Pick and place machine with air pressure sampling plate

A sampling board, placement machine technology, applied in the direction of electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of insufficient intelligence, inaccurate placement, and inability to mix and paste, and achieve accurate air pressure values. Precise patch, can mix and paste accurate and complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

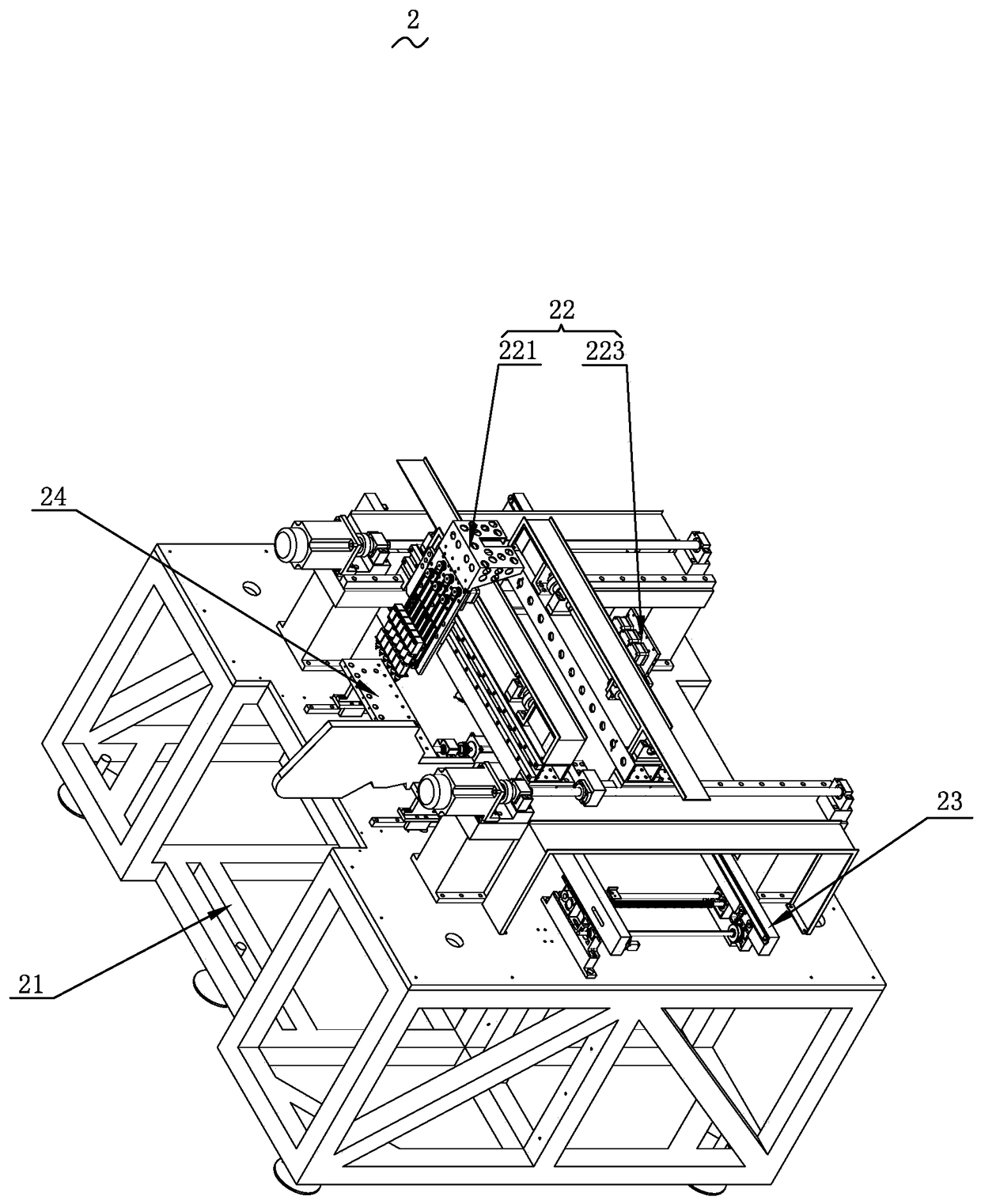

[0016] see figure 1 , a double-head placement machine 2, comprising: a machine platform 21, a placement head 22, a transmission guide rail 23 and two feeding seats 24, wherein the machine platform provides support for the entire double-head placement machine 2, and the placement head 22 Set on the machine platform 21, including the first placement head 221 and the second placement head 223, located above the transmission guide rail 23, and the first placement head 221 and the second placement head 223 are respectively arranged on both sides of the transmission guide rail 23, two fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com