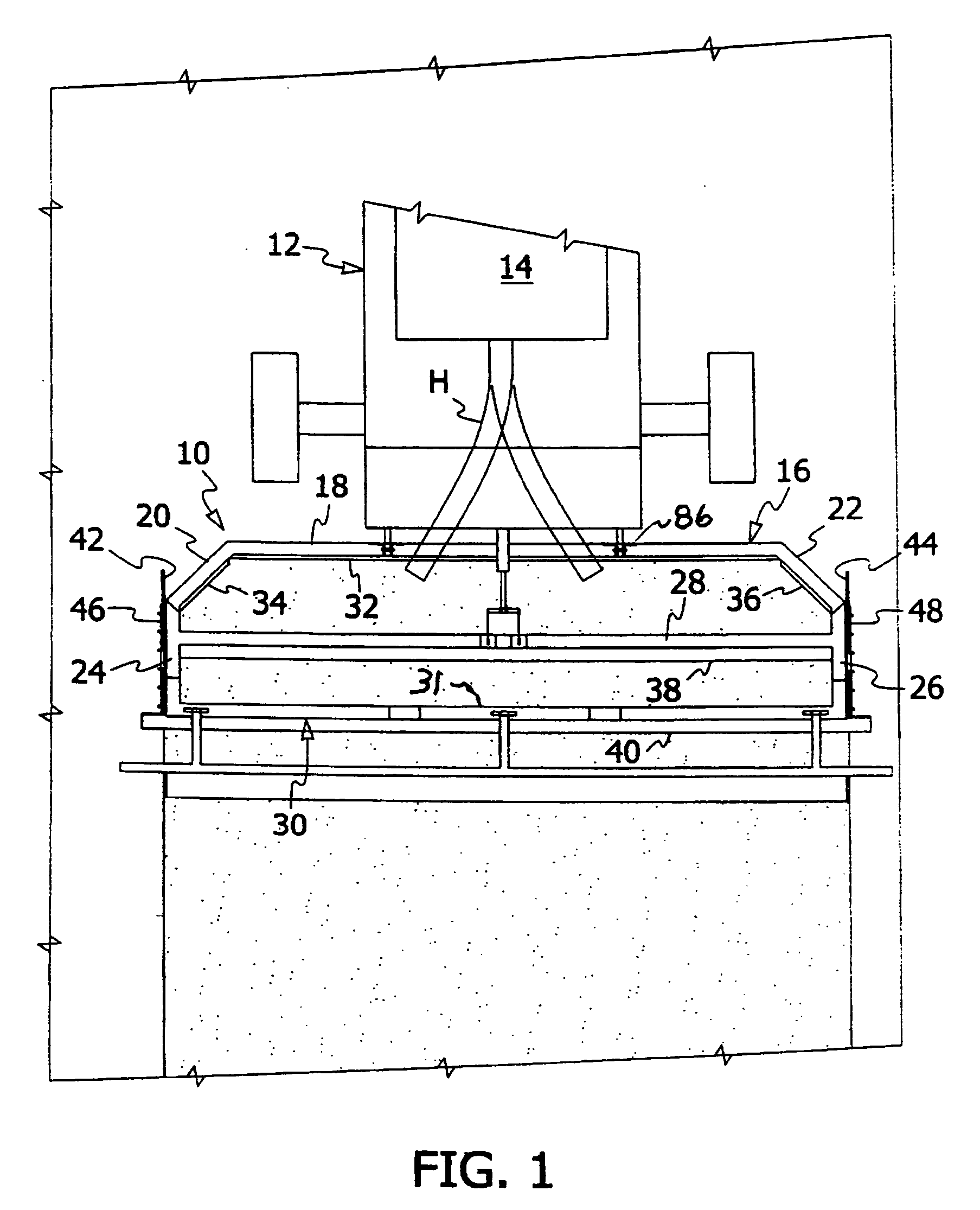

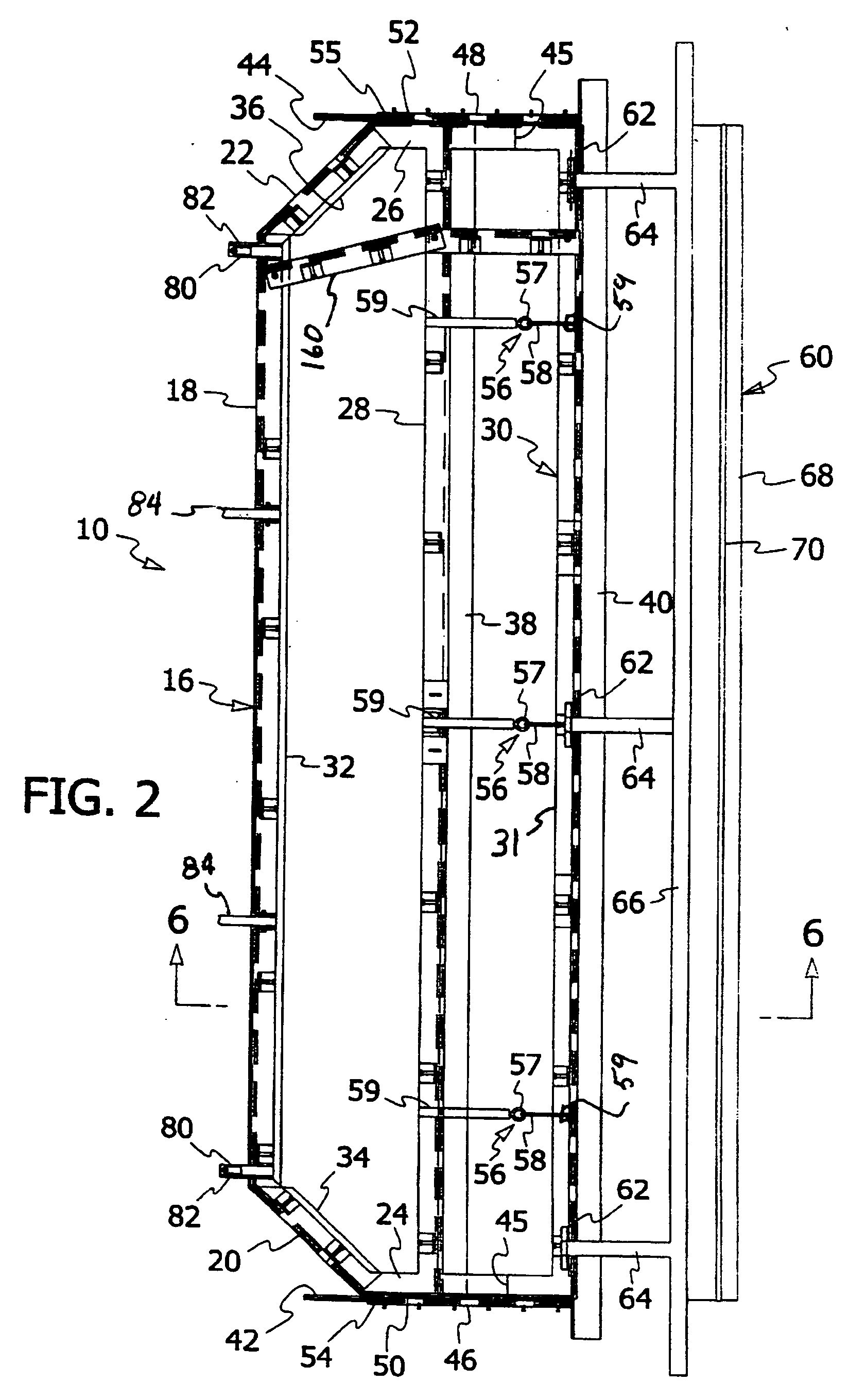

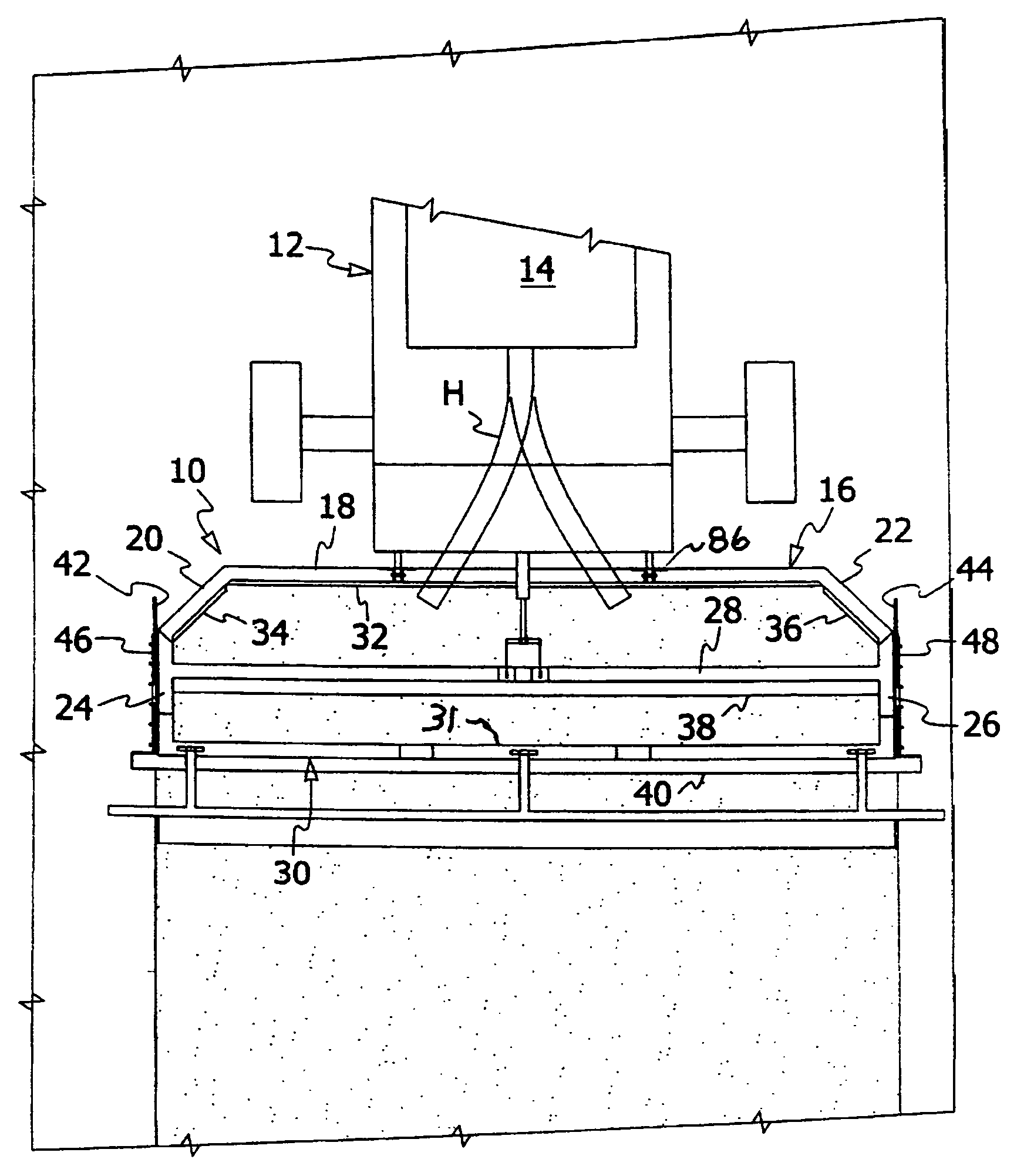

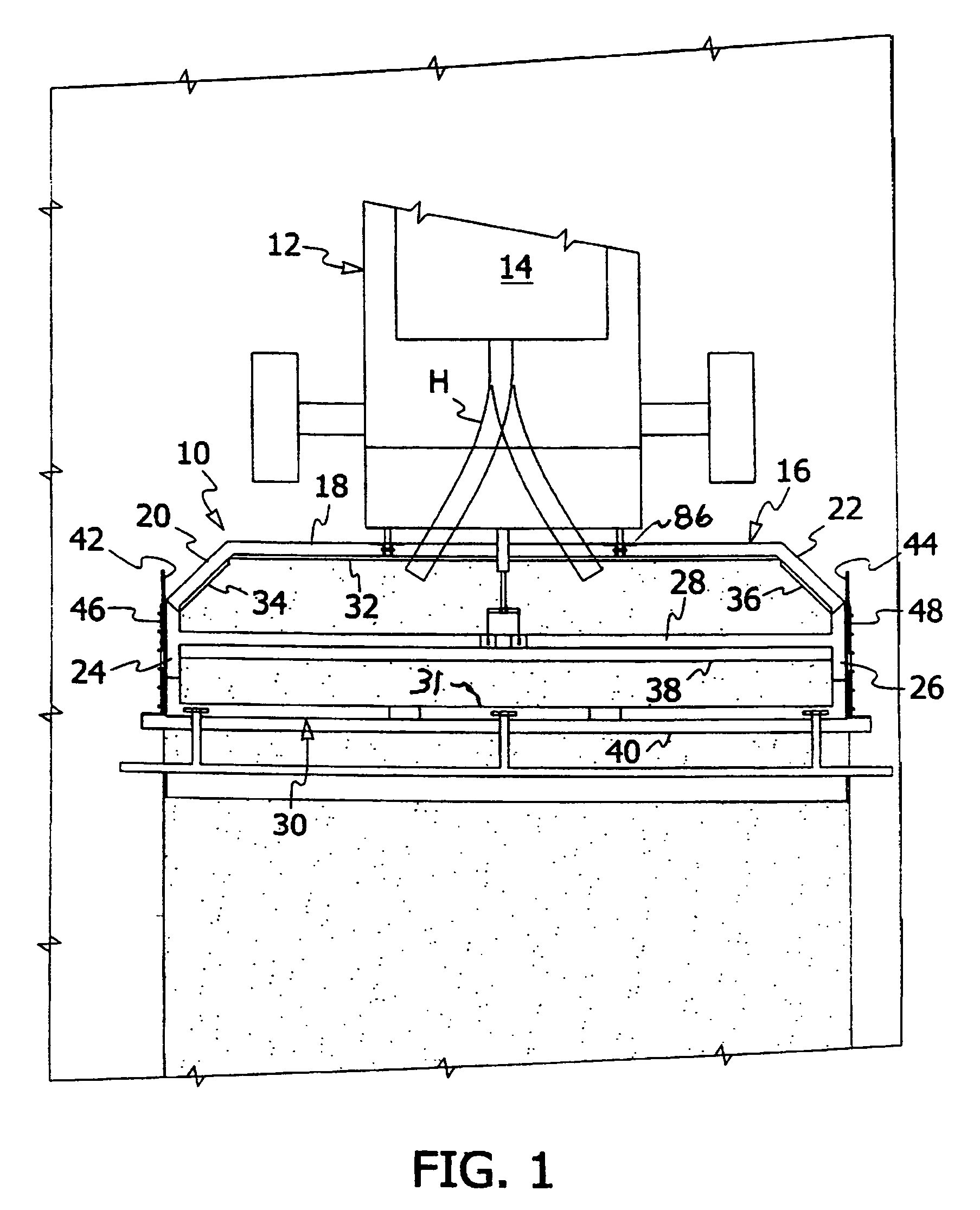

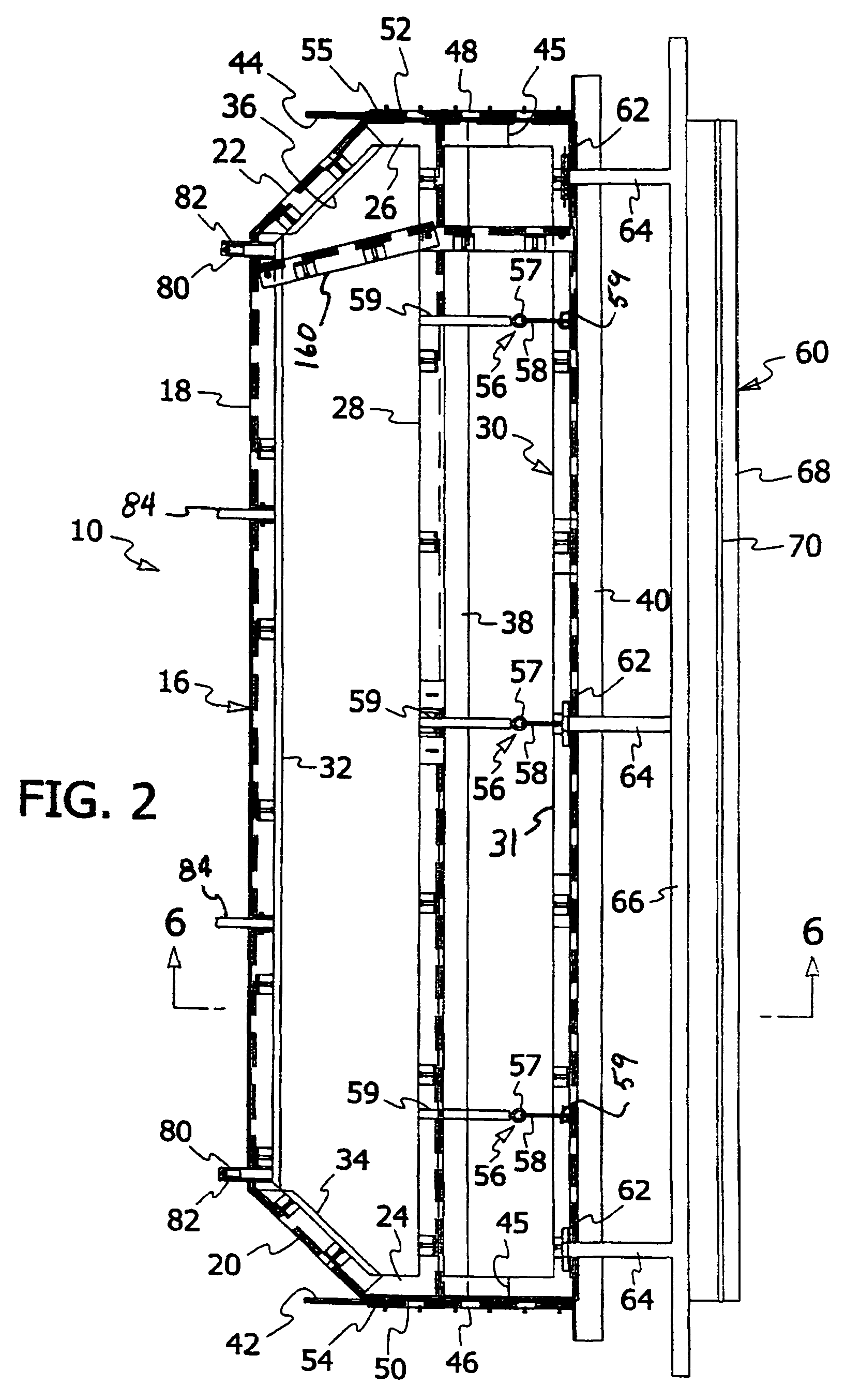

Pavement resurfacing equipment and method of application of polymer emulsion

One embodiment of the invention relates to a flexible sled that conforms to the contour of the pavement for applying a liquid emulsion onto a pavement surface comprising a rigid frame with flexible squeegee assembly adapted to be towed along a pavement surface. Another embodiment of the invention includes a hopper assembly for distributing aggregate. Another embodiment of the invention includes a sled for repairing ruts in wheel lanes of a road. Another aspect of the invention is a polymer emulsion composition having a high coefficient of friction comprising a mixture of polymer resin blended with a mixture of cement and angular sand aggregate and titanium dioxide to provide a solar reflectance index number that ranges from 0.30 to 0.38 and a friction number in the range of 45 to 55. Another aspect of the invention is a polymer emulsion for sealing open graded bituminous asphalt comprising a mixture of polymer resin blended with a mixture of cement and angular sand aggregate which will provide a friction number in the range of 45 to 55 when the ratio of aggregate to cement is 70 / 30.

Owner:LJB GRP

Permeable city pavement structure and rainwater collecting and utilizing system based on permeable pavement

InactiveCN105220597ASolve waterloggingAlleviate water scarcitySewerage structuresPaving detailsPipeflowEngineering

The invention relates to a permeable city pavement structure and a rainwater collecting and utilizing system based on the permeable pavement. The permeable city pavement structure mainly comprises an anti-blocking permeable pavement layer. An open-graded cushion layer, an open-graded upper base layer, an open-graded lower base layer and a non-compaction foundation soil layer are sequentially arranged under the anti-blocking permeable pavement layer. A water drainage pipe with holes is arranged in the open-graded lower base layer. Rainwater continues to seep downwards after being filtered through the anti-blocking permeable pavement layer, a part of the rainwater enters the water drainage pipe after passing through the open-graded cushion layer, the open-graded upper base layer and the open-graded lower base layer, and the other part of the rainwater continues to seep downwards and seeps underground after passing through the non-compact foundation soil layer. By means of the brand-new pavement structure, while the rainwater can be conveyed through a pipeline, the rainwater seeps underground by means of the base layers, and the problem of pavement flood propagation caused when rainfall in a city is large is effectively solved.

