A kind of asphalt for wear layer of extremely thin surface, its mixture and its use

A technology of asphalt mixture and wear layer, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of rapid attenuation of drainage performance and noise reduction effect, high cost, and excessive size, so as to avoid excessive attenuation of surface functions Fast and too large, improve the surface function, the effect of large connected void ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 90 parts of recrossed 70# pitch were heated to 160°C to make it fluid for use. Add 3 parts of dispersing co-solvent N-methylpyrrolidone to extract oil and 3 parts of styrene-butadiene rubber powder into the molten asphalt in turn, and stir for 2 hours. Add 3 parts ethylene methyl acrylate copolymer to the asphalt and stir for 30 minutes to ensure complete melt dispersion. Add 0.02 part of polyphosphoric acid, and continue to stir and react for 2 hours to obtain a finished asphalt product. The performance indicators of the finished modified asphalt are shown in Table 3.

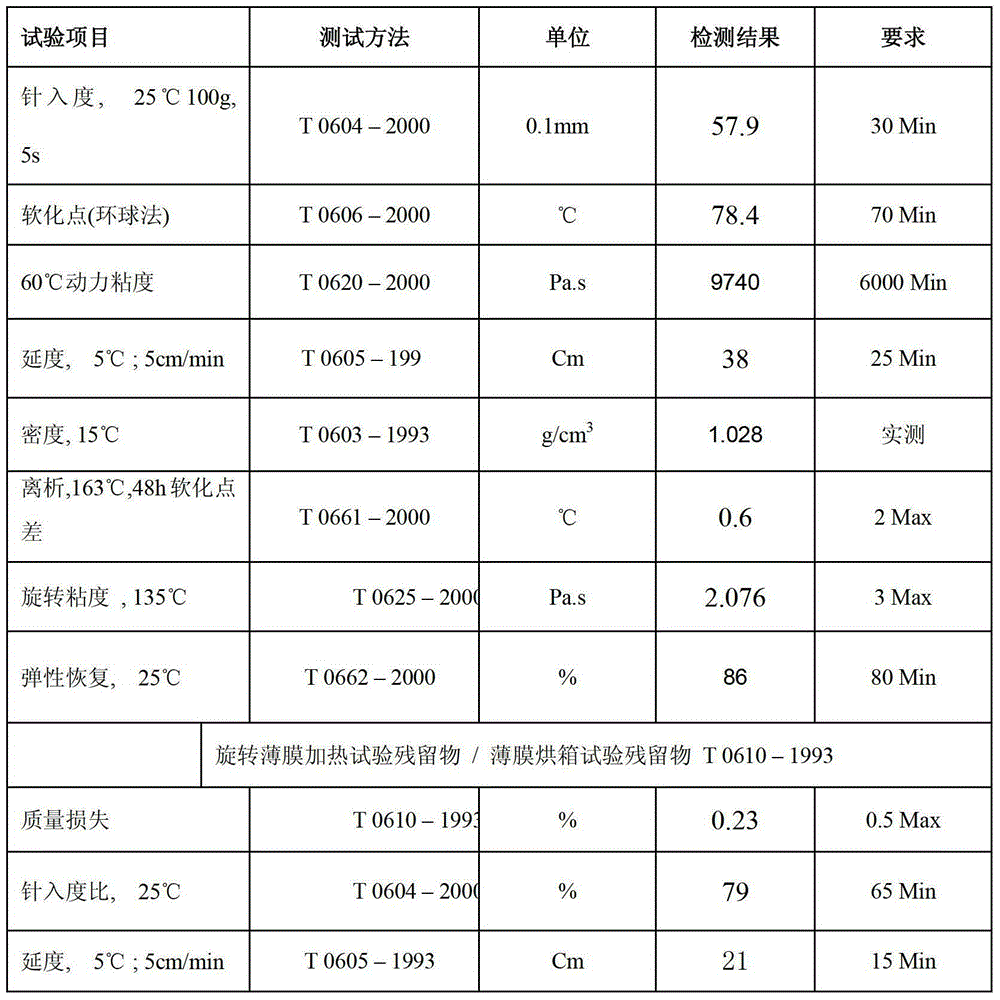

[0046] Table 3 Performance index of modified asphalt for mixture

[0047]

[0048] The design thickness of the mixture in this case is 1.5cm, using 5-8mm basalt, 0-3mm limestone machine-made sand, and limestone ore powder.

