Cement-asphalt composite self-melting snow pavement material and preparation method thereof

A technology for self-melting snow pavement and cement asphalt, applied in ceramic products, other household appliances, applications, etc., can solve the problem of rutting resistance performance that cannot meet load requirements, achieve excellent rutting resistance performance, improve mechanical properties, and simple production technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The cement-asphalt composite self-melting snow pavement material is applied to the upper layer, and the open-graded conductive asphalt concrete with a porosity of 21%~25% is used as the matrix, and the conductive cement mortar is used as the grouting material, which is prepared by the self-leveling pouring method.

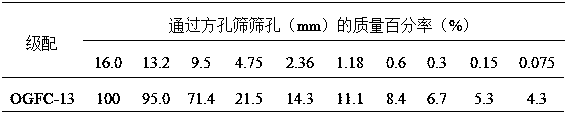

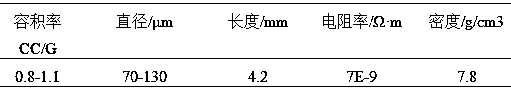

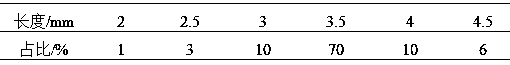

[0038] According to the requirements of "Code for Design of Highway Asphalt Pavement" (JTG D50-2006), the indoor mixture ratio design is carried out according to the OGFC (Open Grading Anti-skid Wear Layer) gradation design method and the asphalt mixture evaluation standard. After design adjustment, the mass ratio of various raw materials in the conductive asphalt concrete matrix is determined to be: coarse aggregate: fine aggregate: filler: asphalt: graphite powder: steel wool fiber = 334:56:1:20:10:16 , and its specific synthesis gradation is shown in Table 1.

[0039] Table 1: Synthetic gradation of conductive asphalt concrete matrix

[0040]

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com