Owner:SHANDONG UNIV

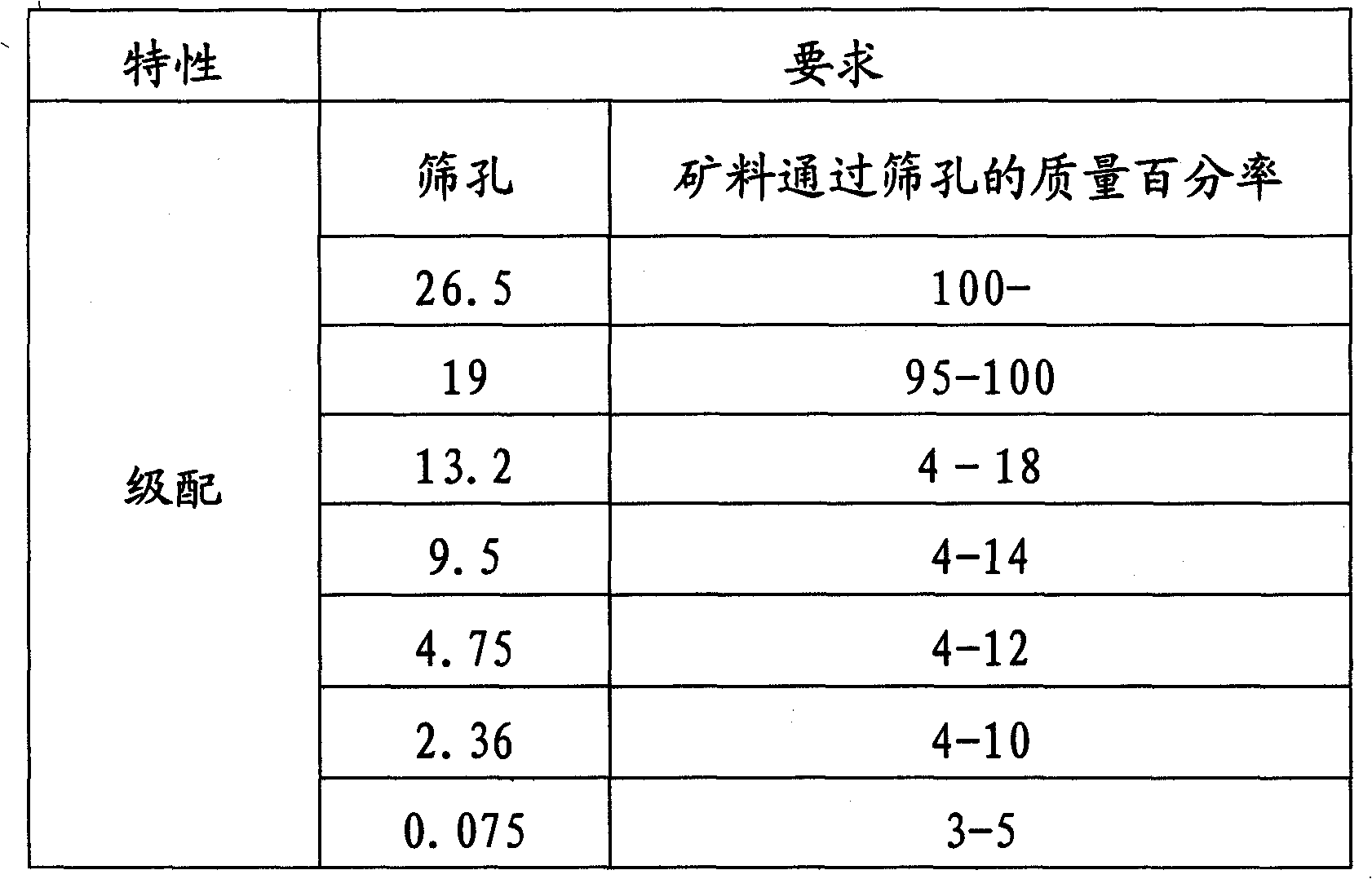

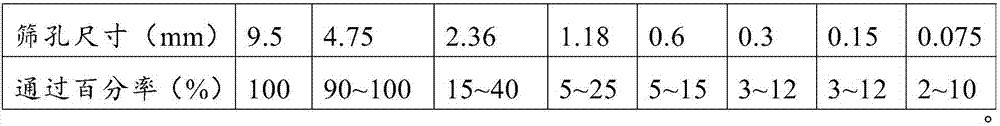

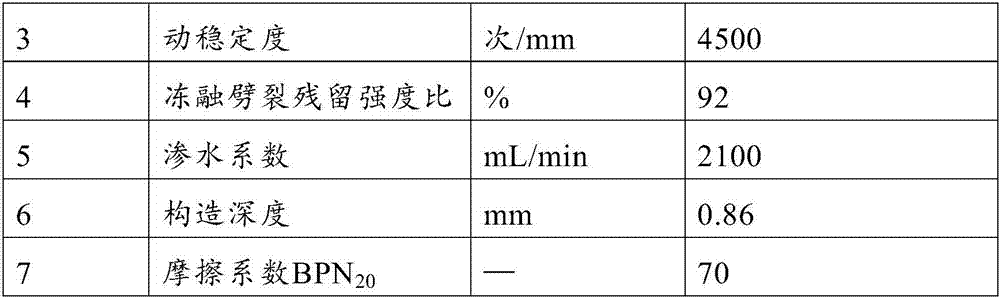

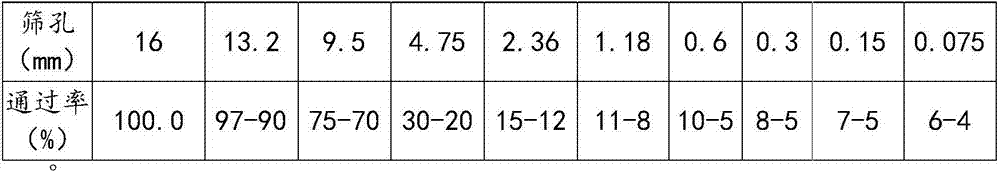

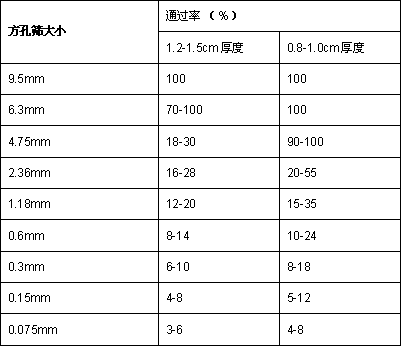

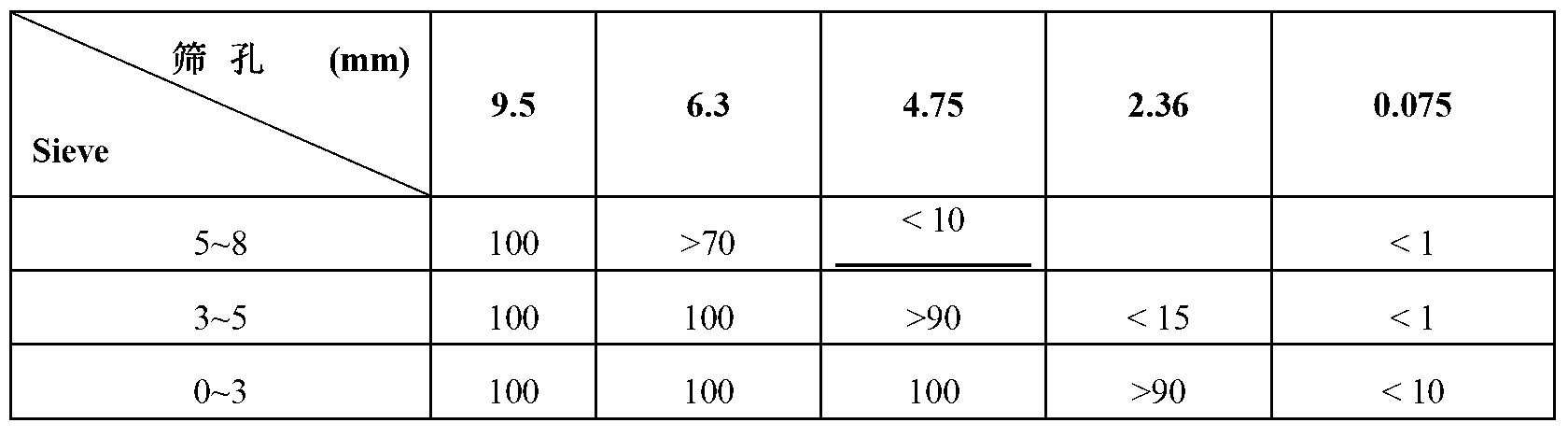

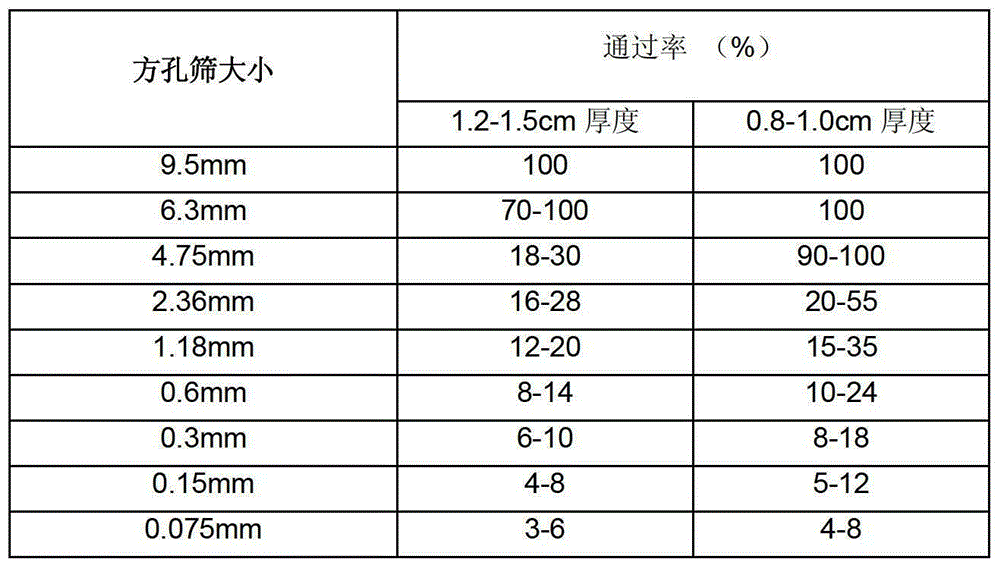

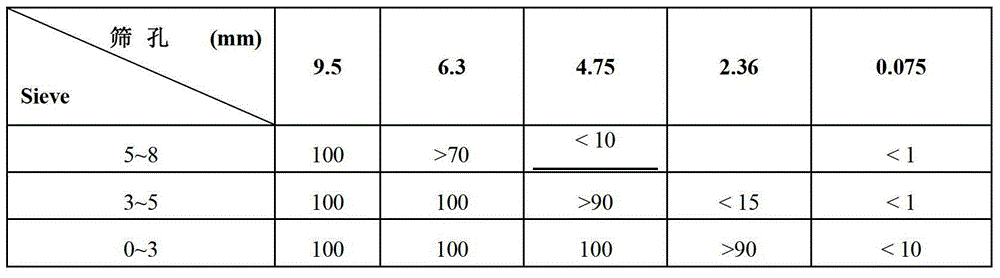

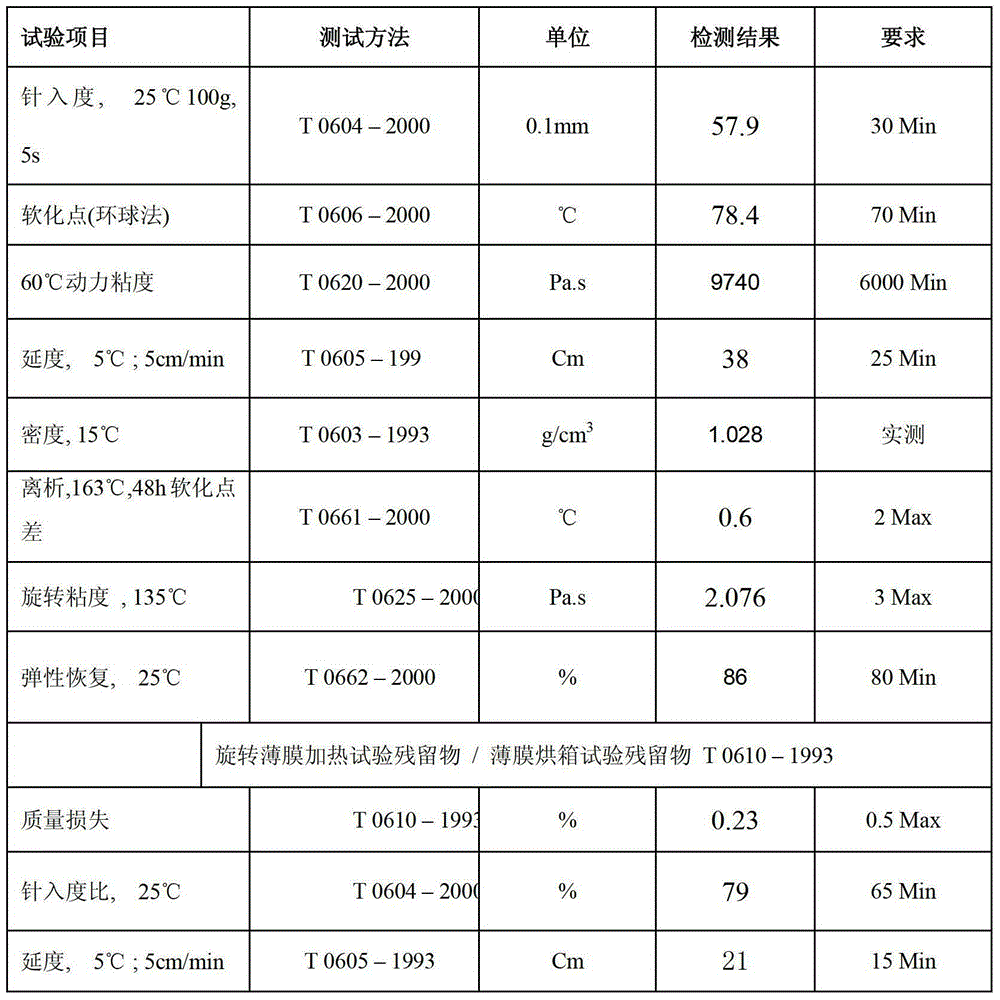

Small-particle-size open-graded asphalt mixture for ultra-thin overlay

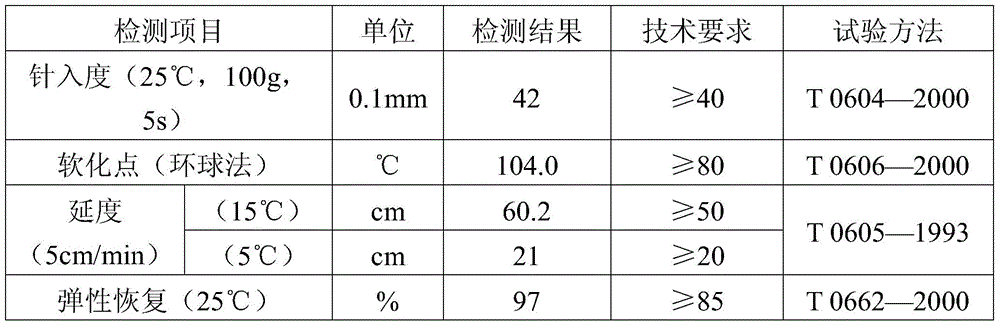

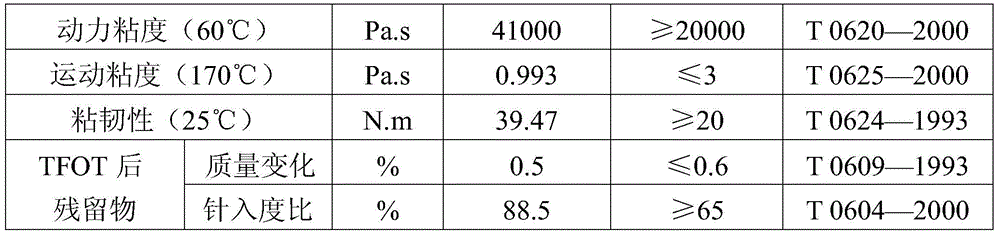

The invention provides a small-particle-size open-graded asphalt mixture for an ultra-thin overlay. The mixture is prepared from 85%-92% by weight of aggregate, 2%-8% by weight of filler and 5.5%-7.5% by weight of polymer modified asphalt, the nominal maximum aggregate size is 4.75 mm and the thickness of a pavement layer is 1.0-1.5 cm; preferably, the aggregate is basalt or diabase, the filler is the mixture of limestone mineral powder and cement in the mass ratio being (1:1)-(3:1), and the polymer modified asphalt is POE composite modified asphalt and has the zero-shear viscosity being 30,000 Pa.s or higher at 60 DEG C and the softening point equal to or higher than 90 DEG C. The small-particle-size open-graded asphalt mixture for ultra-thin overlay can reduce the thickness of a thin overlay, reduce building cost of a project and reduce noise during driving, two levels of hard building stones with the particle size being 3-5 mm or 0-3 mm can be utilized, the environment and resource stress of superfluous corresponding building stones due to large-scale application of SMA (stone mastic asphalt) pavements is reduced, and the small-particle-size open-graded asphalt mixture is ingenious in design, simple and convenient to prepare, low in cost and suitable for large-scale popularization and application.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

Pavement resurfacing equipment and method of application of polymer emulsion

InactiveUS8113736B2Reduce plastic ruttingAvoid flowIn situ pavingsPaving detailsPolymer resinEmulsion

One embodiment of the invention relates to a flexible sled that conforms to the contour of the pavement for applying a liquid emulsion onto a pavement surface comprising a rigid frame with flexible squeegee assembly adapted to be towed along a pavement surface. Another embodiment of the invention includes a hopper assembly for distributing aggregate. Another embodiment of the invention includes a sled for repairing ruts in wheel lanes of a road. Another aspect of the invention is a polymer emulsion composition having a high coefficient of friction comprising a mixture of polymer resin blended with a mixture of cement and angular sand aggregate and titanium dioxide to provide a solar reflectance index number that ranges from 0.30 to 0.38 and a friction number in the range of 45 to 55. Another aspect of the invention is a polymer emulsion for sealing open graded bituminous asphalt comprising a mixture of polymer resin blended with a mixture of cement and angular sand aggregate which will provide a friction number in the range of 45 to 55 when the ratio of aggregate to cement is 70 / 30.

Owner:LJB GRP

Steel bridge light pavement layer structure and paving method

InactiveCN110080087AReduce fatigue stressImprove local stiffnessBridge structural detailsBridge erection/assemblyBridge deckThin layer

The invention provides a steel bridge light pavement layer structure and a paving method and relates to the technical field of steel bridge paving. The fatigue stress of a bridge deck steel structurecan be effectively reduced, the local rigidity of a bridge deck system can be greatly enhanced, and the fatigue life of a steel bridge deck can be prolonged. The steel bridge light pavement layer structure comprises the steel bridge deck, a cement concrete layer, an adhesive layer and a multifunctional thin layer in sequence from bottom to top; the two adjacent layers are connected with each other; a reinforcement mesh is arranged in the cement concrete layer; the reinforcement mesh is fixedly connected with the steel bridge deck through a plurality of short bolt nails; the multifunctional thin layer is an open-graded or cut-off graded asphalt concrete thin layer; and the thickness of the multifunctional thin layer is 10-25 mm. The steel bridge light pavement layer structure provided by the technical scheme of the invention is suitable for steel bridge paving processes of new construction and bridge deck large and medium-sized repairing.