[0049] See Table 4 for the screening results of stone and mineral powder, and Tables 5 and 6 for the test results of aggregate performance.

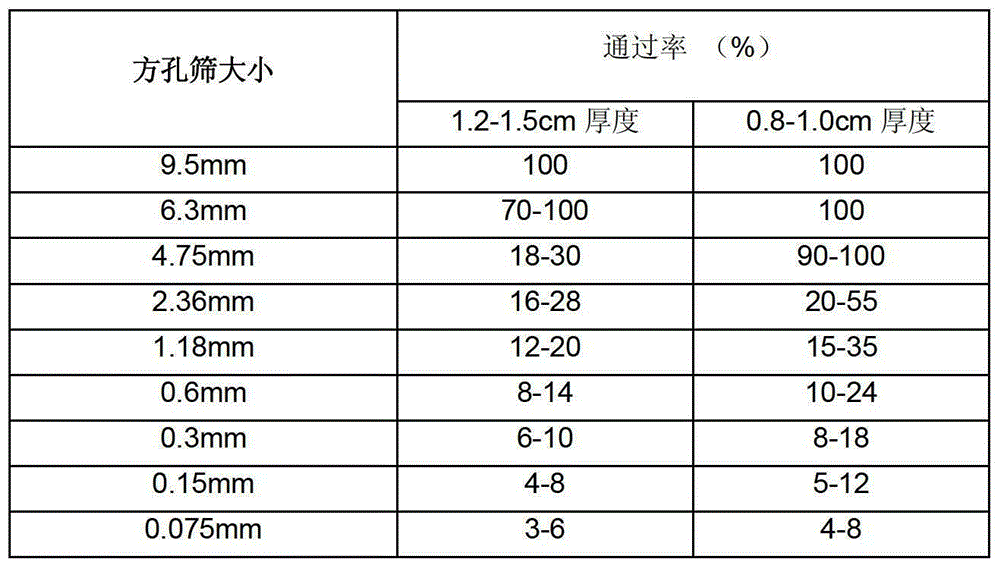

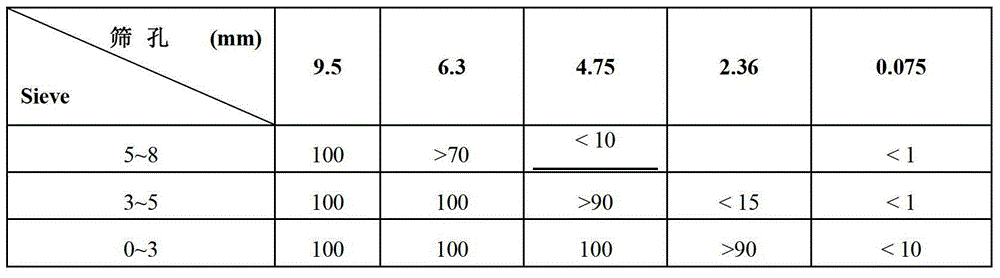

[0050] Table 4 Aggregate screenin...

Embodiment 2

[0066] Heat 94 parts of SBS modified I-B asphalt to 165 degrees Celsius to make it fluid for use, add 1.0 parts of dispersing co-solvent N-methylpyrrolidone, 1.0 parts of furfural extraction oil, and 2 parts of styrene-butadiene rubber powder to the molten asphalt at one time , stir for 2 hours. 2.5 parts of ethylene methyl acrylate copolymer was added to the asphalt, and stirred for 3.5 hours to obtain a finished asphalt product. The performance indexes of the finished modified asphalt are shown in Table 10.

[0067] Table 10 Performance index of modified asphalt for mixture

[0068]

[0069] The design thickness of the mixture in this case is 1.2cm, using 5-8mm basalt, 0-3mm limestone machine-made sand, and limestone ore powder.

[0070] See Table 11 for the screening results of stone and mineral powder, and Tables 12 and 13 for the test results of aggregate performance.

[0071] Table 11 Aggregate screening results

[0072]

[0073] Table 12 Test results of coarse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com