Coloured asphalt concrete permeable brick and preparation method thereof

A technology for colored asphalt and concrete, applied in the field of road pavement materials, can solve the problems of reduced durability of the mixture, loss of water permeable function, deformation of permeable bricks, etc., and achieves the effects of reducing burden, reducing dazzling, and increasing anti-skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Put 85Kg of 90# asphalt heated to 165°C into the mixer, then add 8kg of styrene-butadiene-styrene block copolymer and 7kg of polypropylene to stir while raising the temperature to 180-190°C and stir for 2 Hours or more to make high viscosity (high softening point) modified asphalt;

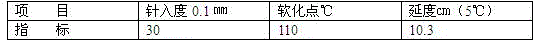

[0027] High viscosity modified asphalt index

[0028]

[0029] 2) Mix the crushed stone with a particle size of 5-15mm and the crushed stone with a particle size of 3-<5mm at 170°C with mineral powder to form a mineral mixture, and the weight ratio of the three is 10:4:1; Add 960Kg of the above-mentioned mineral mixture into the mixing tank of the mixer, dry mix for 5-10 seconds, then add step 1) 40Kg of high-viscosity (high softening point) modified asphalt and mix with the mineral mixture for 15-20 seconds to obtain water permeability Permeable asphalt mix for brick subfloor;

[0030] 3) Take 10.35Kg of the permeable asphalt mixture in step 2) and put it into a 300×300×60mm mold f...

Embodiment 2

[0034] Steps 1), 2), and 3) are the same as steps 1), 2), and 3) in Example 1;

[0035] 4) Mix 9.8Kg of resin 196 with 0.05Kg of cobalt naphthenate and 0.15Kg of methyl ethyl ketone peroxide to make a cement and mix with 190Kg of colored stones to form a colored stone mixture;

[0036] 5) Take the 1.9Kg colored stone mixture from step 4) and put it into the permeable asphalt concrete in step 3), move it to the plane of the mold frame and move it to the forming machine for molding, and demould after 3 hours.

Embodiment 3

[0038] Steps 1), 2), and 3) are the same as steps 1), 2), and 3) in Example 1;

[0039] 4) Mix 9.6Kg of resin 196, 0.2Kg of cobalt naphthenate, and 0.2Kg of methyl ethyl ketone peroxide to make a cement and mix with 133Kg of colored stones to form a colored stone mixture;

[0040] 5) Take the 1.62Kg colored stone mixture from step 4) and put it into the asphalt concrete in step 3), move it to the plane of the mold frame and move it to the forming machine for molding, and demould after 3 hours.

[0041] Selection of permeable brick application occasions:

[0042] 1. Choose permeable bricks with different product specifications and water seepage coefficients according to different uses of the road.

[0043] The use of pedestrian streets: products with specifications of 300×300㎜ or 300×150㎜ should be selected, because the surface of permeable bricks is relatively rough, and products with too small specifications will affect the aesthetic effect of the overall pavement. The thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com