Owner:BEIJING ZHIHUATONG TECH CO LTD

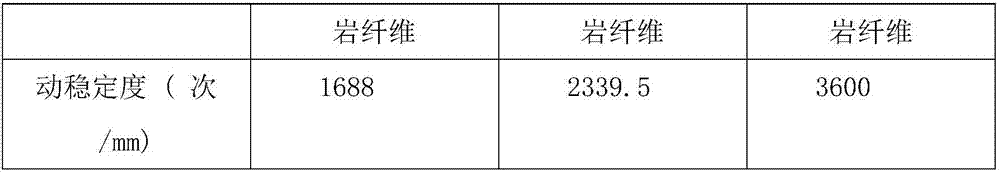

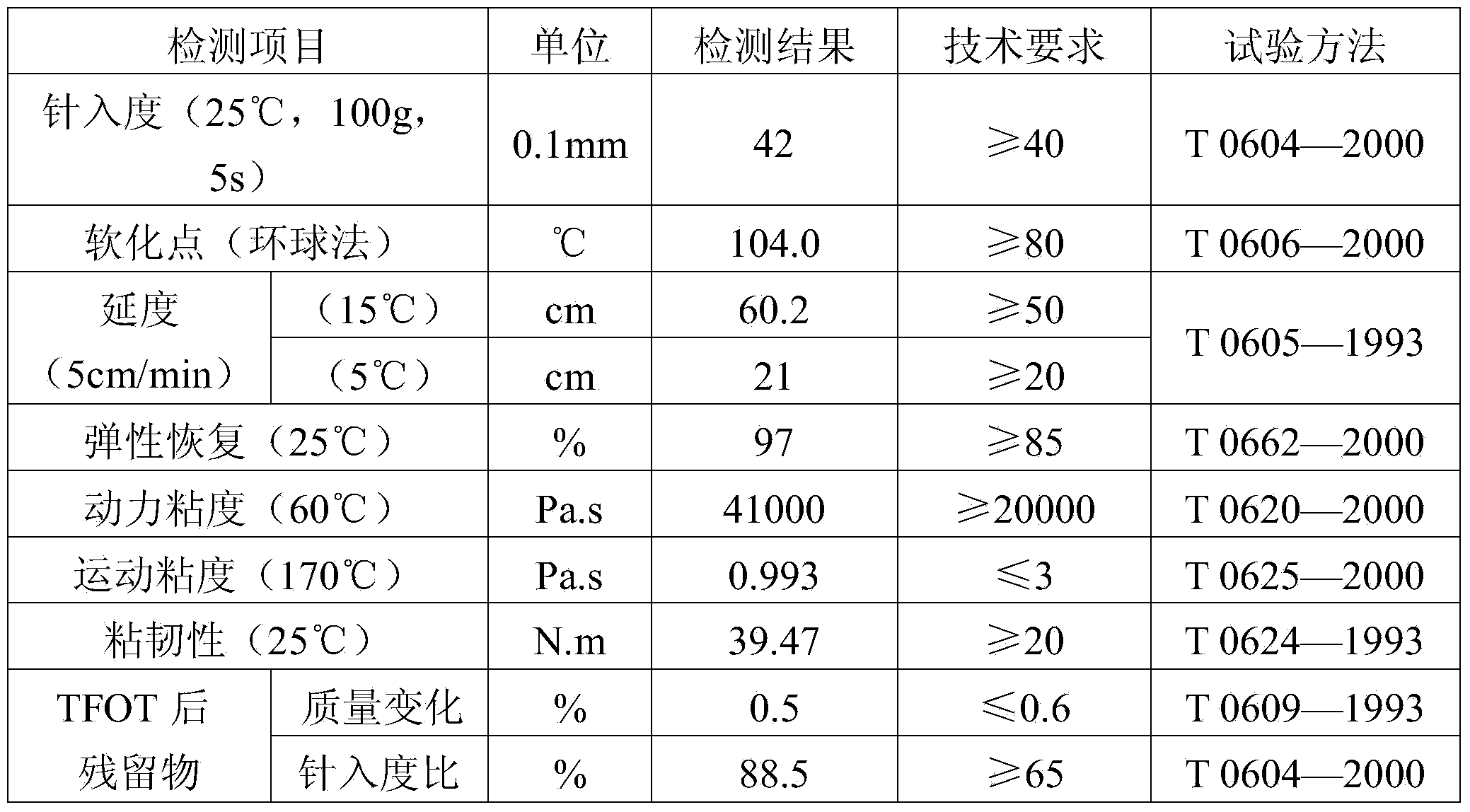

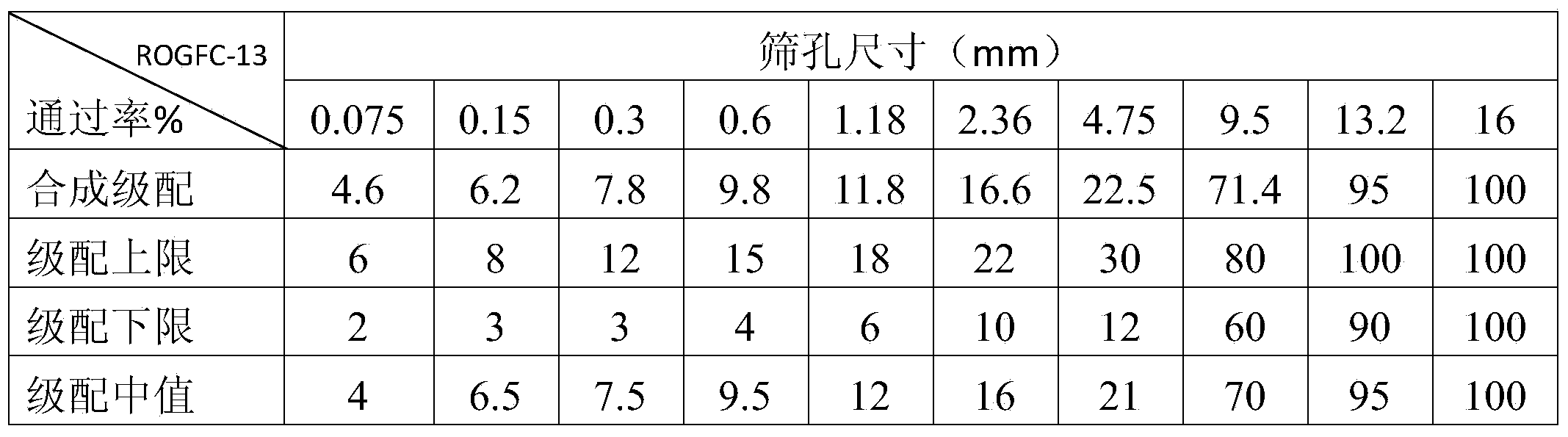

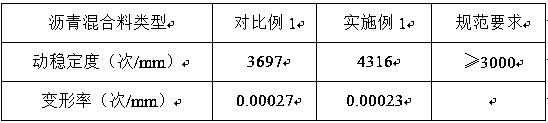

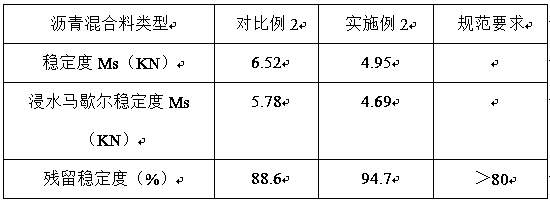

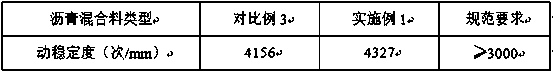

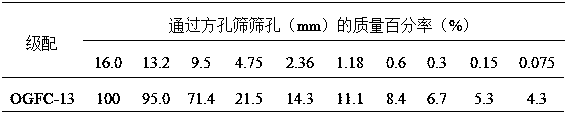

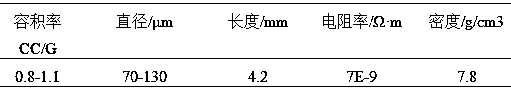

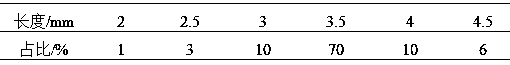

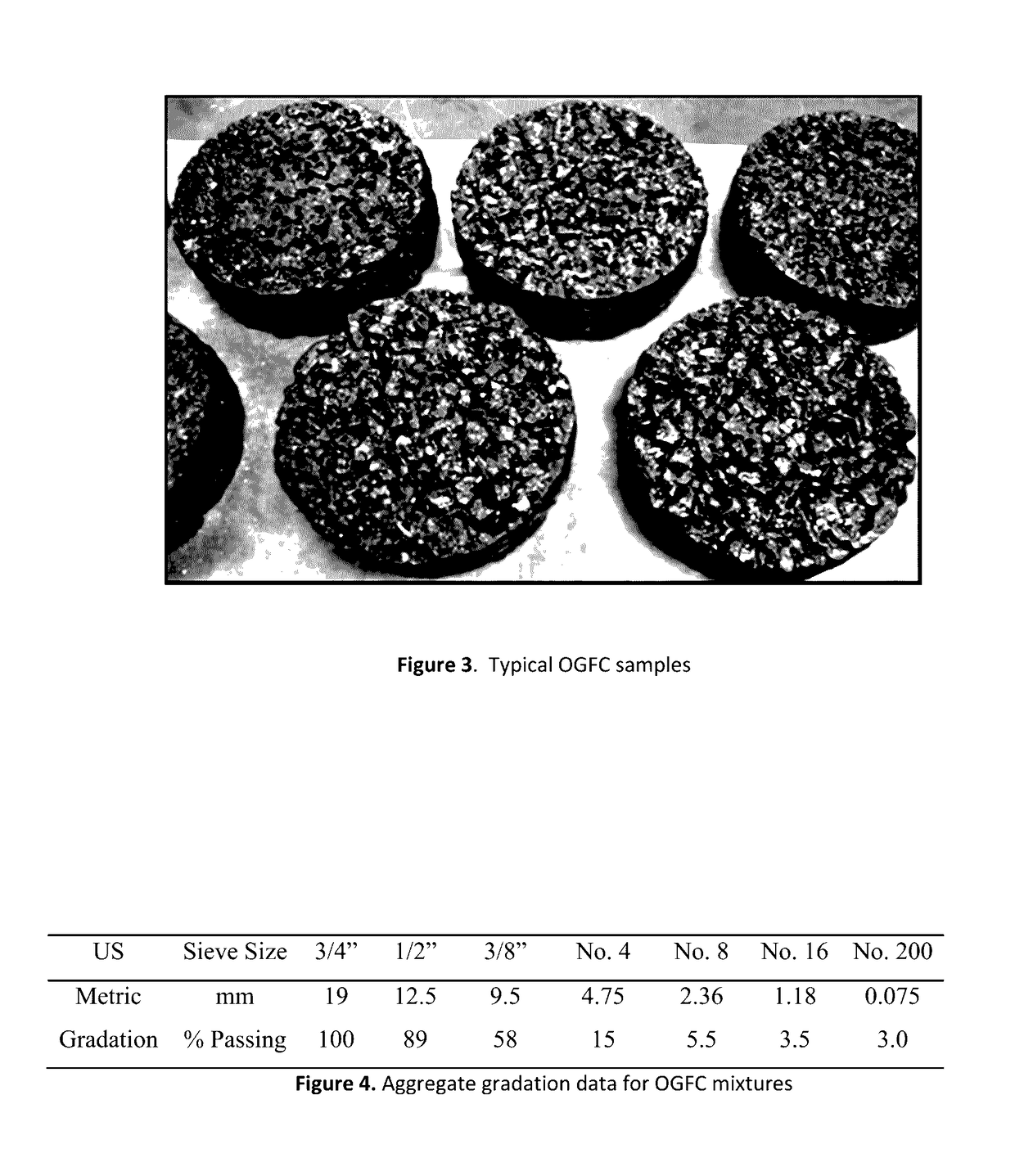

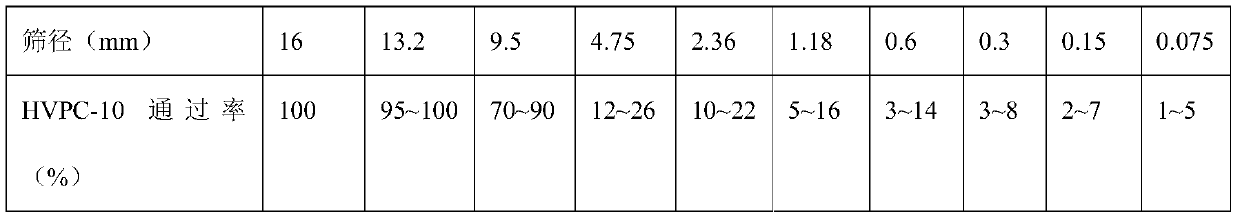

Preparation method of OGFC (Open Graded Friction Course)-13 asphalt mixture doped with short-cut basalt fiber

ActiveCN107188460AImprove high temperature stabilityEnhancement and water stabilityCeramicwareMolten stateOpen grade

The invention discloses a preparation method of an OGFC (Open Graded Friction Course)-13 asphalt mixture doped with short-cut basalt fiber. The method comprises the following steps: firstly heating finished SBS-modified asphalt in a drying oven at 165 DEG C till the SBS-modified asphalt is in a molten state, respectively preheating coarse and fine aggregate in mineral aggregate and mineral powder for six hours or more at 195 DEG C, heating a mixing pot till the mixing temperature reaches 170 DEG C, firstly adding the preheated coarse and fine aggregate into the mixing pot for mixing for 15-18 seconds, then doping short-cut basalt fiber and HVA (High-Viscosity Agent) for mixing for 90 seconds, adding the SBS-modified asphalt subjected to heat preservation for standby for mixing for 90-95 seconds, and finally doping the preheated mineral powder and mixing for 90-95 seconds to prepare the mixture. According to the prepared OGFC-13 asphalt mixture, a proper amount of short-cut basalt fiber is doped into the asphalt mixture, so that the water stability can be improved; meanwhile, the high-temperature-resistant stability can also be improved; the method is simple and convenient to operate; the cost is reduced.

Owner:YANGZHOU UNIV

Asphalt for ultrathin surface wearing layer and mixture and application thereof

The invention relates to an asphalt for an ultrathin surface wearing layer, which comprises 90-96 weight parts of heavy-traffic or conventional modified asphalt and is added with a compound agent, wherein the compound agent consists of the following components in parts by weight: 2-3 parts of polymer, 1-3 parts of rubber and 1.5-3 parts of dispersing aid; and the mixture improves the viscosity and stiffness of asphalt as well as the adhesive force between asphalt and stone, and avoids or reduces the phenomenon that the asphalt floats upward and blocks gaps and consequently causes reduction of the structure depth, drainage performance and denoising effect of the mixture under the action of temperature and traffic load. The invention also discloses a mixture of the asphalt; by adding a grading control point to the mixture and matching the broken grade and the open grade, a stable skeleton embedding extrusion structure and the maximum skeleton gap are obtained, and higher porosity and maximum connection porosity are obtained so as to avoid skeleton instability and consequent surface function attenuation. The invention also discloses an application method of the mixture at the same time.

Owner:BEIJING TONGHUA ROAD MAINTENANCE

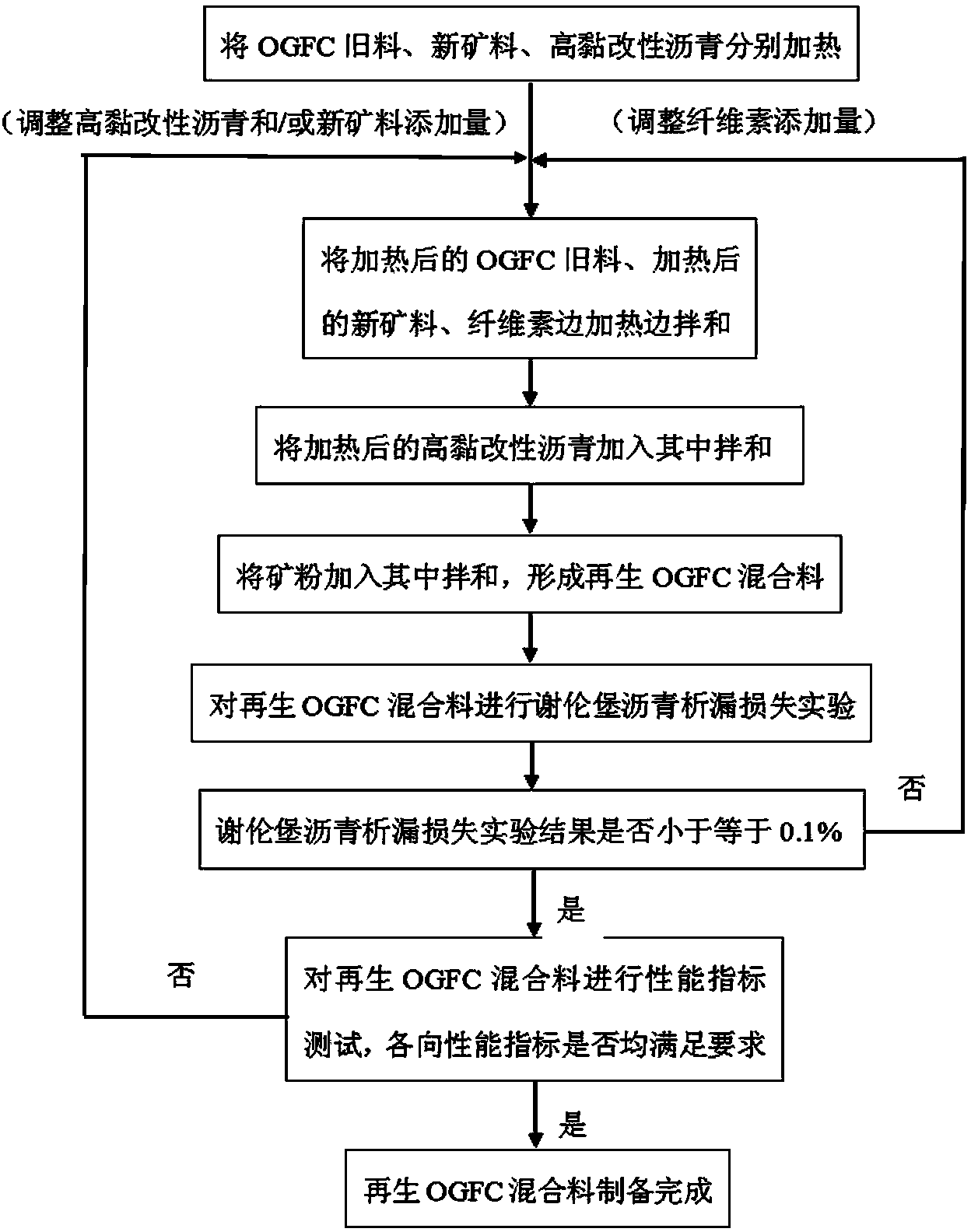

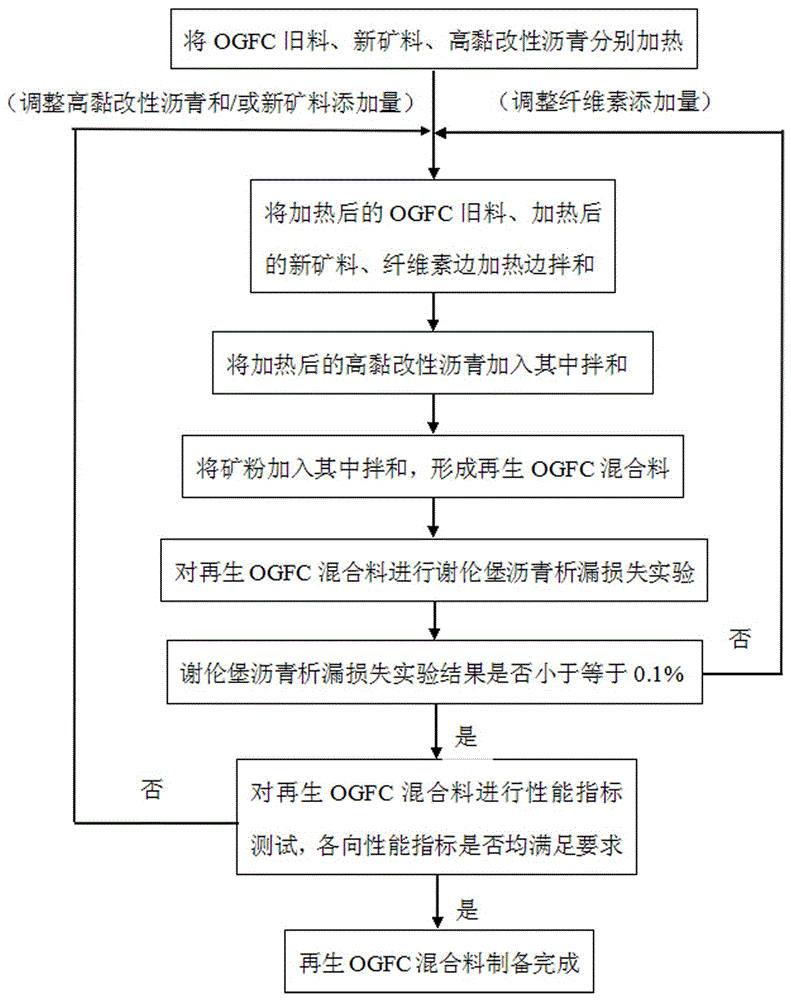

Regenerated OGFC (Open-graded Friction Courses) mixed material and preparation method thereof

ActiveCN104030608ALow costMake the most of potential valueClimate change adaptationCelluloseHyperviscosity

The invention discloses a regenerated OGFC (Open-graded Friction Courses) mixed material and a preparation method thereof. The mixed material comprises cellulose, hyperviscosity modified asphalt, new mineral aggregate, mineral powder and an OGFC old material. The preparation method comprises the following steps: respectively heating the OGFC old material, new mineral aggregate and hyperviscosity modified asphalt; then, mixing the heated OGFC old material and the new mineral aggregate with cellulose; then, adding the heated hyperviscosity modified asphalt into the mixture and mixing; then, adding the mineral powder, continuously mixing to form a regenerated OGFC mixed material; and finally, carrying out a Xielunbao asphalt leakage loss experiment and performance index test on the regenerated OGFC mixed material. The preparation method of the regenerated OGFC mixed material provided by the invention is simple to operate and accurate in result, and the potential value of the OGFC old material is fully utilized and the OGFC old material is reduced to the regenerated OGFC mixed material, so that the cost of OGFC is lowered.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Open-graded lignin fiber asphalt mixture and preparation method thereof

InactiveCN108947331AImprove high temperature stabilityImprove water stabilityCeramicwareFiberDry mixing

The invention discloses an open-graded lignin fiber asphalt mixture and a preparation method thereof. The mixture comprises SBS modified asphalt, lignin fiber and mineral aggregate, wherein the mineral aggregate is composed of aggregate and mineral powder; and the aggregate is divided into three groups according to the particle sizes of 10-15mm, 5-10mm and less than or equal to 3mm. The preparation method of the mixture comprises the following steps: respectively drying the raw materials to constant weight; performing dry mixing on the lignin fiber and the coarse and fine aggregate for 30 seconds at a mixing temperature, adding the constant temperature SBS modified asphalt for performing wet mixing for 3 minutes, and adding the mineral powder for mixing for 90 seconds, thereby obtaining the product. According to the open-graded lignin fiber asphalt mixture provided by the invention, the pavement performance of the mixture can be greatly improved, the operation is simple and convenient,and the cost is saved.

