EVA (ethylene-vinyl acetate copolymer)/SBS (styrene butadiene styrene segmented copolymer) compound modified asphalt stabilized crushed stone permeable base and paving method thereof

A technology of compound modified asphalt and stabilizing gravel, which is applied to buildings, roads, roads, etc., can solve the problems of less consideration of stormwater drainage facilities, spalling durability and stability, and reflection cracks in the pavement surface, and achieves good results. Fatigue resistance and adhesion, good fatigue durability, low temperature cracking temperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

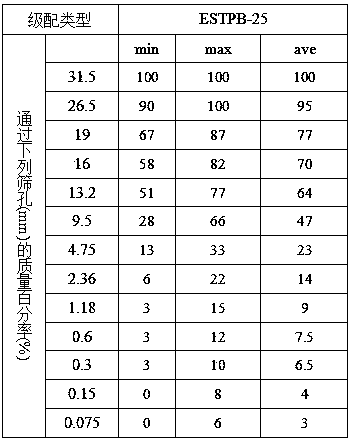

[0047] A macroporous epoxy asphalt macadam drainage base with drainage function is a composite modified asphalt mixed with 4%EVA+3%SBS, with open-graded crushed stone as aggregate, under 170℃-185℃ For the mixture formed by uniform stirring, the design gradation of the aggregate is as follows:

[0048]

Embodiment 2

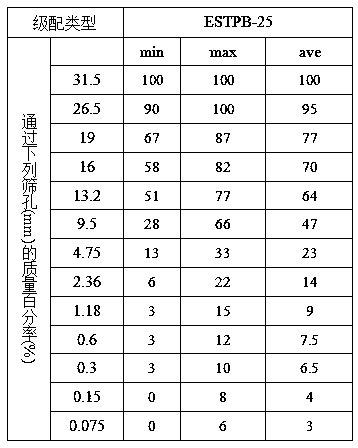

[0050] The difference from Example 1 is that the composite modified asphalt mixed with 4% EVA + 2% SBS is mixed with open-graded crushed stone as the aggregate, and the mixture is uniformly stirred at 170 ℃ -185 ℃. The design gradation of the aggregate is the same as in Example 1. The laying process of the ESTPB-25 modified asphalt macadam drainage base layer is as follows: first, the surface of the base layer should be inspected for quality, and necessary cleaning or milling treatment should be carried out; second, even spray and waterproof Adhesive layer, according to 0.4~0.6kg / m 2 Finally, the ESTPB-25 asphalt stabilized crushed stone drainage base layer was laid, and the paving and rolling was carried out in strict accordance with the construction technical specifications. The paving thickness was 8cm, and the surface layer was constructed after the paving layer was completely cooled.

Embodiment 3

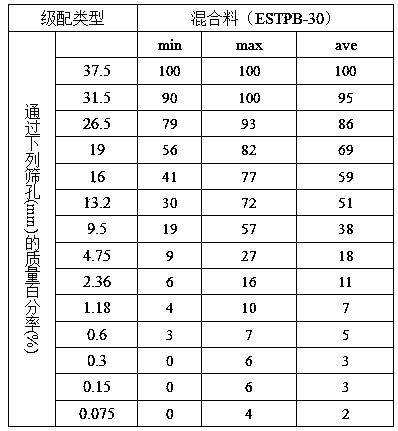

[0052] A macroporous epoxy asphalt macadam drainage base with drainage function, which is a composite modified asphalt mixed with 4% EVA + 3% SBS, with open-graded gravel as the aggregate, at 170℃~185℃ For the mixture formed by uniform stirring, the design gradation of the aggregate is as follows:

[0053]

[0054] The laying process of ESTPB-30 modified asphalt gravel drainage base layer is as follows: first, the surface of the base layer should be inspected for quality, and necessary cleaning or milling treatment should be performed; second, the waterproof adhesive layer should be sprayed evenly, according to 0.4~0.6kg / m 2 Finally, the ESTPB-30 asphalt stabilized crushed stone drainage base layer was laid, and the paving and rolling was carried out in strict accordance with the construction technical specifications. The paving thickness was 12cm. The ESTPB-30 modified asphalt stabilized gravel used in the research The porosity of the base layer is required to reach 19%-24%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com