Owner:泰州学院 +1

Cement-asphalt composite self-melting snow pavement material and preparation method thereof

ActiveCN110272227AImprove dynamic stabilityGood anti-rutting performanceCeramicwareVoid ratioRoad engineering

The invention belongs to the technical field of road engineering materials. A cement-asphalt composite self-melting snow pavement material is characterized in that: an open graded conductive asphalt concrete containing conductive material with a void ratio of 21-25% is taken as a matrix, and a conductive cement mortar containing conductive material is taken as a filling material of the void; the mass percentage of the conductive asphalt concrete is 82%-92%, and the mass percentage of the conductive cement mortar is 8%-18%. The function of self-melting snow on road surface is realized by means of electric heating. The pavement material has the advantages of simple preparation process, good self-melting effect and better rutting resistance than the existing conductive asphalt concrete.

Owner:WUHAN UNIV OF TECH

Preparation method of catalytic degradation type open-graded friction course asphalt mixture

The invention relates to a preparation method of a catalytic degradation type open-graded friction course (OGFC) asphalt mixture, belongs to the technical field of pavement materials, and solves the problems that when nano TiO2 is directly added into OGFC, an addition amount is less, a negative influence is generated, agglomeration is easy to have, a concentration of automotive tail gas at the surface of TiO2 is low, the degradation effect is poor, and recycling is difficult to realize. The method comprises the following steps: firstly performing activation treatment on a 13X molecular sieve to remove impurities and broaden pores of the 13X molecular sieve; and preparing TiO2 sol, adding the activated 13X molecular sieve into the sol, performing ultrasonic oscillation, performing uniform mixing, performing filtration to remove a solution and impurities, performing drying, performing calcination to prepare 13X molecular sieve / nano-TiO2 composite photocatalyst particles, substituting thecomposite photocatalyst particles for fine aggregate according to a certain ratio, mixing a asphalt mixture, performing molding on a test piece, testing the road performance and the effect of degrading tail gas of the catalytic degradation type OGFC asphalt mixture, and combining test results to determine a ratio of substituting the composite photocatalyst for the fine aggregate to prepare the catalytic degradation type OGFC asphalt mixture. The asphalt mixture provided by the invention gives the OGFC the function of catalytically degrading the tail gas and improves air quality.

Owner:NANJING FORESTRY UNIV

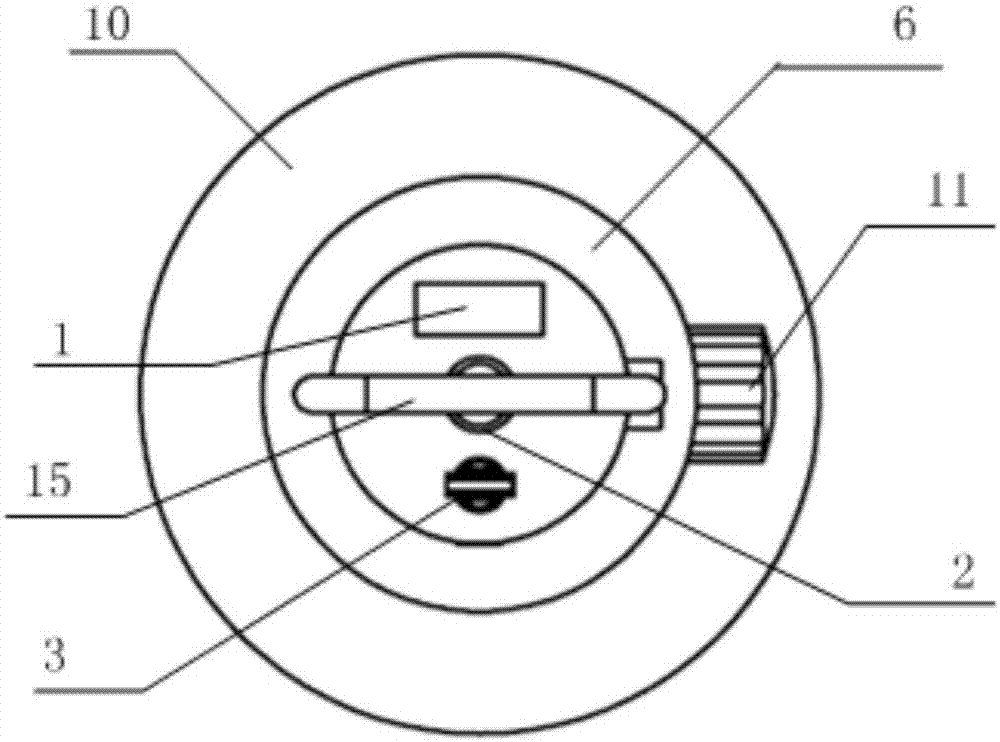

Portable simulation water seepage performance testing instrument and use method thereof

ActiveCN107515182ASolve the effect of hydraulic coefficientSimple and fast operationMeasurement of fluid loss/gain ratePermeability/surface area analysisPorosityTest flow

The invention discloses a portable simulation water seepage performance testing instrument, which comprises a base, a measuring tube, an air pressure slide block, an air pressure control device and a distance measuring module, wherein the base is used for realizing the sealing through contacting with the pavement to be tested; the measuring tube is arranged at the upper part of the base, and is connected with the base through a ventilation pipe; a ventilation switch is arranged on the ventilation pipe; the air pressure slide block is arranged inside the measuring tube and is vertical to the side wall of the measuring tube; the air pressure slide block and the side wall of the measuring tube are in a moving sealing state; the air pressure control device is arranged at the upper part of the measuring tube, and is used for controlling the air entering quantity of the upper part of the air pressure slide block in the measuring tube; the distance measuring module is used for measuring the used time and the displacement of the air pressure slide block in the measuring tube; the measuring tube is a sealed tube; an upper part air inlet is connected with the outside through an air pressure control device; a lower part air outlet is connected with outside air through the ventilation pipe. The air is used for replacing conventional water to be used as a test flow seepage carrier; the precise measurement of the water seepage performance of the large-porosity open-graded pavement can be performed.

Owner:JSTI GRP CO LTD

High-level wide-range pavement with internal drainage structure and construction method thereof

InactiveCN104652222AWill not affect driving safetyIn situ pavingsPaving detailsSurface layerDrainage design

The invention discloses a high-level wide-range pavement with an internal drainage structure and a construction method thereof. The drainage design is performed according to different requirements of an overtaking lane and a traffic lane of the high-level wide-range pavement for drainage, and a scheme that the overtaking lane and the traffic lane are separately paved is adopted; the pavement surface layer of the overtaking lane is made of an open-graded wearing layer permeable material, the underside base layer is made of a dense-graded asphalt mixture, the water-proof treatment is carried out at the middle bonding part; the pavement surface layer of the traffic lane is made of a dense-graded asphalt mixture, the underside base layer is made of an open-graded wearing layer permeable material, and the water-proof treatment is carried out at the middle bonding part of two base layers; the base layer under the traffic lane is properly extended to the base layer under the overtaking lane in a width direction, and the structure layers of the overtaking lane and the traffic lane are subjected to water-proof treatment. The high-level wide-range pavement with the internal drainage structure can be used for solving the problems that the large-aperture drainage pavement surface having a rapid drainage function can be compacted easily under the action of the heavy truck and the drainage capacity can be lost finally. The drainage requirements of common vehicles and overload vehicles can be considered by a specific pavement drainage mode.

Owner:SOUTHEAST UNIV

Coloured asphalt concrete permeable brick and preparation method thereof

The invention discloses a coloured asphalt concrete permeable brick and a preparation method thereof. The preparation method comprises the following steps: for a bottom layer, stirring an open-graded drainage type wearing layer mine material mixture and high-viscosity modified asphalt in a mixer to prepare a permeable asphalt mixture; then, filling a mould with the permeable asphalt mixture according to a specified amount, compacting, and preparing permeable asphalt concrete; mixing required coloured stone, unsaturated resin, an accelerator and a curing agent to prepare a coloured surface layer mixture; adding the coloured surface layer mixture to the bottom layer permeable asphalt mixture to the plane of a mould frame, moving the mould to a brick pressing machine for moulding, and de-moulding after three hours to obtain a coloured asphalt concrete permeable square brick. The road surfaces which are paved by the coloured asphalt concrete permeable bricks have the characteristics that the water permeability is high, the bearing capacity is high, and a very good walking comfort feel is given to people by flexible bottom layers. The city is beautified; the drainage and underground water storage capacity of an urban road are enhanced; positive effects on regulating the weather of the city and keeping ecological balance are achieved.

Owner:SHENYANG URBAN CONSTR ASPHALT CONCRETE FACTORY

EVA (ethylene-vinyl acetate copolymer)/SBS (styrene butadiene styrene segmented copolymer) compound modified asphalt stabilized crushed stone permeable base and paving method thereof

The invention relates to an EVA (ethylene-vinyl acetate copolymer) / SBS (styrene butadiene styrene segmented copolymer) compound modified asphalt stabilized crushed stone permeable base and a paving method thereof. In the aspect of setting urban sewerage systems and expressway road materials, response to rainstorm drainage facility is hardly taken into consideration, and drainage is impeded when rainstorm happens. A paving material disclosed by the invention is prepared from a mixture which is formed by evenly stirring compound modified asphalt, wherein 4% of EVA and 2 to 3% of SBS are adulterated and open-graded crushed stone which is utilized as aggregate under the condition of 170 DEG C to 185 DEG C. Therefore, excellent performance of the mixture of the base is ensured, pavement performance of the base can be better played at the same time, and a function of utilizing the base to effectively draining water is achieved. Compared with an ordinary ATPB (asphalt treated permeable base),fatigue life, a softening point and low-temperature ducility of the EVA / SBS compound modified asphalt stabilized crushed stone permeable base disclosed by the invention are all remarkably improved; furthermore, the problems of poor fatigue durability, poor high-temperature stability, poor low-temperature crack resistance, no environmental friendliness and the like in the prior art can be effectively solved.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Durable ultrathin asphalt skid-resistant surface layer pavement structure and construction method

PendingCN107165016AImprove skid resistanceIncreased durabilityIn situ pavingsTraffic noiseInter layer

The invention discloses a durable ultrathin asphalt skid-resistant surface layer pavement structure and a construction method. The durable ultrathin asphalt skid-resistant surface layer pavement structure comprises a concrete pavement base course or an asphalt pavement base course, and further comprises a wheel-bonding-free interlayer bonding layer and an ultrathin asphalt skid-resistant surface layer, wherein the wheel-bonding-free interlayer bonding layer is spread on the concrete pavement base course or the asphalt pavement base course and used for preventing interlayer slippage damage, and the ultrathin asphalt skid-resistant surface layer is compacted on the wheel-bonding-free interlayer bonding layer, and the compaction thickness of the ultrathin asphalt skid-resistant surface layer is 15mm-25mm; and the ultrathin asphalt skid-resistant surface layer is prepared by adopting an open-graded hot-mix asphalt mixture in a compacted mode, the maximum particle diameter of aggregate of the ultrathin asphalt skid-resistant surface layer is not greater than 9.5 mm, and the asphalt-aggregate ratio is not smaller than 6%; and the wheel-bonding-free interlayer bonding layer is spread by adopting hot-melt type modified asphalt, the spreading used amount of the wheel-bonding-free interlayer bonding layer is 0.1-1 Kg / m<2>, and the curing time for avoiding wheel bonding is shorter than 3 minutes. According to the durable ultrathin asphalt skid-resistant surface layer pavement structure and the construction method, the skid-resistant property is good, the durability is good, the smoothness of a pavement is good, and the traffic noise can be reduced effectively.

Owner:GUANGXI JINMENG ENG

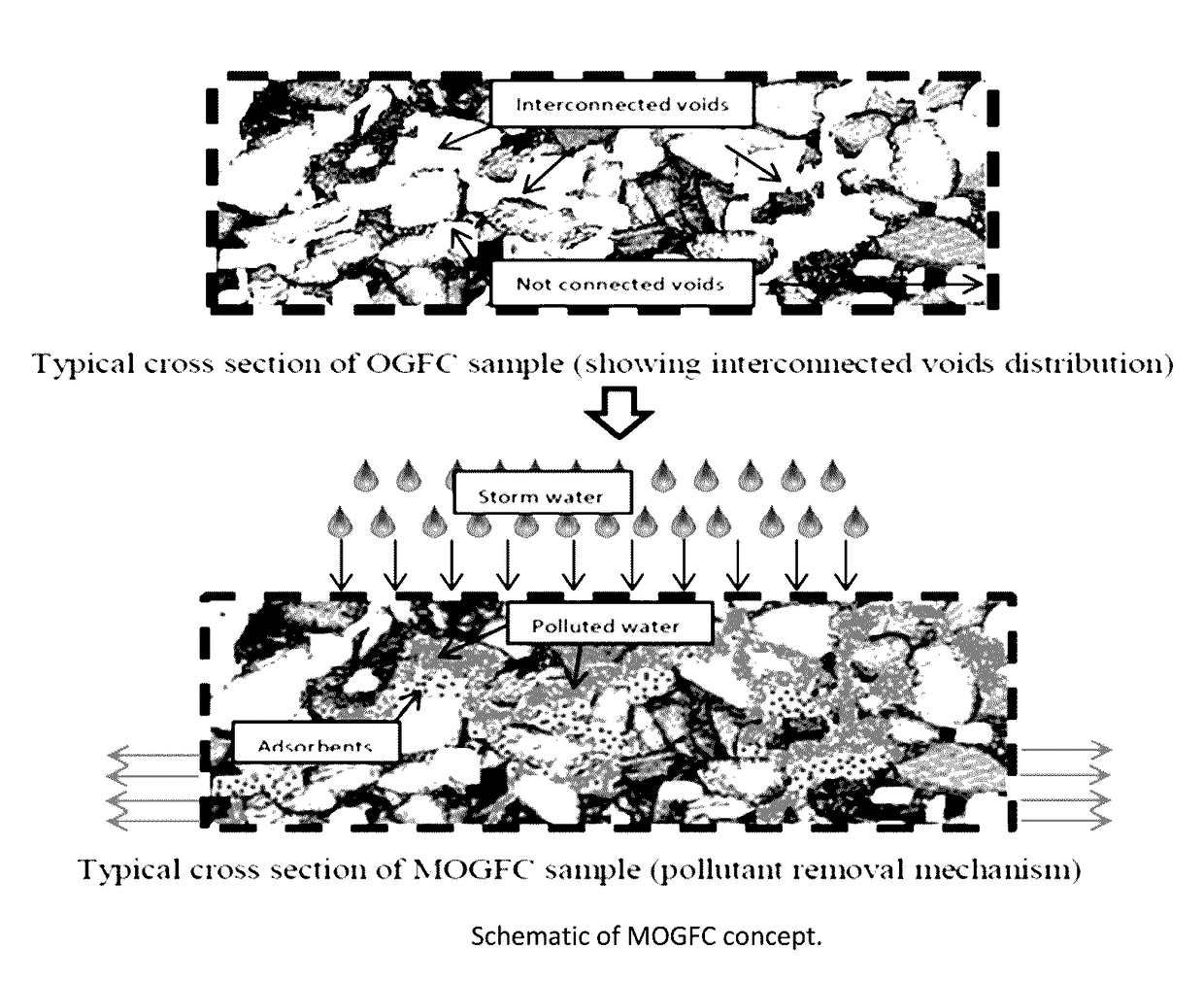

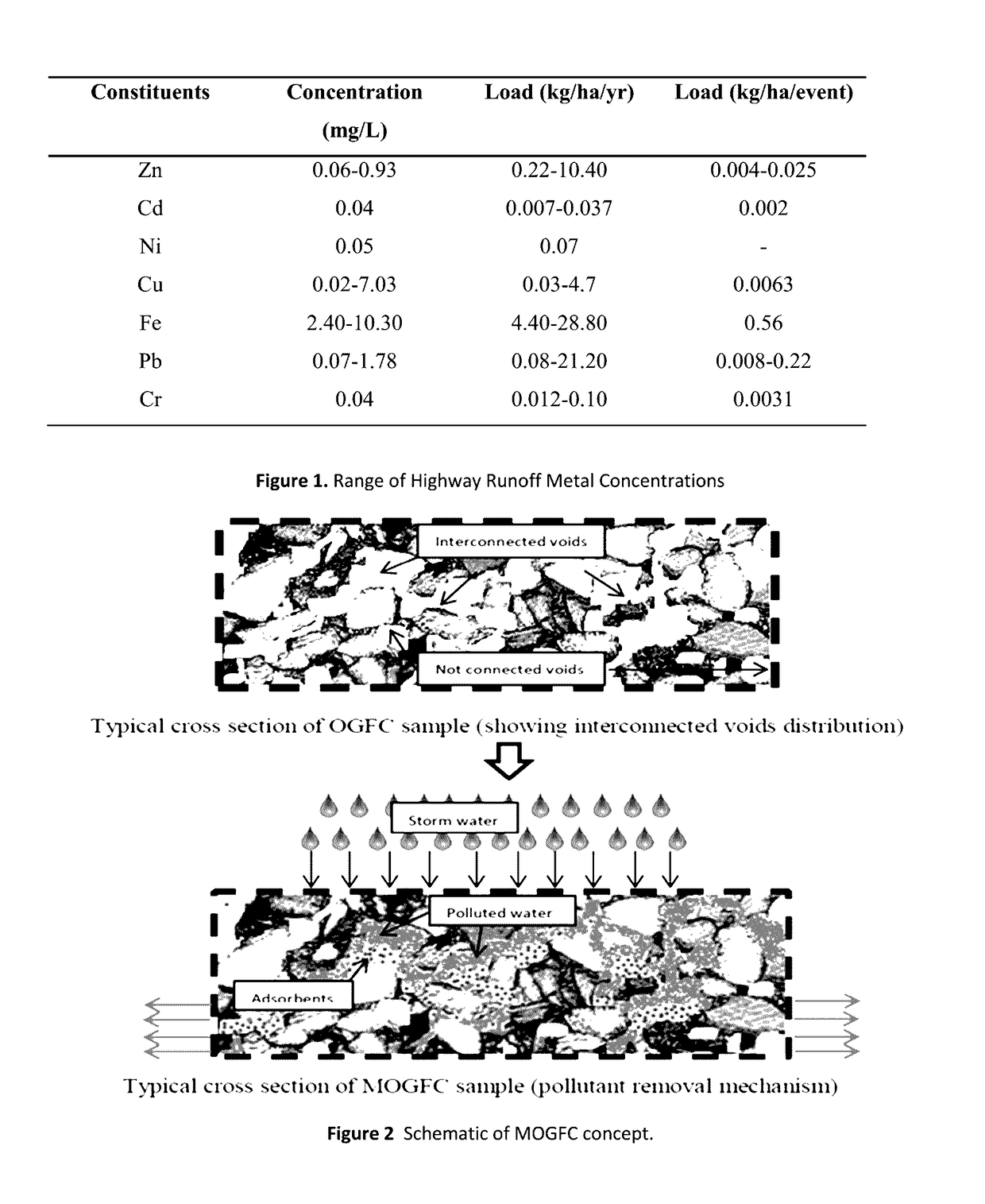

Multi-functional open graded friction course for in situ treatment of highway or roadway runoff

A multi-functional open graded friction course and a method of treating highway water runoff using the multi-functional open graded friction course are described herein. Open graded friction course is treated with an additive or additives, such as, but not limited to, an adsorbent. After treatment with the additive, the additive remains in the void spaces in the open graded friction course, thus creating a multi-functional open graded friction course. When highway or roadway water runoff flows into the void spaces, pollutants, such as heavy metals, are adsorbed by the additives and the water then flows laterally out of the multi-functional open graded friction course.

Owner:UNIVERSITY OF LOUISIANA AT LAFAYETTE

Ultrahigh-viscosity porous antiskid asphalt drainage surface layer

InactiveCN111021182AIncrease viscosityImprove road performanceIn situ pavingsPaving gutters/kerbsCrushed stoneRoad surface

The invention discloses an ultrahigh-viscosity porous antiskid asphalt drainage surface layer which is a mixture formed by taking ultrahigh-viscosity asphalt as a binding material and open graded broken stone as an aggregate through warm mixing. In the implementation process, the void ratio of the surface layer is finally controlled to be 13%-16%, so that the durability of the drainage pavement isimproved, meanwhile, the water seepage capacity is larger than 4000 mL.min <-1 >, the friction coefficient is within the range of 64-67, and good anti-skid performance is achieved. On the basis of reducing the porosity of the asphalt surface layer, the drainage skid resistance is ensured, and the fatigue durability of the drainage pavement structure can be effectively improved.

Owner:SOUTHEAST UNIV

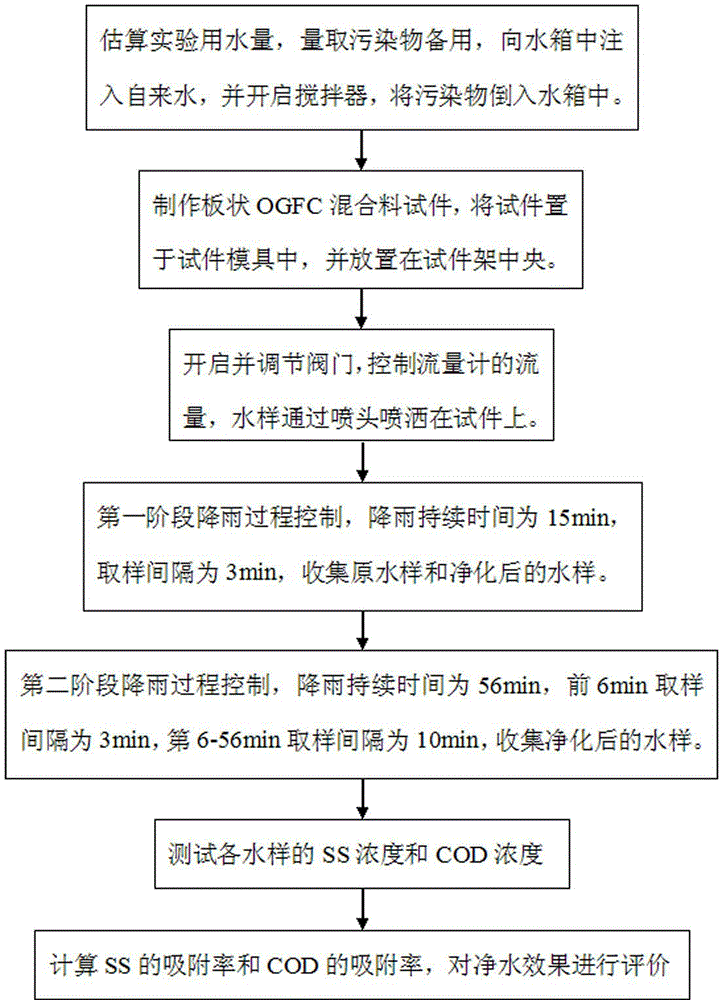

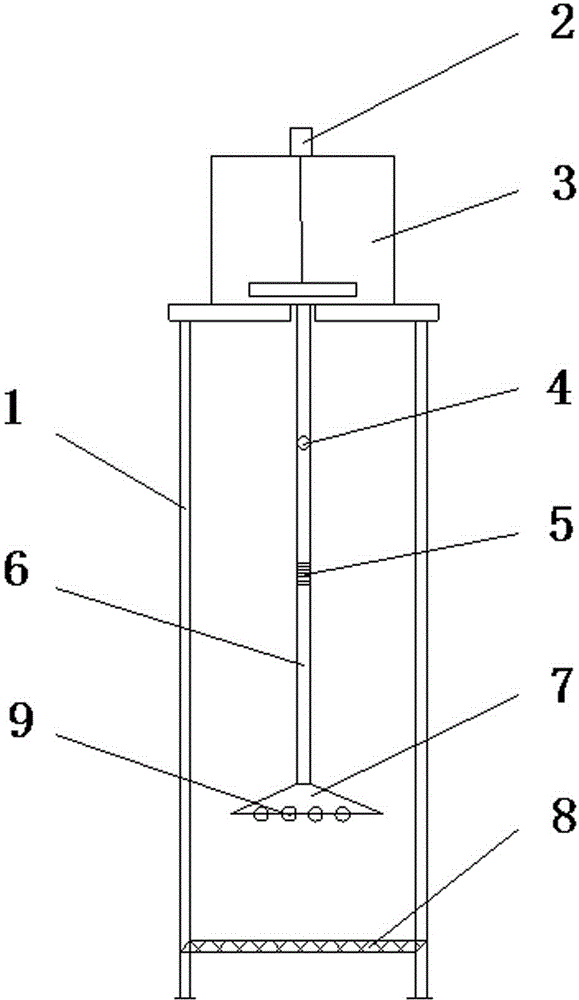

Water purification evaluation method of OGFC (open graded friction course) mixed material on rainfall and device for simulating rainfall

ActiveCN104020278AAlleviate water scarcityRealize comprehensive utilizationMaterial testing goodsMixed materialsEnvironmental engineering

The invention discloses a water purification evaluation method of an OGFC (open graded friction course) mixed material on rainfall and a device for simulating rainfall. The evaluation method comprises: preparing a water sample, preparing an OGFC mixed material sample, controlling the rainfall process, collecting a water sample, determining the concentration of SS and COD, calculating the SS concentration and COD concentration, calculating the SS absorption rate and the COD absorption rate, and further evaluating the water purification effect. The device comprises a framework, a water tank, a flow meter and a water pipe, wherein the framework comprises a support and a sample frame; the water tank is arranged above the framework, and is internally provided with a stirrer; one end of the water pipe is connected with the water tank, and the other end of the water pipe is connected with a sprayer; the water pipe is provided with a valve and the flow meter; the sample frame is arranged on the bottom end of the framework. The water purification evaluation method provided by the invention is simple to operate, evaluates the water purification effect accurately, lays a foundation for the further utilization of rainwater, and has a great significance in relieving the water resource shortage of cities, utilizing rainwater and turning waste of rainwater into wealth.

Owner:威海银通新材料有限公司

Open-graded asphalt mixture with small particle size for ultra-thin overlay

The invention provides a small-particle-size open-graded asphalt mixture for an ultra-thin overlay. The mixture is prepared from 85%-92% by weight of aggregate, 2%-8% by weight of filler and 5.5%-7.5% by weight of polymer modified asphalt, the nominal maximum aggregate size is 4.75 mm and the thickness of a pavement layer is 1.0-1.5 cm; preferably, the aggregate is basalt or diabase, the filler is the mixture of limestone mineral powder and cement in the mass ratio being (1:1)-(3:1), and the polymer modified asphalt is POE composite modified asphalt and has the zero-shear viscosity being 30,000 Pa.s or higher at 60 DEG C and the softening point equal to or higher than 90 DEG C. The small-particle-size open-graded asphalt mixture for ultra-thin overlay can reduce the thickness of a thin overlay, reduce building cost of a project and reduce noise during driving, two levels of hard building stones with the particle size being 3-5 mm or 0-3 mm can be utilized, the environment and resource stress of superfluous corresponding building stones due to large-scale application of SMA (stone mastic asphalt) pavements is reduced, and the small-particle-size open-graded asphalt mixture is ingenious in design, simple and convenient to prepare, low in cost and suitable for large-scale popularization and application.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

A kind of regeneration ogfc mixture and preparation method thereof

ActiveCN104030608BIncluding stabilityIncluding porosityClimate change adaptationCelluloseHyperviscosity

The invention discloses a regenerated OGFC (Open-graded Friction Courses) mixed material and a preparation method thereof. The mixed material comprises cellulose, hyperviscosity modified asphalt, new mineral aggregate, mineral powder and an OGFC old material. The preparation method comprises the following steps: respectively heating the OGFC old material, new mineral aggregate and hyperviscosity modified asphalt; then, mixing the heated OGFC old material and the new mineral aggregate with cellulose; then, adding the heated hyperviscosity modified asphalt into the mixture and mixing; then, adding the mineral powder, continuously mixing to form a regenerated OGFC mixed material; and finally, carrying out a Xielunbao asphalt leakage loss experiment and performance index test on the regenerated OGFC mixed material. The preparation method of the regenerated OGFC mixed material provided by the invention is simple to operate and accurate in result, and the potential value of the OGFC old material is fully utilized and the OGFC old material is reduced to the regenerated OGFC mixed material, so that the cost of OGFC is lowered.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

A kind of asphalt for wear layer of extremely thin surface, its mixture and its use

The invention relates to an asphalt for an ultrathin surface wearing layer, which comprises 90-96 weight parts of heavy-traffic or conventional modified asphalt and is added with a compound agent, wherein the compound agent consists of the following components in parts by weight: 2-3 parts of polymer, 1-3 parts of rubber and 1.5-3 parts of dispersing aid; and the mixture improves the viscosity and stiffness of asphalt as well as the adhesive force between asphalt and stone, and avoids or reduces the phenomenon that the asphalt floats upward and blocks gaps and consequently causes reduction of the structure depth, drainage performance and denoising effect of the mixture under the action of temperature and traffic load. The invention also discloses a mixture of the asphalt; by adding a grading control point to the mixture and matching the broken grade and the open grade, a stable skeleton embedding extrusion structure and the maximum skeleton gap are obtained, and higher porosity and maximum connection porosity are obtained so as to avoid skeleton instability and consequent surface function attenuation. The invention also discloses an application method of the mixture at the same time.

Owner:BEIJING TONGHUA ROAD MAINTENANCE

A kind of asphalt mixture for suppressing reflective cracks of pavement and its preparation method and application

The invention relates to an asphalt mixture for suppressing reflective cracks on road surfaces and its preparation method and application. The mixture includes aggregates, fillers, fiber stabilizers and high-viscosity asphalt binders. The aggregates include coarse aggregates and fine aggregates. The nominal maximum particle size of the asphalt mixture is 19mm, and both the coarse and fine aggregates are made of limestone; in terms of weight percentage, the amount of high-viscosity asphalt binder is 5.5% to 6.9% of the mass of the asphalt mixture, ranging from 60 to 80 mesh 12%~19% of rubber powder, 1‰~3‰ of crosslinking agent, 4.0%~8.0% of modifier, 3.8%~7.6% of viscosity reducer, and the balance is 70# matrix asphalt, and the asphalt mixture is intermittent half Open gradation, porosity 8% to 12%. The asphalt mixture provided by the invention can effectively suppress reflection cracks on the road surface, has low preparation cost, and has good economic and environmental benefits.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Cold-mix semi-flexible composite pavement material and preparation method thereof

The invention discloses a semi-flexible composite pavement material and belongs to the technical field of modern pavements. The semi-flexible composite pavement material comprises the following components in percentage by weight: 65%-75% of gravels or gravel mixtures, 15%-20% of self-made dry powder cement mortar, 3%-8% of emulsified asphalt, 2%-5% of mineral powder and 5%-10% of water. The cold-mix semi-flexible composite pavement material disclosed by the invention is simple and convenient in construction process without using construction machine and equipment used for large-scale production, is mixed and formed at normal temperature without being heated; the subsequent grouting procedure also can be carried out at the normal temperature, thereby saving the energy; and the cold-mix semi-flexible composite pavement material disclosed by the invention has the advantages of energy conservation and environment friendliness. The invention also discloses a preparation method of the semi-flexible composite pavement material. According to the preparation method, the cement mortar is grouted into large-gap open-graded emulsified asphalt mixtures.

Owner:浙江固路交通科技有限公司

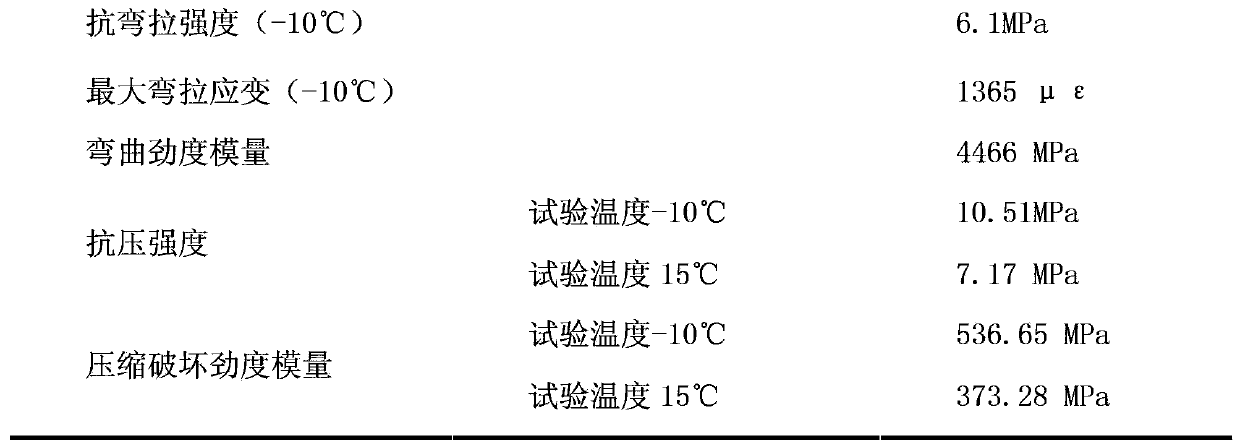

Composition design method of recycled ogfc mixture

ActiveCN104058639BThe composition design method is simpleThe mixing ratio is accurateSolid waste managementFreeze thawingCellulose

The invention provides a composition design method for a regenerated open graded friction course (OGFC) mixture. According to the method, a freeze-thaw splitting strength ratio after a performance improvement test is taken as a performance control index of the regenerated OGFC mixture, if the index does not meet the requirement, cellulose of which the mass is 0.1-0.3 percent of that of the regenerated OGFC mixture is added, the problem that the largest oilstone ratio of the regenerated OGFC mixture is small is solved, and the water damage resistance of the regenerated OGFC mixture is further improved, so that the composition design of the regenerated OGFC mixture is realized. The design method is simple and accurate in proportioning, the potential value of OGFC old materials is fully utilized, the OGFC old materials are reduced into the regenerated OGFC mixture, and the construction cost of the OGFC is further reduced. By adoption of the design method, the water damage resistance of the regenerated OGFC mixture can be well improved, so that the composition design of the regenerated OGFC mixture is realized.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +1

Self-inflow type semi-flexible composite pavement and construction method thereof

The invention relates to a semi-flexible composite pavement of which mixed cement slurry can automatically flow in holes of an asphalt mixture in a construction process. The composite pavement comprises an open-graded macro-porous asphalt mixture structure layer and pavement mortar which is filled in the holes of the macro-porous asphalt mixture, wherein the pavement mortar comprises 30 to 50 percent cement, 20 to 40 percent of sand, 2 to 4 percent of organic binder, 10 to 20 percent of active filler, 3 to 10 percent of shrinkage reducer, 0.2 to 0.5 percent of water reducer, 0.1 to 1 percent of early strength agent and water in an amount of 20 to 28 percent based on the total weight of all the components of the pavement mortar. The composite pavement of the invention has the advantages ofhigh compression strength, short maintenance time, smoothness, compactness, seamlessness, skid resistance, wear resistance, crack resistance, durability and convenient construction. The invention also provides a construction method of the semi-flexible composite pavement. The method comprises the steps of base pavement treatment, open-graded asphalt mixture paving, on-spot pavement mortar stirring and grouting, maintenance and the like. In the construction method of the invention, the mortar is automatically filled in the holes of the asphalt mixture according to the gravity per self and highworkability and fluidity, so influences which are caused by adopting vibration paving on asphalt frameworks are avoided.

Owner:广东龙湖科技股份有限公司

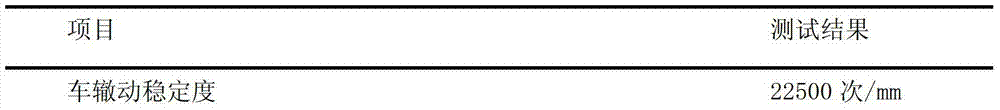

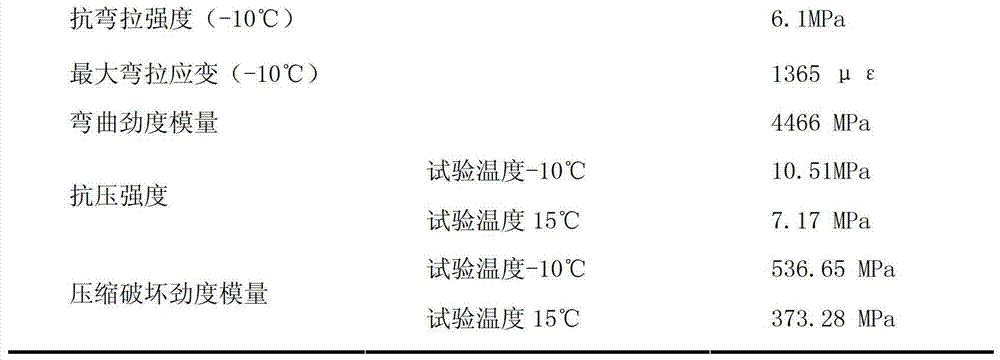

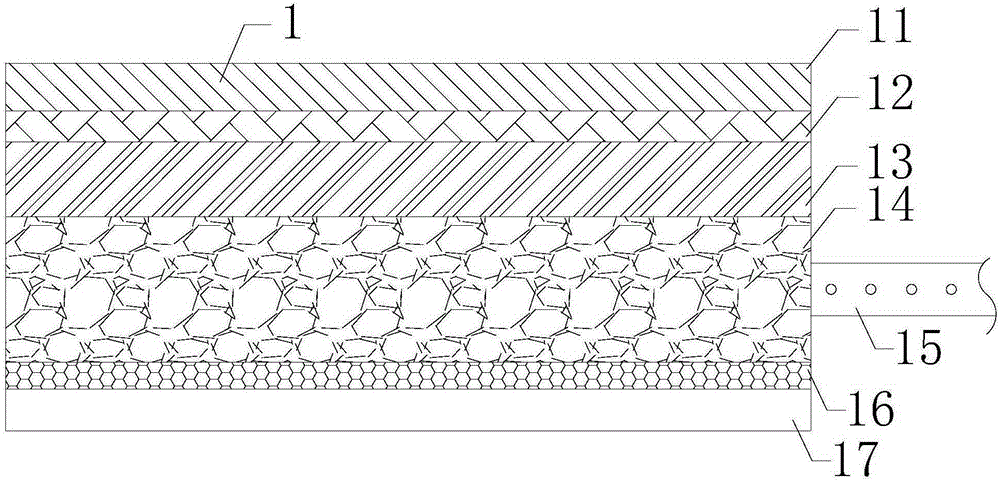

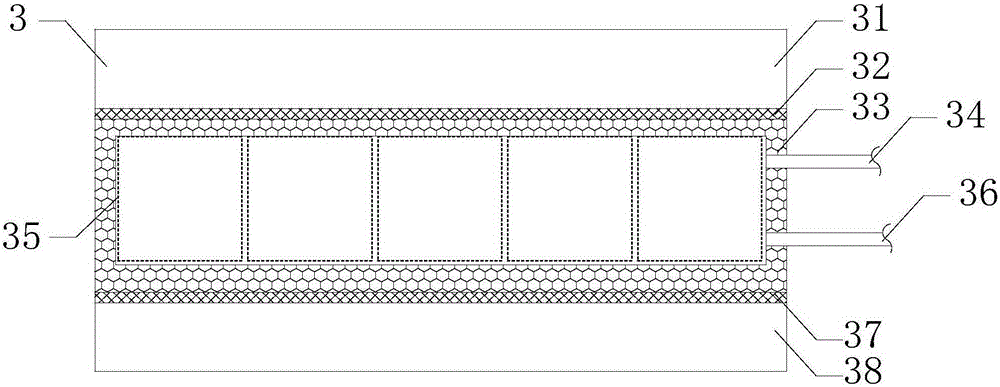

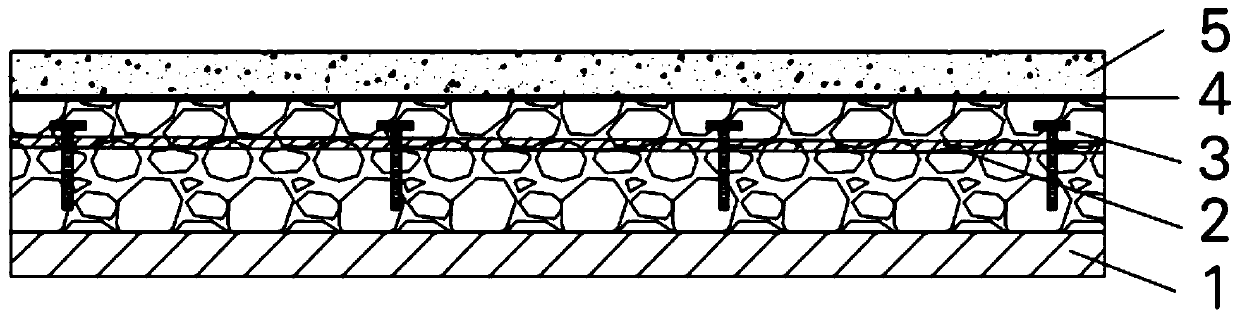

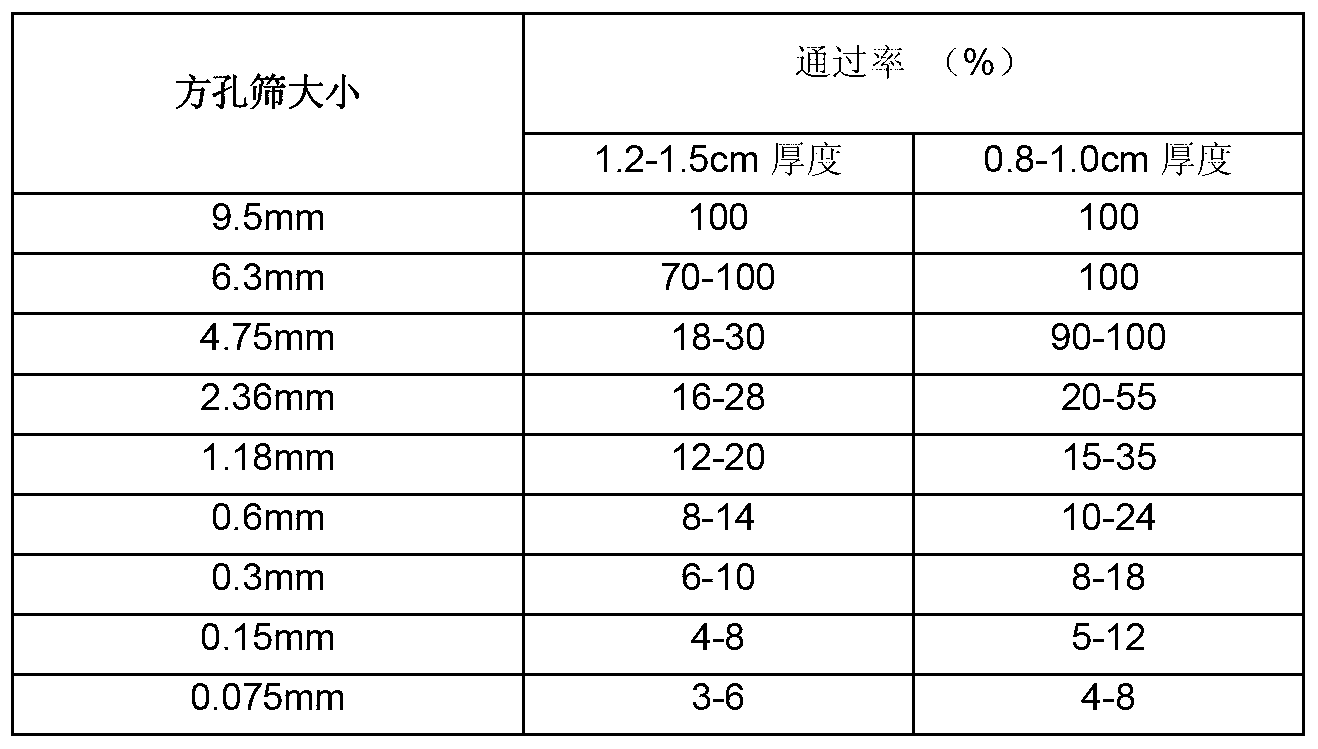

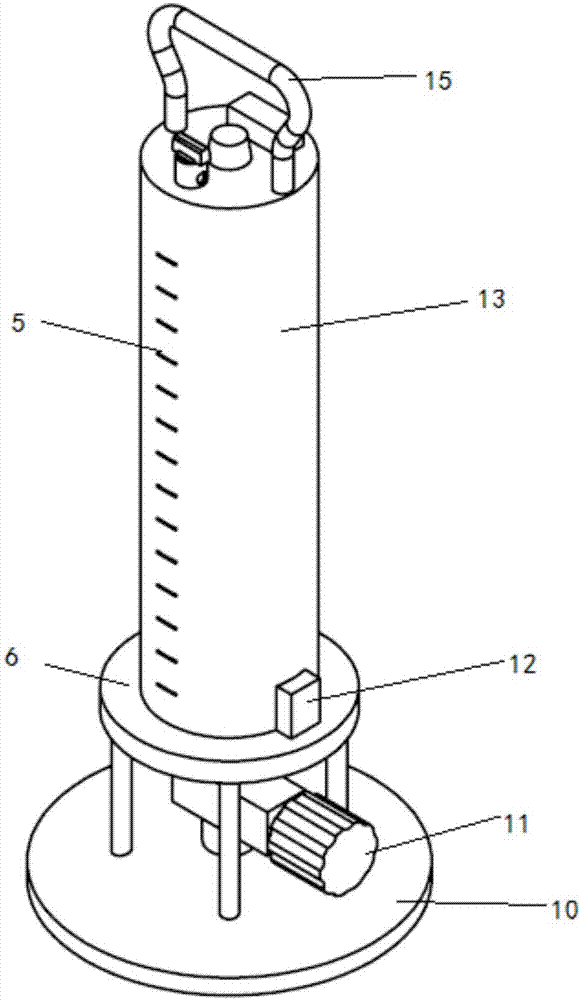

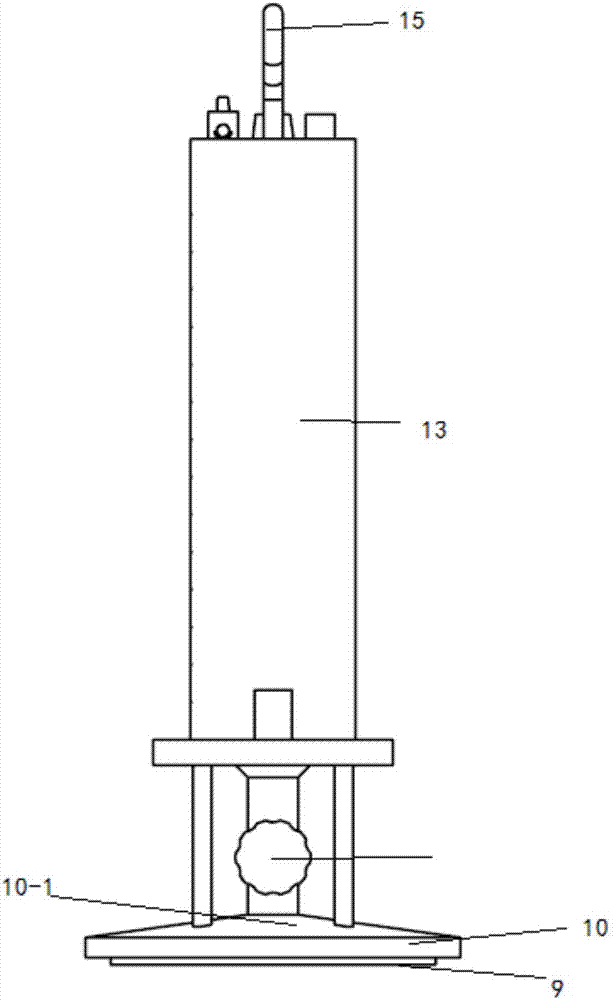

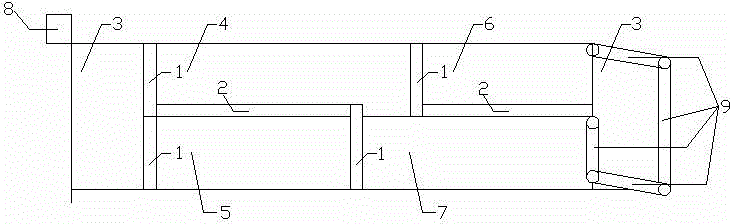

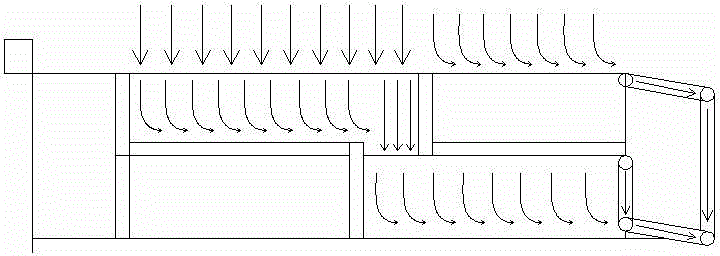

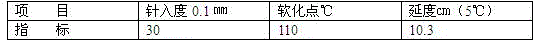

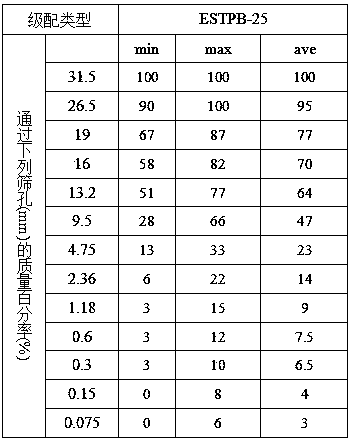

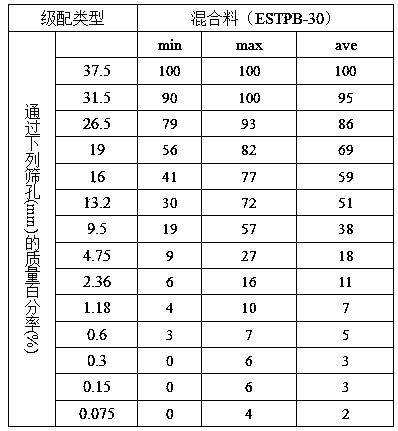

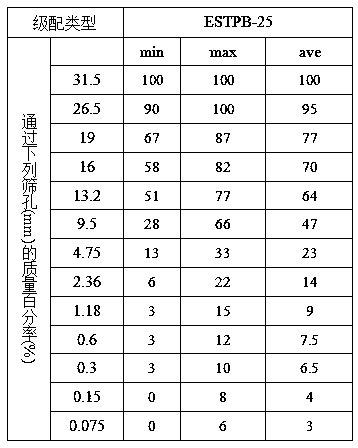

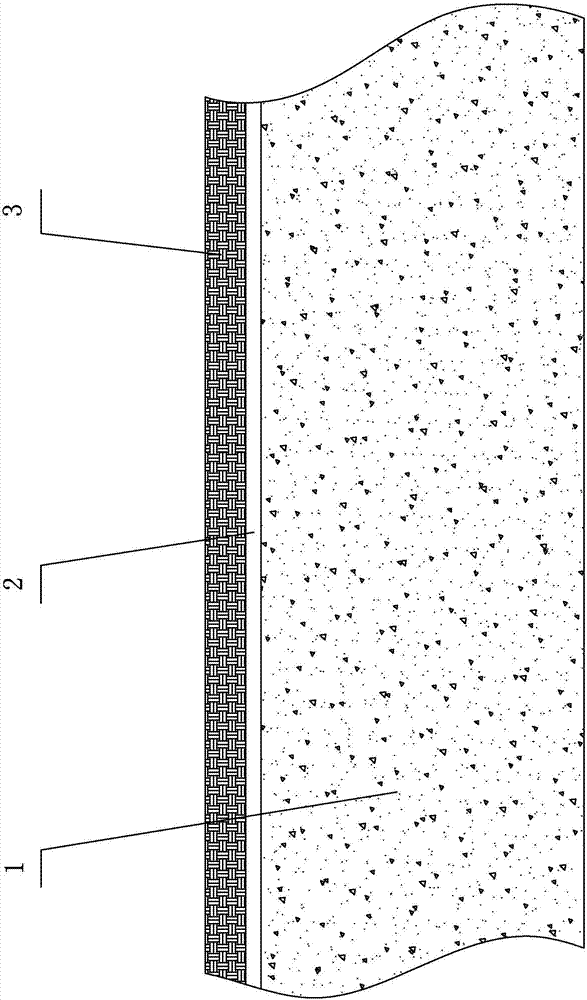

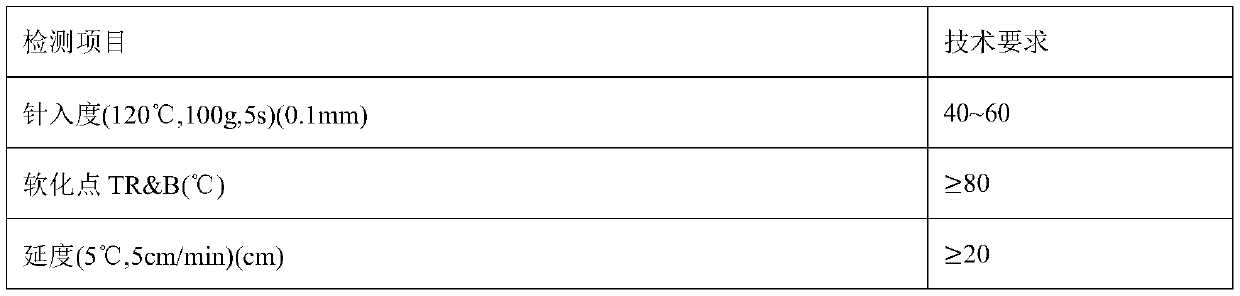

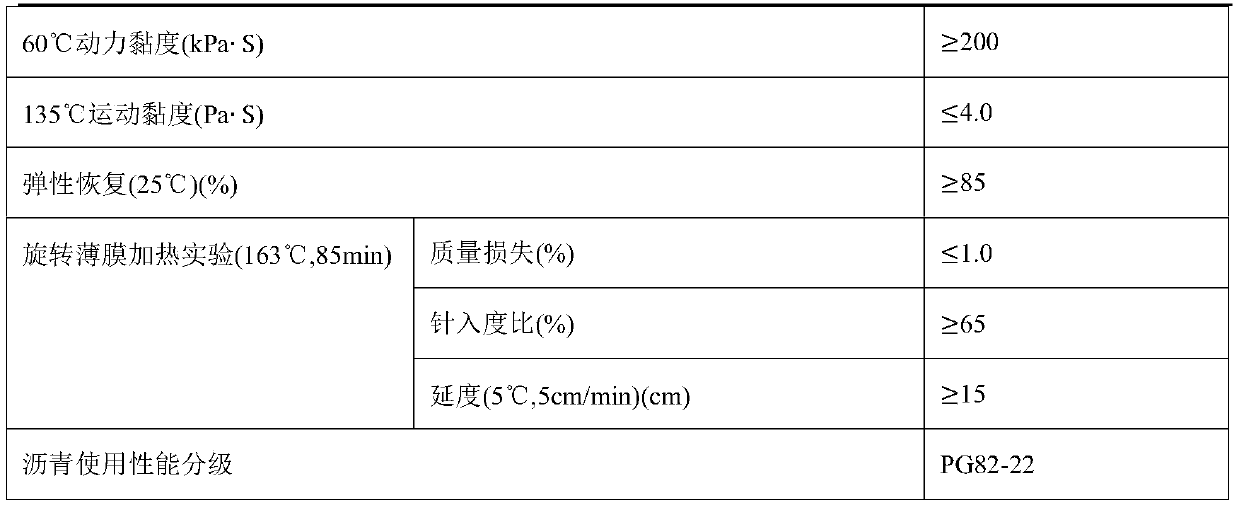

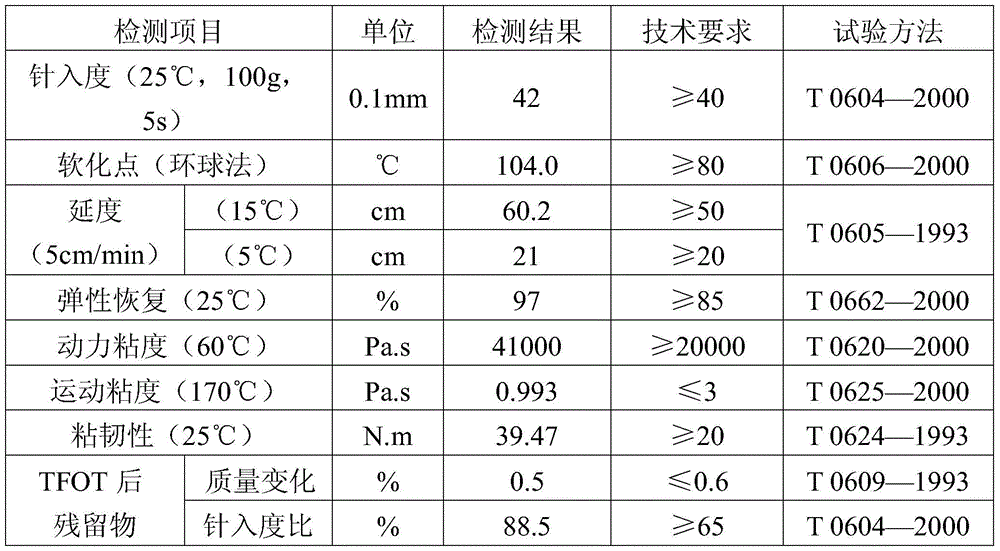

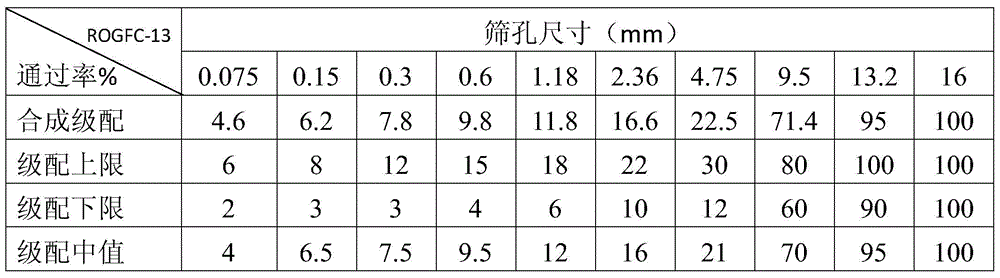

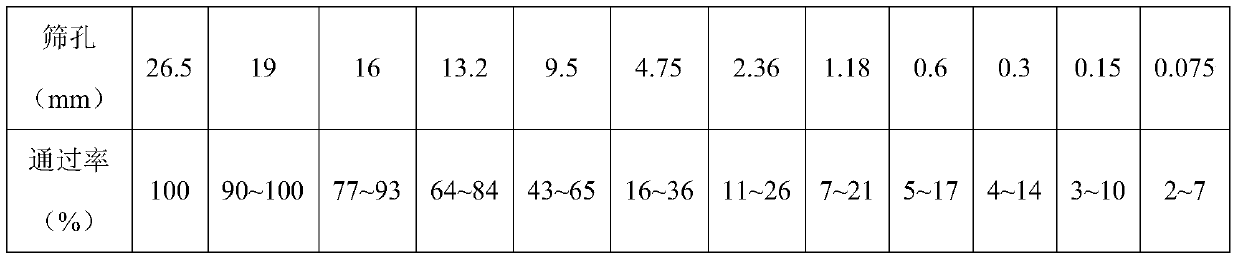

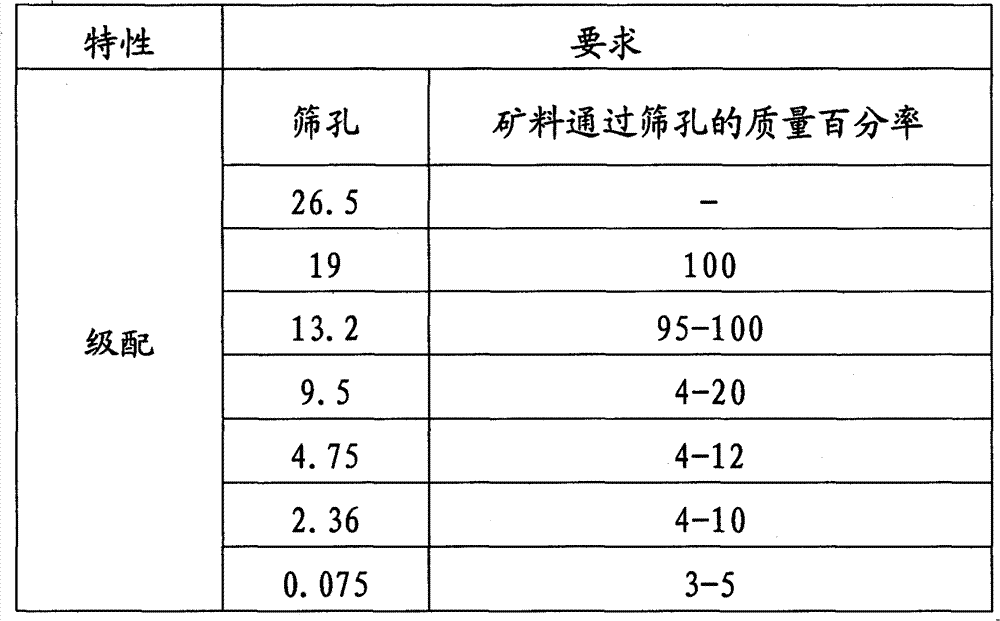

Functional drainage pavement and preparation method thereof[v]

The invention belongs to the technical field of highway construction, and particularly relates to a functional drainage pavement and a preparation method thereof, and a pavement paving material comprises the following components: epoxy asphalt, polyester fibers, a solubilizer, an inorganic pigment, open graded broken stone aggregate and mineral powder. According to the functional drainage pavementprovided by the invention, the mixing temperature is reduced in the construction process, the mixing energy consumption and the mechanical energy consumption are reduced accordingly, meanwhile, the production energy consumption of an epoxy asphalt mixture can be reduced, the aging is reduced, the pavement performance is improved, and due to warm mixing, the construction season is prolonged, and the flexibility of pavement construction is improved.

Owner:江苏千城生态科技有限公司

Cold mix asphalt and its preparation method, as well as the mixture containing the asphalt and its application

ActiveCN103289423BImprove high temperature performanceImprove adhesionBuilding insulationsArray data structureInstability

The invention relates to asphalt for an extremely thin surface wearing layer. The asphalt comprises 90-96 parts by weight of heavy-duty or conventionally modified asphalt, and a mixed preparation is added. The mixed preparation comprises the following components in parts by weight: 2-3 parts of polymer, 1-3 parts of rubber and 1.5-3 parts of dispersing auxiliary. The viscosity and stiffness of asphalt and the anchoring strength of asphalt and stones are improved, and decrease of the texture depth, the drainage performance and noise reduction effects caused by flotation of asphalt and gap block of the mixture under the effect of temperature and traffic load is avoided. The invention further discloses the mixture containing the asphalt. Grading control points are increased in the mixture, and broken grade and opened grade are matched to obtain a stable framework embedding structure and the maximum framework gap so as to obtain greater voidage and maximum communication voidage, so that surface function attenuation caused by instability of the framework is avoided, and meanwhile, the invention discloses a use method of the mixture.

Owner:BEIJING TONGHUA ROAD MAINTENANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Functional drainage pavement and preparation method thereof[v] Functional drainage pavement and preparation method thereof[v]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/a91fb800-bdd1-44ee-aca9-3264b3e73642/BDA0002385825490000071.png)

![Functional drainage pavement and preparation method thereof[v] Functional drainage pavement and preparation method thereof[v]](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/a91fb800-bdd1-44ee-aca9-3264b3e73642/BDA0002385825490000081.png)